Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Gelatinization is easy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

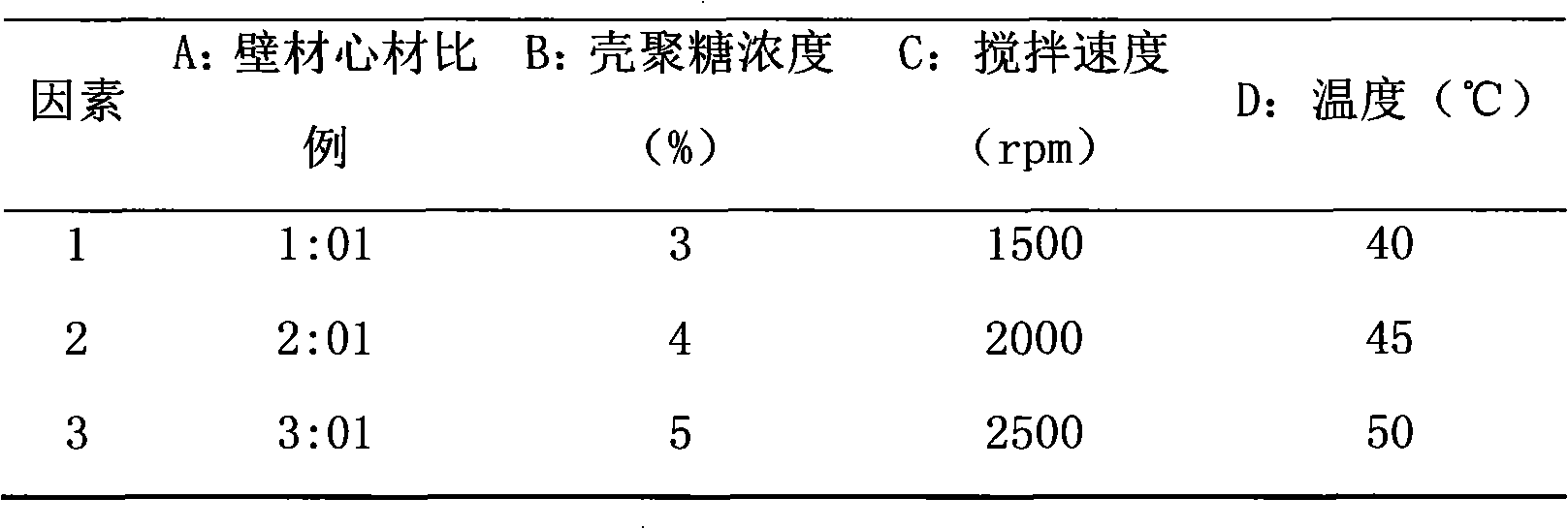

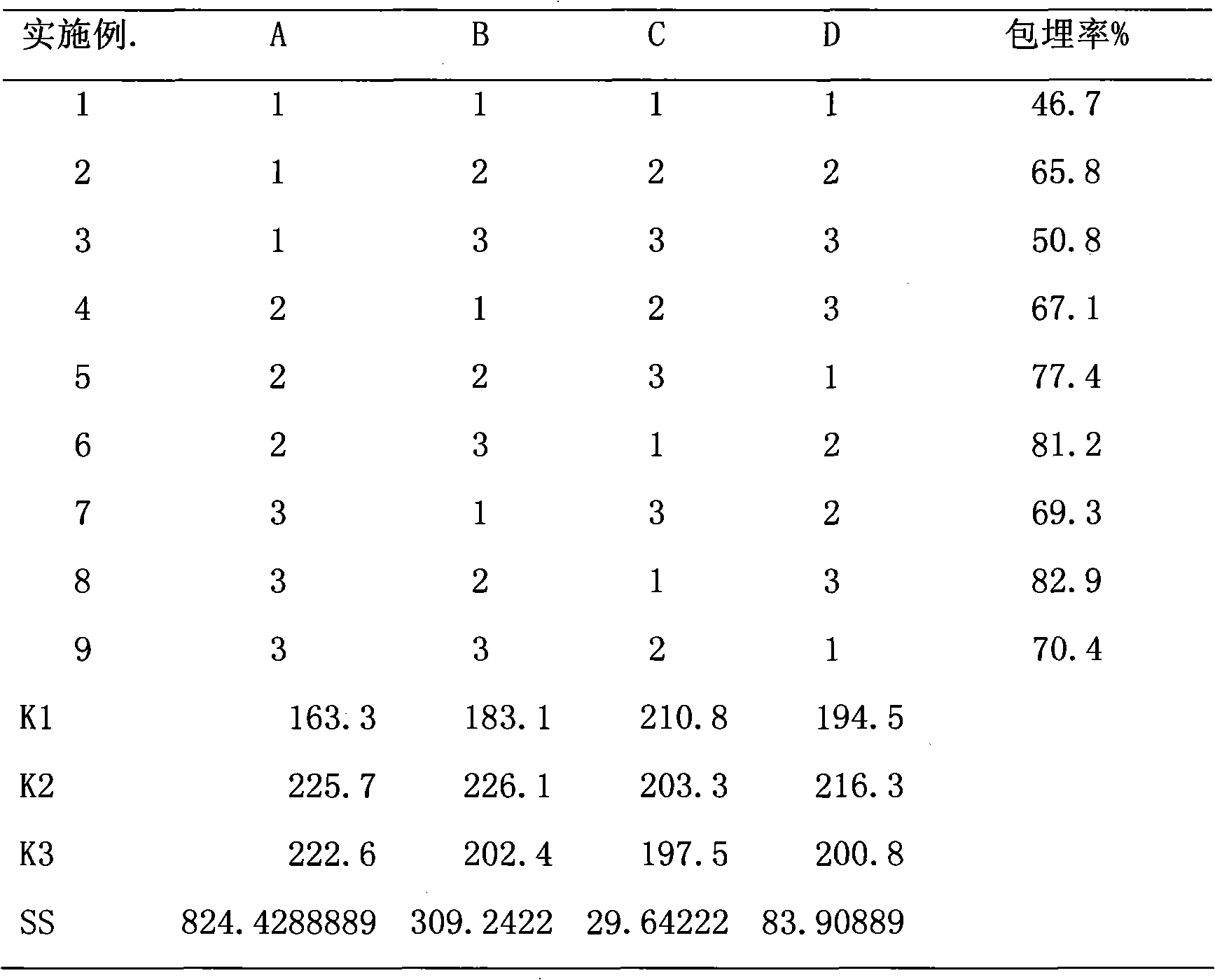

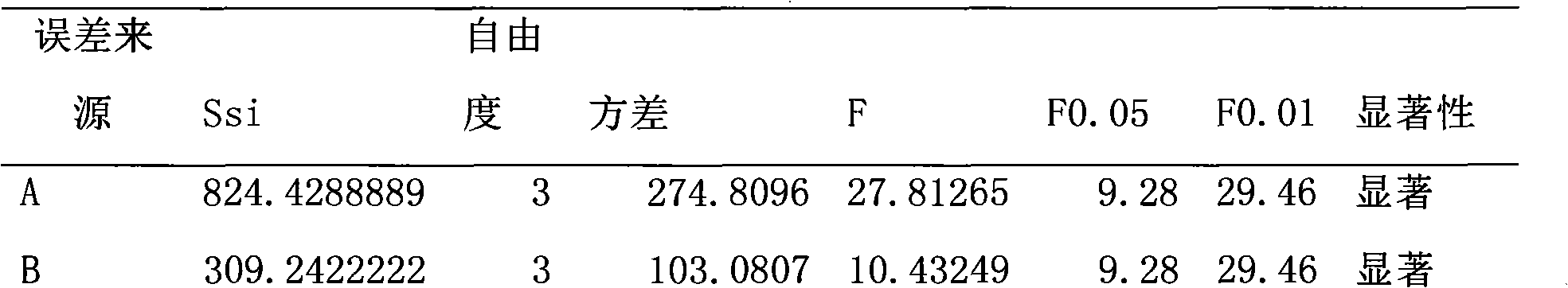

Preparation method of menthol microcapsules

ActiveCN101972619ALow costSimple processTobacco preparationMicroballoon preparationFood additiveMonoglyceride

The invention relates to the technical field of the food additive and the microcapsule equipment capable of controlling the release of bioactive substances, in particular to a preparation method of menthol microcapsules. The preparation method uses menthol, wall material, emulsifier, crosslinking agent, pH regulator and water as the raw materials, wherein menthol is used as the core material, chitosan is used as the wall material, monoglyceride and Tween-40 are used as the compound emulsifier, 10% acetic acid is used as the pH regulator. The preparation method comprises the following steps: emusifying the solution under high pressure, adding modified starch to crosslink, finally adopting the spray drying technology to prepare the powdery menthol microcapsule product. The invention aims to provide a menthol microcapsule preparation method with safe and easy technology and low cost, increase the stability and heat resistance of menthol, control the release process and expand the application range.

Owner:CHINA TOBACCO ZHEJIANG IND

Half-dry rice noodle and preparation method thereof

ActiveCN105410624AMuscular strengthGood elasticityFood ingredient as mouthfeel improving agentLoss ratePowder mixture

The invention discloses a half-dry rice noodle and a preparation method thereof. The half-dry rice noodle comprises the following raw materials: rice, a starch mixture, a fresh fruit and vegetable paste mixture and a fruit and vegetable powder mixture and is prepared by the following steps of fermentation and preprocessing of the rice, mixing of all raw materials, twin-screw extrusion forming, aging, re-steaming, washing and cutting oof noodles, measuring and packing, post-sterilization, cooling and the like. The half-dry rice noodle prepared by the invention has the advantages of smooth and bright appearance, strong gluten power, good elasticity, natural flavor, long shelf time, clear finished product soup and the like, the breaking rate is controlled to be lower than 2%, and the loss rate of cooking is controlled to be lower than 4%. According to the half-dry rice noodle and the preparation method thereof, the problem of the existing rice noodle of single nutrition is solved; the ingredients rich in protein and vitamins are added in the formula, so that the product has comprehensive nutrients; in addition, any preservative, brightening agent and thickening agent are not added in the product, so that the product prepared by the preparation method has excellent taste and is nutrient and healthy.

Owner:GAEA GEM RICE

Stuffing for roasted food and its prepn process

InactiveCN101088345APrevent agingGuaranteed liquidityBakery productsFood preparationMonoglycerideColloid

The present invention relates to one kind of stuffing for roasted food and its preparation process. The stuffing consists of sugar 10-30 wt%, modified starch 0-11 wt%, hydrophilic colloid 0.1-0.6 wt%, steamed monoglyceride 1-5 wt%, potassium sorbate 0.01-0.1 wt%, food water preserver 5-30 wt%, edible essence and / or edible color 0.2-0.5 wt%, and water for the rest, with water content being less than wt%. The stuffing has the synergistic effect of colloid and modified starch, high flowability, high water preserving capacity, high freezing resistance and stable quality, and the roasted food with the stuffing has good taste.

Owner:MASSON GROUP

Environment-friendly type textile sizing agent

Owner:SUZHOU RUNHONG TRADING

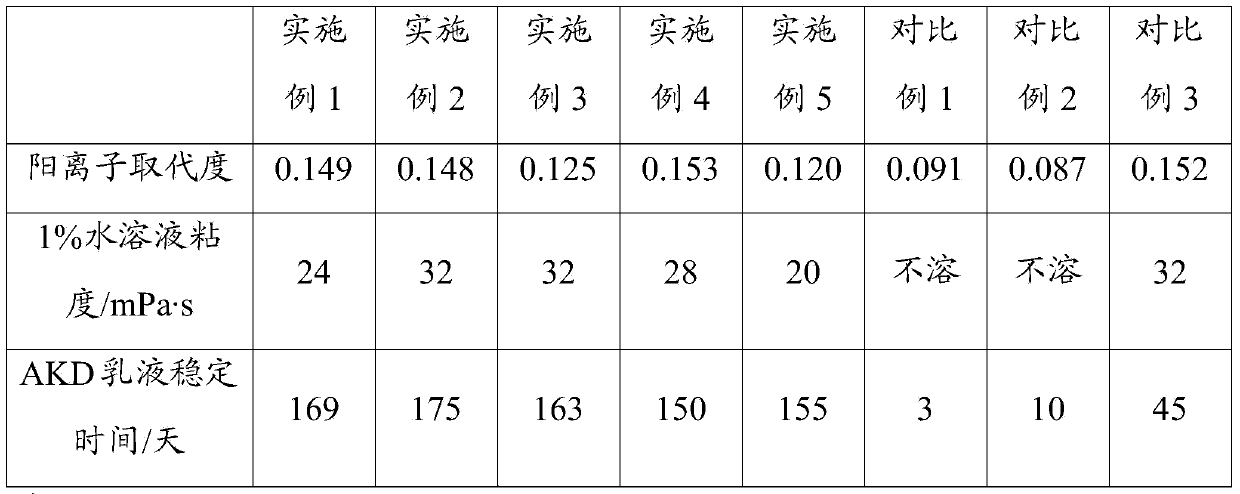

Cationic starch as well as preparation method and application of cationic starch

ActiveCN104193839AHigh degree of cationic substitutionImprove emulsion stabilityWater-repelling agents additionPaper coatingOrganic solventAqueous solution

The invention discloses a cationic starch as well as a preparation method and application of the cationic starch. The preparation method comprises the steps of (1) mixing starch and a water solution of 50-90% of organic solvent, and then, placing the mixture into a reaction vessel; (2) adding a catalyst, stirring and heating to 50-90 DEG C; (3) adding an etherifying agent, and reacting for 1-5h; (4) adding an oxidant, and reacting for 10-60 minutes; (5) adding acid until the pH value of the reaction system is up to 4-7; and (6) carrying out vacuum drying at the temperature of 50-90 DEG C and the vacuum degree of 0.07-0.1MPa to obtain the cationic starch. If the cationic starch obtained by using the preparation method disclosed by the invention is used as an AKD (Alkyl Ketene Dimer) emulsifier, the stability time of the AKD emulsifier at normal temperature can exceed three months.

Owner:GUANGZHOU TINCI MATERIALS TECH +1

Method and device for preparing Shanxi mellow vinegar by liquid-solid technology

ActiveCN1970725AReduce dosageChanging out-of-control situationsVinegar preparationYeastBiotechnology

The invention discloses a manufacturing method of Shanxi mature vinegar through front-diluting and back-fixing technique, which is characterized by the following: adopting sorghum and or maize with random proportion as raw material; adopting fine powder to feed; simplifying antecedent wetting, gelatinizing and saccharifying technique; proceeding continuous manufacturing in the tank at liquid pattern without artificial turning over and pouring; shortening antecedent ferment technique and time; controlling yeast bacterial easily.

Owner:TIANDI YIHAO BEVERAGE JIANGMEN CITY

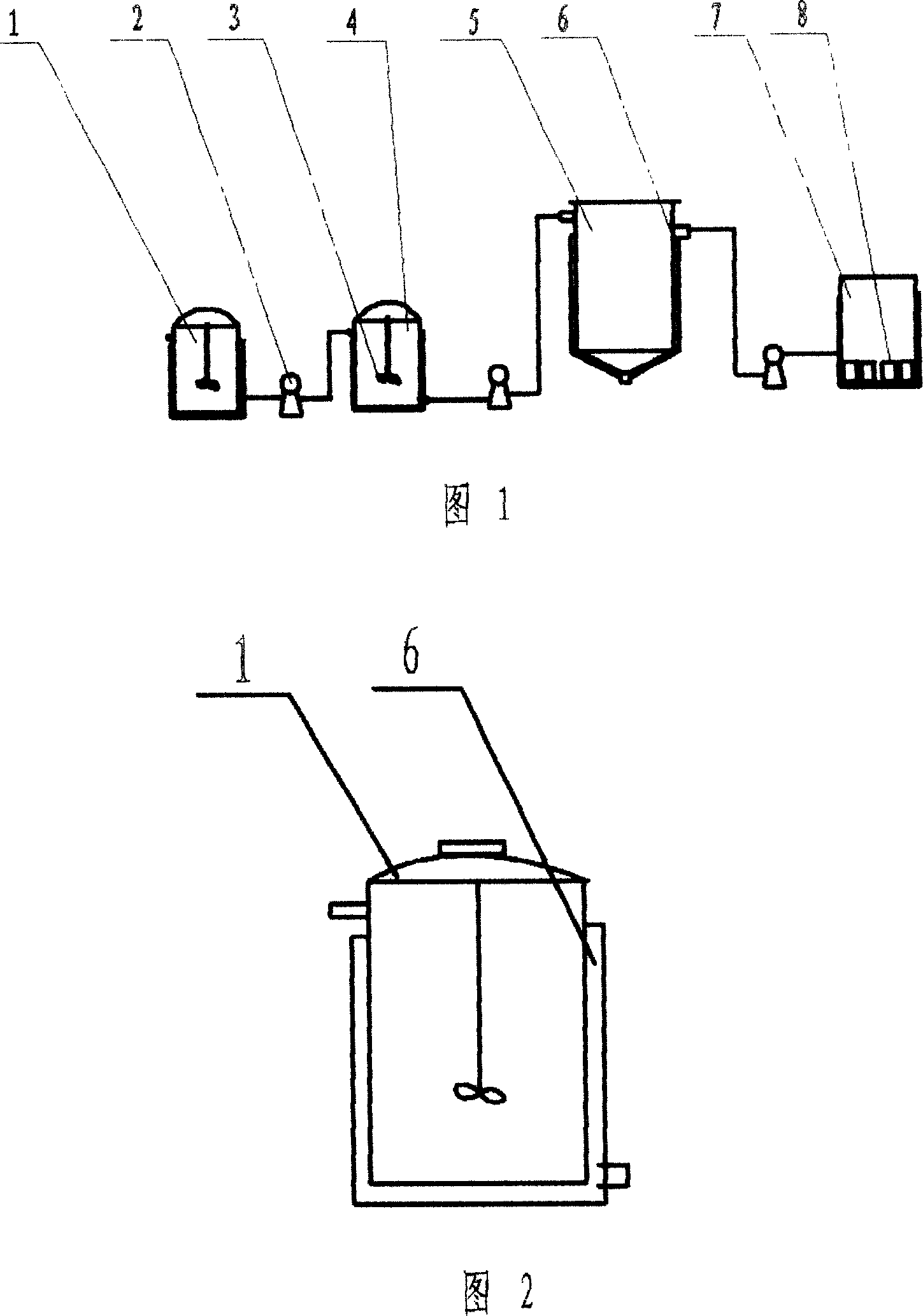

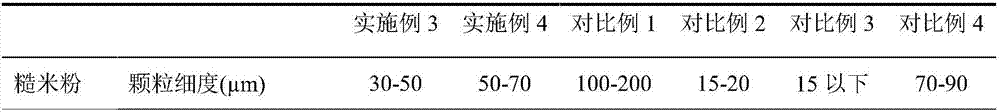

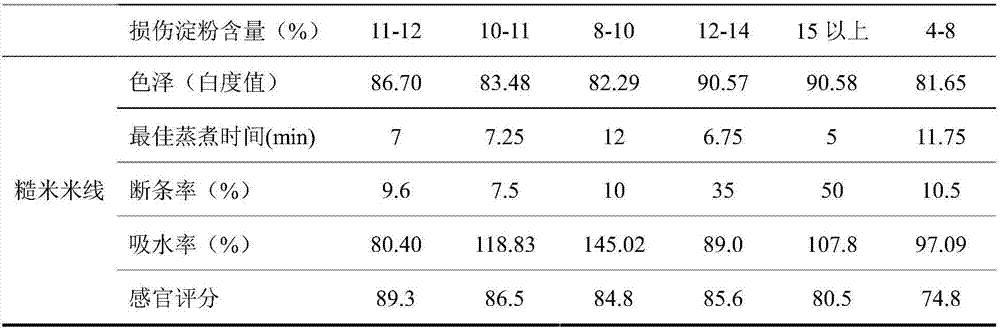

Method for preparing unpolished rice noodles by dry-process micro-grinding

The invention discloses a method for preparing unpolished rice noodles by dry-process micro-grinding. The method comprises the following steps: 1) pre-treating unpolished rice; 2) micro-grinding the unpolished rice: grinding the unpolished rice until the grain fineness is 30mu m to 70mu m; controlling the content of damaged starch to be 12 percent or less; 3) wetting; 4) self-cooking, extruding and shredding; 5) ageing; 6) carrying out repeated evaporation; 7) drying. The sensory quality including the palatability and the like, and the cooking quality including the optimal cooking time, the breaking rate, the water absorption rate and the like of the unpolished rice noodles prepared by adopting a dry-process micro-grinding method are greatly improved; compared with a traditional method for producing the unpolished rice noodles, the method has no sewage emission and the production cost is reduced; the method disclosed by the invention has important significance on improvement of a processing technology level of unpolished rice noodle industry and large-scale production and has a wide industrialization prospect.

Owner:ACAD OF NAT FOOD & STRATEGIC RESERVES ADMINISTRATION

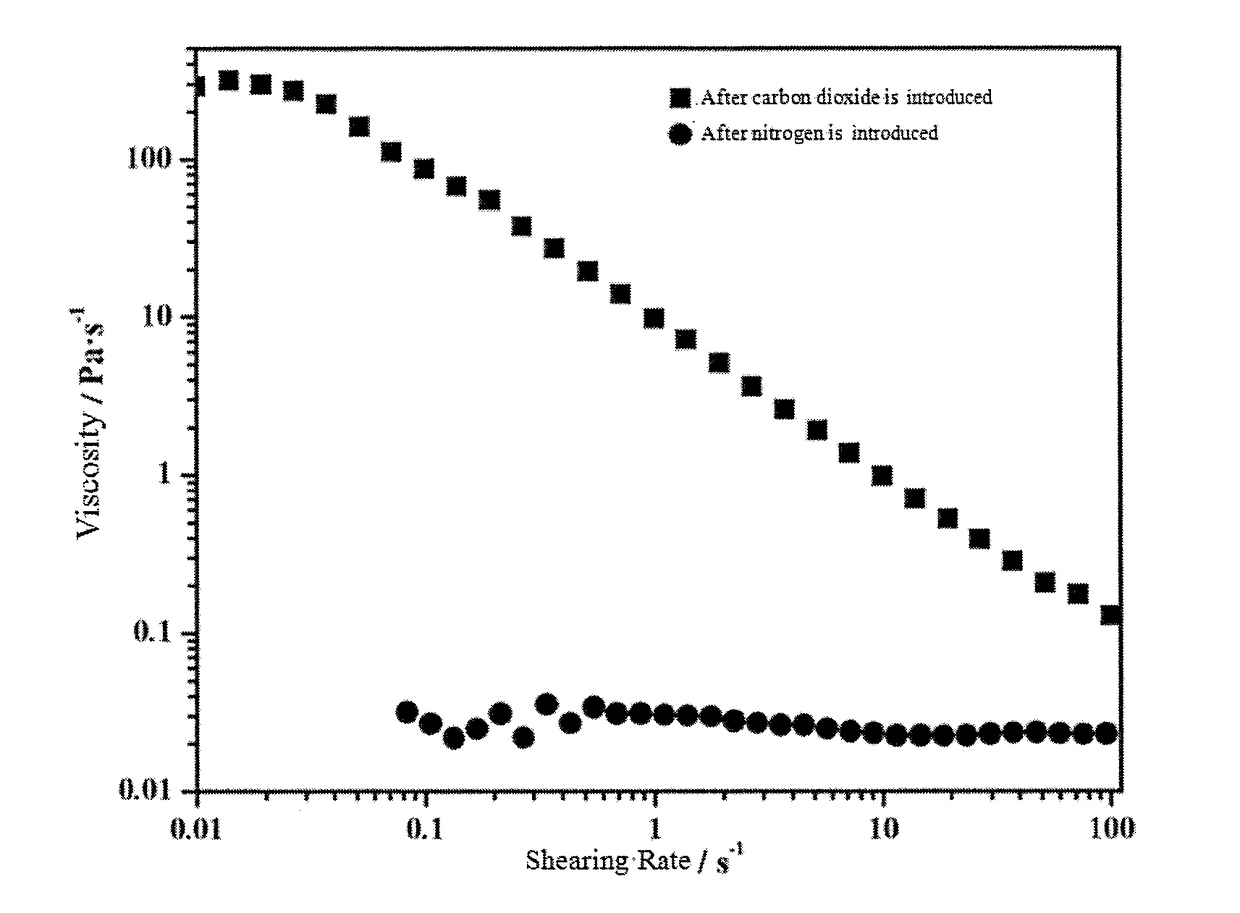

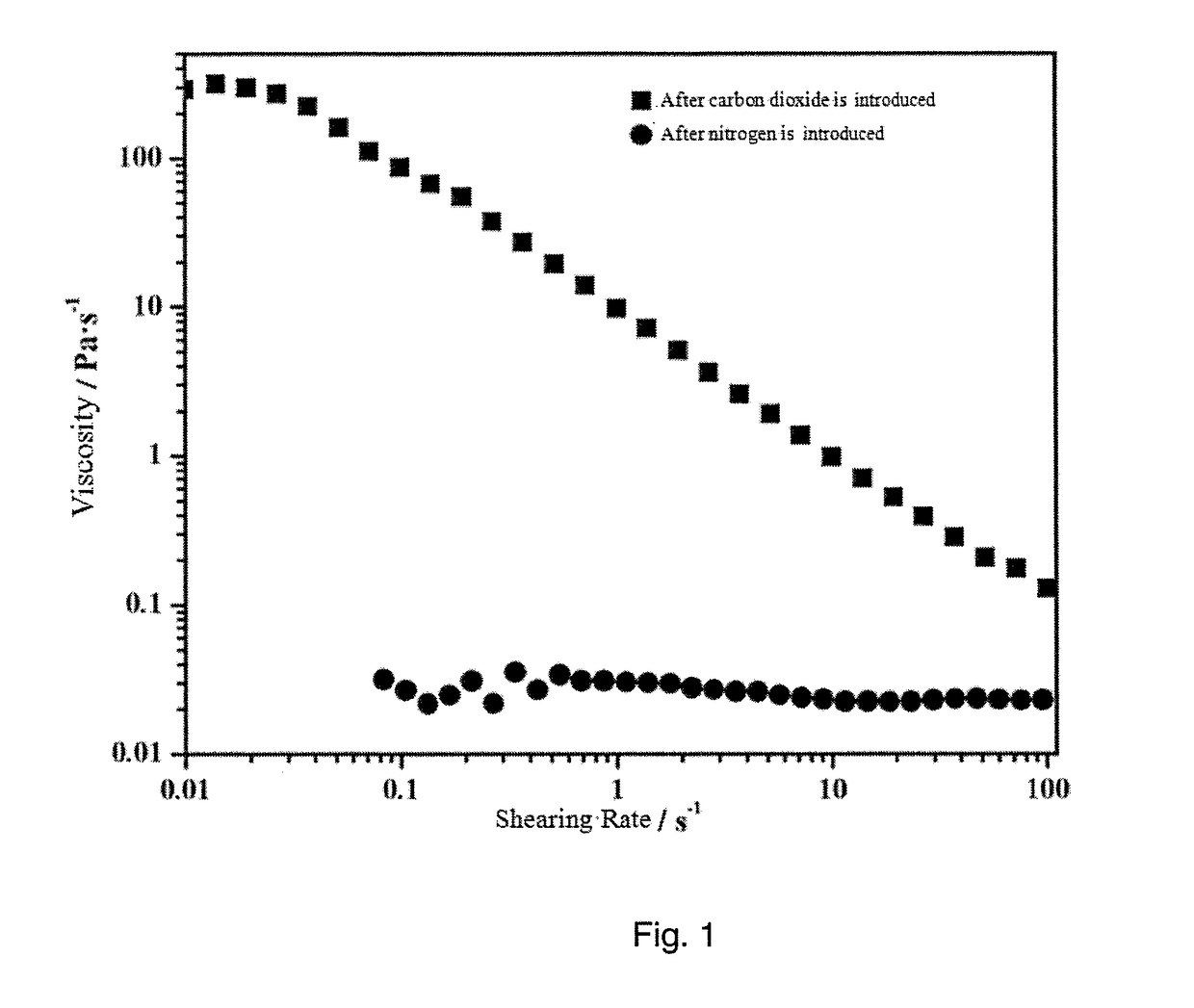

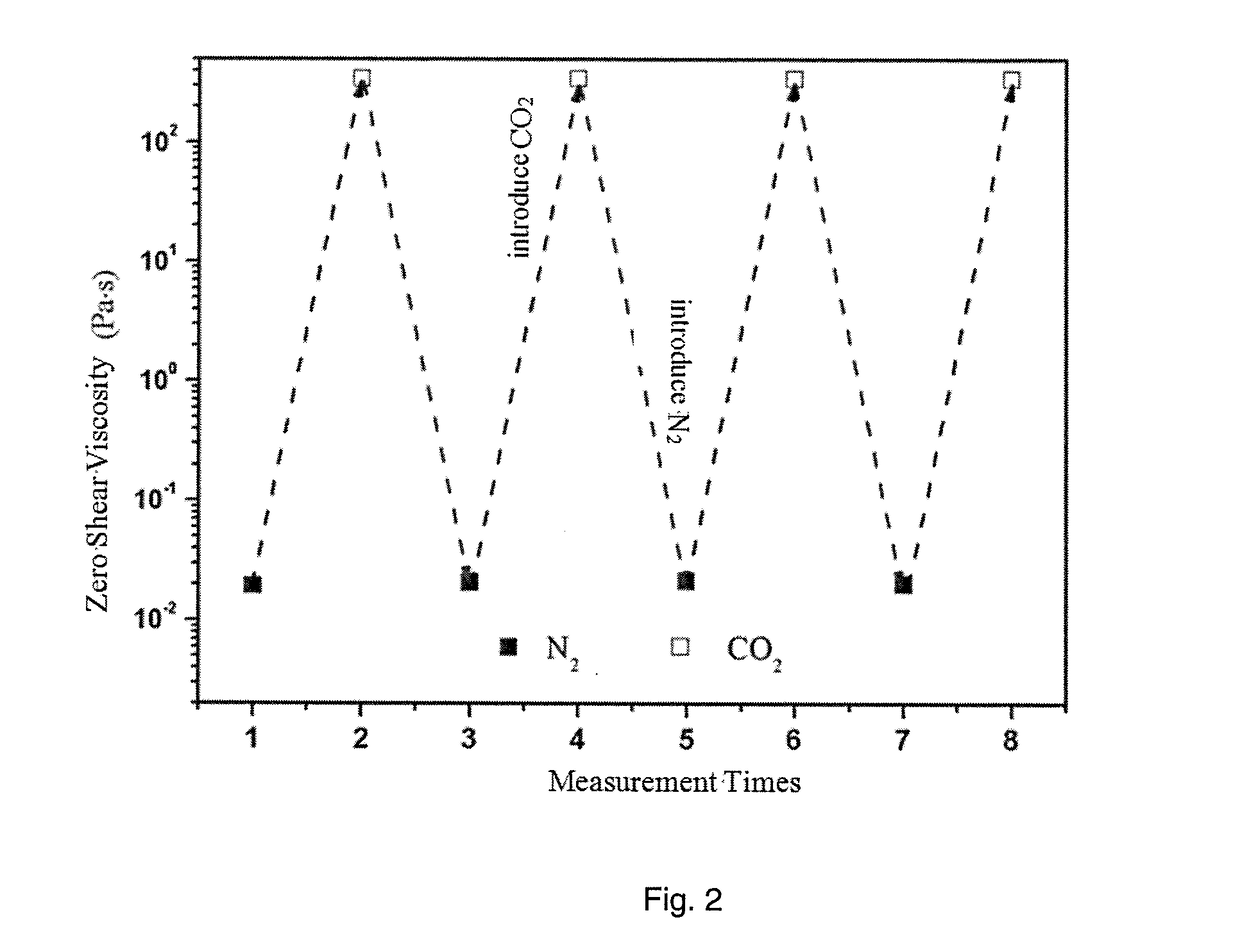

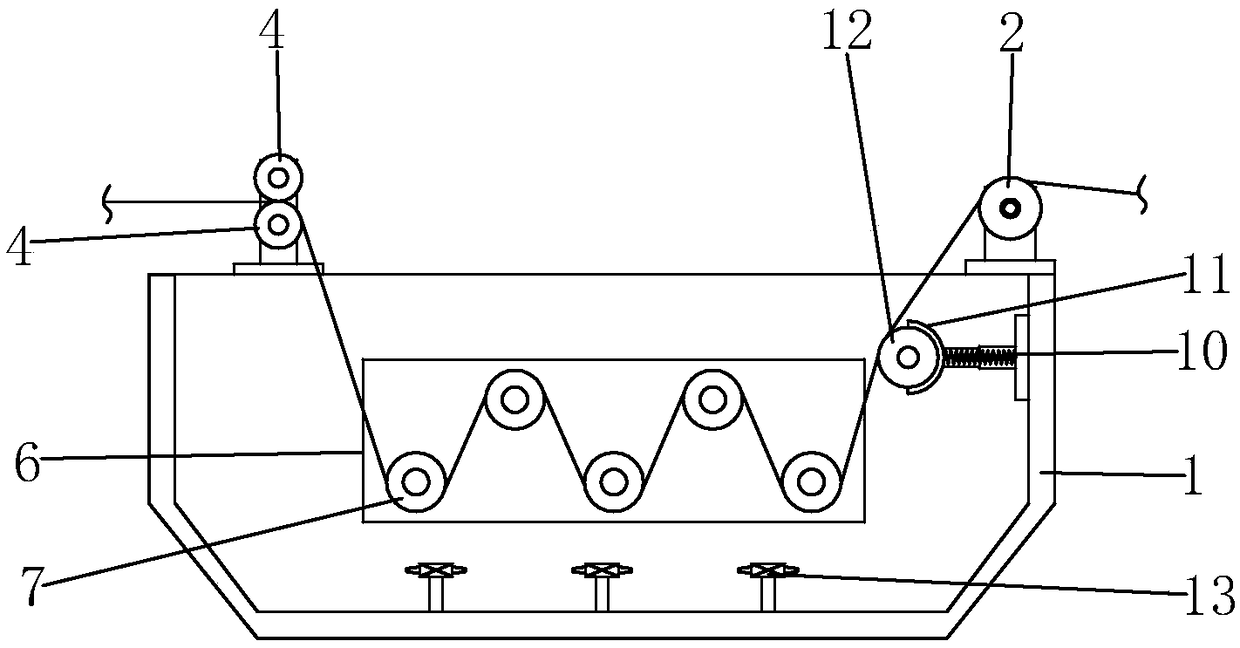

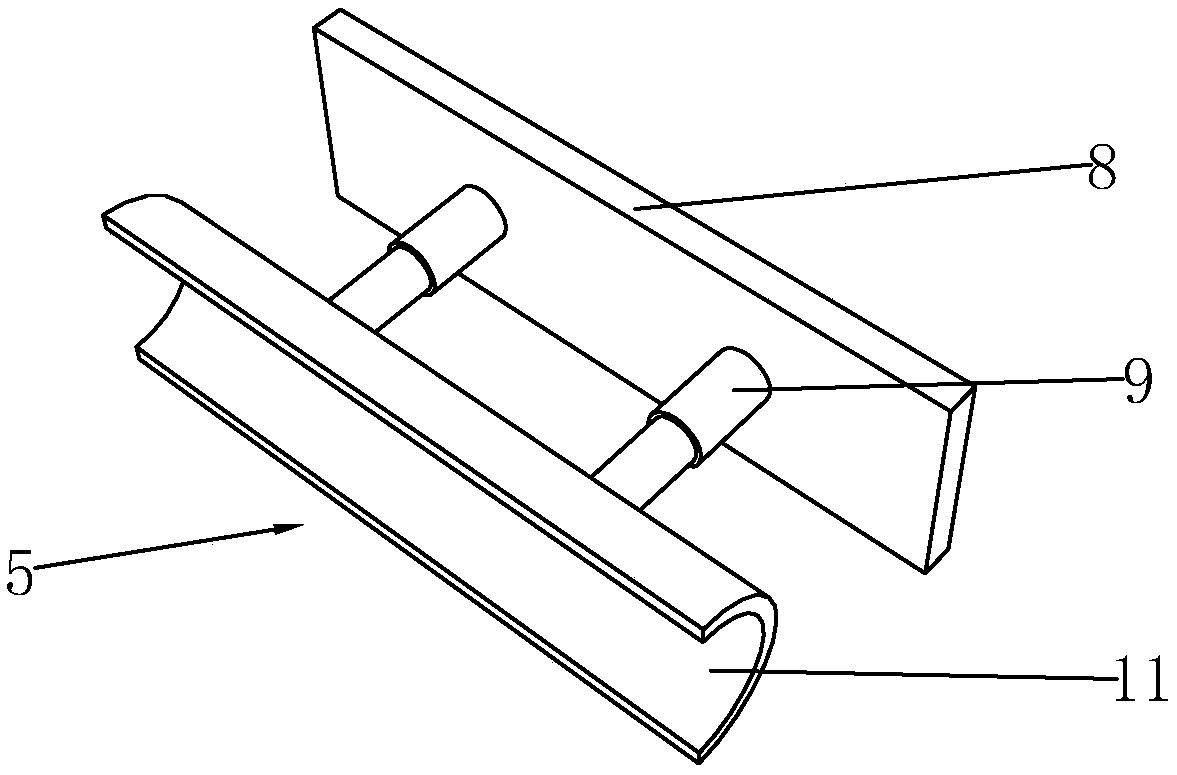

Water solution, clean fracturing fluid and method for fracturing reservoir

ActiveUS20180334611A1Realize comprehensive utilizationSevere contaminationOrganic chemistryDrilling compositionFracturing fluidCis-Butenedioic Acid

The present invention relates to the fracturing field, and discloses a water solution, a clean fracturing fluid, and a method for fracturing reservoir. The water solution contains organic acid amidopropyl dimethylamine, an additive, and water, wherein, the additive is at least one of salicylate, cis-butenedioic acid, o-phthalic acid, dodecyl sulfonate, p-toluene sulfonate, and benzoate. The water solution has high carbon dioxide response performance, a clean fracturing fluid that contains the water solution has superior cyclic utilization performance, and the fracturing fluid can solve the problems of conventional fracturing fluids used in fracturing stimulation of oil and gas reservoirs, including incomplete gel breaking, severe damages to the reservoir, and severe contamination of flow-back fluid, etc.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Method for processing yarn-dyed four-side stretch fabric garment

ActiveCN109097974AClear organizationImprove cohesionLiquid/gas/vapor removalBiochemical treatment with enzymes/microorganismsYarnEngineering

The invention discloses a method for processing a yarn-dyed four-side stretch fabric garment. The method comprises the following steps: (a) alkali soaking; (b) biological enzyme polishing; (c) dyeing;(d) air drying; (e) sizing; (f) weaving; (g) desizing; (h) scouring and bleaching; (i) padding; (j) drying; (k) finishing; and (l) pre-shrinking. The method is simple in process, saves energy and reduces consumption and is easy to control, and an obtained fabric is soft and comfortable in touch and has a fine and soft gloss, good non-ironing property, anti-wrinkle performance and anti-pilling performance and dimensional stability.

Owner:盛泰智造集团股份有限公司

Starch mixed shrimp cracker and preparation method thereof

The invention discloses a starch mixed shrimp cracker, which is prepared from the following components in part by weight: 10 to 20 parts of cassava starch, 15 to 20 parts of potato starch, 70 to 85 parts of corn starch, 2 to 4 parts of shelled shrimps, 1 to 3 parts of white granulated sugar, 2 to 4 parts of refined salt, 1 to 2 parts of monosodium glutamate and 40 to 50 parts of water. The invention simultaneously discloses a method for preparing the starch mixed shrimp cracker. By controlling parameters of a co-rotating twin screw extruder, the prepared starch mixed shrimp cracker is diversified in components, comprehensive in nutrient components, good in mouthfeel, fine in appearance, healthy, safe, simple in processing technology, high in degree of automation and low in labor intensityof a worker, reduces the energy consumption and the processing cost, and can meet the requirement of development of modern enterprises and society.

Owner:NINGBO YINFA GREEN FOOD

Low-pollution textile sizing agent

The invention relates to a low-pollution textile sizing agent. The low-pollution textile sizing agent comprises following components in parts by mass: 64 parts of nano silicon dioxide modified starch, 18 parts of a protein sizing agent, 5 parts of polyvinyl alcohol, 11 parts of polyacrylate emulsion, 2 parts of a modified silicone oil de-foaming agent, 3 parts of protein amino acid, 4 parts of kaolin, 3 parts of sodium sulfamate and 1 part of polyacrylate. The sizing agent with the formula has good film-forming property and permeability; the formula contains less polyvinyl alcohol so that the pollution to the environment is low.

Owner:SUZHOU RUNHONG TRADING

Production process for brewing mature vinegar from glutinous sorghum

ActiveCN109468211APromote reproductionGelatinization is easyBiofuelsMicroorganism based processesRhizopusSorghum

The invention discloses a production process for brewing mature vinegar from glutinous sorghum. The production process for brewing the mature vinegar from the glutinous sorghum comprises the followingsteps: 1, preparing rhizopus bran koji; and 2, carrying out a glutinous sorghum mature vinegar production process. The glutinous sorghum is used as a raw material to brew traditional mature vinegar,traditional steaming is replaced by a process of high-temperature liquidation and low-temperature saccharification, the rhizopus bran koji is added in a saccharification process, alcoholic fermentation is carried out while saccharification, and processes of solid state acetic fermentation, smoking solid-substrate fermentation, vinegar pouring, ageing and the like follow a traditional brewing process for Shanxi mature vinegar. The problem that adhesion and caking of the glutinous sorghum are easily caused after the glutinous sorghum is steamed is solved, raw materials are decomposed fully, theflavor and quality of the mature vinegar are improved, and the yield is increased.

Owner:SHANXI ZILIN VINEGAR

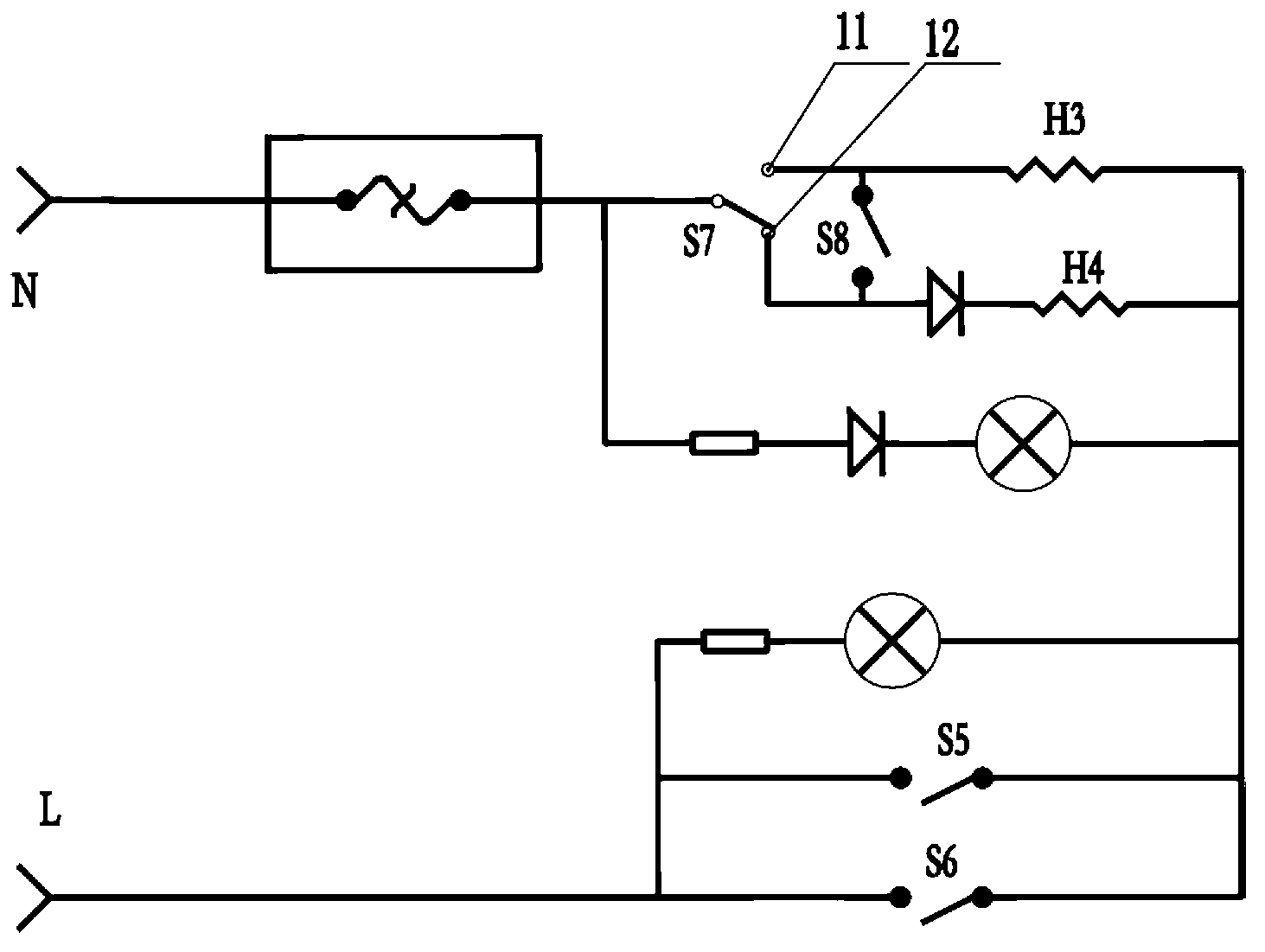

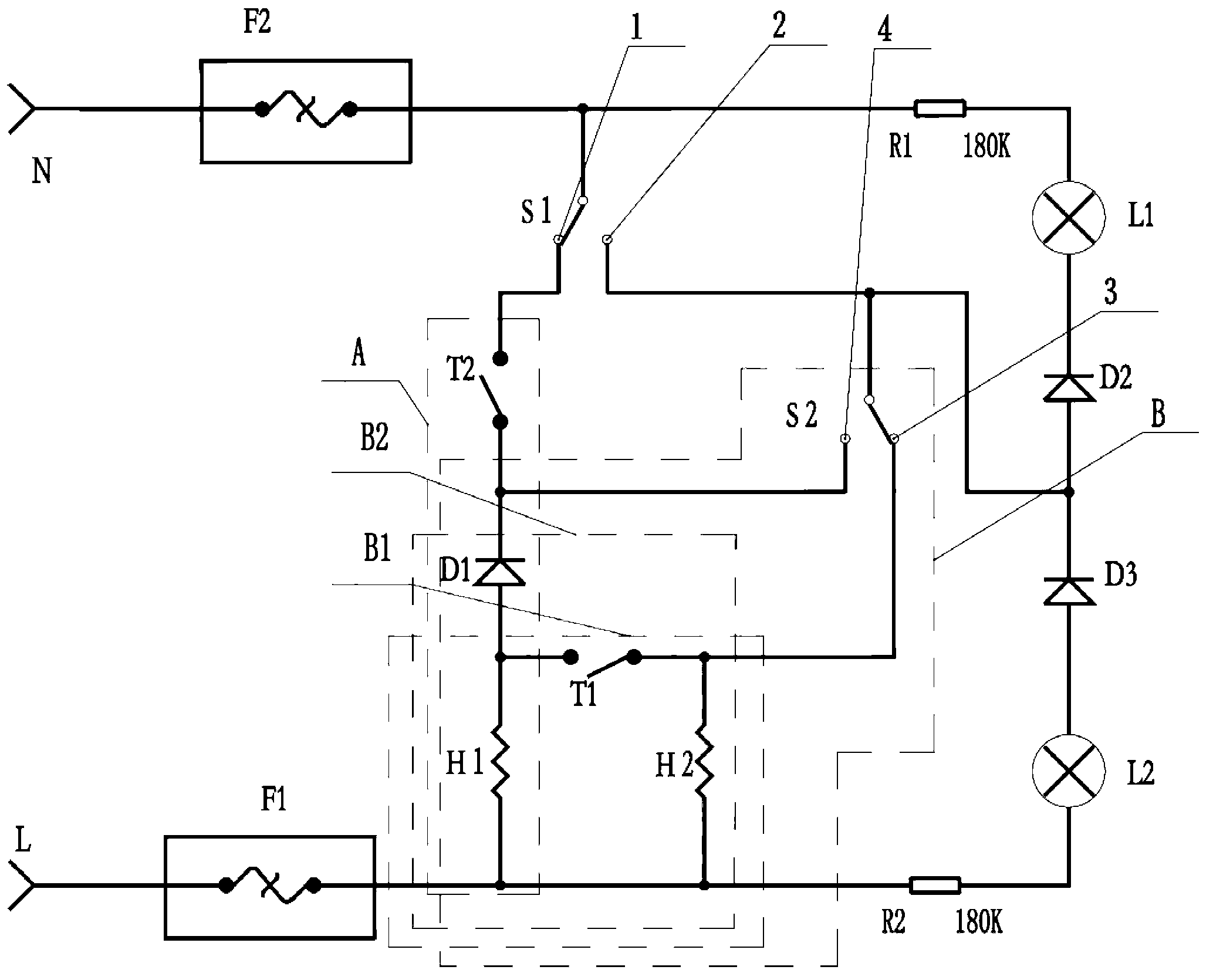

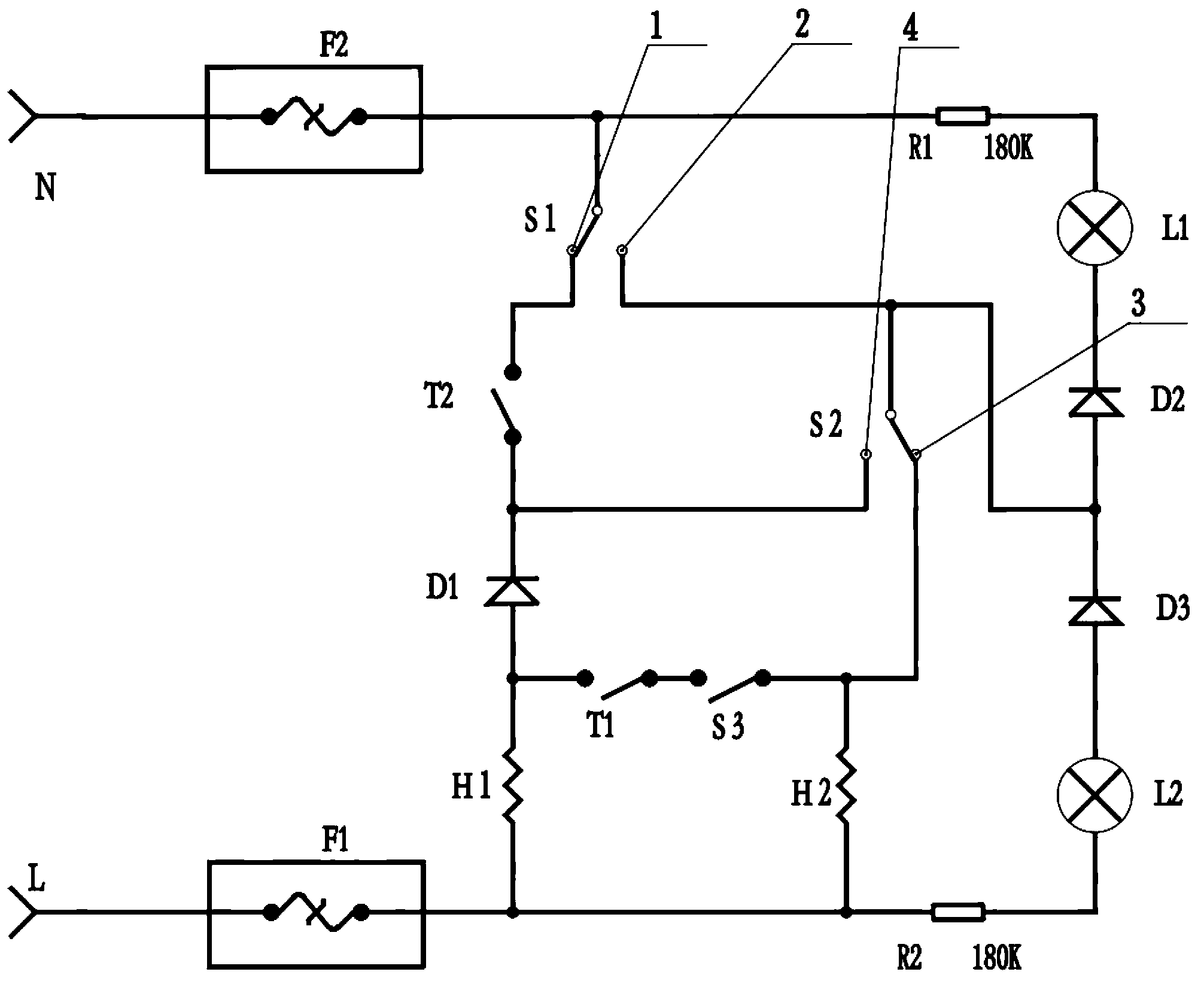

Energy-saving spill-proof mechanical electric rice cooker and energy-saving spill-proof heating circuit thereof

ActiveCN103006055AReduce cooking timeRealize boiling water absorptionBoiling over preventionAuxillary controllers with auxillary heating devicesPower diodeEngineering

The invention discloses an energy-saving spill-proof mechanical electric rice cooker and an energy-saving spill-proof heating circuit thereof, relates to the technical field of kitchen cooking, and solves the technical problems of long rice cooking time, high possibility of spilling of soup and porridge and unstable warm temperature in the mechanical electric rice cooker. A quick-boiling heating circuit in the energy-saving spill-proof heating circuit of the mechanical electric rice cooker comprises a heater H1, a heater H2 and a temperature controller T1 for detecting the top vapor temperature of the electric rice cooker; the temperature controller T1 is connected in series with the heater H1 and connected in parallel with the heater H2; the spill-proof heating circuit comprises a half-power diode D1 and a power adjusting circuit which are connected in series; the power adjusting circuit comprises the heater H1, the heater H2 and the temperature controller T1; the heater H2 is connected in series with the temperature controller T1 and connected in parallel with the heater H1; and an insulation circuit comprises an insulation temperature controller T2, the half-power diode D1 and the heater H1 which are connected in series. The embodiment of the invention is mainly applied to the mechanical electric rice cooker.

Owner:JOYOUNG CO LTD

Sizing method of low-pollution textile slurry

The invention relates to a sizing method of low-pollution textile slurry, which comprises the following steps: pouring slurry into a slurry trough, and heating the slurry in the slurry trough to 52 DEG C; immersing the fabric into the slurry in the slurry trough for 6 minutes while winding the fabric on a frame to tighten the fabric and rolling the fabric at uniform speed so that the slurry is sufficiently and uniformly filled into the fabric, wherein the pressure of the squeezing roller is 12KN; taking out the fabric, putting the fabric in a drying oven, and drying the fabric; immersing the dried fabric into the slurry again for 3 minutes, and rolling the fabric at uniform speed, wherein the pressure of the squeezing roller is 14KN; and taking out the fabric, putting the fabric in a drying oven, and drying the fabric to finish the sizing technique. The method completes the fabric sizing in a twice sizing mode, and designs the technological parameters (mainly temperature of the slurry trough, immersion time for two sizing processes, and pressure of the squeezing roller) according to the specific slurry. The sizing technique is especially suitable for sizing high-count cotton fabrics, and has favorable sizing effect.

Owner:SUZHOU RUNHONG TRADING

Sizing method of environment-friendly textile slurry

ActiveCN103882709ASizing fitImprove sizing effectSucessive textile treatmentsFibre treatmentEngineeringSlurry

The invention relates to a sizing method of environment-friendly textile slurry, which comprises the following steps: pouring slurry into a slurry trough, and heating the slurry in the slurry trough to 55 DEG C; immersing the fabric into the slurry in the slurry trough for 5 minutes while winding the fabric on a frame to tighten the fabric and rolling the fabric at uniform speed so that the slurry is sufficiently and uniformly filled into the fabric, wherein the pressure of the squeezing roller is 13KN; taking out the fabric, putting the fabric in a drying oven, and drying the fabric; immersing the dried fabric into the slurry again for 2 minutes, and rolling the fabric at uniform speed, wherein the pressure of the squeezing roller is 15KN; and taking out the fabric, putting the fabric in a drying oven, and drying the fabric to finish the sizing technique. The method completes the fabric sizing in a twice sizing mode, and designs the technological parameters (mainly temperature of the slurry trough, immersion time for two sizing processes, and pressure of the squeezing roller) according to the specific slurry. The sizing technique is especially suitable for sizing high-count cotton fabrics, and has favorable sizing effect.

Owner:SUZHOU RUNHONG TRADING

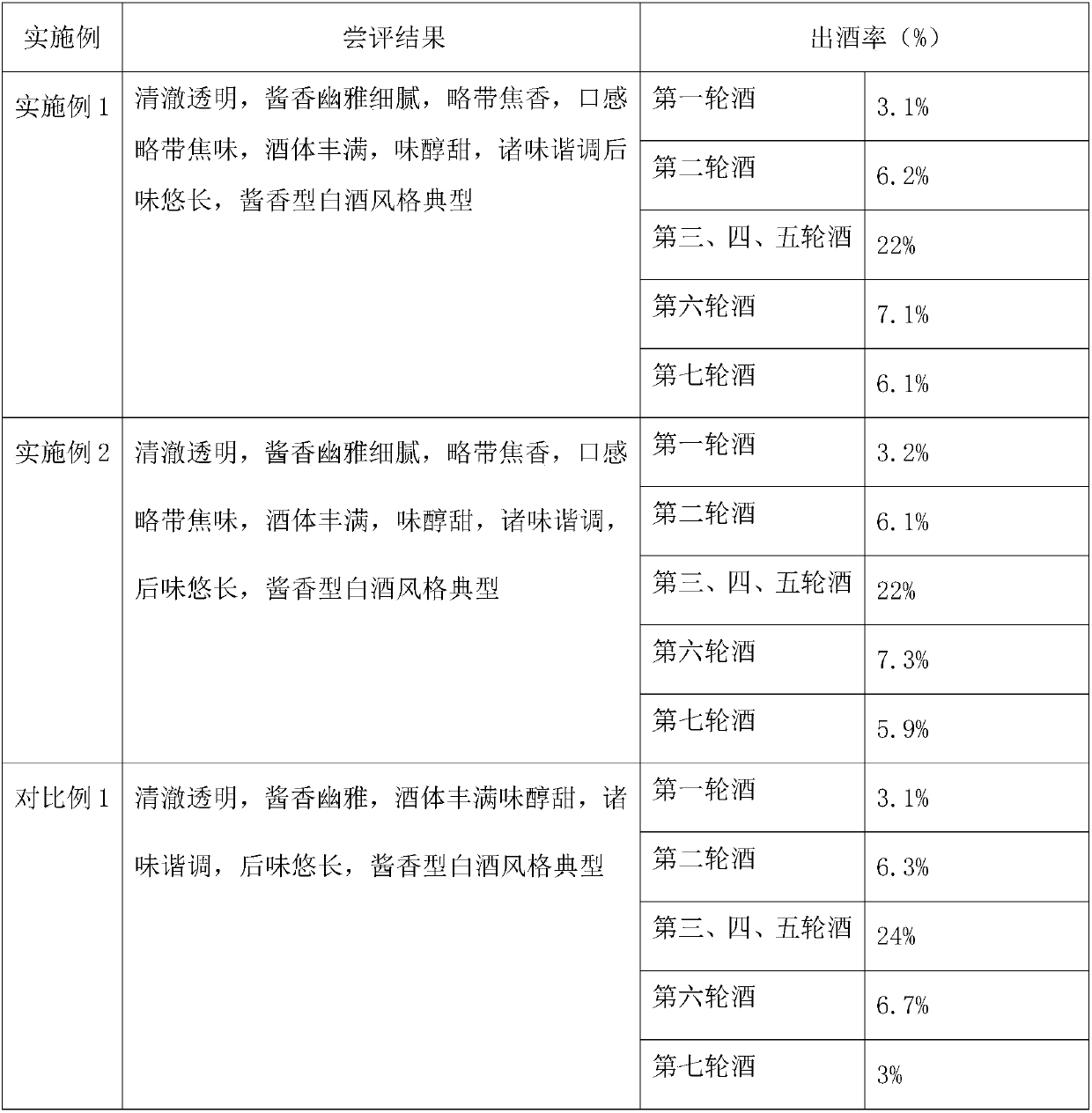

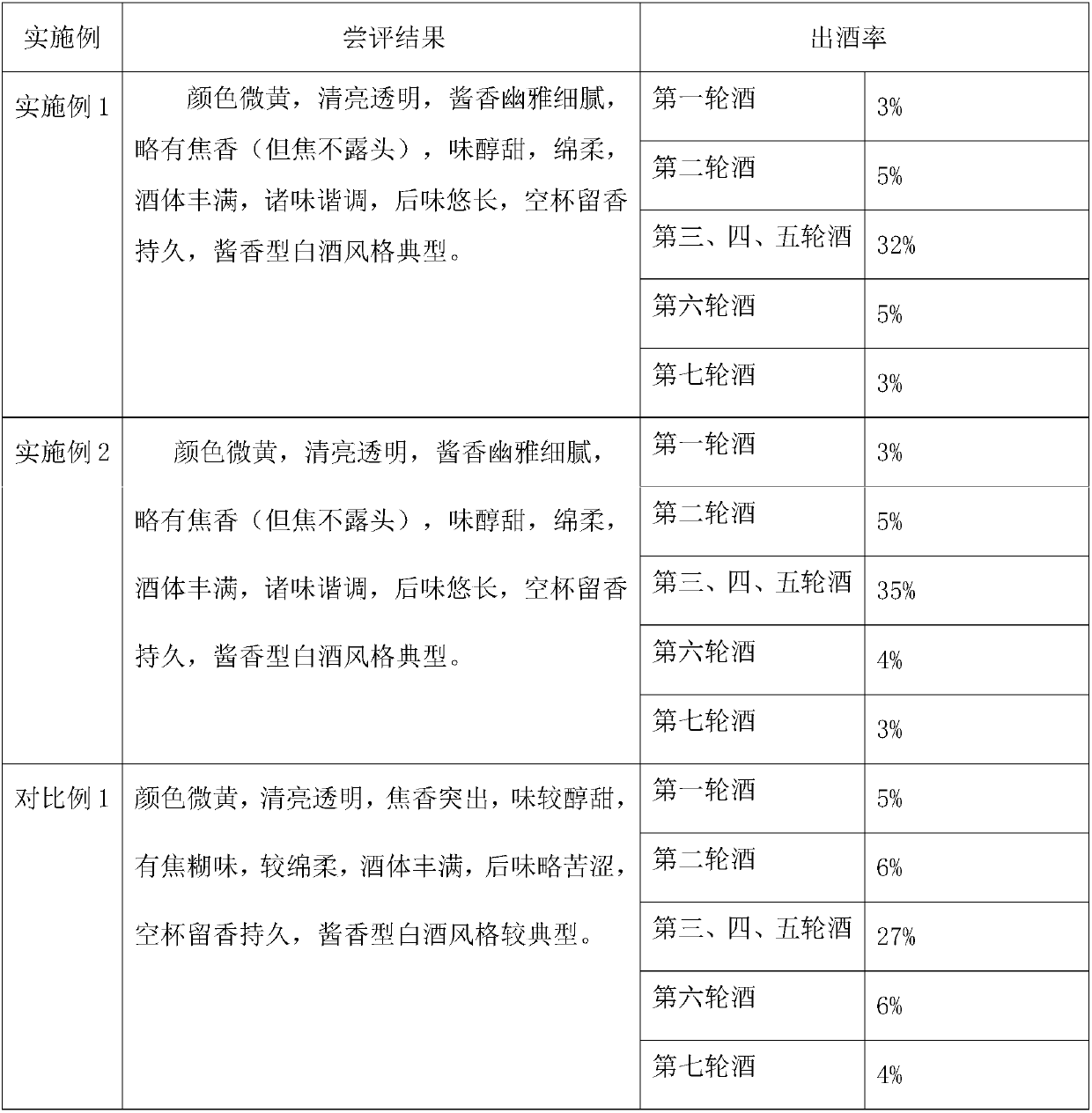

Production method of soy sauce flavor type wine

The invention discloses a production method of soy sauce flavor type wine. The production method comprises the steps of preparing grains, soaking the grains, steaming the grains, accumulating and fermenting, feeding into a tank for fermenting, and distilling to get the wine. After a yeast is added into middle-layer fermented grains obtained after distilling to get the wine for the second time andthe third time, accumulating and fermenting as well as feeding into the tank for fermenting are cyclically carried out for two times, the next round of distilling is carried out, and a scorch aroma taste of the soy sauce flavor type wine is improved, so that the overall quality of the wine is improved. Before the sauce wine is fermented in a fermentation pit for the seventh time, an enhanced yeastis added in an accumulating process and then enters the fermentation pit so as to be fermented, and compared with traditional sauce wine, the liquor yield of the seven-time wine is improved, and thescorch aroma taste is better, so that the overall scorch aroma quality of the wine is improved.

Owner:湖南武陵酒有限公司

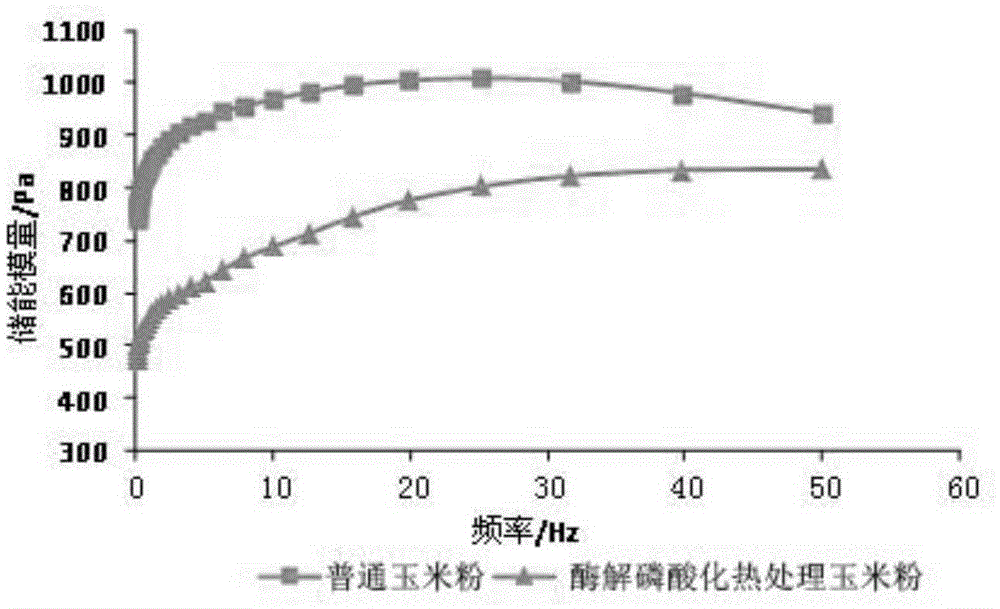

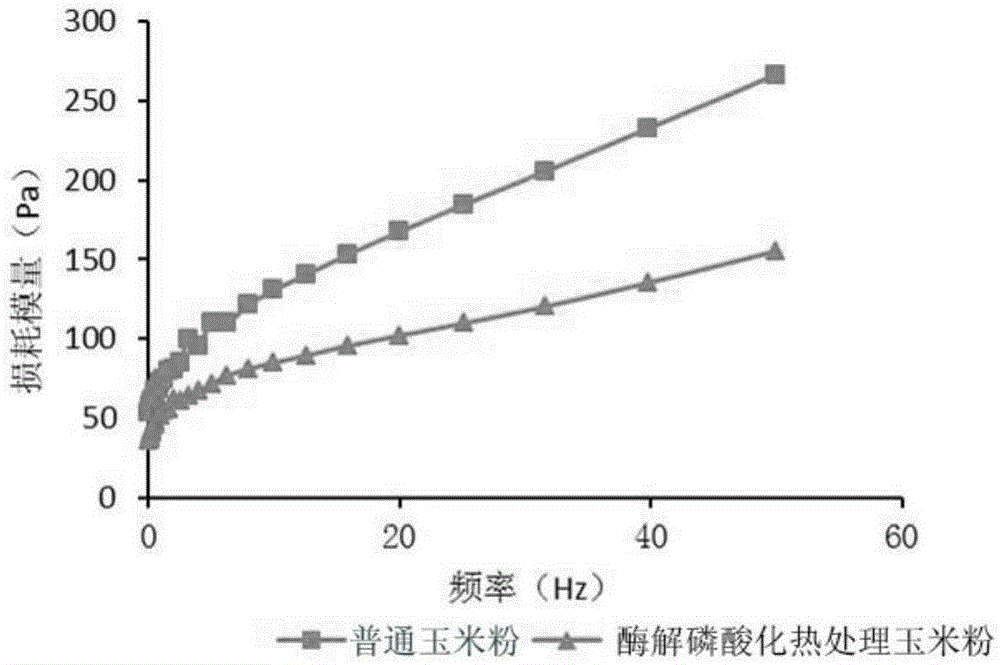

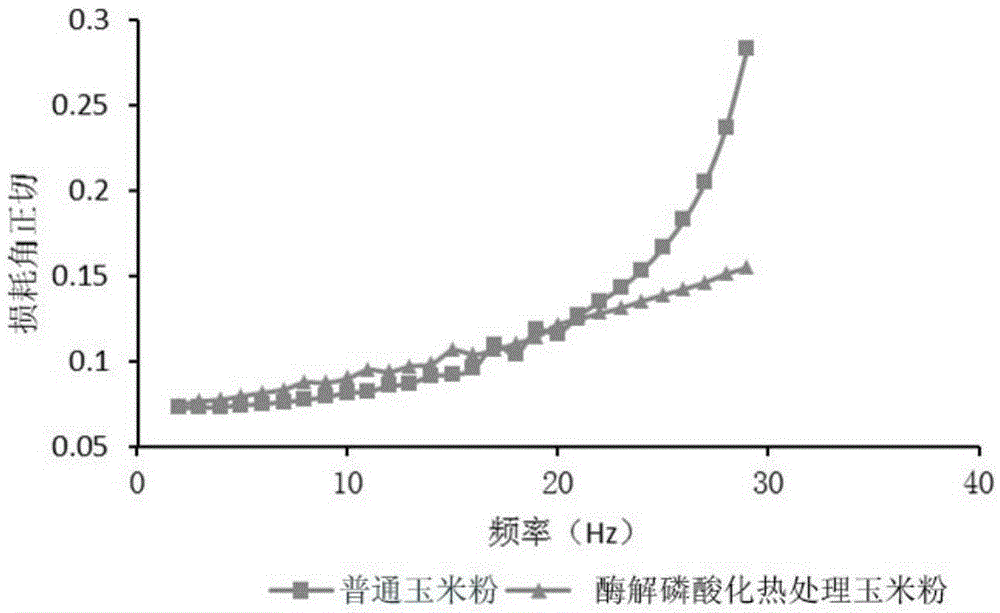

Enzymolysis, phosphorylation and heat treatment method for corn flour

PendingCN105410632AAmino acid content is not reducedRetain nutritional valueFood scienceNeutral proteasePhosphate

The present invention relates to an enzymolysis, phosphorylation and heat treatment method for corn flour. The selected corn flour is fully mixed with water to form a paste-like viscous fluid, neutral protease is added into the paste-like viscous fluid for enzymolysis, then the mixture is heated to inactivate the enzyme, and enzyme inactivated liquid mixture is frozen, dried and pulverized to obtain the enzymatic corn flour. Phosphate esterification reagents are fully and evenly mixed with the enzymatic corn flour, and the mixture is sealed, dried and then placed in a drying oven for heating reaction. The neutral protease and phosphate esterification reagents are used to conduct enzymolysis and chemical modification on the corn flour, lifting the binding of protein to starch granules for degrading the protein into small molecules and releasing organic nutrient substances (starch, polysaccharides, peptides, etc.); wherein the amino acid content remains unchanged to retain the nutritional value, shortcomings of the corn flour, such as poor viscoelasticity, flexibility, etc., are improved since the corn flour itself contains no mucedin. The finished products are exquisite and smooth in taste, relatively suitable for traditional corn food processing.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

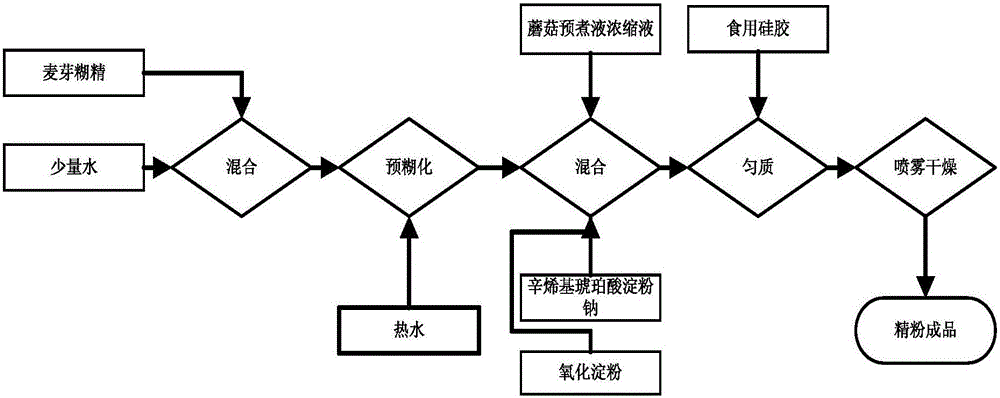

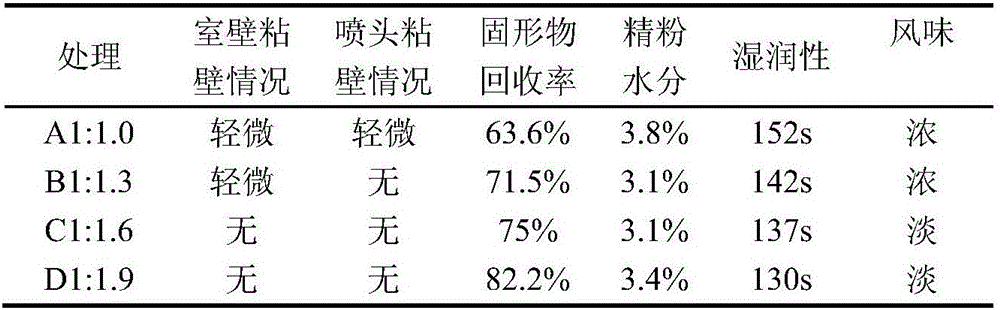

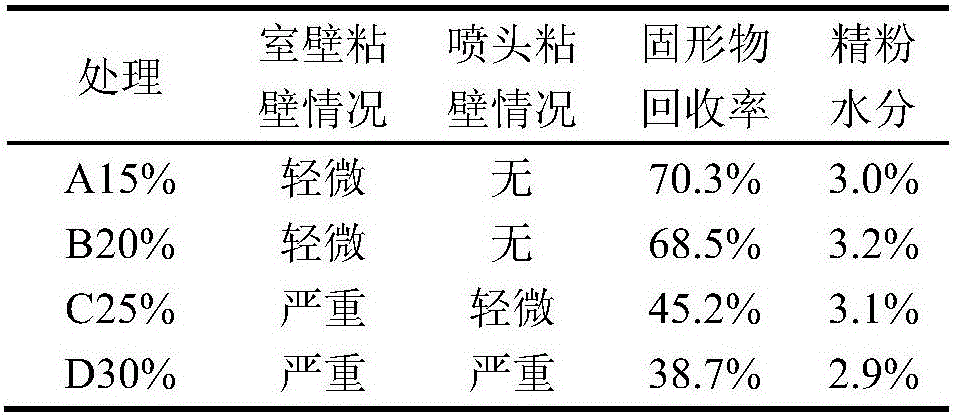

Mushroom powder using agaricus bisporus pre-cooking liquid as raw material and preparation method thereof

InactiveCN106072488AGelatinization is easyLow gelatinization temperatureFood ingredient as anti-caking agentFood shapingFlavorTotal solid content

The present invention discloses mushroom powder using agaricus bisporus pre-cooking liquid as a raw material and a preparation method thereof. The mushroom powder is prepared from the agaricus bisporus pre-cooking liquid, a drying aid and an anti-caking agent, and prepared by a spray drying. A mass ratio of a solid content of the agaricus bisporus pre-cooking liquid to the drying aid is 1:(1-1.6) and the mass of the anti-caking agent is 1-2% of the total solid content mass of the agaricus bisporus pre-cooking liquid and the drying aid. The drying aid consists of the following components in parts by weight: 50-60 parts of maltodextrins, 30-35 parts of oxidized starch and 5-10 parts of sodium starch octenylsuccinate. The product is mellow in the mushroom flavor, the content of crude protein contents is about 16.49%, the total amino acid content is about 11.39%, and the mushroom powder can be used as a very good seasoning product and health-care food raw material. The preparation method improves the utilization value of the agaricus bisporus pre-cooking liquid and greatly reduces the pressures of the enterprise storage and environmental protection.

Owner:INST OF EDIBLE FUNGI FUJIAN ACAD OF AGRI SCI

Textile size applicable to high-count cotton fabrics

The invention relates to a textile size applicable to high-count cotton fabrics. The textile size comprises the following components in mass ratio: 80 parts of nano silicon dioxide modified starch, 10 parts of protein size, 8 parts of polyacrylate emulsion, 2 parts of modified silicone oil defoaming agent, 5 parts of argine monohydrochloride, 2 parts of sodium sulfamate and 2 part of polyacrylate. The size has favorable film forming property and permeability, is particularly applicable to the sizing of the high-count cotton fabrics and is more environment-friendly as the formula does not contain polyvinyl alcohol.

Owner:SUZHOU RUNHONG TRADING

Ruminant feed and preparation method of ruminant feed

ActiveCN104642813AImprove digestibilityPromote digestionAnimal feeding stuffPolygonum fagopyrumBiotechnology

The invention discloses a ruminant feed and a preparation method of the ruminant feed. The ruminant feed comprises the following materials in parts by weight: 70-120 parts of needle mushroom roots, 10-20 parts of bran, 5-10 parts of rice bran, 5-20 parts of bean meal, 5-20 parts of coarse cereal, 5-15 parts of herb of dandelion, 3-7 parts of sow thistle, 3-8 parts of nano montmorillonite and 1-5 parts of a microbial preparation, wherein the microbial preparation comprises streptococcus bovis, ruminobacter amylophilus, ruminococcus flavefaciens, and the coarse cereal is one or more of maize flour, black rice powder, tartary buckwheat, ormosia, mung beans and broad beans. The preparation method comprises the steps of mixing, fermenting, drying, pelleting, and the like. According to the ruminant feed and the preparation method, the needle mushroom roots serve as a principal raw material for preparing the ruminant feed, fermentation is sufficient, and a small number of streptococcus bovis, ruminobacter amylophilus and ruminococcus flavefaciens in a rumen of a ruminant are introduced to the stomach of the ruminant through the feed, so that the digestion rate and the feed intake are increased, and the fattening is realized.

Owner:如意情生物科技股份有限公司

Preparation method of low-pollution textile sizing agent

The invention relates to a preparation method of a low-pollution textile sizing agent. The method comprises the steps of mixing hydroxypropyl modified starch and silicon powder, then feeding the mixture into deionized water, and feeding sodium hydroxide and methyl alcohol into the mixed solution; carrying out hydrolysis, drying and purifying to obtain nanosilicon dioxide modified starch; feeding soyabean protein into sodium hydroxide solution, stirring at constant speed for 15 minutes at the temperature of 45 DEG C, and filtering out precipitate to obtain protein slurry; pouring the nanosilicon dioxide modified starch, the protein slurry, polyvinyl alcohol, polyacrylate emulsion and an organic silicon defoamer into a mixer, and mixing to obtain the low pollution textile sizing agent. The low-pollution textile sizing agent prepared by the method is good in film-forming property and permeability; furthermore, the content of the polyvinyl alcohol in the formulation is lower, so that the low-pollution textile sizing agent is lower in environmental pollution.

Owner:SUZHOU RUNHONG TRADING

Total mixed ration for fattening sheep and production process and application thereof

InactiveCN108935992AIncrease production capacityImprove digestibilityFood processingAnimal feeding stuffBiotechnologyHordeum vulgare

The invention discloses a total mixed ration for fattening sheep and a production process and application thereof. The total mixed ration comprises the following components in parts by weight: 260-340parts of corn, 50-70 parts of soybean meal, 35-45 parts of germ meal, 15-25 parts of wheat middlings, 10-30 parts of bran, 55-65 parts of barley roots, 40-60 parts of stevia, 90-150 parts of peanut seedlings and 45-55 parts of wheat bran, 35-45 parts of yeast and yeast culture, 130-180 parts of gunite corn bran, 75-85 parts of premix and 3-5 parts of soybean oil. The total mixed ration can: maintain the normal internal environment of the rumen, reduce the production of methane and maintain the maximization of effective micoorganisms in the rumen; improve the production performance of fattening sheep; improve the digestibility of the fattening sheep to nutrient substances and increase the utilization rate of effective nutrients; and improve the slaughter performance and meat quality of thefattening sheep, reduce the deposition of fat under the skin and viscera and improve the quality of mutton.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Purple sweet potato composition nutritional instant powder and preparation method

The invention belongs to the field of comprehensive utilization of byproducts and development of health-care foods. Purple sweet potato composition nutritional instant powder provided by the invention is prepared from raw materials in percentage by weight: 20%-30% of edible fungi and 70%-80% of purple sweet potato dreg; the purple sweet potato dreg is a byproduct generated in the production of a purple sweet potato pigment; the edible fungi are fresh artificially-planted or wild edible fungi; the purple sweet potato composition nutritional instant powder is ultrafine powder with the average grain diameter which is less than 0.25 microns. A preparation method is composed of following steps: 1, carrying out curing treatment on purple sweet potato dreg raw materials; 2, carrying out color-protecting treatment on the edible fungi; 3, drying; 4, compounding and roughly crushing; and 5, carrying out ultrafine crushing. The purple sweet potato composition nutritional instant powder is produced by combining and matching the purple sweet potato dreg generated by producing the pigment with the edible fungi, so that the aims of complementing the nutrition and strengthening functions are realized and the product has a special flavor; the comprehensive utilization value of the byproduct generated by generated in the production of the purple sweet potato pigment is improved. The purple sweet potato composition nutritional instant powder is produced by adopting an effective color-protecting measure and an ultrafine crushing technology; the product has a very good brewing instant property and keeps nutrition, functional components and flavor of two ingredients.

Owner:KUNMING MEDICAL UNIVERSITY

Processing method capable of reducing broken rice rate of rice

InactiveCN109590057AReduced adhesion strengthReduce adhesionGrain huskingGrain polishingSurface finishBroken rice

The invention discloses a processing method capable of reducing broken rice rate of rice. The processing method comprises steps of drying, impurity removal, husking, primary rice milling, wetting, drying, secondary rice milling, polishing, color sorting and classification. During polishing, sodium citrate solution is adopted as an additive for primary polishing treatment, then a sodium citrate andhydrogen peroxide mixed solution is used as an additive for secondary polishing treatment, so that starch on the surface of rice can be promoted to be gelatinized to form colloidal films, meanwhile,the starch layer structure on the surface of unpolished rice can be more compact, and the surface finish of the rice is higher.

Owner:湖南金泰米业有限公司

Fermented bean paste and making method thereof

InactiveCN106107546ARich sourcesThe process is simple and reliableFood ingredient as taste affecting agentFood ingredient as flavour affecting agentBiotechnologyVillosa choctawensis

The invention discloses a fermented bean paste and a making method thereof. The fermented bean paste is prepared from, by weight, 45-55 parts of small soybeans, 0.8-1.2 parts of peppers, 3.0-3.4 parts of salt, 7-8 parts of corn wine and 7-8 parts of ginger juice. Through the processes of raw material screening, grinding, soaking, steaming, fermenting, drying and the like, the fermented bean paste rich in fermented bean aroma, delicious, moderate in degree of saltiness, sweet in aftertaste without dregs and bright in color is made.

Owner:贞丰县马氏丰味食品有限责任公司

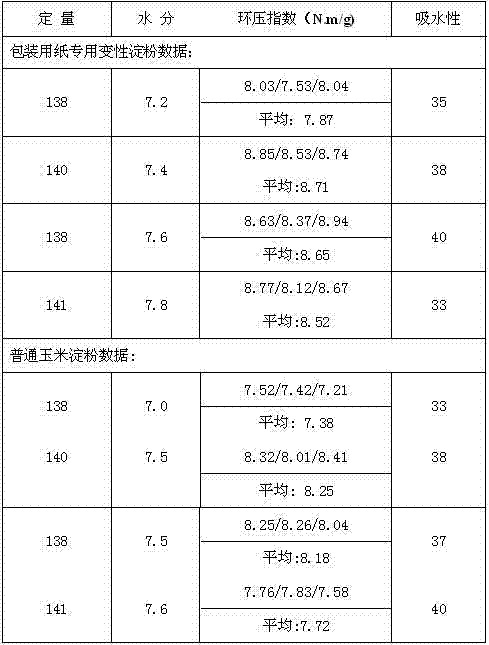

Special modified starch for wrapping paper and production method thereof

ActiveCN102731842AShorten the boil timeEasy to realize the industrialization of special modified starchBiotechnologySODIUM METAPHOSPHATE

The invention provides a special modified starch for wrapping paper and a production method thereof, belonging to the filed of deep processing of maize. The special modified starch is prepared from the following components: in a volume mass ratio, 2250 m<3> to 2750 m<3> of maize starch milk 21Be' ( equivalent to 900 to 1100 Kg of a dry basis), 18 to 22 Kg of sodium tripolyphosphate, 4.5 to 5.5 Kg of sodium trimetaphosphate, 10.8 to 13.2 Kg of urea, 4.5 to 5.5 Kg of sodium hydroxide and 36 to 44 Kg of sodium carbonate. The special modified starch for wrapping paper provided in the invention has the following advantages: the special modified starch is easy to gelatinize and has a low gelatinization temperature and a short gelatinization time; gelatinized liquid has good fluidity, transparency, film forming ability and film strength; and the special modified starch has excellent bonding performance with a variety of fibers and good compatibility with other auxiliary agents.

Owner:JILIN COFCO BIOCHEM

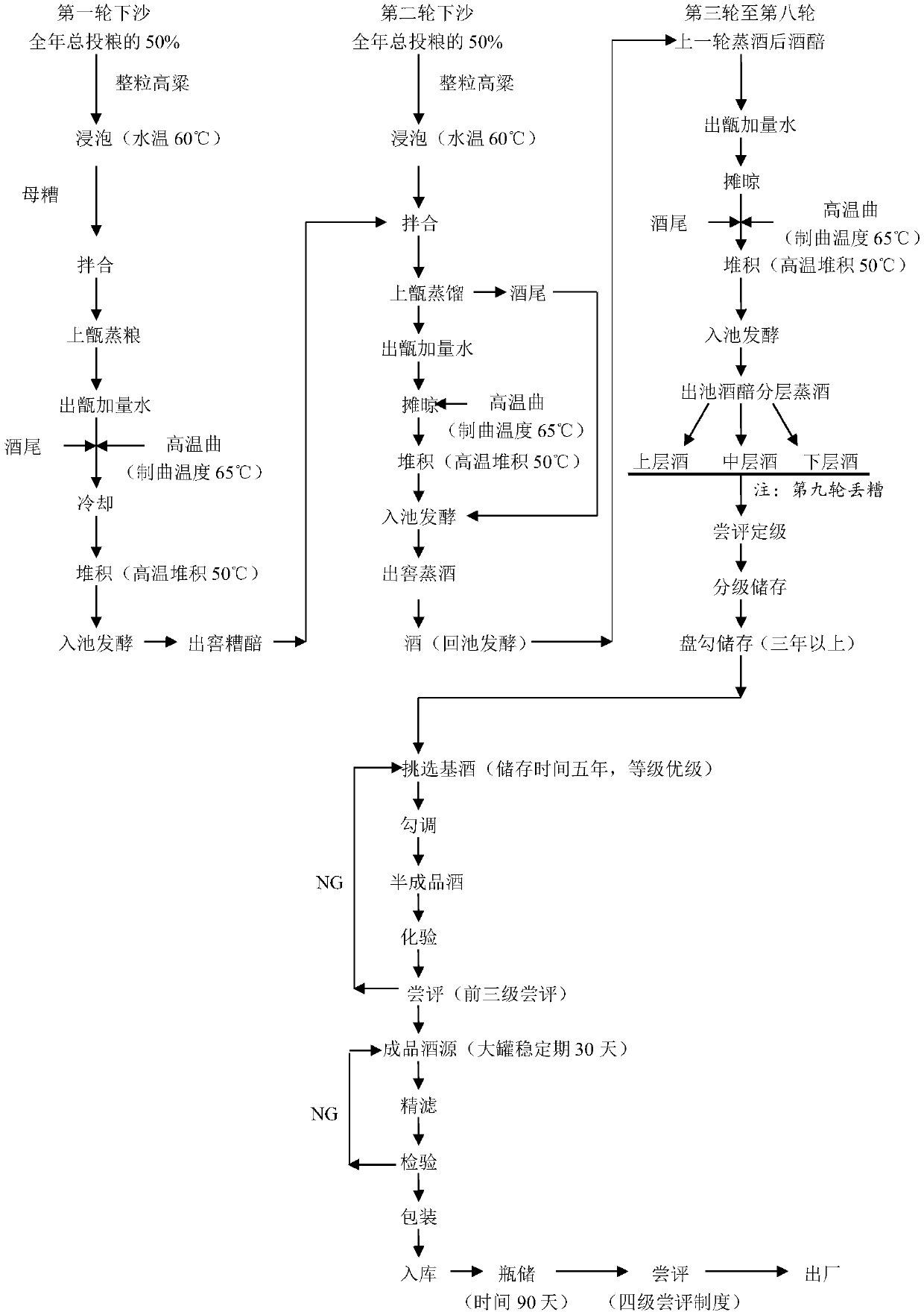

Soy sauce flavor type Chinese spirit preparation method

PendingCN108034543ARemove Lao ChenDissolution rate controlAlcoholic beverage preparationMicroorganismAdditive ingredient

The invention discloses a soy sauce flavor type Chinese spirit preparation method which sequentially comprises grain preparation, a first raw material feeding work procedure, a second raw material feeding work procedure, a distilling and Chinese spirit taking work procedure and a storing work procedure. According to the soy sauce flavor type Chinese spirit preparation method disclosed by the invention, a starter making temperature is 65 DEG C, and a highest stacking temperature is 50 DEG C; under the temperatures, the situations that reaction cannot perform successfully under a low temperatureand generated flavor components and pigment matter are less are avoided, and microorganism activity reduction caused by continuously warming is avoided. The prepared soy sauce flavor type Chinese spirit has scorch aroma, but the scorch aroma is not very obvious; in the first raw material feeding work procedure and the second raw material feeding work procedure, the starter use amount is reduced,production cost is reduced, charring and bitterness of traditional soy sauce flavor type Chinese spirit are avoided, and quality of a Chinese spirit body is improved. Storage time of base Chinese spirit utilized by the maotai-flavor Chinese spirit preparation method disclosed by the invention is 5 years or more, so that harmful ingredients can be volatilized continuously, Chinese spirit molecularassociation is stabler to form macromolecule groups, taste is more mellow and softer, and color of the Chinese spirit body is changed into light yellow from colorless.

Owner:湖南武陵酒有限公司

A preparation method of textile size suitable for high-count cotton fabrics

The invention relates to a preparation method of a textile size applicable to high-count cotton fabrics. The preparation method comprises the steps of: mixing hydroxypropyl modified starch with silicon powder, adding into deionized water, adding sodium hydroxide and methyl alcohol, and carrying out drying and purification after hydrolysis to obtain nano silicon dioxide modified starch; adding soybean protein in sodium hydroxide solution, stirring at a constant speed at 40 DEG C for 15 minutes, and filtering out the precipitates to obtain protein size; pouring the nano silicon dioxide modified starch, the protein size, polyacrylate emulsion and modified silicon oil defoaming agent in a stirrer for stirring and mixing to obtain the textile size applicable to high-count cotton fabrics. The size prepared by the method has favorable film forming property and permeability, is particularly applicable to the sizing of high-count cotton fabrics as the sizing property is excellent, and is more environment-friendly as the formula does not contain polyvinyl alcohol.

Owner:SUZHOU RUNHONG TRADING

Method for preparing high-substitution-degree acetylated starch by coupling electric field with ultrasound waves

The invention discloses a method for preparing high-substitution-degree acetylated starch by coupling an electric field with ultrasound waves. The method comprises the following steps: with various starches as raw materials, preparing starch milk with a certain concentration from the starches by using distilled water, carrying out treatment with an electric field and ultrasound waves, then puttinga sample in a water bath kettle for magnetic stirring, adding acetic anhydride, maintaining the pH value of a reaction system by uisng a NaOH solution, conducting an acetylation reaction, and successively performing drying, smashing and sieving to obtain solid powder, namely the high-substitution-degree acetylated starch. According to the invention, rearrangement of starch molecules is promoted through the cavitation effect of the ultrasound waves, and combination of acetyl and starch molecules is promoted through the coupling effect of the electric field and the ultrasound waves. The preparation process of the high-substitution-degree acetylated starch is safe and short in consumed time, a particle structure is reserved, elution is easy, the obtained starch is good in ageing resistance,and the gelatinization temperature of the starch is reduced. The high-substitution-degree acetylated starch can be used for preparing a disintegrating agent, an adhesive and a filter membrane.

Owner:SOUTH CHINA UNIV OF TECH

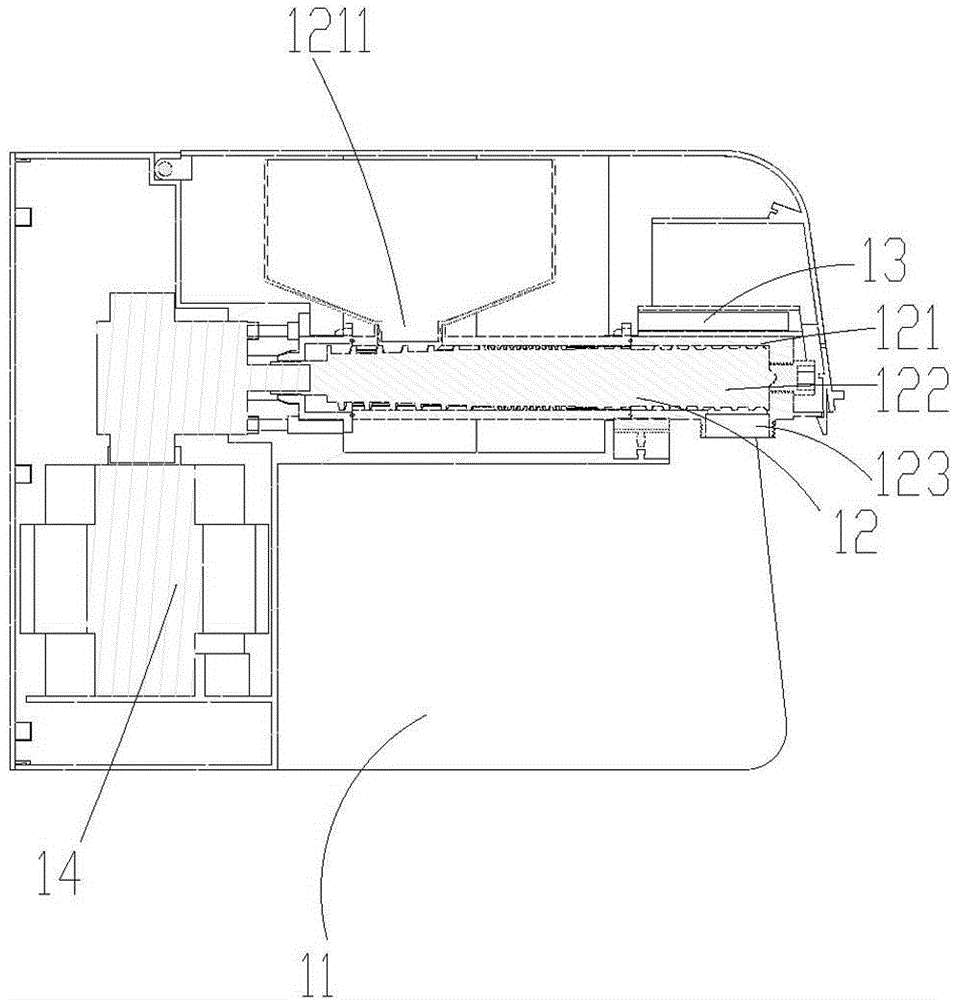

Household rice noodle machine

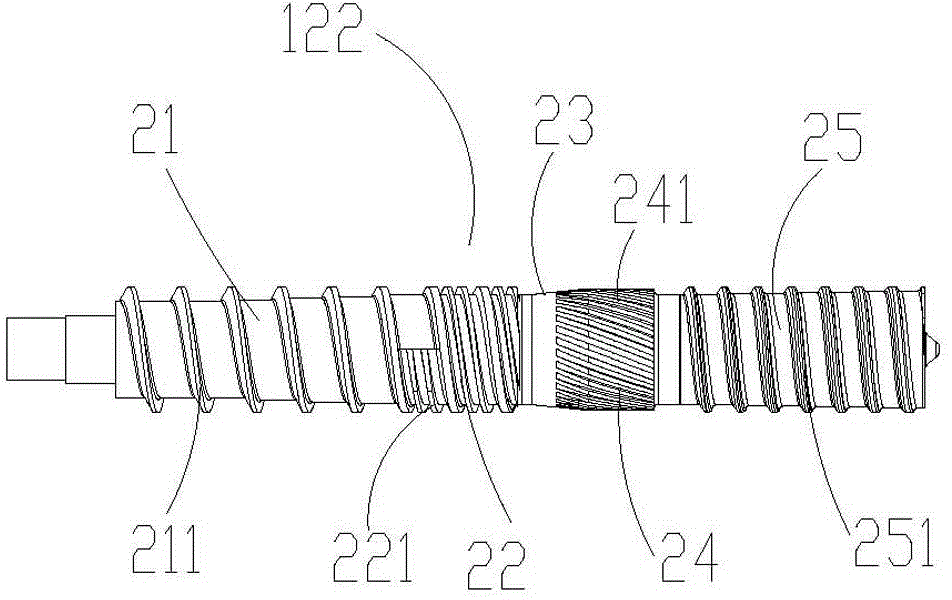

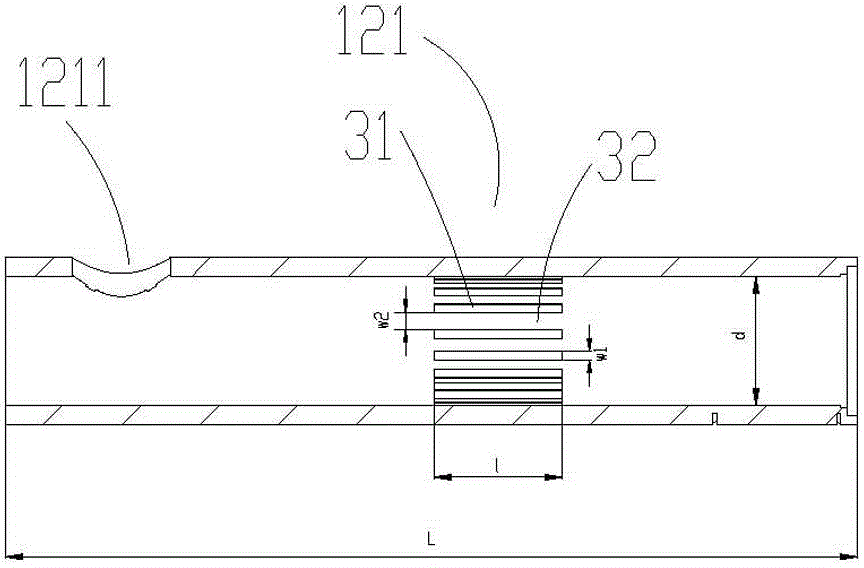

ActiveCN104642865APoor feedingImprove water absorptionFood shapingFood preparationEngineeringRice flour

The invention relates to a household rice noodle machine which comprises a base, a crushing, extruding and forming system, a heating device and a driving system, wherein the crushing, extruding and forming system comprises an extruding and grinding cavity, a screw rod and a forming die head; the heating device is used for heating the extruding and grinding cavity; a feed inlet is formed in one end of the extruding and grinding cavity while the forming die head is formed at the other end of the extruding and grinding cavity; the screw rod is located in the extruding and grinding cavity, and is sequentially provided with a material propelling section, a coarse crushing section, a fine crushing and grinding section and an extruding section along the direction from the feed inlet to the forming die head; the screw rod is integrally formed; grinding helical teeth are uniformly distributed in the circumferential direction of the fine crushing and grinding section; grinding straight teeth corresponding to the grinding helical teeth are formed in the extruding and grinding cavity; the grinding straight teeth are uniformly distributed on the inner surface of the extruding and grinding cavity; a grinding slot is formed between every two adjacent grinding straight teeth; and a grinding gap h1 is formed between each grinding straight tooth and the grinding helical tooth. The household rice noodle machine provided by the invention is provided with the screw rod and the extruding and grinding cavity which is matched with the screw rod, and rice noodles which are relatively good in taste and appearance are prepared.

Owner:JOYOUNG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com