Flattening device and method for circuit board processing

A flattening device and a technology for circuit boards, which are applied in the directions of cleaning methods, separation methods, cleaning methods and utensils using gas flow, which can solve the problems of sticking dust on the surface of flexible circuit boards, uneven substrate tension, and uneven winding. problem, to achieve the effect of convenient and quick dust removal, simple steps and increased tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

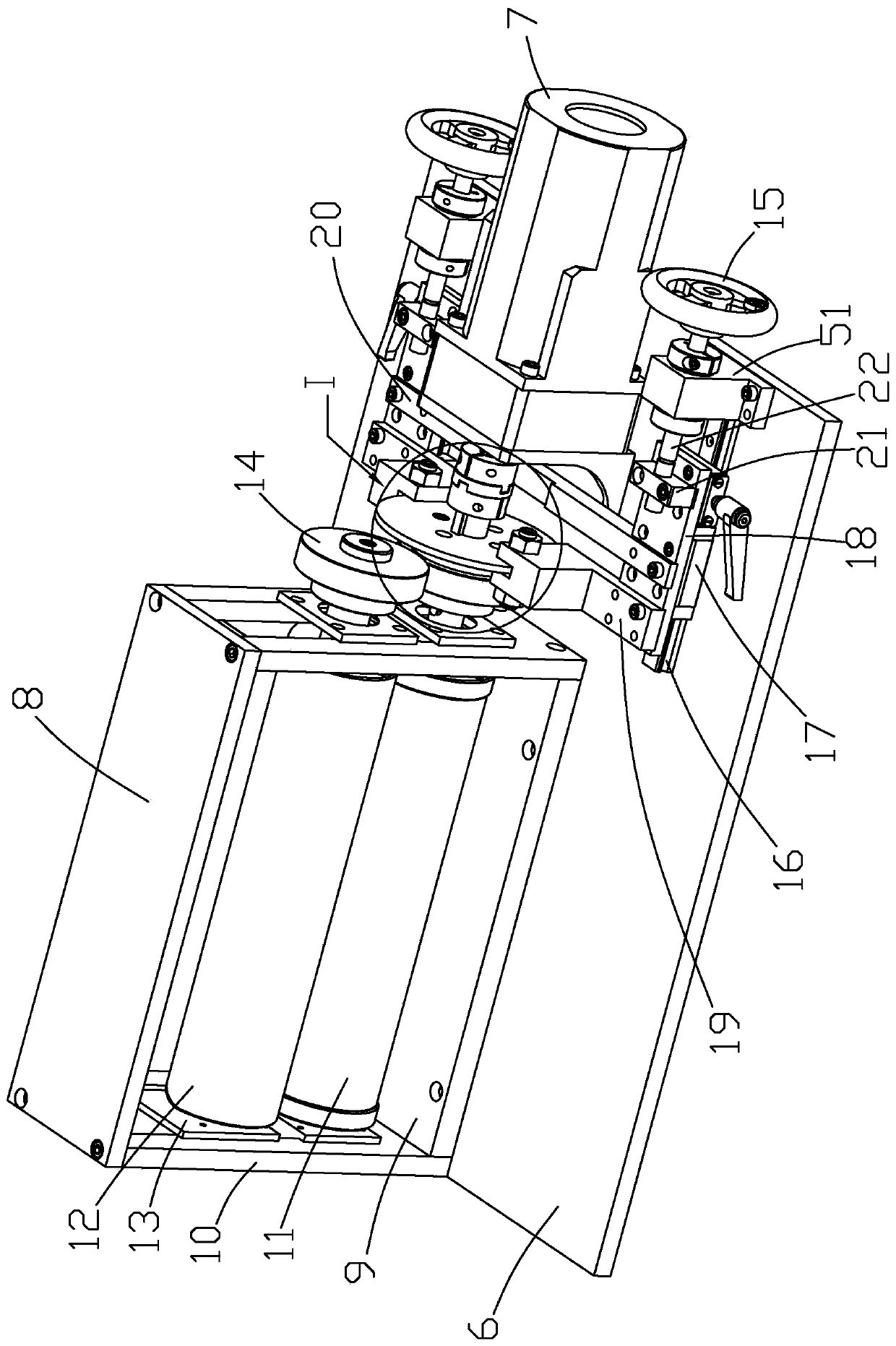

[0060] Such as Figure 1 to Figure 6 As shown, it is a flattening device for circuit board processing in the present invention, including a flattening platform 1, a flattening mechanism 2, a dust suction mechanism 3 and a detection mechanism 4, and the flattening mechanism 2, the dust suction mechanism 3 and the detection mechanism 4 are all located at On the top surface of the unfolding platform 1, the dust suction mechanism 3 and the detection mechanism 4 are located on both sides of the flattening mechanism 2, and the circuit board 5 passes through the dust suction mechanism 3, the flattening mechanism 2 and the detection mechanism 4 in sequence; The design can remove dust from the circuit board 5 that needs to be flattened to prevent dust from adhering to the surface of the circuit board 5 during the flattening process, which will affect the quality and service life of the circuit board 5. The flattening mechanism 2 can The flexible circuit board 5 is flattened to prevent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com