Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about How to "Facilitate unified collection and processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

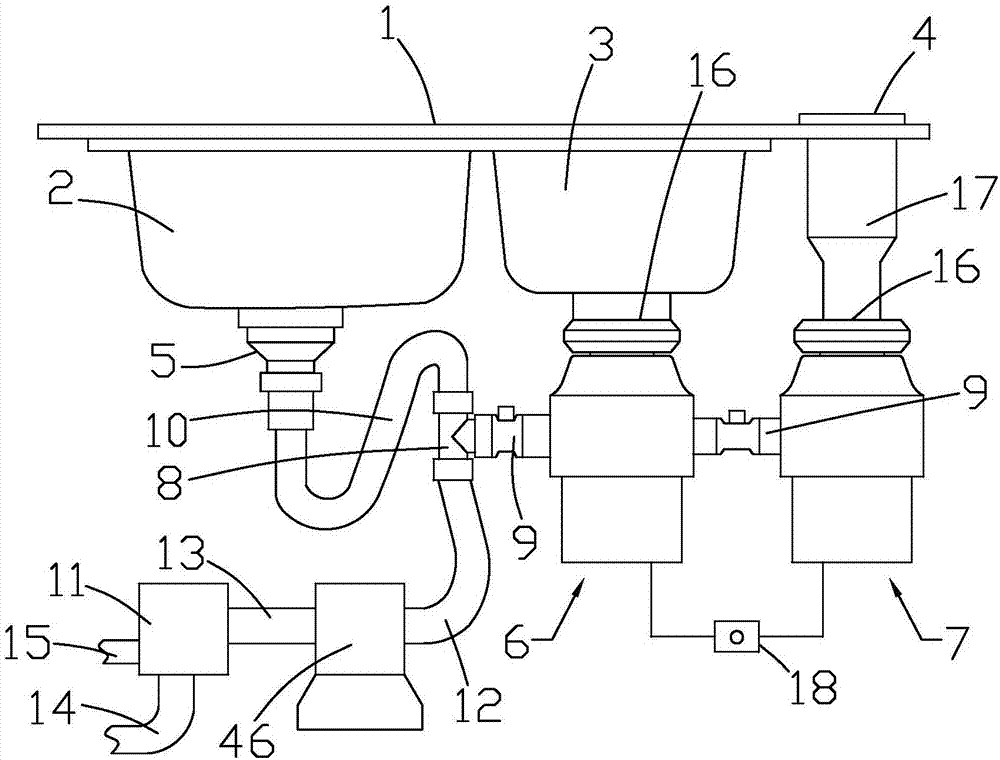

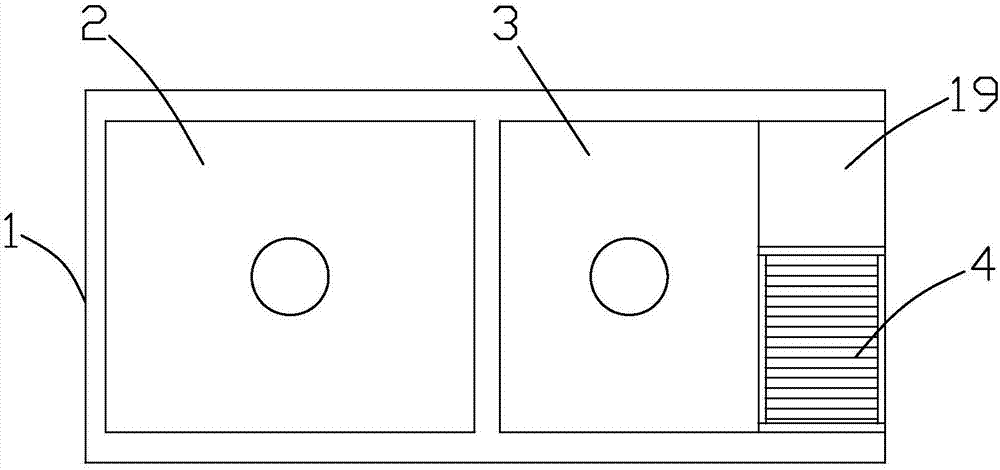

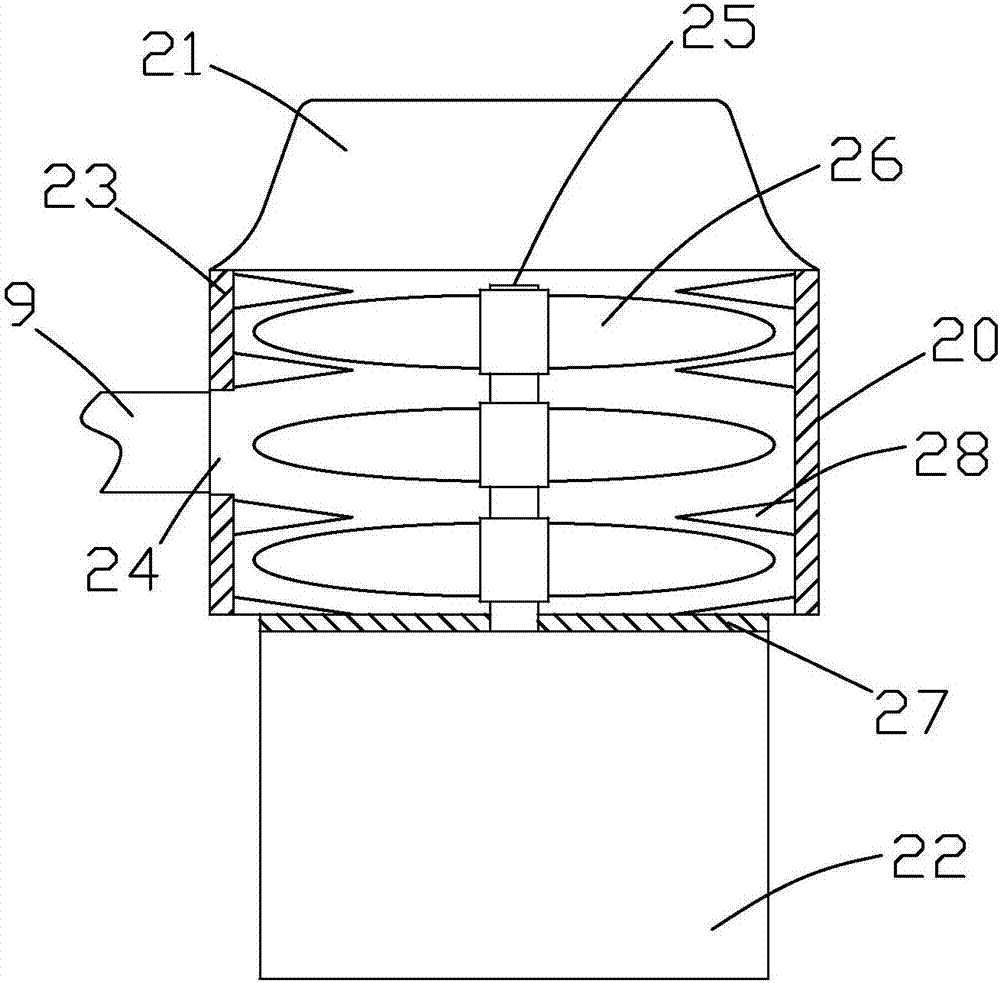

Domestic kitchen sewage treatment device

InactiveCN106968297AEasy dischargeReduce pollutionFatty/oily/floating substances removal devicesTreatment involving filtrationFiltrationOil water

The invention discloses a household kitchen sewage treatment device, which comprises an end cover on which a first water tank, a second water tank and a cutting board are arranged, and also includes a first crushing mechanism, a second crushing mechanism, a filtering device and an oil-water separation device. The first crushing mechanism is fixedly connected under the second water tank through a sealing cover, and a garbage storage tank is provided under the cutting board. A crushing mechanism, the first crushing mechanism is connected with a three-way pipe through a connecting pipe, the three-way pipe is respectively connected to the water interface and the filter device through the first water outlet pipe and the mixing pipe, and the filter device is connected to the oil-water separator through the conduction pipe. The invention has simple structure and strong practicability, not only can quickly realize the separation and filtration of sewage and residue, but also can separate oil pollution and sewage, prevent pipeline from being blocked, and reduce environmental pollution.

Owner:嵊州市卓普净水设备有限公司

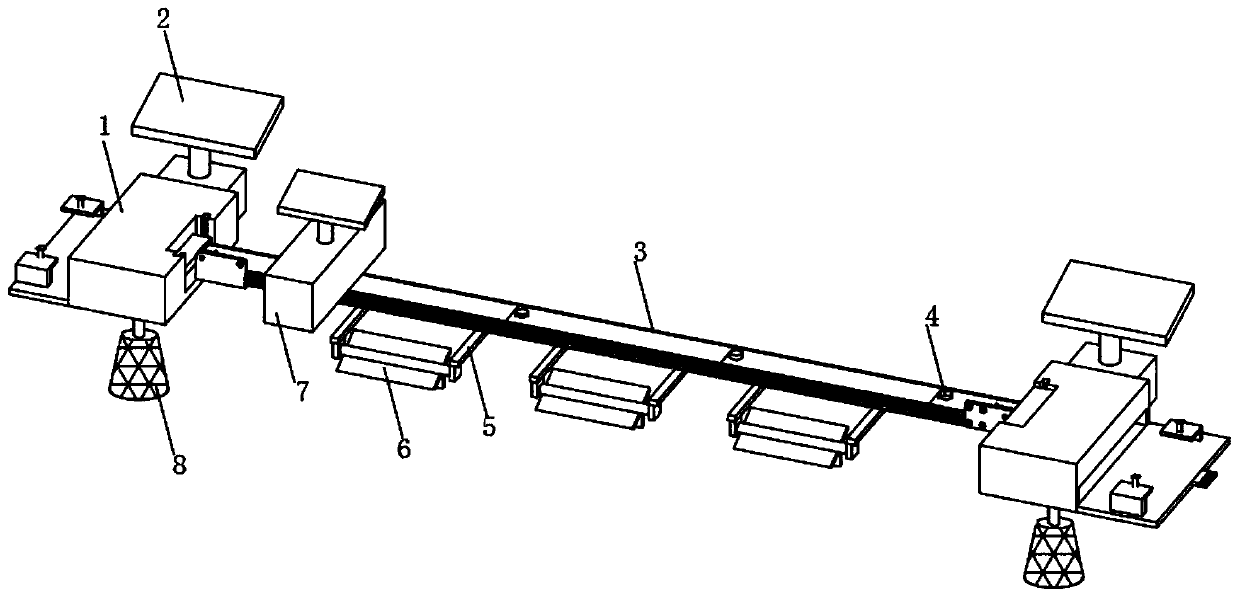

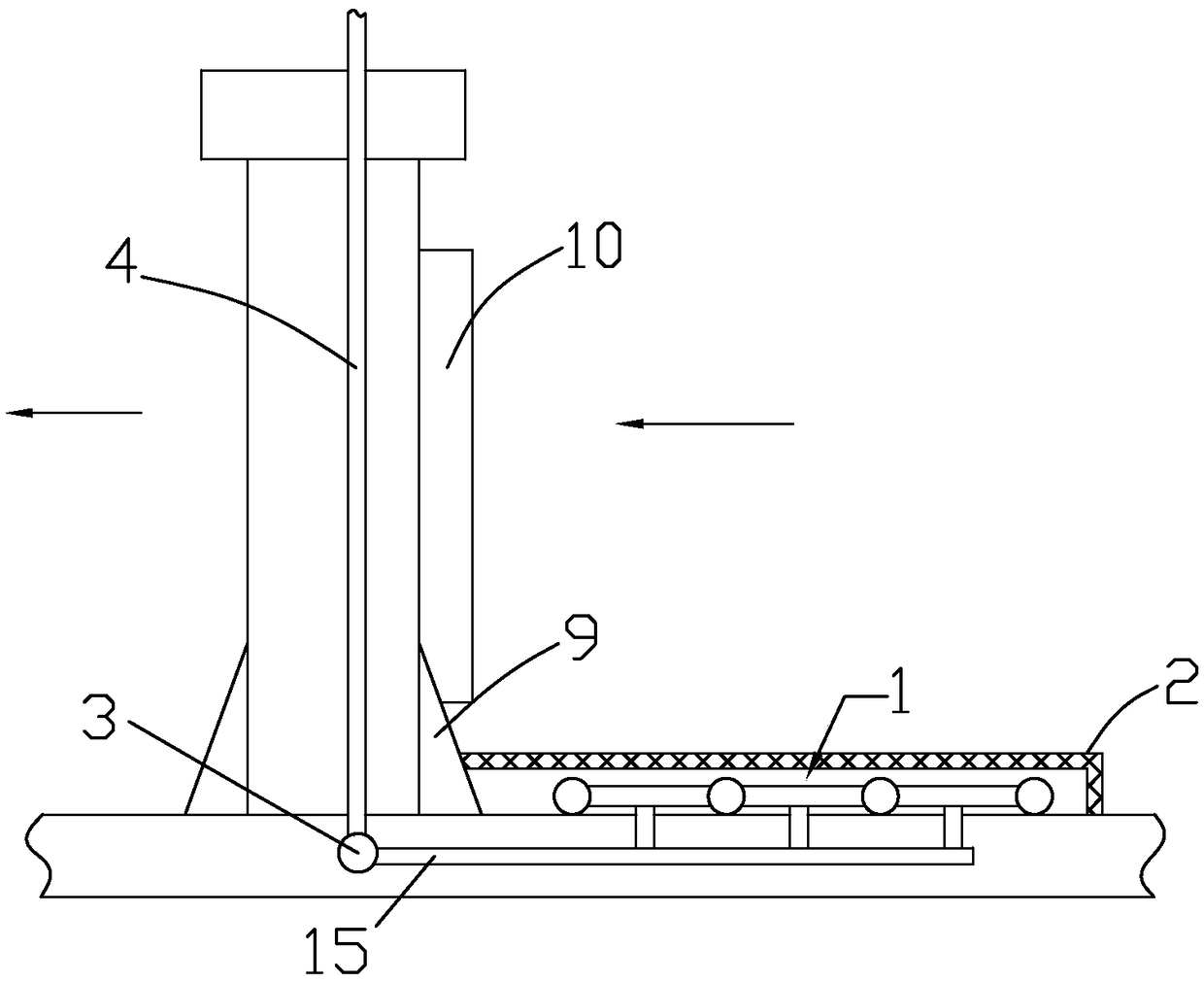

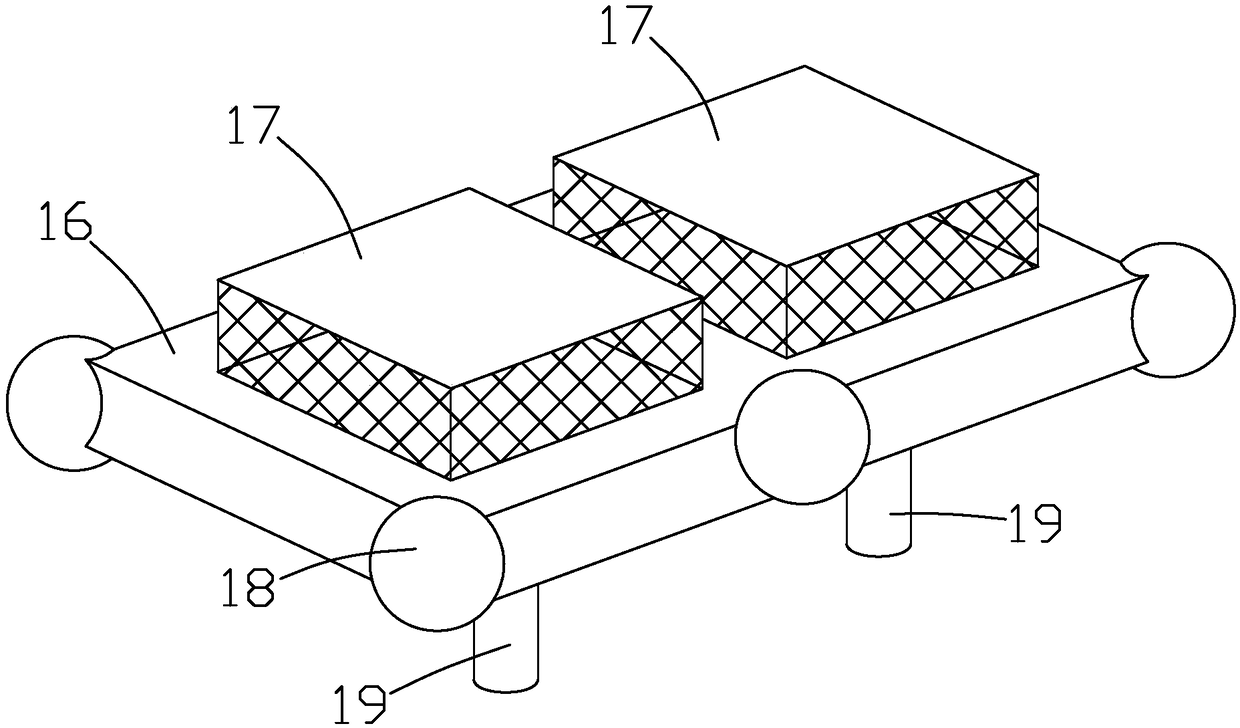

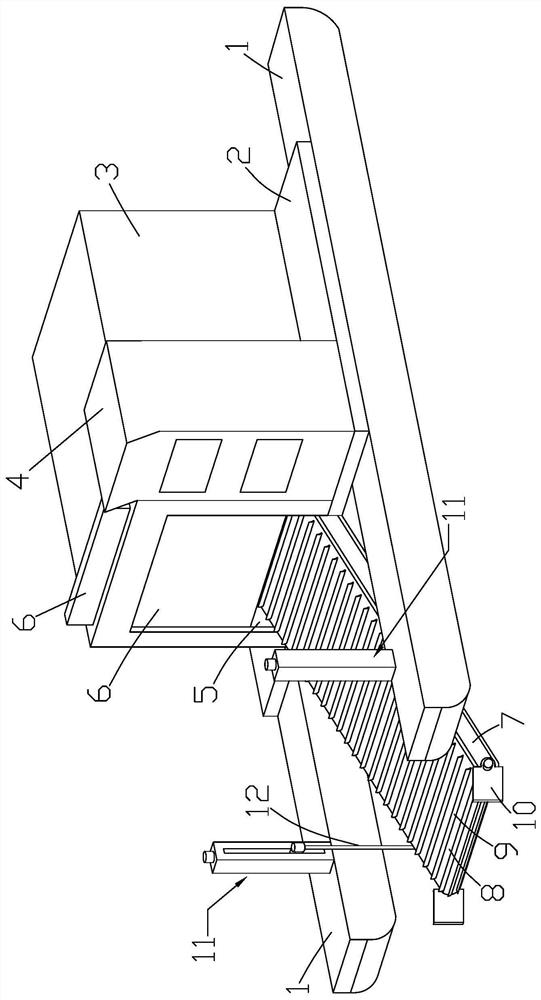

Garbage collection and processing equipment for lake and river channel treatment

The invention discloses a garbage collection and processing equipment for lake and river channel treatment. The garbage collection and processing equipment includes floating plates and cross beams, the two ends of the cross beams are both connected with the floating plates, the bottoms of the floating plates are connected with counterweight net barrels, and load-bearing floating plates are connected to the ends, far away from the cross beams, of the bottoms of the floating plates. When an impeller rotates, garbage in water is turned upwards, the garbage can be attached to the side faces of a net frame, and subsequent collection is facilitated. The garbage on the side face of the net frame can be scraped away by a net plate, the garbage can be treated in time, and meanwhile, the net frame can conduct normal filtering without being blocked. During rotation of the net plate, several cutting blades on the side face of the net plate cut and crush the garbage, the size of the garbage is reduced, transportation of the net plate and storage of a storage box are facilitated, and the occupied space is saved. The width of the river channel or the lake surface is too large, multiple interception devices can be installed according to the actual situation, the multiple cross beams can be used in cooperation to improve the garbage removing efficiency, and dead spots for cleaning are not proneto being left.

Owner:无锡恒诚水利工程建设有限公司

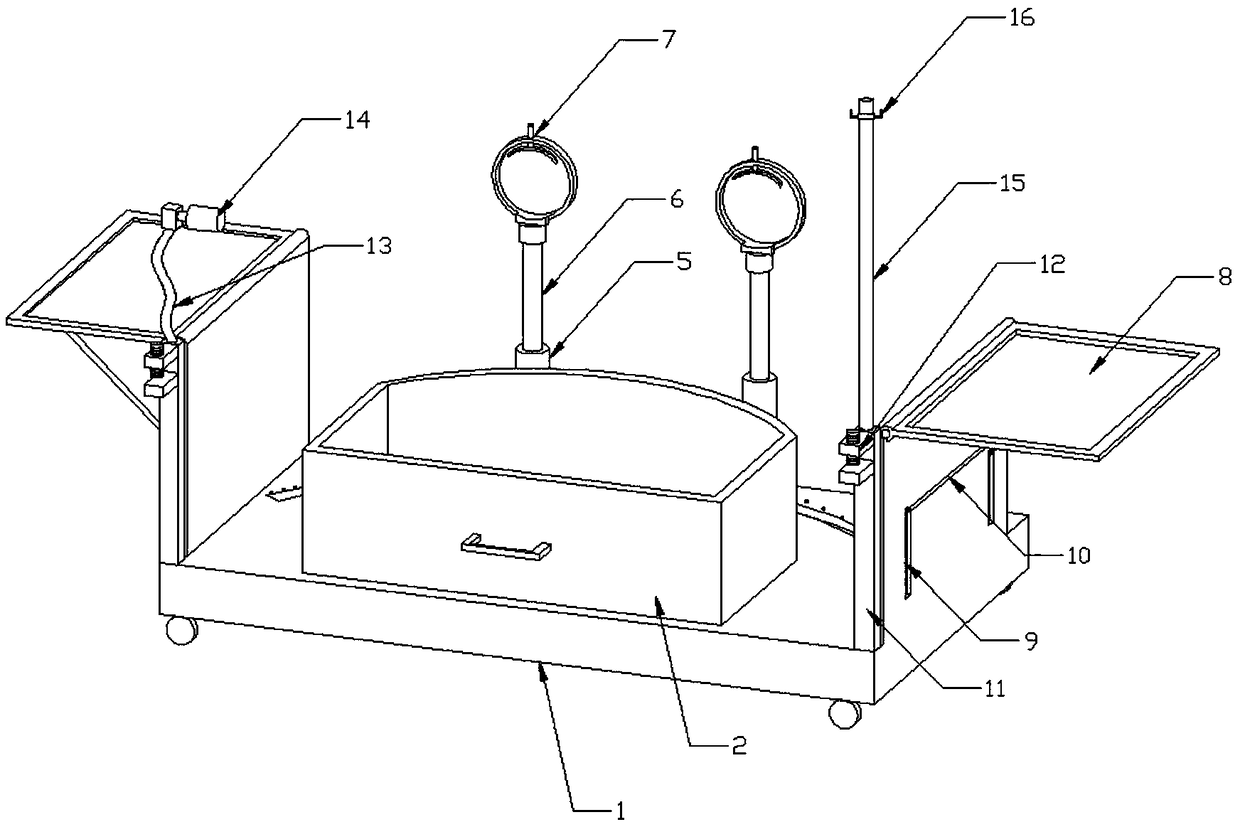

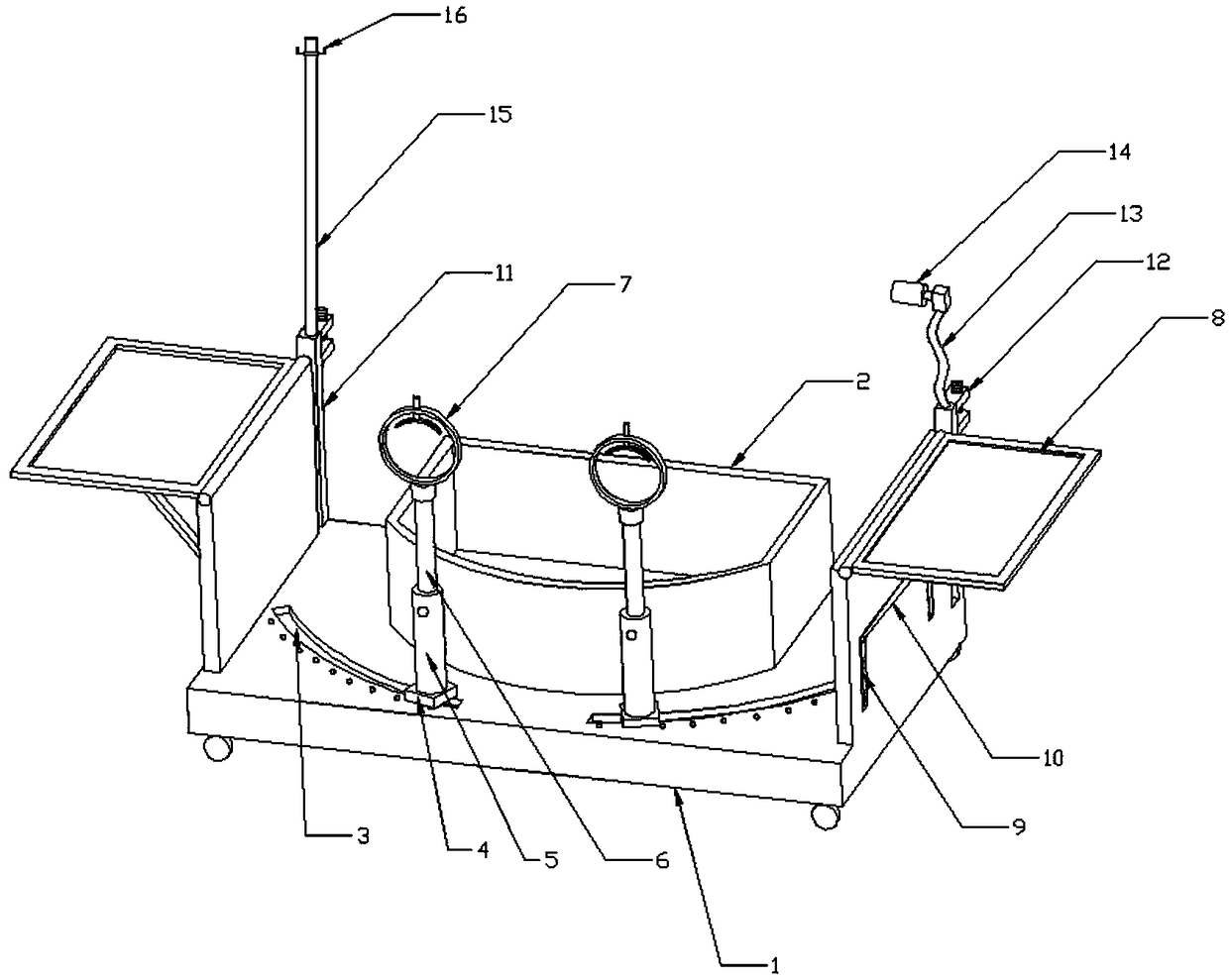

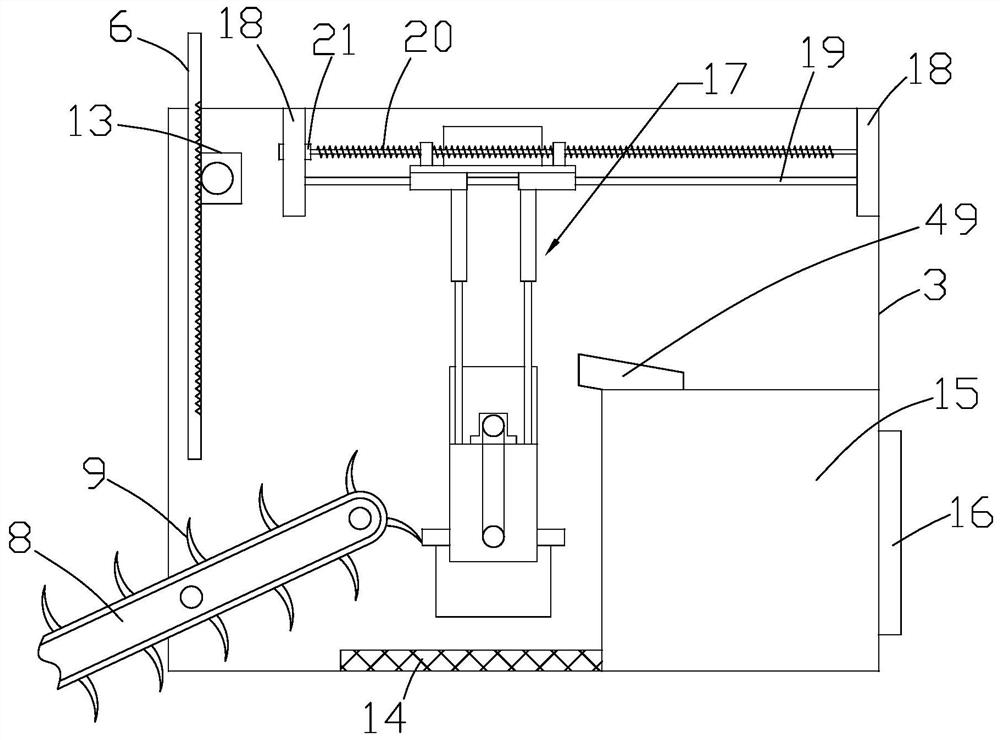

Auxiliary frame for gynecologic surgery

InactiveCN108703858AEasy accessEasy to adjustOperating tablesMedical transportSurgery procedureLED lamp

The invention discloses an auxiliary frame for gynecologic surgery. The auxiliary frame comprises a frame body, a waste box is arranged at the top of a bottom plate of the frame body, a first slidinggroove is formed in the top of the bottom plate of the frame body, a first slider is slidably connected on the first sliding groove, a sleeve is connected at the top of the first slider, a lifting rodis inserted into an inner cavity of the sleeve, a clamping ring is connected at the top of the lifting rod, a storage tray is hinged at the top of a vertical plate of the frame body, positioning columns are symmetrically connected at front ends of the left side and the right side of a bottom plate of the frame body, clamping plates are connected at the tops of the front side walls of the positioning columns, an LED (light-emitting diode) lamp is connected at the top of a gooseneck pipe, and a hook is connected at the top of an infusion rod. The auxiliary frame is reasonable in structure design, the storage tray is horizontal by the aid of a supporting rod, so that surgical instruments are conveniently stored and taken when a surgery is implemented, the height of legs of a patient is adjusted through the lifting rod and the clamping ring, the first slider slides in the first sliding groove, so that the angel between two legs of the patient is adjusted, a body of the patient is conveniently adjusted by a doctor, and swinging of the legs of the patient is prevented, so that the gynecologic surgery is facilitated.

Owner:张凤莲

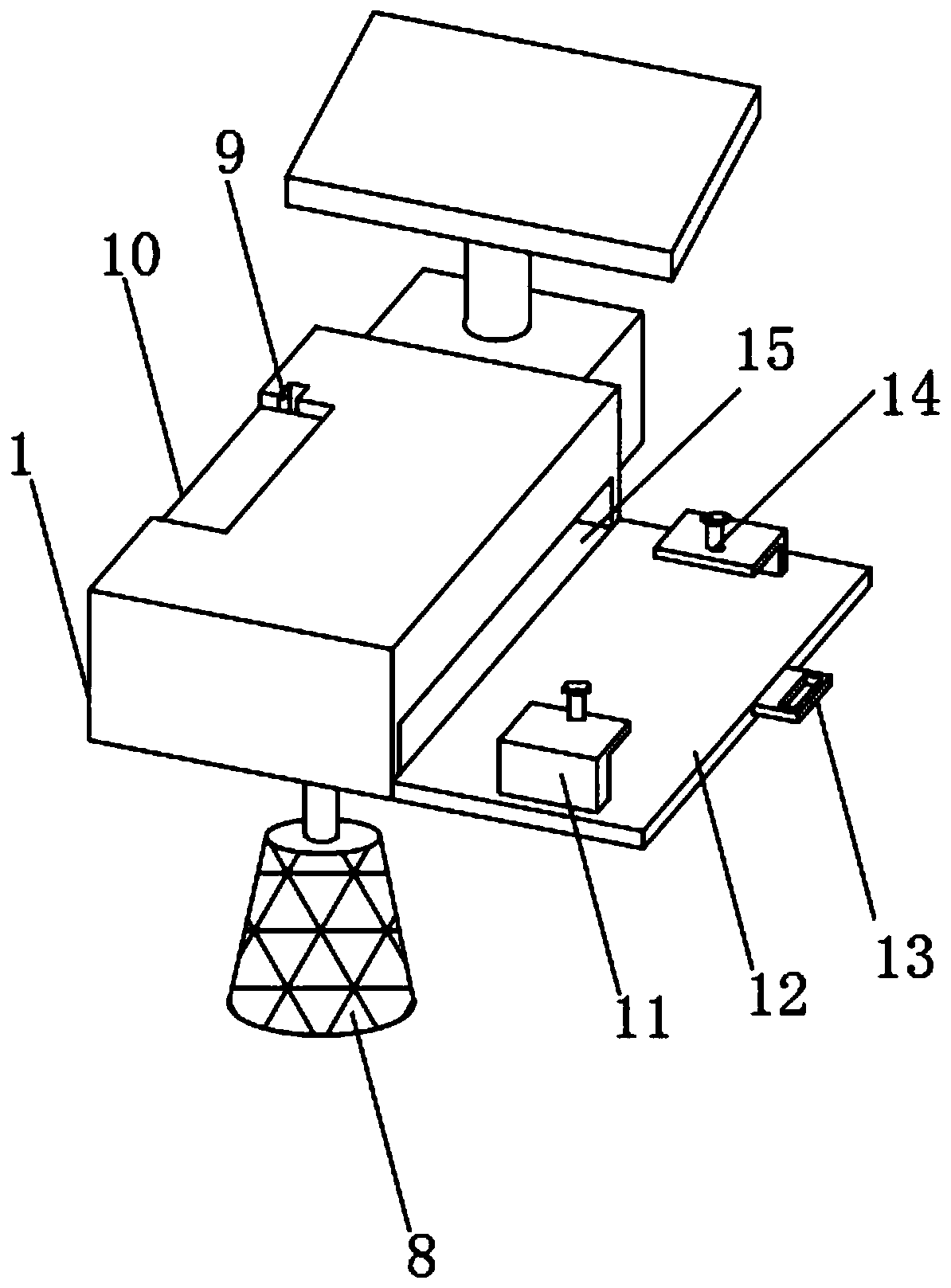

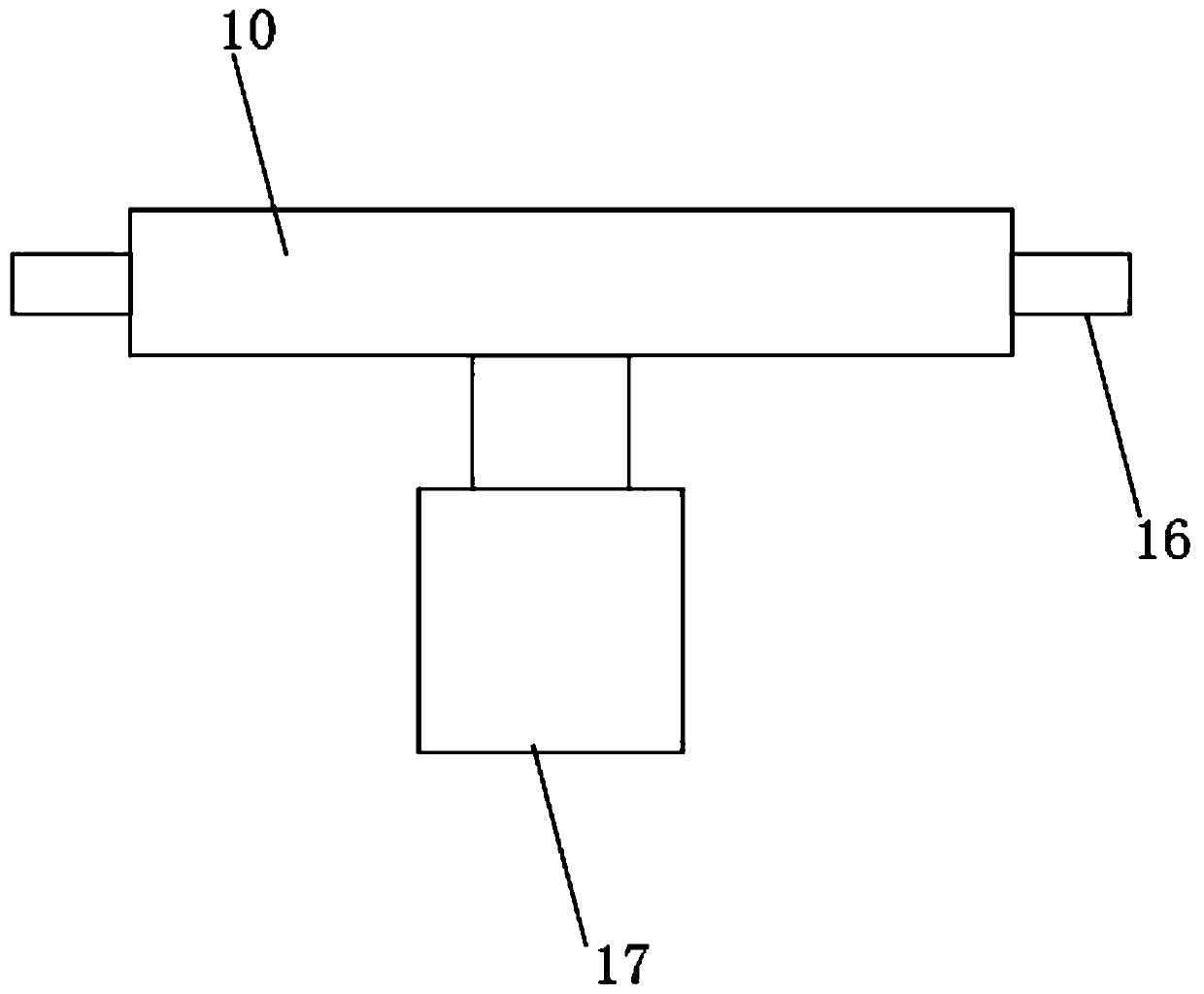

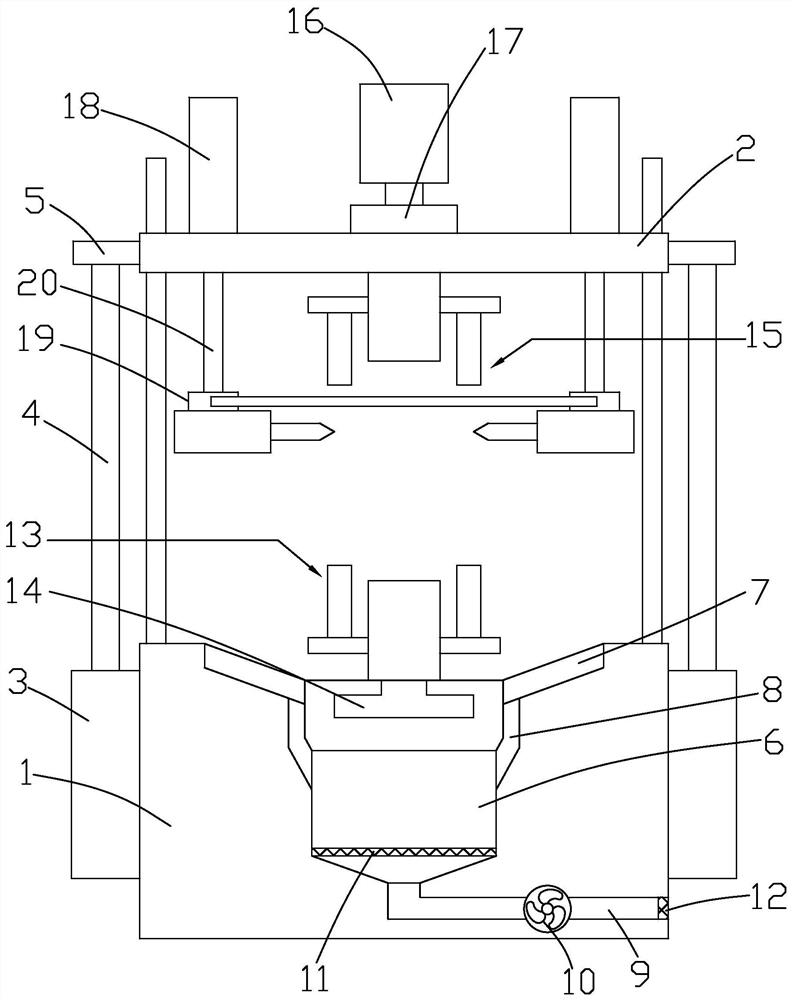

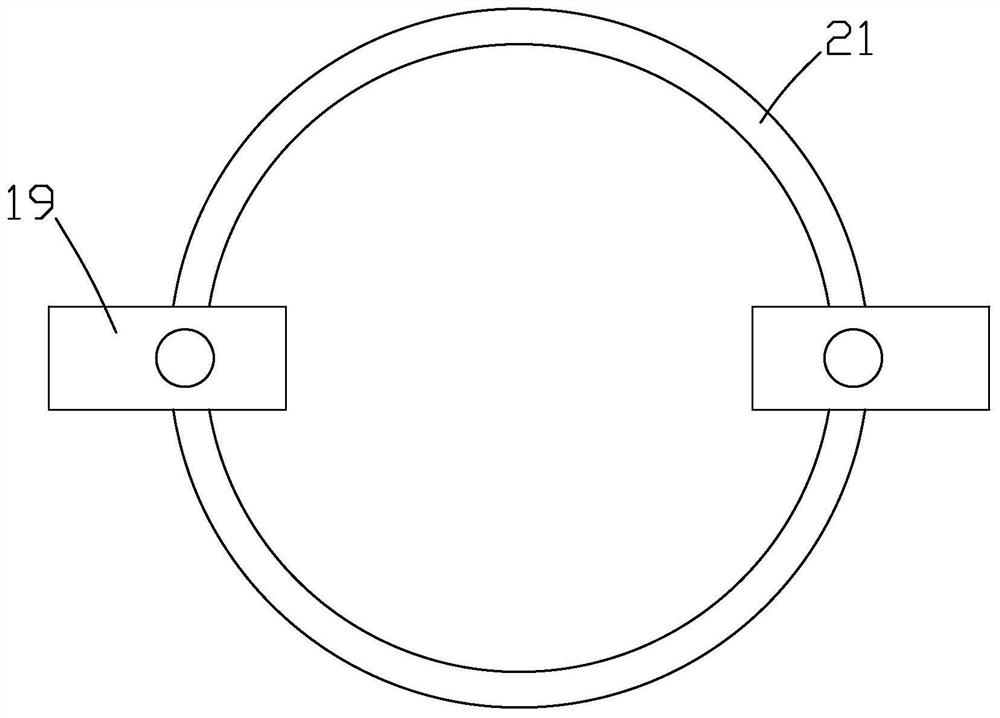

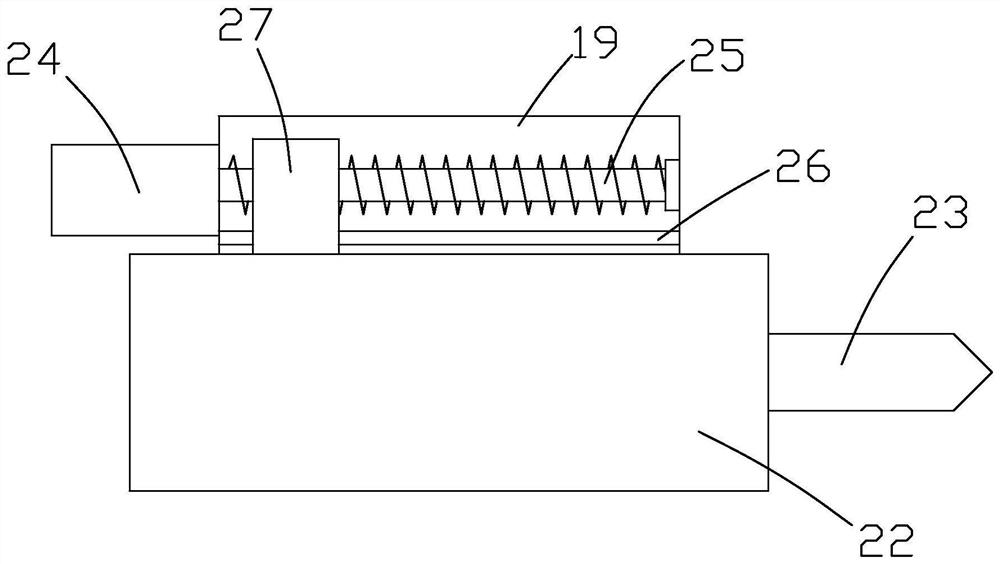

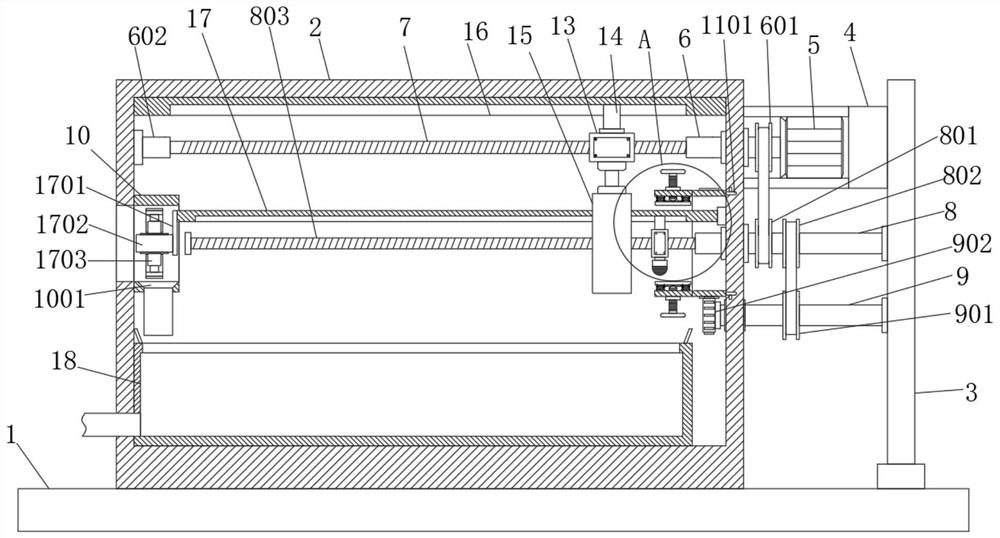

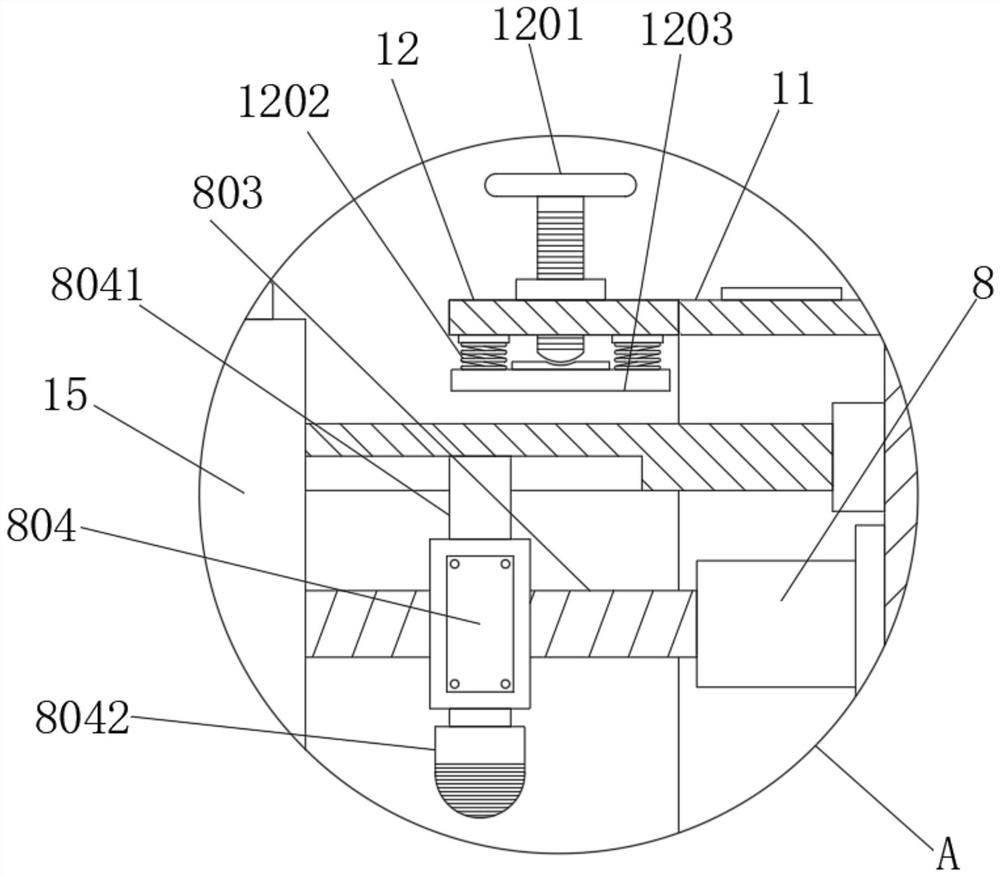

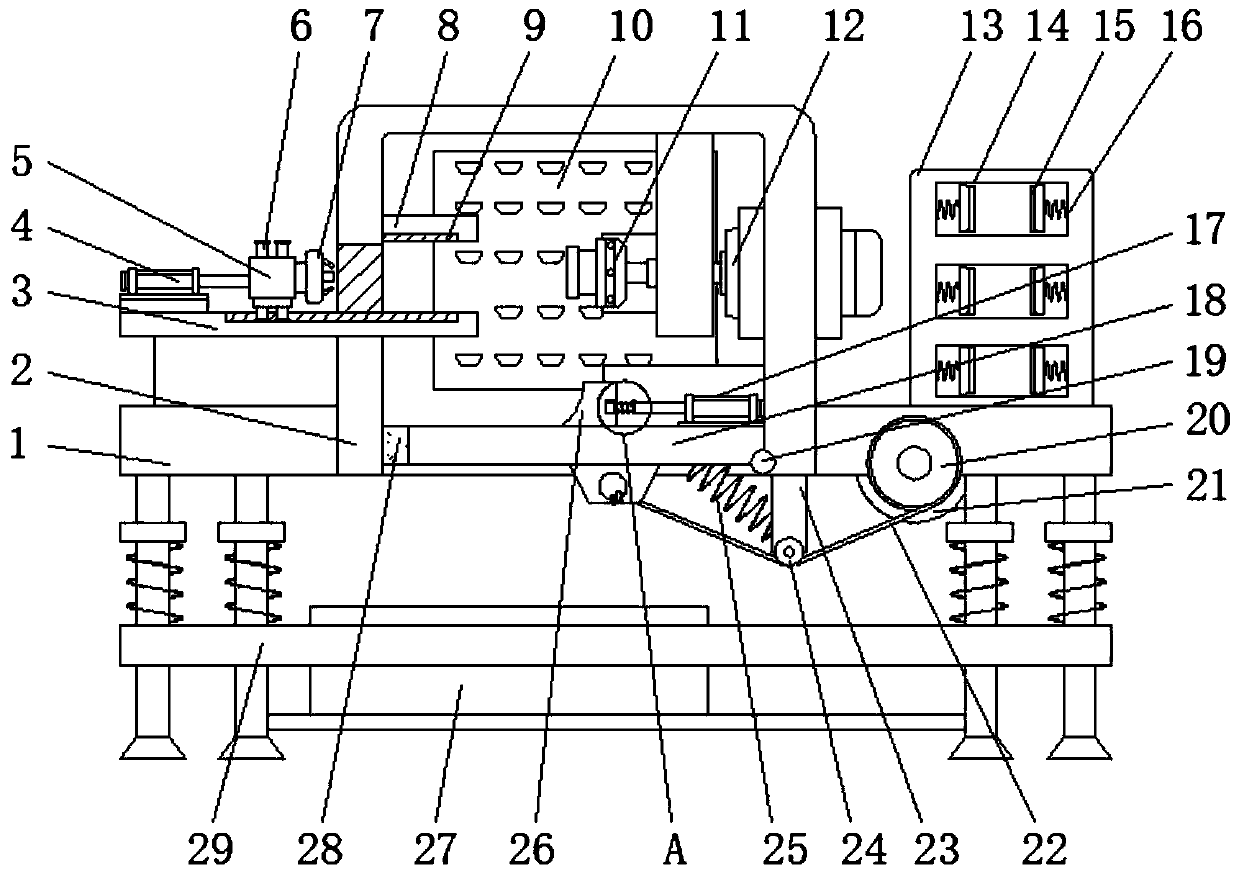

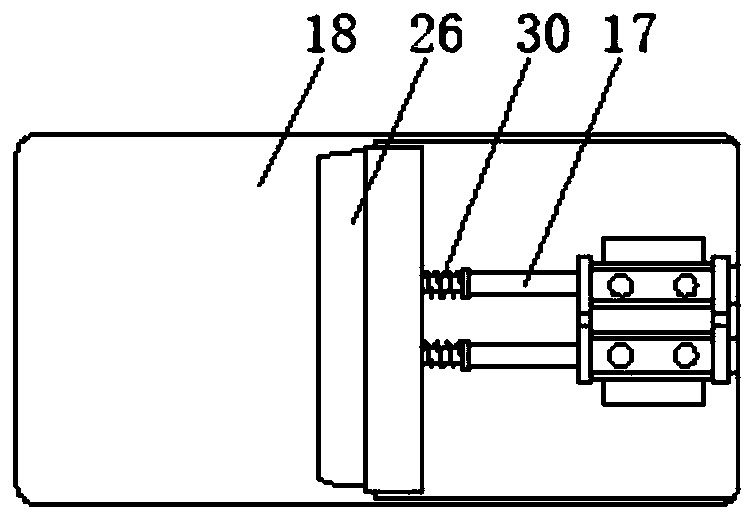

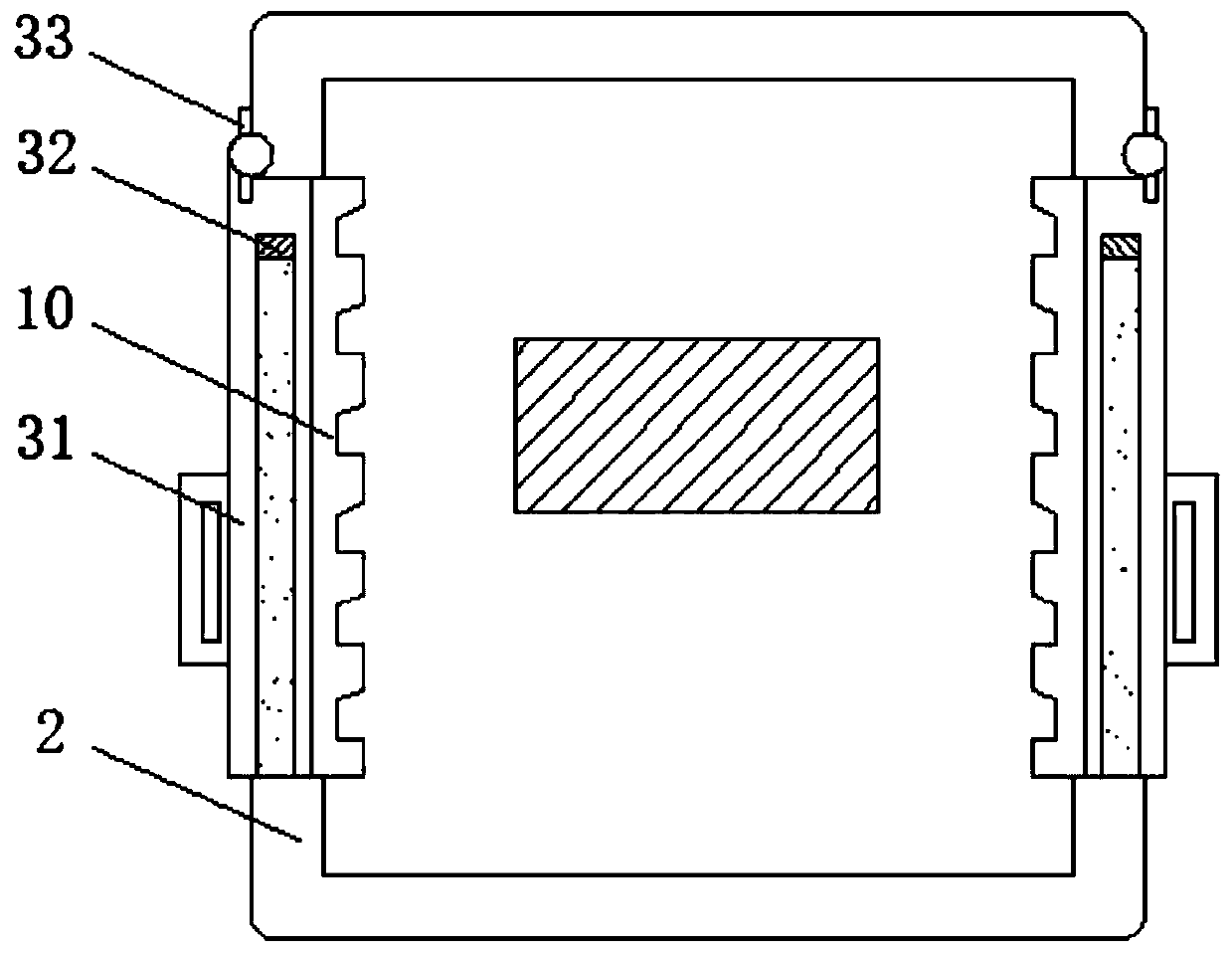

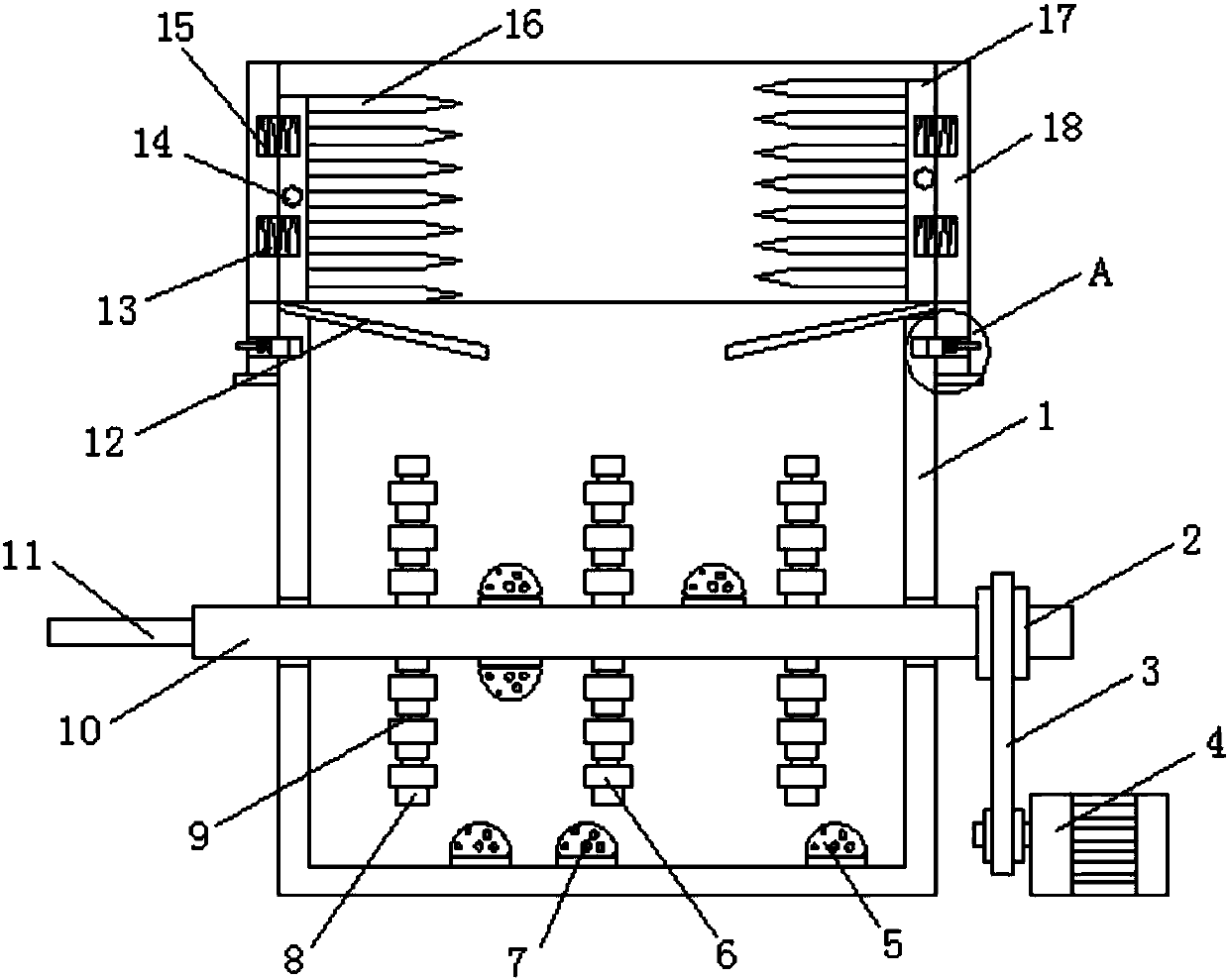

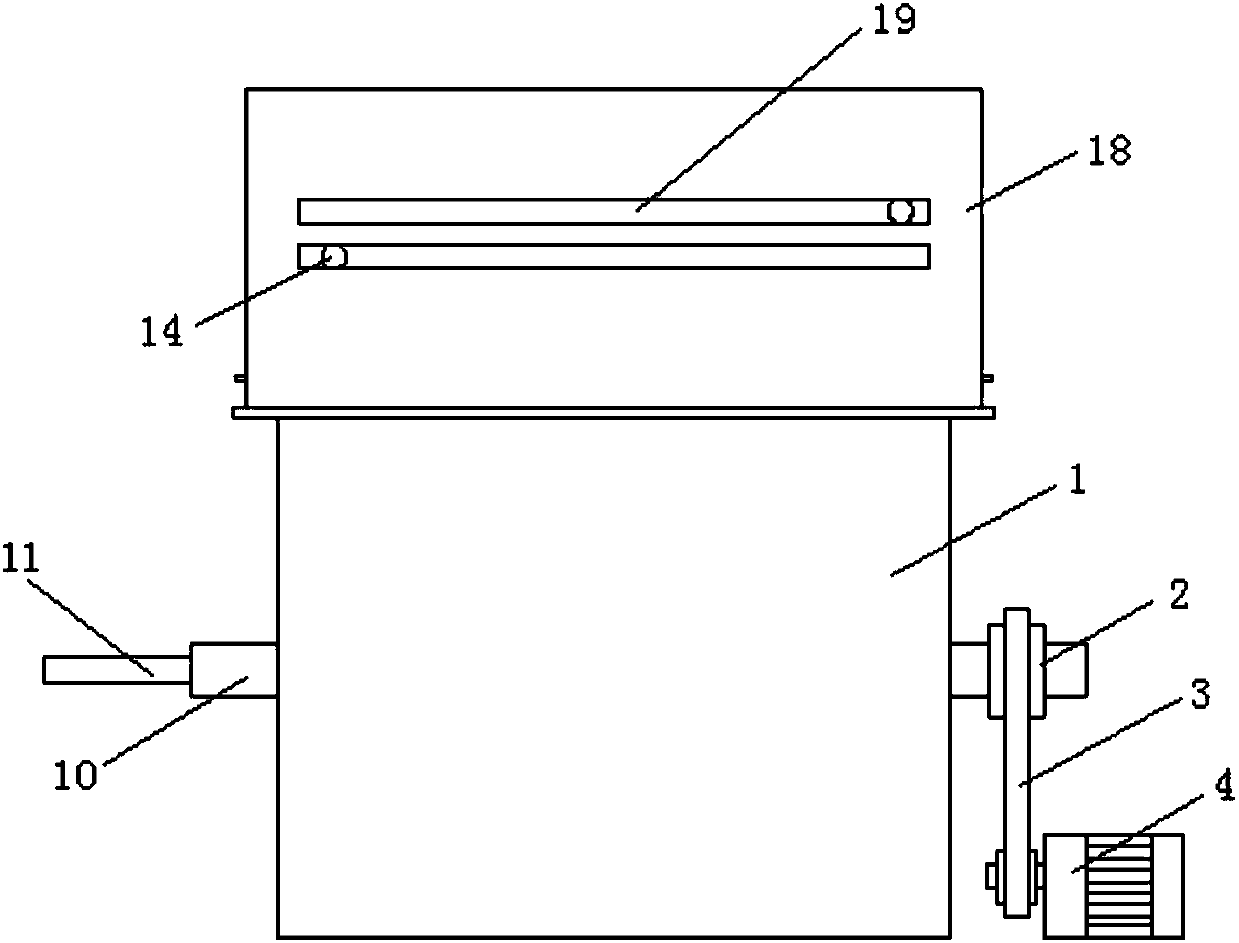

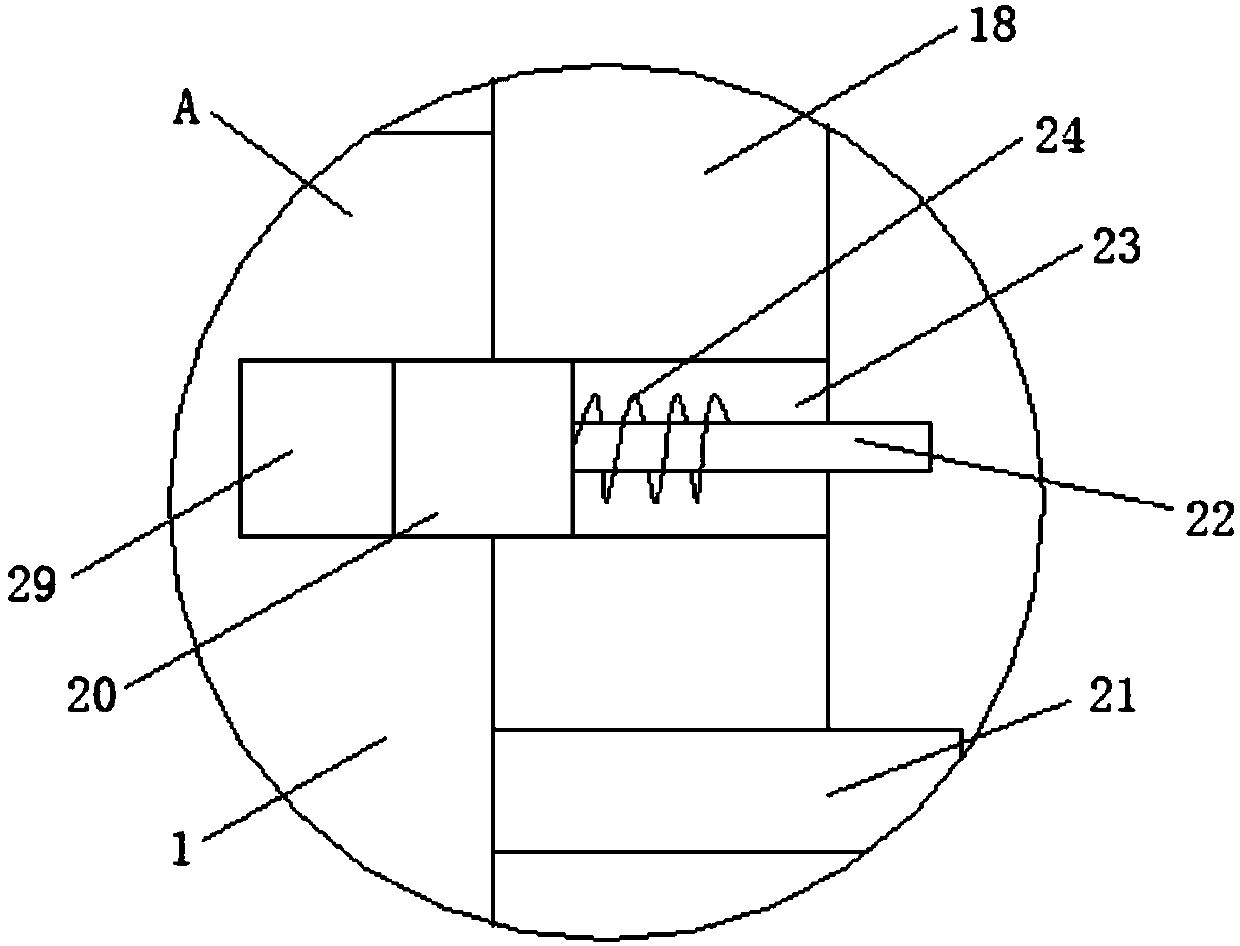

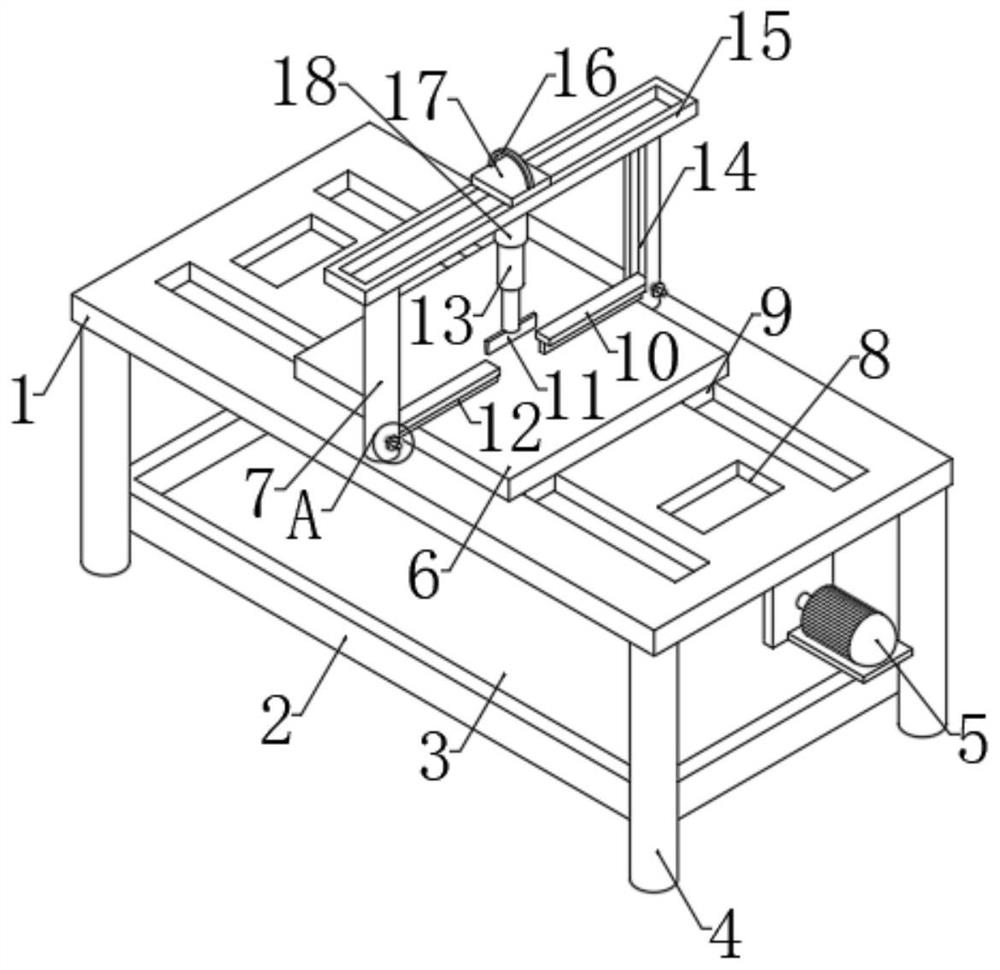

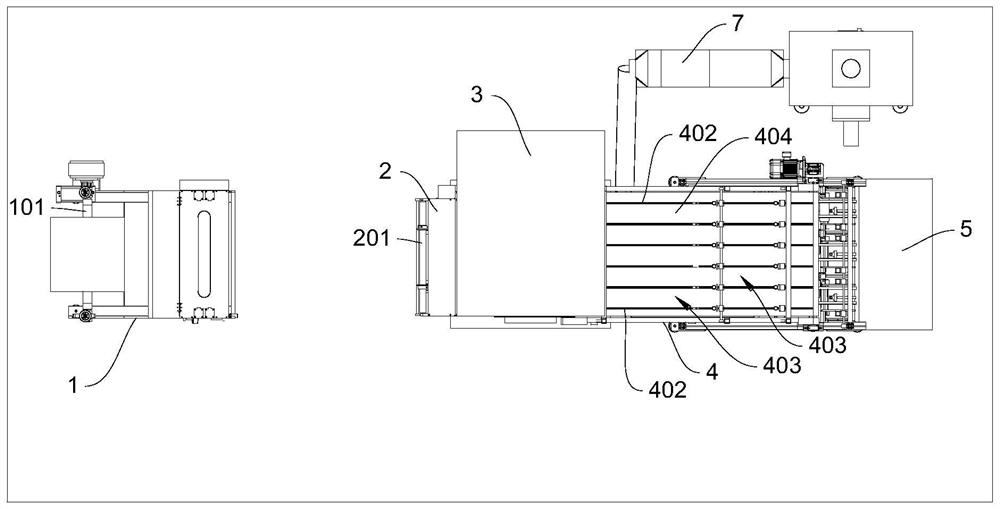

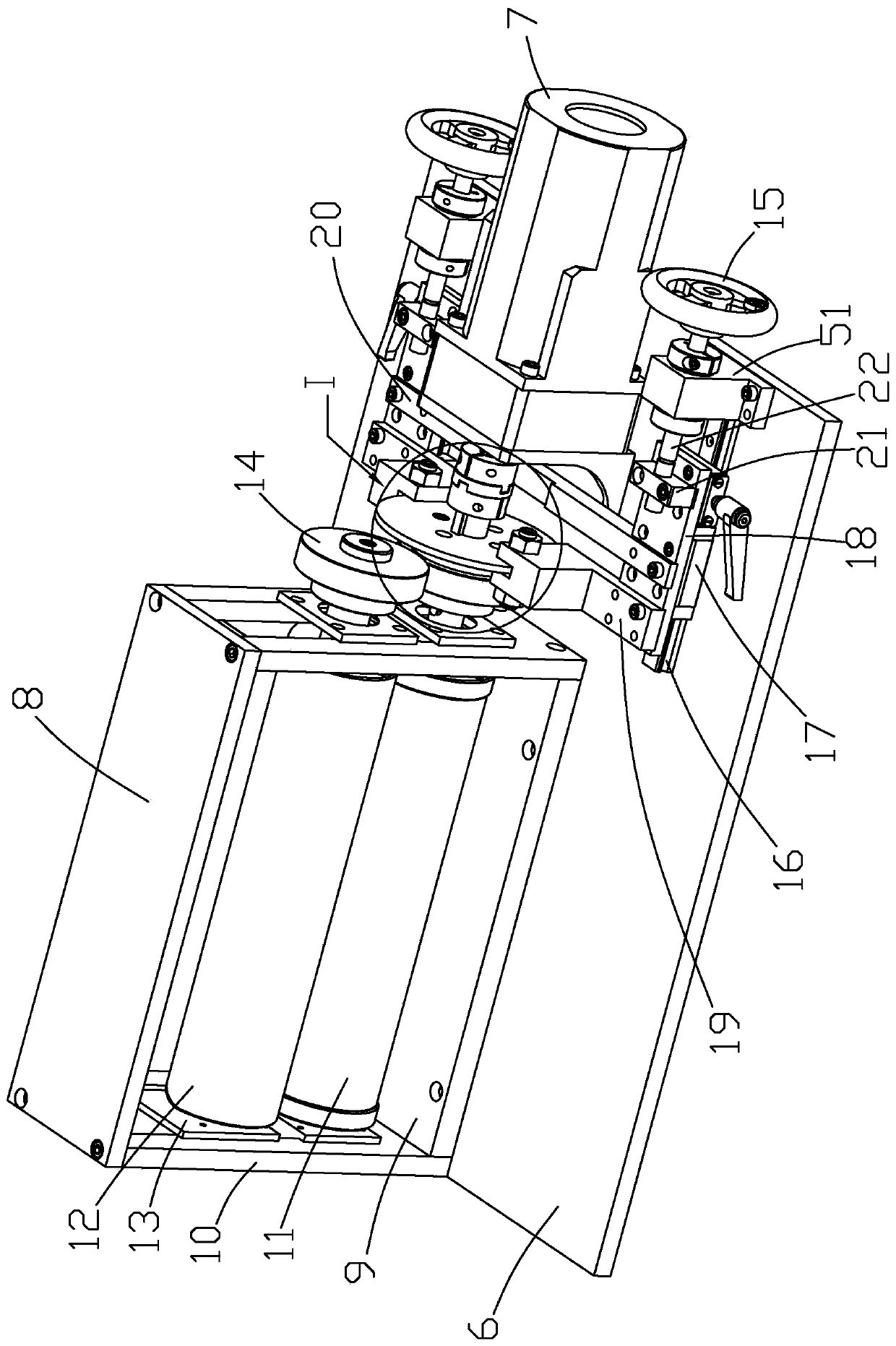

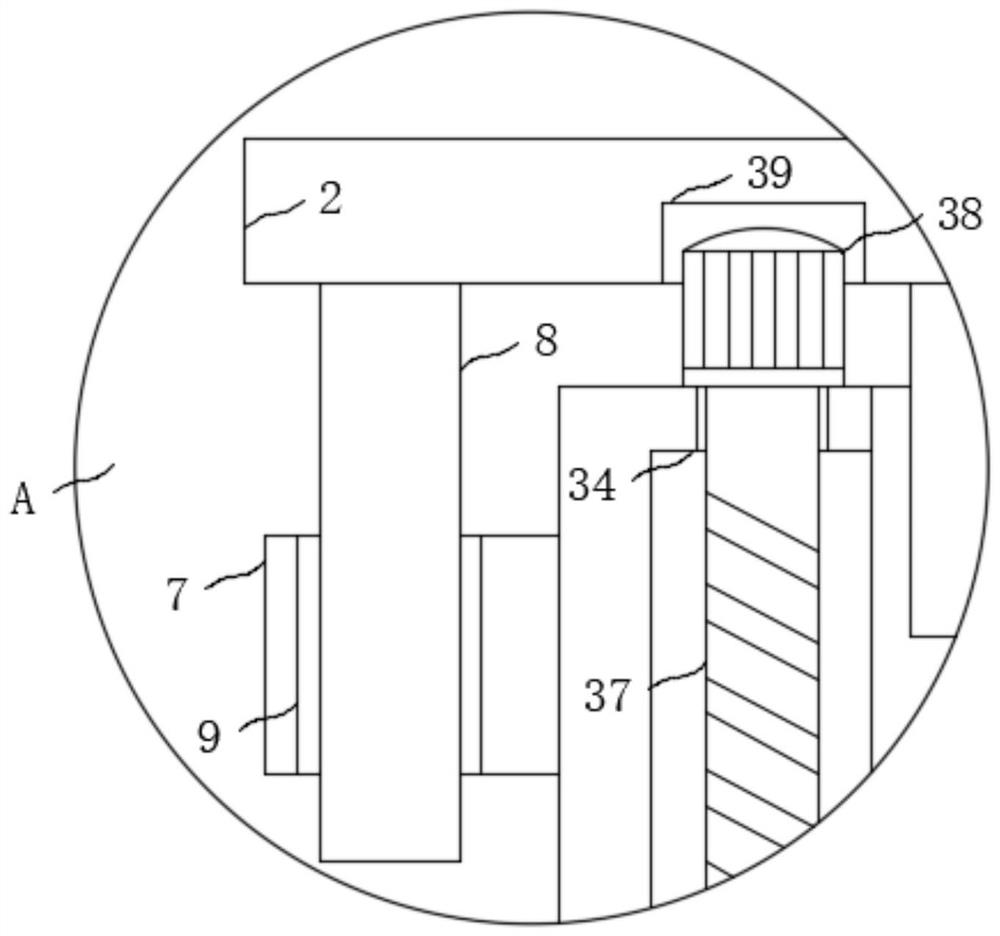

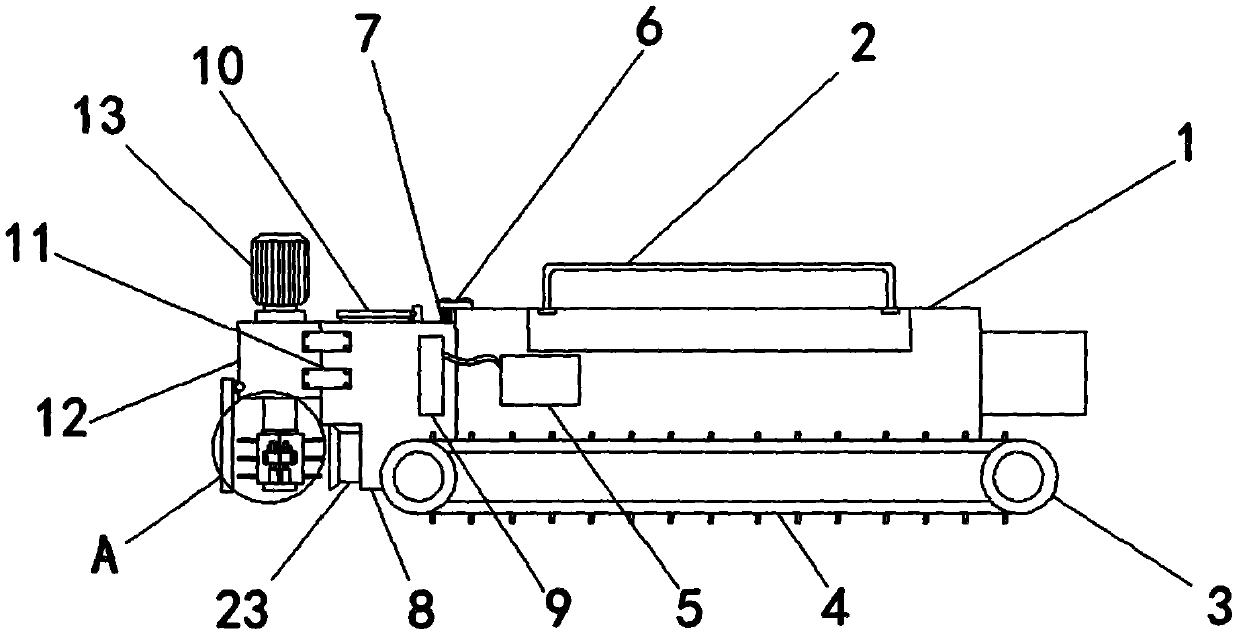

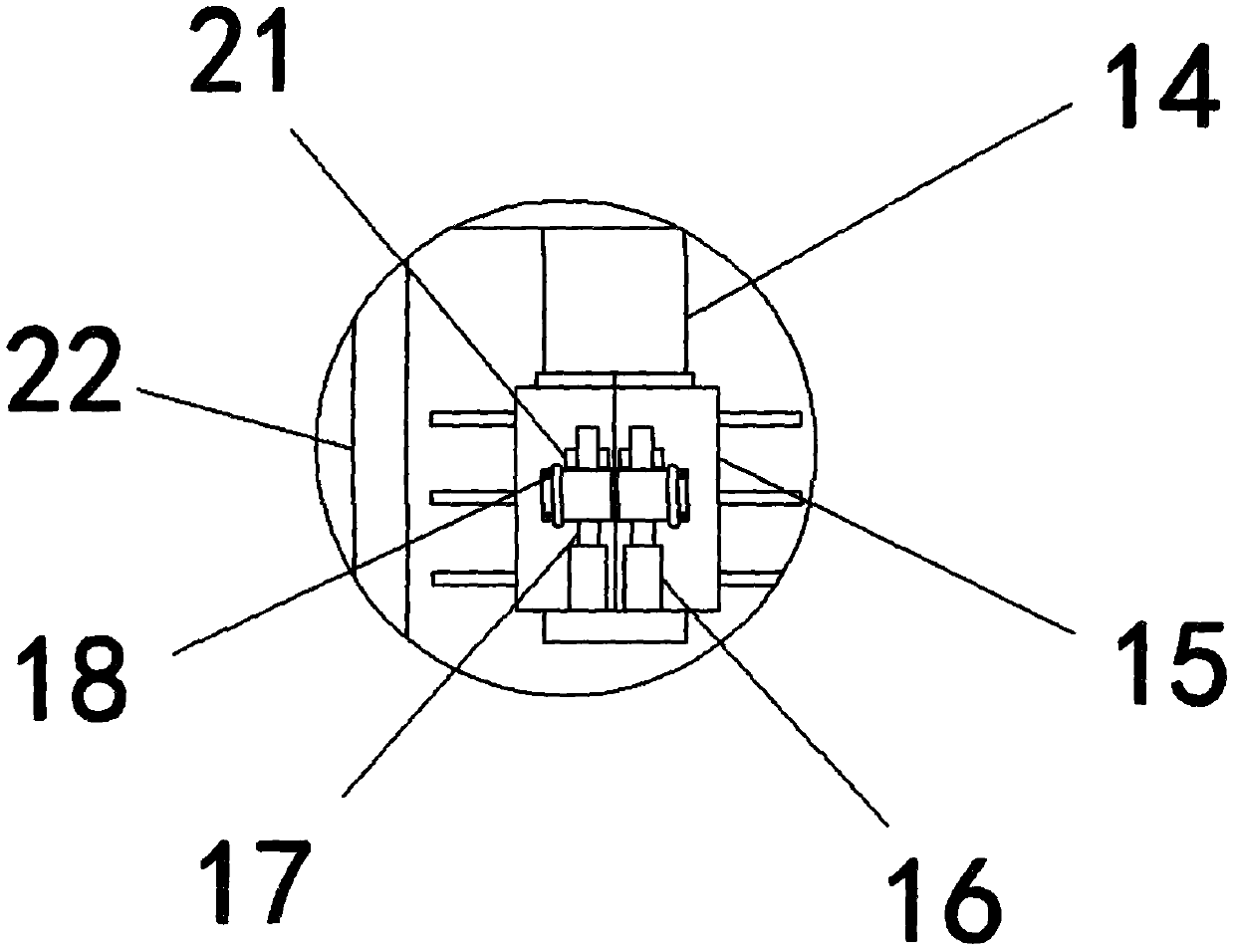

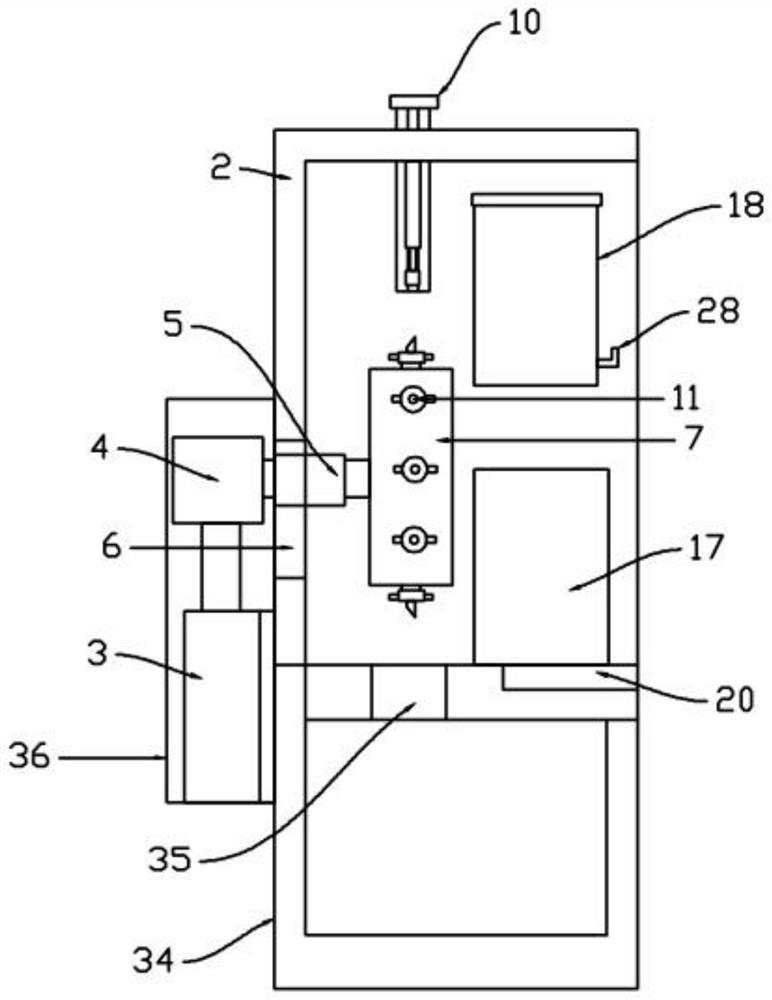

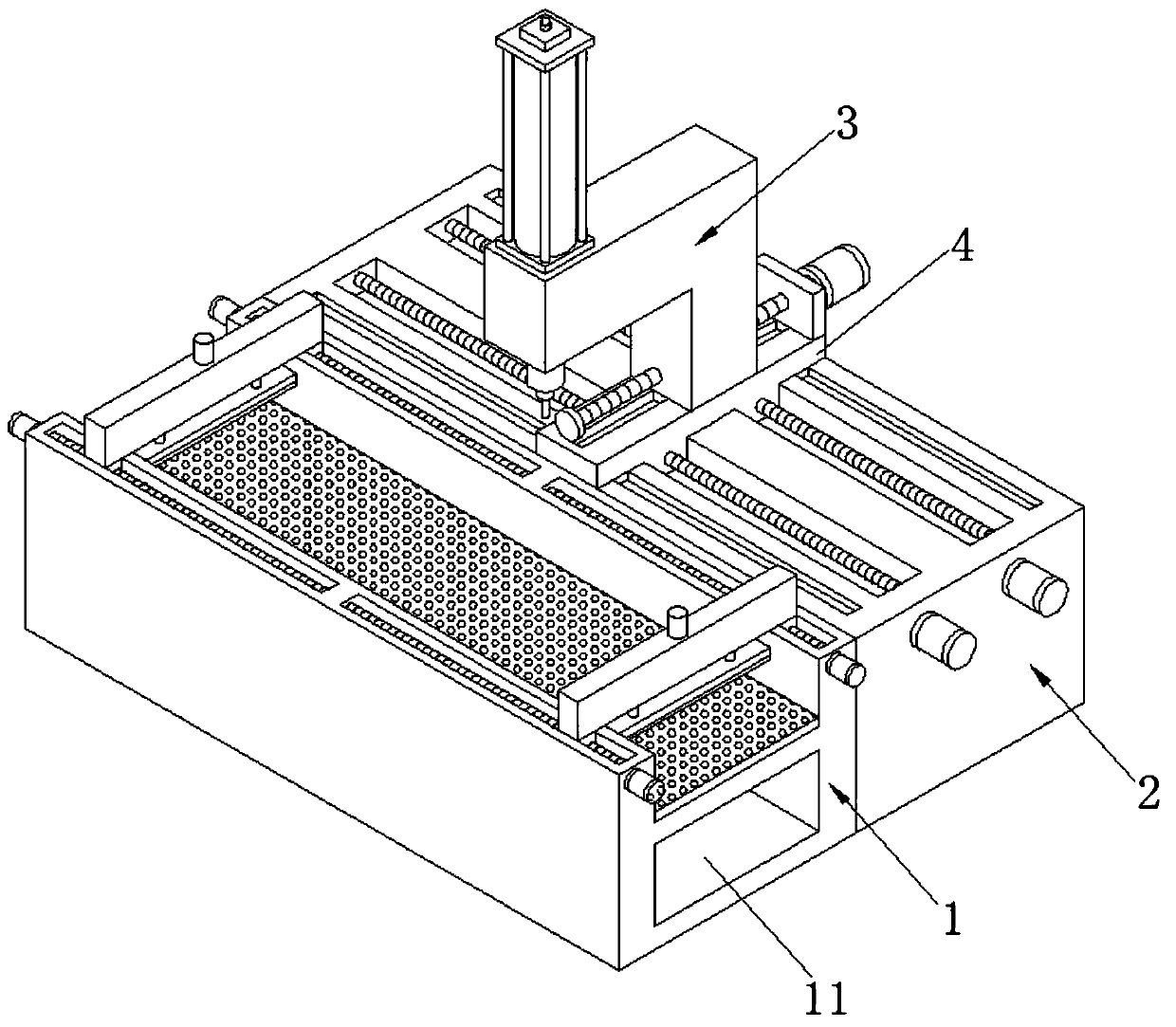

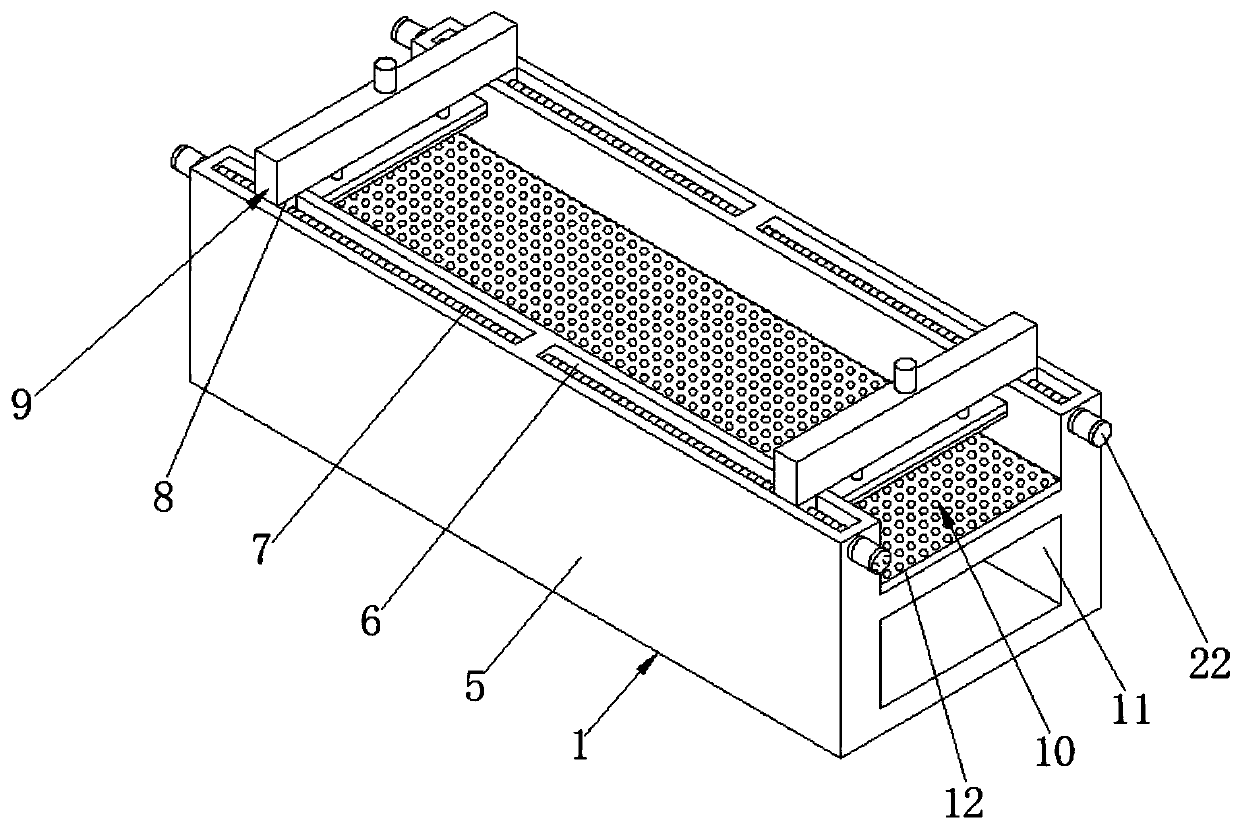

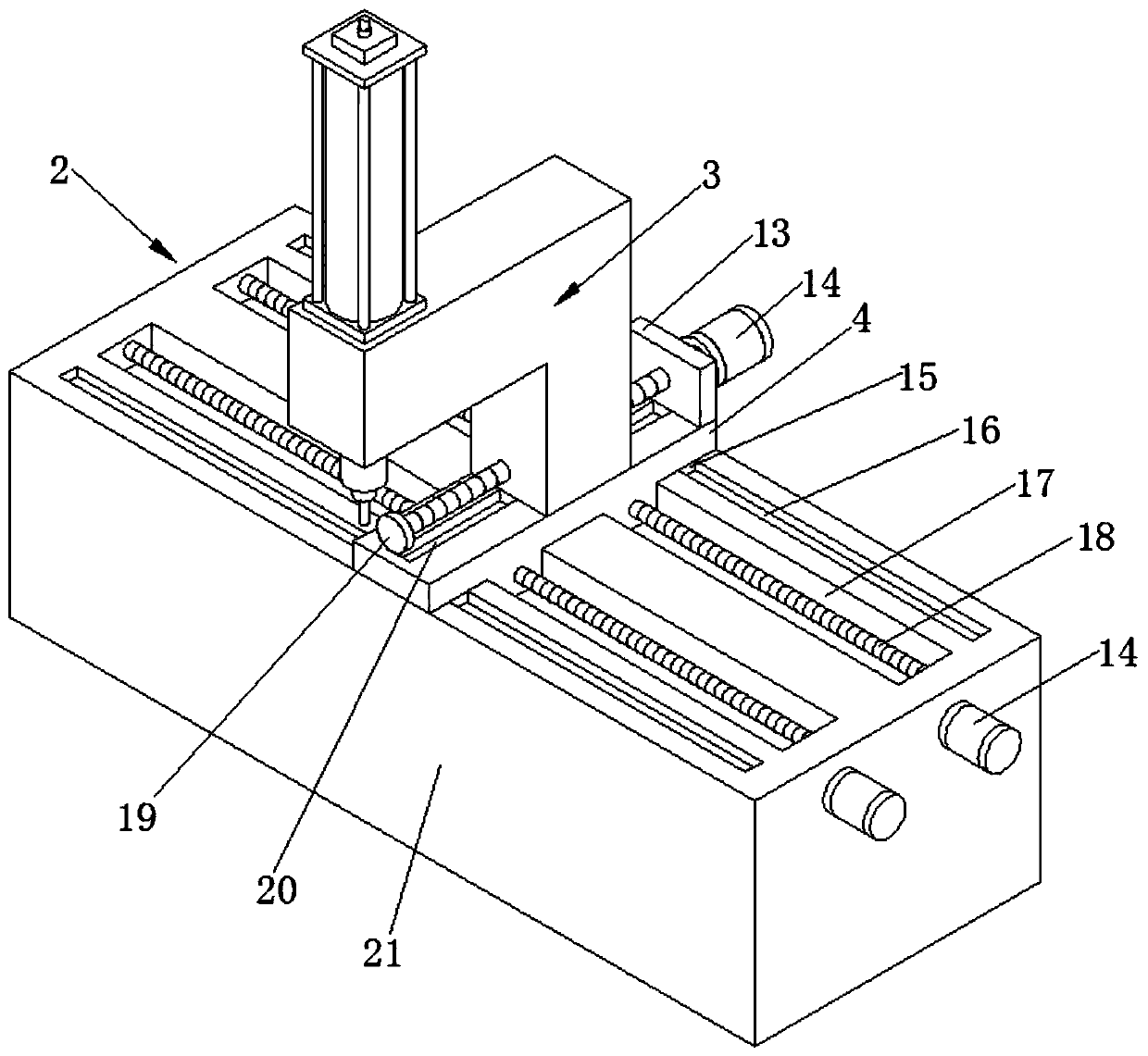

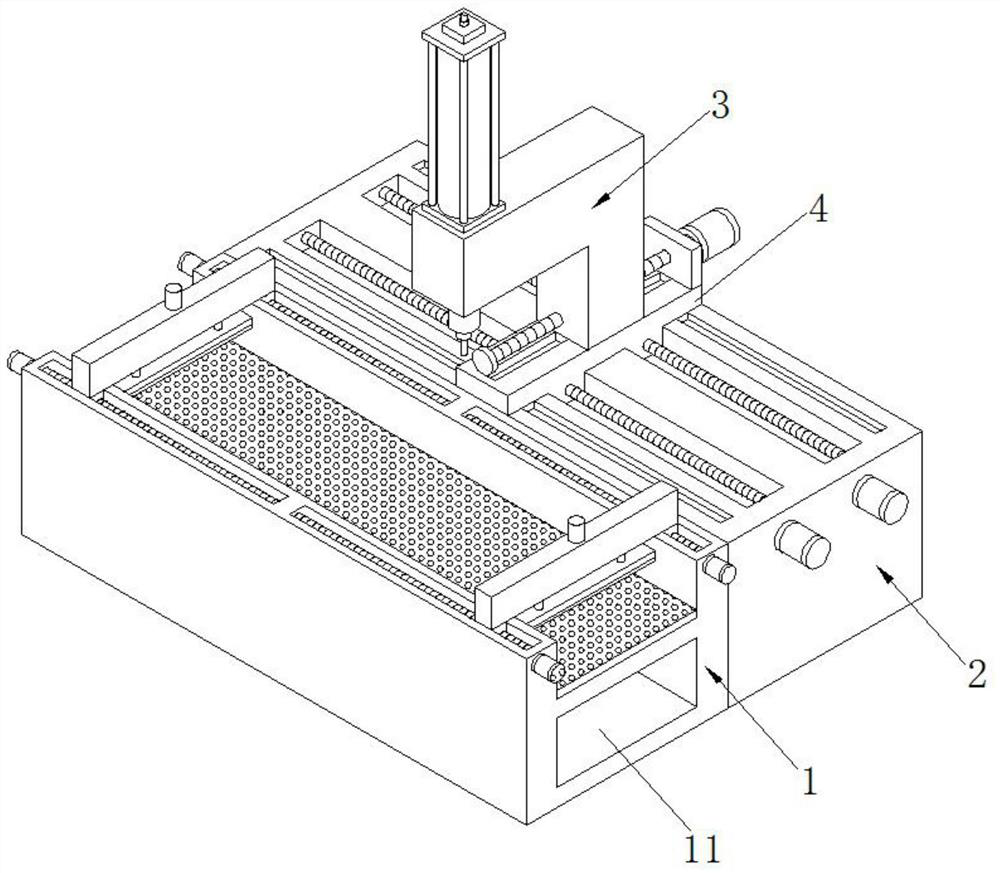

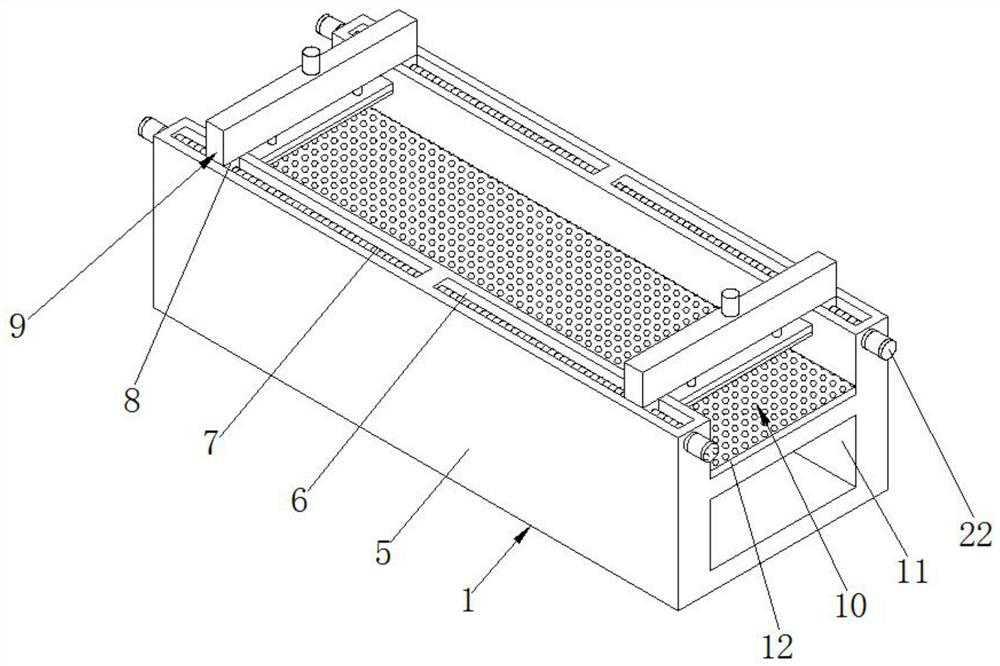

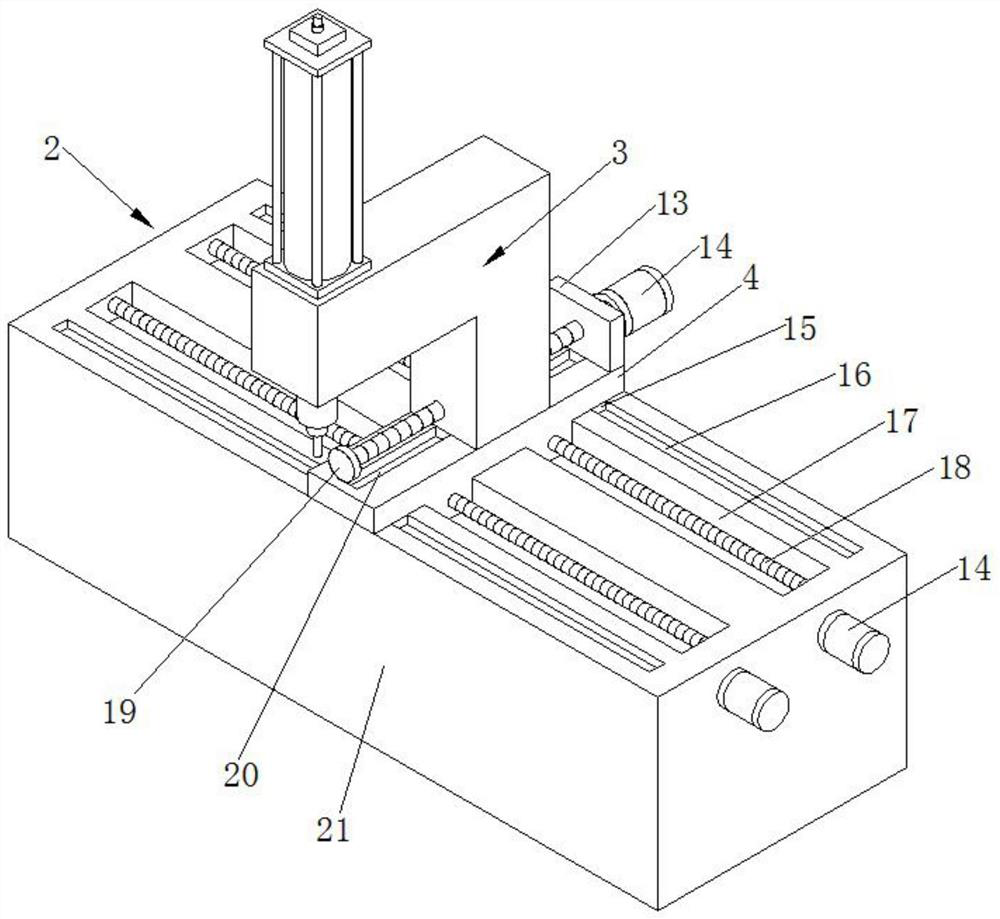

Porous multi-row drilling machine for stainless steel tube silencer connected tubes

ActiveCN111702212AHigh precisionQuality improvementAutomatic control devicesFeeding apparatusReduction driveElectric machinery

The invention discloses a porous multi-row drilling machine for stainless steel tube silencer connected tubes. The porous multi-row drilling machine comprises a machine seat, a lifting table, a fragment processing mechanism, a first clamping mechanism, a second clamping mechanism and a drilling mechanism, the lifting table is connected to the upper part of the machine seat through a lifting assembly, the fragment processing mechanism is located in the machine seat, a supporting table is arranged at the center of the top surface of the machine seat, the first clamping mechanism is rotatably connected to the upper part of the supporting table through a rotating block, the second clamping mechanism is connected to the bottom surface of the lifting table, the second clamping mechanism is connected with a driving motor through a reducer, the reducer and the driving motor are located above the lifting table, and the drilling mechanism is connected to the lifting table. According to the porous multi-row drilling machine for the stainless steel tube silencer connected tubes, the drilling processing of the stainless steel tube silencer connected tubes with different diameters and wall thicknesses can be met, and the practicability and flexibility are greatly improved.

Owner:新昌县长城空调部件股份有限公司

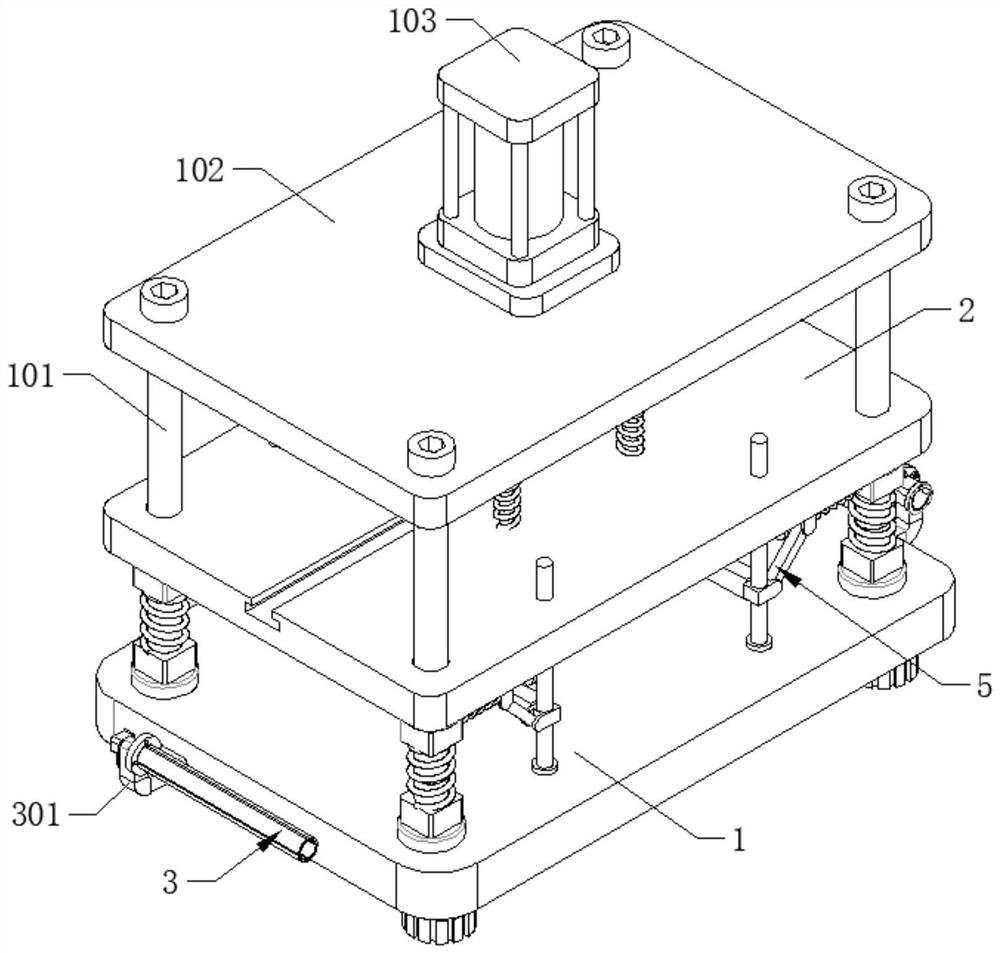

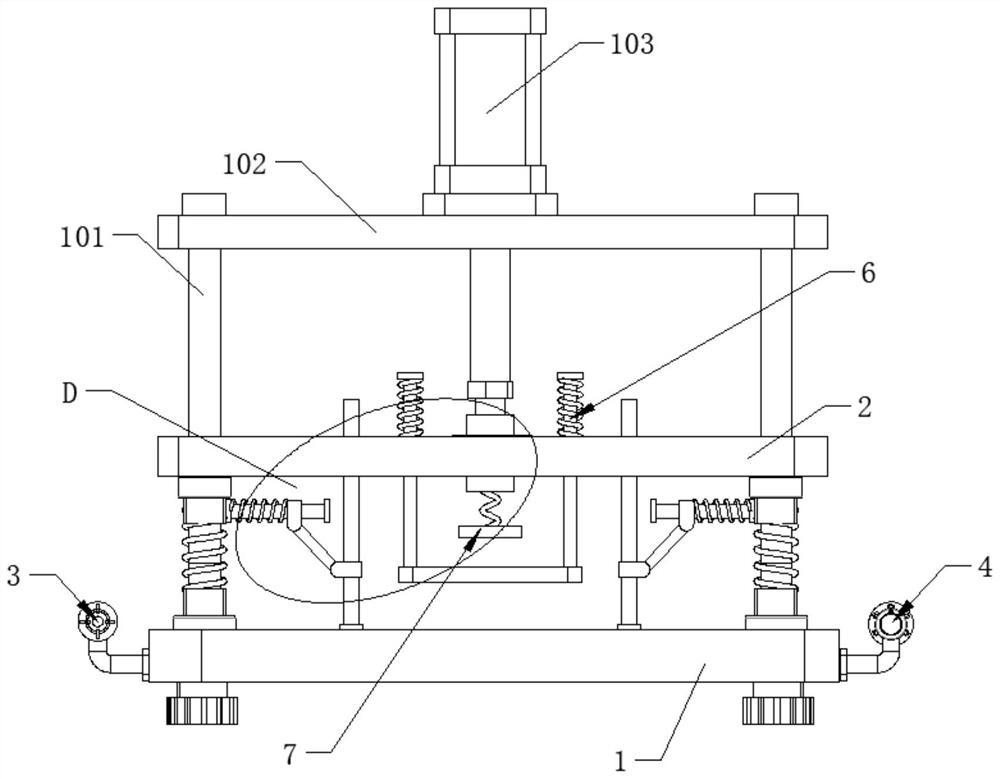

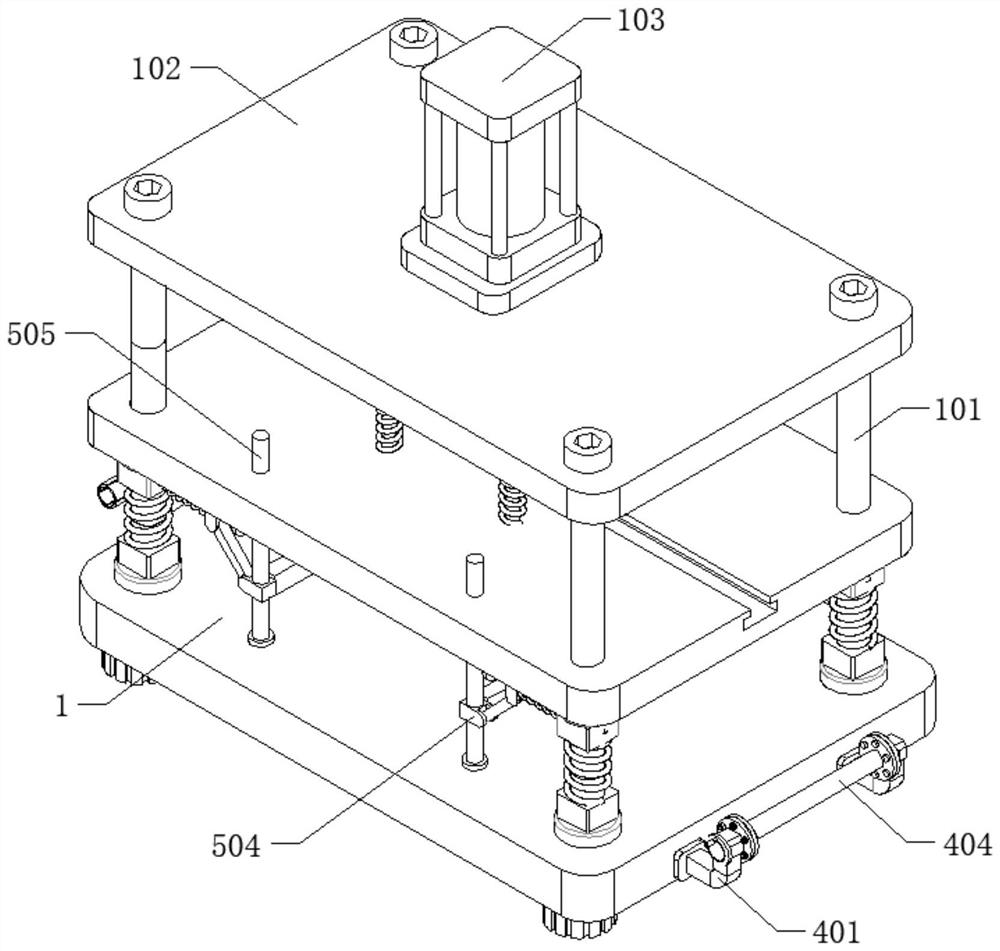

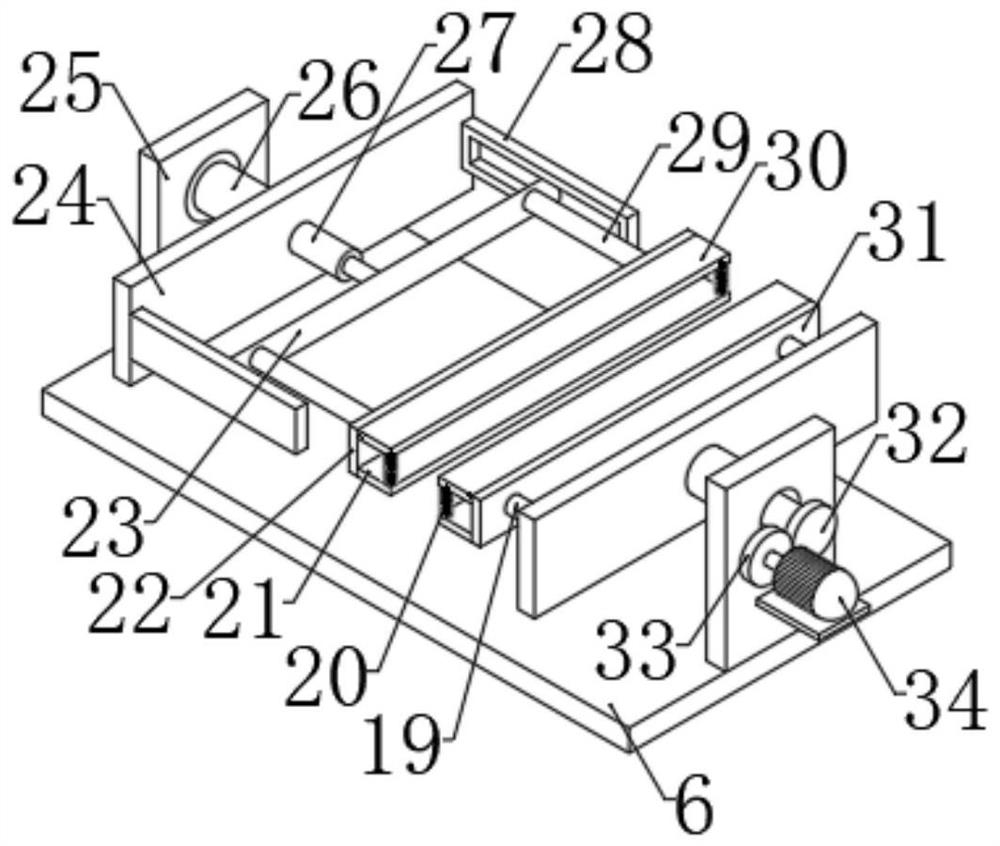

Adhesive tape viscosity detection system for adhesive tape production and use method thereof

ActiveCN112748070AEasy to fixAffect accuracyUsing mechanical meansMaterial analysisAdhesive beltEngineering

The invention discloses an adhesive tape viscosity detection system for adhesive tape production and a use method thereof, and belongs to the technical field of adhesive tape detection devices. The adhesive tape viscosity detection system for adhesive tape production comprises a base, a first supporting rod is connected to the top wall of the base, a top plate is connected to the top wall of the first supporting rod, an air cylinder is connected to the top wall of the top plate, the output end of the air cylinder is connected with a pressing plate, and a connecting block is connected to the bottom wall of the pressing plate and slidably connected to the outer wall of the first supporting rod, a first fixing assembly is connected between the outer wall of the connecting block and the top wall of the base, a second fixing assembly is connected to the bottom wall of the pressing plate, a detection assembly is further connected to the bottom wall of the pressing plate and matched with the second fixing assembly, and a material placing assembly and a winding assembly are connected to the side wall of the base, the material placing assembly and the winding assembly are matched with the first fixing assembly and the second fixing assembly; the detection system is simple in structure and convenient to use, the viscosity of the adhesive tape can be conveniently detected, and the detection data result is precise.

Owner:福建友谊胶粘带集团有限公司

River silt cleaning device and construction method

InactiveCN109056879AExtended service lifeAvoid cloggingSoil-shifting machines/dredgersEngineeringSilt

Owner:ZHEJIANG COLLEGE OF CONSTR

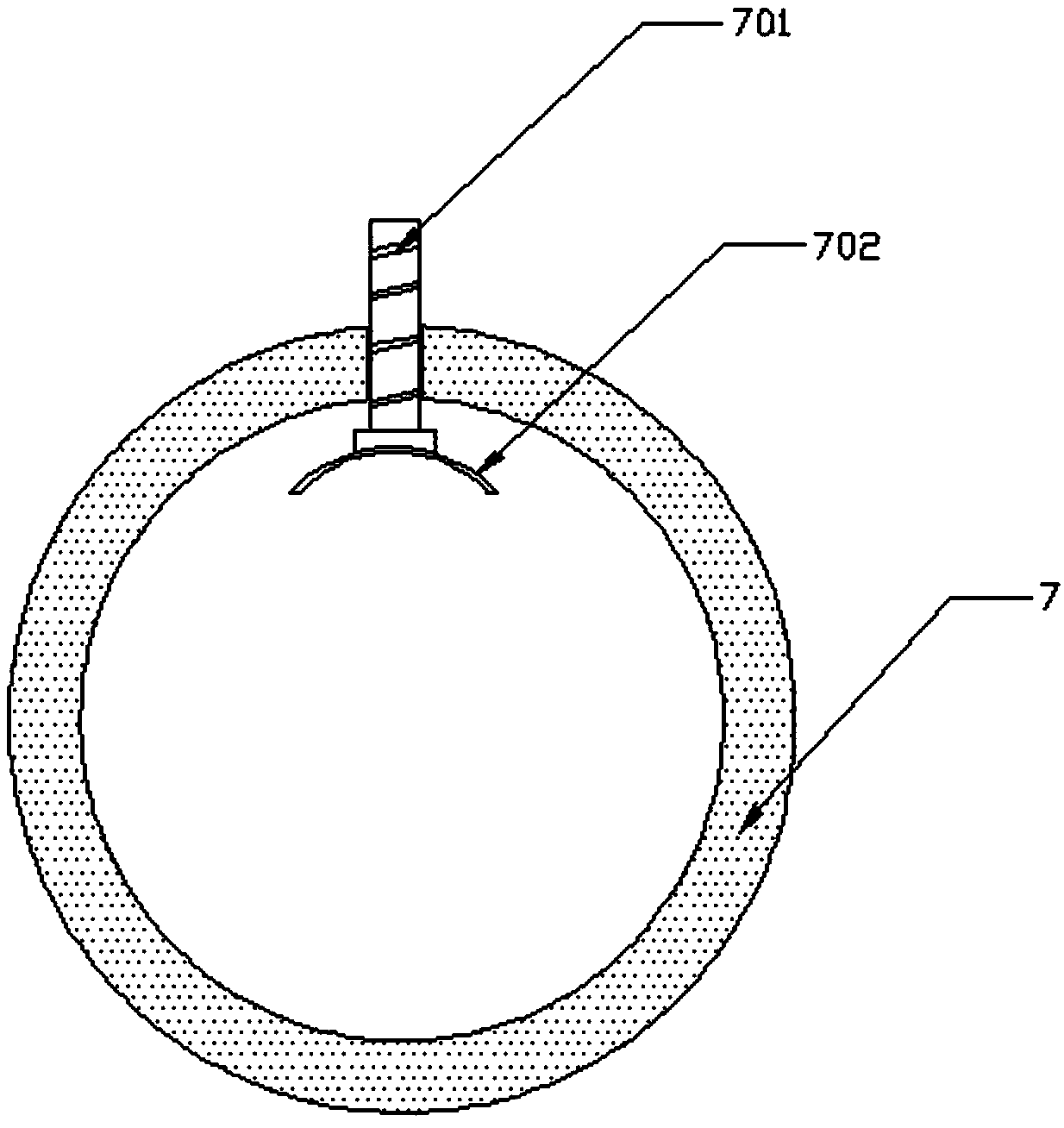

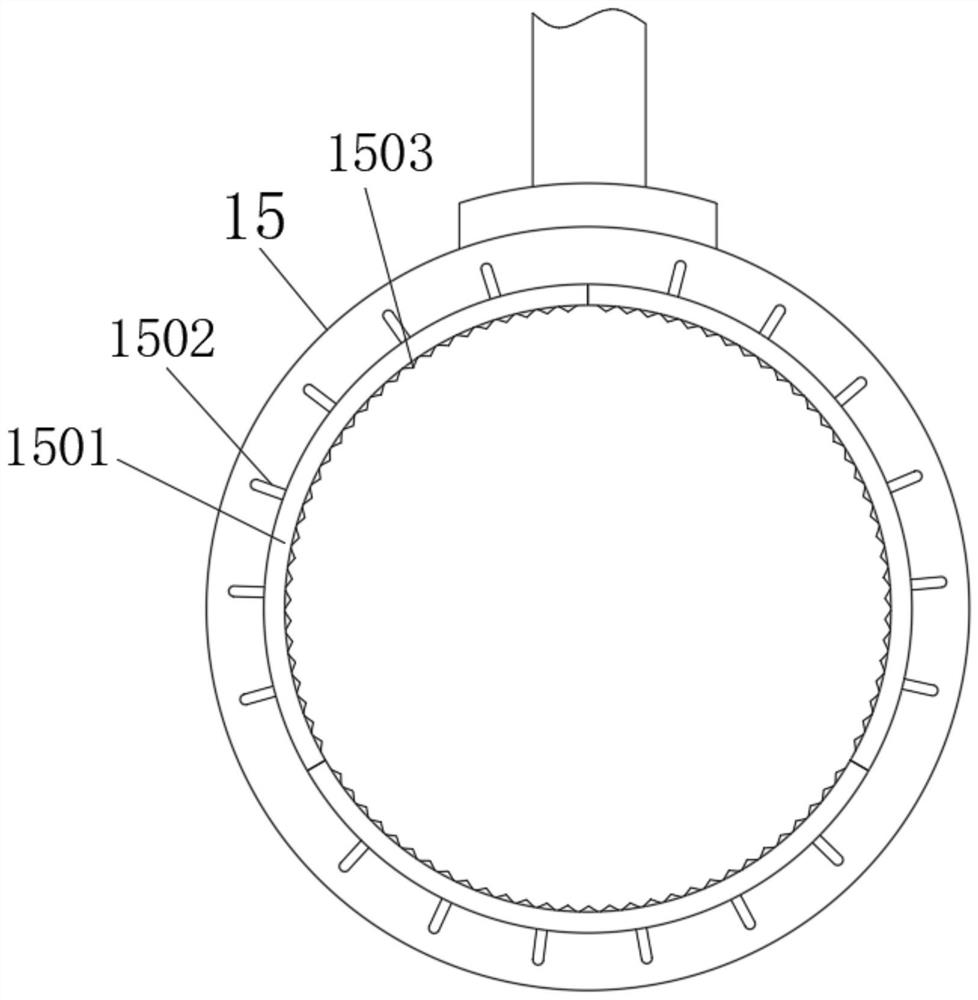

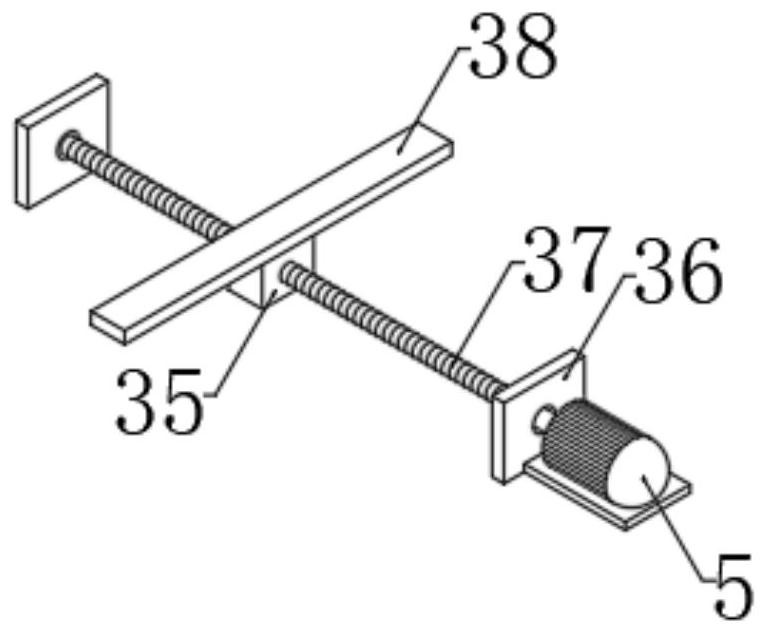

Rust removal device for pipe machining for garbage incinerator

ActiveCN111823113AEfficient removalImprove rust removal effectGrinding carriagesGrinding drivesSlag (welding)Electric machinery

The invention relates to the technical field of steel pipe rust removal, in particular to a rust removal device for pipe machining for a garbage incinerator. The rust removal device comprises a base.A rust removal frame body is fixed to the top of the base, a first limiting guide rail is fixed to the top of an inner cavity of the rust removal frame body, a side fixing plate is fixed to the position, on the right side of the rust removal frame body, of the top of the base, and a fixing frame is fixed to the top of the left side of the side fixing plate. Through the design of the structures such as a drive motor, a first rotary rod, a second rotary rod, a third rotary rod, a first lead screw, a second sliding body and a rust removal barrel, the design scheme can have the characteristics ofbeing simple in structure, convenient to use and good in rust removal effect of pipelines effectively, the rust removal barrel slides on the pipelines needing to be subjected to rust removal back andforth, and in cooperation with rust removal teeth in the rust removal barrel, loose or turned oxide skin, rust, welding slag and other impurities can be effectively removed.

Owner:BRIGHT THERMAL EQUIP CO LTD

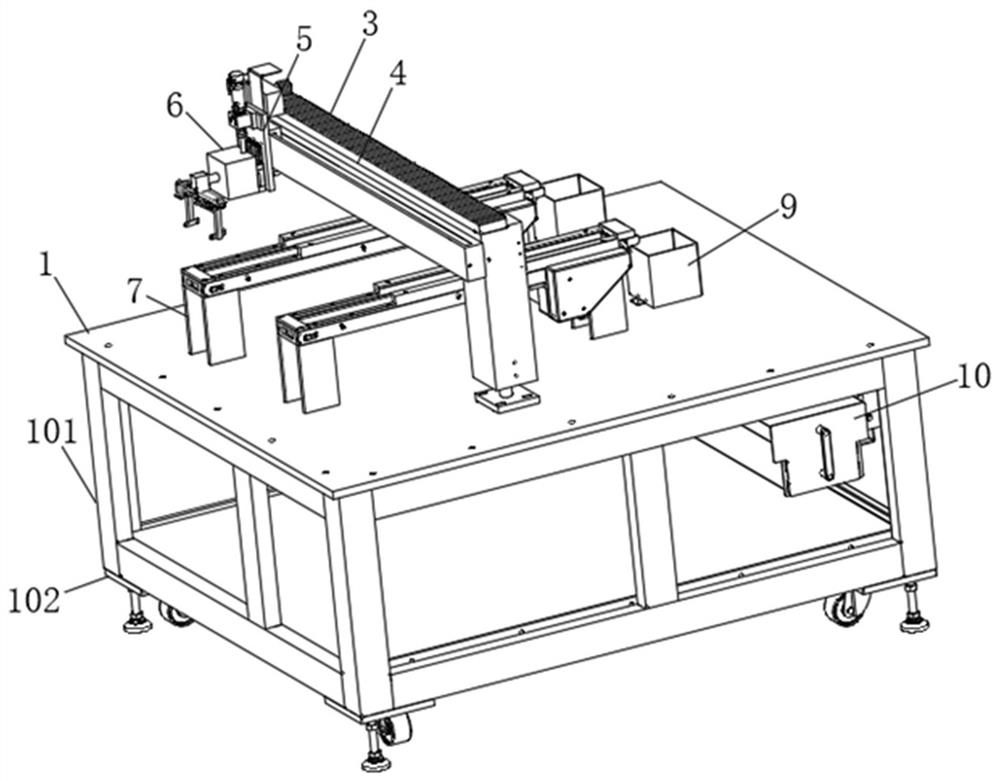

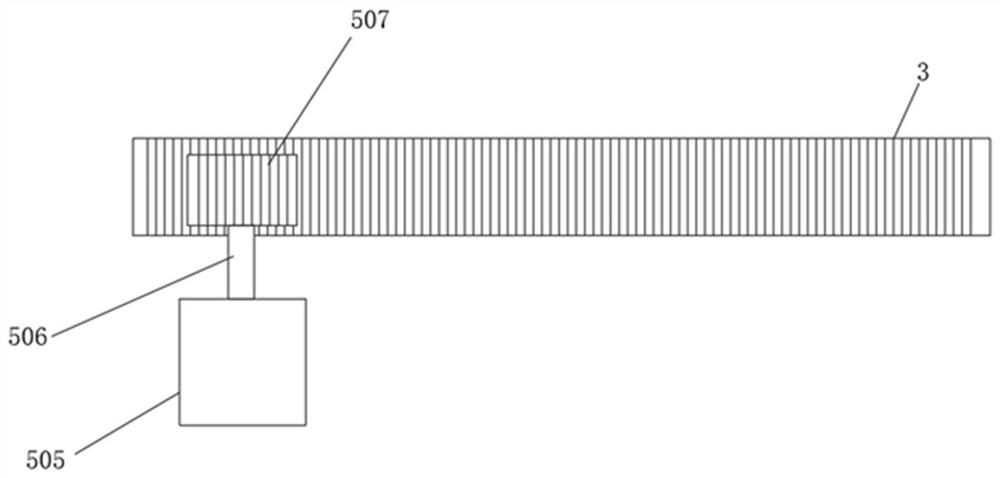

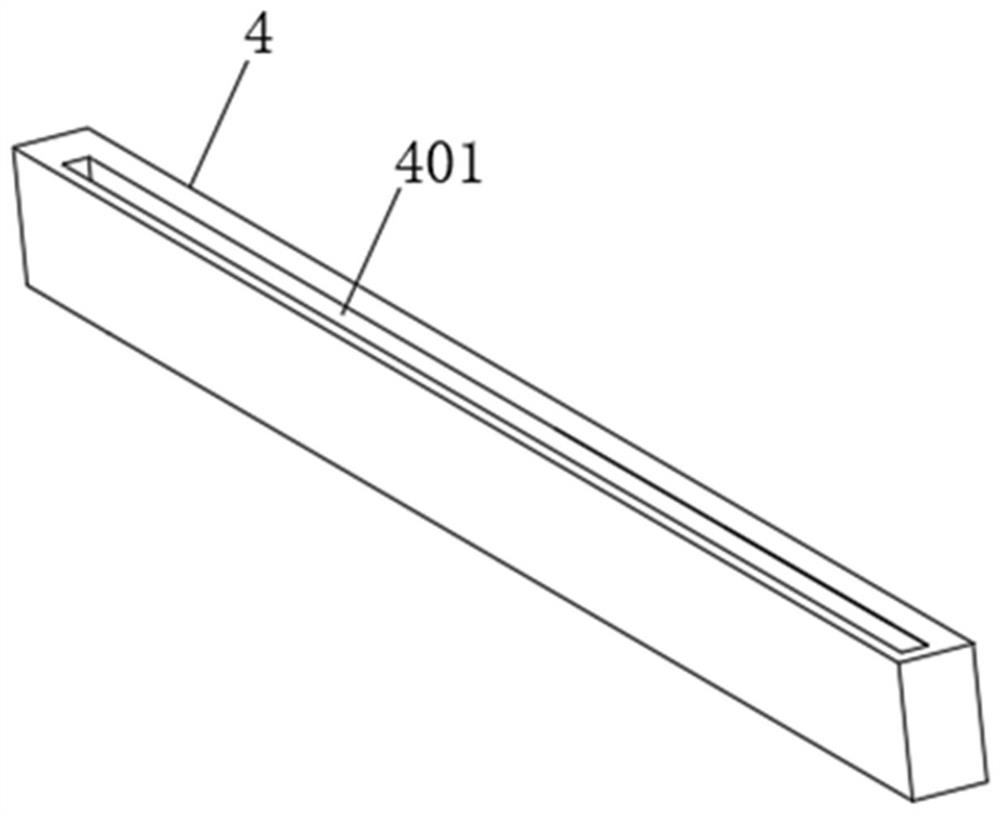

Automatic processing equipment for automobile muffler production

ActiveCN111469007AEffective automatic cleaningReduce work intensityEdge grinding machinesGrinding work supportsElectric machineryMuffler

The invention discloses automatic processing equipment for automobile muffler production and belongs to the field of automobile muffler production. The equipment comprises an equipment body, wherein aprocessing mechanism is fixedly connected to the upper surface of the equipment body, a bottom plate is arranged on the lower surface of the inner wall of the processing mechanism, and a hinge pin isfixedly connected to the right side face of the bottom plate. According to the automatic processing equipment for automobile muffler production, through the arrangement of an electric pushrod, the bottom plate, the hinge pin, a rotary disk, a motor, a connecting belt, a fixed block, a guide wheel, second springs and a scraping plate, scraps fall onto the bottom plate in the processing process, and the motor drives the rotary disk to rotate, so that the connecting belt shrinks to drive the bottom plate to rotate downwards; meanwhile the electric pushrod drives the scraping plate to scrape offthe scraps adhering to the bottom plate, so that the scraps fall into a collection box to facilitate unified collection and treatment; and through cooperation of the scraping plate and multiple otherstructures, the scraps can be effectively cleared automatically, and then the working strength of staff is effectively lowered.

Owner:龙泉奥翔汽车空调有限公司

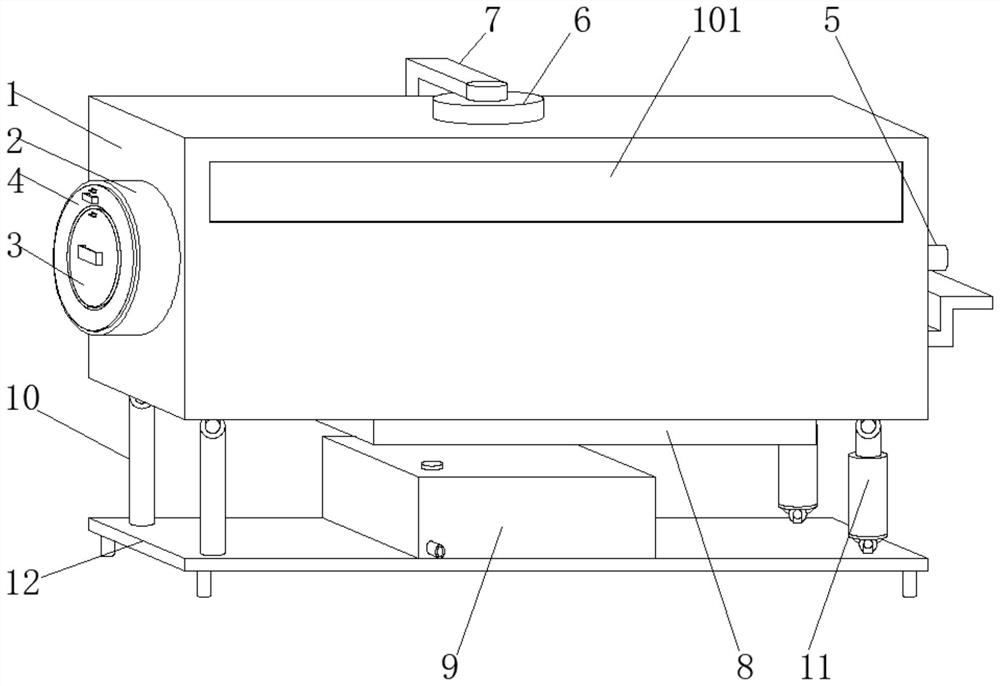

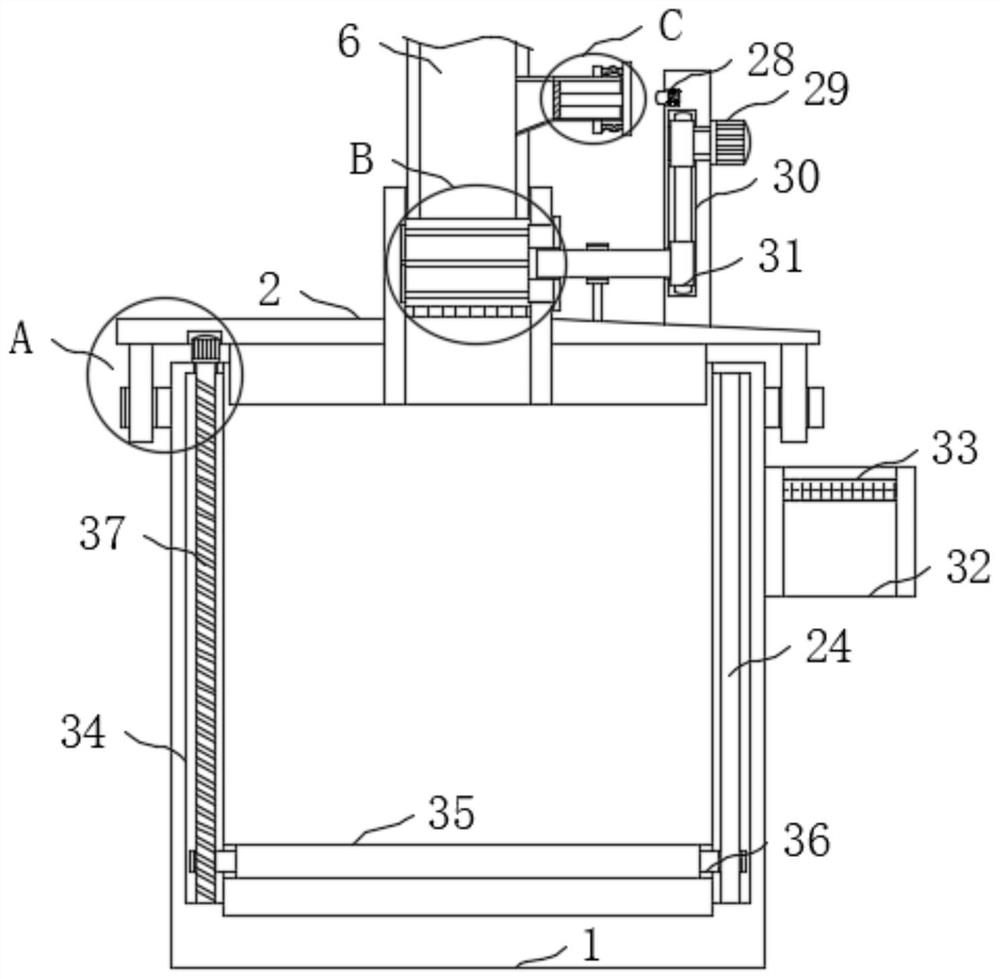

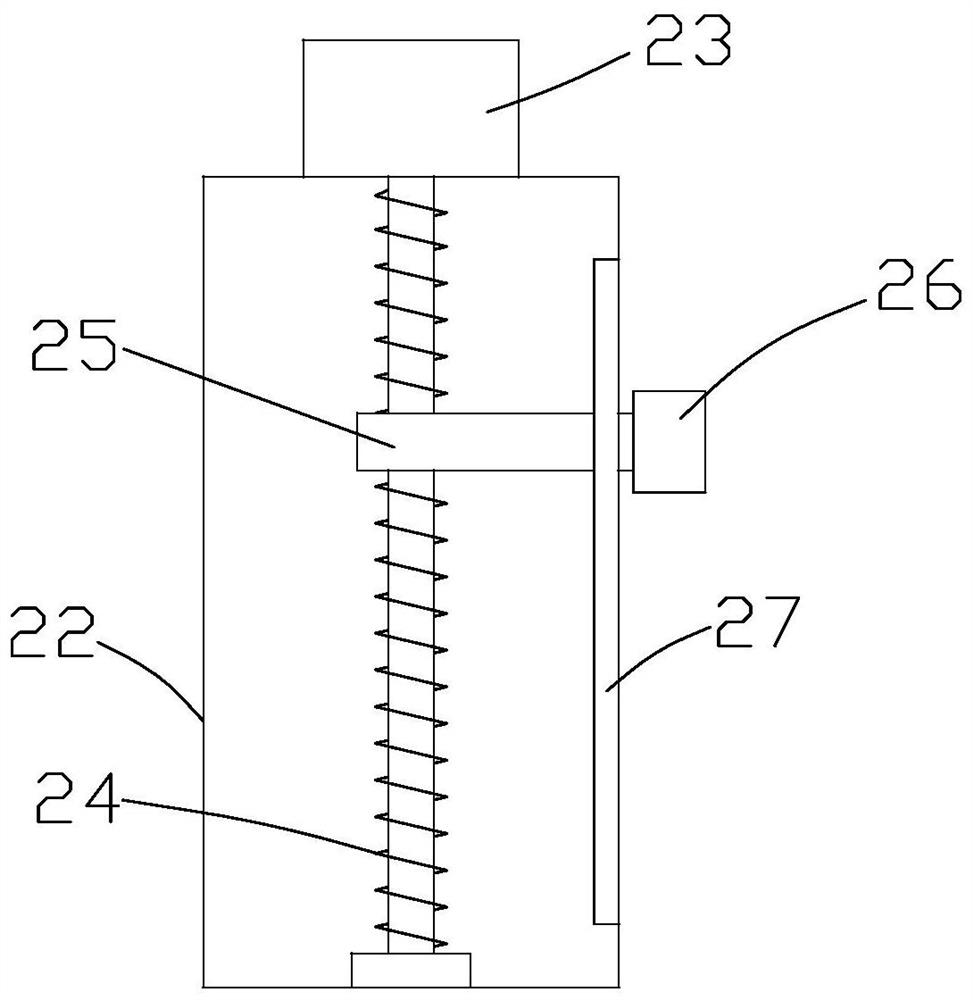

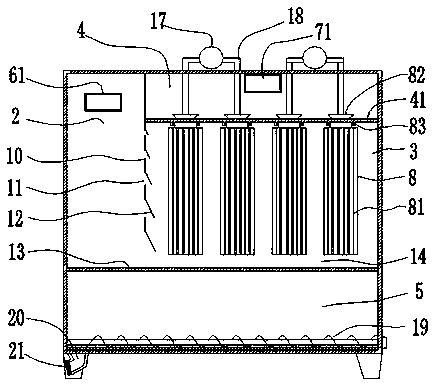

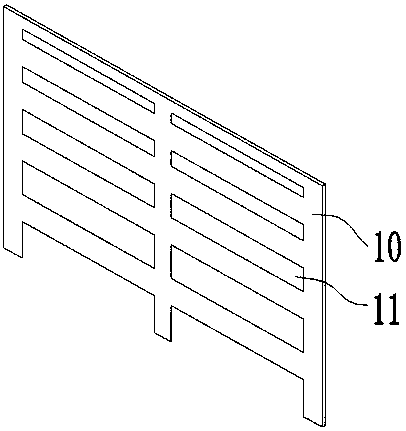

Crushing and cleaning integrated treatment device for waste plastic recovery

InactiveCN107696339AImprove cleaning efficiencyFacilitate unified collection and processingPlastic recyclingMechanical material recoveryEngineering

The invention relates to the technical field of plastic recovery treatment, in particular to a crushing and cleaning integrated treatment device for waste plastic recovery. The crushing and cleaning integrated treatment device comprises a cleaning box and a crushing box. The crushing box is located above the cleaning box. The cleaning box communicates with the interior of the crushing box. The crushing box is arranged at the top of the cleaning box in a sleeving manner. Fixed mechanisms connected with the cleaning box in a cooperating manner are arranged at the bottoms of the left side and theright side of the crushing box. Obliquely-placed transmission plates are further arranged on the two sides of the bottom of the crushing box. Mounting plates are vertically arranged on the left sideand the right side in the crushing box. The faces, away from each other, of the two mounting plates and the inner wall of the crushing box are connected through first springs. According to the crushing and cleaning integrated treatment device, multiple cutting knife plates can be firstly used for cutting waste plastic, the cut plastic can be cleaned in the cleaning box, and the crushing and cleaning integrated treatment device has the beneficial effects of being high in efficiency and simple in operation.

Owner:WUWEI XIAOLIN COMML & TRADE LTD

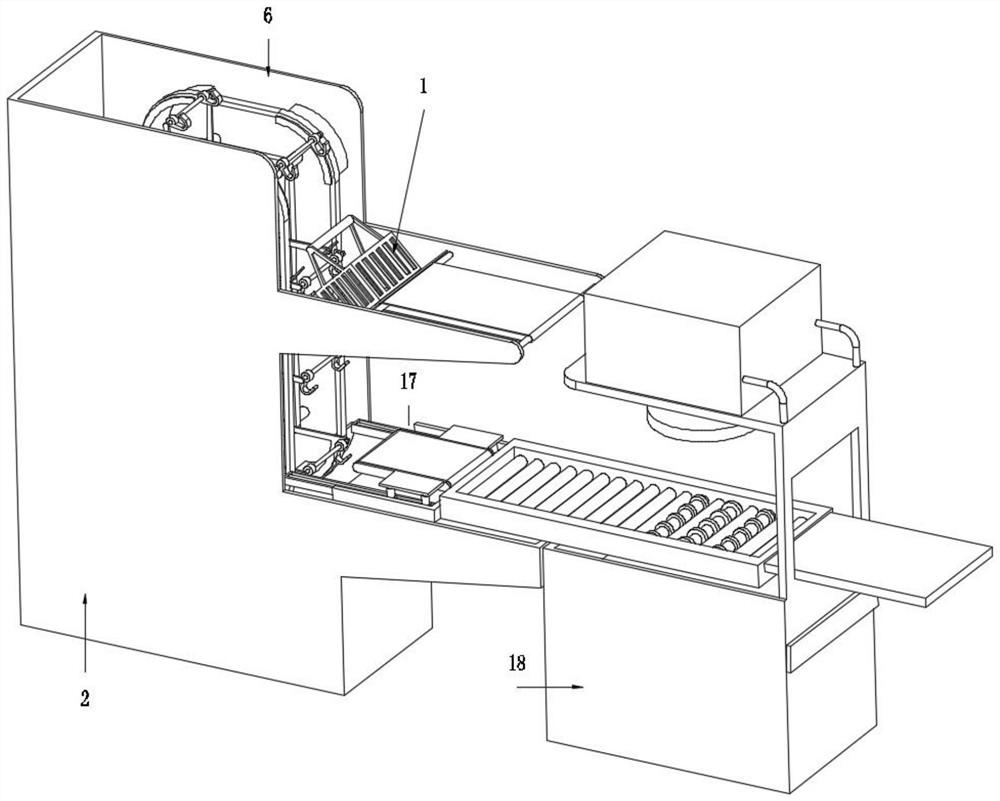

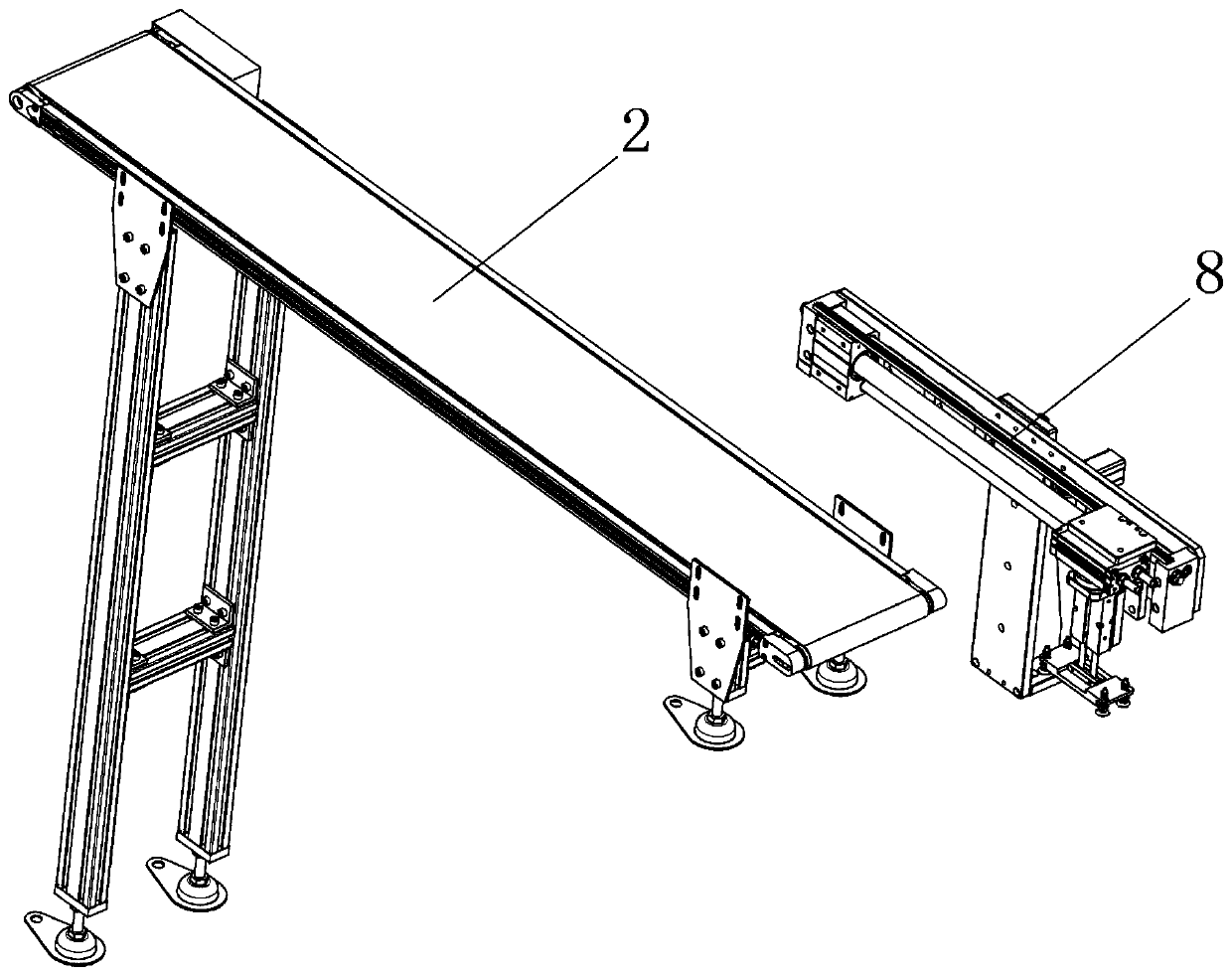

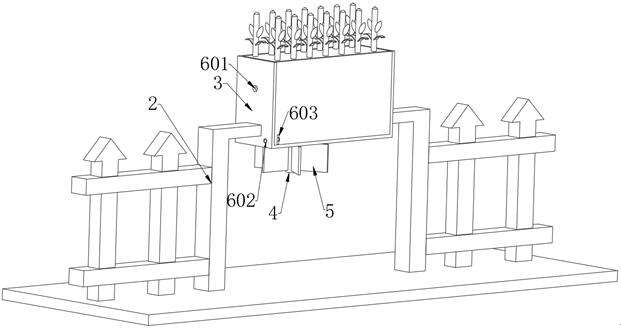

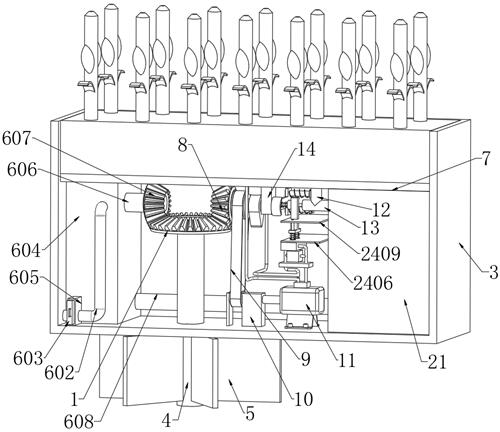

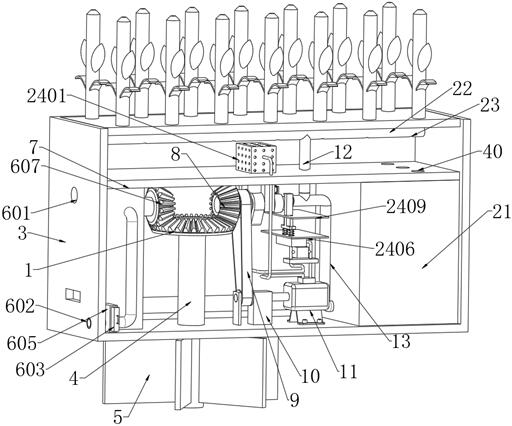

Battery recycling production equipment

InactiveCN114361632AFacilitate unified collection and processingNo harmWaste accumulators reclaimingBattery recyclingElectrical batteryProcess engineering

The invention discloses battery recycling and reusing production equipment in the technical field of battery recycling, the battery recycling and reusing production equipment comprises a material basket, a feeding part, a discharging part and an output cleaning part, the feeding part is used for conveying the material basket to the discharging part, the discharging part is used for conveying the material basket into the discharging part for discharging, and the output cleaning part is used for taking out and cleaning the discharged material basket. The feeding part comprises a discharging battery, the inner walls of the two sides of the discharging battery are rotationally connected with rotating belts, the inner sides of the rotating belts are fixedly connected with supporting arms, the ends of the supporting arms are jointly connected with a synchronous rod, the synchronous rod is externally and rotationally connected with a drag hook, and the drag hook is used for lifting a material basket. And after discharging, the material baskets are taken out through the output cleaning part, then cleaning is conducted, manual participation is not needed in the process, workers cannot be harmed, and meanwhile the production efficiency is improved.

Owner:深圳市浩霸电池有限公司

Titanium alloy processing machine tool and operation method thereof

PendingCN112059664AAdjustable distanceEasy to clamp and fixPositioning apparatusMetal working apparatusGear wheelElectric machinery

The invention discloses a titanium alloy processing machine tool and an operation method thereof. The titanium alloy processing machine tool comprises a workbench, first sliding grooves are formed inthe two sides of the top end of the workbench, and the two sides of the inner walls of the two first sliding grooves are slidably connected with the two sides of two sliding blocks correspondingly. According to the titanium alloy processing machine tool and the operation method thereof, a first sliding rod is arranged, under the cooperative use of a first electric telescopic rod, the first slidingrod and a second push rod, a second push plate is driven to move horizontally, so that the distance between a first push plate and the second push plate can be adjusted, workpieces of different sizescan be clamped and fixed conveniently, and the machining efficiency of the machine tool is improved; and under the acting force of a first clamping plate, a spring and a second clamping plate, the workpieces can be fixed, and the fixing efficiency of the workpieces is improved; and under the cooperative use of a first driving motor, a first gear and a second gear, a turnover plate is driven to rotate, so that the workpieces are turned over, the double faces of the workpieces can be machined conveniently, and the machining efficiency of the workpieces is improved.

Owner:江苏天工科技股份有限公司

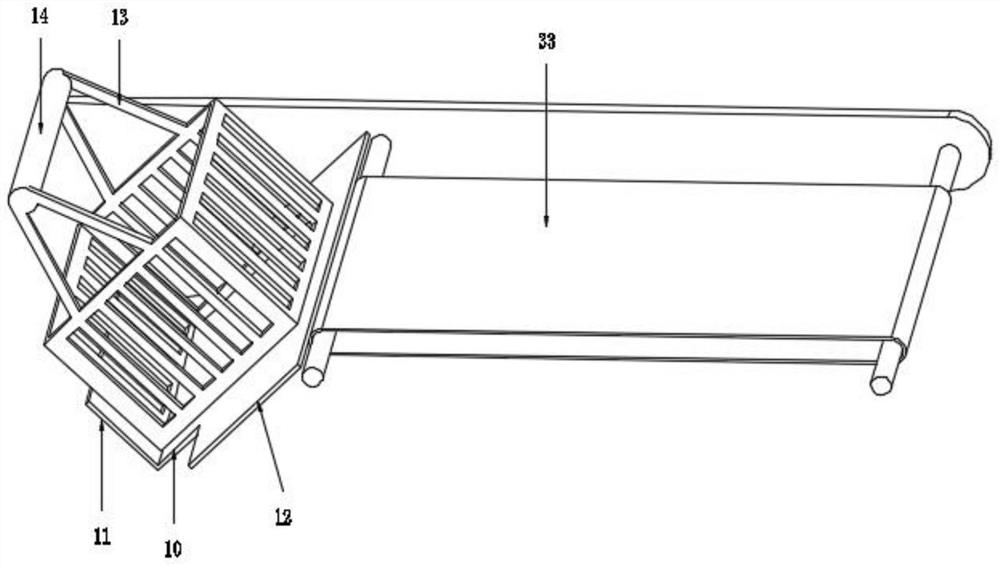

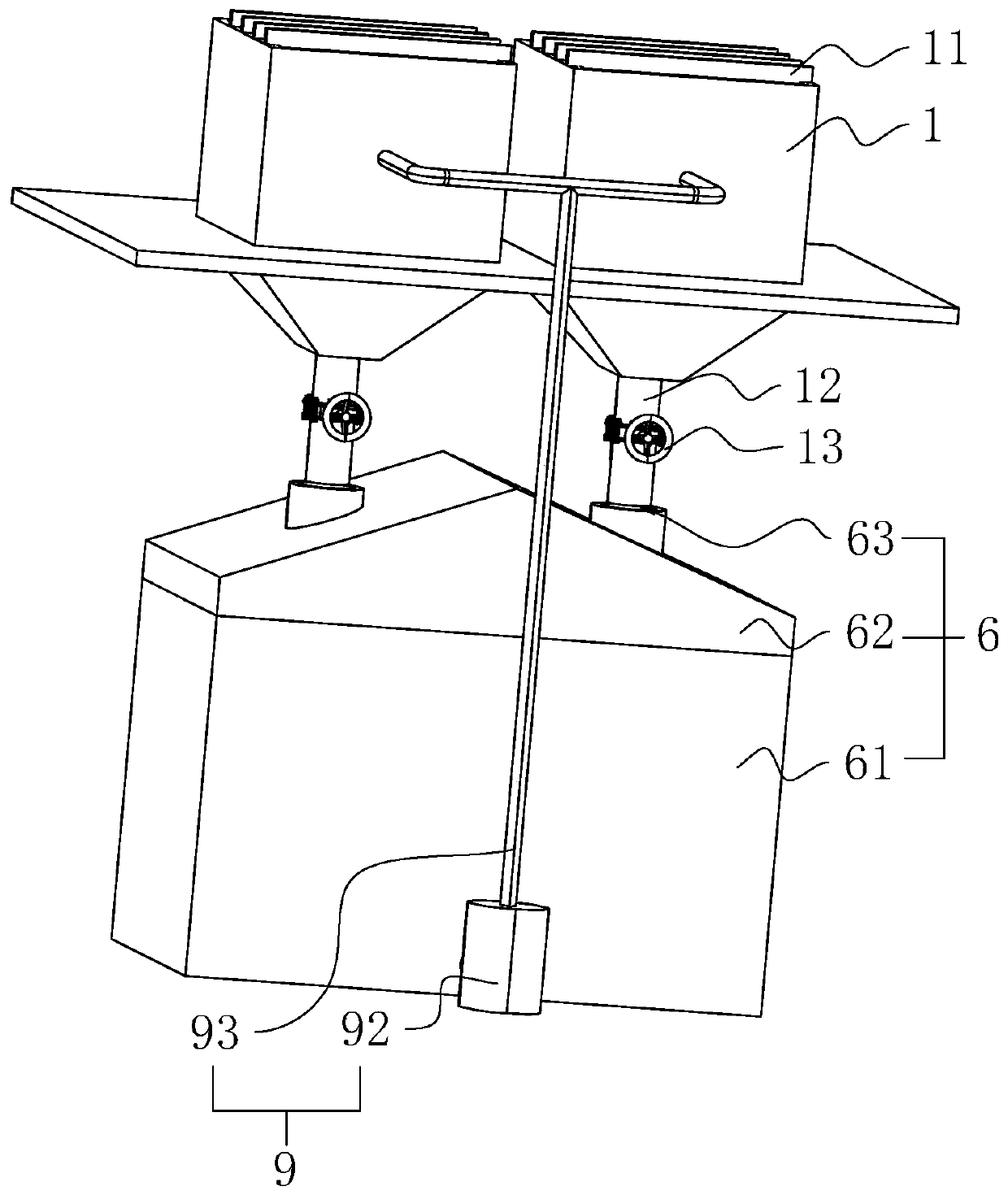

Grabbing and dumping equipment for tea leaf picking box

ActiveCN112020995ASave human effortHigh degree of automationPicking devicesElectric machineryAgricultural engineering

The invention relates to the technical field of tea leaf picking, in particular to grabbing and dumping equipment for a tea leaf picking box. The grabbing and dumping equipment for the tea leaf picking box comprises a base table, a moving assembly, a lifting assembly, a conveying assembly and a clamping assembly, wherein the conveying assembly is driven by a third motor to convey dumped tea leavesto a channel, and the dumped tea leaves enter a storage chamber of a collecting box through the channel, and the tea leaves in the picking box are dumped together in a mechanical mode and are conveyed together through the conveying assembly, so that a large amount of manpower is saved, the automation degree of tea leaf picking is improved, the operation convenience of picking personnel is also improved, the picking personnel only need to place the picking box in the hand at one end of the conveying assembly, meanwhile, the grabbing and dumping equipment is suitable for the situation that plenty of picking personnel exist, and disorder occurs in the process that plenty of picking personnel gather the tea leaves in respective picking box is avoided.

Owner:淮北醴恒净水科技有限公司

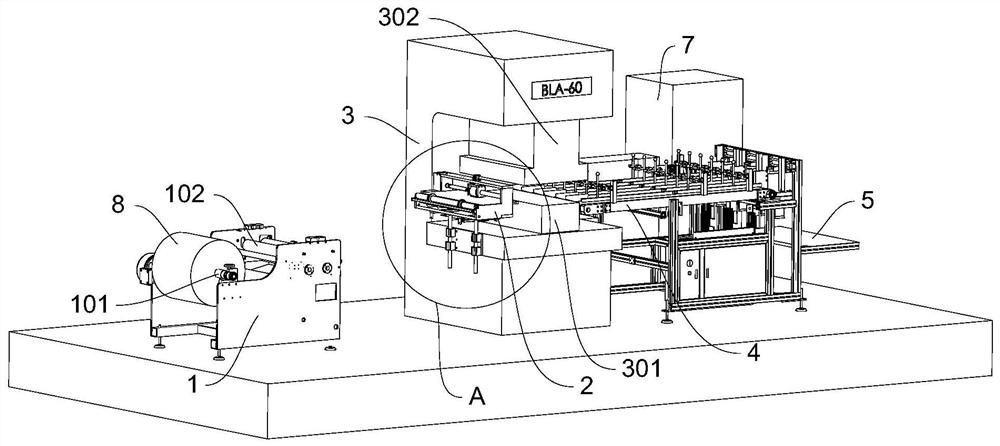

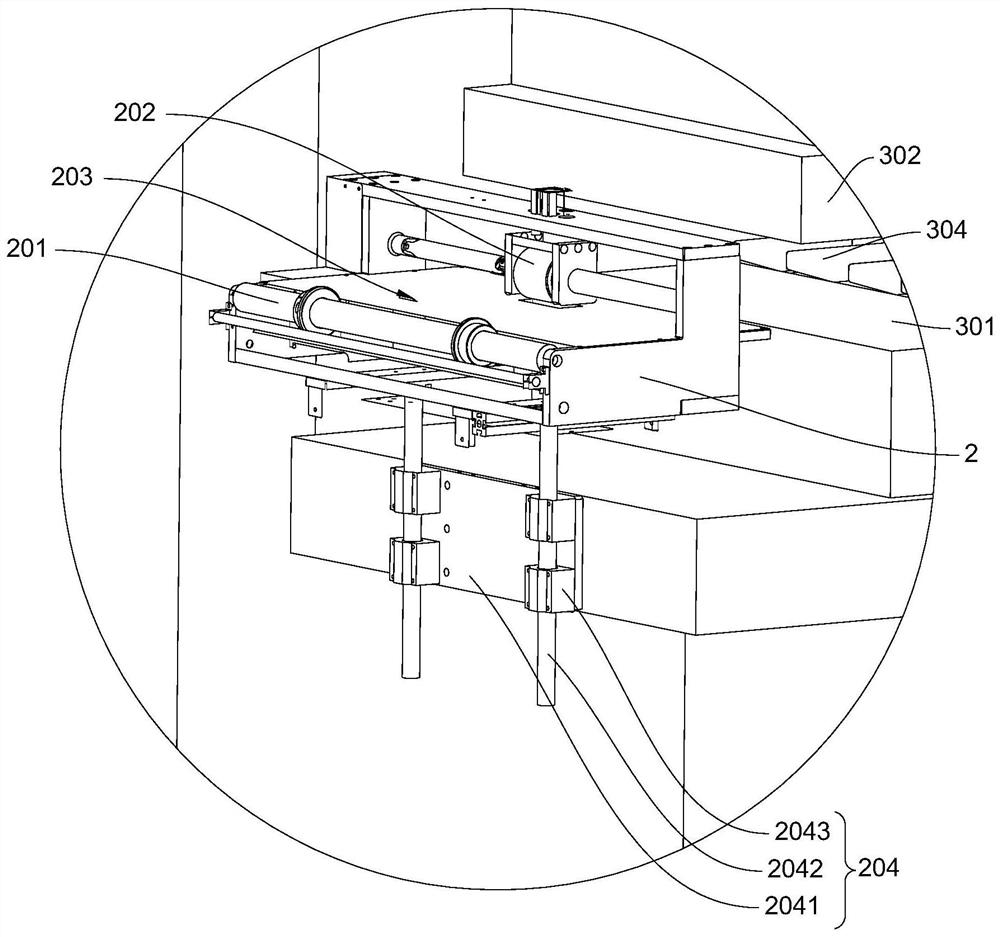

Automatic lunch box production system and method

PendingCN112893620AFacilitate unified collection and processingFacilitate subsequent processingShaping toolsMetal-working feeding devicesAluminum foilWaste material

The invention provides an automatic lunch box production system, and relates to the technical field of die stamping production. The automatic lunch box production system comprises an uncoiler, a feeding machine head, a stamping die, a conveying device and a finished product collecting table which are arranged in sequence, the stamping die is provided with an air blowing device, and the feeding machine head is installed at the feeding position of the stamping die. A raw material roller and an uncoiling roller are arranged in the uncoiler, an aluminum foil roll is installed on the raw material roller, the aluminum foil roll sequentially passes through the uncoiling roller and the feeding machine head to be conveyed into the stamping die to be pressed into a lunch box, the air blowing device blows the pressed lunch box to the conveying device, and the lunch box is conveyed into the finished product collecting table through the conveying device to be collected. The stamping die is connected with a waste collecting device used for collecting waste generated by stamping. The system has the advantages of automatic production and high production efficiency. The invention further provides an automatic lunch box production method. Automatic lunch box production is completed through the steps of preparing, stamping, collecting and the like. The automatic lunch box production method has the advantages of labor saving high in production efficiency.

Owner:东营市倍思特机床设备有限公司

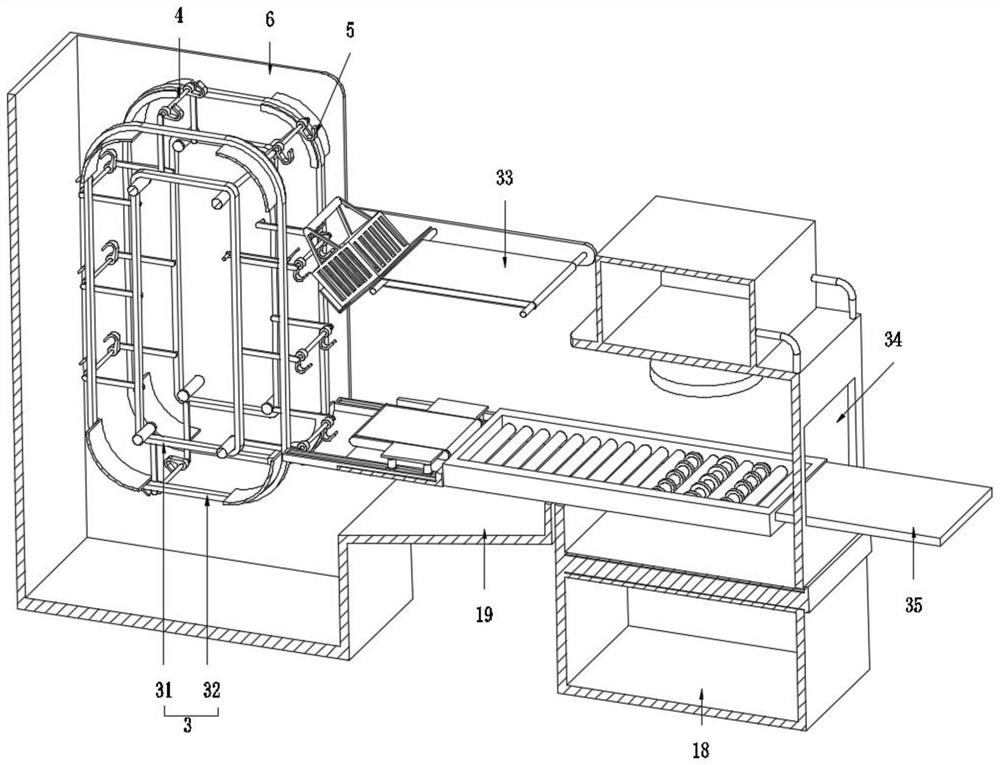

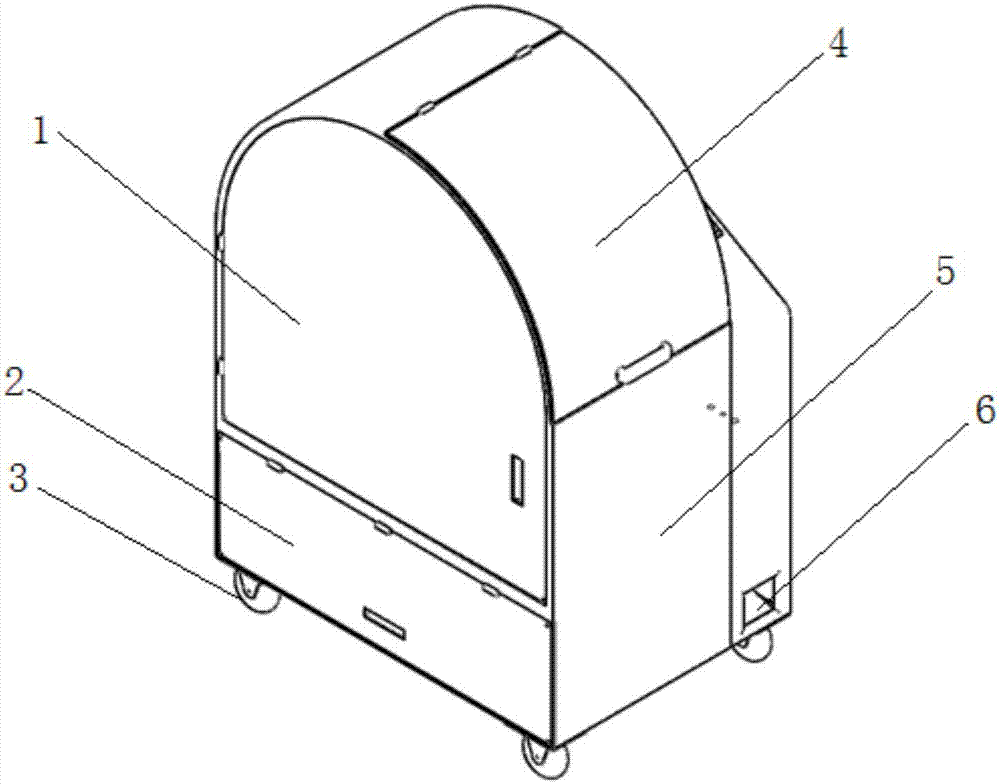

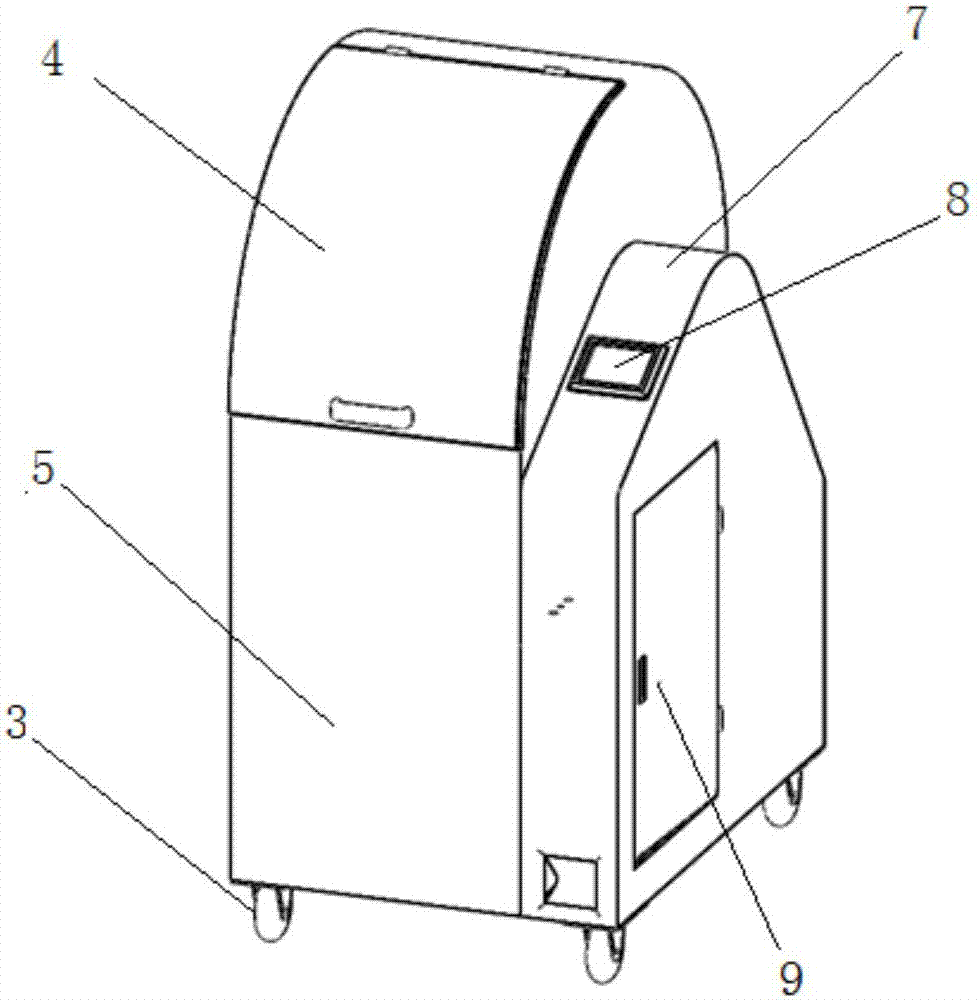

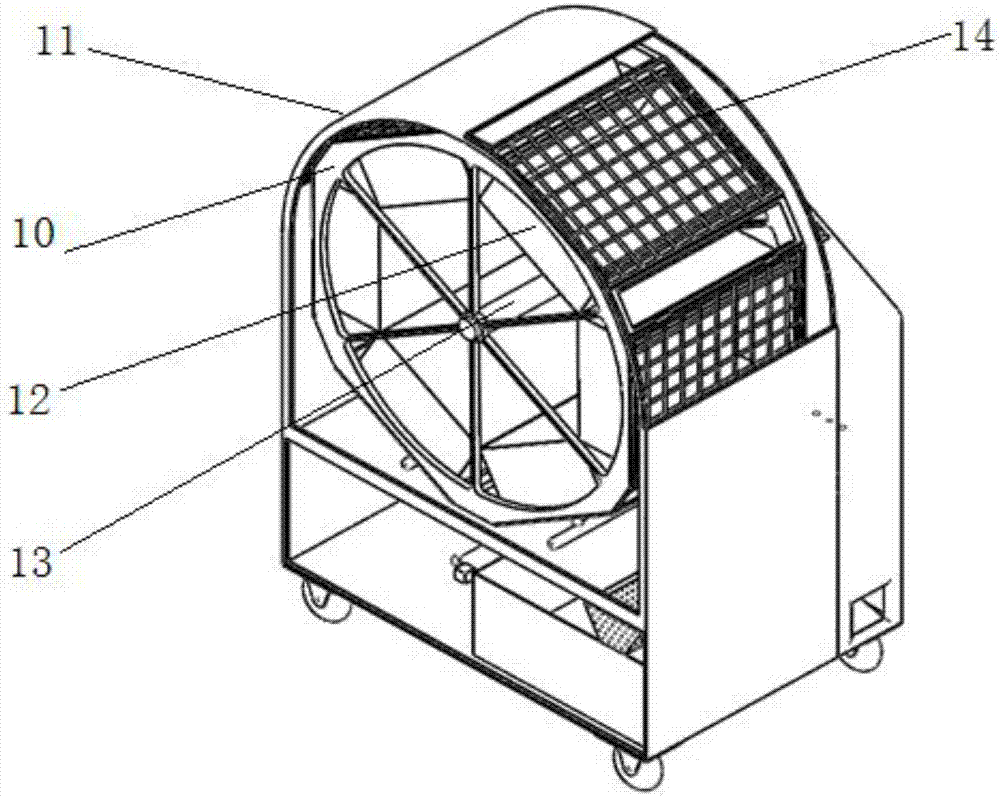

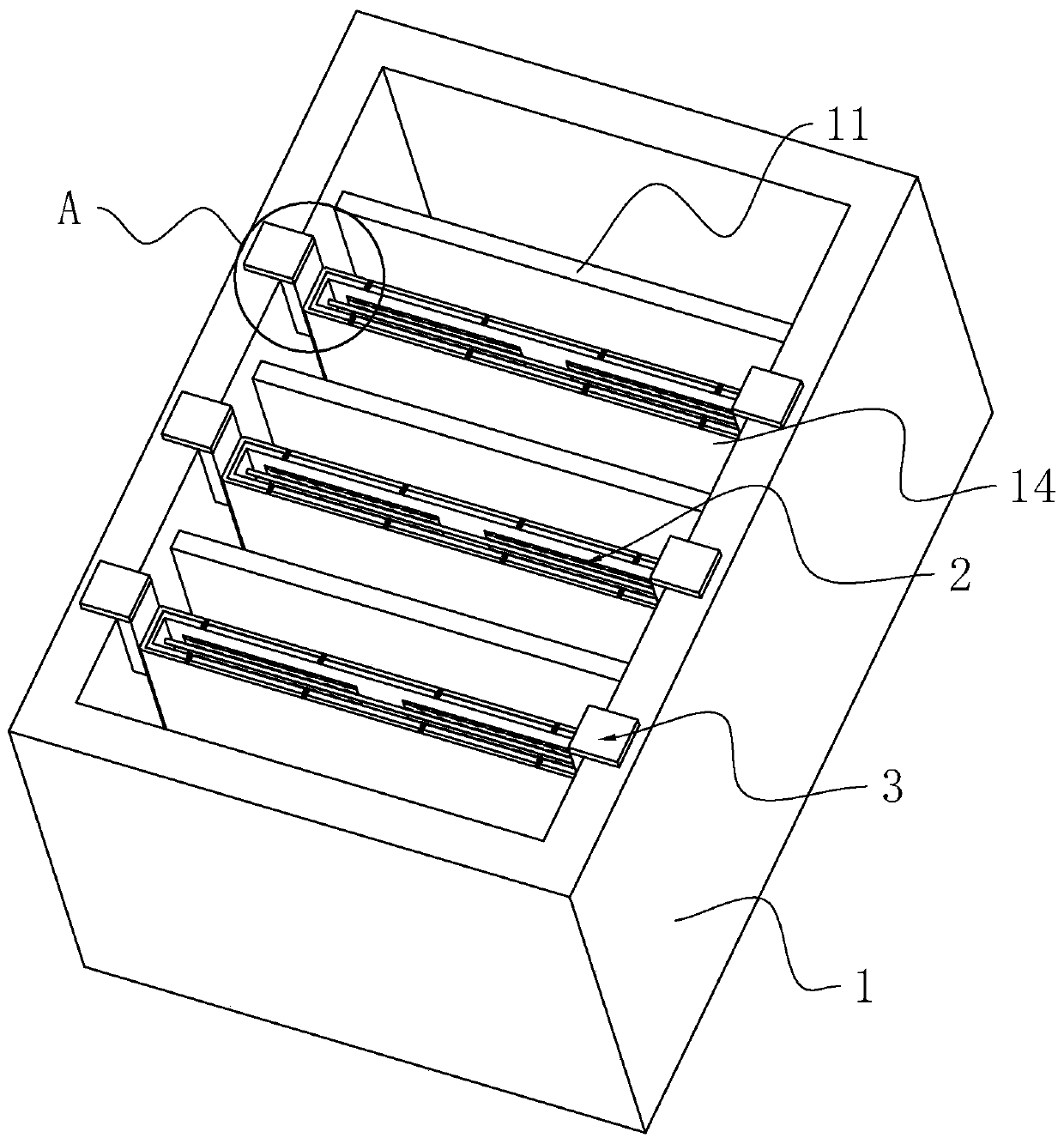

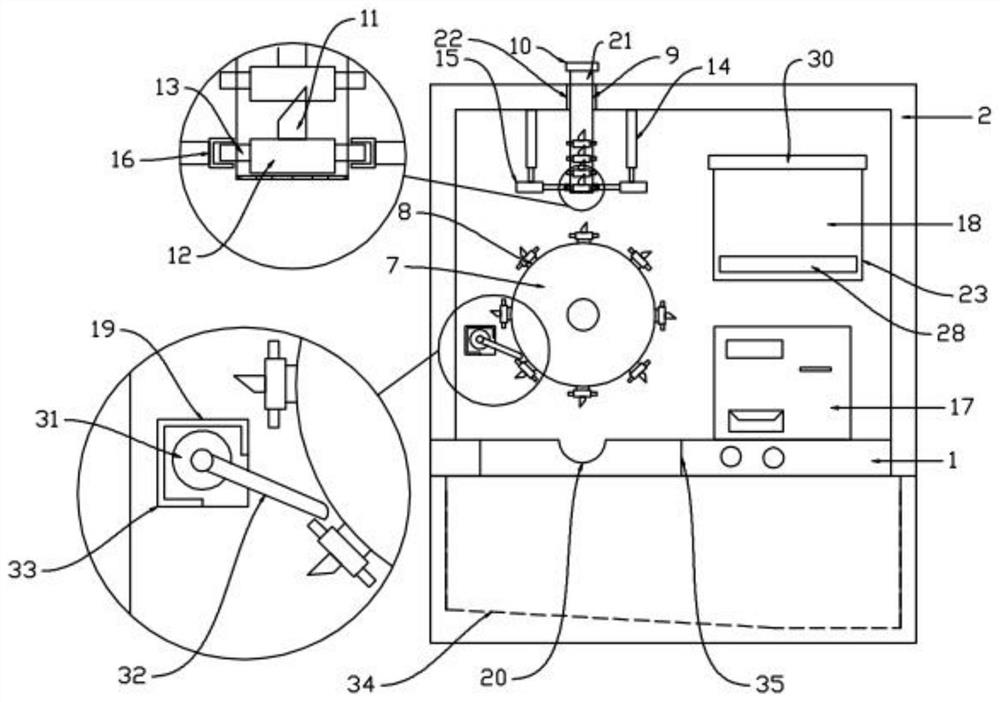

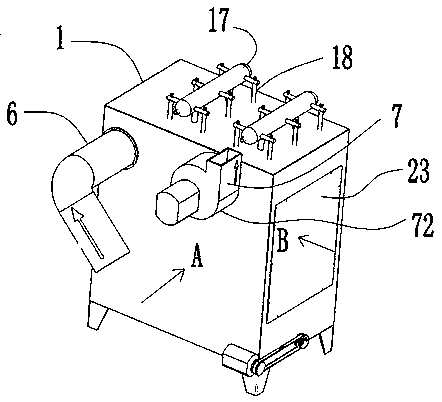

Cleaning machine of experimental animal feeding box

PendingCN107282565AAvoid harmReduce working noiseHollow article cleaningWastewaterStructural engineering

The invention discloses a cleaning machine of an experimental animal feeding box. The cleaning machine comprises a cleaning machine body, a cleaning cabin is arranged on the upper portion of the cleaning machine body, a filter liquid storage cabin is arranged on the lower portion of the cleaning machine body, an electrical cabin is arranged on one side of the cleaning machine body, a servo motor and a control circuit board for controlling the servo motor to work are arranged in the electrical cabin, the cleaning cabin comprises a cage box rolling frame and a fixing shaft, the fixing shaft is fixedly arranged on the inner wall of the cleaning cabin, the cage box rolling frame is arranged on the fixing shaft and can be driven by the servo motor to rotate around the fixing shaft, a cage box mounting station is arranged on the cage box rolling frame, multiple nozzles are formed in the fixing shaft, and a spraying head is arranged at the bottom of the cage box rolling frame; a centrifugal water pump for supplying water to the nozzles and the spraying head is arranged in the filter liquid storage cabin, and cleaning wastewater falling down from the cage box rolling frame flows into the filter liquid storage cabin. According to the cleaning machine, the cleaning effect is met, meanwhile, labor loads are reduced, and the hurt of the noise to workers is avoided.

Owner:西安富康空气净化设备工程有限公司

Environment-friendly mechanical solid-liquid waste separation device

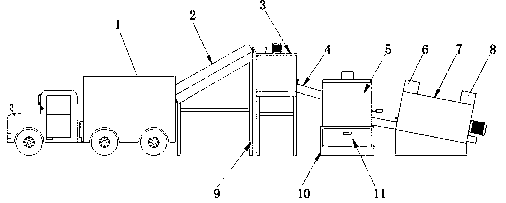

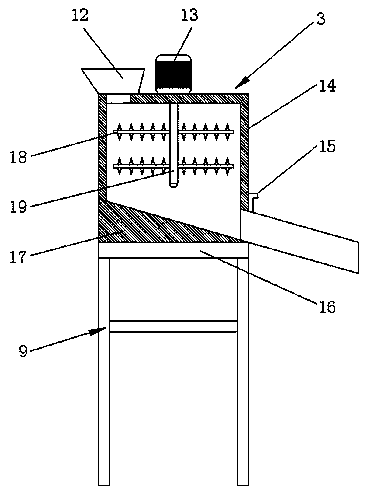

InactiveCN109013668APromote environmental protectionSimple structureSolid waste disposalTransportation and packagingEngineeringTruck

The invention discloses an environment-friendly mechanical solid-liquid waste separation device. The environment-friendly mechanical solid-liquid waste separation device comprises a garbage truck, a conveying device, a crushing device, an extrusion device and a drying device. The garbage truck is connected with the crushing device through the conveying device. The crushing device is fixedly connected with the extrusion device through a delivery pipe. The side, far away from the crushing device, of the extrusion device is fixedly connected with the drying device through a delivery pipe. The crushing device comprises a crushing barrel, a bottom plate, a sliding table and a supporting frame. The supporting frame is used for supporting and fixing the bottom plate to the top end of the supporting frame. The upper end of the bottom plate is fixedly connected with the sliding table. The crushing barrel is fixedly connected to the sliding table. The crushing barrel is provided with a crushingshaft through a first motor. A delivery pipe penetrates through the bottom end of the crushing barrel. The environment-friendly mechanical solid-liquid waste separation device is simple in structure,convenient to use, capable of crushing large garbage conveniently and good in solid-liquid separation effect, and the environmental protection property of the device can be improved.

Owner:海数(青岛)医学科技有限公司

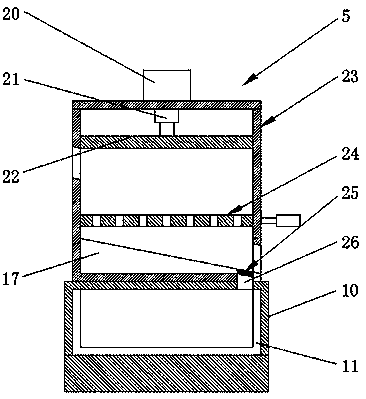

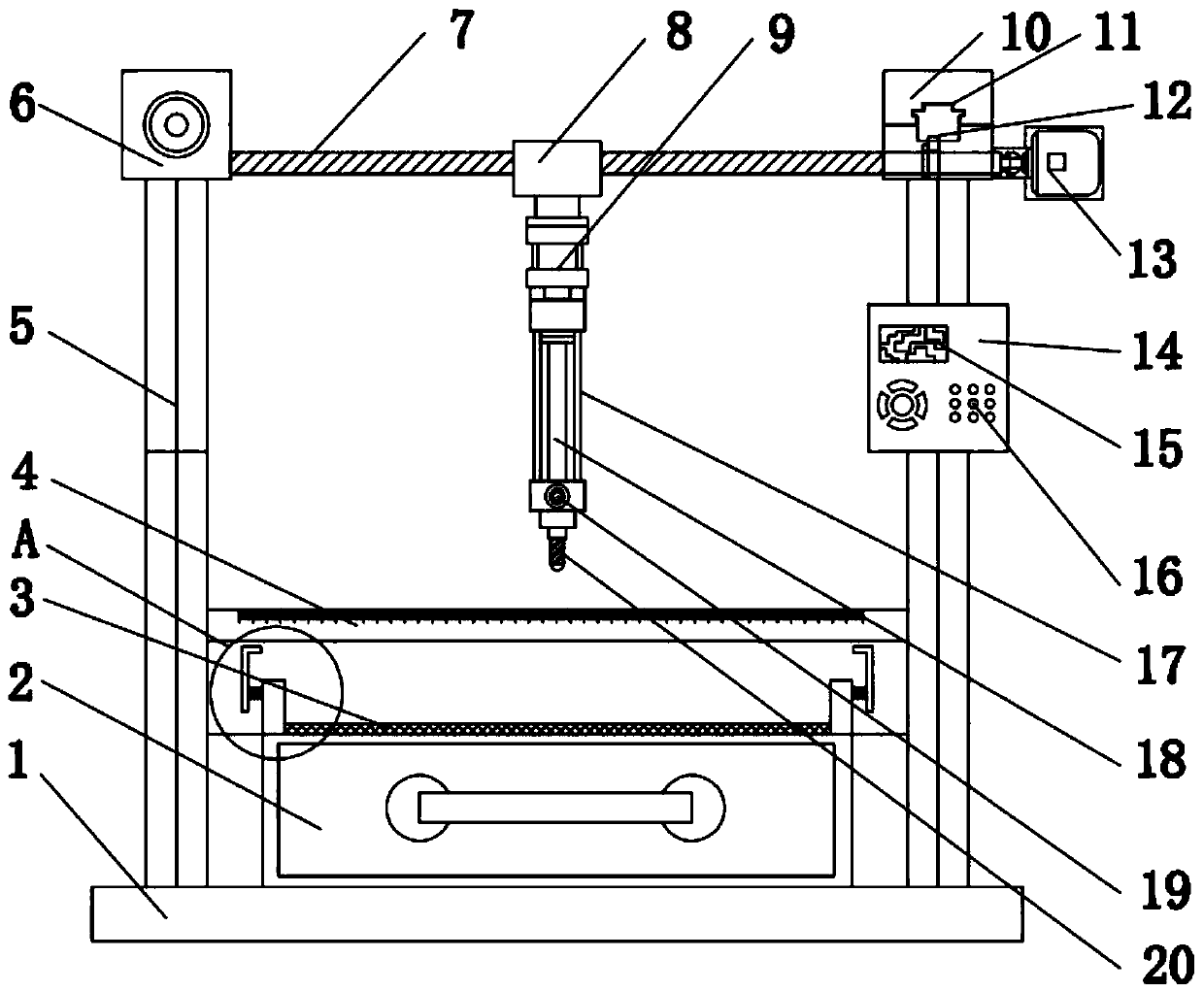

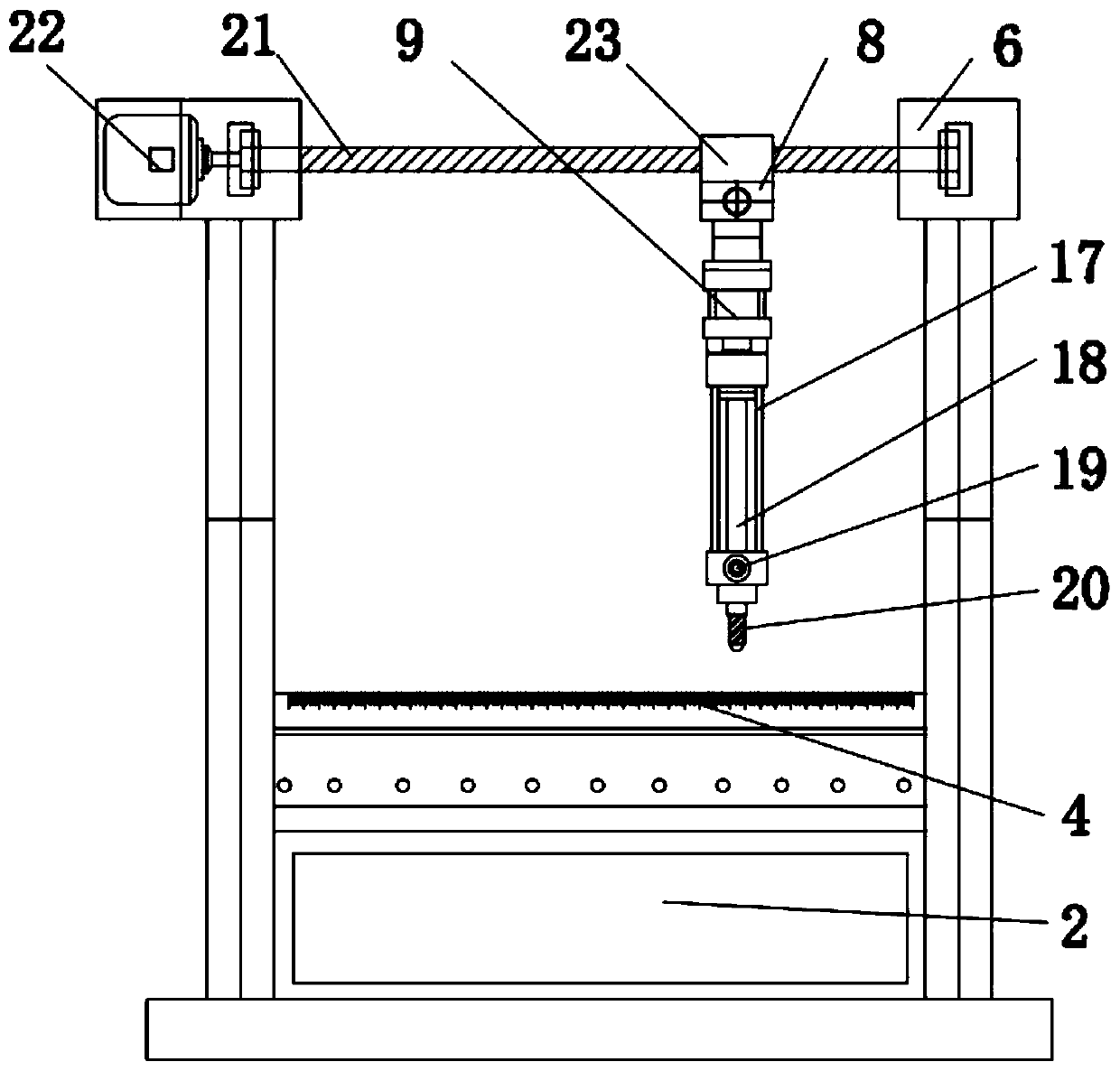

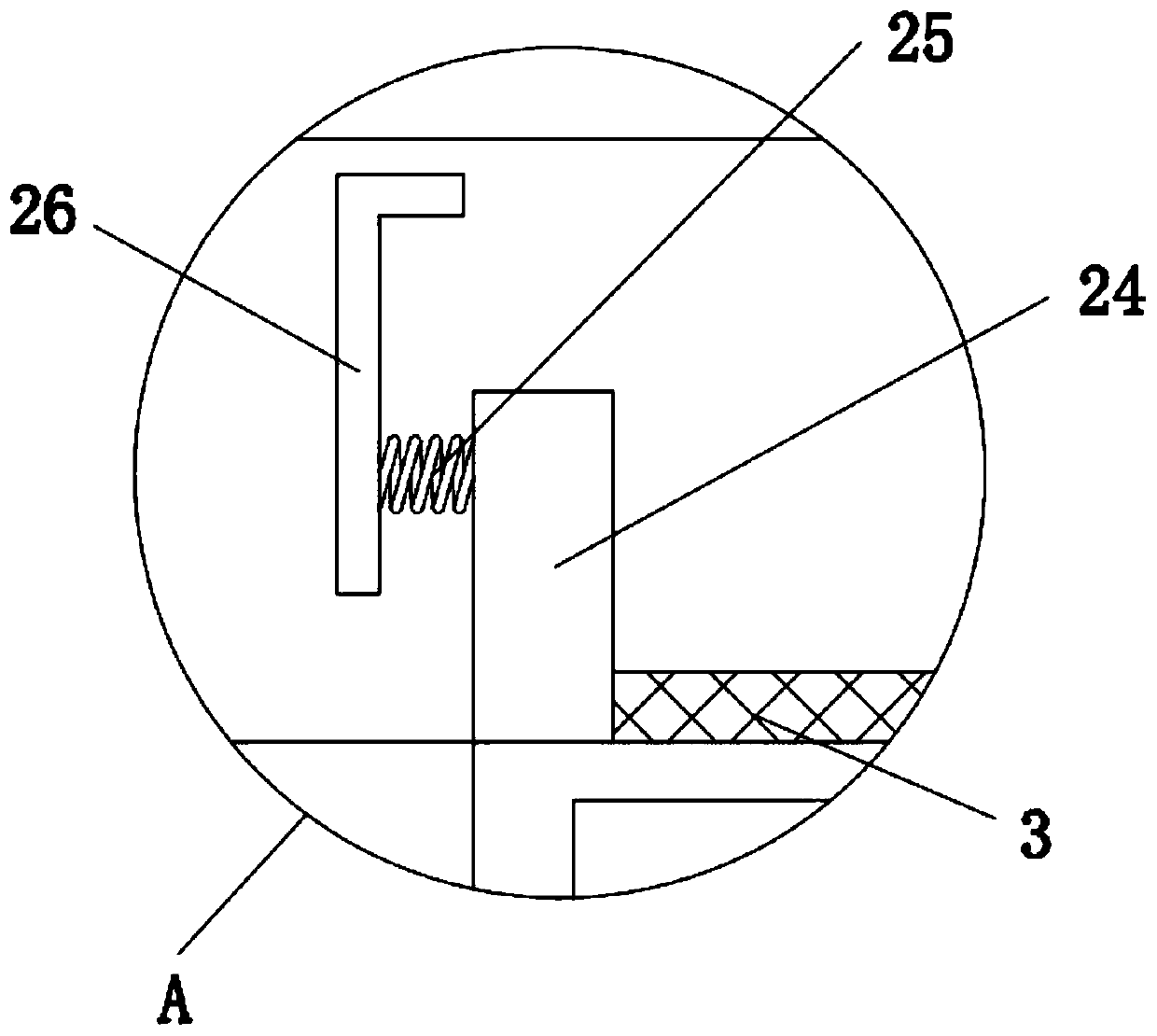

Positioning and punching equipment for civil engineering construction

PendingCN109702902AFacilitate unified collection and processingGuaranteed cleanlinessWorking accessoriesStone-like material working toolsPunchingAir pump

The invention discloses positioning and punching equipment for civil engineering construction. The positioning and punching equipment comprises a base, an air pump and a punching drill bit; a waste box is arranged at the upper end of the base, and a filter screen is installed above the waste box; and the air pump is fixed at the lower end of a first sliding table, the lower end of the air pump isconnected to an air cylinder, and the punching drill bit is installed at the lower end of a piston rod. According to the positioning and punching equipment for civil engineering construction, the waste box is arranged, one layer of filter screen is installed on the waste box, scraps and waste generated by punching on the filter screen can fall into the waste box through holes in the filter screen,the waste box can be used for containing the scraps and the waste generated by punching, so that the scraps and the waste can be conveniently and centralizedly collected and processed, and thus a working table board can keep clean; and each of the front side and the left side of the air cylinder is provided with a camera, so that the cameras can collect digital information on rulers which are located on the front side and the left side of the whole equipment, the information is fed back to a controller, and therefore positioning and punching of the whole equipment can be realized.

Owner:ANHUI UNIV OF SCI & TECH

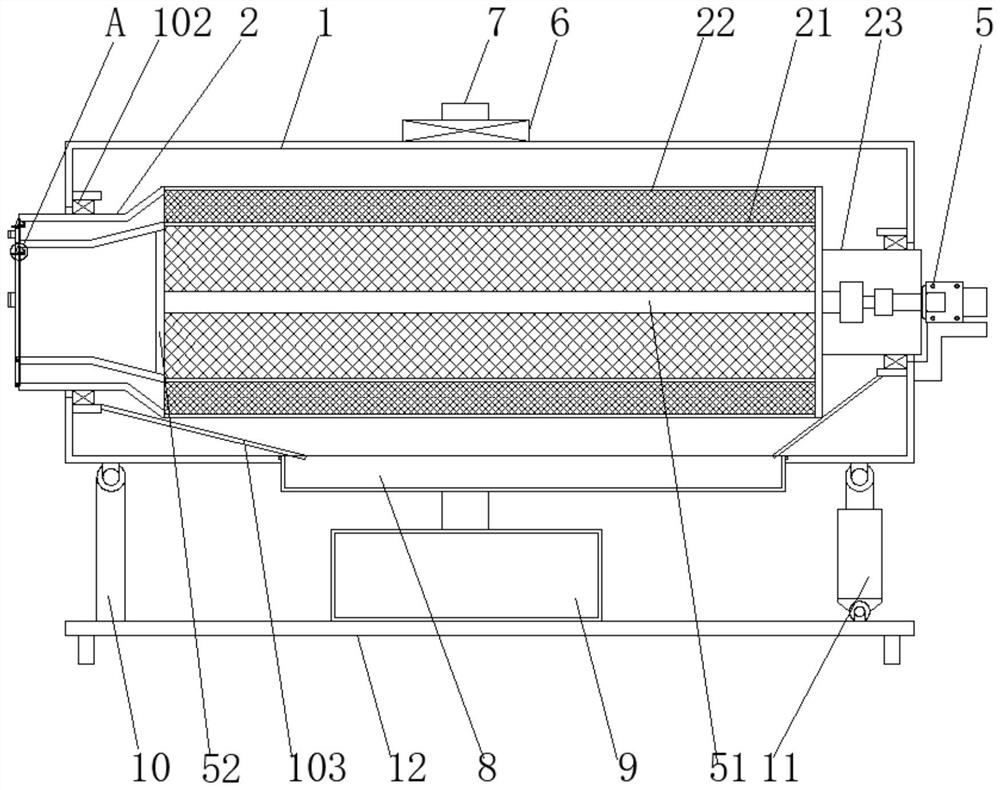

Round screen drum with dustproof effect for rice primary processing

InactiveCN114042619AAvoid scatterReduce environmental pollutionSievingScreeningAgricultural engineeringElectric machinery

The invention discloses a round screen drum with the dustproof effect for rice primary processing, which comprises a shell, wherein a drum screen is installed in the shell, a first-stage sealing cover is hinged to the middle position of a left end opening of the drum screen, and a second-stage sealing cover is hinged to the outer side of the first-stage sealing cover; a driving motor connected to the right end of the shell, wherein an exhaust fan is installed on the top of the shell, an air pipe is connected to the rear side of the exhaust fan, and a particle dust collecting box is slidably connected to the lower portion of the shell; and a dust collection water tank which is arranged below the particle dust collecting box, wherein vertical rods are hinged to the front end and the rear end of the left side of the shell, and a bottom frame is fixed to the lower ends of the vertical rods. According to the round screen drum for rice primary processing, the whole screening mechanism is arranged in the shell, meanwhile, the exhaust fan is arranged to collect dust generated by screening, the problem that dust is scattered all around due to direct exposure of the screen is avoided, unified collection and treatment are facilitated, and the problem that the dust pollutes the environment is effectively solved.

Owner:湖南米米梦工场科技股份有限公司

Flattening device and method for circuit board processing

PendingCN111438924AImprove stabilityImprove reliabilityDispersed particle filtrationCleaning using gasesDust controlEngineering

The invention discloses a flattening device and method for circuit board processing. The flattening device comprises a flattening platform, a flattening mechanism, a dust absorption mechanism and a detection mechanism. The flattening mechanism, the dust absorption mechanism and the detection mechanism are all located on the top surface of the flattening platform, and the dust absorption mechanismand the detection mechanism are located on two sides of the flattening mechanism. A circuit board penetrates through the dust absorption mechanism, the flattening mechanism and the detection mechanismin sequence. The method includes the steps of flattening platform processing, dust absorption mechanism installation, flattening mechanism installation, detection mechanism installation and circuit board flattening detection. According to the flattening device and method for circuit board processing, the circuit board that needs to be flattened can be dedusted, dust is prevented from sticking tothe surface of the circuit board during the flattening process, the circuit board is prevented from wrinkling and unwinding inequality in the manufacturing process, and the processing quality of the circuit board is improved. The flattening detection method of the circuit board is simple in steps, the automatic dust absorption, flattening and scanning of the circuit board can be realized, the phenomenon of wrinkling and unwinding inequality in the manufacturing process can be prevented, and the processing quality of the circuit board is improved.

Owner:浙江新连宇电子有限公司

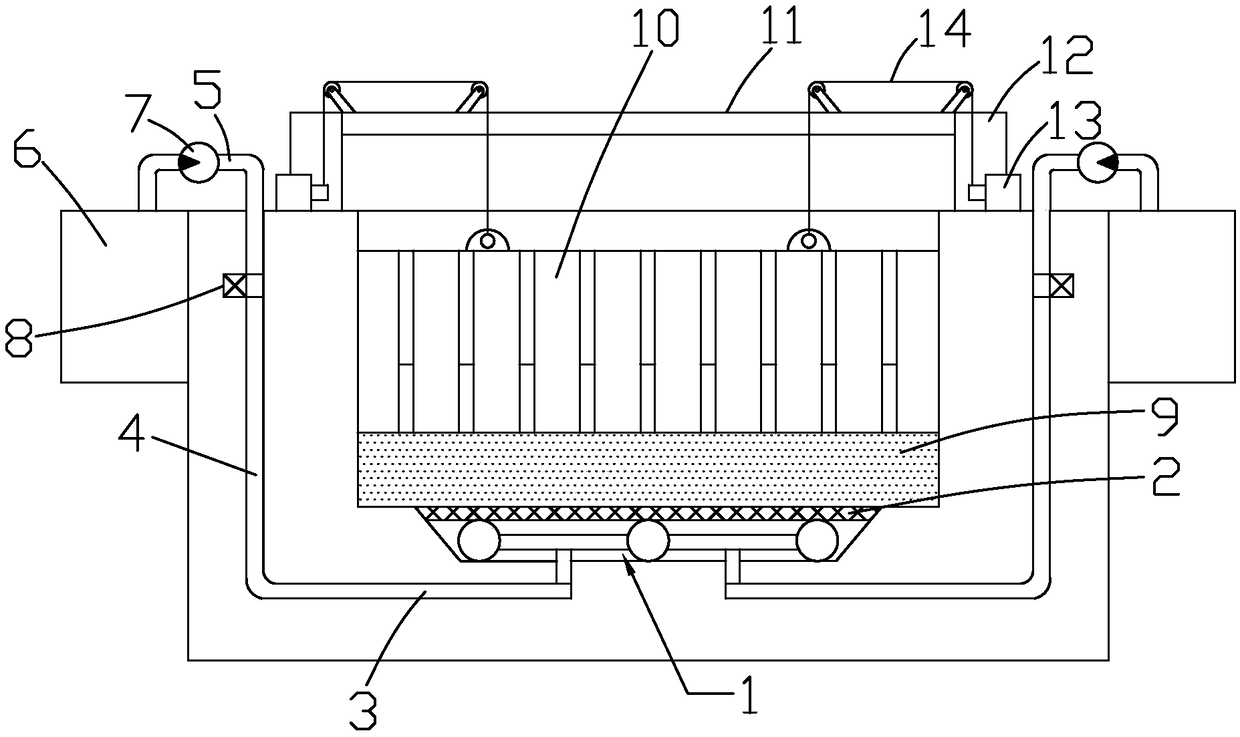

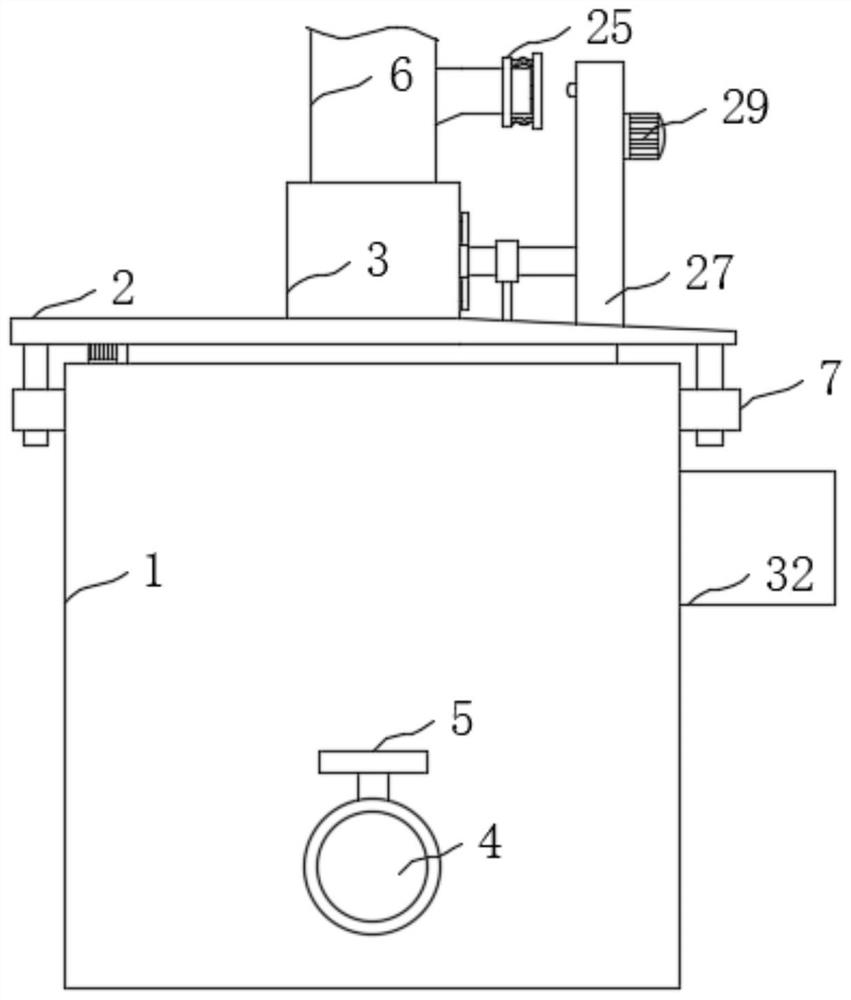

Aquaculture sewage treatment standing tank

InactiveCN112451999AGuaranteed cleanlinessTo ensure the effect of static treatmentSettling tanks feed/dischargePisciculture and aquariaSewage treatmentAquaculture

The invention discloses an aquaculture sewage treatment standing tank which comprises a sealing cover mounted on a tank body, a liquid inlet seat is fixedly mounted on the sealing cover, a liquid inlet pipe is fixedly connected to the liquid inlet seat, a liquid outlet seat is fixedly mounted on the tank body, and a valve is mounted on the liquid outlet seat. A clamping mechanism is arranged between the tank body and the sealing cover; and a silk screen is fixedly arranged on the liquid inlet seat. The aquaculture sewage treatment standing tank has the advantages that impurities with large sizes can be prevented from entering the tank body, the standing capacity of the tank body can be effectively ensured, and when the liquid inlet pipe is blocked, the impurities can be automatically discharged to ensure the smoothness of the liquid inlet seat, so that the sewage discharge and treatment effects are ensured, and after the aquaculture sewage treatment standing tank is used for a period of time, impurities partially accumulated at the bottom of the tank body and adhered to the inner wall of the tank body can be scraped off, so that the impurities can be conveniently discharged from the tank body, the cleanness degree in the tank body can be kept, and the standing treatment effect on sewage is ensured.

Owner:德清瓜山水产养殖有限公司

Intelligent recognition self-propelled paddy field weeding robot

InactiveCN111296050AFacilitate unified collection and processingIncrease the use of spaceGrass dryingMowersAgricultural scienceAgricultural engineering

The invention relates to the technical field of weeding, and discloses an intelligent recognition self-propelled paddy field weeding robot. The intelligent recognition self-propelled paddy field weeding robot comprises a machine body, wherein a lifting handle is fixedly installed at the top of the machine body; moving wheels are fixedly installed at the bottom of the machine body; and a crawler belt is fixedly connected to the exteriors of the moving wheels. According to the intelligent recognition self-propelled paddy field weeding robot, an exhaust fan is arranged on the right sides of bladeshells, cut weeds can enter a weed collecting box through the exhaust fan, and meanwhile, a heating plate is fixedly installed on the front face of the weed collecting box to treat water in the weedsaccording to the characteristics of a paddy field environment, the actual use space of a box body is promoted for facilitating unified collection and treatment of the weeds, a protective shell is arranged on the left side of a motor shell, personnel are prevented from accidentally making contact with and colliding with the blades to be injured, meanwhile, the blade shells are of a spliced type and are installed and limited through the limiting rods, the robot is convenient in disassembly and easy in maintenance, and the crawler belt adapts to paddy field terrains to prevent the device from rollover.

Owner:JINHUA VOCATIONAL TECH COLLEGE

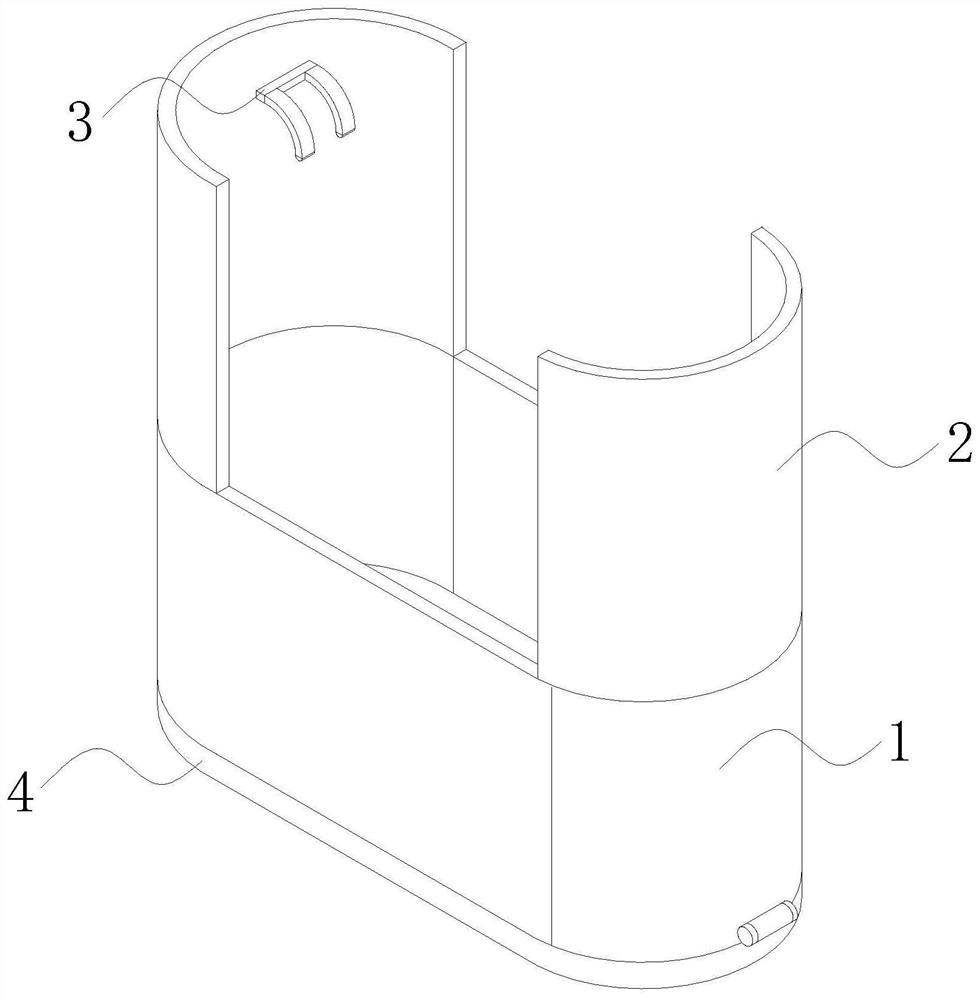

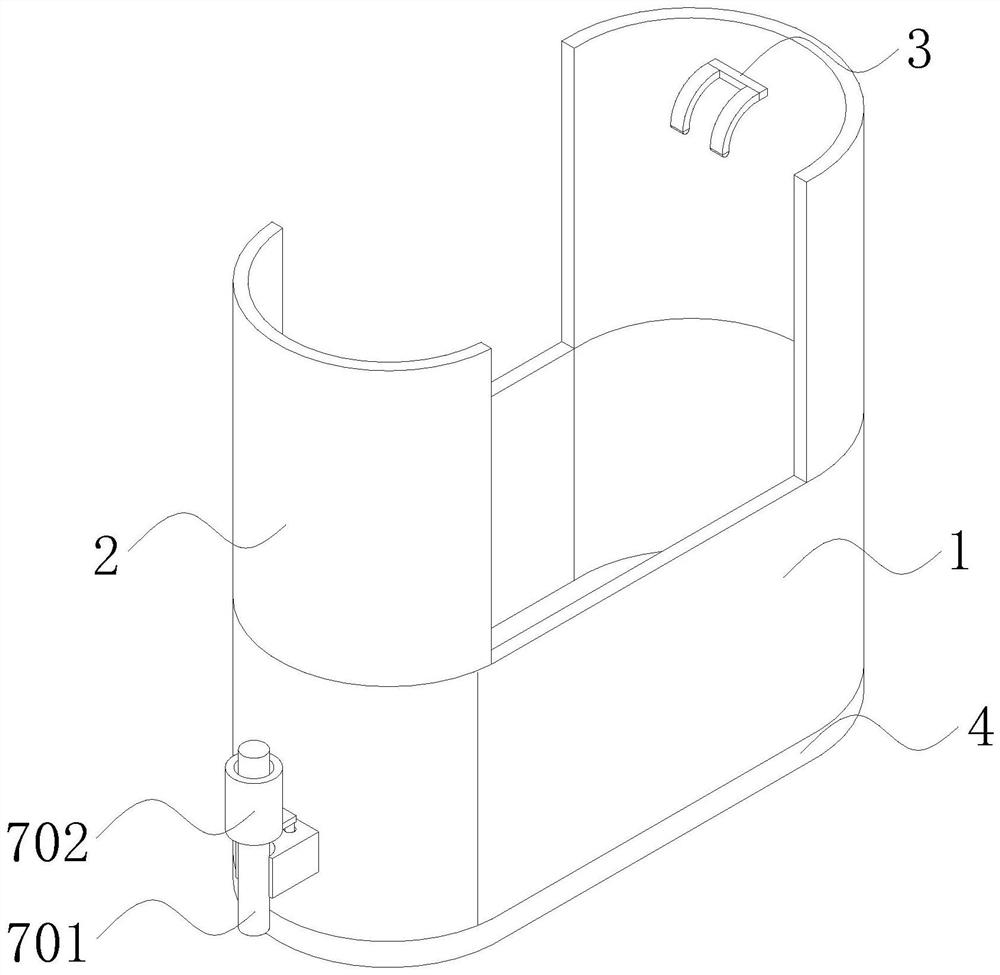

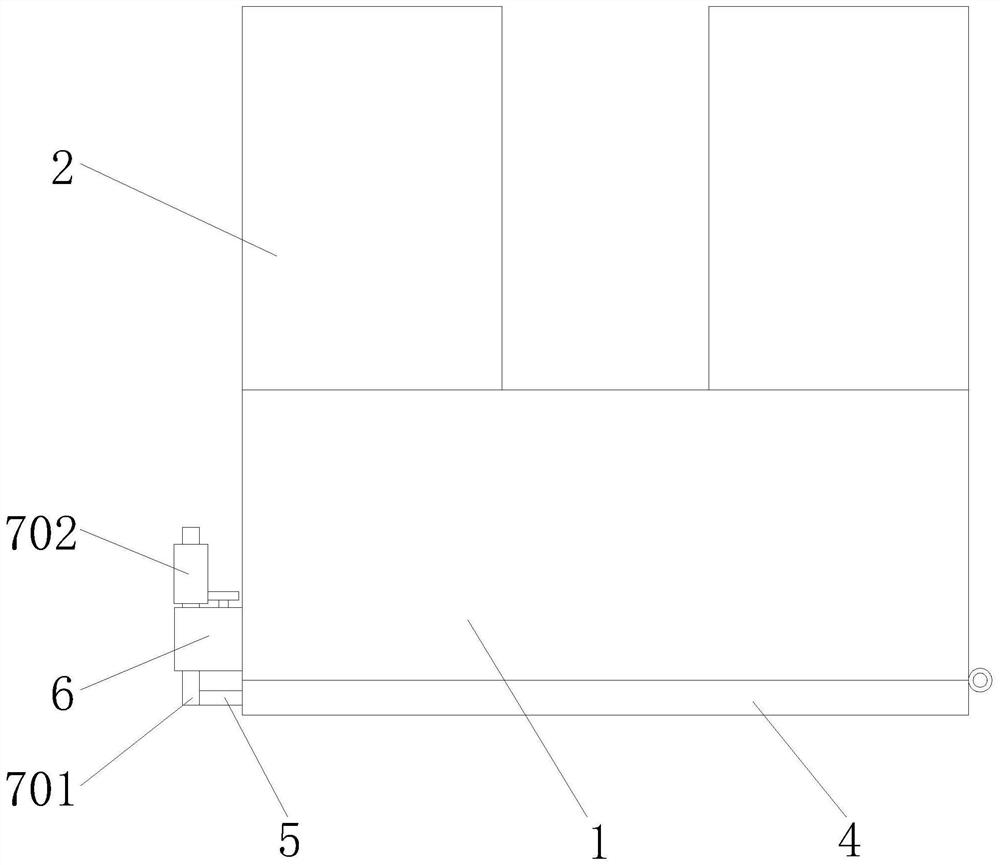

Removing device for medical gloves

InactiveCN113349940AEasy to handleEasy to removeSurgical glovesMechanical engineeringBiomedical engineering

The invention discloses a removing device for medical gloves. The removing device for the medical gloves comprises a collecting shell, and arc-shaped plates are fixedly connected to the left side and the right side of the top of the collecting shell. A collecting shell, a glove removing hook, a protection plate and a limiting mechanism are arranged and used in cooperation, the position of the protection plate can be rapidly fixed, opened and closed through the use of the limiting mechanism, a user can conveniently treat the medical gloves in an inner cavity of the collecting shell, and by means of the use of the glove removing hook, a user can conveniently remove the medical glove on the hand, and the problems that after existing disposable medical gloves are used, due to the fact that the two hands sweat, the medical gloves are tightly attached to the skin, the surfaces of the two hands are prone to being contaminated by contaminants in the removal process, and the existing medical gloves cannot be uniformly collected and treated are solved. The removing device for the medical gloves has the advantages that the gloves can be rapidly removed, and the medical gloves can be conveniently treated.

Owner:会同县健骄皮制品有限公司

Reservoir floating debris cleaning device

ActiveCN109440749BEasy to cleanImprove cleaning efficiencyWater cleaningEngineeringProcess engineering

Owner:浙江景昌建设有限公司

Silver electrolysis process and equipment

ActiveCN110699712AHigh strengthReduce deformationProcess efficiency improvementElectrodesIngot castingSlag

The invention relates to an silver electrolysis process and equipment and belongs to the technical field of silver electrolysis recovery. The silver electrolysis process comprises the following process steps: S1, blowing and smelting silver slag material in a converter to form alloy gold; S2, granulating and drying the alloy gold prepared in S1 to pellet so as to obtain granular alloy gold; S3, adding the granular alloy gold obtained in S2 in a residual anode free electrolytic cell for silver electrolysis, and filtering and collecting silver powder separated out at the cathode of the electrolytic cell; S4, washing the silver powder collected in S3, and drying to obtain clean silver powder; and S5, carrying out ingot casting on the clean silver powder obtained in S4 to obtain silver ingots.The silver electrolysis process has the effect of not generating the residual anode during the silver electrolysis process.

Owner:浙江宏达新材料发展有限公司

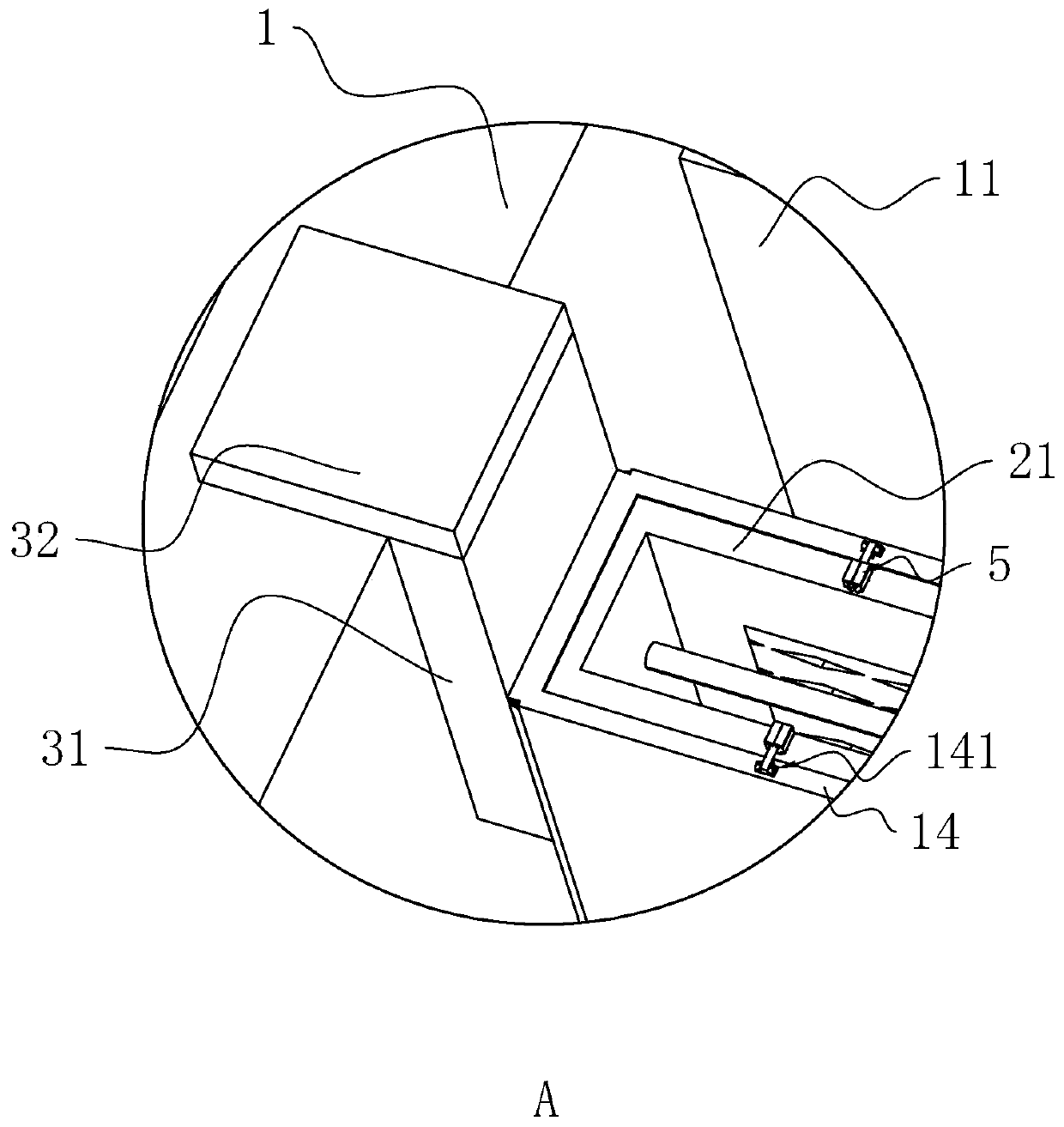

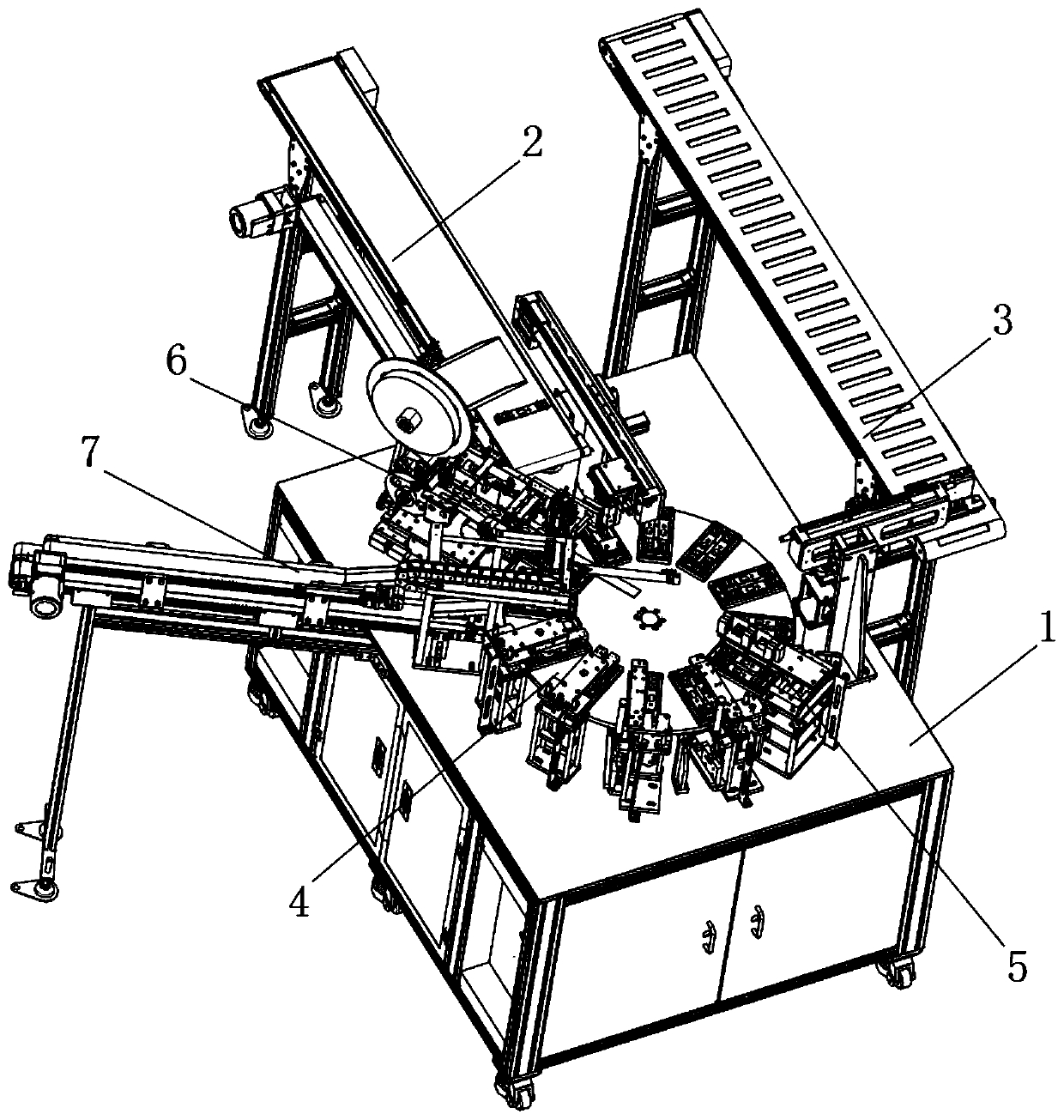

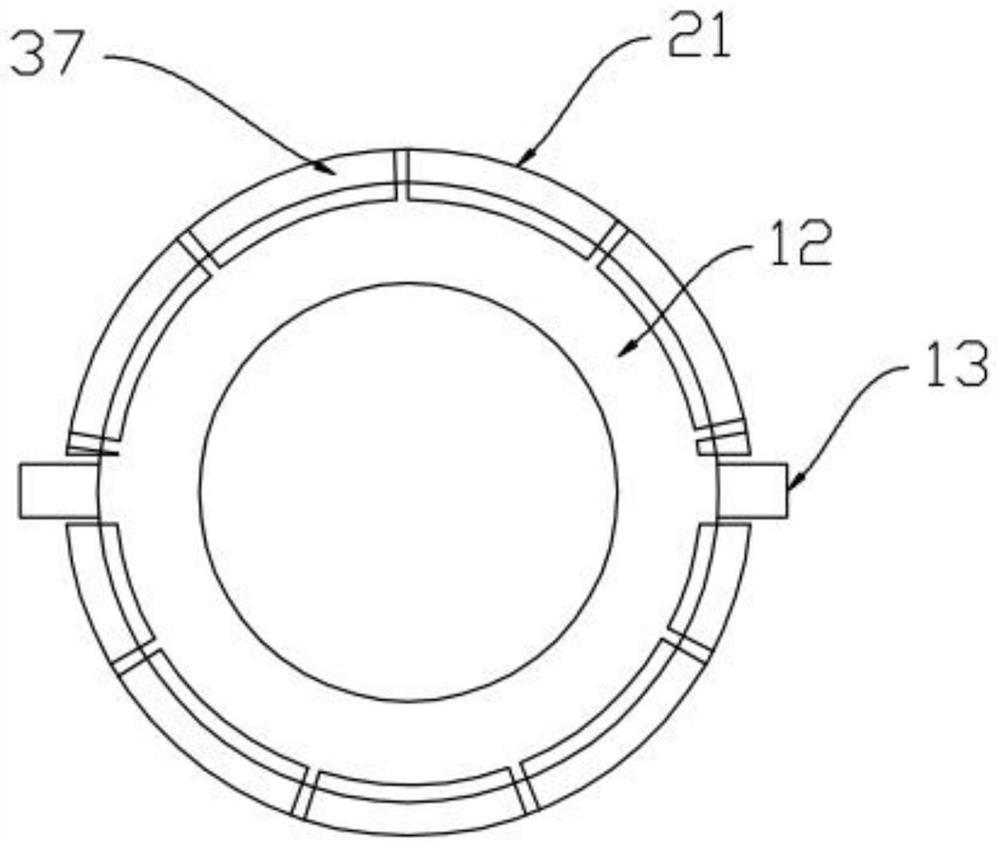

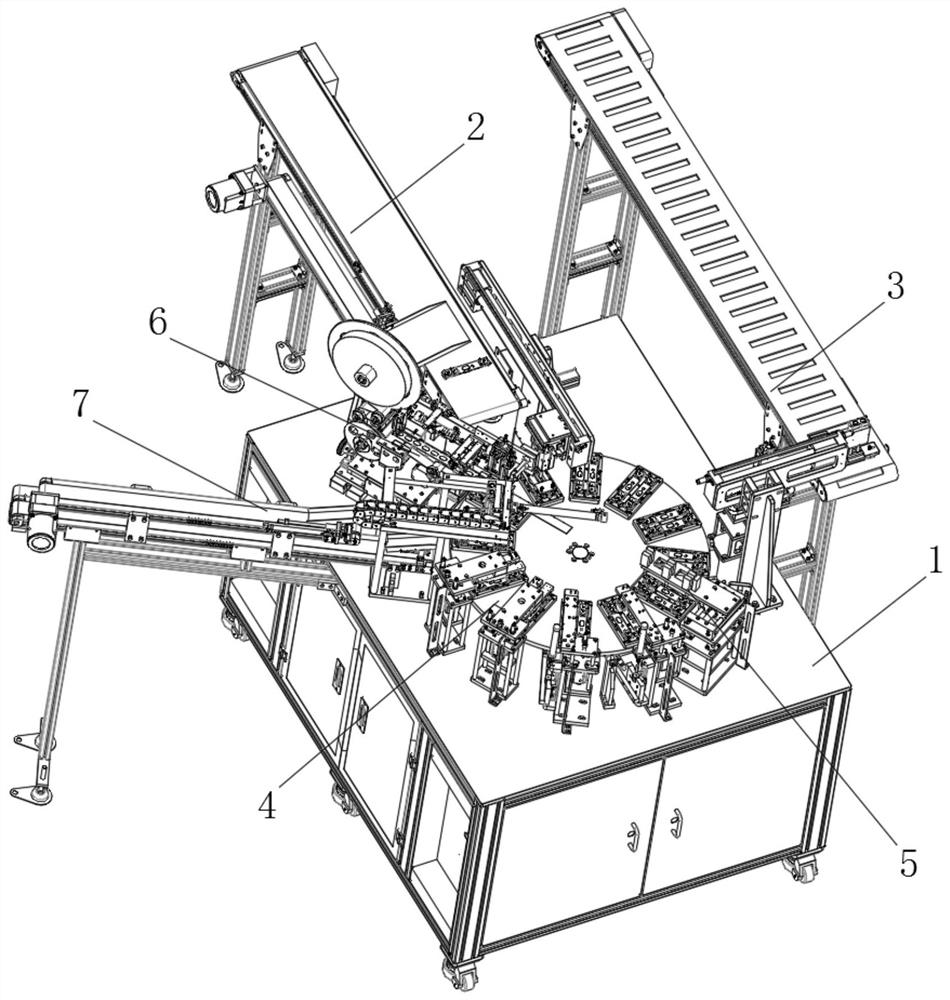

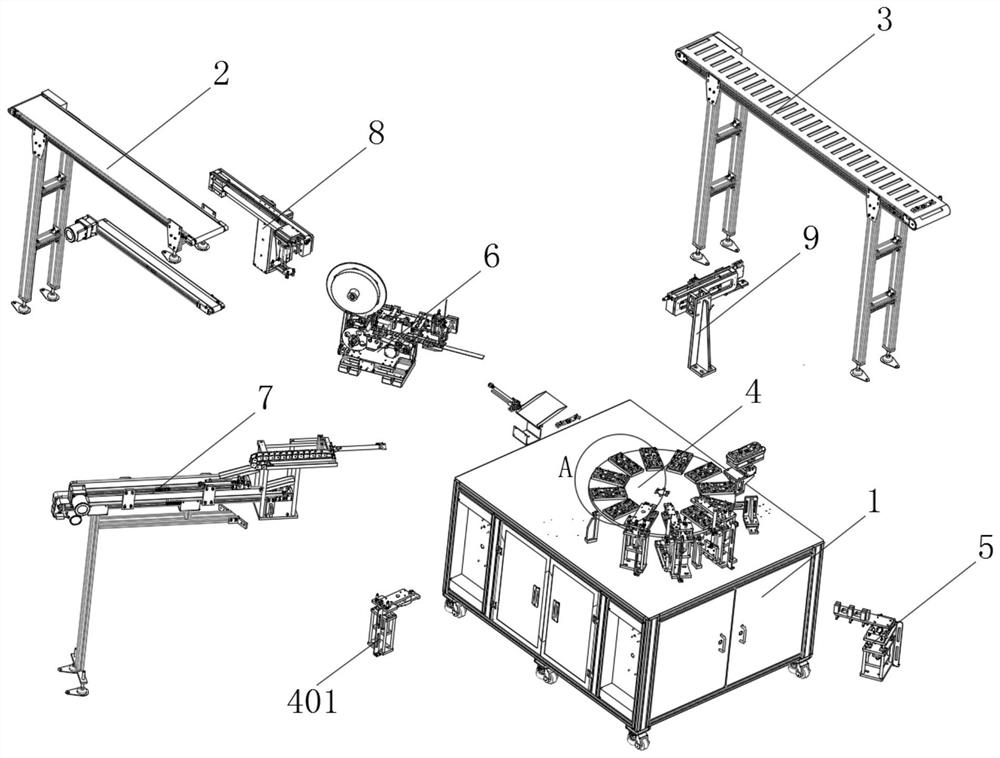

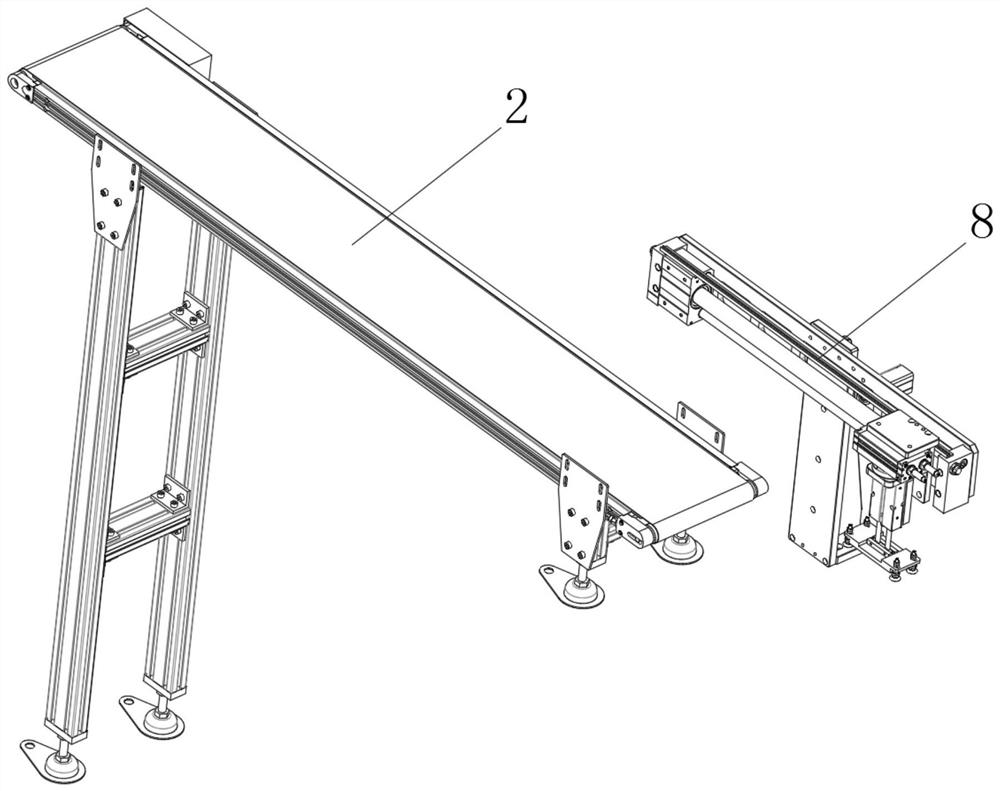

Efficient and environment-friendly paper bag handle-adhering machine capable of automatically feeding

ActiveCN110328895AIncrease capacityEasy to fixBag making operationsPaper-makingPulp and paper industryRadian

The invention discloses an efficient and environment-friendly paper bag handle-adhering machine capable of automatically feeding. The machine comprises a supporting table, a bag feeding disc, a handlefeeding platform, a working disc, a glue coating plate and a pressing seat, wherein the upper end face of the supporting table is horizontally provided with the working disc, and the working disc isof a circular structure. The invention has the beneficial effects that a first conveying belt of the bag feeding disc can be used for synchronously placing multiple paper bags for delivery, and is matched with a plurality of falling and mounting seats of identical radians on the edge of the working disc to load the paper bags, thus improving accommodating capability of the handle-adhering machineto simultaneously perform handle-adhering processing on the paper bags; and meanwhile, the paper bags are clamped in a clamping groove for handle-adhering processing, two baffle blocks at the two endsof the clamping groove are matched to clamp the paper bags, so that the paper bags can be stably and firmly fixed, thus ensuring that the positions during paper bag gluing, handle adhering and flattening are more accurate so as to improve the paper bag processing quality of the handle-adhering machine; and finally, a fifth motor sleeves on three second sleeve columns to drive a glue box to move front and back for adjustment, thus ensuring the gluing position to the paper bags is more accurate.

Owner:NINGBO FEIHONG STATIONERY

Intelligent flower bed guardrail

ActiveCN112610067ARealize automatic wateringEasy to useDispersed particle filtrationSelf-acting watering devicesAgricultural engineeringStructural engineering

The invention relates to the field of road guardrails, in particular to an intelligent flower bed guardrail. The intelligent flower bed guardrail comprises a guardrail body arranged on the ground, wherein a flower groove is fixedly connected to the side wall of the guardrail body; a partition plate is fixedly connected to the side wall of the flower groove; the upper side wall of the partition plate is filled with soil; a rotating shaft is rotatably connected to the side wall of the bottom of the flower groove; a driving bevel gear is fixedly connected to one end of the rotating shaft, and the other end of the rotating shaft penetrates through the bottom of the flower groove and is fixedly connected with blades; a fixing plate is fixedly connected to the lower side wall of the partition plate; and a rotating rod is rotatably connected to the side wall of the fixing plate, and one end of the rotating rod is fixedly connected with a first driven bevel gear. The intelligent flower bed guardrail has the advantages that flowers and grass in the flower groove can be automatically watered through natural wind energy; the use is more convenient; meanwhile, watering can be performed according to the moisture content in soil, and death of the flowers and grass caused by excessive watering is avoided; and dust in air can be collected and treated, and the purpose of purifying the air is achieved.

Owner:王翊彤

A laboratory automatic blood lipid testing device

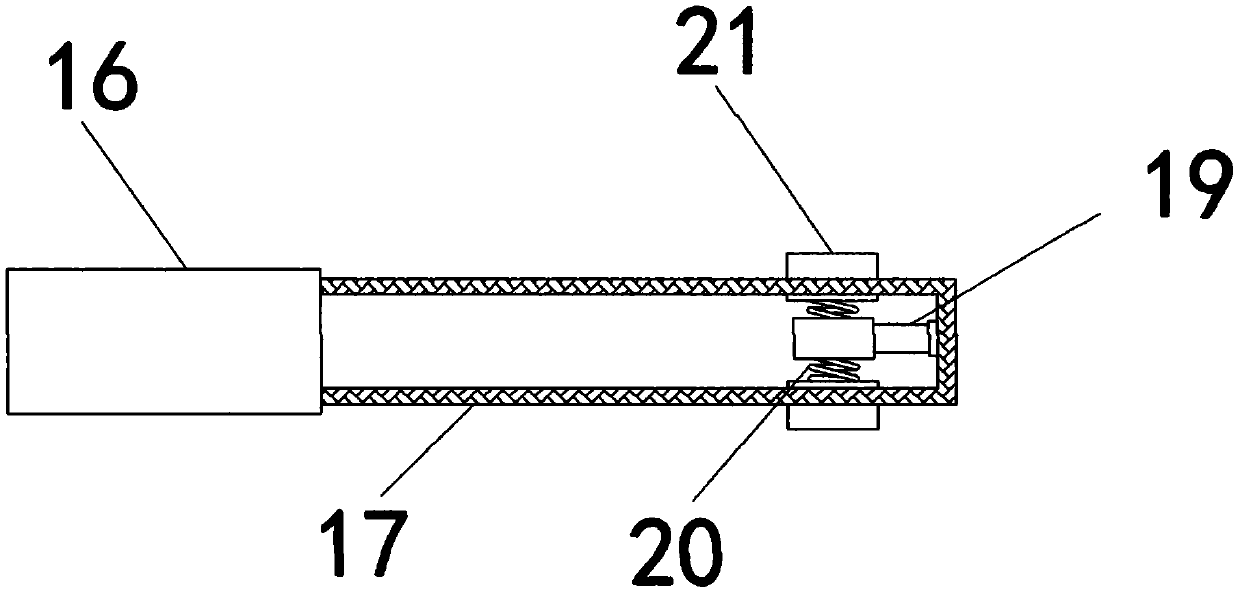

ActiveCN111616719BImprove inspection efficiencyReduce the burden onMedical applicatorsDiagnostic recording/measuringBlood collectionBlood lipids

The invention relates to an automatic blood lipid testing device for a laboratory. A support frame is arranged on the base, an electric push rod 1 and a motor 1 are arranged on the rear side of the support frame body, and an output end of the motor 1 is provided with an electric push rod 4 and an electric push rod 4 There is a turntable, the outer side of the turntable is evenly distributed with several inserts along the circumference, the upper side of the support frame is provided with a self-service blood collection needle mechanism, and the self-service blood collection needle mechanism is provided with several blood collection needles, and the lower ends of the blood collection needles are provided with There is a sleeve, the two sides of the sleeve are provided with fixed blocks, the upper side of the support frame and the two sides of the self-service blood collection needle mechanism are provided with two electric push rods, three electric push rods, and one end of the three-phase electric push rod close to each other. All are provided with gripping hands, a blood lipid analyzer is provided on the upper side of the base, a disinfection article access mechanism and a sampling needle pulling mechanism are provided on the inner side of the support frame, and a recovery mechanism is provided below the base. The invention has the advantages that the blood lipid testing efficiency is improved, the burden on doctors is reduced, and it is safe and hygienic.

Owner:日照市中心血站

A self-feeding high-efficiency environmental protection paper bag pasting and pulling machine

ActiveCN110328895BIncrease capacityEasy to fixBag making operationsPaper-makingElectric machineryProcess engineering

The invention discloses an efficient and environment-friendly paper bag handle-adhering machine capable of automatically feeding. The machine comprises a supporting table, a bag feeding disc, a handlefeeding platform, a working disc, a glue coating plate and a pressing seat, wherein the upper end face of the supporting table is horizontally provided with the working disc, and the working disc isof a circular structure. The invention has the beneficial effects that a first conveying belt of the bag feeding disc can be used for synchronously placing multiple paper bags for delivery, and is matched with a plurality of falling and mounting seats of identical radians on the edge of the working disc to load the paper bags, thus improving accommodating capability of the handle-adhering machineto simultaneously perform handle-adhering processing on the paper bags; and meanwhile, the paper bags are clamped in a clamping groove for handle-adhering processing, two baffle blocks at the two endsof the clamping groove are matched to clamp the paper bags, so that the paper bags can be stably and firmly fixed, thus ensuring that the positions during paper bag gluing, handle adhering and flattening are more accurate so as to improve the paper bag processing quality of the handle-adhering machine; and finally, a fifth motor sleeves on three second sleeve columns to drive a glue box to move front and back for adjustment, thus ensuring the gluing position to the paper bags is more accurate.

Owner:NINGBO FEIHONG STATIONERY

Die-cutting device for tungsten steel knife processing

The invention discloses a die-cutting device for tungsten steel knife processing. The die-cutting device comprises a loading assembly, a punching assembly, a punch and a connecting base, wherein one side of the punching assembly fits to the loading assembly; the connecting base is arranged on the punching assembly; the punch is mounted on the connecting base; the top end of the loading assembly isequipped with a limiting assembly; the limiting assembly comprises a fixed base, a pushing rod and a pressure plate; a power supply is embedded into the fixed base; the loading assembly comprises a base, fourth threaded rods, a die-cutting board and a first motor; a groove and a plurality of groups of opposite parallel movable slots are separately formed in the top end of the base; the inner wallof the bottom end of the groove is connected to the die-cutting board; the fourth threaded rods are mounted in the movable slots; movable blocks sleeve the fourth threaded rods; and the top ends of the movable blocks are fixedly connected to the bottom end of the fixed base. The die-cutting device for tungsten steel knife processing disclosed by the invention is reasonable in design, is convenient to use, and has the advantage of being convenient to regulate.

Owner:深圳市粤海翔精密科技有限公司

Dust collection and filtration method for rail grinding vehicle dust collecting system

PendingCN110339658AExpand the range of installation applicationsSave installation spaceCombination devicesGrinding/polishing safety devicesFiltrationProduct gas

The invention discloses a dust collection and filtration method for a rail grinding vehicle dust collecting system. The method integrates a first stage filtering space and a second stage filtering space together for dust collection and filtration, that is, the first stage filtering space and the second stage filtering space are disposed inside one box body, an air inlet pipe is communicated with the first stage filtering space, an air outlet pipe is communicated with the second stage filtering space, and a plurality of filter cylinders are installed in the second stage filtering space; duringdust collection, high-temperature dust gas is sent into the first stage filtering space through the air inlet pipe for collision with the circumferential wall of the first stage filtering space to achieve first stage filtration, and then the filtered dust gas enters the second stage filtering space for second stage filtration by the filter cylinders. The method provided by the invention mainly hasthe advantages that the total installation space is greatly reduced, the installation application range in various rail grinding vehicles is expanded, and on the premise of meeting the requirements of first stage filtration, the first stage filtering space is reduced and simplified.

Owner:湖南东洲电气科技有限公司

A punching device for tungsten steel knife processing

The invention discloses a die-cutting device for tungsten steel knife processing. The die-cutting device comprises a loading assembly, a punching assembly, a punch and a connecting base, wherein one side of the punching assembly fits to the loading assembly; the connecting base is arranged on the punching assembly; the punch is mounted on the connecting base; the top end of the loading assembly isequipped with a limiting assembly; the limiting assembly comprises a fixed base, a pushing rod and a pressure plate; a power supply is embedded into the fixed base; the loading assembly comprises a base, fourth threaded rods, a die-cutting board and a first motor; a groove and a plurality of groups of opposite parallel movable slots are separately formed in the top end of the base; the inner wallof the bottom end of the groove is connected to the die-cutting board; the fourth threaded rods are mounted in the movable slots; movable blocks sleeve the fourth threaded rods; and the top ends of the movable blocks are fixedly connected to the bottom end of the fixed base. The die-cutting device for tungsten steel knife processing disclosed by the invention is reasonable in design, is convenient to use, and has the advantage of being convenient to regulate.

Owner:深圳市粤海翔精密科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com