Household rice noodle machine

A rice noodle machine, household technology, applied in application, food preparation, food forming and other directions, can solve the problems of small water absorption space, small matching space, unfavorable rice noodle forming, etc., to reduce power requirements, speed up feed speed, increase water absorption effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

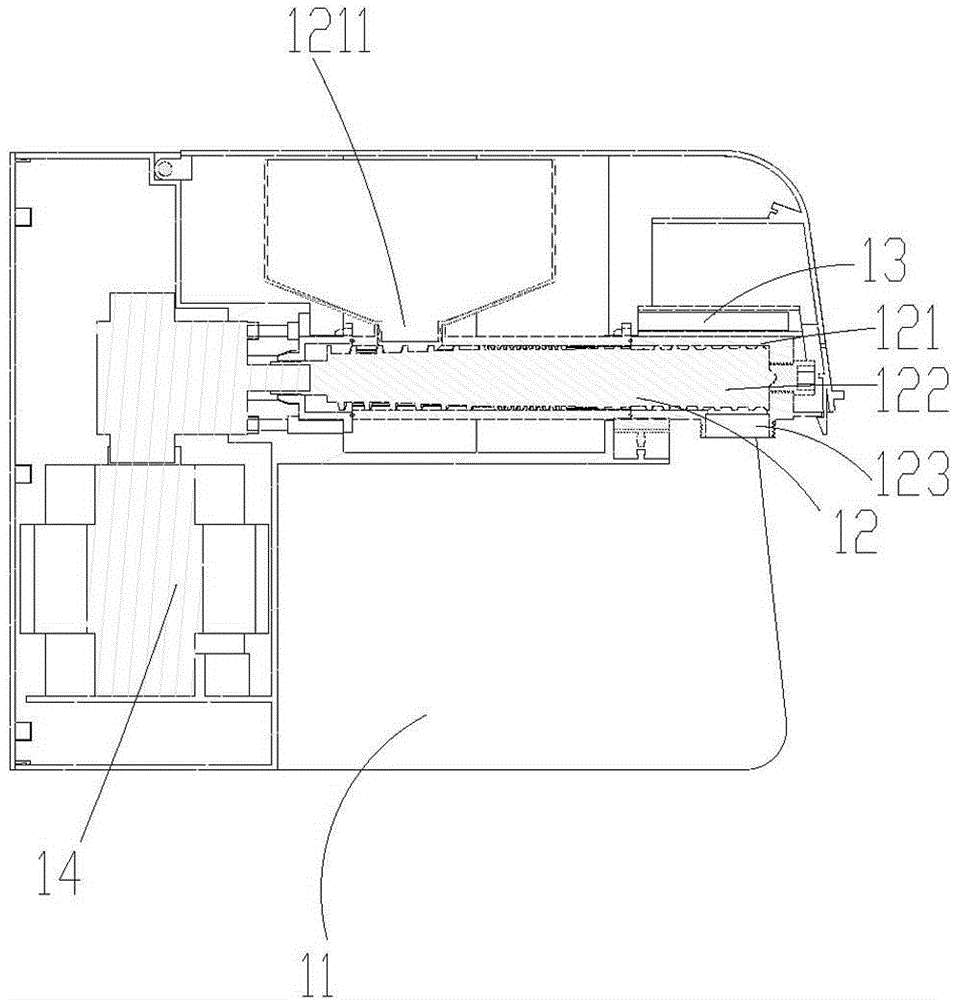

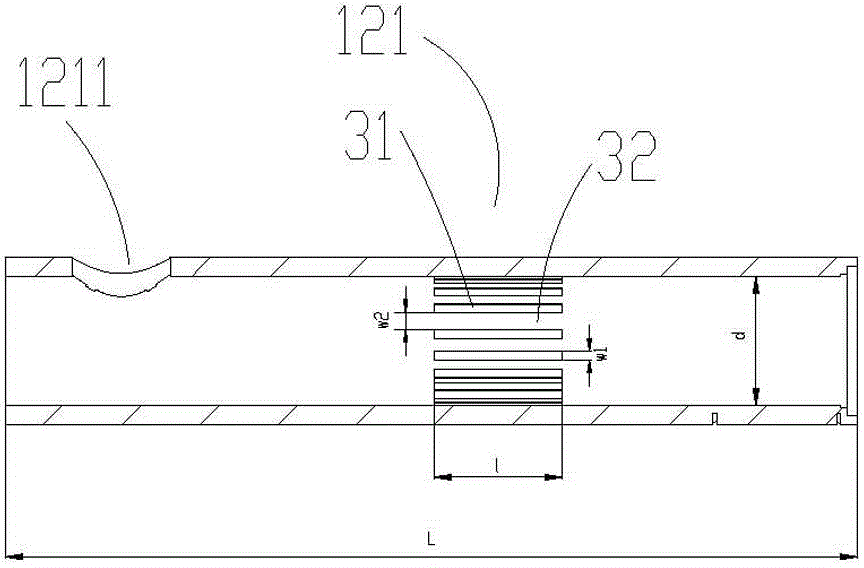

[0038] Such as Figure 1 to Figure 7 Described is the first embodiment of the present invention, a household rice noodle machine, including a machine base 11, a crushing extrusion molding system 12, a heating device 13, and a drive system 14, and the crushing extrusion molding system includes an extrusion grinding chamber 121, a screw 122 and a forming die 123, the heating device 13 heats the extrusion grinding chamber 121, one end of the extrusion grinding chamber 121 is provided with a feed port 1211, and the other end of the extrusion grinding chamber 121 is provided with a molding The die head 123 , the screw rod 122 is located in the extrusion grinding chamber 121 , and the screw rod 122 is connected with the driving system 14 .

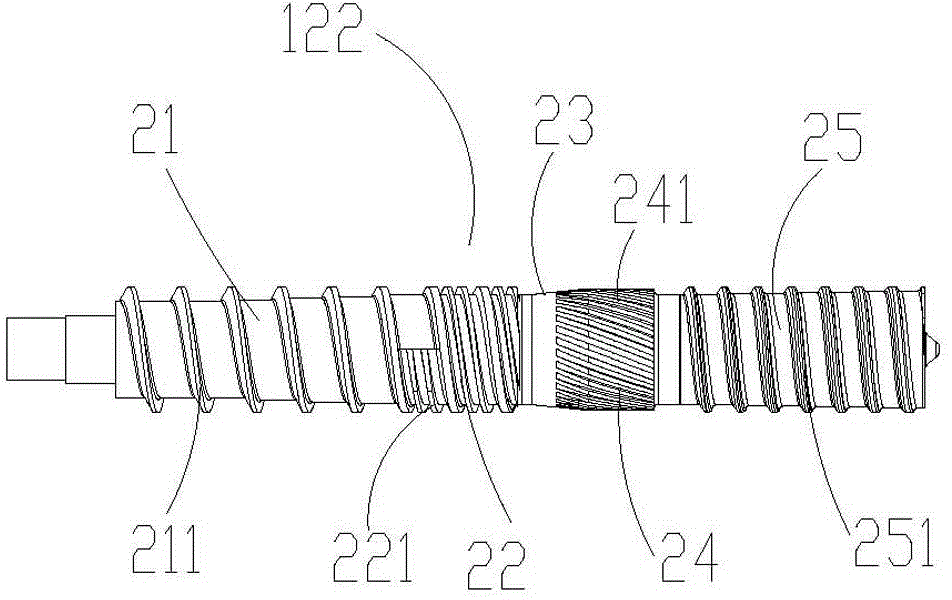

[0039] refer to Figure 1 to Figure 2 , the screw 122 is sequentially provided with a material propulsion section 21, a coarse crushing section 22, a grinding transition section 23, a fine crushing grinding section 24 and an extrusion section 2...

Embodiment approach

[0053] refer to Figure 10 It is the second embodiment of the present invention, and the difference from the above embodiment is that the extrusion grinding chamber 121 is also provided with an auxiliary pushing rib 41 corresponding to the material propulsion section 21, the coarse crushing section 22 and the extrusion section 25. The auxiliary pushing ribs 41 and the ground straight teeth 31 are parallel to each other, and a pushing rib groove 42 is formed between adjacent auxiliary pushing ribs 41 .

[0054] With the structure described in this example, the auxiliary pushing ribs 41 are set in the parts of the extrusion grinding chamber 121 corresponding to the material propulsion section 21, the coarse crushing section 22, and the extrusion section 25, which can act together with the screw rod 122 during the feeding process to speed up the process. The feeding speed of the rice raw material, meanwhile, between each auxiliary pushing rib 41 also forms the pushing rib groove ...

Embodiment approach 3

[0057] refer to Figure 11 It is the third embodiment of the present invention, and the difference from the above embodiment is that the heating device 13 includes a heating pipe 51 and a heat conducting material 52, the heat conducting material 52 is attached to the extrusion grinding chamber 121, and the heat conducting material 52 The corresponding extruding section 25 is set.

[0058] By adopting the structure described in this example, the heating device 13 can preheat or maintain the temperature required for making rice noodles, which is beneficial to the gelatinization of rice starch and makes the gel easy to form, so that the mixing of starches is uniform, which is more conducive to the molding of rice noodles, thereby To increase the output of rice noodles, the design of the heating tube 51 and the heat-conducting material 52 is convenient for disassembly between the heating device 13 and the extrusion grinding chamber 121, which is convenient for users to clean. In a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com