Method for annealing and pickling 409L stainless steel

A stainless steel and pickling technology, which is applied in the field of annealing and pickling, can solve problems such as unsatisfactory results, reduced profit margins, and incomplete removal of scale

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

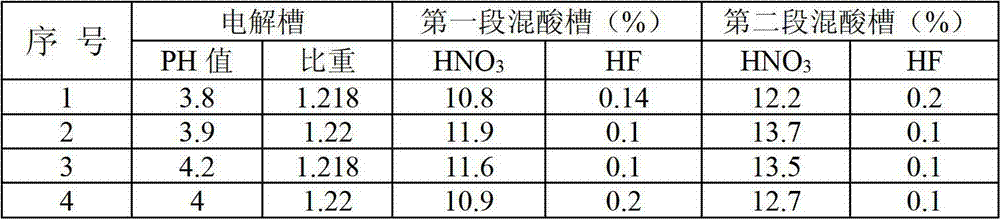

[0047] Taking 409L stainless steel with a thickness of 0.5mm, 1.0mm, and 1.2mm as an example, the method of the present invention is further described, which mainly includes the steps of heating furnace annealing treatment, neutral salt electrolysis treatment, and two-stage pickling treatment. Among them, the heating furnace is a continuous annealing furnace, which is divided into seven heating sections that can be independently controlled by temperature feedback, and the effective width of the furnace is 1550mm.

[0048] (1) The atmosphere of the heating furnace is adjusted so that the excess oxygen concentration is controlled at about 4%.

[0049] (2) The heating temperature is controlled between 700-1100°C (see Table 1 for the specific heating temperature), and the heating time is controlled at about 2 minutes per mm thickness.

[0050] Table 1 Embodiment 1 heating furnace temperature control and heating time

[0051]

[0052] (3) The neutral salt used in electrolysis i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com