Composite phase change material and preparation method thereof as well as bituminous mixture

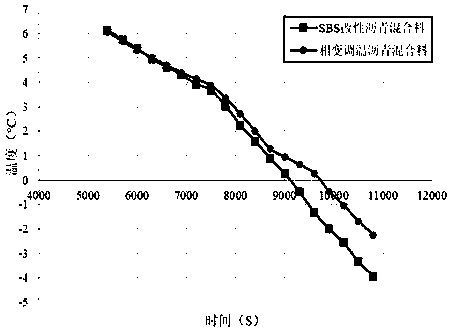

A composite phase-change material and hybrid material technology, applied in the field of functional materials, can solve problems such as inability to effectively alleviate low-temperature disease, affect overall pavement performance, and loss of phase-change materials, so as to shorten the occurrence time, duration, and delay of extreme low temperature Occurrence and duration of extreme low temperatures, snow and icing mitigation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The preparation method of the granular composite phase change material of the present embodiment is carried out according to the following steps:

[0033] Step (1), dry the phase-change microcapsules and epoxy resin in an oven at 80°C for later use;

[0034] Step (2), weighing an appropriate amount of phase change microcapsules and epoxy resin, mixing 3 parts of phase change microcapsules, 7 parts of epoxy resin and 0.09 part of alumina to obtain a mixed material;

[0035] Step (3), put the mixed material in step (2) into the Micro27GL-40D twin-screw extruder, use the extruder to heat through different sections, including: feeding zone temperature: 265°C, 2-section temperature: 270°C, 3-section temperature: 280°C, 4-section temperature: 280°C, 5-section temperature: 285°C, 6-section temperature: 285°C, 7-section temperature: 285°C, 8-section temperature: 285°C, 9-section Section temperature: 280°C, 10 section temperature: 280°C, mold mouth section temperature: 275°C, a...

Embodiment 2

[0044] The preparation method of the granular composite phase change material of the present embodiment is carried out according to the following steps:

[0045] Step (1), dry the phase-change microcapsules and epoxy resin in an oven at 80°C for later use;

[0046] Step (2), weighing an appropriate amount of phase-change microcapsules and epoxy resin, mixing 2 parts of phase-change microcapsules, 8 parts of epoxy resin and 0.08 parts of alumina to obtain a mixed material;

[0047] Step (3), put the mixed material in step (2) into the Micro27GL-40D twin-screw extruder, use the extruder to heat through different sections, including: feeding zone temperature: 265°C, 2-section temperature: 270°C, 3-section temperature: 280°C, 4-section temperature: 280°C, 5-section temperature: 285°C, 6-section temperature: 285°C, 7-section temperature: 285°C, 8-section temperature: 285°C, 9-section Section temperature: 280°C, 10 section temperature: 280°C, mold mouth section temperature: 275°C, ...

Embodiment 3

[0056] The preparation method of the granular composite phase change material of the present embodiment is carried out according to the following steps:

[0057] Step (1), dry the phase-change microcapsules and epoxy resin in an oven at 80°C for later use;

[0058] Step (2), weighing an appropriate amount of phase change microcapsules and epoxy resin, mixing 3 parts of phase change microcapsules, 7 parts of epoxy resin and 0.18 parts of alumina to obtain a mixed material;

[0059] Step (3), put the mixed material in step (2) into the Micro27GL-40D twin-screw extruder, use the extruder to heat through different sections, including: feeding zone temperature: 265°C, 2-section temperature: 270°C, 3-section temperature: 280°C, 4-section temperature: 280°C, 5-section temperature: 285°C, 6-section temperature: 285°C, 7-section temperature: 285°C, 8-section temperature: 285°C, 9-section Section temperature: 280°C, 10 section temperature: 280°C, mold mouth section temperature: 275°C, ...

PUM

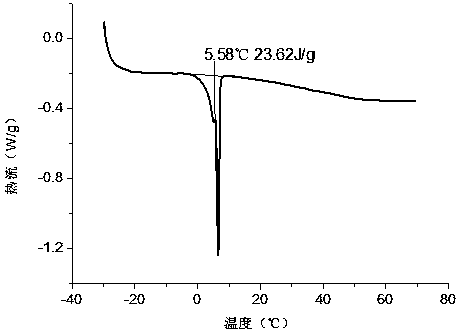

| Property | Measurement | Unit |

|---|---|---|

| phase transition temperature | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

| phase transition enthalpy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com