Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Minimize heat" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

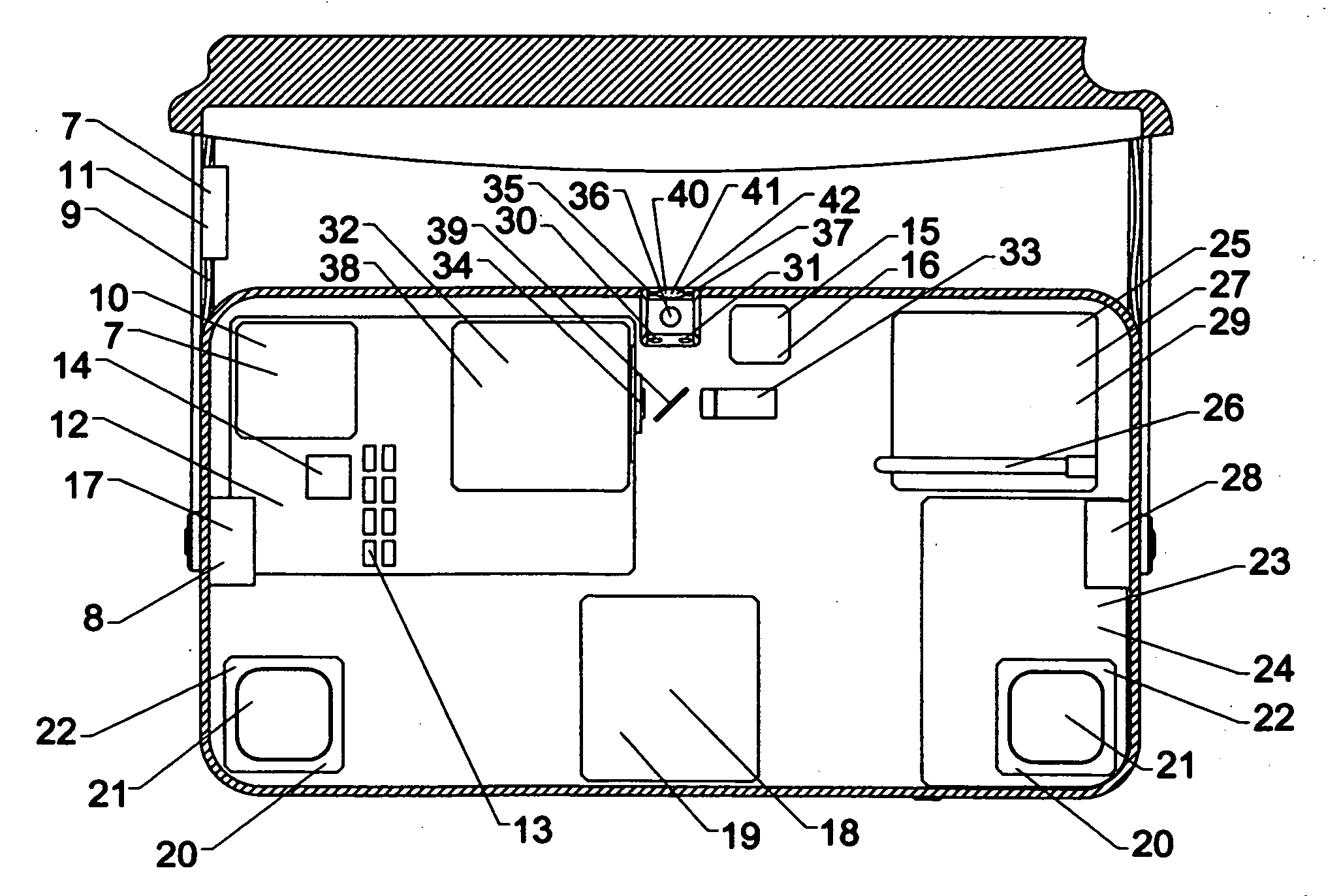

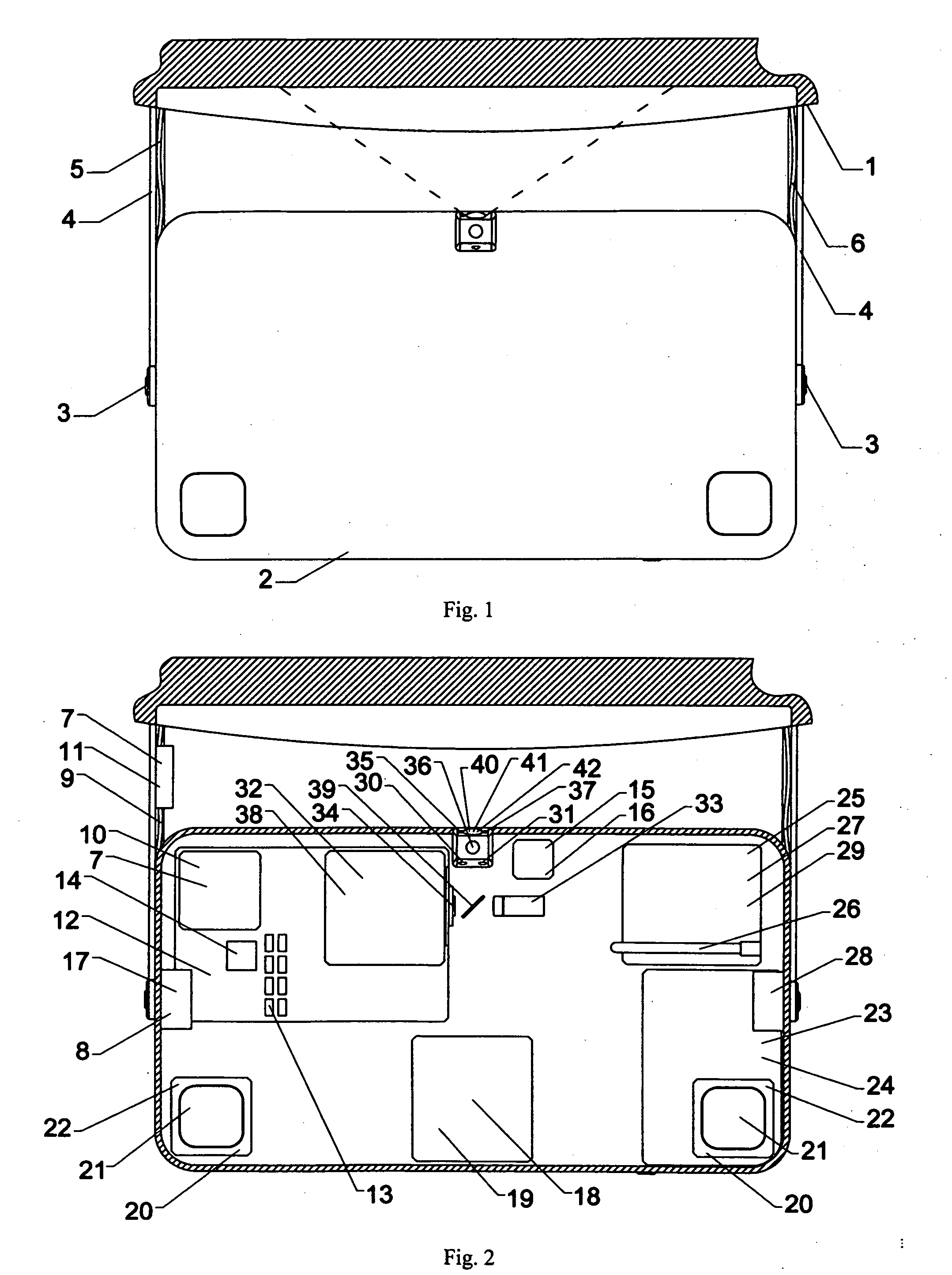

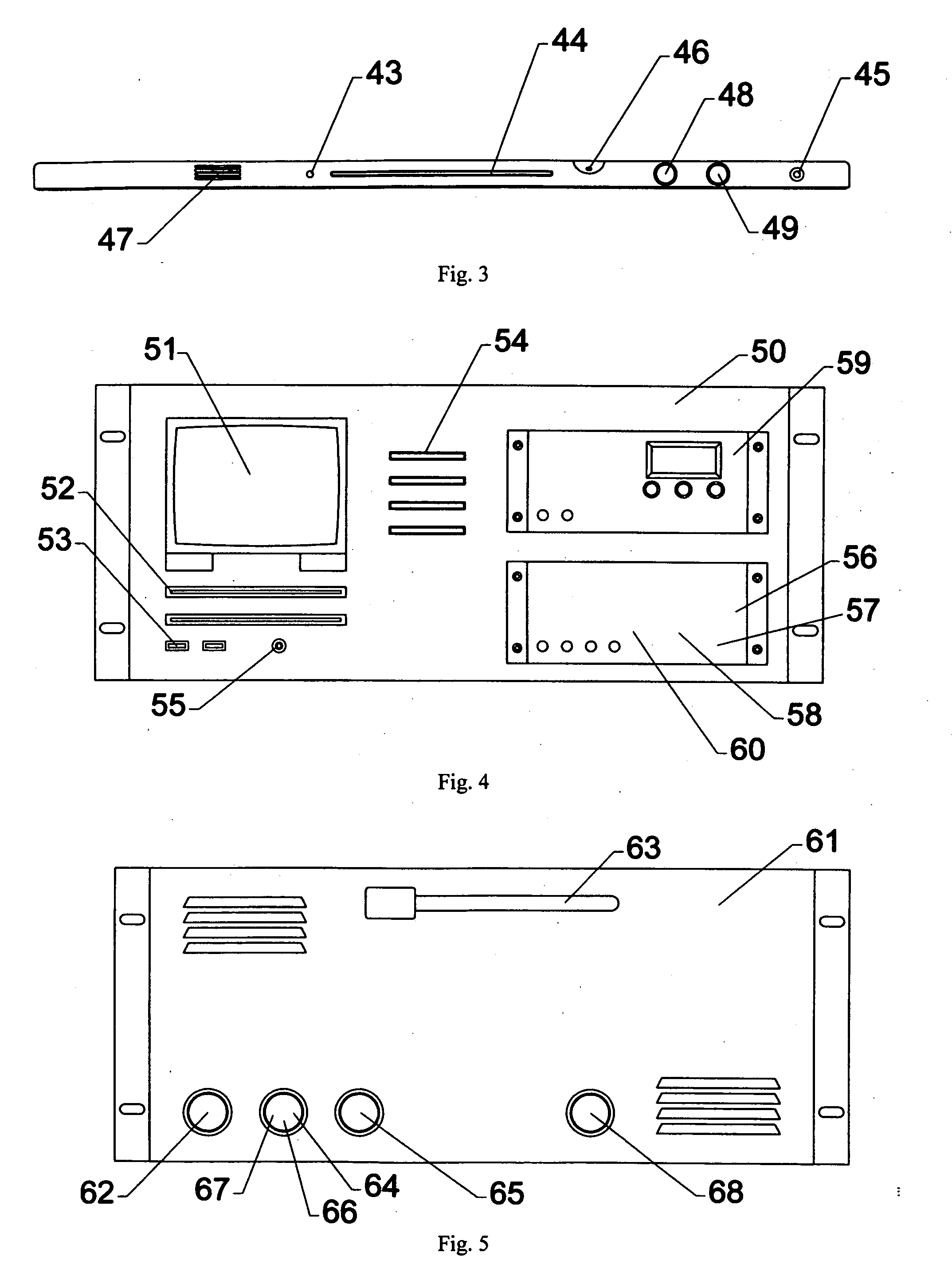

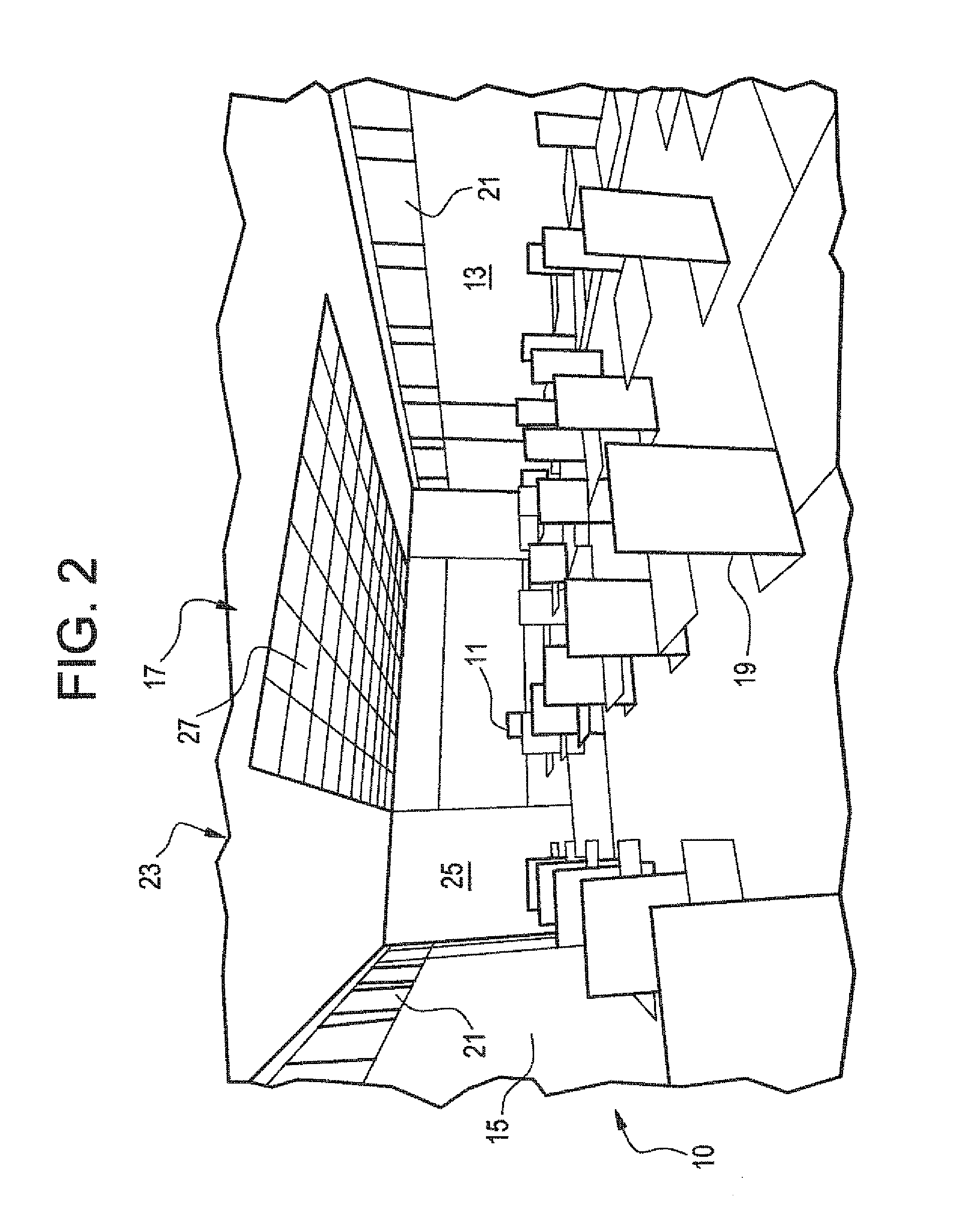

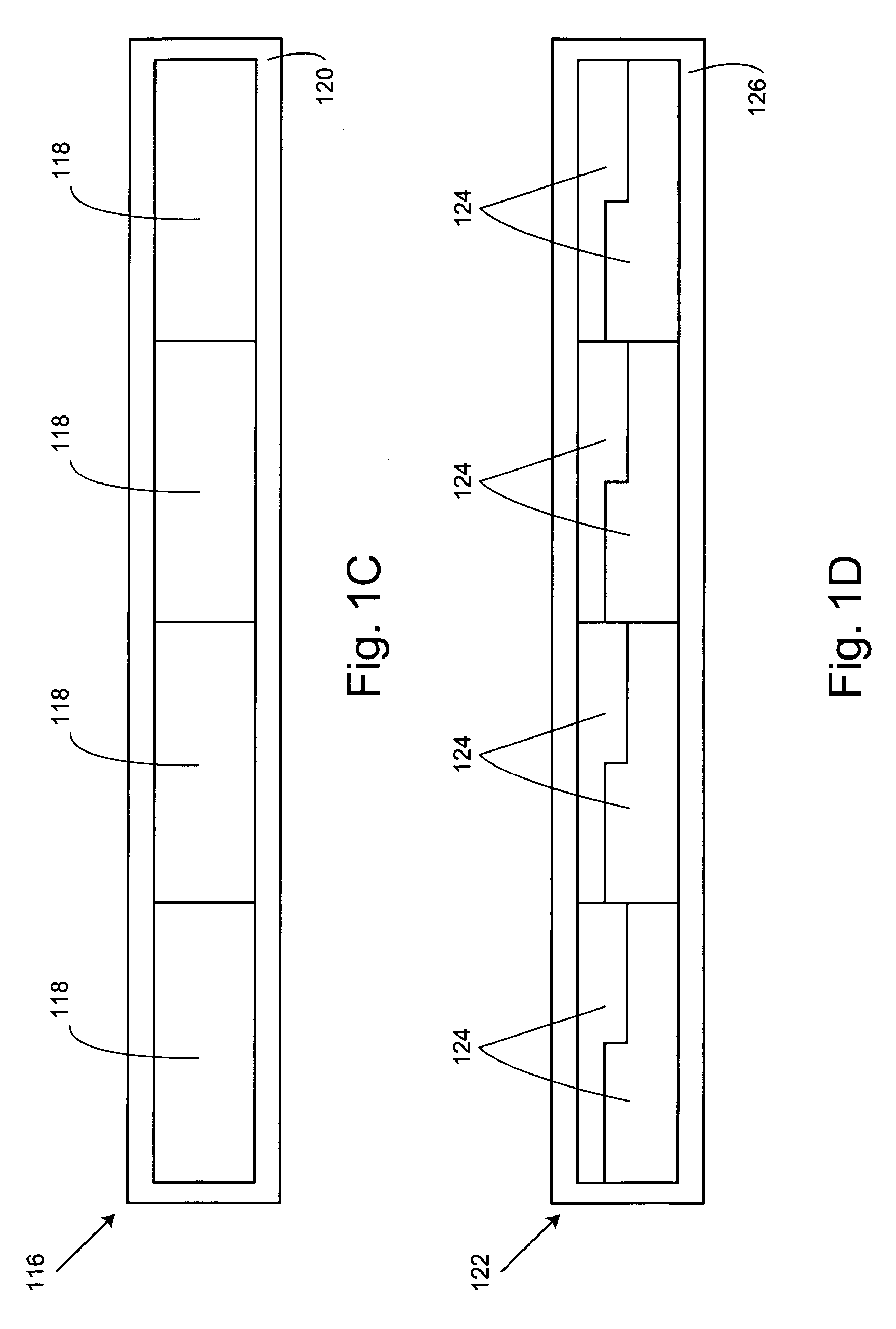

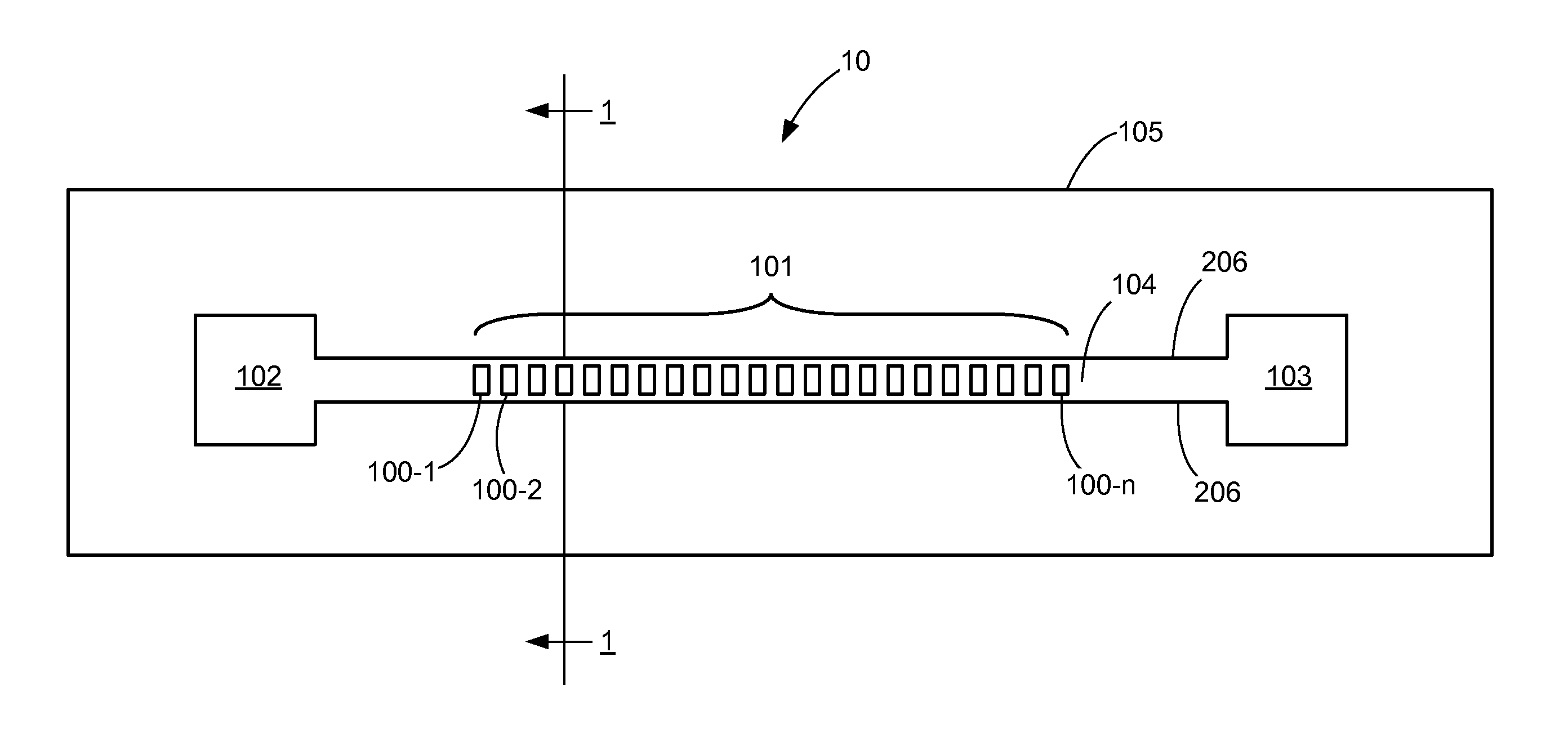

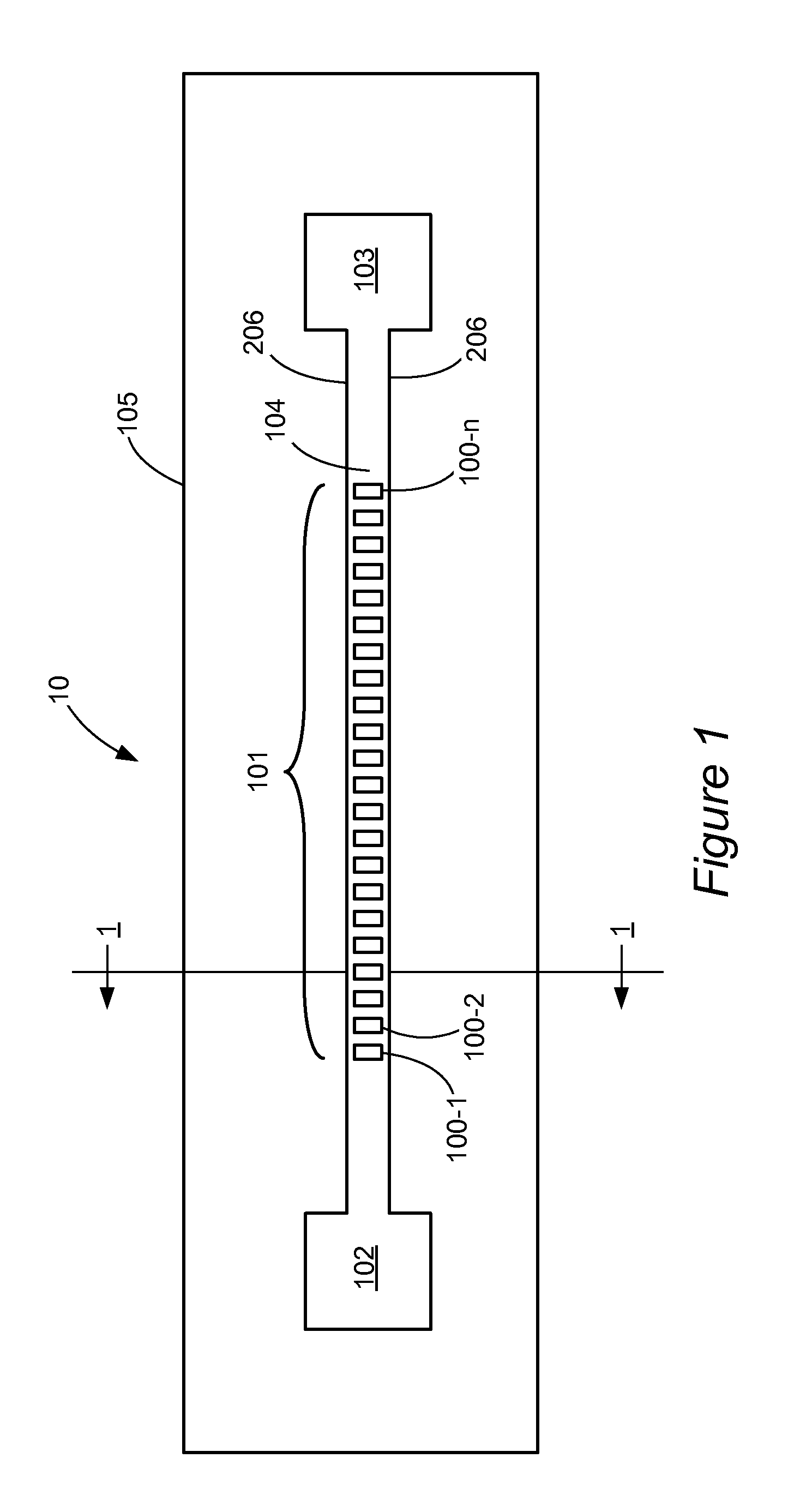

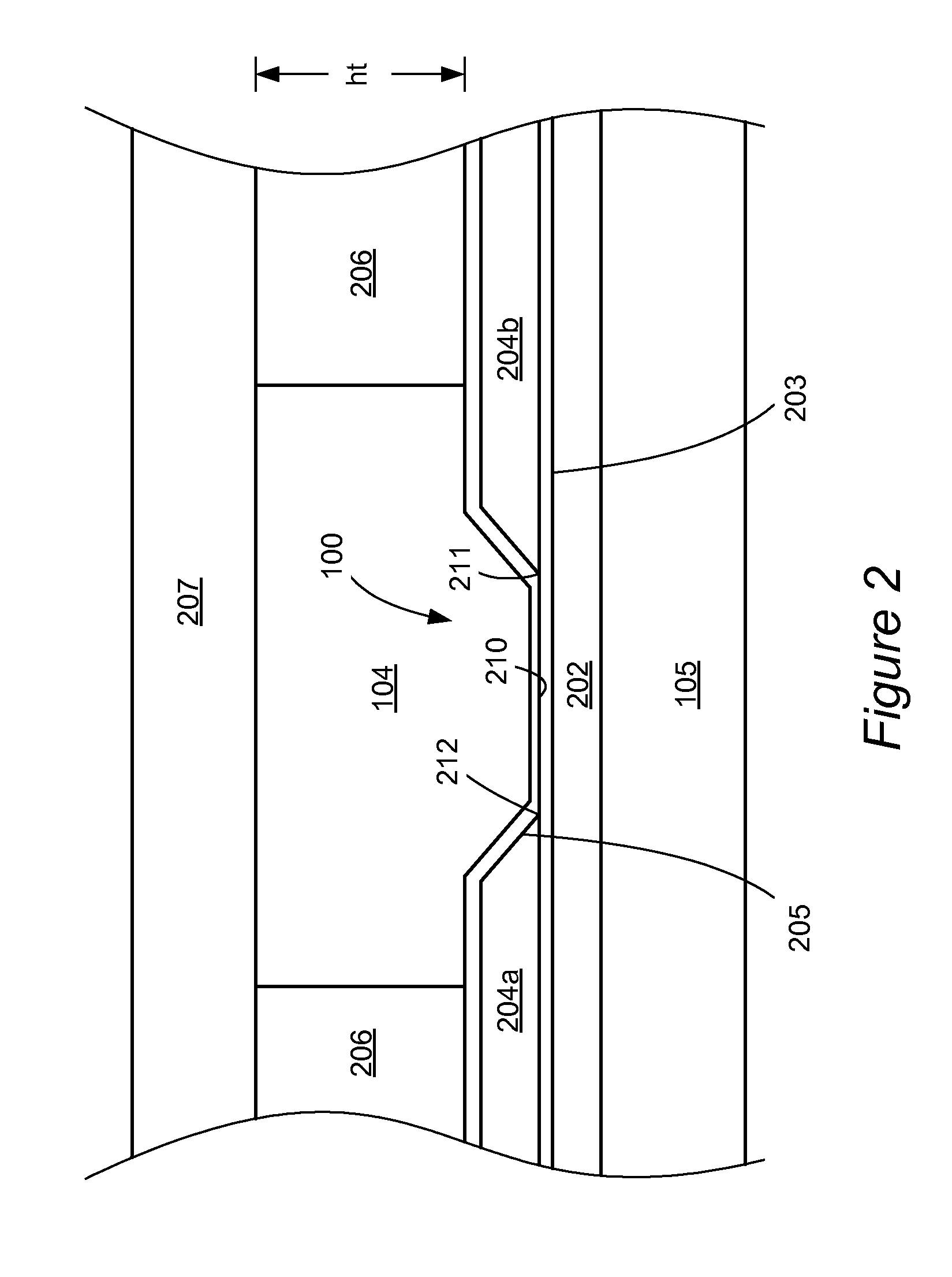

Passenger tray convenience system

InactiveUS20090288123A1Minimize heatLess heatStoolsClosed circuit television systemsAirplaneProjection system

An aircraft entertainment, gaming, internet, telephone, information, menu selection, ordering and purchasing system, video projection system, and seat occupied system providing pre-flight, in-flight, post-flight passenger entertainment, internet, information, menu selection, ordering and purchasing, via projected video or image, and a seat occupied system, integrated into an aircraft passenger seat tray. The aircraft passenger seat tray being an all in one convenience system for the aircraft passenger while allowing the normal use of the aircraft passenger seat tray for the resting and support of meal trays, drinks, business usage, etc.

Owner:HAVLOVICK RON G +1

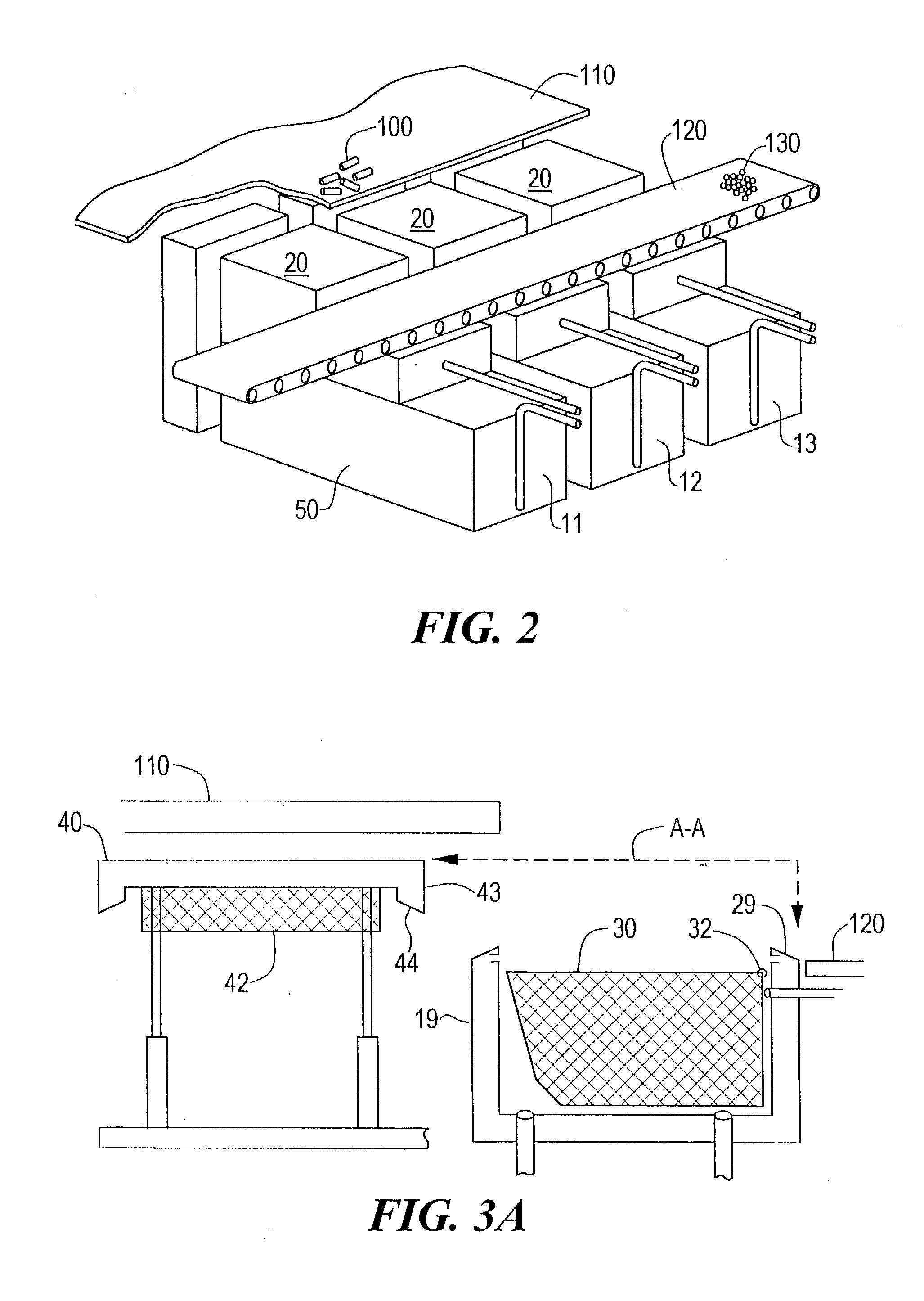

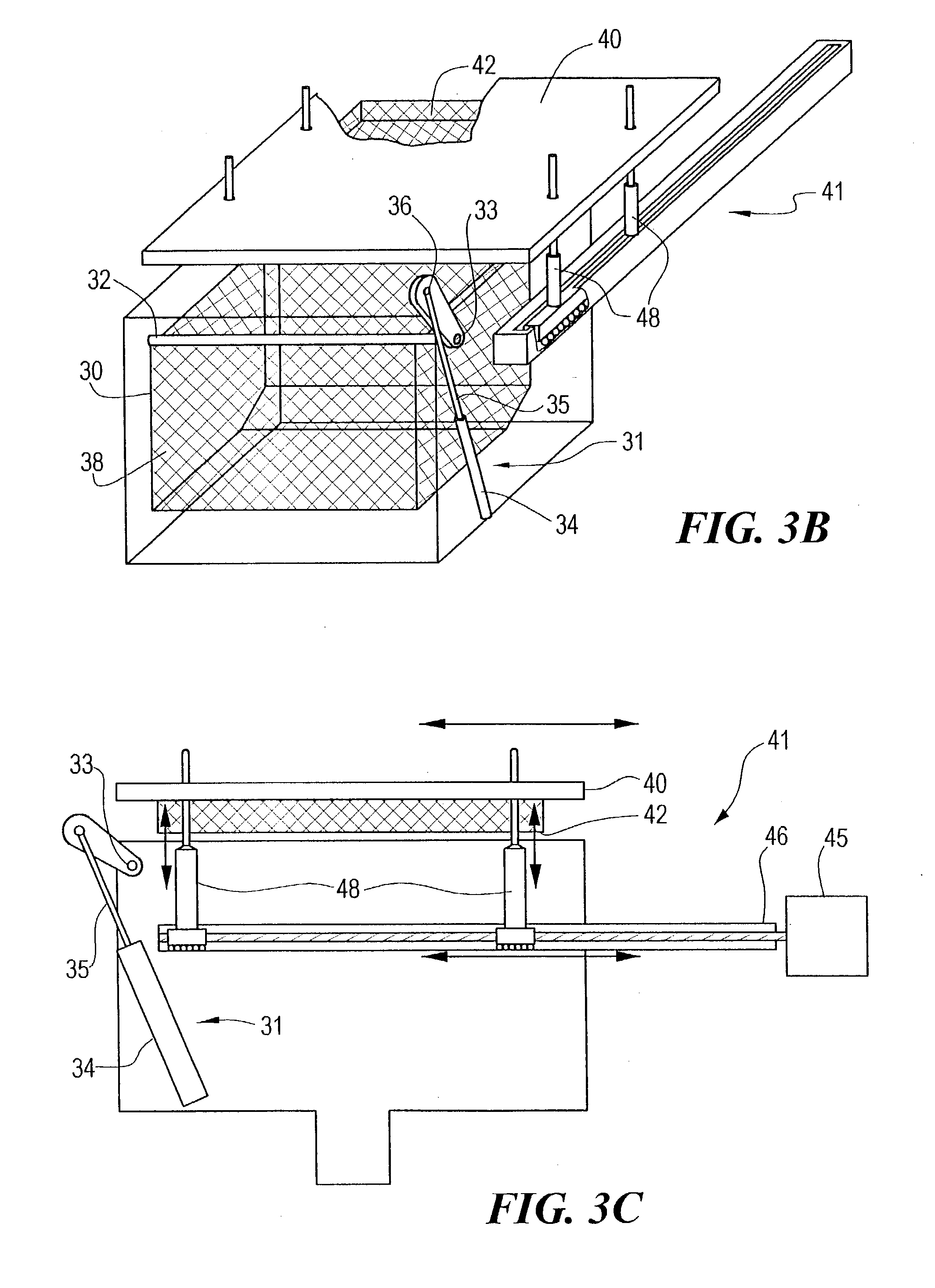

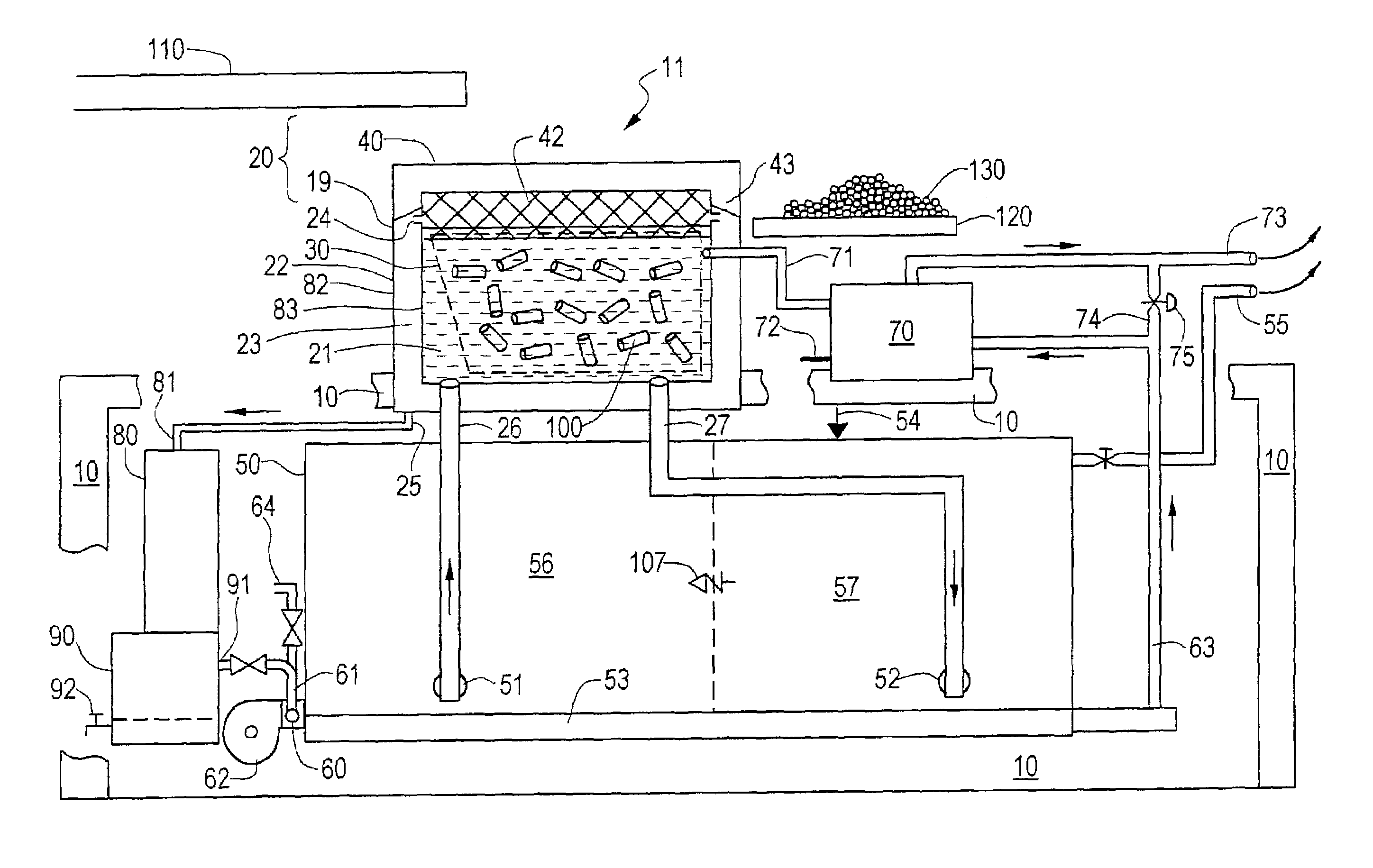

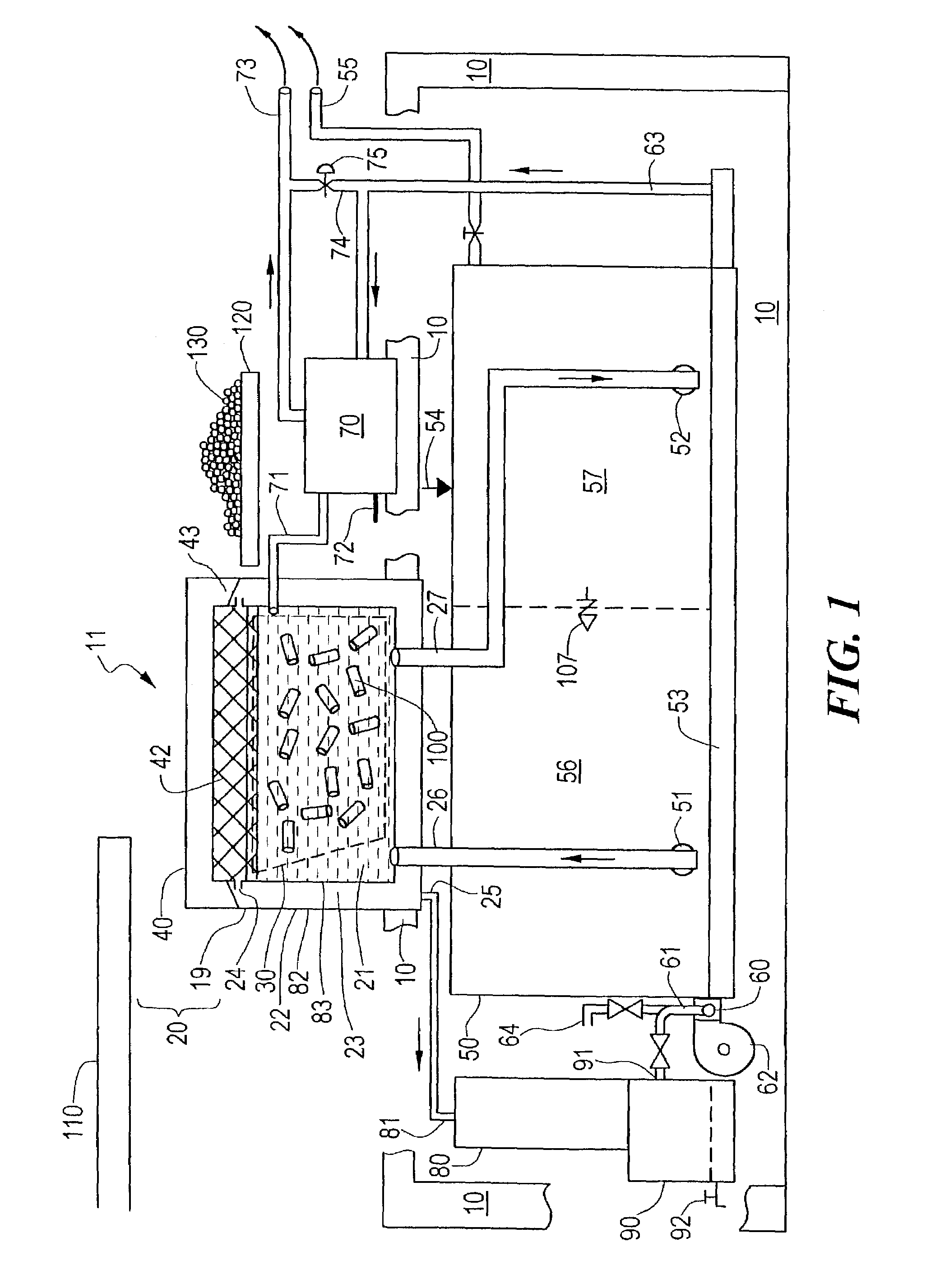

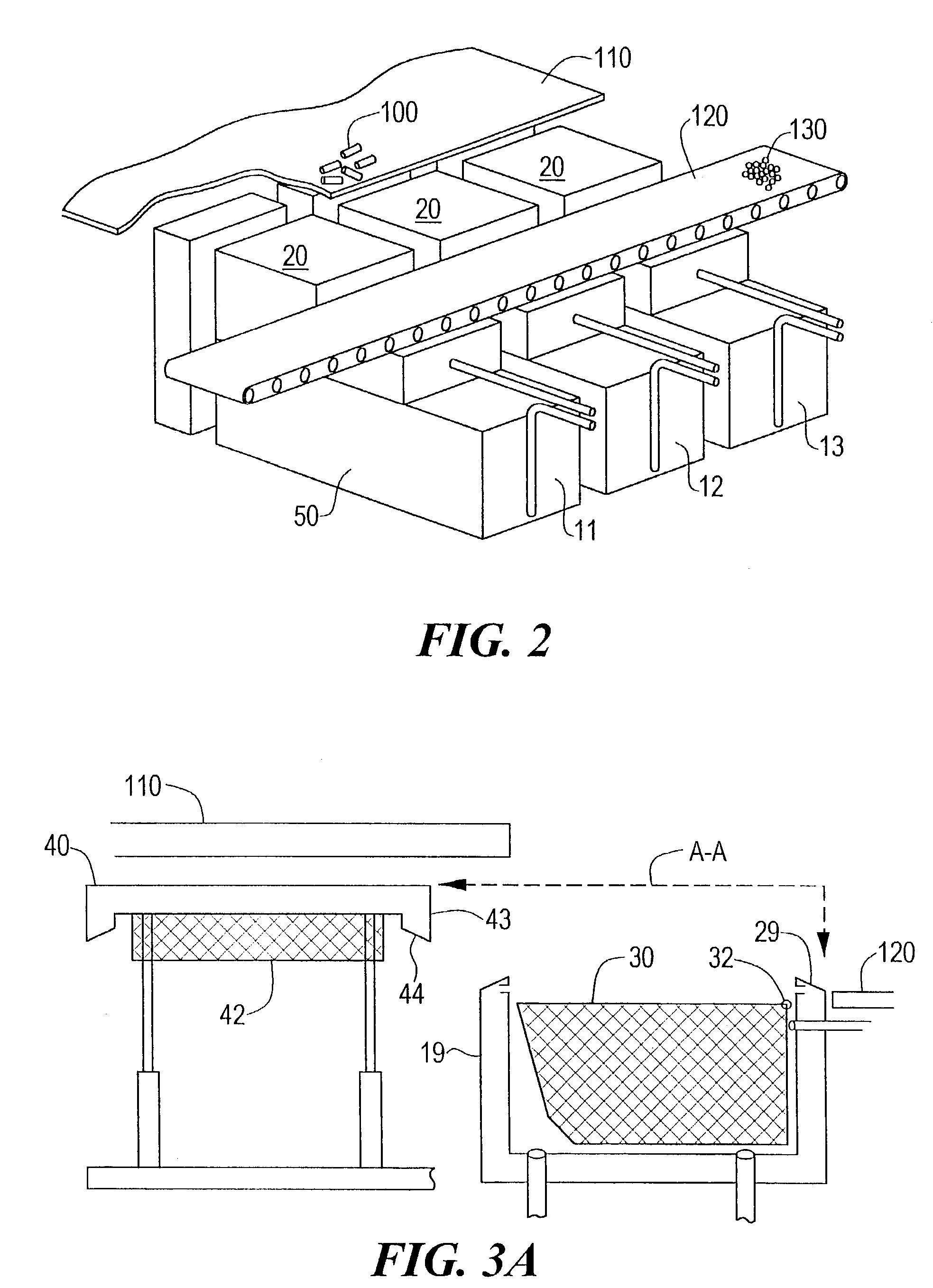

Batch thermolytic distillation of carbonaceous material

InactiveUS20030196884A1Minimizes disposal problemMinimizing substantially exposure to riskCharging-discharging device combinationsDirect heating destructive distillationDistillationTin

A distillation system is provided for batch thermolytic distillation of lump carbonaceous material, such as lump wood and shredded rubber tires. The system preferably includes multiple distillation units mounted side-by-side. Each unit includes a reactor bath for holding molten tin at approximately 455° C., a two-compartment reservoir for storing molten tin, and a porous basket pivotally mounted within the reactor bath for tipping motion. A process for batch thermolytic distillation of lump carbonaceous material includes rotating the porous basket into a reactor bath by rotating the basket about an axis passing through the reactor bath; putting a charge of wood into the basket; closing a retractable lid onto the reactor bath; filling the reactor bath with molten material to produce gas and char by thermolytic conversion of the charge, draining the reactor bath of molten material while the lid is closed; quenching the char in the reactor bath with steam; opening the lid; and tipping the char from the basket.

Owner:SECTOR CAPITAL CORP

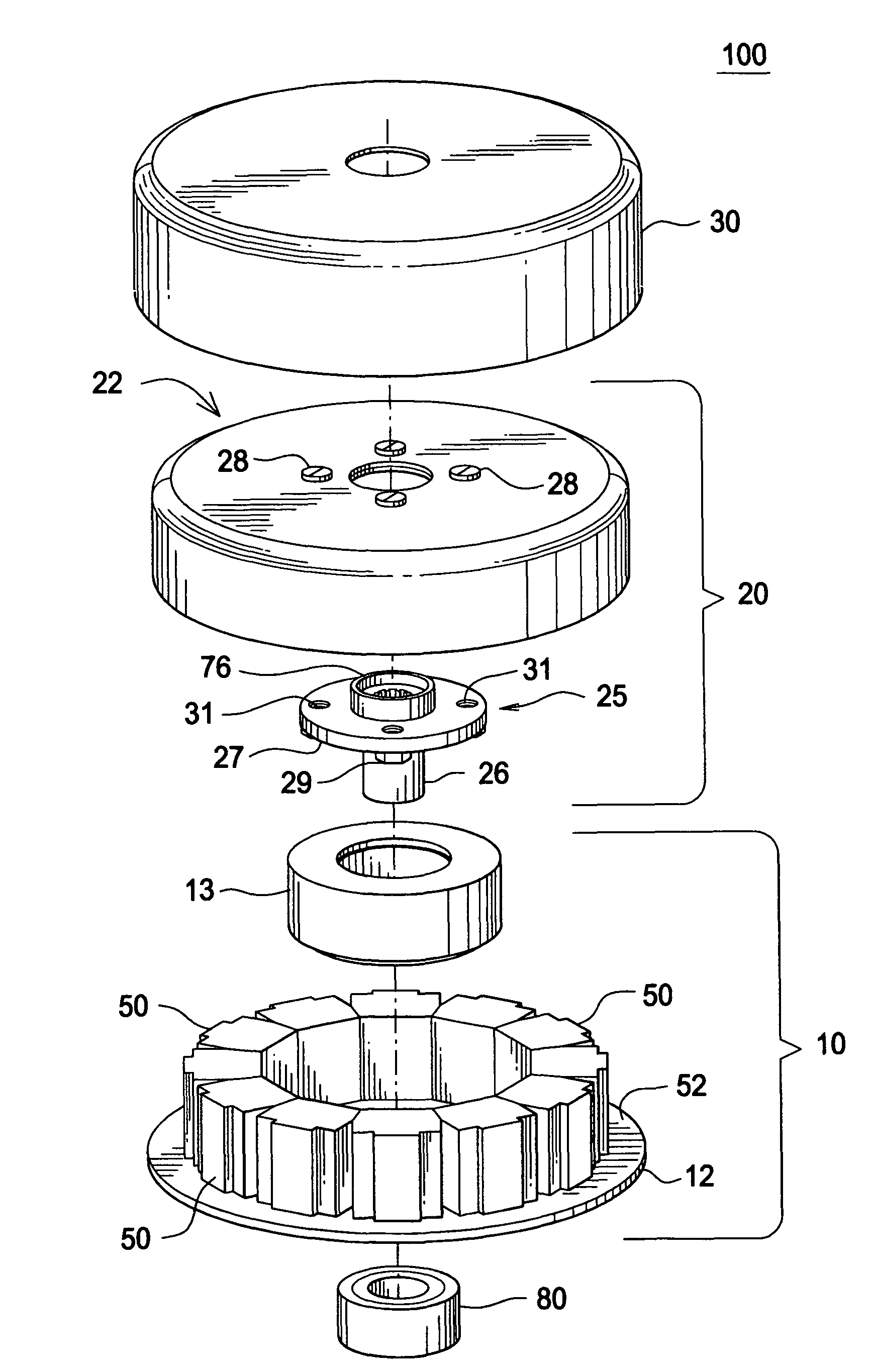

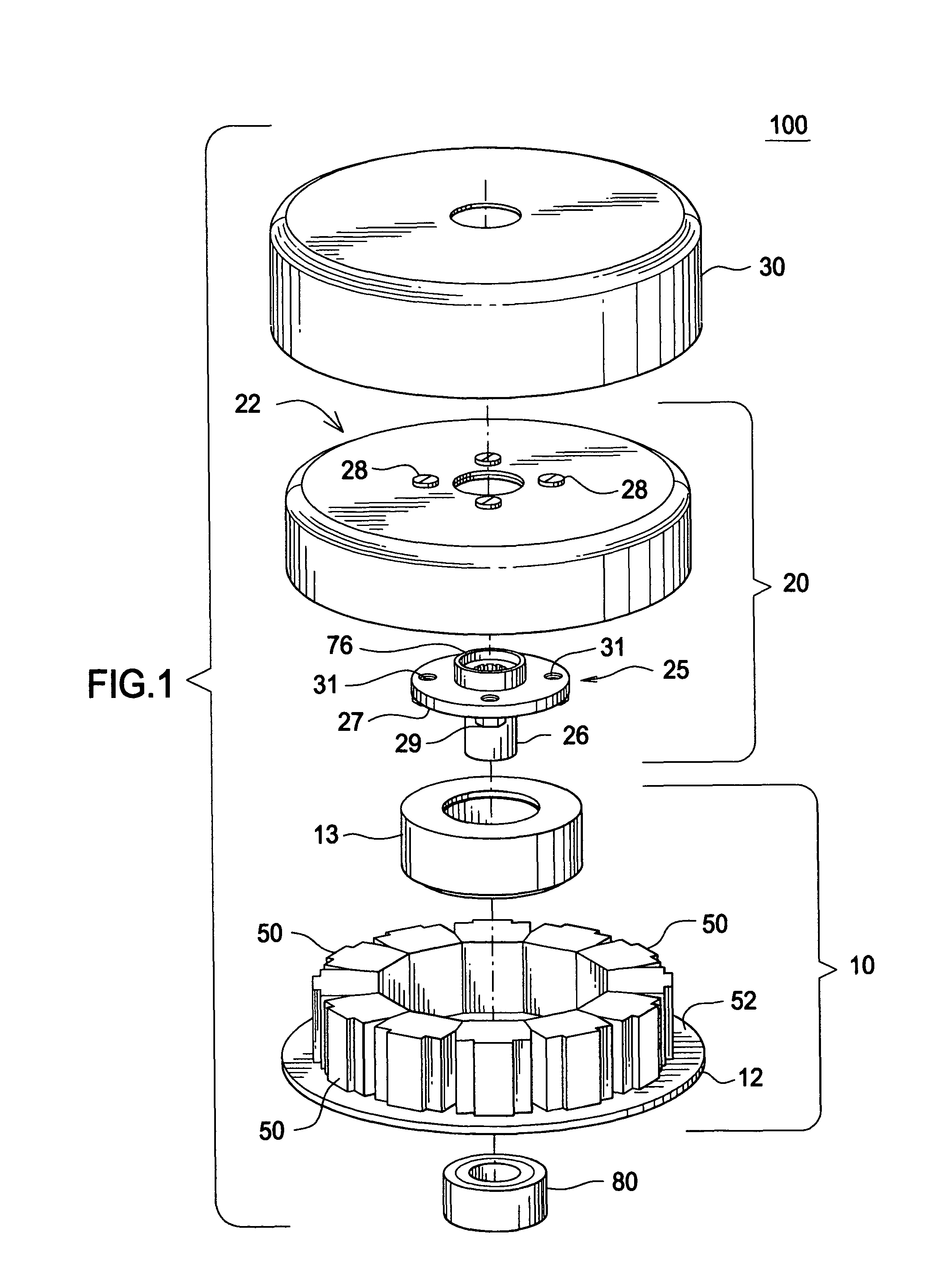

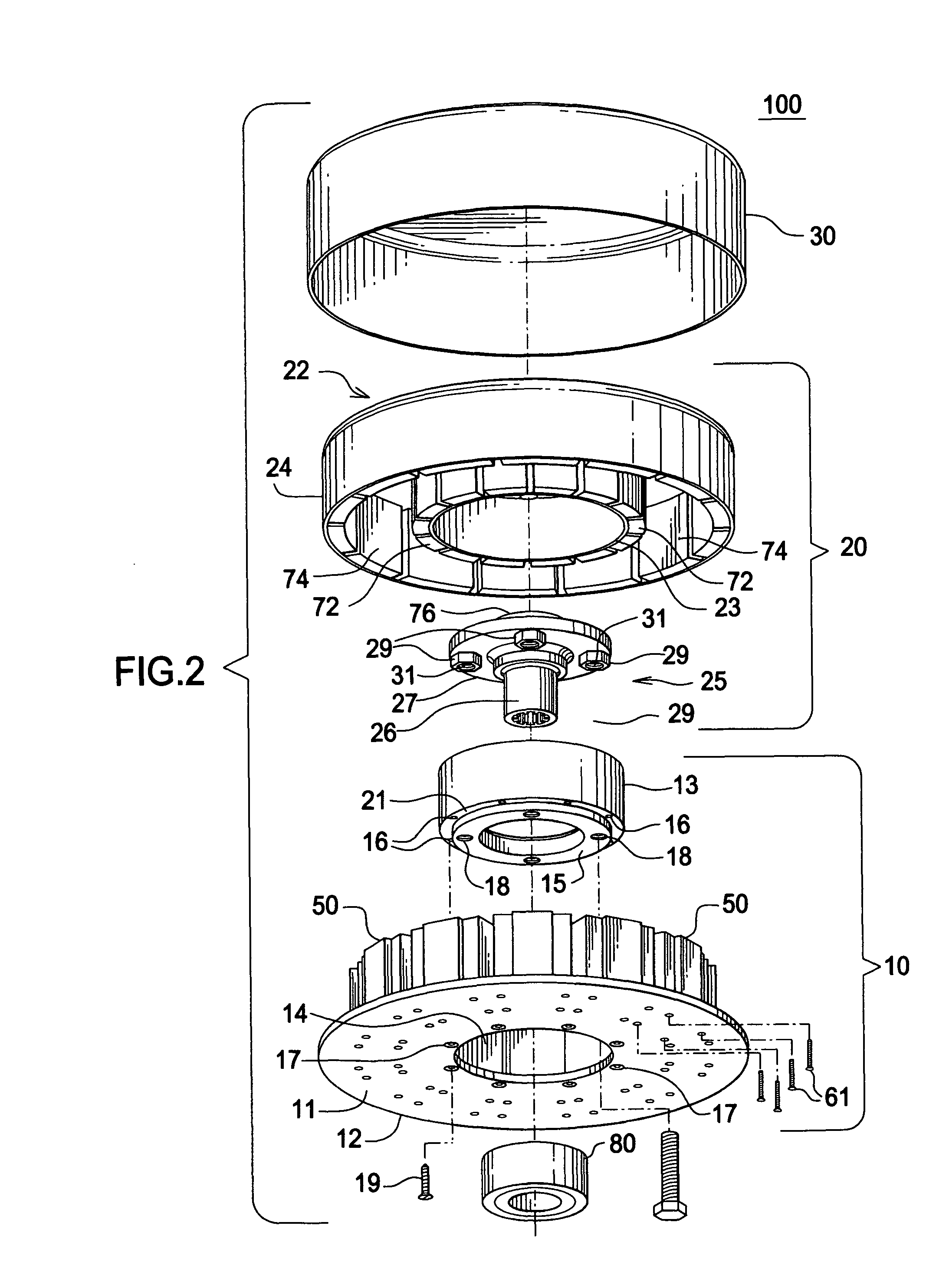

Brushless disk DC motor

InactiveUS7898134B1Increase powerIncrease torqueSynchronous generatorsMagnetic circuit rotating partsRing patternMagnetic poles

A brushless disk DC motor that exhibits high power density and light weight and is capable of power regeneration and reverse operation employs a flat circular non-ferrous stator plate having a plurality of electromagnets mounted in a ring pattern on an inner face thereof. Permanent magnets are mounted in equal numbers in inner and outer ring patterns on the outer and inner cylindrical surfaces, respectively, of a pair of steel rotors of different diameter that rotate in concert. The stator plate and the pair of rotors are axially aligned such that the inner and outer rings of permanent magnets rotate adjacent to and inside and outside, respectively, the ring of electromagnets. The electromagnets utilize tape-wound amorphous metal cores to minimize eddy currents and resultant iron losses and to permit the use of heavier gauge copper windings to minimize resistive power losses. A greater number of poles in the form of permanent magnets can be accommodated, the number being limited only by the diameter of the rotor, thus providing increased power and torque over prior art brushless DC motors having a limited number of poles. The present motor exhibits up to 200% more starting torque, thus eliminating the need for a gear box or clutch in electric vehicle applications.

Owner:SHAW BILL S

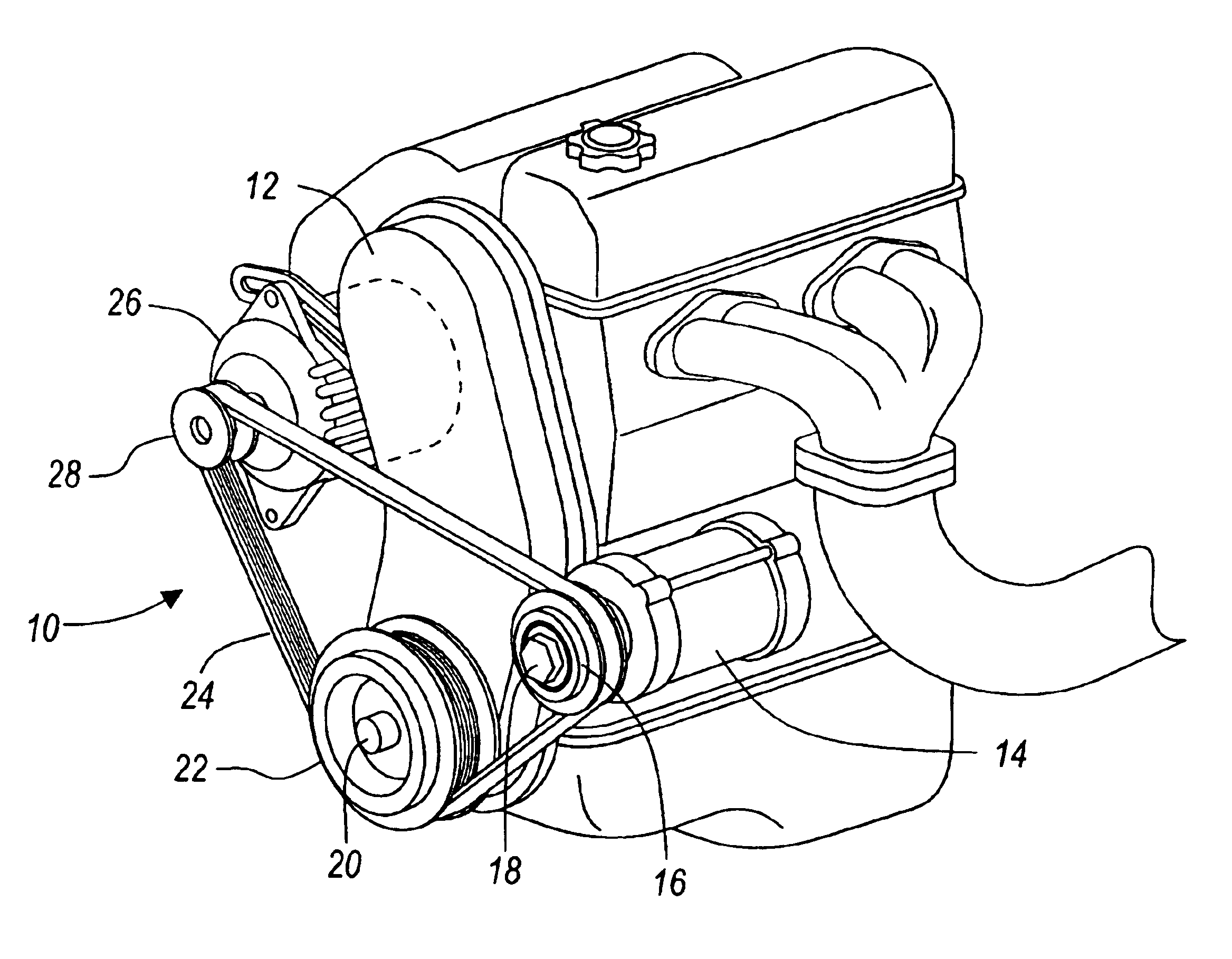

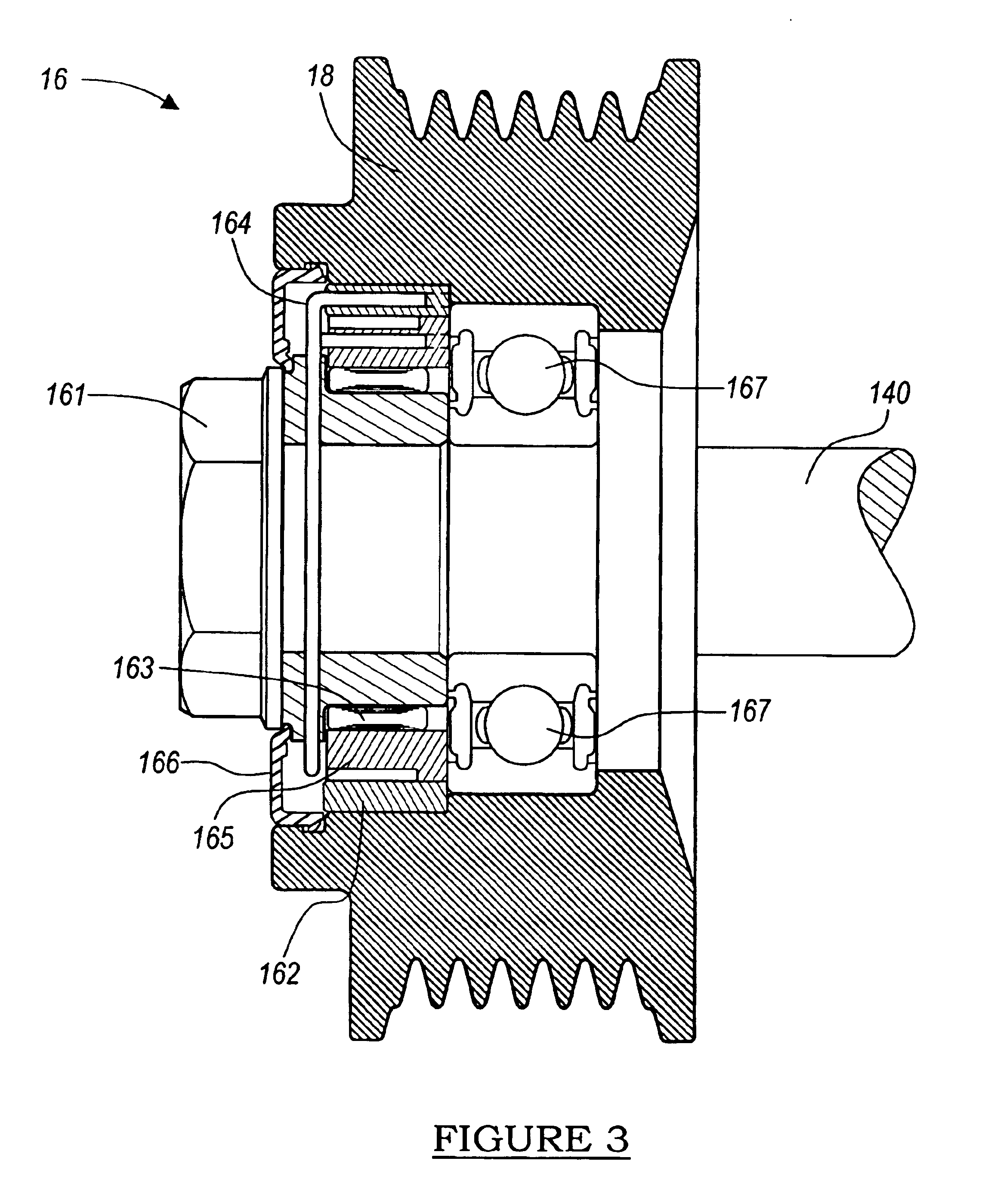

Starter pulley with integral clutch

InactiveUS6848552B2Start fastReduce noisePower operated startersMechanical actuated clutchesExternal combustion engineFuel efficiency

Starter motor systems are described, wherein the systems include a unidirectional clutch system that cooperates with a pulley system to start an internal combustion engine through the front-end accessory drive system. The starter motor systems are especially well suited for new, high fuel efficiency automobiles in which the engine is shut down (e.g., when the automobile stops) and subsequently started (e.g., when the accelerator pedal is depressed).

Owner:NTN CORP

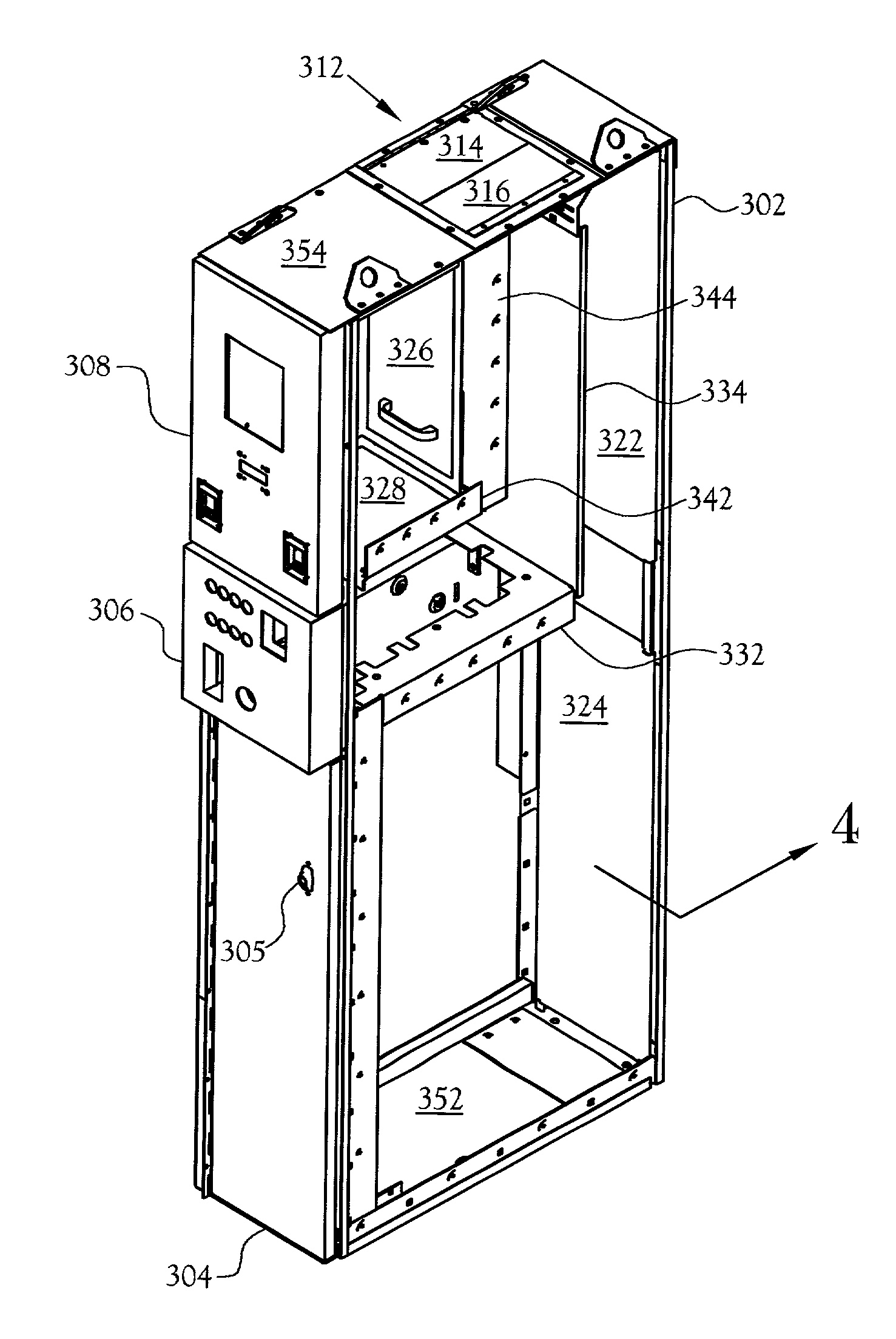

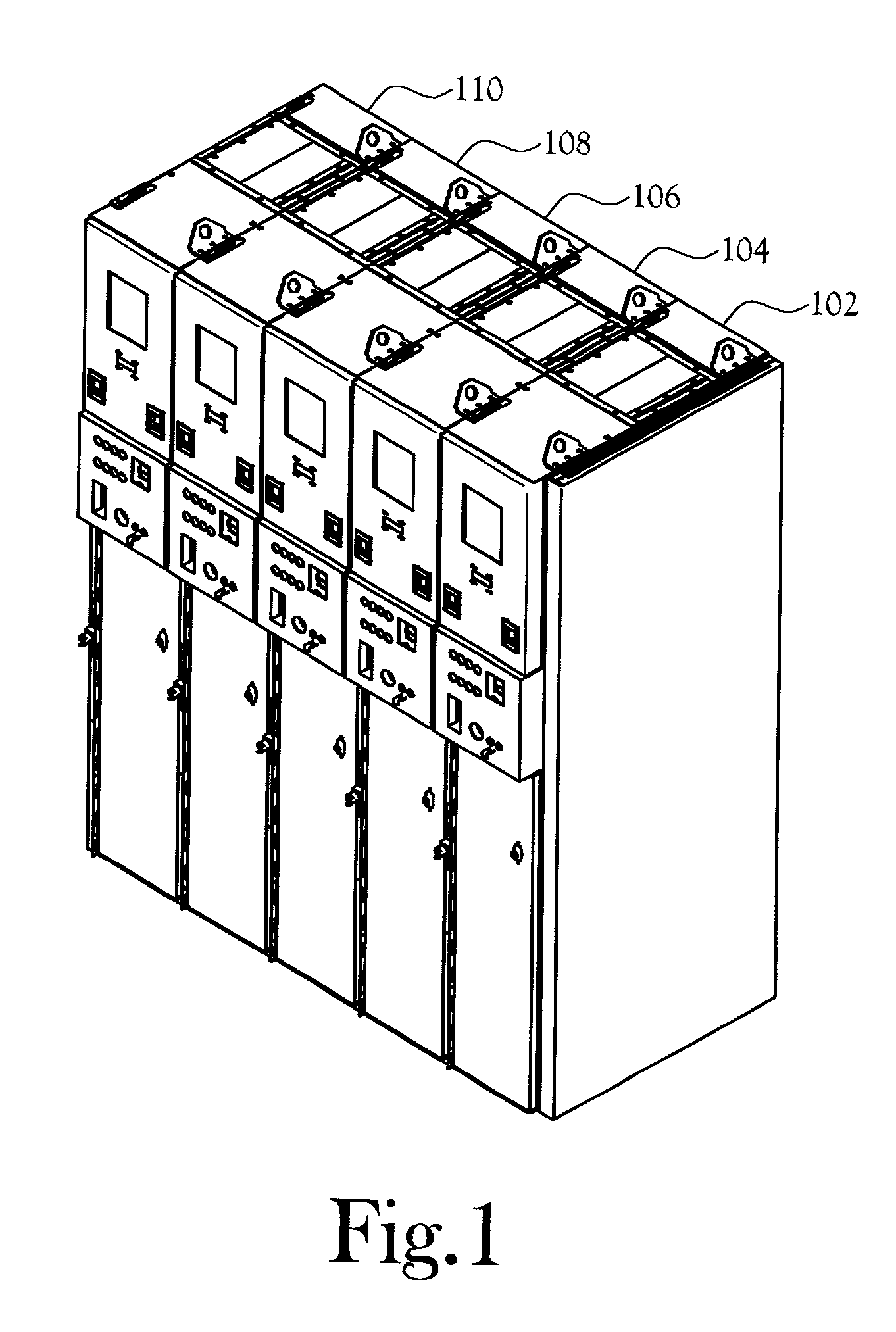

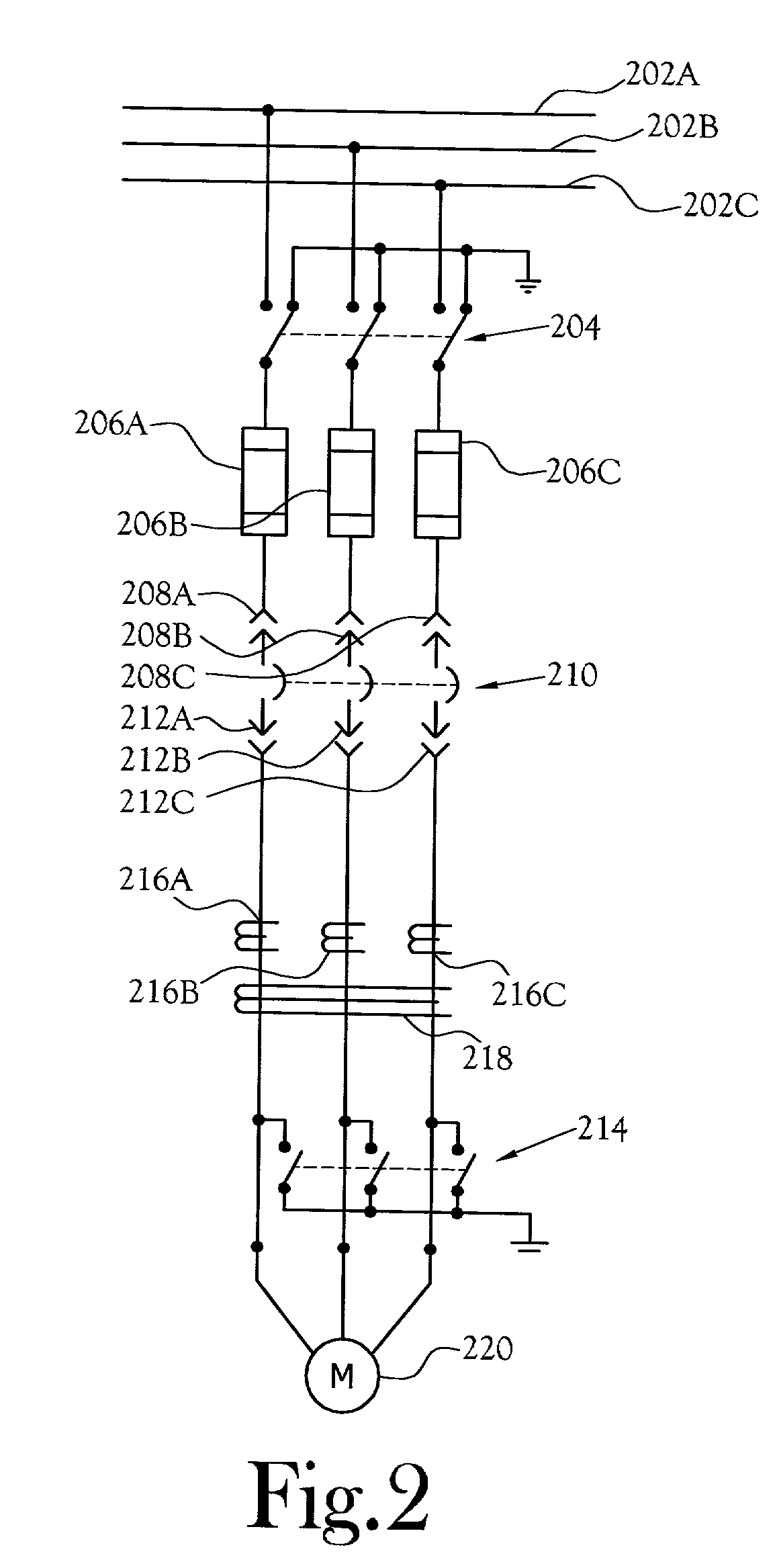

Medium voltage motor control center arc resistant enclosure

InactiveUS7140702B2Minimize componentMinimize fabrication stepShow cabinetsSwitchgear arrangementsElectrical connectionEngineering

A medium voltage controller for electrical equipment, such as motors, transformers, reactors, and capacitors, having an arc resistant cabinet, swaged internal electrical connections, a one-piece self-aligning withdrawable finger cluster, a pull-out instrument compartment, a load discharge device, cast fuse holders, disconnect switch, a switch illuminator, low power current transformers, and an optical temperature measuring system. The arc resistant cabinet relies on the pressure generated by an arc fault to provide the sealing action to contain the fault forces. The cabinet's rear panels are inside the cabinet and the panel lips mate to edges of the cabinet opening. The front doors each have a series of latching tabs along one side and a hinge along the opposing side. A dimple-in-a-dimple joint provides shear strength for panel joints. At the top of the cabinet is an exhaust vent.

Owner:SQUARE D CO

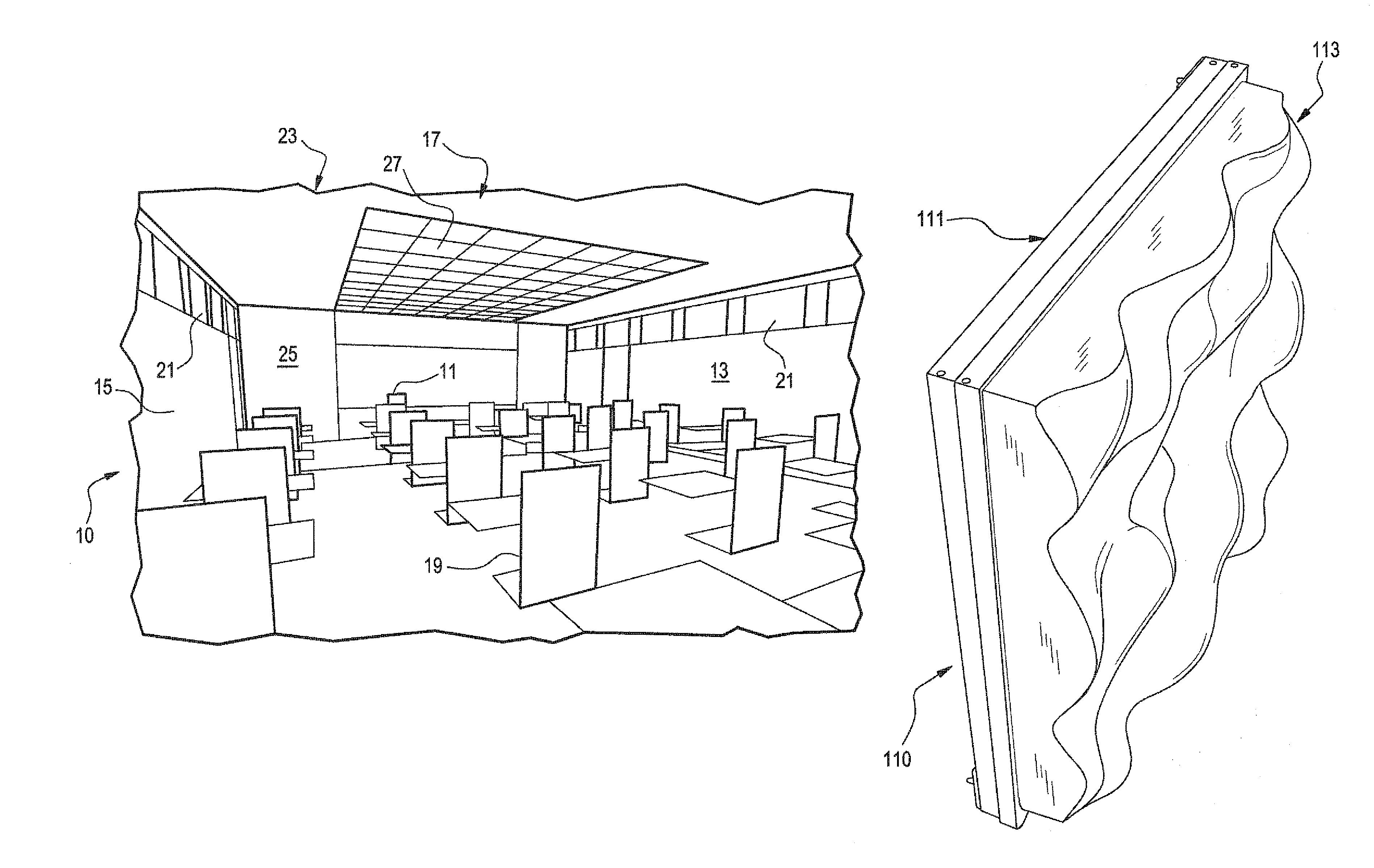

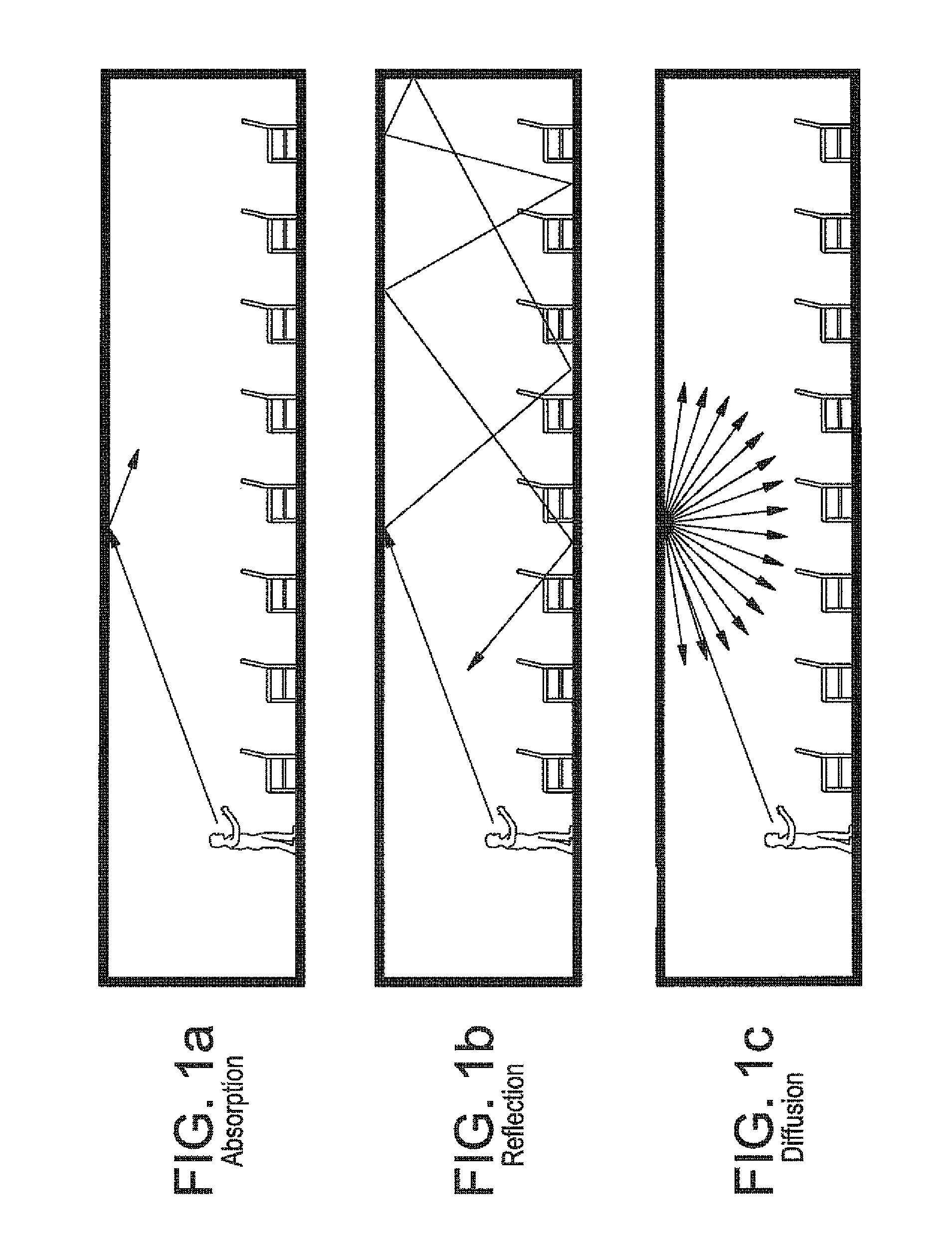

Combination light diffuser and acoustical treatment and listening room including such fixtures

Combination light diffusion with either sound diffusion or absorption is provided in a single lighting fixture, to provide uniform luminosity and sound control. The traditional flat light diffuser is replaced with a translucent acoustical element which either diffuses sound or absorbs the sound. The sound diffuser topology includes random surfaces, geometrical shapes, number theoretic diffusers or optimized rectilinear or curvilinear surfaces. The translucent sound absorber includes microperforated or microslit panels, as well as translucent fabrics and microperforated, translucent wood veneers.

Owner:DANTONIO PETER

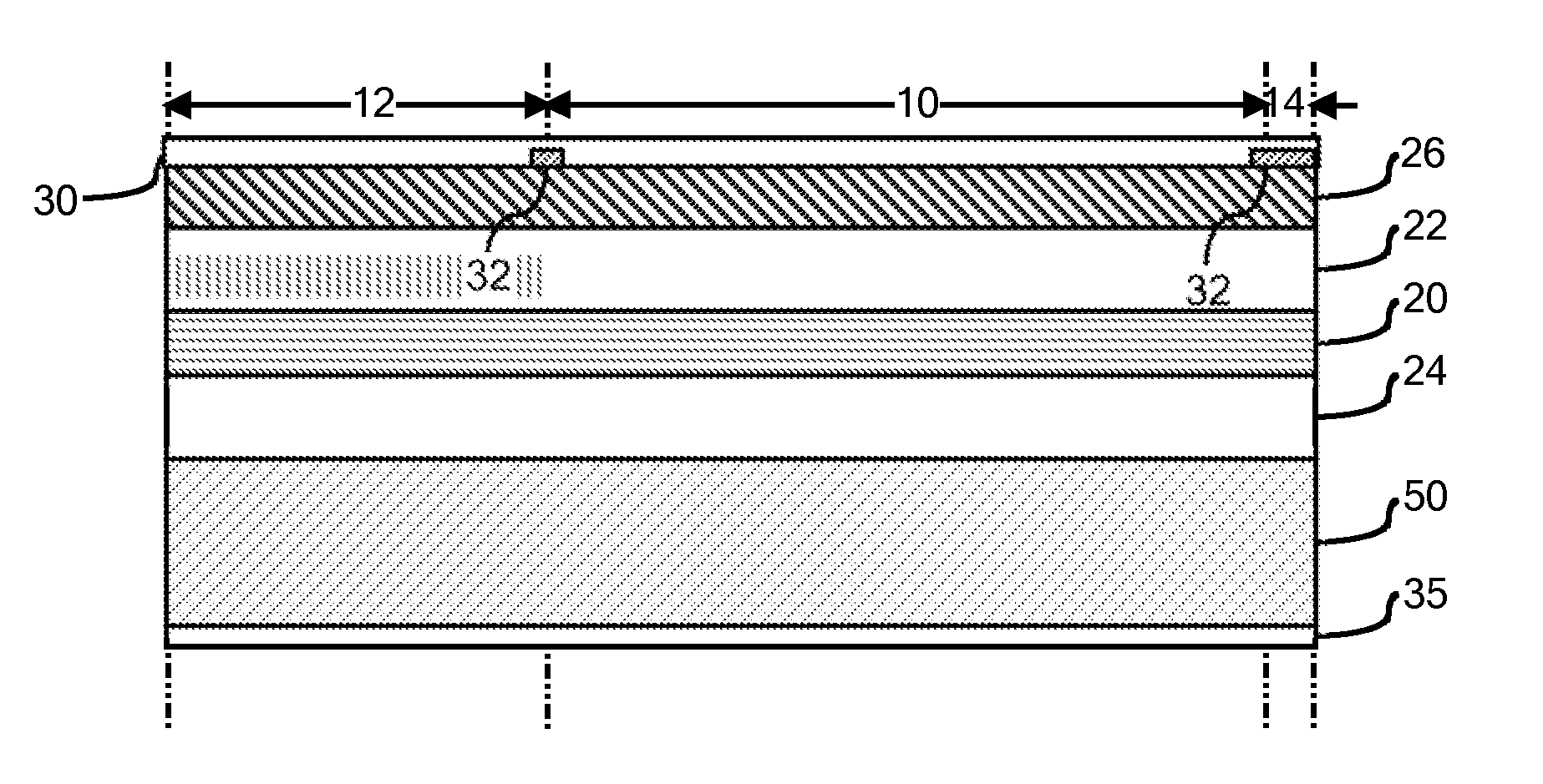

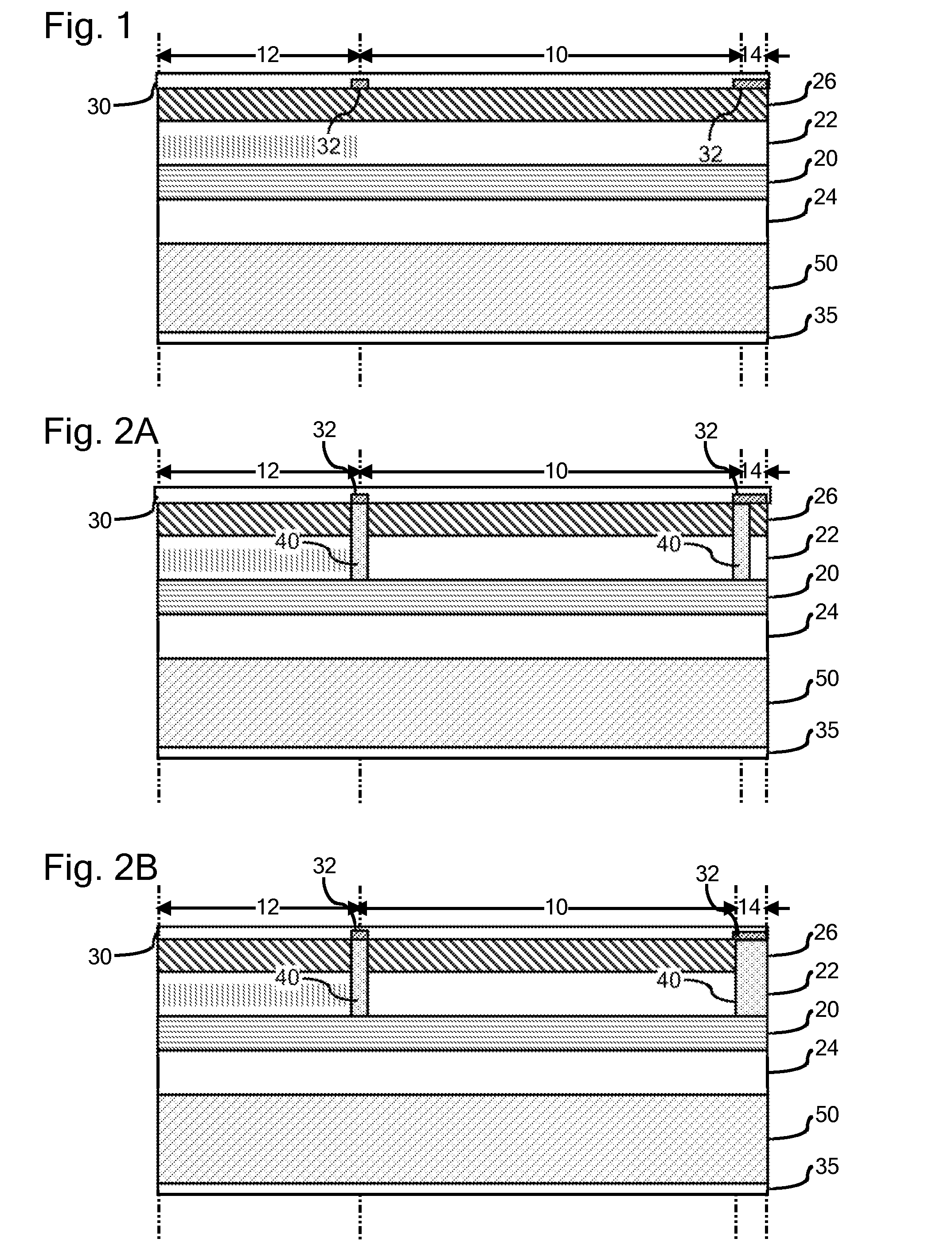

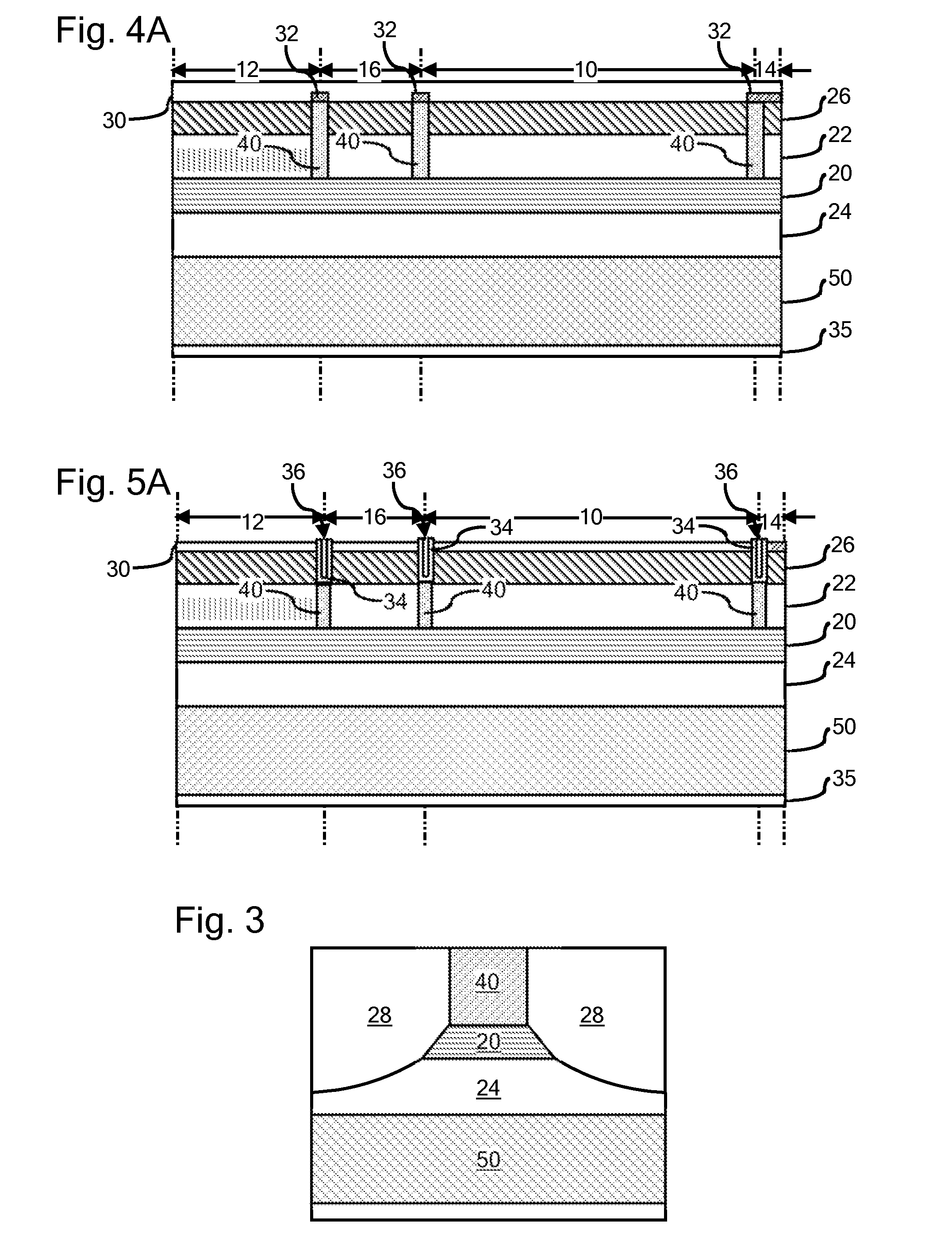

P-type isolation between qcl regions

ActiveUS20120236889A1Reduce currentMinimize heatLaser detailsLaser optical resonator constructionElectrical isolationDopant

A quantum cascade laser and its method of fabrication are provided. The quantum cascade laser comprises one or more p-type electrical isolation regions and a plurality of electrically isolated laser sections extending along a waveguide axis of the laser. An active waveguide core is sandwiched between upper and lower n-type cladding layers and the active core and the upper and lower n-type cladding layers extend through the electrically isolated laser sections of the quantum cascade laser. A portion of the upper n-type cladding layer comprises sufficient p-type dopant to have become p-type and to have become an electrical isolation region, which extends across at least a part of the thickness upper n-type cladding layer along a projection separating the sections of the quantum cascade laser.

Owner:THORLABS QUANTUM ELECTRONICS

Adaptive anti-glare light system and associated methods

ActiveUS8901850B2Good colorCounteract effect of glareLighting support devicesElectrical apparatusCountermeasureLength wave

Owner:LIGHTING SCI GROUP

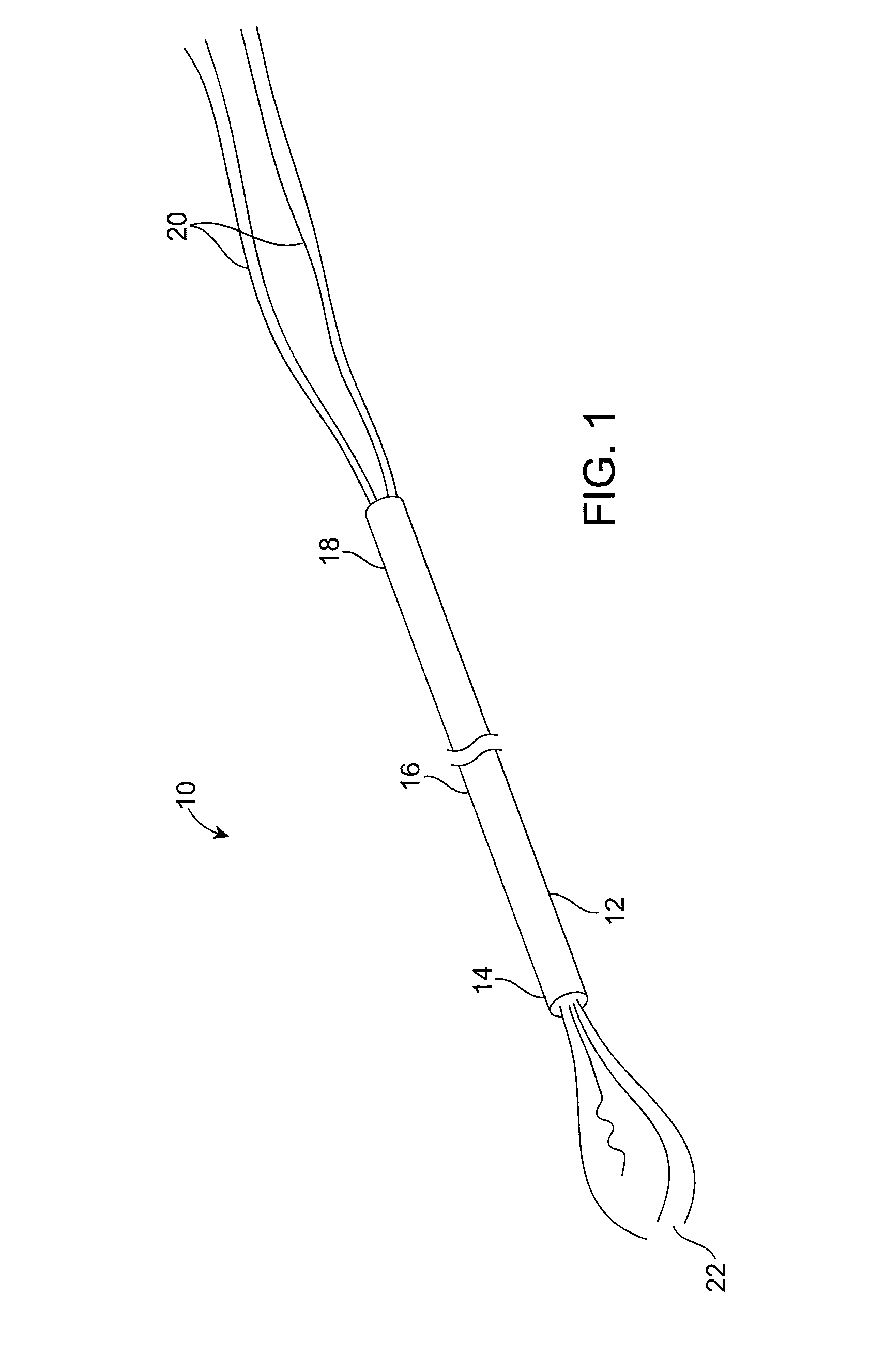

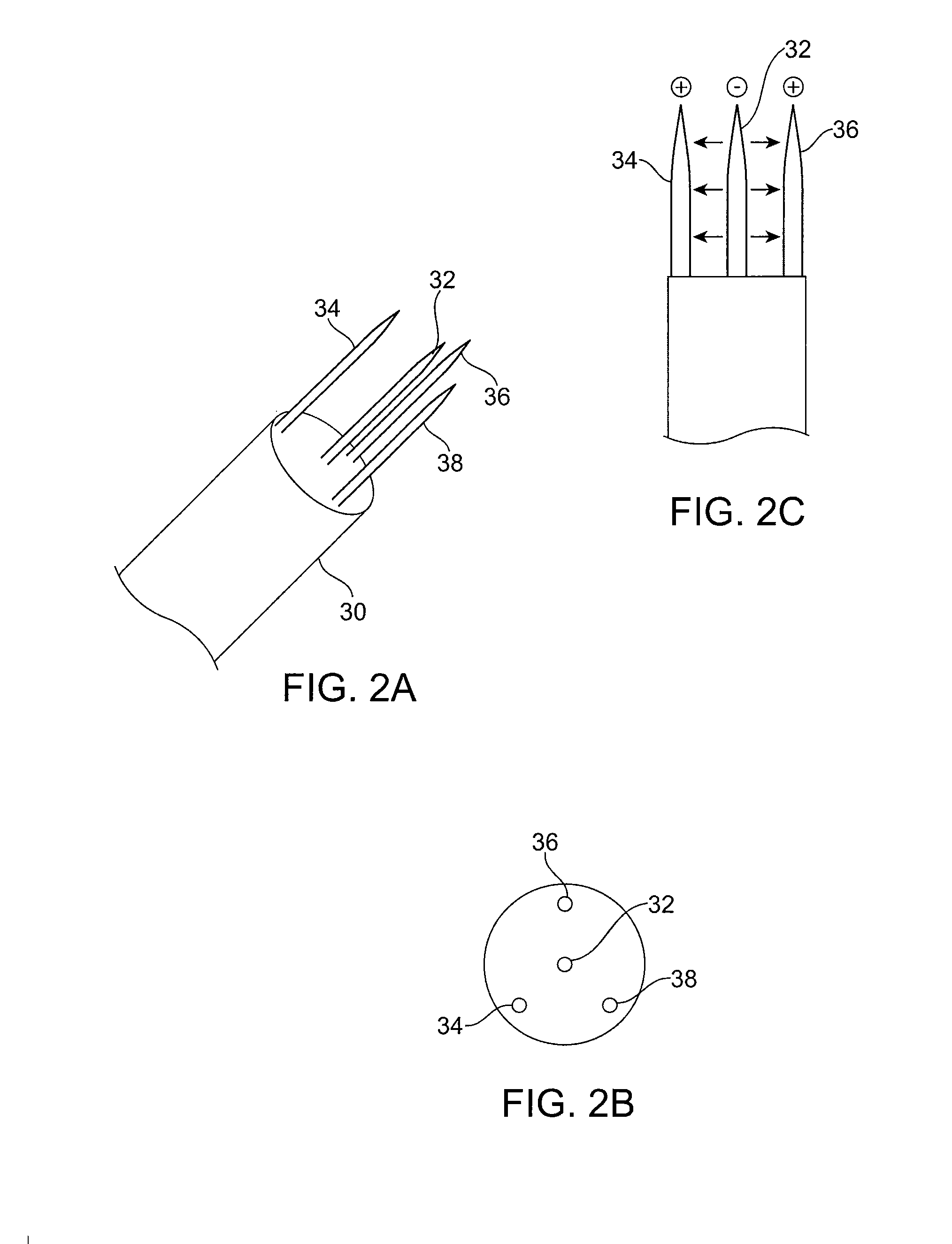

Device and method for destruction of cancer cells

InactiveUS20080071265A1Minimize heatReduce heatElectrotherapySurgical needlesElectric fieldSelective ablation

The present invention provides devices and systems, as well as methods, of electric field delivery and non-thermal or selective ablation of target tissue regions, including selective ablation of cancerous cells and solid tumors. A method of the present invention includes delivering an electric field to a tissue, including positioning an electrode within a target tissue region comprising cancerous cells, and applying an alternating electrical current to the target tissue so as to non-thermally ablate cancerous cells of the target tissue region around the electrodes.

Owner:LAZURE SCI

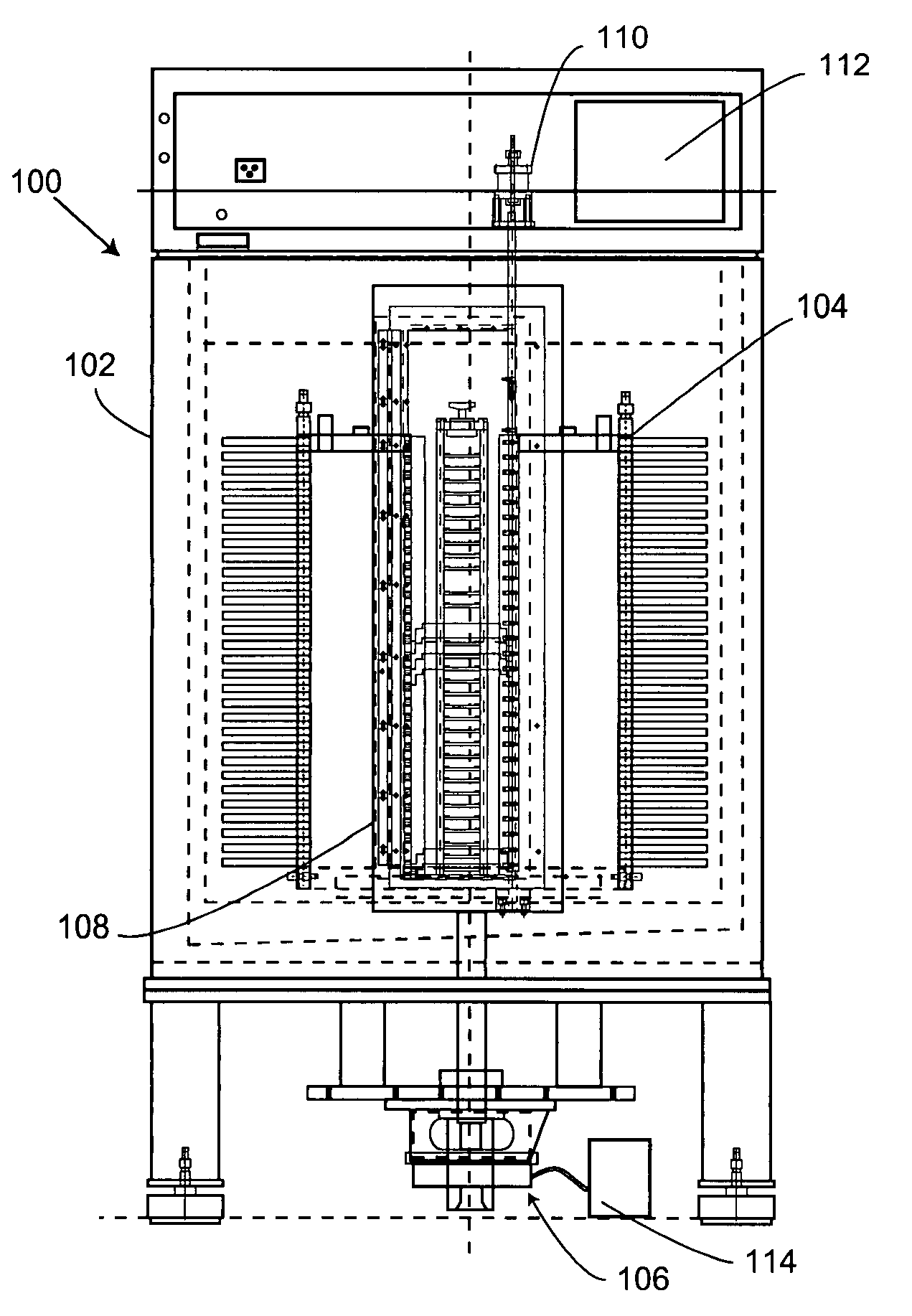

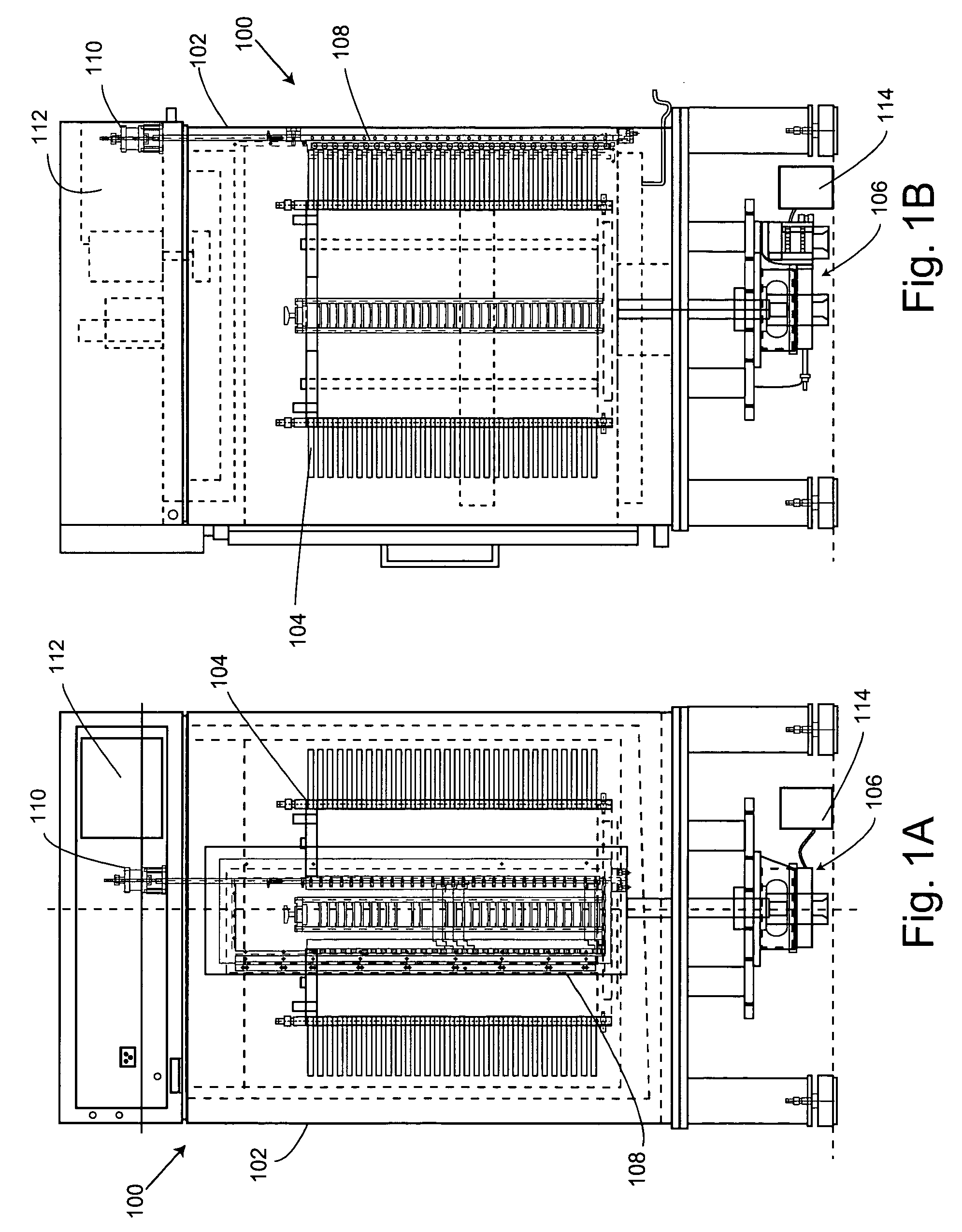

High throughput incubation devices and systems

InactiveUS20060270027A1Minimize airMinimize heatBioreactor/fermenter combinationsBiological substance pretreatmentsBiomedical engineeringMoving parts

The invention provides efficiently automated incubation devices that reduce the number of powered moving parts in the devices and the amount of air transfer between environments that are internal and external to the devices. Related systems are also provided.

Owner:IRM

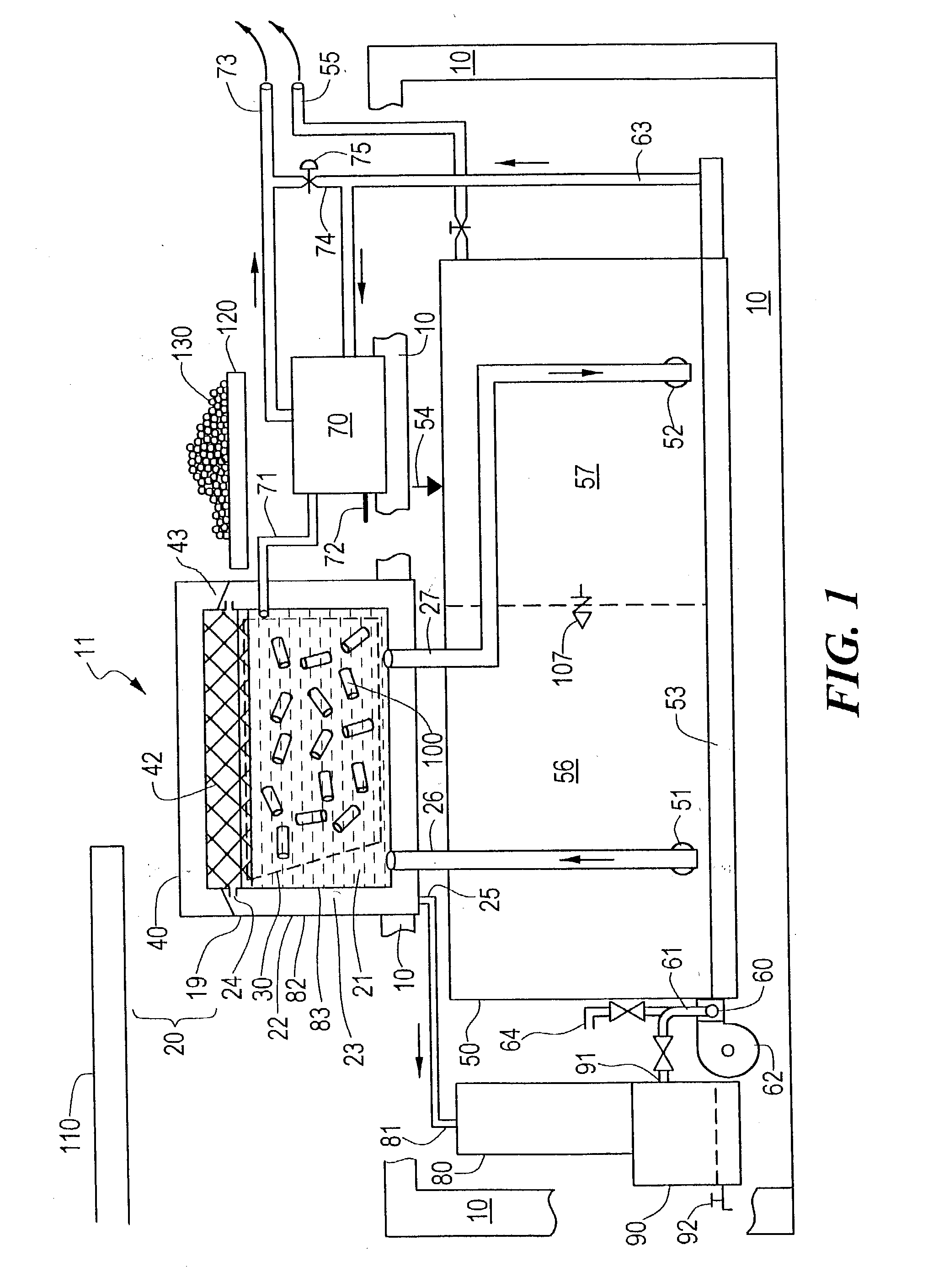

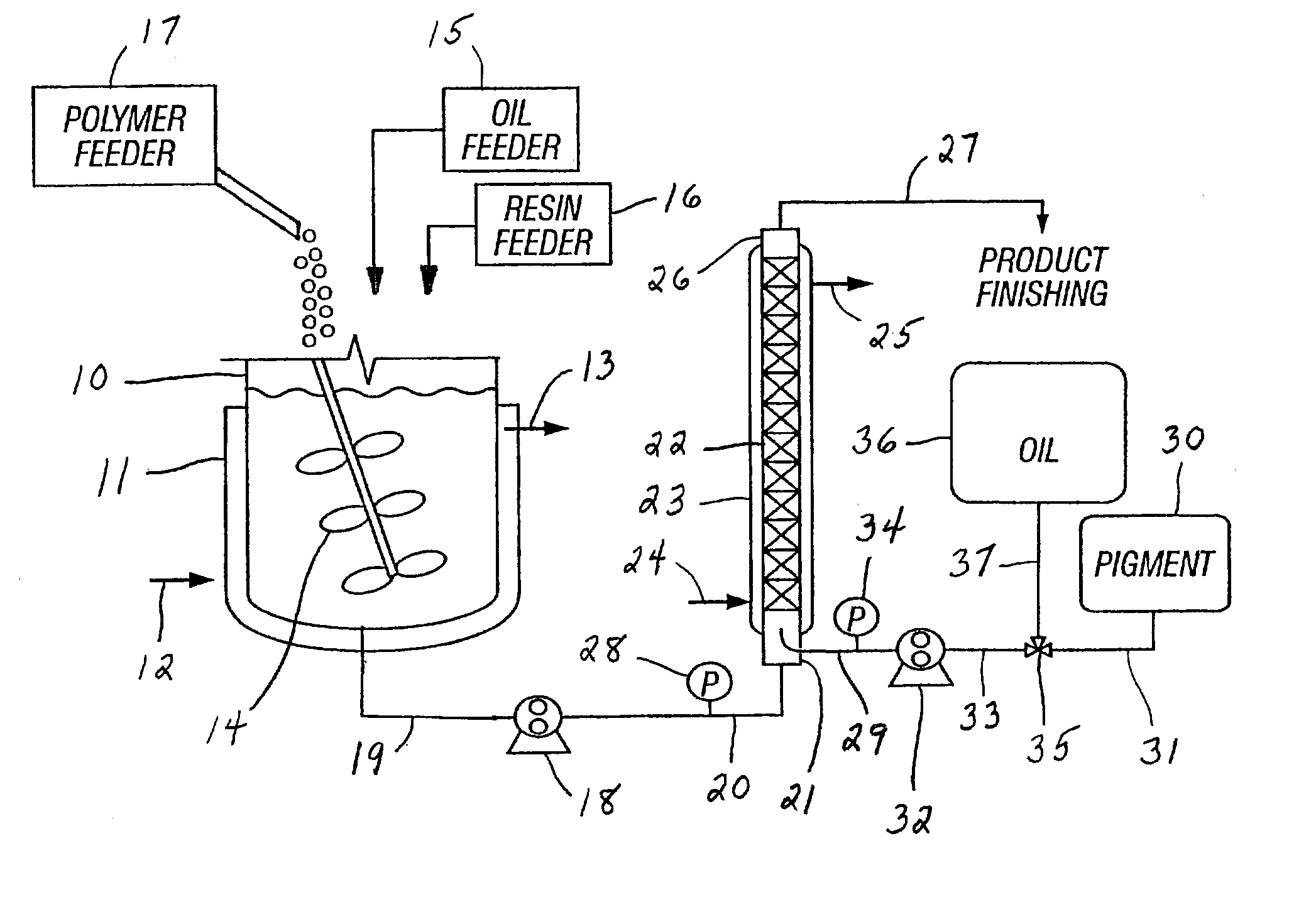

Batch thermolytic distillation of carbonaceous material

InactiveUS7056422B2Minimizes disposal problemMinimizing substantially exposure to riskCharging-discharging device combinationsDirect heating destructive distillationDistillationTin

A distillation system is provided for batch thermolytic distillation of lump carbonaceous material, such as lump wood and shredded rubber tires. The system preferably includes multiple distillation units mounted side-by-side. Each unit includes a reactor bath for holding molten tin at approximately 455° C., a two-compartment reservoir for storing molten tin, and a porous basket pivotally mounted within the reactor bath for tipping motion. A process for batch thermolytic distillation of lump carbonaceous material includes rotating the porous basket into a reactor bath by rotating the basket about an axis passing through the reactor bath; putting a charge of wood into the basket; closing a retractable lid onto the reactor bath; filling the reactor bath with molten material to produce gas and char by thermolytic conversion of the charge, draining the reactor bath of molten material while the lid is closed; quenching the char in the reactor bath with steam; opening the lid; and tipping the char from the basket.

Owner:SECTOR CAPITAL CORP

Micro-fluidic pump

A micro-fluidic pump comprises one or more channels having an array of resistive heaters, an inlet, outlet and a substrate as a heat sink and a means of cooling the device. The pump is operated with a fire-to-fire delay and / or a cycle-to-cycle delay to control the pumping rate and minimize heating of liquid inside the pump during its operation.

Owner:LEXMARK INT INC

Packed storage phosphor screens or panels

ActiveUS20040070328A1Minimize heatSmall differenceCathode ray tubes/electron beam tubesOther accessoriesCarbon dioxideRelative humidity

A packed phosphor screen or panel consisting of at least one flat square or rectangular screen or panel, optionally packed apart in a wrapper foil, and a sealed package, wherein said package is layered in form of an asymmetrical barrier layer foil, said foil comprising an inner flexible thermoplastic polymer layer and an outer polymer layer in adhesive contact with an aluminum layer situated inbetween said inner flexible thermoplastic polymer layer and said outer polymer layer, wherein said foil is characterized by adhesive forces, between said outer polymer layer and said aluminum layer, of more than 2.5 N / mm<2 >following DIN 53 357, by a permeation to water vapor of less than 0.01 g per sq.m. in an environment having a temperature of 23° C. and a relative humidity of 75% RV for 24 hours following DIN 53 122, and by a permeation of less than 0.01 cm<3 >per sq.m. per 24 hours and per bar for each of oxygen, carbon dioxide and nitrogen following DIN 53 380 (ISO 2556, ASTM D 1434).

Owner:T2PHARMA GMBH

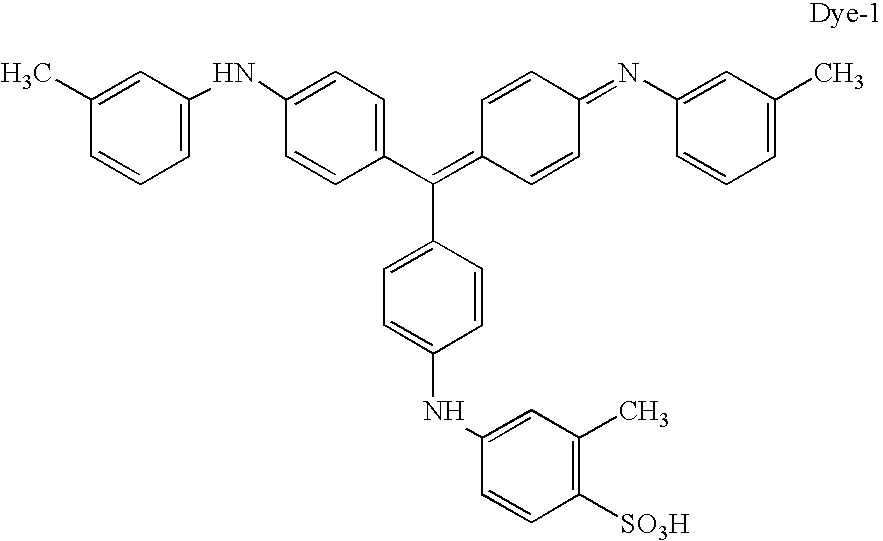

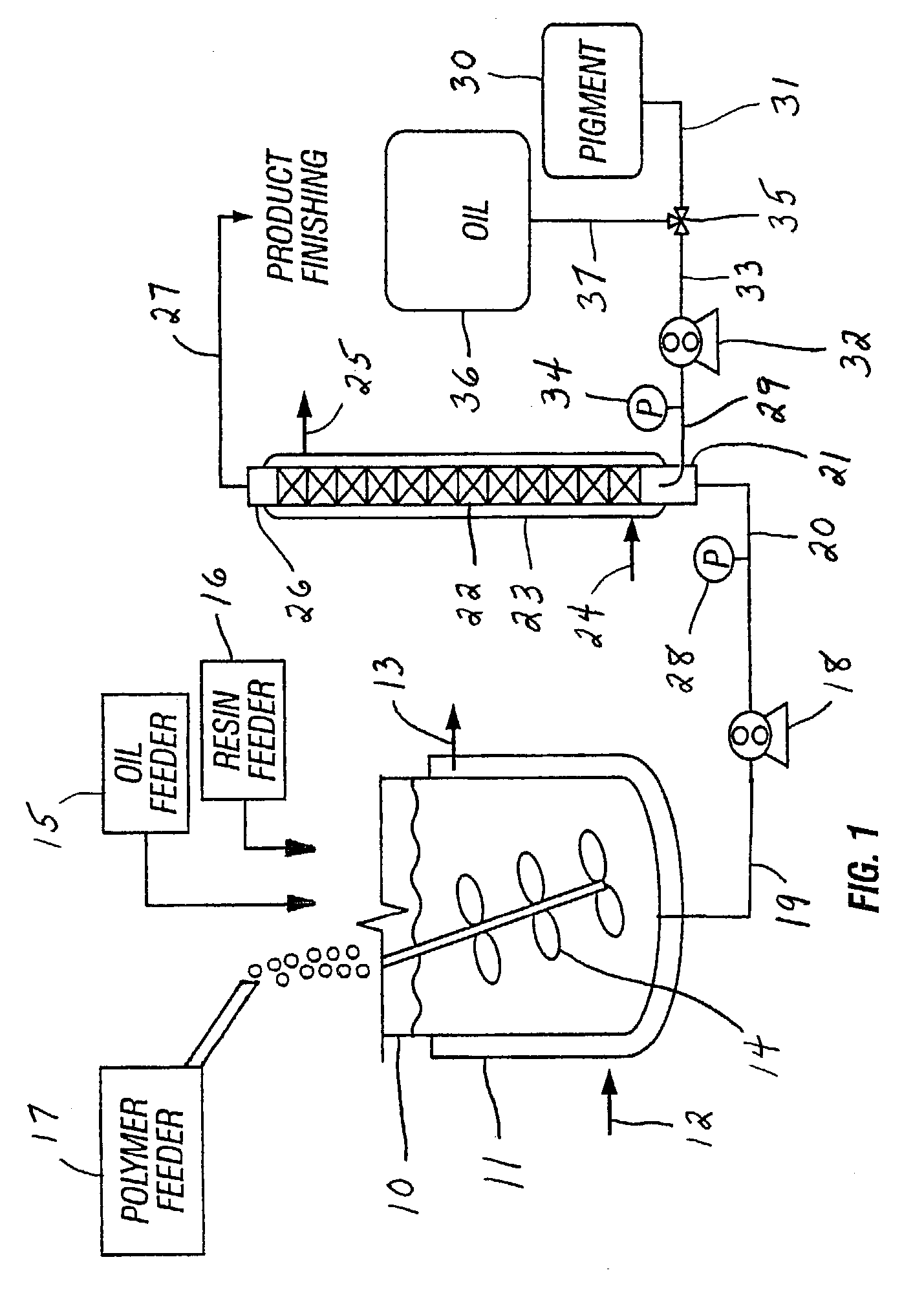

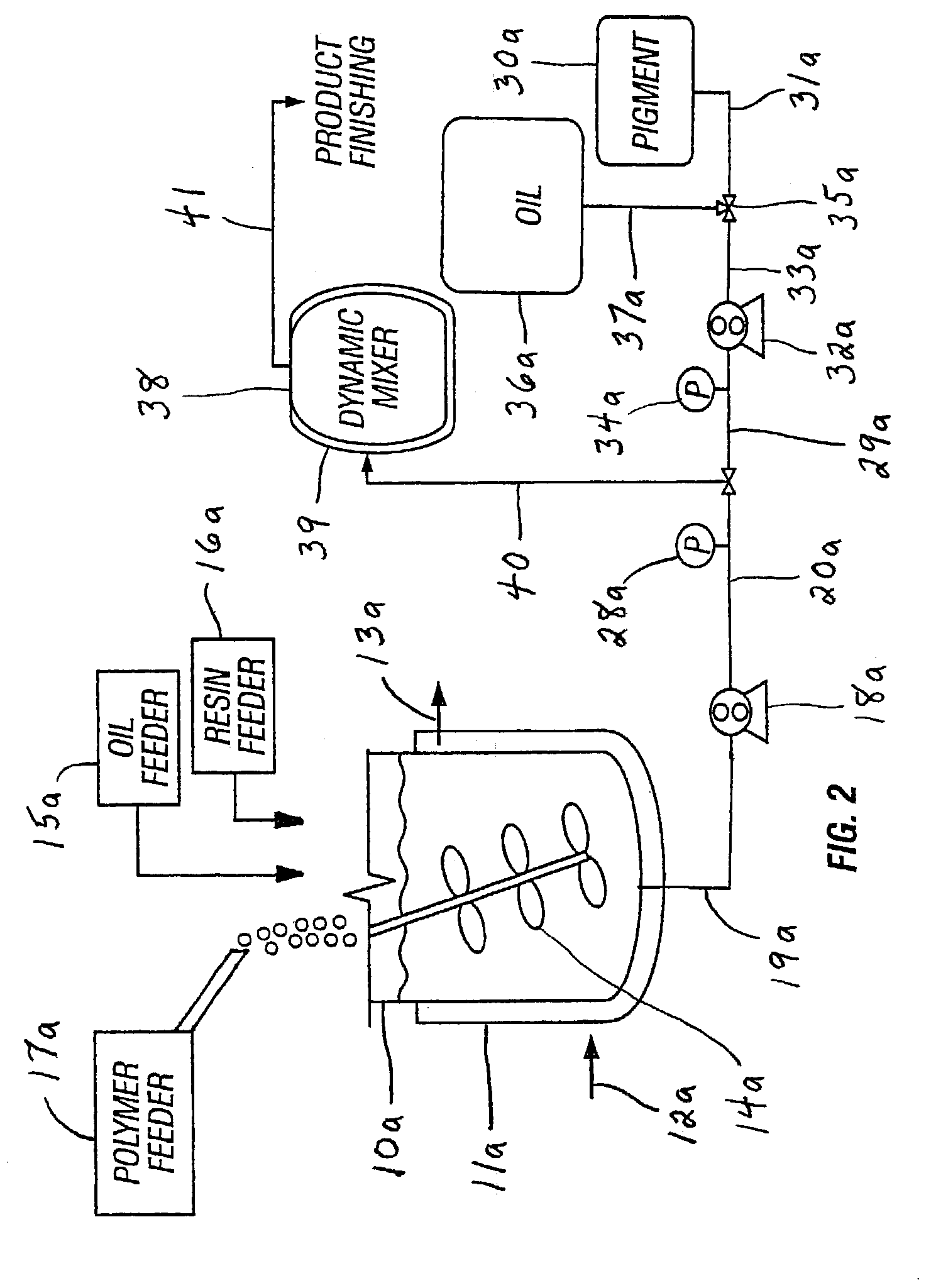

Method of post mixing additives to hot melt adhesives

InactiveUS7059760B2Minimize costMinimize heatTransportation and packagingMixer accessoriesHot-melt adhesiveUv absorber

A method and apparatus for post mixing an additive with a hot melt adhesives. The method includes the steps of providing a source of molten hot melt adhesive, feeding the hot melt adhesive to an inlet of a mixer, simultaneously feeding an additive for the hot melt adhesive to the inlet of the mixer, mixing the additive and molten hot melt adhesive in the mixer to form a homogeneous mixture, and recovering the homogenous mixture. The additive is preferably selected from wetness indicators, antimicrobial agents, pigments, dyes, ultraviolet light absorbers, antioxidants, fluorescent agents, pH indicators and fragrances. The method may be practiced either on a batch basis, or on a continuous basis. The apparatus includes a vessel containing molten hot melt adhesive, a mixer located downstream from the vessel, the mixer having an inlet and an outlet, a first pump located between the vessel and the mixer for pumping molten hot melt adhesive from the vessel to the inlet of the mixer, a source of an additive for the hot melt adhesive, and a second pump located between the source of the additive and the mixer for pumping the additive to the inlet of the mixer. The mixer may comprise either a static mixer or a dynamic mixer.

Owner:BOSTIK INC

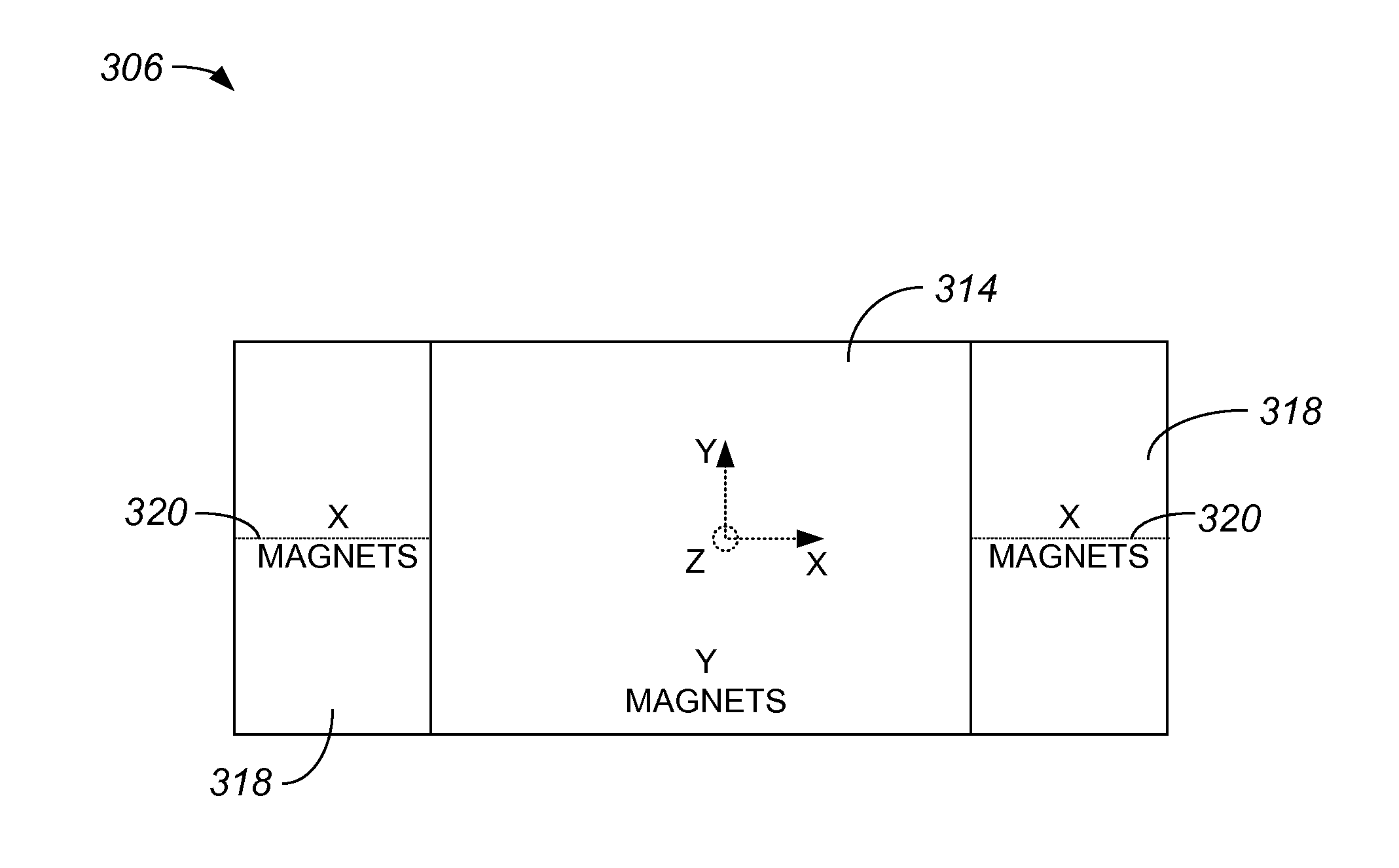

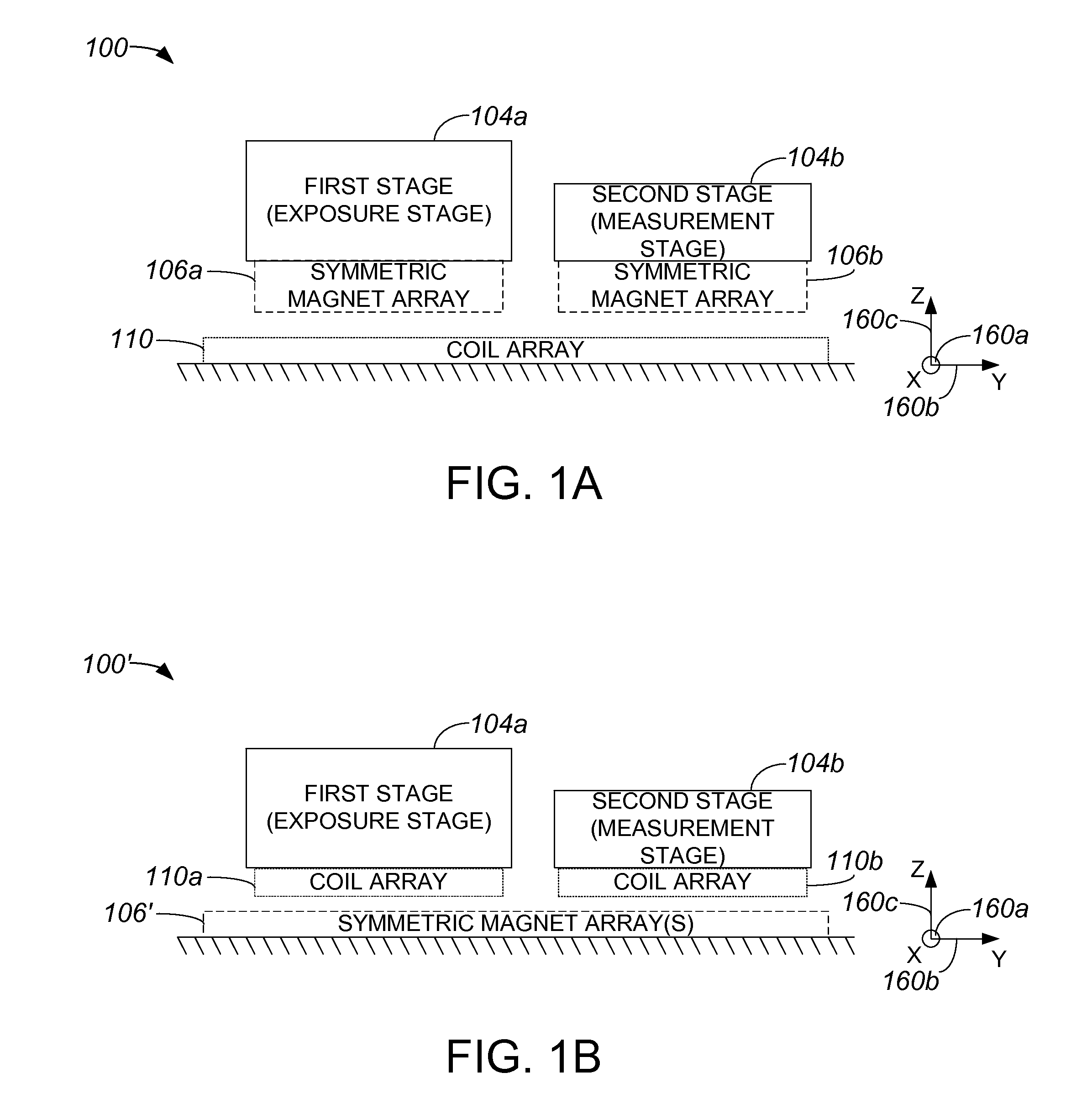

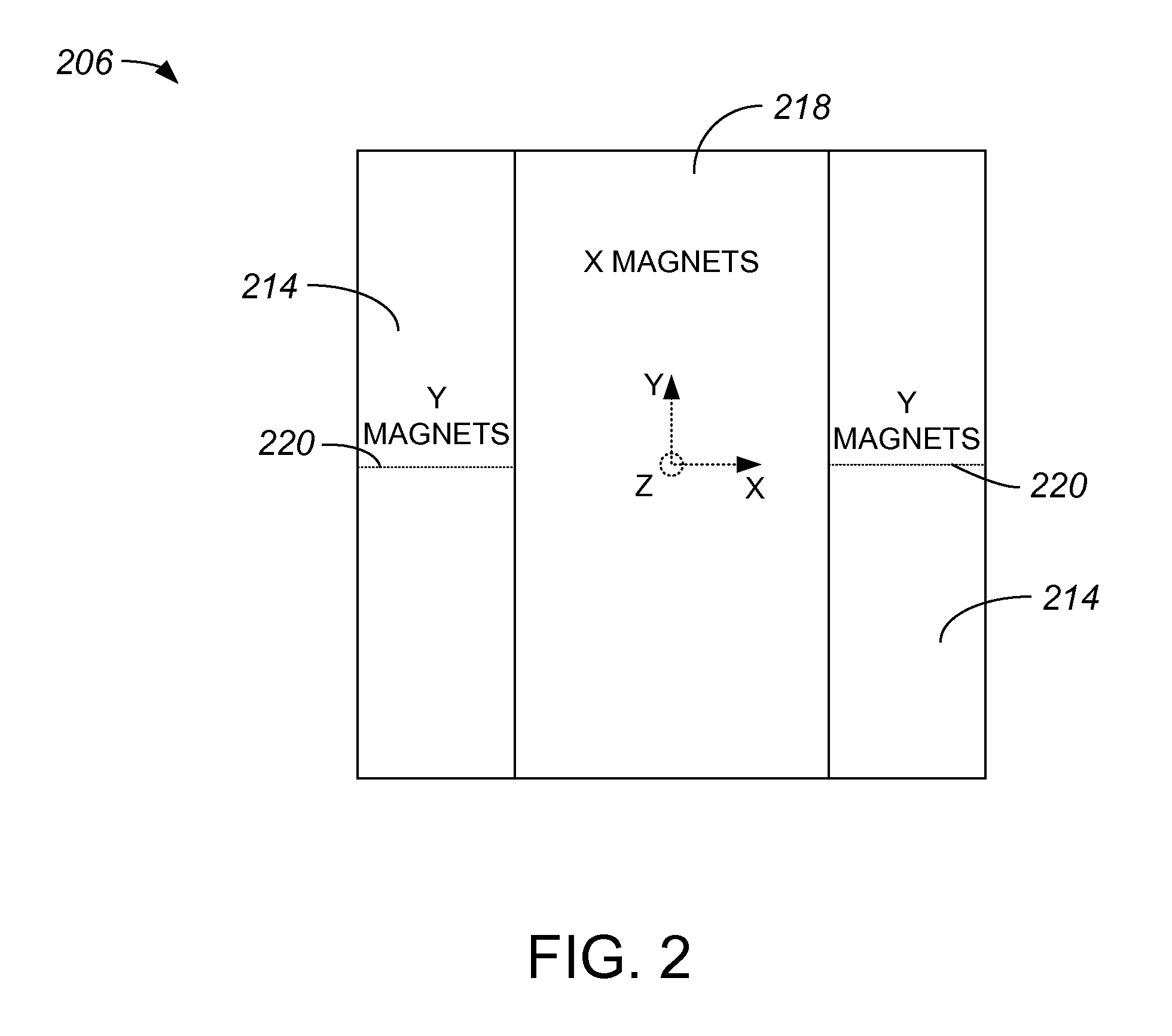

Magnet Array Configuration for Higher Efficiency Planar Motor

InactiveUS20130258307A1Minimize heat outputMinimize power consumptionMagnetic circuitPhotomechanical exposure apparatusPlanar motorMagnet

According to one aspect, a stage apparatus includes a first surface, a second surface, an overall magnet array, and a plurality of coils. The overall magnet array is mounted on the first surface, and includes an X magnet array and a Y magnet array. The coils are mounted on the second surface, and include a first coil that cooperates with the X magnet array to control force on the first surface along an x-axis. The coils also include a second coil that cooperates with the Y magnet array to control force on the first surface along a y-axis. The second coil cooperates with the overall magnet array to control force applied to the first surface in a direction normal to the first surface. The first coil does not cooperate with the overall magnet array to control the force applied in the direction normal to the first surface.

Owner:NIKON CORP

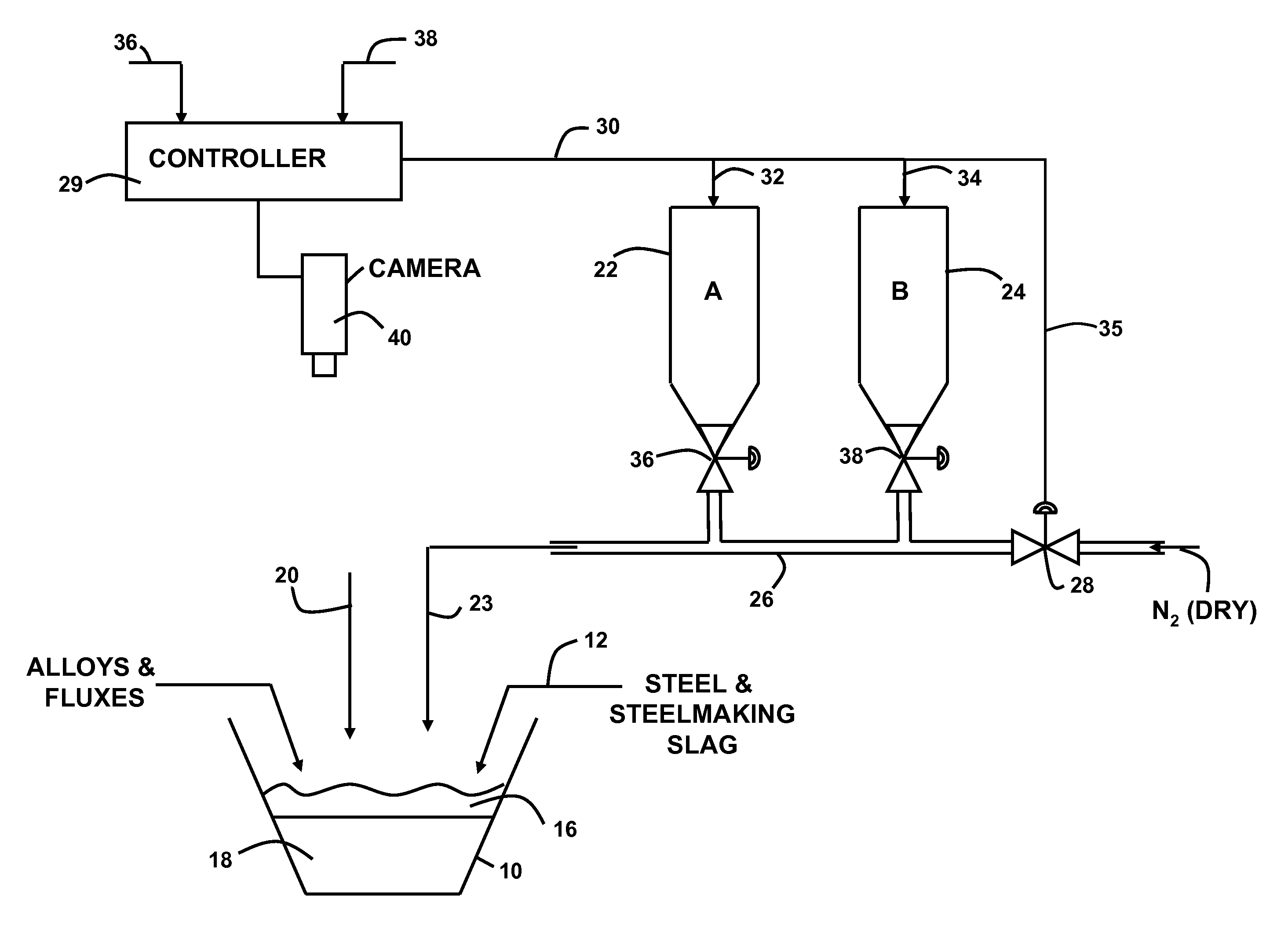

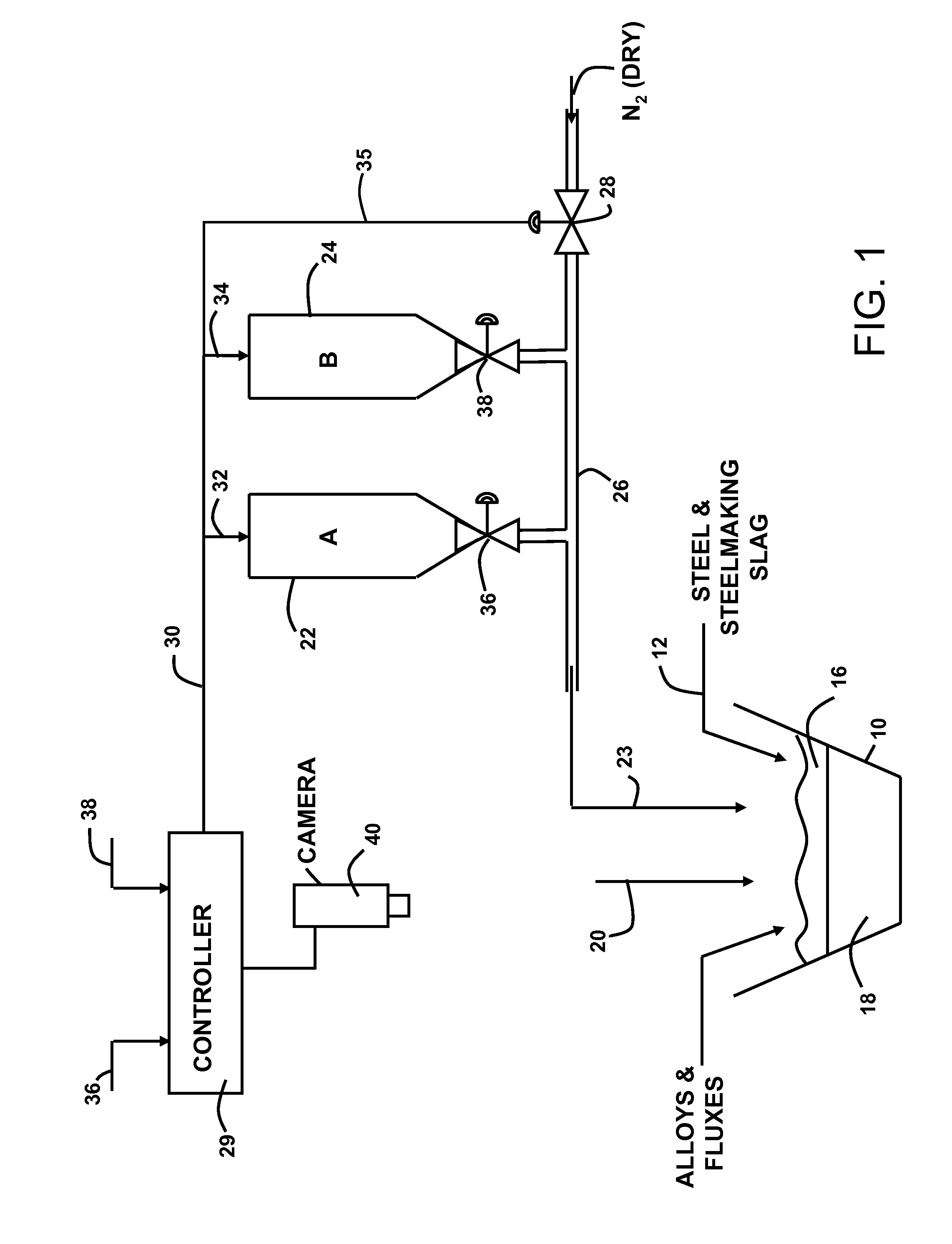

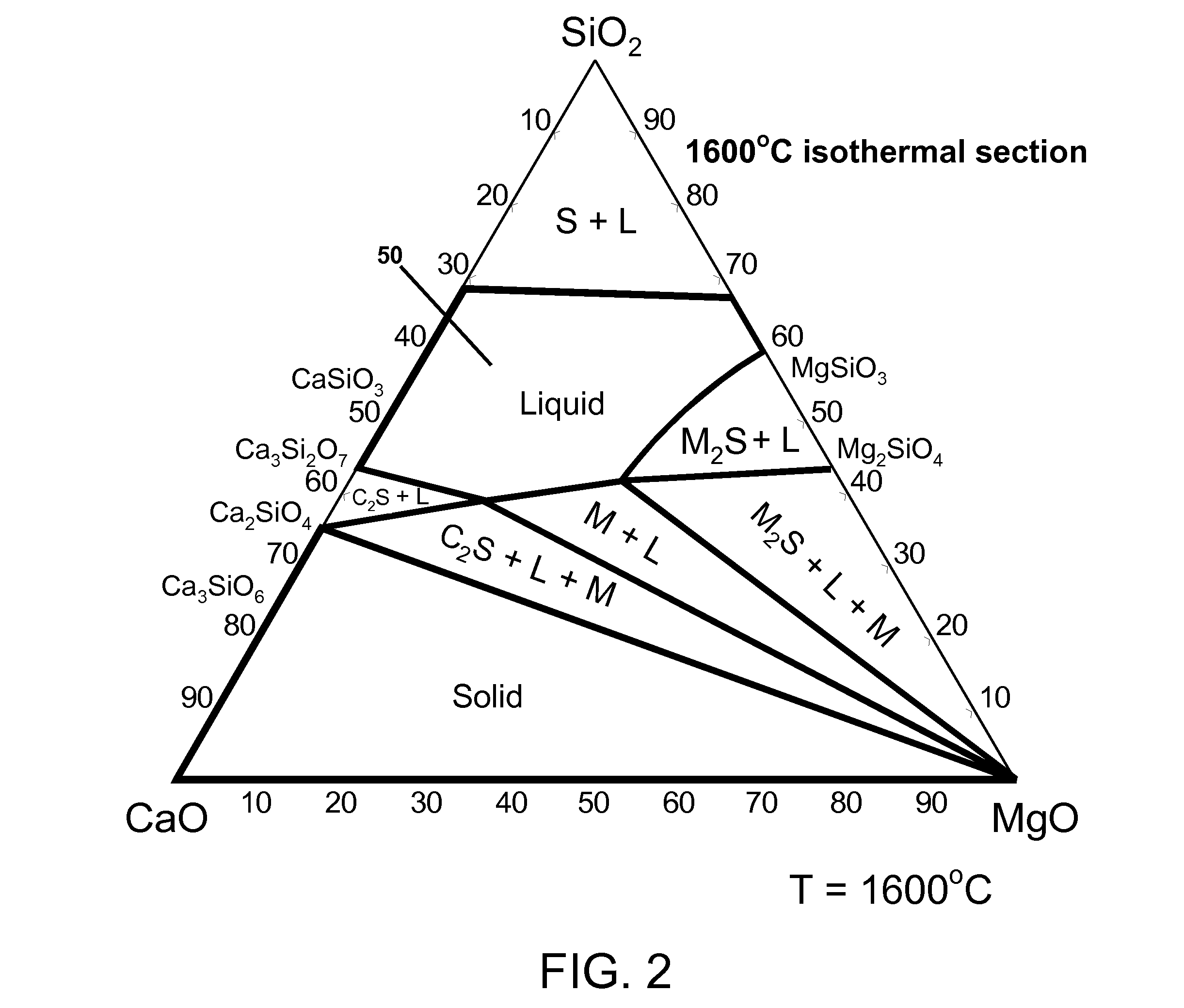

Composition for reducing the oxygen potential of slag

InactiveUS20130019715A1Easy to producePromote productionBlast furnace componentsBlast furnace detailsSteelmakingSilicon oxide

A slag composition containing steelmaking slag and from about 0.3 to about 10 weight percent of reducing agent. The steelmaking slag contains from about 20 to about 55 weight percent of calcium oxide, from about 8 to about 50 weight percent of ferrous oxide, from about 4 to about 20 weight percent of magnesium oxide, from about 8 to about 30 weight percent of silicon oxide, from 0.5 to about 10 weight per cent aluminum oxide, and from about 0.5 to about 10 weight percent of manganese oxide. The reducing agent contains from about 15 to about 70 weight percent of calcium carbide and from about 10 to about 50 weight percent silicon carbide, wherein the ratio of calcium carbide to silicon carbide is between 0.7 and 7.

Owner:NUFLUX

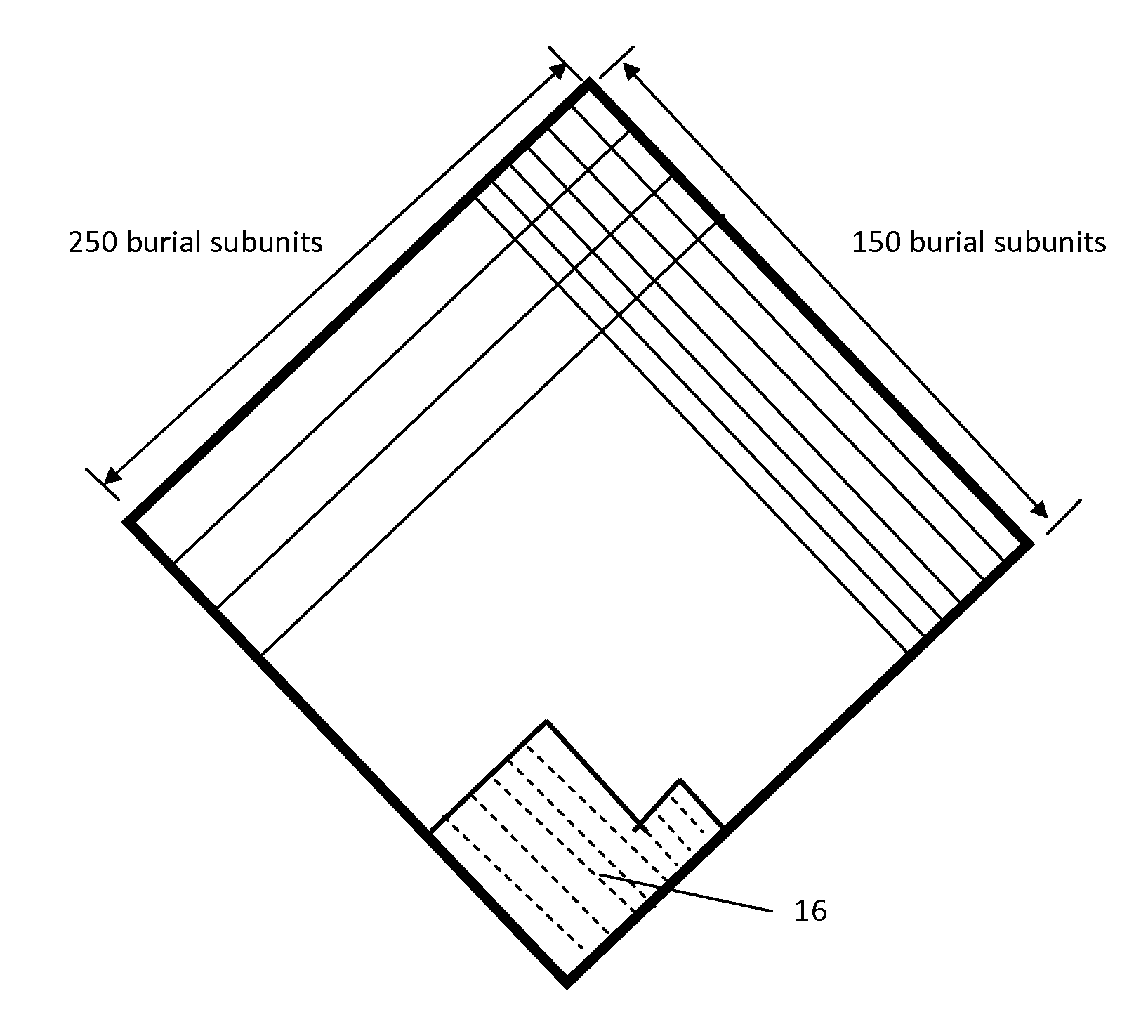

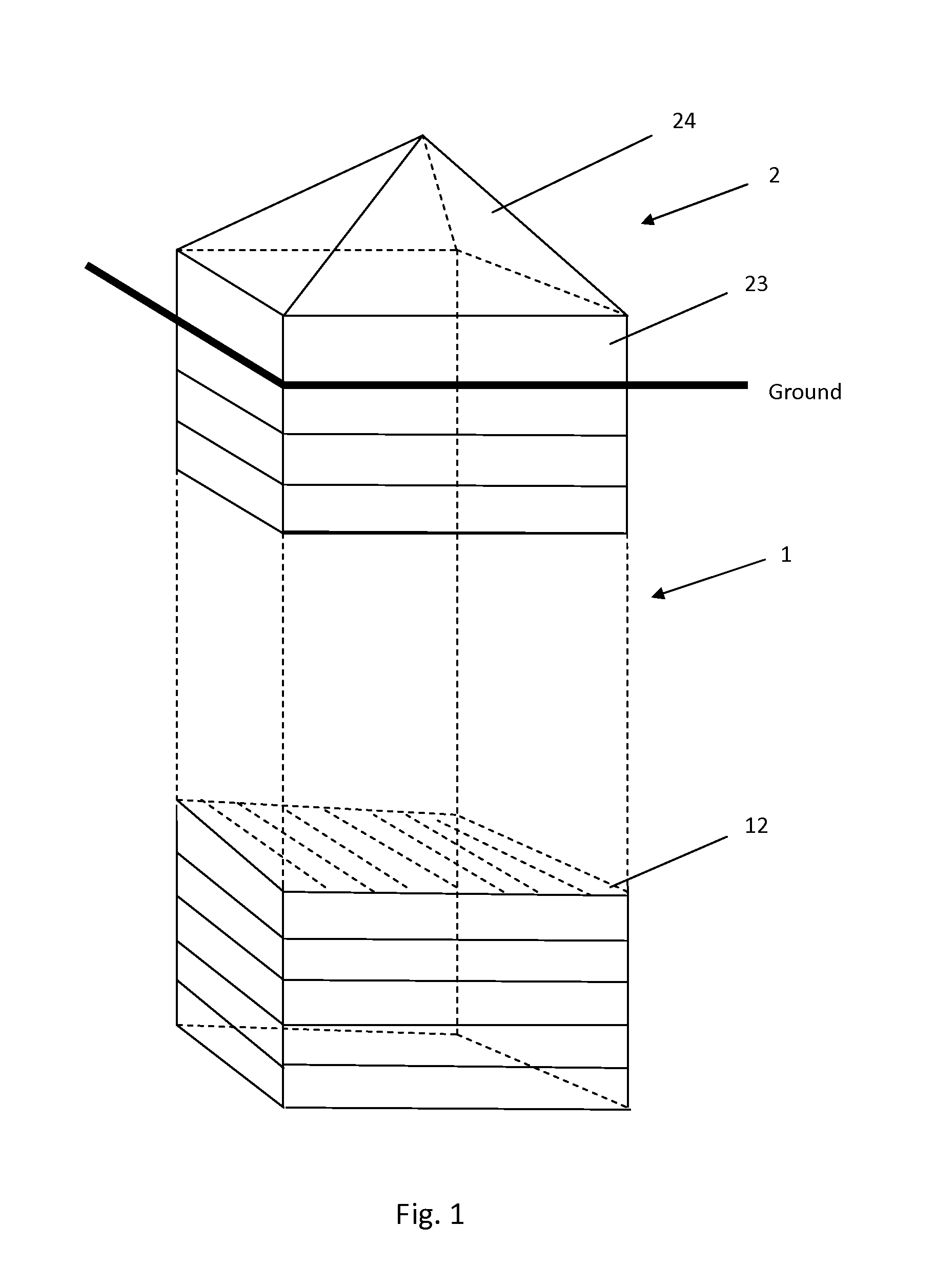

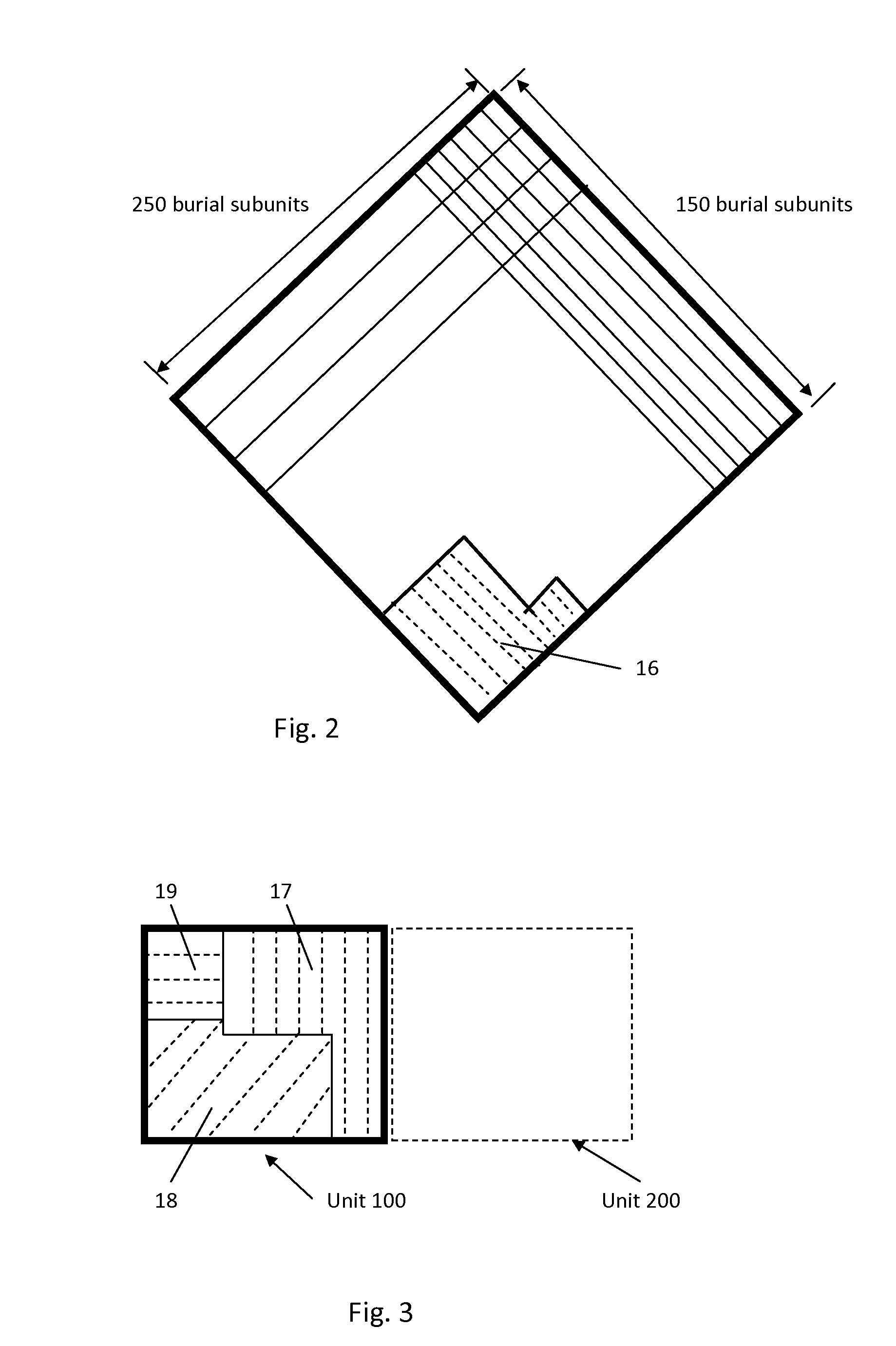

Modern green environmental public mausoleum/cemetery

InactiveUS20130019544A1Increase capacityIts social cost may become even heavierBurial vaultsMonumentsGreen environmentEngineering

The present invention relates to a public cemetery complex, which comprises at least one main burial unit comprising an underground portion and an overground portion, wherein the underground portion is a vertical structure of multiple layers, and each two adjacent layers are separated by a barrier compartment; while each layer contains a number of burial subunits for placement of coffins, the burial subunit is filled up to a predetermined height with a burial material; and the overground portion is a cover portion of the main burial unit for forming an identification sign of the main burial unit; wherein a ground floor for use as a working area and several upper floors for storage of niches and materials are included in interior of the overground portion, while a management area and a worship area are arranged peripherally around the overground portion.

Owner:NG SEE YING BETTY +1

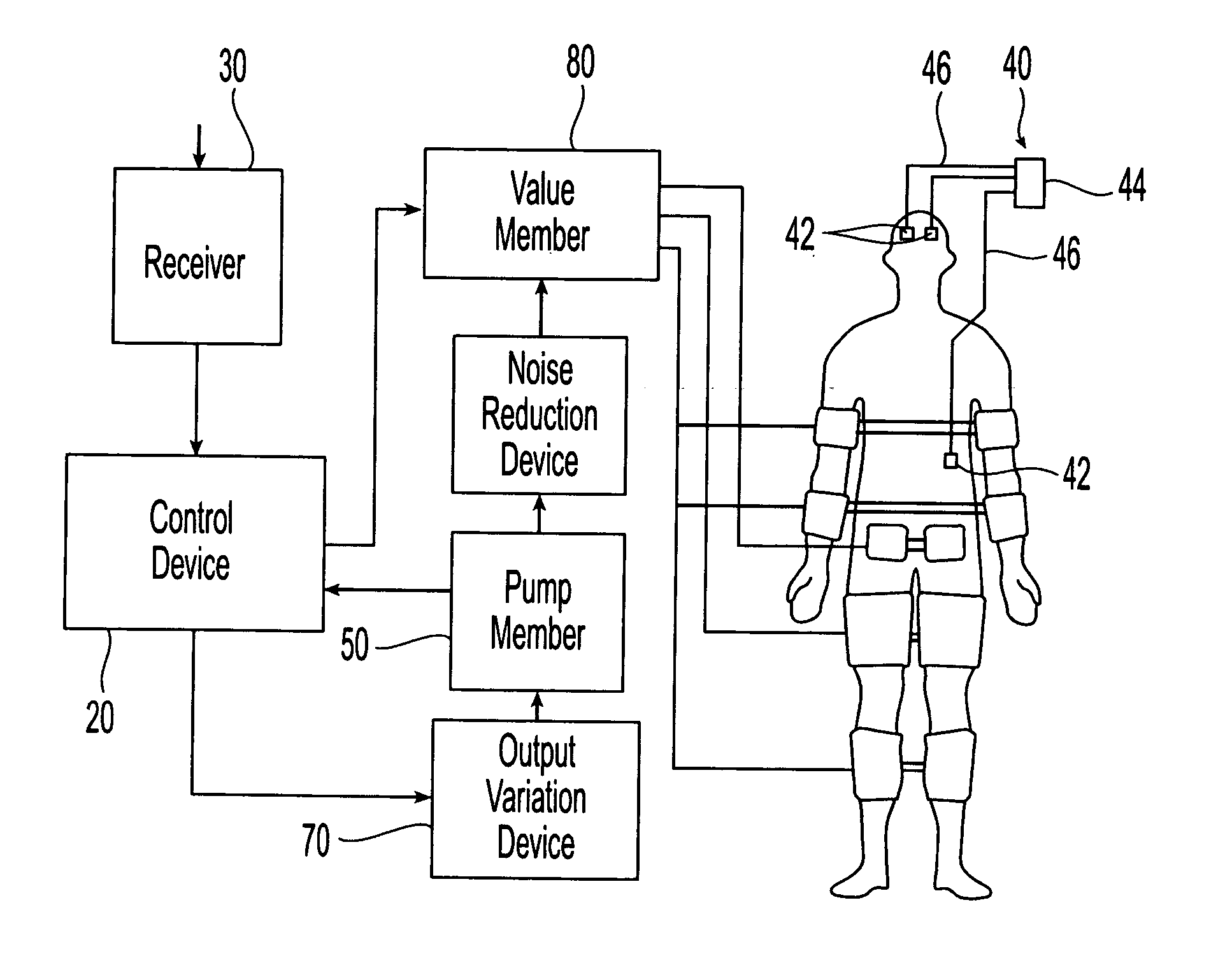

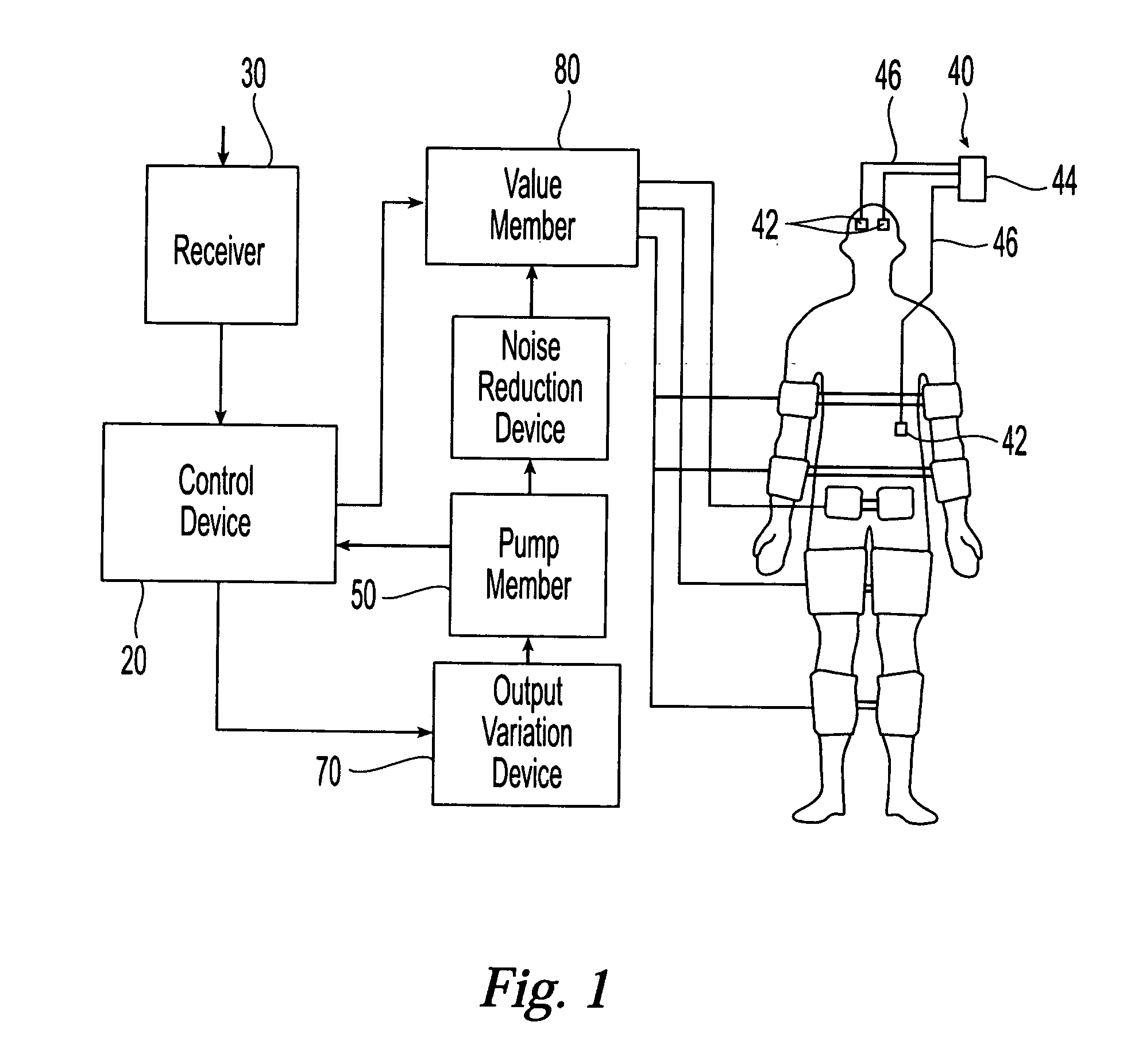

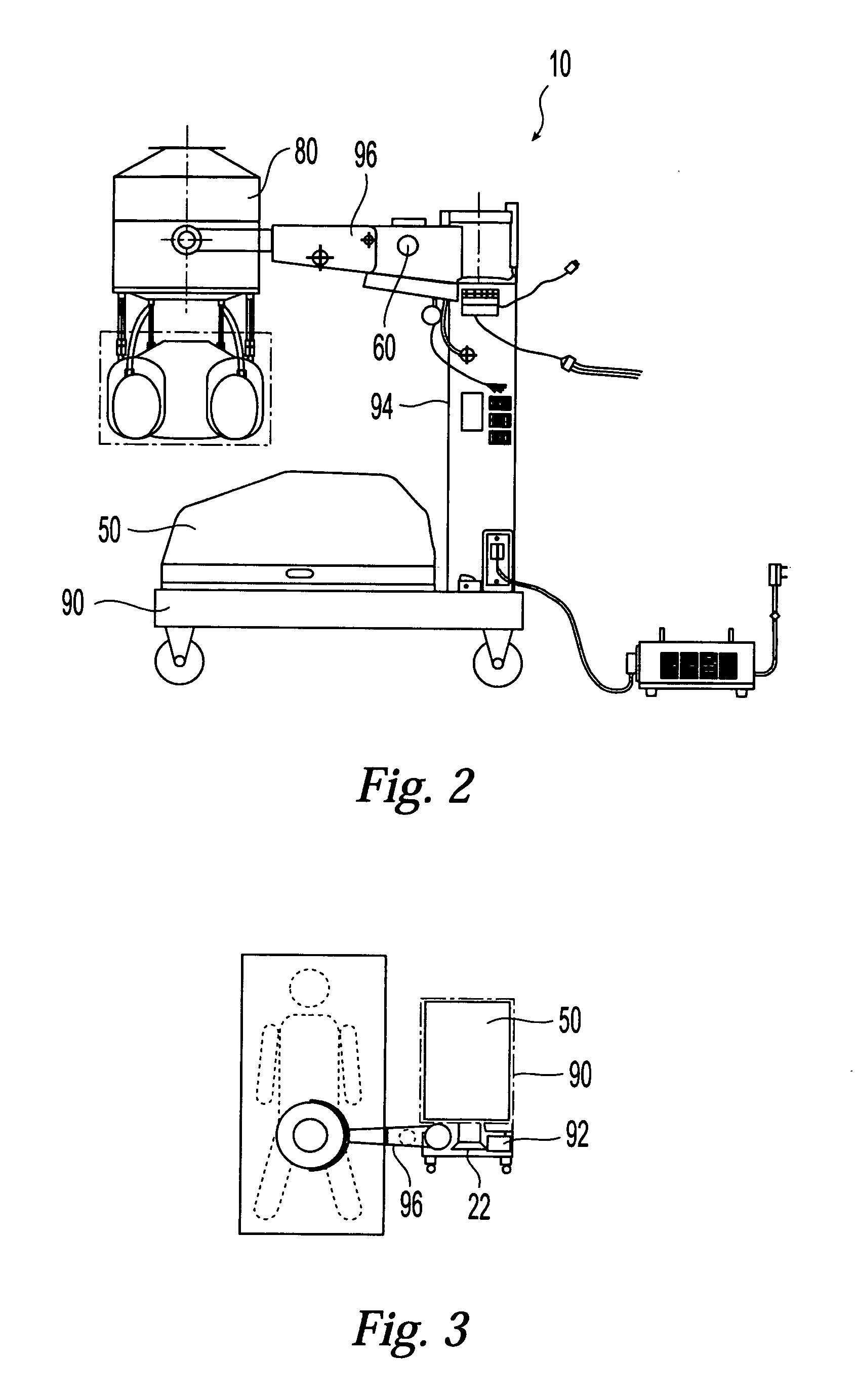

External counter pulsation apparatus

InactiveUS20050111996A1Reduce energy consumptionMinimize heatElectrotherapyPneumatic massageTreatment resultsEnergy expenditure

The present invention relates to an external counter pulsation apparatus that provides an improved treatment results while having a reduced energy consumption, noise, and / or heat during operation and / or an increased mobility. The counter pulsation apparatus can have a pump member for producing a fluid medium and a valve member for selectively allowing the fluid medium to inflate and deflate a fluid pouch adapted to be mounted onto a body portion of the patient. A control device can be provided to control the inflation and deflation of the valve member in accordance with a physical signal of a patient. An output variation device can be provided to vary the fluid medium output from the pump member to maintain the fluid medium pressure at a predetermined value. Additionally or alternatively, one or more of the pump member, the valve member, the control device, and the output variation device can be movable to the patient's location to carry out the counter pulsation treatment. A carrier member can be provided to facilitate the transportation of one or more of the control device, the pump member, the valve member, and the output variation device.

Owner:LIVING DATA TECH APP

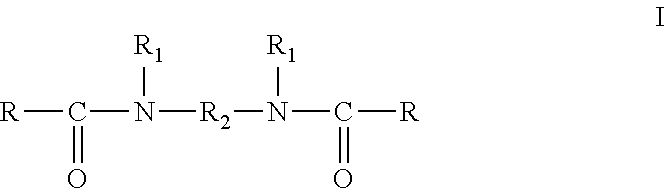

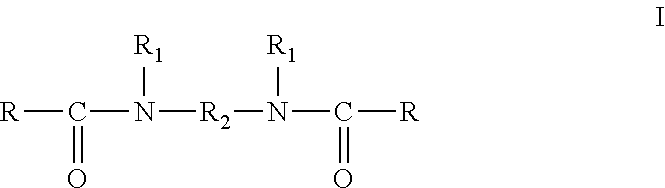

Drag Reducing Compositions and Methods of Manufacture and Use

ActiveUS20140360588A1Minimize agglomerationMinimize heat stability problemOther chemical processesLiquid carbonaceous fuelsPolyolefinFriction reducing

A drag reducing composition for use in hydrocarbon streams which contains a finely divided, solid polyolefin friction reducing agent, a suspending medium comprised of water and a liquid organic carrier containing from 10 to 14 carbon atoms and having at least one hydroxyl group and a partitioning agent comprising a compound having a hydrophobic group and a hydrophilic group and exhibiting at least some surface activity.

Owner:FLOWCHEM LLC

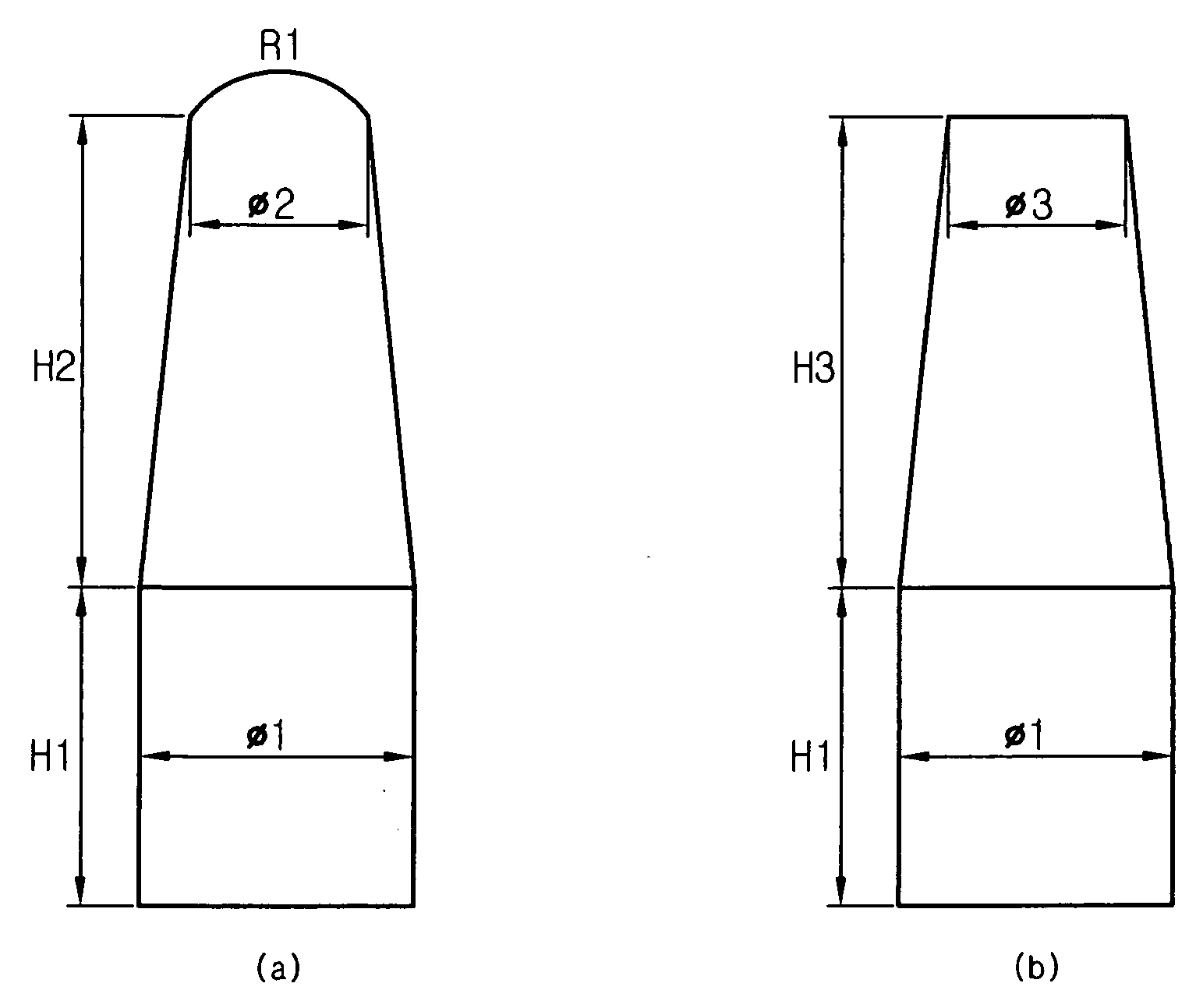

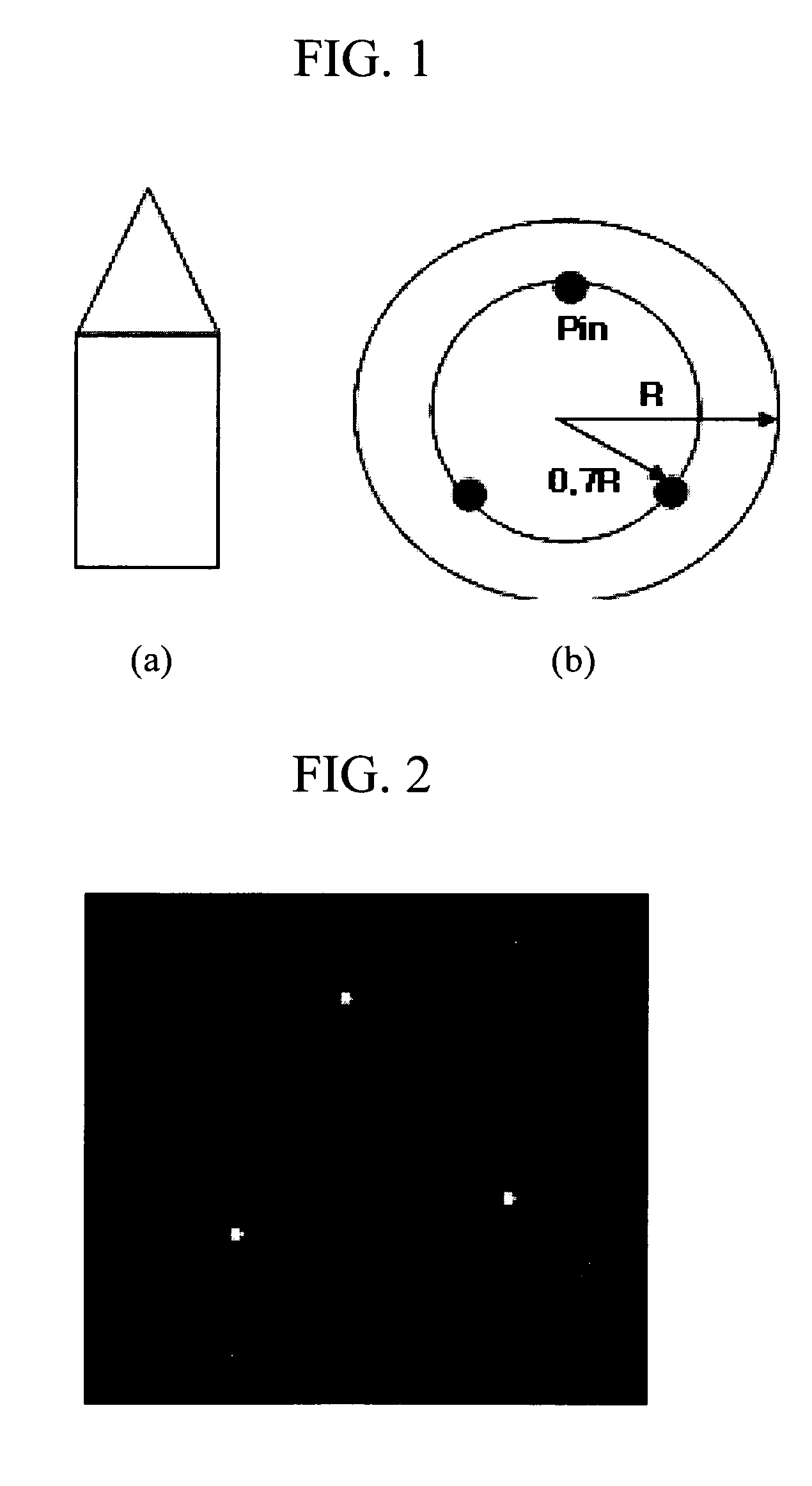

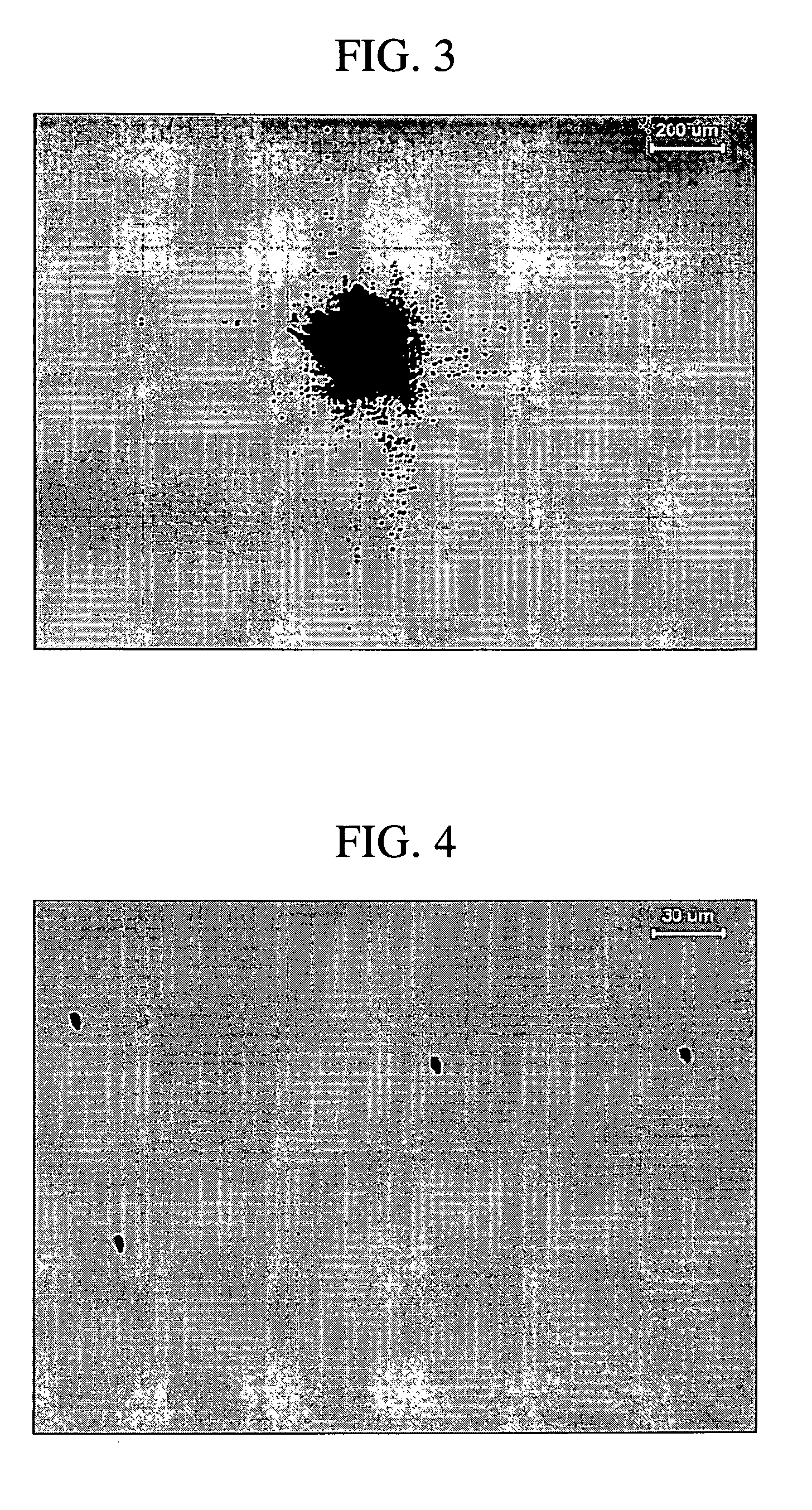

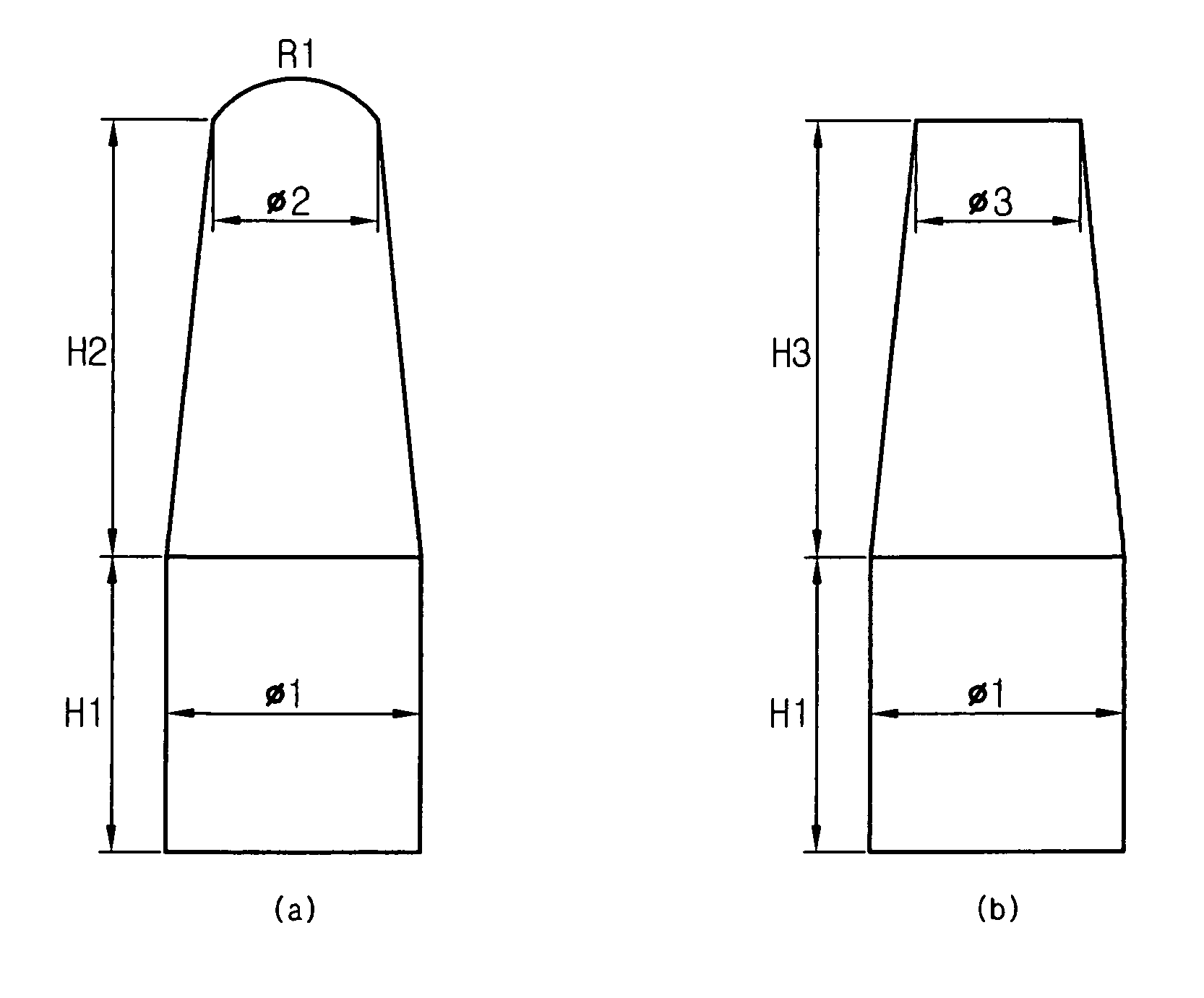

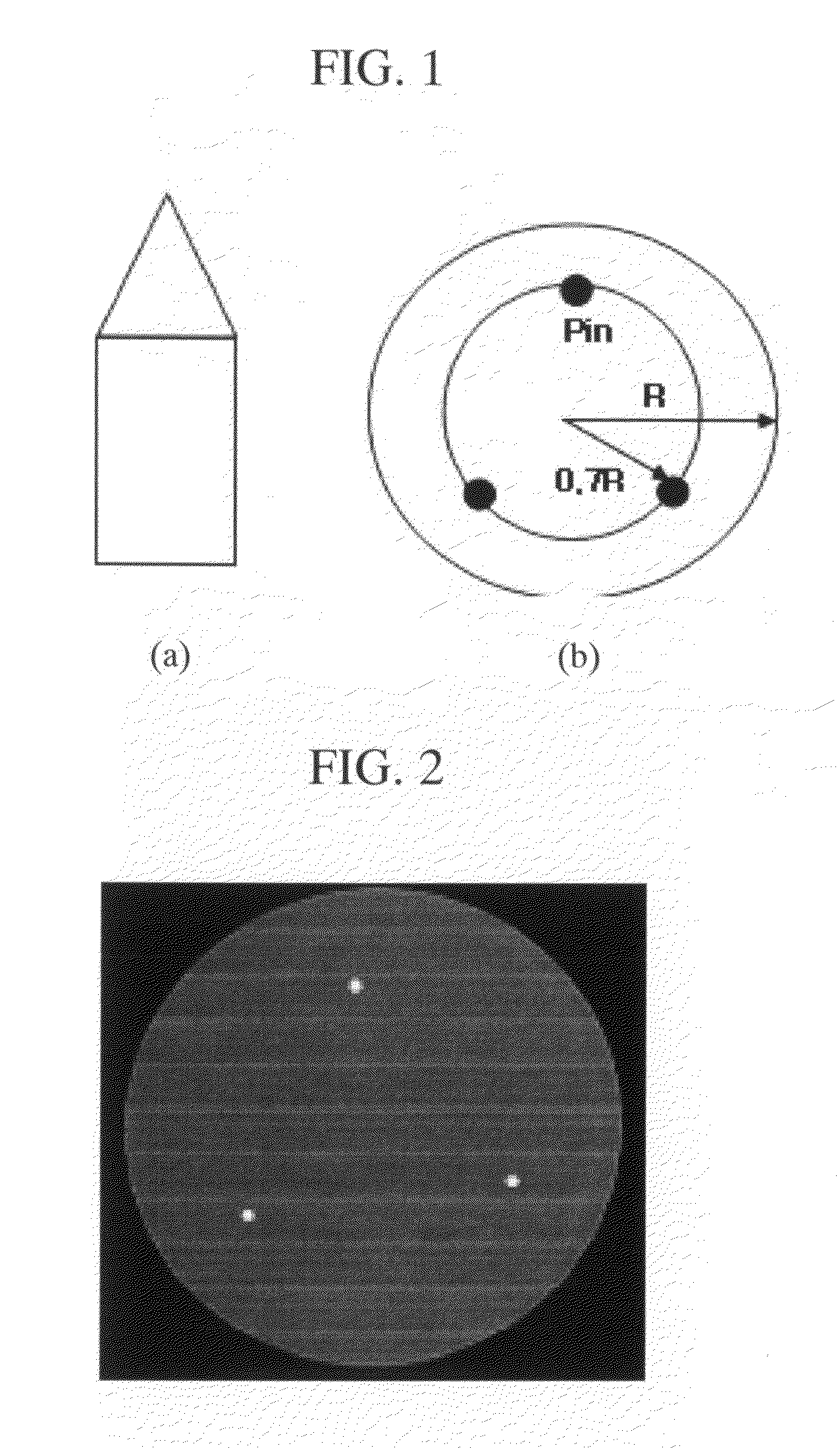

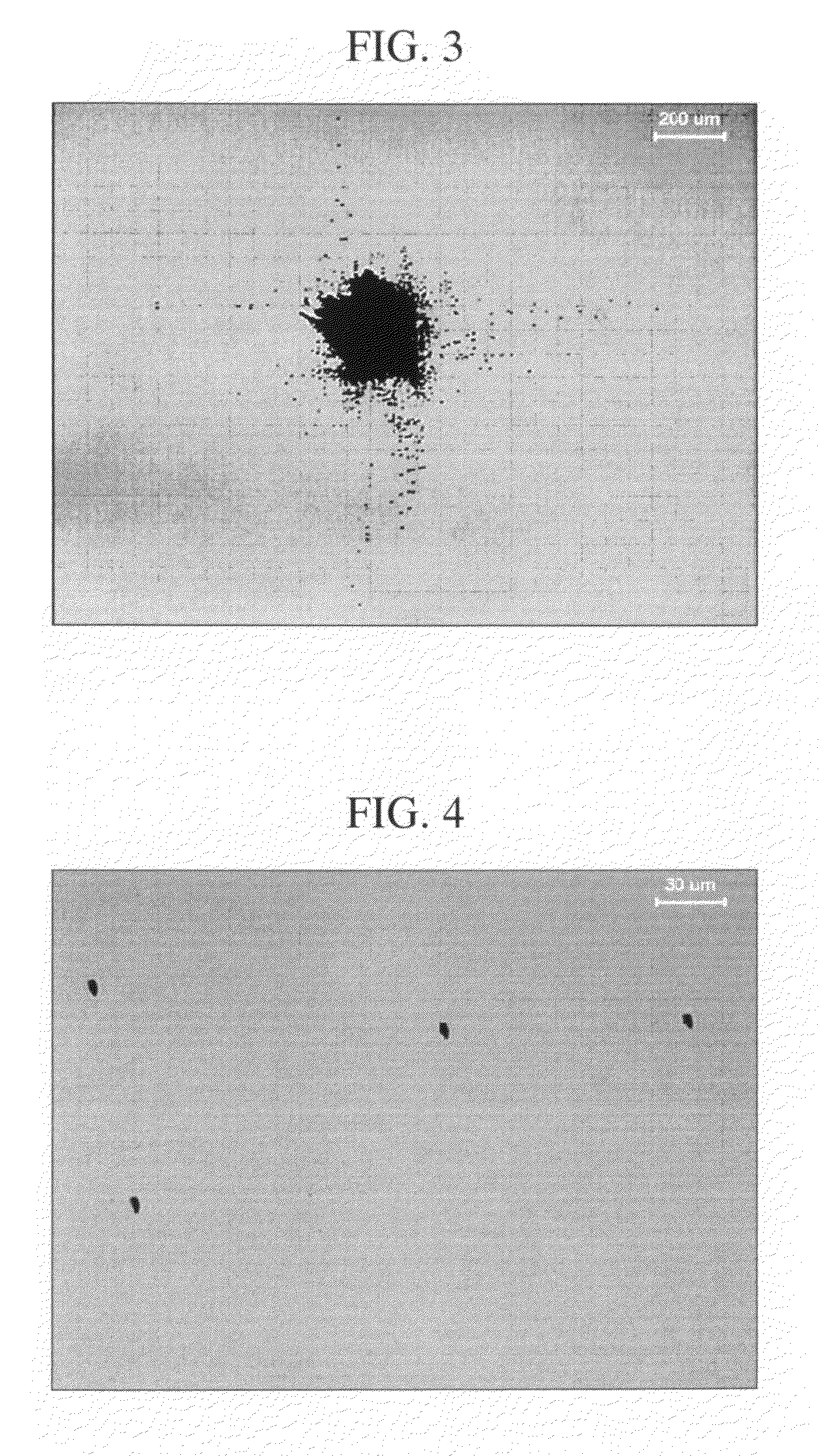

Wafer support pin for preventing slip dislocation during annealing of water and wafer annealing method using the same

ActiveUS20080176415A1Simple structureHeat loss minimizationLiquid surface applicatorsSemiconductor/solid-state device manufacturingOptoelectronicsRapid thermal annealing

A wafer support pin has a front end contacted with a wafer such that the front end is flat or rounded. Thus, gravitational stress is minimized during annealing the wafer, thereby minimizing slip dislocation. This wafer support pin is suitably used for annealing of a wafer, particularly high temperature rapid thermal annealing of a large-diameter wafer.

Owner:LG SILTRON

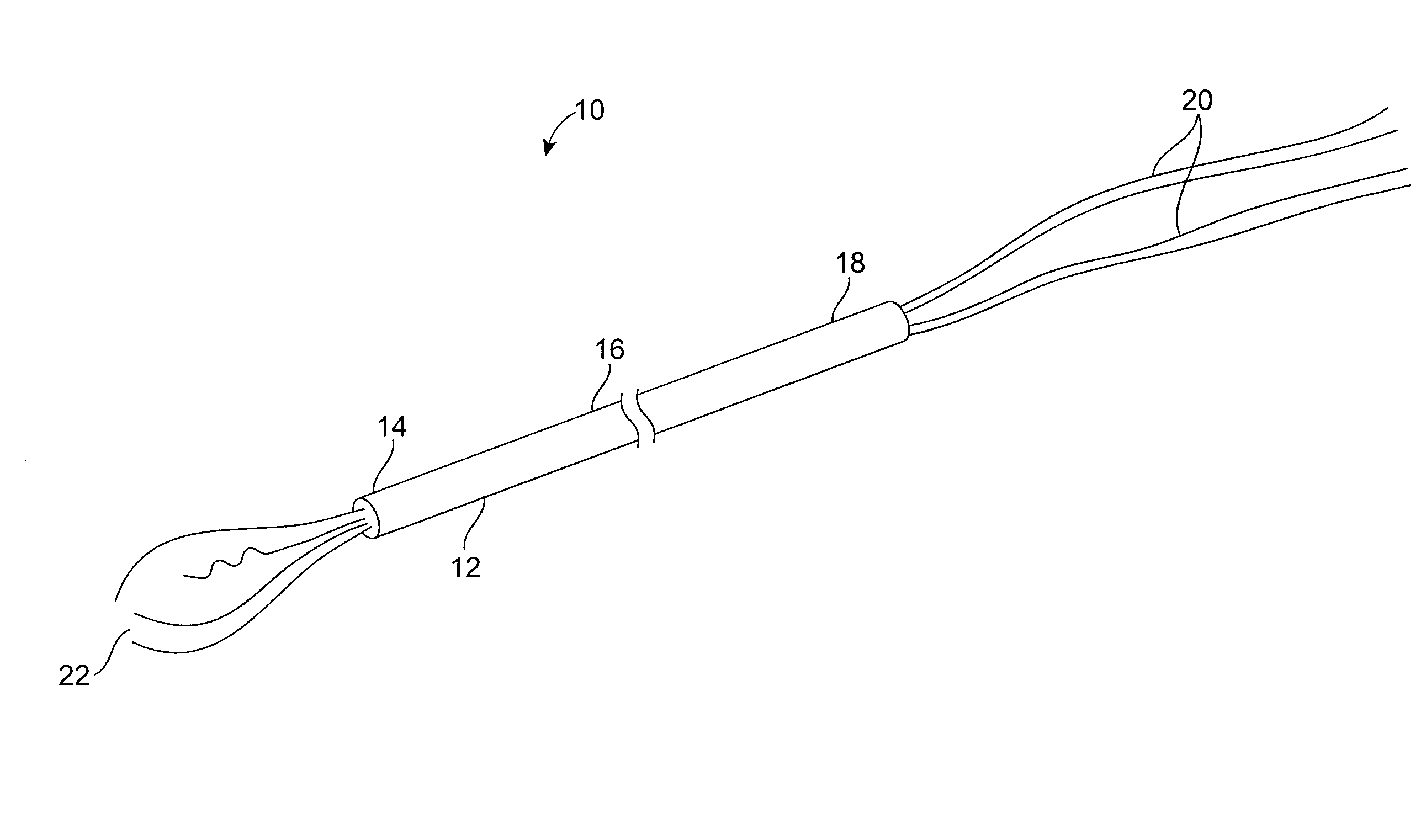

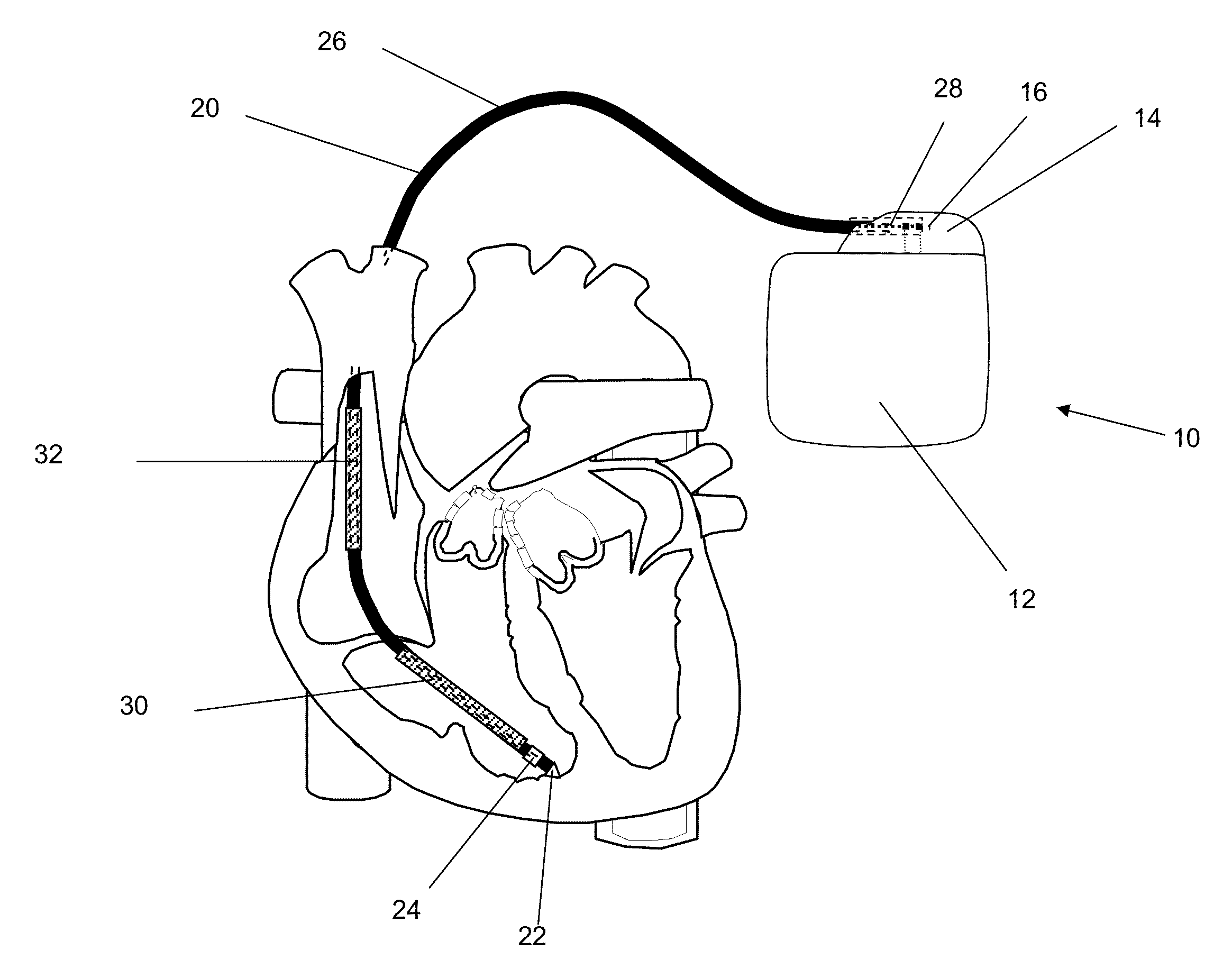

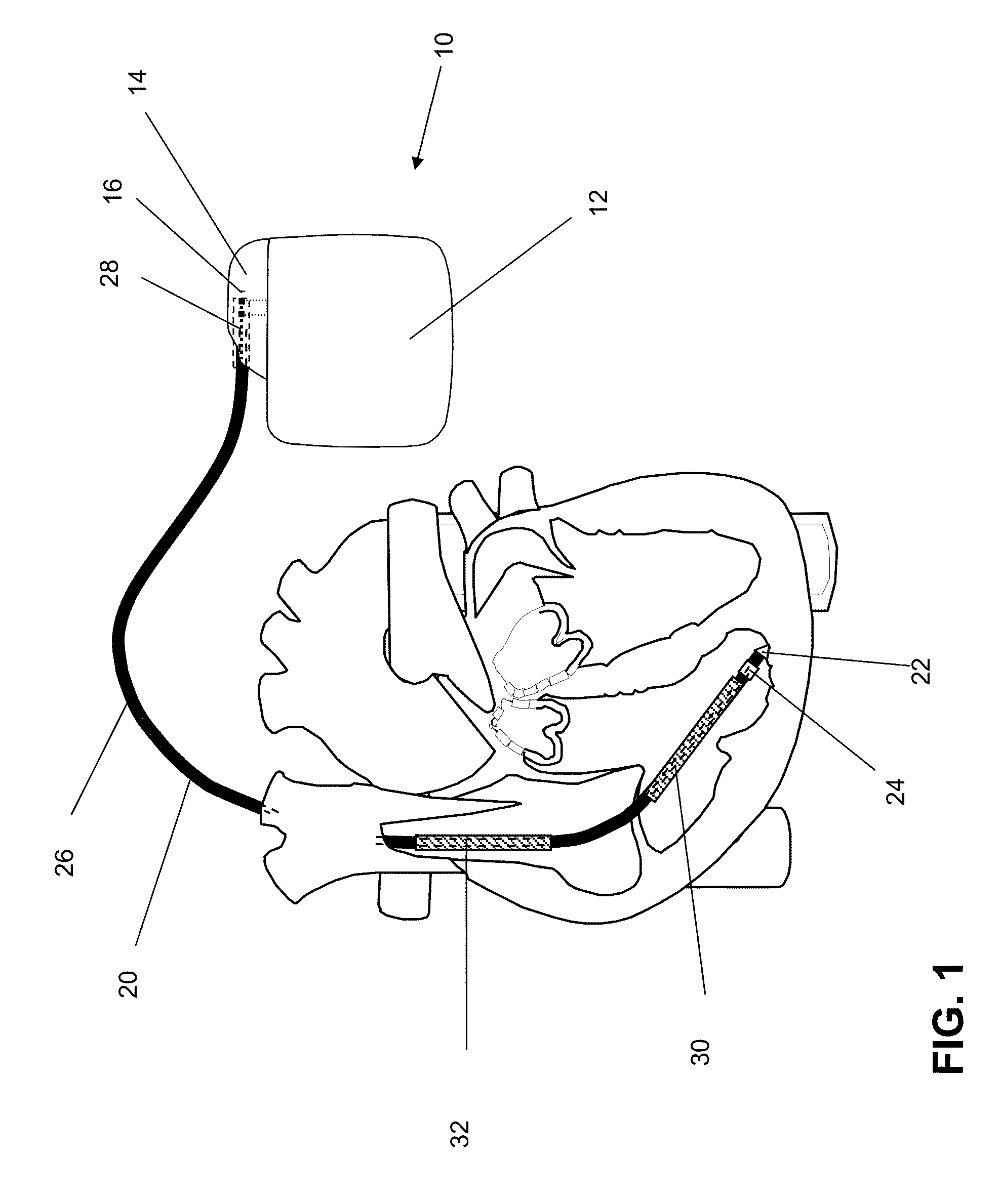

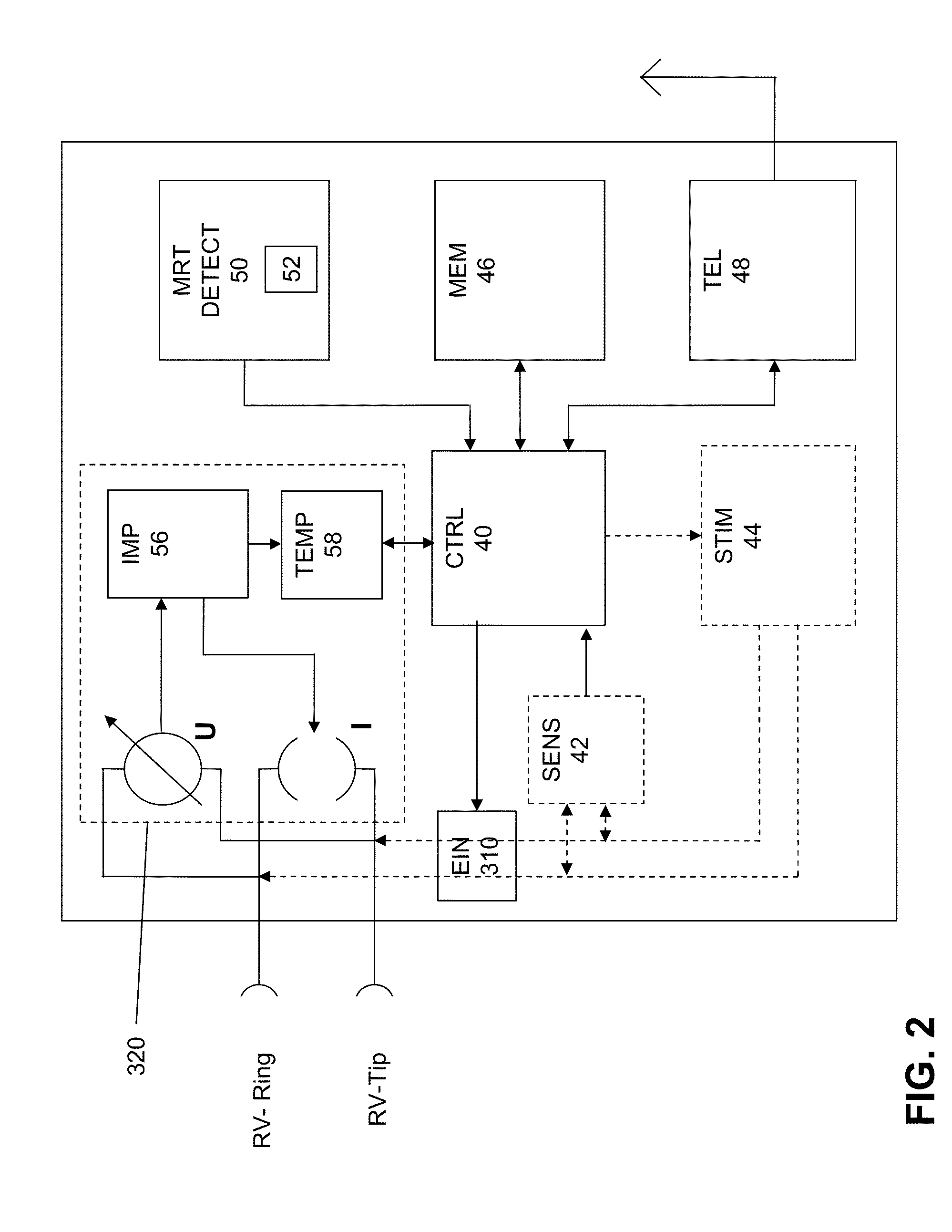

Temperature sensor for an implantable medical apparatus

ActiveUS20130090707A1Minimize heatCost reductionTransvascular endocardial electrodesHeart stimulatorsElectricityBiomedical engineering

A temperature sensor for detecting heating of at least one electrode pole of a temporarily or permanently implantable electrode line or a similar implant having at least one elongated electrical conductor which is connected to at least one electrode pole. The temperature sensor has an impedance detecting unit or is connected to one and is configured for evaluating an electrode pole impedance detected by the impedance detecting unit in such a manner that the evaluation takes place with respect to a temperature-dependent feature of the electrode impedance. The impedance detecting unit is electrically connected to the at least one electrode pole or is configured and arranged to be electrically connected to the at least one electrode pole.

Owner:BIOTRONIK SE & CO KG

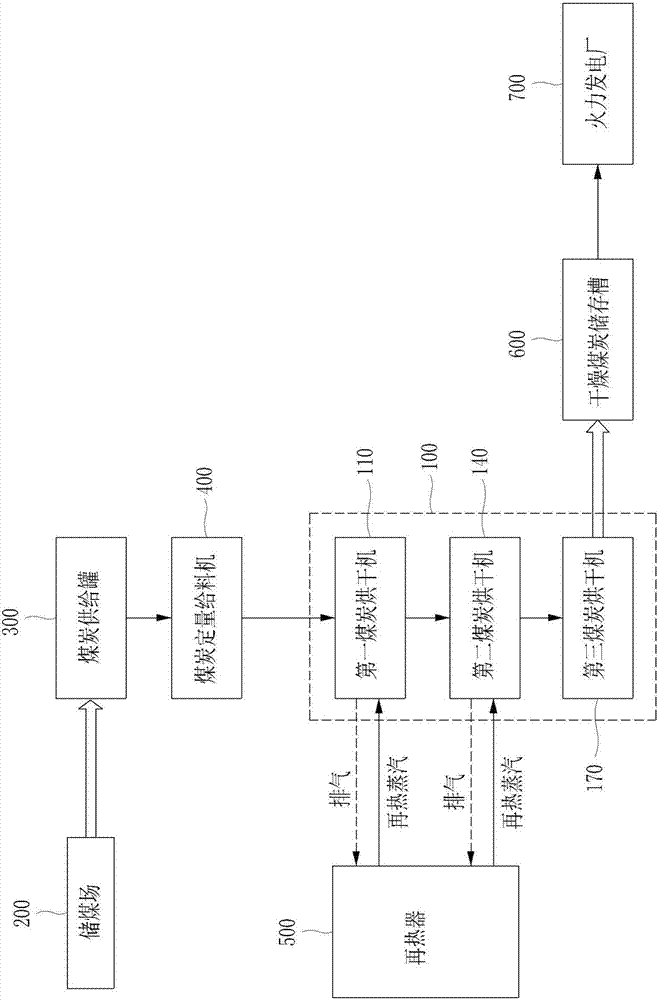

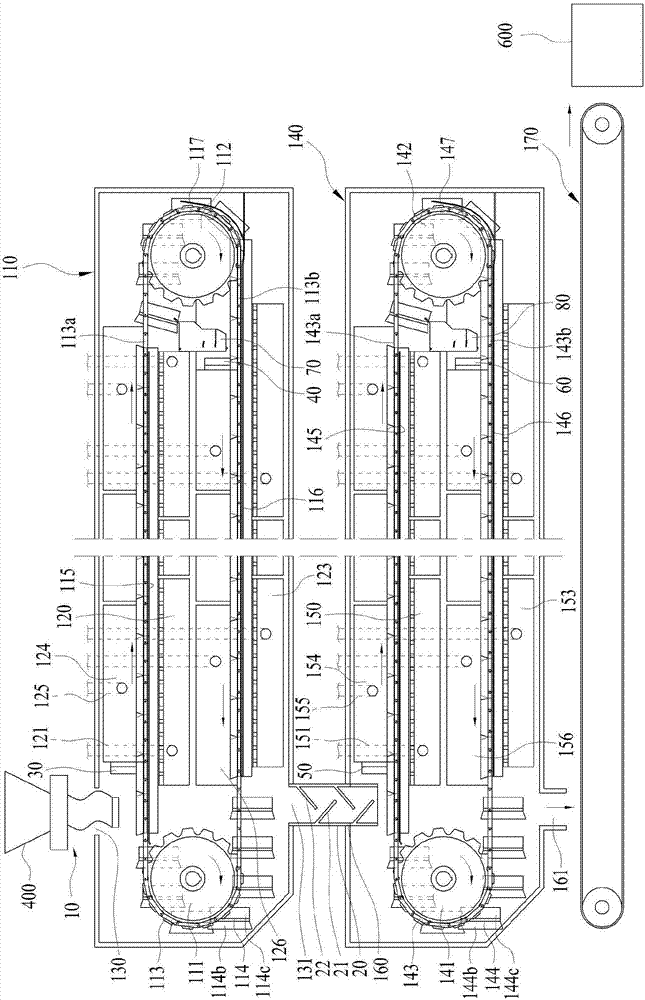

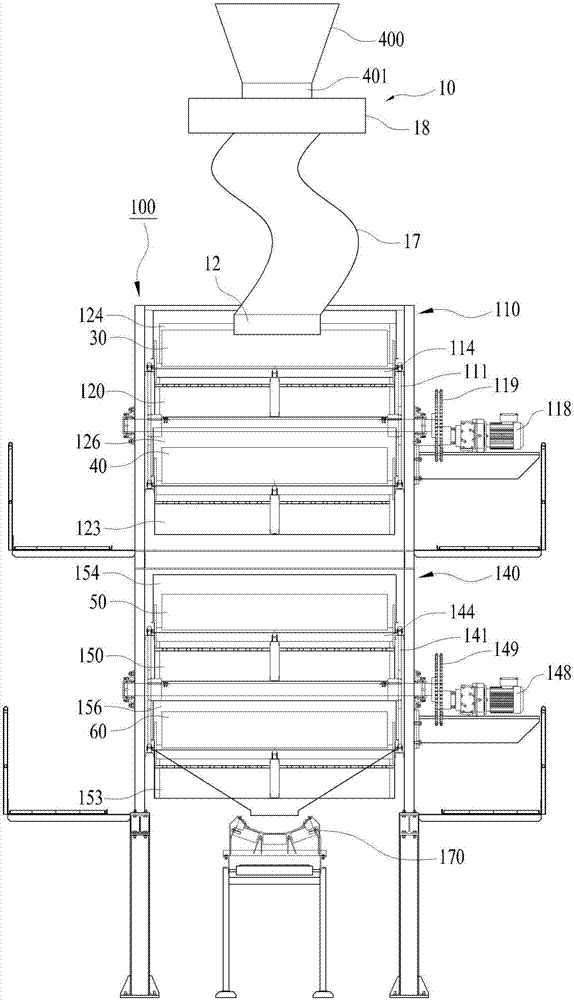

Dust reduction apparatus depending on supply of falling coal in coal drying apparatus using reheat steam

InactiveCN107110600AAvoid incomplete combustionMinimize heatDrying solid materials with heatGranular material dryingEngineeringReducer

The present invention relates to a dust reduction apparatus which minimizes dust generation when coal is dropped and supplied from an upper dryer to a lower dryer in a multi-stage dryer for drying coal using reheat steam. The present invention relates to a coal drying apparatus using reheat steam, the apparatus being configured so that coal which has been dried primarily in a first coal dryer is inputted into a second coal dryer and thus is secondarily dried. The apparatus comprises a fixed quantity coal supplier for supplying a fixed amount of coal onto the surface heading for the top of a first transfer plate, and comprises a dust reducer consisting of: an inlet pipe coupled by a bearing to a discharge port of the fixed quantity coal supplier; a worm wheel coupled to the outer circumferential surface of the inlet pipe; a worm which is coupled by a gear to the worm wheel and which rotates by means of rotational force delivered from a motor; a bent pipe having an upper end coupled to the inlet pipe; and an outlet pipe coupled to one end of the bent pipe. In addition, the apparatus comprises: a first flattening device for uniformly dispersing and flattening a coal pile which is transferred after being dropped and inputted from the dust reducer onto the surface heading for the top of an upper first transfer plate; a first coal receiver which has a plurality of panels fixedly installed therein radially at a certain angle about a rotation axis between a pair of first driven sprockets; a second flattening device for uniformly dispersing and flattening the coal pile which is transferred after being dropped and inputted from the first coal dryer to the surface heading for the top of a lower first transfer plate through rotation of the first driven sprockets; a third flattening device for uniformly dispersing and flattening the coal pile which is transferred after being dropped and inputted from the first coal dryer to the surface heading for the top of an upper second transfer plate of the second coal dryer; a second coal receiver which has a plurality of panels installed therein radially at a certain angle about a rotation axis between a pair of second driven sprockets; and a fourth flattening device for uniformly dispersing and flattening the coal pile which is dropped and inputted from the second coal receiver to the surface heading for the top of a lower second transfer plate through rotation of the second driven sprockets, wherein the first coal receiver receives the coal pile dropped from the surface of the upper first transfer plate, is rotated according to the rotation of the first driven sprockets, and thereafter inputs the coal pile onto the surface of the lower first transfer plate to thereby inhibit dust, and the second coal receiver receives the coal pile dropped from the surface of the upper second transfer plate, is rotated according to the rotation of the second driven sprockets and thereafter inputs the coal pile onto the surface of the lower second transfer plate to thereby inhibit dust.

Owner:HANKOOK TECH

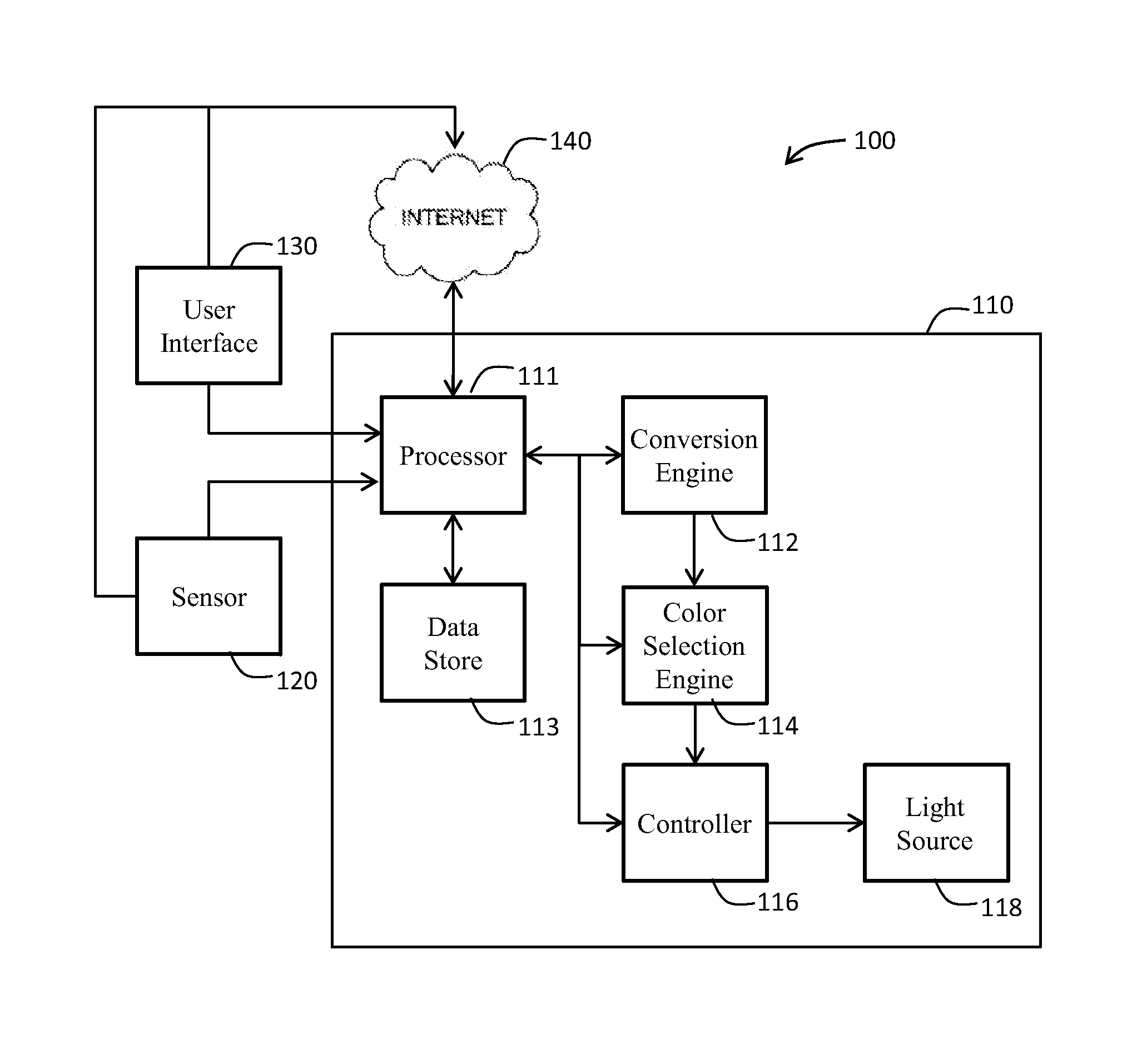

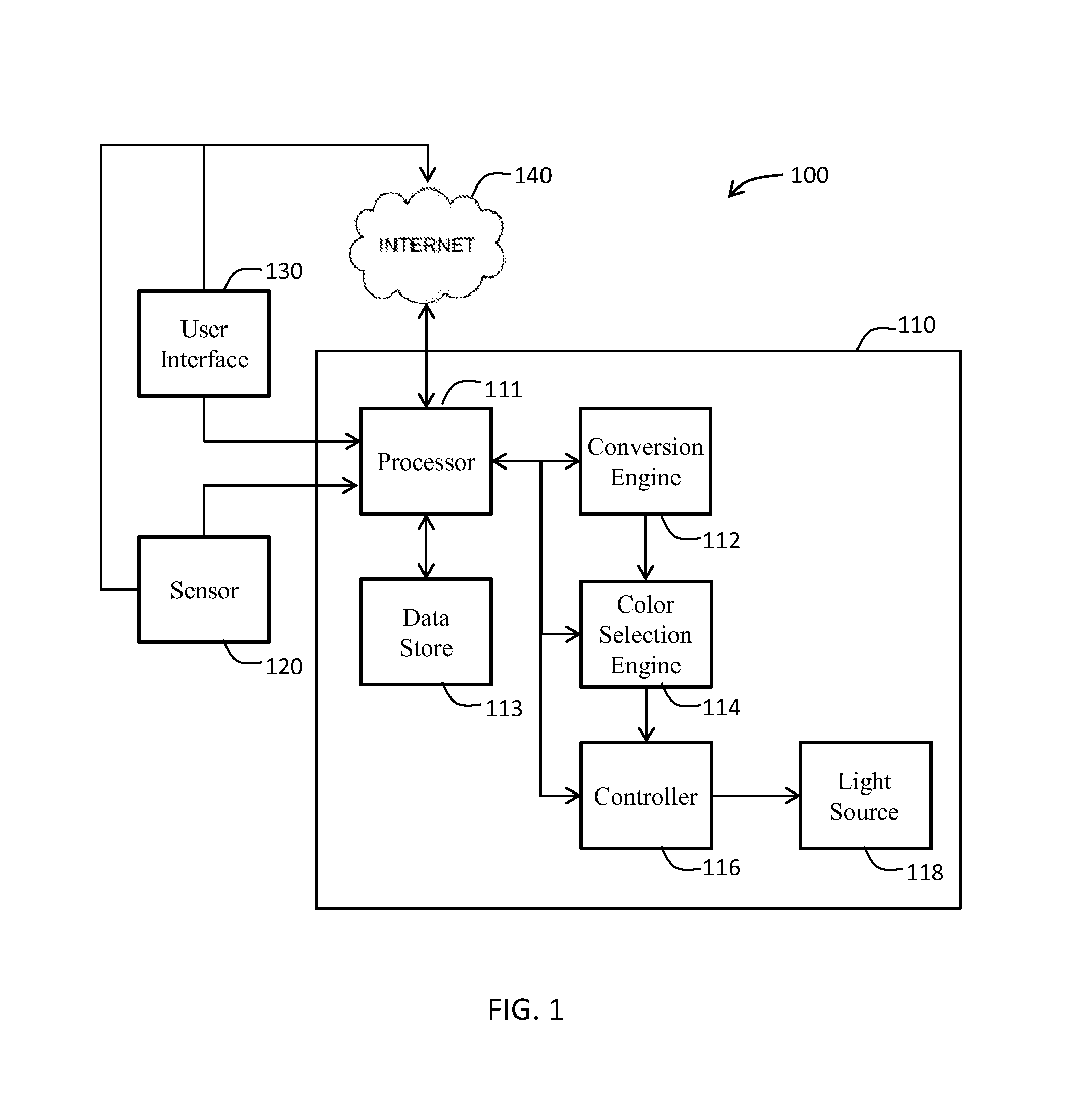

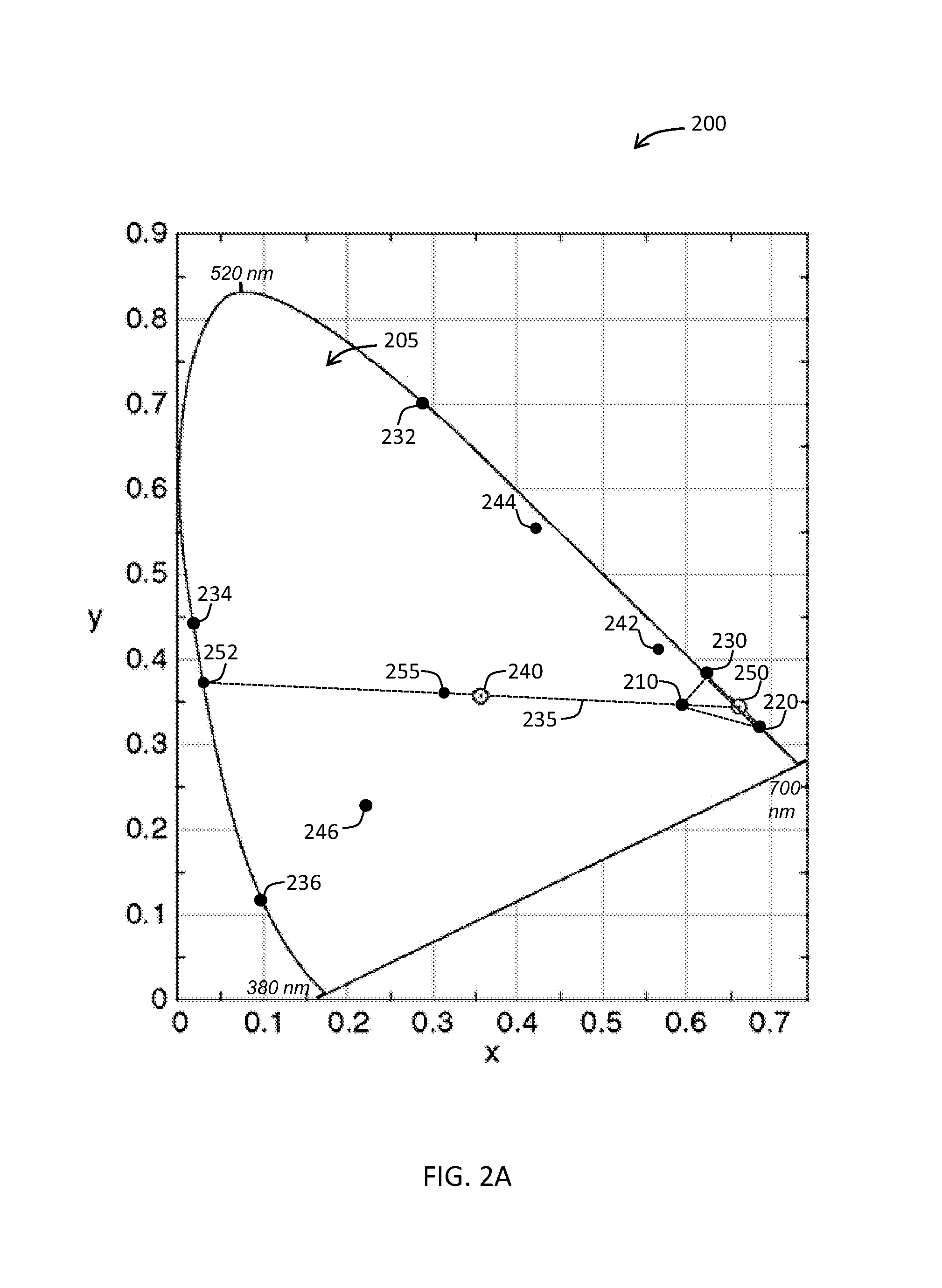

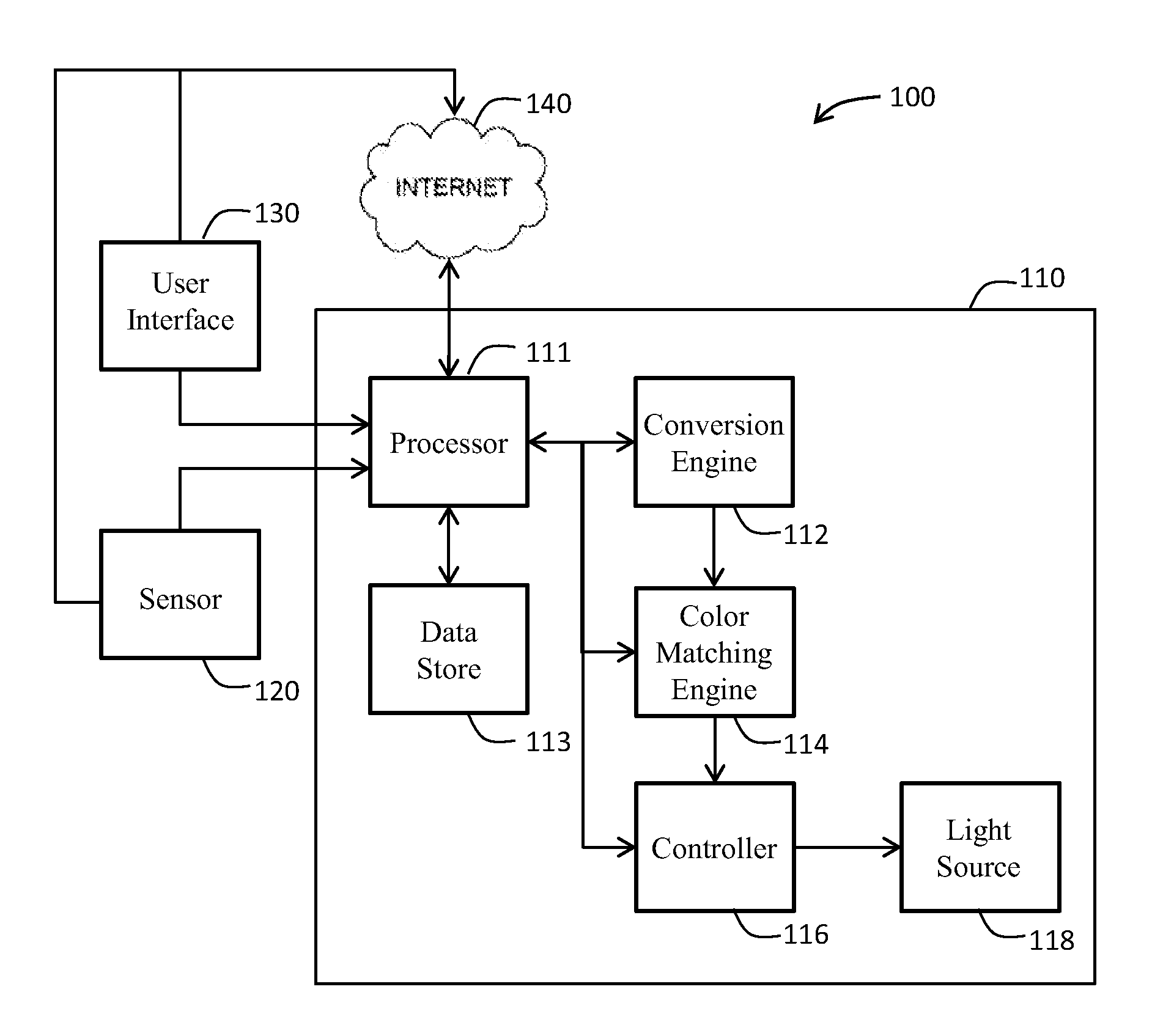

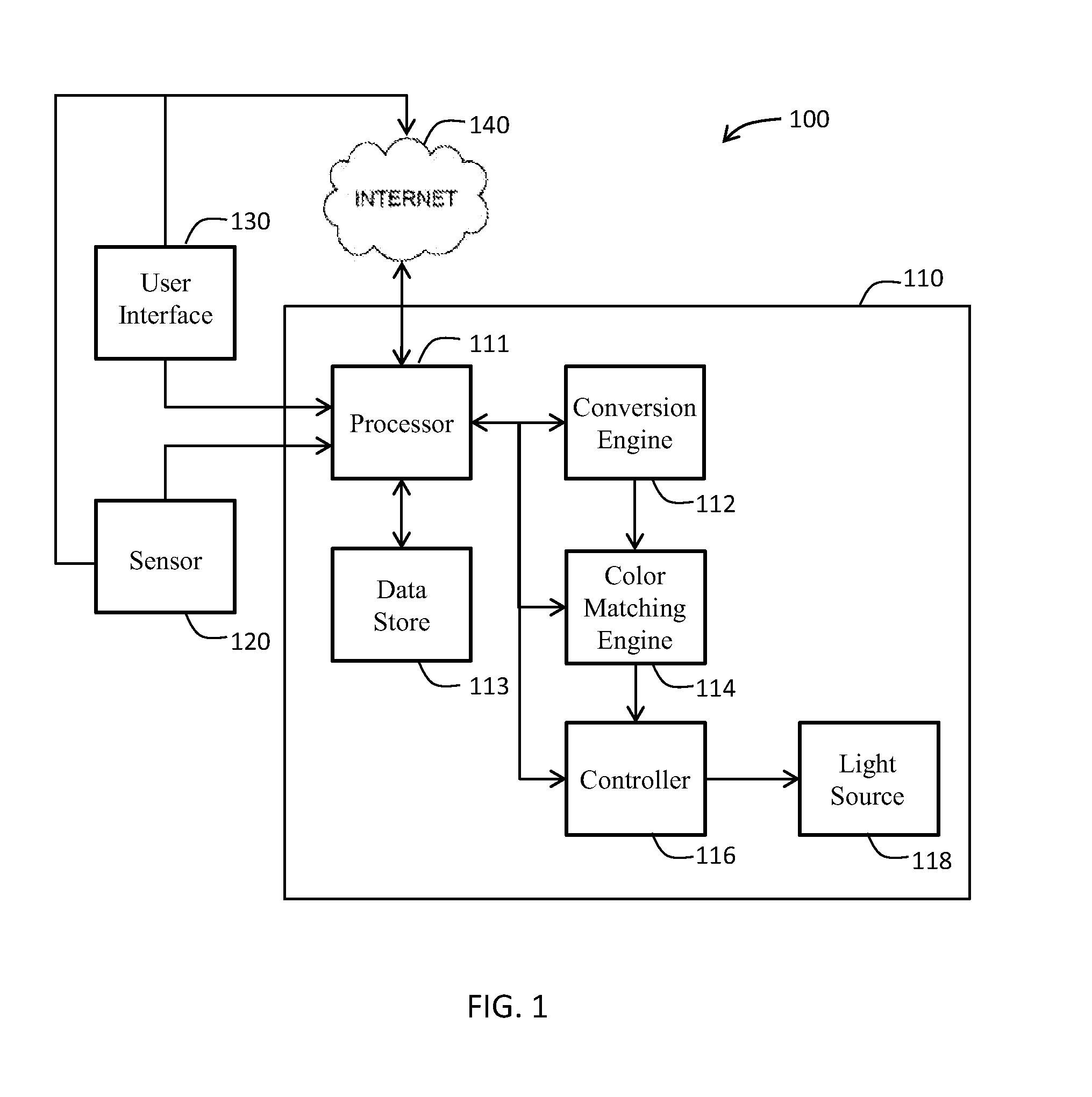

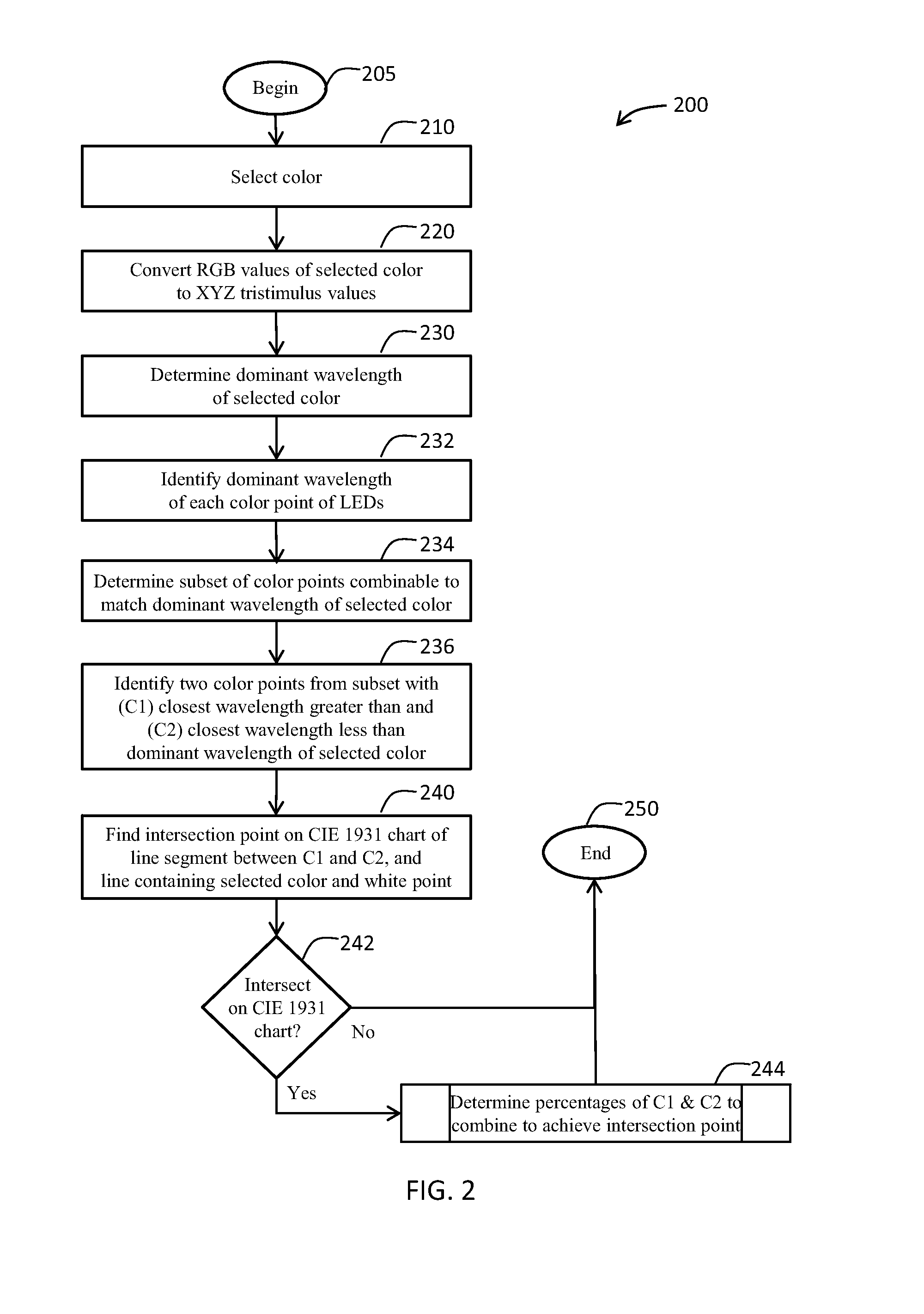

Adaptive light system and associated methods

ActiveUS20130293158A1Good colorImprove energy efficiencyVehicle headlampsElectrical apparatusLength waveLighting system

An adaptive light system including a color matching engine, a controller, and a plurality of light sources each configured to emit a source light. The color matching engine determines a dominant wavelength of a selected color, and a combination of the light sources that the controller may operate to emit a combined wavelength that approximately matches the dominant wavelength of the selected color. A color capture device transmits a source color signal designating the selected color. A method of adapting light comprises receiving a selected color, converting a value representing a dominant wavelength of the selected color, determining a combination of and percentages of colors emitted by the plurality of light sources that may be combined to form an adapted light that matches the selected color, and operating the light sources along with a white light to emit the adapted light.

Owner:HEALTHE INC

Container system including lid with improved finger accommodativeness

InactiveUS20220024657A1Minimize heat and transferConvenient and hands-free transportationTravelling sacksClosures with lifting/suspending meansMechanical engineeringCentral region

The invention provides a container lid with a connected (e.g. pivotally connected) handle and methods thereof. The handle includes a handle stem, a first carrying, extension, and a second carrying extension that are converged to a central region of the handle. The lid exhibits numerous technical merits such as improved finger accommodativeness, simplicity in usage, and easy manufacturability, among others.

Owner:DENG HAISHAN

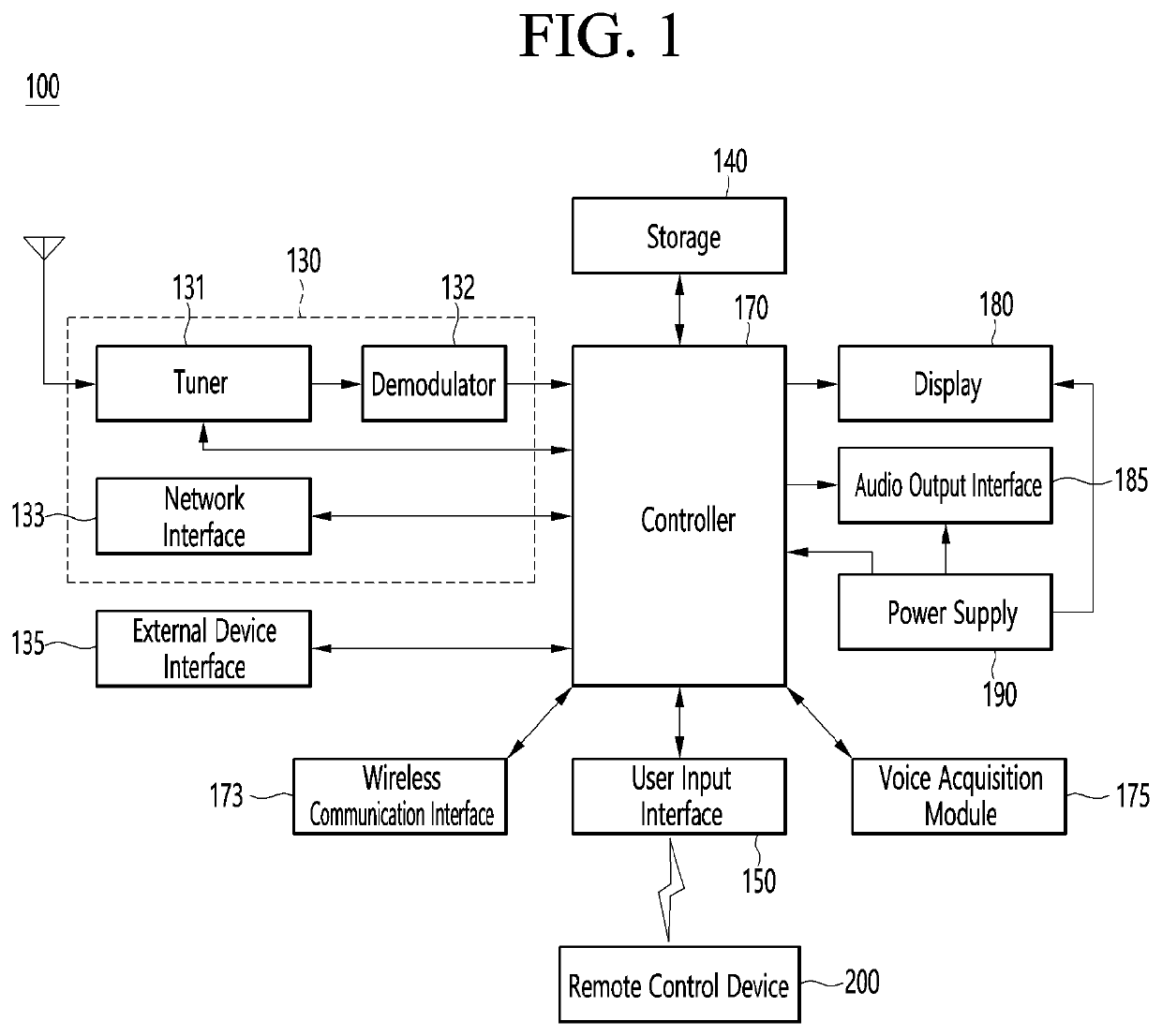

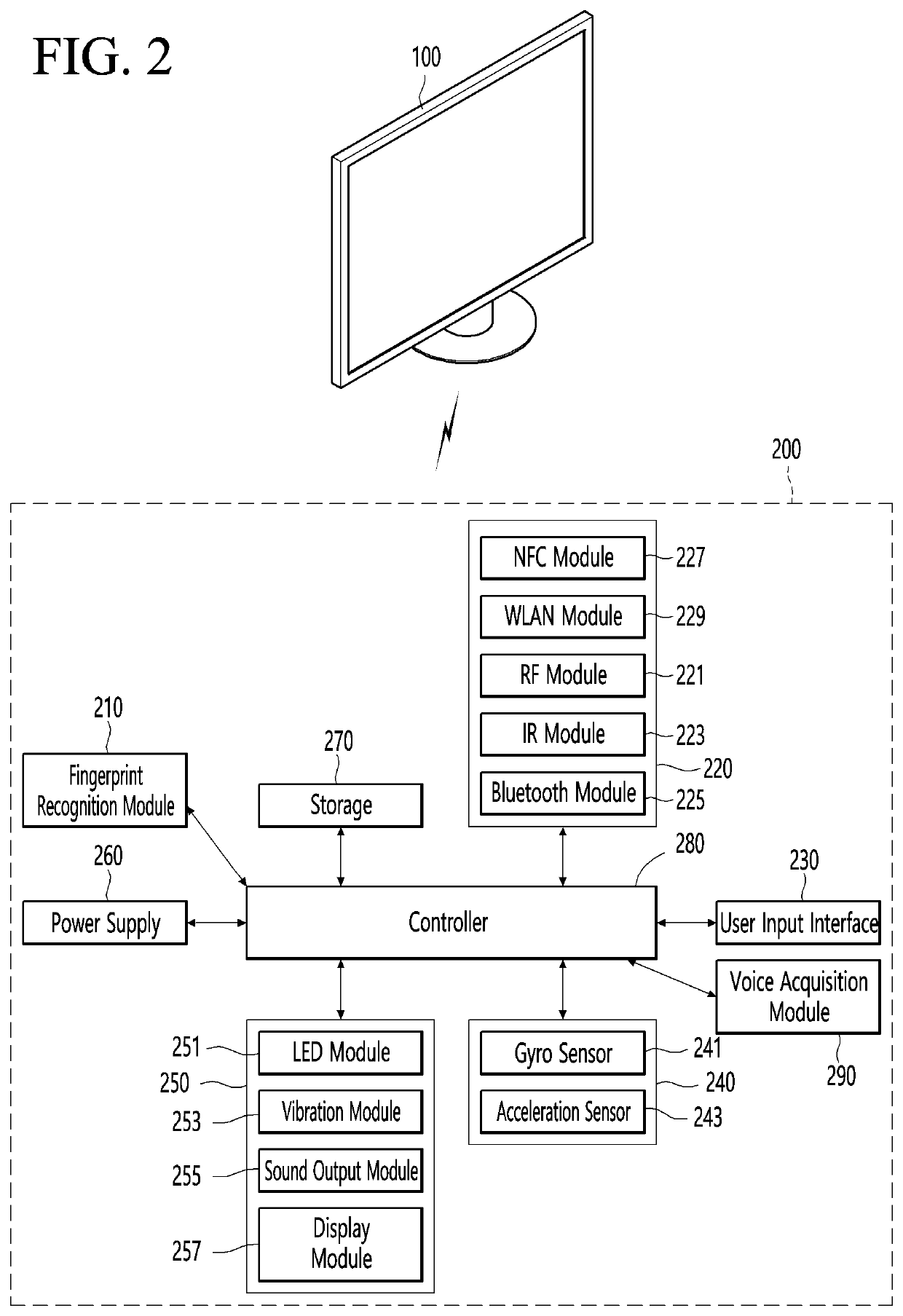

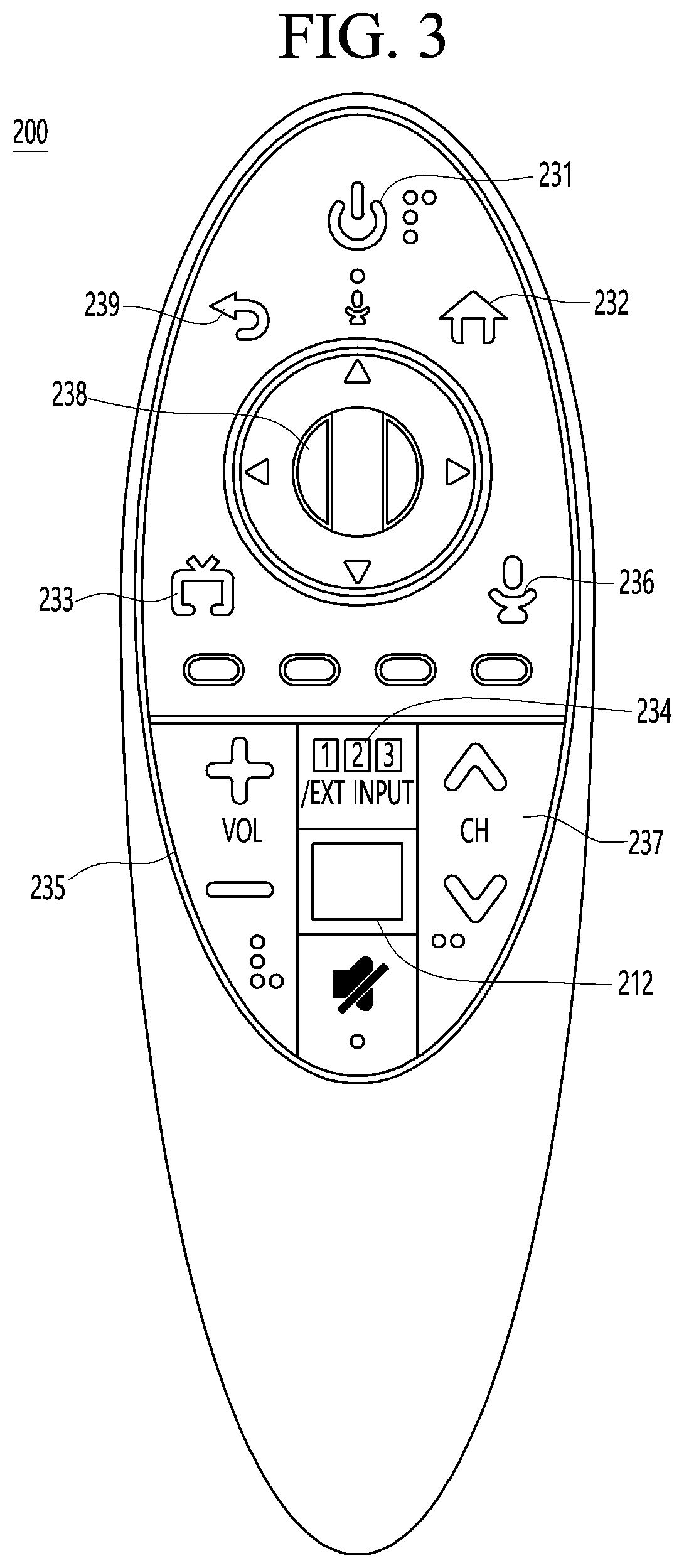

Display device

ActiveUS20220021935A1Reduce input switching timeQuick switchTelevision system detailsDigital data processing detailsComputer hardwareDisplay device

The present disclosure provides a display device that includes an external input interface including an input port connected to a source device, and a processor configured to detect that a source device is connected through an unselected input port of a plurality of input ports, activate an external input interface corresponding to the unselected input port, perform a connection process between the source device and the external input interface, deactivate error detection operation between the source device and the external input interface, generate fake connection information for maintaining connection between the source device and the external input interface based on information input to the external input interface from the source device, and switch the external input interface to a standby mode.

Owner:LG ELECTRONICS INC

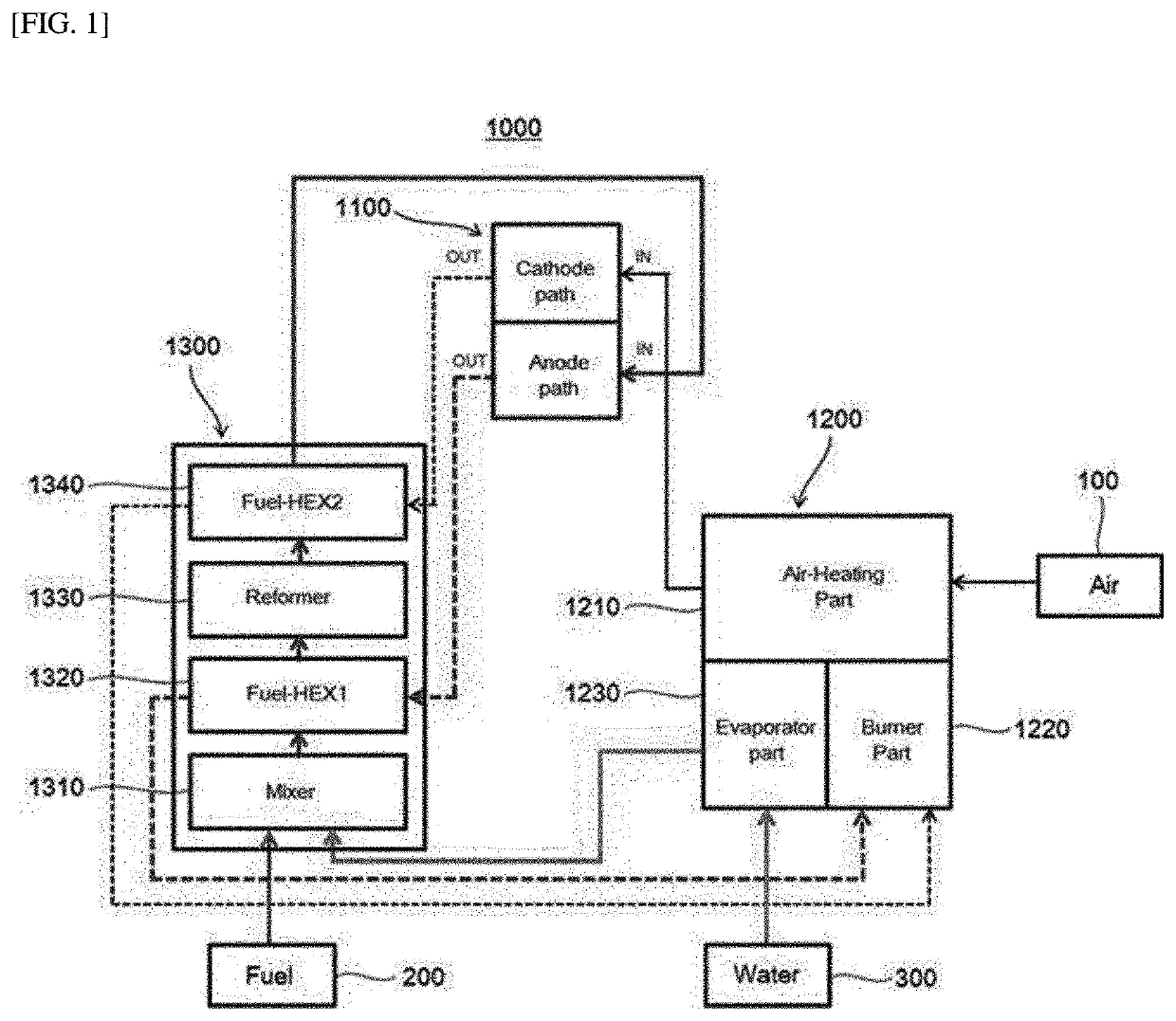

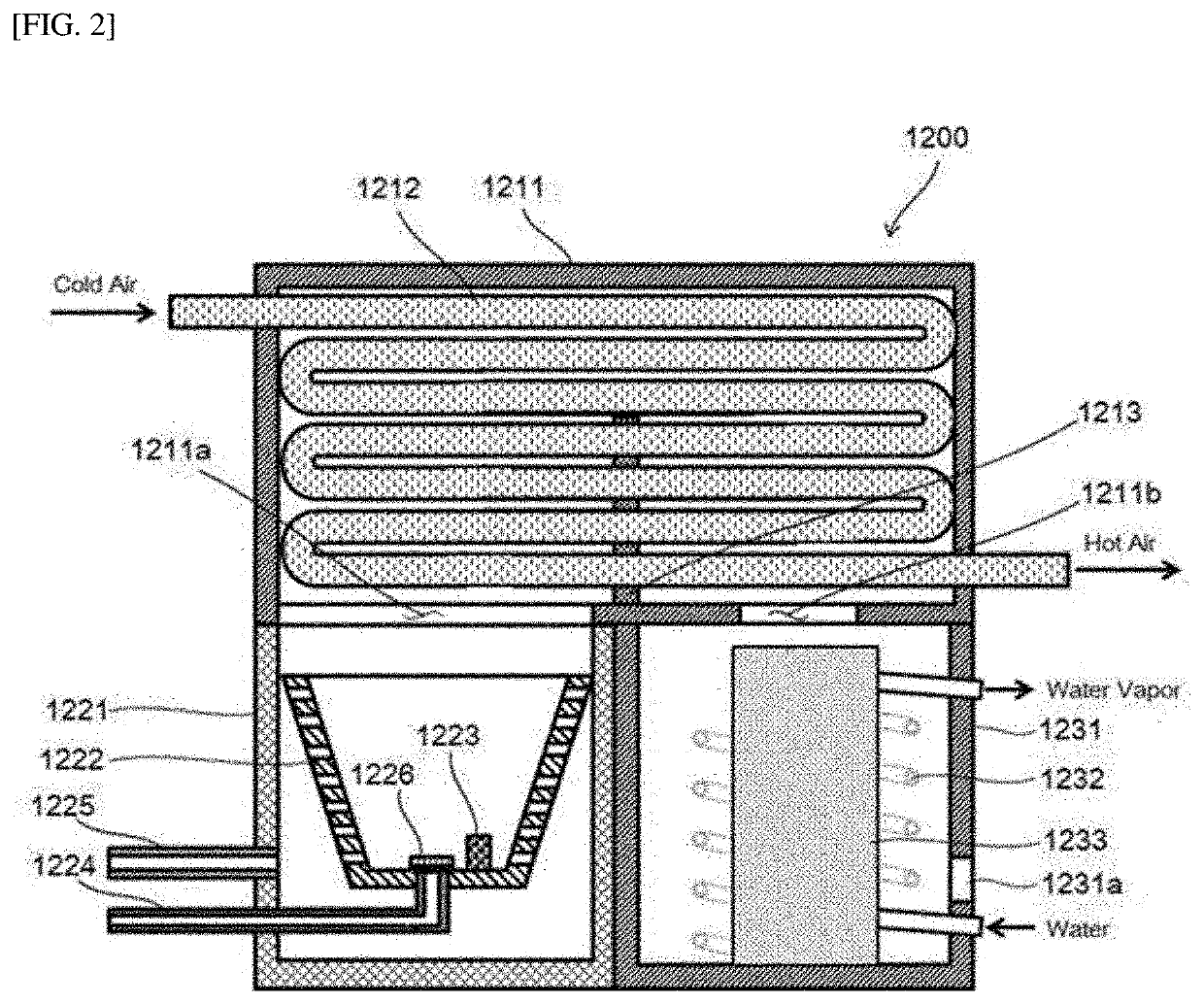

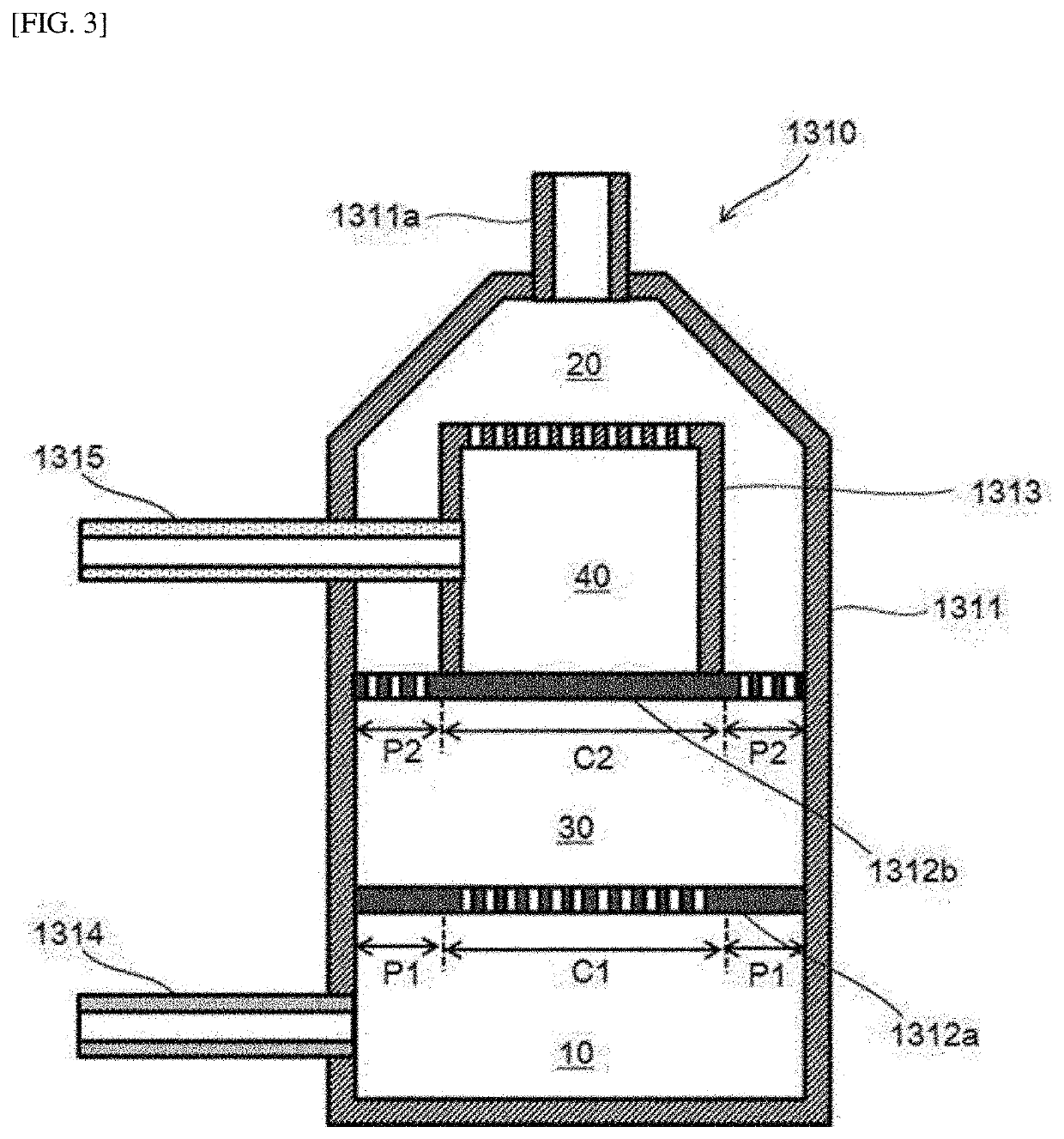

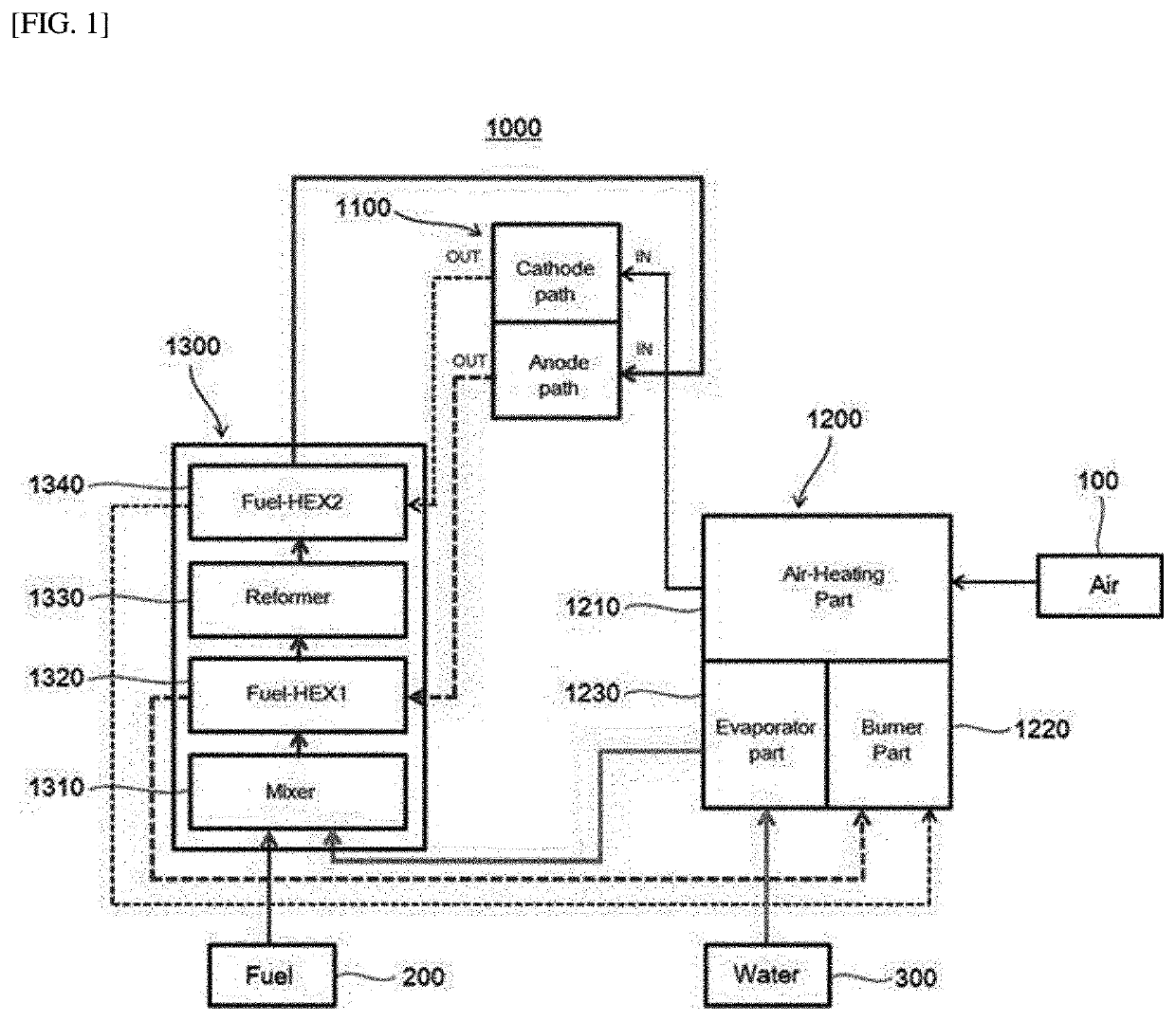

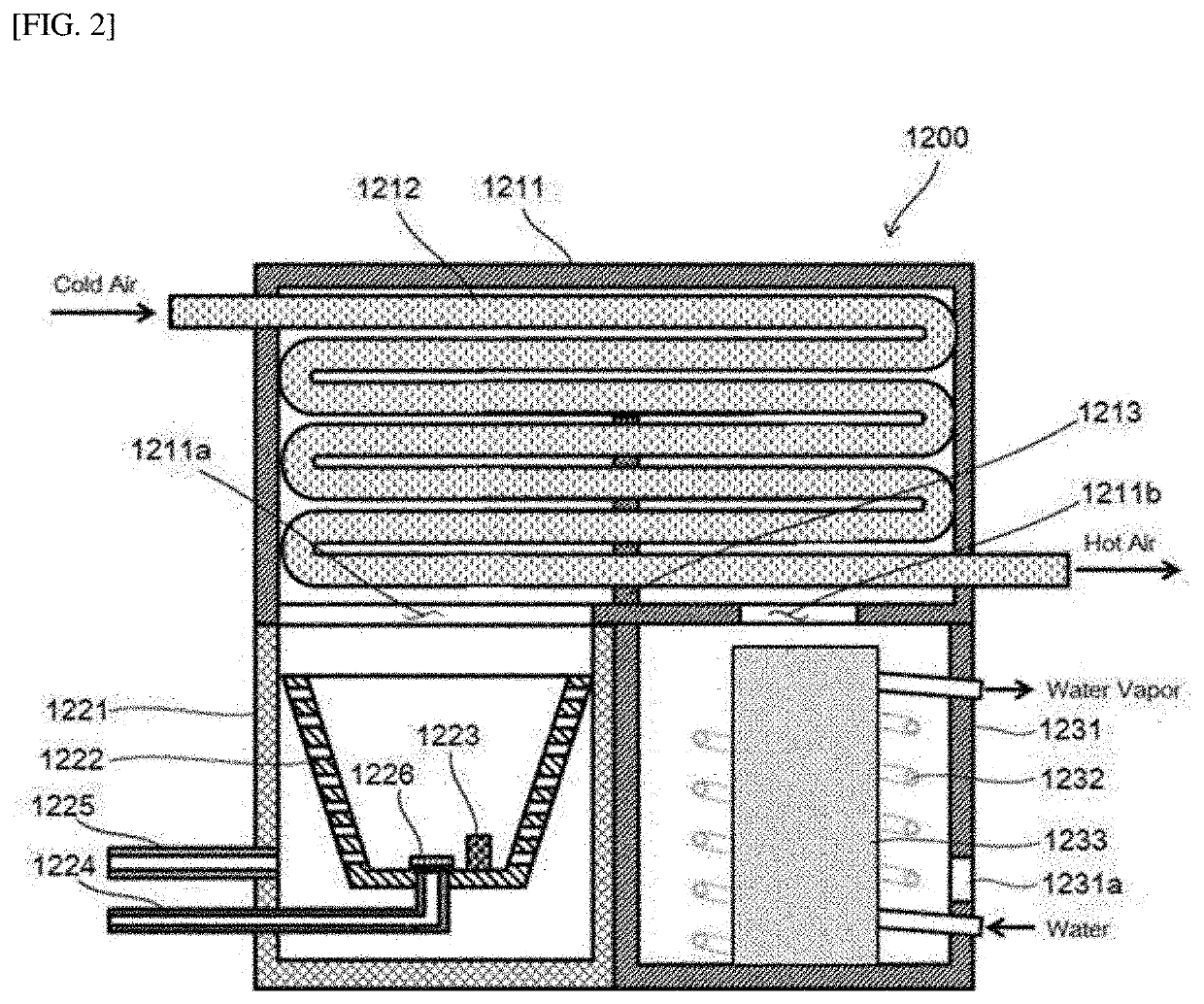

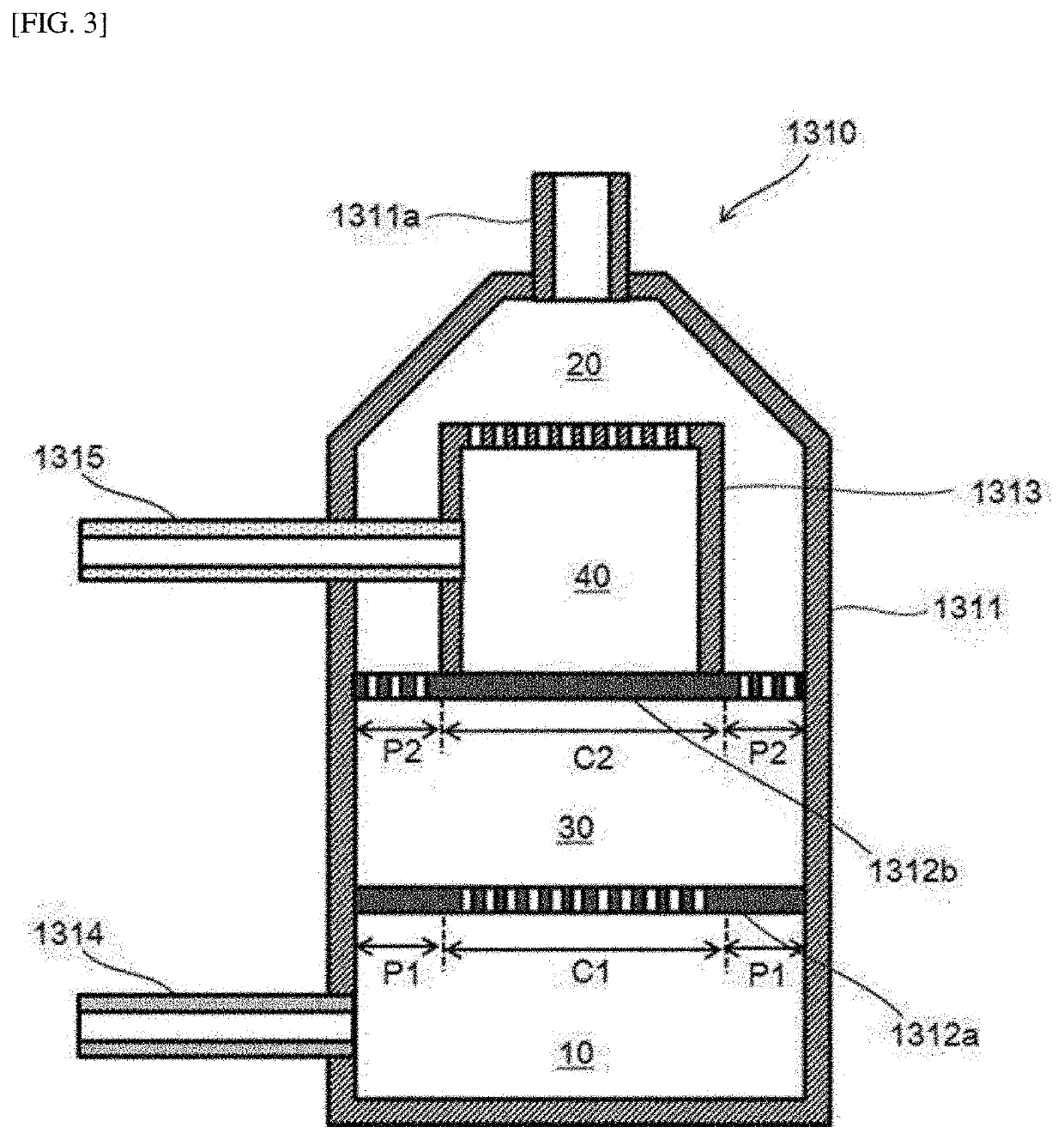

Fuel cell system

ActiveUS20210083307A1Simplify the assembly processMinimize heatFuel cell heat exchangeReactant parameters controlThermodynamicsFuel cells

A fuel cell system is disclosed. The fuel cell system comprises: a fuel cell module including a plurality of unit cells for generating electrical energy by using oxygen of air and hydrogen of a reformed fuel gas; a first module including a burner part which burns an unreacted fuel gas and air discharged from the fuel cell module, an air-heating part which heats air through heat exchange with a hot combustion gas and a flame generated by the burner part and supplies the heated air to the fuel cell module, and a water vapor generation part which converts water, flowing through an inner portion thereof, into water vapor through heat exchange with a hot combustion gas generated by the burner part; and a second module which mixes a fuel supplied from an external fuel supply source and water vapor supplied from an water-vapor generator part, allows a water vapor reformation reaction to occur, and supplies a reformed fuel gas to the fuel cell module.

Owner:MICO POWER LTD

Fuel cell system

ActiveUS11223058B2Improve thermal efficiencyImprove efficiencyFuel cell heat exchangeReactant parameters controlThermodynamicsFuel cells

A fuel cell system is disclosed. The fuel cell system includes: a fuel cell module including a plurality of unit cells for generating electrical energy by using oxygen of air and hydrogen of a reformed fuel gas; a first module including a burner part which burns an unreacted fuel gas and air discharged from the fuel cell module, an air-heating part which heats air through heat exchange with a hot combustion gas and a flame generated by the burner part and supplies the heated air to the fuel cell module, and a water vapor generation part which converts water, flowing through an inner portion thereof, into water vapor through heat exchange with a hot combustion gas generated by the burner part; and a second module which mixes a fuel supplied from an external fuel supply source and water vapor supplied from a water-vapor generator part.

Owner:MICO POWER LTD

Drag reducing compositions and methods of manufacture and use

ActiveUS9267094B2Reduce resistanceMinimize agglomerationLiquid carbonaceous fuelsPipeline systemsPolyolefinFriction reducing

A drag reducing composition for use in hydrocarbon streams which contains a finely divided, solid polyolefin friction reducing agent, a suspending medium comprised of water and a liquid organic carrier containing from 10 to 14 carbon atoms and having at least one hydroxyl group and a partitioning agent comprising a compound having a hydrophobic group and a hydrophilic group and exhibiting at least some surface activity.

Owner:FLOWCHEM LLC

Wafer support pin for preventing slip dislocation during annealing of water and wafer annealing method using the same

ActiveUS7767596B2Simple structureMinimize heatLiquid surface applicatorsSemiconductor/solid-state device manufacturingWaferingOptoelectronics

A wafer support pin has a front end contacted with a wafer such that the front end is flat or rounded. Thus, gravitational stress is minimized during annealing the wafer, thereby minimizing slip dislocation. This wafer support pin is suitably used for annealing of a wafer, particularly high temperature rapid thermal annealing of a large-diameter wafer.

Owner:LG SILTRON

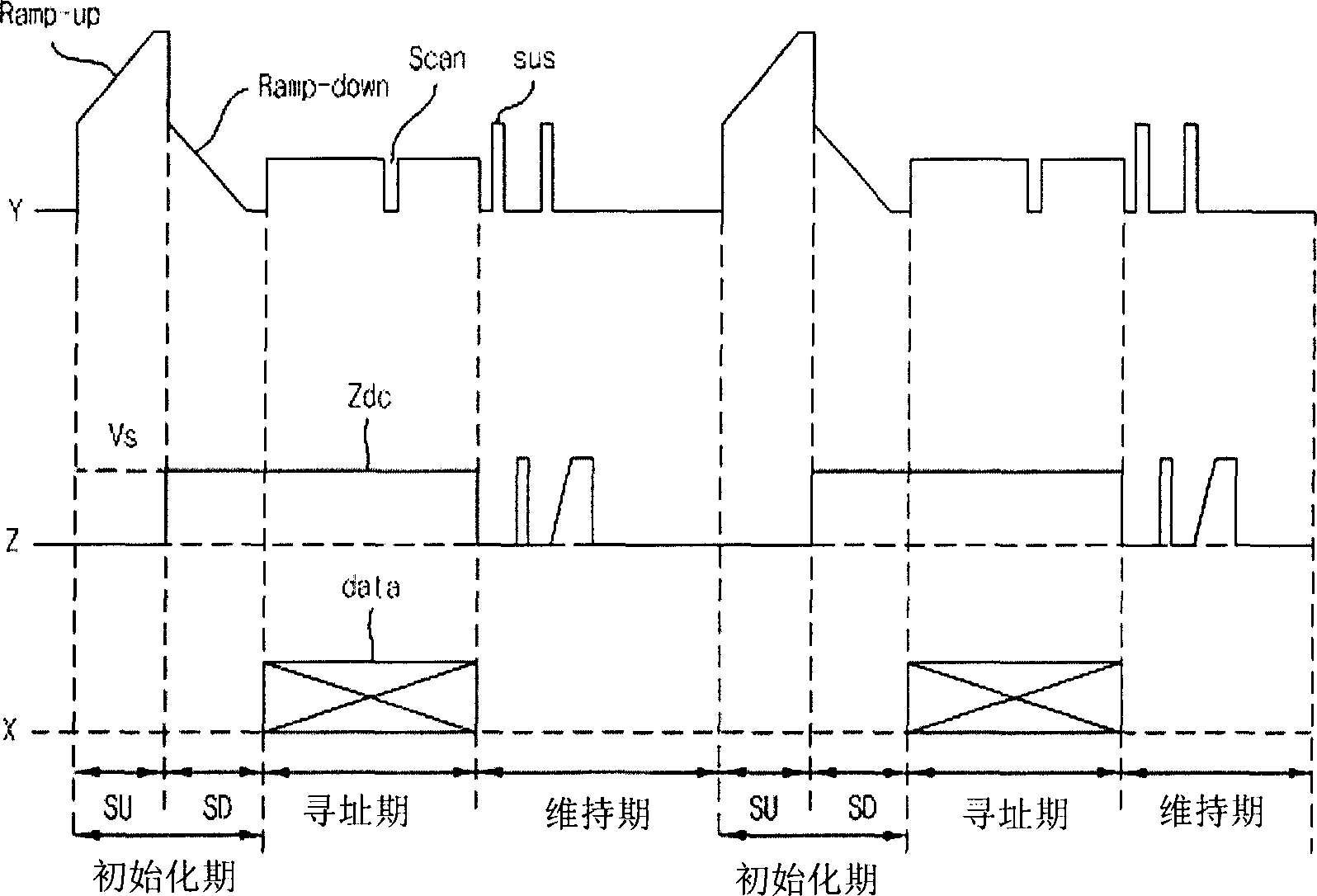

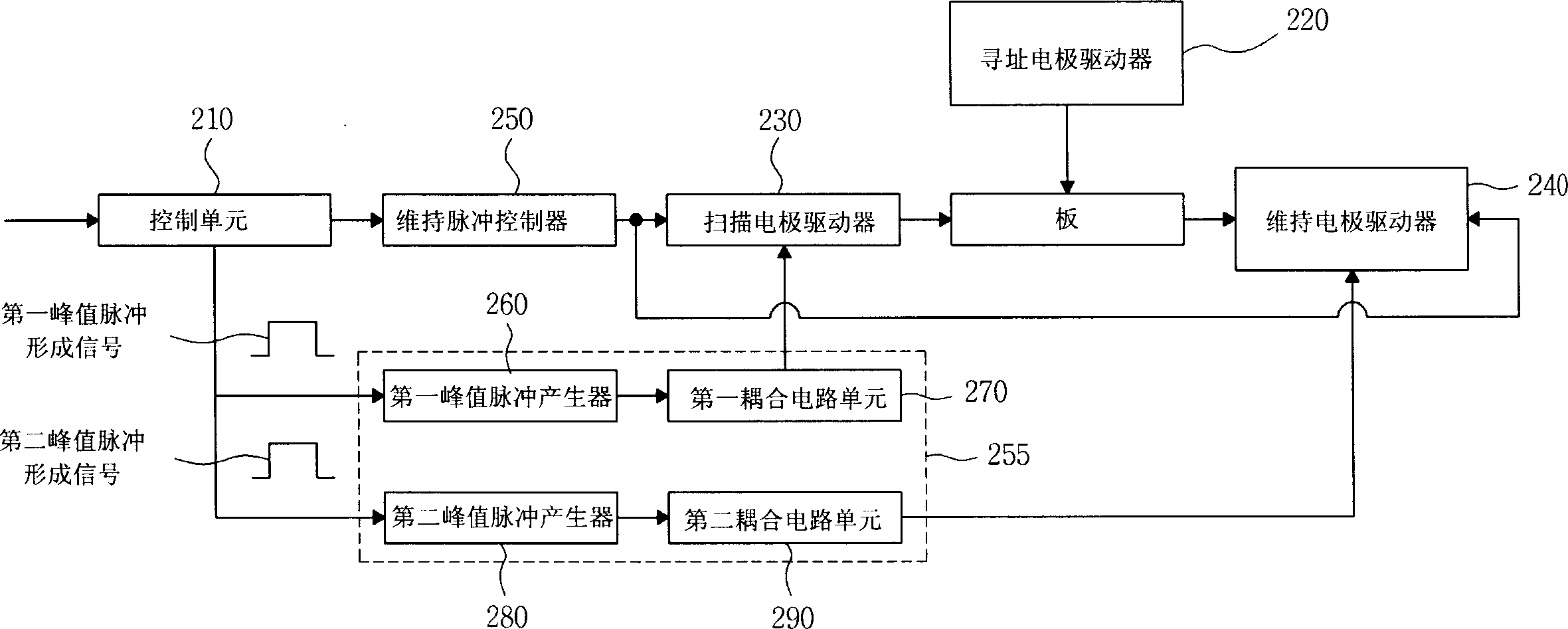

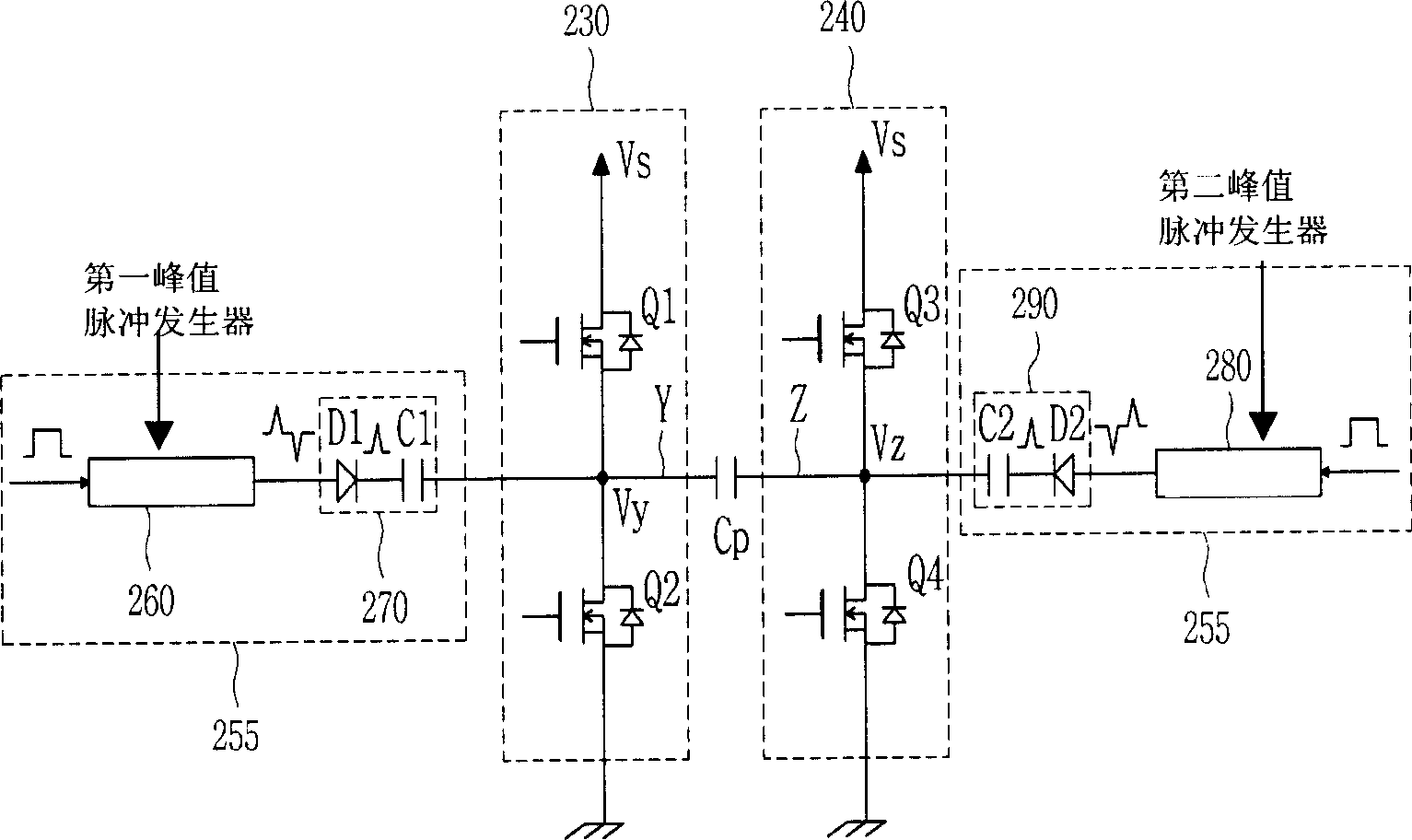

Plasma display apparatus and driving method thereof

InactiveCN1728212AGuaranteed reliabilityGuaranteed uptimeStatic indicating devicesCold-cathode tubesBrightness perceptionHeat generation

Provided are an apparatus and method for driving a plasma display panel, which are capable of increasing the brightness of the plasma display panel and minimizing power consumption and the amount of heat generation without increasing the number of sustain pulses. The plasma display apparatus includes: a plasma display panel including a scan electrode and a sustain electrode; a scan electrode driver for applying a first sustain pulse to the scan electrode; a sustain electrode driver applying a second sustain pulse to the sustain electrode alternately with the first sustain pulse; and a peak pulse applying unit causing a peak pulse to overlap the first sustain pulse and the second sustain pulse when the first sustain pulse and the second sustain pulse are alternately applied to the scan electrode and the sustain electrode.

Owner:LG ELECTRONICS INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com