Online SO3 measuring system and method

A measurement system and detector technology, applied in the direction of measurement devices, sampling, instruments, etc., can solve the problems of inaccurate measurement, inability to monitor in real time, complex system, etc., and achieve the effect of avoiding dissolution, simple structure and accurate measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

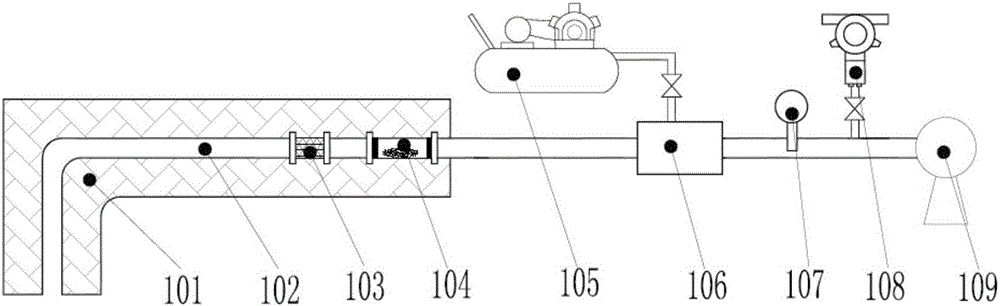

[0027] Specific implementation mode one: as figure 1 As shown, the online sulfur trioxide measurement system described in this embodiment includes a heater 101, a sampling pipe 102, a filter 103, a reaction pipe 104, an air compressor 105, a diluter 106, a flow meter 107, a hydrogen chloride detector 108 and Sampling pump 109;

[0028] The filter 103, the reaction tube 104, the diluter 106, the flowmeter 107, the hydrogen chloride detector 108, and the sampling pump 109 are connected successively through connecting pipes, the outlet of the sampling pipe 102 is connected with the inlet of the filter 103, and the outlet of the filter 103 is The inlet end of the reaction tube 104 is connected through the first connecting pipe, the outlet end of the reaction tube 104 is connected with the inlet end of the diluter 106 through the second connecting pipe, and the outlet end of the diluter 106 is connected with the sampling pump 109 through the third connecting pipe. The flow meter 1...

specific Embodiment approach 2

[0029] Embodiment 2: The sampling tube 102 described in this embodiment is made of polytetrafluoroethylene, an inert material, so as to avoid reaction with sulfuric acid vapor at high temperature. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0030] Embodiment 3: The filter described in this embodiment is a heat-resistant quartz filter or a ceramic filter, which can remove dust particles in the sampled flue gas. Other compositions and connections are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com