Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

79results about How to "Eliminate dead space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

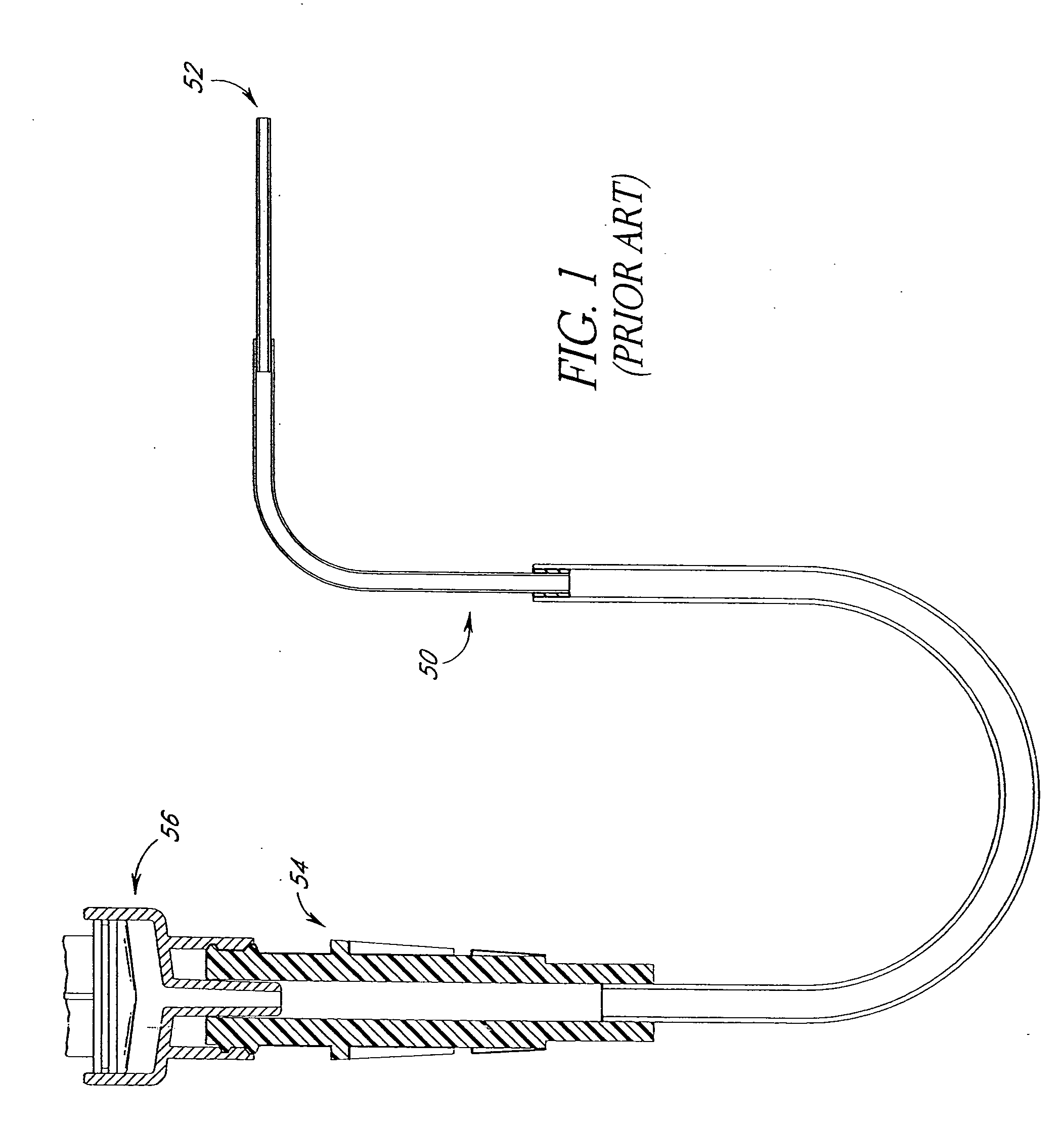

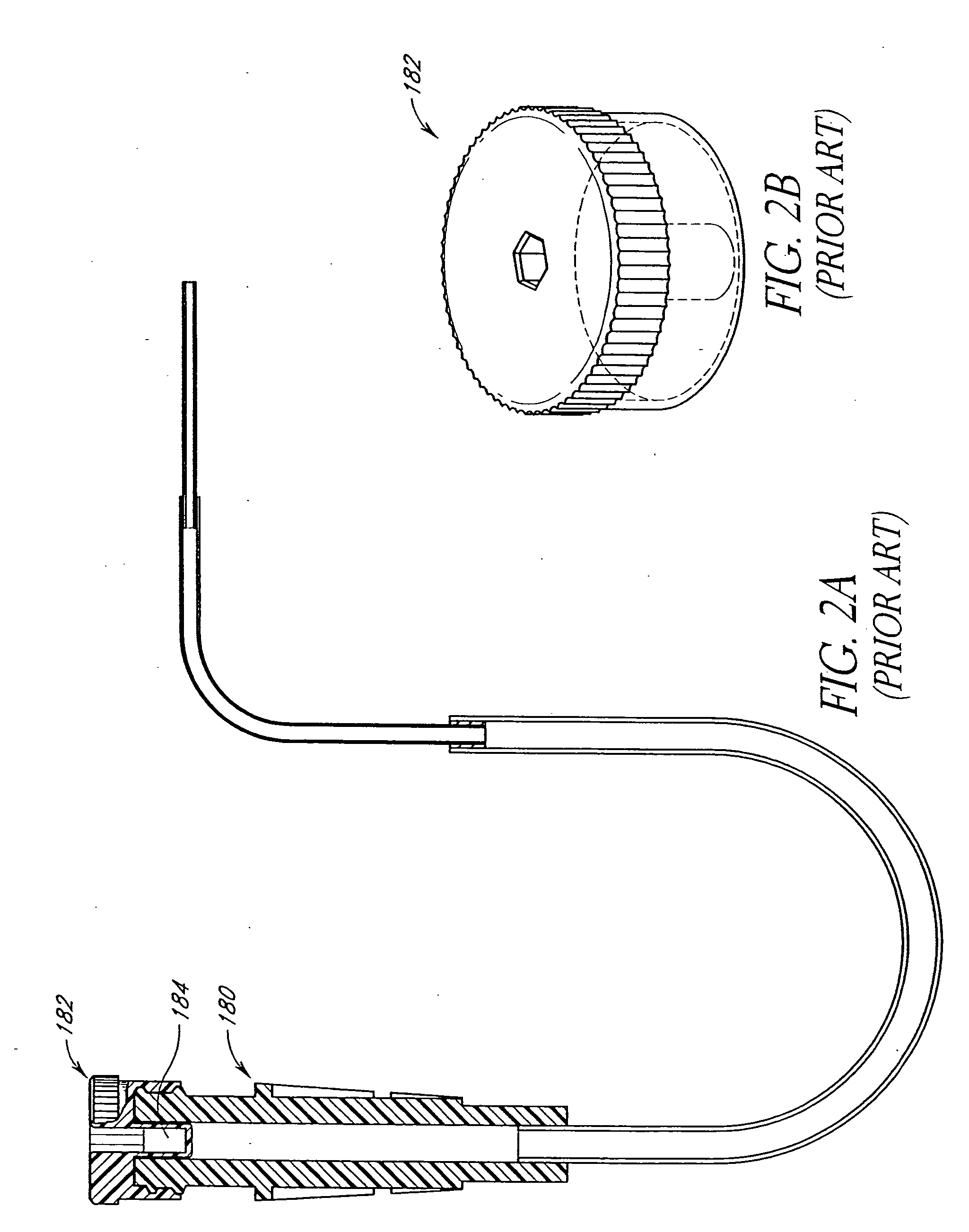

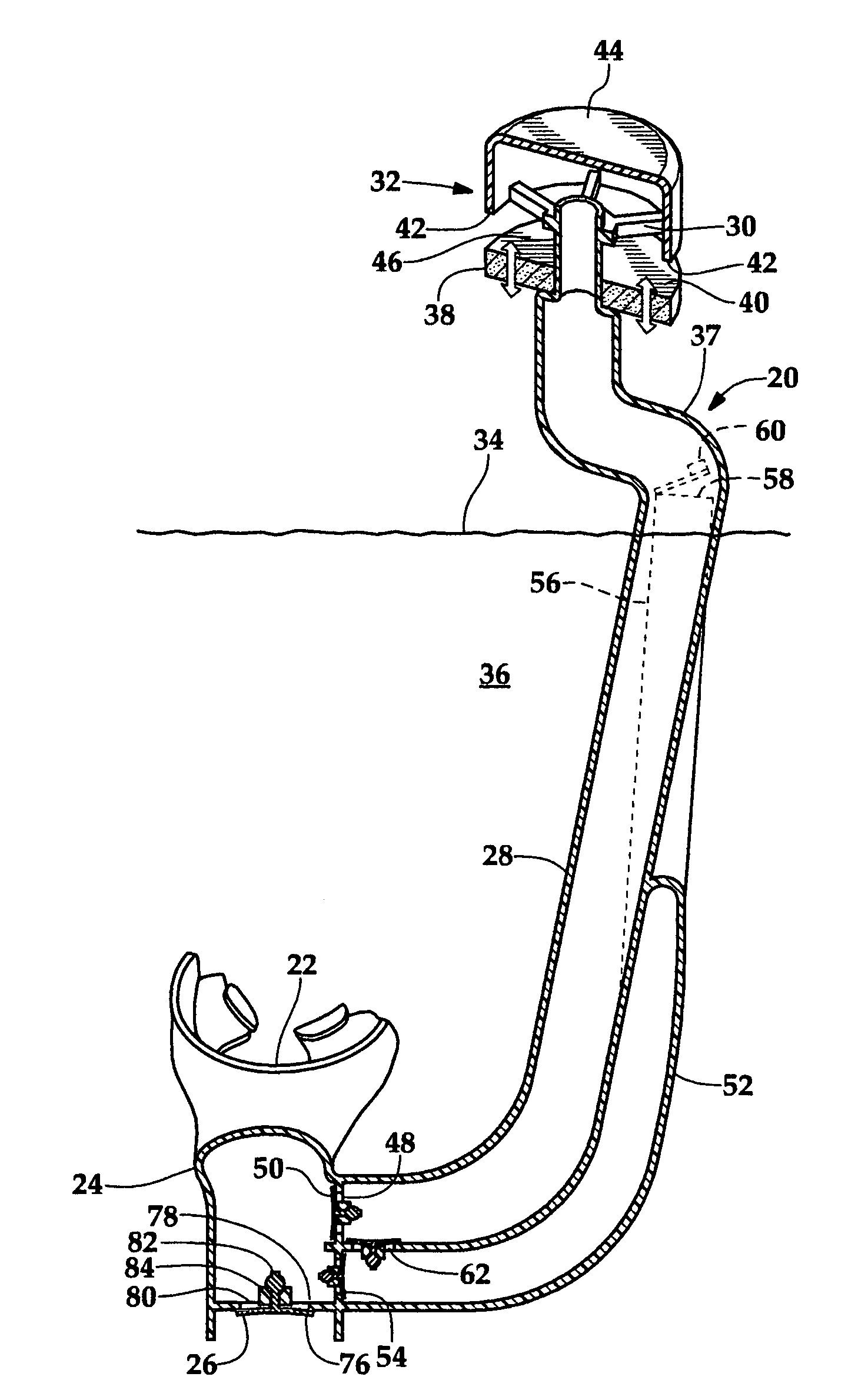

Positive flow valve

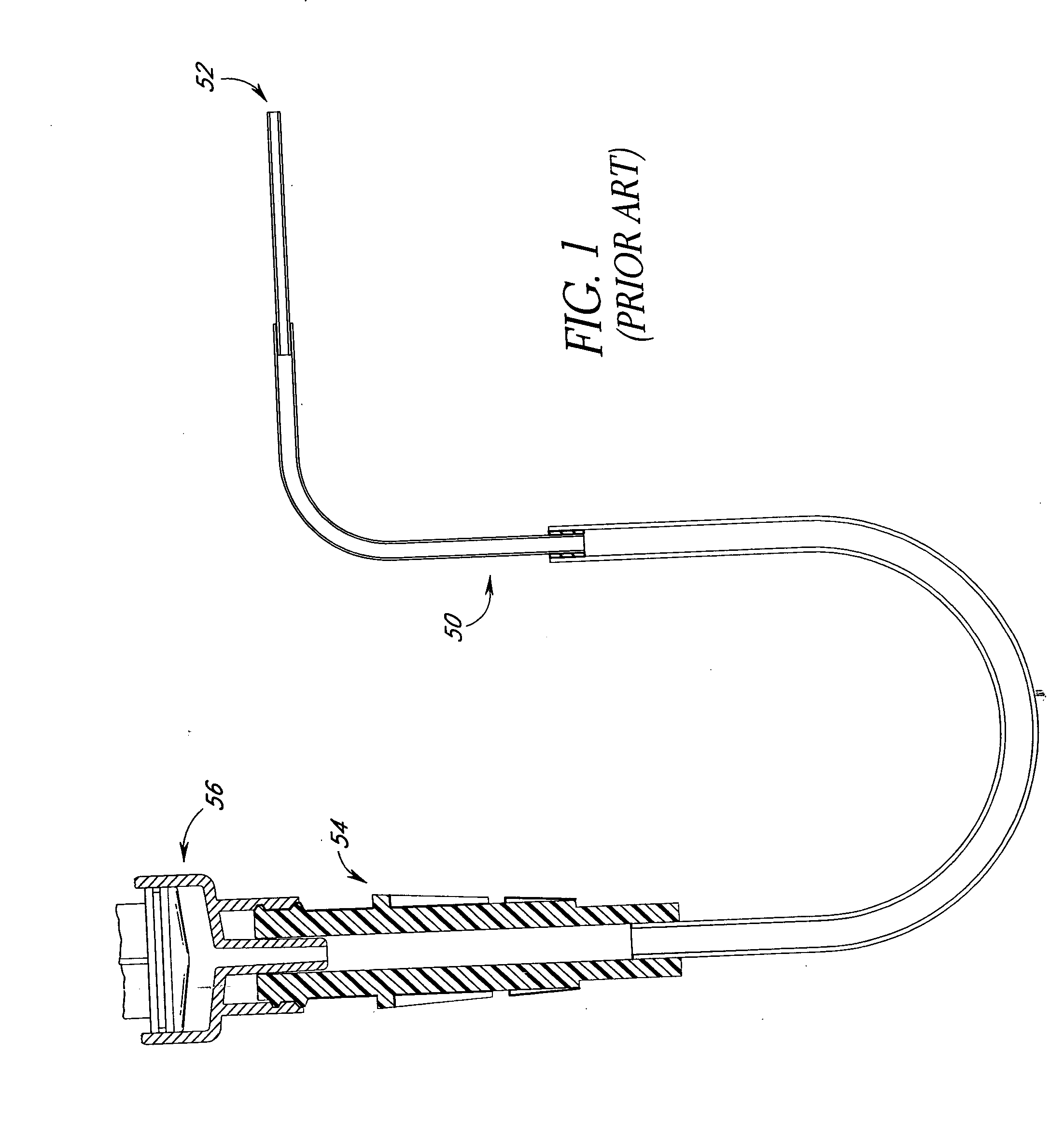

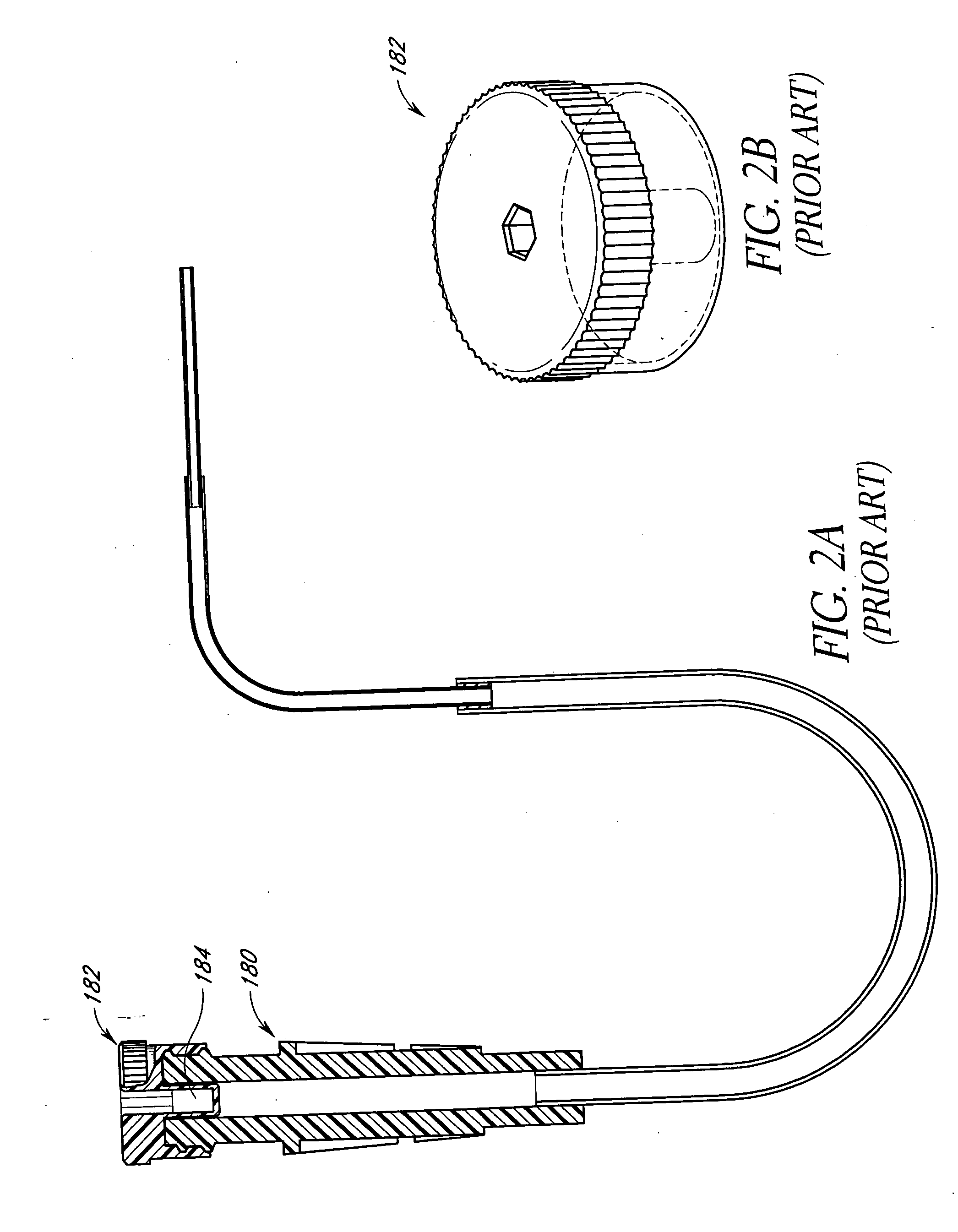

InactiveUS6932795B2Reduce liquid volumeIncrease volumeValve arrangementsInfusion devicesNoseEngineering

A closed system, spikeless, positive-flow valve device includes a body defining an internal cavity. At the proximal end of the body is an opening which is preferably sufficiently large to receive an ANSI standard tip of a medical implement. The valve includes a plastic, resilient silicon seal which fills the upper cavity and opening with an oval seal cap having a slit. The opening presses the oval seal cap to keep the slit closed in the decompressed state. The slit opens as the nose of the medical implement compresses the seal into the cavity and the seal cap is free from the opening. The housing also includes a fluid space which facilitates fluid flow between the medical implement and a catheter tip. The fluid space within the valve automatically and reversibly increases upon insertion of the medical implement into the cavity and decreases upon withdrawal of the medical implement, such that a positive flow from the valve toward the catheter tip is effected upon withdrawal of the medical implement, thereby preventing a flow of blood from a patient into the catheter when the medical implement is removed from the valve.

Owner:ICU MEDICAL INC

Positive flow valve

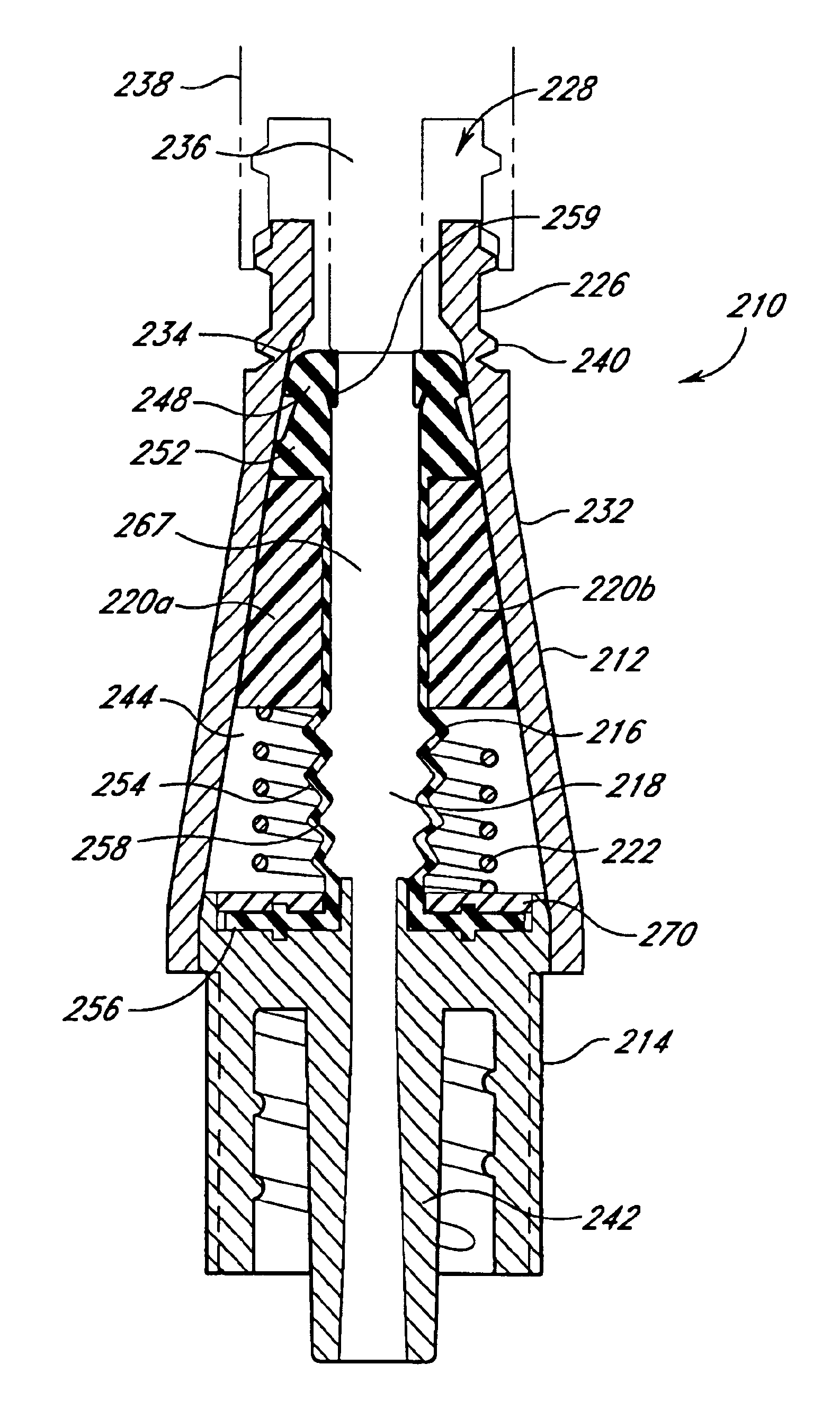

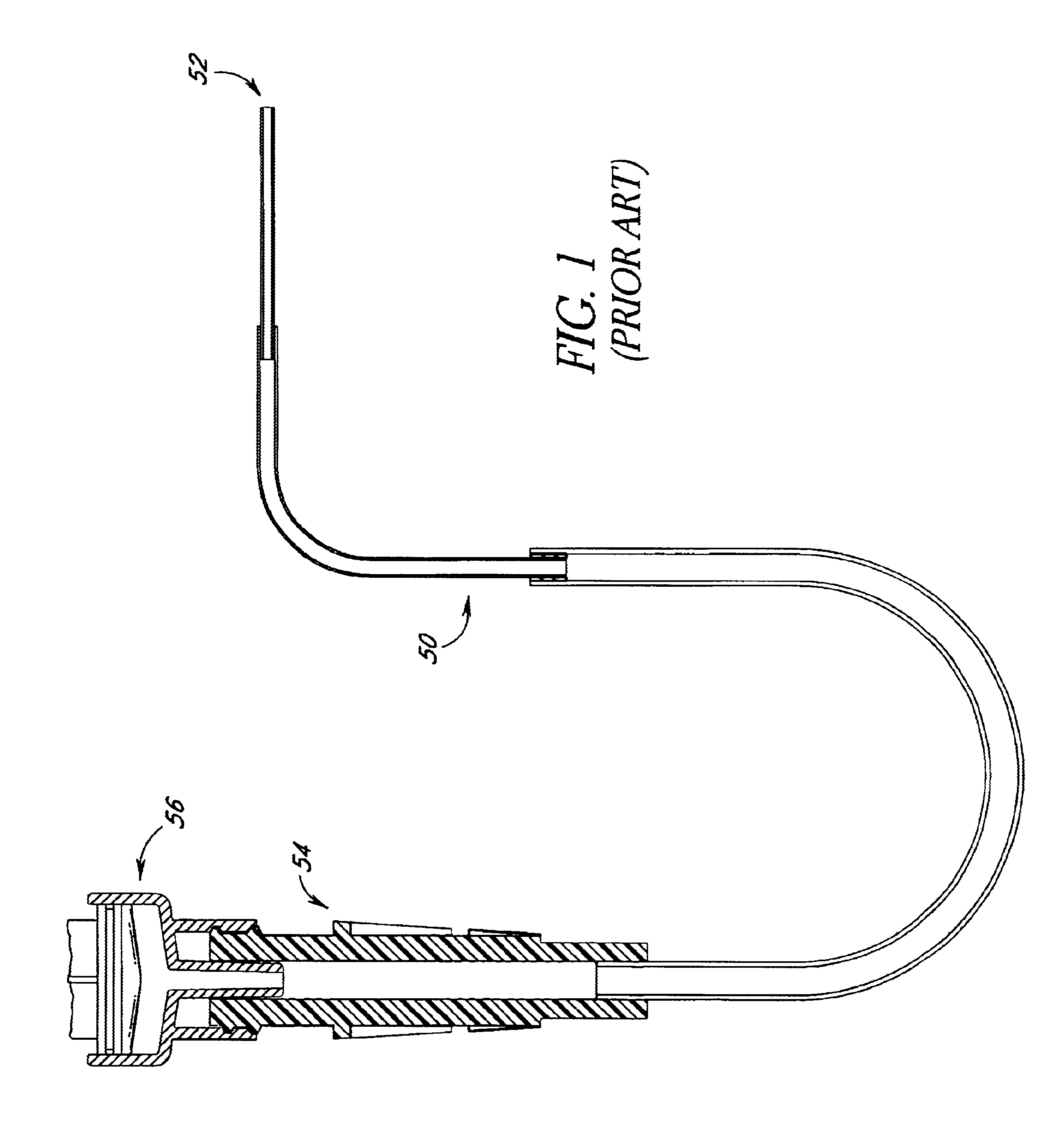

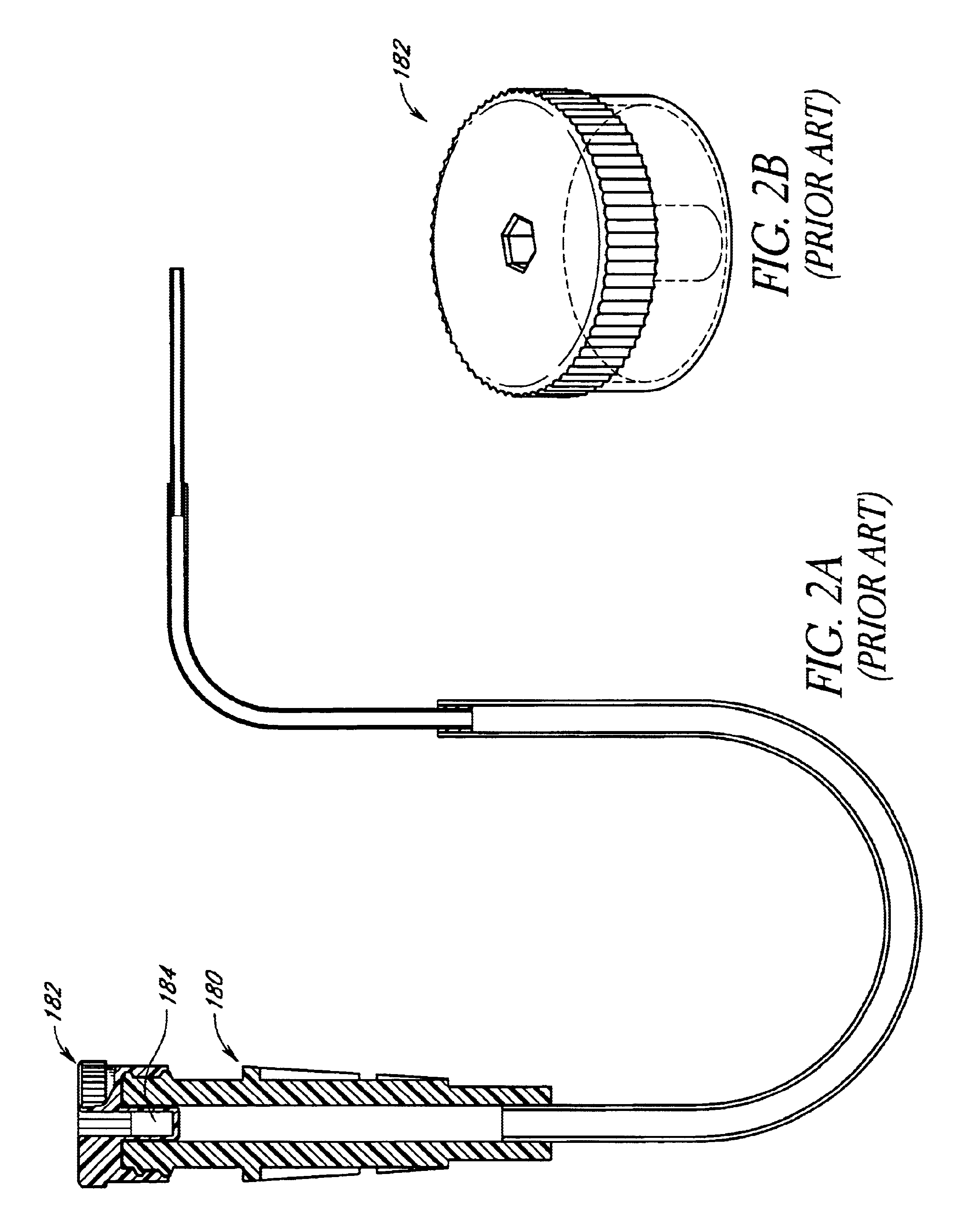

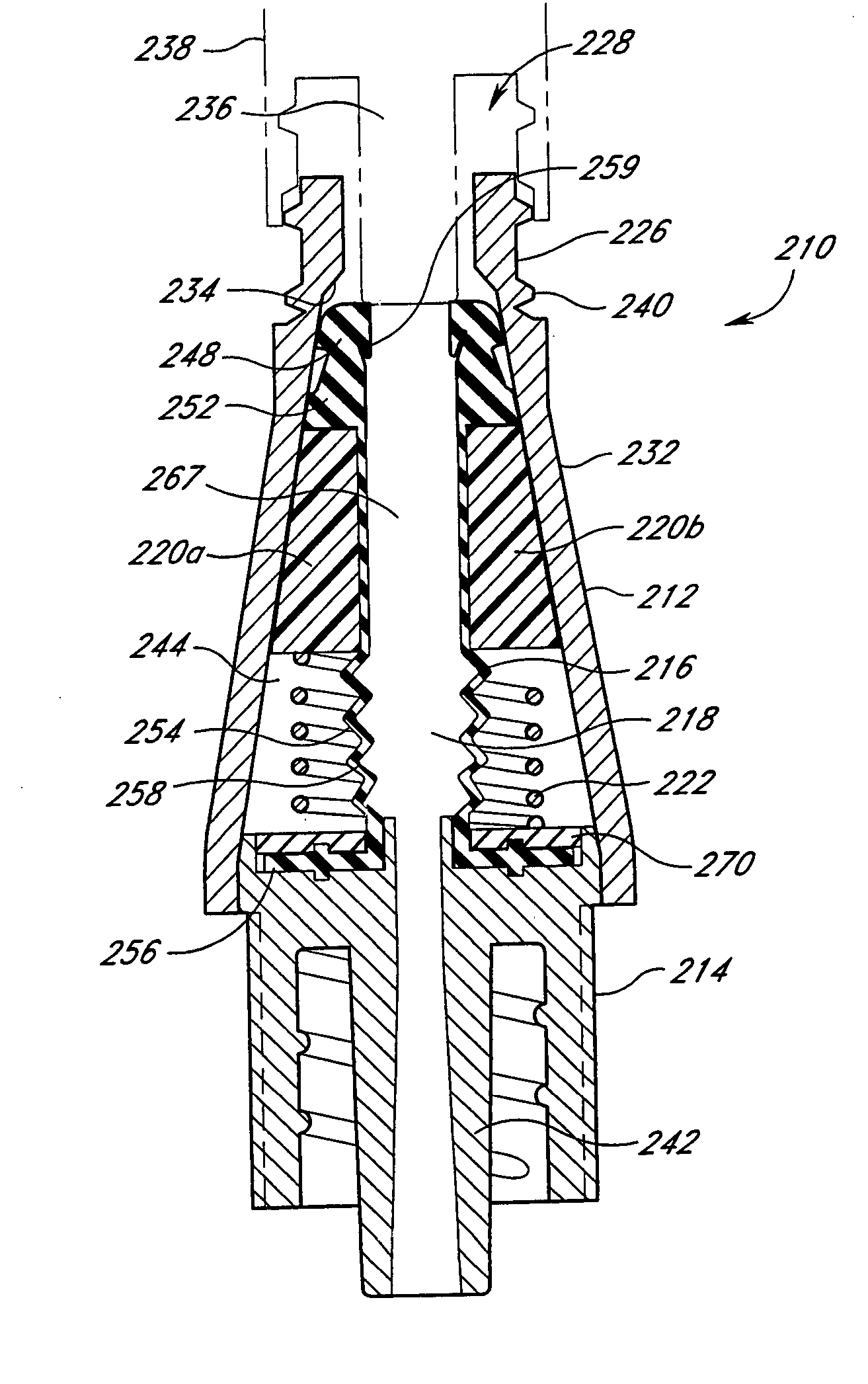

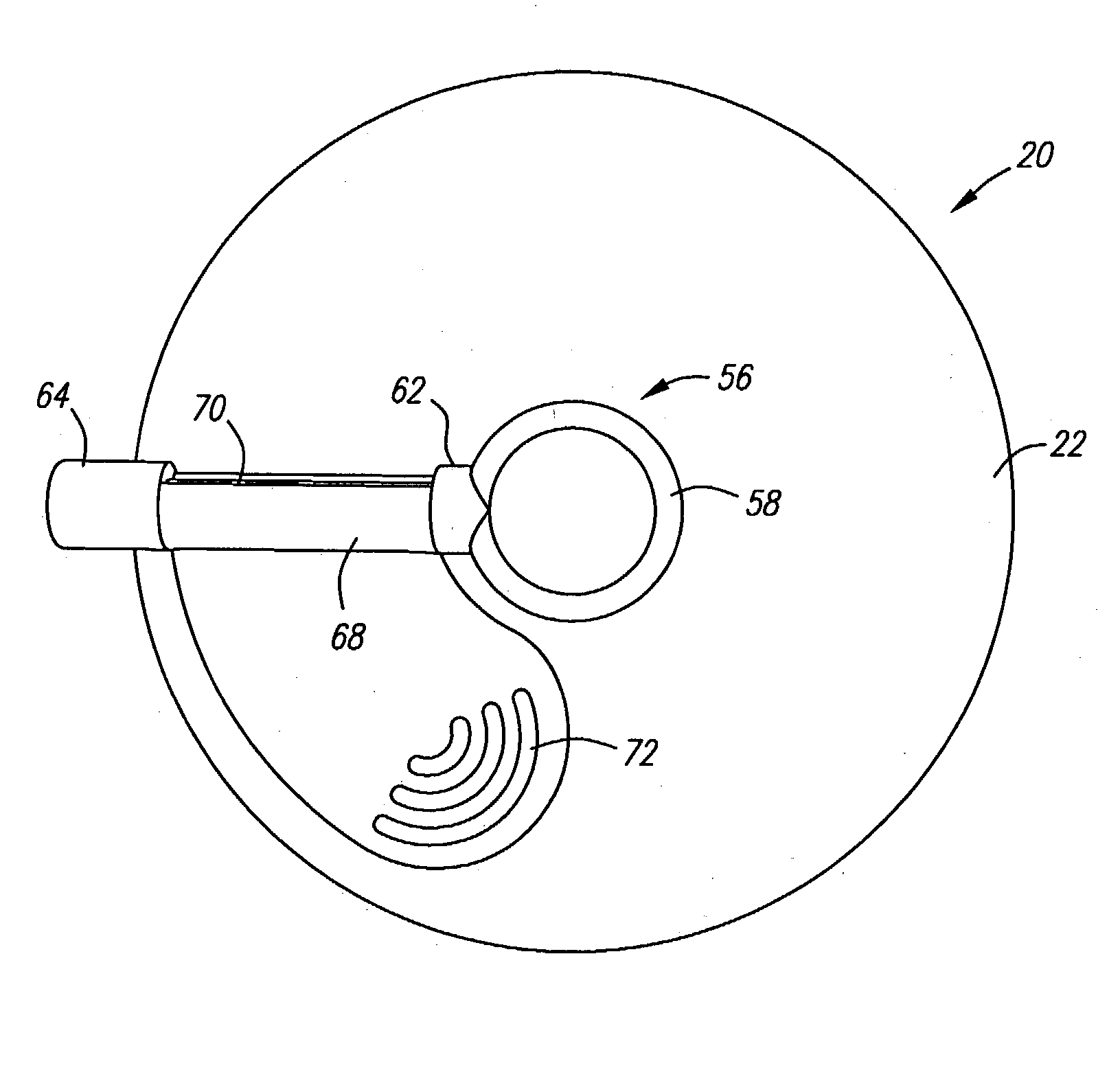

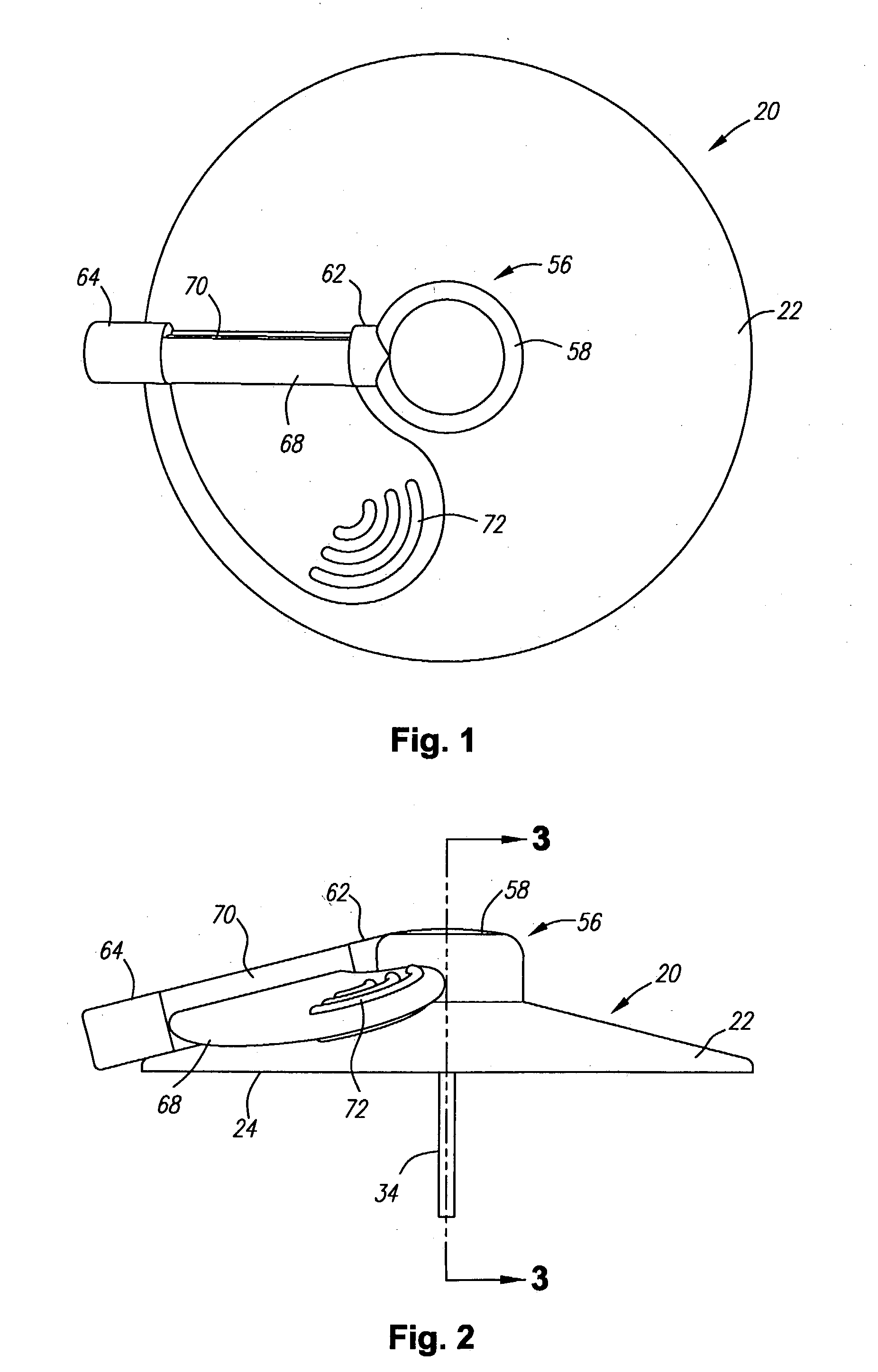

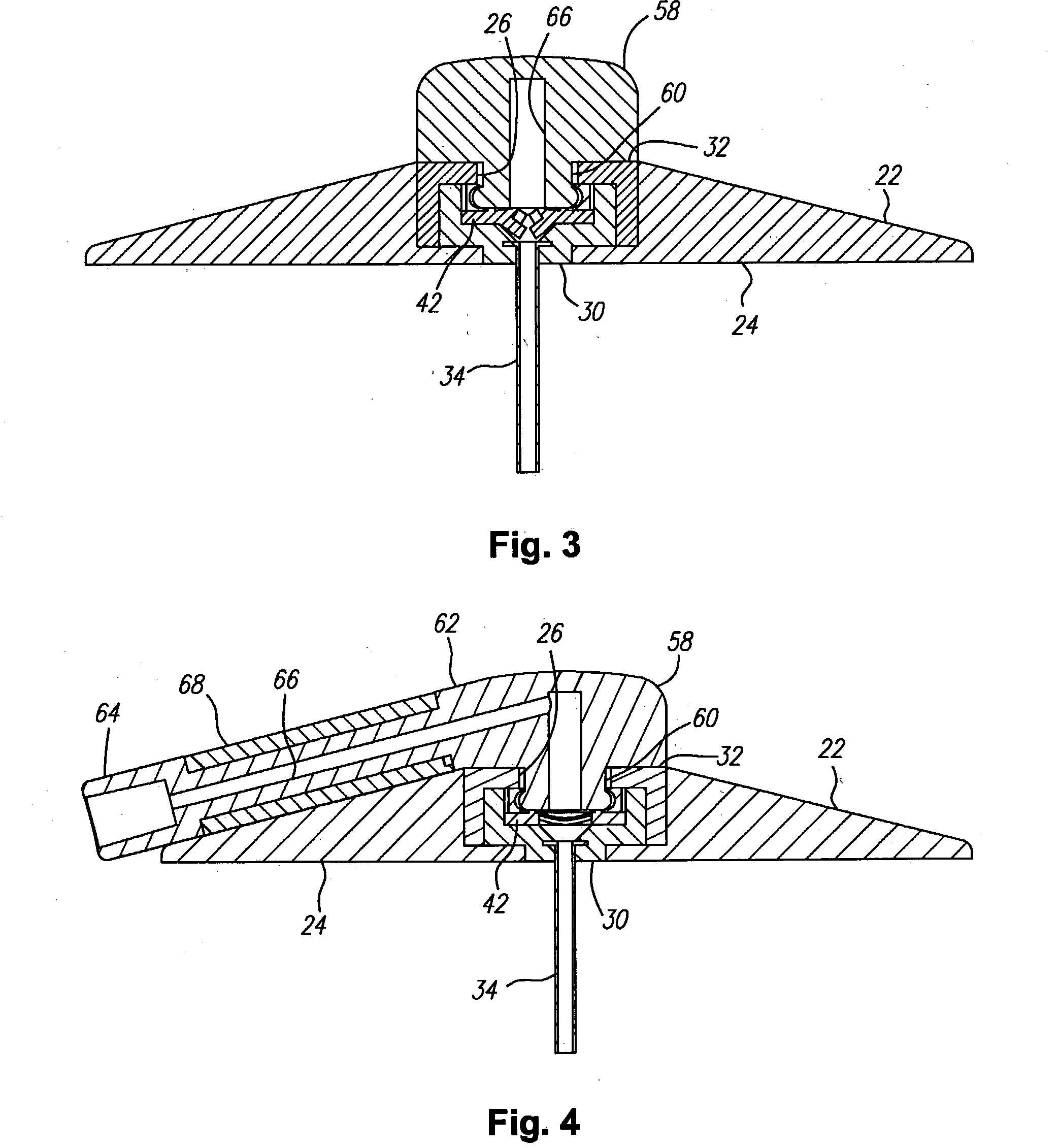

InactiveUS20050222541A1Reliable and repeatable performanceEliminate dead spaceValve arrangementsInfusion devicesNoseEngineering

A closed system, spikeless, positive-flow valve device includes a body defining an internal cavity. At the proximal end of the body is an opening which is preferably sufficiently large to receive an ANSI standard tip of a medical implement. The valve includes a plastic, resilient silicon seal which fills the upper cavity and opening with an oval seal cap having a slit. The opening presses the oval seal cap to keep the slit closed in the decompressed state. The slit opens as the nose of the medical implement compresses the seal into the cavity and the seal cap is free from the opening. The housing also includes a fluid space which facilitates fluid flow between the medical implement and a catheter tip. The fluid space within the valve automatically and reversibly increases upon insertion of the medical implement into the cavity and decreases upon withdrawal of the medical implement, such that a positive flow from the valve toward the catheter tip is effected upon withdrawal of the medical implement, thereby preventing a flow of blood from a patient into the catheter when the medical implement is removed from the valve.

Owner:LOPEZ GEORGE A +6

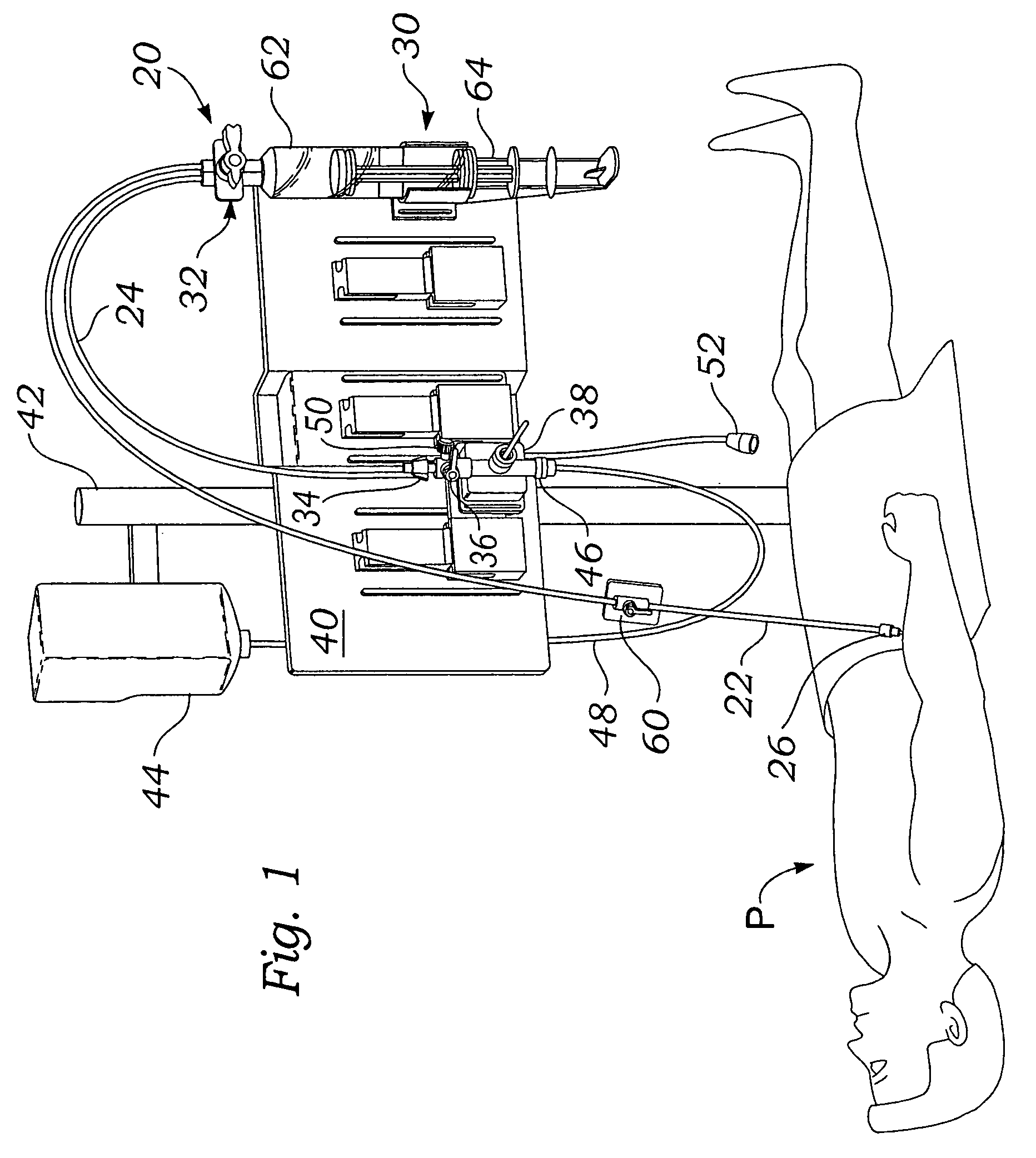

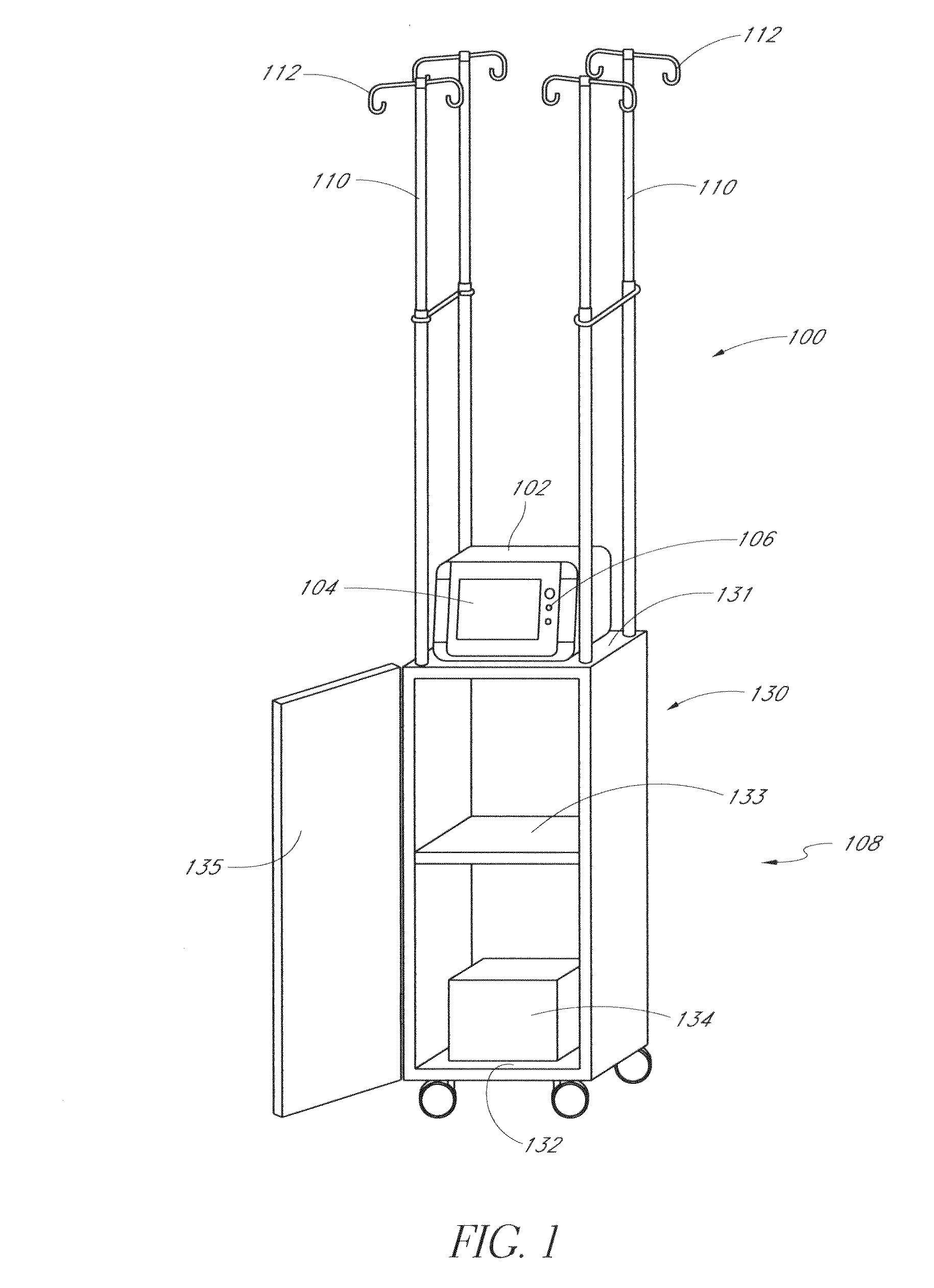

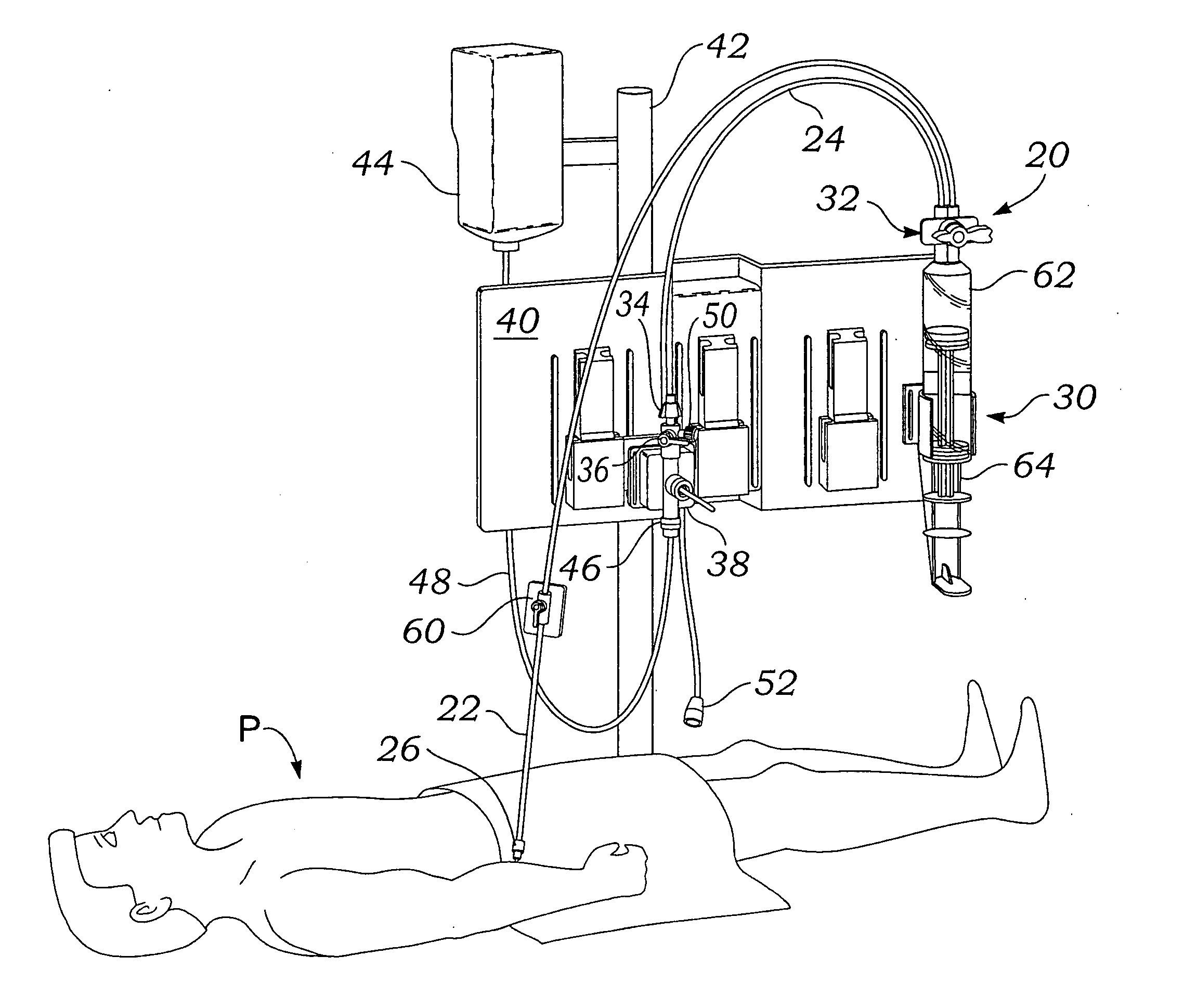

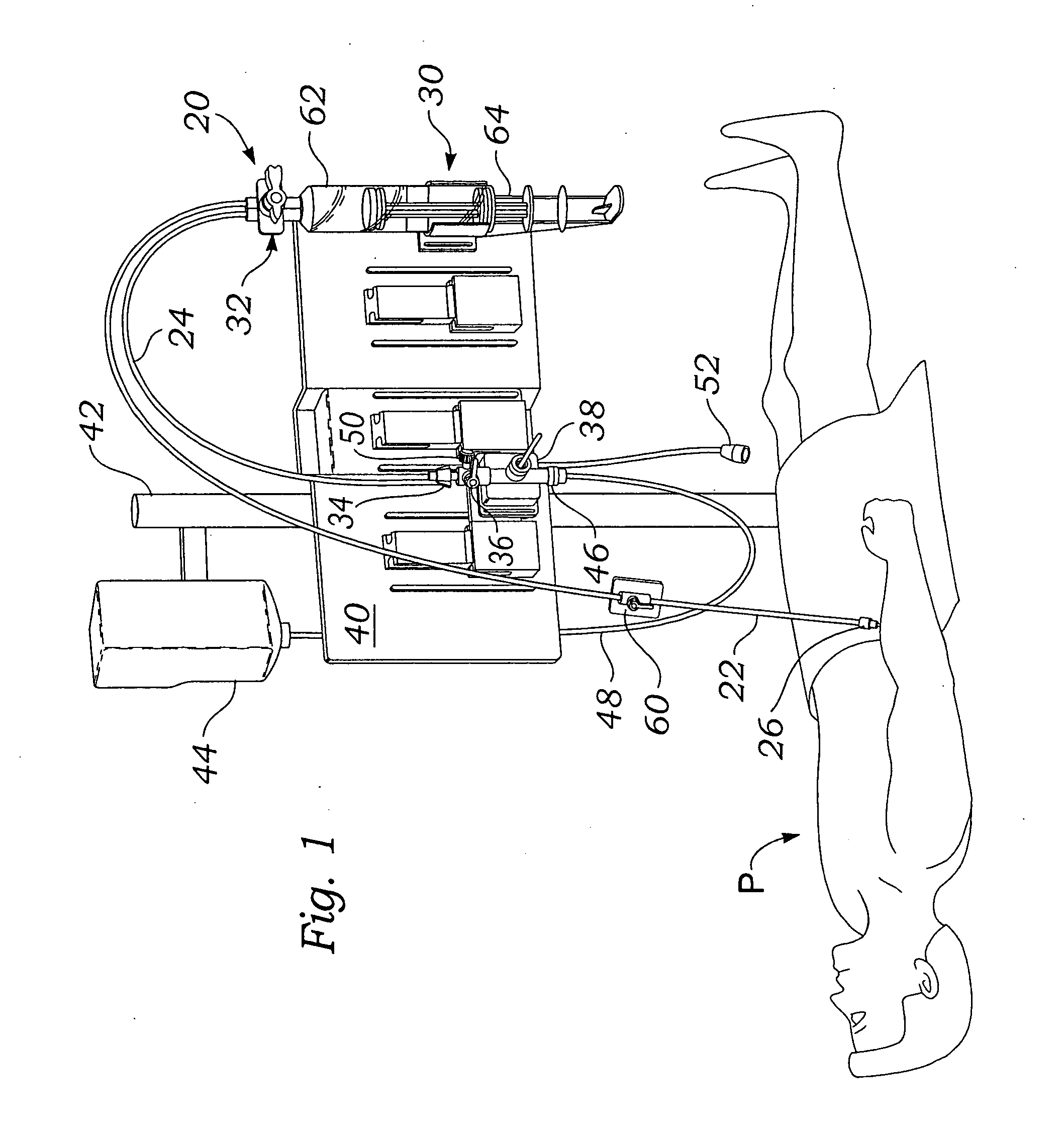

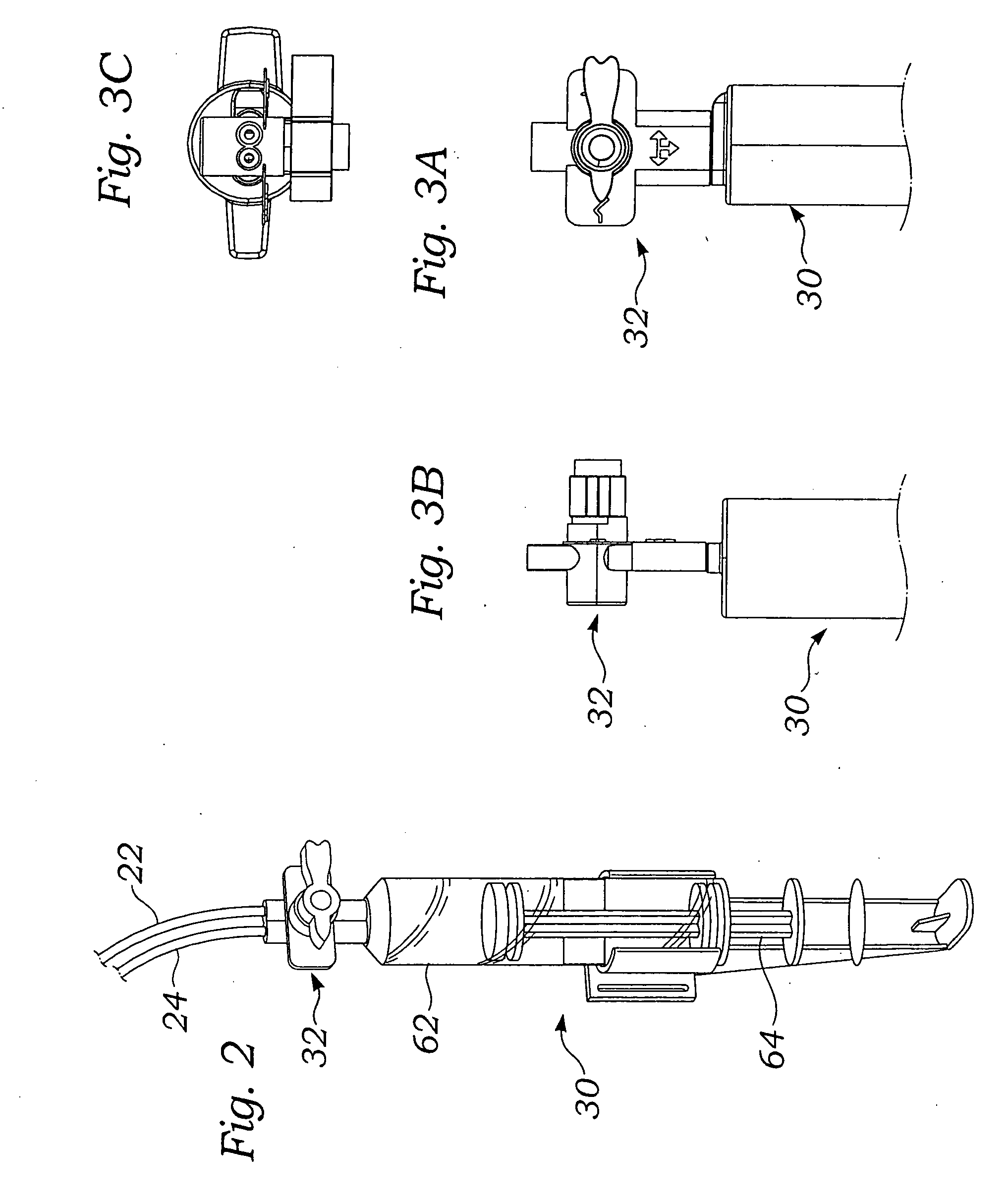

Closed blood sampling system with isolated pressure monitoring

ActiveUS7744573B2Easy to optimizeImprove pressure qualityCatheterIntravenous devicesMedical intensive care unitIntensive care

Owner:EDWARDS LIFESCIENCES CORP

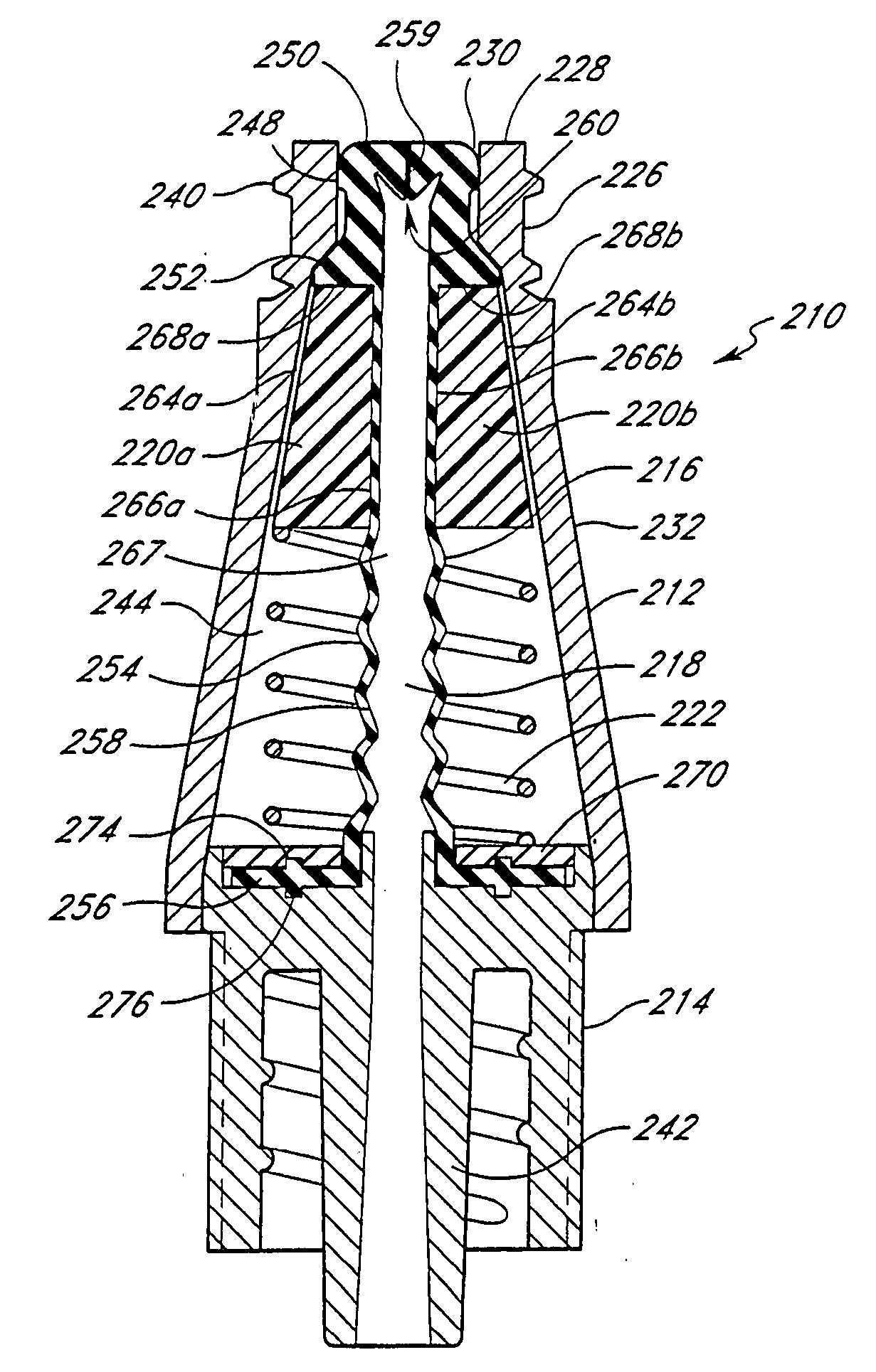

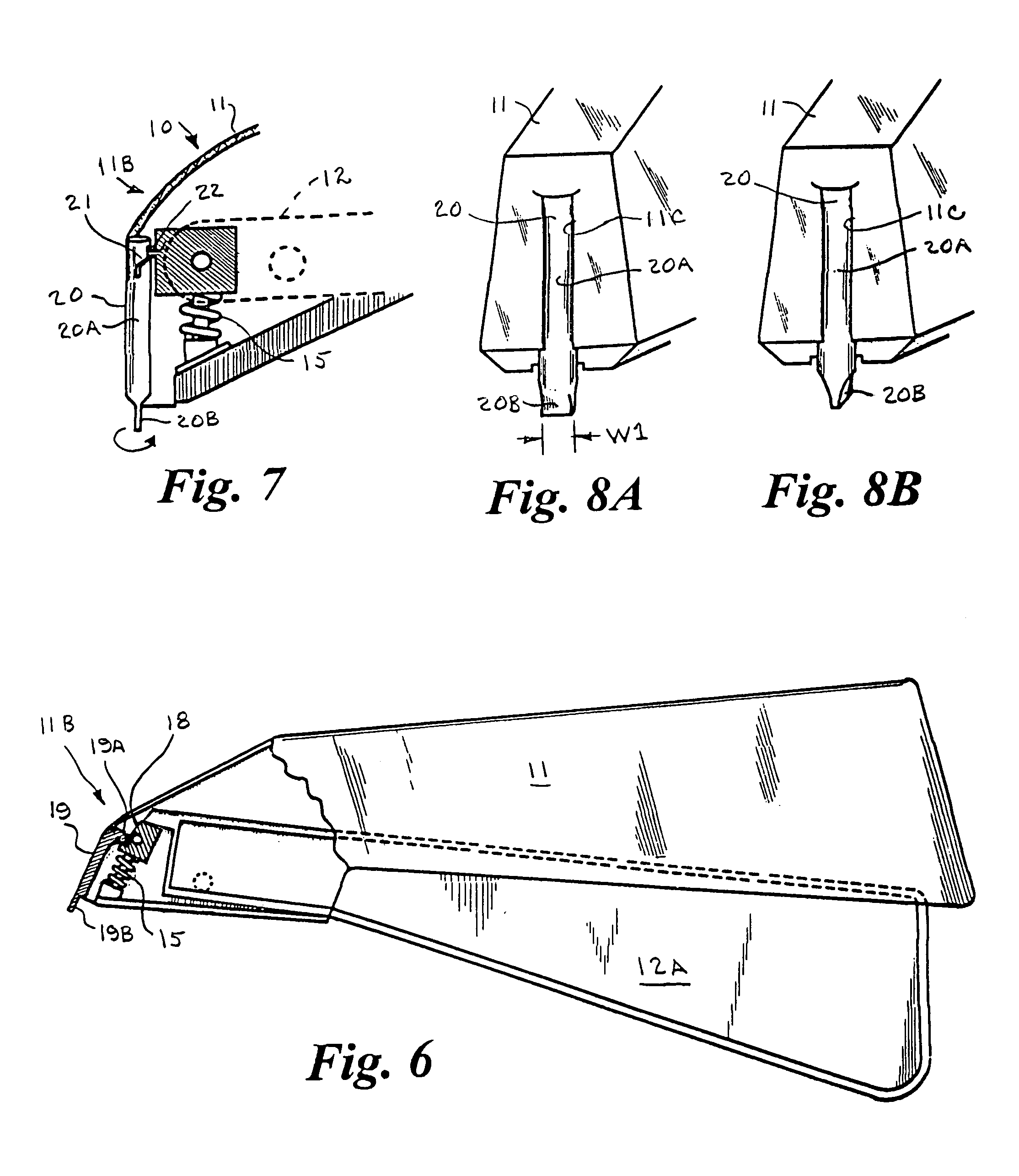

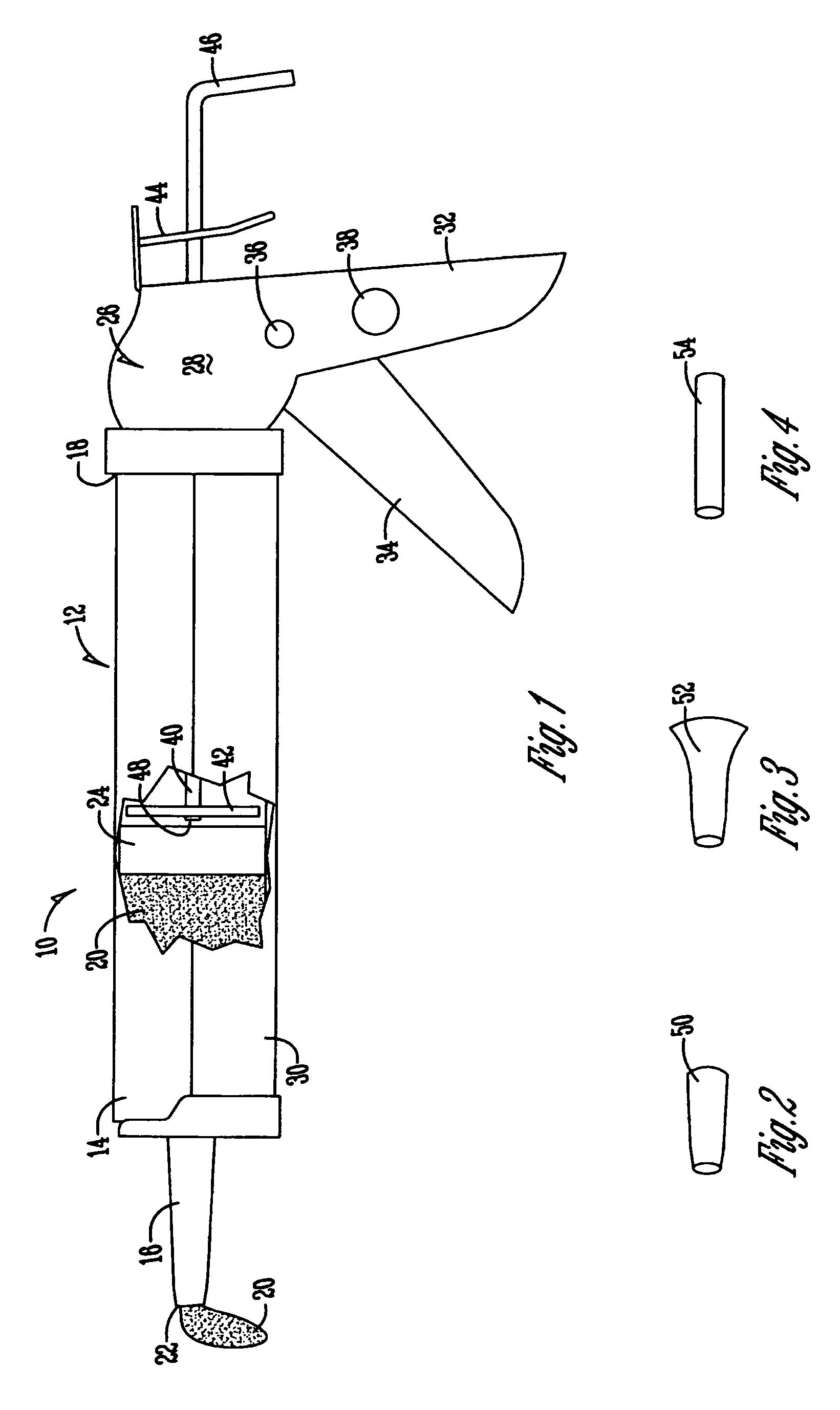

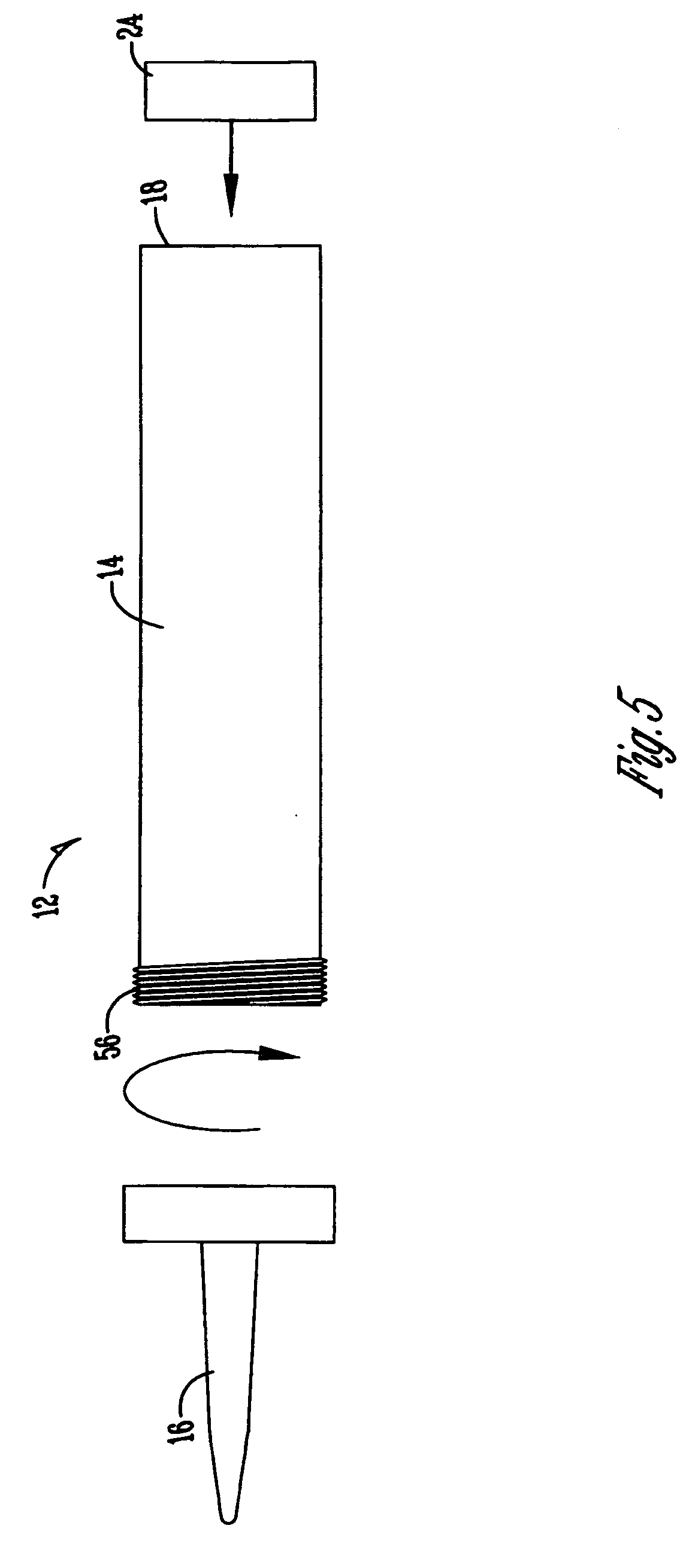

Apparatus and method for delivery of therapeutic and/or diagnostic agents

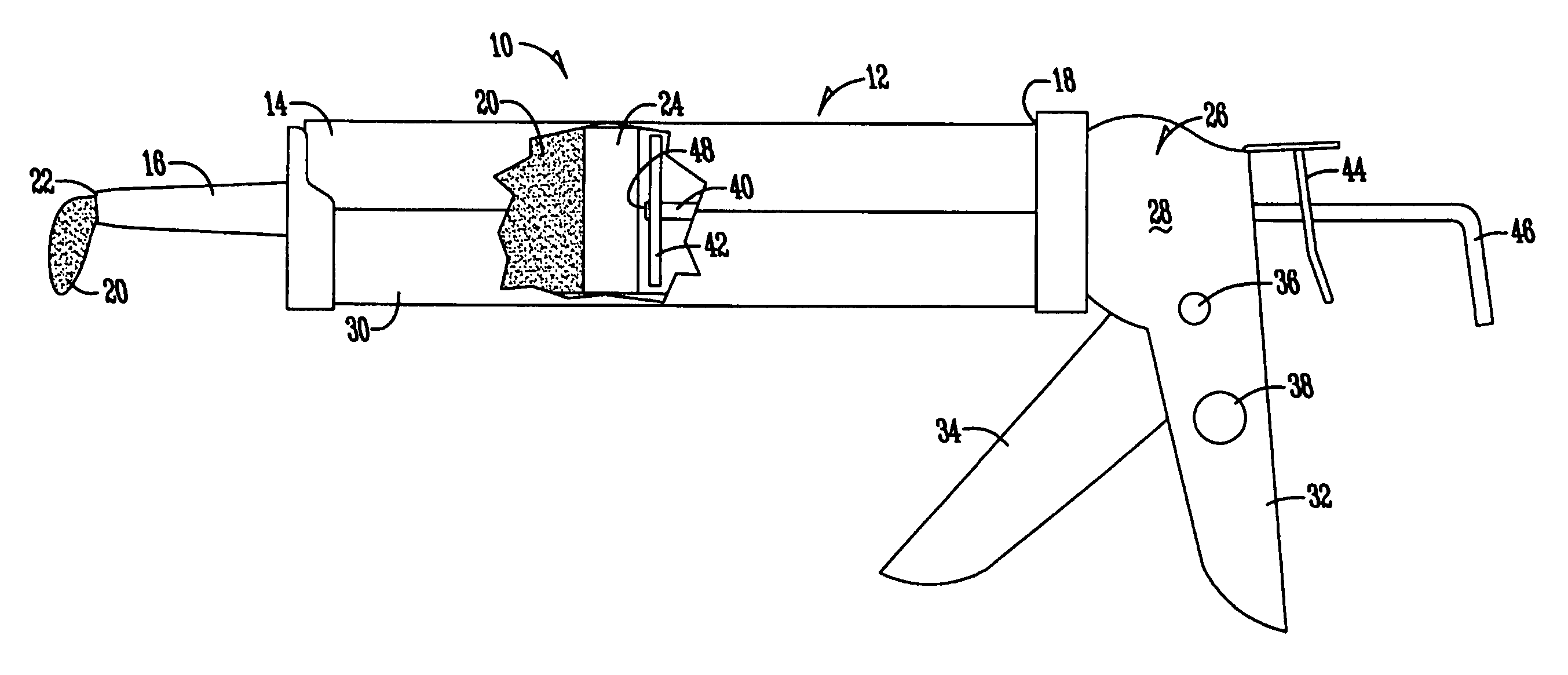

ActiveUS20050119611A1Accurate delivery of therapeuticEliminate dead spaceAutomatic syringesDigestive systemMovement controlBiomedical engineering

A system for delivery of therapeutic and / or diagnostic agents into a living body includes a port assembly having a cannula extending from the mounting side, a port opening away from the mounting side and a resilient barrier between the port and the cannula. An access hub includes a connector positionable at the port for opening the resilient barrier. The access hub is movable in the port assembly, is engaged therewith through a resilient ring coupling and forms a seal with the resilient barrier, reducing the amount of volume to be primed. Inserters, both disposable and reusable, include the cannula insertion member as part of the assembly. A spring loaded port driver is operatively mounted within the housing with movement controlled by a latch. The driver includes a seat for receipt of a port assembly. The cannula insertion member is nonremovably fixed in a socket in the port driver in the disposable assembly. In the reusable inserter, the cannula insertion member is slidably mounted within a socket associated with the latch. Slidable movement is limited by locking shoulders. The socket is split and may be splayed to release the cannula insertion member following use.

Owner:MEDSOLVE TECH

Positive flow valve

InactiveUS20060200090A1Reliable and repeatable performanceEliminate dead spaceMedical devicesIntravenous devicesNoseEngineering

A closed system, spikeless, positive-flow valve device includes a body defining an internal cavity. At the proximal end of the body is an opening which is preferably sufficiently large to receive an ANSI standard tip of a medical implement. The valve includes a plastic, resilient silicon seal which fills the upper cavity and opening with an oval seal cap having a slit. The opening presses the oval seal cap to keep the slit closed in the decompressed state. The slit opens as the nose of the medical implement compresses the seal into the cavity and the seal cap is free from the opening. The housing also includes a fluid space which facilitates fluid flow between the medical implement and a catheter tip. The fluid space within the valve automatically and reversibly increases upon insertion of the medical implement into the cavity and decreases upon withdrawal of the medical implement, such that a positive flow from the valve toward the catheter tip is effected upon withdrawal of the medical implement, thereby preventing a flow of blood from a patient into the catheter when the medical implement is removed from the valve.

Owner:LOPEZ GEORGE A +6

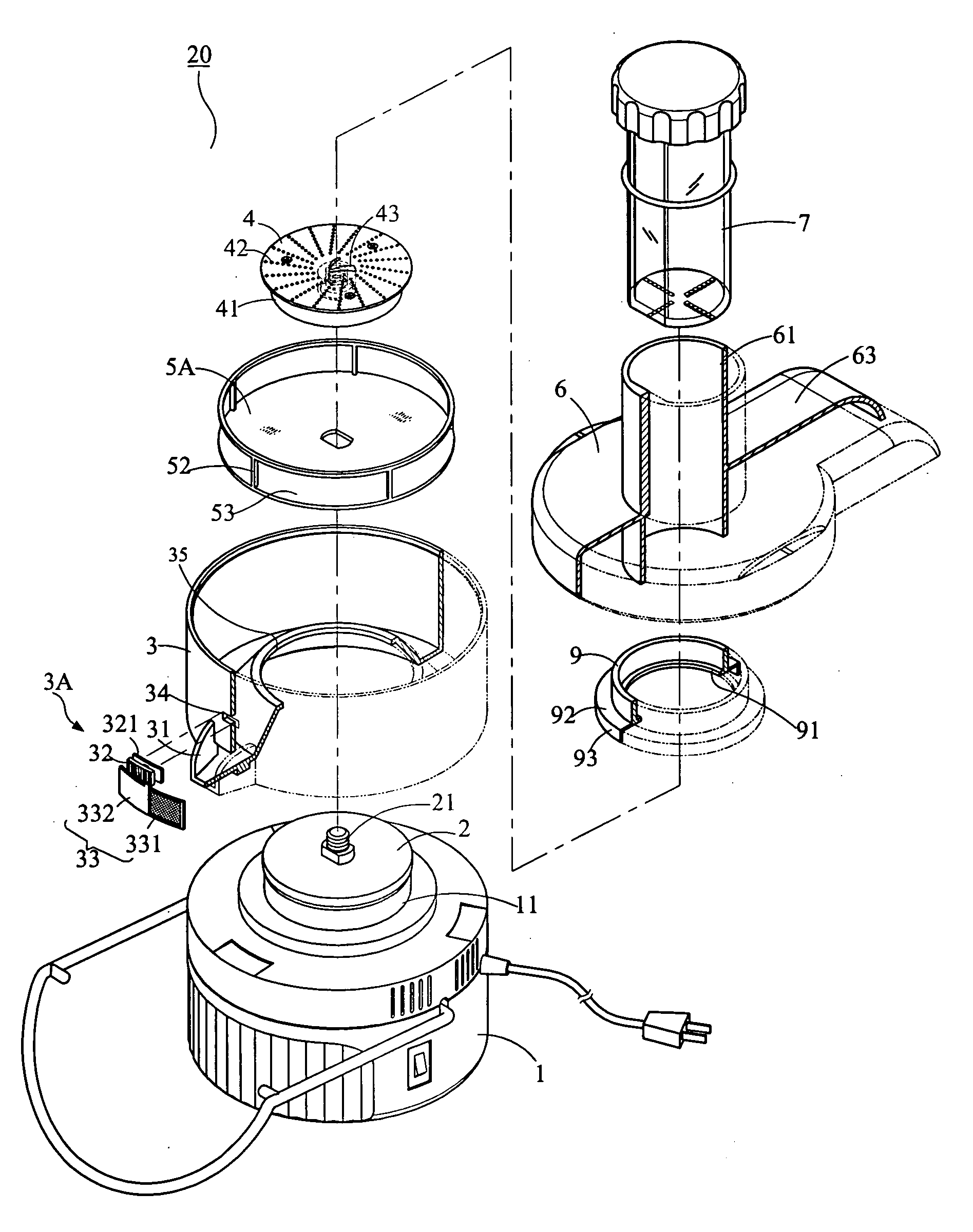

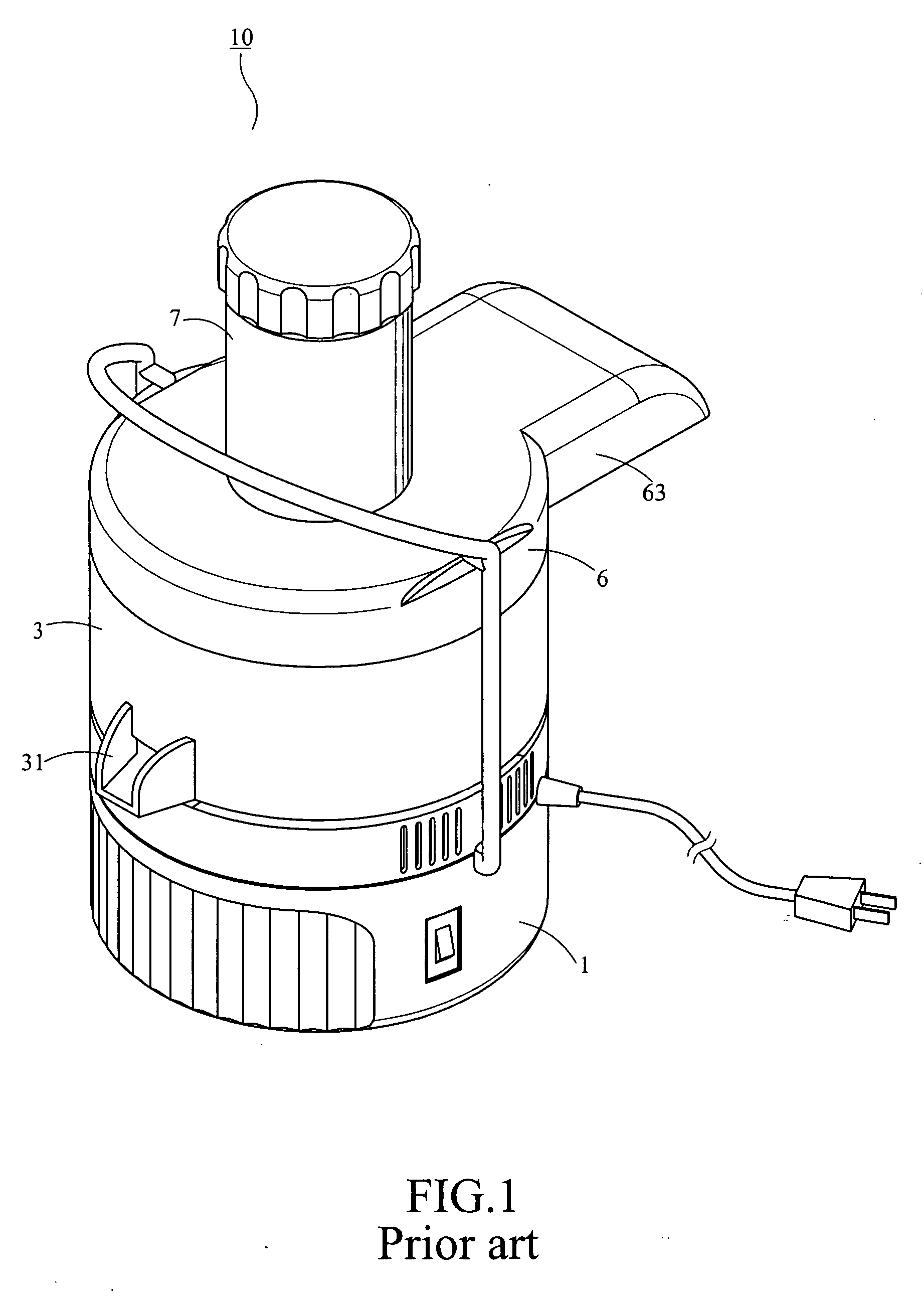

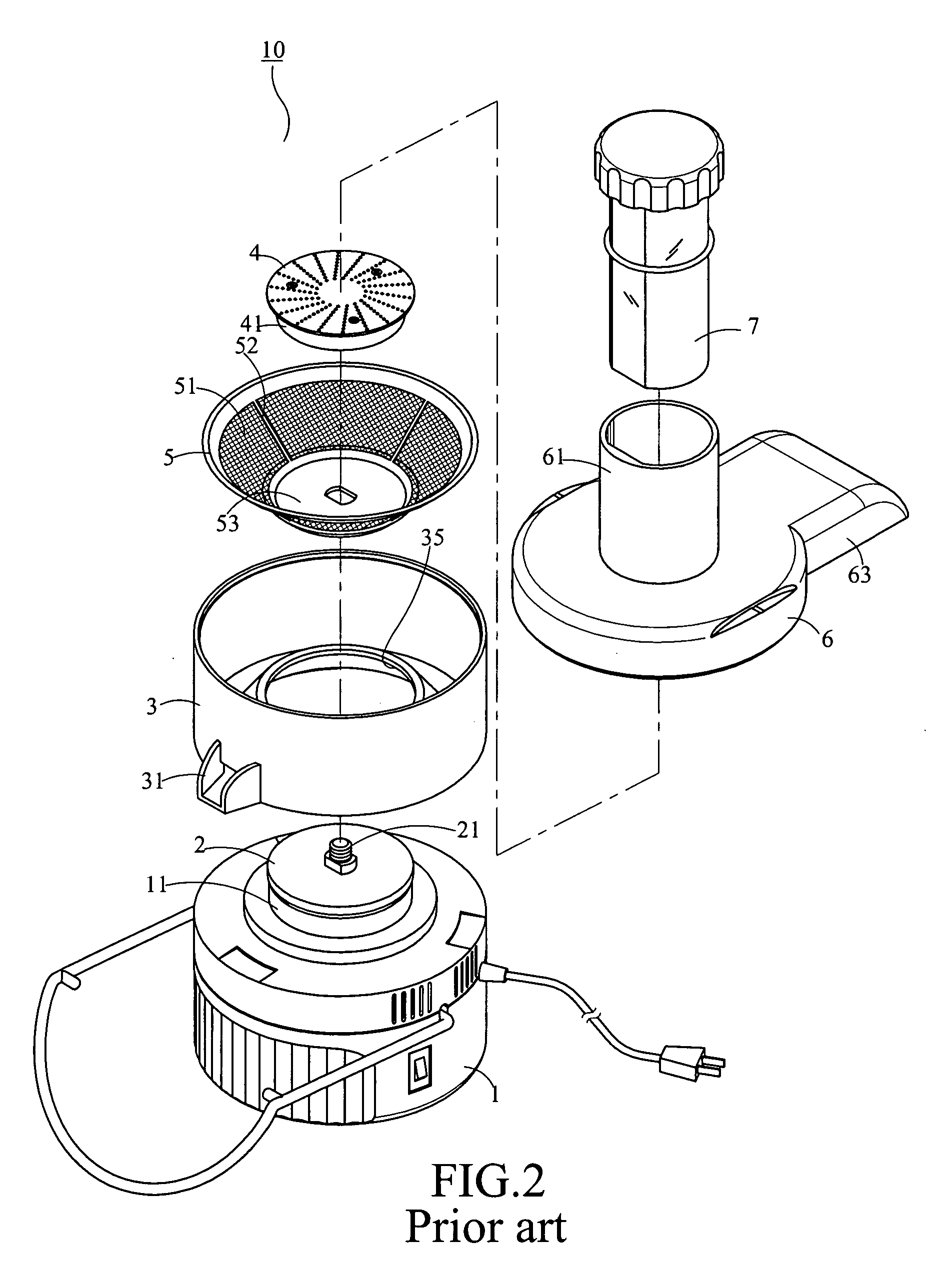

Pulp squeezer

InactiveUS20060191425A1Eliminate dead spaceJuice extractionCentrifugesFruit juicePulp and paper industry

A squeezer can be used to produce a pulp contained juice instead of the conventional squeezer only provided juice. The squeezer comprises a motor base, a rotary disk, a bowl, a cutter disk, a mask, an upper lid and a feed tube passed through a receiving opening of the upper lid. In which, a circular lid is introduced between the bottom end of a receiving opening and the cutter disk. The cutter disk has a ring type press plate relative to the cutter disk in an up and down relationship. A gap kept between the ring type plate and the cutter disk allows shredded fruits to be macerated to form pulp contained juice and then drained out. The mask is composed of a support frame and a watertight base. Because the mask has no meshes, the pulp contained juice can be led into the bowl.

Owner:CHANG MING SHIH

Wallless monolith columns for chromatography

InactiveUS20050155933A1Eliminate dead spaceIon-exchange process apparatusOther chemical processesChemistrySurface layer

A monolith column for chromatography comprising a monolith rod encased with a tubular structure wherein the mass of the interior surface layer of said tubular structure intercalate by an encasing process into the surface layer of said monolith rod through the micro-cavities of said surface layer of said monolith rod, forming a hybrid layer shared by both said monolith rod and said tubular structure.

Owner:ARCHIDEX

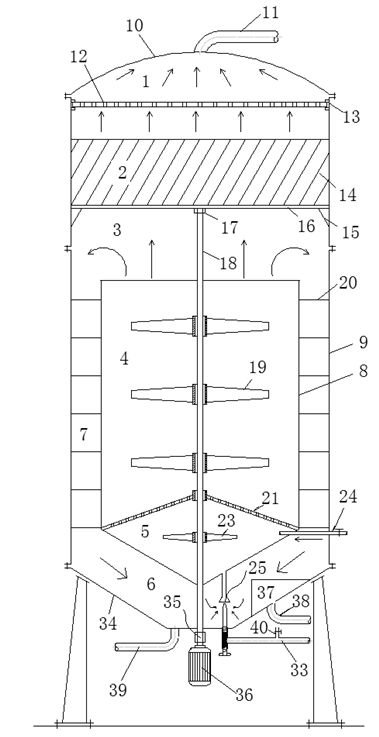

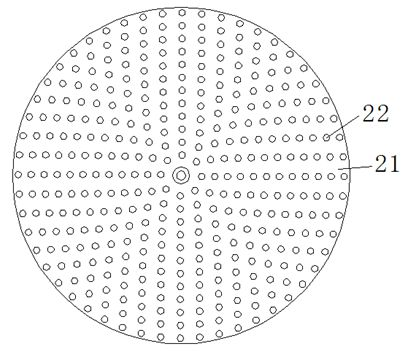

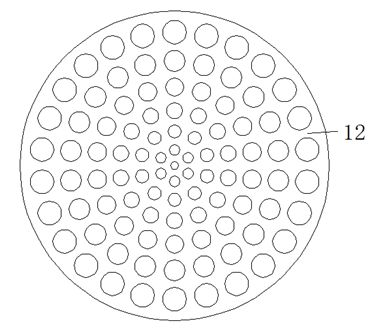

Integrated water purifying and processing equipment

ActiveCN102001769AGuaranteed concentrationReduce dosageMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationFlocculationSludge

The invention discloses integrated water purifying and processing equipment. The equipment comprises an external barrel and an internal barrel, wherein a convex head is arranged at the top of the external barrel; a water outlet is formed in the center of the convex head; a conical bottom plate is arranged at the bottom of the external barrel; a mixer motor and a speed reducer are arranged in the center of the bottom of the conical bottom plate; the speed reducer is provided with a stirring shaft; the side wall of the conical bottom plate is provided with a dredge pipe; an escape pipe is arranged at the bottom of the conical bottom plate; the inner side of the external barrel is divided into a clean water zone, an inclined tube settling zone, a mud and water separating zone, a secondary cluster flocculation zone, a primary flocculation reaction zone and a mud collection zone in turn from top down; a sludge concentrating zone is arranged between the internal barrel and the external barrel; the equipment is provided with a coagulant quick coagulation device and a sludge hydraulic automatic backflow device to keep the concentration of the sludge in the reaction zone stable; the sludge concentrating zone is provided with a spiral bevel plate to efficiently concentrate the sludge; and the clean water zone is provided with a water collecting plate to realize pressure effluent. The equipment has a simple structure, compact layout and high space utilization rate, is convenient to operate, and is suitable for clarifying tap water in middle-sized and small cities and purifying industrial water by primarily removing turbidity.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

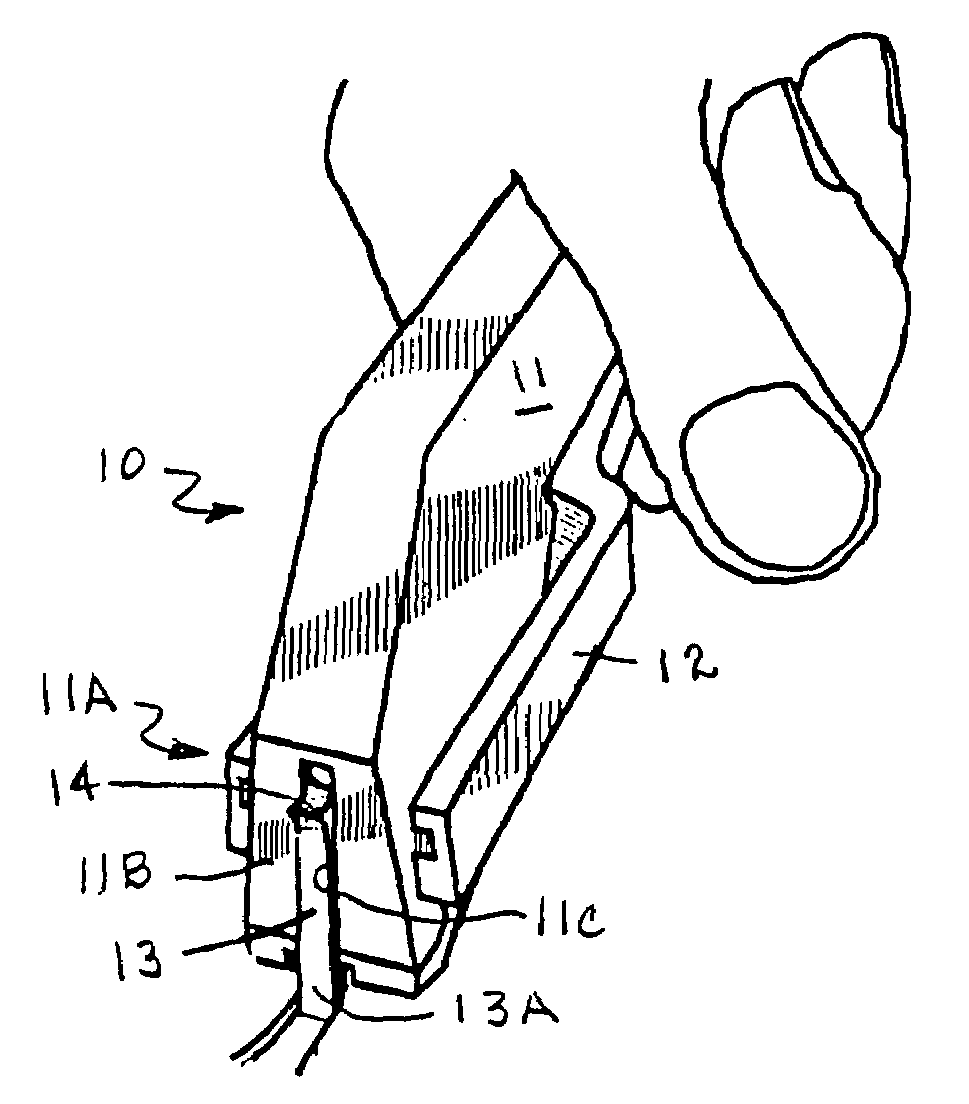

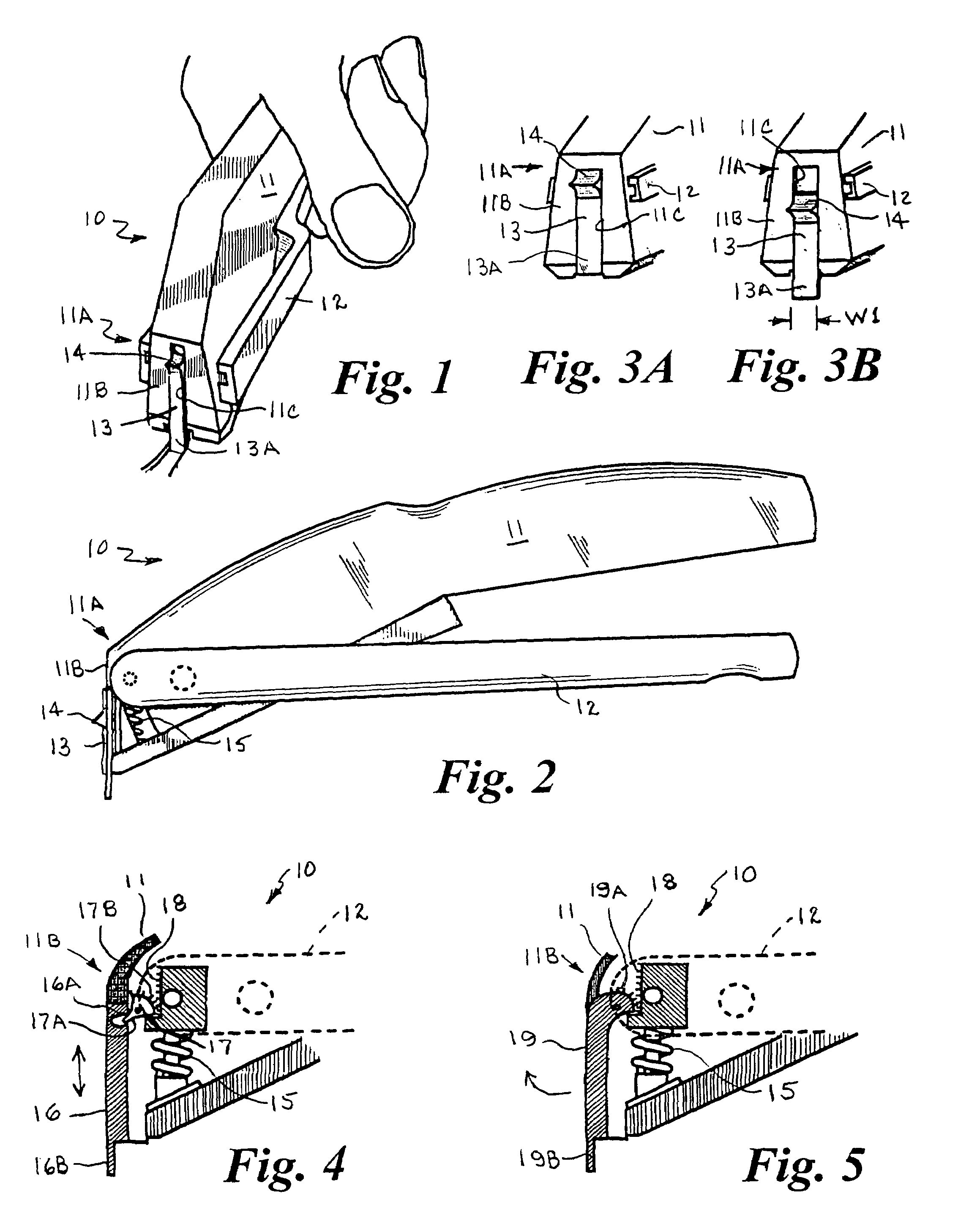

Tissue aligning surgical stapler and method of use

InactiveUS7004950B1Easy constructionReduce manufacturing costSuture equipmentsStapling toolsSurgical departmentSurgical Staplers

Owner:COLLINS JAMES R +2

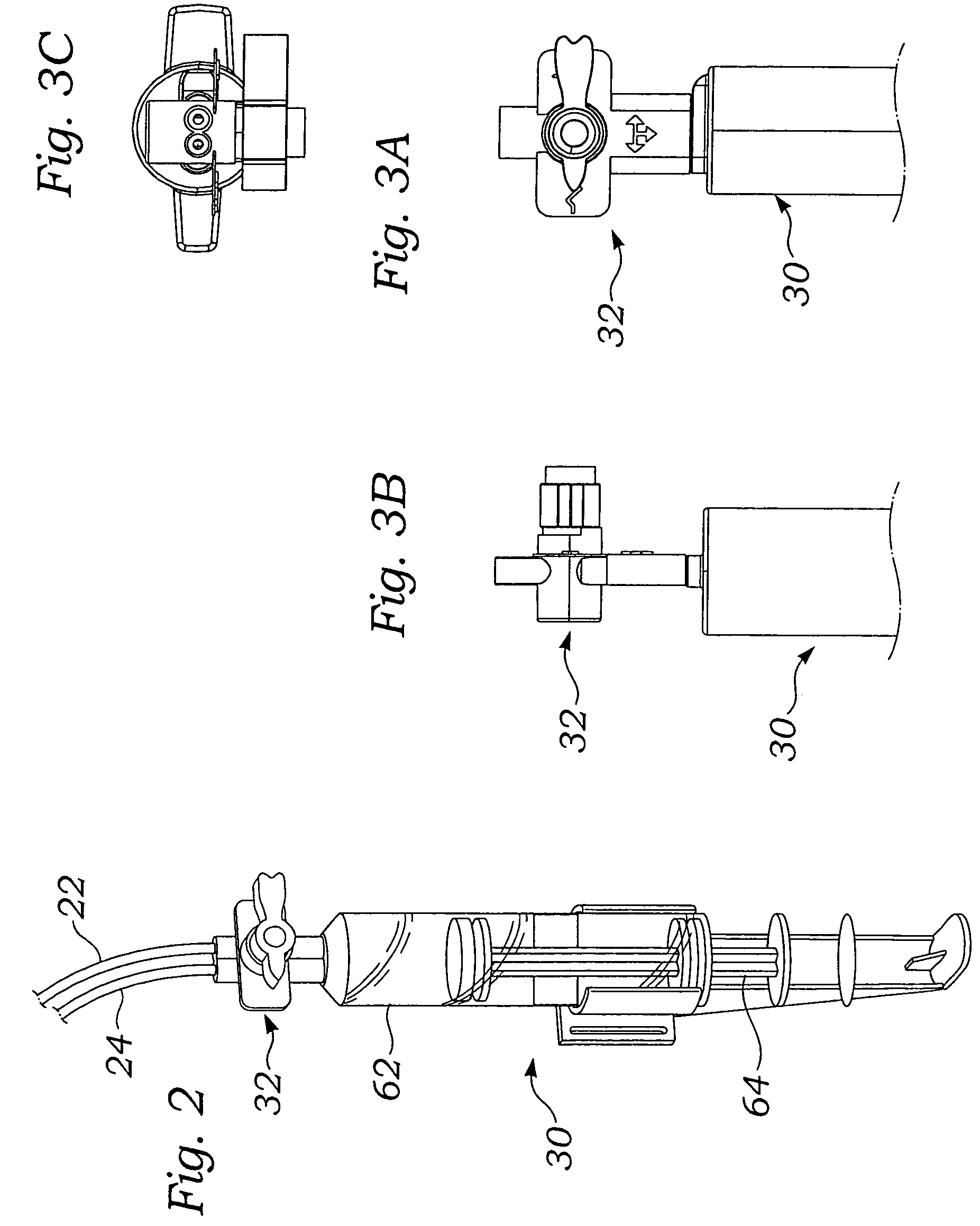

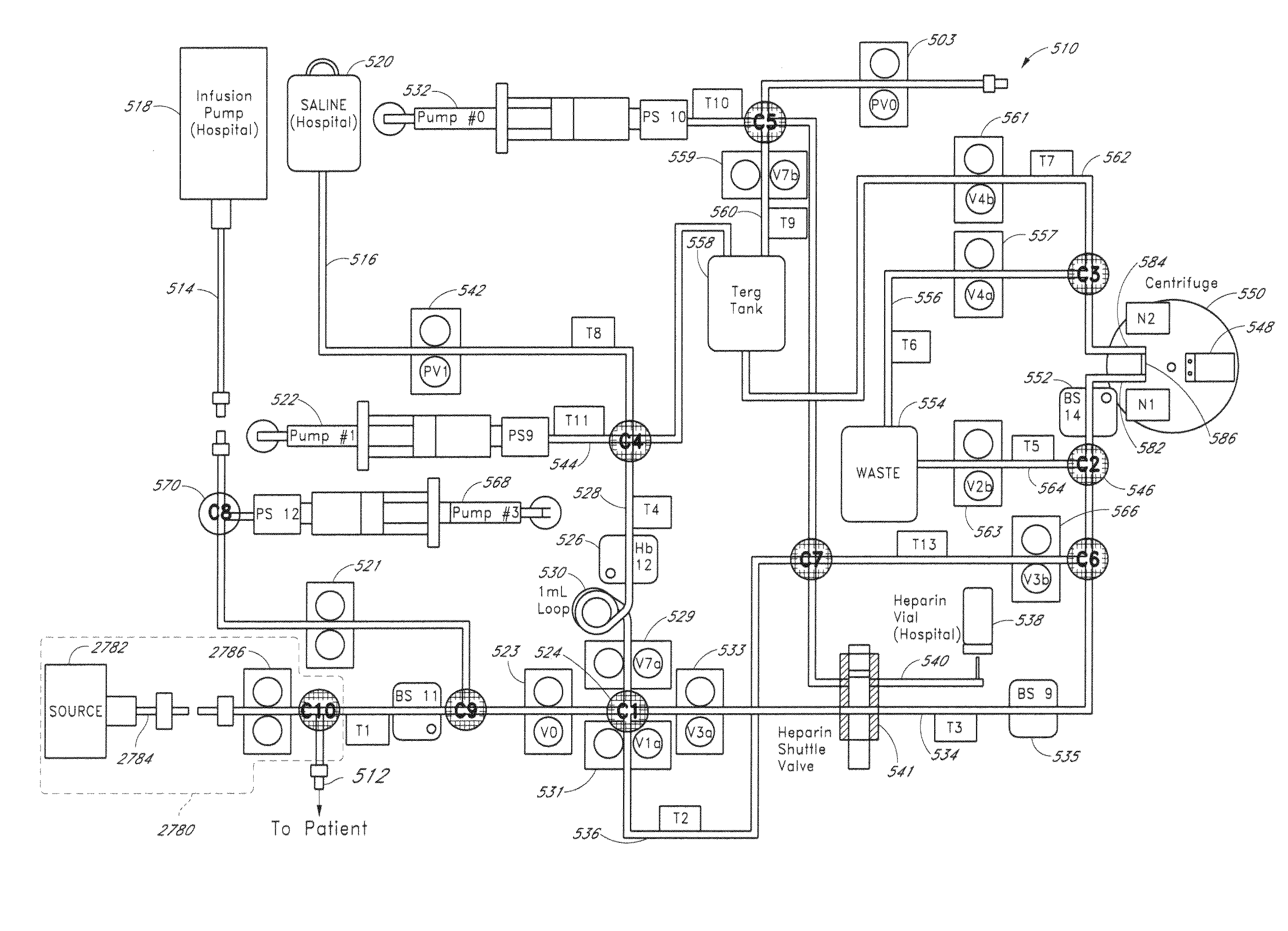

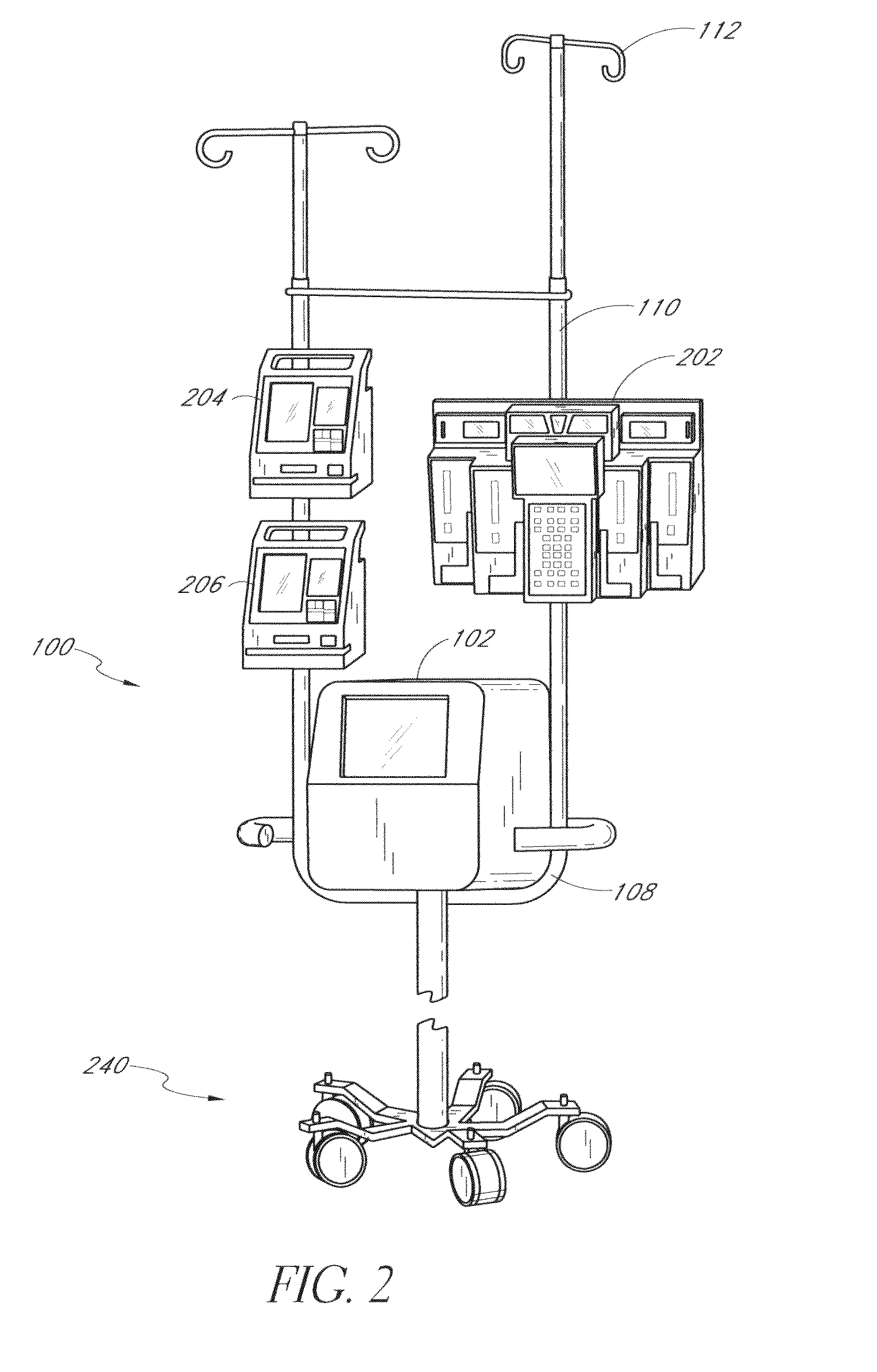

Adjustable connector and dead space reduction

InactiveUS20110092784A1Improve fluid flowEliminate dead spaceDiagnostics using lightDrug and medicationsAnalyteMonitoring system

Methods and systems for determining the concentration of one or more analytes from a sample such as blood or plasma are described. The systems described herein can be configured to withdraw a certain volume of sample from a source of bodily fluid, direct a first portion of the withdrawn sample to an analyte monitoring system and return a second portion of the sample to the patient. The analyte monitoring system can be connected to the source of bodily fluid via a connector that is configured to maintain uniform velocity across the connector and reduce the dead space volume.

Owner:OPTISCAN BIOMEDICAL

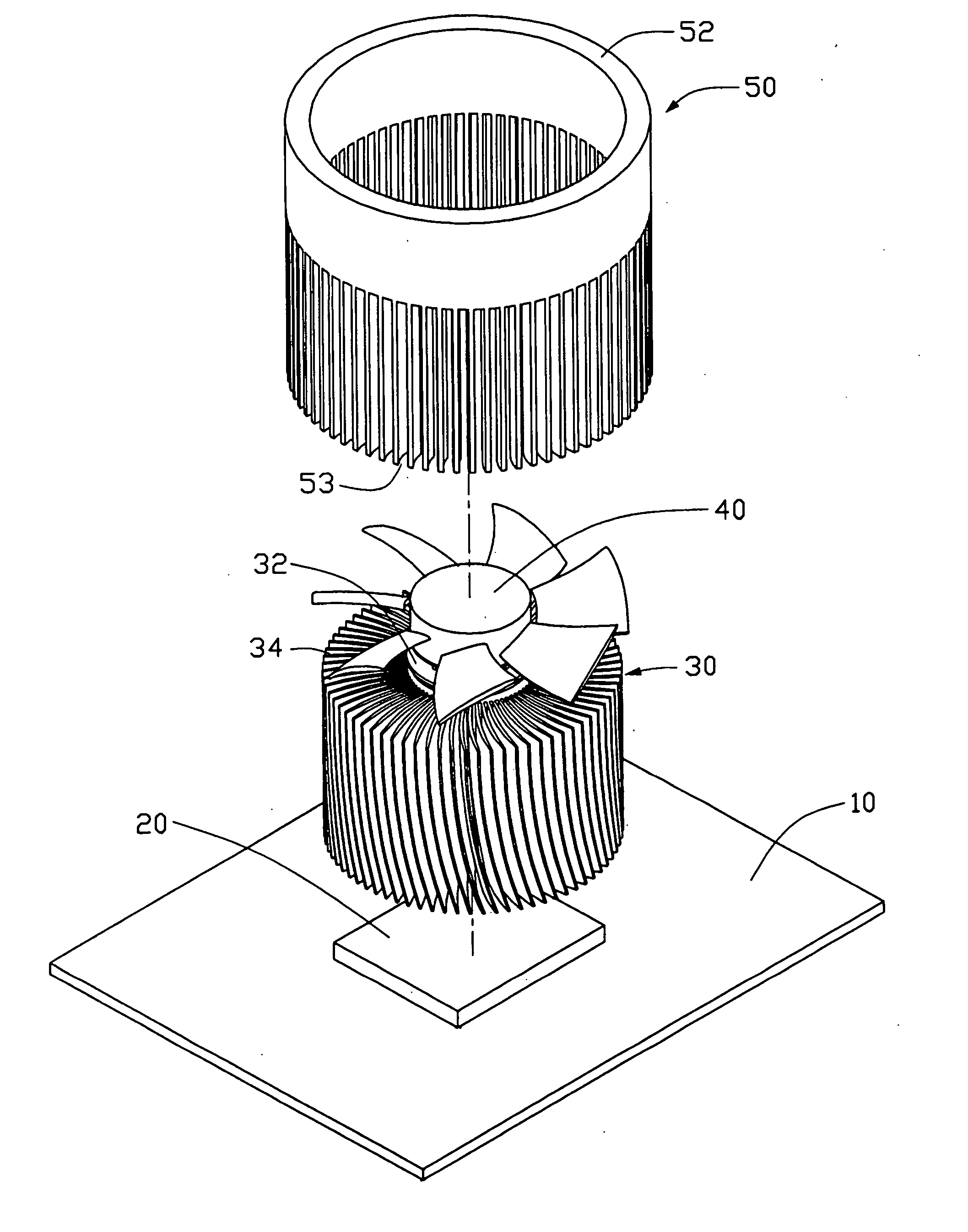

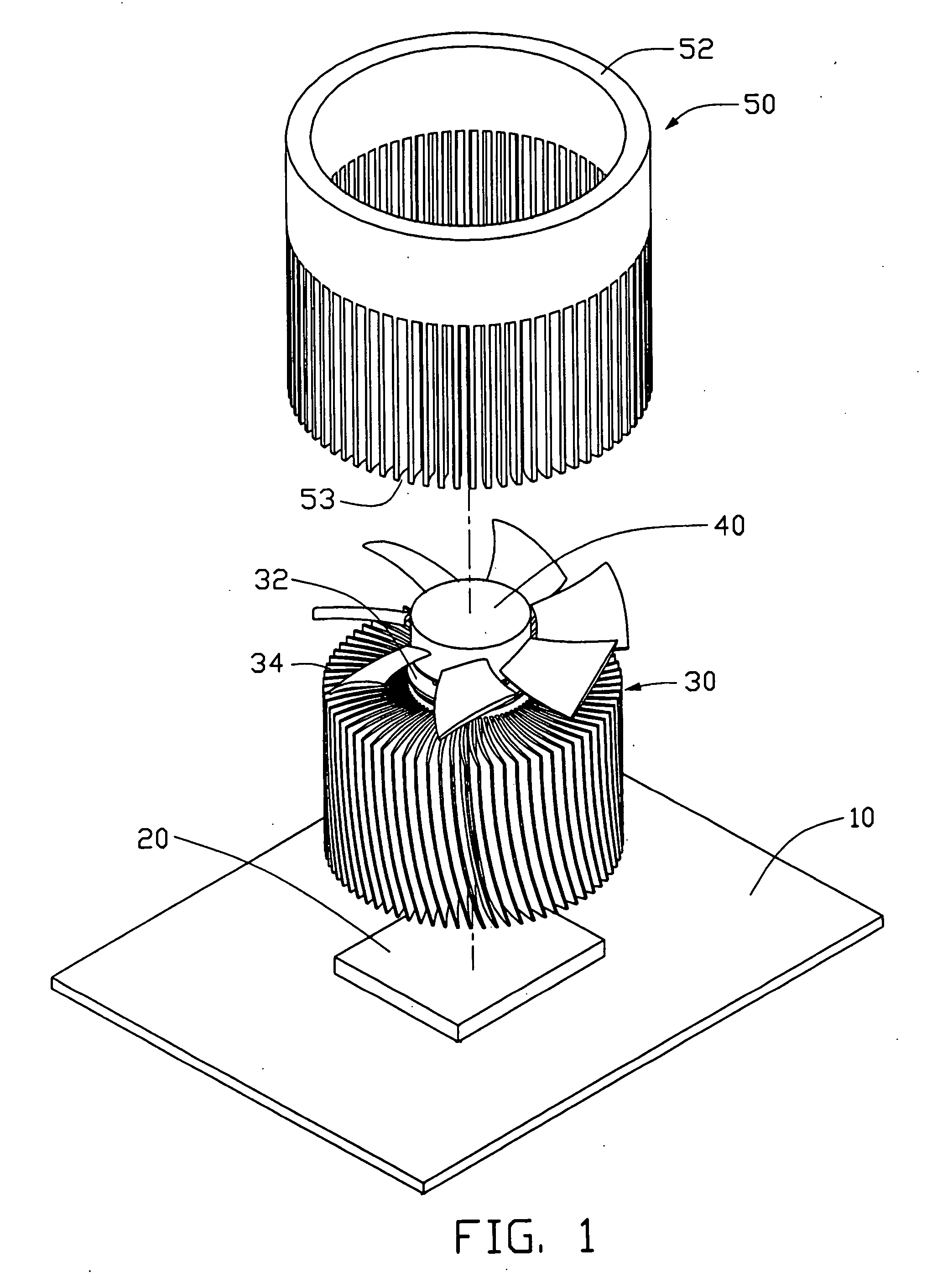

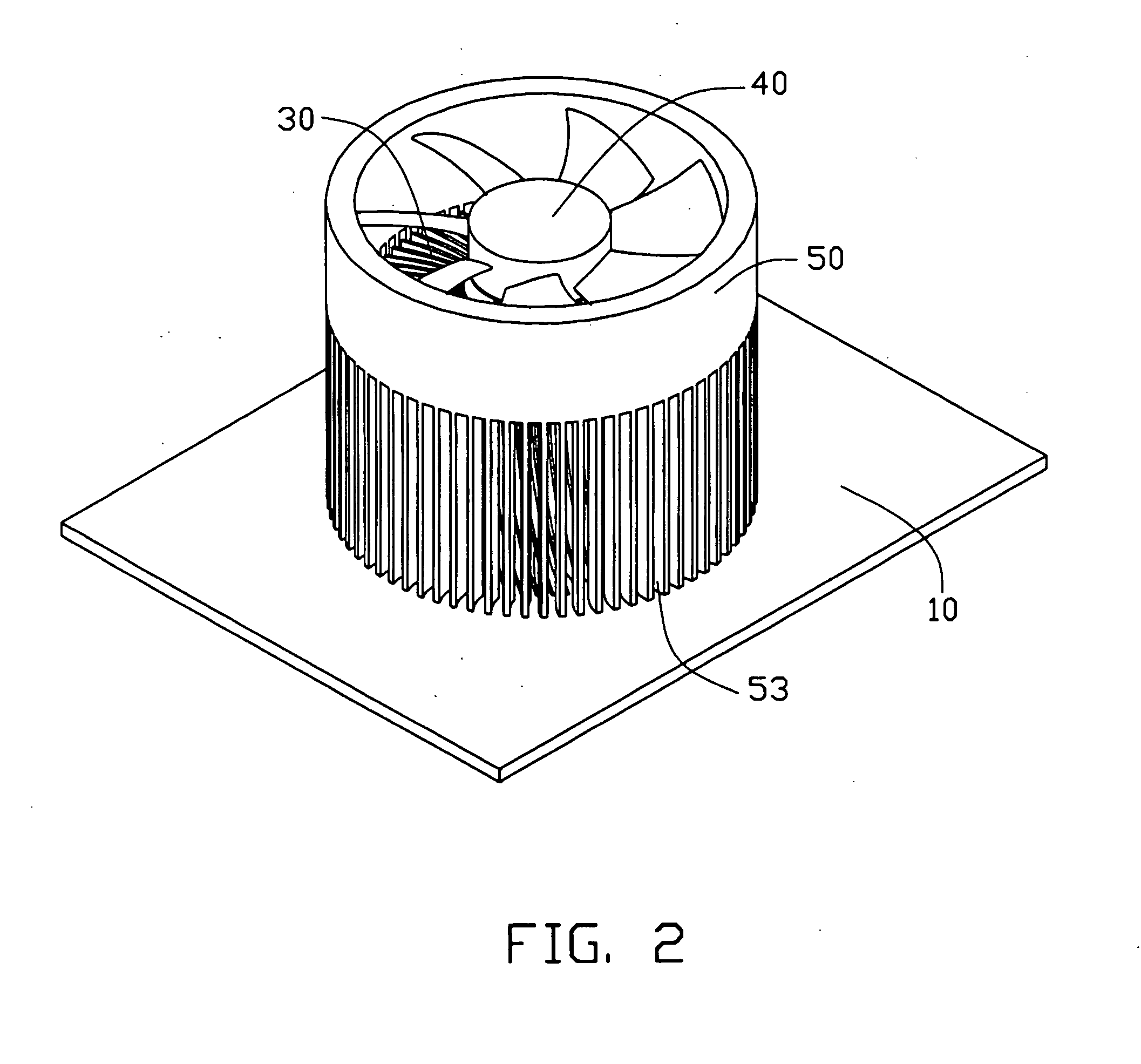

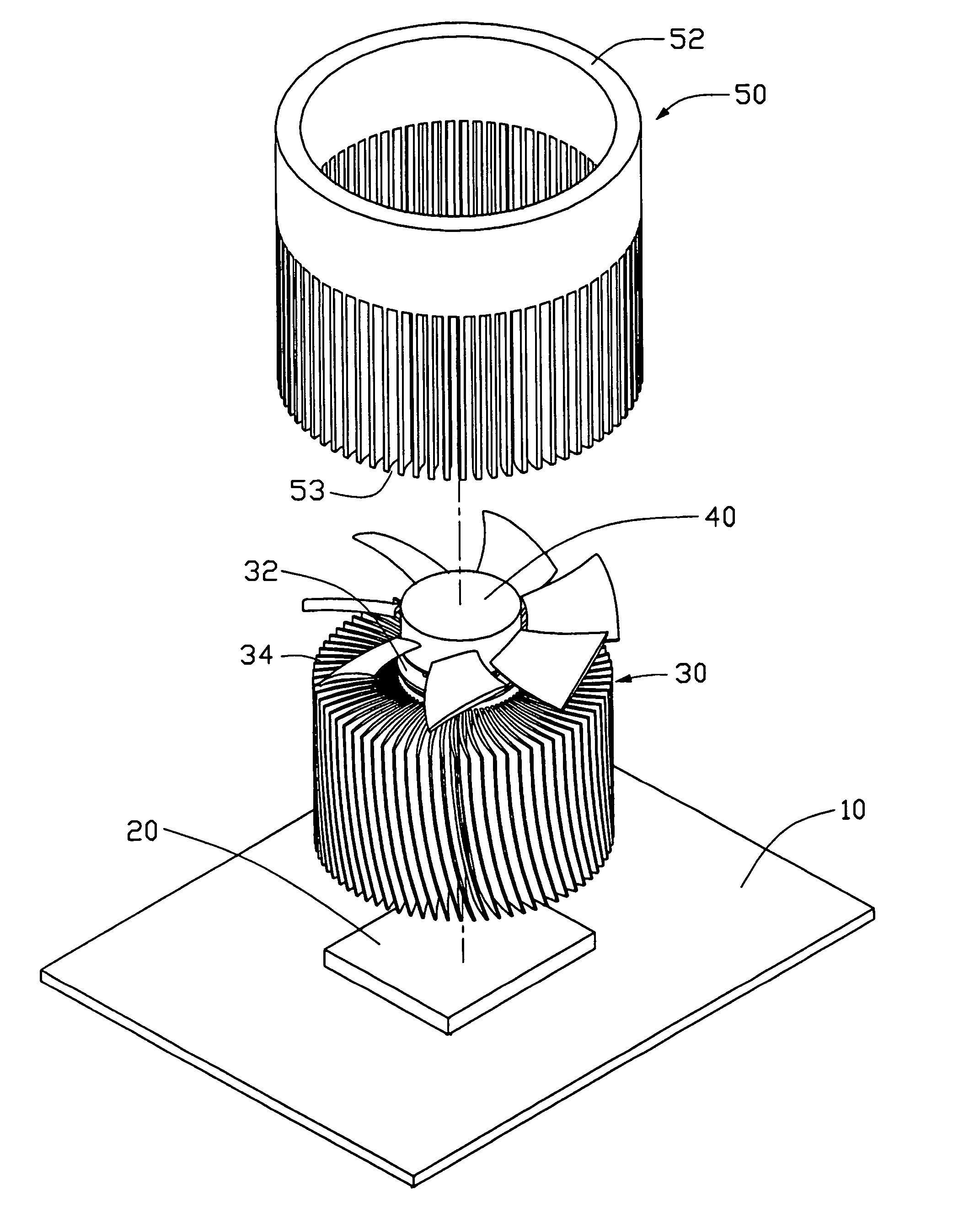

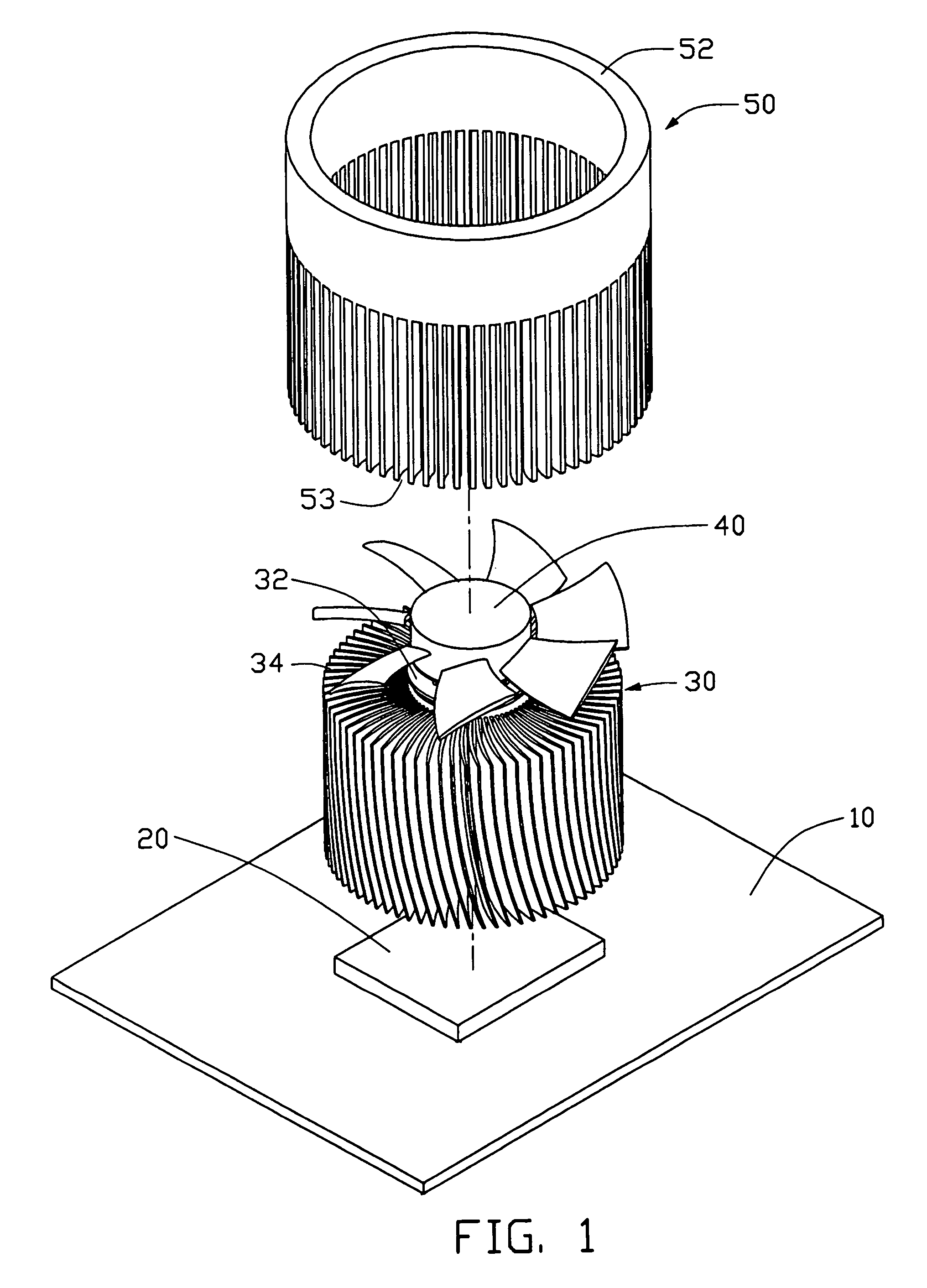

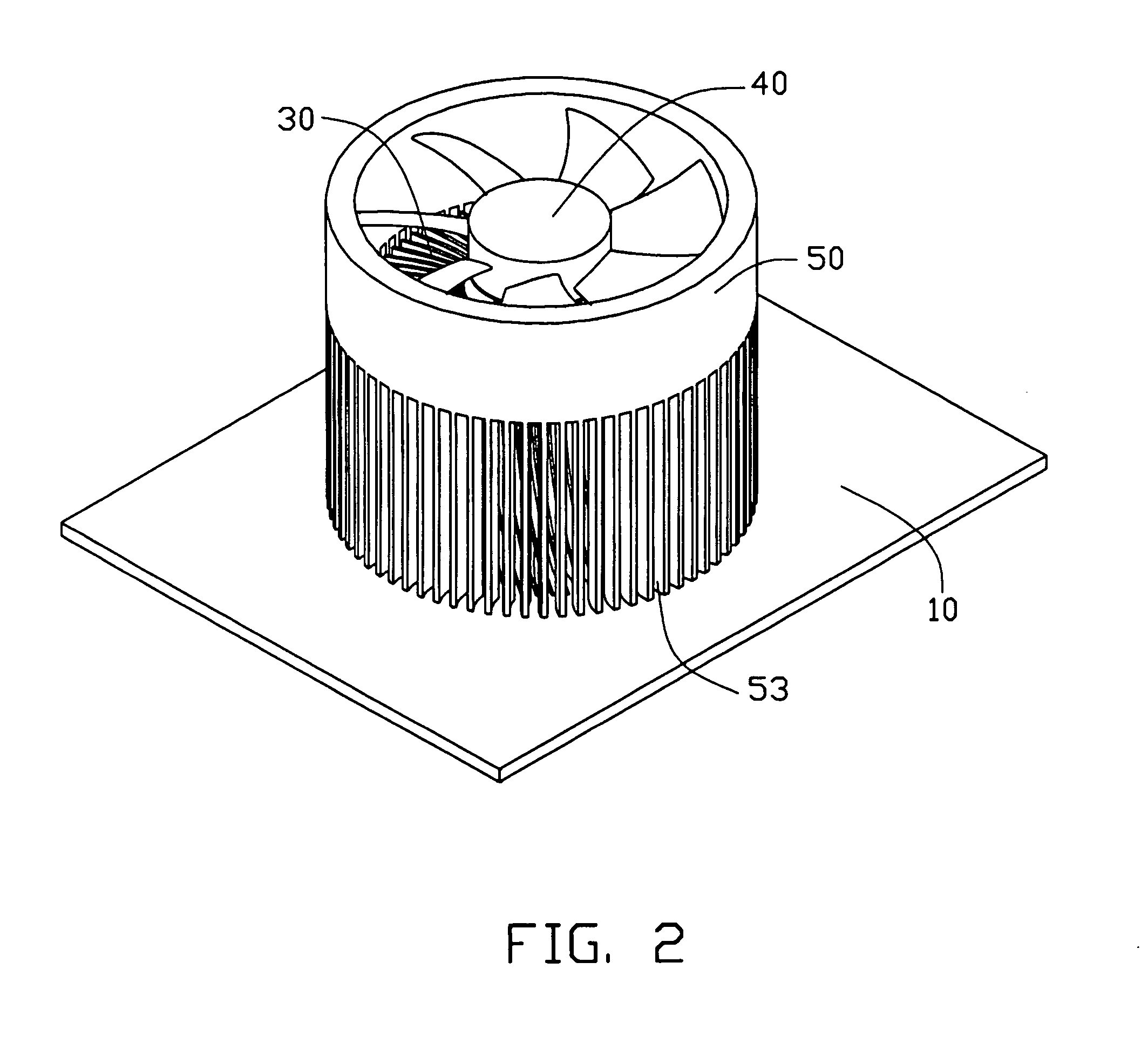

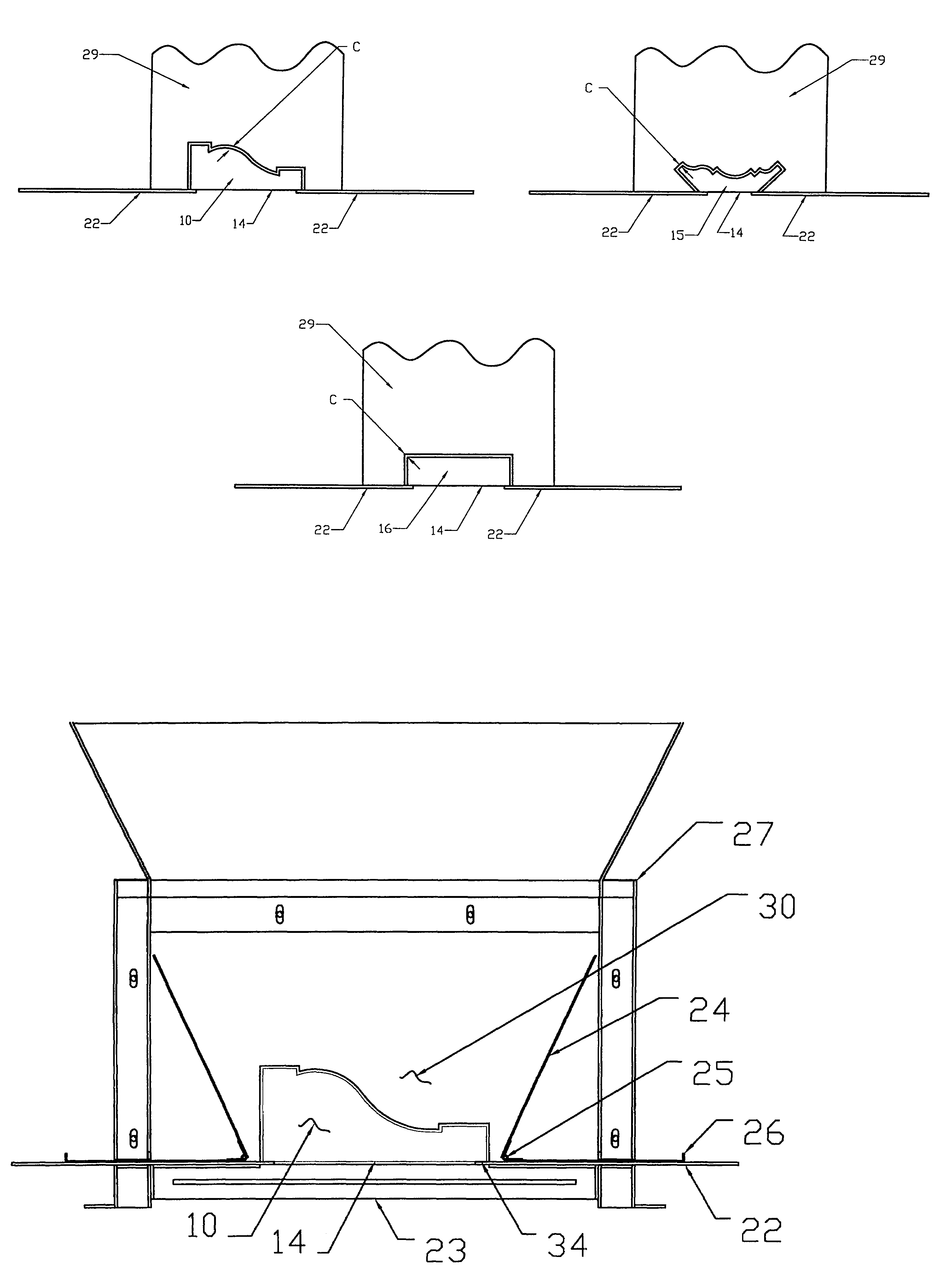

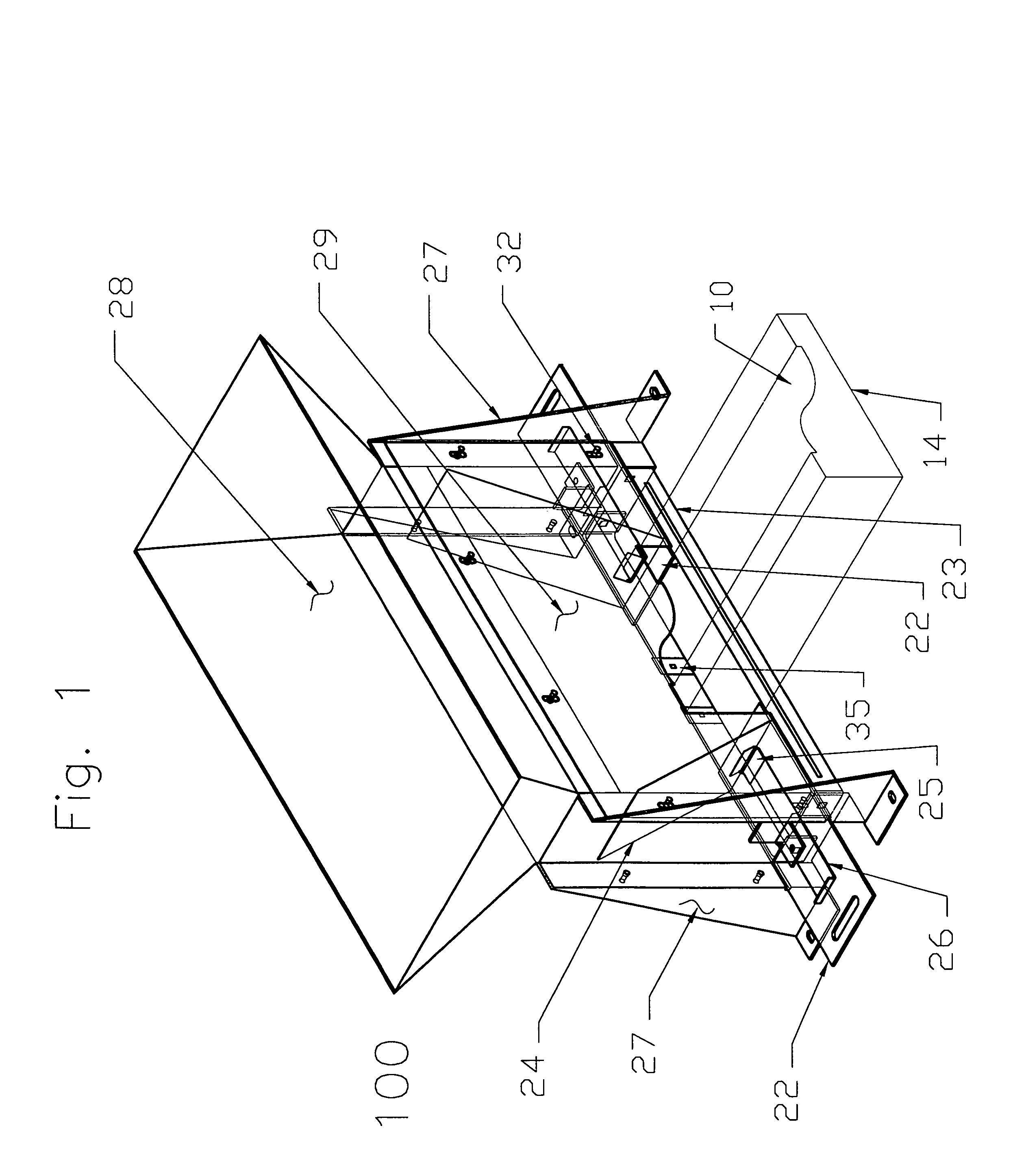

Heat dissipation device assembly with fan cover

InactiveUS20050269060A1Eliminate dead spaceImprove cooling effectDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat spreader

A heat dissipation device assembly comprises a heat sink having a columniform conductive core and a plurality of fins arranged radially around the conductive core, a columnar fan cover housing the heat sink and defining a first open end and a second open end, and a fan located at the second open end of the fan cover. Pluralities of channels are formed between the radiation fins. A plurality of elongated slot surrounding the heat sink is defined in the fan cover and extends from the first open end of the fan cover to the second open end. The airflow provided by the fan travels through the channels and the slots to outside of the fan cover.

Owner:HON HAI PRECISION IND CO LTD

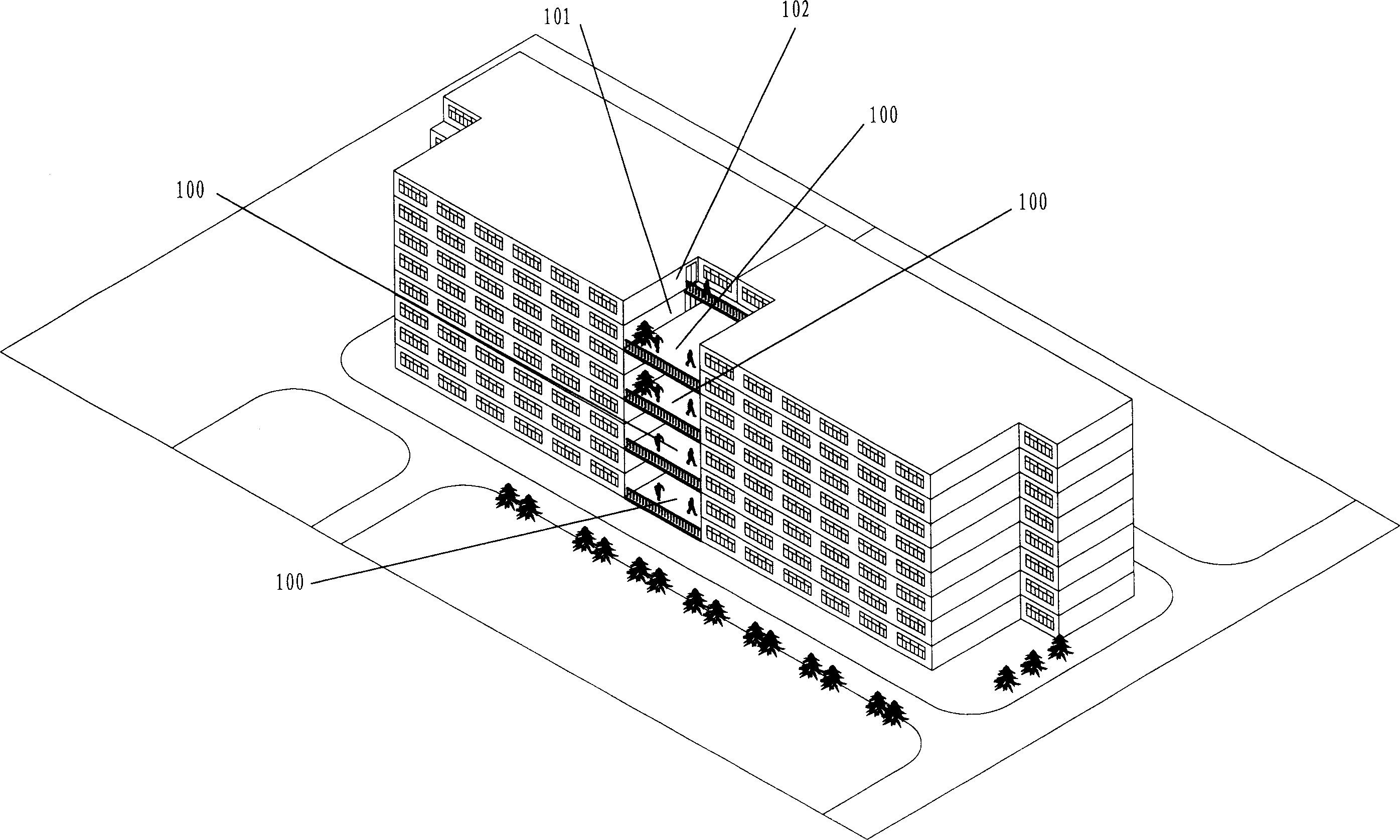

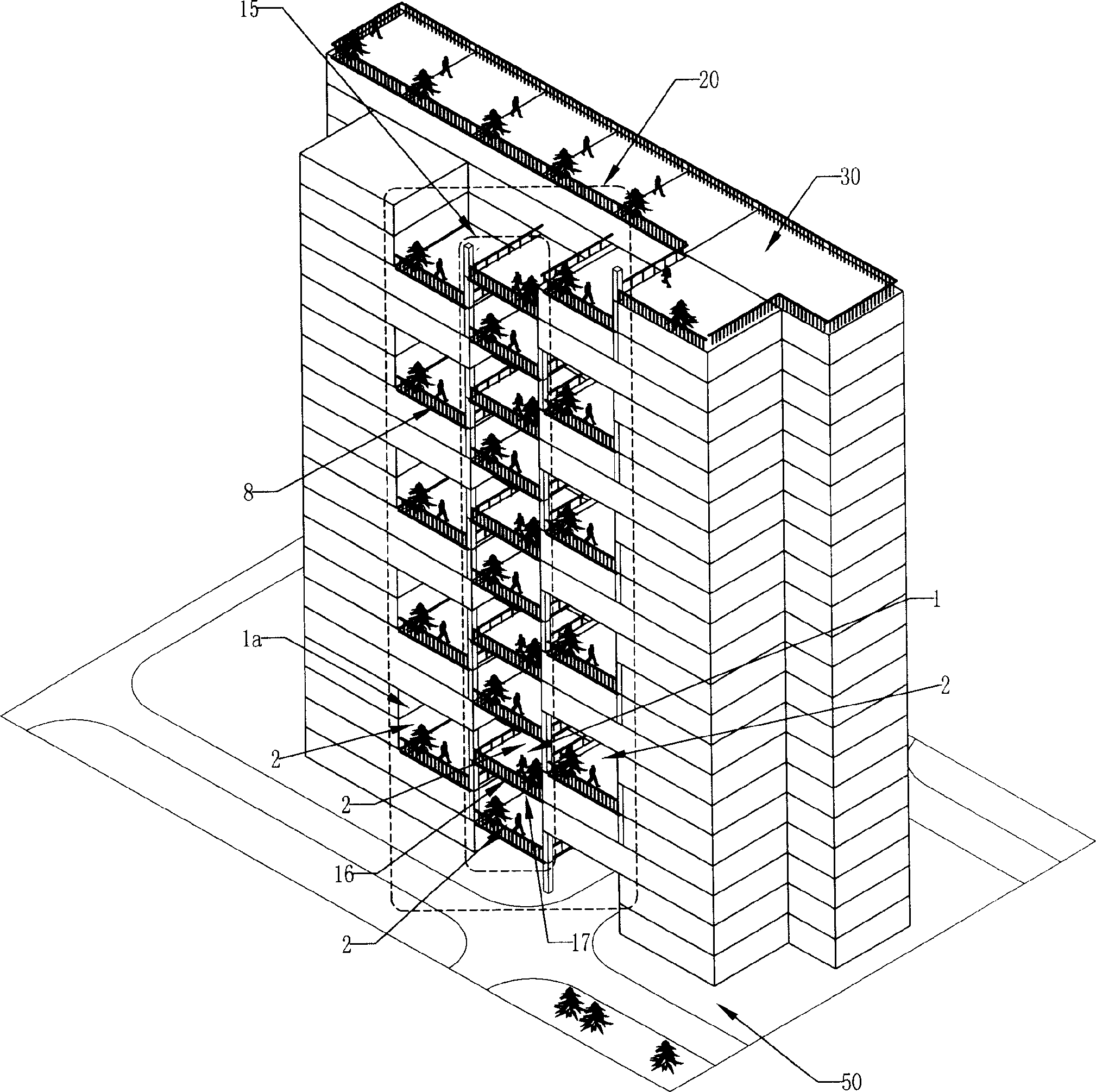

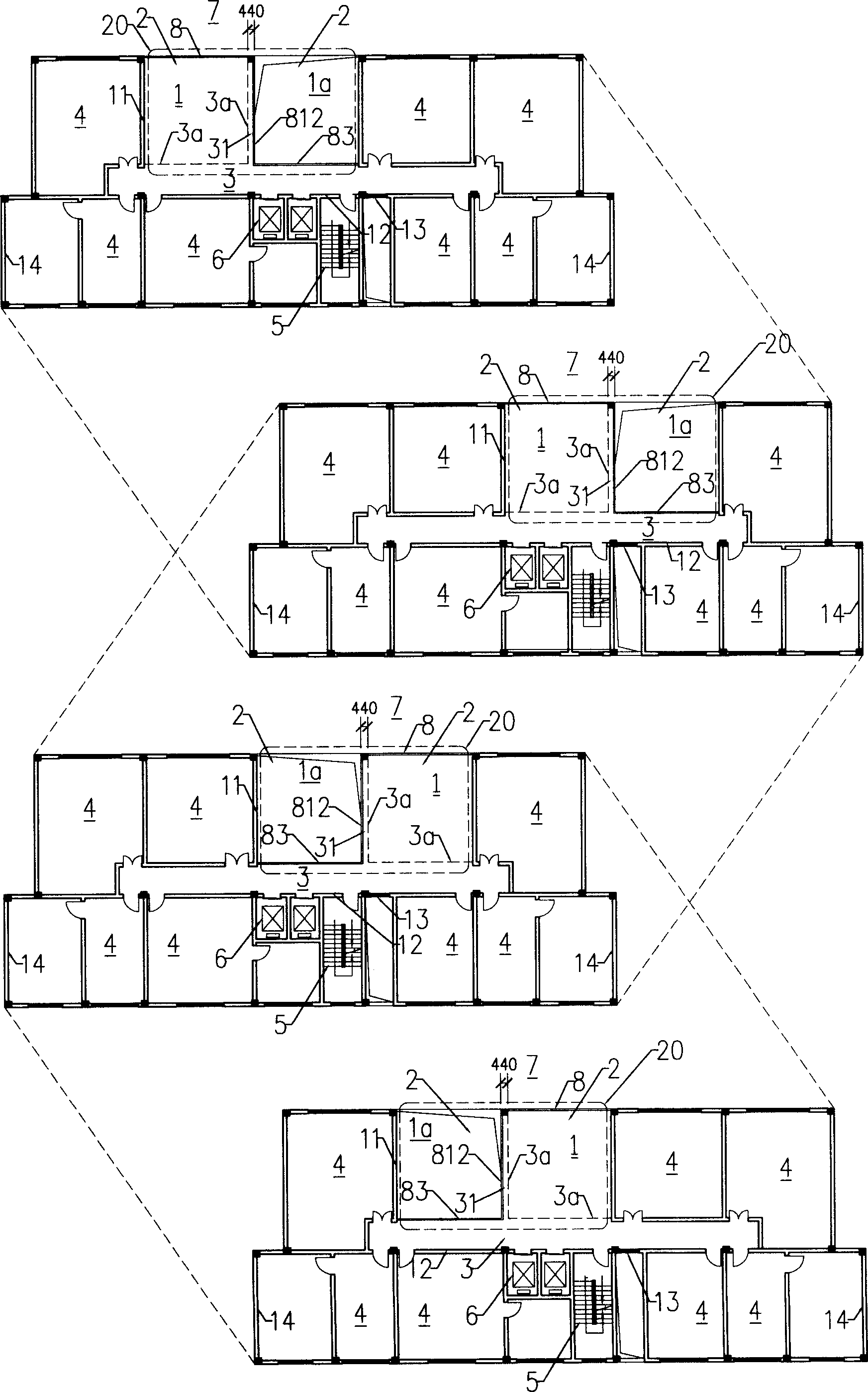

Multistory building

Owner:郭建军

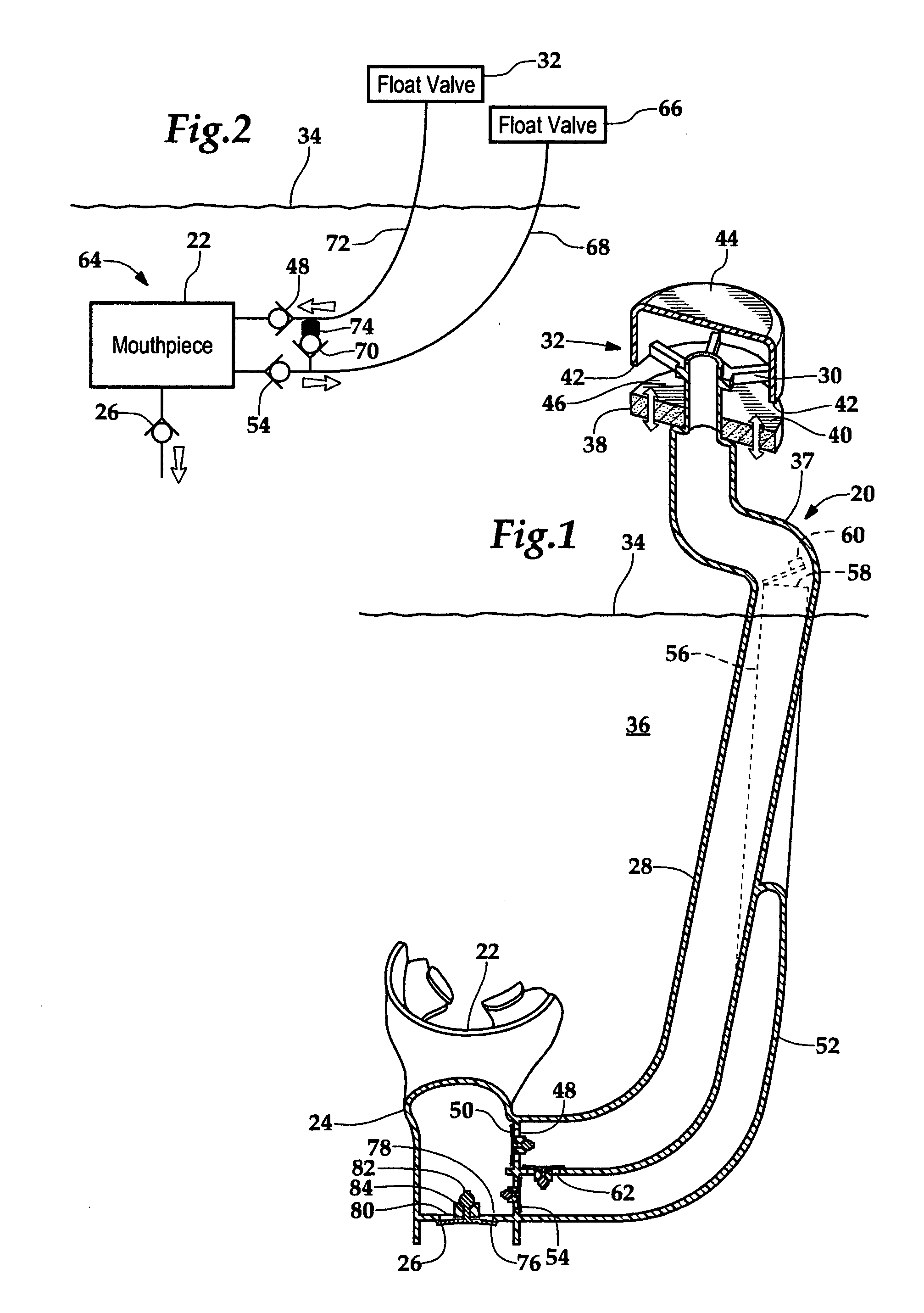

Low physiological deadspace snorkel

InactiveUS20060102176A1Eliminate the problemEliminates the dead airspaceBreathing masksUnderwater equipmentInhalationIntensive care medicine

A snorkel has an inhalation tube and a check valve near a mouthpiece which allows air to flow toward the mouthpiece, and a float valve which closes the inhalation tube. An exhalation tube has a second check valve also located near the mouthpiece which only allows air to flow into the exhalation tube. The snorkel has a purge valve positioned below the mouthpiece. A further check valve is positioned between the inhalation tube and the exhalation tube to allow air or water in the exhalation tube to pass to the inhalation tube placed as close to the first check valve as possible. The exhalation tube outlet orifice may be closed by a simple gravity actuated valve which will float open during a dive. Alternatively the exhalation tube outlet orifice may be closed by a float valve.

Owner:JUNCK MARLIN

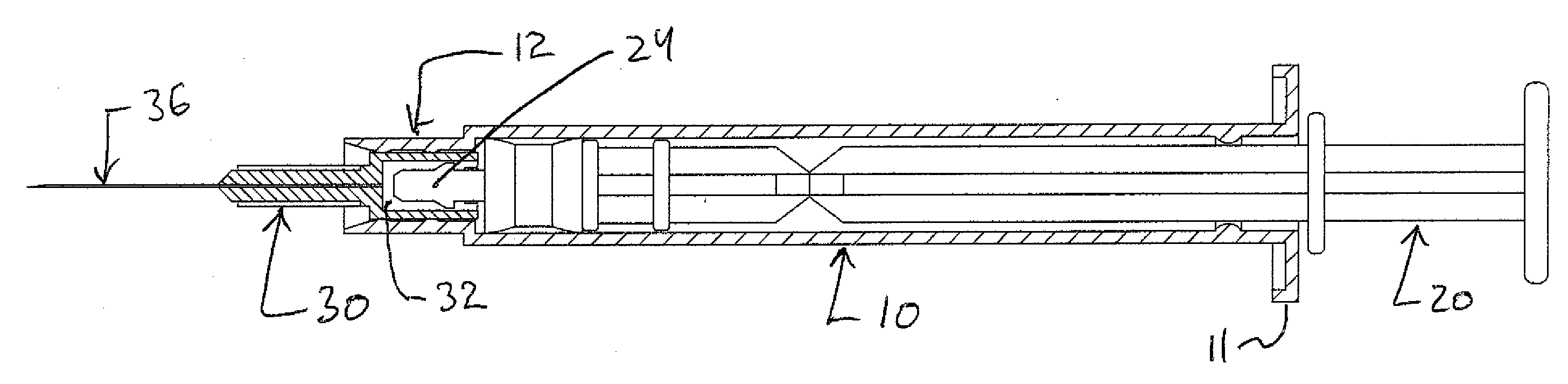

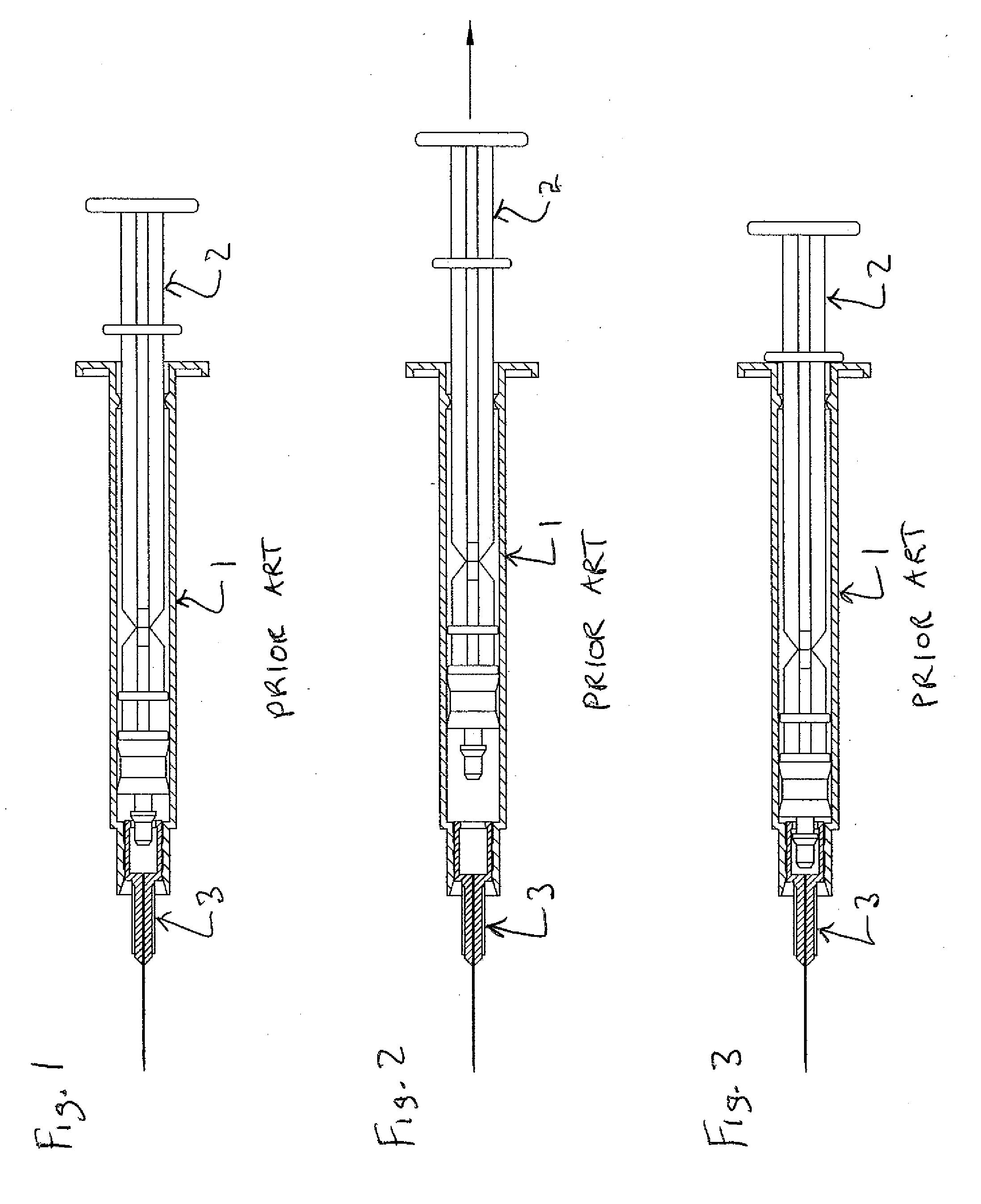

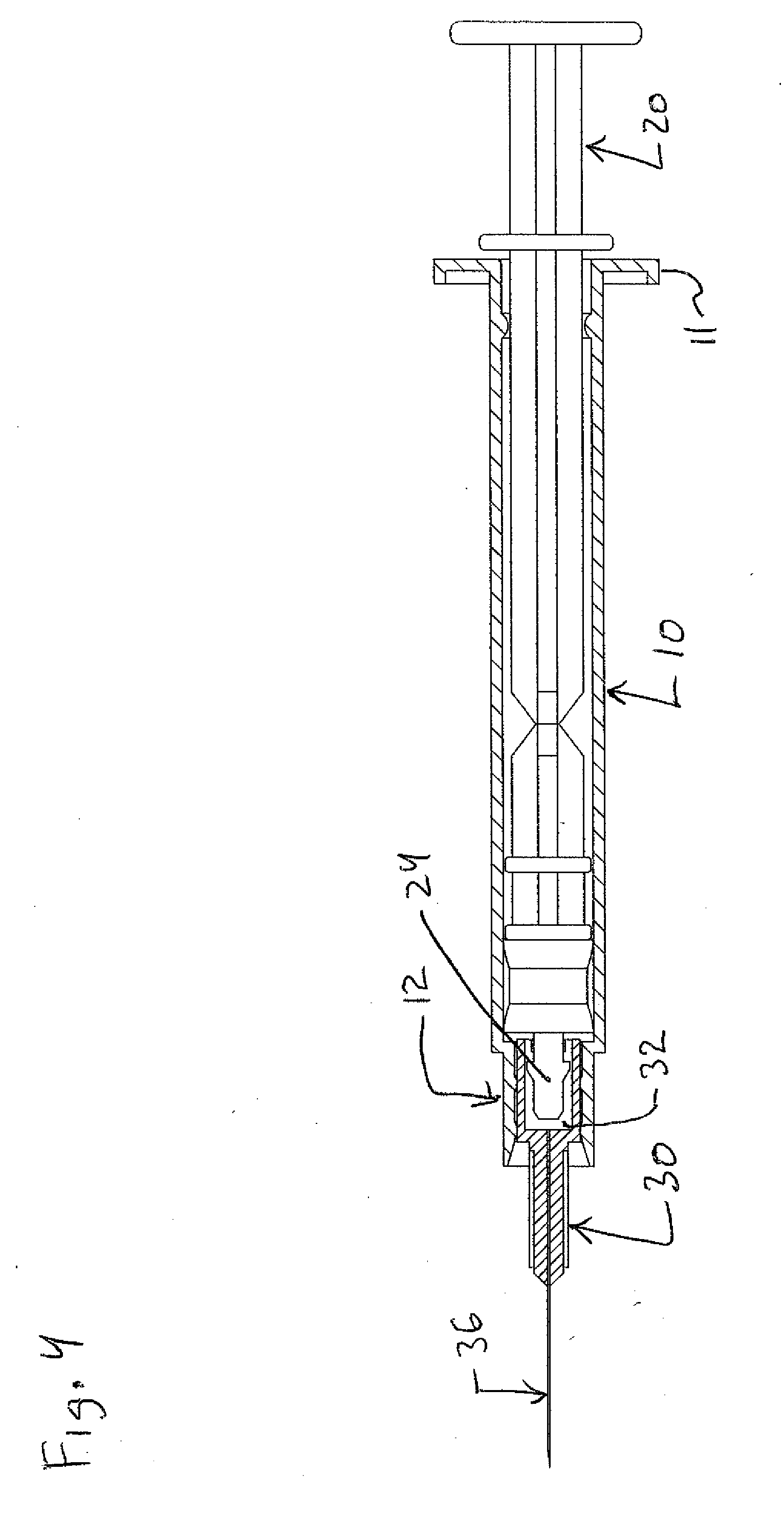

Syringe with retractable needle support

InactiveUS20080154212A1Easily and simply retractedAvoid possibilityIntravenous devicesEngineeringSyringe needle

An injection device includes a barrel, a plunger having a portion structured and arranged to move within the barrel, a needle support, and a locking arrangement. The locking arrangement may at least one of selectively lock a proximal end portion of the plunger to the needle support and automatically lock a proximal end portion of the plunger to an outer portion of the needle support. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:STAT MEDICAL DEVICES

Blocking type intravenous infusion catheter device

PendingCN108578825AEliminates the risk of thrombosisEliminate dead spaceMedical devicesHaemostasis valvesInfusion catheterIntravenous Infusions

The invention provides a blocking type intravenous infusion catheter device which comprises a rigid needle tube, a needle tube base, a flexible infusion catheter and an infusion catheter base, whereinthe rigid needle tube is used for piercing skin and vein walls; the bottom end of the needle tube is fixed in the needle tube base; the infusion catheter base is hermetically connected with the bottom end of the infusion catheter; the front end of the needle tube penetrates through a sealing plug and is positioned in the inner cavity of the infusion catheter; and the tip of the needle tube is exposed from an opening in the top end of the infusion catheter. The blocking type intravenous infusion catheter device is characterized by also comprising a movable blocking component which is externally isolated, at least the blocking part of the blocking component can enter the inner cavity of the infusion catheter through the inner cavity of the infusion catheter base under the driving of the external force, and the blocking part of the blocking component can move to the opening in the top end of the infusion catheter along the inner cavity of the infusion catheter and block the opening so asto prevent the blood from entering the inner cavity of the infusion catheter and simultaneously prevent the liquid medicine from entering veins.

Owner:ZHEJIANG BAIHUO HEALTH TECH CO LTD

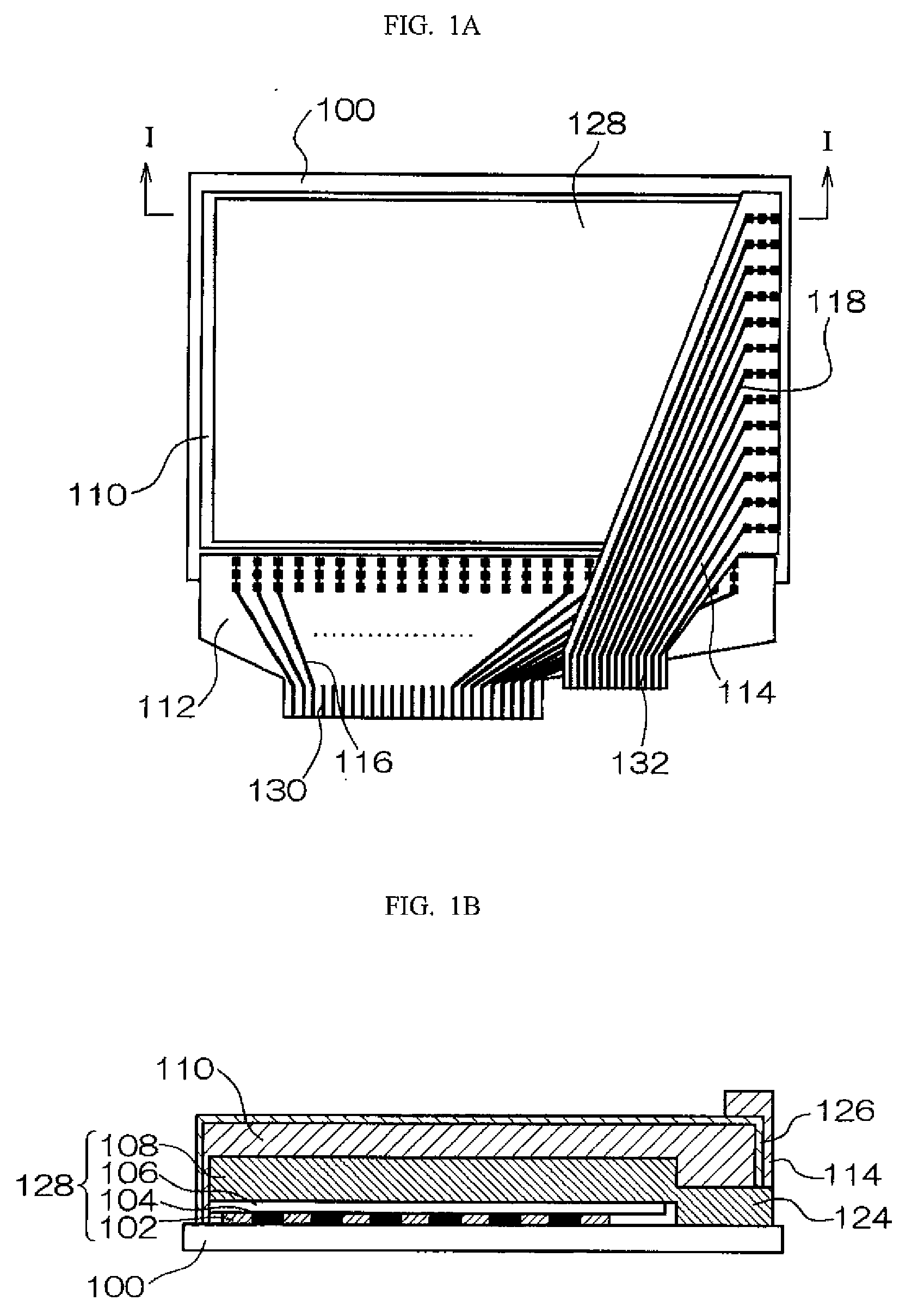

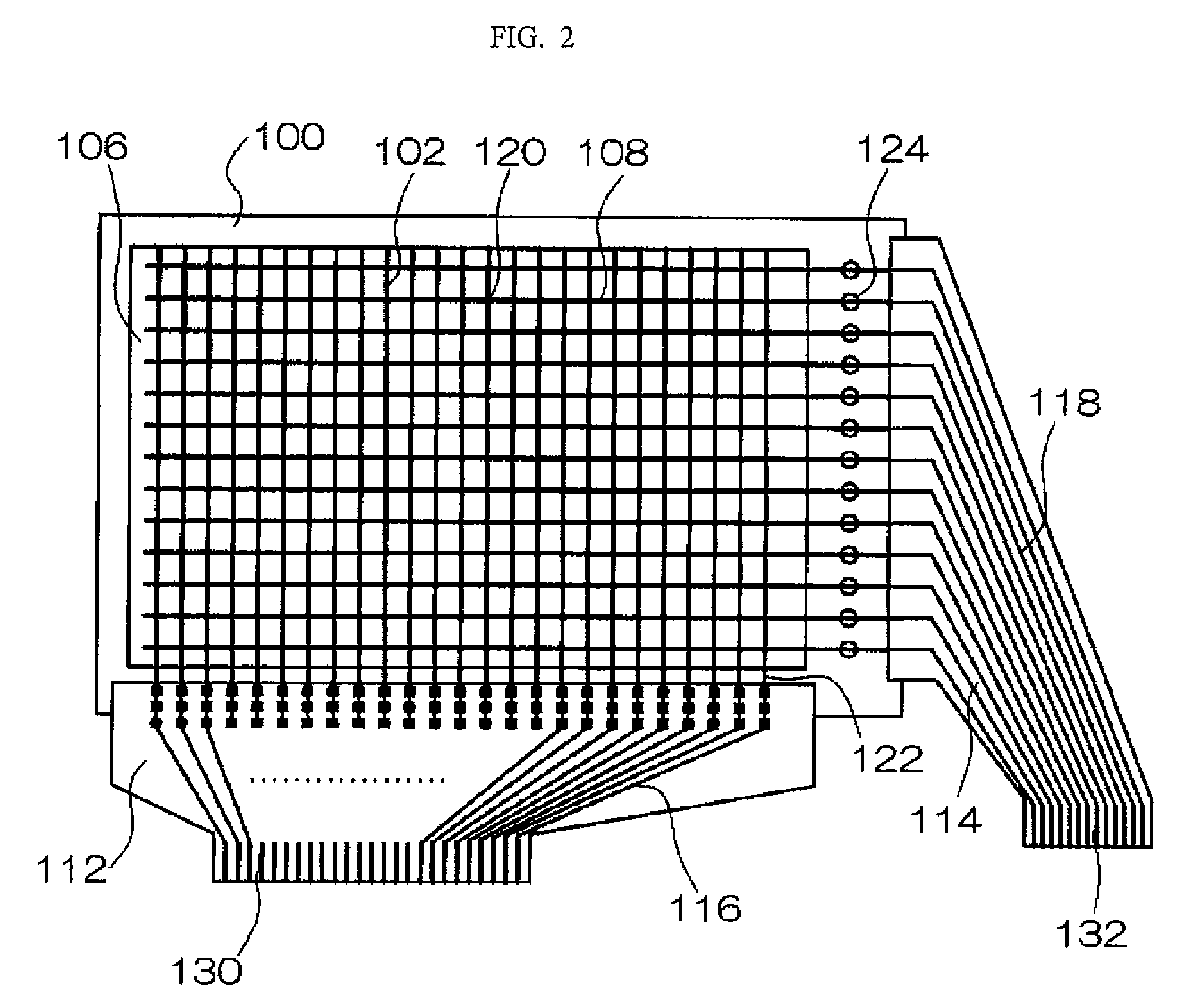

Display device

ActiveUS20080137275A1Eliminate dead spaceReduce dead spaceDischarge tube luminescnet screensDigital data processing detailsEngineeringDisplay device

The invention provides a display device including: a first electrode and a second electrode which are disposed in different directions from each other on a flexible substrate; an optical functional layer disposed between the first and second electrodes; and a display unit having a display pixel formed at a rectangular area of overlap between the first and second electrodes in the direction of lamination of the electrodes, in which the first and second electrodes are respectively connected to a first flexible wiring member at a first region of a periphery of the flexible substrate and a second flexible wiring member at a second region adjacent to the first region, one of the first and second flexible wiring members is adhered onto the display unit, and a first connection portion and a second connection portion for connecting the flexible wiring members with external drive units are disposed at the same region on the periphery of the flexible substrate.

Owner:UDC IRELAND

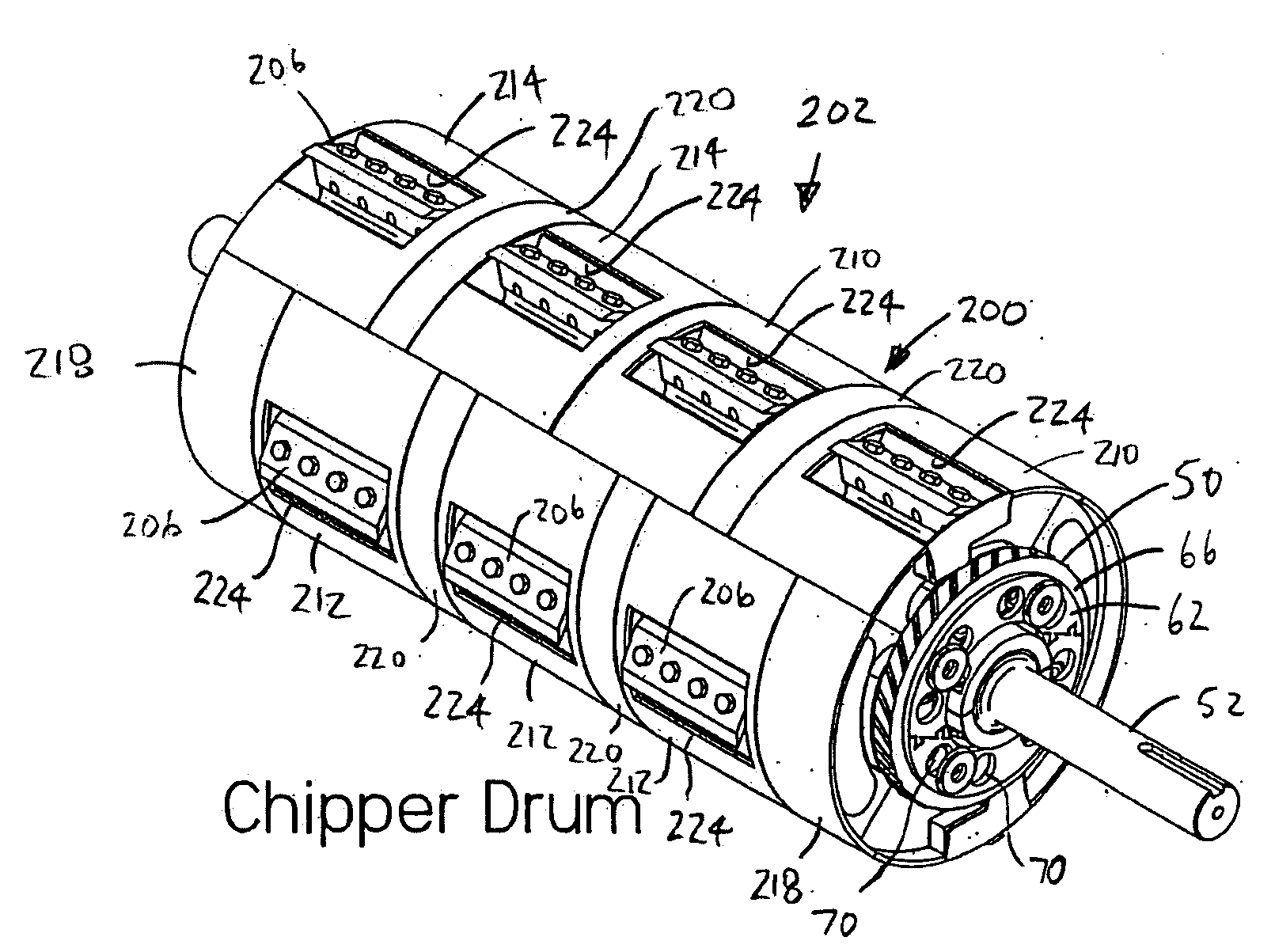

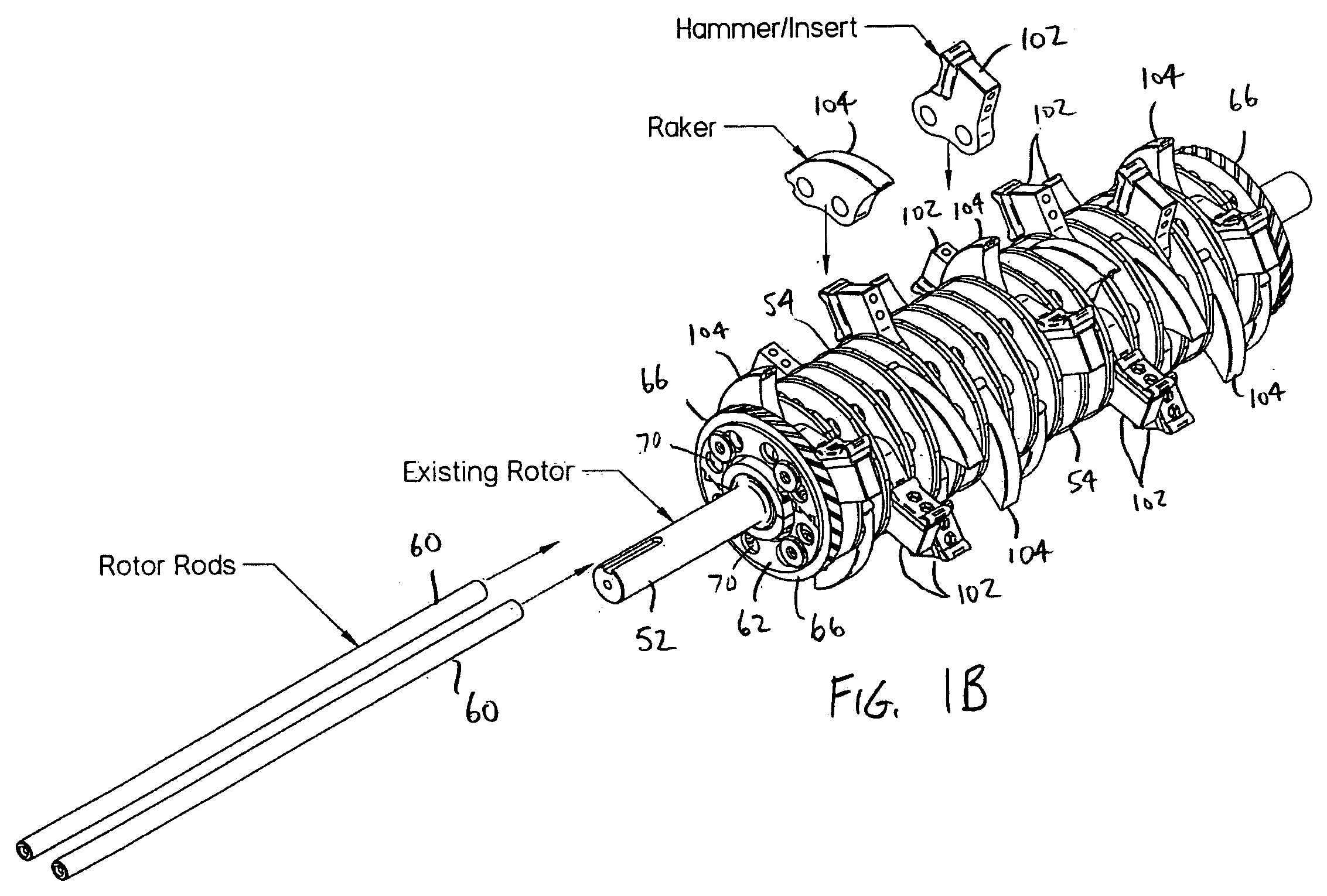

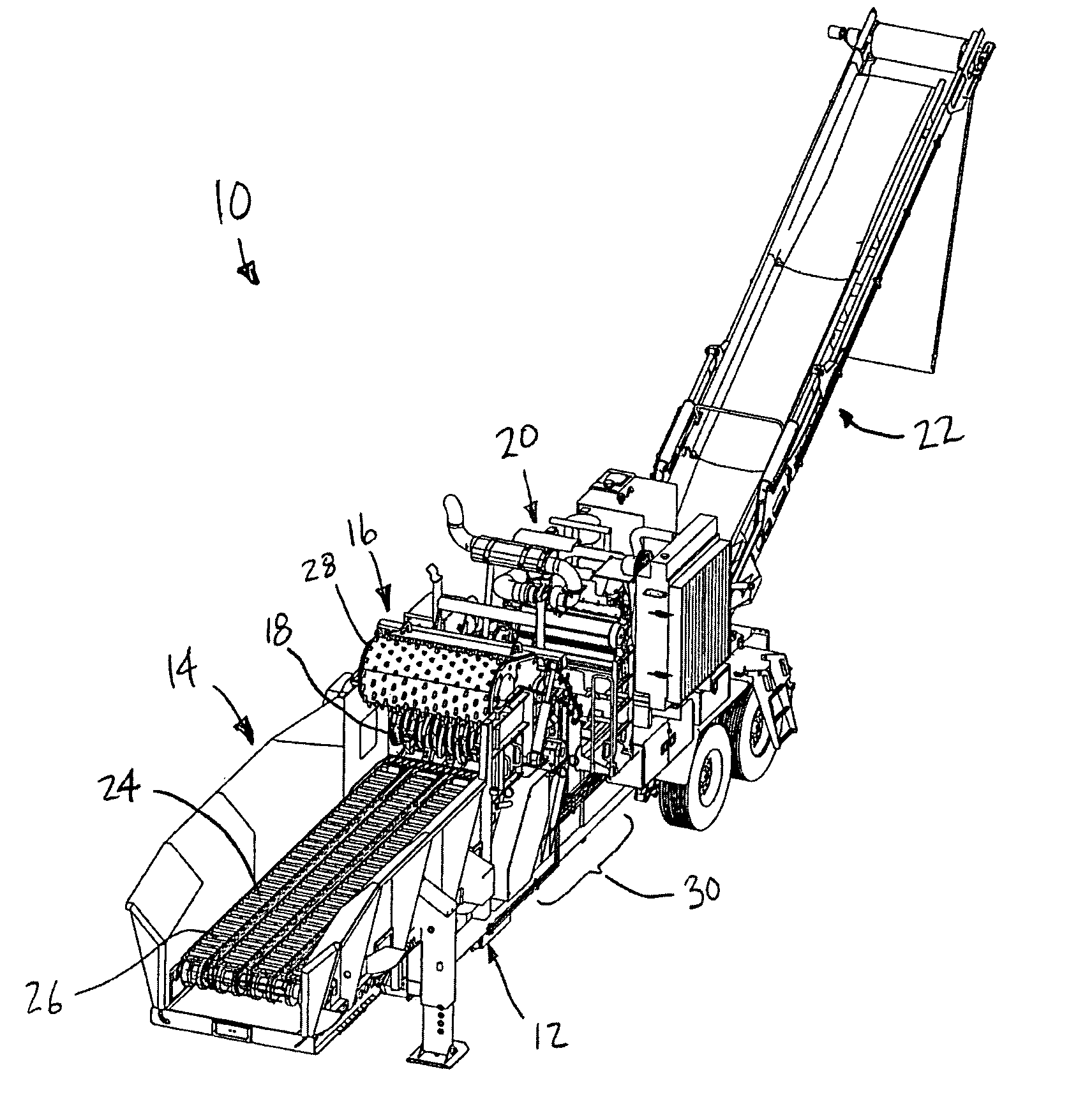

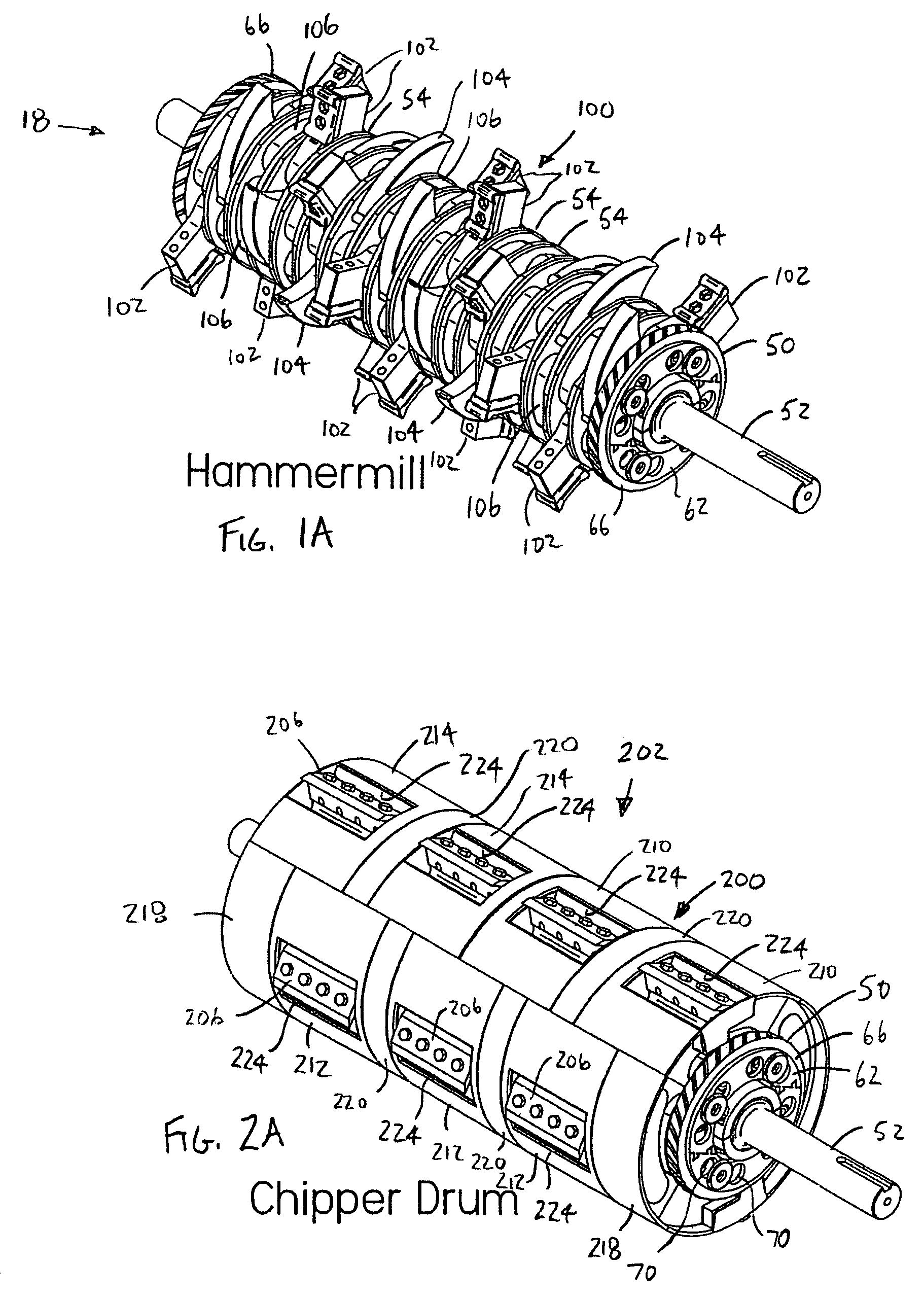

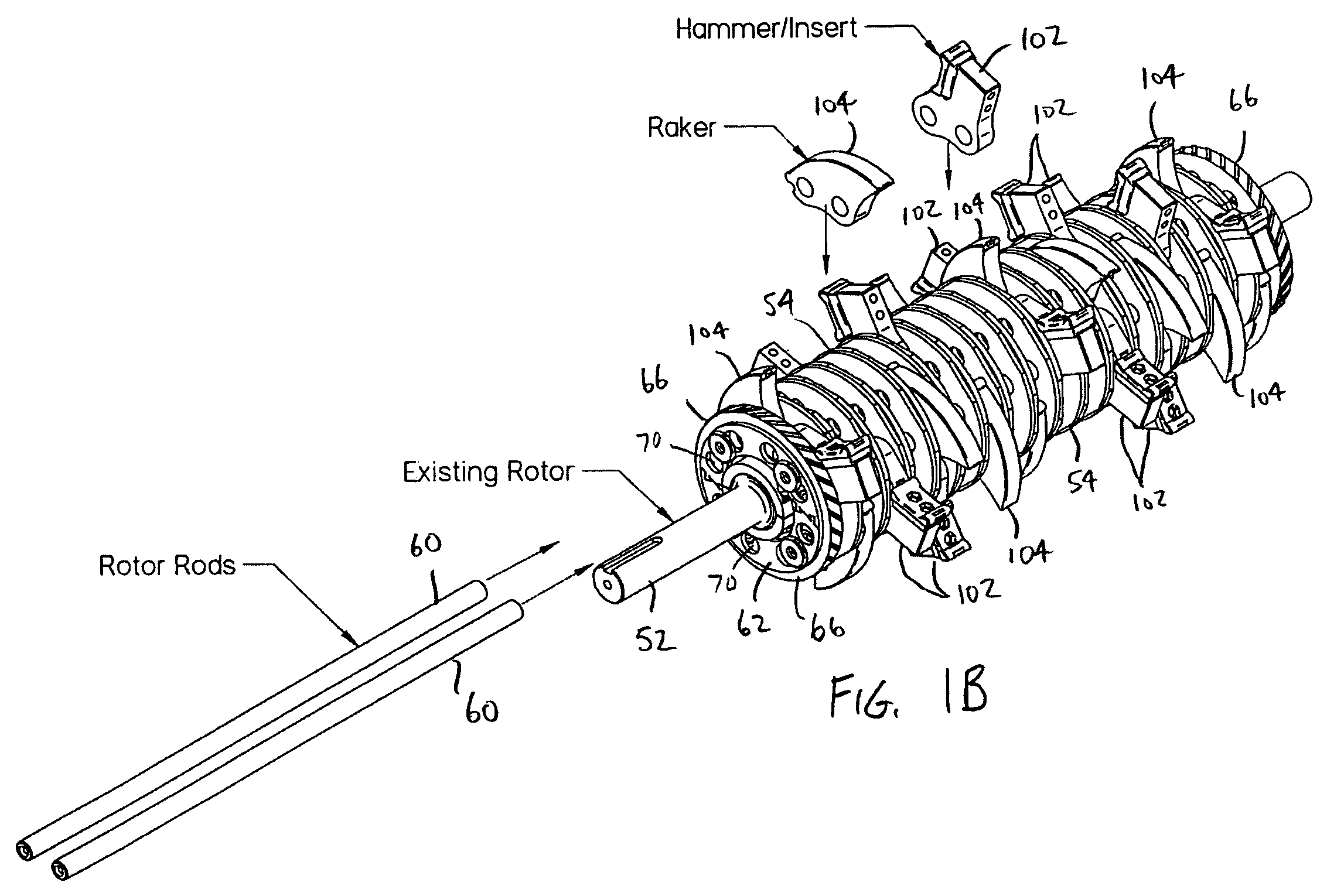

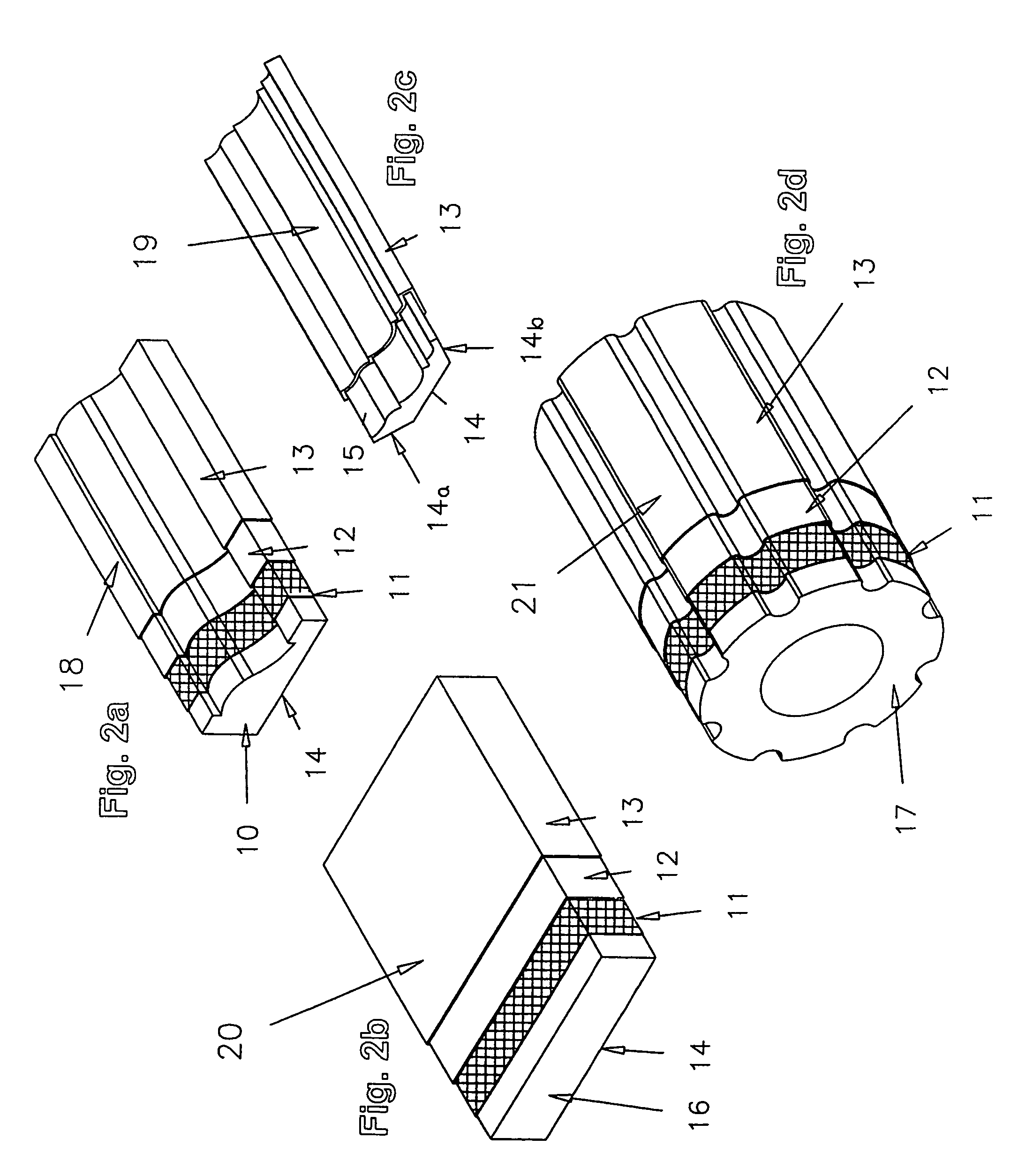

Interchangable chipper inserts for wood grinder

ActiveUS20100206973A1Facilitate quick and easy reversing and replacementEasy to installMetal sawing devicesShearing machinesWood grinderKnife blades

A plurality of chipper inserts that may be installed on a hammermill rotor in place of the hammer inserts to selectively convert the rotor to a chipper. The chipper inserts include drum surfaces that cooperatively define a chipper drum. The chipper inserts may include cutter inserts that have a cutter disposed in a cutter pocket. The chipper drum may be a generally continuous cylindrical interrupted essentially only by the cutter pockets. The cutters and cutter pockets may be positioned in essentially any desired pattern around the drum. The chipper inserts may include a left cutter insert, a center cutter insert, a right cutter insert and three different size spacer inserts. The different types of cutter inserts and spacer inserts may be installed about the rotor with at least one left cutter insert mounted on the left end of the chipper drum and at least one right cutter insert mounted on the right end of the chipper drum. The chipper inserts may be configured in quadrant sections, such that it takes four inserts to extend around the rotor.

Owner:ALAMO GROUP

Interchangable chipper inserts for wood grinder

ActiveUS8061640B2Facilitate quick and easy reversing and replacementEasy to installMetal sawing devicesShearing machinesWood grinderEngineering

Owner:ALAMO GROUP

Food delivery apparatus and method of use

InactiveUS20060246187A1Eliminate dead spaceAvoid problemsReady-for-oven doughsLiquid surface applicatorsFood deliveryEngineering

A food delivery apparatus that includes a container having a nozzle and a moveable bottom opposite the nozzle, a food product held within the container, and an applicator used to move the bottom toward the nozzle. A method of dispensing the food product from the container including positioning the nozzle to the mouth of a user and engaging the applicator to dispense the food product through the nozzle of the container. The method also including the step of placing a removable tip upon the nozzle to protect the nozzle from contaminates. A kit for delivering food product to the user including a container having a nozzle upon a first end and an opening at a second end, a food product to be placed into the container, and a bottom for fitting within the container.

Owner:EGOLF VINCENT S +1

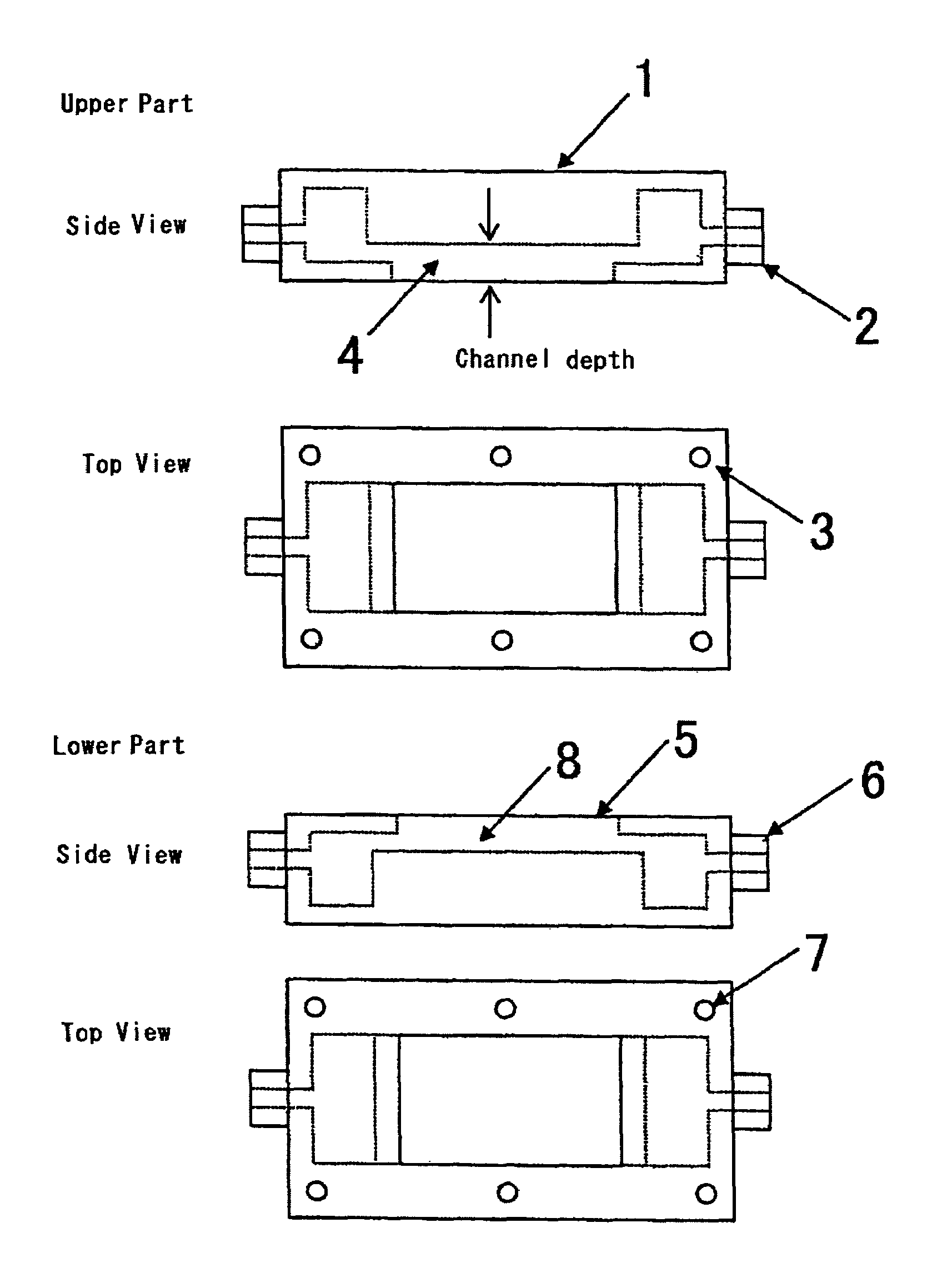

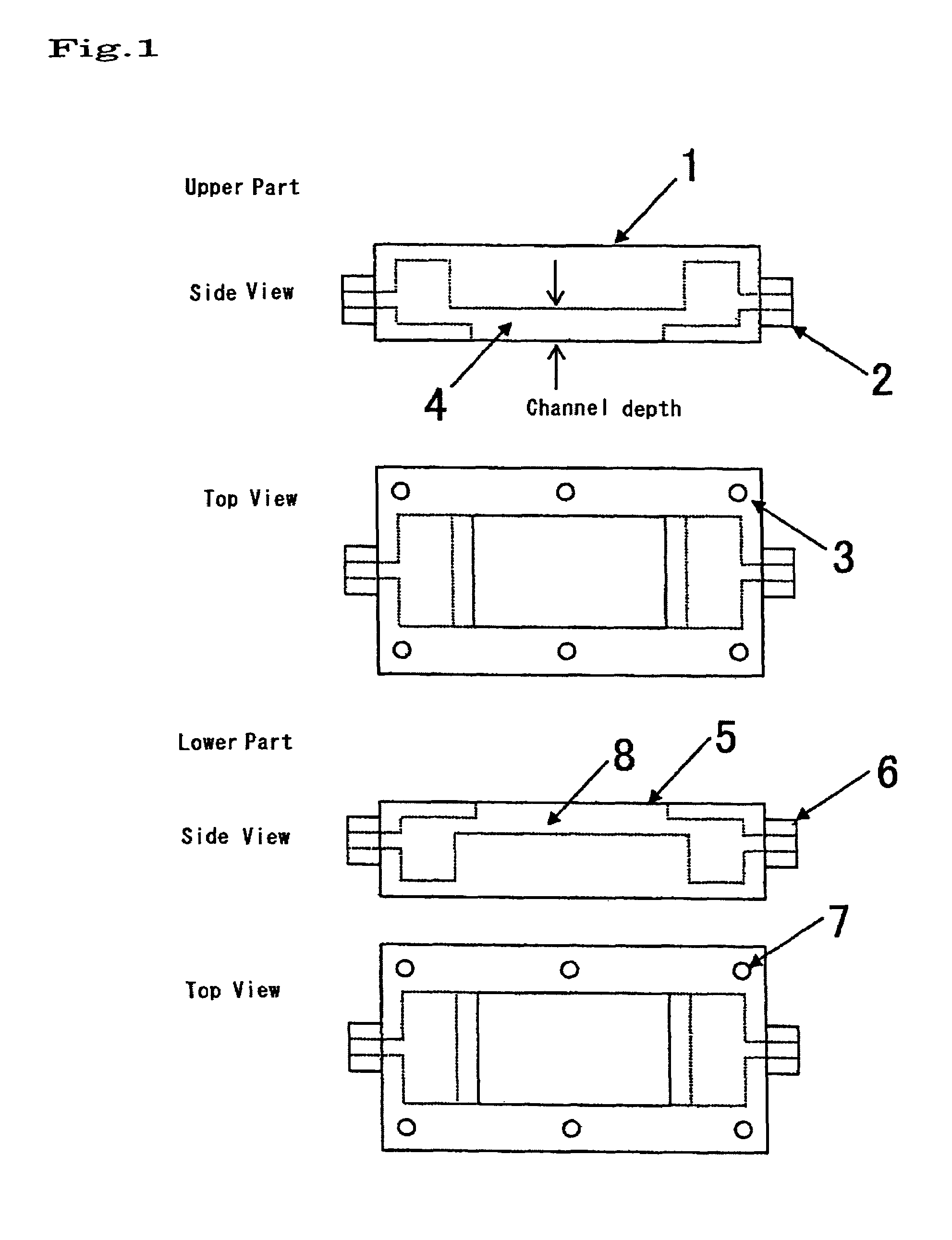

Device and method for culturing cells

ActiveUS7358082B2Inhibition releaseEliminate dead spaceBioreactor/fermenter combinationsBiological substance pretreatmentsCulture cellBiology

Owner:FUJIFILM HLDG CORP +1

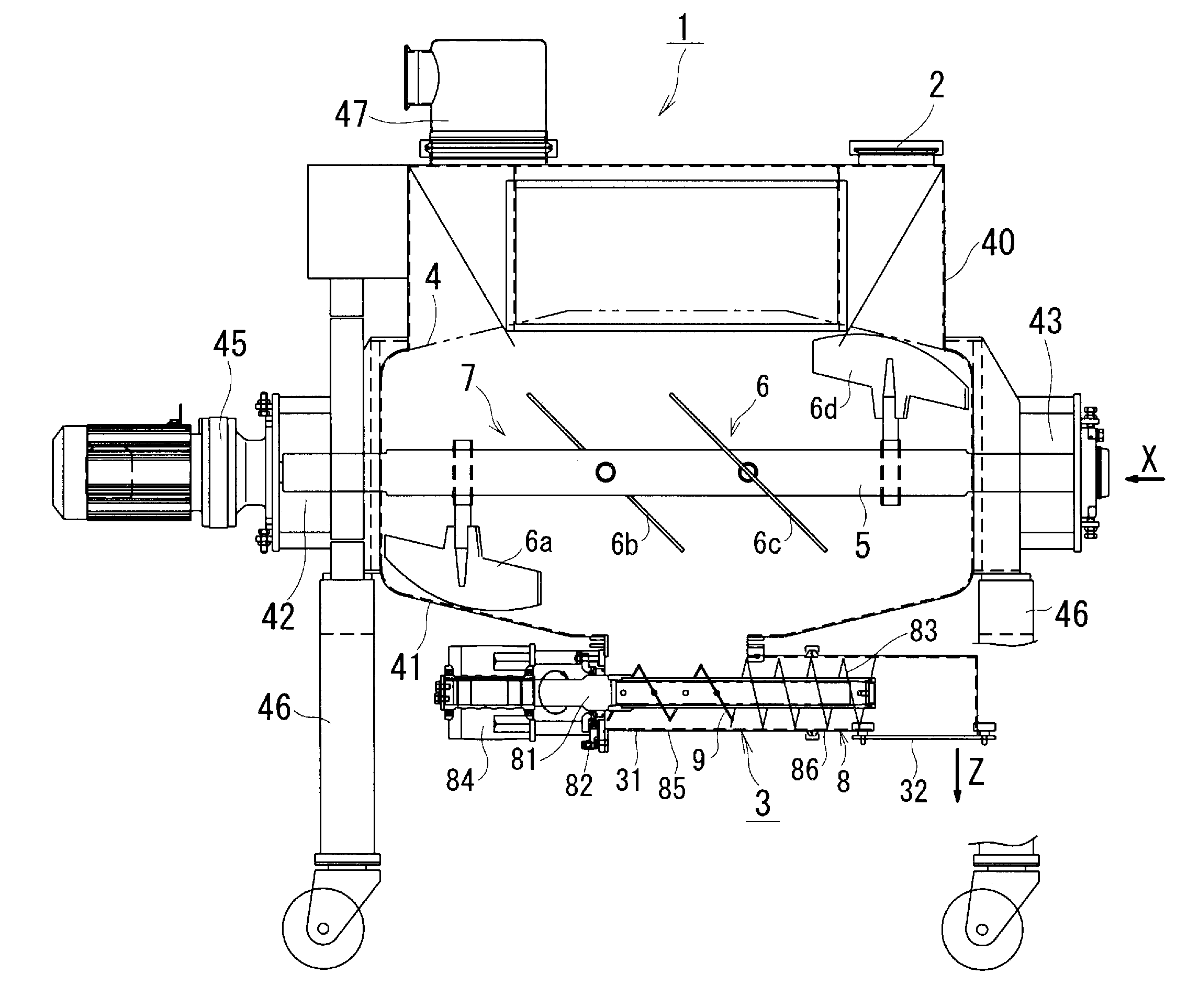

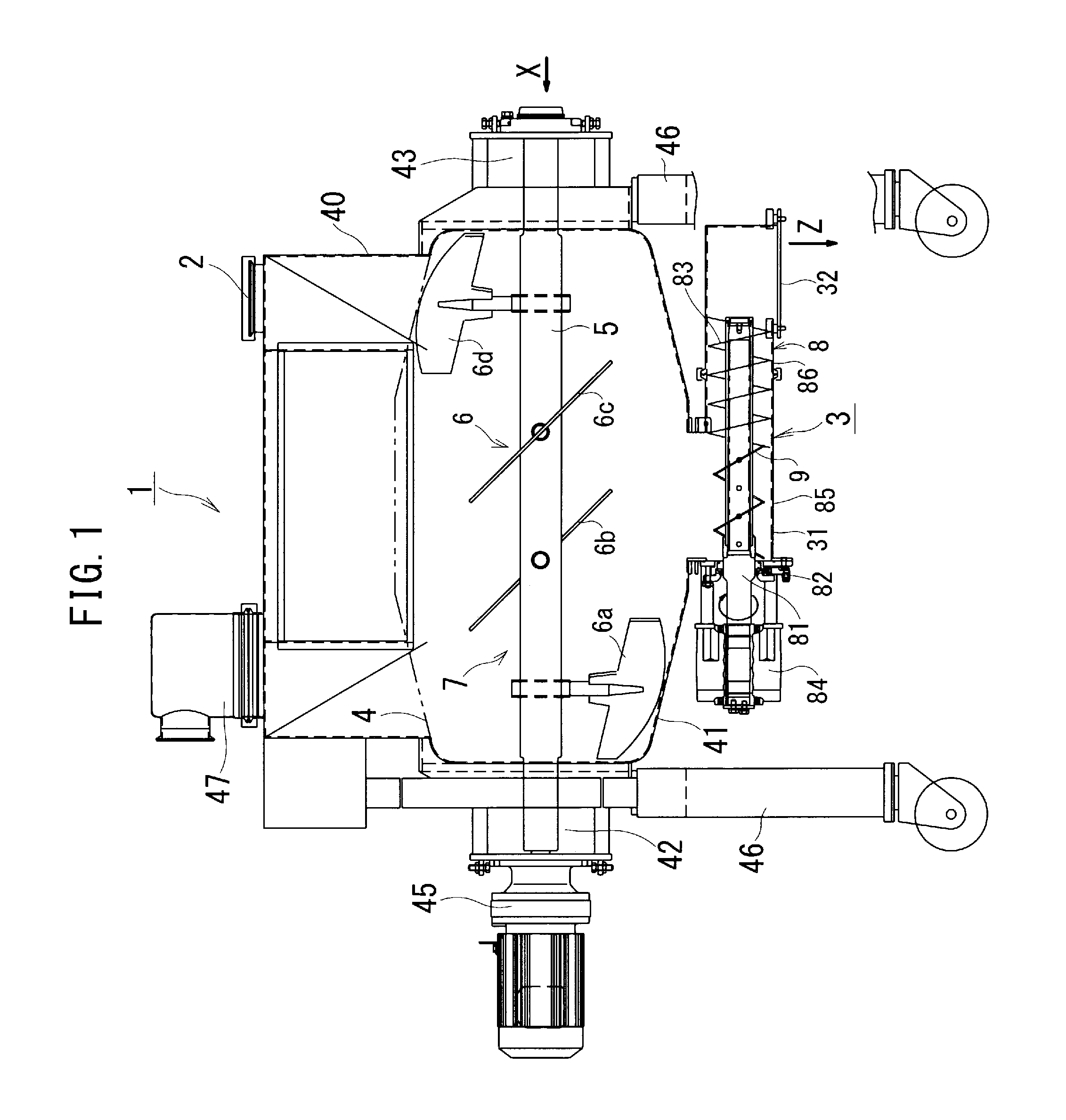

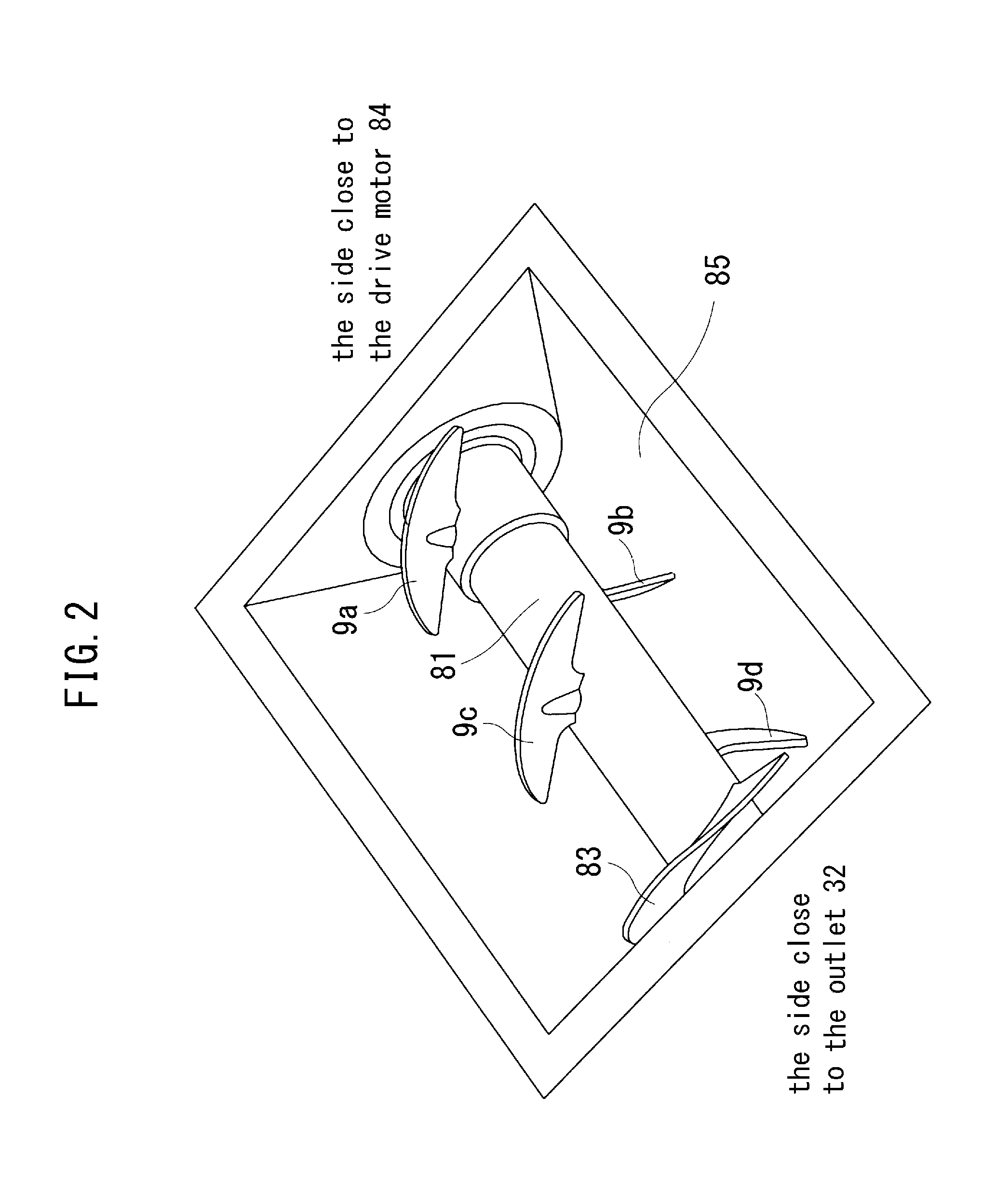

Powder/particulate material agitator

ActiveUS20110255364A1Simple processReduce manufacturing costRotary stirring mixersTransportation and packagingEngineeringParticulate material

An agitator 1 has a vessel 4 provided between an upper powder / particulate material supplier 2 and a lower powder / particulate material discharger 3 to hold therein powder / particulate material to be stirred. The agitator 1 also has a stirrer 7 provided in the vessel 4 to have a stirrer rotating shaft 5 arranged in a horizontal direction and main paddles 6 fastened to the rotating shaft 5, and a multi-feeder 8 provided in the powder / particulate material discharger 3 to have both forward rotation and reverse rotation. The multi-feeder 8 has a discharger rotating shaft 81 and small-size auxiliary paddles 9 integrally rotated with the rotating shaft 81 and designed to be smaller in size than the main paddles 6. In the state of stirring the powder / particulate material in the vessel 4 by means of the stirrer 7, the agitator 1 has stirring assist function during reverse rotation of the multi-feeder 8 to cause the auxiliary paddles 9 to stir up the powder / particulate material in the powder / particulate material discharger 3 and feed the powder / particulate material back into the vessel 4. The agitator 1 also has discharge function during forward rotation of the multi-feeder 8 to discharge the powder / particulate material out of the powder / particulate material discharger 3 and the vessel 4. This arrangement effectively prevents the powder / particulate material from being accumulated in any dead space, while reducing the total height of the powder / particulate material discharger of the agitator.

Owner:TSUKASA

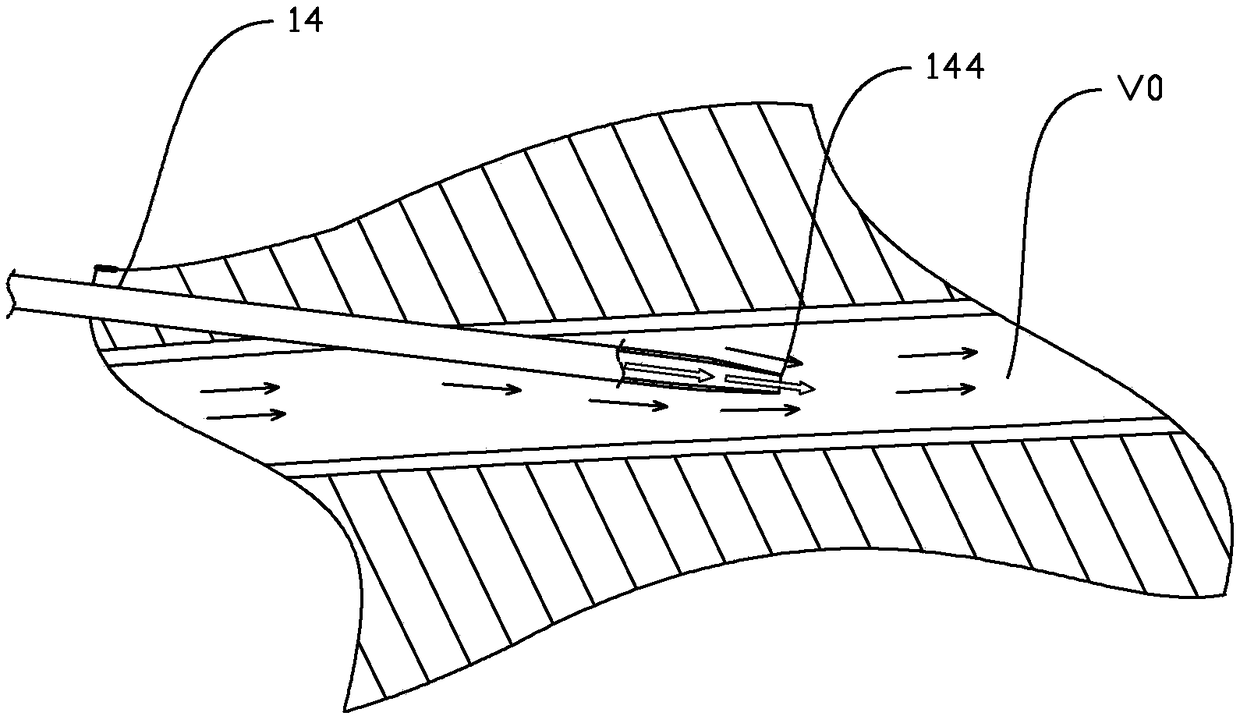

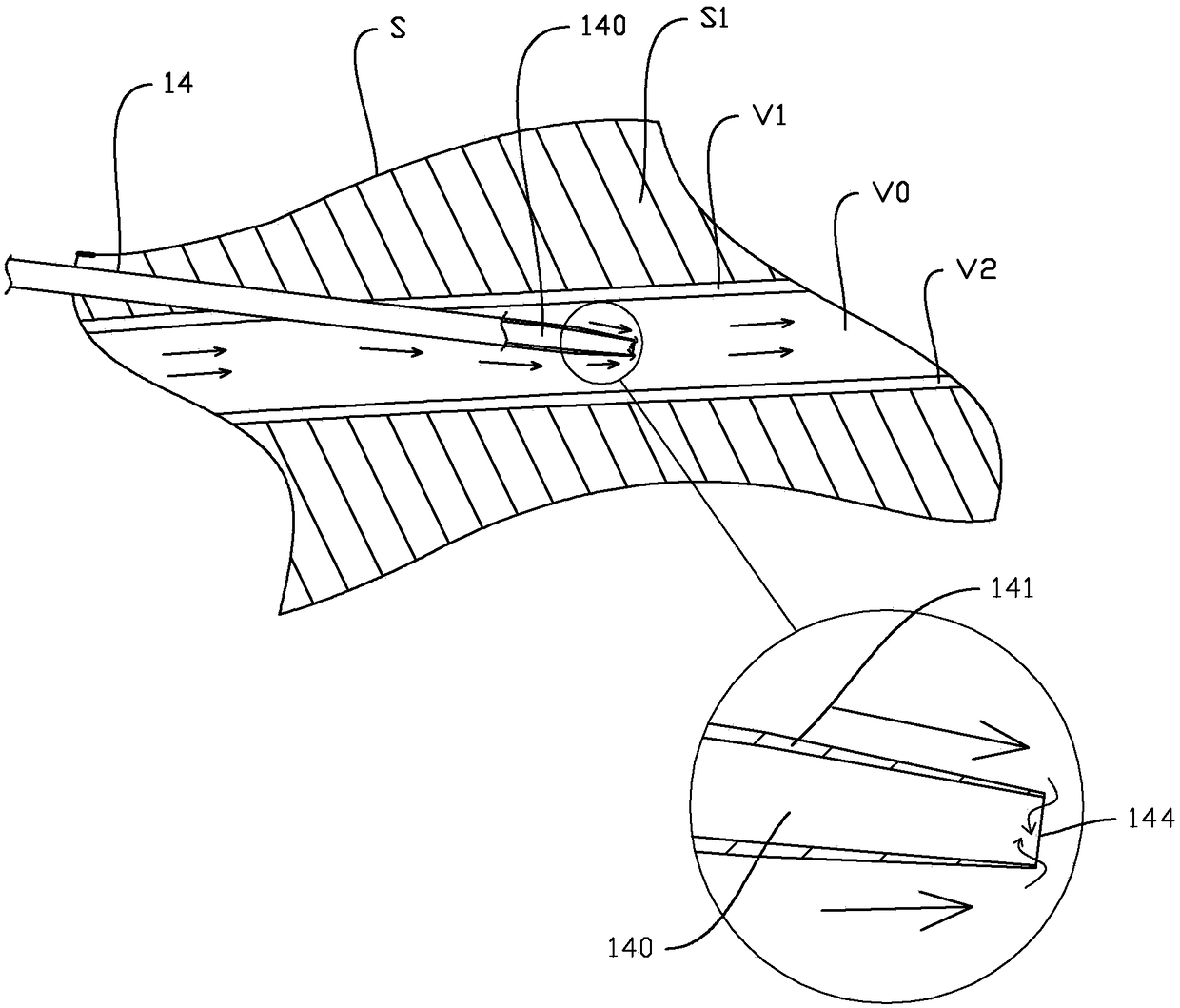

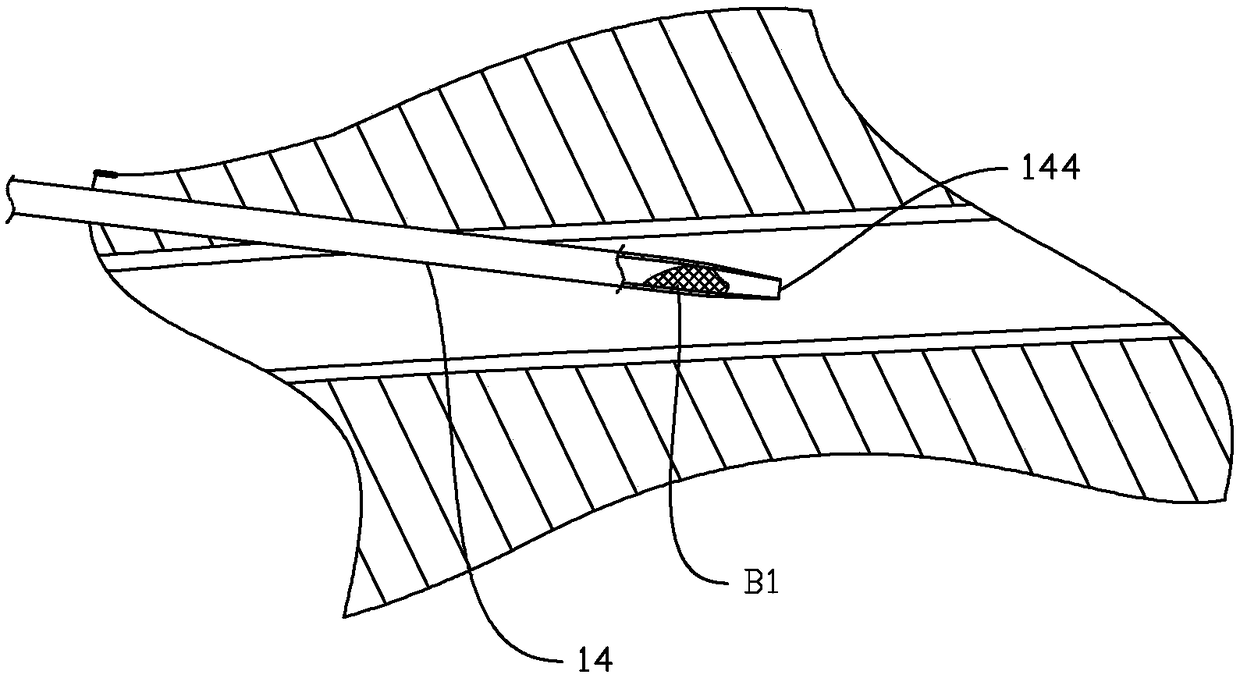

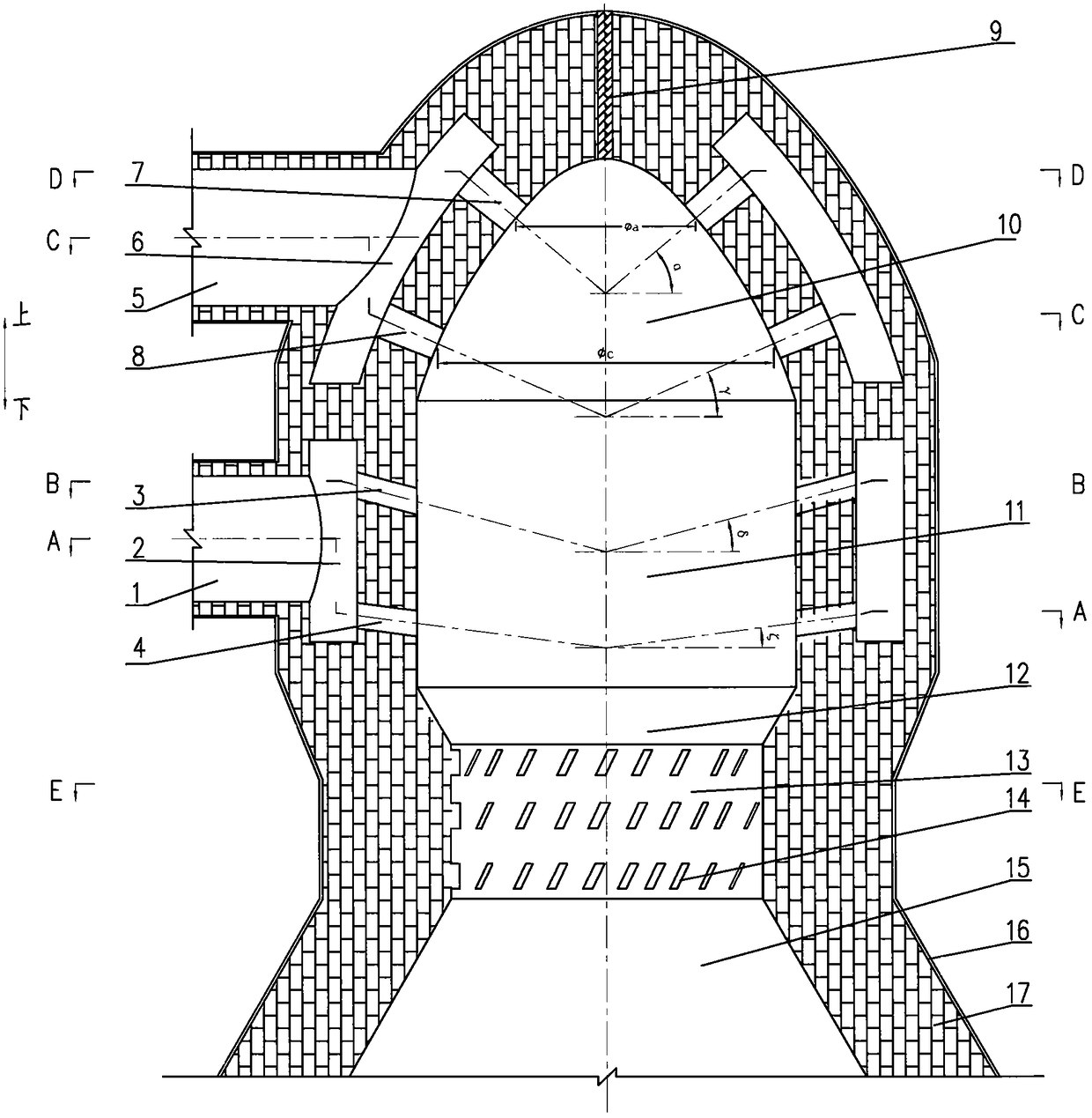

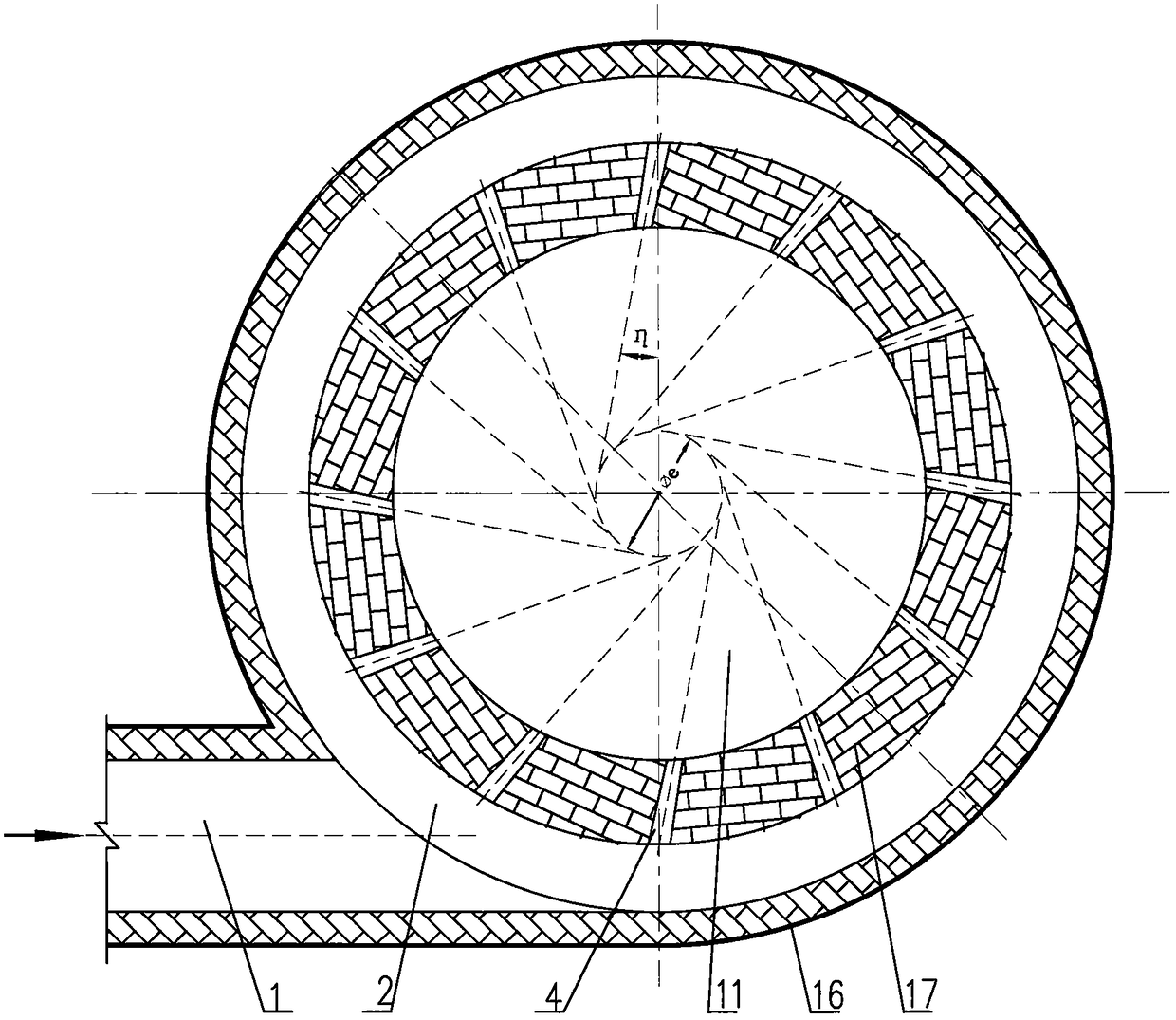

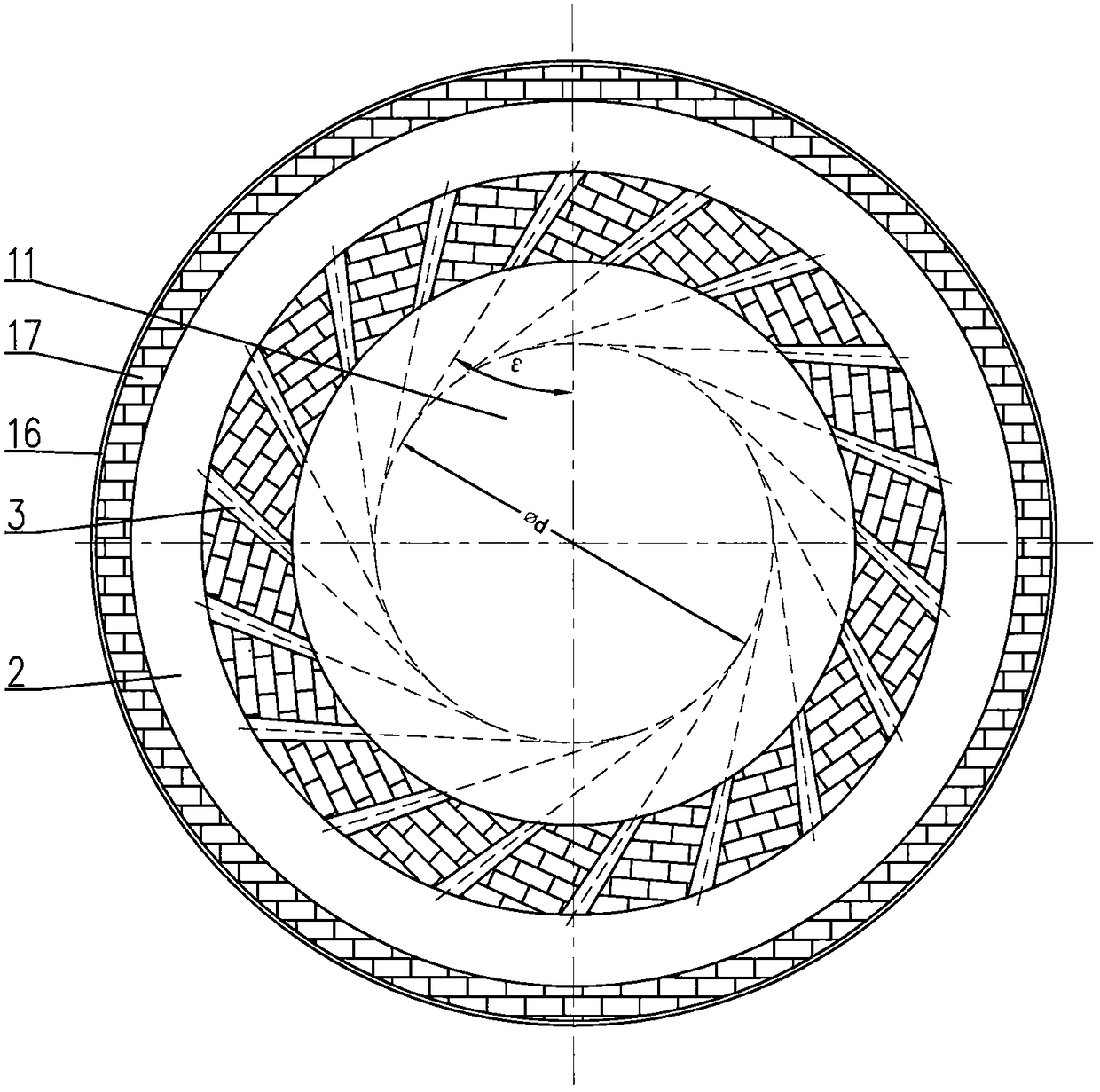

Three-dimensional vortex burner

InactiveCN108662581AEasy to adjustAvoid damageNon-combustible gases/liquids supplyGaseous fuel burnerThermal energyNitrogen oxide

The invention relates to a three-dimensional vortex burner and belongs to the technical field of thermal power engineering. The three-dimensional vortex burner is primarily characterized by being provided with an air inlet and a coal gas inlet entering tangentially, a catenary convoluted rectifying room, a primary air nozzle and a secondary air nozzle which are arranged in layers and different indirection and a diversion trench reinforcing throat, so that air is supplied to form conical spiral vortexes to inject the coal gas to fit an extremely low coal gas pressure and staged burning and thick and light burning are achieved to reduce emission of nitric oxide. The three-dimensional vortex burner is full in burning and small in resistance loss, and is particularly suitable for various industrial kilns which are high in power, low in coal gas calorific value, low in coal gas pressure, great in pressure fluctuation and high in demand on emission of nitric oxide. Energy conservation and emission reduction are achieved.

Owner:姜凤山

Heat dissipation device assembly with fan cover

InactiveUS7055578B2Eliminate dead spaceImprove cooling effectDigital data processing detailsSemiconductor/solid-state device detailsEngineeringHeat spreader

A heat dissipation device assembly comprises a heat sink having a columniform conductive core and a plurality of fins arranged radially around the conductive core, a columnar fan cover housing the heat sink and defining a first open end and a second open end, and a fan located at the second open end of the fan cover. Pluralities of channels are formed between the radiation fins. A plurality of elongated slot surrounding the heat sink is defined in the fan cover and extends from the first open end of the fan cover to the second open end. The airflow provided by the fan travels through the channels and the slots to outside of the fan cover.

Owner:HON HAI PRECISION IND CO LTD

Coating chamber and templates to produce decorative mouldings

InactiveUS6974502B2Eliminate dead spaceLiquid surface applicatorsCovering/liningsExpanded polystyreneMechanical engineering

A method and apparatus to impart a coating layer on the surface of decorative mouldings that are widely used in the externally insulated finishing systems (EIFS) in the construction industry. The method is a sequence of mechanically advancing a core, constructed from pre-formed expanded polystyrene (EPS, in a straight horizontal plane through a coating chamber / hopper with templates conforming to the desired decorative profile. The apparatus is a rectangular box with a funneled opening at the top with adjustable internal plates to direct the material from the sides of the box toward the pre-formed core that is being coated. Two plates on the bottom of the box support the pre-formed core and are adjustable to leave an opening in the center so that excess material can fall through the bottom after coating the last core. The templates are designed to be interchangeable with other coating apparatus designed by the inventor to produce start strips, decorative mouldings, wall panel sections and columns commonly used in the construction industry.

Owner:RAPONE SANTO P

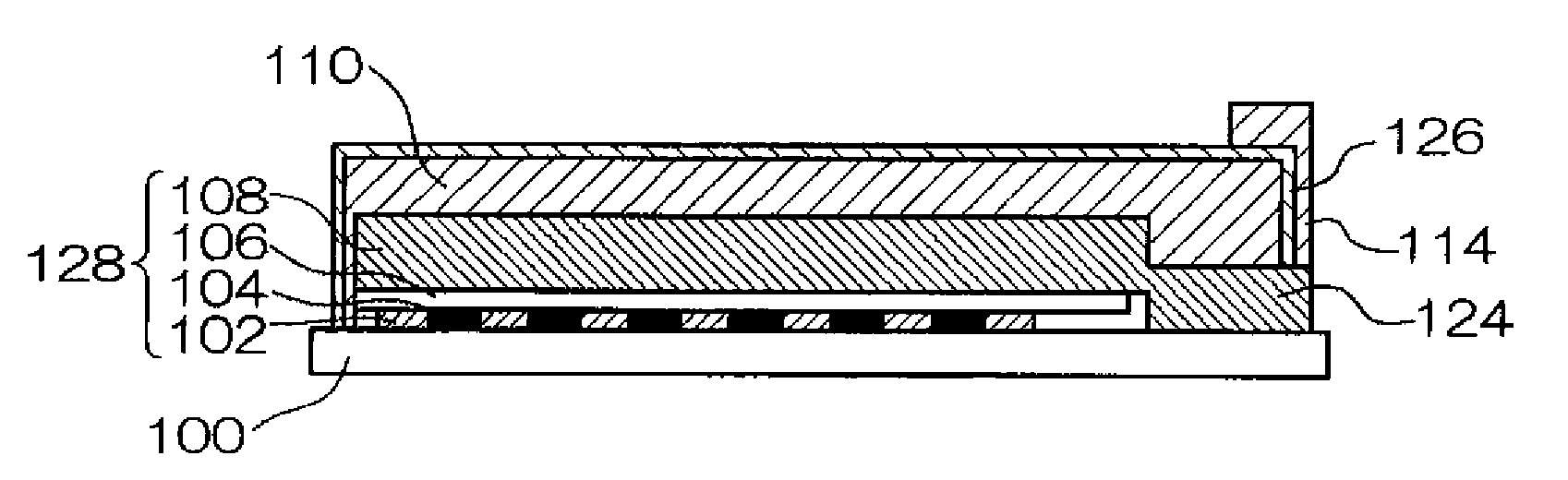

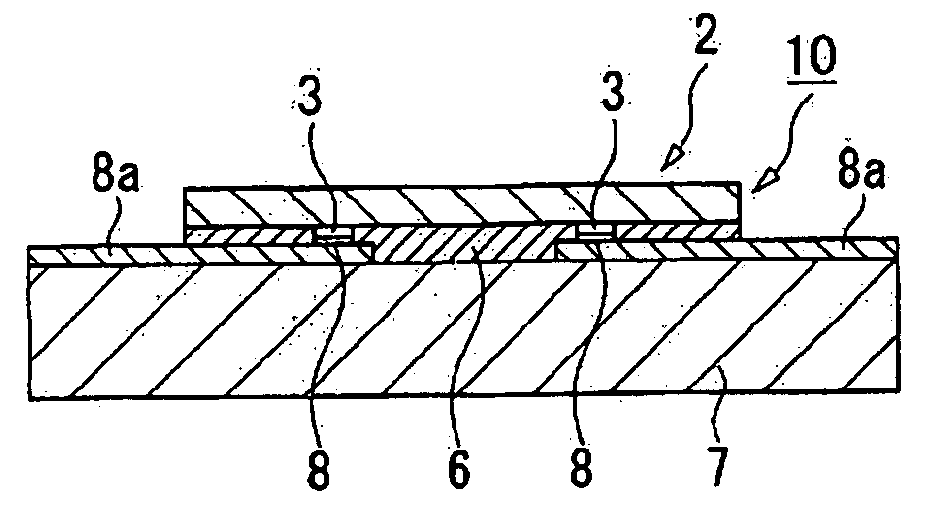

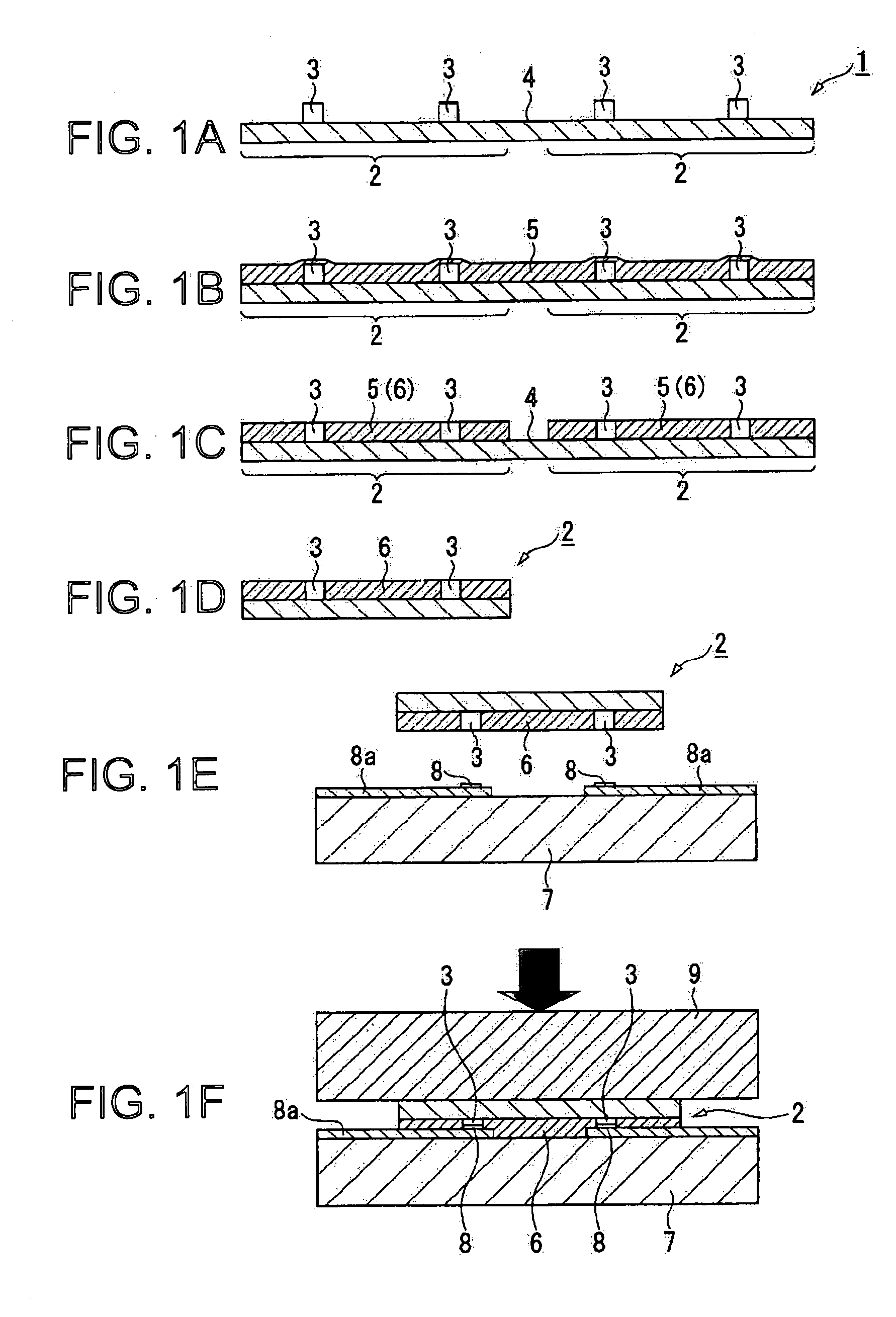

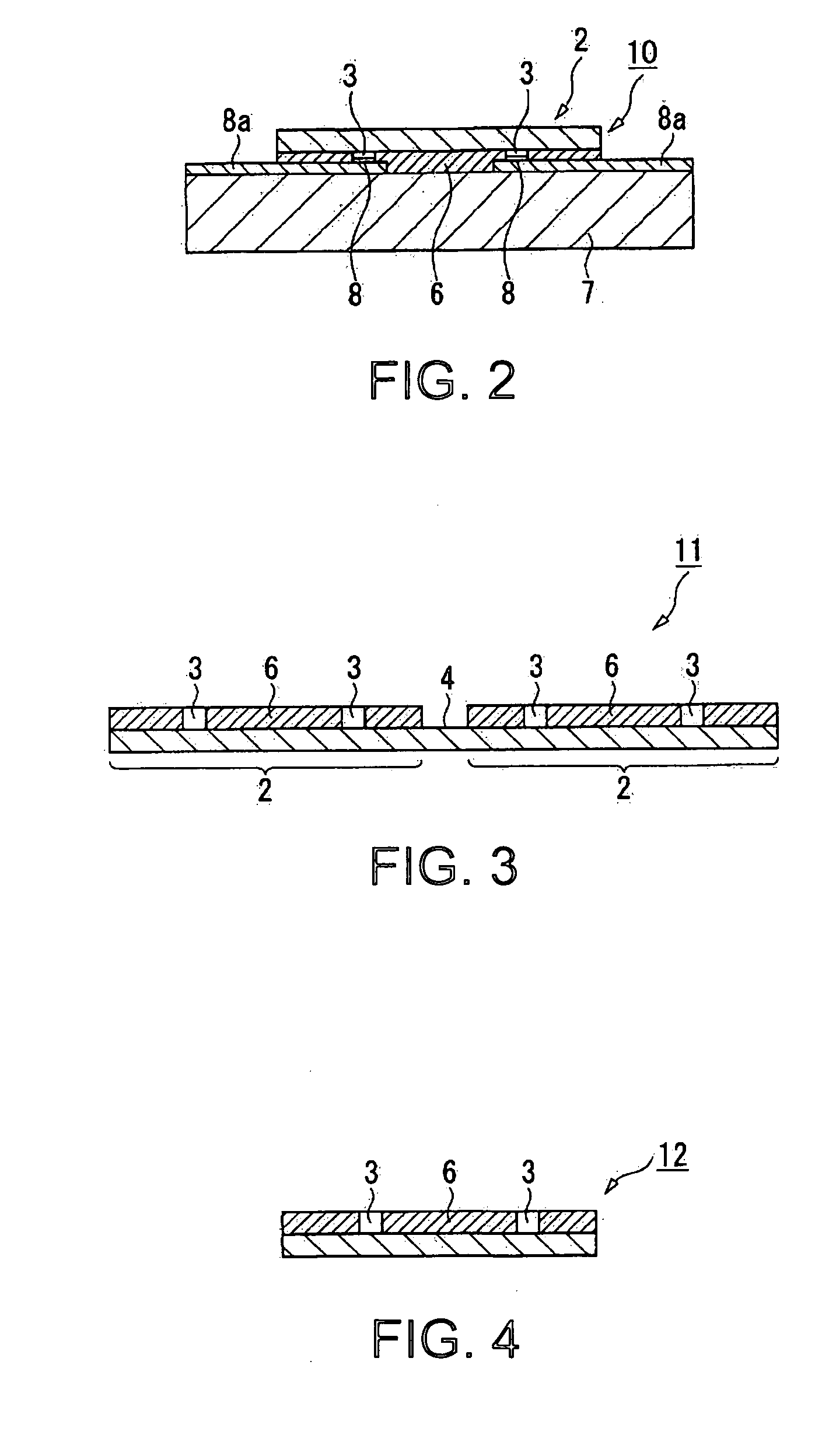

Method of manufacturing semiconductor device, semiconductor device, and mounting structure of semiconductor device

InactiveUS20060055036A1High-density mountingReduce installation costsSemiconductor/solid-state device detailsSolid-state devicesDevice materialAdhesive

A method of manufacturing a semiconductor device, including the following steps, forming a resin layer on a surface of a semiconductor chip, the surface is provided with a bump formed thereon, the resin layer having photosensitivity and adhesiveness, exposing an upper surface of the bump by removing a part of the resin layer right above the bump by exposing and then developing the resin layer, and bonding the semiconductor chip provided with a resin film formed of the resin layer face-down to a substrate, the bump of the semiconductor chip and a conductive section of the substrate being electrically connected by the resin film functioning as an adhesive.

Owner:SEIKO EPSON CORP

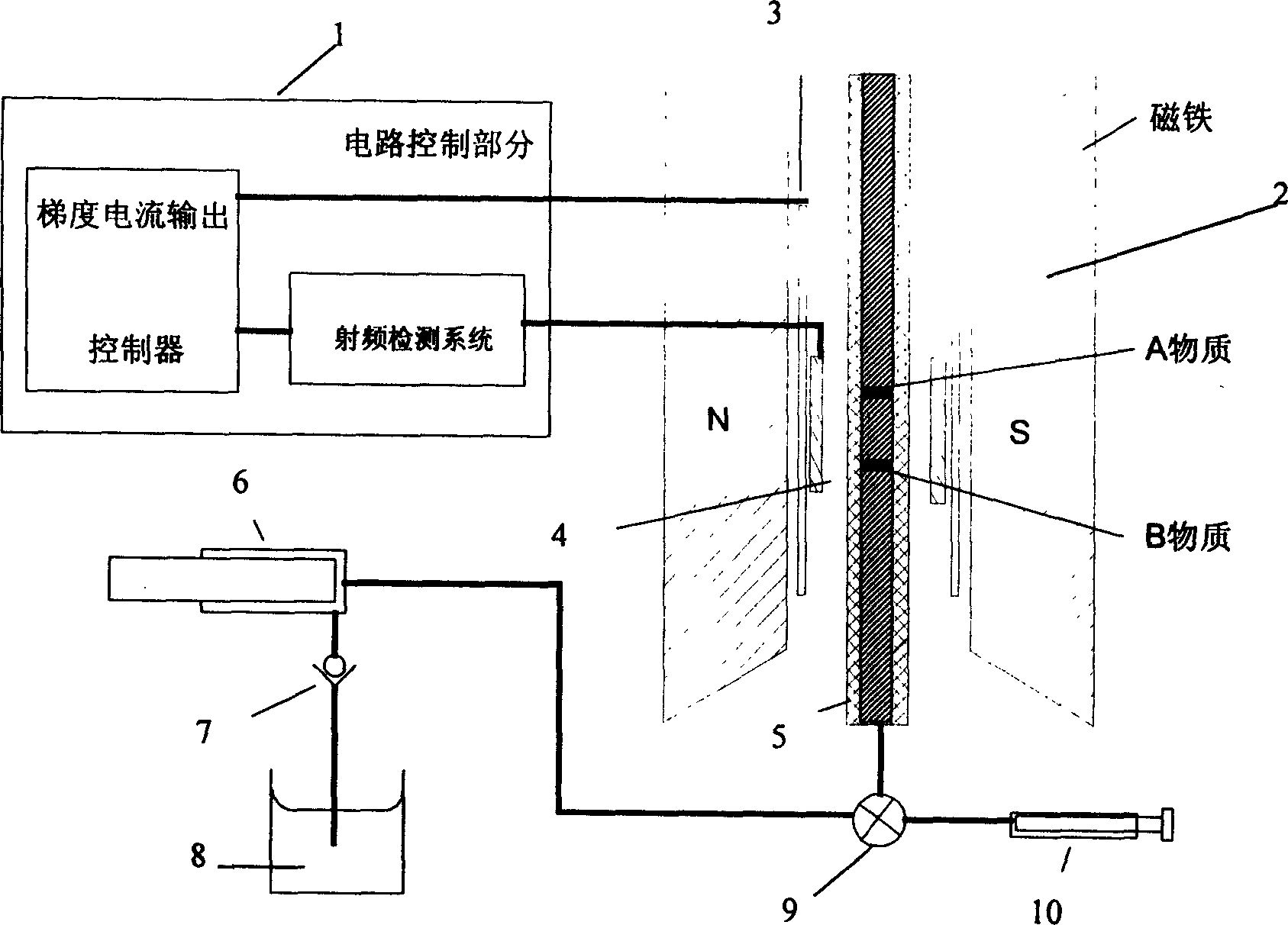

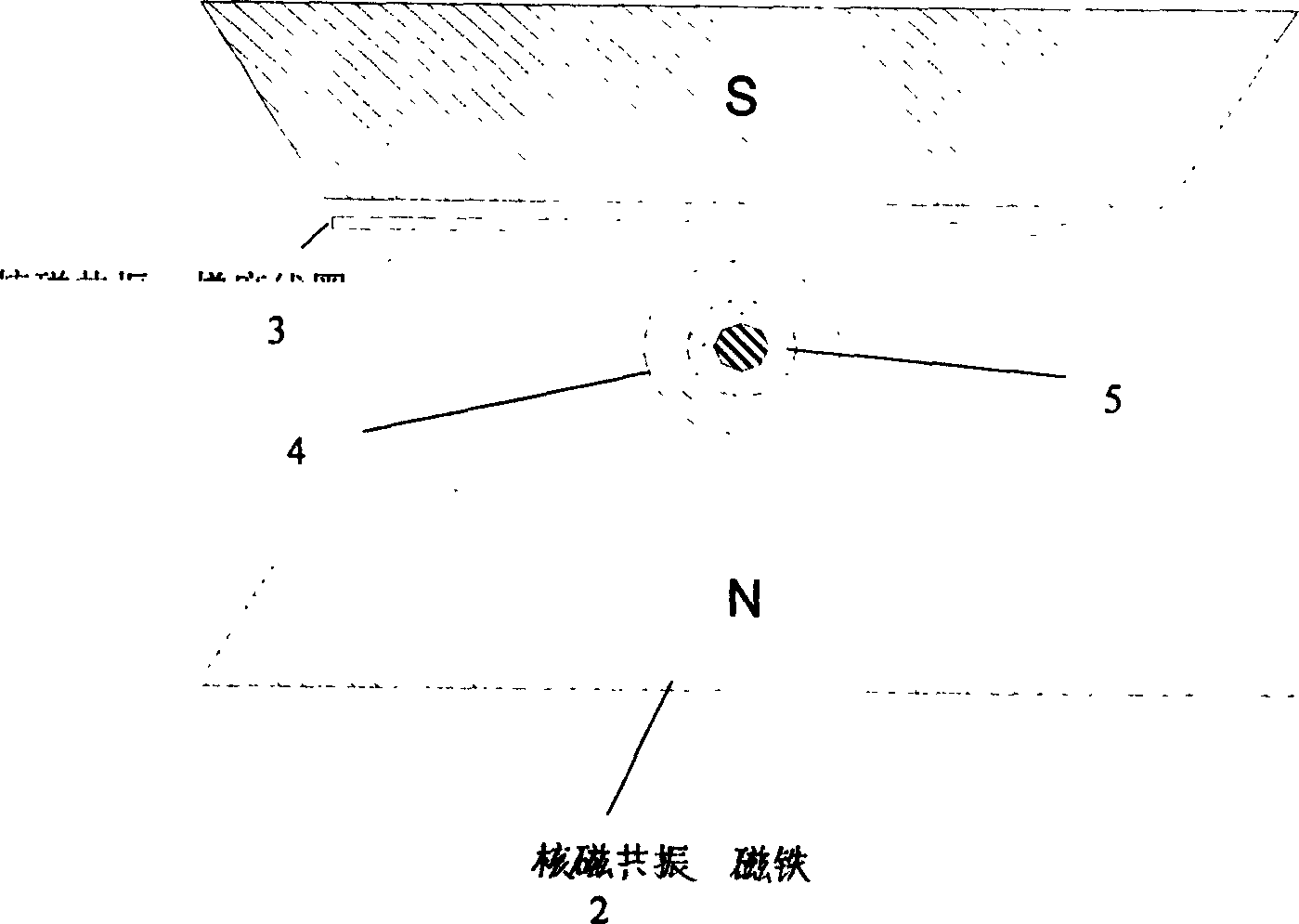

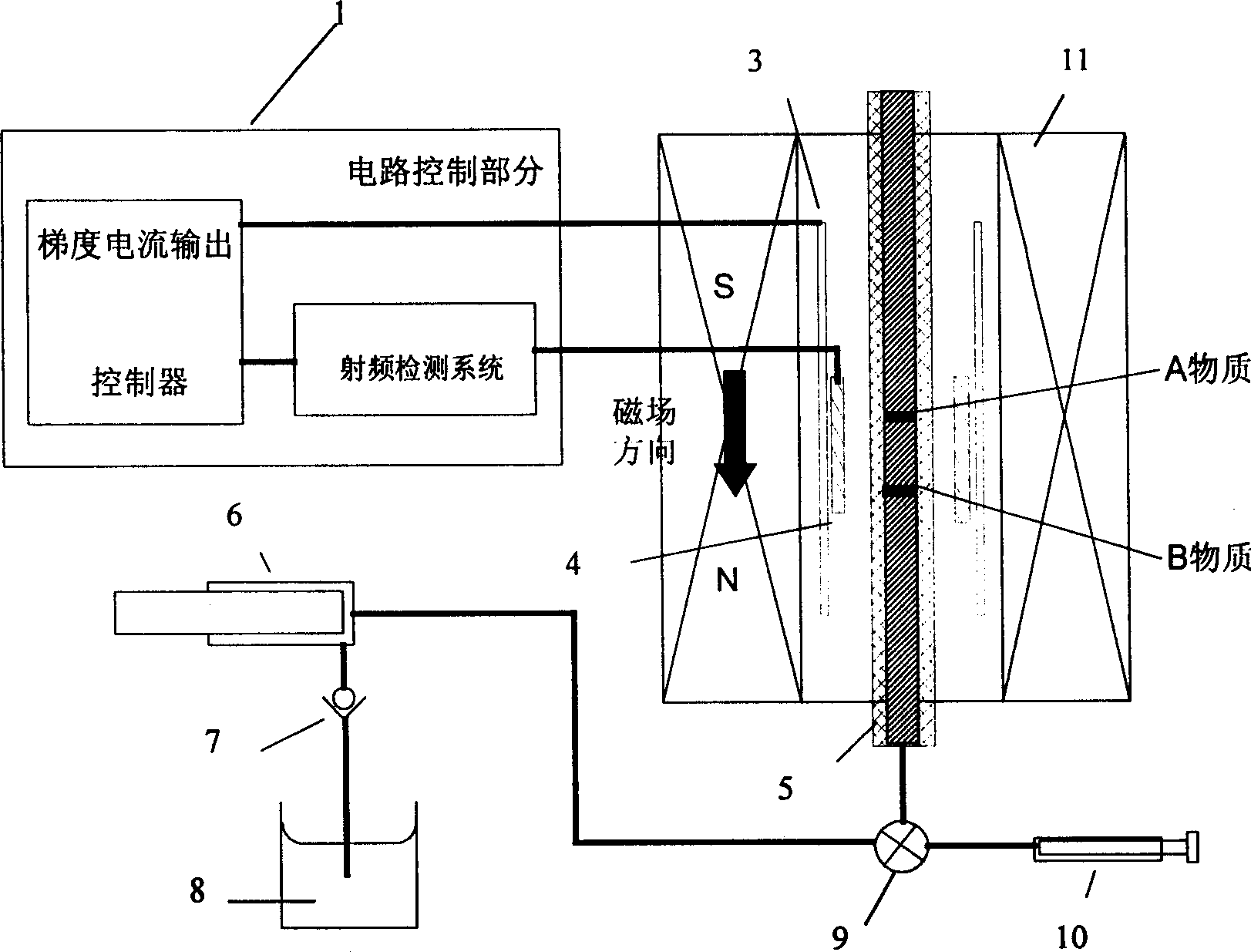

High performance spectrmeter for liquid chromatography and magnetic resonance imaging

InactiveCN1696705ANo lossImprove effective utilizationComponent separationAnalysis using nuclear magnetic resonanceSolid-state nuclear magnetic resonanceNMR - Nuclear magnetic resonance

An image and spectrum analyzer is composed of high efficient liquid phase chromatograph system and nuclear magnetic resonance system. It is featured as setting chromatographic column in central hole of measuring probe placed between two gradient coils set between two cylindrical magnetic poles if normal magnet is applied or setting chromatographic column in central hole of measuring probe placed in gradient coil set in cylindrical superconductive magnet if superconductive magnet is applied.

Owner:谢寰彤

Closed blood sampling system with isolated pressure monitoring

ActiveUS20070179407A1Easy to optimizeImprove pressure qualityCatheterIntravenous devicesLine tubingStopcock

A closed blood sampling system within a pressure monitoring line having a control valve that enables a clearance reservoir to be isolated from the pressure column when no samples are being taken. The valve is a stopcock-like device that includes a rotating valve member and attached control handle with clear visible and tactile indicators for the mode of operation. The rotating valve member has a number of internal and circumferential channels for connecting or disconnecting select ports in the core of the valve. By isolating the clearance reservoir, the quality of the pressure signal is improved such that the sampling line can be lengthened for greater convenience in the intensive care or operating room. The valve may also incorporate a blunt cannula sampling site therewithin.

Owner:EDWARDS LIFESCIENCES CORP

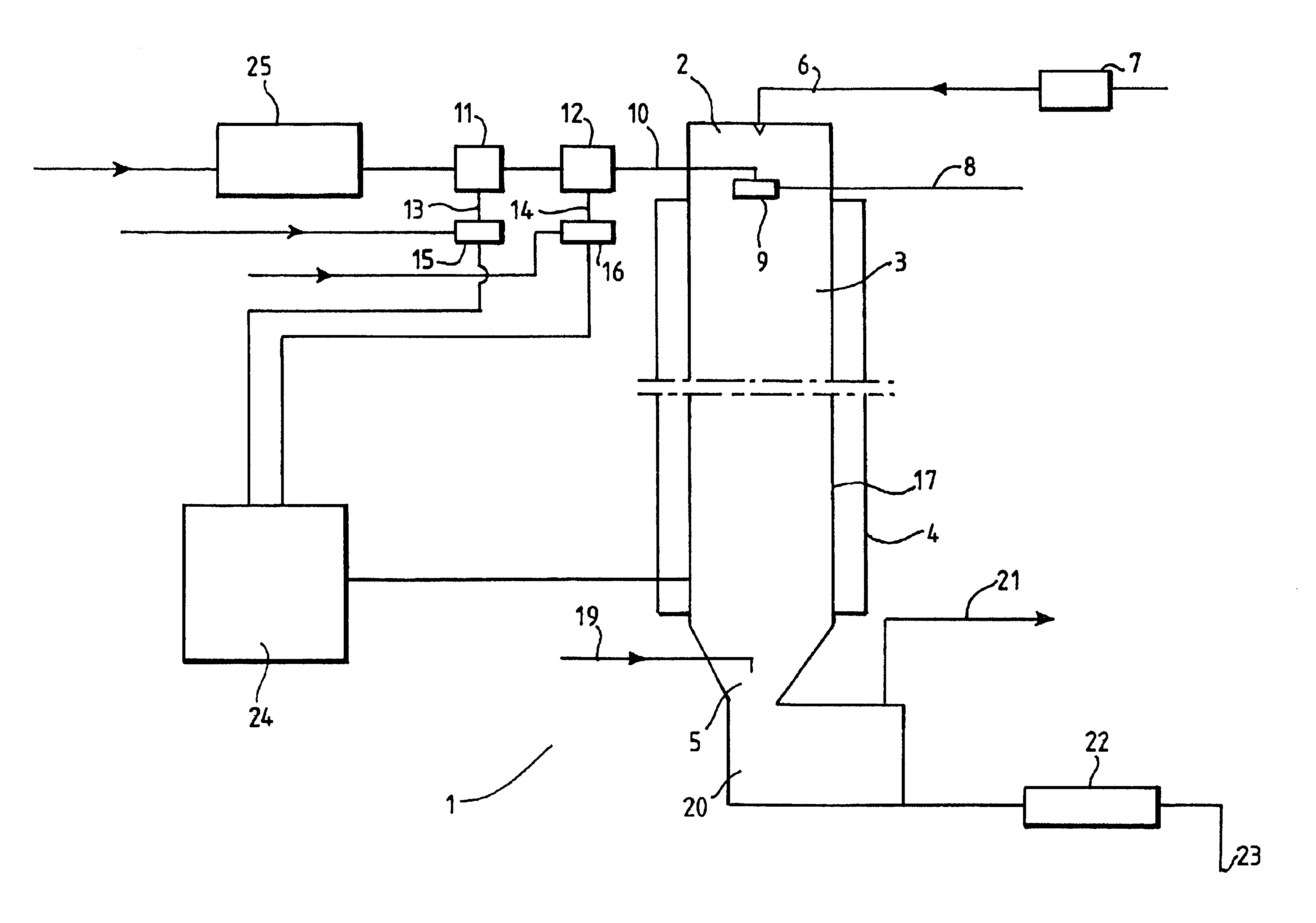

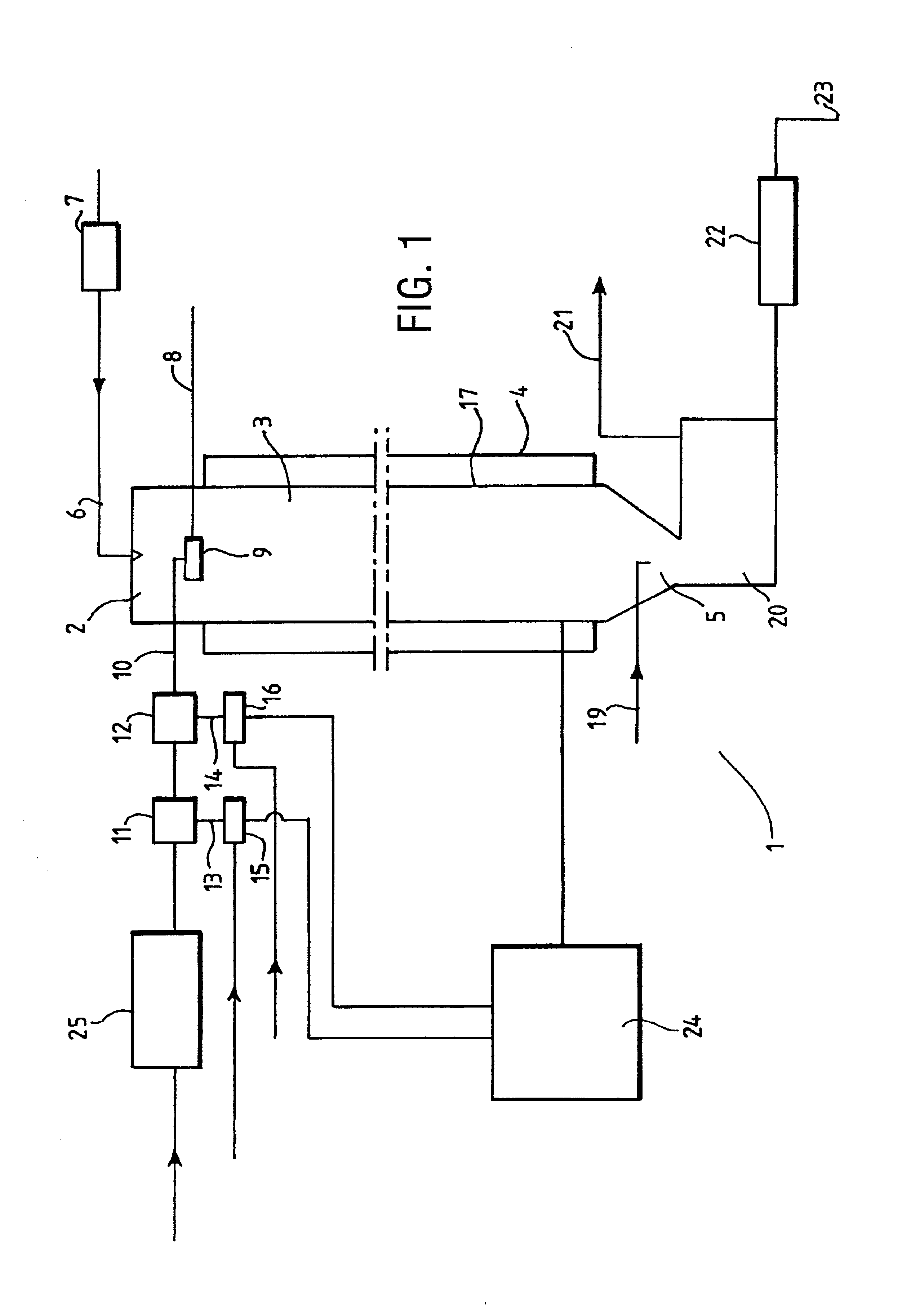

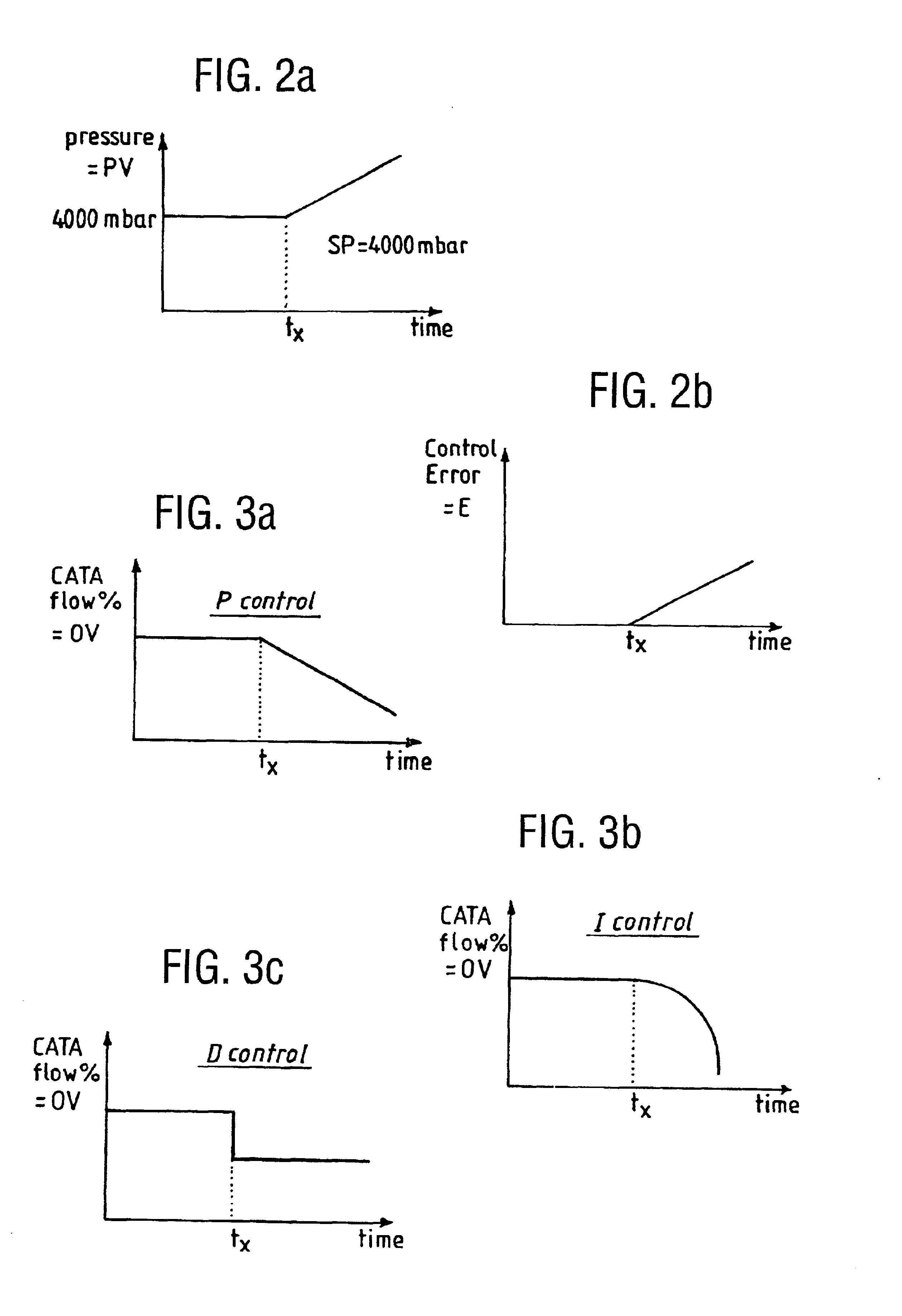

Polymerization reactor and process

InactiveUS6964753B2Easy to manufactureReducing required overall length and heightProcess control/regulationFluid pressure controlOligomerViscosity

A continuous static polymerization reactor unit for the production of liquid polymers, in particular high viscosity organopolysiloxanes, in a predetermined viscosity range comprises a reactor (1) a supply means (10,25) for supplying monomers and / or oligomers to an inlet means (2), and an outlet means (5). The inlet means (2) is adapted for the introduction of a reaction mixture into a reaction chamber (3), and a means for introducing at least one viscosity controlling agent into the supply means is provided to form a reaction mixture with monomers and / or oligomers (11,13,15,12,14,16). The unit is adapted to maintain the values of temperature and flow rate of the resulting reaction mixture / polymer in the reaction chamber (3) substantially constant. A control means (24) is used to detect any variation from a predetermined pressure drop value between the inlet means (2) and the outlet means (5), and should such a variation occur the control means (24) is also used to compute and control a compensating rate of introduction of one or more of the at least one viscosity controlling agents to cause the pressure drop between the inlet means (2) and the outlet means (5) to revert to the predetermined value. A process for making liquid polymers within a predetermined viscosity range is also disclosed.

Owner:DOW CORNING SA

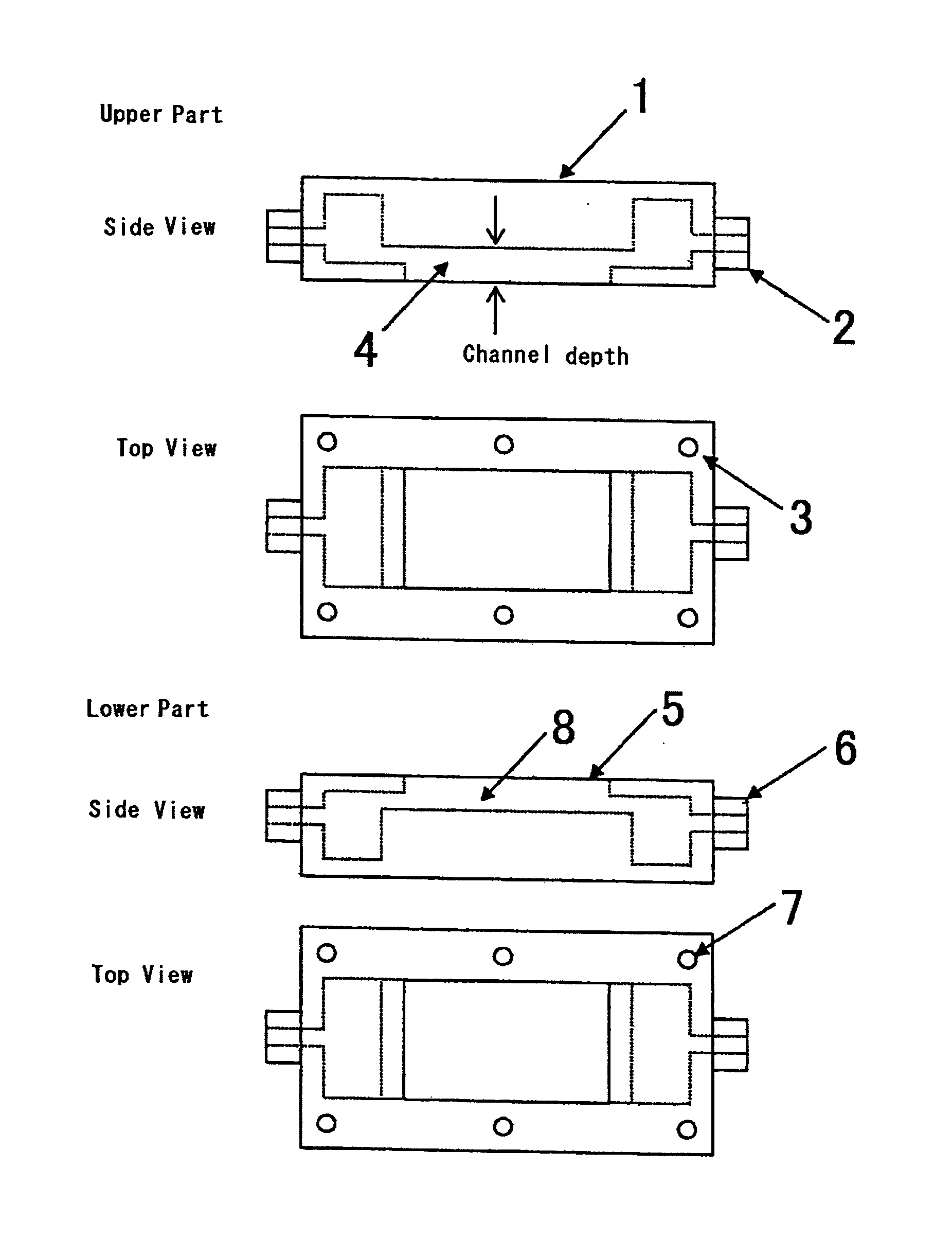

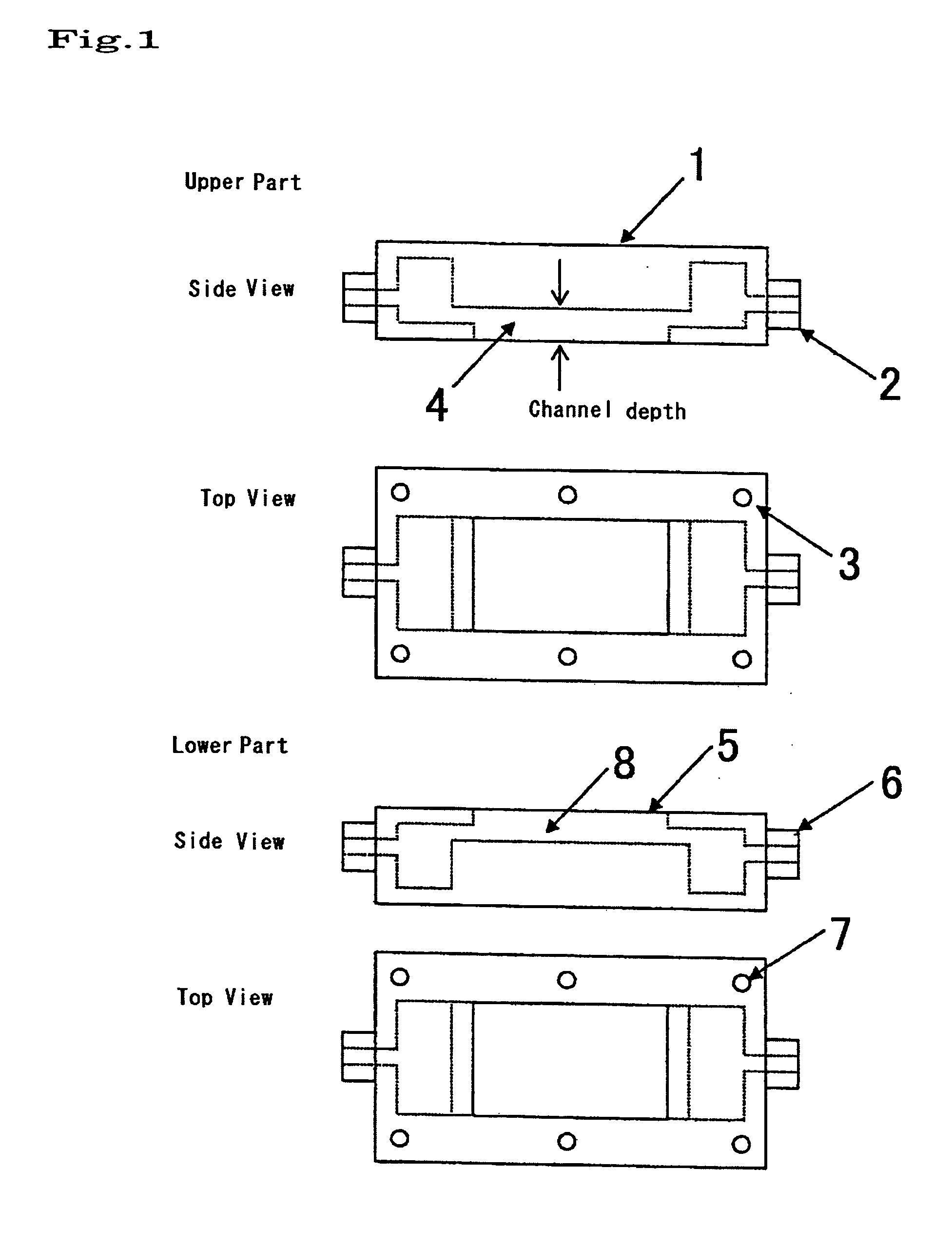

Device and method for culturing cells

ActiveUS20050042745A1Prevent releaseEliminate dead spaceBioreactor/fermenter combinationsBiological substance pretreatmentsPolymer gelBiology

An object of the present invention is to construct a culture device optimized for culturing animal cells. The present invention provides a device for culturing cells which comprises at least one water-containing polymer gel film for adhering animal cells onto at least one surface of the film, and has a structure capable of supplying different liquids to both sides of the film.

Owner:FUJIFILM HLDG CORP +1

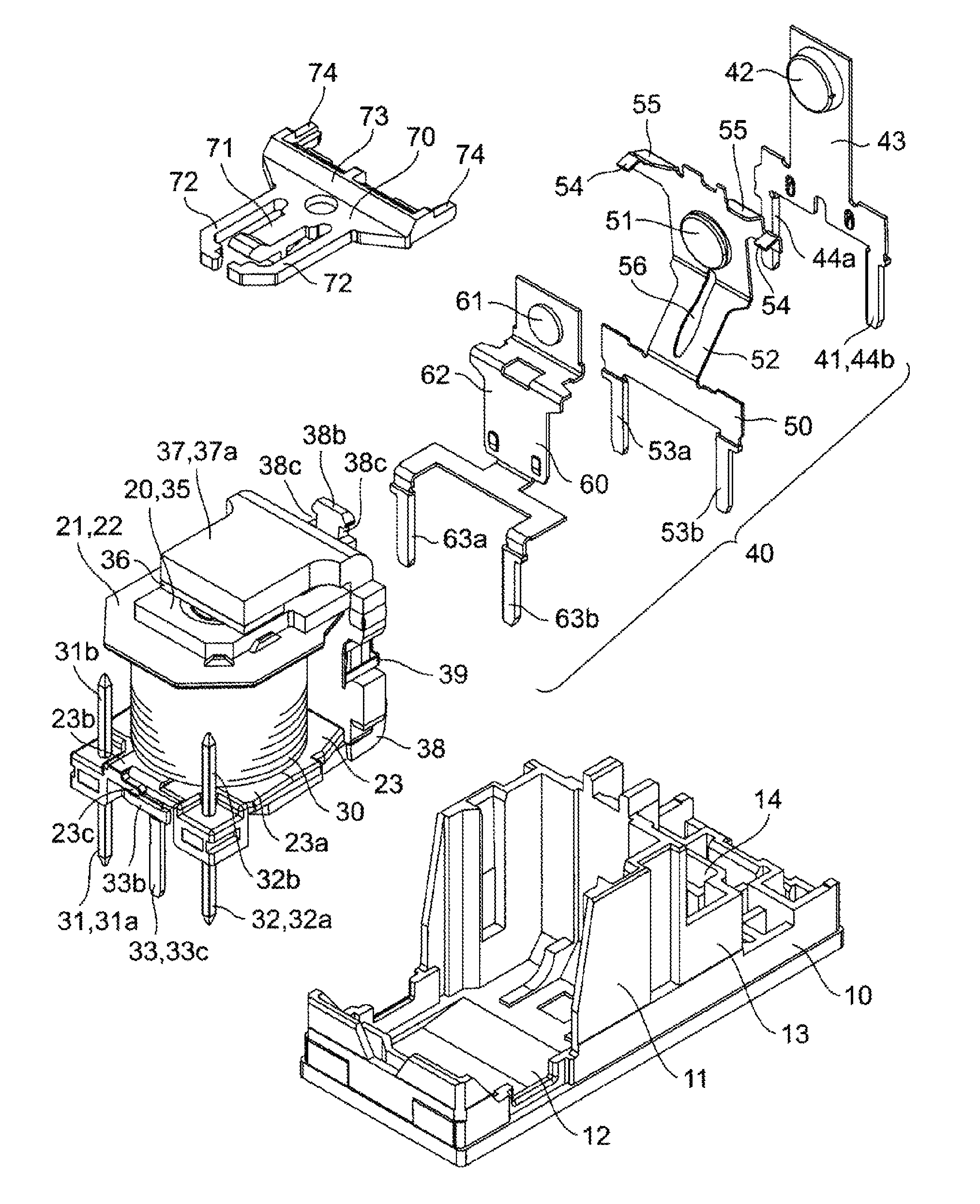

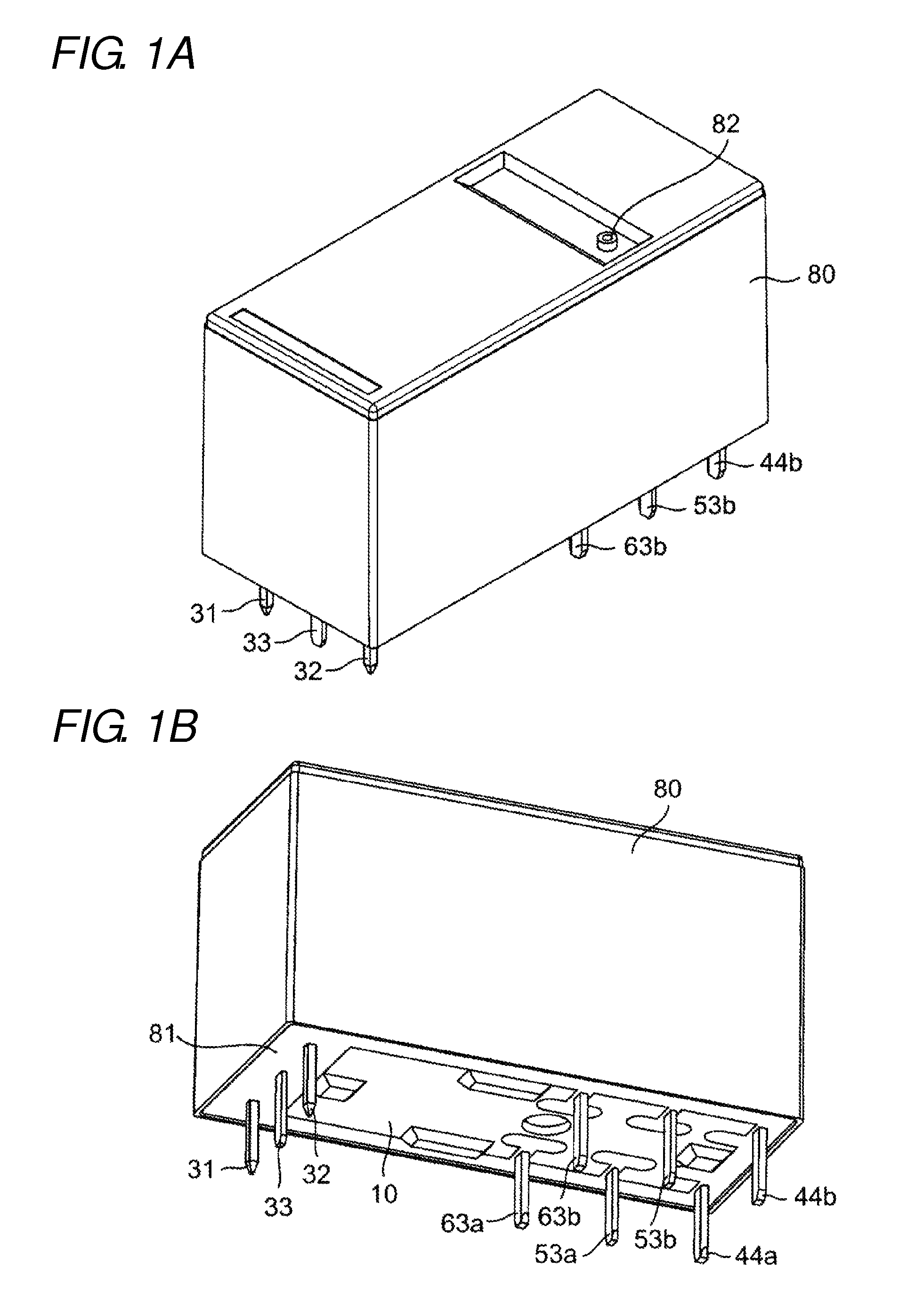

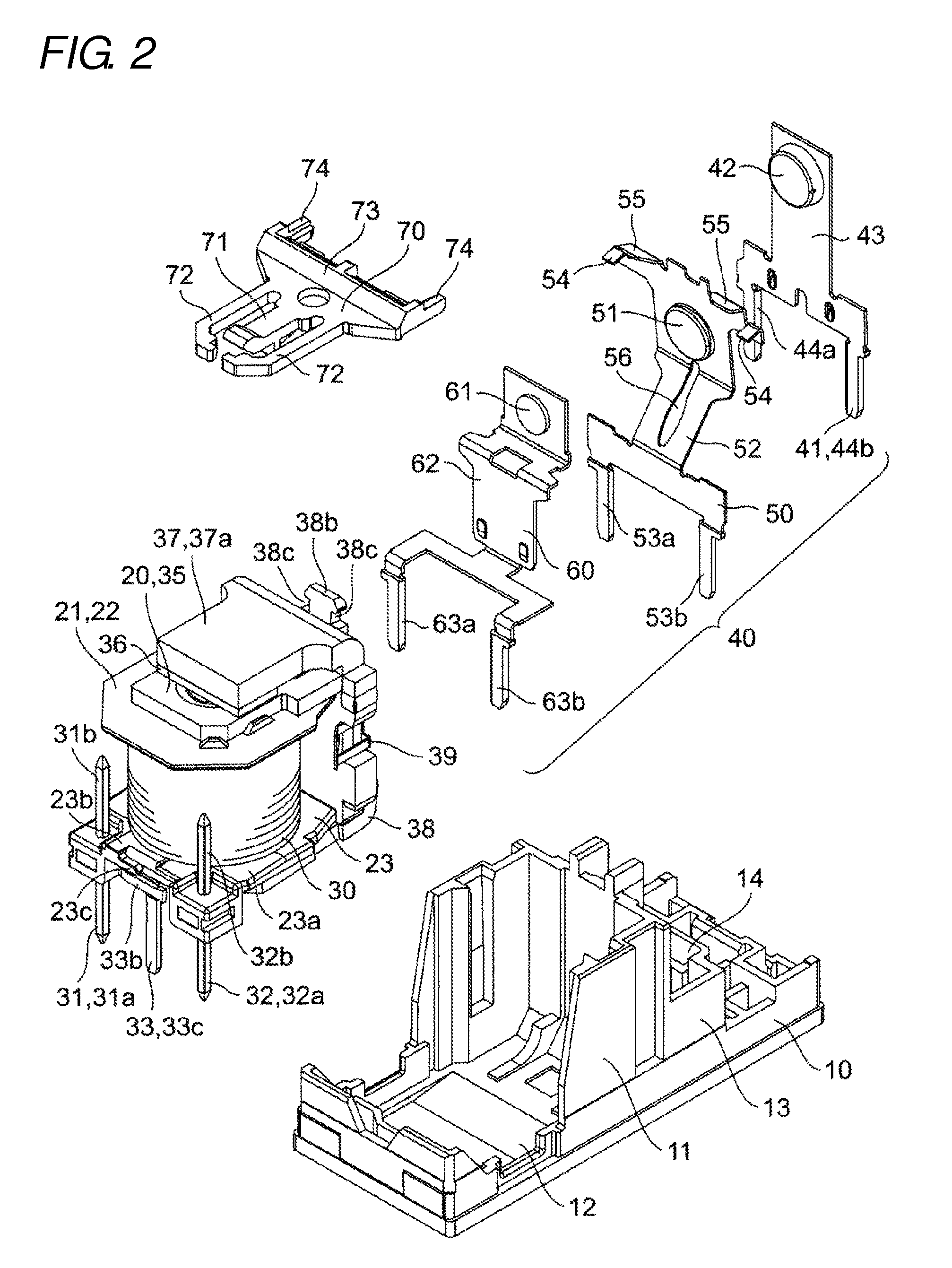

Electromagnet device and electromagnetic relay using the same

ActiveUS9437382B2Simple working processImprove efficiencyElectromagnetic relay detailsCoilsEngineeringElectromagnet

An electromagnet device has a spool having a guard portion at at least one end thereof, a coil wound around a body portion of the spool, and a coil terminal press-fitted in the guard portion. A lead wire of the coil is tied up to a tying-up portion of the coil terminal projected from the guard portion. The tying-up portion is folded toward the guard portion of the spool after the lead wire of the coil is tied up to the tying-up portion of the coil terminal extending in a direction receding from the spool.

Owner:ORMON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com