Tunnel furnace with energy recycling system

An energy recovery, tunnel furnace technology, applied in furnaces, furnace types, furnace components, etc., to achieve the effect of reducing dead space, improving effect, and reducing heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

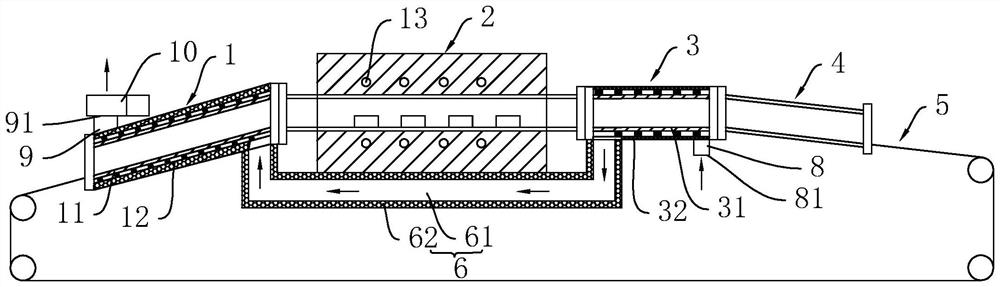

[0031] One end of the cooling channel body 31 facing the furnace body 2 also has a flange, through which the cooling channel body 31 is fixedly connected to one end of the furnace body 2 . The cooling channel body 31 is generally horizontal. The outlet section 4 is fixedly connected to the end of the cooling channel body 31 away from the furnace body 2 through a flange, the outlet section 4 can be inclined, and the conveying device 5 sends the workpiece from the end of the outlet section 4 away from the furnace body 2 .

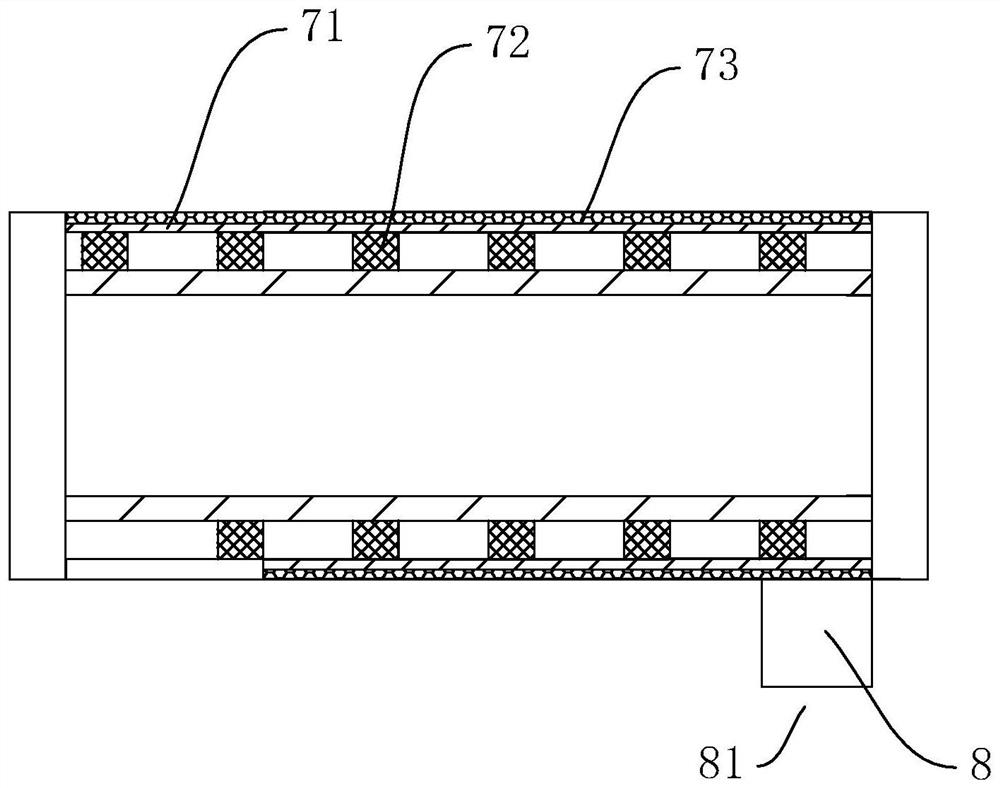

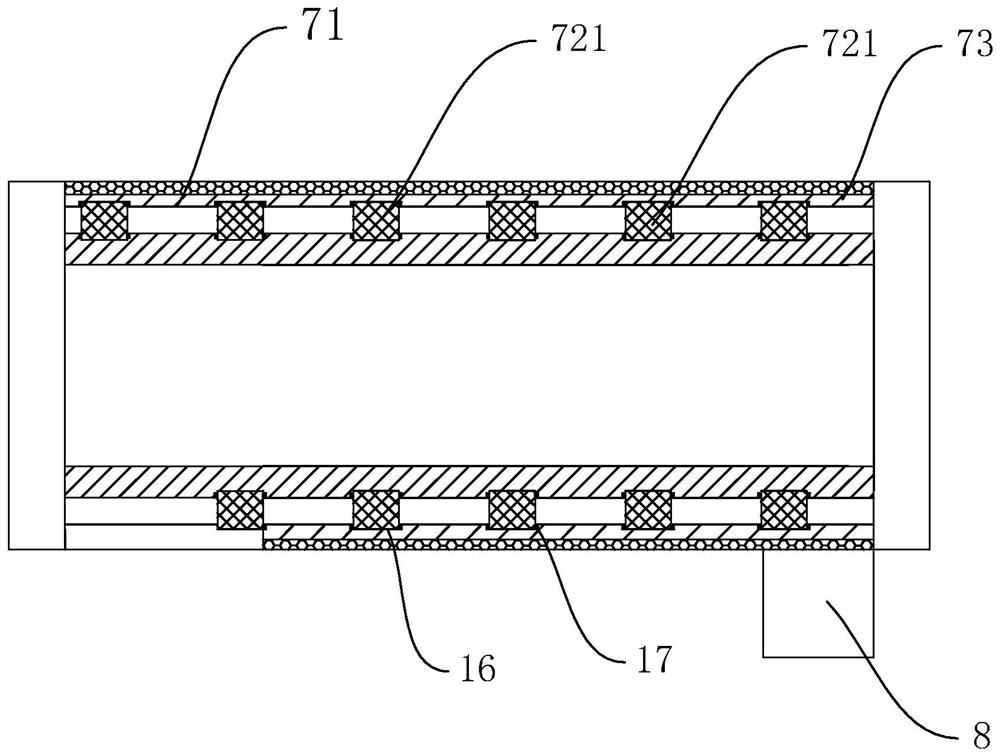

[0032] refer to figure 1 and figure 2 , the energy recovery area 32 and the energy utilization area 12 both include a heat exchange cavity 71 arranged outside the entrance channel body 11 or outside the cooling channel body 31, a deflector 72 connected to the inner wall of the heat exchange cavity 71, and a heat exchange chamber 72 arranged on the heat exchange The heat exchange insulation layer 73 on the outer wall of the cavity 71, the cross section of ...

Embodiment 2

[0043] All of the above are preferred embodiments of the application, and are not intended to limit the protection scope of the application. Therefore, all equivalent changes made according to the structure, shape, and principle of the application should be covered by the protection scope of the application. Inside.

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com