Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30results about How to "Extend the heat transfer path" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

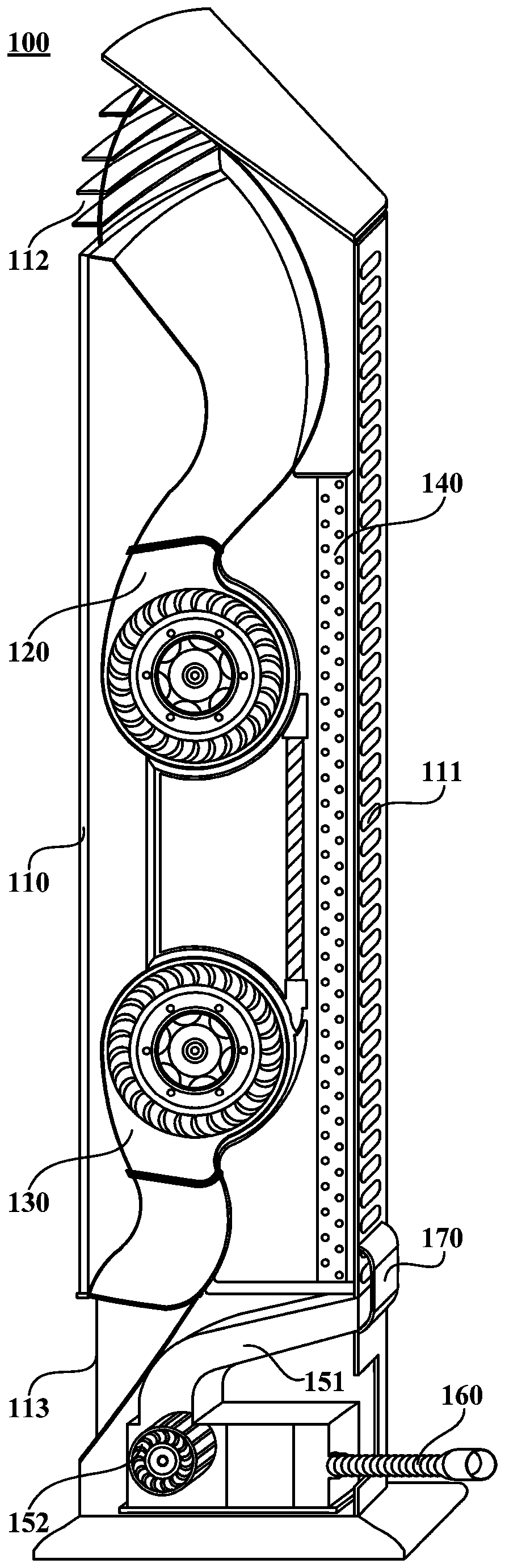

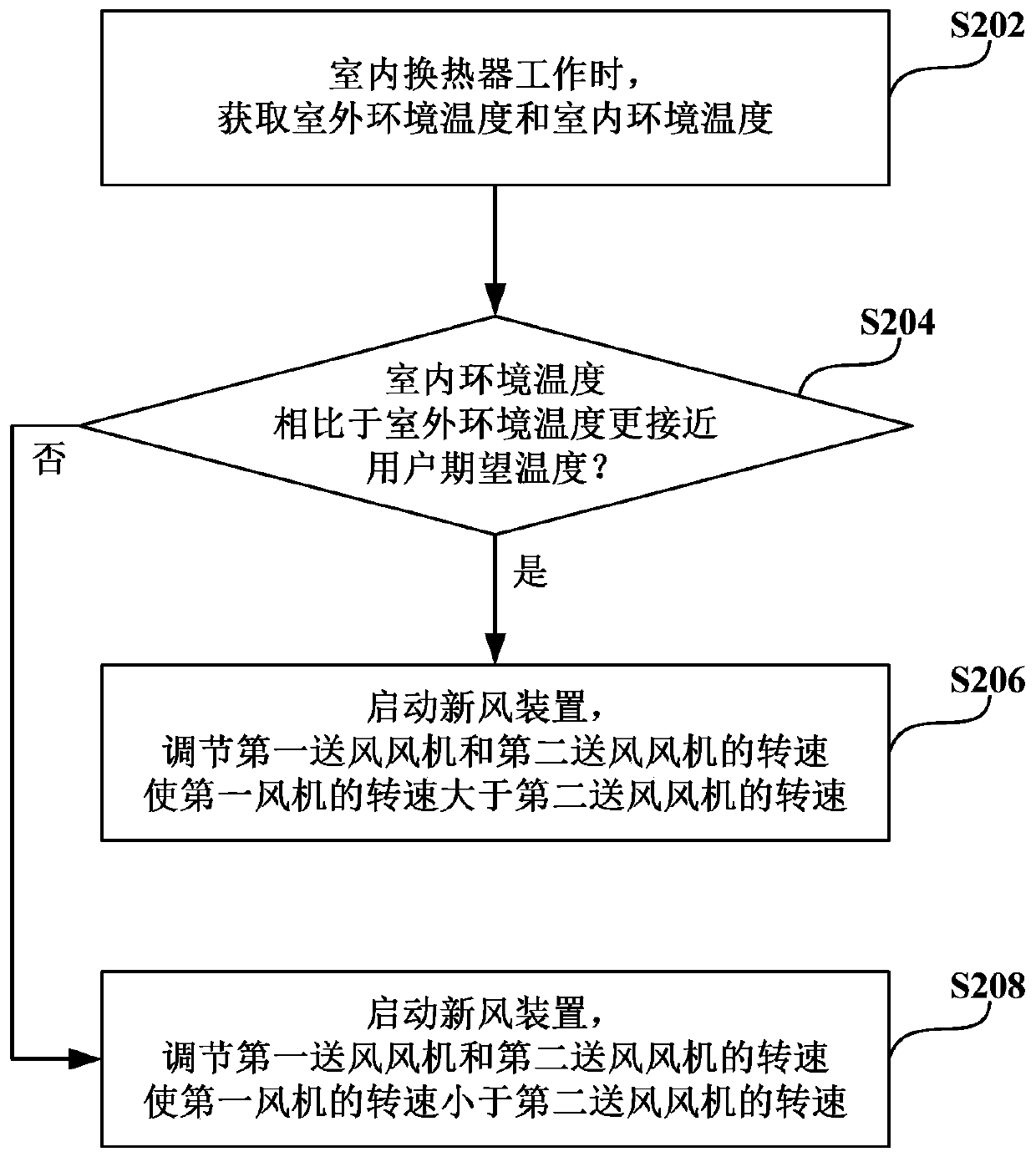

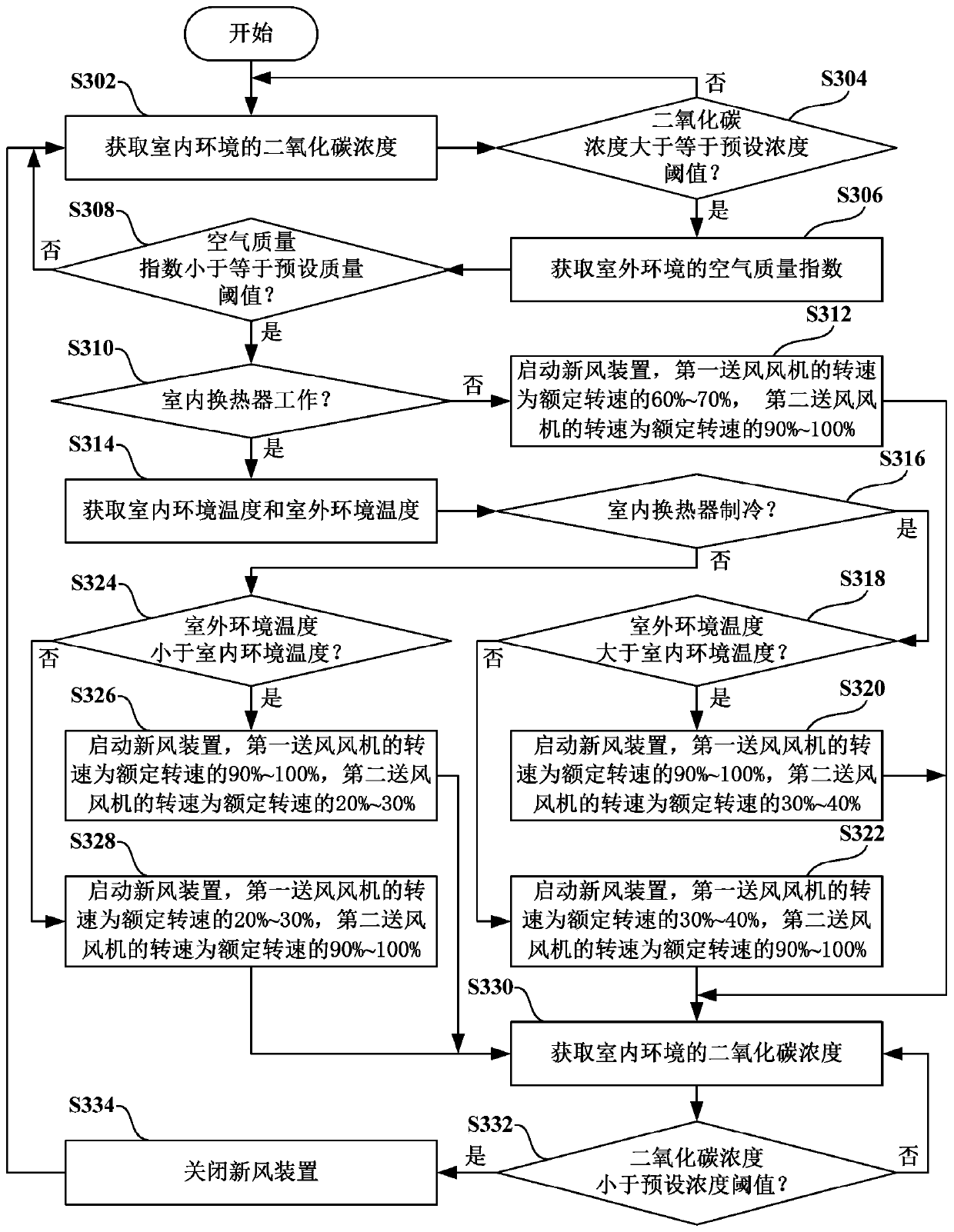

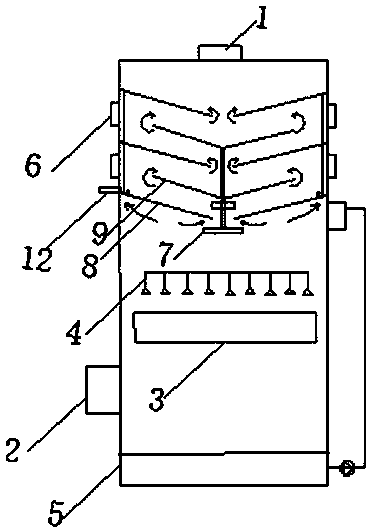

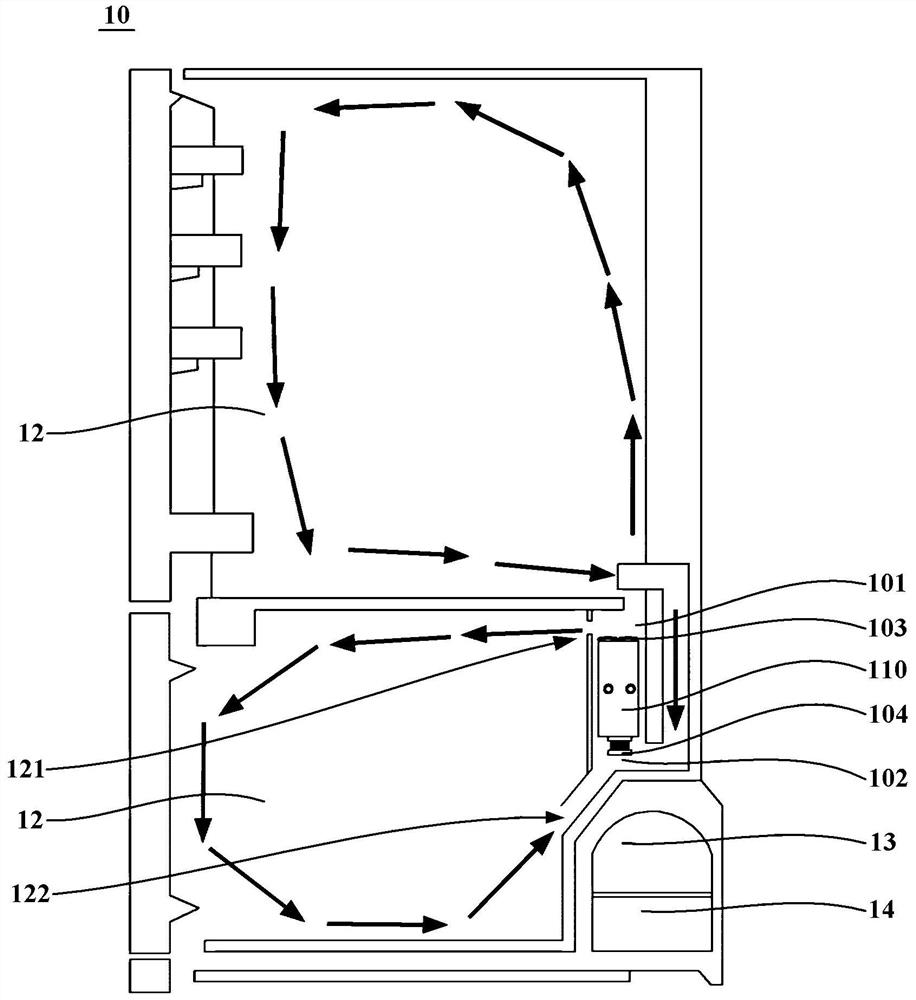

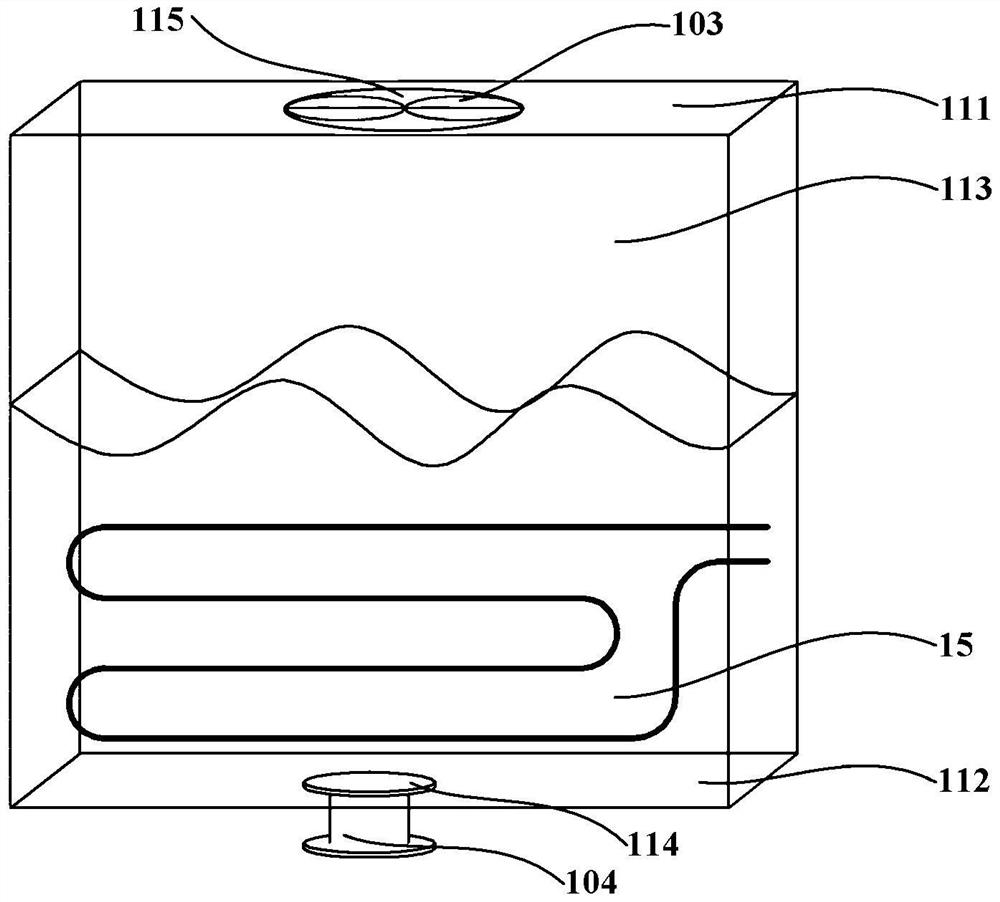

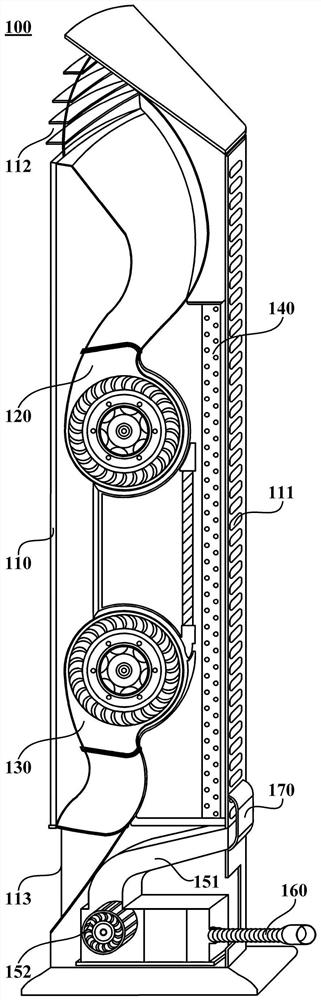

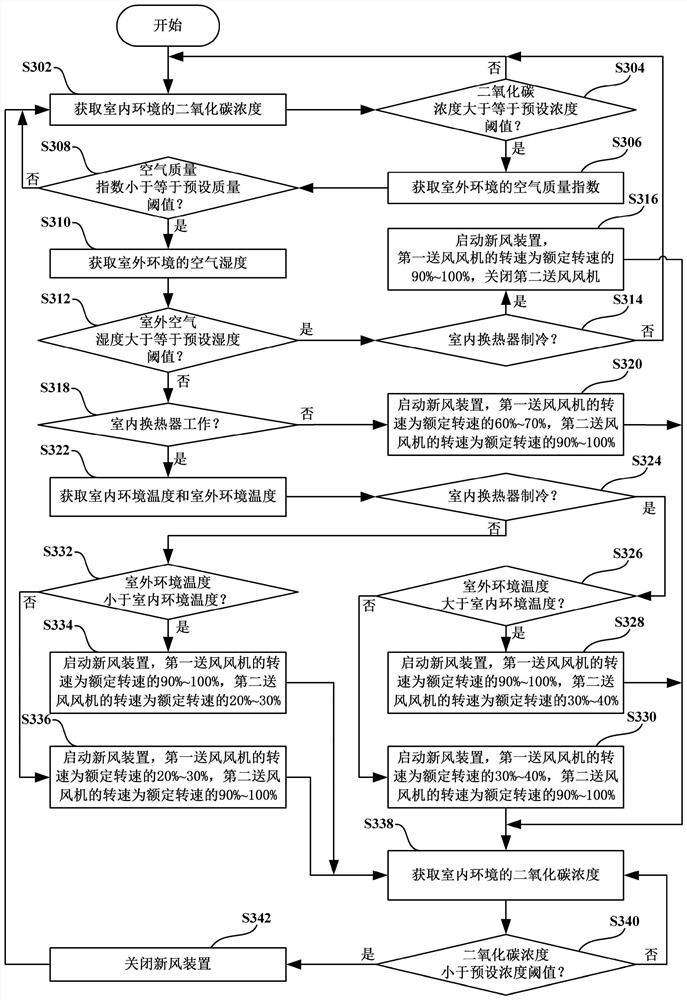

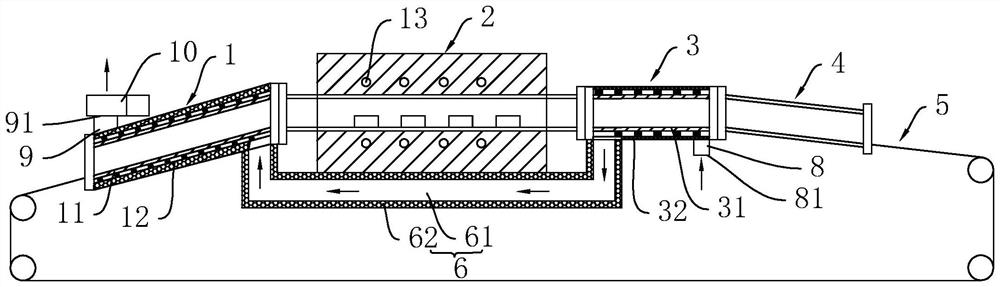

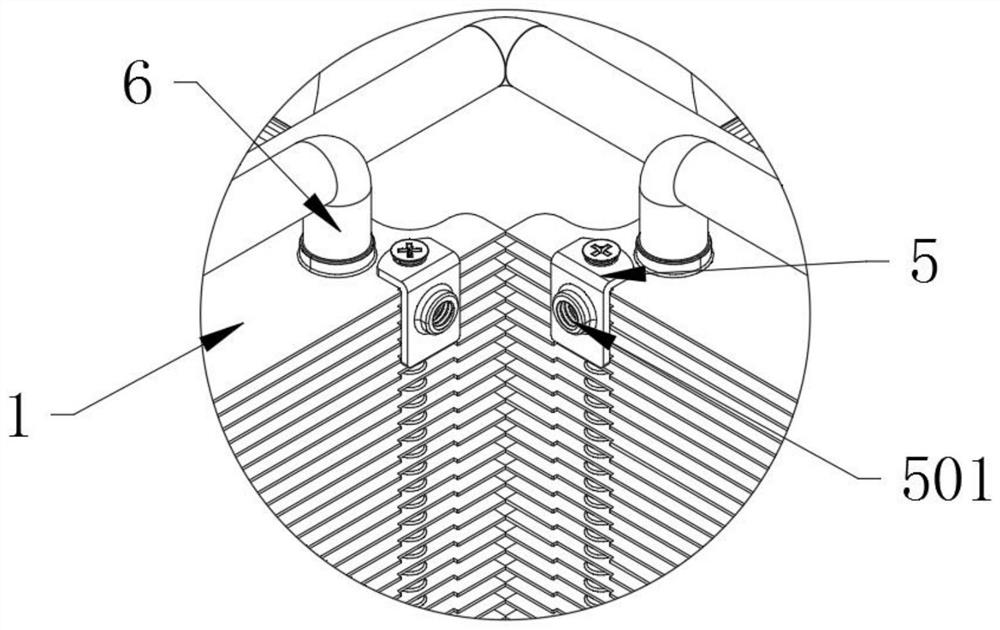

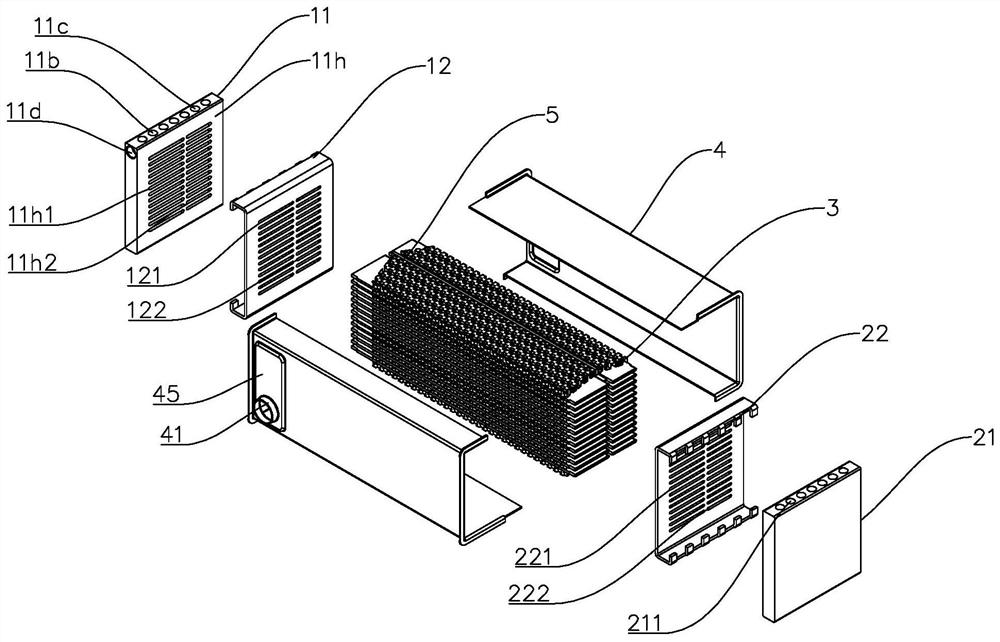

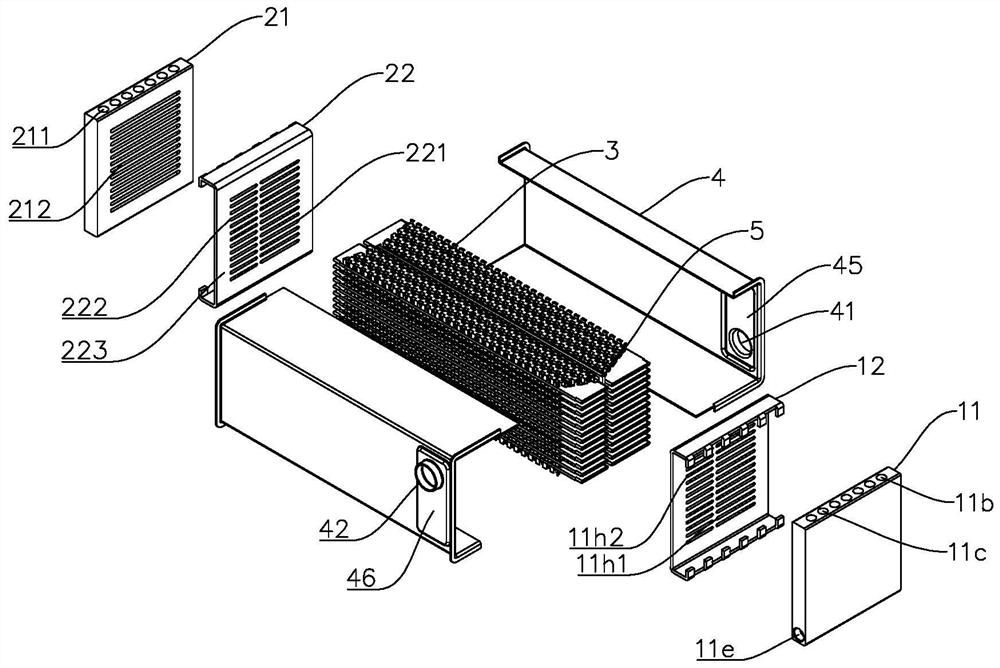

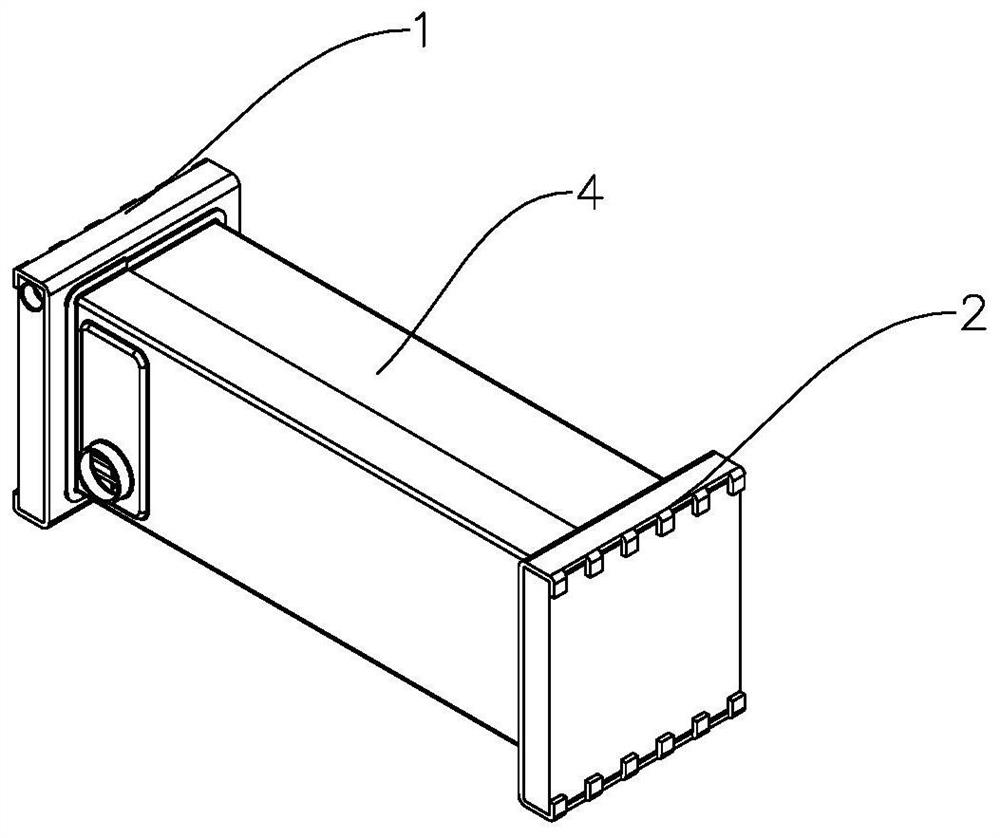

Control method for indoor unit of air conditioner and indoor unit of air conditioner

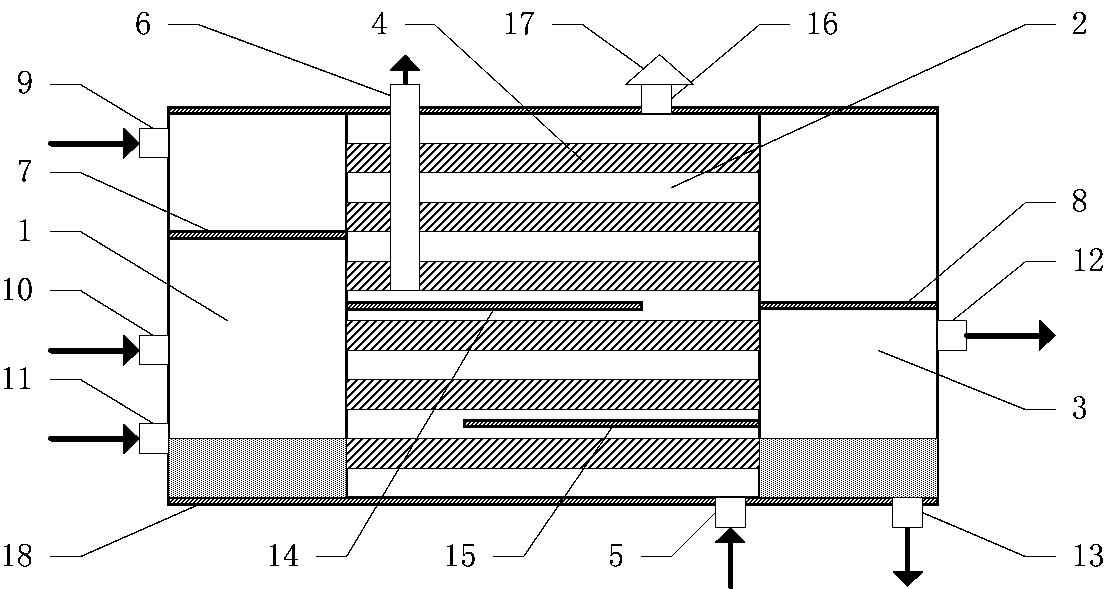

ActiveCN110410970AExtend the heat transfer pathShorten the flow pathMechanical apparatusSpace heating and ventilation safety systemsEngineeringHeat exchanger

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

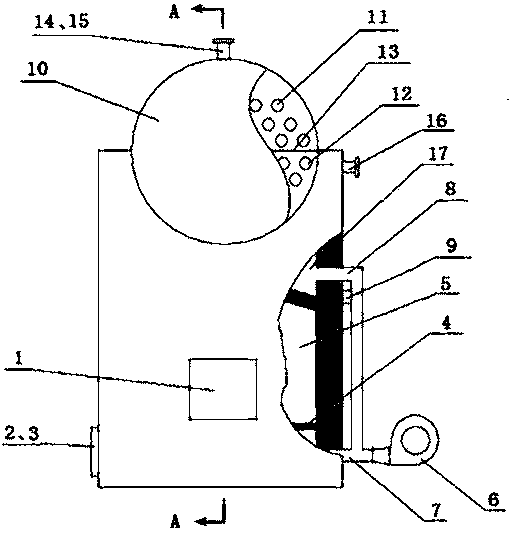

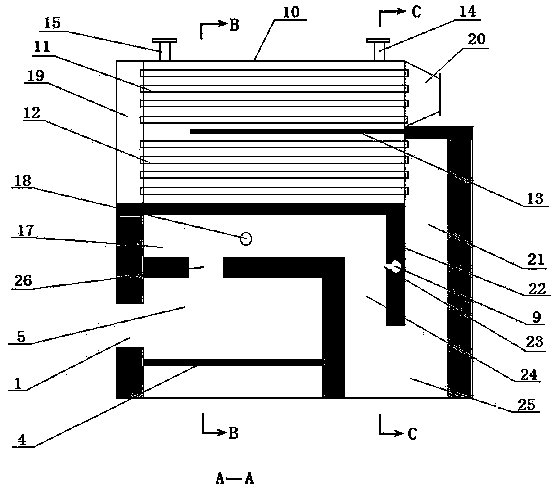

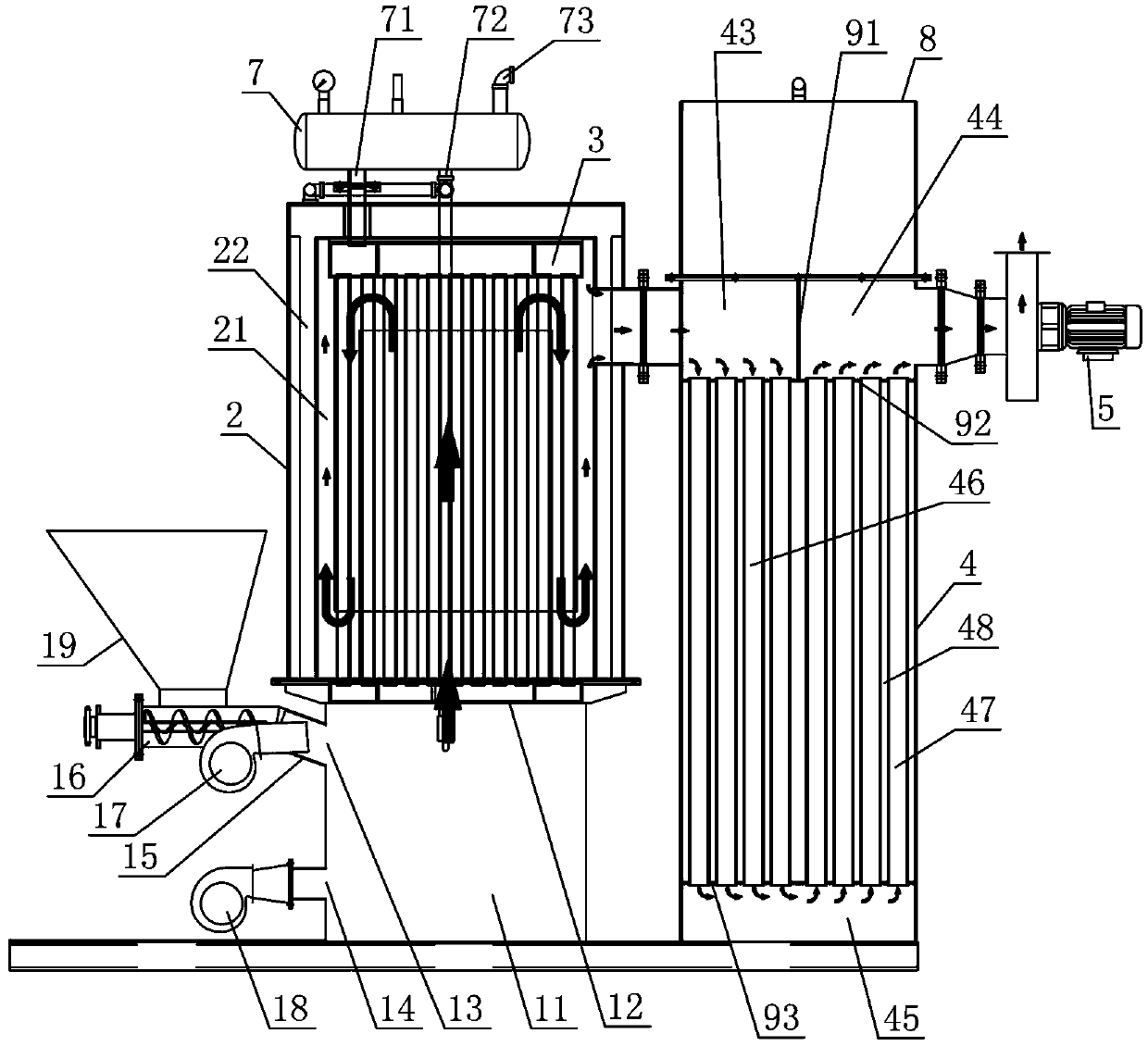

Energy-collecting heat exchange environment-friendly boiler

InactiveCN104279548AReduce outputGuaranteed convective exchangeSolid fuel combustionWater heatersCombustion chamberAtmospheric air

The invention relates to an energy-collecting heat exchange environment-friendly boiler. The boiler comprises a boiler body, wherein the boiler body comprises a hearth and a secondary combustion chamber which is arranged above the hearth and is communicated with the upper side of the hearth; a heat exchanger is arranged above the boiler body; a back wall of the secondary combustion chamber is a windward wall; a flame path is formed between the back wall of the secondary combustion chamber and a back wall of the hearth; a flue is formed between a back wall of the boiler body and the windward wall; on the lower part of the windward wall, a space formed by the back wall of the hearth, left and right walls of the boiler body and the back wall of the boiler body is taken as a dust settling chamber; the flame path is communicated with the flue through the dust settling chamber, thereby forming a U-shaped channel. By adopting the energy-collecting heat exchange environment-friendly boiler, in order to solve the problem concerned with dust reduction, the windward wall is arranged in front of the flue, the upper part of the windward wall is connected with the top of the secondary combustion chamber, and the lower part of the windward wall is suspended into the settling chamber; the flame path, the settling chamber and the flame path construct the U-shaped channel; under the action of wind power and gravity, ash included in smoke gas can be settled in the settling chamber, so that the emission of ash into the atmospheric air is reduced.

Owner:李雨田

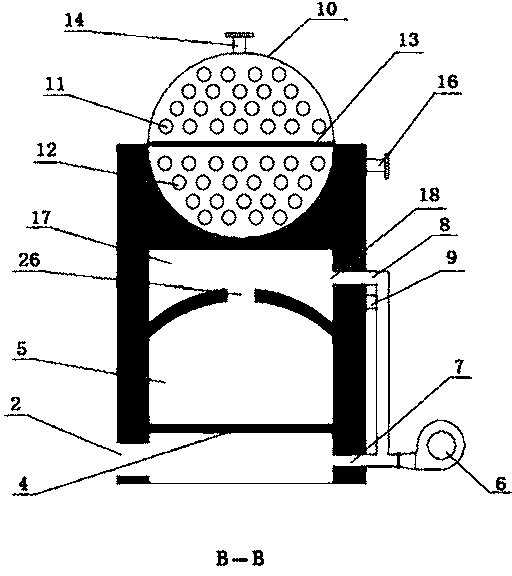

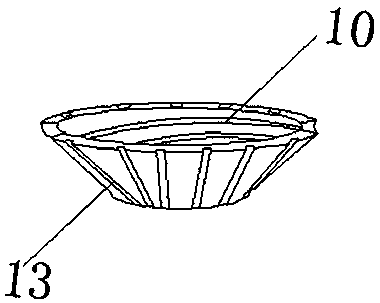

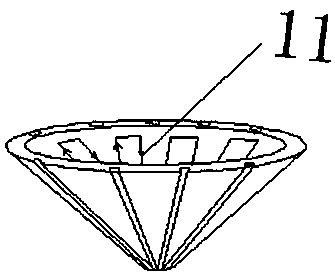

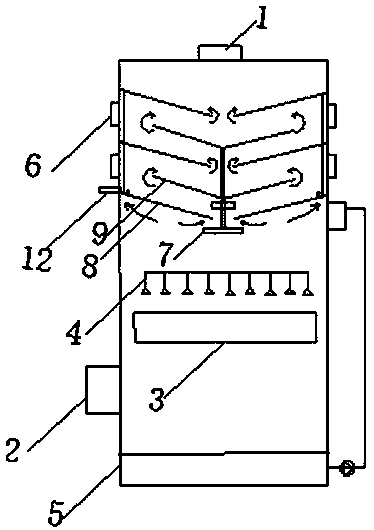

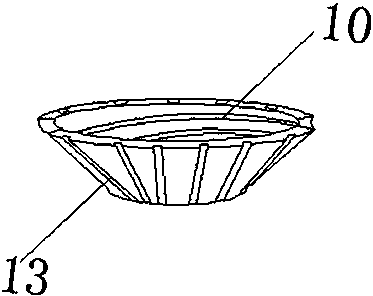

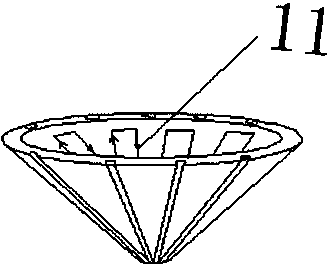

Cooling tower with water mist processing device

ActiveCN109631615ASave waterIncrease the heat exchange areaHeat exchange apparatusTrickle coolersWater pipeWave shape

The invention provides a cooling tower with a water mist processing device. The cooling tower can work in different ways and can improve efficiency of water mist. Through first and second mist removing devices which are arranged in a stagger mode, the limited space in the tower can be rationally and fully used. Cone and semicircular cone shapes are arranged in a matched mode. Compared with a traditional s-shaped dewatering plate or a wave-shaped dewatering device, the hear exchange area is enlarged, heat exchanging is improved, and the water mist removing effect is improved. The second mist removing devices are located at the center of the tower body. The second water mist removing devices are adjacent in an up and down mode and communicate with each other by a circulation main pipe. Cooling capacity of fluid can be improved by parallel connection. Through lateral plate mist removing devices on two sides, full heat exchanging effect is achieved to air around the tower body wall. A gridshape is arranged in a matched mode and corresponds to a draught fan outside, and therefore free adjusting and shifting between mist removing and tower body heat exchanging modes can be achieved. Through cooling liquid grooves, circulation water grooves and upper and lower water pipes, a cooling source can be adopted alternatively, water resource is saved, real-time adjusting is conducted based on the temperature requirements, and intelligent temperature control of mist removing is achieved.

Owner:东营海能石油装备有限责任公司

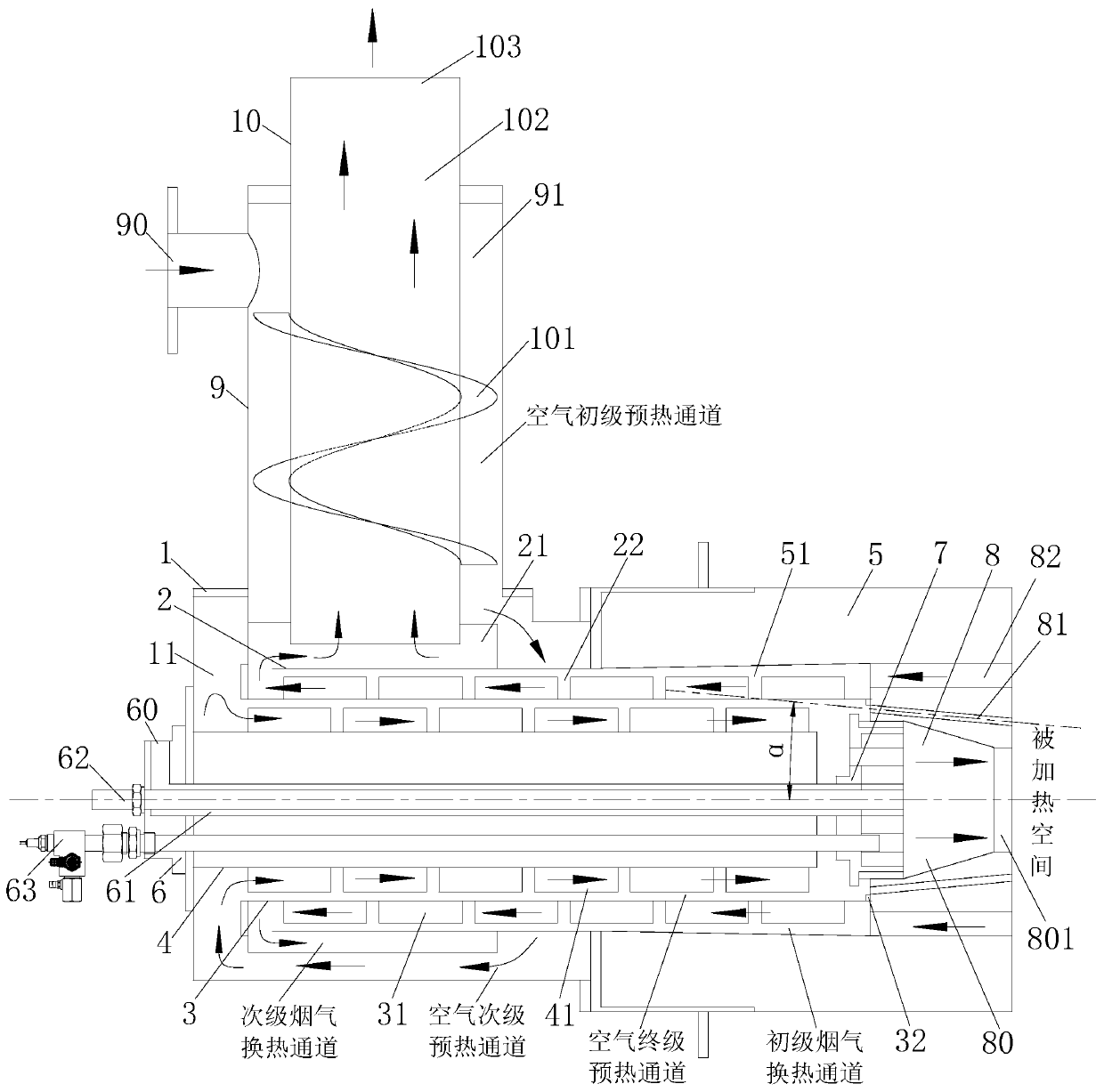

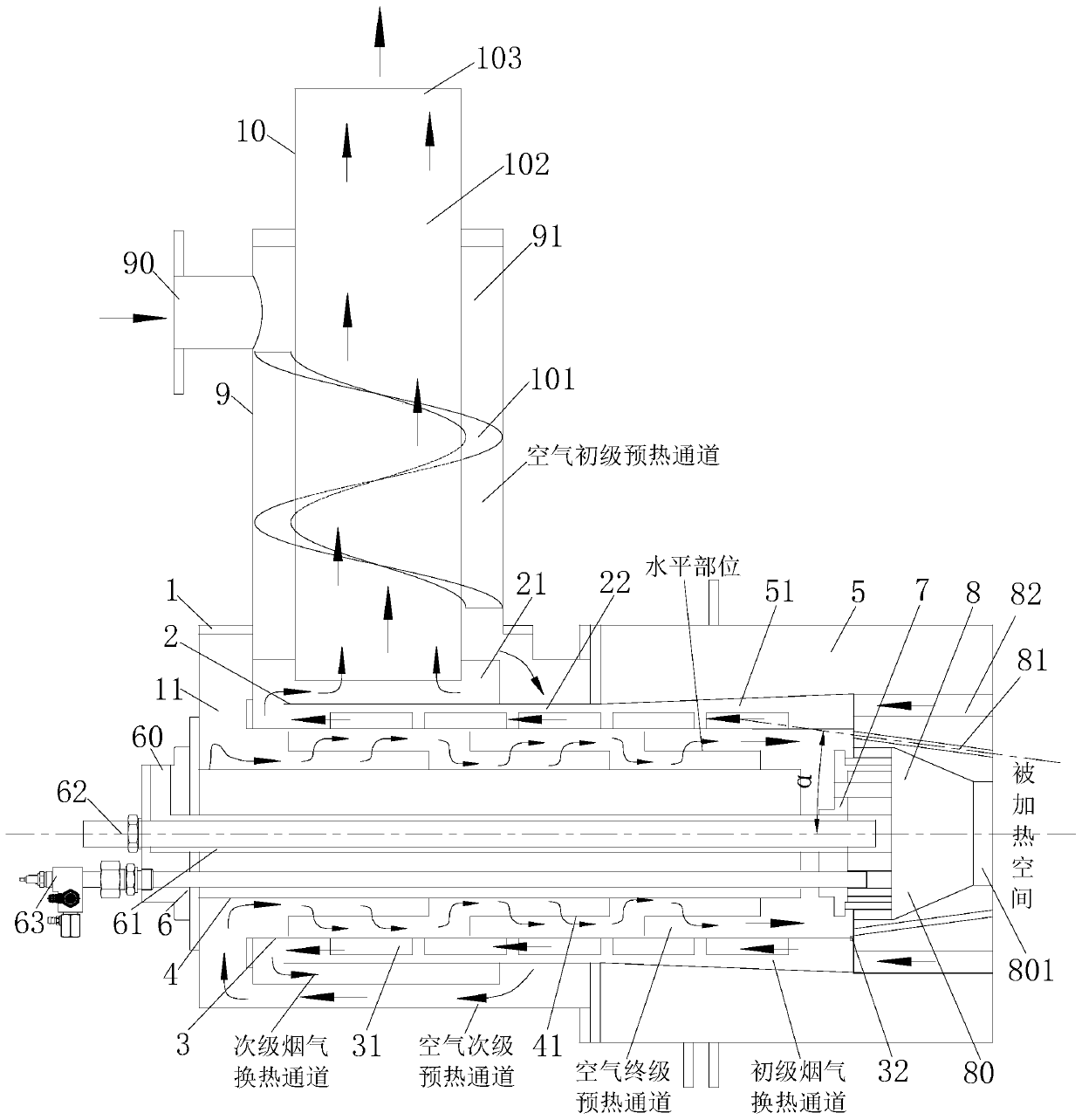

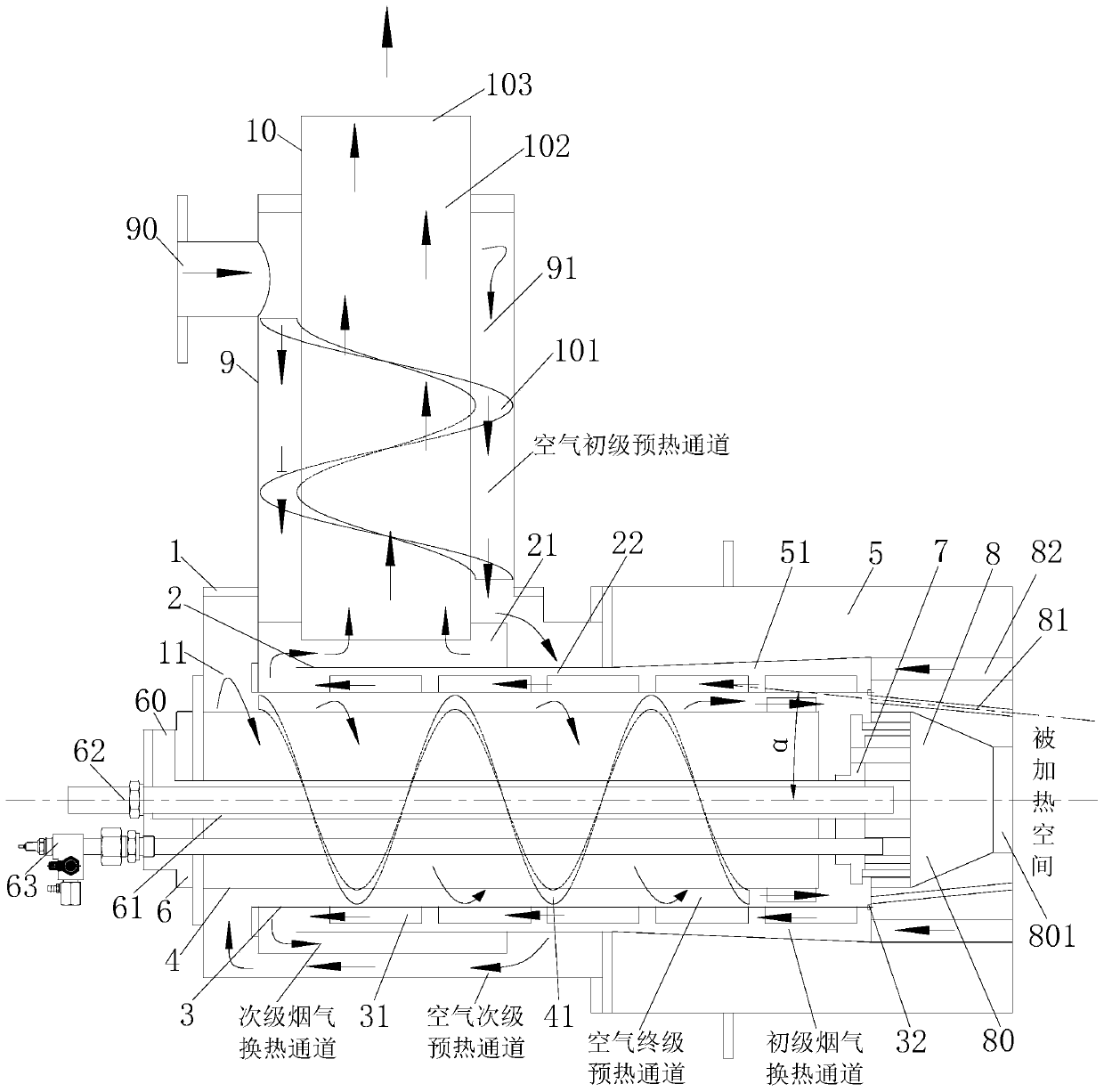

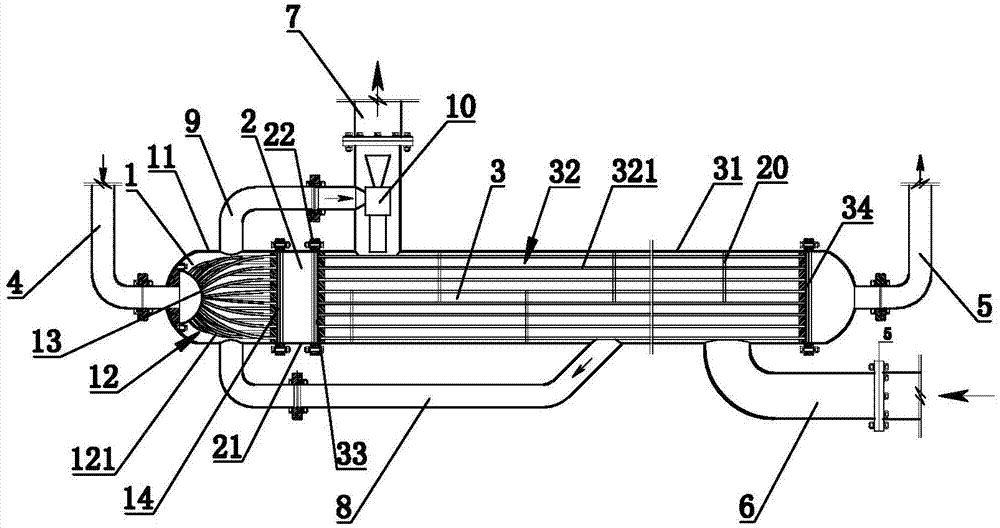

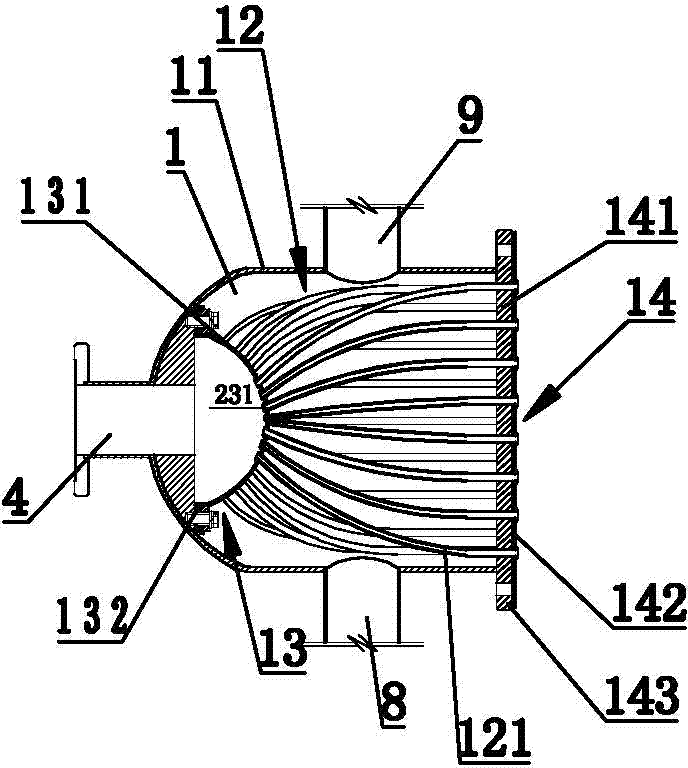

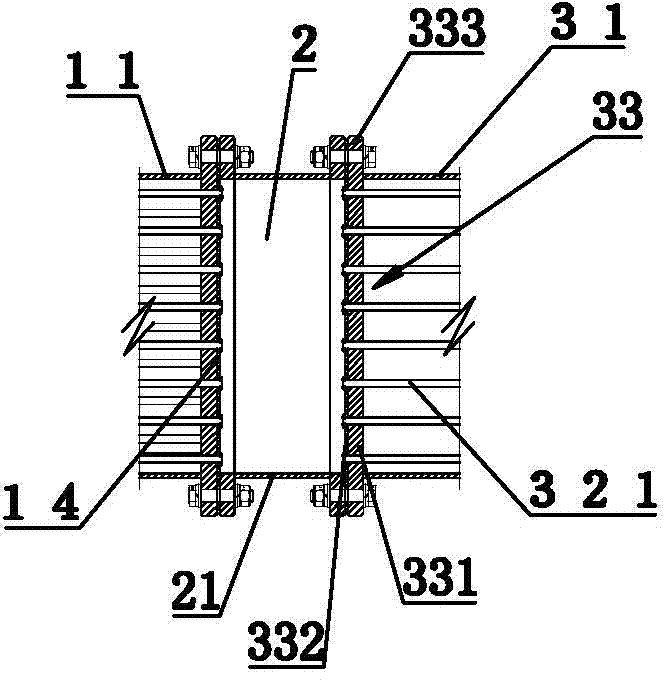

Multistage preheating dual-mode low-NOx self-preheating burner

PendingCN110864289AIncrease profitExtend the heat transfer pathIndirect carbon-dioxide mitigationGaseous fuel burnerCombustorFlue gas

The invention relates to a multistage preheating dual-mode low-NOx self-preheating burner, belongs to the technical field of industrial combustors, and is mainly used for industrial furnace kilns in the industries of steel, color, machinery, aviation, forging, ceramics and the like. According to the burner, a burner shell is installed at one end of a flue gas flow guiding device, a tiling is installed at the other end of the flue gas flow guiding device, a burner core is mounted on the tiling, an air flue gas deflector is mounted in the burner shell, the air flue gas deflector is matched withthe flue gas flow guiding device, one end of a heat exchanger is mounted on the air flue gas deflector, the other end of the heat exchanger is connected with the tiling, one end of an air guide cylinder is installed on the burner shell, the other end of the air guide cylinder is located in the heat exchanger, one end of a burner end cover and one end of an air cylinder are installed on the burnershell, a smoke exhaust pipe is installed in the air cylinder, and the smoke exhaust pipe is connected with the air flue gas deflector.

Owner:HANGZHOU ZHONGJING TECH CO LTD

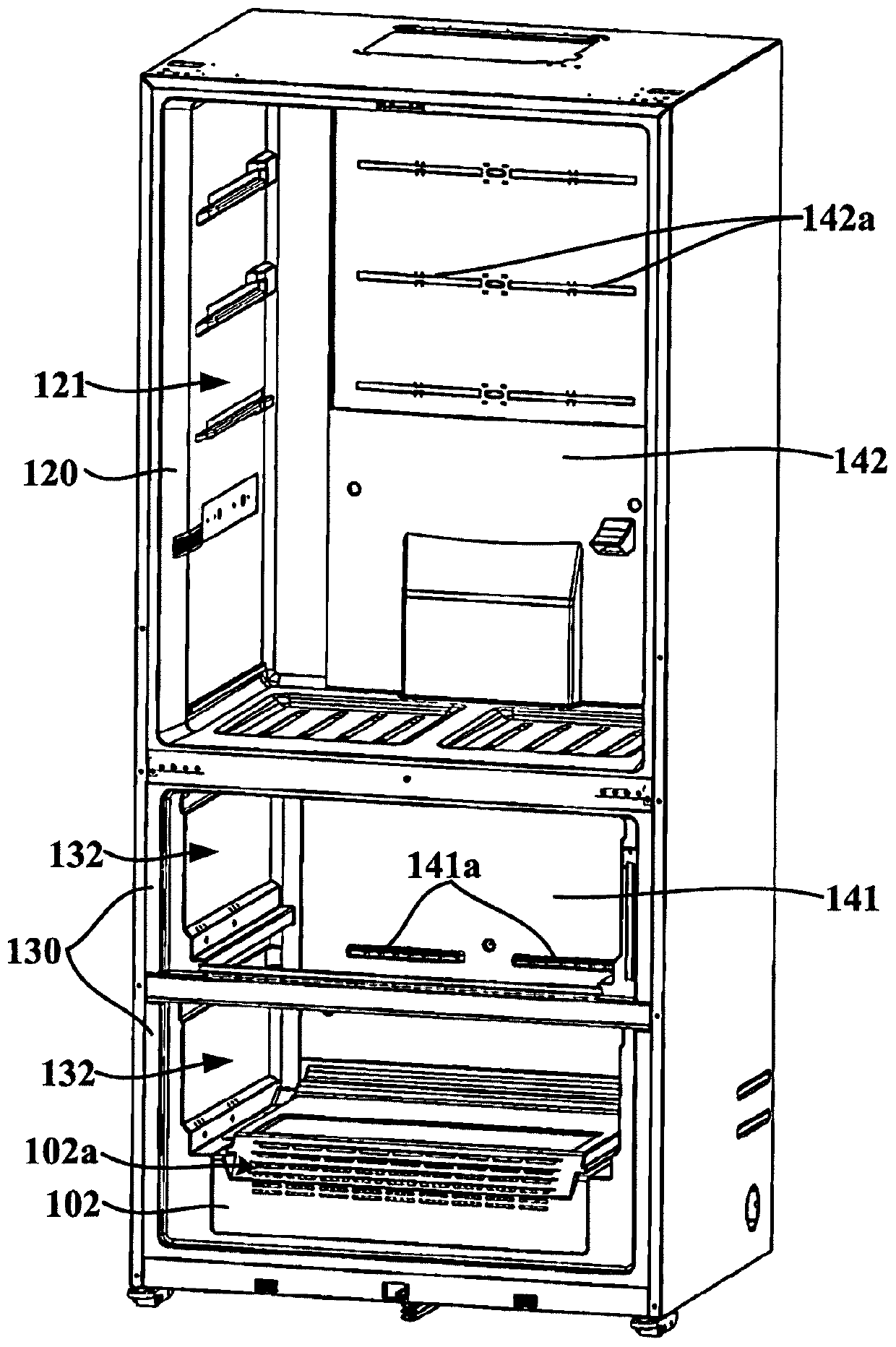

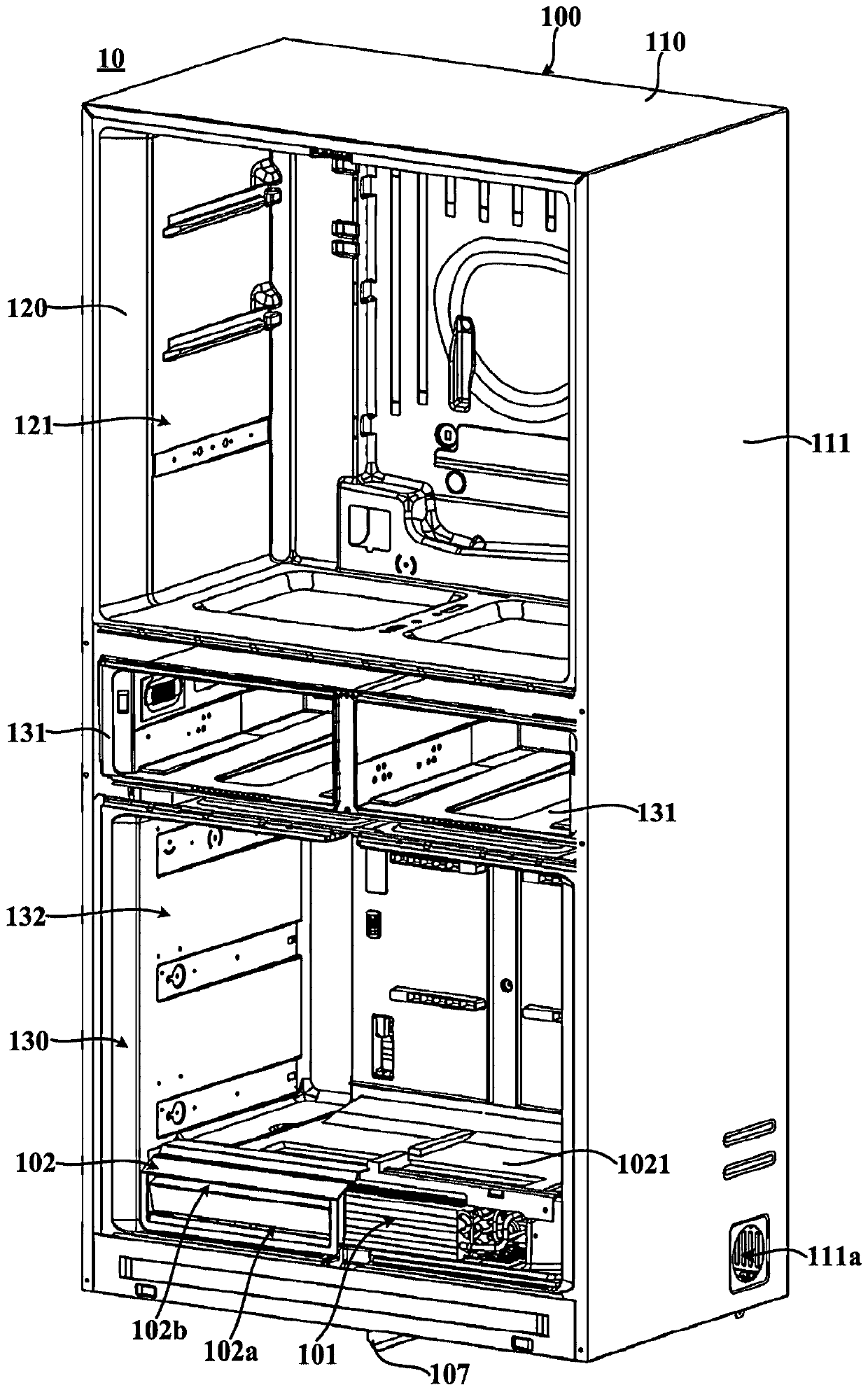

Refrigerator with freezing chamber realizing air return at front side of cooling chamber

PendingCN110375493AGuaranteed cooling effectReduce bendingLighting and heating apparatusDomestic refrigeratorsCooling chamberRefrigeration

The invention provides a refrigerator with a freezing chamber realizing air return at the front side of a cooling chamber. The refrigerator comprises a refrigerator body and an evaporator, wherein therefrigerator body comprises a freezing inner container located at the lower part of the refrigerator body, the freezing inner container is provided with the cooling chamber located at the bottom andthe freezing chamber located above the cooling chamber in a defined mode, so that the cooling chamber occupies the lower space in the freezing inner container, the freezing chamber is lifted, the bending degree of a user during article taking and placing operation in the freezing chamber is reduced, and the use experience of the user is improved. In addition, the evaporator is arranged in the cooling chamber, at least one front air return inlet communicating with the freezing chamber is formed in the front side of the cooling chamber, so that the return air flow of the freezing chamber flows from the front side of the evaporator to the middle of the evaporator through at least one front air return inlet, and then flows backwards to exchange heat with the evaporator, the heat exchange pathbetween the return air flow and the evaporator is prolonged, and then the refrigeration effect of the refrigerator can be ensured.

Owner:QINGDAO HAIER REFRIGERATOR CO LTD +1

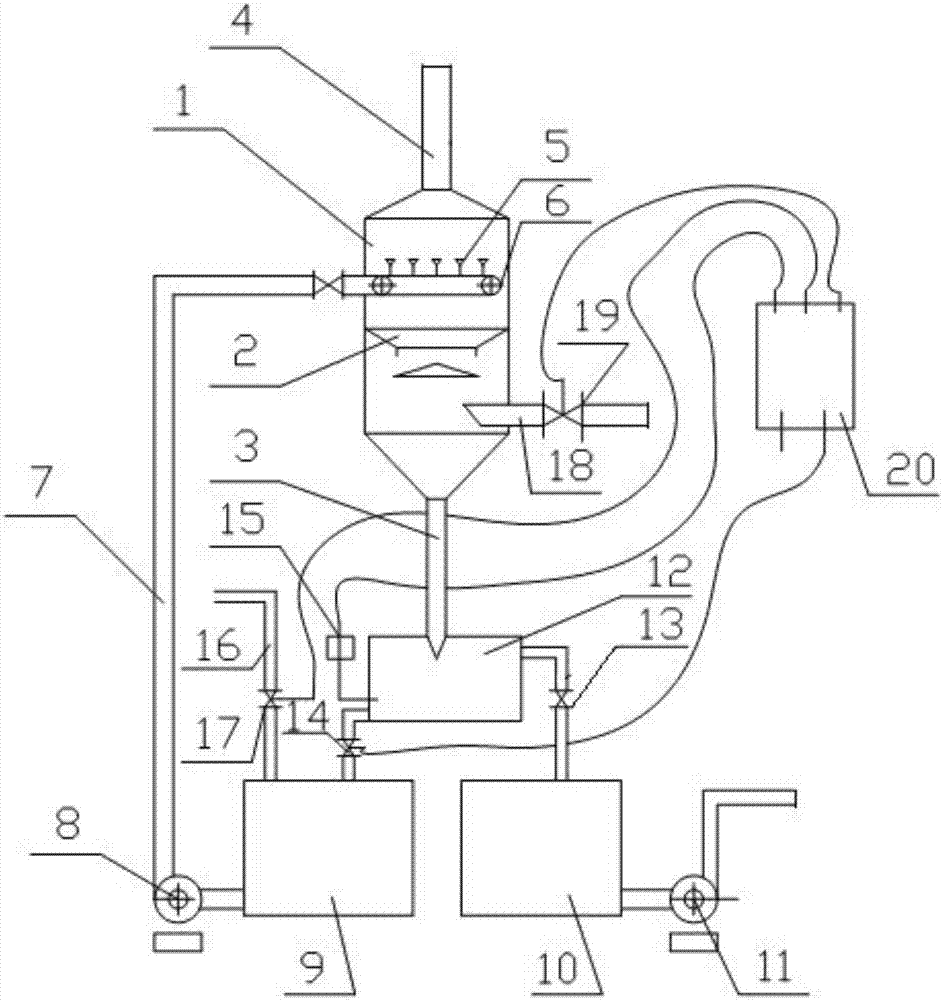

Waste steam recovery and utilization device

PendingCN107246810AEfficient recyclingSimple structureDirect contact heat exchangersHeat exchange apparatusProcess engineeringThermal water

The invention relates to a waste steam recovery and utilization device which comprises a steam absorption tower, a mixing barrel and a PLC controller; the bottom of the steam absorption tower is connected with a gas inlet pipe for inputting steam into the steam absorption tower; the steam absorption tower is internally provided with a nozzle component for spraying misty cold water upward and changing the misty cold water into hot water by being subjected to heat exchange with steam; the bottom of the steam absorption tower is connected with the mixing barrel through a descending water pipe and conveys the hot water to the mixing barrel; and the PLC controller is arranged on the outer side of the steam absorption tower and controls the hot water in the mixing barrel through the temperature of the hot water in the mixing barrel to continuously carry out heat exchange with the steam in the steam absorption tower for rising temperature or directly discharges the hot water for use. The waste steam recovery and utilization device has the beneficial effects of simple structure, convenience in use, little investment, and capabilities of effectively recovering waste steam and achieving the purpose of energy conservation.

Owner:广西糖业集团红河制糖有限公司

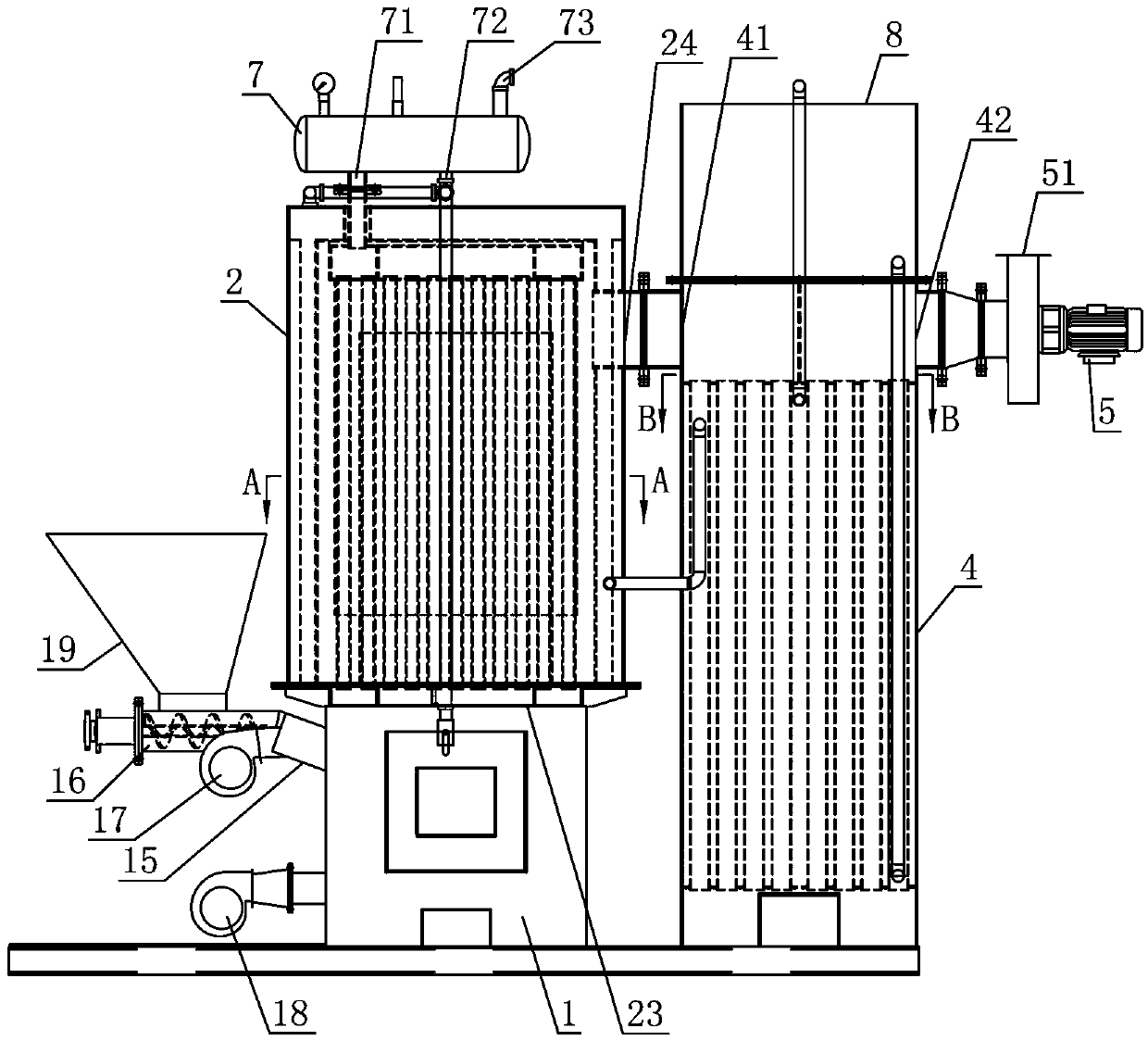

Biomass steam generator

PendingCN110469833ABurn fullyExtend the heat transfer pathFuel feeding arrangementsSteam boilersCombustion chamberFlue gas

The invention discloses a biomass steam generator. The biomass steam generator comprises a combustion chamber with a furnace cavity, a steam chamber with a first sealed cavity and a heat exchanger; atotal flue gas outlet is formed in the top of the combustion chamber, a feed inlet and an air supplement inlet are formed in the side wall of the combustion chamber; a first flue gas inlet is formed in the bottom of the steam chamber, the steam chamber is located above the combustion chamber, and the first flue gas inlet and the total flue gas outlet communicate in a sealed mode; a water jacket group is arranged in the first sealed cavity; a first flue gas outlet is formed in the side wall of the steam chamber, the first flue gas outlet communicates with a second flue gas inlet of the heat exchanger, and an induced draft fan is arranged at the second flue gas outlet of the heat exchanger; a water outlet of the heat exchanger sequentially communicates with the water jacket group through a water inlet pipe, a water pump and a water outlet pipe, and a steam inlet pipe of an air manifold sequential penetrates through through holes in the top of the steam chamber in a sealed mode and extends into the water jacket group. The biomass steam generator is simple and compact in structure, small in space occupation, full in combustion of biomass fuels and high in heat exchange efficiency.

Owner:张家港市天源机械制造有限公司

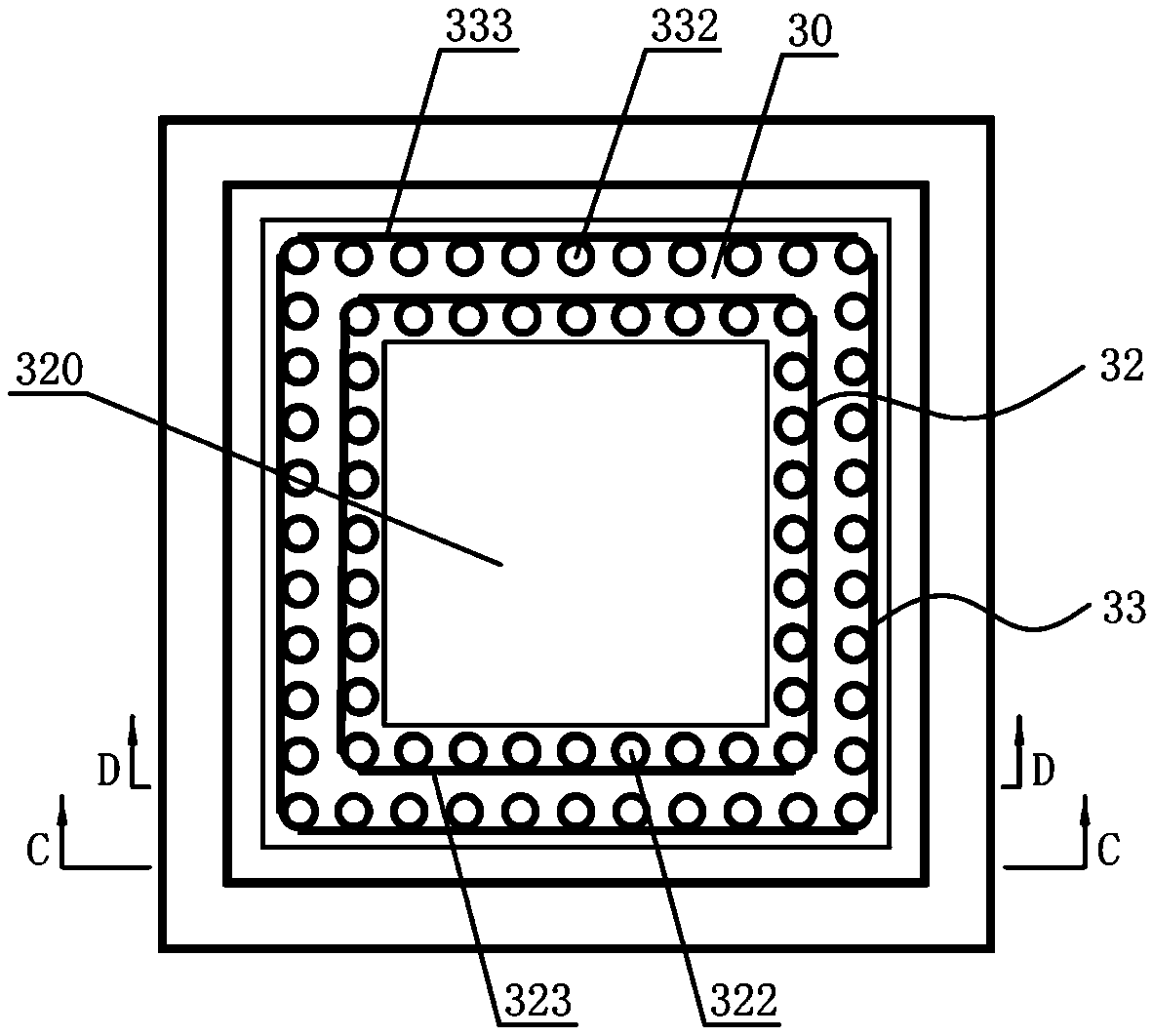

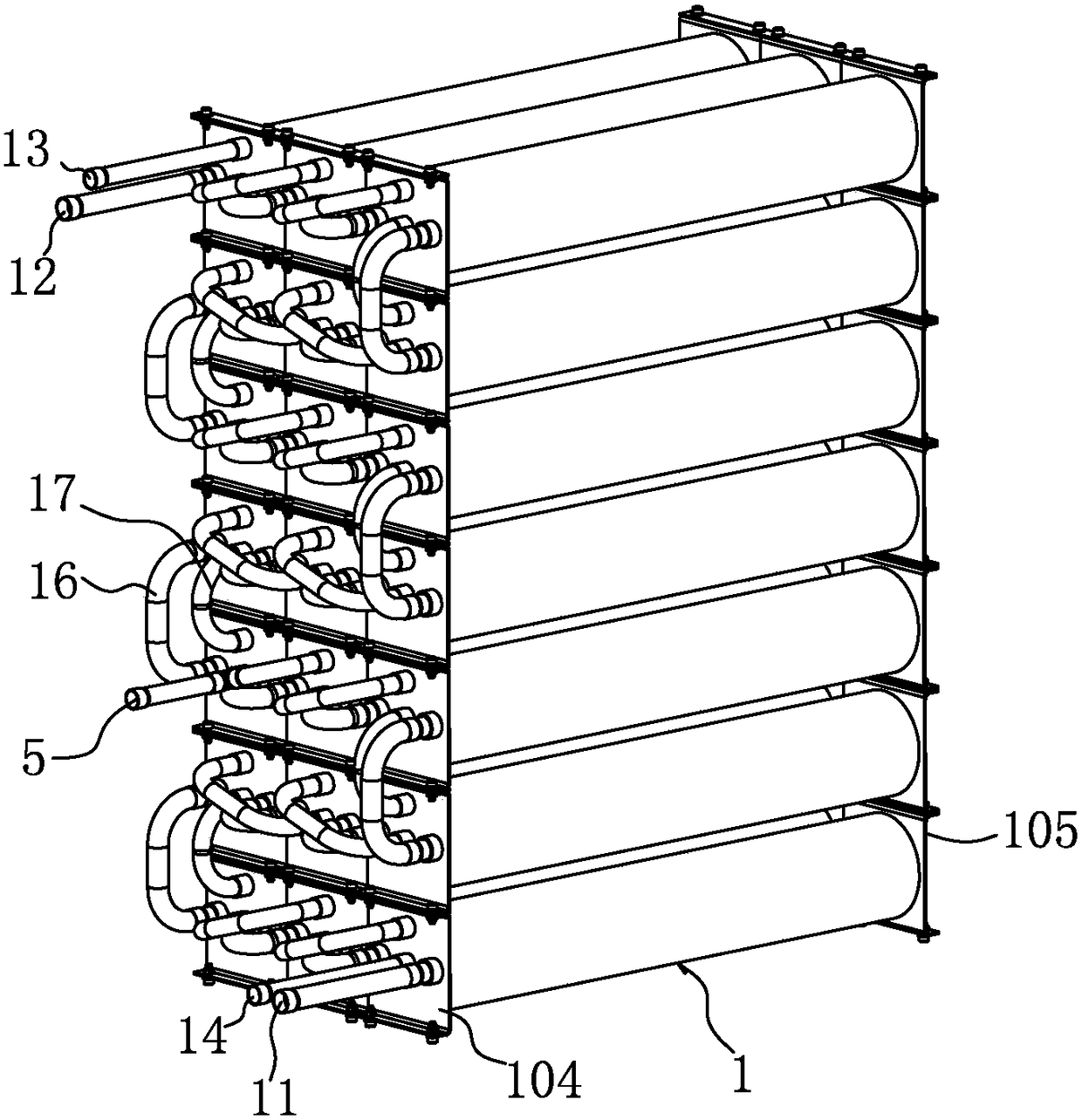

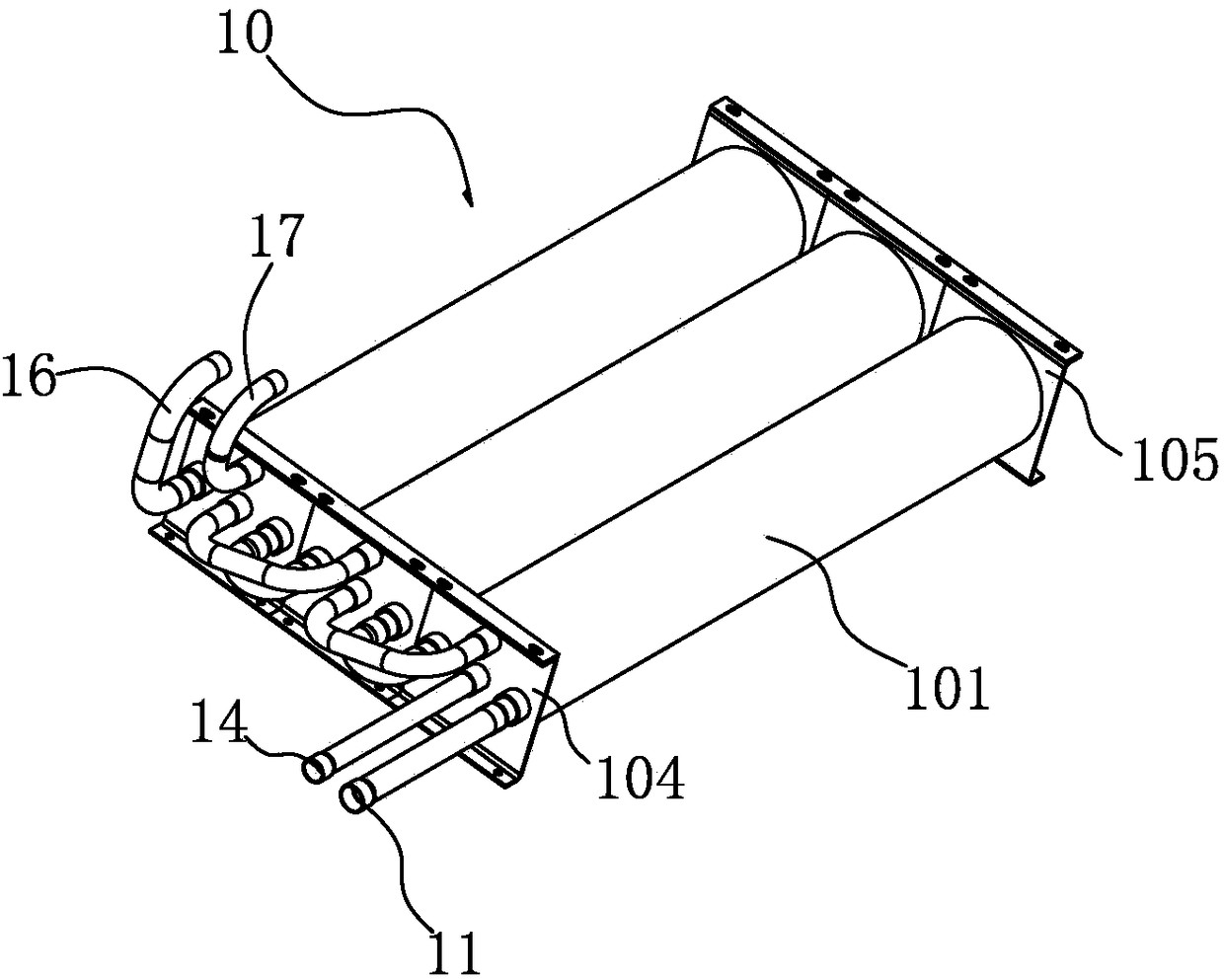

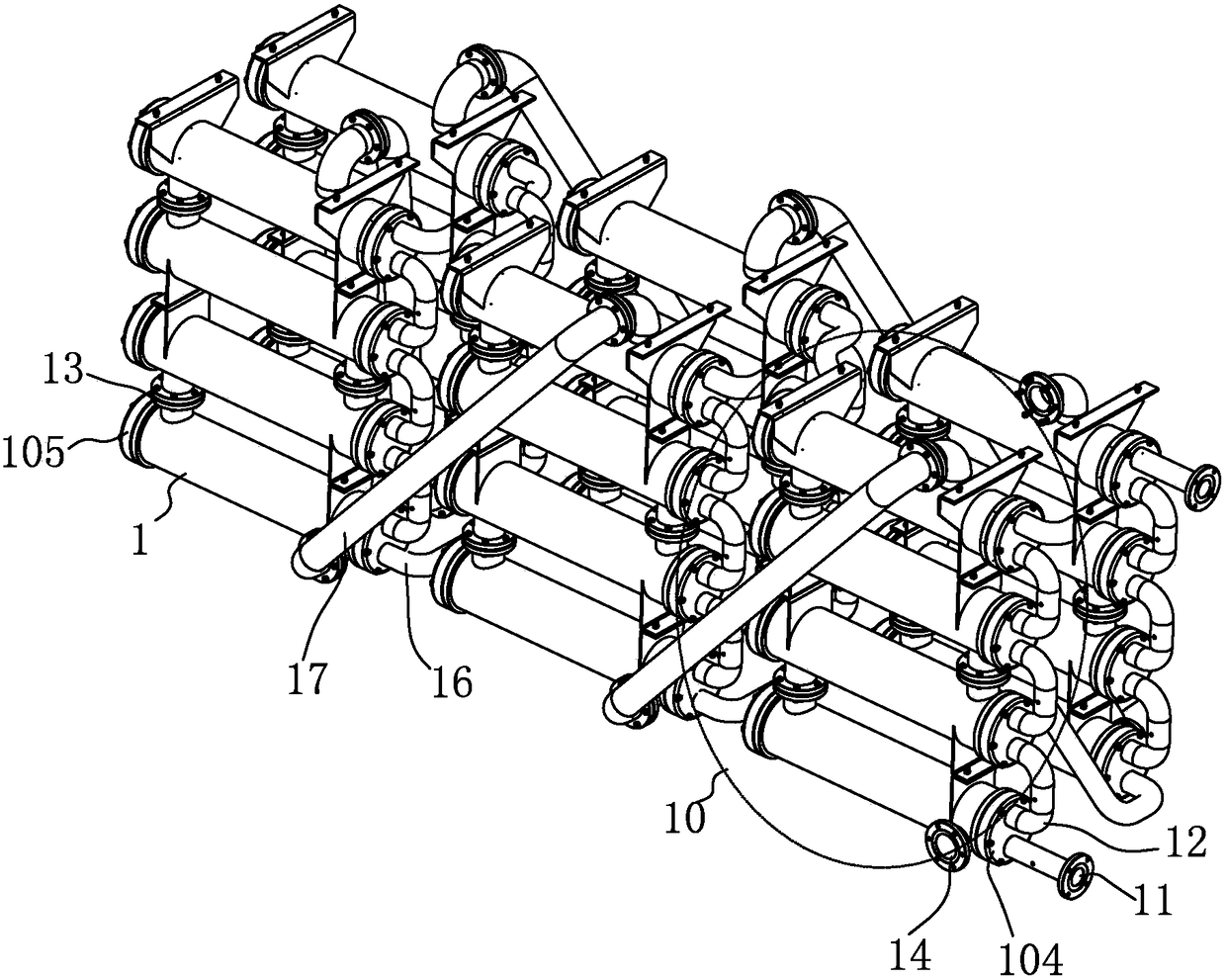

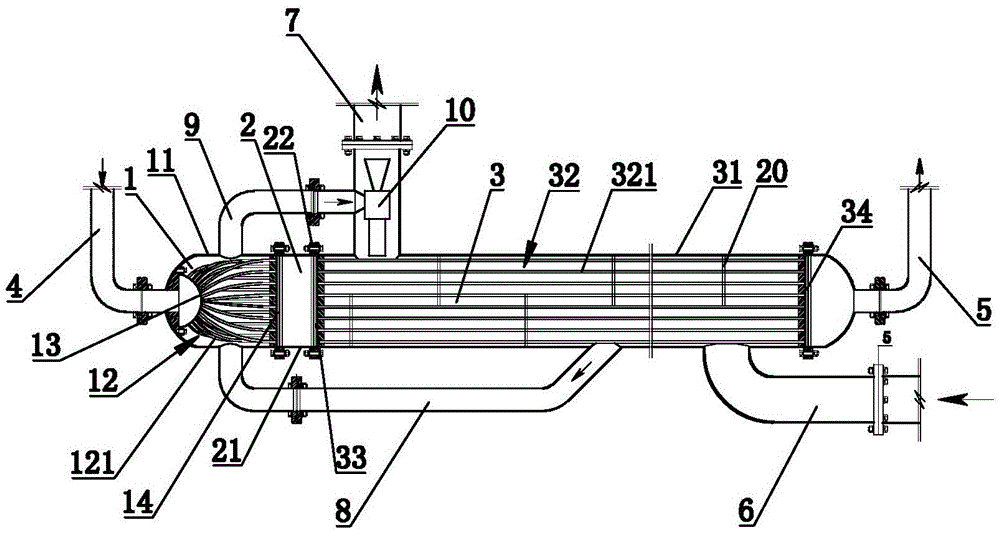

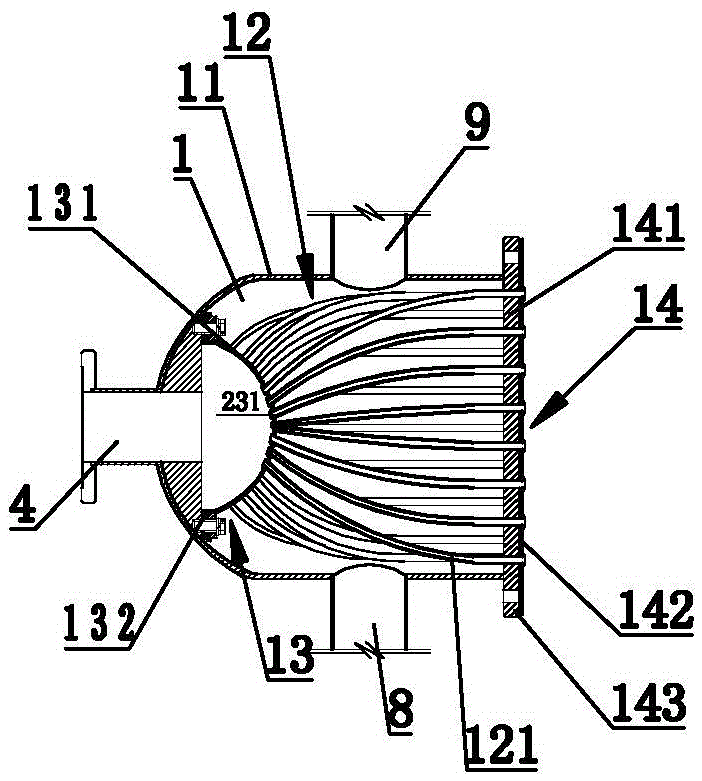

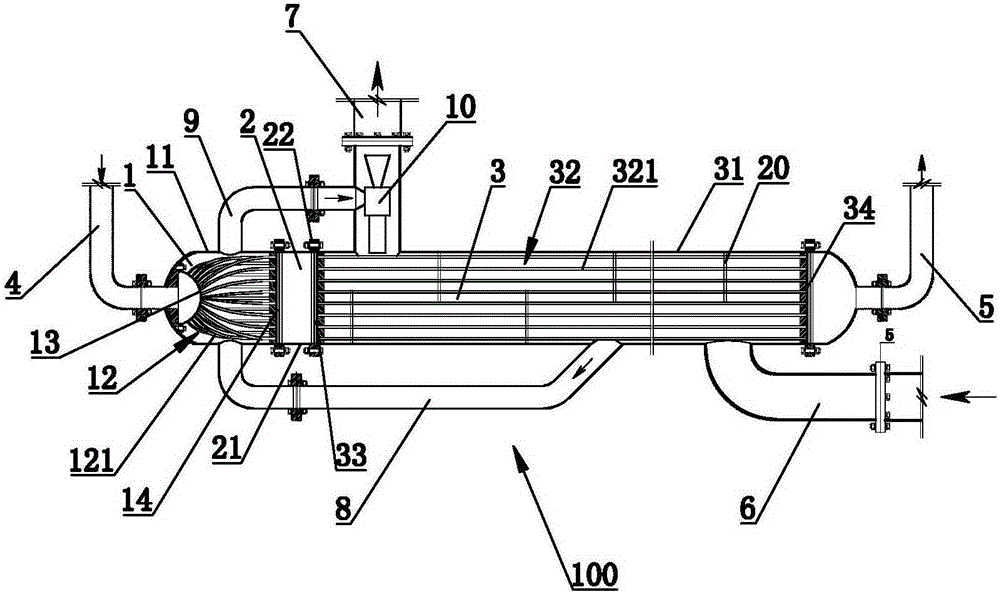

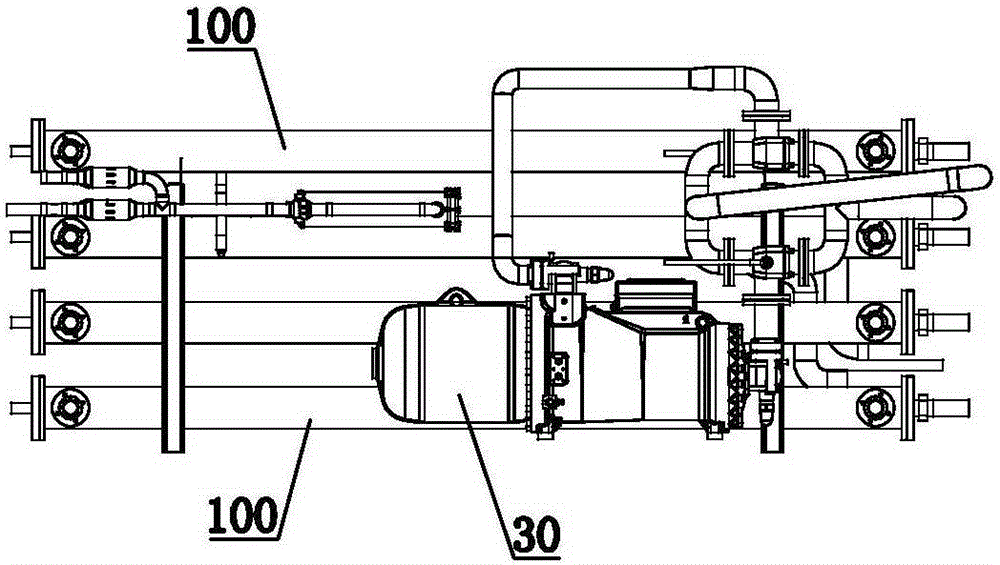

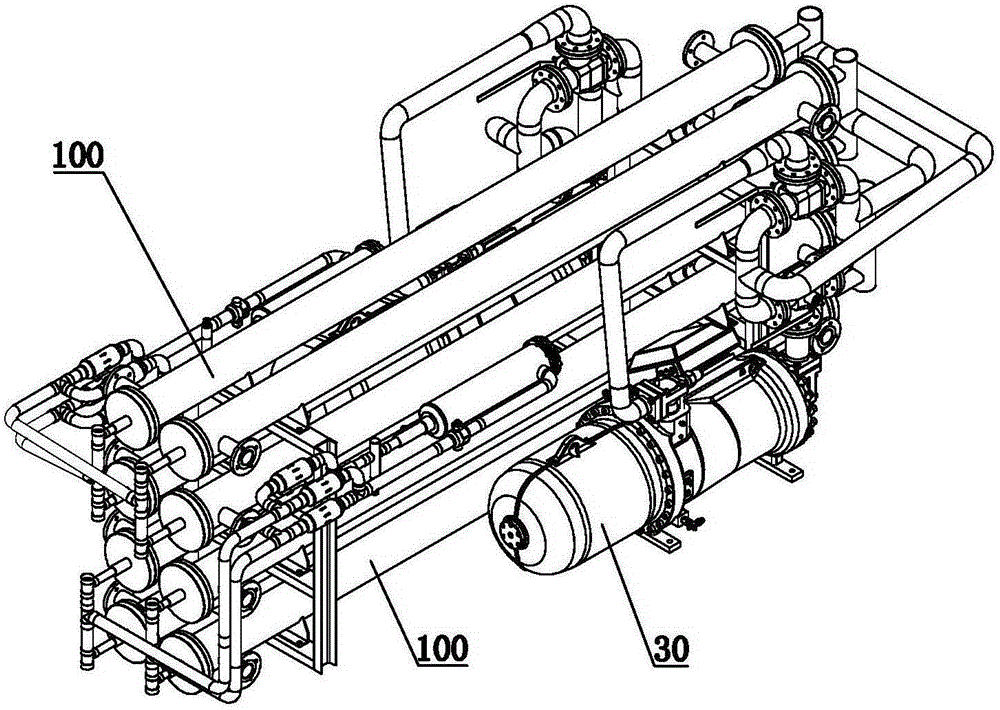

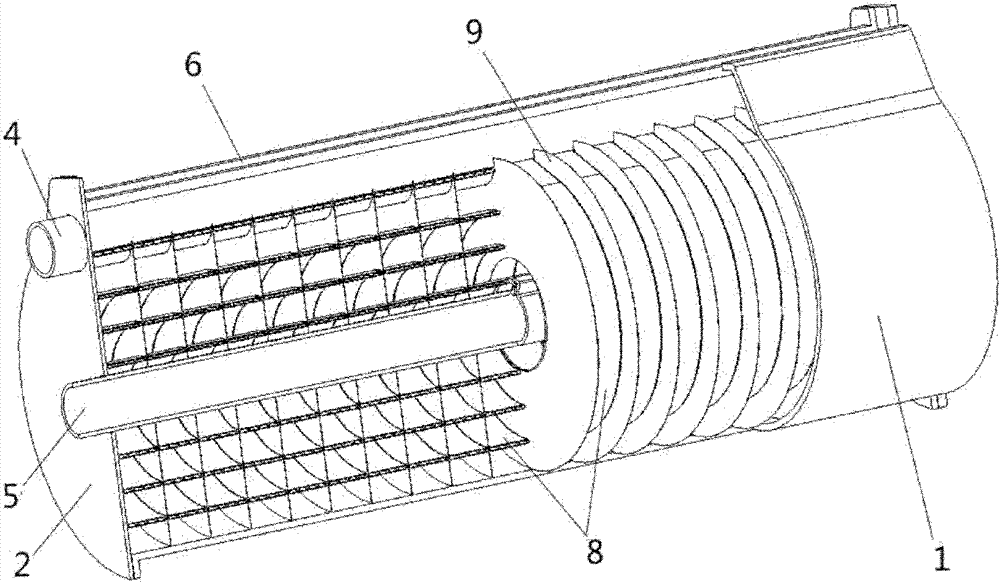

Heat exchanger for heat pump, and heat pump applying same

ActiveCN104266408AExtend the heat transfer pathImprove heat transfer efficiencyMechanical apparatusHeat pumpsRefrigerantEngineering

The invention discloses a heat exchanger for a heat pump. The heat exchanger comprises an auxiliary heat exchange cabin, a buffer cabin and a main heat exchange cabin which are sequentially connected, wherein the main heat exchange cabin comprises a main heat exchange cabin shell, a main heat exchange tube bundle is arranged in the main heat exchange cabin shell, one end of the main heat exchange tube bundle is communicated with the buffer cabin through a first main heat exchange tube plate, and the other end of the main heat exchange tube bundle is communicated with a refrigerant drainage tube through a second main heat exchange tube plate; the auxiliary heat exchange cabin comprises an auxiliary heat exchange cabin shell, a capillary tube bundle is arranged in the auxiliary heat exchange cabin, one end of the capillary tube bundle is communicated with a refrigerant supply tube through a capillary tube liquid distributor, and the other end of the capillary tube bundle is communicated with the buffer cabin through a capillary tube plate; the buffer cabin comprises a buffer cabin shell, the main heat exchange cabin is provided with a main water inlet tube and a main water outlet tube, the auxiliary heat exchange cabin is provided with a water absorption tube connected to the main heat exchange cabin and an auxiliary water outlet tube connected to the main water outlet tube. The invention further discloses a heat pump applying the heat exchanger above. A refrigerant in the main heat exchange tube of the heat pump disclosed by the invention is balanced, and the heat exchange efficiency is high.

Owner:SHANDONG HONGLI HEAT PUMP ENERGY

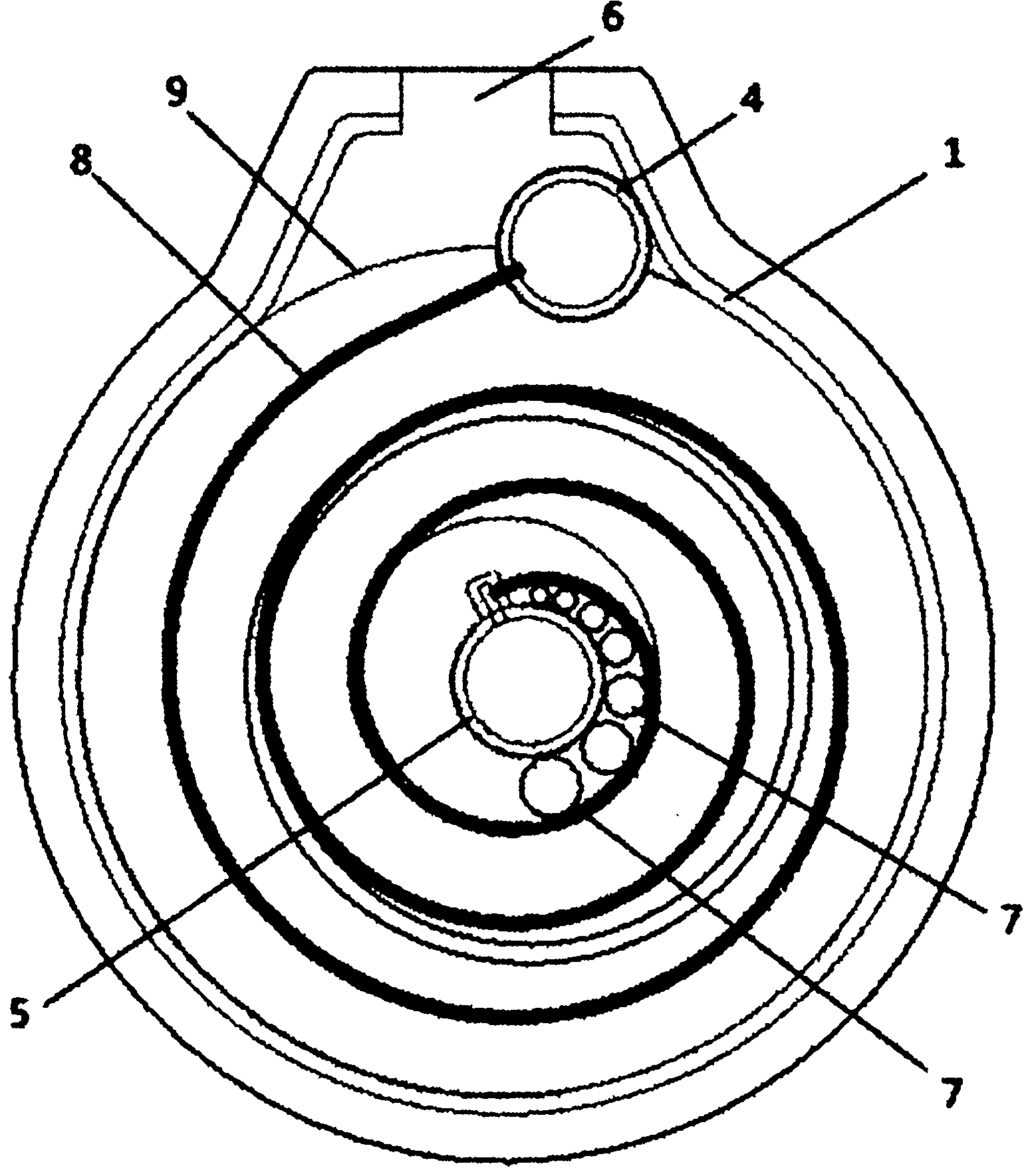

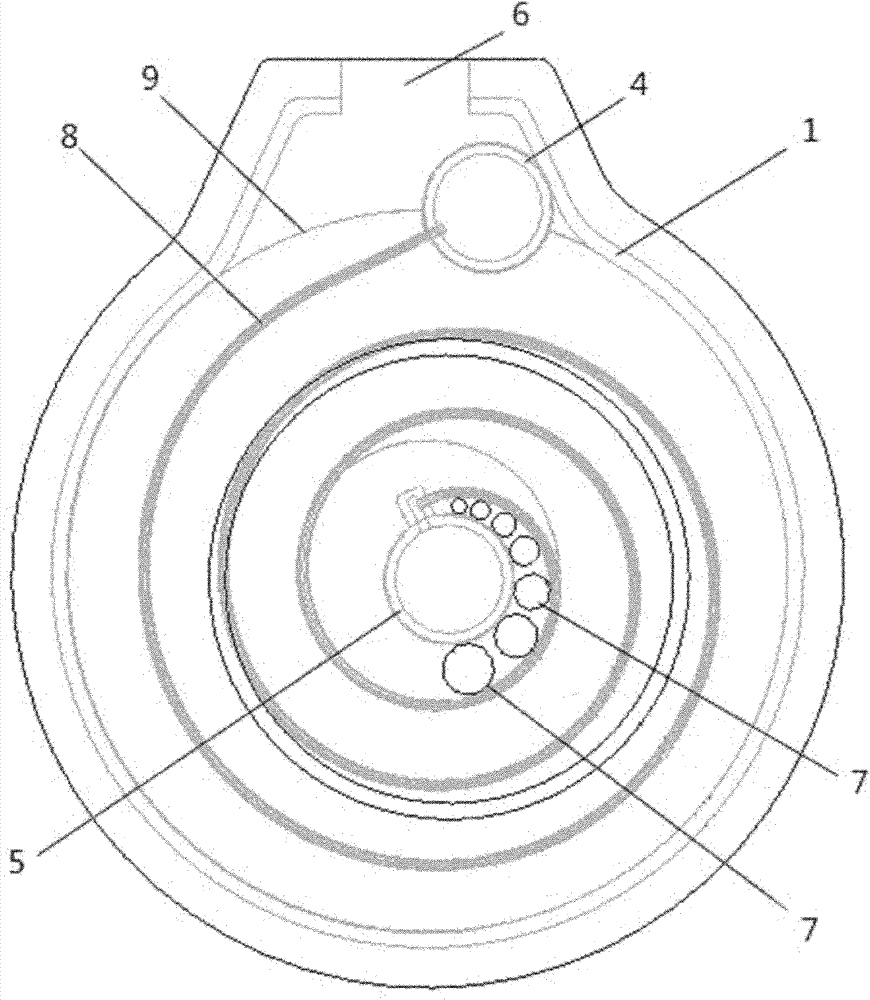

Vortex parallel flow countercurrent evaporator for automotive air conditioner

ActiveCN102032722ASmooth circulationIncrease the itineraryEvaporators/condensersVehicle heating/cooling devicesAutomobile air conditioningThermal expansion

The invention relates to a vortex parallel flow countercurrent evaporator for an automotive air conditioner, which comprises a plurality of vortex type flat tubes, wherein the vortex type flat tubes are arranged in parallel, extended to form a vortex shape and separated by fins; refrigerant runners are formed in cavities of the vortex type flat tubes; the adjacent vortex layers of individual vortex type flat tubes are in sealing connection by the fins on two sides to form secondary refrigerant runners exchanging heat with refrigerants; inlets and outlets of each refrigerant runner are communicated with one another respectively; the inlets and outlets of each secondary refrigerant runner are communicated with one another respectively; and the refrigerants in the refrigerant runners and secondary refrigerants in the secondary refrigerant runners flow reversely. The vortex parallel flow countercurrent evaporator for the automotive air conditioner has a simple structure, occupies a small area, is difficult to deform by stress, vibration, thermal expansion and the like under severe conditions to influence the sections of the runners, makes smooth the circulation of the refrigerant, remarkably increases the travel of the refrigerant, improves the refrigeration efficiency and greatly reduces machining difficulties.

Owner:浙江兰通空调设备有限公司

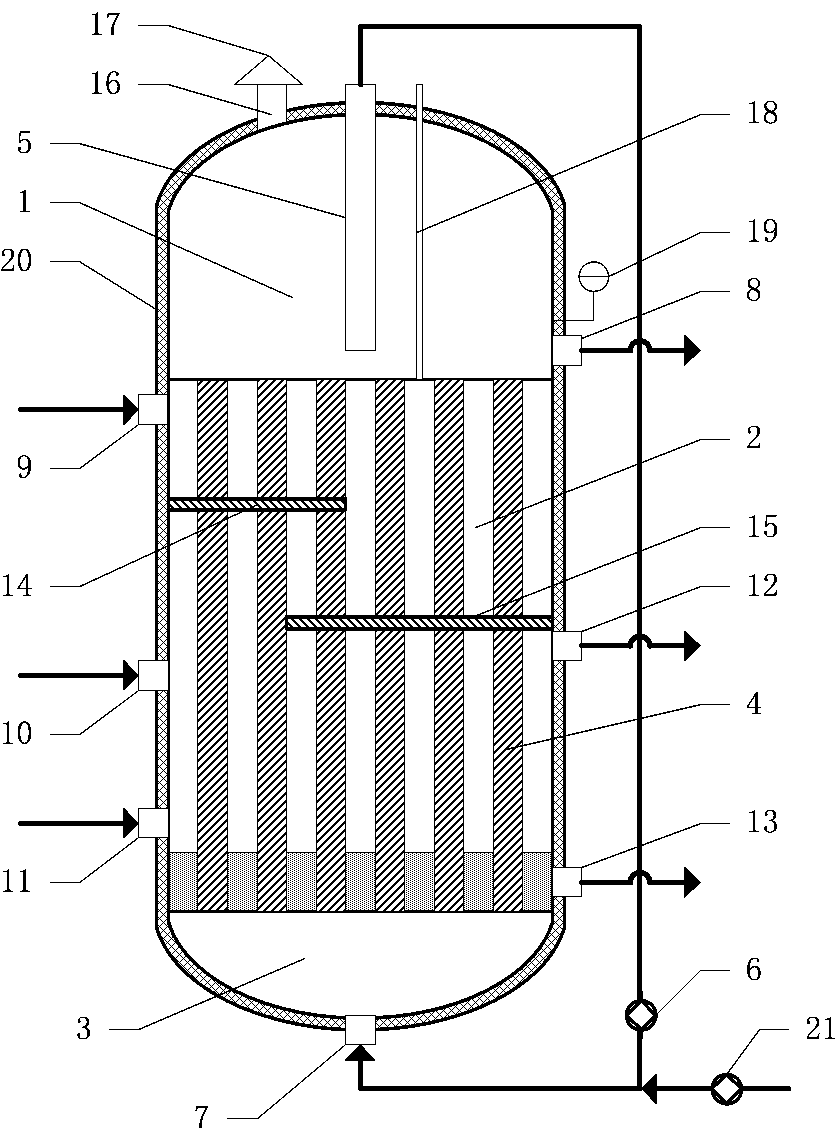

Vertical multi-source steam waste heat recovery energy-saving device

InactiveCN108709439BMaximize recyclingSolving Recycling ProblemsHeat exchanger casingsStationary tubular conduit assembliesPharmacyProcess engineering

Owner:周封

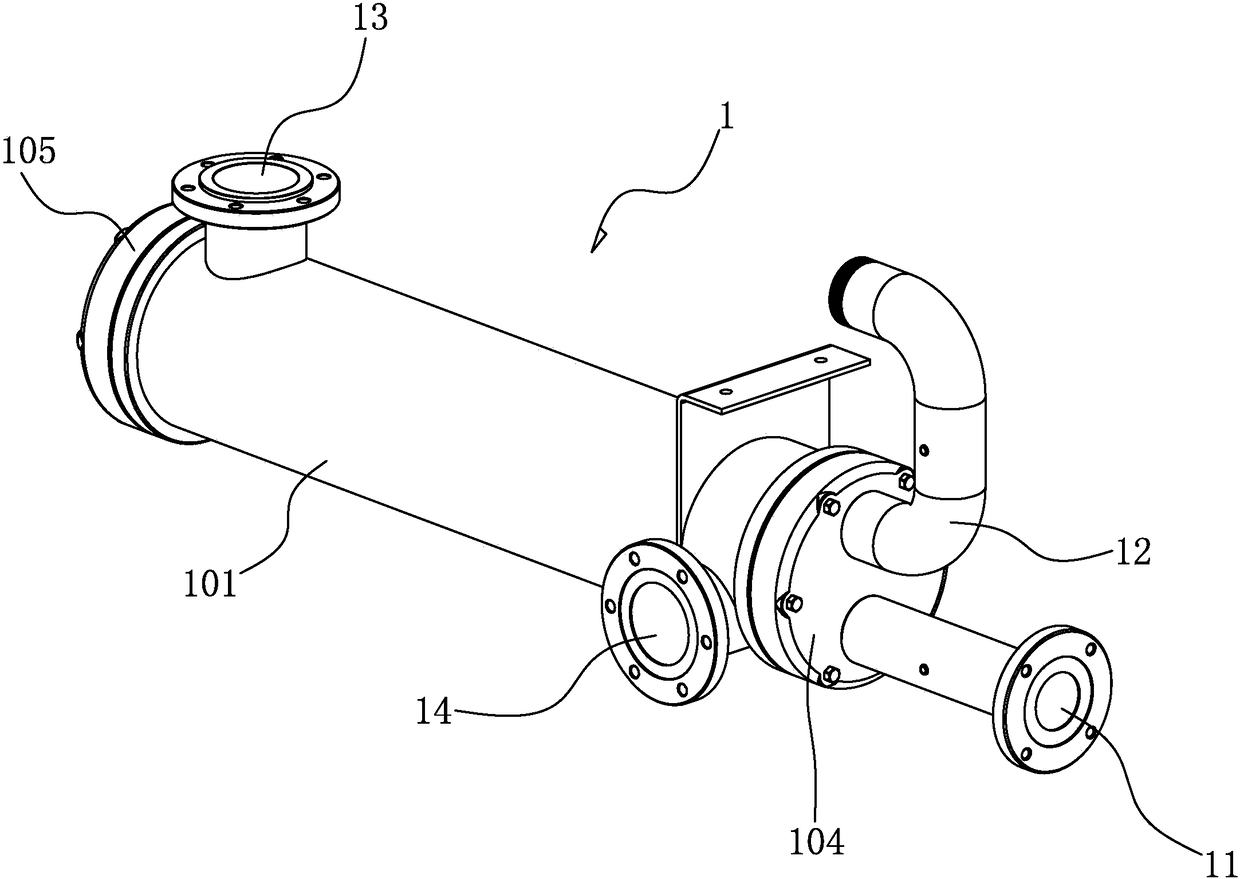

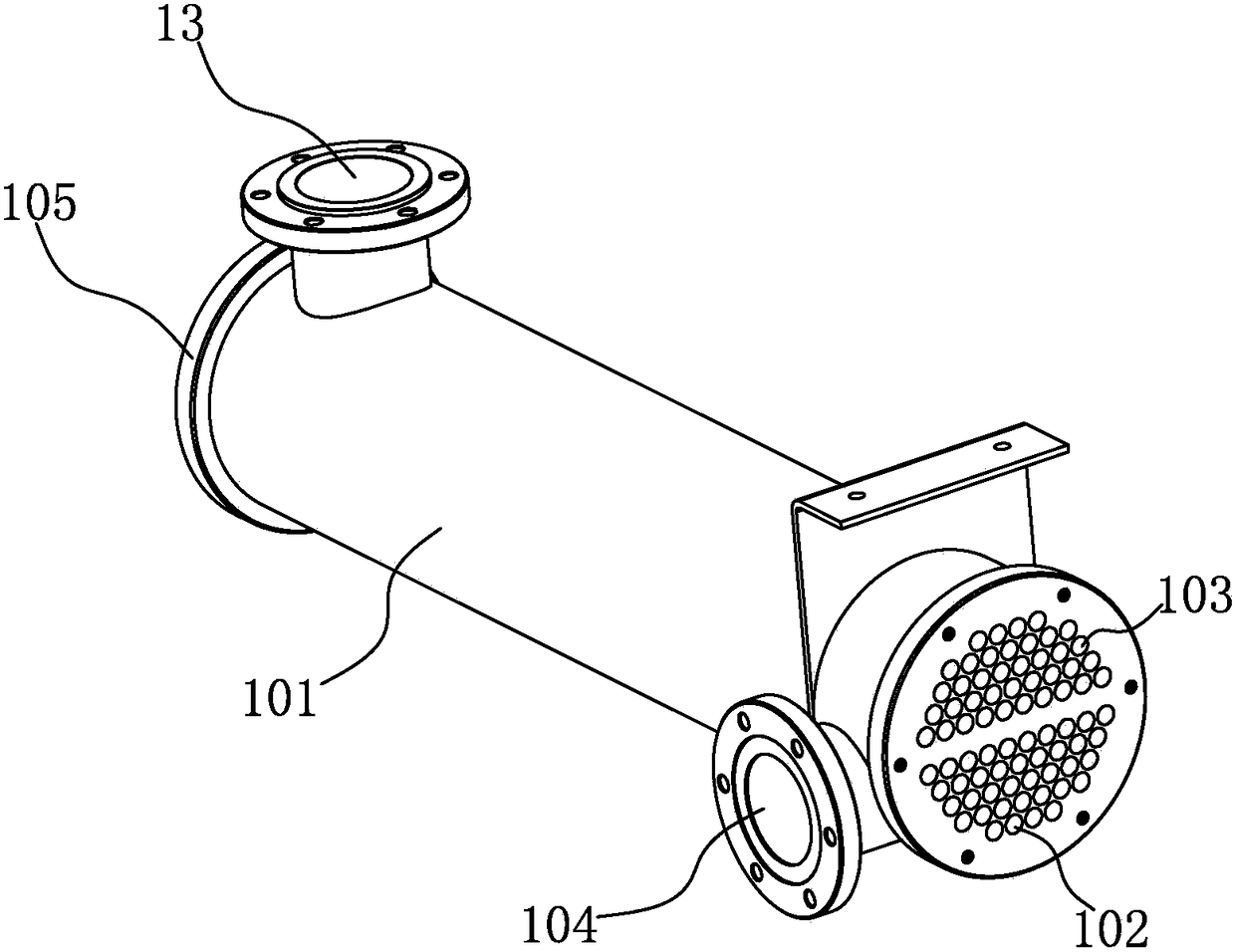

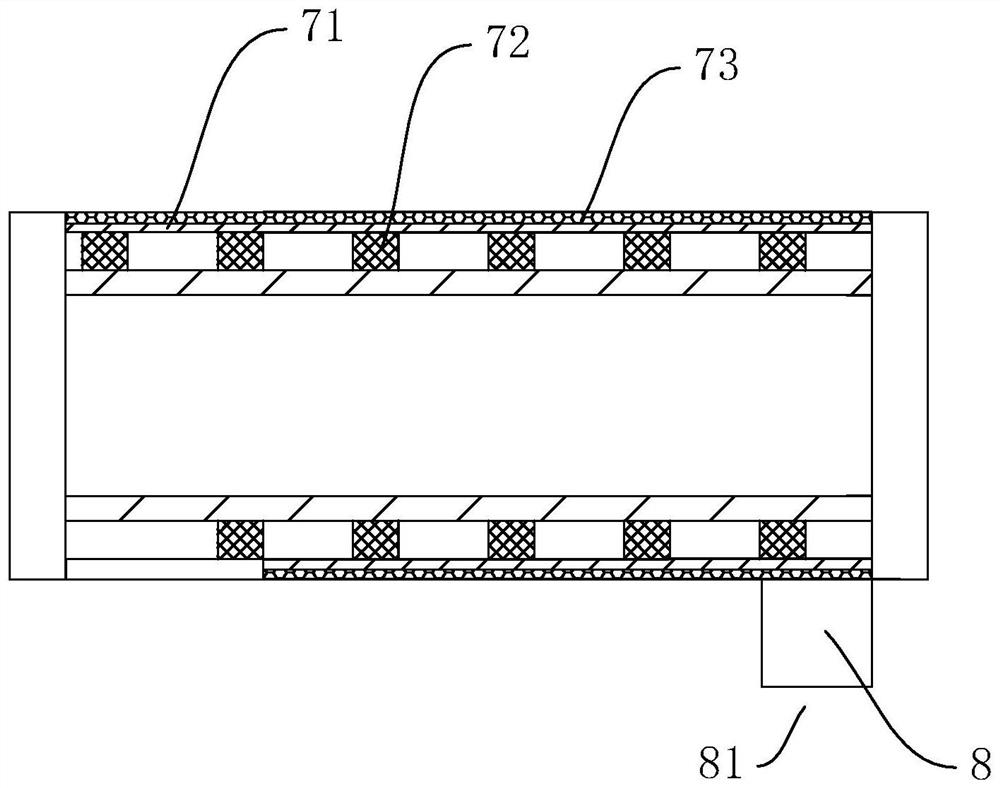

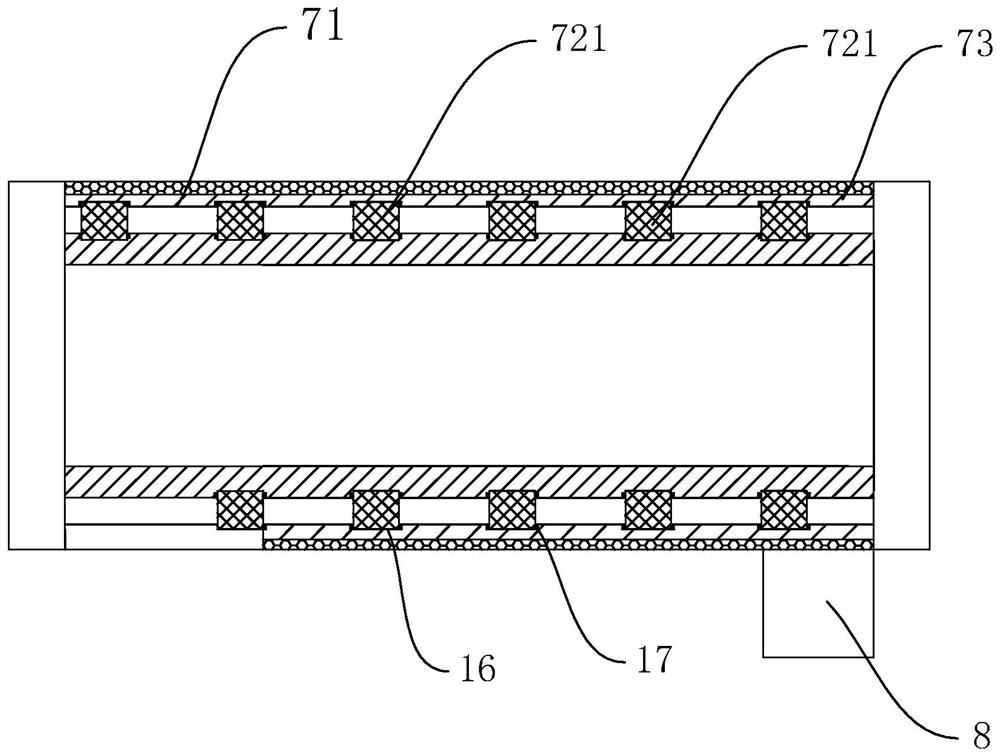

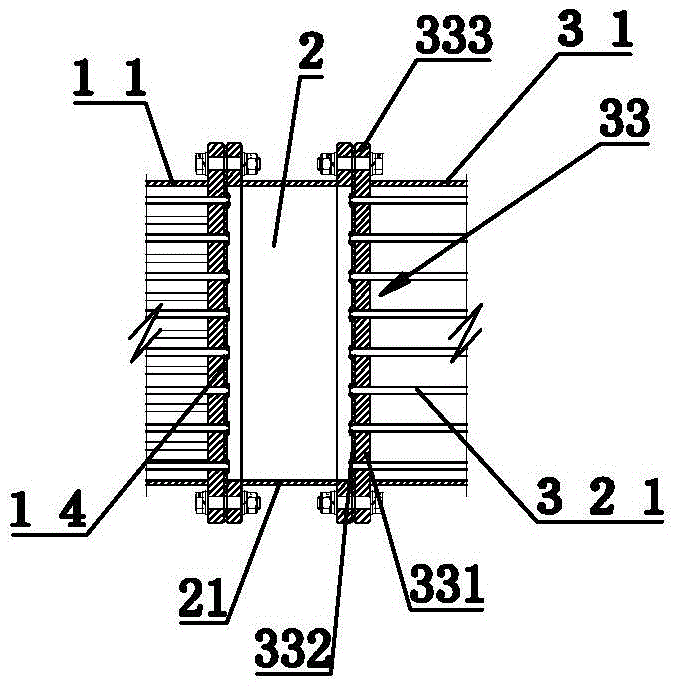

A casing condenser

ActiveCN105758069BExtend the heat transfer pathImprove heat exchange efficiencyEvaporators/condensersEngineeringWater pipe

The invention discloses a tube-in-tube condenser for an air source heat pump device. The tube-in-tube condenser comprises a plurality of condenser units. The condenser units are serially connected with one another, water inlets, water outlets, refrigerant inlets and refrigerant outlets are formed in the condenser units, tube pass channels and shell pass channels which are separated from one another are formed in each condenser unit, and each tube pass channel comprises at least two parallel and twined water pipes; the shell pass channels are communicated with the refrigerant inlets and the refrigerant outlets. The tube-in-tube condenser has the advantages that the tube-in-tube condenser comprises the multiple condenser units, the condenser units are distributed by means of arraying, accordingly, the sufficient condenser units can be mounted in limited spaces, heat exchange paths with sufficient lengths can be obtained, and the heat exchange efficiency can be improved; the condenser units are of parallel tube-in-tube structures, so that the lengths of the tube pass channels can be extended to the greatest extent in limited spaces of tubular shells, and the long heat exchange distances can be obtained; the flow of water can be improved.

Owner:SUZHOU HOTFROM HEAT PUMP EQUIP TECH CO LTD

refrigerator

ActiveCN106196846BSolve frostingSustainable frost-free operationLighting and heating apparatusDefrostingIceboxLiquid state

The invention provides a refrigerator. The refrigerator comprises a storage chamber and an evaporator and further comprises a liquid storage device, an air return duct and an air supply duct, wherein the liquid storage device contains liquid-state fluid with the freezing point lower than a preset threshold value, and the evaporator is immersed in the liquid-state fluid; airflow from the storage chamber is guided into the liquid-state fluid through the air return duct and subjected to heat exchange with the liquid-state fluid so as to be cooled; and airflow penetrates through the liquid-state fluid to escape to the space above the liquid level of the liquid-state fluid is returned to the storage chamber through the air supply duct. According to the refrigerator, by arranging the evaporator in the liquid-state fluid with the low freezing point, the problem of frosting of the evaporator of the refrigerator can be solved, the evaporator can operate in a frost-free mode continuously, the performance of a refrigerating system is improved, and energy consumption is reduced. Meanwhile, the situation that temperature fluctuation of the storage chamber of the refrigerator is large due to defrosting of the evaporator can be avoided.

Owner:QINGDAO HAIER SMART TECH R & D CO LTD +1

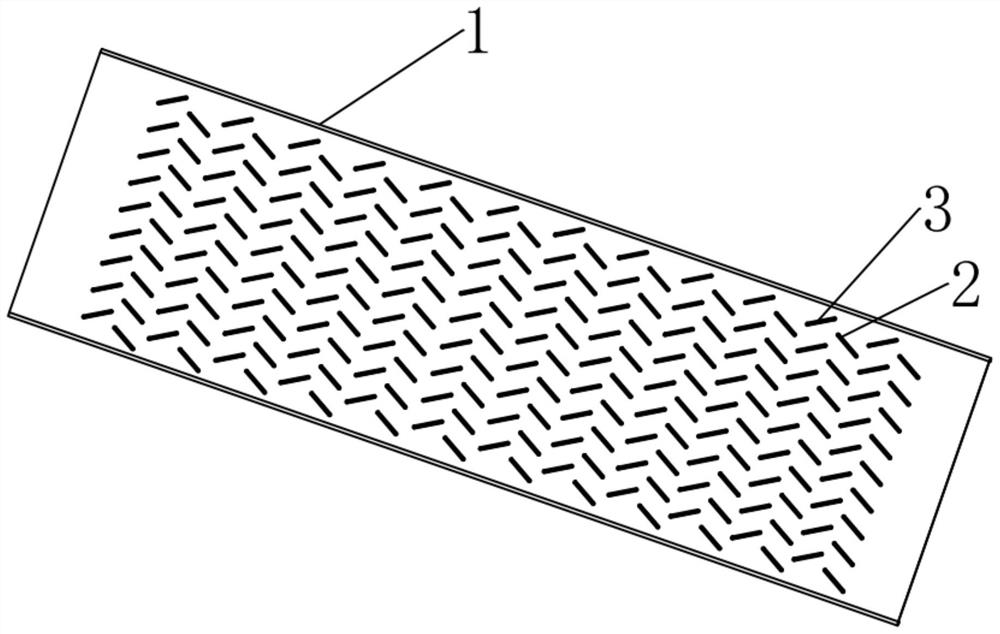

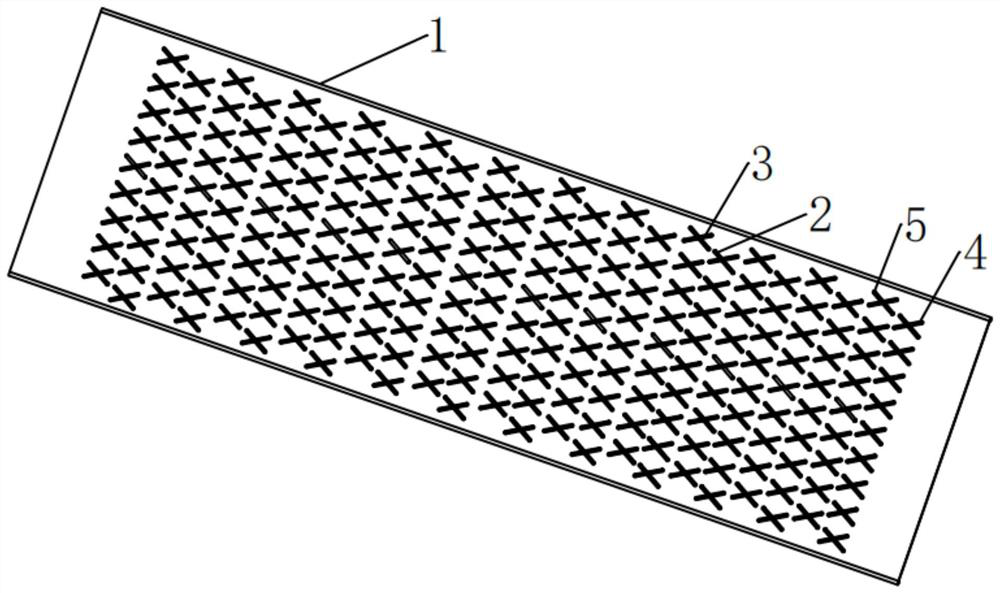

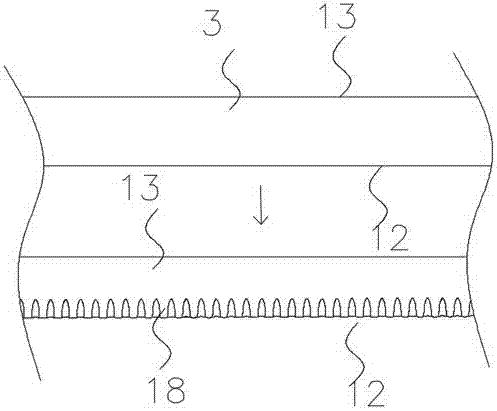

Straight groove flow guide staggered dotting pipe

PendingCN113483592AIncrease contact areaImprove heat transfer effectHeat exchanger casingsTubular elementsEngineeringPipe

The invention discloses a straight groove flow guide staggered dotting pipe, and belongs to the technical field of heat dissipation pipes. The staggered dotting pipe comprises a pipe body, wherein first straight grooves and second straight grooves are formed in the upper side face of the pipe body, third straight grooves and fourth straight grooves are formed in the lower side face of the pipe body, the multiple first straight grooves, the multiple second straight groove rows, the multiple third straight groove rows and the multiple fourth straight groove rows form the first straight groove rows, the second straight groove rows, the third straight groove rows and the fourth straight groove rows correspondingly, the first straight grooves and the third straight grooves are arranged in a staggered and crossed mode, the outer side walls of the bottoms of the first straight grooves abut against the outer side walls of the bottoms of the third straight grooves, the second straight grooves and the fourth straight grooves are arranged in a staggered and crossed mode, and the outer side walls of the bottoms of the second straight grooves abut against the outer side walls of the bottoms of the fourth straight grooves. The grooves in different directions are formed in the upper side face and the lower side face, so that a plurality of S-shaped circulation paths are formed in the pipe body, the heat dissipation effect of the pipe body is improved, and the turbulent flow effect is achieved.

Owner:NANNING ANHE MECHANICAL EQUIP CO LTD

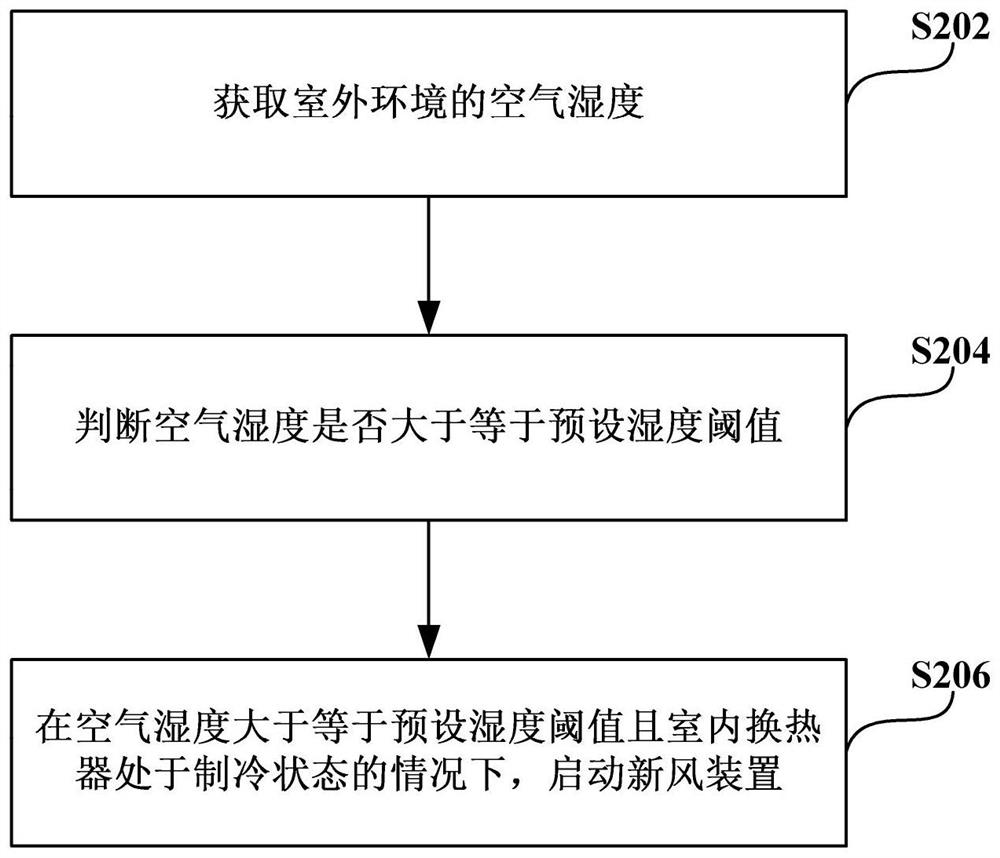

Control method for air-conditioning indoor unit and air-conditioning indoor unit

ActiveCN110285546BAvoid discomfortExtend the heat transfer pathMechanical apparatusSpace heating and ventilation safety systemsAmbient humidityFresh air

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

A shell and tube condenser

ActiveCN105910346BExtend the heat transfer pathImprove heat exchange efficiencyEvaporators/condensersWater flowEngineering

The invention discloses a shell-and-tube condenser for air source heat pump units. The shell-and-tube condenser is composed of multiple condenser units connected in series. A tube pass channel and a shell pass channel isolated from each other are formed in each condenser unit, wherein the tube pass channel is communicated with a water inlet and a water outlet, and the shell pass channel is communicated with a refrigerant inlet and a refrigerant outlet. With the order of water flow as a reference, among the multiple condenser units connected in series, the water outlet of the first condenser unit is communicated with the water inlets of the subsequent condenser units through a pipeline, low-temperature water flows into the water inlet of the first condenser unit, and is heated gradually into hot water, and the hot water flows out of the water outlet of the last condenser unit. The condenser is composed of multiple condenser units which are distributed in whole columns, so that enough condenser units can be installed in a limited space, a long enough heat transfer path is obtained, and the efficiency of heat exchange is improved.

Owner:SUZHOU HOTFROM HEAT PUMP EQUIP TECH CO LTD

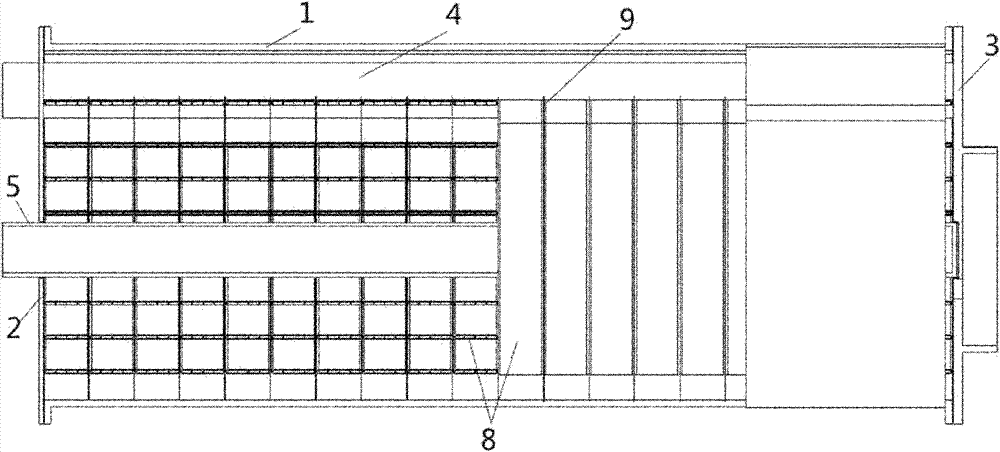

Horizontal multisource steam waste heat recovery energy-saving device

InactiveCN108692595AMaximize recyclingSolving Recycling ProblemsSteam/vapor condensersStationary tubular conduit assembliesProcess engineeringSewage treatment

The invention provides a horizontal multisource steam waste heat recovery energy-saving device, and belongs to the technical field of energy conservation and environmental friendliness. The horizontalmultisource steam waste heat recovery energy-saving device comprises a liquid inlet chamber, a heat exchange chamber, a liquid outlet chamber, row tubes, a steam isolation plate, a liquid isolation plate and the like. Inlets for waste steam and waste condensate water at different pressures and temperatures are formed according to the heat exchange gradient, so that the problem of integrated mixing and recycling of steam and the waste condensate water under different pressures is solved; the multilayer steam isolation plate is matched with the staggered separation of the row tubes, and the liquid isolation plate is used for adjusting the flow direction of liquid, so that the heat exchange efficiency is further improved; effective separation of the waste steam is realized, the treatment capacity of the waste steam is reduced, and the obvious effects of environmental friendliness and energy conservation are achieved; and the horizontal multisource steam waste heat recovery energy-savingdevice is used as an auxiliary adjusting device of an MVR (mechanical vapor recompression) system, so that the MVR system is stably and efficiently operated, the maximum utilization of the waste steamis realized, and the energy-saving effect is obvious. The horizontal multisource steam waste heat recovery energy-saving device has the advantages of high integration level, the simple structure andlow equipment investment and can be widely applied to waste heat recovery and utilization in the industry and field of food, feed, chemical engineering, pharmacy, sewage treatment and the like.

Owner:周封

A cooling tower with water mist treatment device

ActiveCN109631615BIncrease the heat exchange areaImprove heat transfer effectHeat exchange apparatusTrickle coolersTemperature controlCooling tower

The invention provides a cooling tower with a water mist processing device. The cooling tower can work in different ways and can improve efficiency of water mist. Through first and second mist removing devices which are arranged in a stagger mode, the limited space in the tower can be rationally and fully used. Cone and semicircular cone shapes are arranged in a matched mode. Compared with a traditional s-shaped dewatering plate or a wave-shaped dewatering device, the hear exchange area is enlarged, heat exchanging is improved, and the water mist removing effect is improved. The second mist removing devices are located at the center of the tower body. The second water mist removing devices are adjacent in an up and down mode and communicate with each other by a circulation main pipe. Cooling capacity of fluid can be improved by parallel connection. Through lateral plate mist removing devices on two sides, full heat exchanging effect is achieved to air around the tower body wall. A gridshape is arranged in a matched mode and corresponds to a draught fan outside, and therefore free adjusting and shifting between mist removing and tower body heat exchanging modes can be achieved. Through cooling liquid grooves, circulation water grooves and upper and lower water pipes, a cooling source can be adopted alternatively, water resource is saved, real-time adjusting is conducted based on the temperature requirements, and intelligent temperature control of mist removing is achieved.

Owner:东营海能石油装备有限责任公司

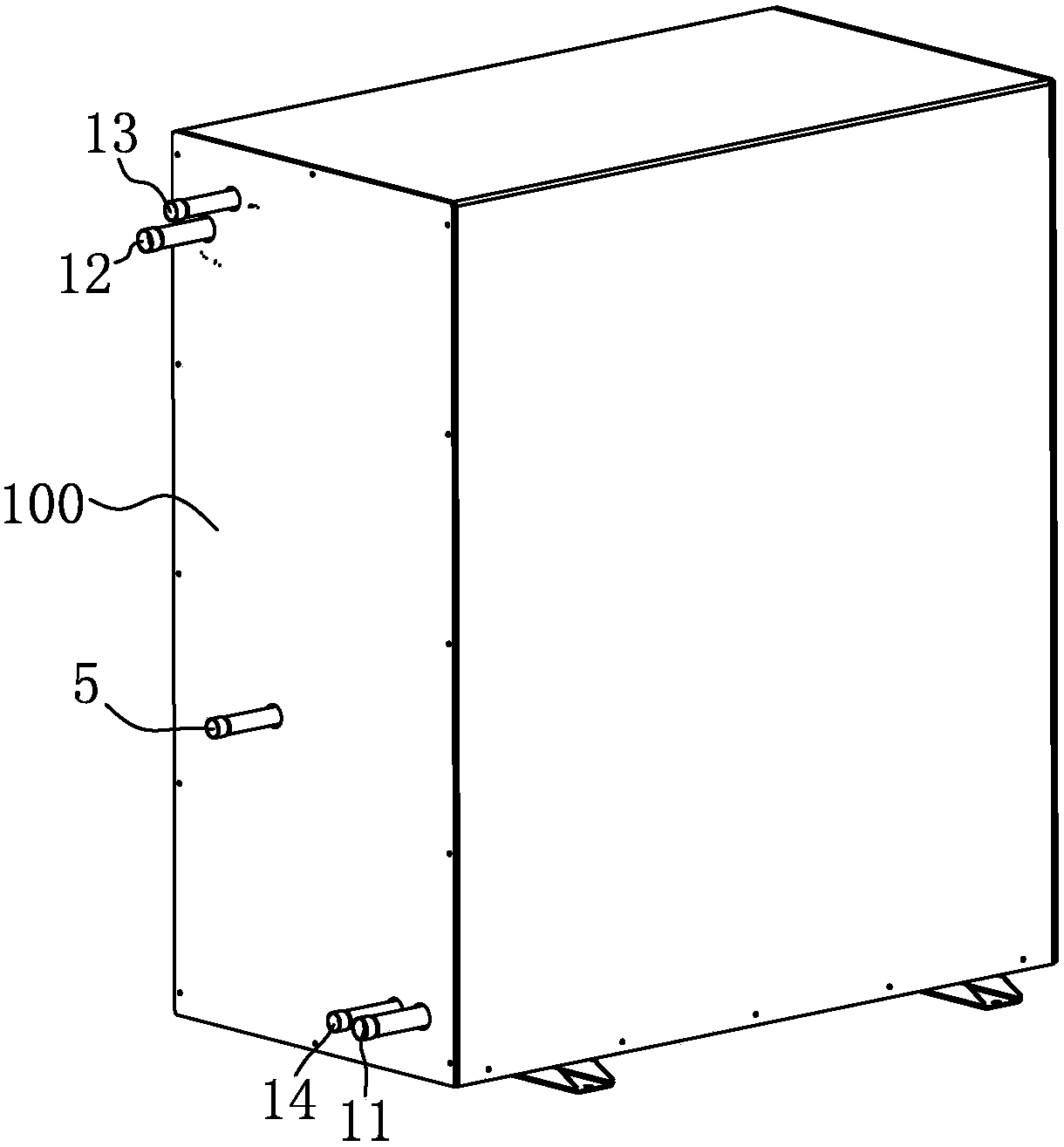

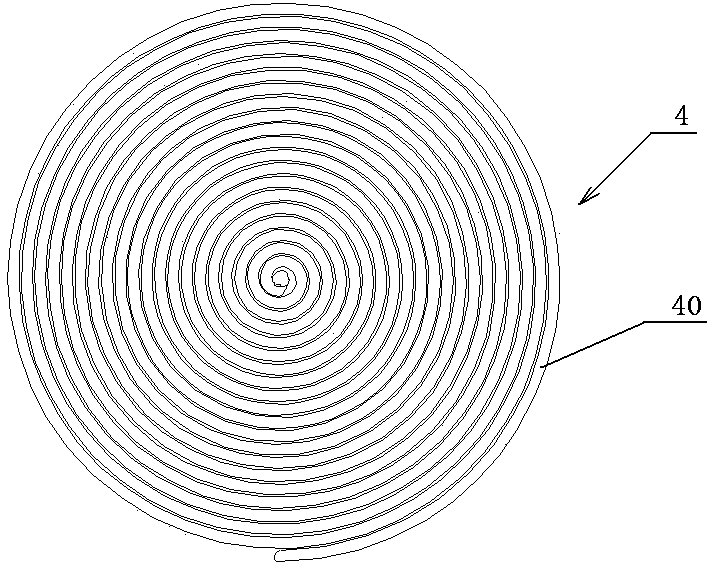

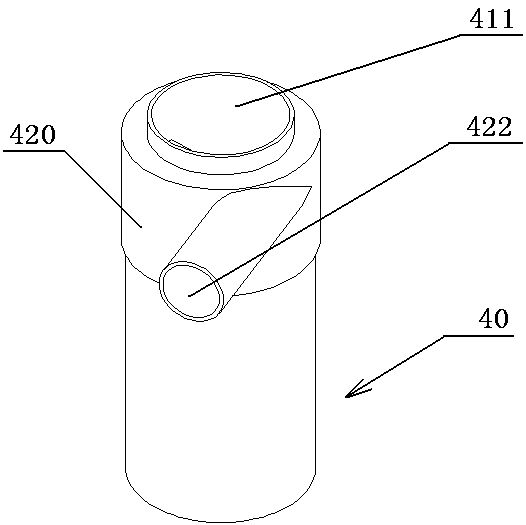

Waste water waste heat recovery device and shower device comprising same

PendingCN108225059ACompact structureExtend the heat transfer pathHeat exchanger casingsStationary tubular conduit assembliesWater dischargeRecuperator

The invention discloses a waste water waste heat recovery device and a shower device comprising the same, belongs to the technical field of heat exchangers, and aims to achieve the energy saving effect. The waste water waste heat recovery device comprises a waste heat waste water collecting container (2), and an outlet of the container communicates with a hot water inlet (411) of a heat exchanger.The waste water waste heat recovery device is characterized in that the heat exchanger is a sleeve backflow heat exchanger, a sleeve is in a disc shape formed through layer-by-layer winding, and thewinding sleeve backflow heat exchanger is formed. An inner pipe of the sleeve is a hot water pipe of the heat exchanger. The high temperature end of the winding sleeve backflow heat exchanger is in the center of the winding sleeve backflow heat exchanger. The sleeve is a hose. The pipe wall of the inner pipe of the sleeve is thinner than that of an outer pipe of the sleeve. A hot water outlet of the heat exchanger is higher than the disc-shaped sleeve (4) of the winding sleeve backflow heat exchanger. The shower device comprises a water feeding device, a water discharging device and a water heater and is characterized in that the shower device further comprises the a waste water waste heat recovery device, discharged water enters the waste heat waste water collecting container, and fed water passes through a cold water pipeline of the winding sleeve backflow heat exchanger and then enters the water heater.

Owner:吴新祥

Horizontal multi-source steam waste heat recovery energy-saving device

InactiveCN108692595BMaximize recyclingSolving Recycling ProblemsSteam/vapor condensersStationary tubular conduit assembliesPulp and paper industrySewage treatment

The invention provides a horizontal multisource steam waste heat recovery energy-saving device, and belongs to the technical field of energy conservation and environmental friendliness. The horizontalmultisource steam waste heat recovery energy-saving device comprises a liquid inlet chamber, a heat exchange chamber, a liquid outlet chamber, row tubes, a steam isolation plate, a liquid isolation plate and the like. Inlets for waste steam and waste condensate water at different pressures and temperatures are formed according to the heat exchange gradient, so that the problem of integrated mixing and recycling of steam and the waste condensate water under different pressures is solved; the multilayer steam isolation plate is matched with the staggered separation of the row tubes, and the liquid isolation plate is used for adjusting the flow direction of liquid, so that the heat exchange efficiency is further improved; effective separation of the waste steam is realized, the treatment capacity of the waste steam is reduced, and the obvious effects of environmental friendliness and energy conservation are achieved; and the horizontal multisource steam waste heat recovery energy-savingdevice is used as an auxiliary adjusting device of an MVR (mechanical vapor recompression) system, so that the MVR system is stably and efficiently operated, the maximum utilization of the waste steamis realized, and the energy-saving effect is obvious. The horizontal multisource steam waste heat recovery energy-saving device has the advantages of high integration level, the simple structure andlow equipment investment and can be widely applied to waste heat recovery and utilization in the industry and field of food, feed, chemical engineering, pharmacy, sewage treatment and the like.

Owner:周封

Tunnel furnace with energy recycling system

ActiveCN114608317AReduce heat loadEnergy-saving effectFurnace typesHeat transfer modificationMechanical engineeringCooling channel

The invention discloses a tunnel furnace with an energy recycling system, which comprises an inlet section, a furnace pipe body, an energy recovery section and an outlet section which are sequentially connected, and the energy recovery section comprises a cooling channel body and an energy recovery area arranged outside the cooling channel body. The inlet section comprises an inlet channel body and an energy utilization area arranged outside the inlet channel body, an energy conveying body used for conveying heat-conducting media is arranged between the energy recycling area and the energy utilization area, and the energy recycling area is provided with a medium inlet used for inputting the heat-conducting media. The energy utilization area is provided with a medium outlet used for discharging the heat-conducting medium, and the medium inlet or the medium outlet is provided with a power piece used for driving the heat-conducting medium to flow. According to the tunnel furnace with the energy recycling system, energy can be recycled, and the better energy-saving effect is achieved.

Owner:JIAXING HEYI IND RESISTANCE FURNACE CO LTD

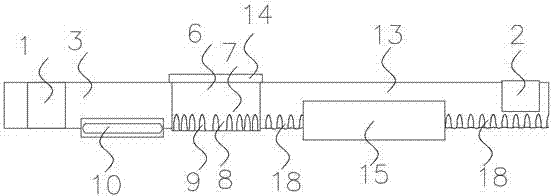

Winding sheet high frequency welding feeding device

The invention discloses a winding sheet high frequency welding feeding device. The winding sheet high frequency welding feeding device comprises a feeding roller couple, a high frequency magnetic induction line heating coil, a press-rolling roller couple, a cooling assembly and a discharging roller couple. A winding sheet material strap is conveyed in from the feeding roller couple, sequentially machined by the high frequency magnetic induction line heating coil, the press-rolling roller couple and the cooling assembly, and then conveyed out from the discharging roller couple. By using the winding sheet high frequency welding feeding device, the heat exchanging side edge of the winding sheet material strap can be subjected to hot rolling in the feeding process, a non-flat surface is pressed out at the end of the heat exchanging side edge, after spiral welding is conducted, a concave-convex heat exchanging face is formed, the heat exchanging area is increased, and the heat exchanging efficiency is improved; and the welded side edge of the winding sheet material strap is still a flat surface, and the welded side edge of the winding sheet material strap and a main pipe can be conveniently welded, and the heat exchanging effect is improved under the premise that welding is not affected.

Owner:江阴戴勒姆动力设备有限公司

Heat pump heat exchanger and heat pump using the same

ActiveCN104266408BReduce surface tensionRealize the buffering effectMechanical apparatusHeat pumpsCapillary TubingRefrigerant

The invention discloses a heat pump heat exchanger, which comprises a secondary heat exchange cabin, a buffer cabin and a main heat exchange cabin which are connected in sequence; Heat pipe bundle, one end of the main heat exchange tube bundle communicates with the buffer compartment through the first main heat exchange tube plate, and the other end of the main heat exchange tube bundle communicates with the refrigerant exhaust pipe through the second main heat exchange tube plate; The cabin includes the shell of the auxiliary heat exchange cabin, and the auxiliary heat exchange cabin is provided with a capillary tube bundle, one end of the capillary tube bundle is connected with the refrigerant supply pipe through a capillary liquid separator, and the other end of the capillary tube bundle is connected with the buffer cabin through a capillary tube plate; The cabin includes a buffer cabin shell; the main heat exchange cabin is provided with a main water inlet pipe and a main water outlet pipe, and the auxiliary heat exchange chamber is provided with a water suction pipe connected to the main heat exchange chamber and an auxiliary water outlet pipe connected to the main water outlet pipe. The invention also discloses a heat pump using the heat exchanger. The pressure of the refrigerant in the main heat exchange tube of the present invention is balanced and the heat exchange efficiency is high.

Owner:SHANDONG HONGLI HEAT PUMP ENERGY

Auxiliary heat conduction device for iron and steel metallurgical continuous casting mold

Owner:佛山市顺德区晟凌五金实业有限公司

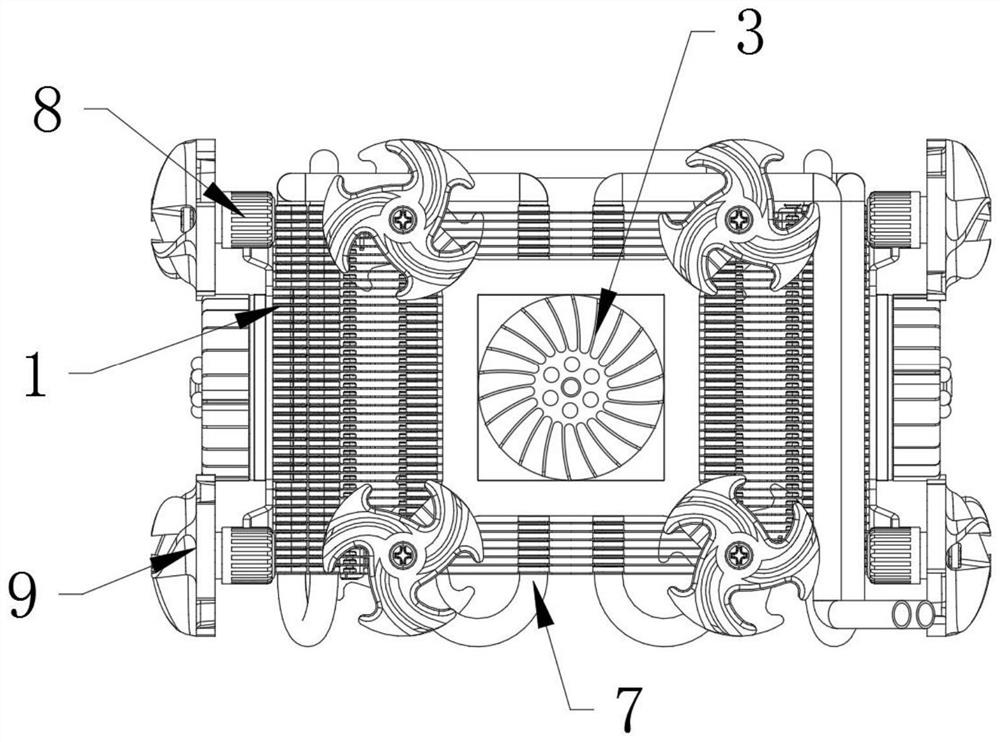

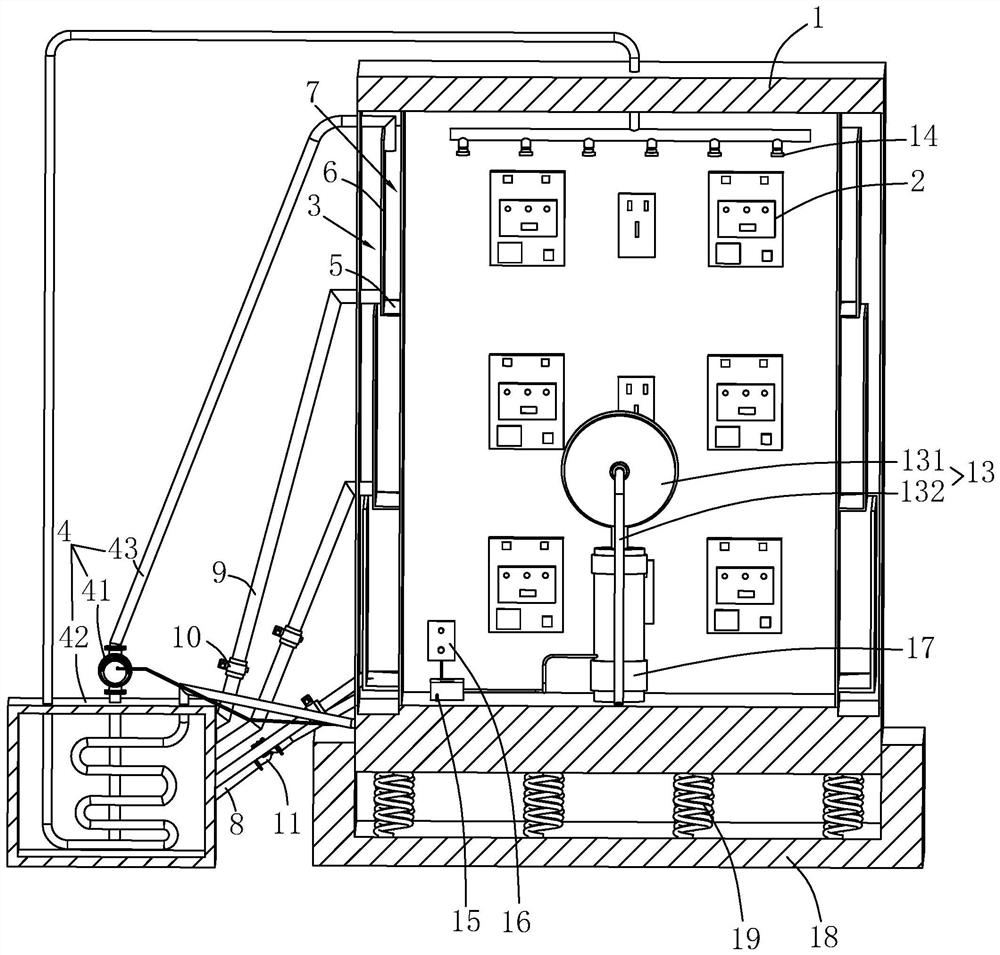

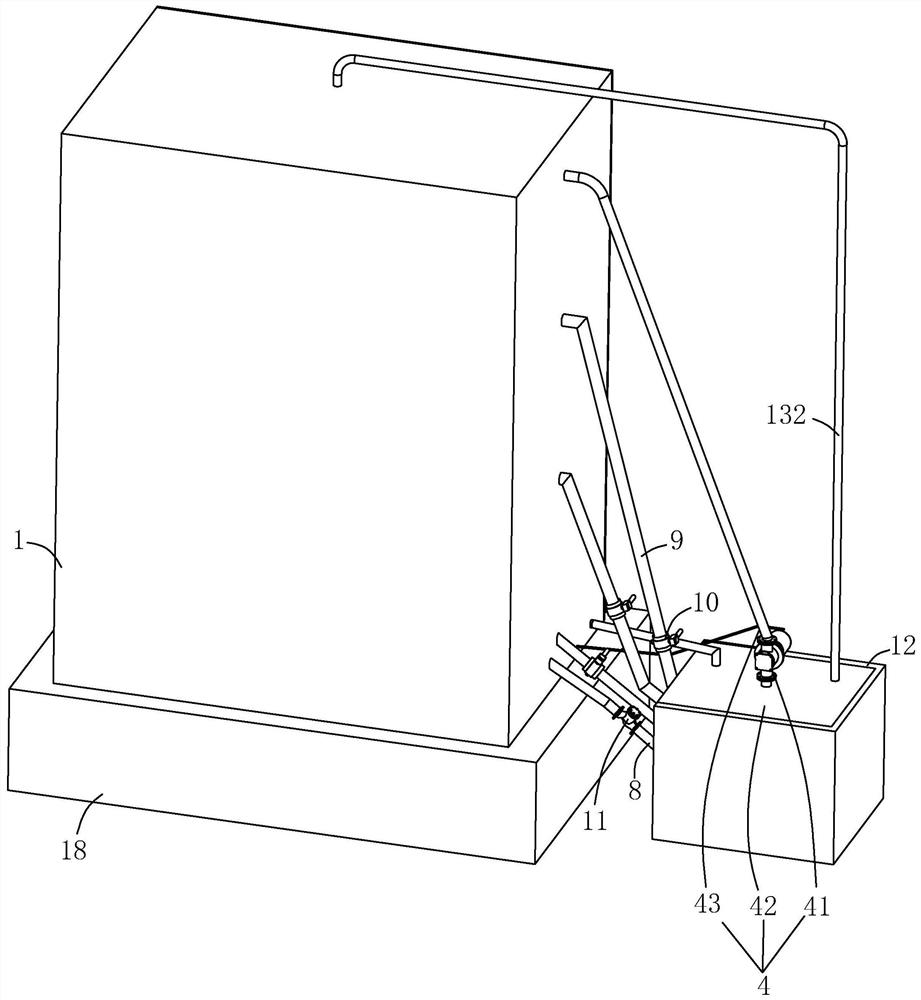

A shock-absorbing and heat-dissipating power cabinet for electric power engineering

ActiveCN111786274BImprove cooling effectImprove liquiditySubstation/switching arrangement cooling/ventilationSubstation/switching arrangement casingsEngineeringPower engineering

Owner:四川中迪电力工程有限公司

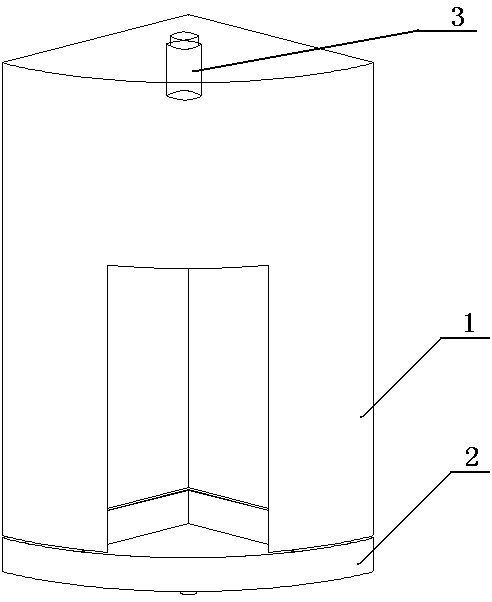

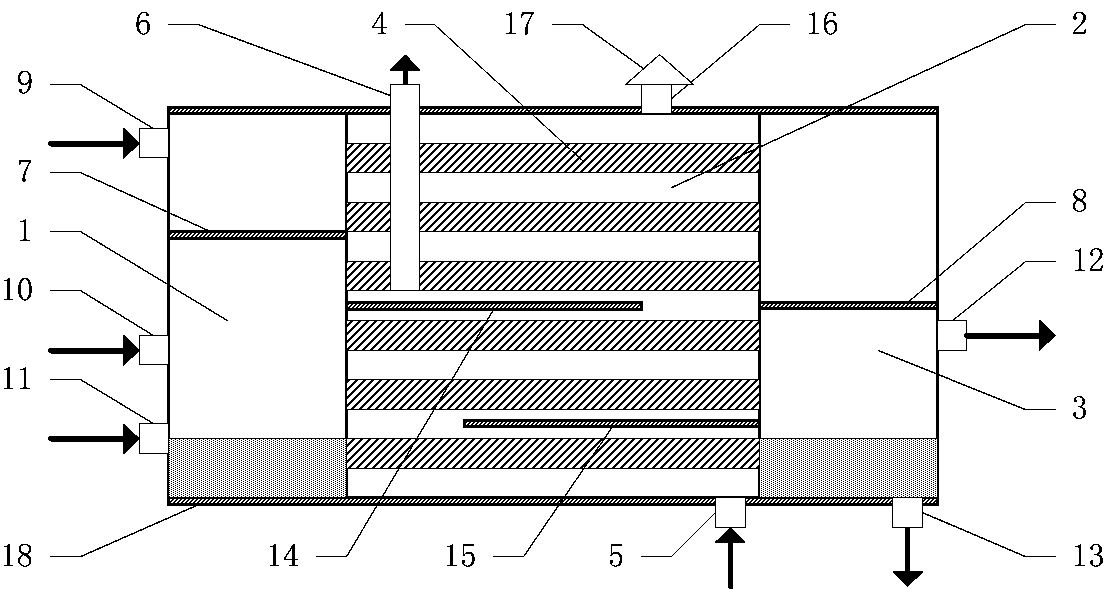

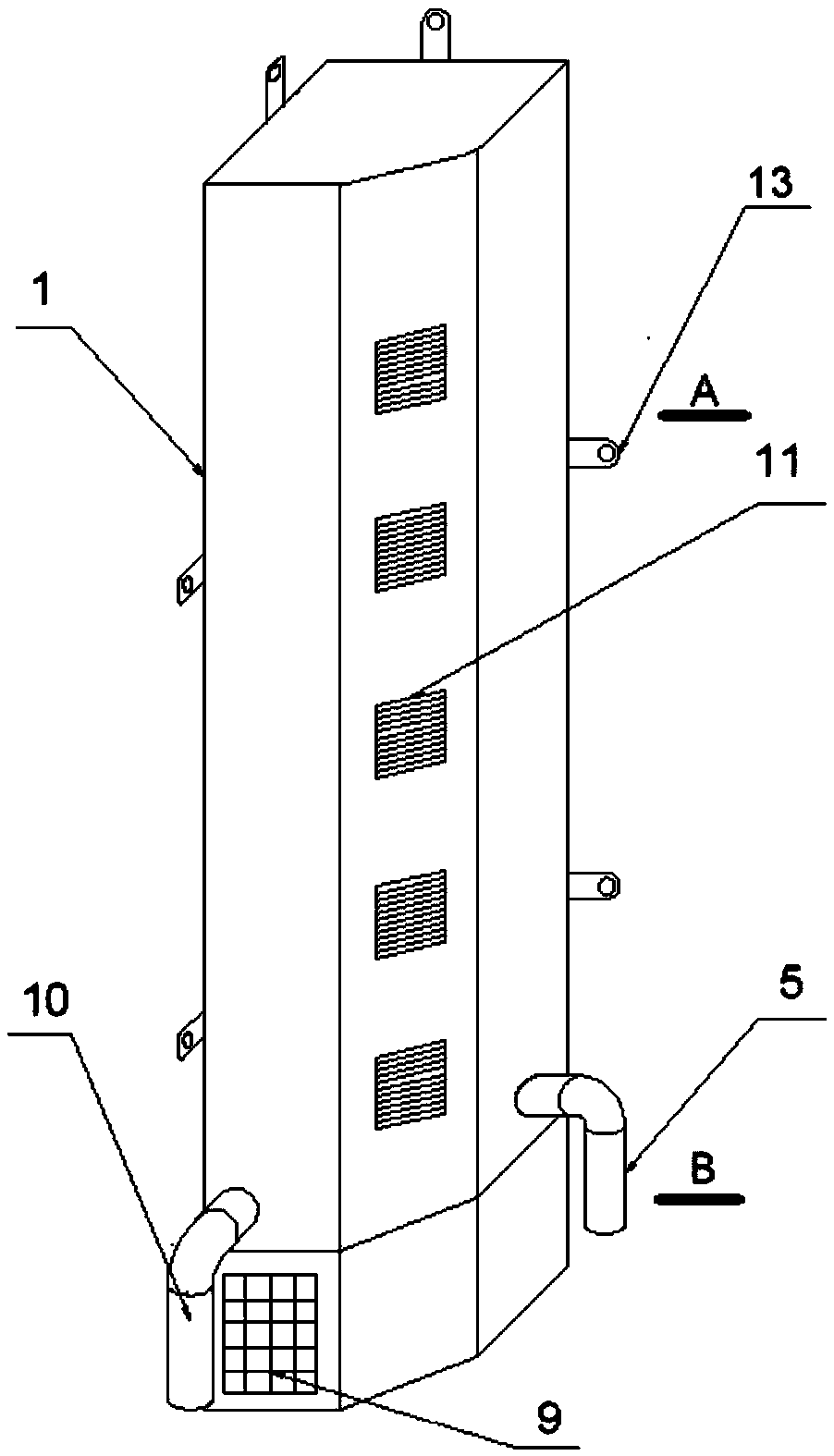

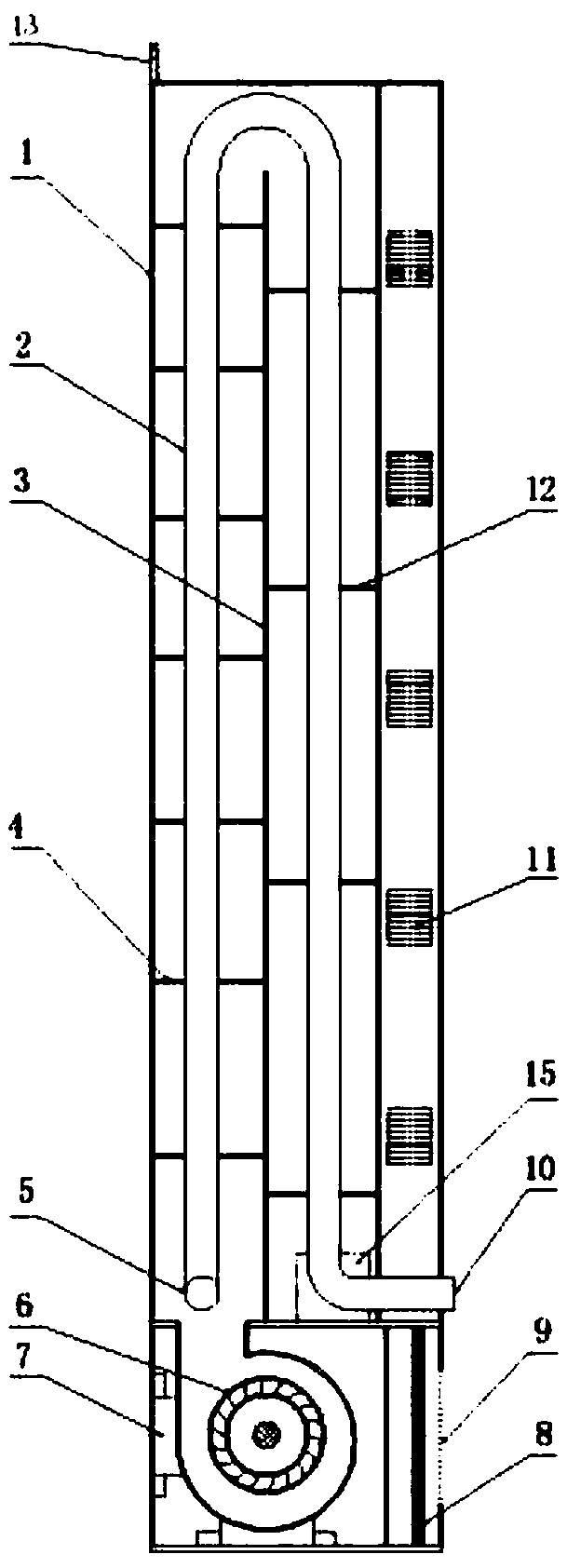

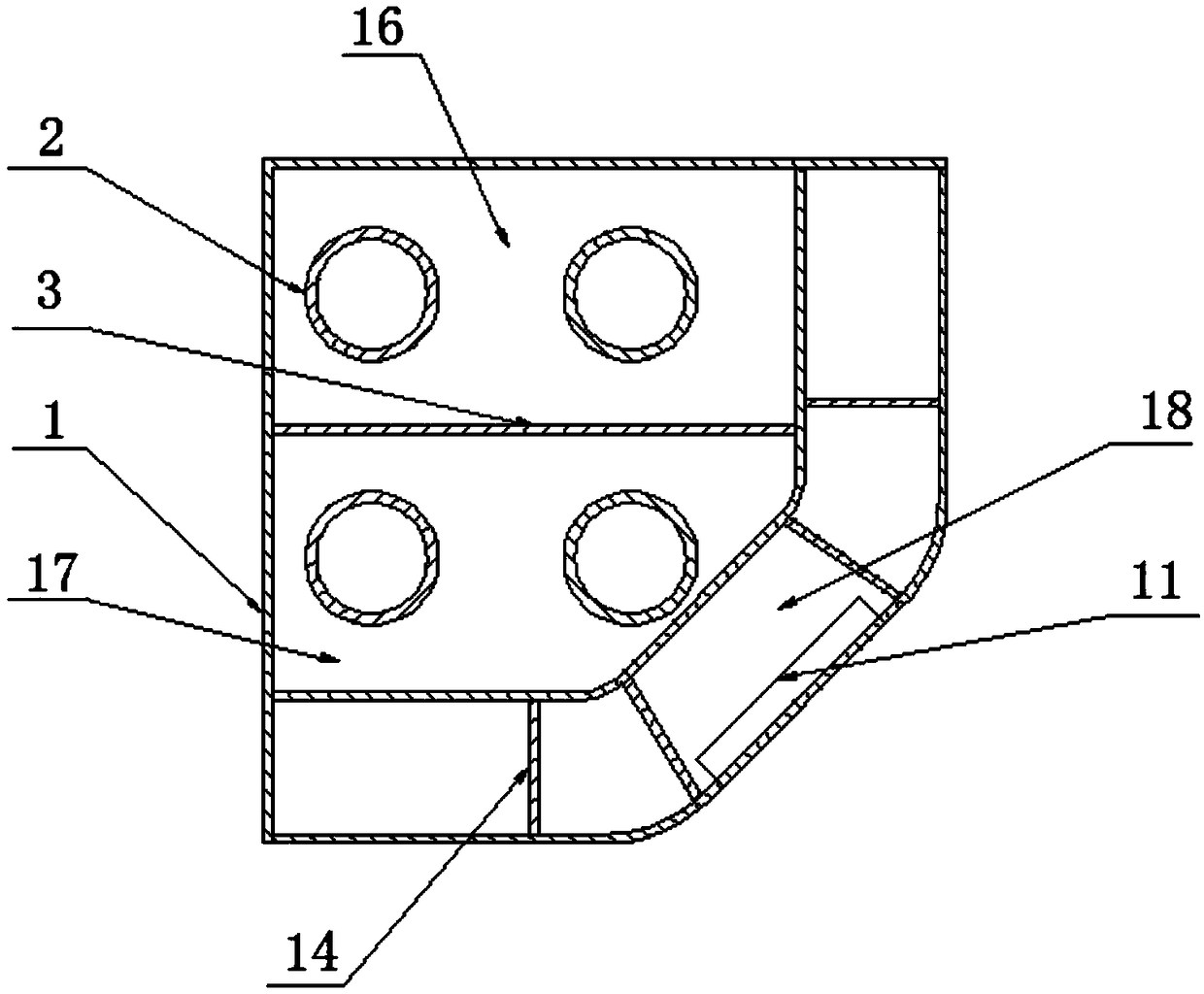

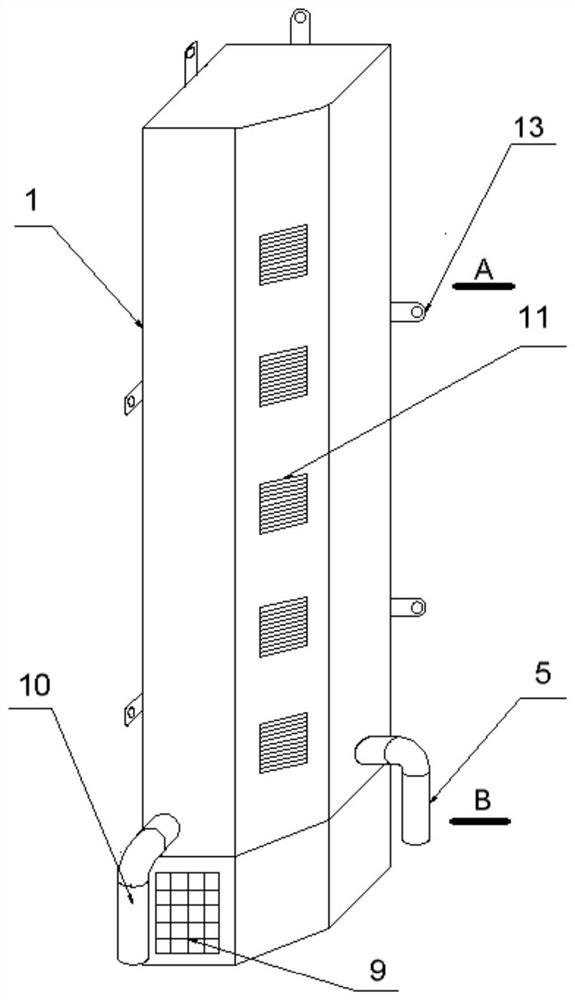

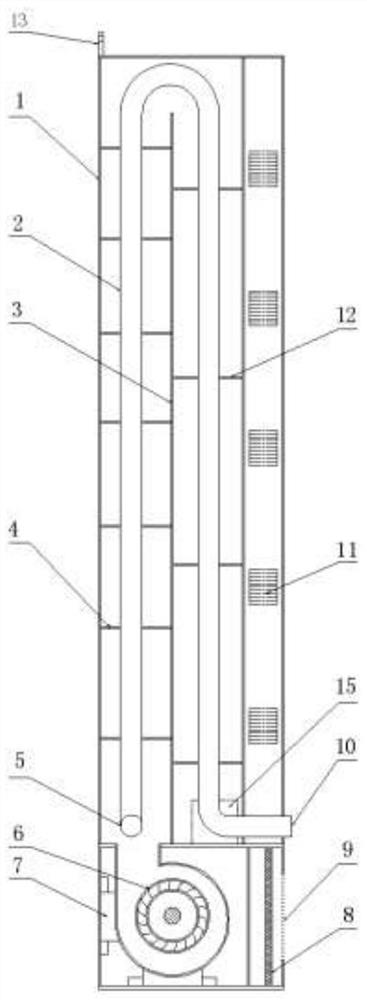

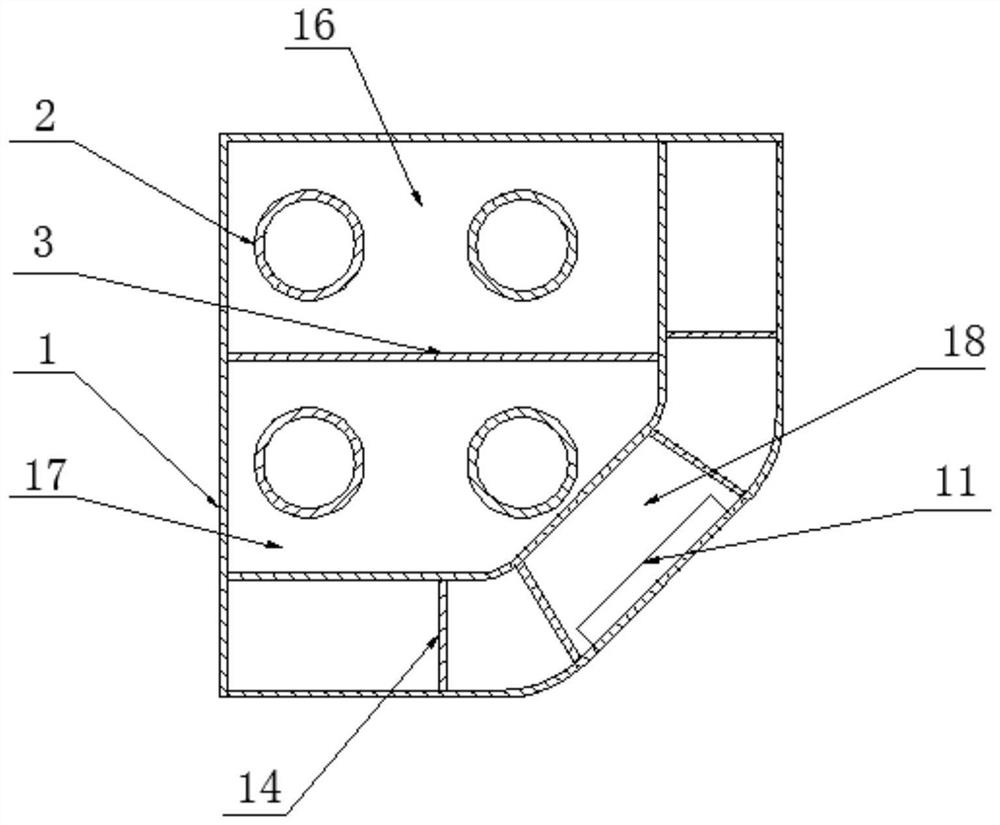

Wall corner vertical type forced-convection heat transfer device

ActiveCN108731509AQuality improvementAchieve elevationDispersed particle filtrationStationary conduit assembliesEngineeringThermal water

The invention provides a wall corner vertical type forced-convection heat transfer device which comprises a shell, a radiating pipe, a vertical baffle, a baffle plate, a draught fan, a filter and a fixed plate. The shell is divided into two parts, and the upper part of the shell is divided into an inner shell and an outer shell. The vertical baffle and the radiating pipe are arranged in the innershell, wherein a water inlet opening is formed at one end of the lower portion of the radiating pipe, and a backwater opening is formed at the other end of the lower portion of the radiating pipe. Thedraught fan and the filter are arranged in the lower part of the shell, wherein the draught fan and the filter are fixed by a clamping seat of the draught fan. An air outlet of the draught fan is faced to a lateral radiating pipe of one side of the water inlet opening, and the air outlet of the draught fan is connected with the bottom end of the rear heat exchange air duct in a direct communicating mode. The lower part of a shell panel is provided with an air inlet faced to the filter. The air purified and filtered by the filter is sucked into a heat exchange channel outside the radiating pipe through the draught fan, the air flow flows around the radiating pipe and the baffle plate located in the heat exchange channel, and the air flow and hot water in the radiating pipe carry out the heat exchange, to meet the requirement of the temperature of out wind. According to the wall corner vertical type forced-convection heat transfer device, indoor temperature rise and air purification andcirculation are realized. The device is simple in structure, convenient to install and maintain, environmentally friendly and capable of saving energy.

Owner:CHINA UNIV OF MINING & TECH

A corner vertical forced convection heat exchange device

ActiveCN108731509BQuality improvementAchieve purification effectDispersed particle filtrationStationary conduit assembliesThermodynamicsAir cleaning

The invention provides a wall corner vertical type forced-convection heat transfer device which comprises a shell, a radiating pipe, a vertical baffle, a baffle plate, a draught fan, a filter and a fixed plate. The shell is divided into two parts, and the upper part of the shell is divided into an inner shell and an outer shell. The vertical baffle and the radiating pipe are arranged in the innershell, wherein a water inlet opening is formed at one end of the lower portion of the radiating pipe, and a backwater opening is formed at the other end of the lower portion of the radiating pipe. Thedraught fan and the filter are arranged in the lower part of the shell, wherein the draught fan and the filter are fixed by a clamping seat of the draught fan. An air outlet of the draught fan is faced to a lateral radiating pipe of one side of the water inlet opening, and the air outlet of the draught fan is connected with the bottom end of the rear heat exchange air duct in a direct communicating mode. The lower part of a shell panel is provided with an air inlet faced to the filter. The air purified and filtered by the filter is sucked into a heat exchange channel outside the radiating pipe through the draught fan, the air flow flows around the radiating pipe and the baffle plate located in the heat exchange channel, and the air flow and hot water in the radiating pipe carry out the heat exchange, to meet the requirement of the temperature of out wind. According to the wall corner vertical type forced-convection heat transfer device, indoor temperature rise and air purification andcirculation are realized. The device is simple in structure, convenient to install and maintain, environmentally friendly and capable of saving energy.

Owner:CHINA UNIV OF MINING & TECH

A shell and tube heat exchanger, a heat exchanger group and a heat pump unit

ActiveCN104215094BReduce flow rateIncrease heat transfer areaEvaporators/condensersStationary tubular conduit assembliesPlate heat exchangerShell and tube heat exchanger

Owner:SHANDONG HONGLI HEAT PUMP ENERGY

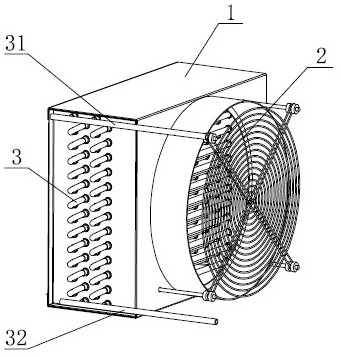

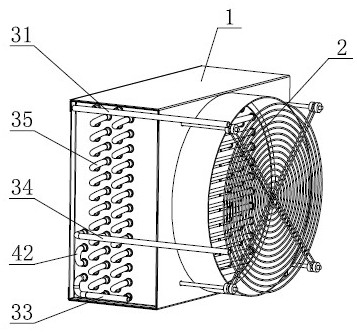

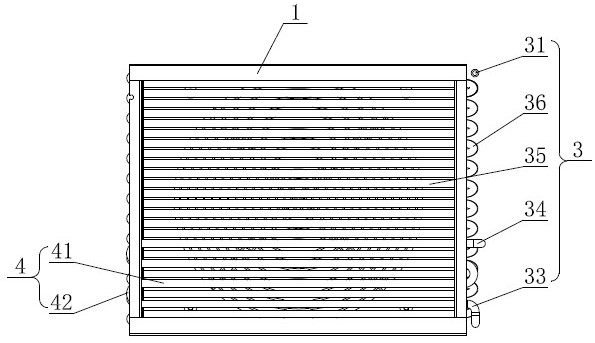

Finned heat exchanger

PendingCN112212718AExtend the heat transfer pathReduce the temperatureStationary tubular conduit assembliesTubular elementsCold airEngineering

The invention discloses a finned heat exchanger. A suction fan is arranged on one side face of a housing, an air suction opening is formed in the other opposite side face of the housing, at least onerefrigerating pipe set is arranged in the housing, and a refrigerant inlet pipe and a first discharge pipe communicate with the refrigerating pipe sets respectively. One end of the first discharge pipe communicates with a drying filter of a refrigerating system, and the other end of the first discharge pipe communicates with a second discharge pipe through a circuitous pipe. According to the finned heat exchanger, the second discharge pipe is arranged on the first discharge pipe through the circuitous pipe, part of a liquid refrigerant in the first discharge pipe returns to the air suction opening of the housing through the circuitous pipe to conduct secondary heat exchange with cold air, and under the condition that the finned heat exchanger is low in power and small in size, the heat exchange path of the refrigerant is further prolonged through the circuitous pipe returning to the air suction opening, the larger heat exchange area is obtained, and the heat exchange efficiency is higher.

Owner:无锡帕捷科技有限公司

Heat exchanger

PendingCN112682982AImprove heat transfer effectExtend the heat transfer pathEvaporators/condensersHeat exchanger casingsEngineeringMechanical engineering

The invention discloses a heat exchanger. The heat exchanger comprises a first flow collecting piece, a second flow collecting piece, a heat exchange core body, a shell and a partition plate, the shell, the first flow collecting piece and the second flow collecting piece act in a matched mode and are used for wrapping the heat exchange core body in a surrounding mode so as to seal an inner cavity of the shell, and the partition plate and the shell form a first cavity and a second cavity; and the first cavity and the second cavity communicate with each other at the end, away from a first opening and a second opening of the shell, of the partition plate, the first opening and the second opening are formed in the two opposite side walls of the shell, at least part of a first heat exchange pipe is located in the first cavity, and at least part of a second heat exchange pipe is located in the second cavity. According to the heat exchanger, the first fluid in the first heat exchange pipe exchanges heat with the second fluid in the first cavity, the first fluid in the second heat exchange pipe exchanges heat with the second fluid in the second cavity, the circulation path of the second fluid is approximately in a U shape, the heat exchange path of the second fluid can be increased, the heat exchange effect of the first fluid and the second fluid can be improved, and thus the heat exchange performance of the heat exchanger is improved.

Owner:HANGZHOU SANHUA RES INST CO LTD

Vortex parallel flow countercurrent evaporator for automotive air conditioner

ActiveCN102032722BAffect smoothnessCompact structureEvaporators/condensersVehicle heating/cooling devicesAutomobile air conditioningEngineering

The invention relates to a vortex parallel flow countercurrent evaporator for an automotive air conditioner, which comprises a plurality of vortex type flat tubes, wherein the vortex type flat tubes are arranged in parallel, extended to form a vortex shape and separated by fins; refrigerant runners are formed in cavities of the vortex type flat tubes; the adjacent vortex layers of individual vortex type flat tubes are in sealing connection by the fins on two sides to form secondary refrigerant runners exchanging heat with refrigerants; inlets and outlets of each refrigerant runner are communicated with one another respectively; the inlets and outlets of each secondary refrigerant runner are communicated with one another respectively; and the refrigerants in the refrigerant runners and secondary refrigerants in the secondary refrigerant runners flow reversely. The vortex parallel flow countercurrent evaporator for the automotive air conditioner has a simple structure, occupies a small area, is difficult to deform by stress, vibration, thermal expansion and the like under severe conditions to influence the sections of the runners, makes smooth the circulation of the refrigerant, remarkably increases the travel of the refrigerant, improves the refrigeration efficiency and greatly reduces machining difficulties.

Owner:浙江兰通空调设备有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com