Energy-collecting heat exchange environment-friendly boiler

A heat-exchanging boiler technology, which is applied in the boiler field, can solve the problems of excessive smoke and dust emissions, impermeable fuel combustion, and low furnace temperature, and achieve the effects of reducing emissions, reducing production, and using a wide range of fuels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

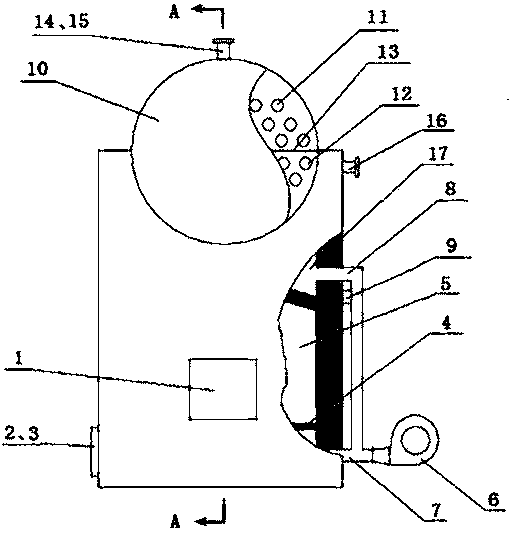

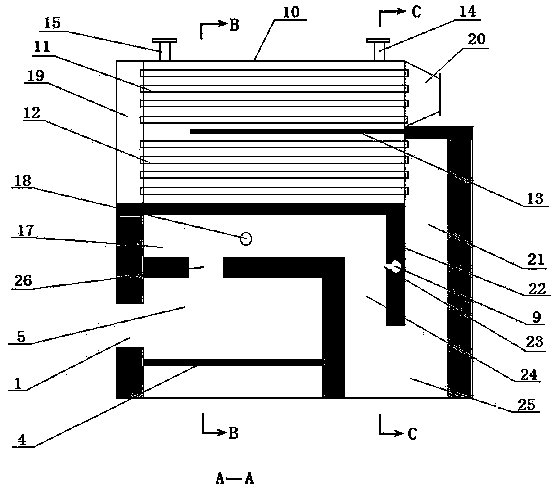

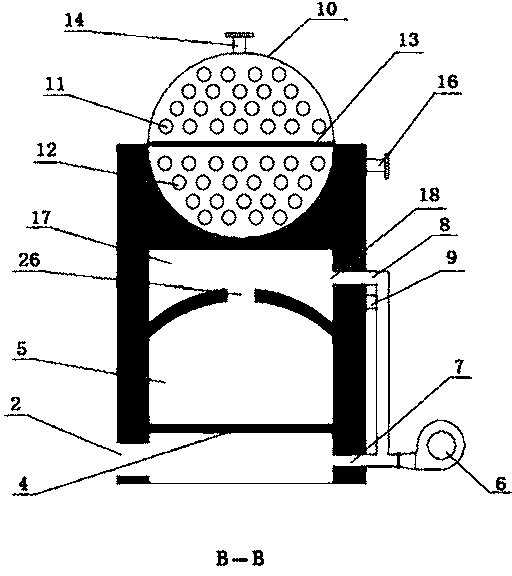

[0021] The boiler includes a furnace 5, a secondary combustion chamber 17 that is arranged on the furnace 5 and communicates with it through the fire guide hole 26, the furnace 5 communicates with the secondary combustion chamber 17 through the fire guide hole 26, and is provided on the secondary combustion chamber 17. Heat exchanger 10 is arranged, and this boiler is also provided with air supply device, and the secondary and tertiary ventilation holes on secondary combustion chamber 17 side walls and rear wall are connected with air supply device. The air supply device is a primary air duct 7 , a secondary air duct 8 and a tertiary air duct 9 connected with the blower.

[0022] The present invention uses refractory bricks, refractory cement, fire grate 4, furnace door 1, and ash removal door 2 to build a furnace 5. The top of the furnace 5 is arched, and a fire guide hole 26 is left on the top of the furnace 5, and then built on the furnace. A secondary combustion chamber 17...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com