Novel support method applicable to shallow-buried subsurface tunnel of soft soil stratum

A technology of shallow burial and underground excavation and tunneling, which is applied in the direction of tunnels, tunnel linings, earthwork drilling and mining, etc. It can solve the problems of difficult to control the deformation of the surrounding environment, the inability to divert the traffic volume of cars, and the leakage of water in the support system, etc., and achieve good deformation Control ability, high rigidity, anti-pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

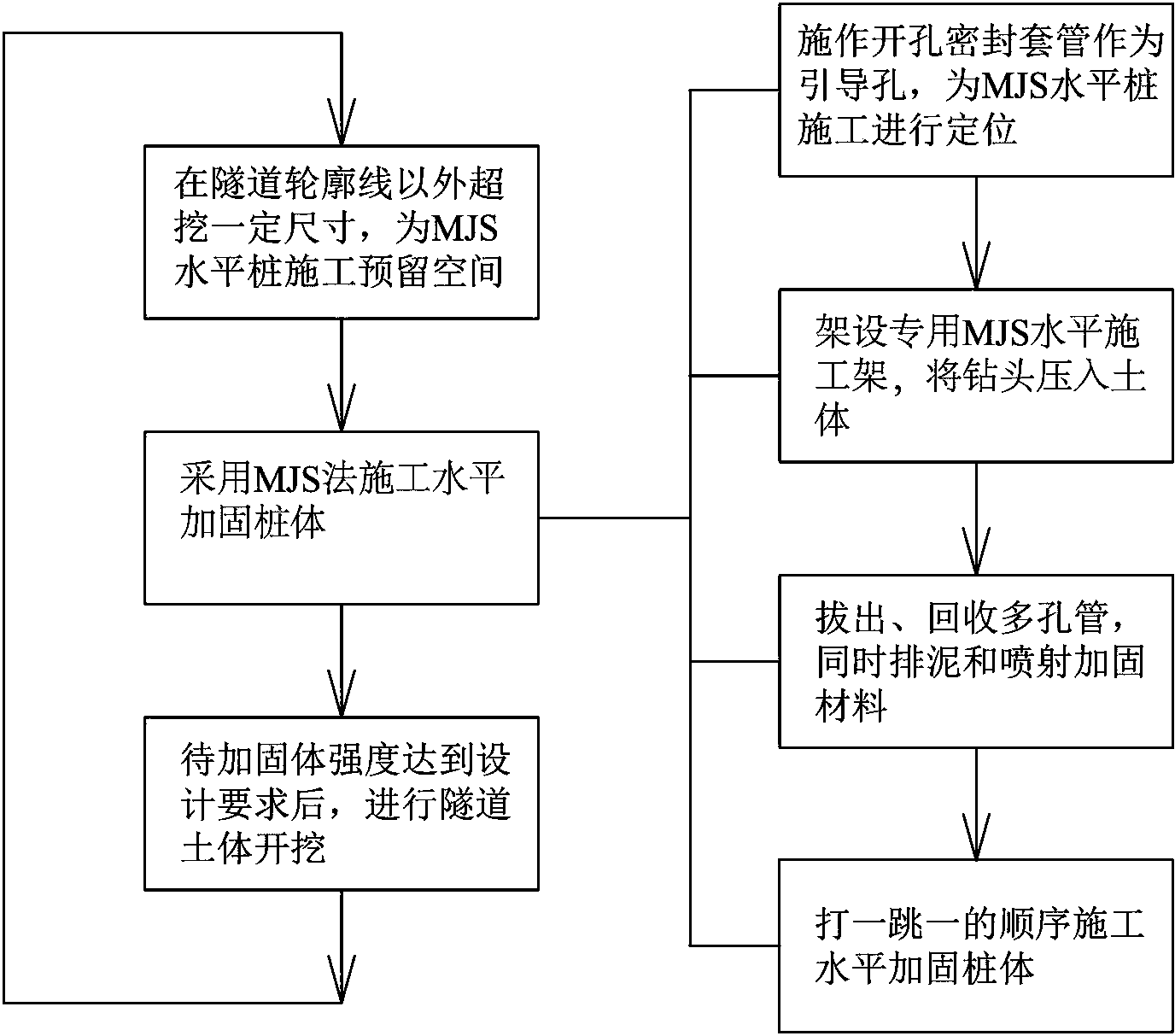

[0028] Embodiment 1: as figure 1 As shown, it is a schematic flow chart of a new support method suitable for shallow buried tunnels in soft soil strata provided by the present invention. The new support method is mainly used in shallow buried tunnels in muddy soil. construction, especially tunnels with high groundwater levels and high requirements for surrounding environmental protection.

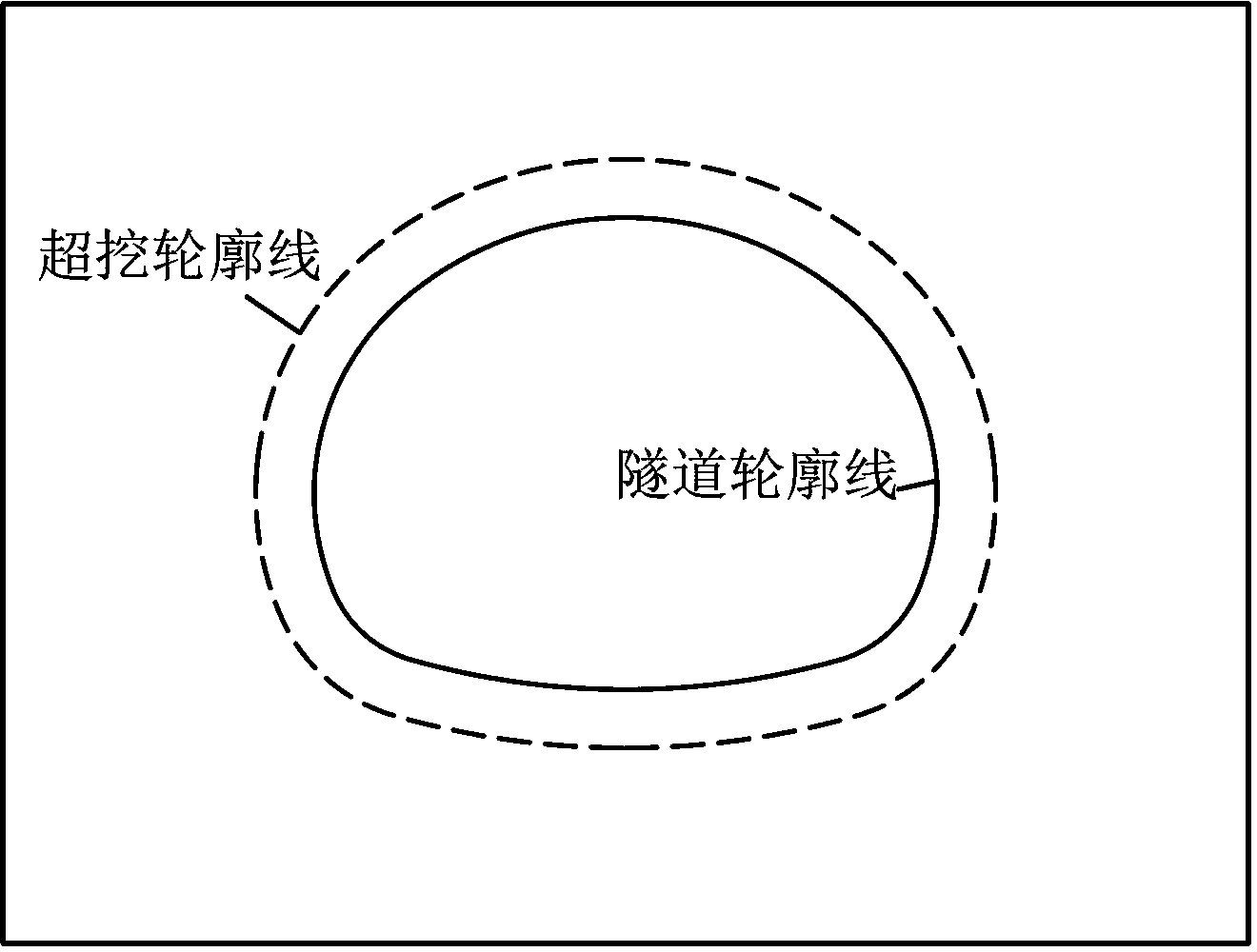

[0029] Such as Figure 2~Figure 4 As shown, the implementation steps of the new support method include: ① Over-excavate a certain size outside the tunnel outline to reserve space for the construction of MJS horizontal piles; ②Use the MJS method to construct horizontal pile reinforcement; ③After the strength of the reinforced body meets the design requirements , to excavate the tunnel soil.

[0030] In step ①, the minimum overbreak size should be determined according to the required shape and range of the reinforcement body and under the premise of ensuring the normal construction of the M...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com