Dust collection and filtration method for rail grinding vehicle dust collecting system

A filtration method and technology for a dust collection system, which are applied in separation methods, chemical instruments and methods, grinding/polishing equipment, etc., can solve the problems of the complex structure of the dust collection system, the small size of the secondary filtration device, and the reduction of the filtration effect of the secondary filtration. and other problems, to achieve the effect of facilitating unified collection and processing, expanding the scope of installation and application, and reducing the space for primary filtration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

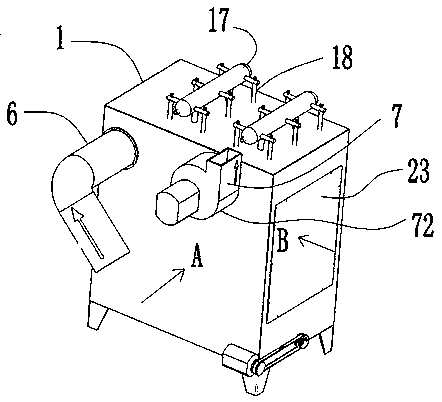

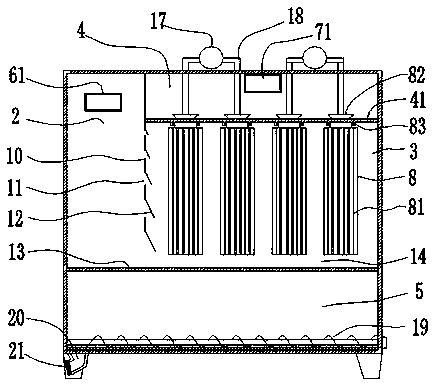

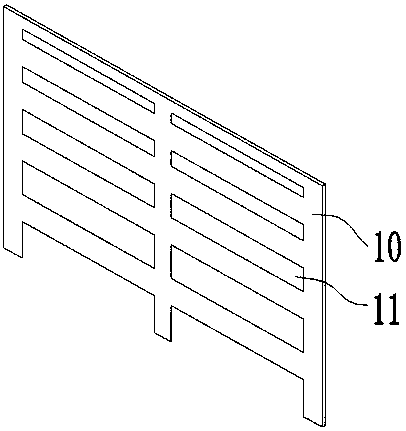

[0049] Such as figure 2 As shown, a dust suction and filtration method for the dust collection system of a track grinding vehicle, which integrates the primary filter space 2 and the secondary filter space 3 for dust suction and filtration, that is, a The primary filter space 2 and the secondary filter space 3 connect the intake pipe 6 with the primary filter space 2, the air outlet pipe 7 communicates with the secondary filter space 3, and a plurality of filter cartridges 8 are installed in the secondary filter space 3; When vacuuming, the high-temperature dust gas is first sent into the primary filter space 2 through the intake pipe 6, and the dust gas collides with the surrounding wall of the primary filter space 2 for primary filtration, and then enters the secondary filter space for use. The filter cartridge 8 performs secondary filtration to the dust gas.

[0050] The above-mentioned primary filter space 2 is mainly to filter out the high-temperature dust with a large ...

Embodiment 2

[0059] Such as Figure 8 to Figure 10 As shown, the difference from Embodiment 1 is that the dust interception impeller 9 is installed at the air outlet 61 of the air intake pipe of the primary filter space 2; the dust interception impeller 9 includes an axle 91 and a plurality of dust interception blades 92; The dust gas sprayed into the tuyere 61 first impacts the dust-cutting blade 92 of the dust-cutting impeller 9 and makes the dust-cutting impeller 9 rotate. After the blade 92 collides with the dust intercepting blade 92, part of the dust falls under the action of gravity, which can make the dust gas complete the first filtration in the first-stage filtering space 2 .

[0060] The installation mode of described dust interception impeller 9 comprises following two kinds:

[0061] One is to install the wheel shaft 91 of the dust-intercepting impeller 9 above the air inlet pipe outlet 61, so that the bottom of the dust-intercepting impeller 9 is facing the air outlet, as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com