Adhesive tape viscosity detection system for adhesive tape production and use method thereof

A detection system and tape technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems of difficulty in ensuring complete consistency, difficulty in accurate tape viscosity, and troublesome operation, and achieve accurate detection data results, simple structure, and convenient detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

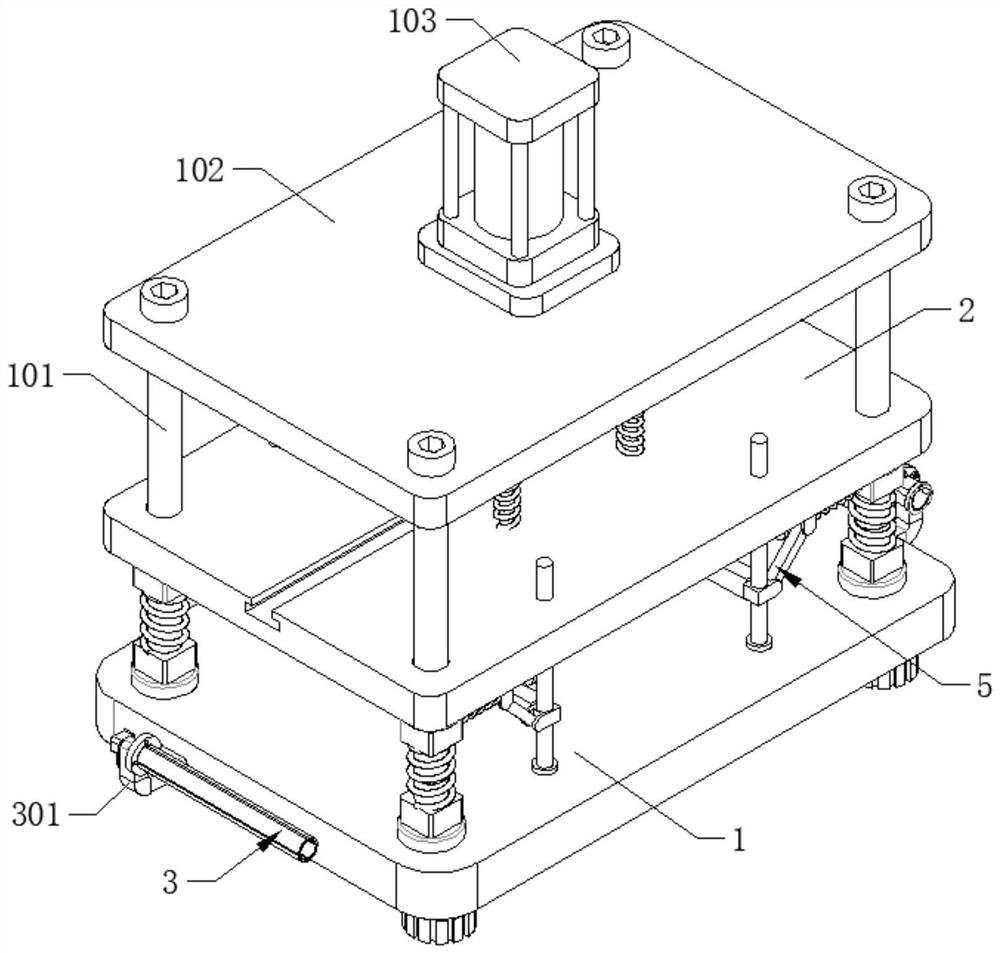

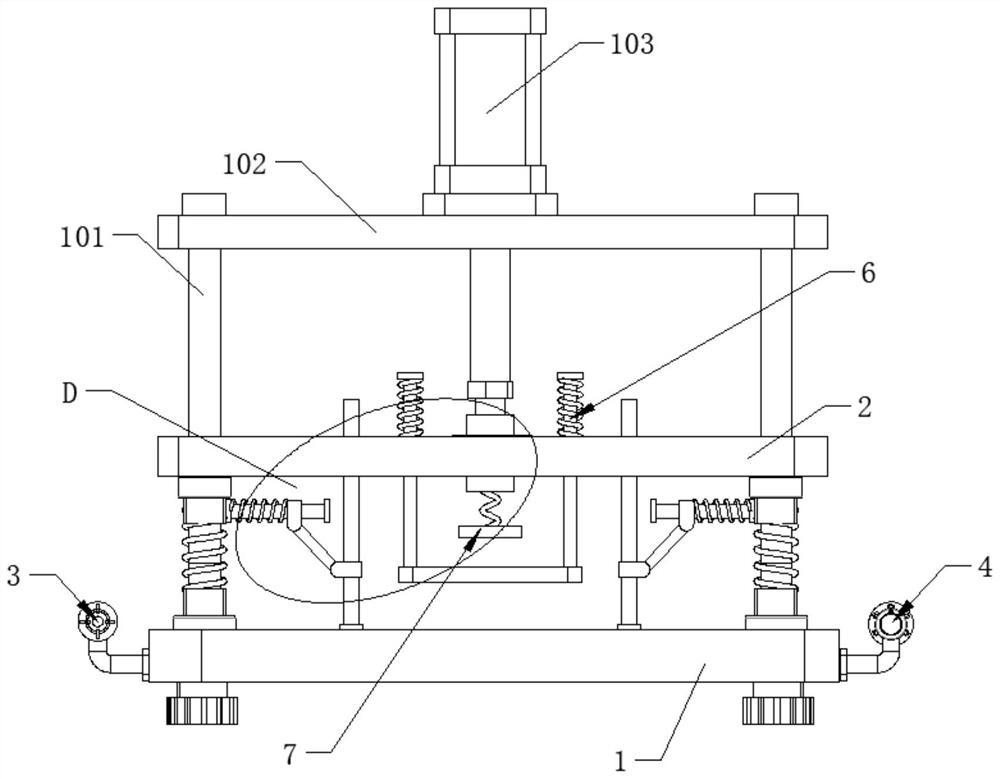

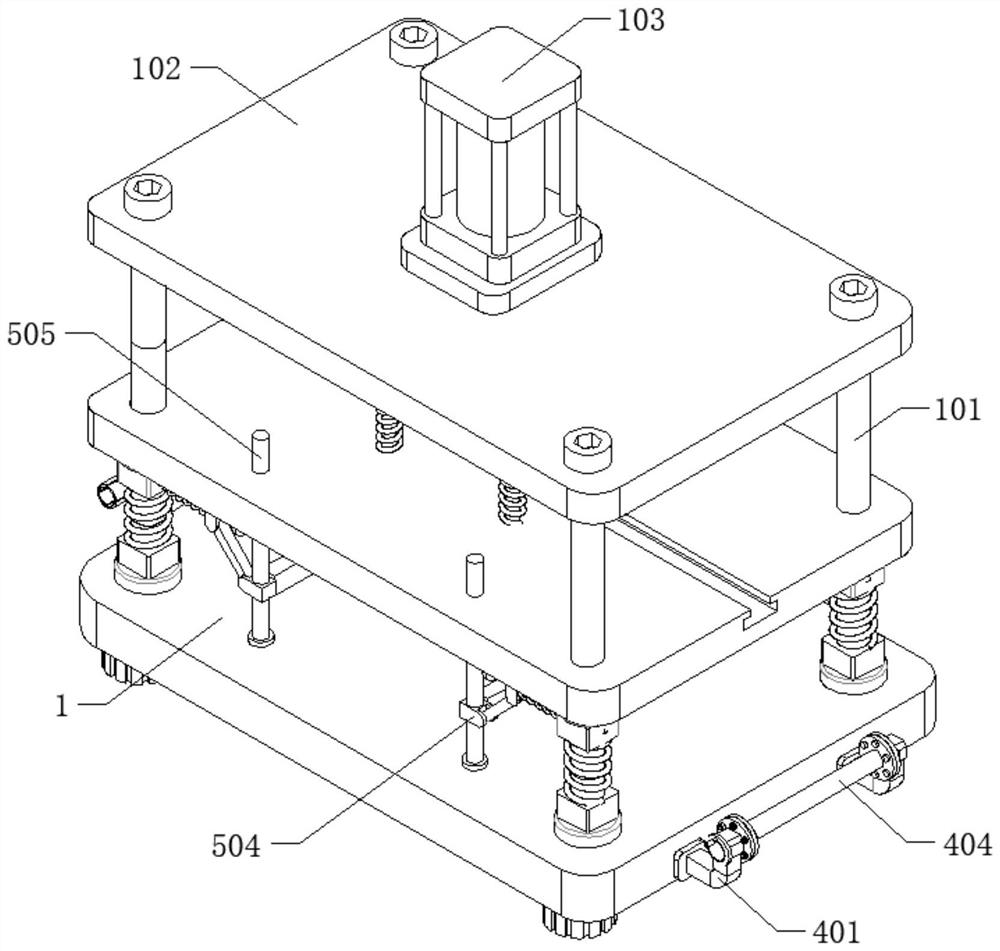

[0042] refer to Figure 1-11 , a tape viscosity detection system for tape production, comprising a base 1, a first support rod 101 is connected to the top wall of the base 1, a top plate 102 is connected to the top wall of the first support rod 101, and a cylinder 103 is connected to the top wall of the top plate 102 , the output end of the cylinder 103 is connected to the pressure plate 2, the pressure plate 2 is slidably connected to the outer wall of the first support rod 101, the bottom wall of the pressure plate 2 is connected to the connecting block 201, the connecting block 201 is slidably connected to the outer wall of the first support rod 101, the connecting block 201 A first fixing assembly 5 is connected between the outer wall and the top wall of the base 1, a second fixing assembly 6 is connected on the bottom wall of the pressing plate 2, and a detection assembly 7 is also connected on the bottom wall of the pressing plate 2, and the detection assembly 7 and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com