Simple method for deformation control during carburizing and quenching of large-diameter heavy-duty gears

A technology of carburizing and quenching and deformation control, which is applied in the direction of manufacturing tools, coatings, furnace types, etc., can solve the problems of large amount of deformation and high scrap rate during carburizing and quenching, and achieve high precision of deformation control, simple operation and low equipment cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

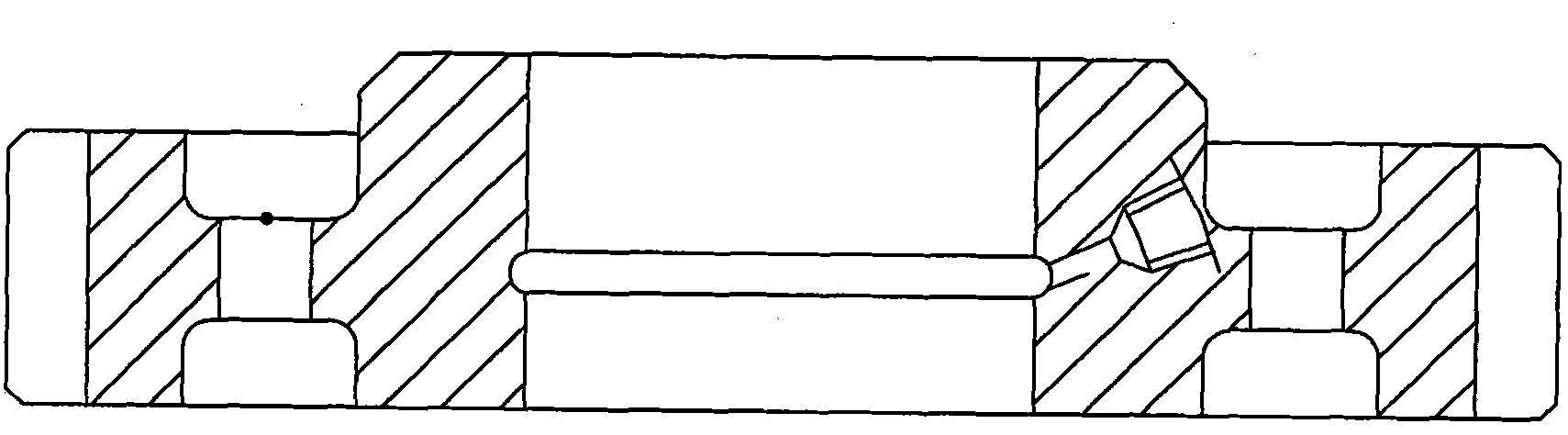

Image

Examples

Embodiment

[0032] Steel parts made of 20CrMnTi

[0033] Part name: gear a, b

[0034] Material: 20CrMnTi

[0035] Technical requirements: carburized layer depth ≥ 1.5mm

[0036] Tooth surface hardness HRC55-60

[0037] Hardness in quenching depth: 550HV1

[0038] Main dimensions of gears (Table 1)

[0039] Table 1 Main dimensions of gears

[0040]

workpiece

modulus

(m)

Pitch circle

diameter

d(mm)

Addendum circle

diameter

da(mm)

Web thickness

Degree c(m)

tooth width

b(mm)

dh(mm)

gear a

6

φ370

φ384

20

66

φ90

[0041] gear b

6

φ354

φ366

20

60

φ90

[0042] The following process measures are adopted: normalizing the gear forging blank (940-950℃×2.5h) → carburizing the workpiece in direction A (920℃×8-9h) → normalizing in direction B (880℃×1.5h- 2h)→static oil quenching ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com