Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Good deformation control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

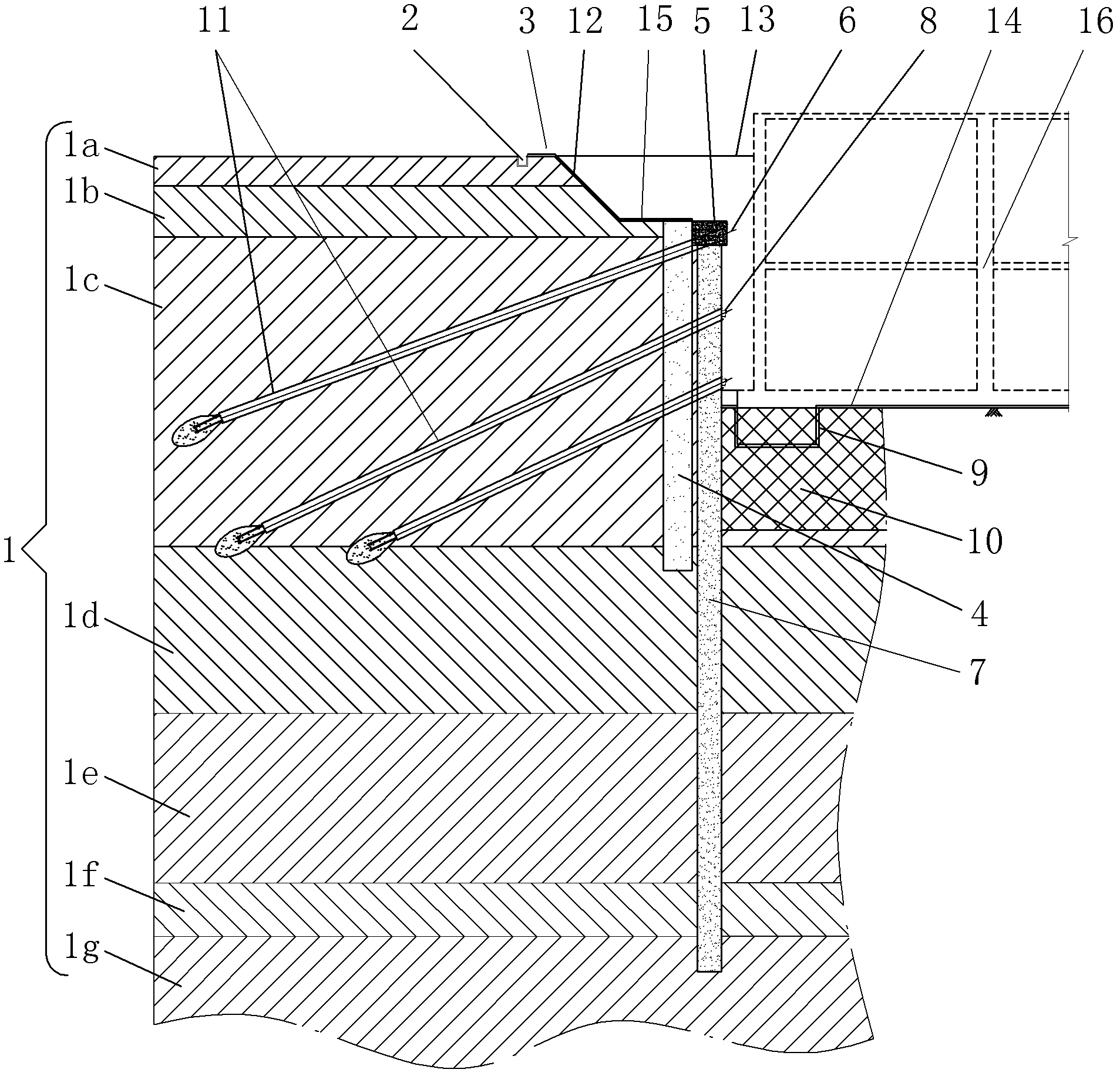

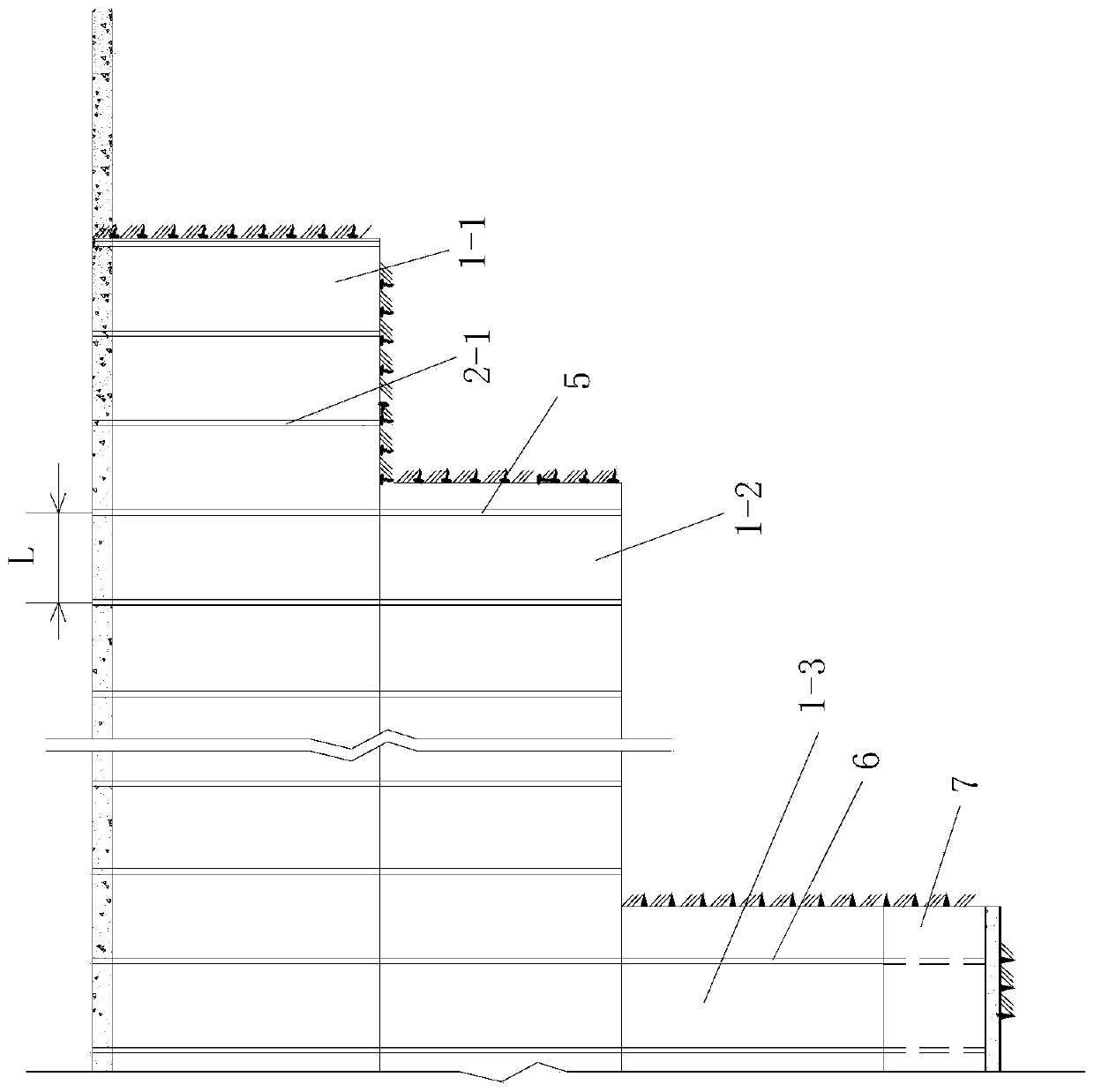

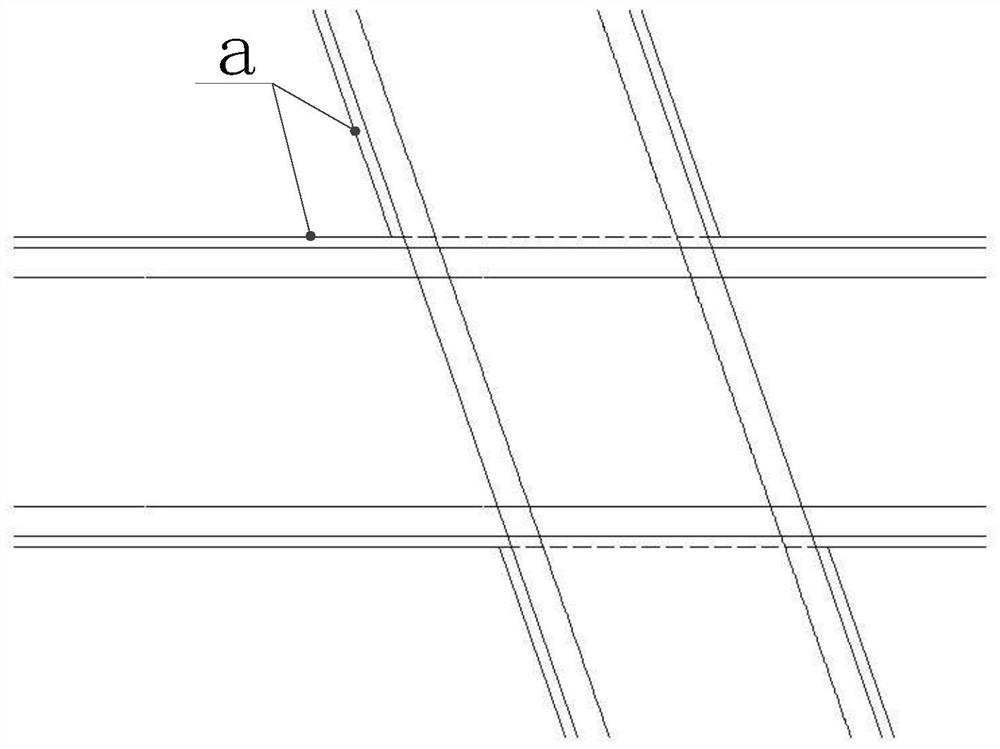

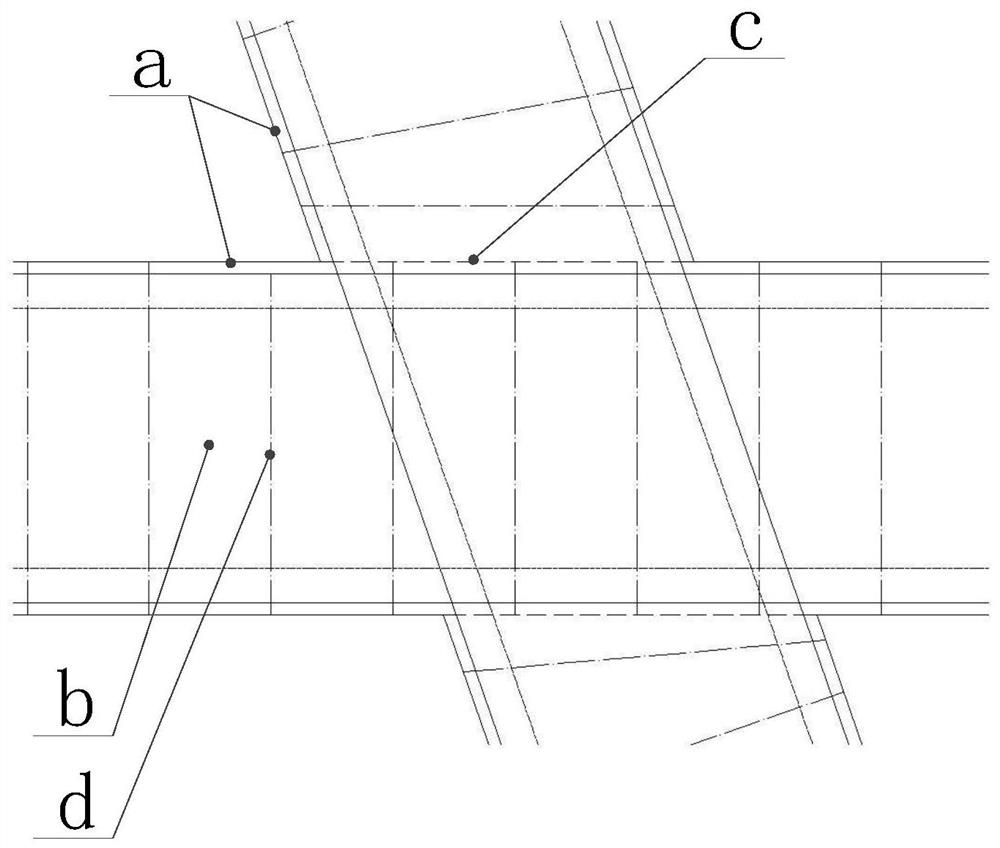

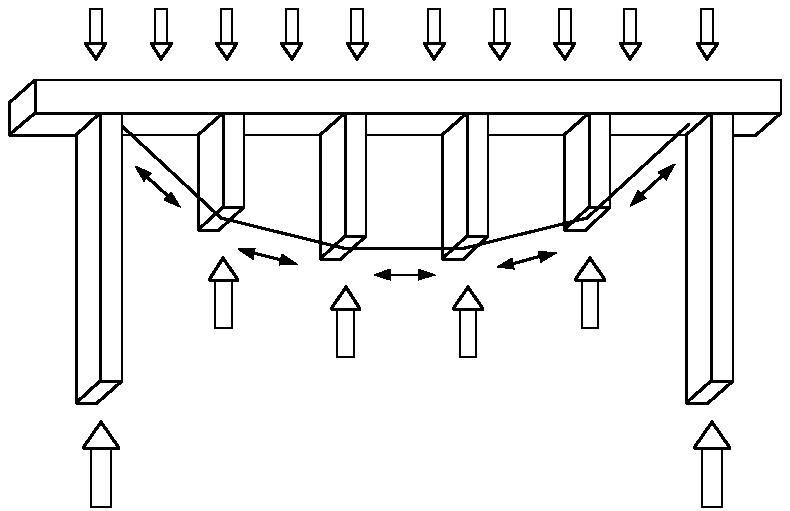

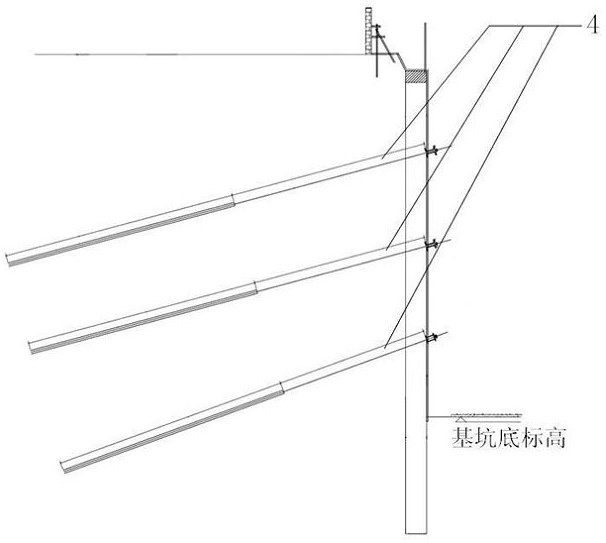

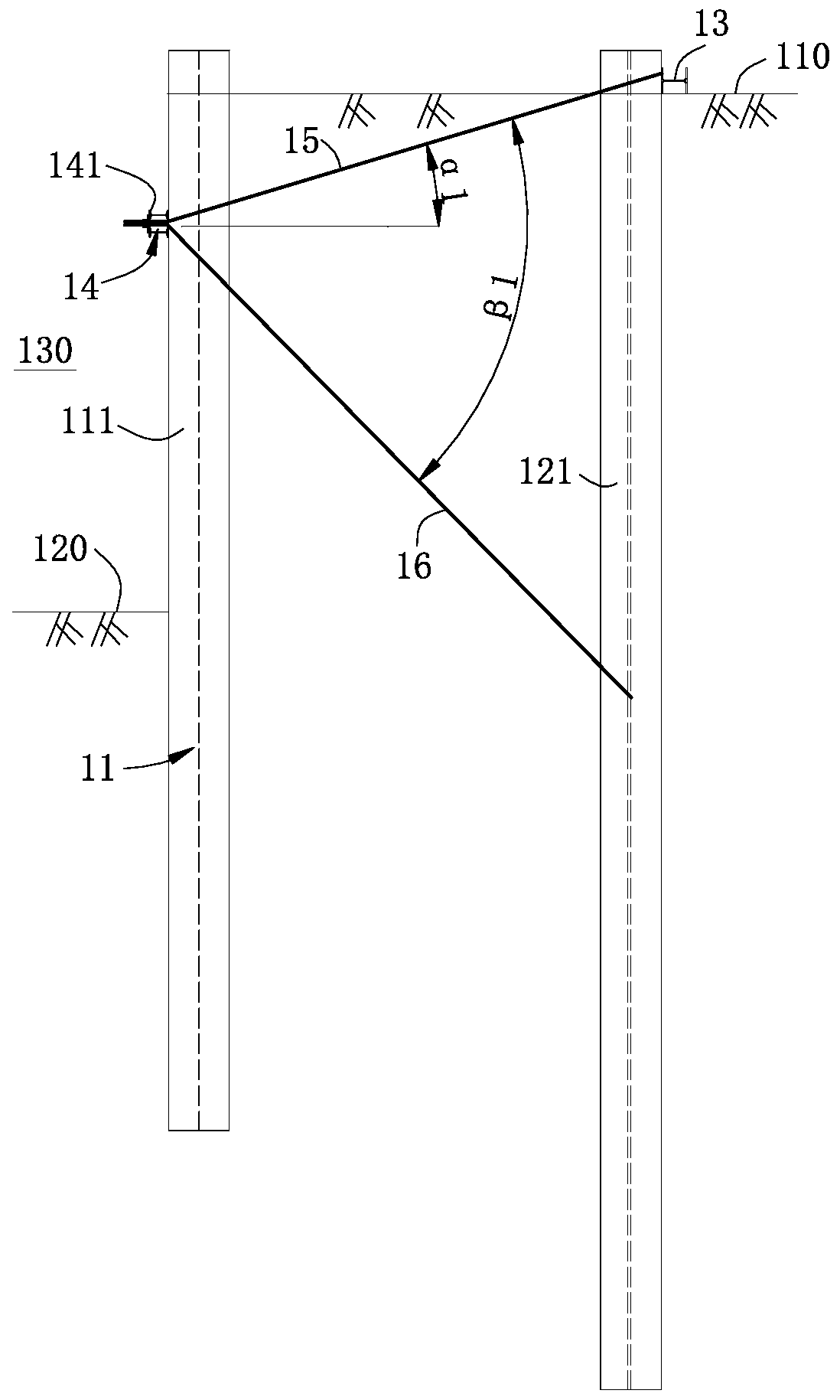

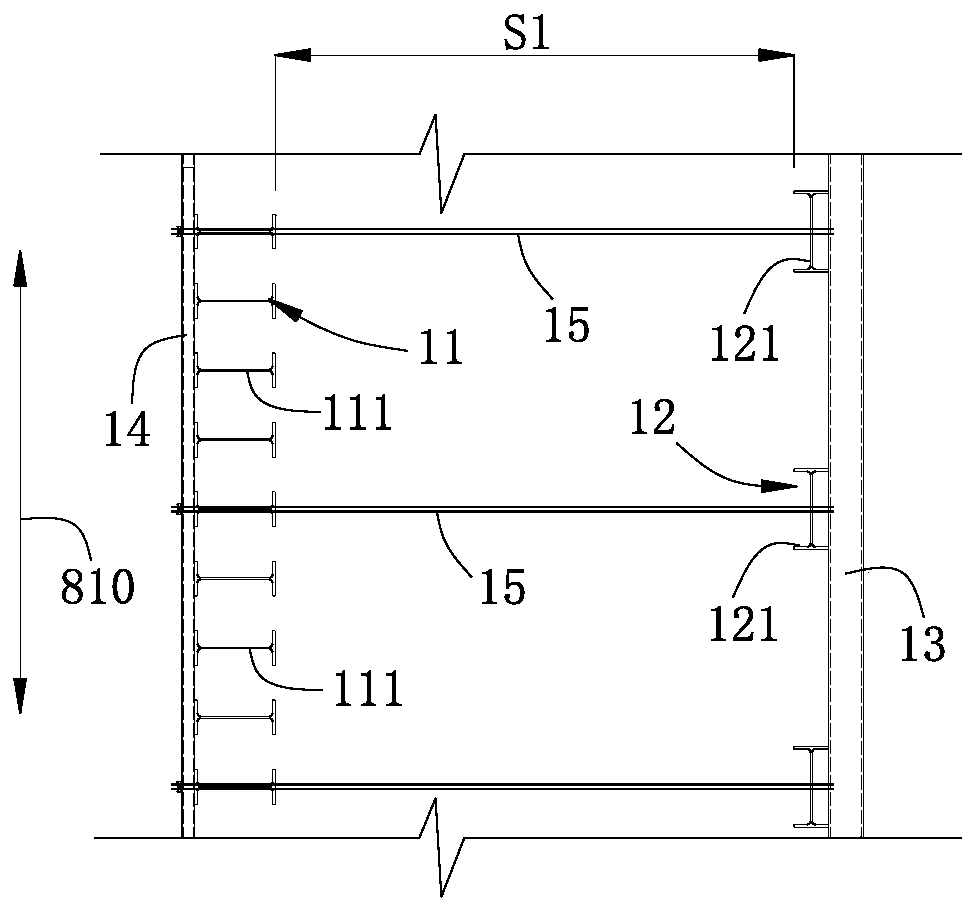

Foundation pit support construction method combining horizontal rotary jet-grouting soil bolting and bore concrete piles

ActiveCN102518135AOutstanding and Beneficial Technical EffectsControl deformation valueExcavationsBulkheads/pilesEngineeringDeformation control

The invention belongs to the technical field of foundation pit supporting for high-rise buildings, in particular to a foundation pit support construction method combining horizontal rotary jet-grouting soil bolting and bore concrete piles, which includes steps: firstly, constructing water-stop mixed piles and bored concrete piles according to a preset foundation pit; and secondly, performing soil excavation and soil bolting layer by layer and section by section. The foundation pit support construction method has the advantages that the foundation pit support constructed by the method is high in deformation control performance and stability and especially applicable to projections with high requirements on foundation pit deformation, and the method is applicable to mega-area foundation pit supporting in soft soil areas with failure of using internal support structures, limited slope reduction conditions and excavation depth limited within 15m, and meets the requirement that development and utilization of urban underground space continue to develop.

Owner:BIAOLI CONSTR GROUP

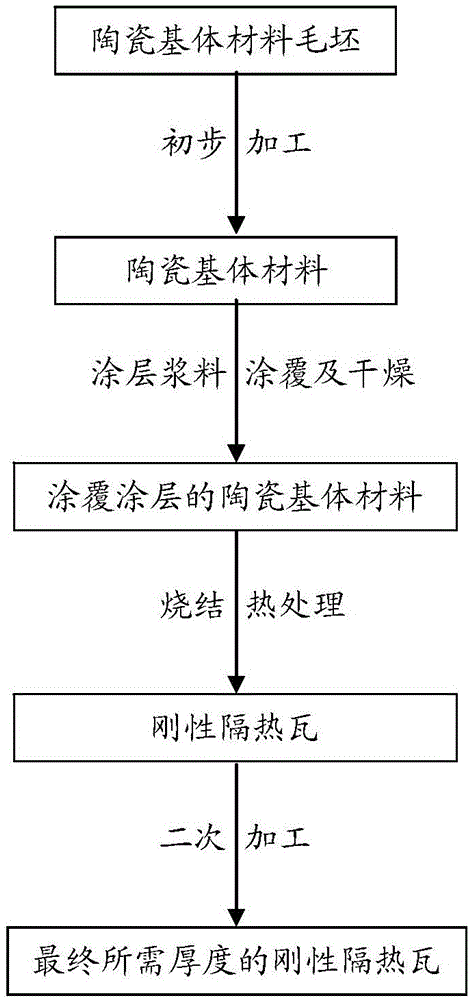

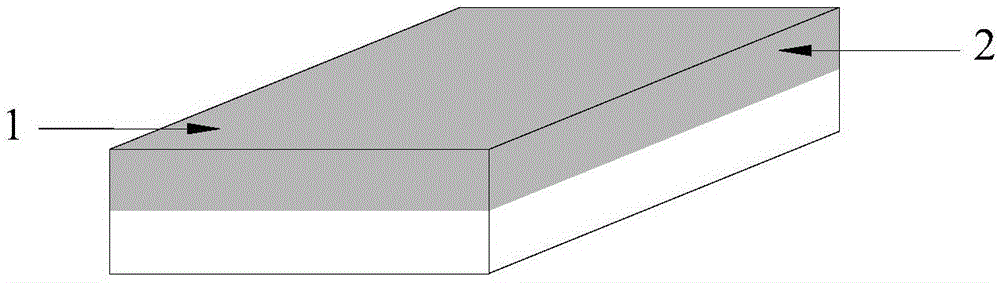

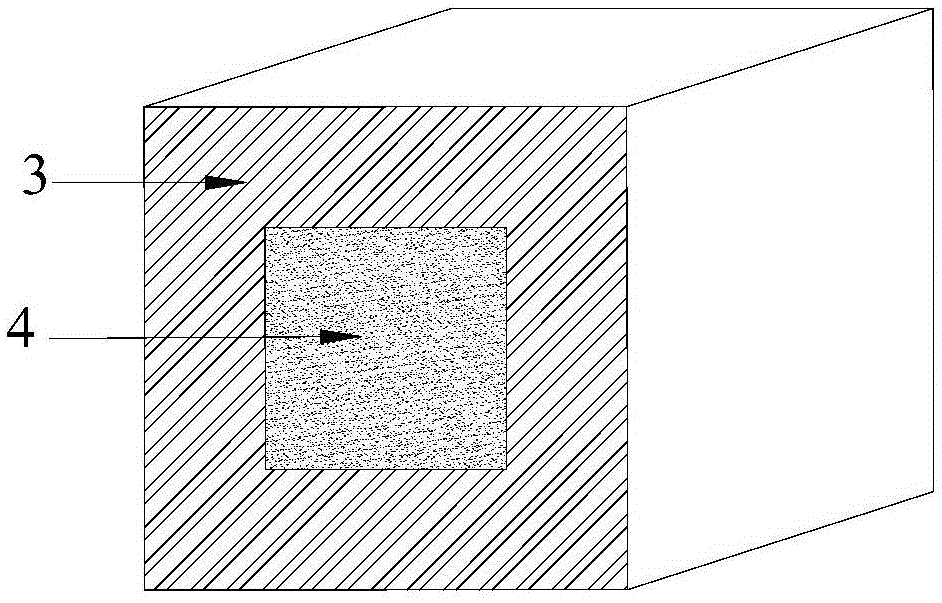

Deformation control method in rigid heat-insulating tile coating forming process

The invention relates to a deformation control method in a rigid heat-insulating tile coating forming process, belongs to the technical field of a porous ceramic heat-insulating material, and can be used for preparing a heat shielding material of an aircraft such as a space shuttle and the like. The method comprises: applying coating slurry to the surface of a rigid heat-insulating tile ceramic base body which is initially processed to a certain thickness and shape; after drying, putting the coated base body material at a high temperature to be sintered for thermal treatment; after sintering for thermal treatment, taking out the base body material from the high-temperature environment and cooling the base body material to room temperature; and finally carrying out secondary processing to reduce the base body material to the finally required thickness. Compared to a conventional method which directly processes the base body material to the finally required thickness and then carries out coating forming, deformation of the rigid heat-insulating tile in the coating forming process can be effectively controlled.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

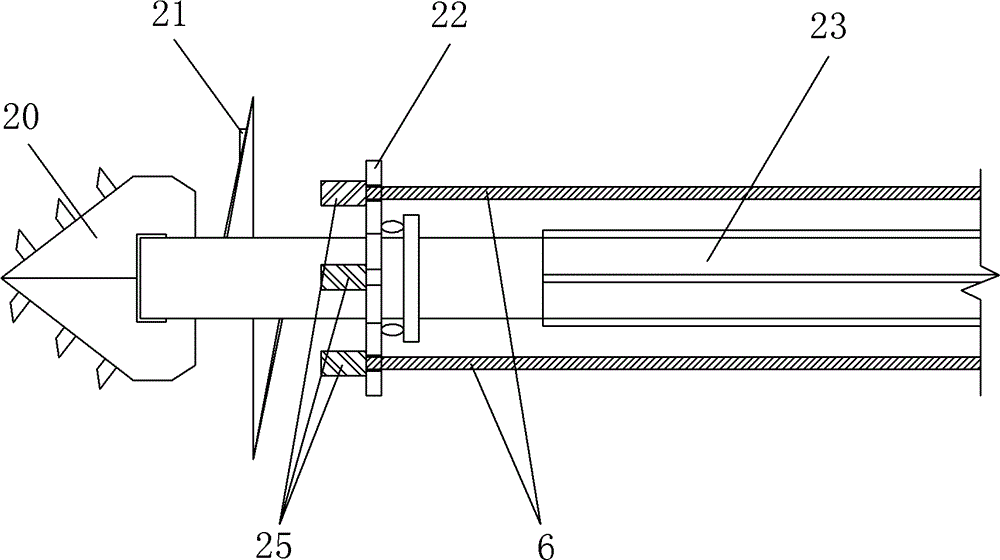

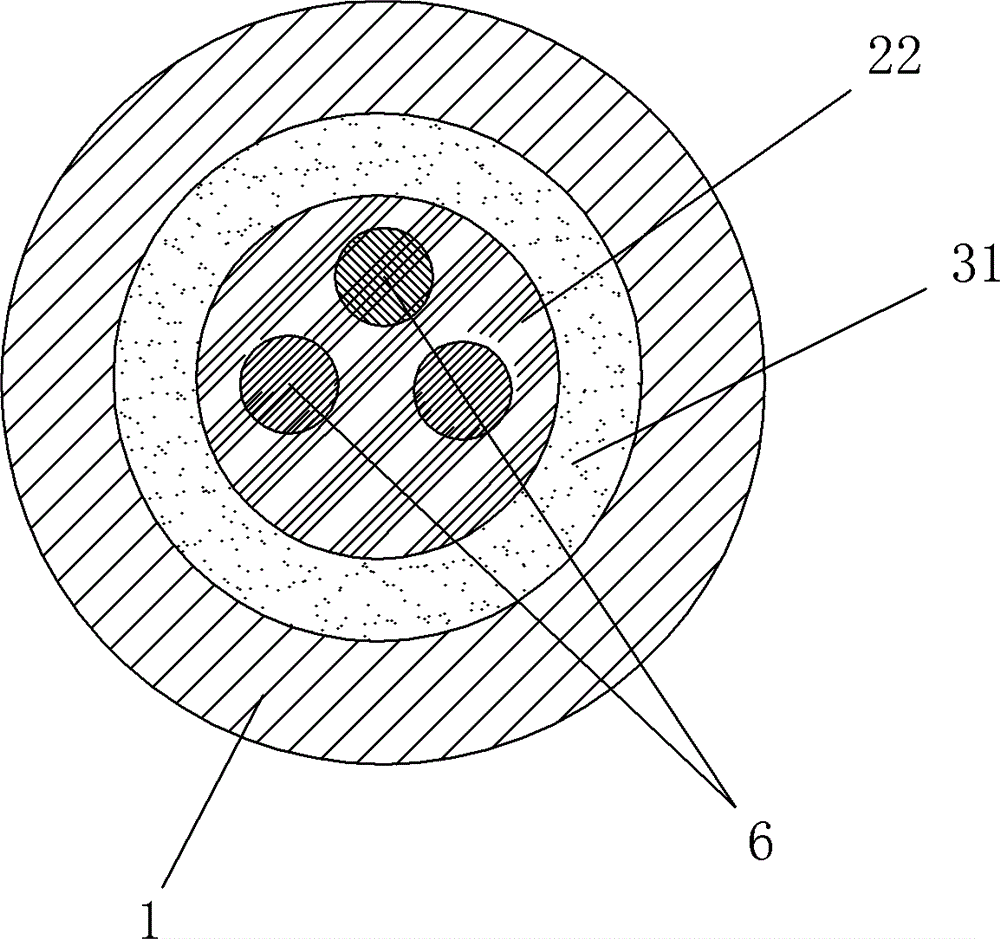

High-pressure gas multistage pre-splitting grouting transformation method for surrounding rock of deep soft rock roadways

ActiveCN105156134AGood injectabilityPrevent closureUnderground chambersFluid removalHigh pressureMechanical property

The invention relates to a high-pressure gas multistage pre-splitting grouting transformation method for surrounding rock of deep soft rock roadways. The high-pressure gas multistage pre-splitting grouting transformation method has the advantages that the surrounding rock of the deep soft rock roadways is subjected to multistage pre-splitting by the aid of high-pressure gas, special propping agent materials are added into popping agent containers when last-stage gas pre-splitting is carried out, the particle sizes of the propping agent materials are larger than those of cement particles, the propping agent materials are used for propping crack of the artificially pre-split expanded surrounding rock, the crack can be prevented from being closed again under the effect of deep high ground stress, the groutability of the surrounding rock can be improved, then the surrounding rock with the crack can be grouted and reinforced, weak surrounding rock structures and mechanical properties of the roadways can be greatly transformed, the surrounding rock of the deep soft rock roadways can be stably controlled, and difficult problems of closing of crack of existing surrounding rock of existing deep soft rock roadways, extremely poor groutability of the existing surrounding rock and poor grouting effects can be solved; the weak surrounding rock structures and the mechanical properties can be obviously transformed and enhanced, and the bearing capacity of the surrounding rock can be improved; high-pressure gas pre-splitting holes and grouting holes of the surrounding rock are combined with one another, and the high-pressure gas multistage pre-splitting grouting transformation method is easy to operate and implement in fields.

Owner:CHINA UNIV OF MINING & TECH

Simple method for deformation control during carburizing and quenching of large-diameter heavy-duty gears

InactiveCN102010973AEasy to operateGood deformation controlSolid state diffusion coatingFurnace typesDeformation controlHeavy duty

The invention relates to the technical field of carburizing and quenching as well as deformation control of steel work-pieces, and particularly relates to a simple method for deformation control during the carburizing and quenching of large-diameter heavy-duty gears. In the method, the deformation control can be carried out on the carburizing and quenching of the steel work-pieces by adopting simple facilities under simple operation conditions, so as to reach the expected effect and improve the product quality. The method comprises the following steps of: normalizing of steel work-piece, carburization of the steel work-pieces placed in a direction A, normalization of the steel work-pieces placed in a direction B, quenching of the steel work-pieces placed in the direction B in a static oil, and tempering. The method has the significances of breaking through the situation that the deformation control of the carburizing and quenching of the large-diameter complicated heavy-duty face gears can be controlled only by adopting complicated facilities and complicated technological operations, and simultaneously developing a simple and practical way for the deformation control during the carburizing and quenching of the large-diameter complicated heavy-duty face gears.

Owner:CRRC QISHUYAN CO LTD

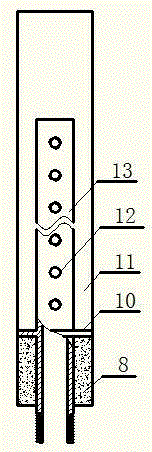

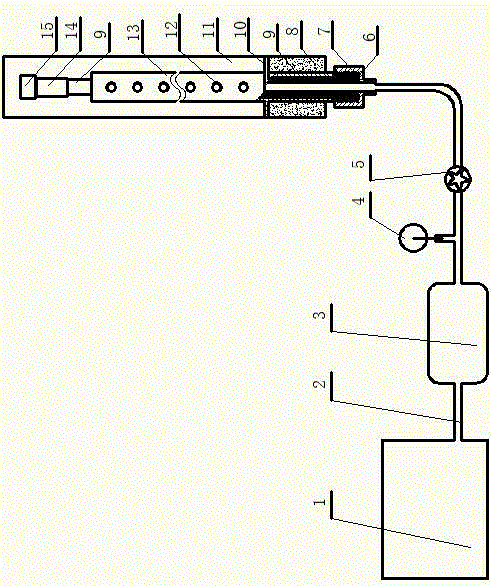

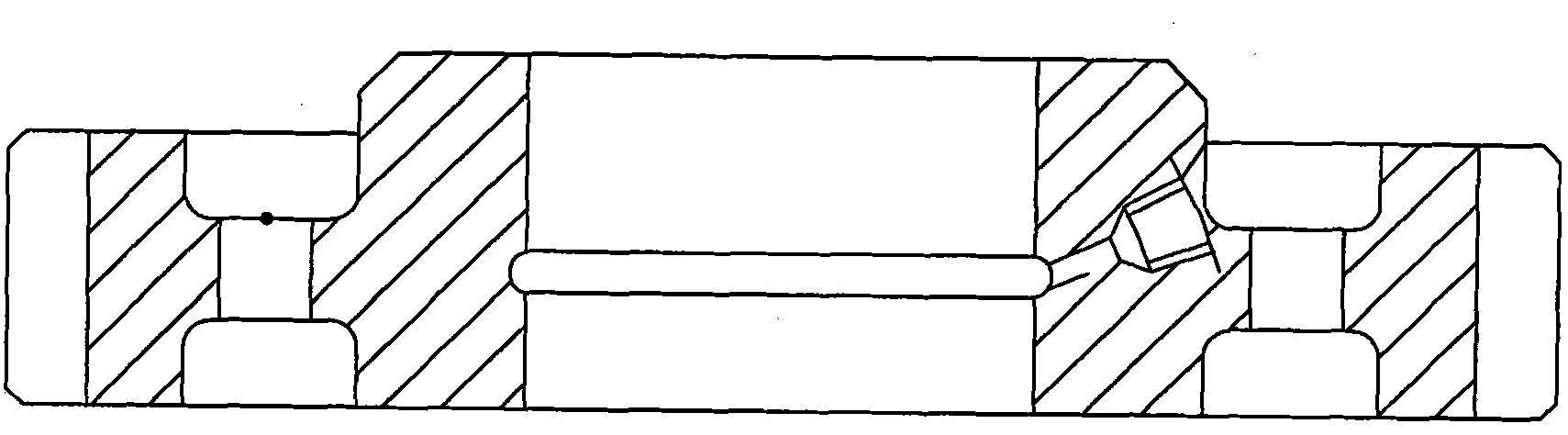

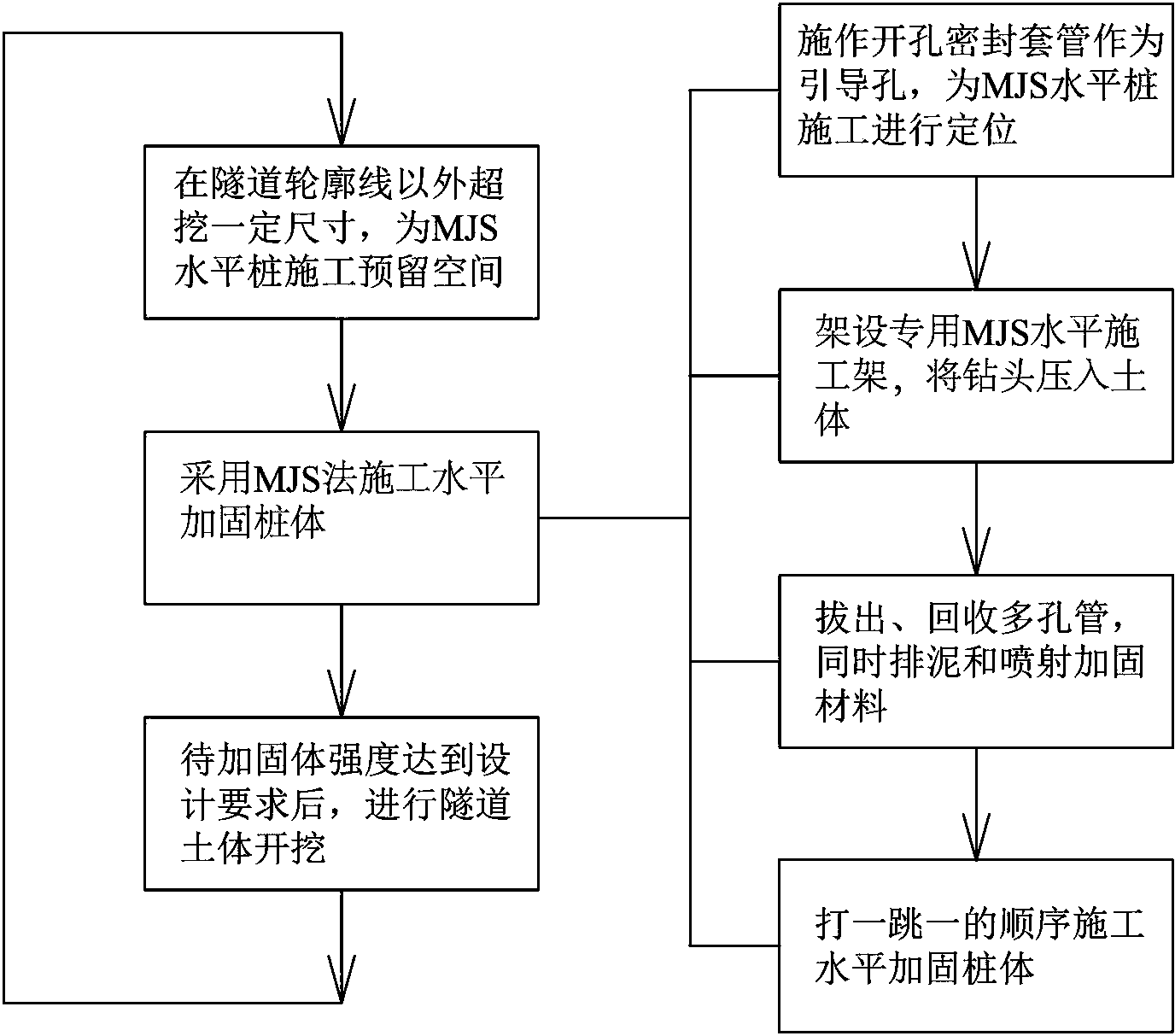

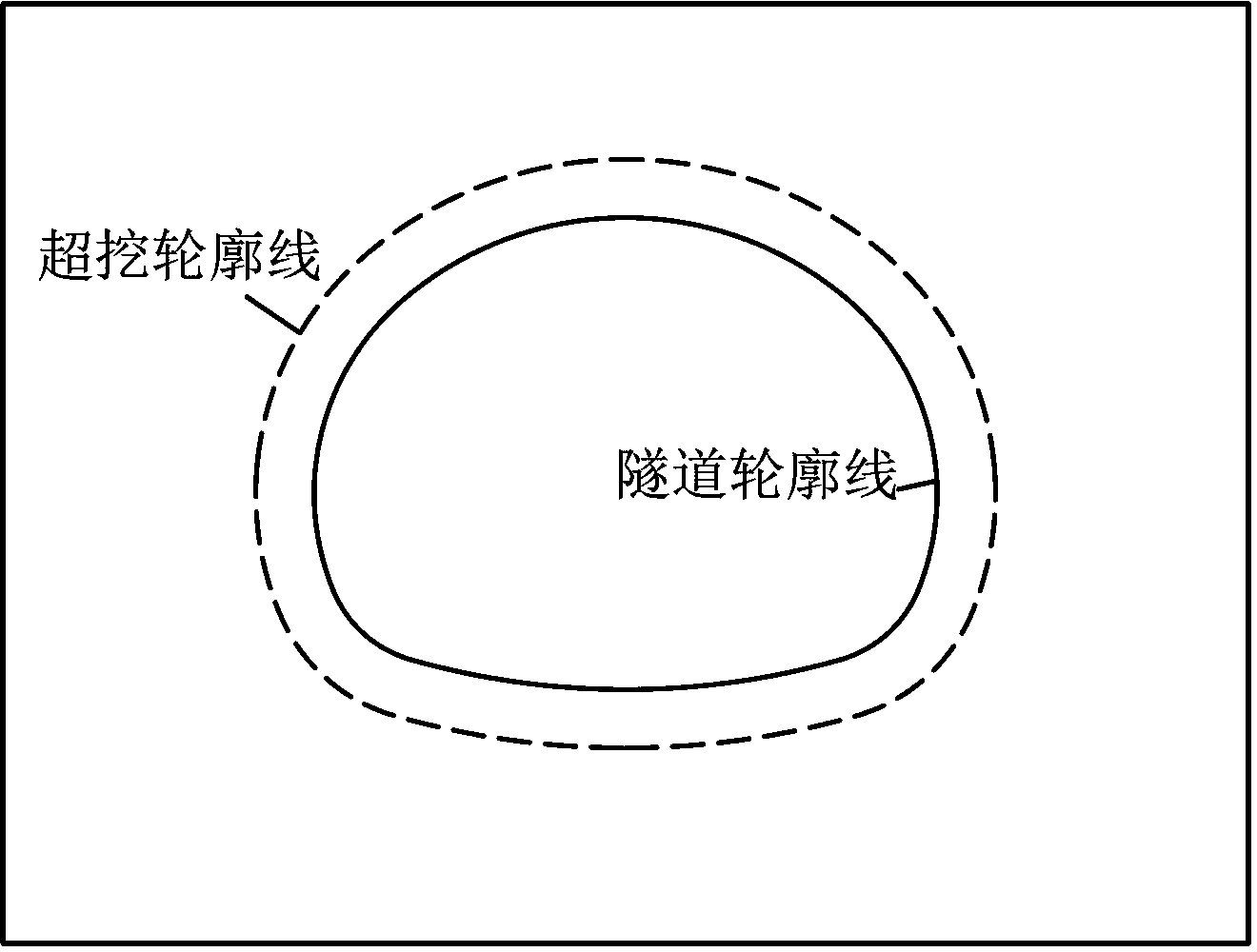

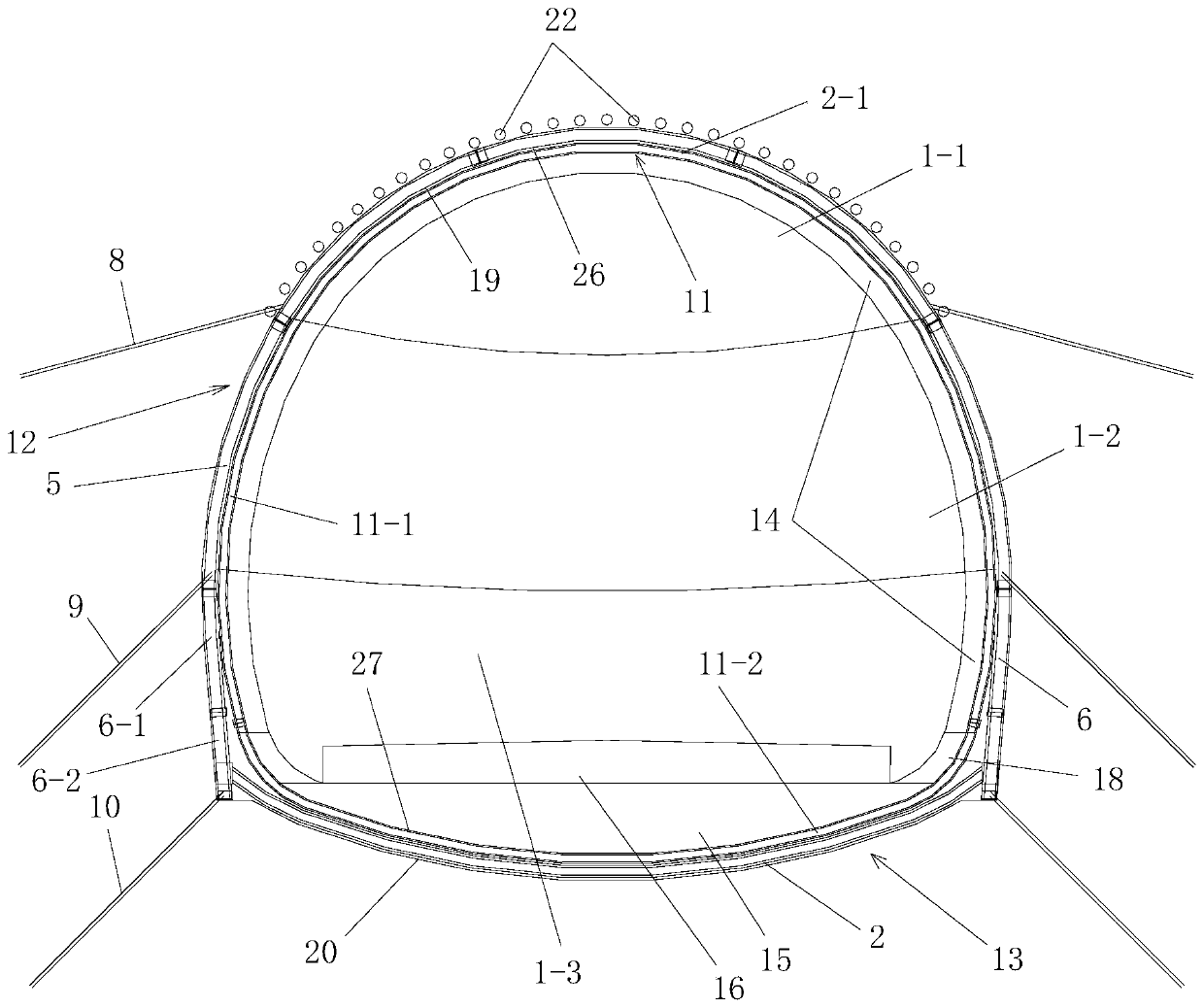

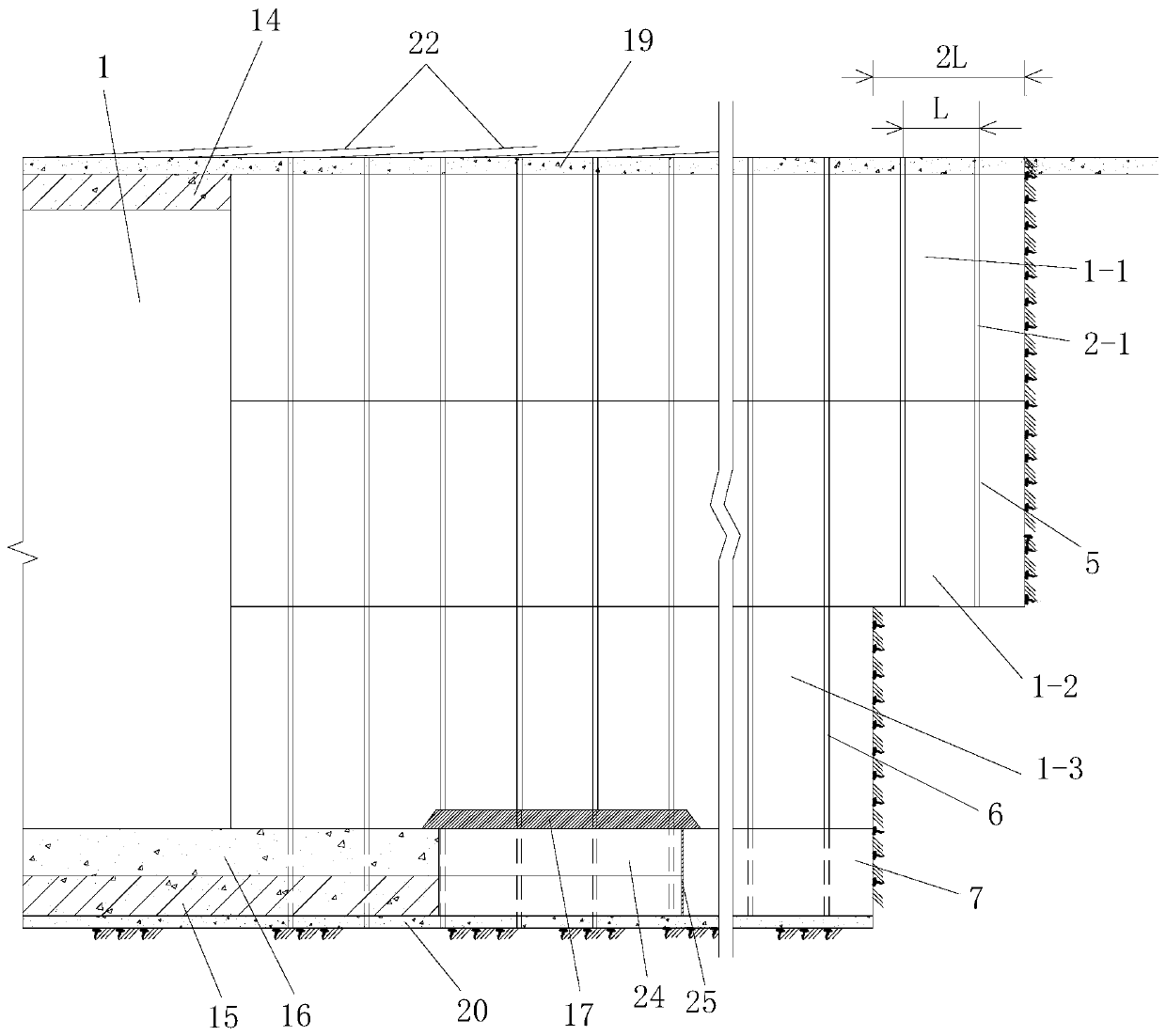

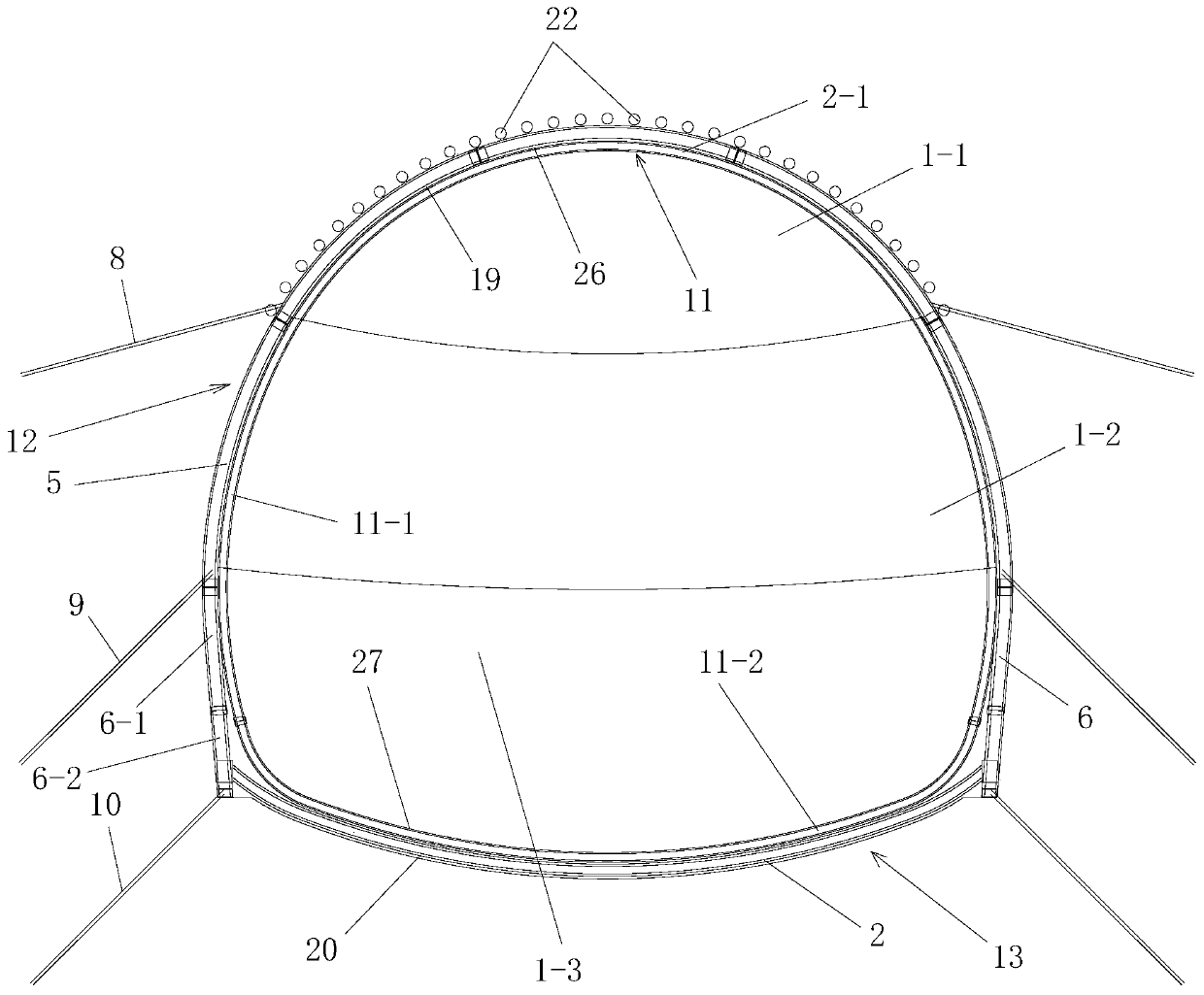

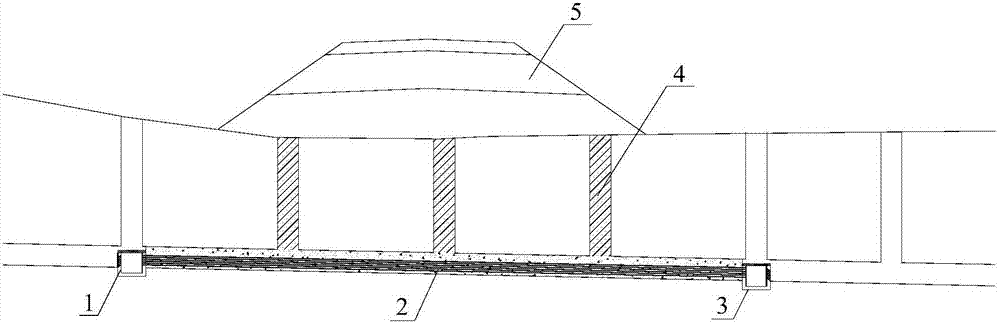

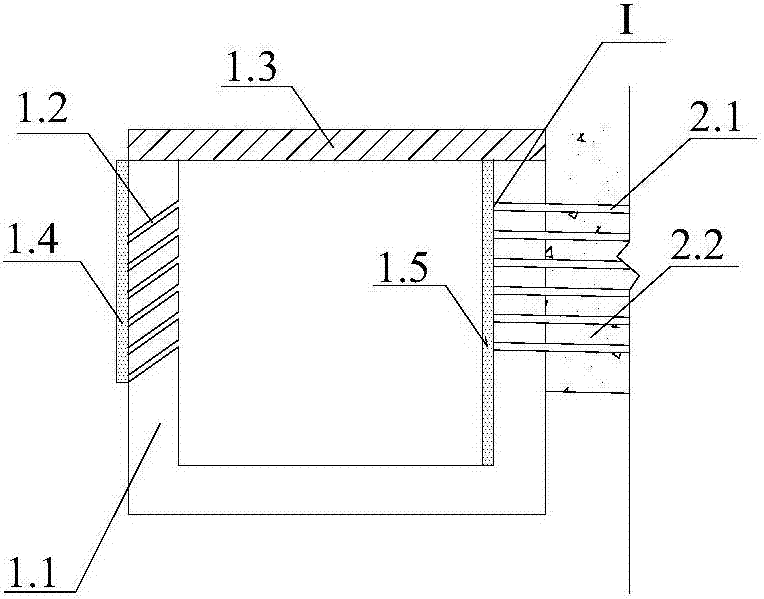

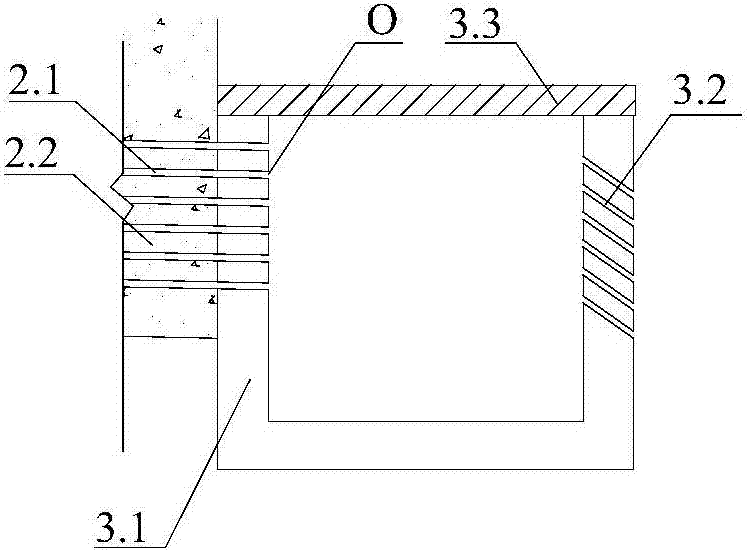

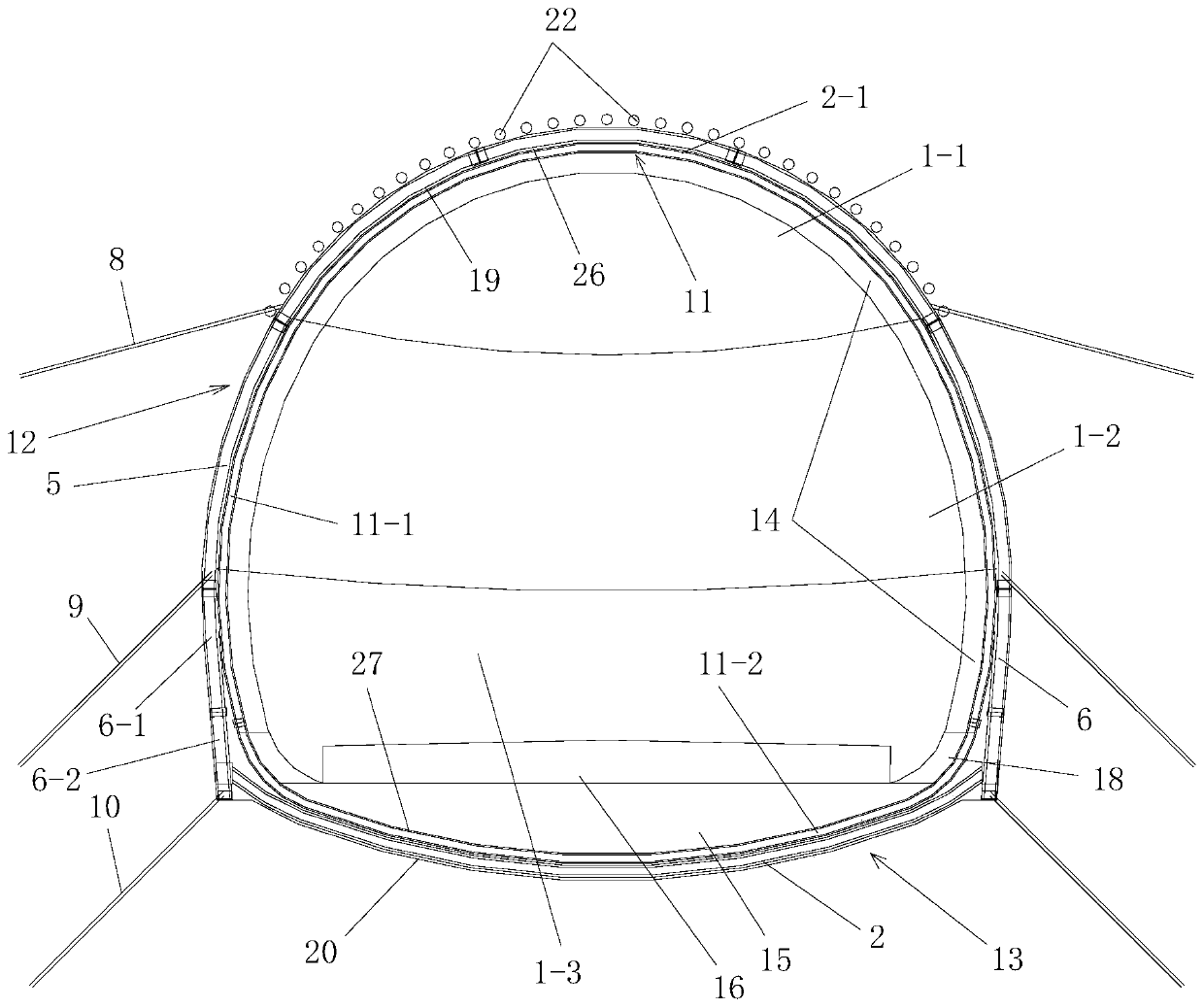

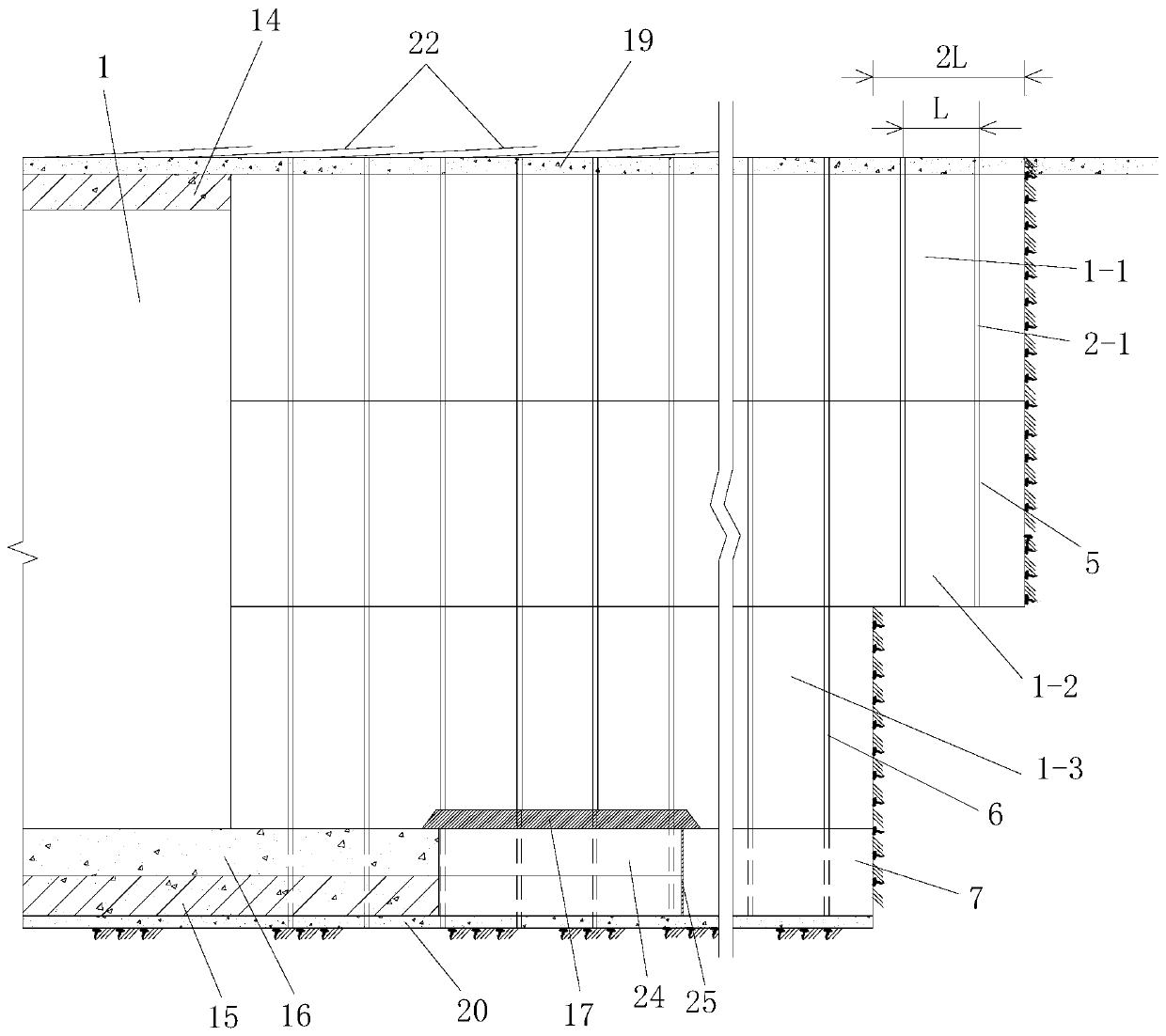

Novel support method applicable to shallow-buried subsurface tunnel of soft soil stratum

InactiveCN104033160AIncrease stiffnessGood deformation controlUnderground chambersTunnel liningHazardous substanceHigh pressure

The invention relates to a novel support method applicable to a shallow-buried subsurface tunnel of a soft soil stratum. The novel support method is invented to solve the problem that a reinforcing system of the existing shallow-buried undermining method cannot be applied to mucky soil stratum conditions. The method applies a metro jet system (MJS) to the shallow-buried undermining method, and extends an application scope of the shallow-buried undermining method.Since the quality of a horizontal reinforcing pile body of the MJS is reliable, the reinforcing pile body can also serve as an initial liner of the tunnel, and a cross section and a reinforcing scope of the reinforcing pile body can be adjusted to a great extent.According to the method, with the adoption of the MJS, construction parameters are controllable during a whole course, a construction process has very small influence on an environment, no hazardous substance is discharged outwards at the same time, and pollution to a surrounding soil body and a water area can be avoided.The method is economical, reliable and wide in application scope.

Owner:TONGJI UNIV

Little deformation welding process for mini car rear-axle housing

InactiveCN101407013AGood deformation controlReduce the number of equipmentArc welding apparatusEngineeringEnergy consumption

The invention discloses a small deformation welding process for a rear-axle housing of a mini vehicle, which belongs to the field of mechanical processing. The process comprises the welding of a middle segment assembly of a rear axle of the mini vehicle, the welding of a axle sleeve assembly of the rear axle of the min vehicle and the welding of the rear-axle housing assembly of the mini vehicle. The process has the advantages that: 1. a connecting disk is unnecessarily processed after being welded; 2. the welding order (welding unit) is reset for easy deformation control; 3. by adopting the rigid clipping welding, the product quality is ensured; and 4. compared with the prior art, the process has the advantages of few equipment, low process cost, low energy consumption, low processing cost, small manufacturing area, smooth logistics and high labor capacity.

Owner:CHENGDU HANYAN TECH +1

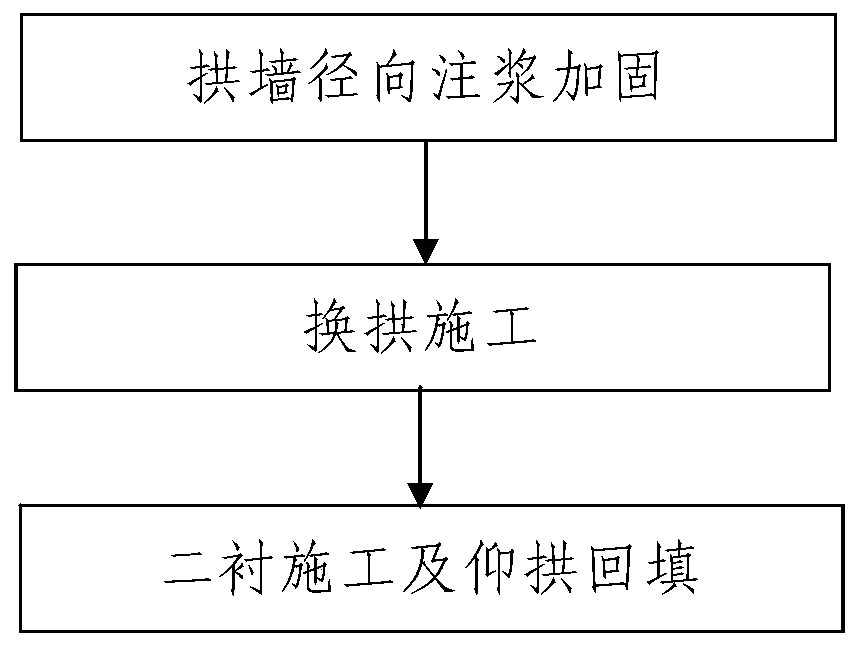

Method for beyond-limit arch replacing construction during preliminary bracing of large-section loess tunnel

ActiveCN110656959AThe method steps are simpleReasonable designUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a method for beyond-limit arch replacing construction during preliminary bracing of a large-section loess tunnel. The method includes the steps of firstly, conducting radial grouting reinforcement on an arch wall, wherein radial grouting reinforcement is conducted on an arch replacing required section where arch replacing is required in the constructed loess tunnel from back to front; and secondly, conducting arch replacing construction, wherein a reinforced preliminary bracing structure in the arch replacing required section is detached, and preliminary bracing construction is conducted on the arch replacing required section synchronously in the detaching process. The method is simple in step, reasonable in design, simple in construction and good in use effect; theradial grouting reinforcement is conducted on the arch wall to reinforce the arch wall of a tunnel hole first, so the structural stability of the tunnel in the arch replacing process is ensured; segmented reinforcing is conducted on the preliminary bracing structure of the tunnel through a plurality of sleeve arch units for a reinforced sleeve arch in the arch replacing required section, so detaching is convenient; and moreover, the sleeve arch units are complementary and together improve the supporting force, so the adverse effects on the structural stability of the tunnel in the detaching process of each sleeve arch unit can be effectively reduced, and the safety and reliability of the arch replacing construction process are ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

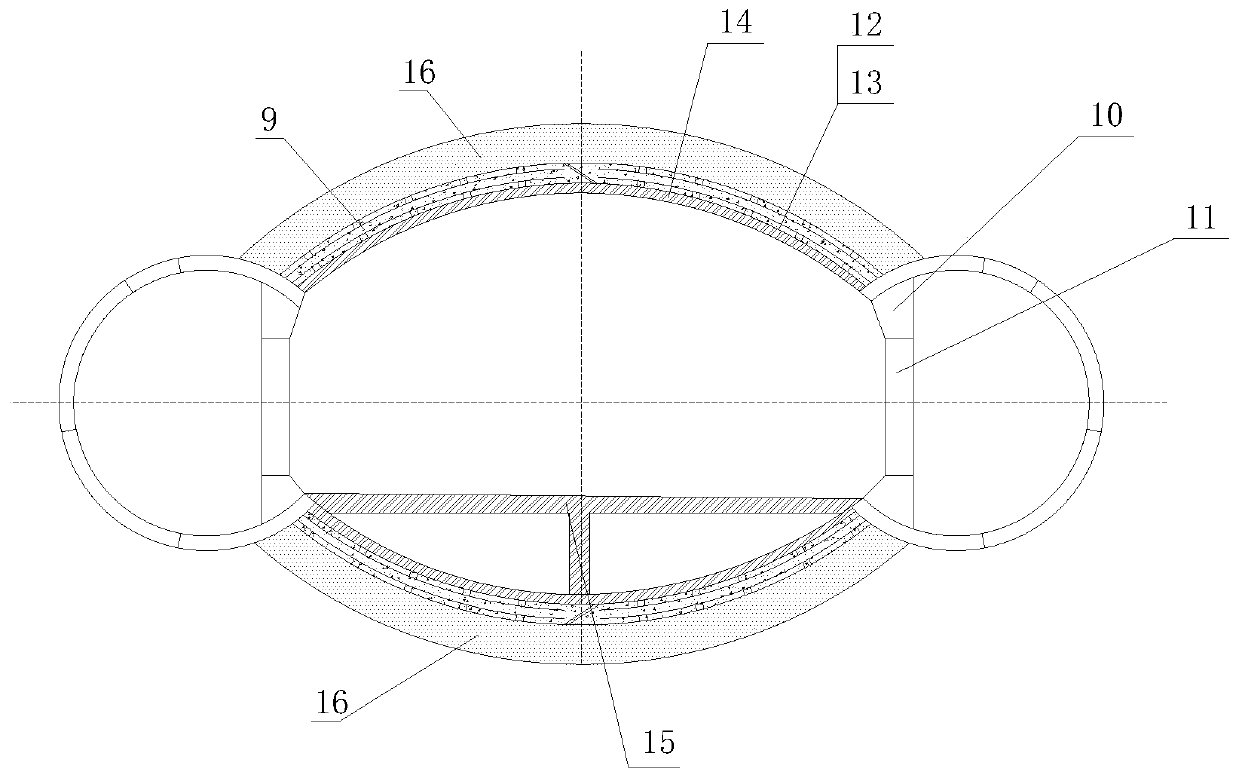

Soft soil stratum subway station expansion method and structure based on inserted beam freezing method

ActiveCN111305851AStabilized soil structureImprove construction efficiencyUnderground chambersTunnel liningSoil scienceStructural engineering

The invention provides a soft soil stratum subway station expansion method and structure based on an inserted beam freezing method. The soft soil stratum subway station expansion structure comprises shield tunnels, a middle platform connected between the two parallel shield tunnels and communicating with the shield tunnels, and frozen soil layers wrapping the outer side of the middle platform; themiddle platform comprises a top lining unit, a bottom lining unit, side columns and a structural bottom plate, the top lining unit and the bottom lining unit are arranged between the shield tunnels and are symmetrical up and down, and the frozen soil layers are distributed along the arched outer surfaces of the top lining unit and the bottom lining unit; the two side ends of the bottom lining unit and the two side ends of the top lining unit are connected and supported through the side columns; and the structural bottom plate is arranged above the bottom lining unit and is kept on the same horizontal plane with the two ends of the bottom lining unit. The method solves the problem of large deformation of subways and surrounding soil caused by serious soil moving in an expansion mode, and has the advantages of being high in construction efficiency, short in construction period and high in safety.

Owner:SHIJIAZHUANG TIEDAO UNIV +1

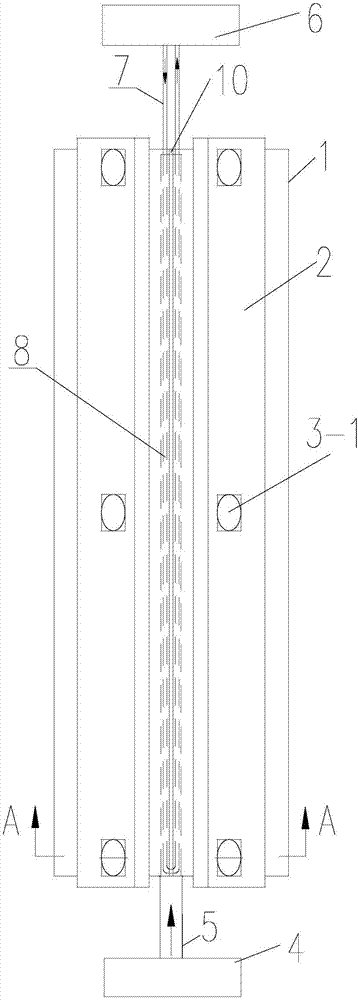

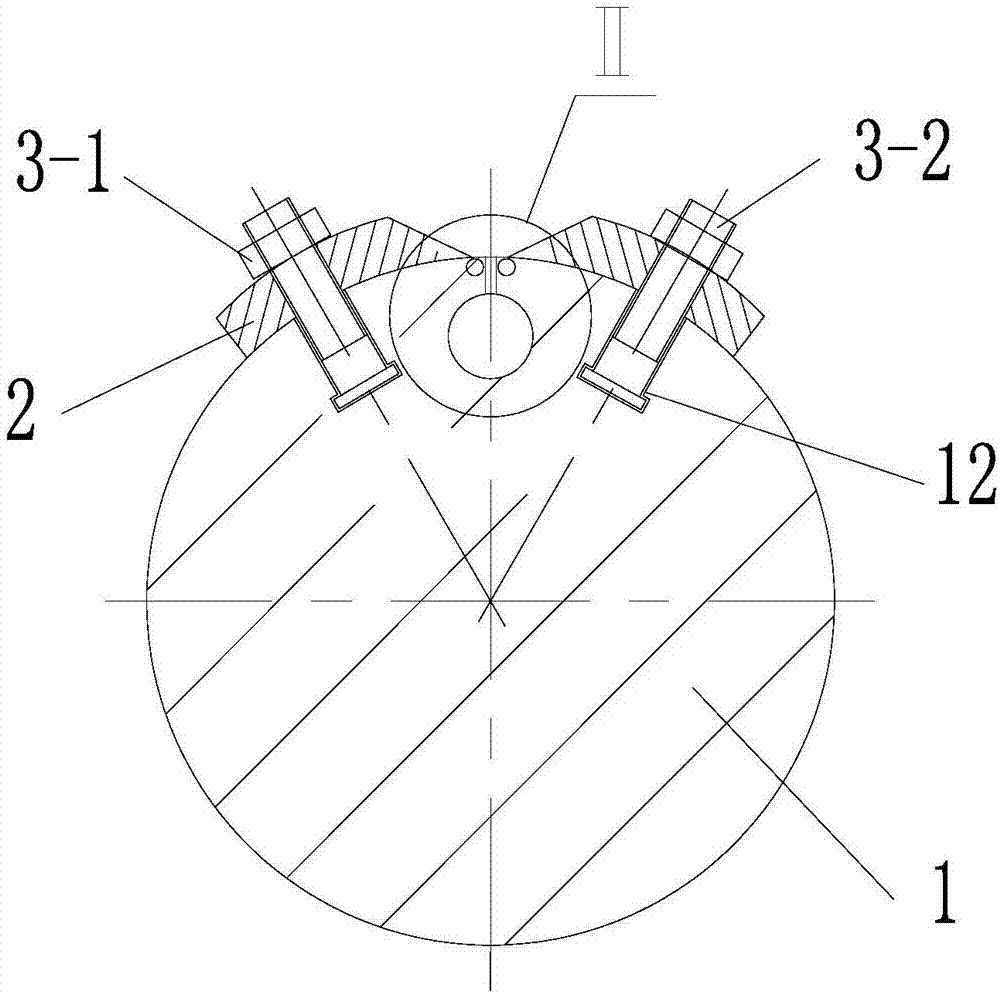

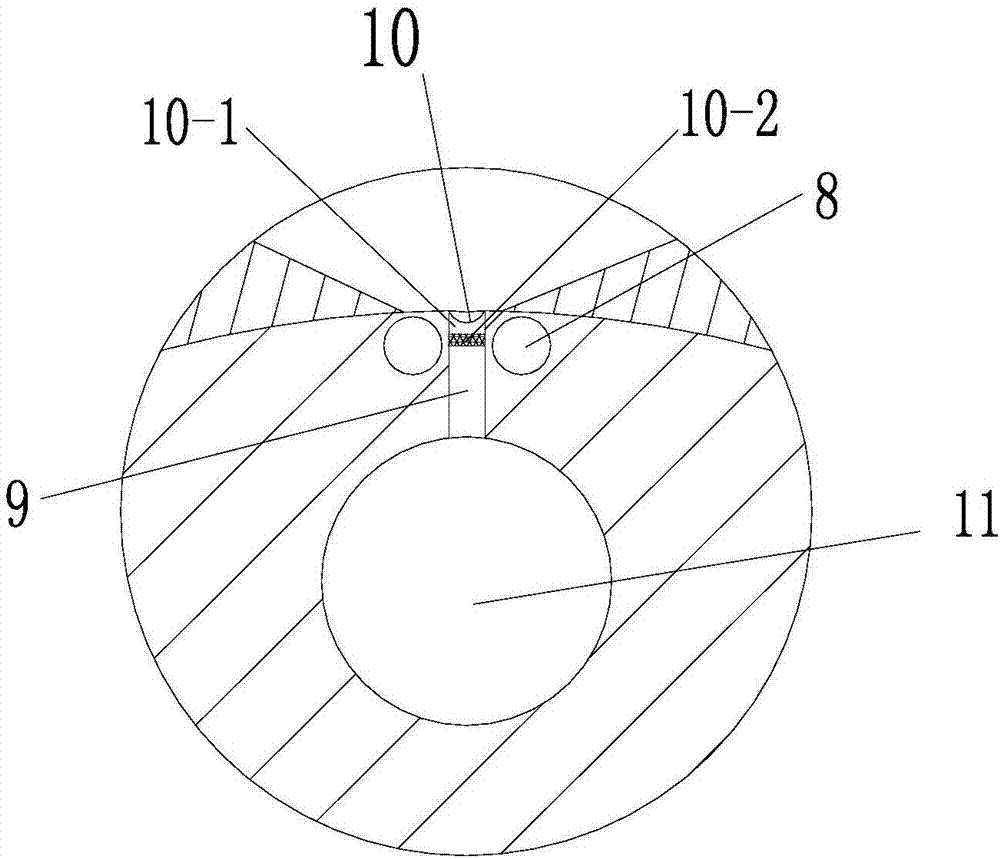

Control system and method for weld-forming of thin-walled pipe

ActiveCN107186342AIncrease stiffnessGuarantee the quality of back weld formationMetal working apparatusLaser beam welding apparatusControl systemPipe fitting

The invention discloses a control system and method for weld-forming of a thin-walled pipe. The control system comprises a welding tool used for weld-forming of the thin-walled pipe and a quality control device used for controlling the quality of longitudinal joints, welded by the welding tool, of the thin-walled pipe. The method comprises the following steps of 1, assembling the welding tool and the to-be-welded thin-walled pipe; 2, debugging the welding tool; 3, initializing the quality control device; 4, starting welding the to-be-welded thin-walled pipe; 5, acquiring real-time welding data of the thin-walled pipe; 6, judging whether the real-time welding data of the thin-walled pipe are abnormal or not; 7, judging whether the thin-walled pipe is defective or not; 8, judging whether the thin-walled pipe is deformed or not; and 9, carrying out stress relaxation on the thin-walled pipe. According to the control system and method for weld-forming the thin-walled pipe, the welding tool provides stable protective gas flow and double cooling measures for the to-be-welded thin-walled pipe, the welding quality of the to-be-welded thin-walled pipe is monitored in real time through the quality control device, so that the residual stress is eliminated, the fatigue life is prolonged, and the stress corrosion resistance is improved.

Owner:XIAN UNITED PRESSURE VESSEL CO LTD

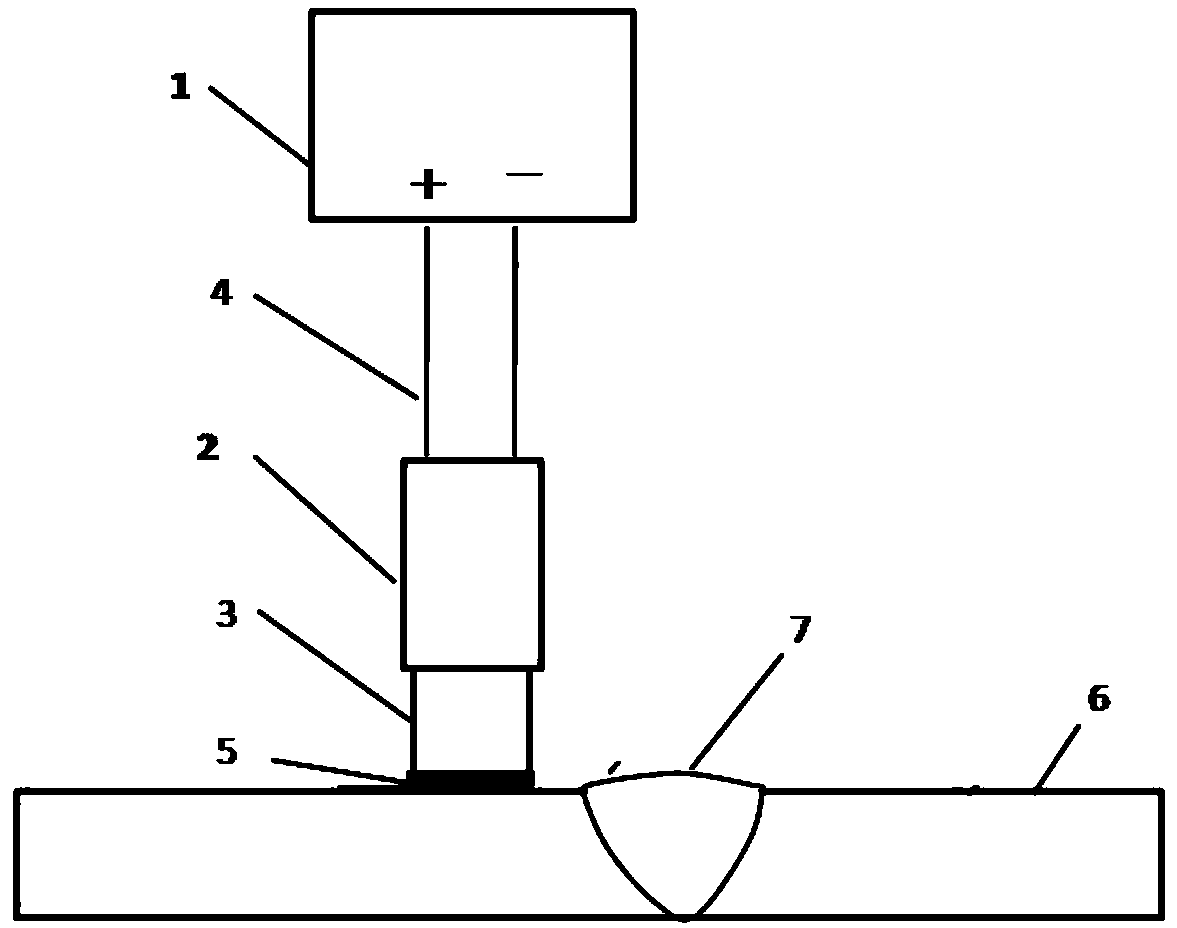

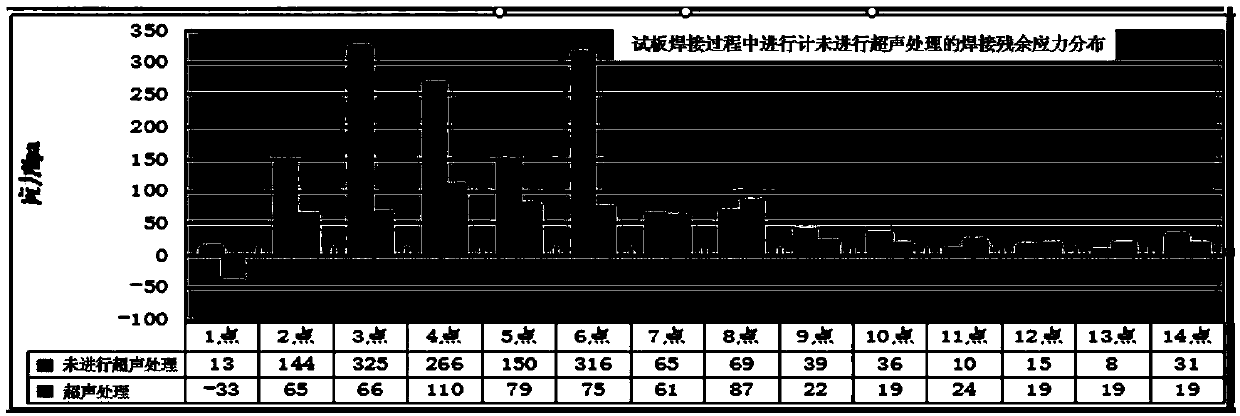

Welding deformation control method based on high-energy ultrasonic treatment

InactiveCN109570793ALower yield strengthFacilitated releaseWelding apparatusStress distributionStress concentration

The invention specifically relates to a welding deformation control method based on high-energy ultrasonic treatment. The welding deformation control method based on the high-energy ultrasonic treatment comprises the following steps that (1) an ultrasonic transducer is arranged at a appropriate position of a workpiece to be welded; (2) the ultrasonic transducer and an ultrasonic power supply are connected; (3) ultrasonic processing parameters are set; (4) the workpiece is welded; and (5) ultrasonic processing is conducted, specifically, a joint is still in a high temperature state after weldedmetal solidified, the ultrasonic power supply is started to drive the ultrasonic transducer, and ultrasonic energy is injected into the workpiece welded joint and a heat affected zone, and work is stopped until set processing time. According to the welding deformation control method based on high-energy ultrasonic treatment, the existing welding technology and process of the product is not changed, the equipment is simple, the technology is concise, the welding deformation can be effectively controlled by adjusting three parameters of an ultrasonic frequency, power and processing time, and meanwhile stress concentration can be eliminated and even stress distribution is lowered.

Owner:SICHUAN AEROSPACE LONG MARCH EQUIP MFG CO LTD

Tunnel portal section pre-reinforcement and excavation construction method based on partition blasting

ActiveCN110847929AConstruction safetyStable structureUnderground chambersTunnel liningArchitectural engineeringStructural engineering

The invention discloses a tunnel portal section pre-reinforcement and excavation construction method based on partition blasting. The construction method comprises the following steps of 1, precipitation pre-reinforcement; 2, earth surface pre-reinforcement, and specifically, reinforcing the surface of a backfill section in a construction tunnel portal section through adopting a cement soil stirring pile; and 3, tunnel excavation construction, and specifically, carrying out excavation construction from rear to front in a plurality of excavation sections, wherein the process comprises the following steps of surveying and setting out, performing drilling and blasting construction, excavating an upper portal body, excavating a middle portal body and excavating a lower portal body. The construction method is reasonable in design, simple and convenient in construction and good in use effect; the underground water level is reduced through precipitation pre-reinforcement, and then surroundingrock is effectively reinforced; after the backfill section is subjected to surface pre-reinforcement through using the cement soil stirring pile, a three-step synchronous excavation mode is used forcarrying out partition blasting excavation, so that it is ensured that the tunnel excavation process is safe and reliable and a tunnel structure is stable.

Owner:CHINA RAILWAY 20 BUREAU GRP

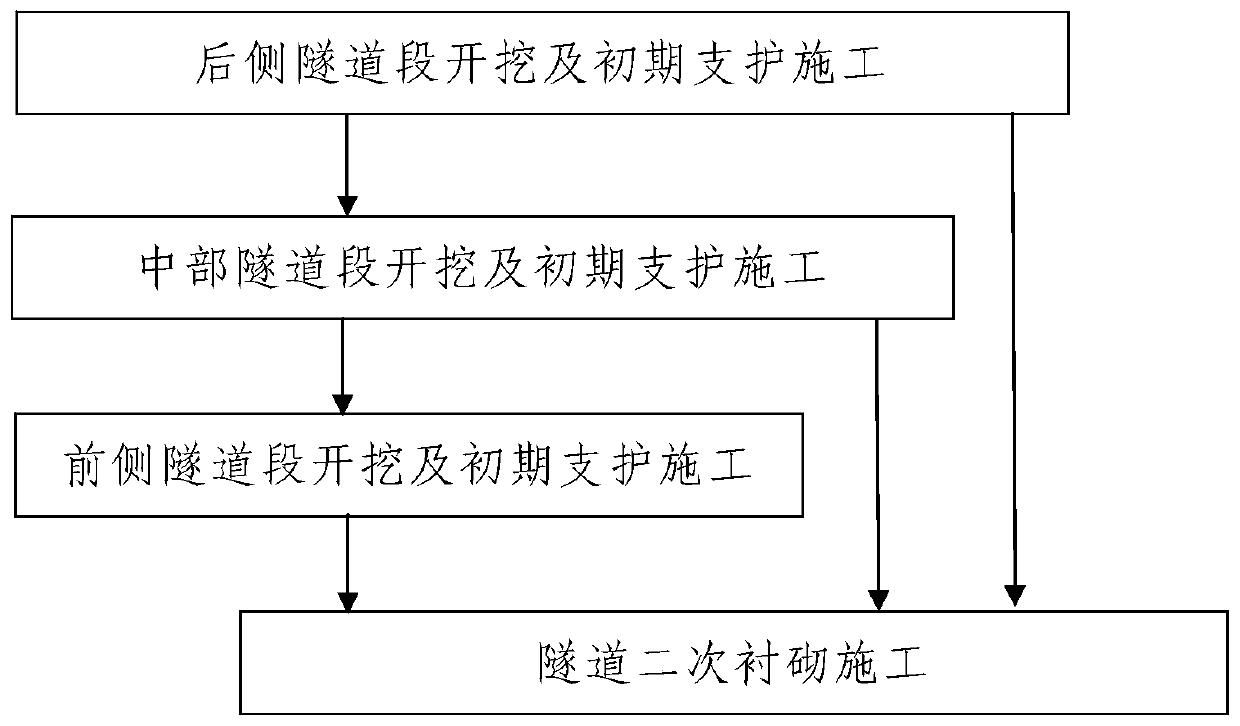

Tunnel construction method for passing through boundary strata of earth and stone

ActiveCN110985003AEffective reinforcementThe method steps are simpleUnderground chambersDrainageArchitectural engineeringDrilling and blasting

The invention discloses a tunnel construction method for passing through the boundary stratum of earth and stone. The tunnel construction method comprises the following steps: I, excavation of a reartunnel segment and initial supporting construction; II, excavation of a middle tunnel segment and initial supporting construction; III, excavation of a front tunnel segment and initial supporting construction, wherein the rear tunnel segment, the middle tunnel segment and the front tunnel segment are all three-step synchronous excavated tunnel segments; and in the process of excavation from rear to front, constructing the secondary lining of the tunnel on the inner side of the initial supporting structure of the constructed tunnel from rear to front. The tunnel construction method has the advantages of reasonable design, simple construction and good use effect. The tunnel construction method selects an appropriate drilling and blasting method according to the position relationship betweenthe earth and stone interface and a tunnel hole, adopts a three-step synchronous excavation way to carry out blasting excavation, can ensure the safe and reliable excavation process of the tunnel passing through the boundary stratum of earth and stone, and can ensure the stable structure of the tunnel. Moreover, in the excavation process, the initial supporting structure and the secondary lining of the tunnel are adopted to provide stable and reliable supporting for the large-section tunnel.

Owner:THE NO 6 ENG CO LTD OF CHINA RAILWAY 20TH BUREAU GRP

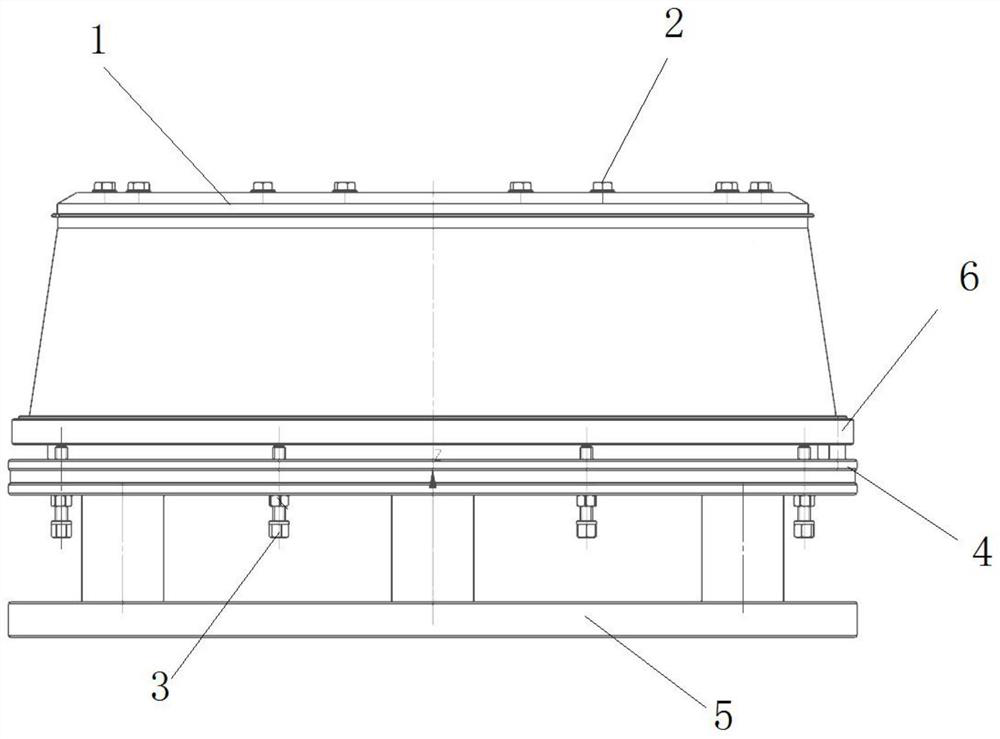

Forming device and method for twisted variable-thickness composite material structure

The invention belongs to a forming technology for a resin matrix composite material preform, and specifically relates to a forming device and method for a twisted variable-thickness composite materialstructure. Due to insufficient machining accuracy for a preform and a limit of a weaving process, a difference exists between the thickness of the weaved preform of a blade and a theoretical thickness of the blade, and the phenomena of secondary bonding and compaction with a molded surface, of the preform, exist in a die assembly process. The forming device for the twisted variable-thickness composite material structure comprises a base, a transversal press block and a longitudinal block, wherein the upper surface of the base is the same as the lower surface of the twisted preform, the combined lower surface of the transversal press block and the longitudinal block is the same as the upper surface of the twisted preform, and accurate deformation control over the variable-thickness preformof the blade from a planar state to a twisted state is realized, so that the deformation accuracy is remarkably increased, and the deformation process is controllable; and the problem of local extrusion or slide deformation which is brought by simultaneous compression of preforms in areas with different thicknesses, is avoided.

Owner:AVIC BEIJING AERONAUTICAL MFG TECH RES INST

Precise control method for electron beam welding deformation of rotor type parts

ActiveCN110977131AImprove rigidityIncrease rigidityElectron beam welding apparatusDeformation controlWelding deformation

The invention discloses a precise control method for electron beam welding deformation of rotor type parts, and belongs to the technical field of rotor type part electron beam welding. The method comprises the following steps of 1, designing an electron beam welding structure; 2, determining electron beam welding parameters; 3, designing an electron beam welding tool; 4, adjusting the material state of parts before welding; 5, determining part welding shrinkage; and 6, performing electron beam welding of the rotor type parts. For structural characteristics of rotor type parts, the technology starts from the aspects of improving parts rigidity, realizing rigid fixation, reducing residual stress, improving the distribution uniformity of residual stress and the like, corresponding technological measures are adopted, electron beam welding deformation precise control is realized, and compared with the prior art, by adopting the technology, the parts are high in connecting quality, low in cost, wide in technological adaptability and good in deformation control effect.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Subway station extension method and structure based on concrete-filled steel tube beam insertion method

InactiveCN112302666AImprove construction efficiencyImprove securityUnderground chambersTunnel liningArchitectural engineeringEngineering

The invention relates to a subway station extension method and structure based on a concrete-filled steel tube beam insertion method. The subway station extension method comprises the steps that a transverse through middle platform is built between existing bidirectional parallel shield tunnels to form an extension structure; and corresponding upper through holes and lower through holes are obliquely formed in segments of the two shield tunnels, jacking bent steel pipes are inserted from the through holes to be transversely connected to serve as external supports, a lining structure is constructed after soil is excavated on the inner side, and through connection is achieved after the segments at shield tunnel connectors are detached. Small expansion, downward storey addition and step-by-step expansion can be achieved, and the subway station extension method is suitable for expansion of subway stations with strict control over ground displacement and ground surface settlement and construction of shallow soil, soft stratums and large-span underground spaces.

Owner:CHINA RAILWAY FIRST SURVEY & DESIGN INST GRP

Deformation control method for numerical control machining of overall aircraft emergency gate

InactiveCN109581971AMake sure the thicknessAchieve deformation controlProgramme controlComputer controlNumerical controlMachine parts

The invention discloses a deformation control method for numerical control machining of an overall aircraft emergency gate. The deformation control method comprises the following steps that the machining deformation direction and deformation quantity of a to-be-machined part are analyzed, and a preliminary pre-judged result of machining deformation is obtained; the reversible deformation quantityrequired by the to-be-machined part is estimated according to the preliminary pre-judged result, and required preload is obtained; a preload clamping tool is designed and manufactured according to thecalculation result; preload clamping of the to-be-machined part is conducted through the preload clamping tool; and the to-be-machined part is machined in a preload clamping state. According to the deformation control method for numerical control machining of the overall aircraft emergency gate, the great deformation control effect is good, and the deformation control method further has the advantages of low implementation cost, easy realization and high feasibility and is suitable for large-scale industrial production and popularization.

Owner:COMAC +1

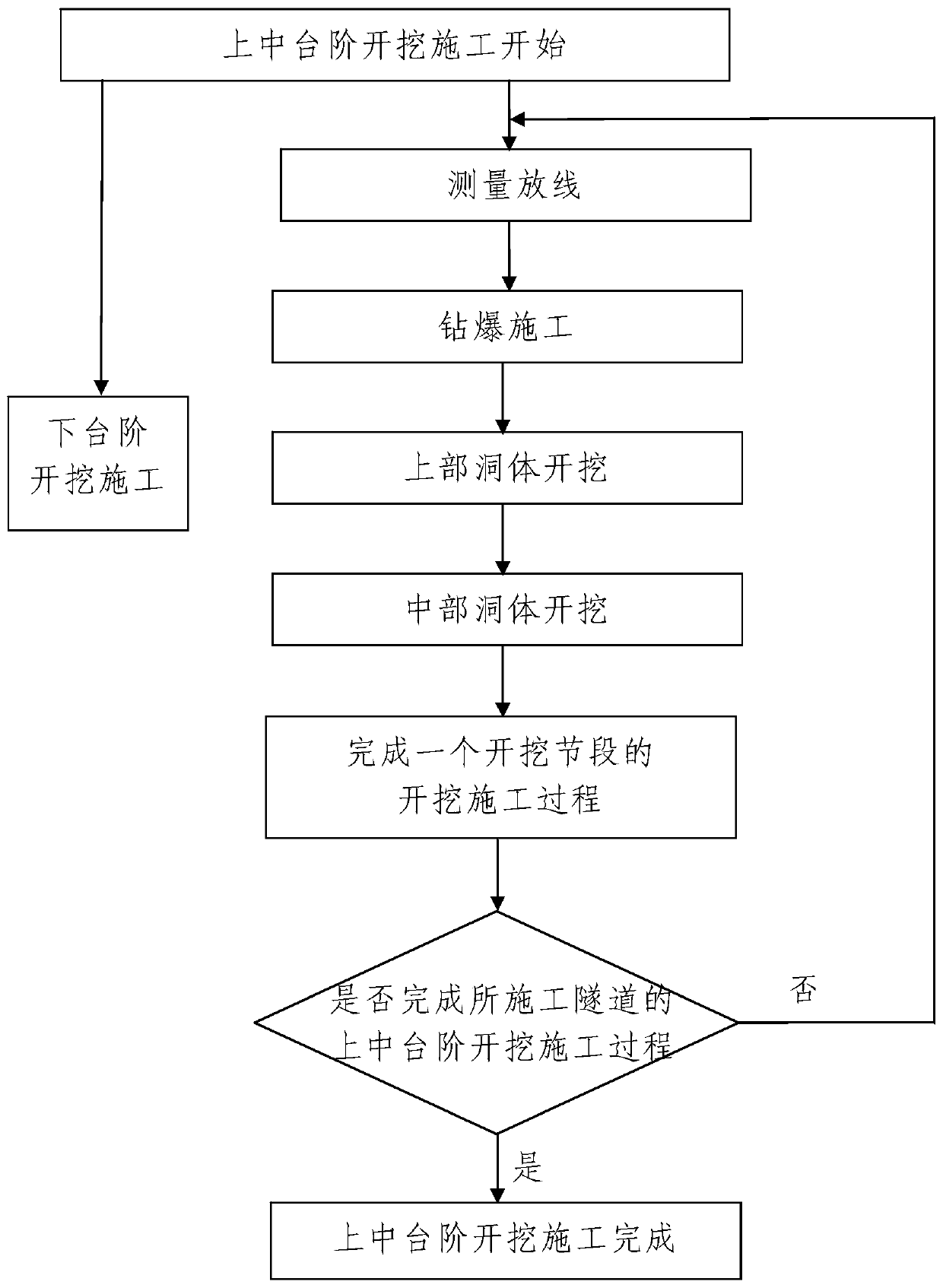

Large-section tunnel stability control construction method capable of passing through earth and stone boundary stratum

ActiveCN110863832AThe method steps are simpleReasonable designUnderground chambersBlastingArchitectural engineeringStructural engineering

The invention discloses a large-section tunnel stability control construction method capable of passing through an earth and stone boundary stratum, and an earth and stone interface is positioned in an upper hole of a constructed tunnel. During excavation construction on the constructed channel, the large-section tunnel stability control construction method comprises the following steps: I, upperand middle step excavation step: performing upper and middle step excavation construction on the constructed tunnel in multiple excavation sections from rear to front, wherein the process of performing upper and middle step excavation construction on any excavation section comprises surveying and setting out, drilling and blasting construction, upper hole excavation and middle hole excavation; andII, lower step excavation construction. The large-section tunnel stability control construction method is reasonable in design, is simple and convenient in construction, is good in use effect, separately performs blasting region division on an upper blasting region in an upper step and a middle blasting region on a middle step, defines layout position of each blast hole in each blasting region, can effectively prevents tunnel face collapse or arch crown collapse caused by relatively great vibrations generated by blasting while large-section once explosive load is too great, ensures a safe andreliable tunnel excavation process, and can ensure a stable tunnel structure.

Owner:CHINA RAILWAY 20 BUREAU GRP

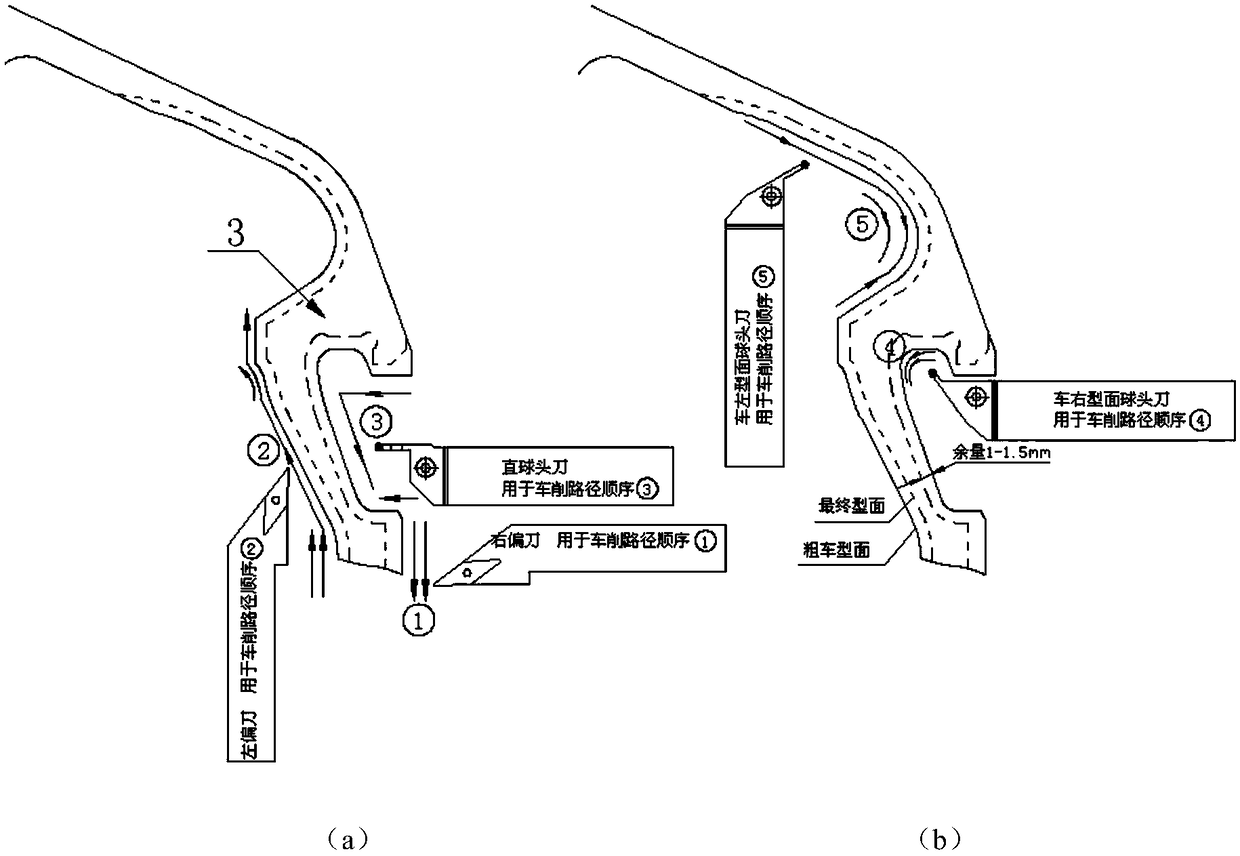

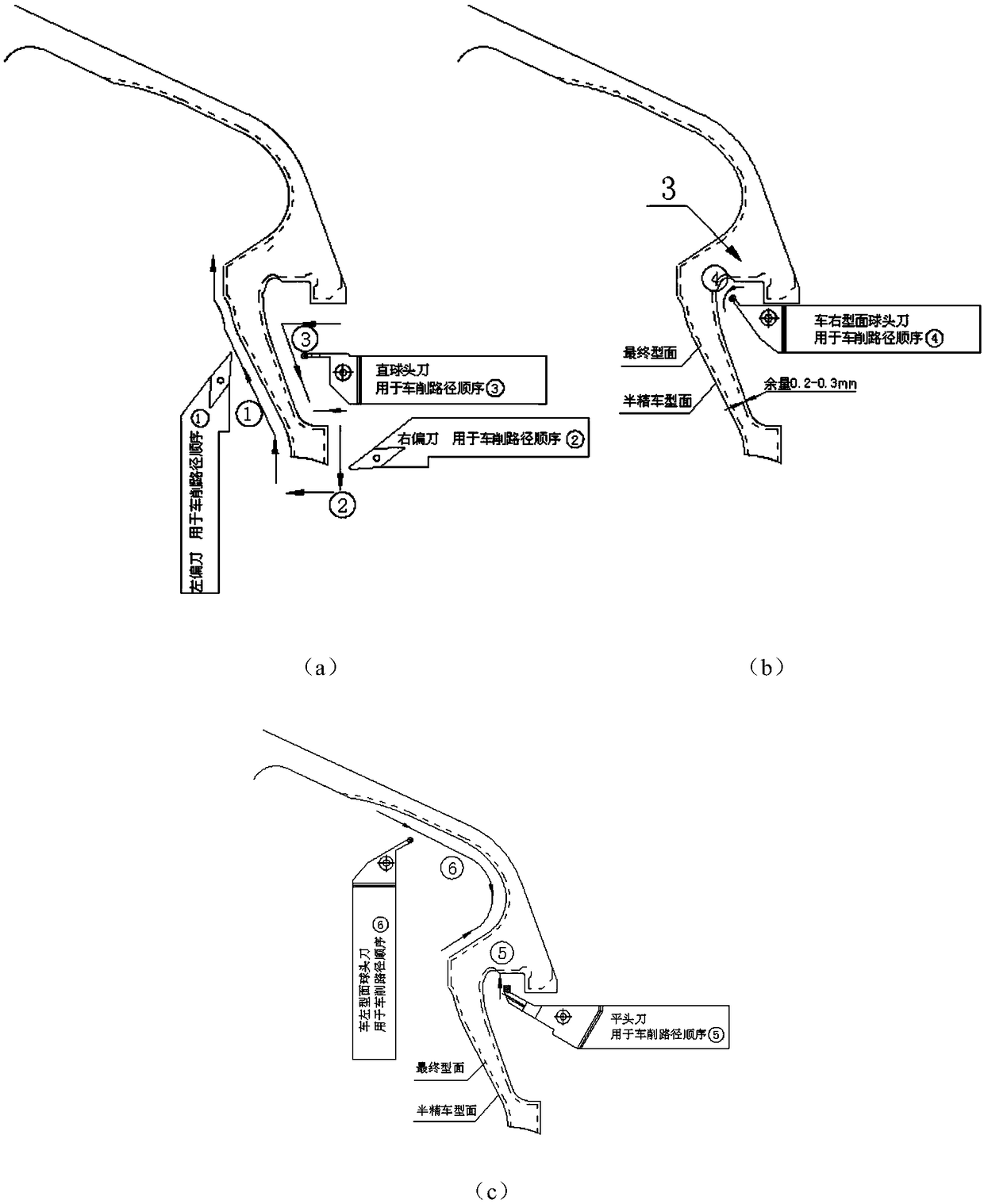

Method for turning complex thin-wall part profile by adopting quasi-symmetric layered circulation

ActiveCN108655417AEffectively control deformation of processing partsEffective control of deformationTurning machinesFree stateEngineering

The invention discloses a method for turning a complex thin-wall part profile by adopting a quasi-symmetric layered circulation. The method is characterized in that the integral part of a rotary bodypart is clamped in a local unrestraint mode, and the two ends profiles of the complicated thin-walled part to be machined are placed in an unconstrained free state, then a single-step layered circulation is adopted, and the quasi-symmetric layered turning mode of rough turning, semi-finish turning, fine turning and the finish turning are sequentially adopted in one procedure so as to turn the twoends profiles of the part to be machined. According to the method, only one procedure and one clamping are needed, and the machining of the local two ends profiles of the part can be completed, the part does not need to be turned over in the machining process, and the deformation control effect is good.

Owner:AECC AVIATION POWER CO LTD

Milling tool for conical thin-walled part

InactiveCN112091665AReduce manufacturing costManufacturing precision requirements are lowPositioning apparatusMetal-working holdersEngineeringDeformation control

The invention relates to a milling tool for a conical thin-walled part, and a brand-new structural tool for milling the thin-walled conical part is designed and manufactured by analyzing part characteristics. A tool support mechanism, a tool adjustable mechanism, a tool axial datum and a tool pressing mechanism are included. The deformation control effect on the conical thin-walled part is remarkable, all mechanisms of the tool are simple in cooperation, and reliability is high. Tool operation is convenient.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

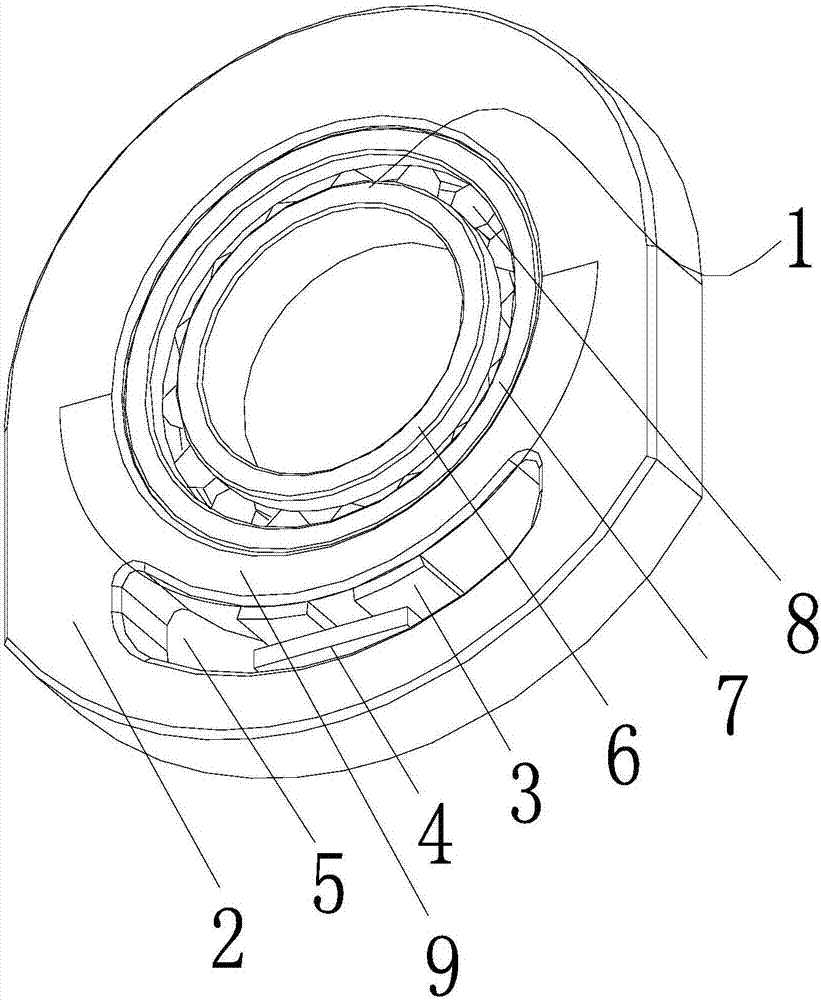

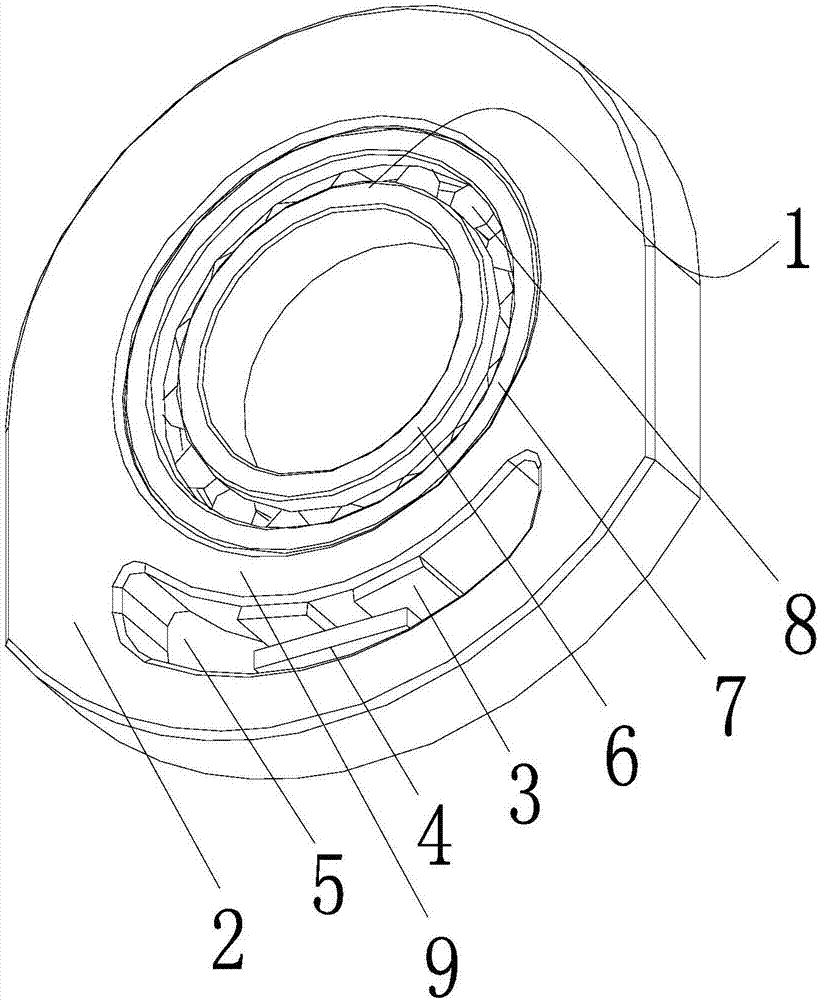

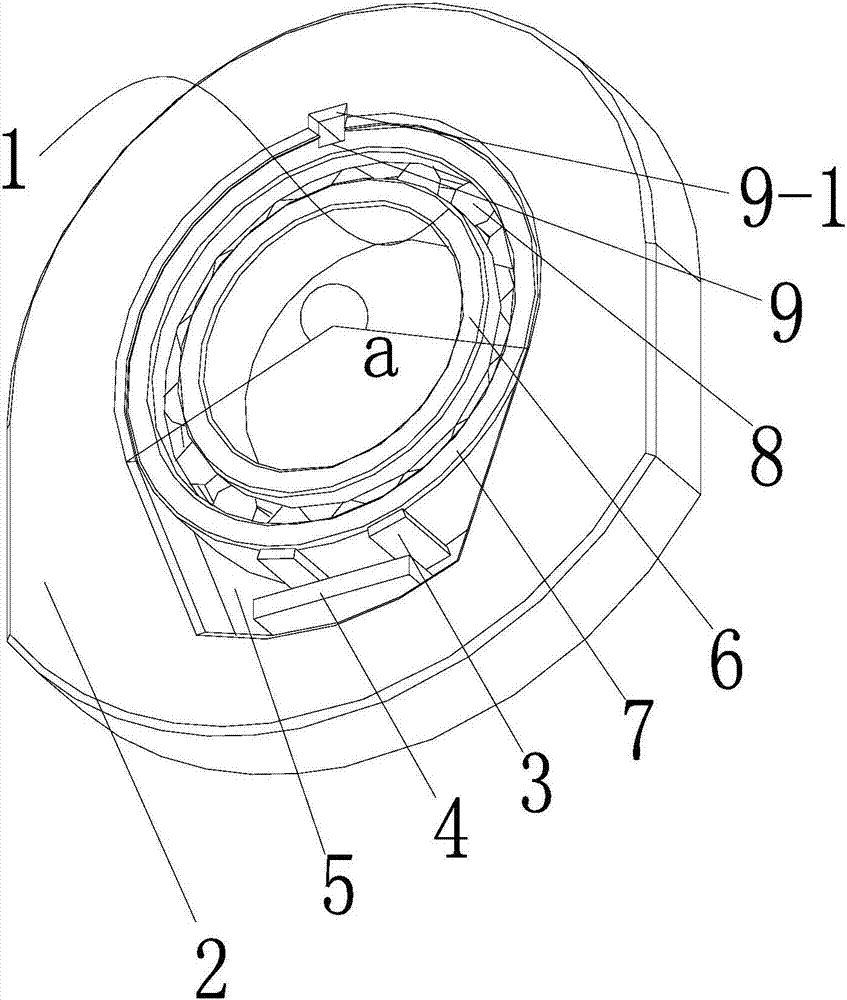

Pressure measuring device

PendingCN107238453ASimple structureLow costWeighing apparatus using elastically-deformable membersApparatus for force/torque/work measurementEngineeringForce sensor

The invention provides a pressure measuring device which comprises a bearing, a bearing housing and a force sensor, wherein the bearing is arranged inside the bearing housing; and the force sensor is arranged at the outer side of the outer ring of the bearing or is arranged on the bearing housing. According to the pressure measuring device, the force sensor is clung to the outer ring of the bearing or is arranged on the bearing housing, the tensile force is measured in an indirect measurement mode, and the pressure measuring device is simple in structure and low in cost; as the pressure measuring device is arranged on a fixing component, normal operation of equipment is not affected, and meanwhile a relatively accurate metering value is ensured; due to a force sensor mounting position, the situation that the bearing is interfered when the force sensor is mounted and is fixed through a key is avoided, and good fixation of the bearing is achieved; since a bearing wrapping angle and a partition plate thickness are reasonably set up, mounting reliability and stability of the bearing are ensured, deformation of the fixing component is well controlled, the measurement range of force is controlled, and relatively high sensitivity is maintained.

Owner:TAICANG RONGCHI MOTOR

High speed railway foundation reinforced structure with undamaged karez function and construction method

ActiveCN107974875ARealize the water functionRealize the non-destructive purpose of water passing functionRailway tracksClimate change adaptationStructure of the EarthHoneycomb

The invention provides a high speed railway foundation stabilization structure with an undamaged karez function and a construction method to solve the technical problems of stably reinforcing the highspeed railway karez foundation and maintaining the karez function for a long period of time, the high speed railway foundation stabilization structure with the undamaged karez function and the construction method can improve the function of the high speed railway roadbed construction passing through the karez foundation, and has the characteristics of low construction investment, high operabilityand the like. The high speed railway foundation reinforced structure with the undamaged karez function includes a filtering pond, a water-passing pond, a honeycomb-shaped reinforced body and a vertical shaft filling body, wherein, the filtering pond is arranged at the bottom of the vertical shaft of an upper stream of a karez closed conduit outside the embankment side slope toe; the water-passingpond is arranged at the bottom of the vertical shaft of a downstream of the karez closed conduit outside the embankment side slope toe; the honeycomb-shaped reinforced body is filled in the karez closed conduit between the filtering pond and the water-passing pond; and the vertical shaft filling body is filled in the karez vertical shaft in the range of the embankment foundation base.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

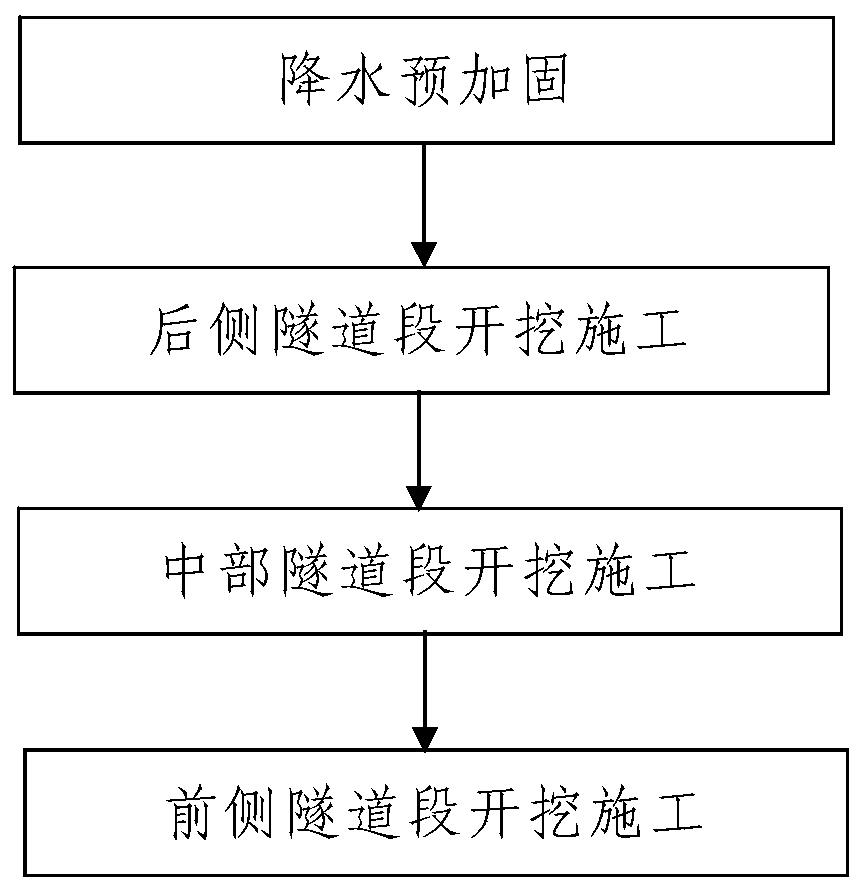

Construction method of soil-stone boundary tunnel passing through loess valleys

ActiveCN110700860AEffective reinforcementThe method steps are simpleUnderground chambersTunnel liningGround water levelStructure support

The invention discloses a construction method of a soil-stone boundary tunnel passing through loess valleys. The construction method comprises the following steps of 1, precipitation pre-reinforcement; 2, excavation construction of a rear side tunnel section; 3, excavation construction of a middle tunnel section; and 4, excavation construction of a front side tunnel section, wherein the middle tunnel section and the front side tunnel section are three-step synchronous excavation tunnel sections; and in the excavation process from back to front in the step 2, the step 3 and the step 4, primarysupport is synchronously carried out on the excavated tunnel from back to front, and secondary lining of the tunnel is constructed on the inner side of the constructed and formed tunnel primary support structure from back to front. The construction method is reasonable in design, simple and convenient to construct and good in use effect, the underground water level is reduced through precipitationpre-reinforcement, surrounding rock is effectively reinforced, then blasting excavation is carried out in a three-step excavation mode, so that the excavation process of the soil-stone boundary tunnel passing through the loess valleys can be ensured to be safe and reliable, and the stability of the tunnel structure can be ensured.

Owner:CHINA RAILWAY 20 BUREAU GRP

Milling tool for cambered-surface thin-wall casing part

PendingCN112719372AReduce manufacturing costManufacturing precision requirements are lowMilling equipment detailsPositioning apparatusDeformation controlIndustrial engineering

The invention discloses a milling tool for a cambered-surface thin-wall casing part. The milling tool comprises a tool bottom plate, auxiliary supporting blocks, fixed supporting seats, transverse supporting blocks, adjustable supporting rods and a locking nut; the multiple auxiliary supporting blocks and the multiple fixed supporting seats are installed on the tool bottom plate through bolts; the upper portions and the lower portions of the fixed supporting seats are connected with the transverse supporting blocks, and the transverse supporting blocks are provided with the multiple adjustable supporting rods through nuts; the adjustable supporting rods are connected with the auxiliary supporting blocks in an abutting mode; and effective matching of part inner molded surfaces and clamp auxiliary supporting surfaces is ensured. According to the milling tool, the deformation control effect on the cambered-surface thin-wall casing part is remarkable, the tool is convenient to operate, all mechanisms of the tool are easy to match, the reliability is high, and the tool has a remarkable part deformation control effect.

Owner:SHENYANG FORTUNE PRECISION EQUIP CO LTD

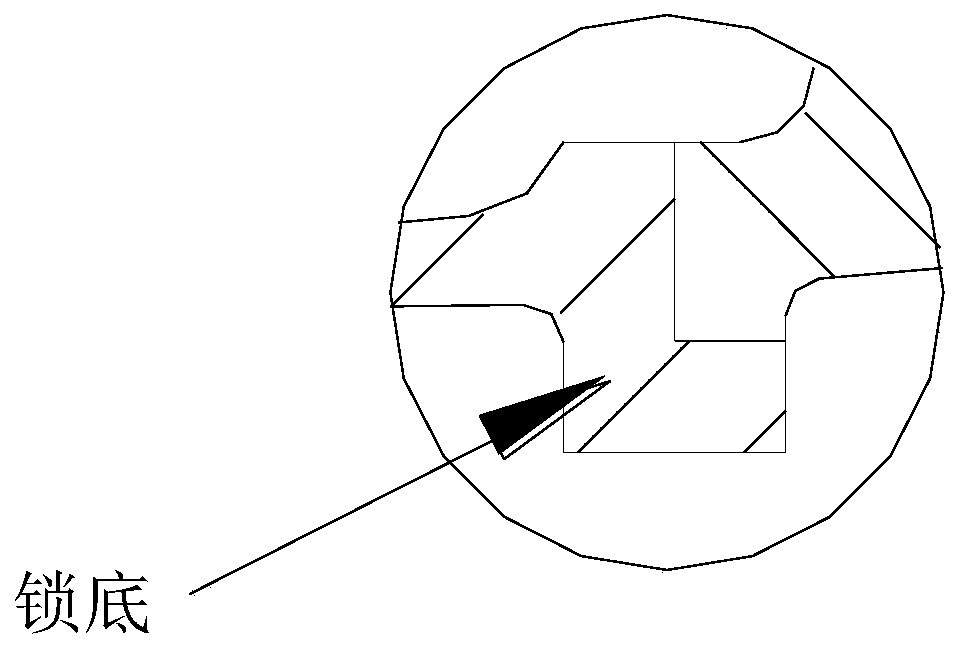

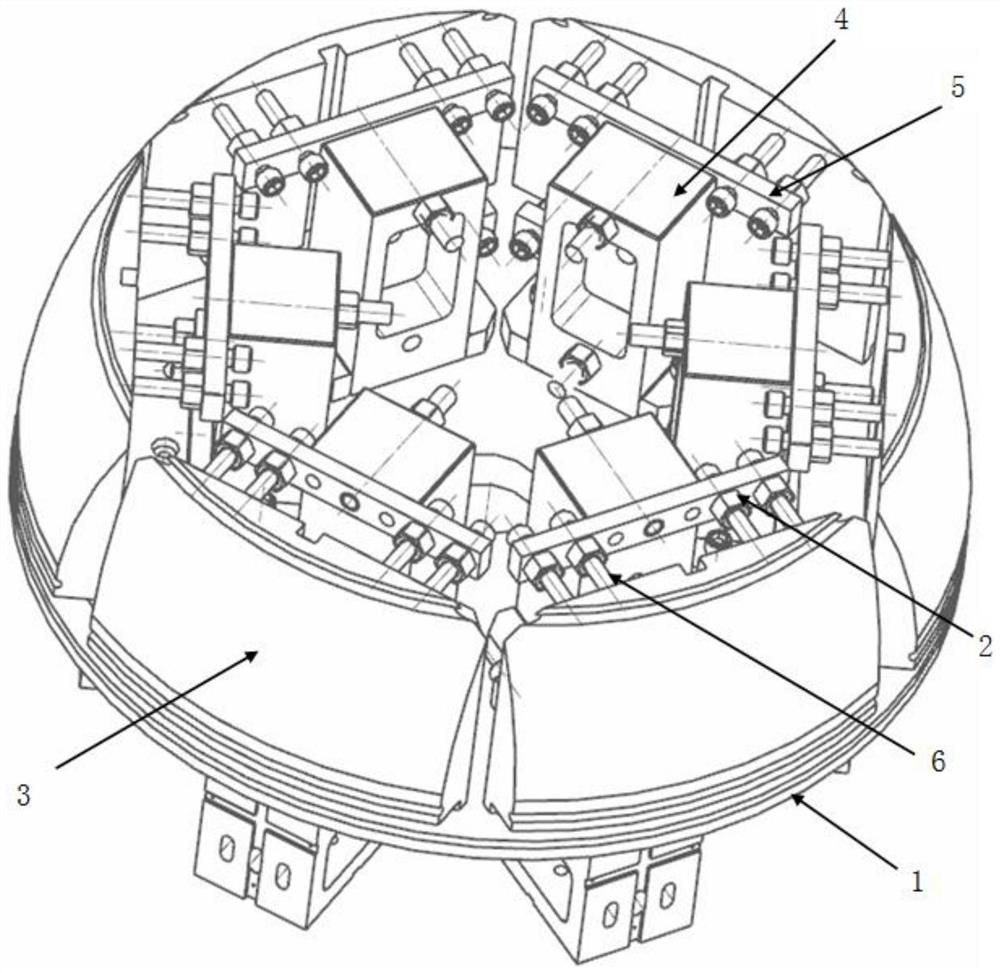

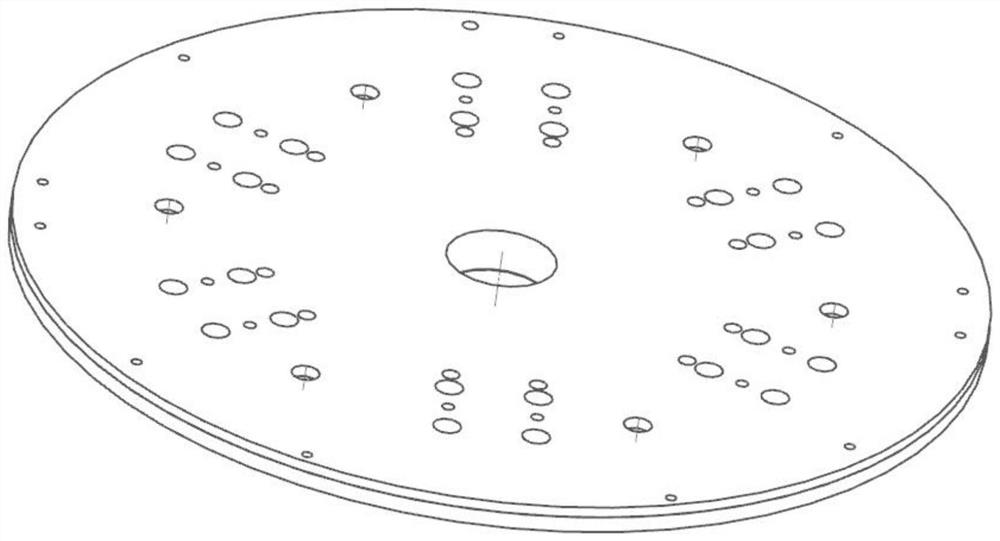

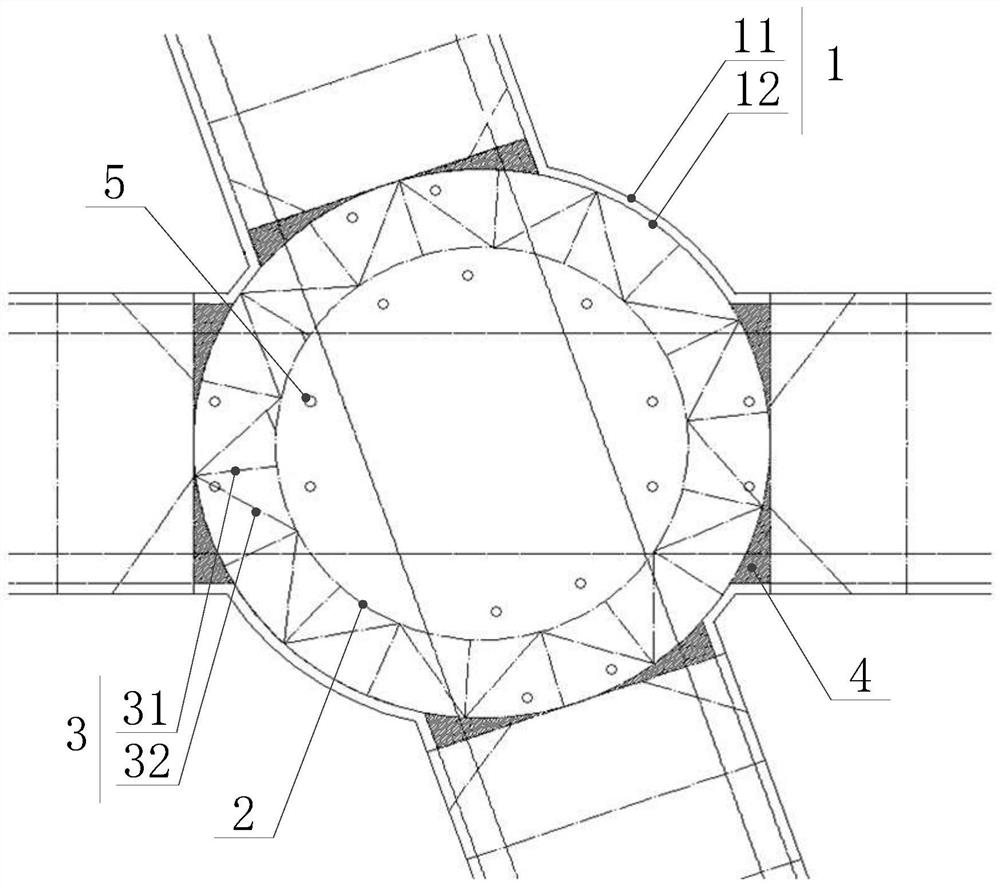

Supporting system at transfer node of urban rail transit transfer station and construction method

PendingCN112281861AReasonable structure layoutIncrease stiffnessExcavationsBulkheads/pilesSupporting systemArchitectural engineering

The invention provides a supporting system at a transfer node of an urban rail transit transfer station and a construction method of the supporting system at the transfer node of the urban rail transit transfer station. The supporting system at the transfer node of the urban rail transit transfer station comprises an outer ring support, an inner ring support and an inner and outer ring connectingcomponent, wherein the outer ring support is arranged at the joint of multiple rail transit lines, the inner ring support and the outer ring support are concentrically arranged, and the inner ring support is a large ring beam inner ring support to replace a diagonal bracing system to improve the overall rigidity of the supporting system. A multi-ring stress system is reasonable in structural layout, the overall rigidity is high, the deformation control effect is good, the compression resistance of concrete is fully utilized, the water and soil pressure on the outer side of the supporting structure is converted into the compression bearing capacity of supporting components; and meanwhile the supporting structure has the advantages that the construction efficiency is high, the construction period is saved, no diagonal bracing structure is arranged on inner side of the inner ring support, and the earthwork unearthing space is increased to the maximum extent.

Owner:GUANGZHOU METRO DESIGN & RES INST

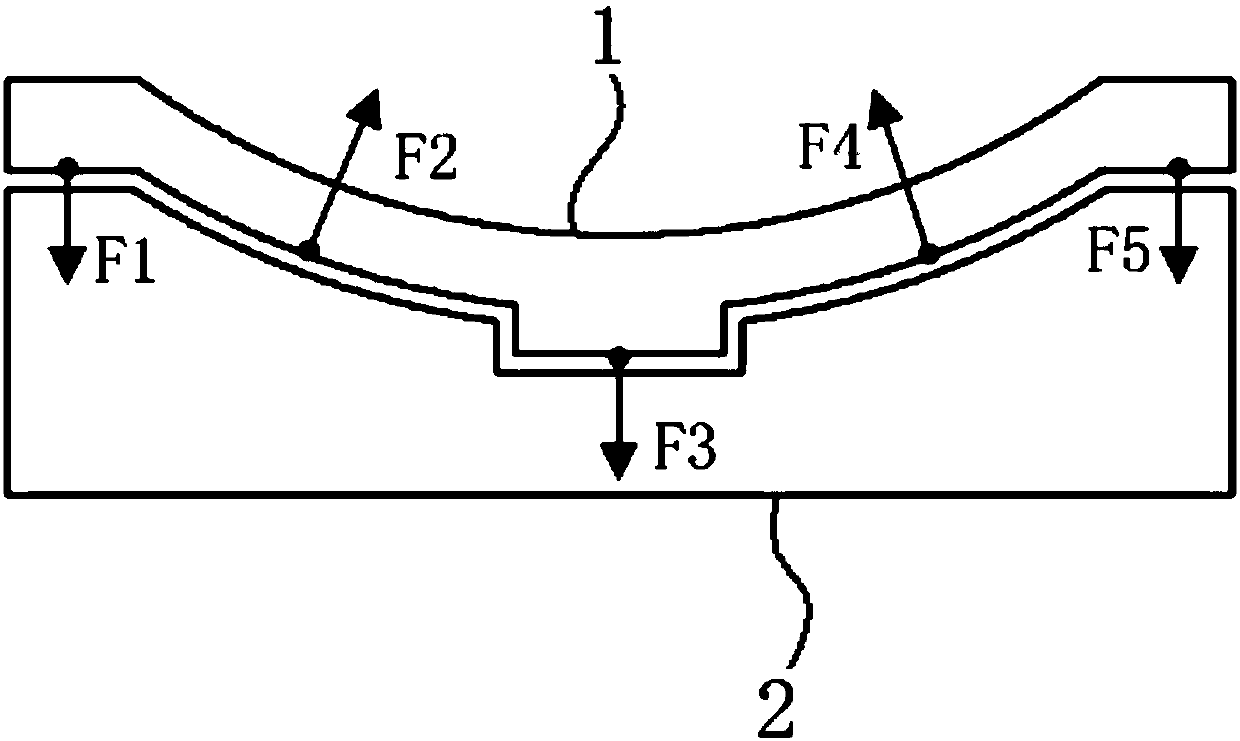

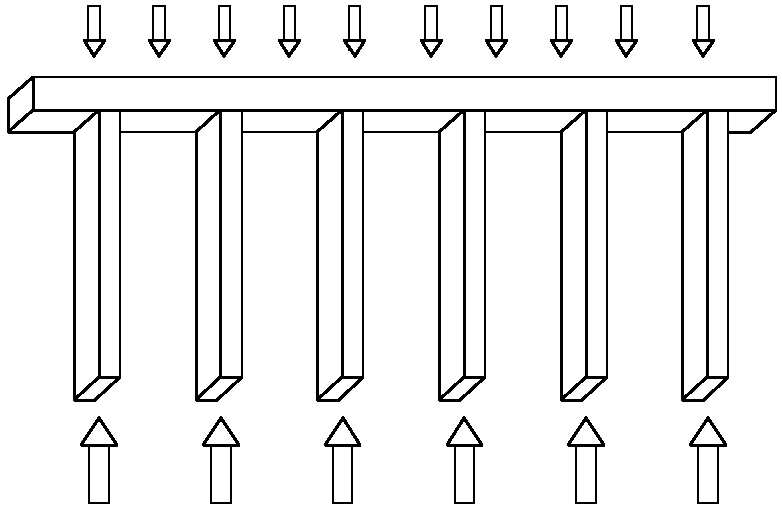

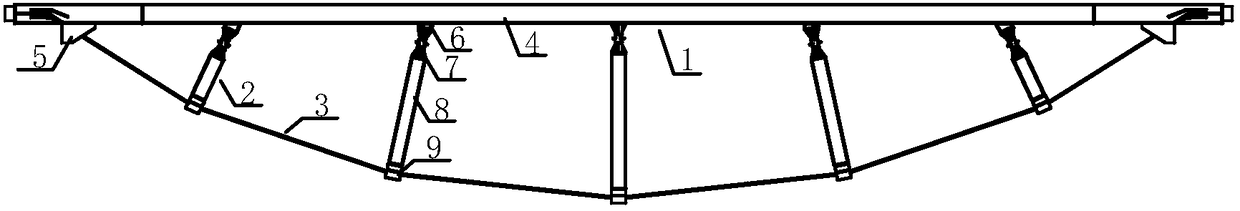

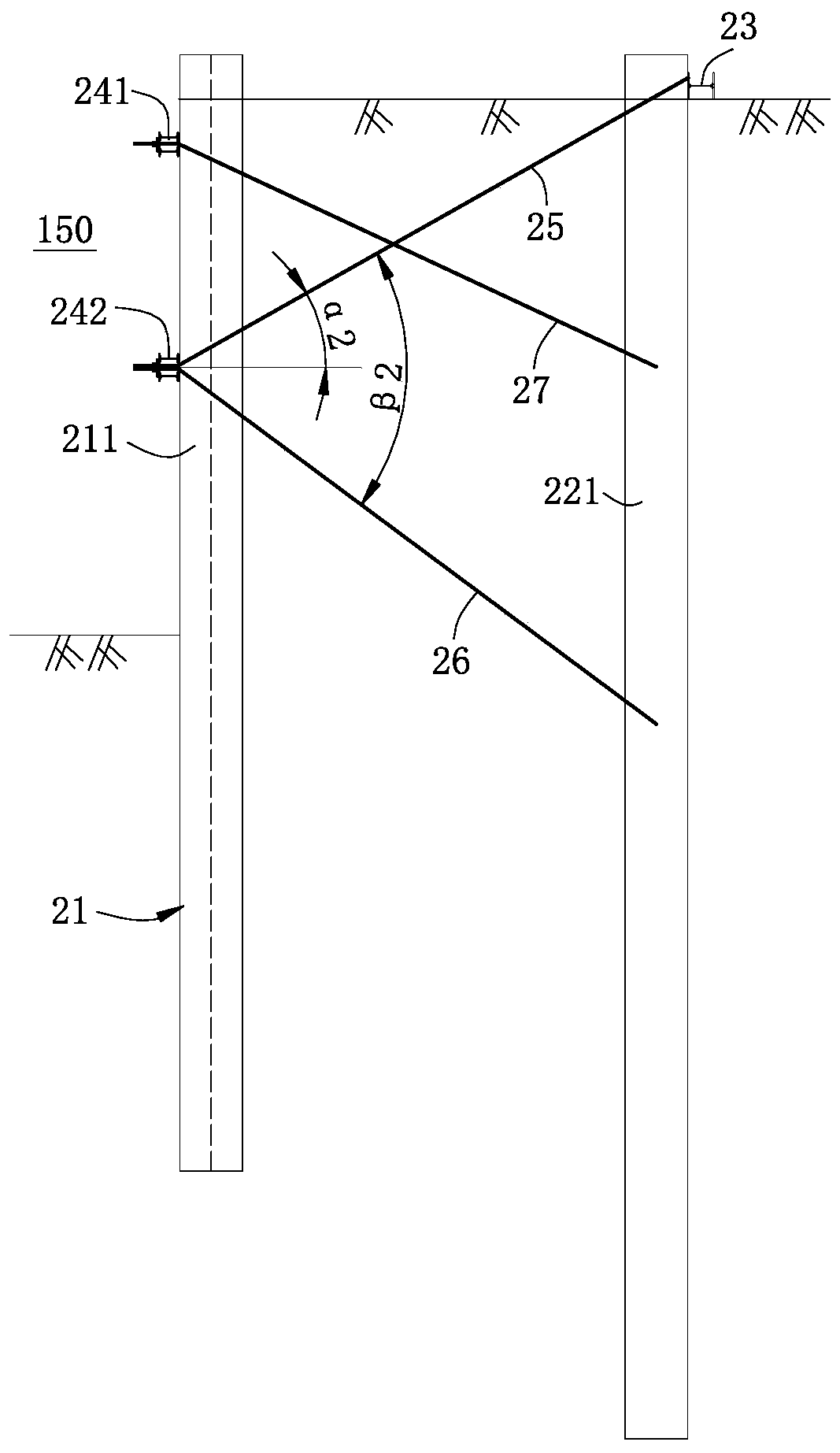

Prestressed fish belly sill with inclined stay bars for retaining and protecting for deep foundation excavation

InactiveCN108560564AReduce friction lossTake full advantage of tensile strengthGirdersJoistsPurlinAxial pressure

The invention discloses a prestressed fish belly sill with inclined stay bars for retaining and protecting for deep foundation excavation. The prestressed fish belly sill with the inclined stay bars for retaining and protecting for deep foundation excavation comprises a waist beam, at least one stay bar and at least one pull cable; the stay bars are positioned on angular bisectors of the adjacentpull cables, length adjusting devices are serially connected into the stay bars, and the pull cables comprise stand cables. Two ends of the fish belly sill are spliced with adjacent surrounding purlins, and symmetric or angle brace supports are arranged at the ends of the fish belly sill. By application of prestress and the supporting effect of the stay bars to the waist beam, the bending stiffness of the fish belly sill is high, the number of braces can be reduced, and thus, an operation space in the pit is increased. The stay bars are only subjected to axial pressure, and are high in stability bearing capacity; the lengths of the stay bars are adjusted according to monitoring data, and deformation of a foundation pit supporting structure can be controlled well; and by mounting of the standby cables, the rigidity and emergency capacity of the fish belly sill are improved.

Owner:SOUTHEAST UNIV

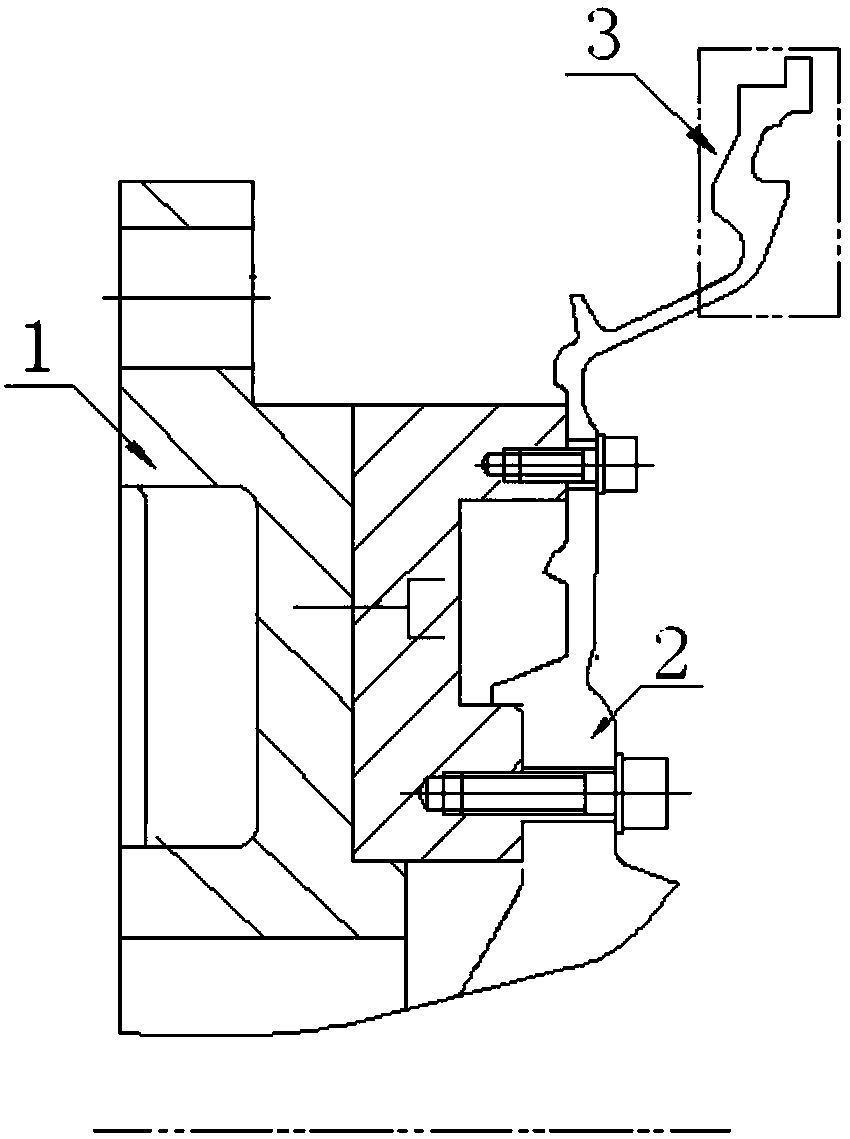

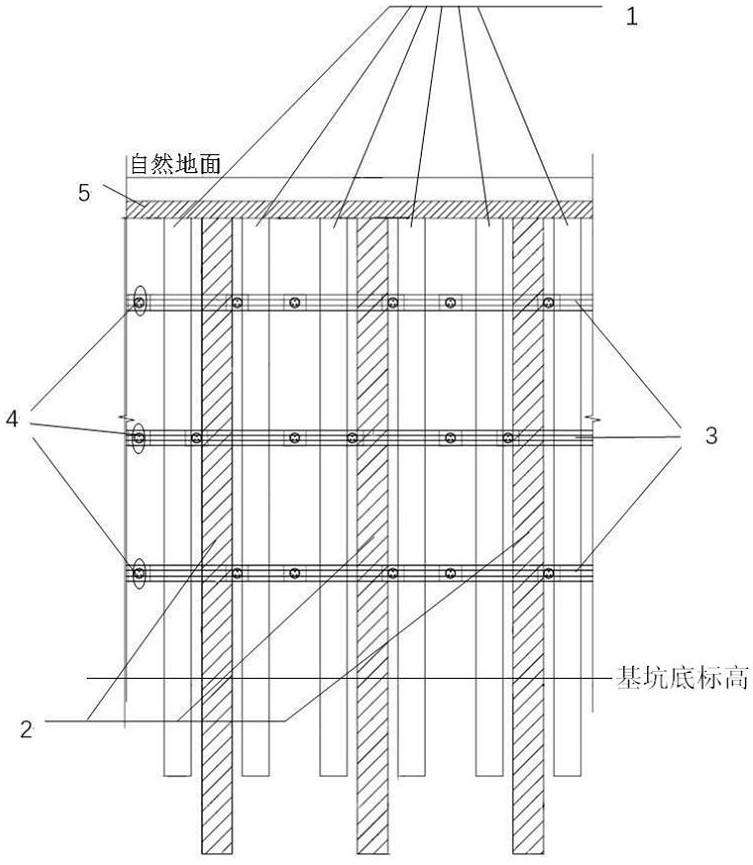

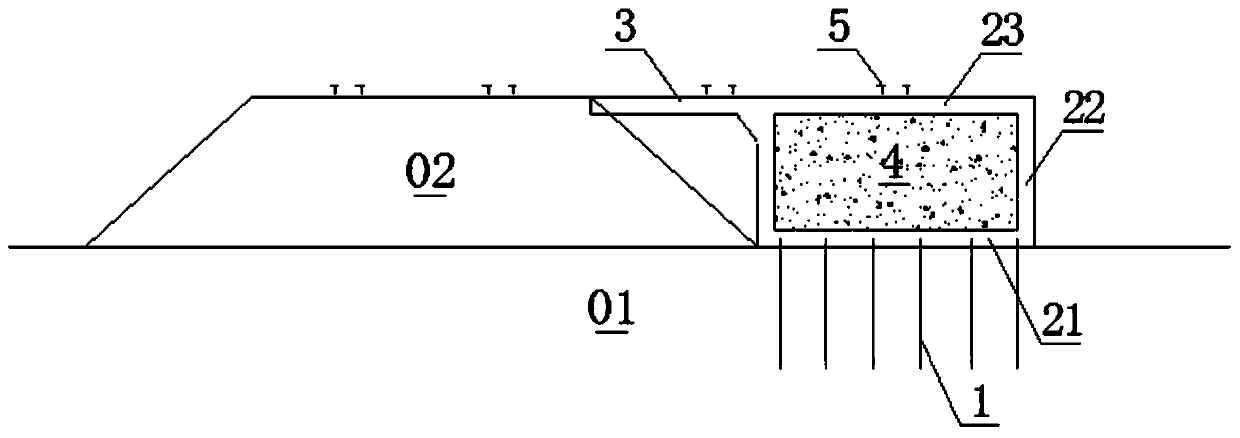

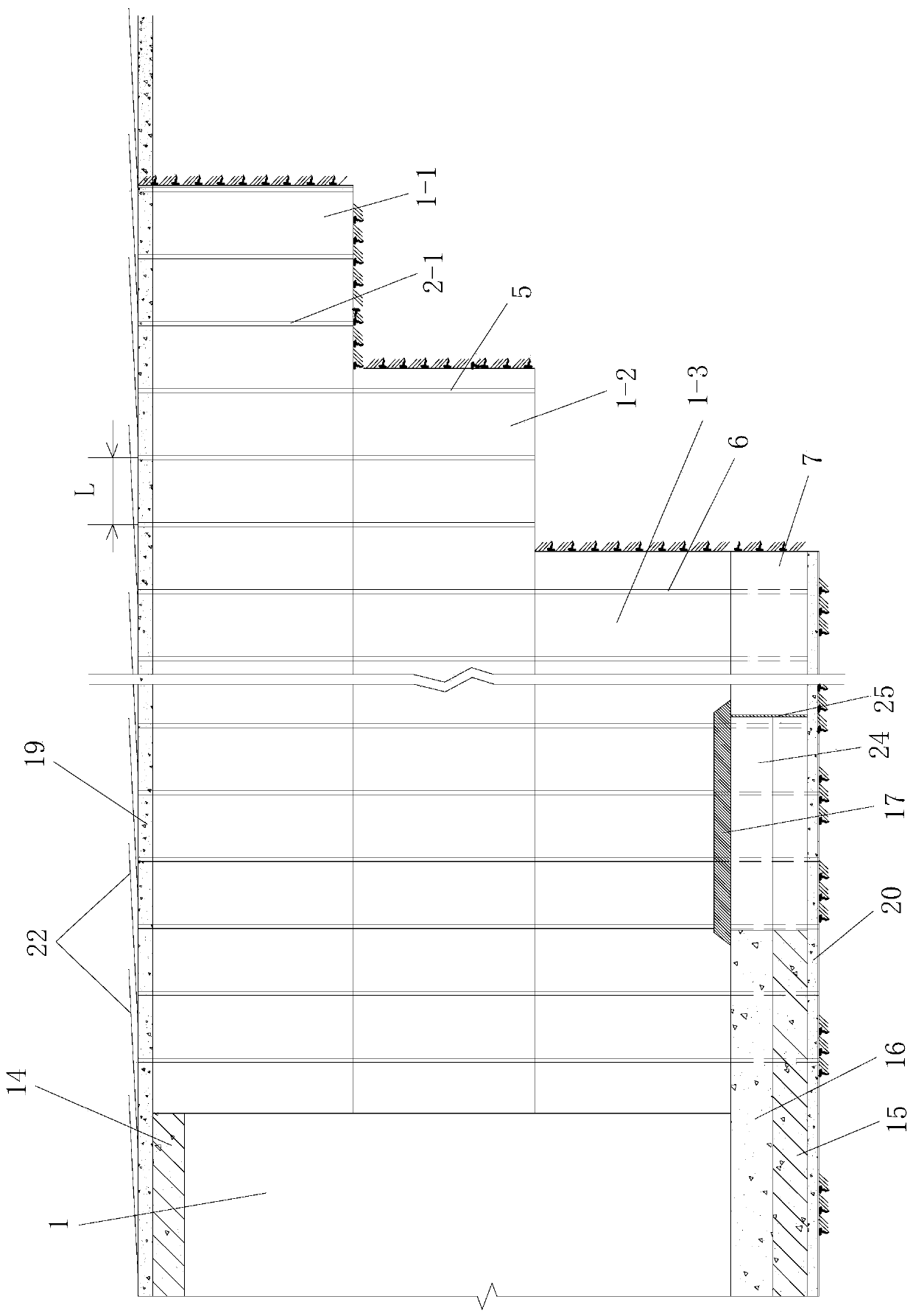

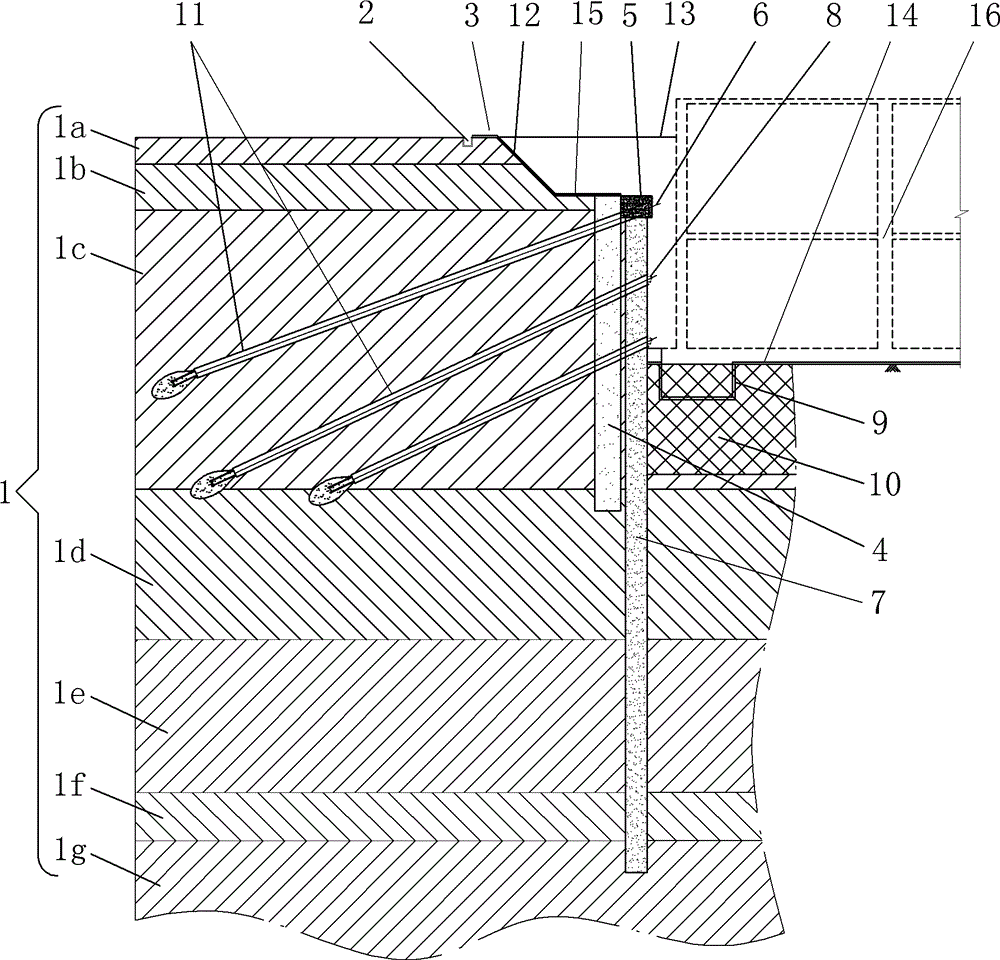

Pile-anchor supporting foundation pit deepening and reinforcing supporting structure and construction method thereof

PendingCN112081118AGood deformation controlIncrease stiffnessExcavationsBulkheads/pilesPre stressArchitectural engineering

The invention relates to a pile-anchor supporting foundation pit deepening and reinforcing supporting structure and a construction method thereof. The reinforcing supporting structure comprises original supporting piles (1), waist beams (3) and original pre-stressed anchor cables which are in an original pile-anchor supporting system, newly-added long supporting piles (2), newly-added pre-stressedanchor cables (4) and newly-arranged crown beams (5); the newly-added long supporting piles (2) are arranged between the original supporting piles (1) and penetrate through the whole foundation pit by a new excavation depth, and the tops of the newly-added long supporting piles (2) are flush with the tops of the original supporting piles (1) and are connected into a whole in a pouring mode through the newly-arranged crown beams (5); and the newly-added pre-stressed anchor cables (4) are distributed between the new piles and the old piles, and the outer ends of the newly-added pre-stressed anchor cables (4) are fixed to the waist beams (3). A reinforcing mode that the long supporting piles and the pre-stressed anchor cables are inserted between the original supporting piles is adopted, thewaist beams, the anchor cables and the newly-arranged crown beams are connected to form a unified whole with an original supporting structure, the overall rigidity and the cooperative deformation capacity of an enclosure structure can be effectively improved, and the bearing capacity of the enclosure structure is enhanced.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Rock foundation existing high-speed railway embankment force balance assisting widening structure and construction method

PendingCN110761127AAvoid Vertical DistortionAvoid disadvantagesRailway tracksRailway embankmentRc frames

The invention discloses a rock foundation existing high-speed railway embankment force balance assisting widening structure and a construction method. The assisting widening structure comprises a plurality of grouting anchor rods, a reinforced concrete frame structure, a reinforced concrete cantilever plate and a filling body, wherein the plurality of grouting anchor rods are used for being arranged in a rock foundation outside a slope foot of an existing embankment at intervals, the reinforced concrete frame structure is used for being arranged on the rock foundation outside the slope foot ofthe existing embankment, all the grouting anchor rods are connected to the bottom of the frame structure, one end of the reinforced concrete cantilever plate is connected to the top of the frame structure, the other end of the reinforced concrete cantilever plate is arranged on an existing embankment road shoulder structure, the top surface of the frame structure, the top surface of the cantilever plate and the top surface of the existing embankment are flush, and the filling body fills a cavity in the frame structure. By using the assisting widening structure, the high bearing capacity and anchoring force of the rock foundation are fully utilized, the weight of the frame structure and the internal filling body of the frame structure are utilized, pulling force generated by the grouting anchor rods is combined, and load acting on the cantilever plate by a train is resisted, so that adverse vertical deformation generated when the train passes through the cantilever plate can be avoided, and an existing high-speed railway is not influenced.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Deep-buried loess tunnel deformation control construction structure based on cover arch and method

PendingCN110671132AReasonable designEasy constructionUnderground chambersTunnel liningArchitectural engineeringDeformation control

The invention discloses a deep-buried loess tunnel deformation control construction structure based on a cover arch and a method. The structure comprises a tunnel primary support structure body for primary support of a tunnel and the reinforcement cover arch arranged on the inner side of the tunnel primary support structure body, wherein the tunnel primary support structure body and the reinforcement cover arch form a reinforced primary support structure body. The method comprises the following steps of 1, carrying out tunnel excavation and primary support; and 2, carrying out reinforcement arc arch construction. The structure and the method have the advantages of being reasonable in design, simple and convenient in construction and good in use effect, the reinforcement cover arch is adopted to reinforce the tunnel primary support structure body and form the reinforced primary support structure body, an isolation layer is arranged between the reinforcement arc arch and the tunnel primary support structure body, in addition, the reinforcement cover arch adopts a plurality of cover arch units to reinforce the tunnel primary support structure body in a segmented mode, so that the construction is simple and convenient, moreover, the reinforced primary support structure body formed by construction has certain self-adaptive capacity and can effectively adapt to the deformation condition of soil mass on the peripheral side of the tunnel, and therefore the deformation resistance of the reinforced primary support structure body can be effectively enhanced.

Owner:CHINA RAILWAY 20 BUREAU GRP

Construction Method of Composite Foundation Pit Support with Horizontal Jet Grouting Soil Anchor and Cast-in-situ Pile

ActiveCN102518135BControl deformation valueEasy constructionExcavationsBulkheads/pilesDeformation controlHigh rise

The invention belongs to the technical field of foundation pit supporting for high-rise buildings, in particular to a foundation pit support construction method combining horizontal rotary jet-grouting soil bolting and bore concrete piles, which includes steps: firstly, constructing water-stop mixed piles and bored concrete piles according to a preset foundation pit; and secondly, performing soil excavation and soil bolting layer by layer and section by section. The foundation pit support construction method has the advantages that the foundation pit support constructed by the method is high in deformation control performance and stability and especially applicable to projections with high requirements on foundation pit deformation, and the method is applicable to mega-area foundation pit supporting in soft soil areas with failure of using internal support structures, limited slope reduction conditions and excavation depth limited within 15m, and meets the requirement that development and utilization of urban underground space continue to develop.

Owner:BIAOLI CONSTR GROUP

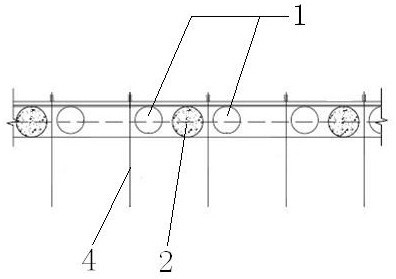

Deep anchor pull pile supporting system and construction method thereof

PendingCN111335327ASmall footprintIncrease construction costsExcavationsBulkheads/pilesSupporting systemPurlin

The invention discloses a deep anchor pull pile supporting system. The deep anchor pull pile supporting system comprises anchor rope piles and anchor piles arranged on the sides, away from a foundation pit, of the anchor rope piles, first anchor ropes A and second anchor ropes A are arranged between the anchor rope piles and the anchor piles; an inner row anchor rope surrounding purlin A is arranged on the inner sides of the anchor rope piles; an outer row anchor rope surrounding purlin is arranged on the outer sides of the tops of the anchor piles; one end of each first anchor rope A penetrates through the corresponding anchor rope pile and then is connected to the inner row anchor rope surrounding purlin A, and the other end of each first anchor rope A extends upwards in the inclined direction, penetrates through the corresponding anchor pile and then is connected to the outer row anchor rope surrounding purlin; and one end of each second anchor rope A penetrates through the corresponding anchor rope pile and then is connected to the inner row anchor rope surrounding purlin A, and the other end of each second anchor rope A extends downwards in the inclined direction and is connected to the corresponding anchor pile. The invention further discloses a construction method of the deep anchor pull pile supporting system. The deep anchor pull pile supporting system and the construction method thereof can be carried out within a limited construction range and can improve construction efficiency.

Owner:JIANGSU DONGHENAN GEOTECHNICAL TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com