Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

160results about How to "Effective temperature regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

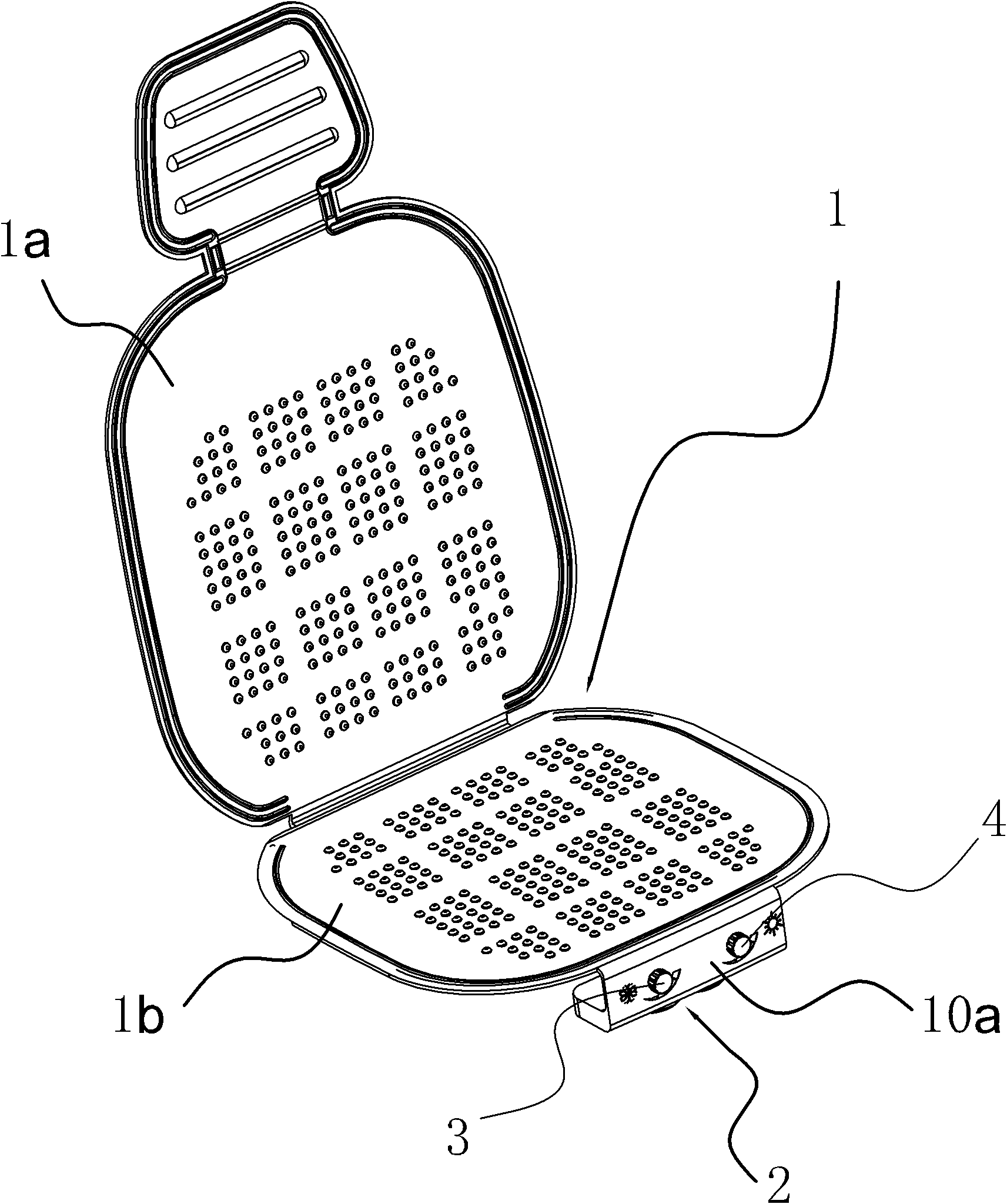

Cold-heat type automobile seat cushion

InactiveCN102310793AIncrease temperatureEffective temperature regulationSeat heating/ventillating devicesTemperature controlEngineering

The invention provides a cold-heat type automobile seat cushion, belonging to the technical field of automobiles and solving the problems that the traditional automobile seat cushion cannot provide refrigerating and heating functions simultaneously. The cold-heat type automobile seat cushion comprises a cushion body which is internally provided with a temperature control member and a temperature-controlled adjusting device for adjusting the cold and heat temperatures of the cushion body. The cold-heat type automobile seat cushion is characterized in that the temperature-controlled member is ametal plate clamped inside the cushion body; the temperature-controlled adjusting device is arranged at the side part of the cushion body and comprises a casing and a conducting strip, a refrigerating strip, a heat radiator and a fan which are sequentially arranged inside the casing; the conducting strip and the metal plate are connected to form a whole; one end face of the refrigerating strip istightly attached and fixed with one side end face of the conducting strip; the other end face of the refrigerating strip is tightly attached and fixed with the heat radiator; and ventilating ports are arranged on the corresponding wall bodies of the casing. The temperature control over the conducting strip is realized by using a semiconductor refrigerating strip, thereby the adjustment on the cold and heat temperature of the cushion body is realized. The cold-heat type automobile seat cushion has a simple structure and convenience for use.

Owner:TAIZHOU TAI CHENG ELECTRONICS TECH

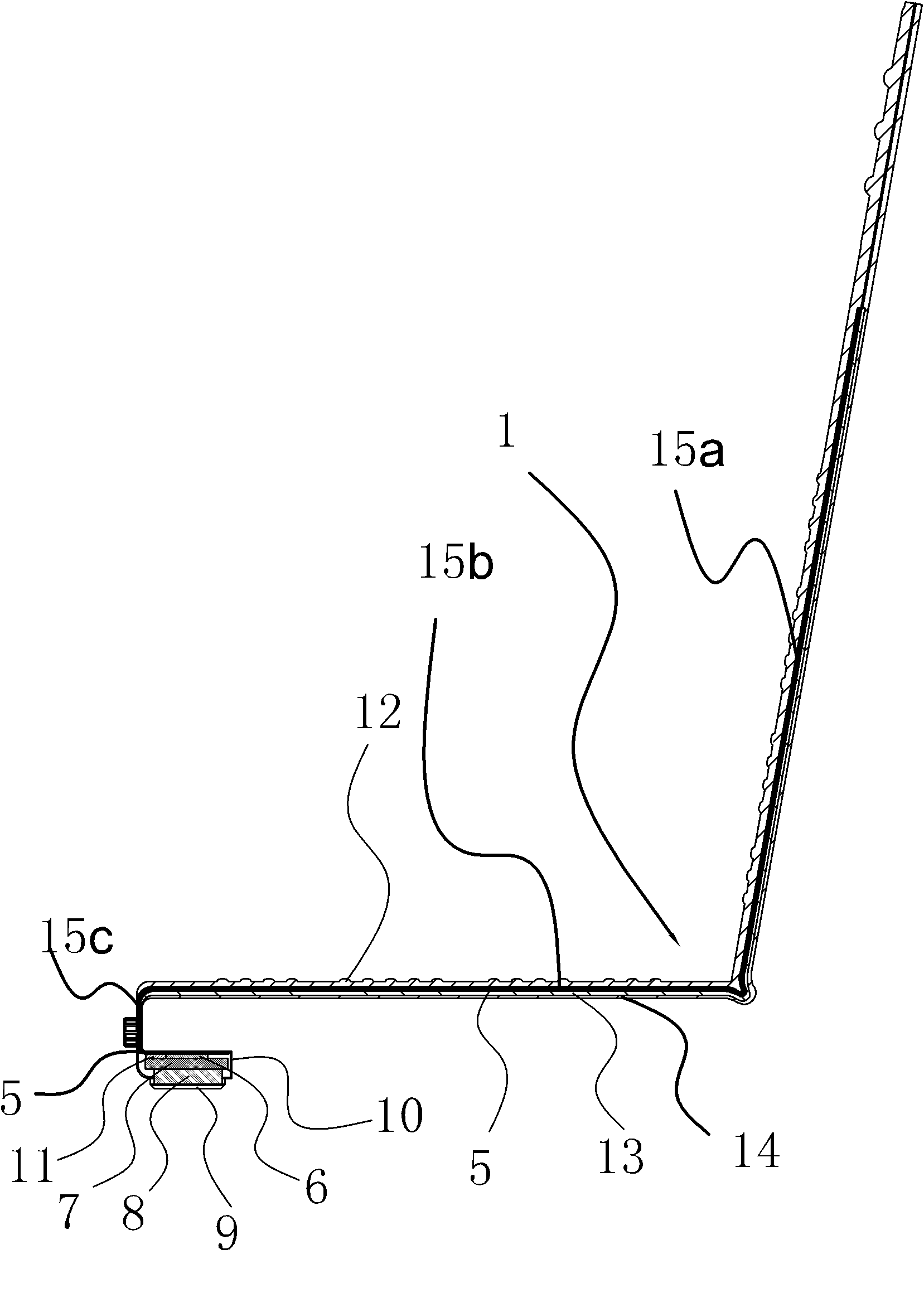

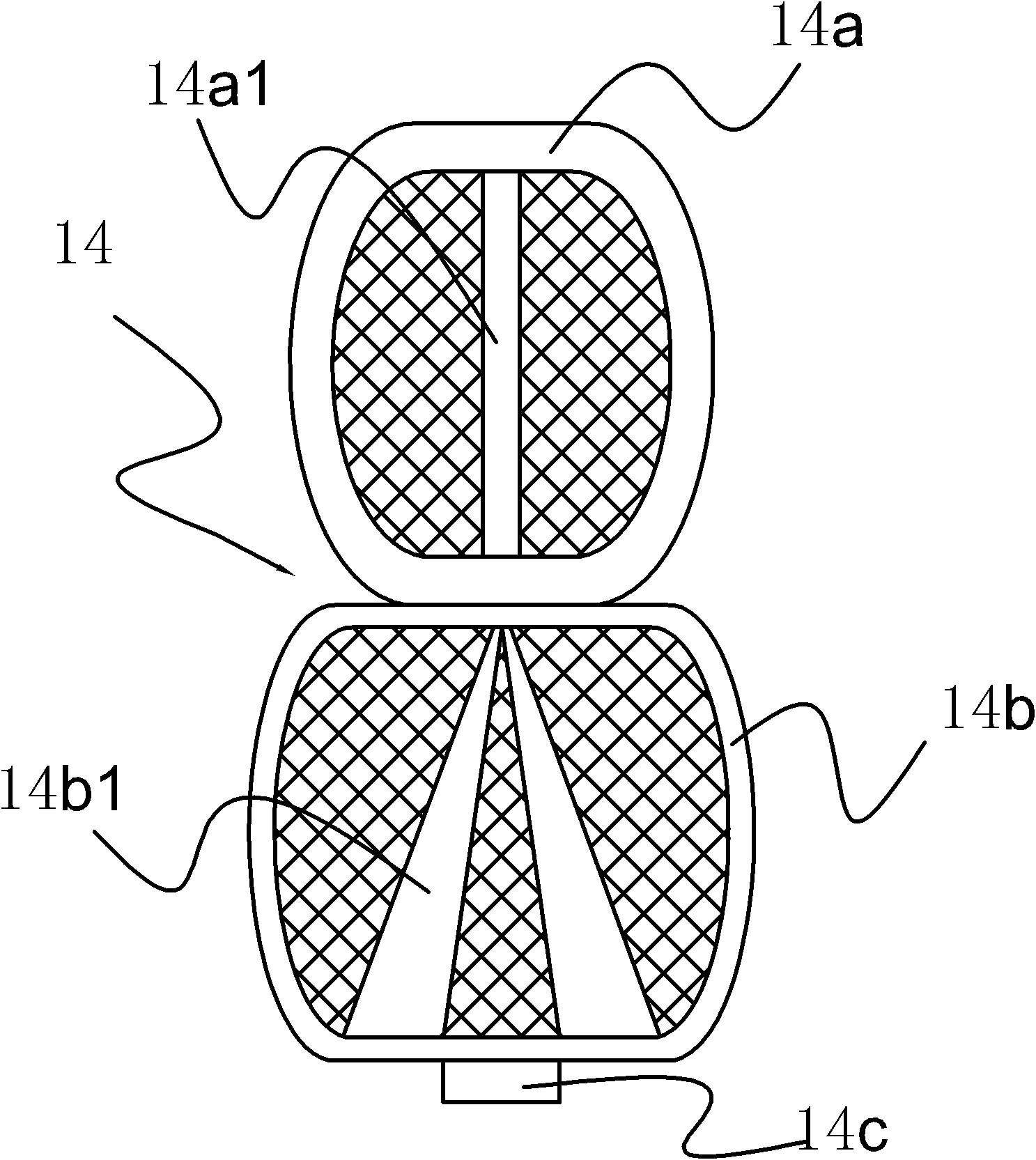

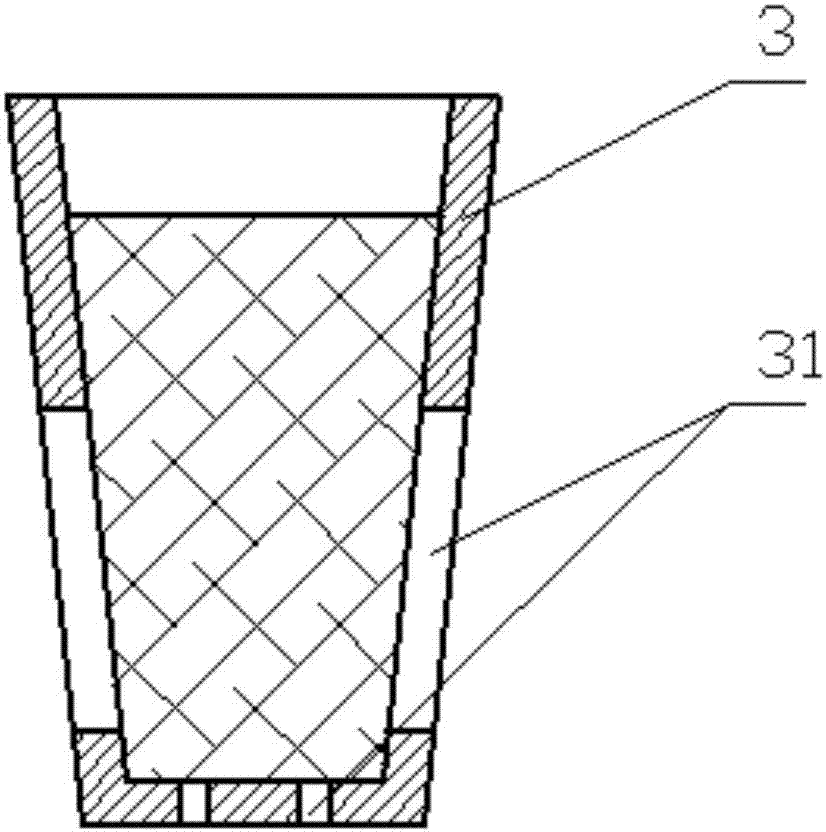

Porous ceramic atomization heating component of electronic cigarette

ActiveCN104886785APrevention of dry burningAvoid disadvantages such as burnt smellTobacco devicesElectrical resistance and conductanceTar

The invention discloses a porous ceramic atomization heating component of electronic cigarette. The porous ceramic atomization heating component of the electronic cigarette comprises a ceramic rod, a heating wire, an atomization pipe and a pedestal, the atomization pipe is vertically arranged on the pedestal, a notch is formed in the top or bottom of the atomization pipe, the ceramic rod is transversely arranged in the notch in the top or bottom, wherein the ceramic rod is made of oleophilic modified porous ceramic, the heating wire winds the surface of the ceramic rod, the heating wire is connected with a battery through a lead, a hollow sealing sleeve and a sealing ring are arranged at the notch of the atomization pipe, and an air hole communicated with the outside is opened in the pedestal. The porous ceramic atomization heating component of the electronic cigarette is capable of avoiding the disadvantages of dry burning, burnt smell and the like of a fiber rope, the oleophilic modified high-porosity porous ceramic is capable of more quickly conducting tobacco tar, the atomized smoke amount is large, and meanwhile, the PTC alloy heating wire can change the resistance thereof along with the temperature change so as to effectively regulate the temperature, and the smoke quality is more stable.

Owner:HUBEI CHINA TOBACCO IND +1

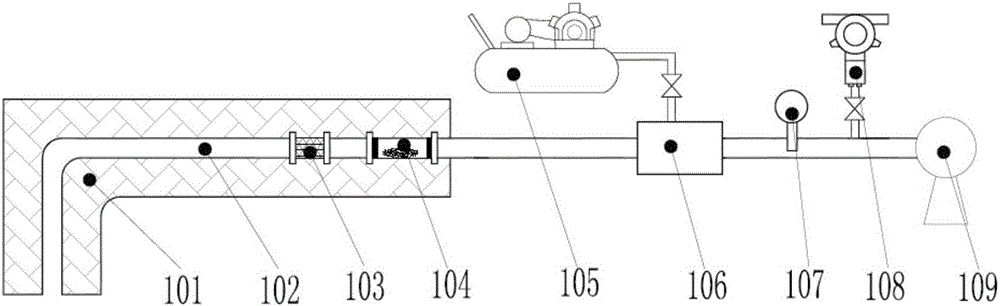

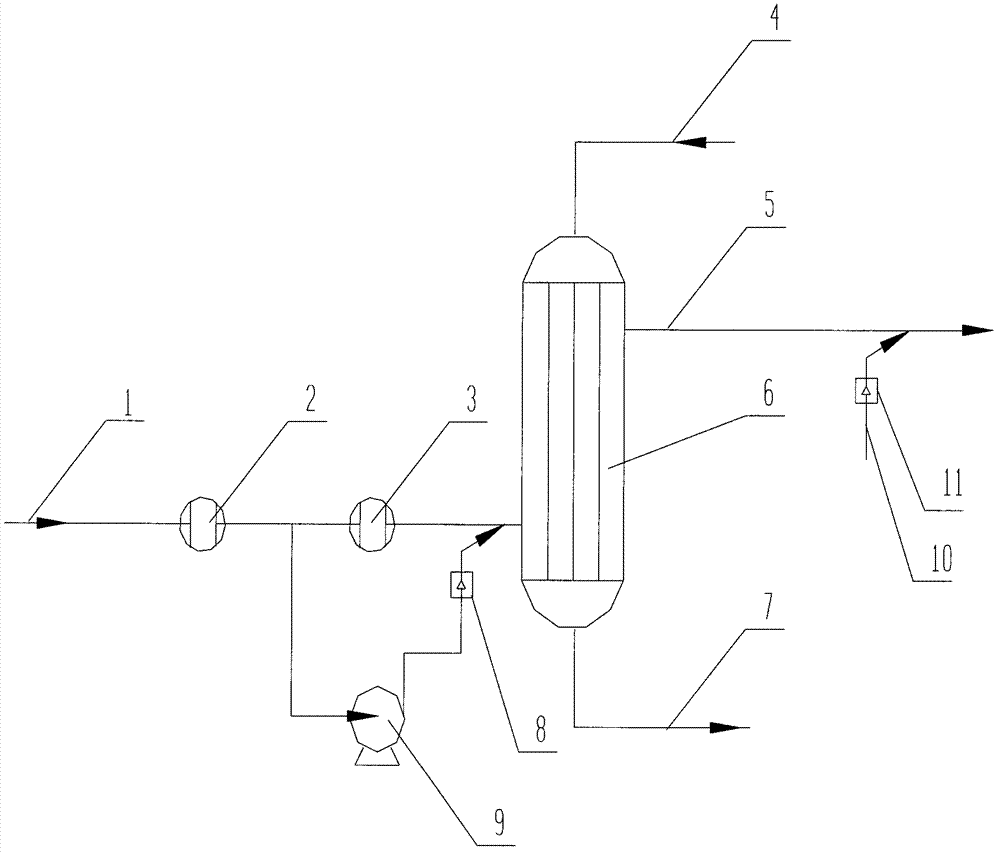

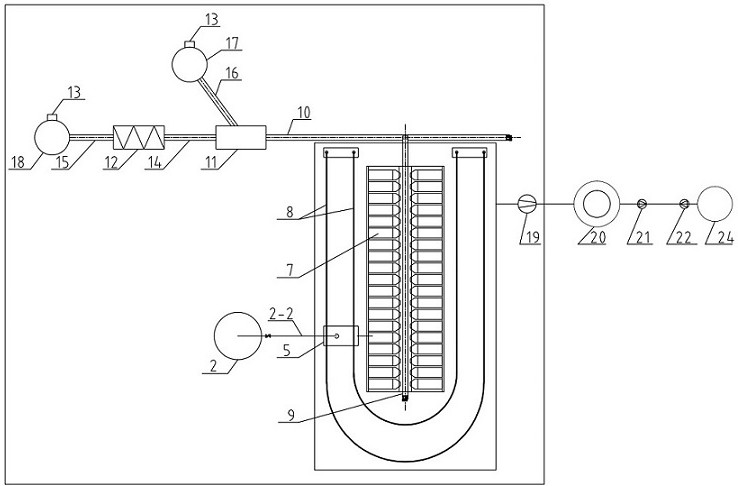

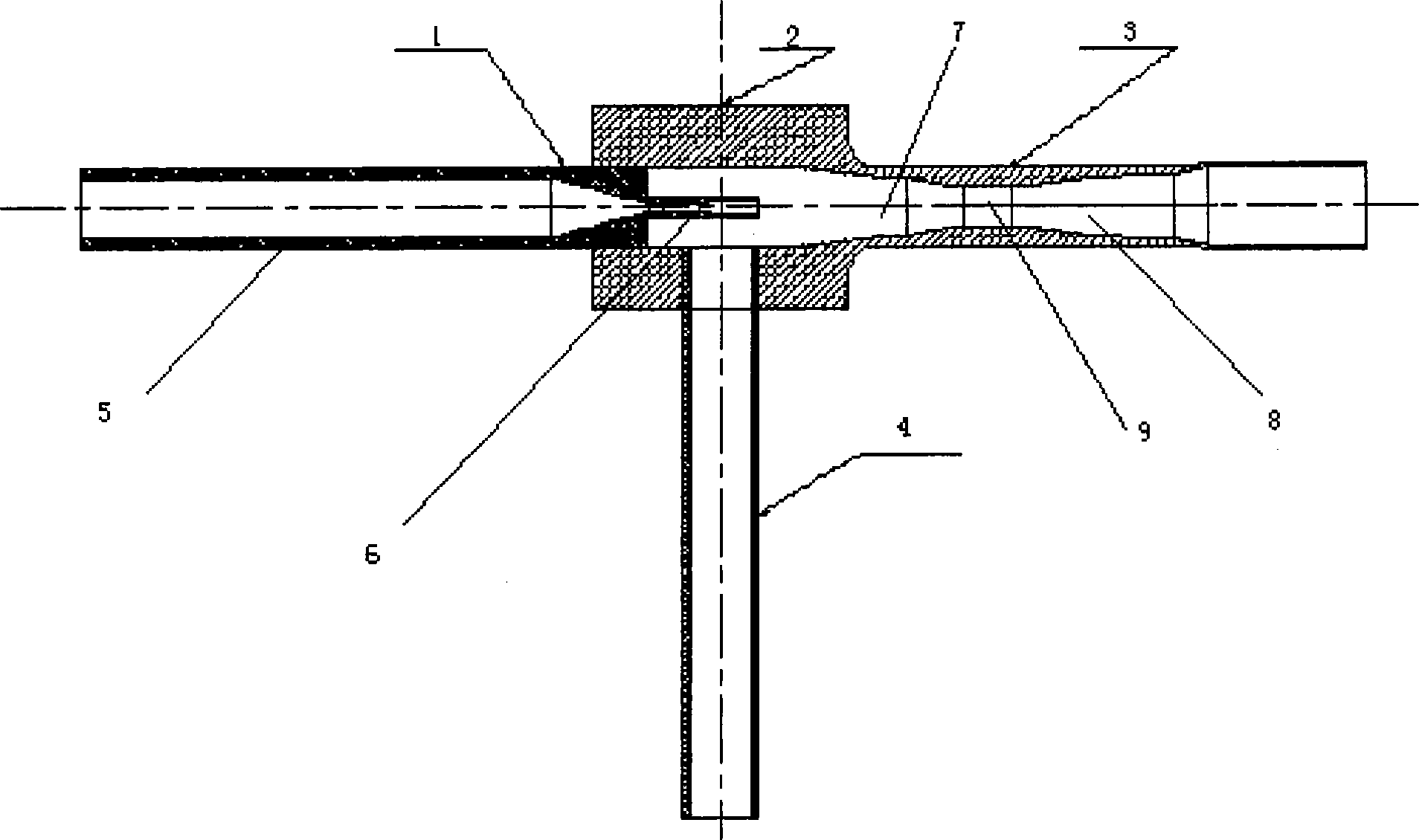

Online SO3 measuring system and method

InactiveCN106596198AEfficient removalEffective temperature regulationWithdrawing sample devicesAnalysing gaseous mixturesEngineeringAir compressor

The invention relates to an on-line SO3 measuring system and a method thereof, belongs to the field of gas sampling and measuring, and in order to solve the problems of complex system, inaccurate measurement and incapability of real-time monitoring of SO3 measuring systems in the prior art. The on-line SO3 measuring system comprises a heater, a sampling tube, a filter, a reaction tube, an air compressor, a diluting device, a flow meter, a hydrogen chloride detector and a sampling pump. When flue gas passes through the high temperature heater, sulfuric acid droplets are all converted into sulfuric acid vapor, and a quartz or ceramic filter can effectively remove dust particles in a sample gas. The sulfuric acid vapor can be reacted with calcium chloride in the reaction tube to produce hydrogen chloride, according to a value displayed by the hydrogen chloride detector, a sample gas dilution ratio, and stoichiometric coefficient ratio of the sulfuric acid vapor and the hydrogen chloride, the concentration of the sulfuric acid vapor is determined, and then the concentration of SO3 in the flue gas is determined. The on-line SO3 measuring system is mainly used for sampling and measuring of SO3 / H2SO4 in the flue gas emitted from coal-fired boilers.

Owner:HARBIN INST OF TECH

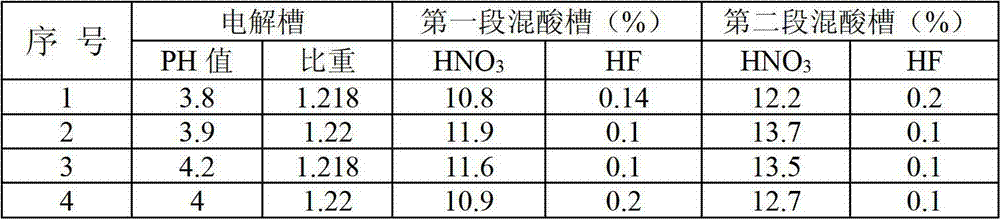

Method for annealing and pickling 409L stainless steel

InactiveCN102864459AEffective adjustment of specific gravityEffectively adjust PH valueHeating timeElectrolysis

The invention discloses a method for annealing and pickling 409L stainless steel through neutral salt electrolyzing and mixed acid pickling technology. The method comprises the steps as follows: a, annealing, controlling the concentration of excess oxygen to 3 to 5%, controlling the heating temperature to 950-1100 DEG C, wherein the heating time is 1 to 3 minutes per millimeter based on thickness; b, electrolyzing, and controlling the specific gravity of neutral salt to 1.2 to 1.24, pH to 3.5 to 4.5, temperature to 70 to 90 DEG C, and current strength in electrifying to 4500 to 5500A; and c, pickling, wherein pickling solution in the first stage includes 9 to 13% of HNO3 and 0.1 to 0.2% of HF, pickling solution in the second stage includes 11 to 15% of HNO3 and 0.1 to 0.2% of HF, the temperature of the pickling solutions in the two stages is at 50 to 60 DEG C, and the pickling time is 30 to 50 seconds. With the adoption of the method disclosed by the invention, the collinear annealing and pickling of FeCr system and FeCrNi system stainless steels can be achieved; and good 2D surface can be obtained.

Owner:YUNNAN TIANGAO NICKEL IND CO LTD

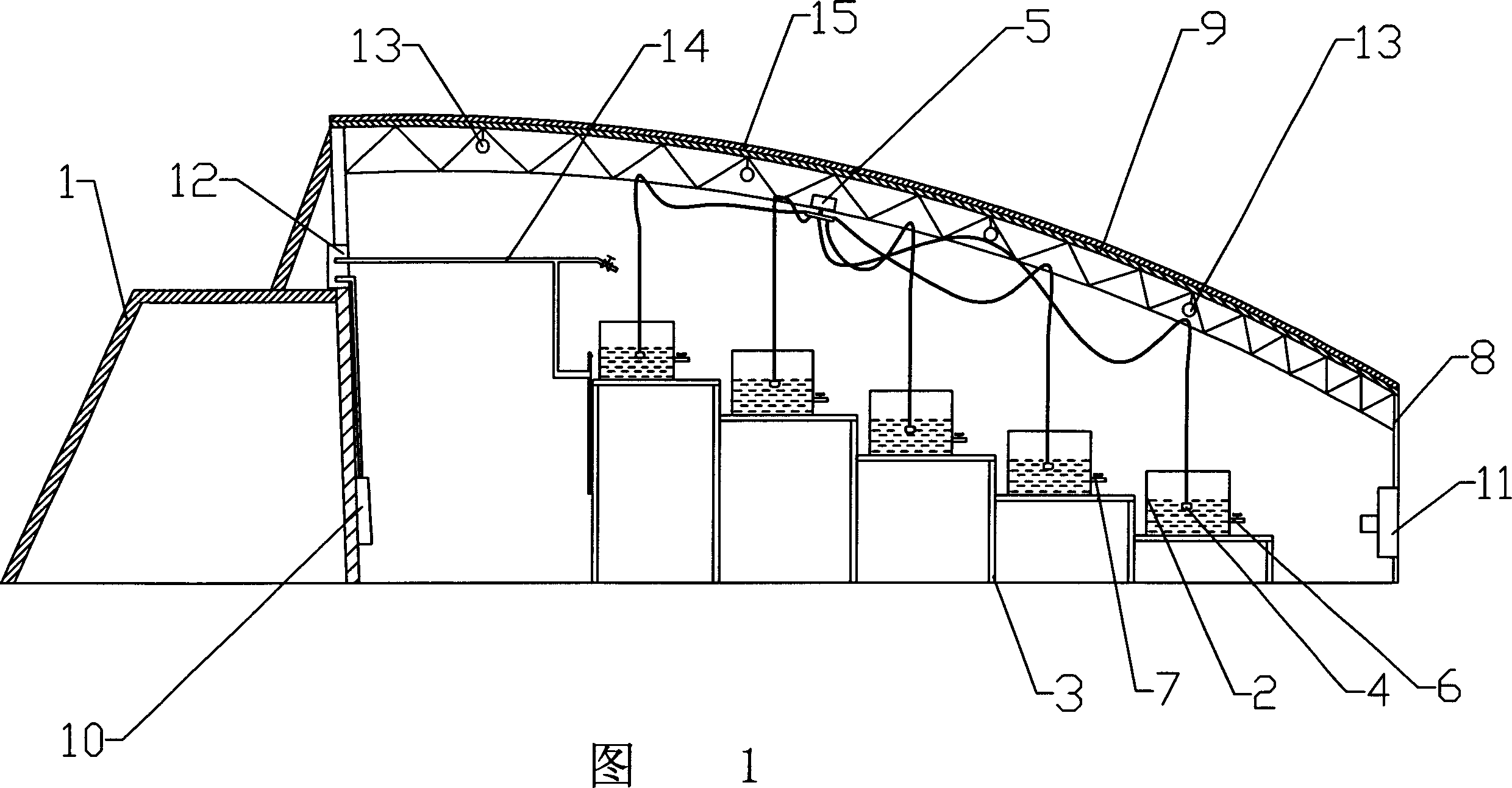

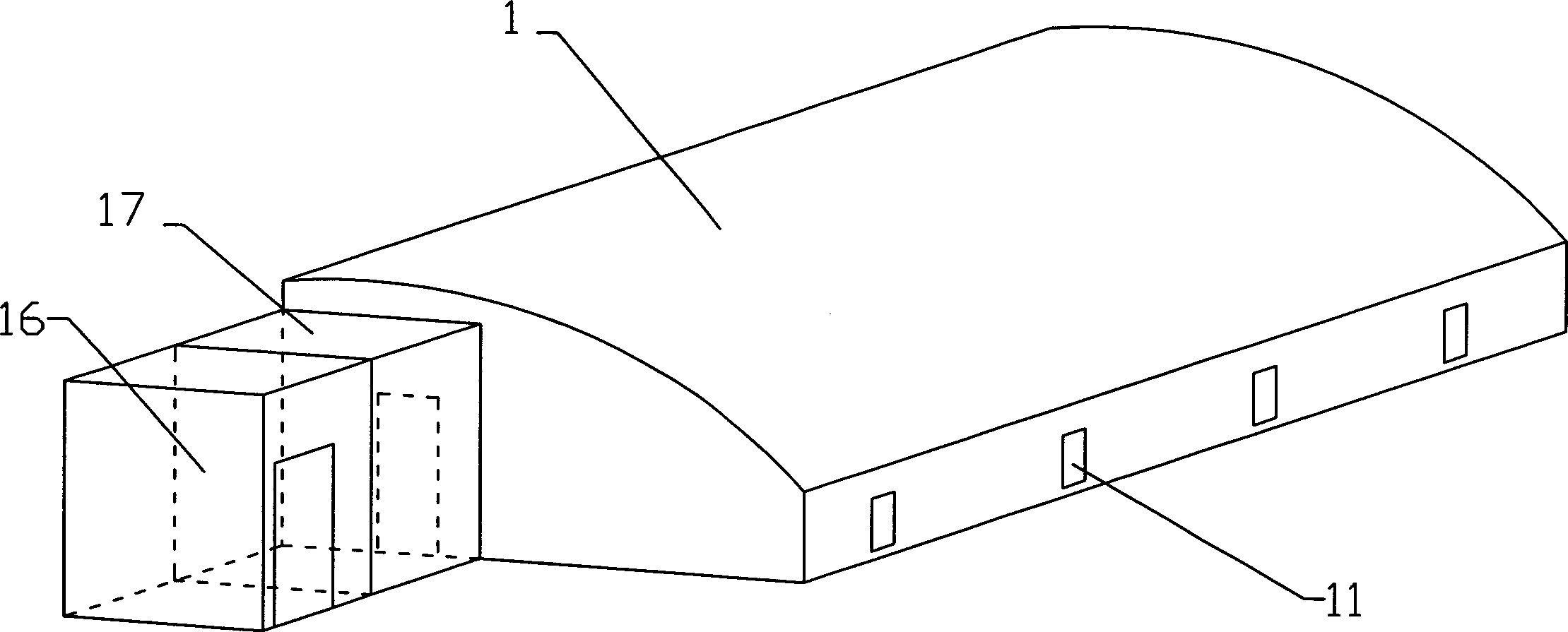

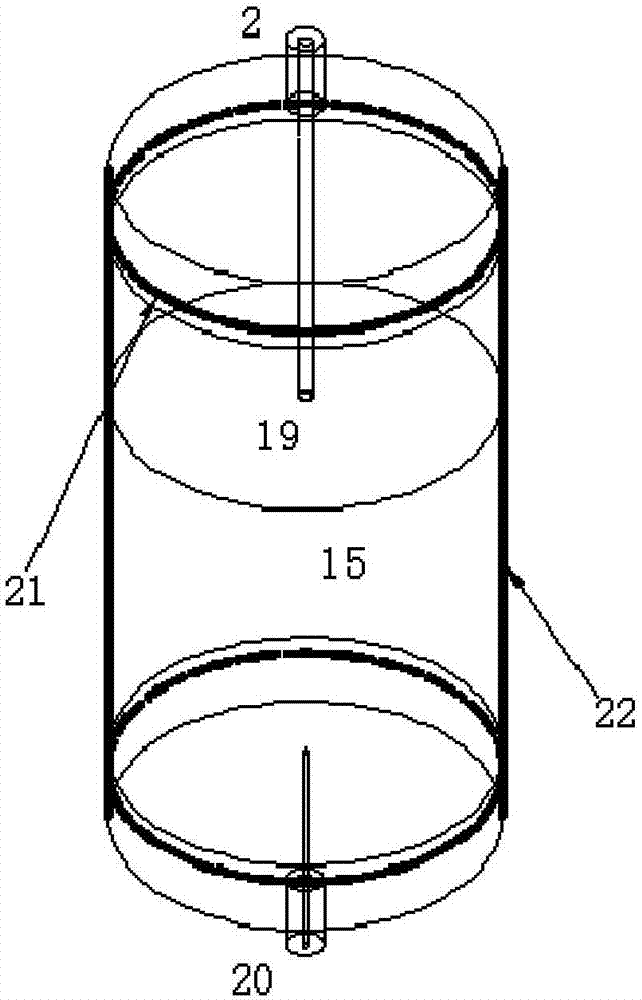

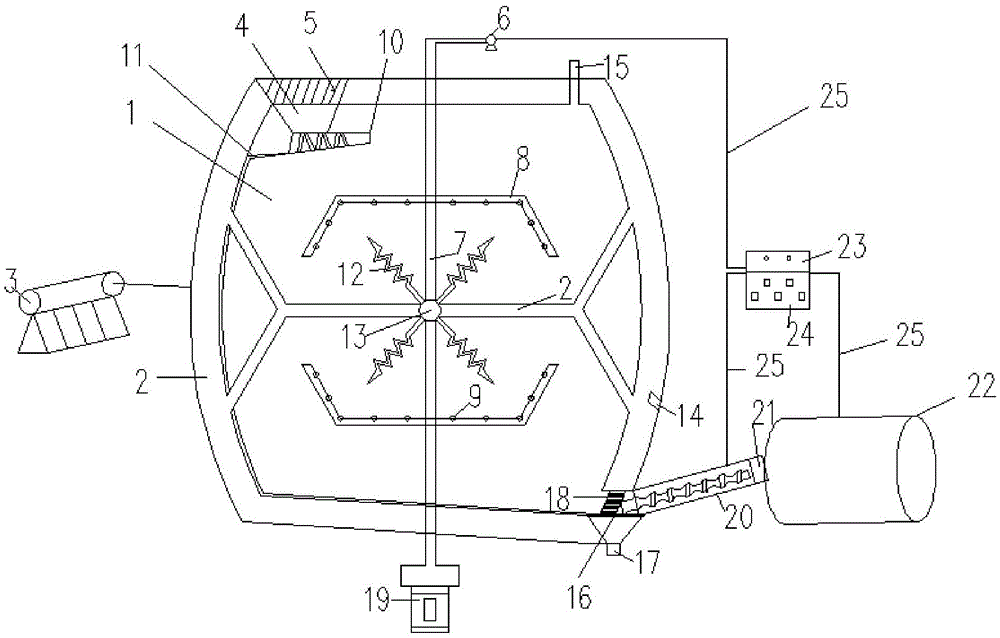

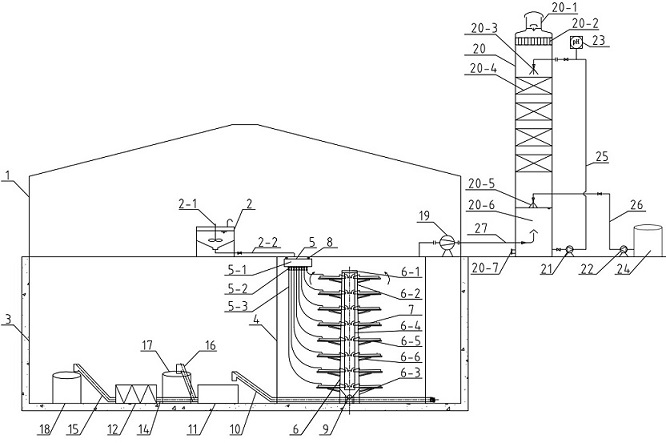

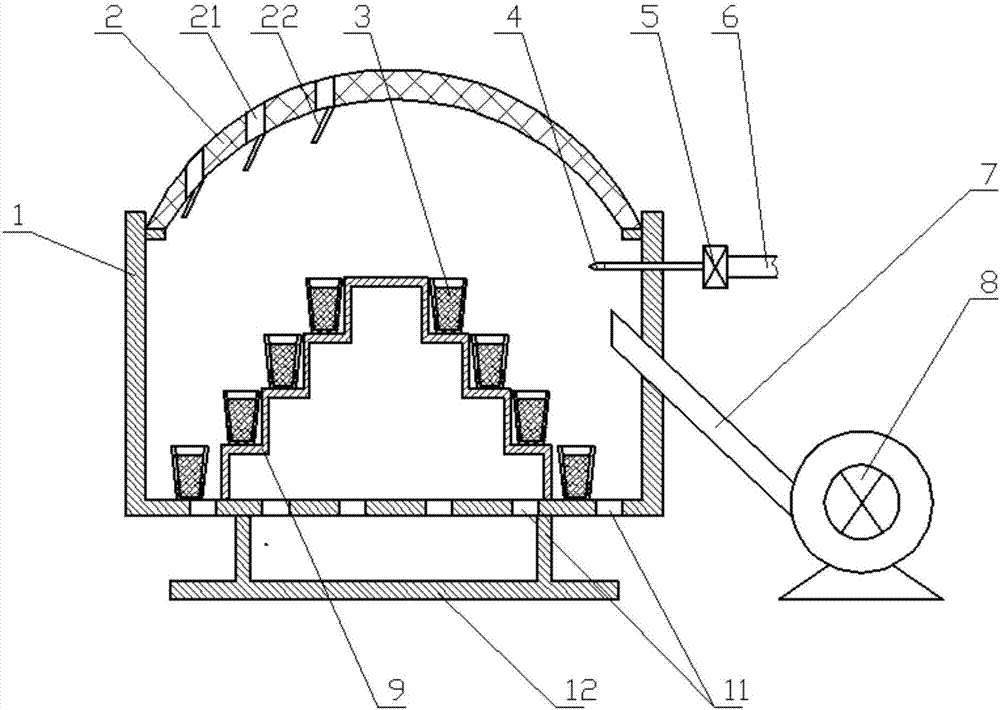

Closed type spirulina breeding device

InactiveCN1786146ANot easy to polluteAvoid harmBioreactor/fermenter combinationsBiological substance pretreatmentsDiseaseEngineering

The invention discloses a sealed type screw algae cultivation setting. It includes big shed body and transparent container. The big shed is set cascade supporting; the transparent container is set qi of chong channel ascending adversely setting. The big shed includes supporting wall, supporting framework, photic film. It is set heating, exhaustion installation, purger, lighting device, and humidity control device. Its gateway is set buffering room, changing room. The screw algae are not easy to be harmed by pollution and damage by disease and insect. So it has better market and practice generalization application value.

Owner:SHOUGUANG FUKANG PHARMA

Method for reducing energy consumption of device for preparing olefins from oxy-compound

ActiveCN102951982AAvoid smallLess quantityHydrocarbon from oxygen organic compoundsGas phaseChilled water

The invention provides a method for reducing energy consumption of a device for preparing olefins from an oxy-compound. The method comprises the following steps that: a liquid oxy-compound raw material is firstly preheated to a certain temperature by a raw material preheater and then is divided into two parts, one part is heated and gasified by a raw material gasifier to become a gas phase raw material and the other part is atomized to become an atomized liquid phase raw material; the gas phase raw material and the atomized liquid phase raw material are mixed in front of a raw material / reaction gas heat exchanger and enter the raw material / reaction gas heat exchanger in the form of mist flow to carry out full heat exchange with oil gas generated through high-temperature reaction from a reactor so as to recover the high-temperature level heat of the oil gas generated through high-temperature reaction, the raw material after recovering the high-temperature level heat is totally gasified to become the high-temperature gasified raw gas and the high-temperature gasified raw gas then enters the reactor to undergo reaction; and the oil gas generated through high-temperature reaction from the reactor undergoes heat exchange in the raw material / reaction gas heat exchanger and then is sent to a rear chilled water washing system. The method has the advantages that the heat exchange effect of the heat exchanger can be effectively improved, the volume of the heat exchanger can be reduced and the energy consumption of the device can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

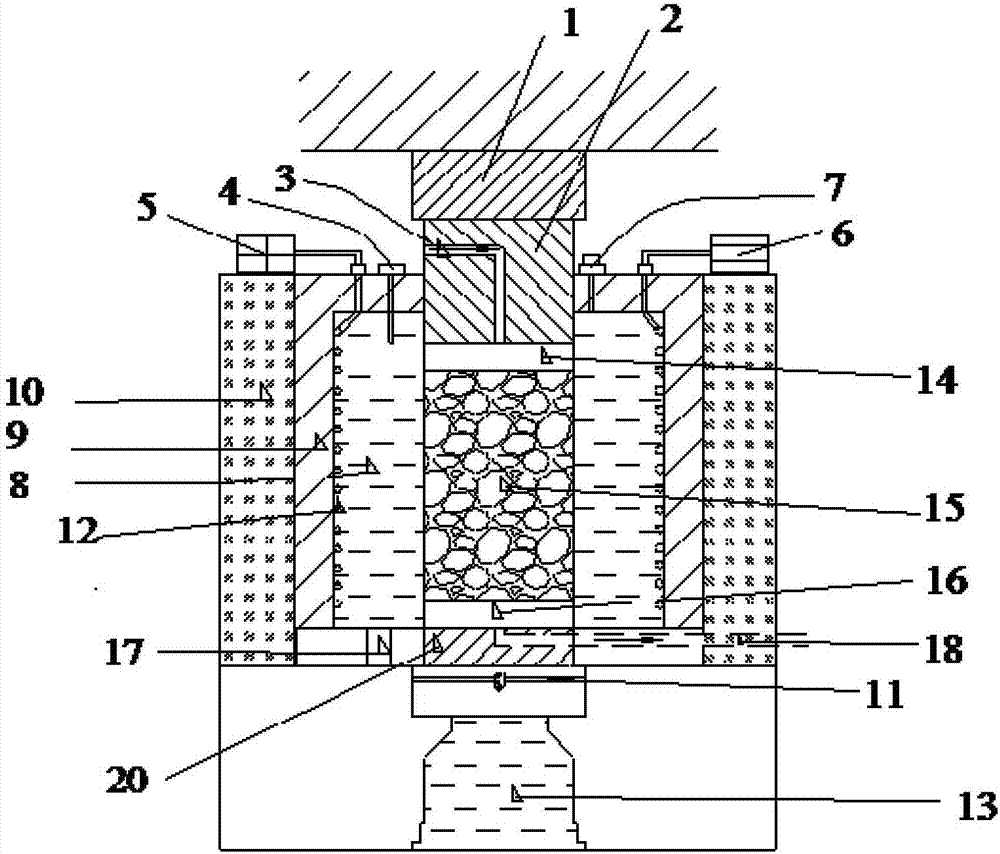

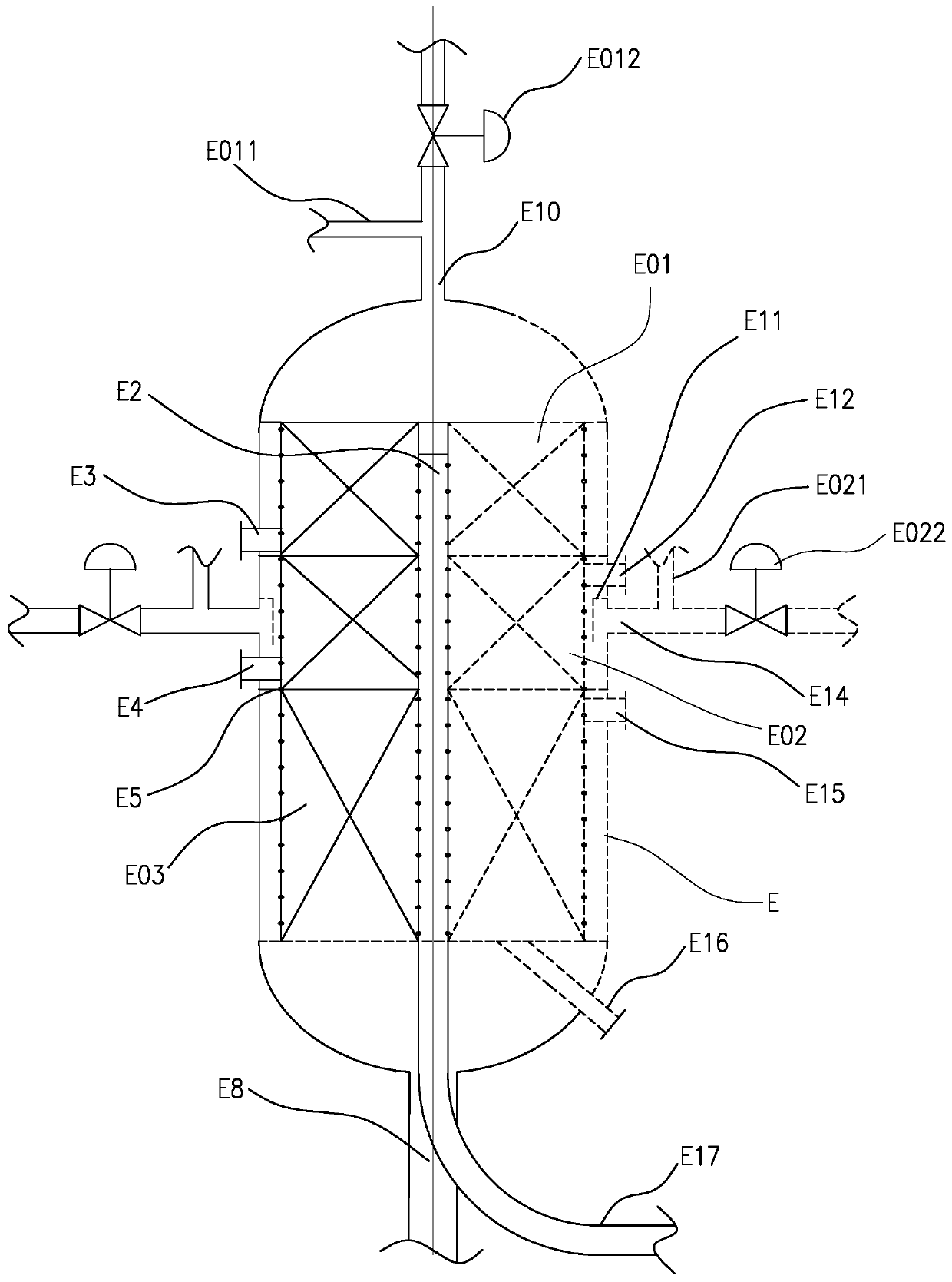

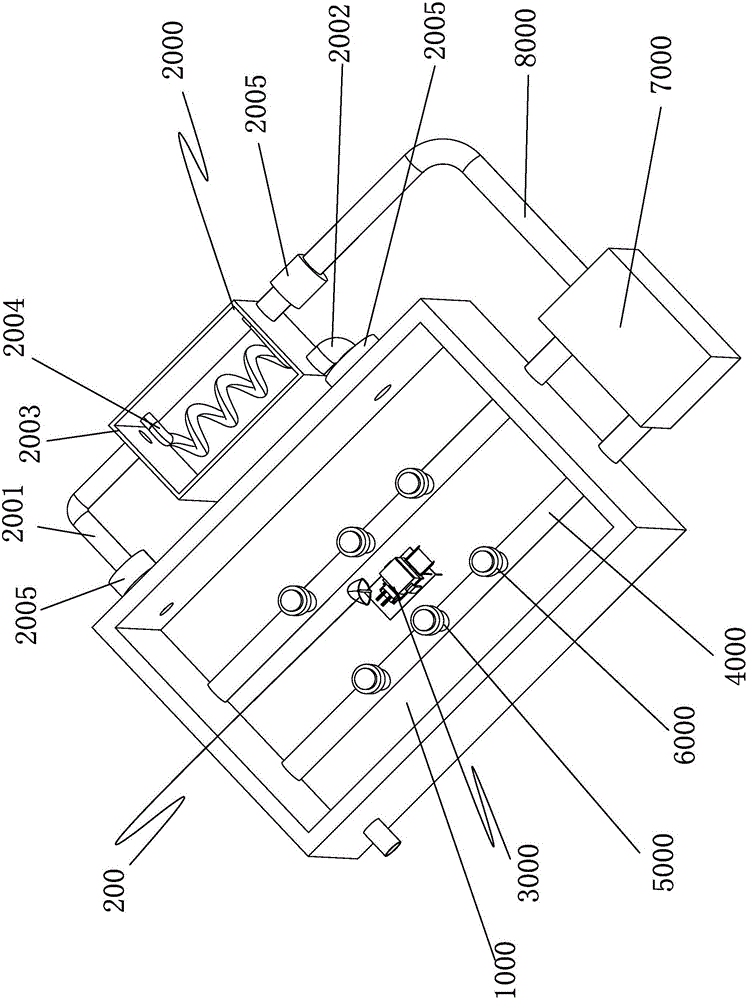

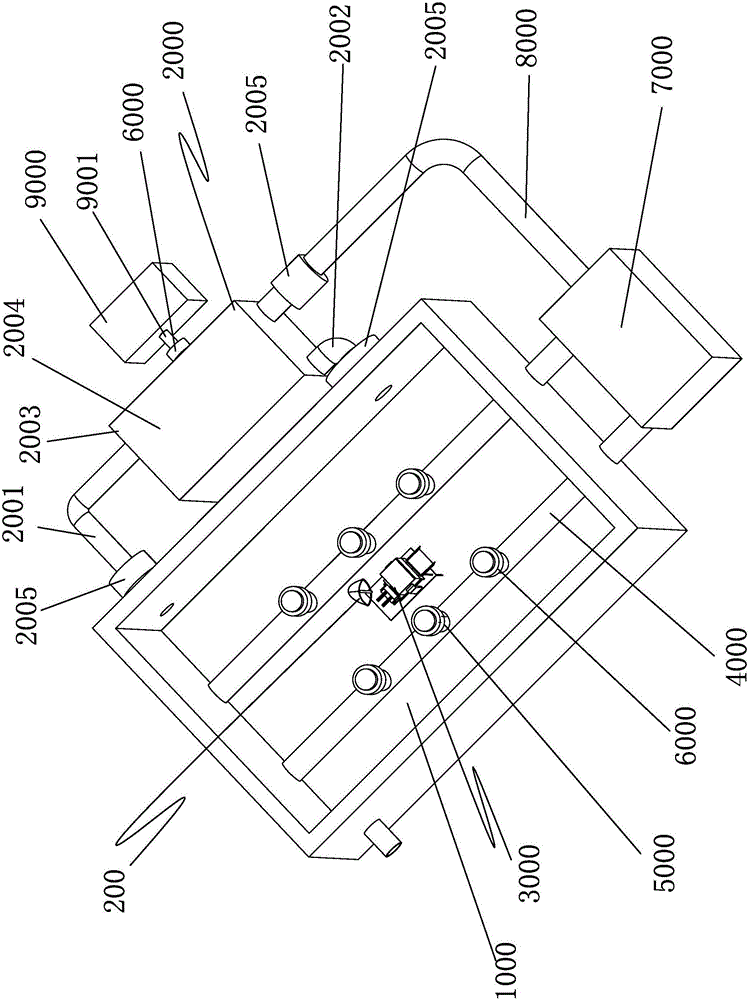

Rock coupling penetration test apparatus and rock coupling penetration test method

InactiveCN107063962AAvoid getting lostEffective temperature regulationPermeability/surface area analysisAutomatic controlMulti field

The invention relates to a rock coupling penetration test apparatus and rock coupling penetration test method, and specifically relates to a rock coupling penetration test apparatus and a rock coupling penetration test method under the temperature-stress-seepage-chemistry multi-field coupling effect. The rock coupling penetration test apparatus comprises a computer control console, a water storage box, a pressure chamber, a booster cylinder, an oil-water converter, a temperature control system, a chemical solution self-preparation system and a pipeline system. The rock coupling penetration test method comprises: preparing and installing a sample; installing a temperature device; setting temperature control; carrying out a temperature test; and automatically controlling the test to enter a stabilization stage. According to the present invention, based on the problems of simple heating mode of the temperature control system, narrow temperature change range, single function and less test condition in the existing rock coupling penetration test apparatus, the temperature can be effectively adjusted while the pH value of the chemical solution can be automatically controlled, the problem that the easy volatilization of CO2 from the carbonic acid solution causes the reduced acidity can be solved, and the rock penetration and mechanical property test research under the water rock action condition can be really reflected.

Owner:HOHAI UNIV

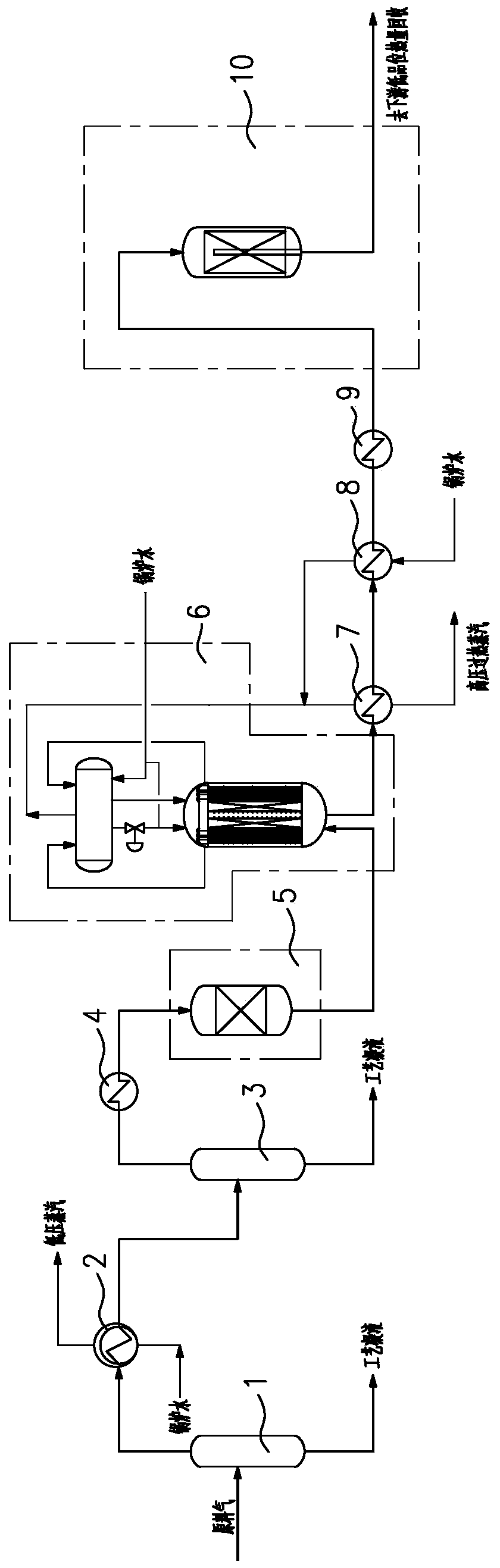

High-concentration carbon monoxide controllable semi-isothermy conversion process for carbonyl synthesis

ActiveCN110550602AAddress reactivitySolve the problem of difficult temperature controlHydrogenEnergy inputHigh concentrationHigh carbon

The invention relates to a high-concentration carbon monoxide controllable semi-isothermy conversion process for carbonyl synthesis. The application range is wide, and raw materials with the volume content of a carbon monoxide dry basis being 30-90% and with the volume ratio of water / extra-dry gas being 0.1-1.6 are adopted; the technological process is short, the number of equipment is small, control is easy, and the investment and operation costs are low; by arranging a controllable semi-isothermy saturated steam generation system with a control valve, the temperature of shift gas can be quickly and effectively adjusted, the steam generating pressure is not affected, the problems that a gas conversion reaction of the raw materials with the high carbon monoxide content is prone to overtemperature and difficult temperature control are solved, the grade of byproduct saturated steam is increased to the largest extent, and the yield of low-pressure saturated steam with low utilization value is decreased; high-pressure saturated steam can be overheated, arranging of an external overheating furnace or heat combination with other devices is not needed, and thus the investment and operation difficulty is lowered; and as for the working condition that the temperature needs to be increased at the terminal stage of a catalyst, only the opening degree of the control valve needs to be appropriately adjusted, and thus operation is convenient.

Owner:SINOPEC NINGBO ENG +2

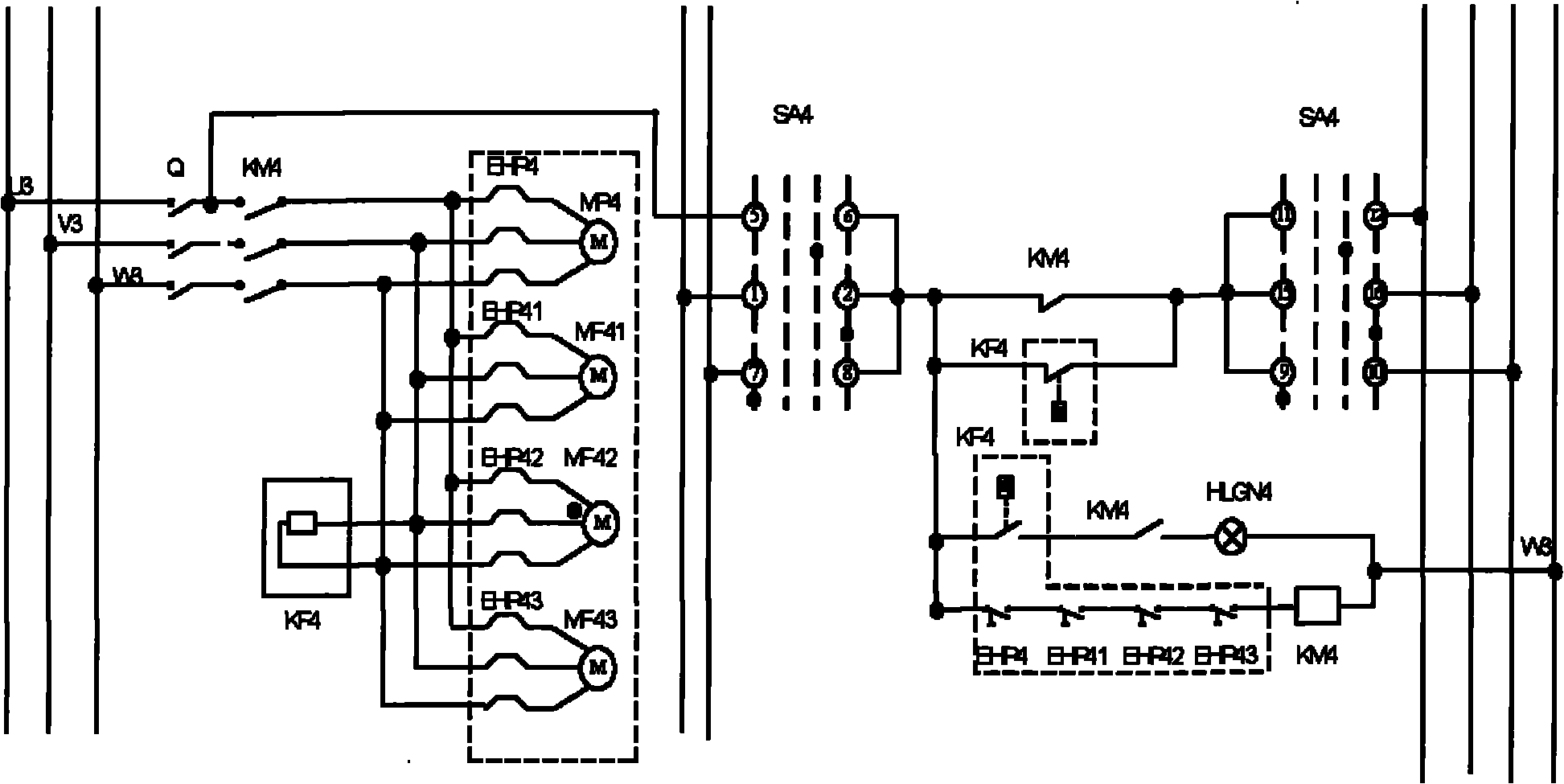

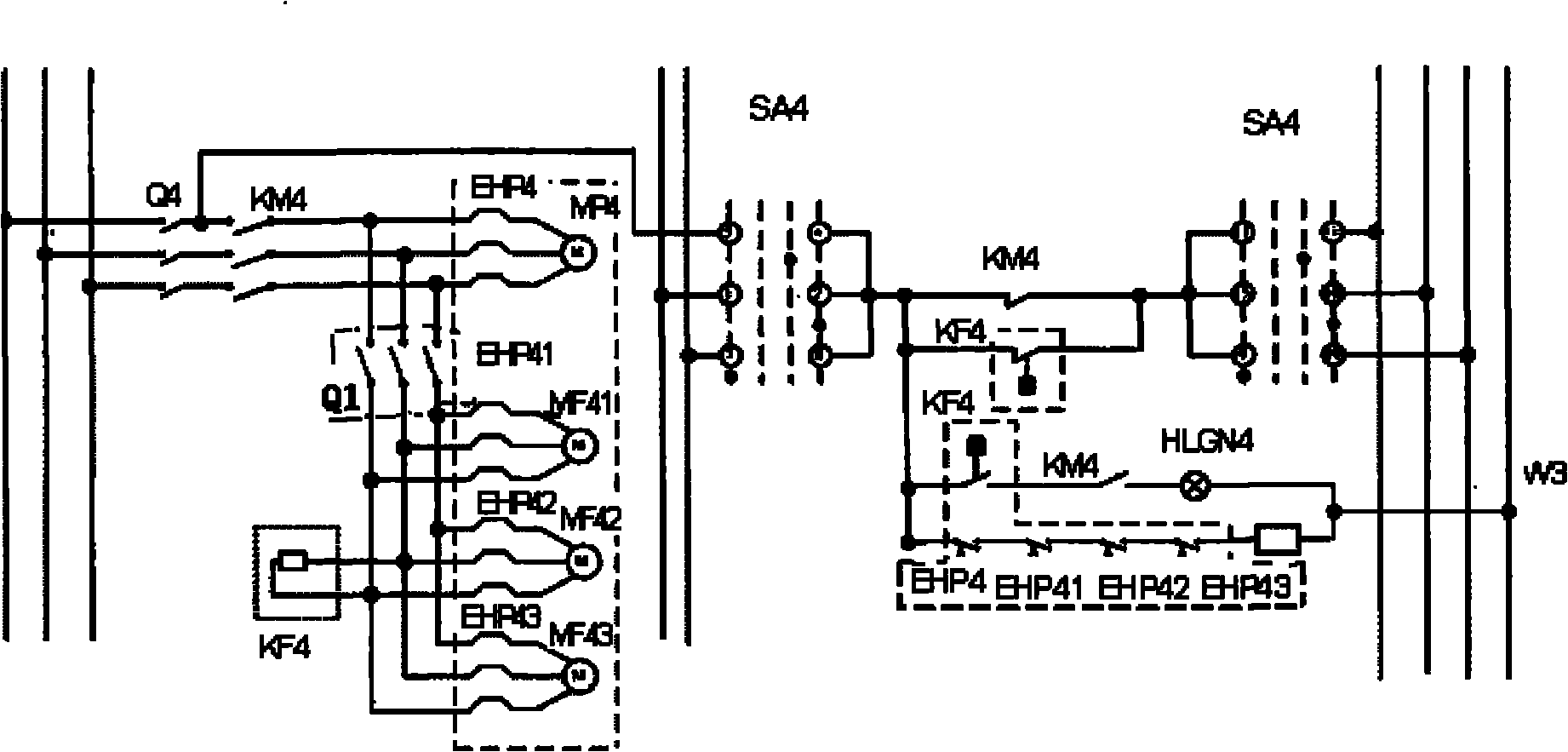

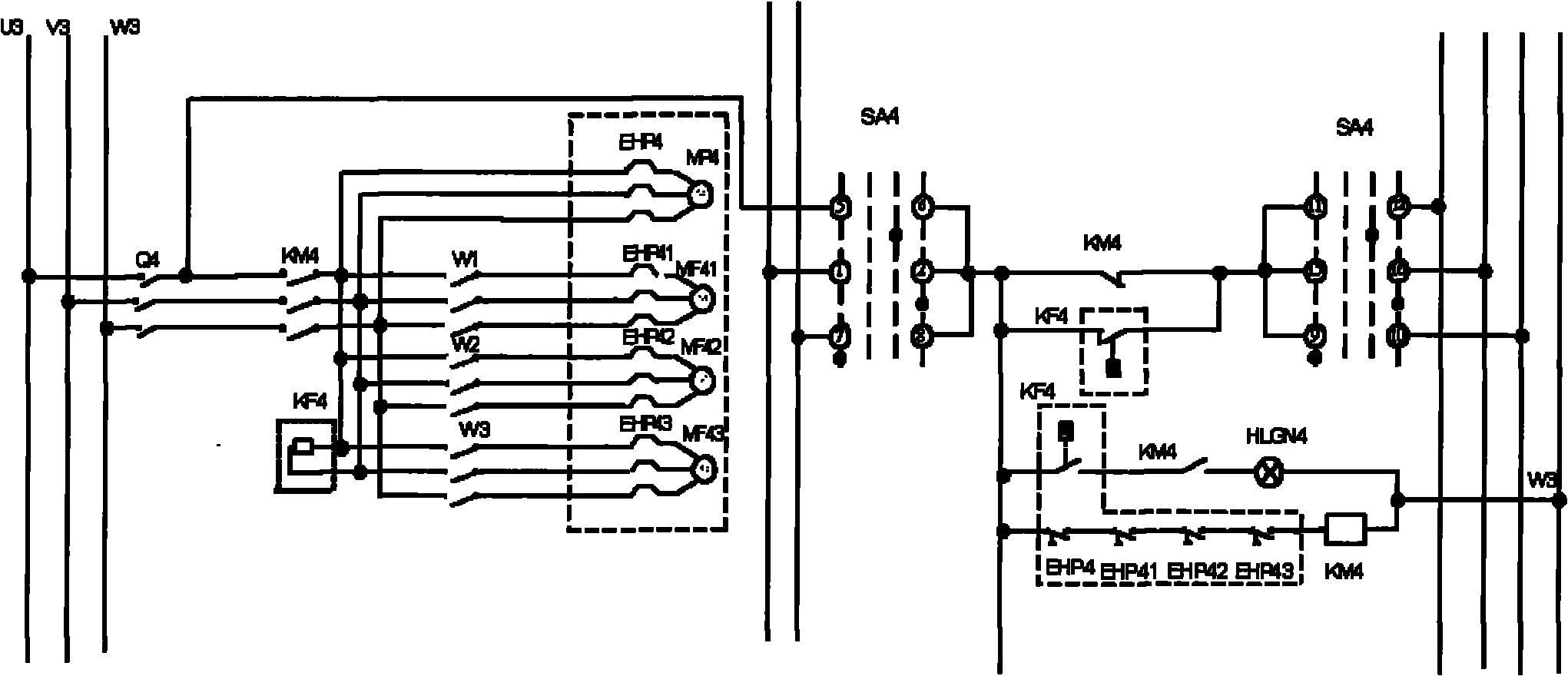

Method and device for controlling transformer cooling system

InactiveCN102109860AEffective temperature regulationReduce energy consumptionTransformers/inductances coolingTemperatue controlTransformerEngineering

The invention discloses a method and a device for controlling a transformer cooling system. The system comprises a transformer submersible pump, fans and an intelligent control device. The method comprises the following steps of: (a) operating the submersible pump of a working group of the transformer cooling system; and (b) determining the number of input fans according to the oil temperature of a transformer. The method and the device for controlling the transformer cooling system can adapt to the changes of ambient temperatures in different seasons; and by the method and the device, the temperature of the transformer can be effectively adjusted, the energy consumption of a cooling fan motor can be reduced, energy conservation and consumption reduction can be realized and the cooling system can be operated optimally.

Owner:CHINA SHENHUA ENERGY CO LTD +2

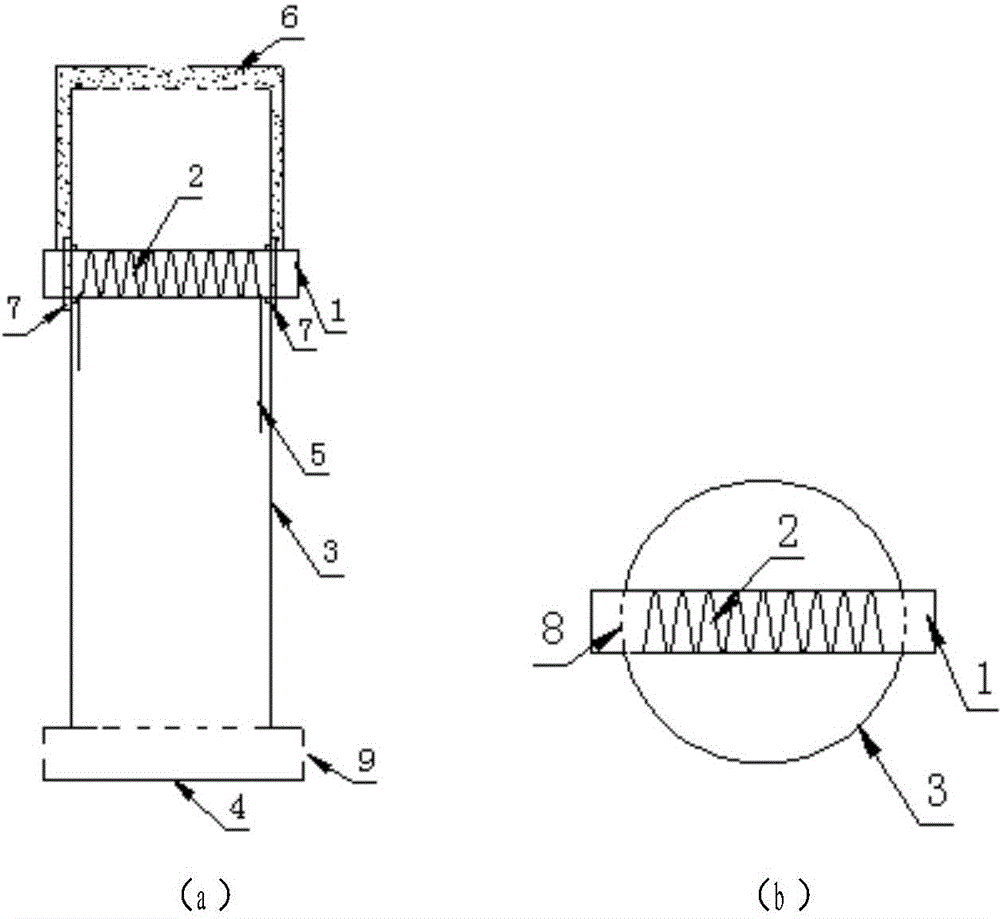

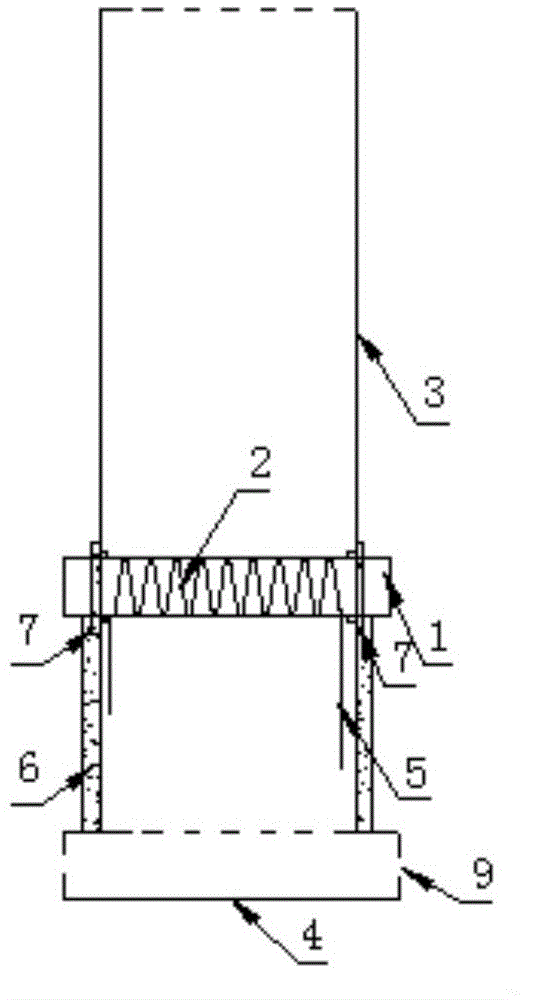

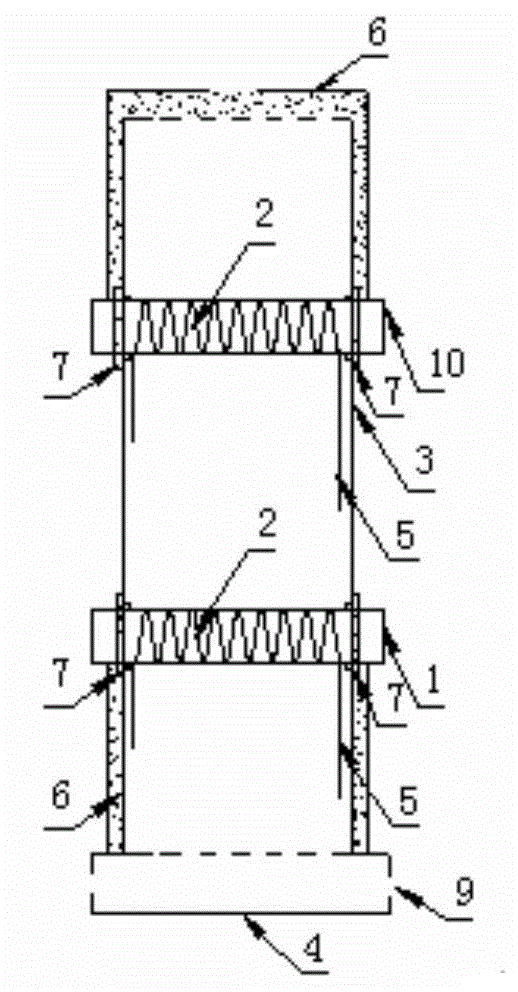

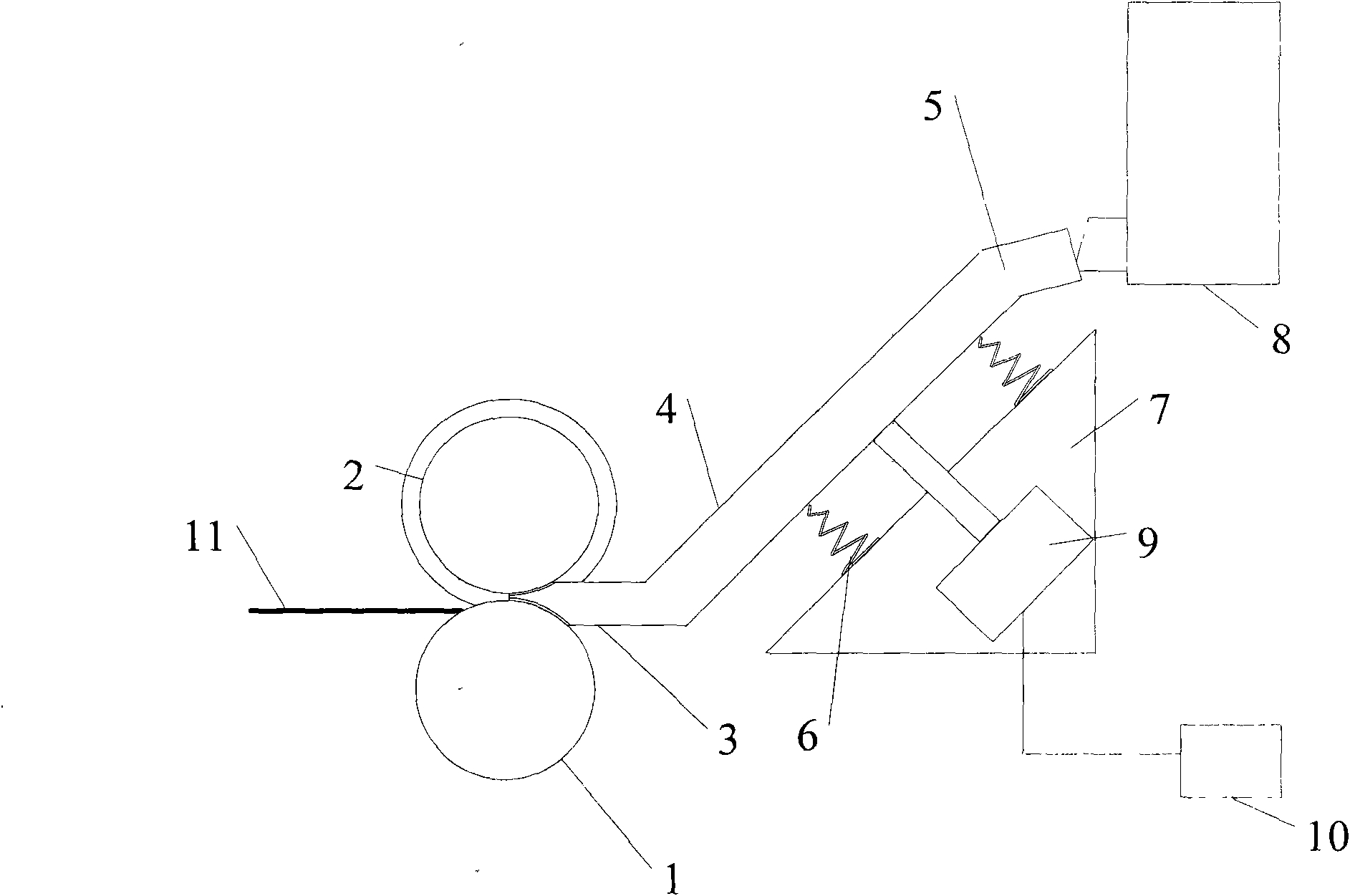

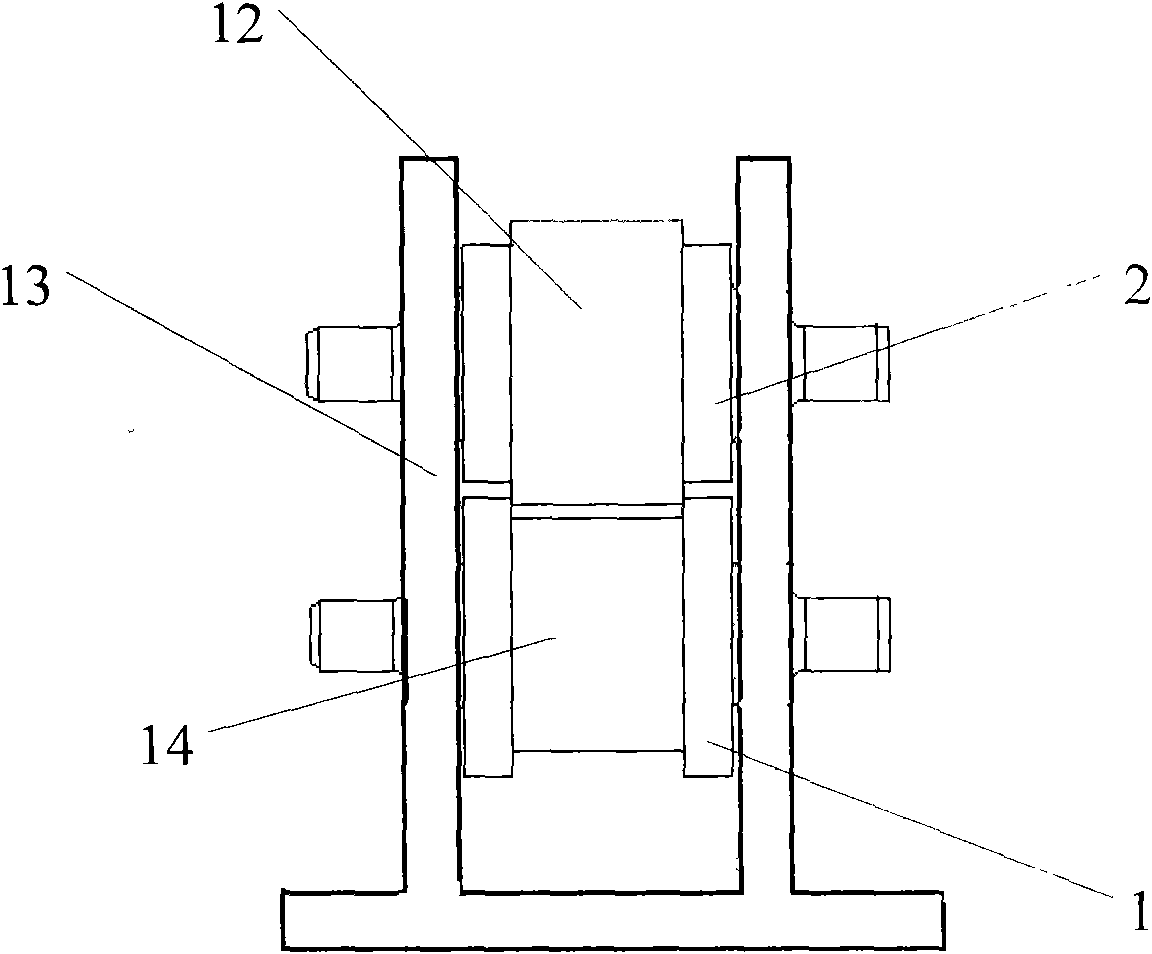

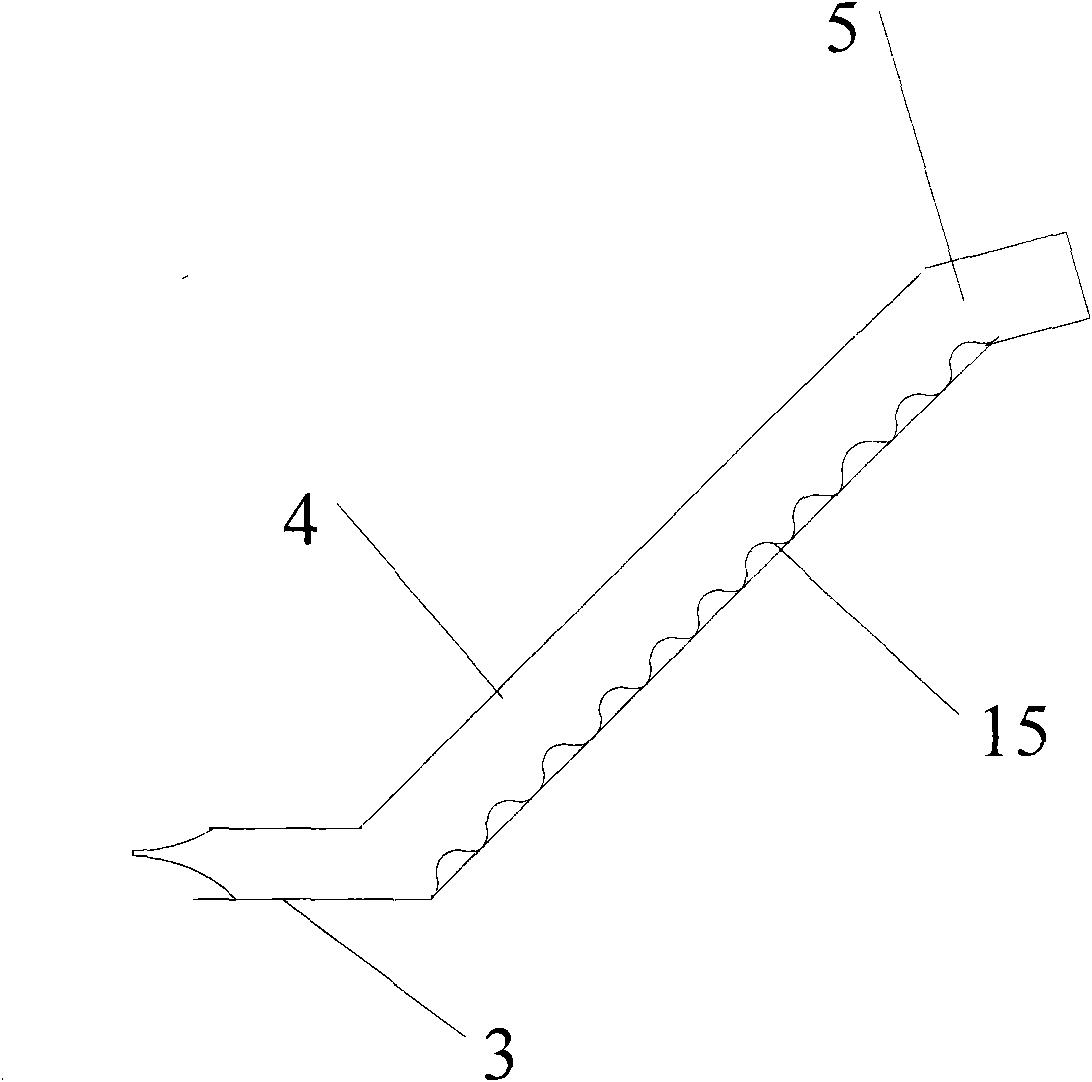

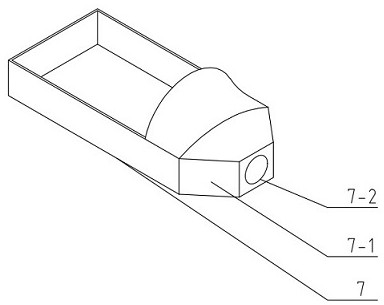

Continuous rheomolding device for manufacturing metal plate strips

InactiveCN101890431AIncreased speed of continuous rheological formingGood formabilityMetal rolling arrangementsEngineeringAlloy

The invention provides a continuous rheomolding device for manufacturing metal plate strips. The device comprises an inclined plate, a base, an electromagnetic vibration exciter and a double-roller rolling mill and is characterized by also comprising the double-roller rolling mill, wherein the inclined plate is formed by connecting a feeding section, a pulping section and a discharging section in turn; the lower side of a bottom plate of the pulping section is connected with the upper end of a spring; the lower end of the spring is fixed on the base; one end of the electromagnetic vibration exciter is fixed on the base, and the other end of the electromagnetic vibration exciter is connected with the lower side of the bottom plate of the pulping section; and gaps are formed between the bottom plate and two side plates of the discharging section and the roll surfaces of upper and lower rollers of the double-roller rolling mill. The range of vibration frequency which can be provided by the electromagnetic vibration exciter adopted by the device is expanded greatly and the vibration frequency is adjusted so that an alloy structure can be improved more effectively and molten metal is prevented from crusting on the surface of the inclined plate.

Owner:NORTHEASTERN UNIV

Temperature regulation-control method and system of data center machine room

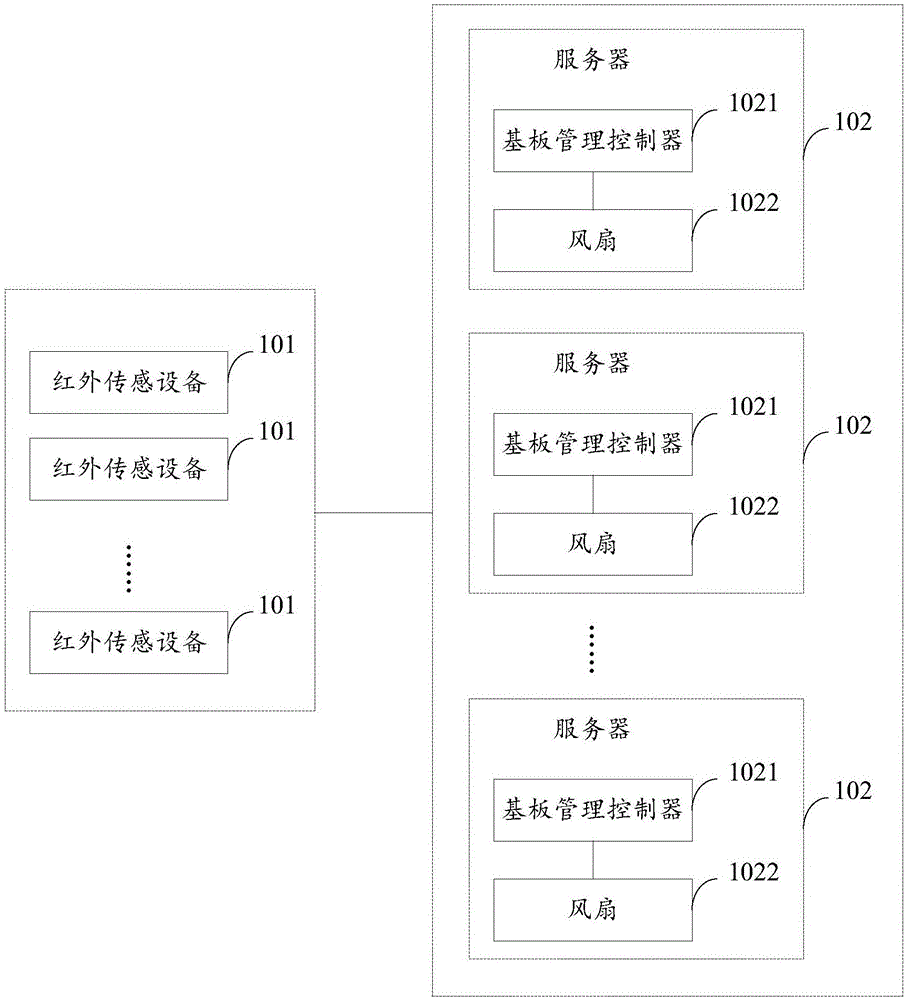

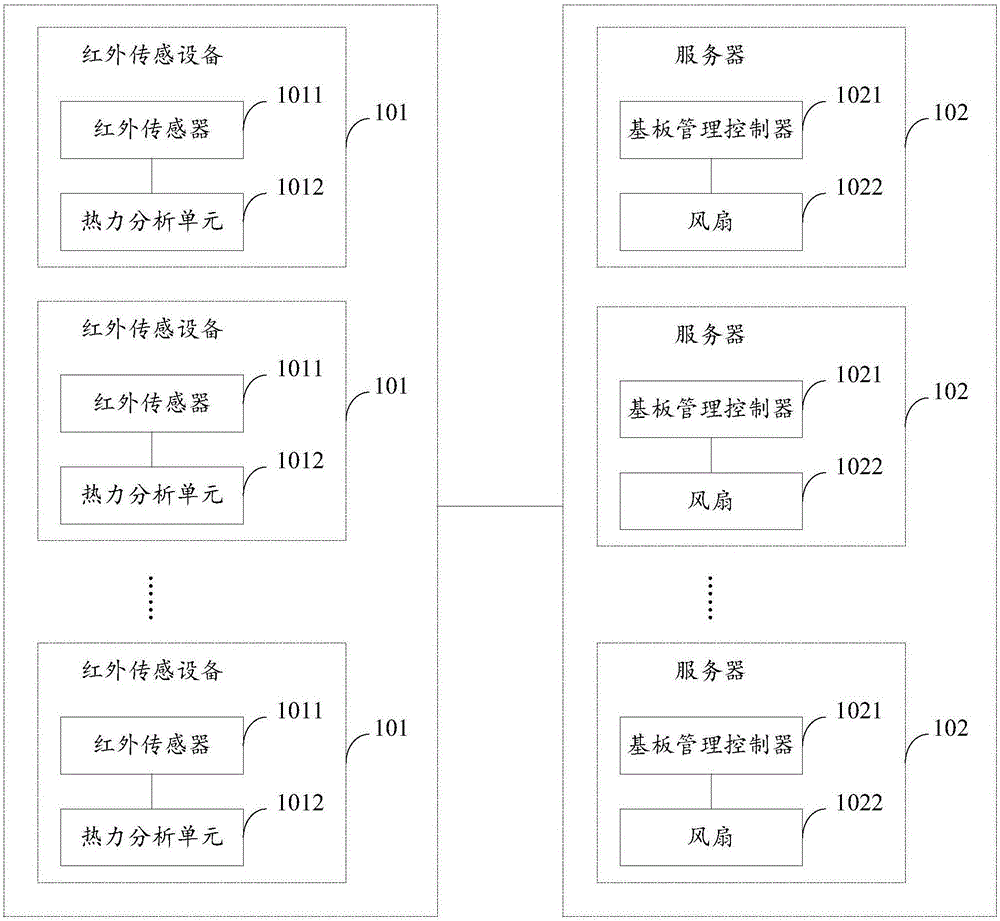

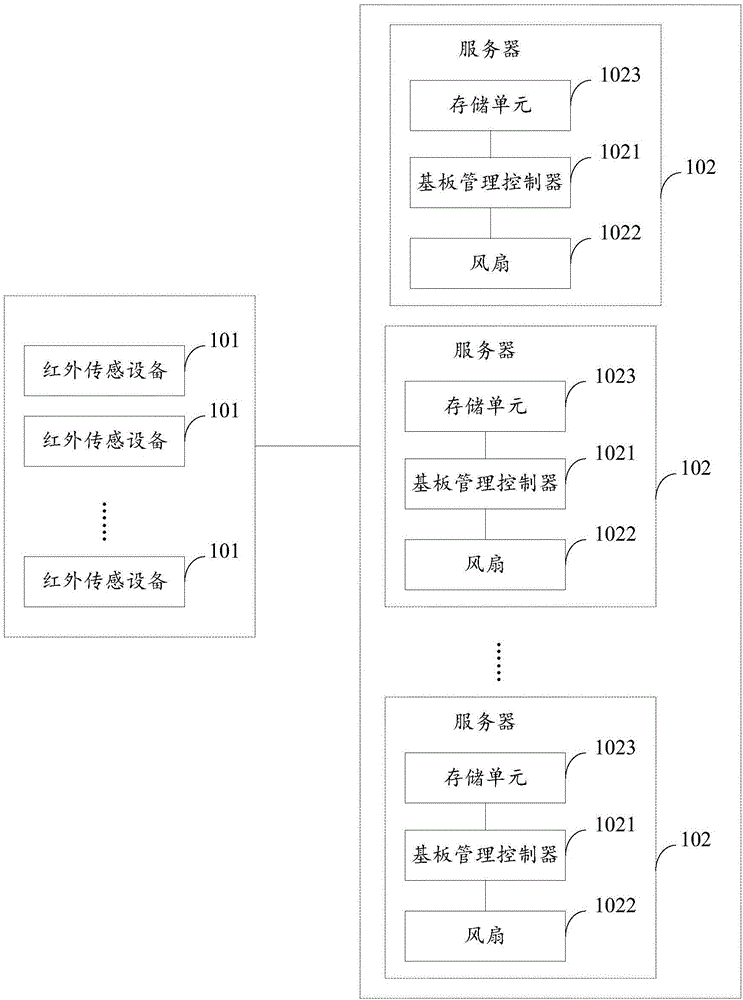

The invention provides a temperature regulation-control method and system of a data center machine room. The temperature regulation and control system comprises at least one infrared sensing device and at least one server; both the infrared sensing device(s) and the server(s) are positioned in the data center machine room; each infrared sensing device collects a temperature value and sends the collected temperature value to the corresponding server; each server comprises a substrate management controller and a fan; and the substrate management controller receives the temperature sent by the infrared sensing device, and controls the rotating speed of the fan of the corresponding server according to the received temperature value. According to the scheme, effective temperature regulation and control are realized.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

Household garbage fermentation and fertilizer making device and method

ActiveCN105461367AAvoid blockingBlocking implementationClimate change adaptationOrganic fertilisersFermentationScrew conveyor

The invention discloses a household garbage fermentation and fertilizer making device and method. A device body is a fermentation bin. A feed inlet and an air outlet are formed in the upper portion of the fermentation bin. A feeding baffle is arranged at the feed inlet. The lower portion of the fermentation bin is provided with a liquid outlet used for draining percolate and a discharge outlet used for outputting fermented materials. A breaking device is arranged in the fermentation bin and composed of a plurality of sets of breaking blades distributed in a cross shape, and has two perpendicular rotary dimensionalities. Household garbage to be treated passes through a spiral conveying machine through the feed inlet to enter the fermentation bin where a hot water pipeline is laid, is broken and fermented and then enters a dehydration pelleting and drying system from the position of a discharge baffle. According to the household garbage fermentation and fertilizer making device and method, breaking, stirring, heating, fermentation, dehydration pelleting and drying are integrated, garbage is converted into fertilizer, the energy is nature is effectively utilized, the running cost is reduced, the resources are effectively utilized while the environment problem is solved, the garbage is made profitable, and a new approach for effectively treating household garbage is provided.

Owner:ZHEJIANG UNIV

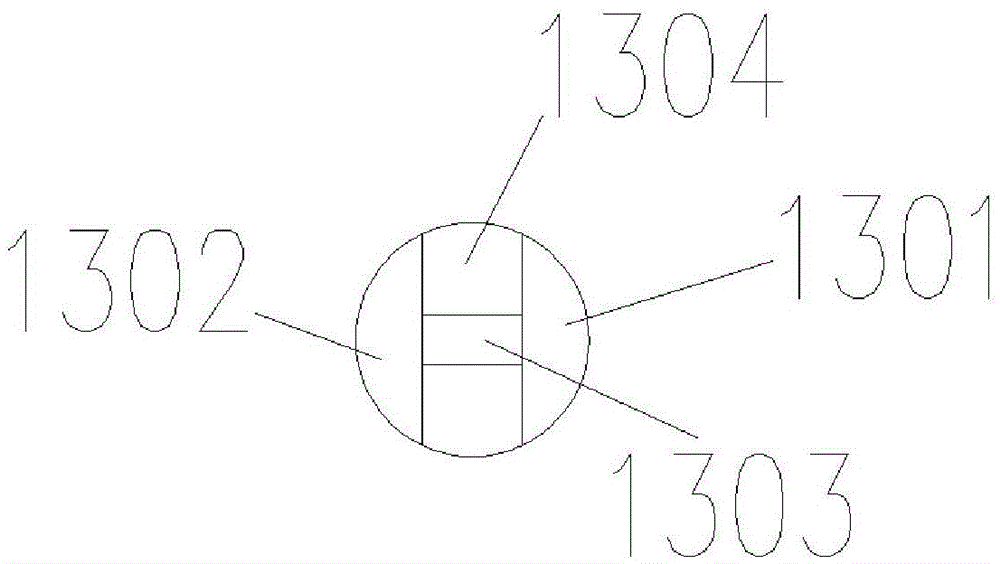

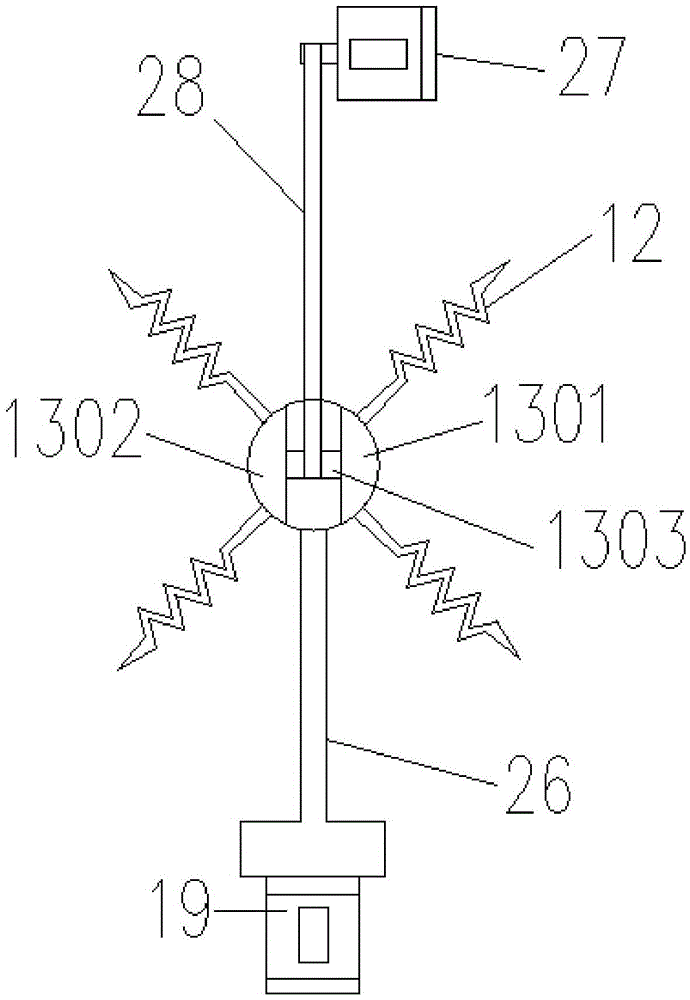

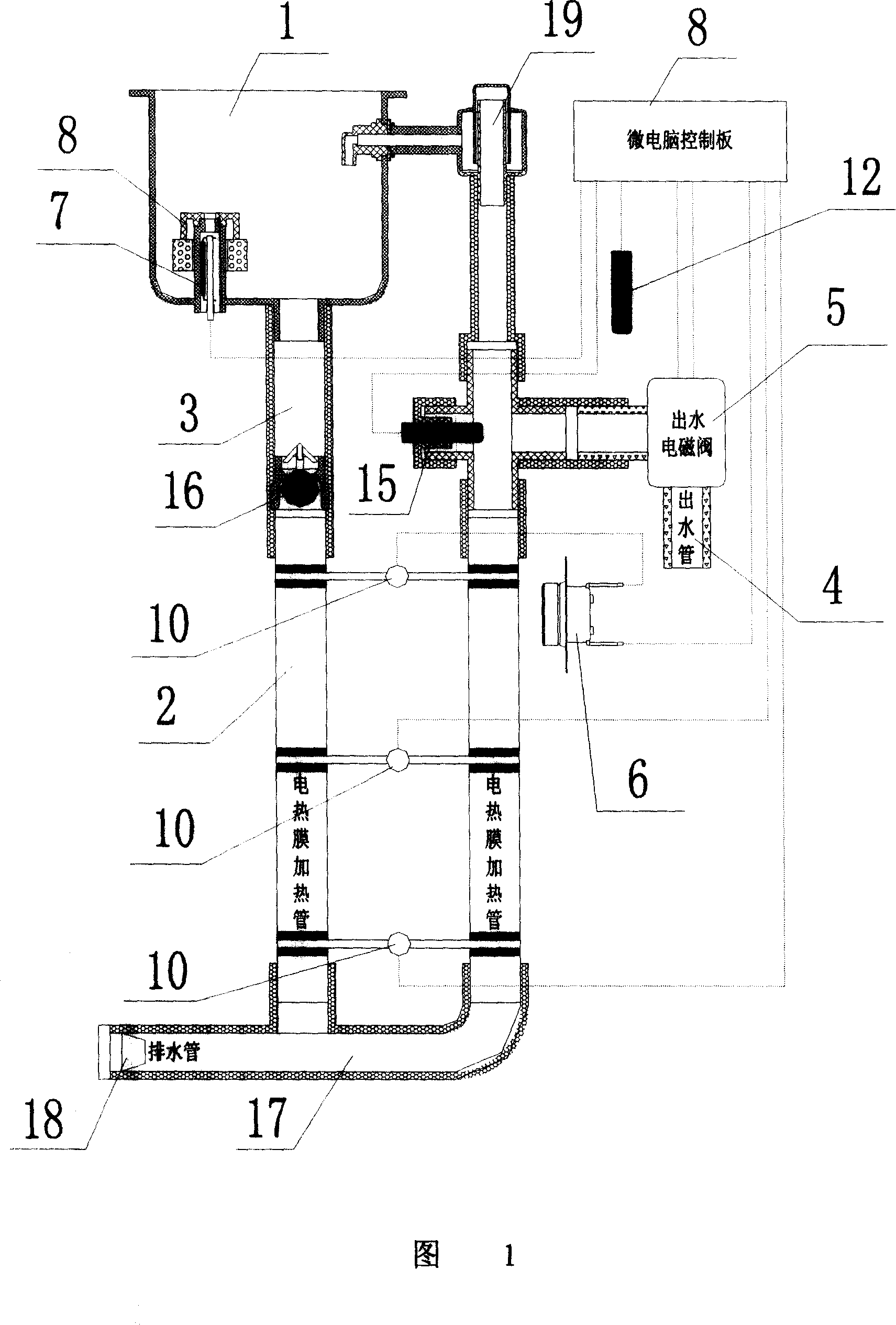

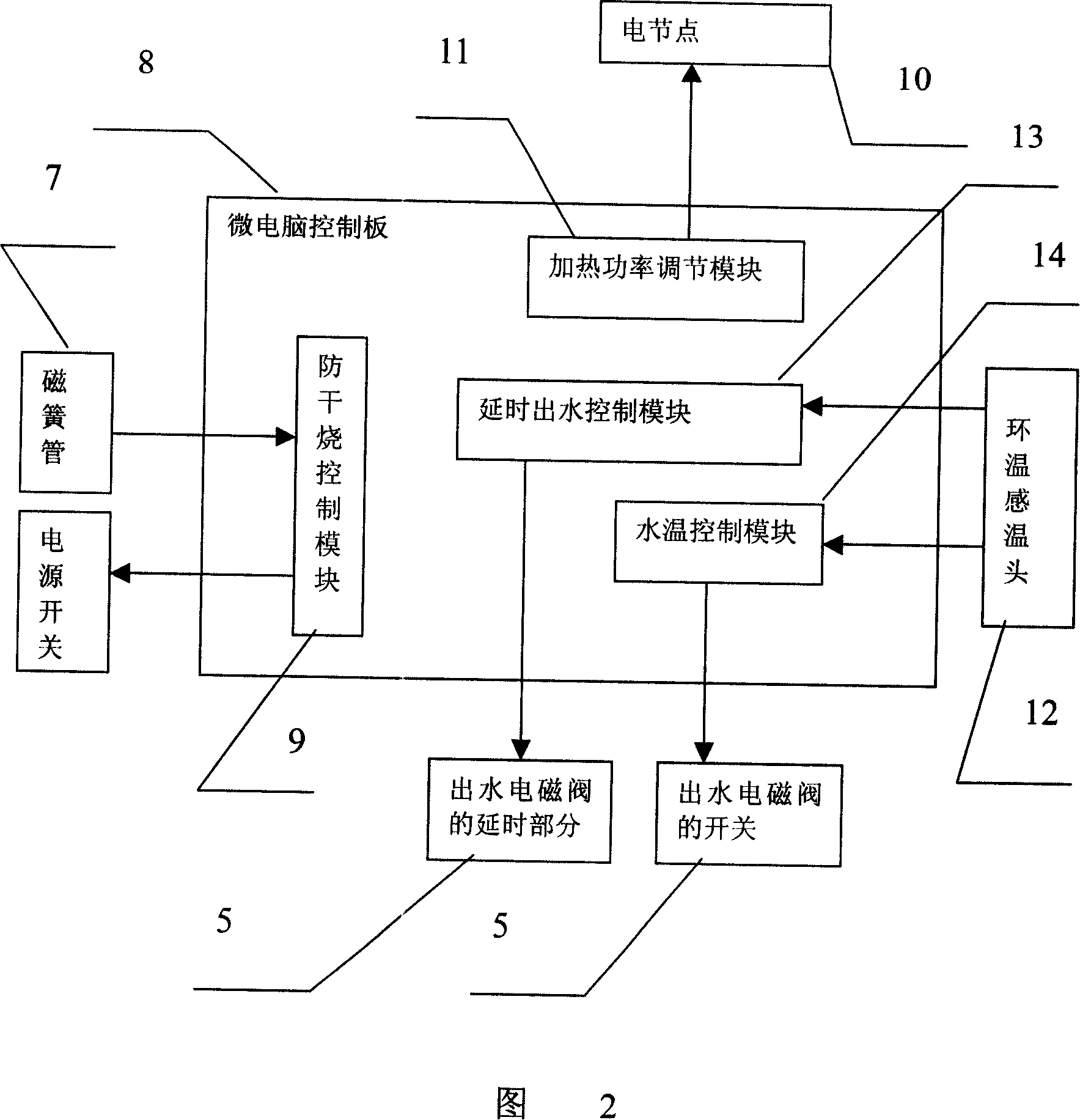

Drinking water apparatus with no heat bag

InactiveCN101093101AStable water temperatureEnhanced anti-dry performanceBeverage vesselsWater heatersTime delaysElectromagnetic valve

This invention relates to a no hot bladder drinking fountain including a shell, a water tank on the shell and a quick heater set in the shell, in which the tank is connected to an intake pipe connecting to the water inlet of the heater, the outlet is connected with the outtake pipe set with a hot water switch, said quick heater is connected with a supply switch, the outlet switch includes an outlet electromagnetic valve with a time delay function, said water fountain also includes a central temperature sensor head connected with a microcomputer control plate including: an accurate water-temperature control module used in sending instructions for setting delay time to the outlet valve.

Owner:浪木电器集团有限公司

Method for preparing biological organic fertilizer from pig manure

InactiveCN107840720AHighlight substantiveSignificant progressBio-organic fraction processingExcrement fertilisersSludgeMushroom

The invention relates to a method for preparing biological organic fertilizer from pig manure. The organic fertilizer is prepared from the following raw materials in parts by weight: 80 to 160 parts of the pig manure, 15 to 40 parts of rice bran, 20 to 30 parts of silkworm excrement, 45 to 65 parts of sludge, 8 to 18 parts of urea, 8 to 12 parts of mushroom residue, 0.05 to 0.5 part of fungicide and the like. The preparation method comprises the steps: preparing the raw material, stacking, adding the fungicide, stirring and fermenting and sieving. The biological organic fertilizer prepared bythe method disclosed by the invention has the characteristics of having a high biological organic matter content, improving soil, preventing soil hardening, effectively inhibiting harmful bacteria insoil, effectively and quickly promoting crop growth and the like.

Owner:广西武宣金泰丰农业科技发展有限公司

Method for producing bio-organic fertilizer by sheep manure

InactiveCN107827608APromote absorptionIncrease profitExcrement fertilisersBioloigcal waste fertilisersMicrobial agentSludge

The invention relates to a method for producing a bio-organic fertilizer by sheep manure. The bio-organic fertilizer is prepared from, by weight, 80-160 parts of sheep manure, 15-40 parts of rice bran, 20-30 parts of silkworm excrement, 45-65 parts of sludge, 8-18 parts of urea, 0.05-0.5 parts of microbial agents and the like. The preparation method includes the steps: raw material proportioning;strip stacking; microbial agent adding; stirring fermentation; separating and screening. The prepared bio-organic fertilizer has the advantages that the content of bio-organic substances is high, soilis improved, soil hardening is prevented, harmful bacteria in soil can be effectively restrained, and growth of crops can be effectively and rapidly facilitated and the like.

Owner:广西武宣金泰丰农业科技发展有限公司

Intensive production system for treating kitchen waste through hermetia illucens breeding

PendingCN112997968AEasy to handleWith mobile feedingDispersed particle separationAnimal husbandryHermetiaFishery

The invention relates an intensive production system for treating kitchen waste through hermetia illucens breeding, which is layered and partitioned. The system is divided into a kitchen waste distribution chamber and an odor purification device on the ground layer as well as a feeding room and a separation operation device on the underground layer. The homogenized kitchen waste materials are input into a suspension type feeding trolley. The upper end of the suspension type feeding trolley is connected to a suspension type feeding trolley track, and movable material ramming is conducted on a breeding frame. A plurality of layers of breeding boxes are horizontally placed on the breeding frame, and hermetia illucens larvae are pre-added into the boxes. After ramming and feeding for a plurality of days, the fecula and the imagoes are simply collected and transported to a separation operation device. The odor in the feeding room is collected under negative pressure and is discharged after reaching the standard through the odor purification device. According to the intensive production system, multiple links such as material conveying, material ramming, collecting, screening, drying, metering and packaging and deodorization can be automatically completed, labor and land are saved, the working efficiency is high, the produced dry hermetia illucens and fecula can be recycled, and economic benefits are achieved.

Owner:慕峰 +1

Full conversion process for high-concentration carbon monoxide

ActiveCN110498391AExtensive processShort processEnergy inputHydrogen productionHigh concentrationTemperature control

The invention relates to a full conversion process for high-concentration carbon monoxide. The process provided by the invention has a short flow, a system is reliable and has small resistance, equipment has a less number and a small occupied area, and is simple to control, and the investment and operating costs are low; a segmented axial-radial shift reactor is used, so that the problems of easyover temperature and difficult temperature control caused by change of load of feed gas having a high content of carbon monoxide in a shift reaction are solved, and compared with an axial shift reactor with stratified air inflow, the segmented axial-radial shift reactor has reduced shift furnace pressure drop and a reduced diameter and height of equipment, so that the equipment investment is greatly reduced; high-pressure saturated steam produced by a controllable isothermal reactor can be superheated, so that an external superheating furnace or combination with other devices for heating is not needed, and the investment and operation difficulty are reduced; improvement of a water-gas ratio of the system can be satisfied by using a method of spraying chilled water and supplementing self-produced saturated steam, high-pressure superheated steam is not need to be introduced from outside of a boundary area, so that energy consumption is reduced; and a temperature-controllable saturated steam generating system with a control valve is arranged, so that the temperature of shift gas can be quickly and effectively adjusted.

Owner:SINOPEC NINGBO ENG +2

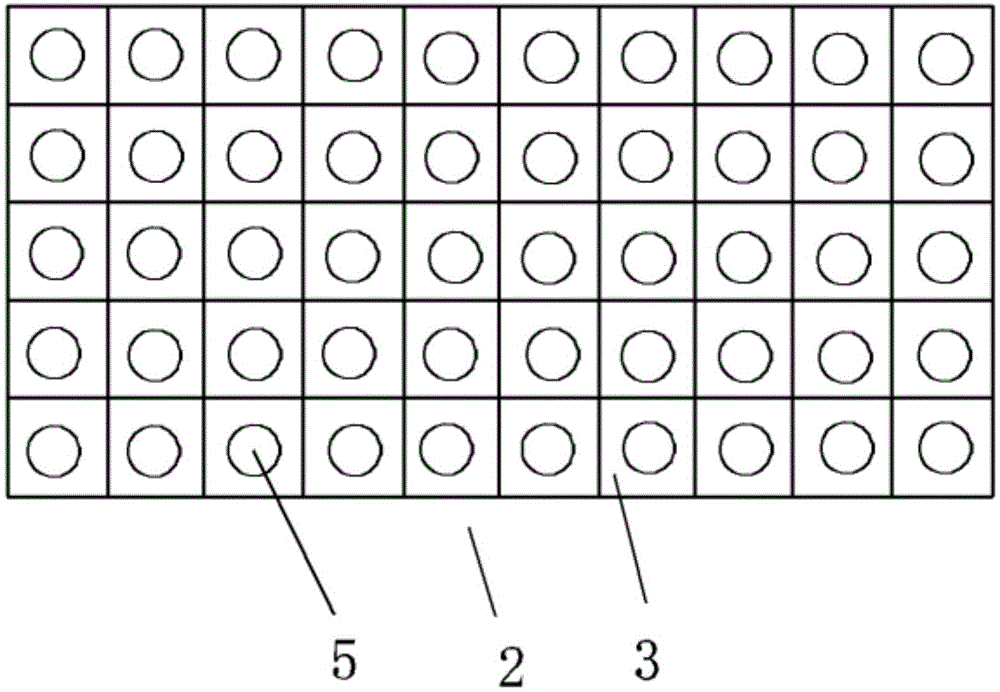

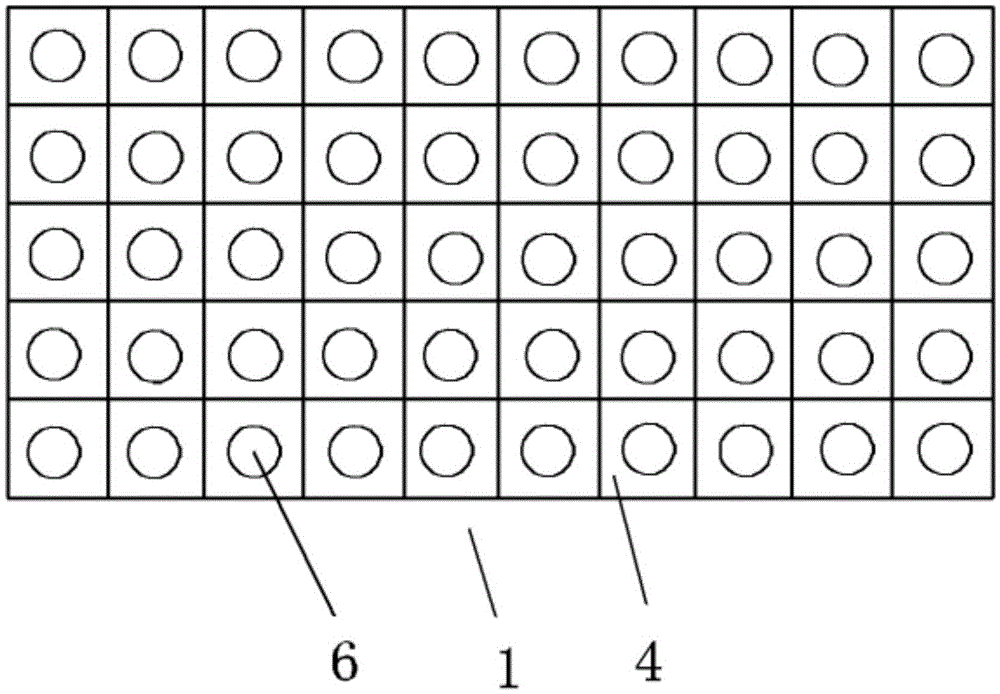

Outdoor sports wear fabric

InactiveCN103132328AReasonable structural designLight textureVegetal fibresProtective garmentBonding strengthFabric structure

The invention provides outdoor sports wear fabric which is composed of surface layer fabric and lining fabric. The surface layer is a breathable waterproof windproof coating, the lining layer is a fabric lining layer, and the surface layer is formed on the lining layer fabric through a scrapper coating technique. The outdoor sports wear fabric is reasonable in fabric structure design, light in fabric quality, high in bonding strength between fabric layers, waterproof and windproof in surface layer fabric, good in air permeability, capable of adjusting human body temperature effectively and good in ductility and absorption of perspiration of the lining fabric, the water vapor in a human body can be discharged rapidly, and therefore the human body is kept fresh and cool all the time.

Owner:KUSN ZHOUSHI TOWN JISHENG CLOTHING FACTORY

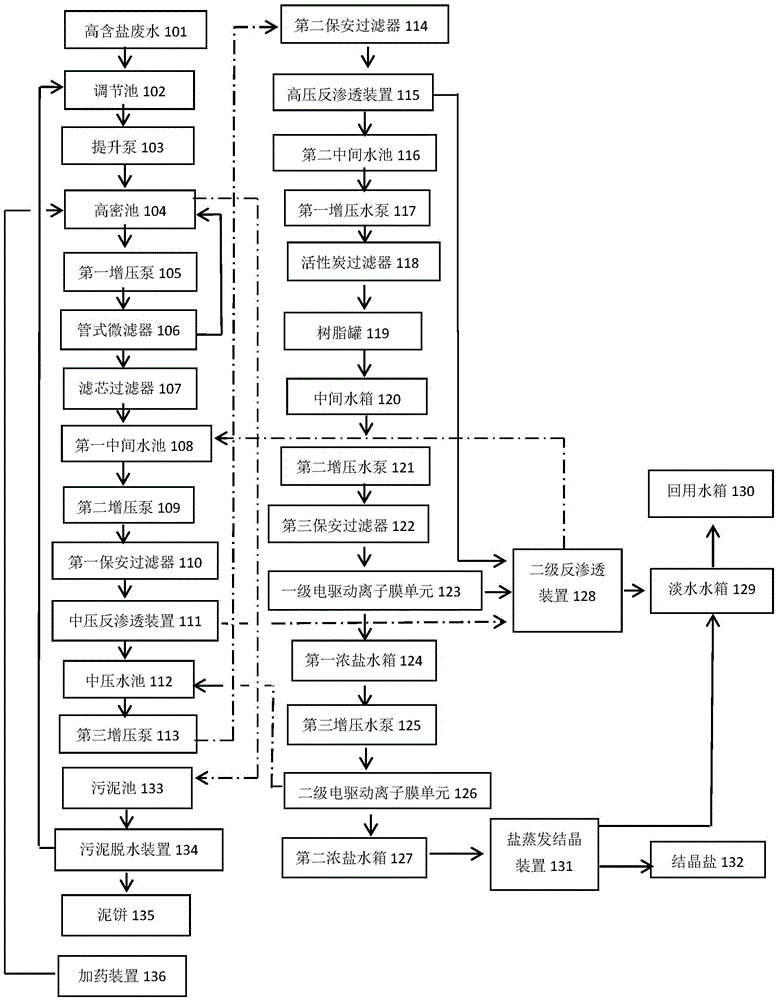

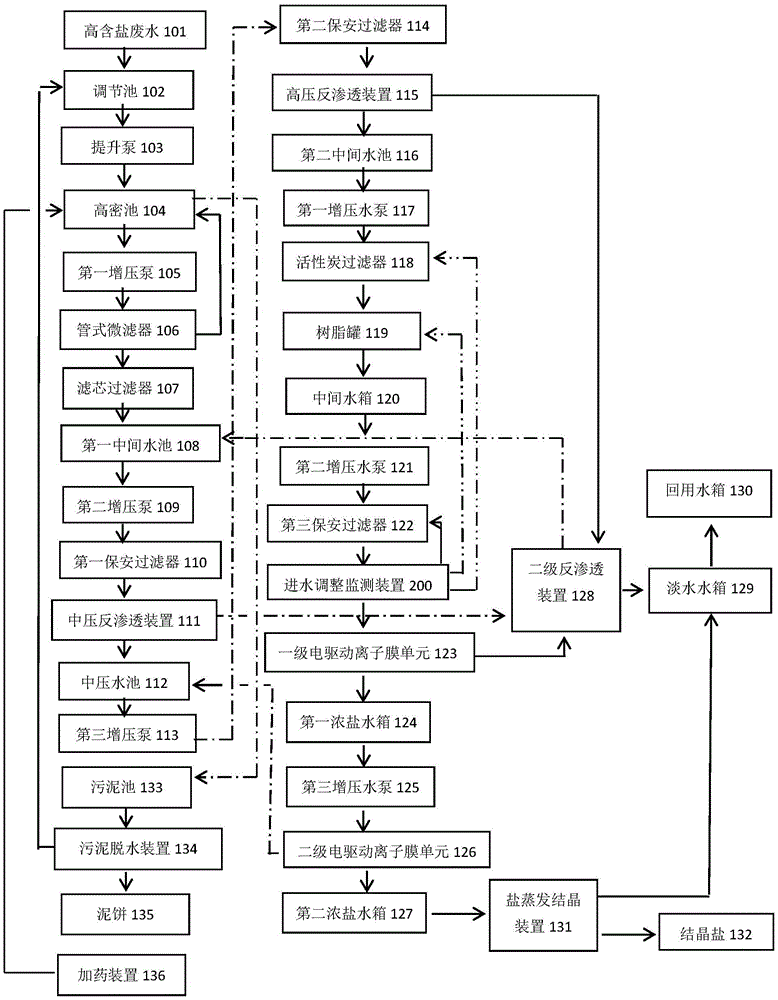

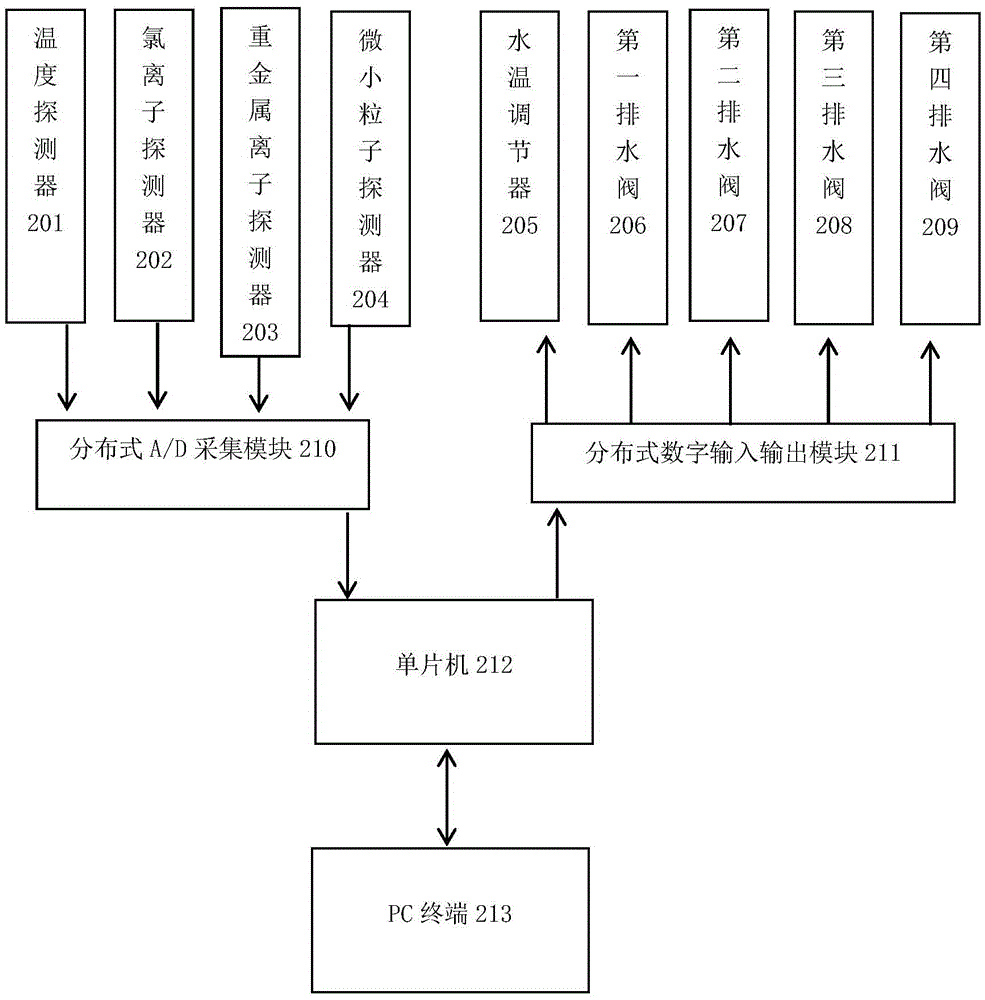

Reduction treatment method for high-salt wastewater

ActiveCN105600983APrevent scalingPollution suppressionSludge treatment by de-watering/drying/thickeningWater treatment parameter controlHigh concentrationReduction treatment

The invention relates to a reduction treatment method for high-salt wastewater. According to the method, the high-salt wastewater is pretreated and then subjected to reduction treatment, and reduction treatment comprises preliminary reduction treatment and deep concentration treatment; specifically, the pretreated wastewater is subjected to preliminary reduction treatment through a medium-pressure reverse osmosis device and a high-pressure reserve osmosis device, reverse osmosis production water and a reverse osmosis concentrated salt solution are obtained, the reverse osmosis concentrated salt solution is treated through a fed water adjustment and monitoring device and then sent to a first-level electric drive ion membrane unit and a second-level electric drive ion membrane for deep concentration treatment, and a high-concentration salt solution is obtained. With the adoption of the reduction treatment method for the high-salt wastewater, 95% or more of the wastewater solution can be recovered to a fresh water tank, and the wastewater is recycled.

Owner:乌海市倍杰特环保有限公司

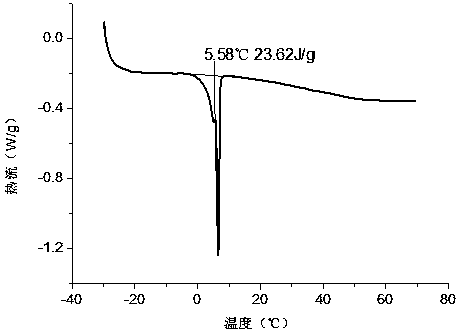

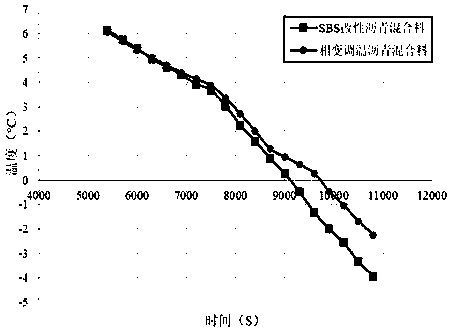

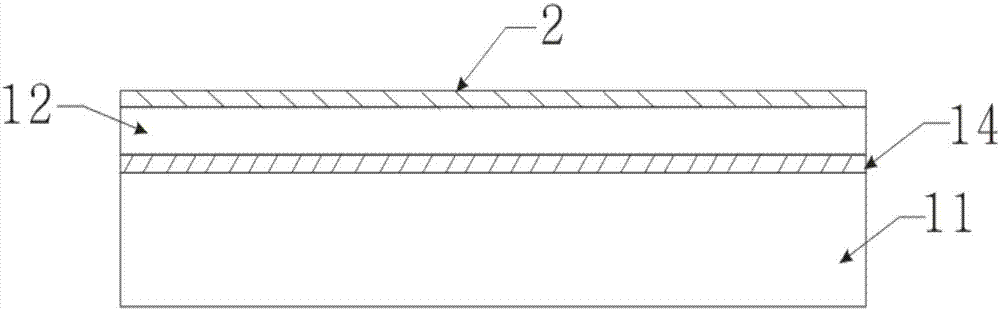

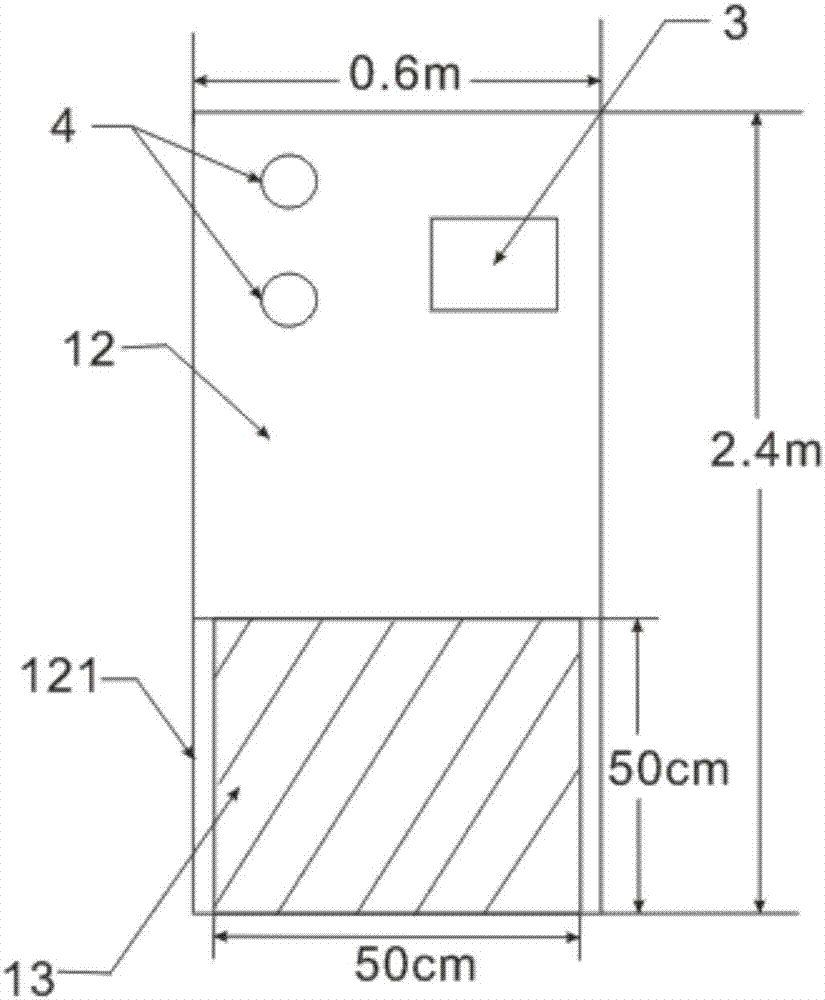

Composite phase change material and preparation method thereof as well as bituminous mixture

The invention relates to a composite phase change material and a preparation method thereof as well as a bituminous mixture, belonging to the field of functional materials. The preparation method comprises the following steps: mixing a dried organic phase change material with epoxy resin according to a mass ratio, and adding aluminum oxide, wherein the adding amount of the aluminum oxide is 2-6% of the mass of the organic phase change material; uniformly mixing, and then putting into a twin-screw extruder to utilize extruder to extrude and mold the mixture heated at different sections, cuttinginto rectangular particles, and then solidifying; when the product has a certain strength and does not deform, taking out the particles and carrying out particle-particle separation until the productis completely solidified so as to obtain the granular composite phase change material. The preparation method provided by the invention effectively adjusts the temperature and the adding amount of the phase change material, and enables the phase change material to stably exist in the bituminous mixture, so that the temperature is more effectively adjusted, the icing is suppressed, and the other service properties of a road surface is guaranteed. The phase change modified asphalt has a phase-transition temperature between 4-6 DEG C and latent heat of phase change of greater than 20J / g, and cansolve the problems such as ice formation, frost formation and snow accumulation on the road surface.

Owner:BROADVISION ENG CONSULTANTS +1

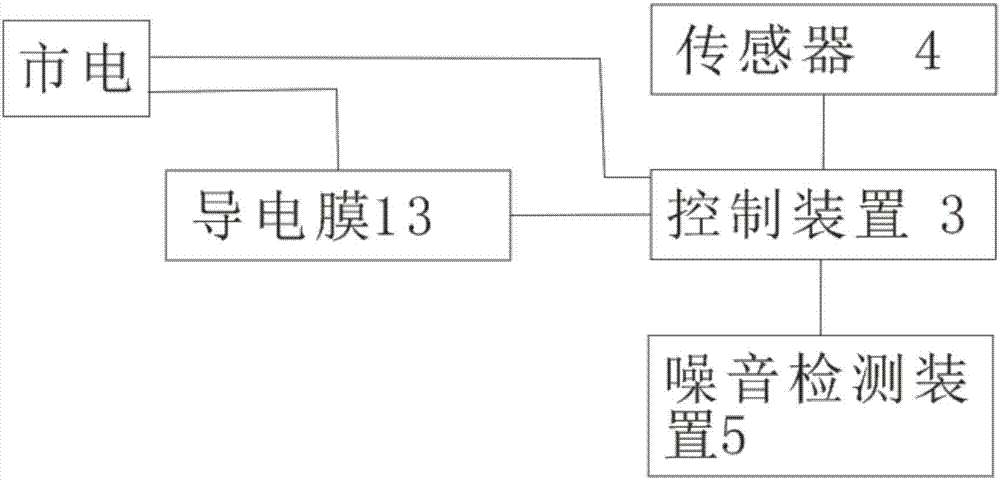

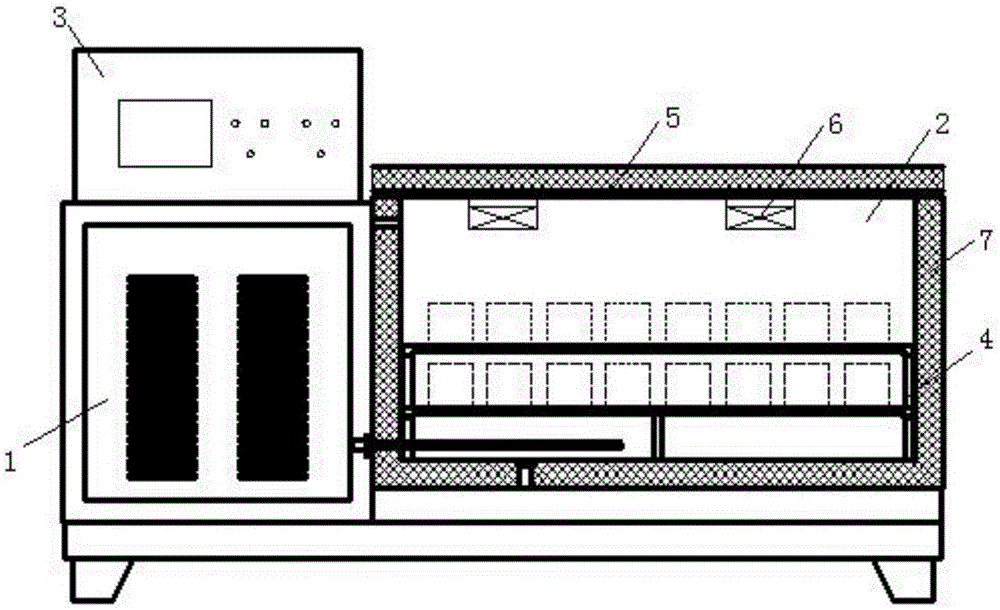

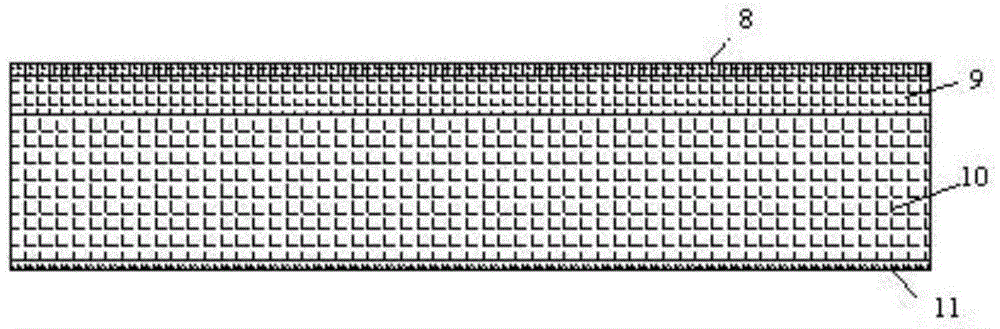

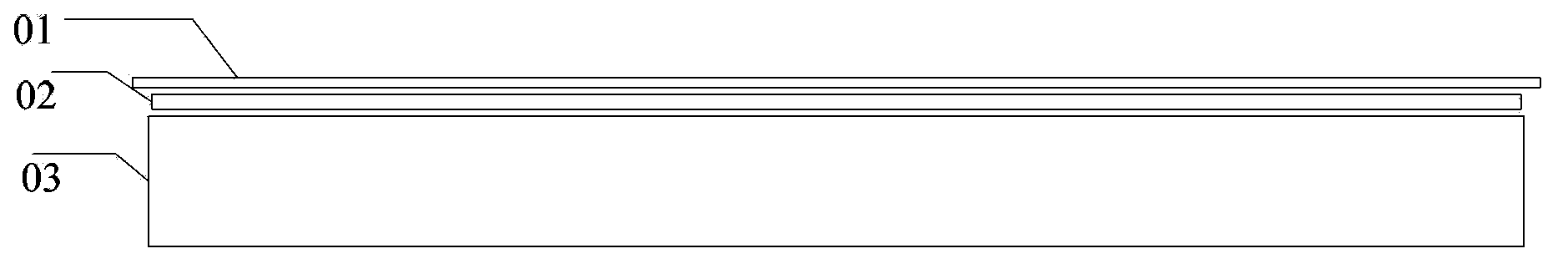

Internal wall heat-insulation fireproof functional wallboard with electro-thermal film

PendingCN107268831AFlame retardant hasWaterproofLighting and heating apparatusWallsTemperature controlEngineering

The invention discloses an internal wall heat-insulation fireproof functional wallboard with an electro-thermal film. The wallboard comprises an inner wallboard body and a facing material, wherein the inner wallboard body is a composite plate and comprises a heat-insulation flame-retardant plate and a base plate, the heat-insulation flame-retardant plate and the base plate are adhered together through an adhesive layer, a conductive area is arranged on the base plate, and the conductive area is covered with the electro-thermal film; the surfaces of the base plate and the conductive area are coated with the facing material, and the electro-thermal film is electrified to generate heat. By means of the structure, heat and cold of a wall can be effectively prevented from invading indoors, and the temperature of the indoor environment is kept normal; meanwhile, the electro-thermal film is arranged on the base plate and has a heating function, the functional wallboard capable of achieving automatic heating and intelligent temperature control is formed, the indoor temperature is effectively adjusted, and the energy consumption is greatly reduced; the heating area is large, and the functional wallboard has excellent heat insulation, waterproof and dehumidifying functions, so that the heat is not absorbed by the wall and is released outdoors, a constant comfortable temperature is kept in a room, and the room is particularly suitable for babies or elder people to live in.

Owner:深圳市廷宏科技有限公司

A sulfate test chamber with a high-temperature resistant layer

InactiveCN105547977AUniform temperatureImprove test precision and test accuracyWeather/light/corrosion resistanceHeating systemTest chamber

A sulfate test chamber with a high-temperature resistant layer is provided. The sulfate test chamber comprises a machine case, a test piece case and an electric control case. A water box, a refrigerating system, a heating system and a liquid feeding and discharging system are disposed in the machine case. A microcomputer is disposed in the electric control case and is used for system integration control of the systems in the machine case. Water streams in the water box are conveyed to the test piece case through the liquid feeding and discharging system after temperatures of the water streams are respectively adjusted by the refrigerating system and the heating system. A bracket is disposed in the test piece case. A test piece is disposed on the bracket. The high-temperature resistant layer is disposed on the inner wall of the test piece case and comprises a stainless steel liner layer, a high-temperature resistant mineral wool layer, a polyurethane high-temperature resistant layer and a surface layer. The high-temperature resistant mineral wool layer is disposed at one side of the polyurethane high-temperature resistant layer, and the surface layer is disposed at the other side of the polyurethane high-temperature resistant layer. The stainless steel liner layer is disposed at the other side of the high-temperature resistant mineral wool layer.

Owner:SUZHOU DONGHUA TESTING INSTR

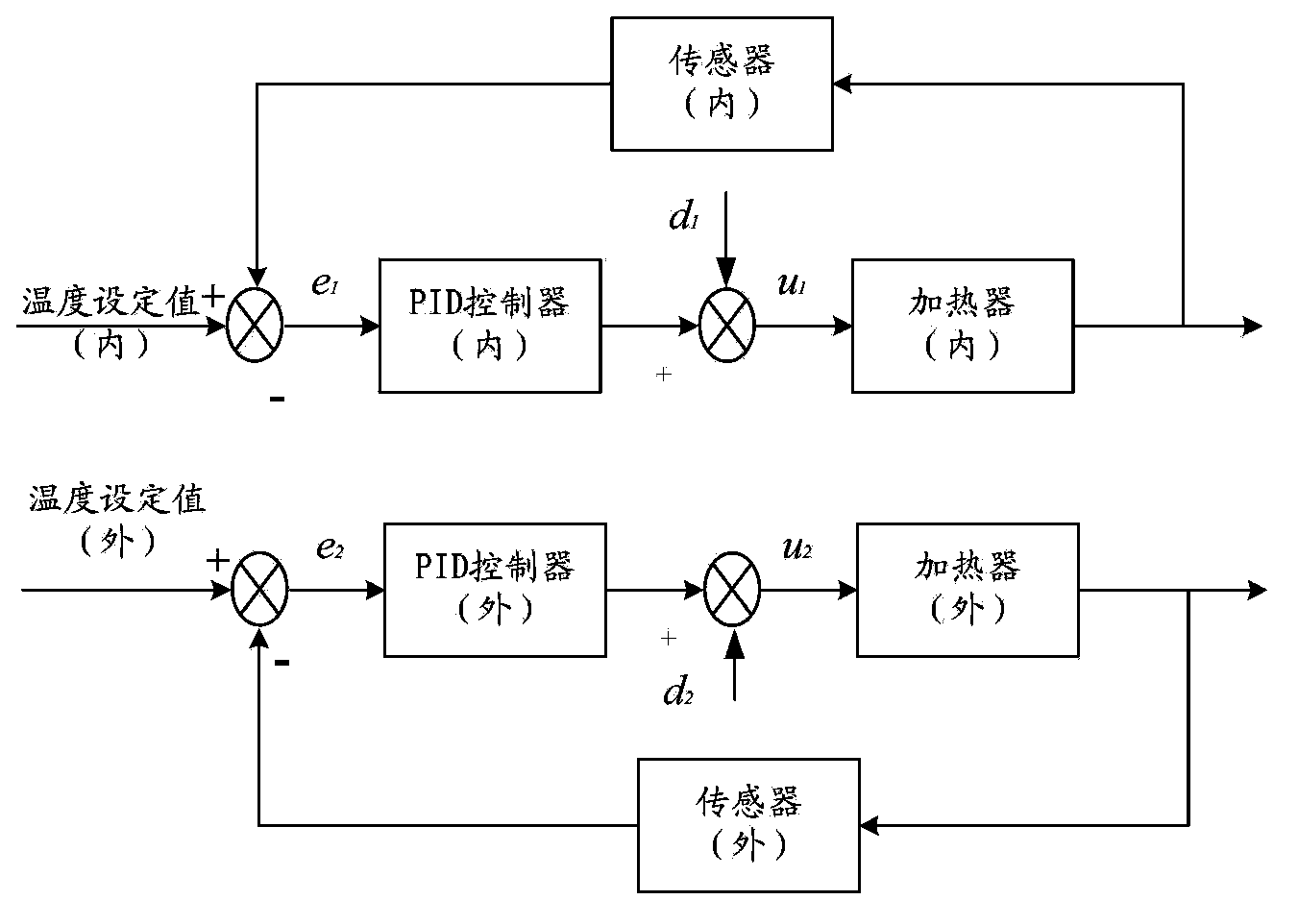

Method and system used for heating wafers on static chuck, and CVD equipment

InactiveCN103805966ASuppression of temperature disturbancesGuaranteed temperatureChemical vapor deposition coatingEngineeringEquipment use

The invention discloses a method used for heating wafers on a static chuck. The static chuck comprises a first heating zone corresponding to a first heater, and a second heating zone corresponding to a second heater. The method comprises following steps: a first target temperature of the first heating zone and a second target temperature of the second heating zone are obtained; a first detecting temperature of the first heating zone and a second detecting temperature of the second heating zone are detected; a first error signal is calculated according to the first target temperature and the first detecting temperature, and a second error signal is calculated according to the second target temperature and the second detecting temperature; a first correcting signal and a second correcting signal are calculated according to the first error single and the second error single respectively; and control signal of the first heater and control signal of the second heater are obtained according to the first correcting signal and the second correcting signal respectively. The method is capable of adjusting temperature changing speed of different heating zones of the heaters effectively, and inhibiting temperature disturbance effectively. The invention also provides a system and CVD equipment used for heating the wafers on the static chuck.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

Solar water heater

InactiveCN1584441AEffective temperature regulationStable temperatureSolar heating energySolar heat devicesThermal waterWater temperature

A solar water heater consists of a body, an intake part and a feeding part. The body is formed by: a solar energy-collecting panel, a water-tank with a sub-tank on its upper portion, and a shower in the tank. A floater and a one-way valve are installed in the sub-tank to control water intake and to prevent from back-flow respectively. Water in the sub-tank is automatically fed via the shower to the tank when heated water in the tank is reduced in use. The water temperature can be regulated effectively and stably to make users more comfortable.

Owner:于林鹏

Compressing and injecting mixed cycle refrigerating method and device for electric refrigerator

InactiveCN101109595AImprove cooling effectLower energy consumption levelsFluid circulation arrangementRefrigeration devicesTemperature differenceEngineering

The invention provides a method for compression-jetting mixed circulation refrigeration for a refrigerator and the arrangement for the circulation refrigeration. Wherein, an injector is connected between the outlets of two evaporimeters of the refrigerating chamber and the freezing chamber of the refrigerator and an air-return pipe of the compressor, so as to mix the refrigerant of different pressures generated by the two evaporimeters of the refrigerating chamber and the freezing chamber, hence form a mixed flow of moderate pressure, which enters into the air-return pipe of the compressor, this will increase the pressure of the returned air of the compressor, and reduce the pressure ratio, and improve the refrigerating performance of the compressor. The invention is of simple structure, easy to manufacture, low cost, and runs reliably, is applicable for connecting with pipelines of different refrigerator systems to improve the evenness and controllability of the temperature in the refrigerating chambers, and reduce the loss in useable energy due to too high temperature difference in the refrigerating chambers, hence to save energy for refrigerators. The invention is applicable for industrial production.

Owner:CENT SOUTH UNIV +1

Camellia amplexicaulis cultivation device

InactiveCN107155681APromote growthIncrease humidityClimate change adaptationGreenhouse cultivationCamellia amplexicaulisSolenoid valve

The invention discloses a camellia amplexicaulis cultivation device, comprising a box body whose bottom wall is provided with a plurality of first water through holes, a box cover which is arranged on the upper end of the box body, a planting container which is arranged in the box body, an automatic spraying mechanism, and an air supply mechanism. The lower part of the planting container is provided with a plurality of second water through holes. The automatic spraying mechanism comprises a spray nozzle, a humidity sensor, a solenoid valve, and a water supply pipeline. The spray nozzle is arranged in the box body and is connected with the water outlet end of the water supply pipeline. The humidity sensor is arranged in the box body. The solenoid valve is arranged on the water supply pipeline. The humidity sensor is electrically connected with the solenoid valve. The air supply mechanism comprises a fan and an air tube. The air tube is arranged in the box body and is corresponding to the spray nozzle. The air tube is connected with the air outlet end of the fan. The device can automatically spray water mist through the automatic spraying mechanism, so as to improve humidity in the box body. Through the air supply mechanism, air is supplied into the box body, so as to improve air permeability in the box body and be beneficial for growth of camellia amplexicaulis.

Owner:防城港市林木良种繁育中心苗圃

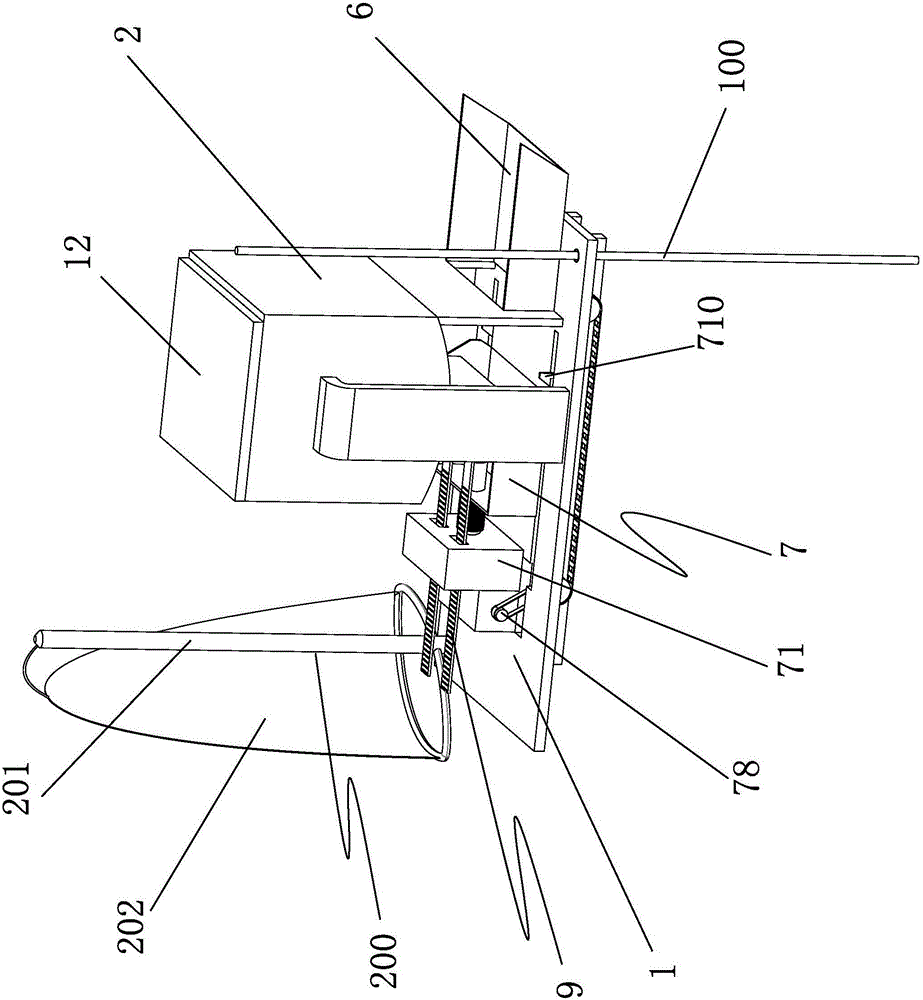

Fishery aquaculture system capable of control pond water temperature

InactiveCN105941201ASimple structureEffective temperature regulationClimate change adaptationPisciculture and aquariaAquatic productEngineering

The invention discloses a fishery aquaculture system capable of control pond water temperature comprising a pond; a pond water heat exchange system is installed at the outer side of the pond; a feeding device is installed in the middle of the pond; the feeding device comprises a floating platform; an ejection device which can eject material in a feeding tray out of a discharging seat is installed on the floating platform; a scraper mechanism which can centralize material in the front end of the feeding tray to the rear of the feeding tray is installed on the ejection device; a locating pole is installed on the floating platform on one end of which the discharging seat is installed; a wind sail mechanism, which can make the floating platform rotate about the locating pole as the wind alters directions so that it can adjust feeding direction, is installed on the other end of the floating platform. The purpose of the invention is to overcome the deficiency of the prior art and to provide a fishery aquaculture system with simple structure and capable of control pond water temperature with which the pond water temperature can be adjusted so that aquatic products can overwinter safely, the cultivation effect is good, the dispersibility of bait is good, and the feeding scope is wide.

Owner:ZHONGSHAN NUODUN SCI RES TECH SERVICE CO LTD

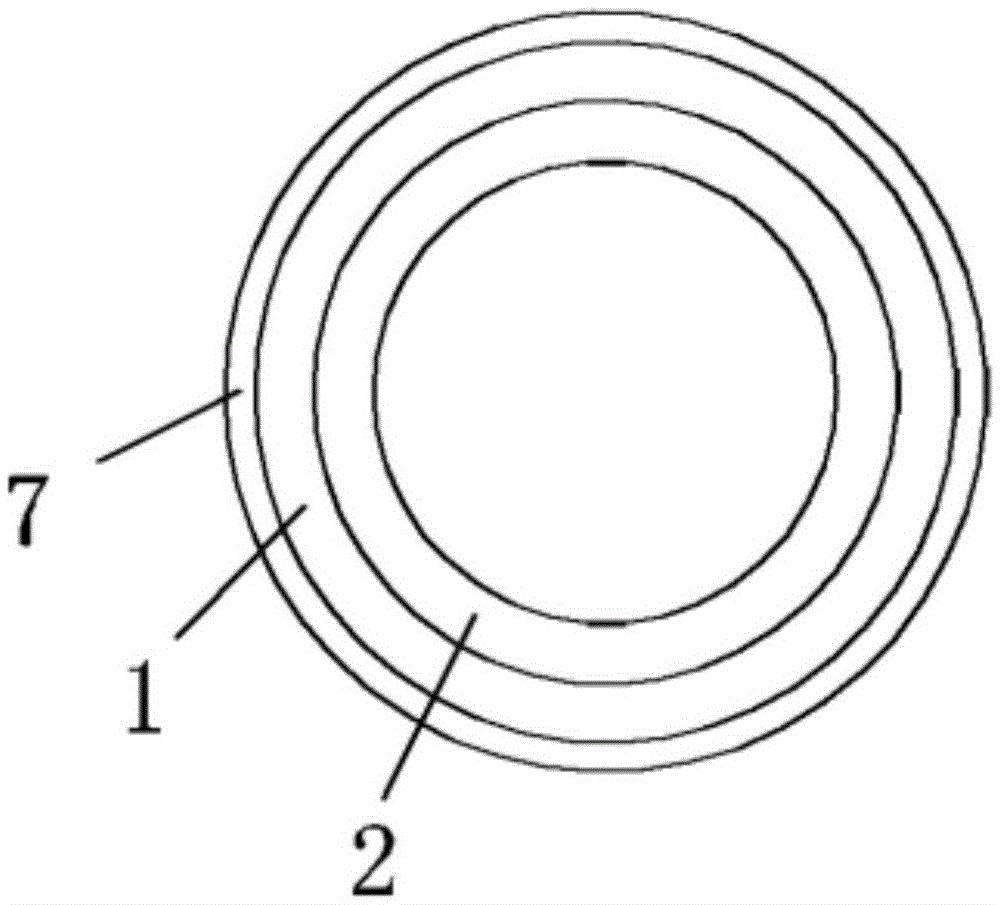

Steering wheel capable of conducting heating according to hand temperature

ActiveCN105539566AMeet actual needsEffective temperature regulationElectric heatingHand wheelsElectricitySteering wheel

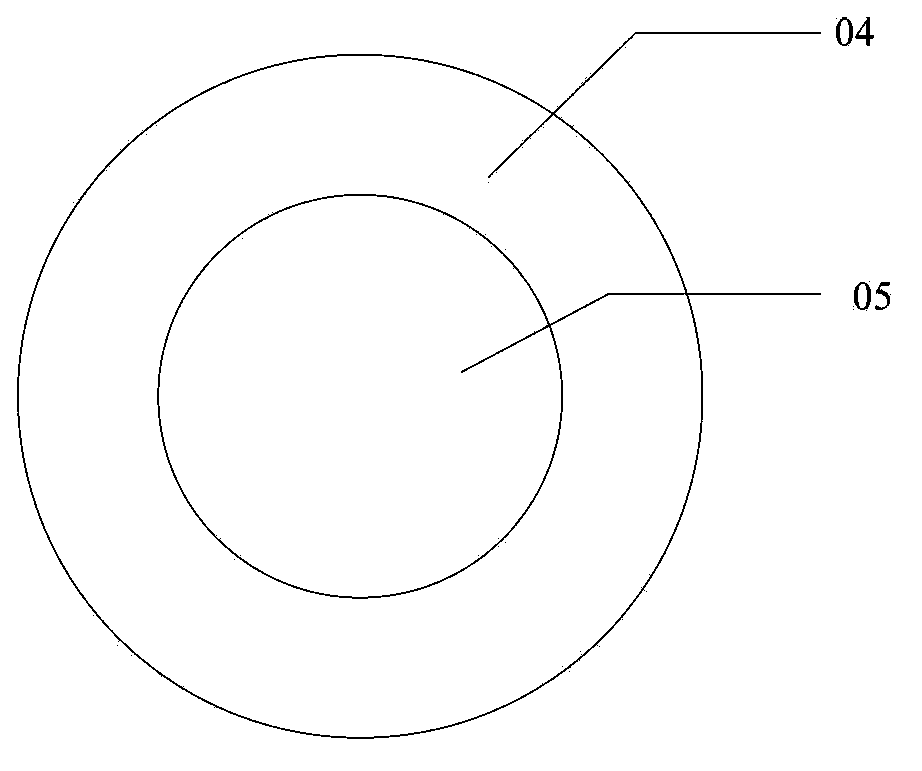

A steering wheel capable of conducting heating according to hand temperature comprises an annular outer layer and an annular inner layer, wherein the inner layer is wrapped in the outer layer, and the inner layer and the outer layer are divided into a plurality of inner-layer accommodating grooves and outer-layer accommodating grooves which have the same shape and same area and are attached correspondingly; an electric heating element is arranged in each inner-layer accommodating groove, and a temperature sensing element is arranged in each outer-layer accommodating groove to be used for acquiring the temperature value and comparing the temperature value with a preset low-temperature threshold value and a preset high-temperature threshold value after sensing hand temperature independently, outputting a heating electric signal to an electric heating element if the temperature value is lower than the low-temperature threshold value so that the electric heating element can be switched on to conduct heating, outputting a cooling electric signal to the electric heating element if the temperature value is higher than the high-temperature threshold value so that the electric heating element can stop heating, and outputting a thermoregulation electric signal to the electric heating element if the temperature value is between the low-temperature threshold value and the high-temperature threshold value (low-temperature threshold value<=temperature value<= high-temperature threshold value) so that the electric heating element can conduct thermoregulation.

Owner:徐菊红

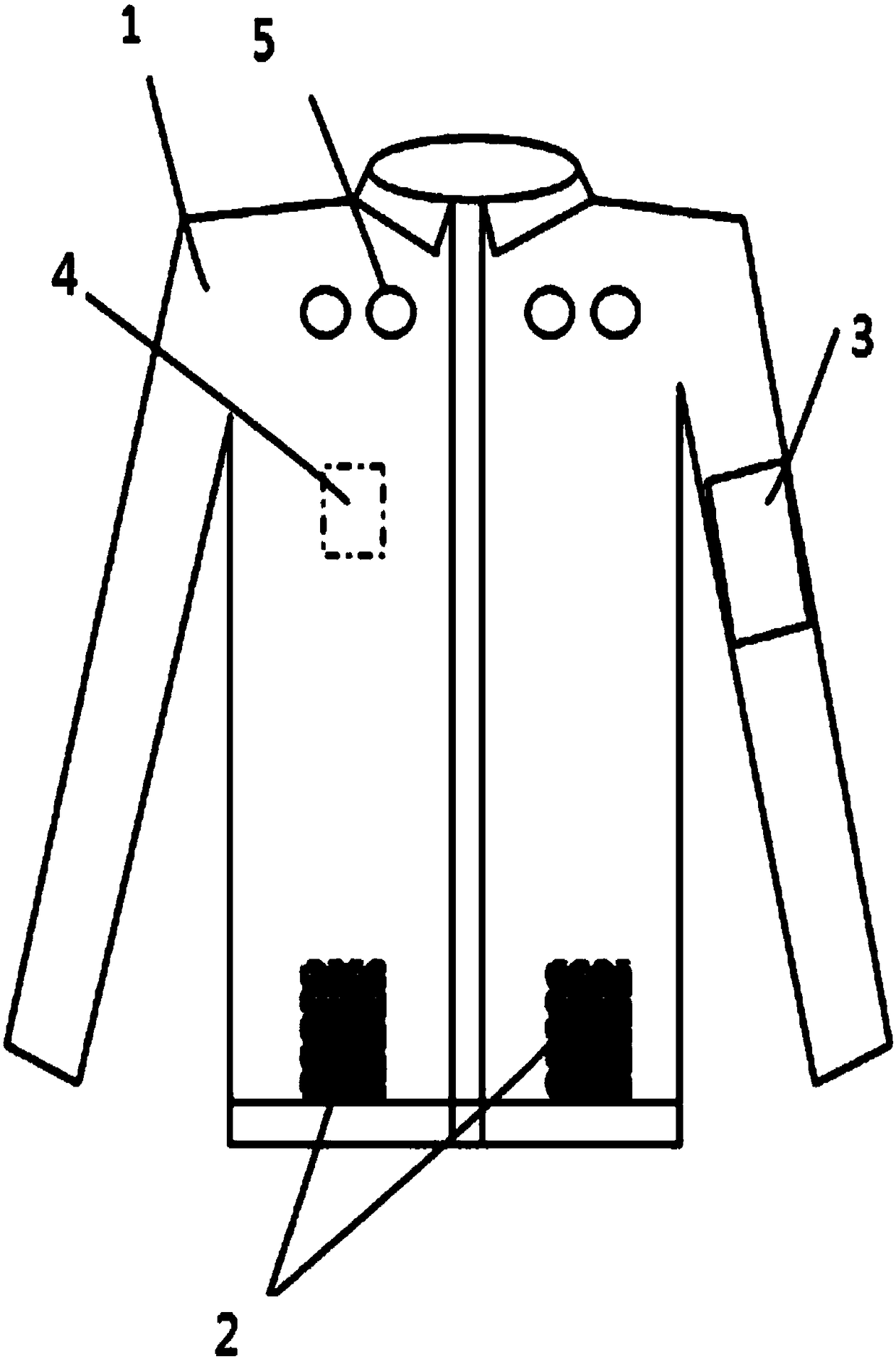

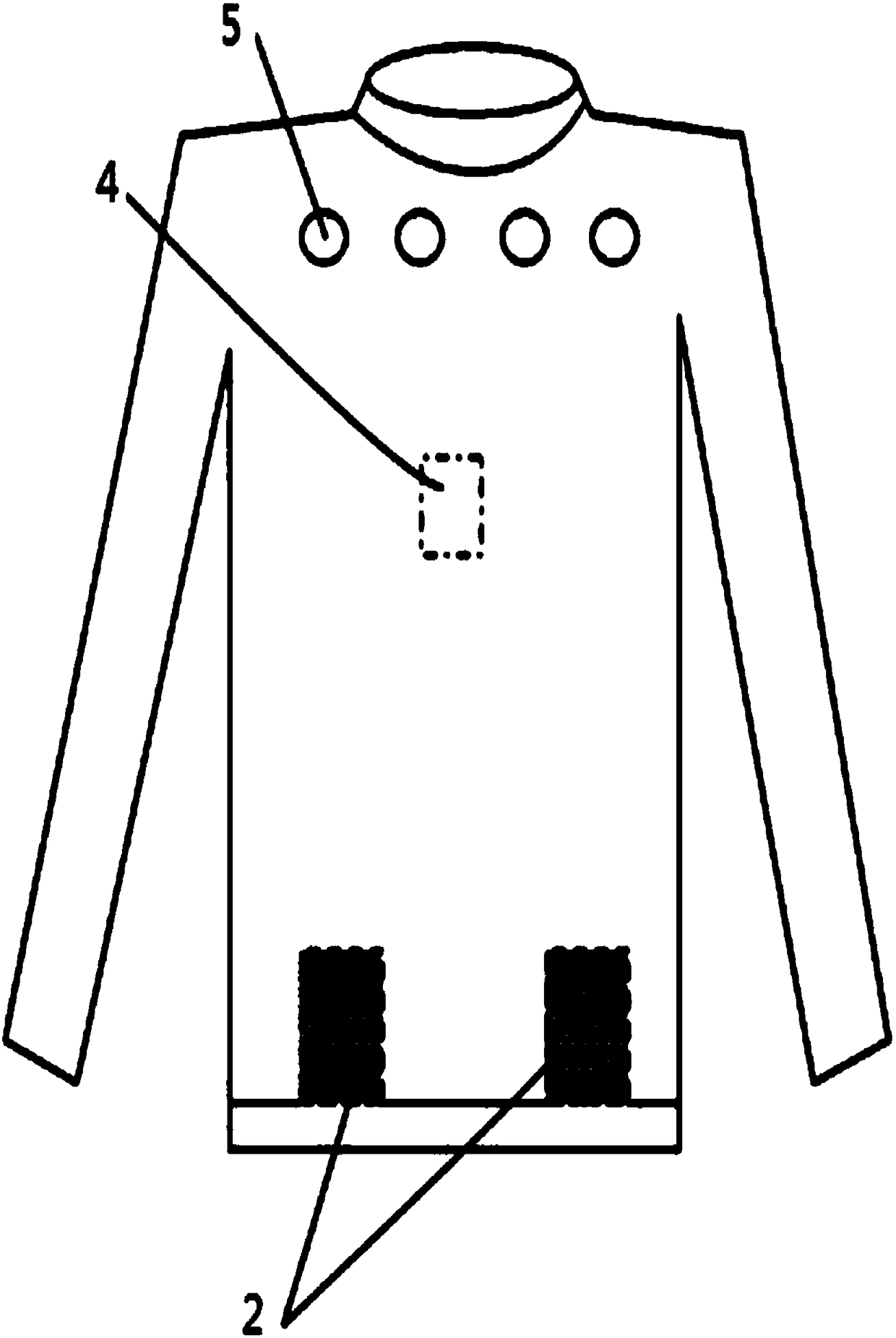

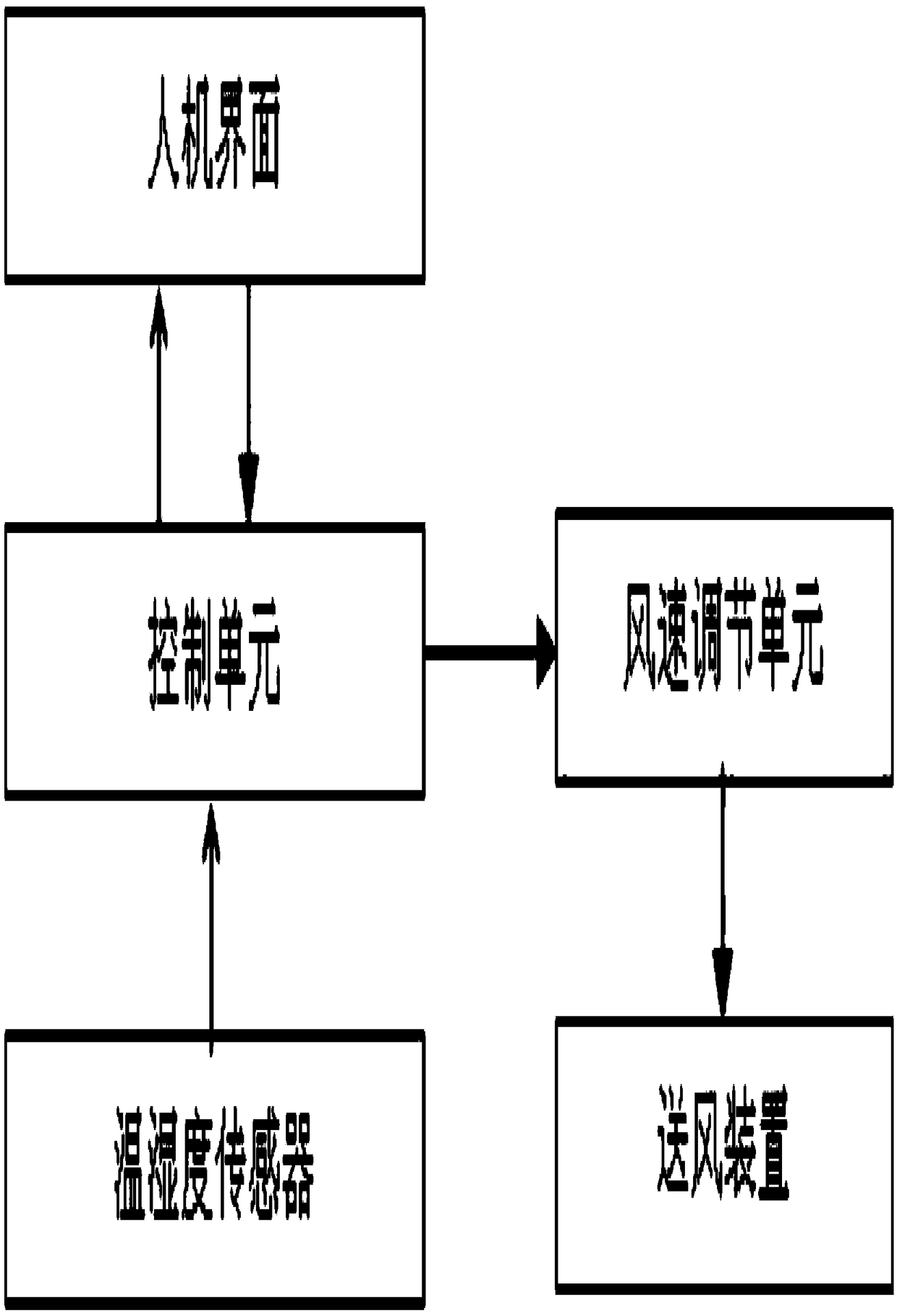

Intelligent garment capable of adjusting micro-climate in garment

InactiveCN108451073AEffective adjustment of wind speedEffective speed adjustmentGarment special featuresProtective garmentThermal comfortAir blower

The invention discloses an intelligent garment capable of adjusting the micro-climate in the garment. The intelligent garment comprises a garment body, air supply devices, a detection device and a control device. Air inlets are formed in positions corresponding to air inlet ends of the air supply devices, of the garment body; air outlets are formed in the garment body; the air supply devices and the air outlets are arranged on the lower and upper sides of the garment body respectively; the detection device can detect the temperature and humidity of the garment body in real time, and transmitsthe signal to the control device; the control device can compare the signal with pre-set parameters so as to determine whether it is necessary to adjust the wind speed of the air supply devices to improve the thermal comfort of the human body, improve the working efficiency, and ensure the health and safety of the workers. The air inlets and the air outlets are formed in the upper side and the lower side of the garment body respectively, which can allow smooth following of air; air blowers can supply air, which can prevent the defect of garment inflation due to vertical air supply; and devicescan be placed in pockets, detachment is facilitated, and the weight of the garment body is reduced.

Owner:HAIAN RUNDE CLOTHING CO LTD

Method for preparing bio-organic fertilizer from biogas residues

InactiveCN107954759APromote absorptionIncrease profitBio-organic fraction processingExcrement fertilisersSludgeMicrobial agent

The invention relates to a method for preparing bio-organic fertilizer from biogas residues. The organic fertilizer is prepared from the following raw materials in parts by weight: 80-160 parts of thebiogas residues, 15-40 parts of rice bran, 20-30 parts of silkworm excrement, 45-65 parts of sludge, 8-18 parts of urea, 8-18 parts of bagasse, 10-16 parts of waste molasses, 10-18 parts of waste tealeaves, 10-12 parts of peanut stalk root powder, 0.05-0.5 part of microbial agents and the like. The method comprises the following steps: raw material proportioning, strip stacking, adding of the microbial agents, stirring fermentation and separating screen processing. The bio-organic fertilizer prepared with the method has the characteristics that the content of bio-organic matter is high, soil is improved, soil hardening is prevented, harmful bacteria in the soil can be effectively inhibited, growth of crops can be promoted effectively and rapidly and the like.

Owner:广西武宣金泰丰农业科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com