Method for preparing high-substitution-degree acetylated starch by coupling electric field with ultrasound waves

A technology of electric field coupling and high substitution, which is applied in the field of starch compound modification and application, can solve the problems of affecting product performance, environmental pollution, and severe toxicity, and achieve the reduction of paste temperature, increase of economic and social value, and easy paste effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A method for preparing acetylated starch with high degree of substitution by electric field coupling ultrasound, comprising the steps of:

[0034] (1) Potato starch is configured into starch milk with a mass concentration of 30%;

[0035] (2) Put the starch milk in a 20kV electric field for 30 minutes, then ultrasonically treat it in a 660W ultrasonic water bath for 30 minutes, and control the ultrasonic temperature at 30°C;

[0036] (3) Place the treated starch milk in a water bath at 30°C with magnetic stirring (300rpm) for 5min, add acetic anhydride with 12% starch mass dropwise, and maintain the pH of the reaction system with 4% (w / w) NaOH solution The value is between 8.0 and 8.5, and the process needs to be completed within 0.5h. Continue to maintain the pH at 8.0 to 8.5 and stir for 1 hour;

[0037] (4) After the reaction was completed, the pH was adjusted to 6.5 with 10 wt% hydrochloric acid, washed 3 times with distilled water, and the reaction product was pl...

Embodiment 2

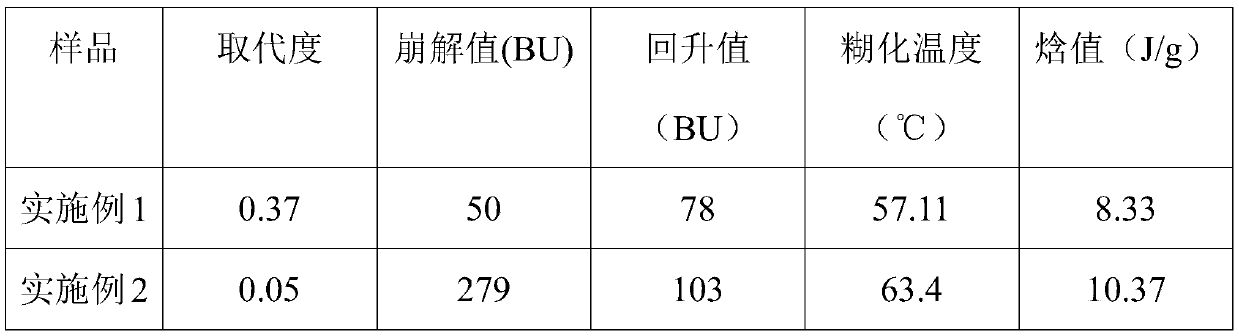

[0039] Compared with the potato acetate starch of Example 1, the processing method of Example 2 is the same as that of Example 1 except that it does not undergo electric field and ultrasonic pretreatment, and the potato acetate starch substitution degree and disintegration prepared by Example 1 and Example 2 Value, recovery value, gelatinization temperature and enthalpy value determination result are as follows table 1:

[0040] Determination of the degree of substitution, adhesiveness and thermal properties of acetylated starch with high degree of substitution: use titration method to determine the degree of substitution of acetylated starch; use distilled water to make starch milk with a mass fraction of 6%, and use Brabender (Micro Visco-Amylo-Graph) The gelatinization properties of starch were analyzed by an analyzer; starch and water were added into an aluminum pan at a ratio of 3:7 (w / w), and the thermal properties were analyzed by a differential calorimetry scanner (DSC-...

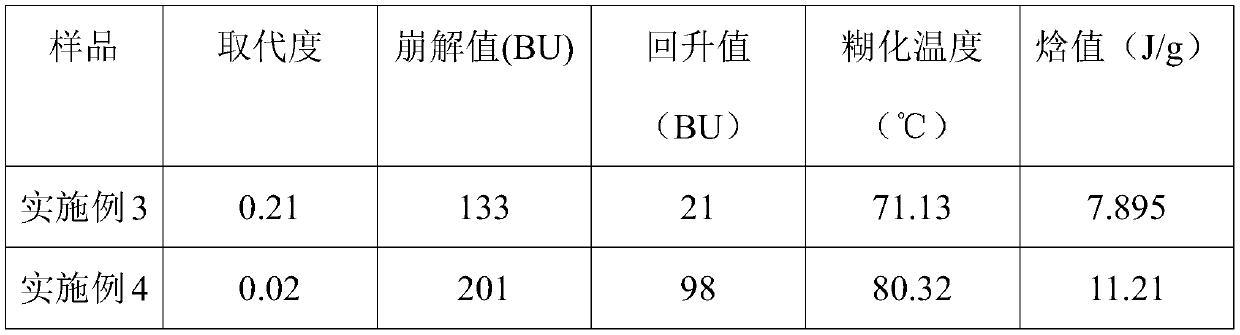

Embodiment 3

[0045] A method for preparing acetylated starch with high degree of substitution by electric field coupling ultrasound, comprising the steps of:

[0046](1) Waxy cornstarch is configured into starch milk with a concentration of 30%;

[0047] (2) Put the starch milk in an 800W ultrasonic water bath for ultrasonic treatment for 45 minutes, the ultrasonic temperature was controlled at 35°C, and then treated in a 30kV electric field for 45 minutes;

[0048] (3) Place the treated starch milk in a water bath at 30° C. for 5 minutes with magnetic stirring (300 rpm), add acetic anhydride with 10% starch quality dropwise, and maintain the reaction system with 4% (w / w) NaOH solution. The pH value is between 8.0 and 8.5, and the process needs to be completed within 0.5 hours. Continue to maintain the pH at 8.0 to 8.5 and stir for 1 hour;

[0049] (4) After the reaction was completed, the pH was adjusted to 6.5 with 10% hydrochloric acid, washed three times with distilled water, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com