Milling tool for cambered-surface thin-wall casing part

A part processing and milling technology, which is used in the milling and clamping of cambered thin-walled casing parts, as well as in the field of general-purpose jigs. It can solve the problems of excessive roundness, unevenness, deformed wall thickness, etc. The effect of low cost, manufacturing precision requirements and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

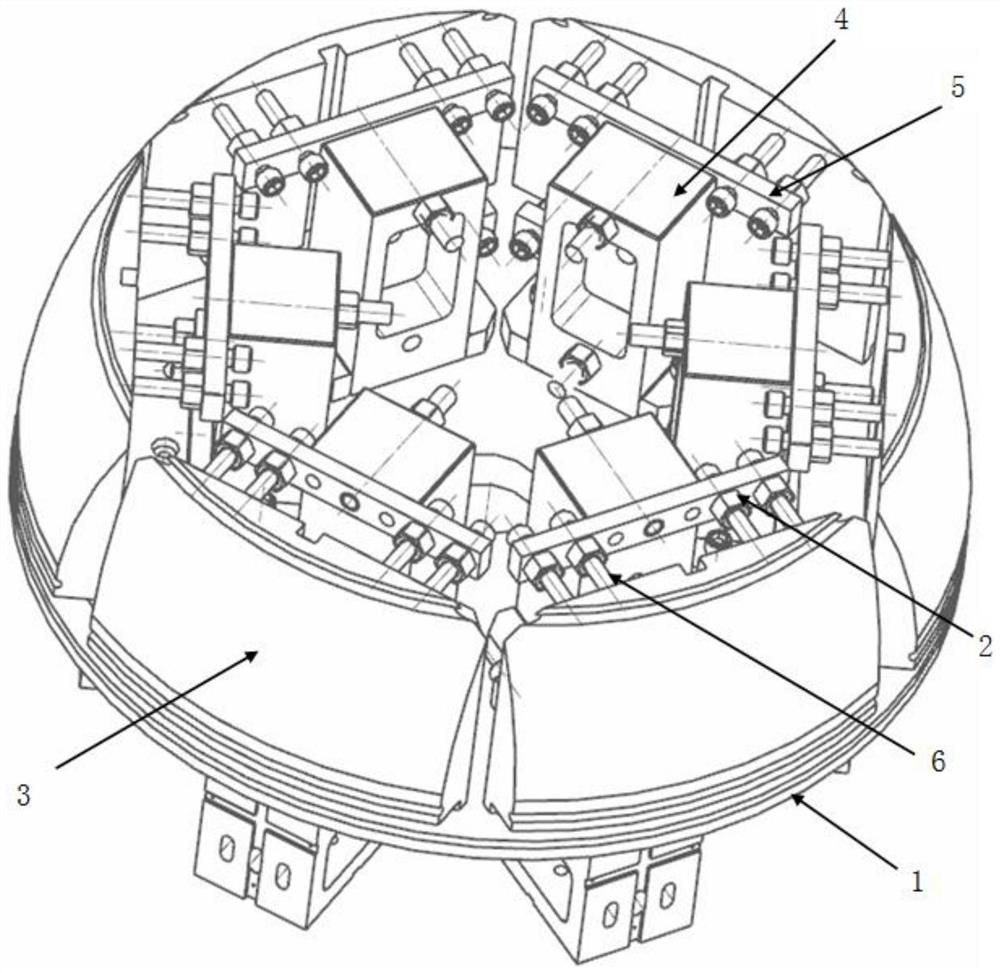

[0021] combined with Figure 1-6 and reference numerals describe the present invention in detail.

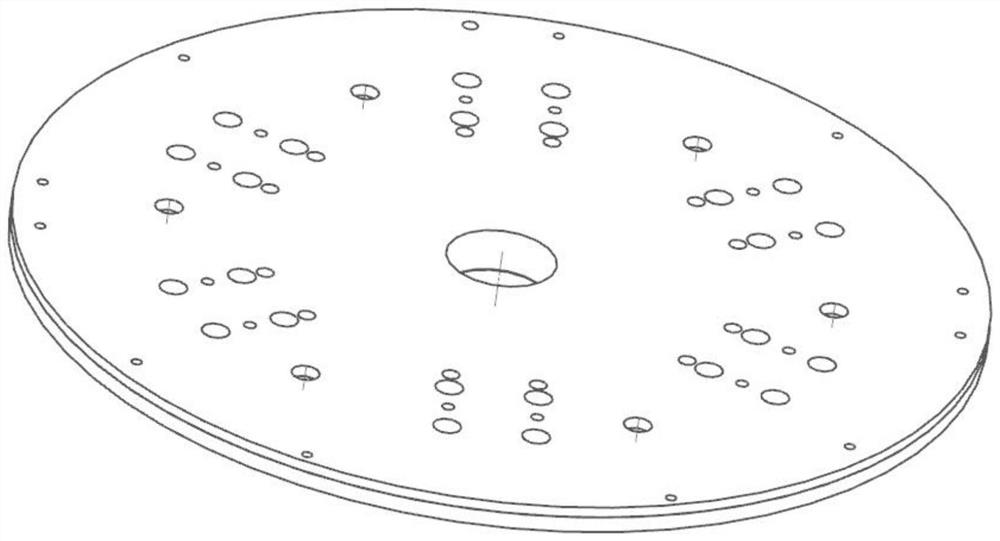

[0022] A milling tooling for arc-surface thin-walled casing parts, including a tooling base plate 1, an auxiliary support block 3, a fixed support seat 4, a lateral support block 5, an adjustable support rod 6, and a lock nut 2;

[0023] A plurality of auxiliary support blocks 3 and a plurality of fixed support seats 4 are installed on the tooling base plate through bolts;

[0024] The upper and lower parts of the fixed support seat 4 are connected with transverse support blocks 5, and the transverse support blocks 5 are equipped with a plurality of adjustable support bars 6 through nuts 2; the adjustable support bars 6 are connected to the auxiliary support blocks 3; the internal profile of the parts is guaranteed to be consistent with the Clamps assist support surfaces for effective fit.

[0025] The auxiliary support block 3 is made of high-strength resin material with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com