Forming device and method for twisted variable-thickness composite material structure

A molding device and composite material technology, which is applied in the field of molding devices of torsionally variable thickness composite material structures, can solve the problems of blade structure deformation, insufficient processing accuracy, and the position of the blade weaving structure does not match the theoretical position, etc., to achieve easy deformation control, torsion small trend effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

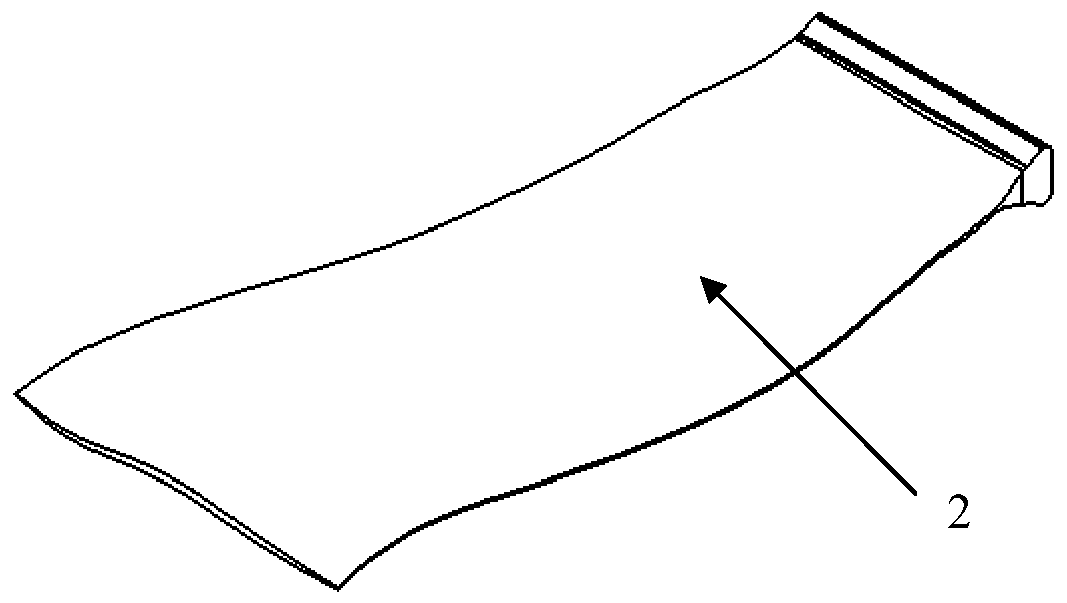

[0040] The blade preform 20 is a fan blade preform with a variable thickness of 2.5D woven structure. The material is CCF800, and the fiber volume content of the material is 58%±3%. Among them, CCF800 is a 12K grade T800 carbon fiber fabric developed by Shandong Weihai. The injection resin adopts ACTECH1304 high-toughness liquid molding resin from AVIC Composite Materials Co., Ltd. The outer dimension of the blade preform 20 is 780mm×320mm (length×width).

[0041] Processing blade preform deforming device 10, deforming device 10 consists of base 1, pressing blocks 3, 4, 5, 6, 7 and positioning bolt 8. Base 1 is processed based on the lower surface of preform 20, pressing blocks 3, 4 , 5, 6, 7 are processed and combined based on the upper surface of the preform 20; the material of the base 1, the pressing blocks 3, 4, 5, 6, 7 and the positioning bolt 8 is 45# steel.

[0042] A hydraulic control system is provided on each positioning bolt 8. The hydraulic device can make the position...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com