Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Economic recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulose oxidation by nitrogen dioxide in a perfluorinated tertiary amine solvent

ActiveUS7645874B2Efficiently oxidizedReduce usageBiocideOrganic active ingredientsAqueous alcoholNitrogen dioxide

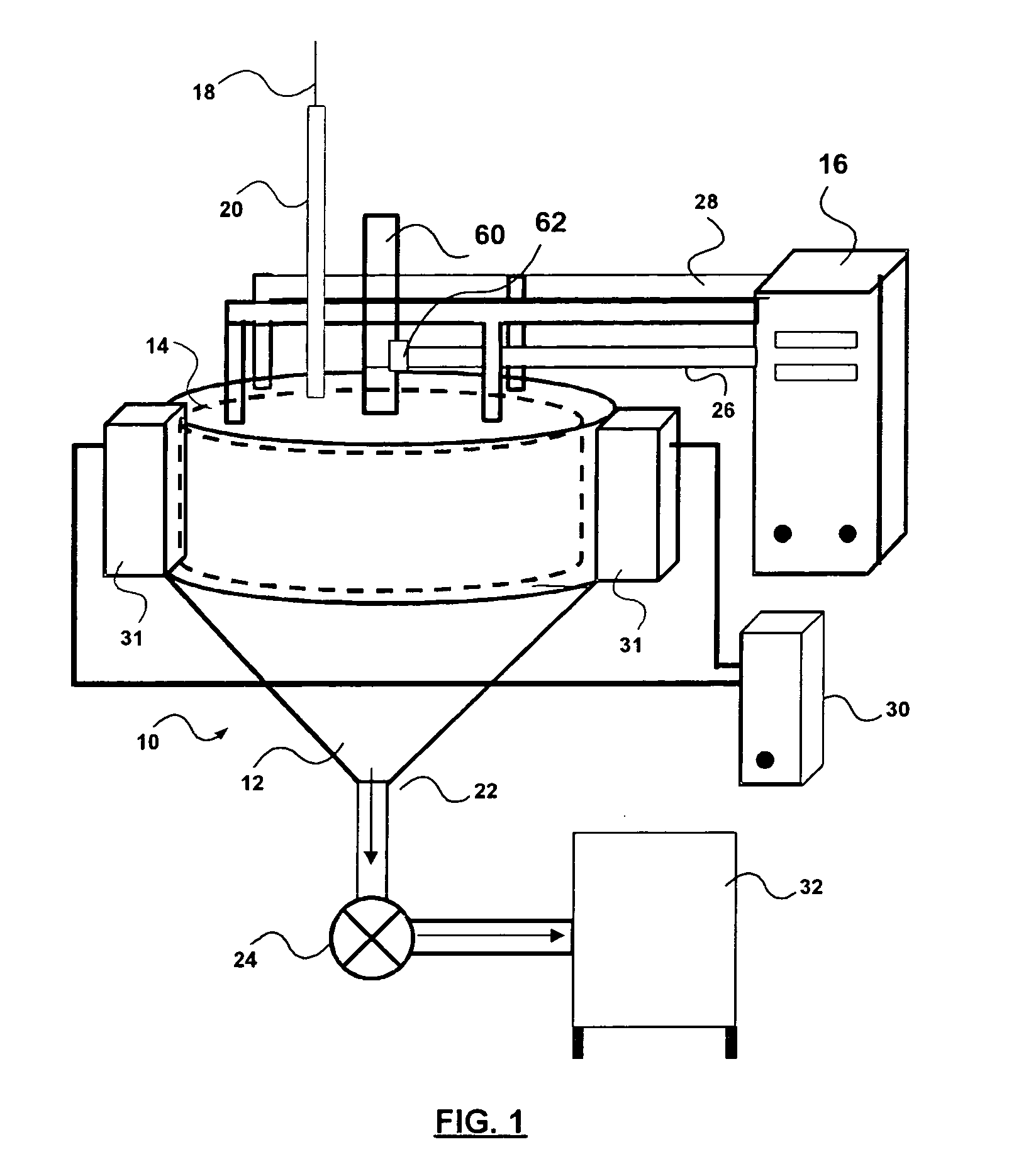

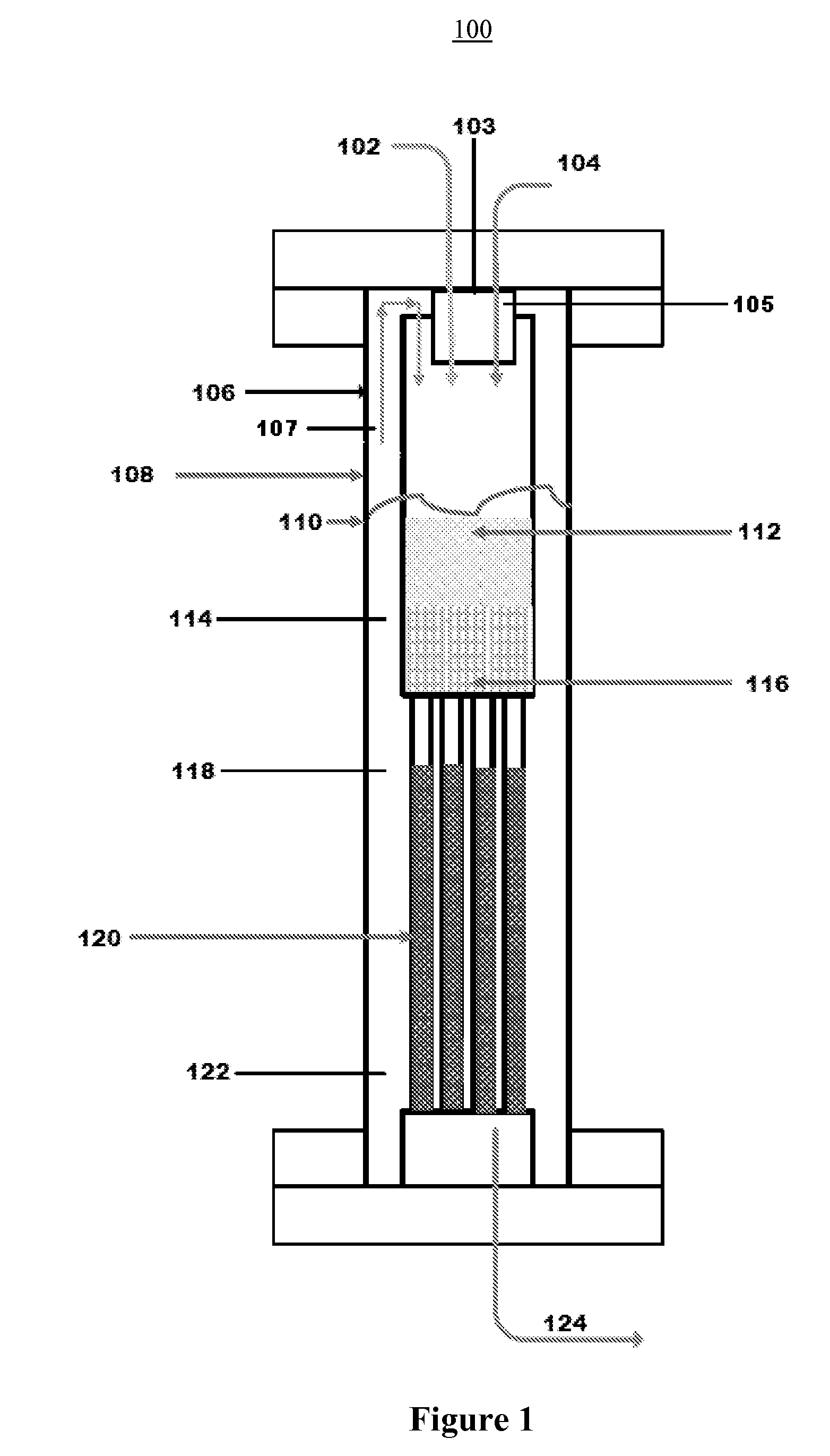

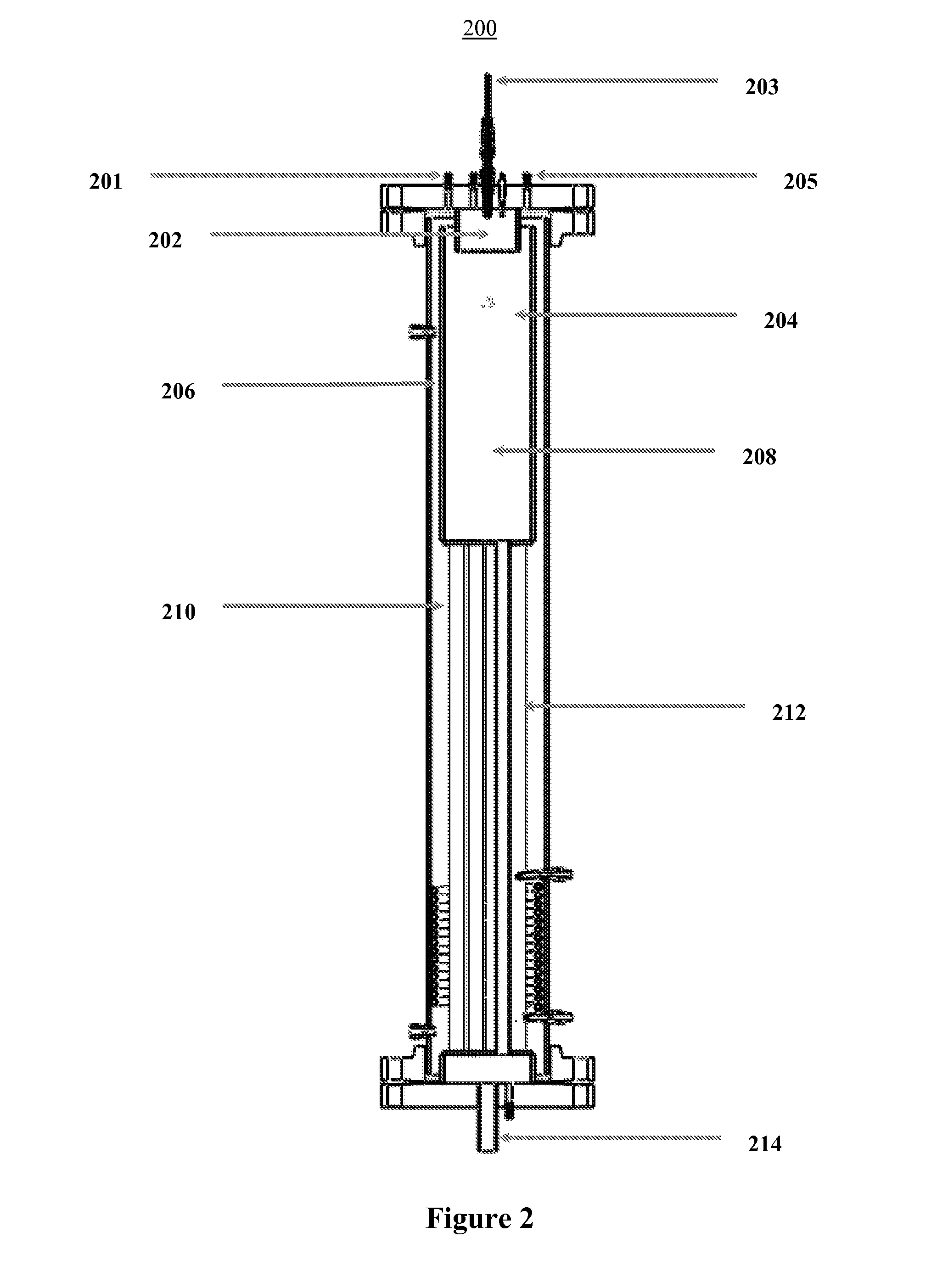

This invention relates to a process for preparing bioabsorbable oxidized cellulose comprising combining cellulose material, with nitrogen dioxide and a nonaqueous solvent chosen from the class of perfluorinated tertiary amines. This invention also relates to a method of oxidizing cellulose material comprising introducing a solvent into the vessel, circulating the solvent through the cellulose material, adding nitrogen dioxide to said vessel containing the solvent and cellulose in the required amounts, circulating the solution for 7 to 24 hours while controlling the reaction temperature, and isolating the oxidized material. Preferably, isolation of the oxidized product is followed by first washing the oxidized cellulose material with cold water, then washing the oxidized cellulose material with an aqueous alcohol solution several times, then washing the material with 100% alcohol several times, and finally drying the oxidized material.

Owner:DEPUY SYNTHES PROD INC

Cellulose oxidation by nitrogen dioxide in a perfluorinated tertiary amine solvent

ActiveUS20070054880A1Efficiently oxidizedReduce usageBiocideOrganic active ingredientsNitrogen dioxideAqueous alcohol

This invention relates to a process for preparing bioabsorbable oxidized cellulose comprising combining cellulose material, with nitrogen dioxide and a nonaqueous solvent chosen from the class of perfluorinated tertiary amines. This invention also relates to a method of oxidizing cellulose material comprising introducing a solvent into the vessel, circulating the solvent through the cellulose material, adding nitrogen dioxide to said vessel containing the solvent and cellulose in the required amounts, circulating the solution for 7 to 24 hours while controlling the reaction temperature, and isolating the oxidized material. Preferably, isolation of the oxidized product is followed by first washing the oxidized cellulose material with cold water, then washing the oxidized cellulose material with an aqueous alcohol solution several times, then washing the material with 100% alcohol several times, and finally drying the oxidized material.

Owner:DEPUY SYNTHES PROD INC

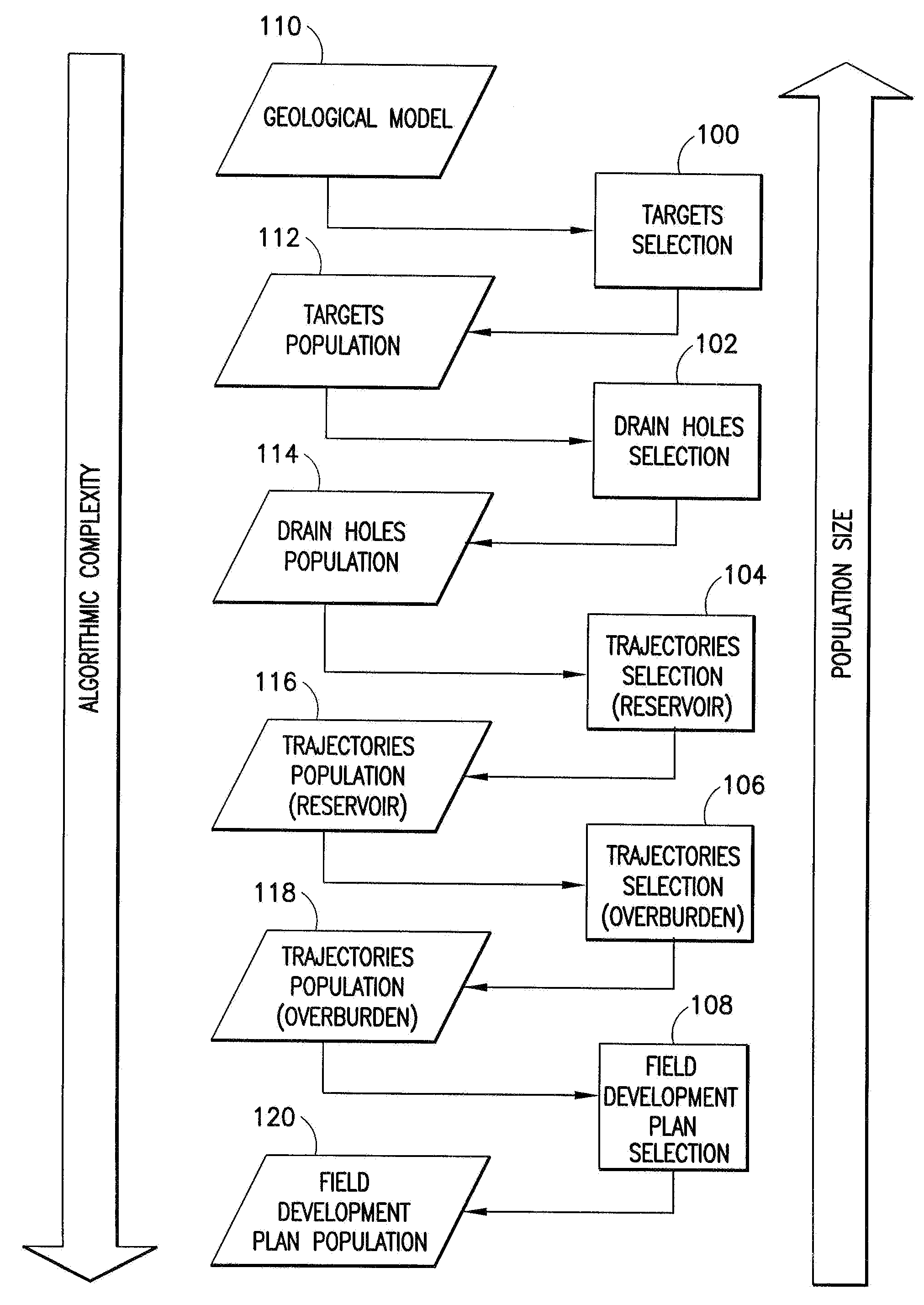

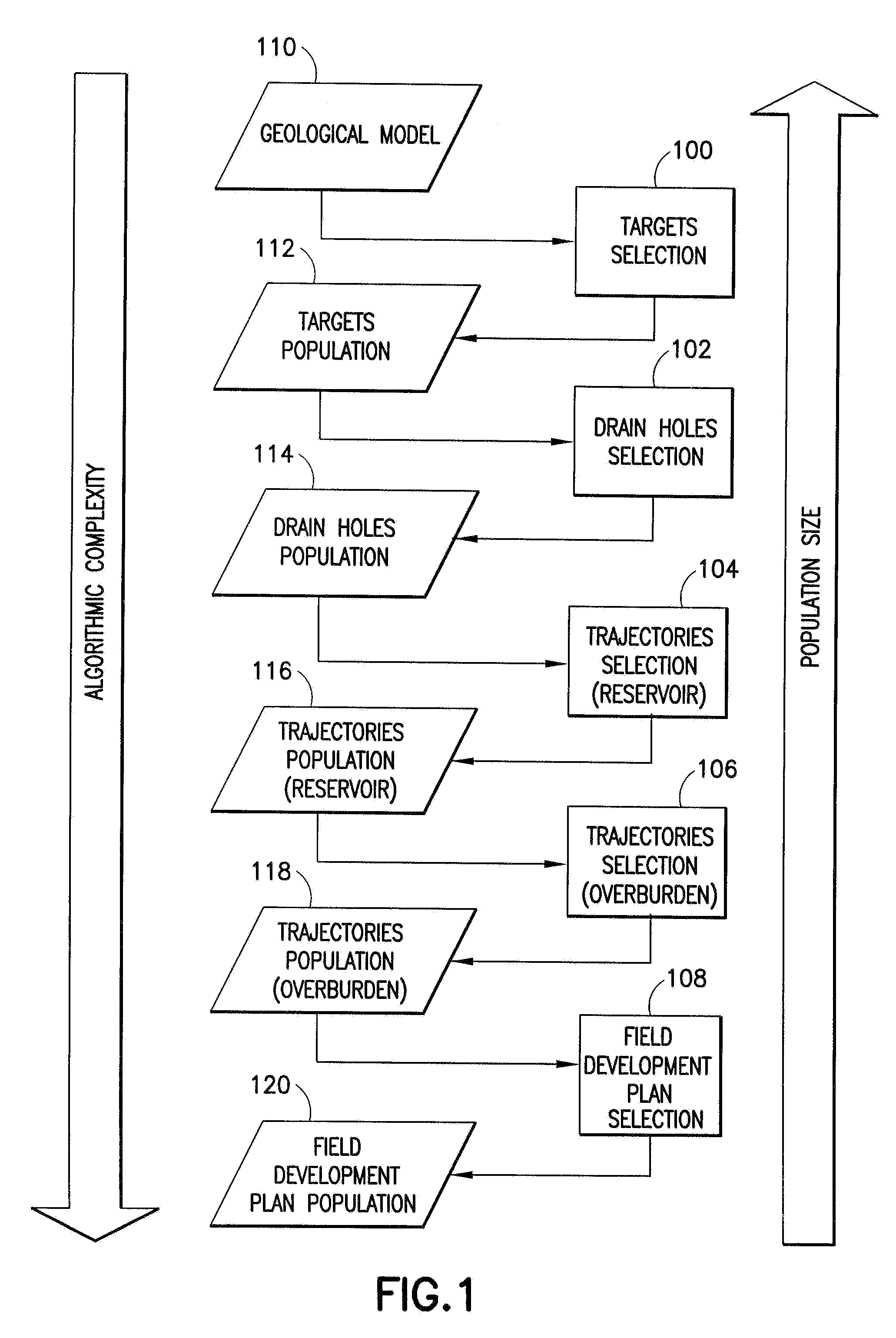

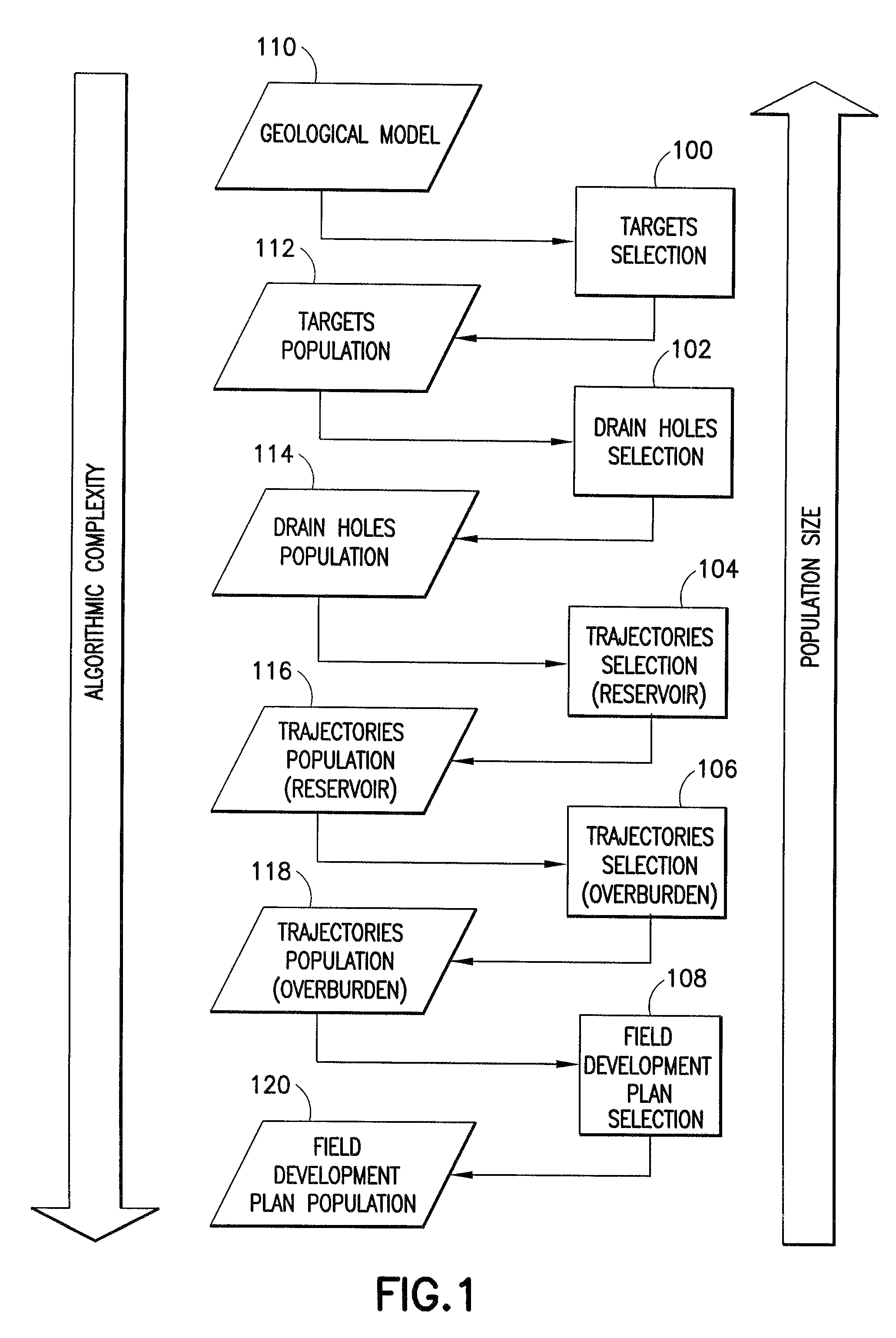

Automated field development planning of well and drainage locations

ActiveUS20080300793A1Reduce in quantityLess timeElectric/magnetic detection for well-loggingFluid removalPopulation sizeTool use by animals

A hybrid evolutionary algorithm (“HEA”) technique is described for automatically calculating well and drainage locations in a field. The technique includes planning a set of wells on a static reservoir model using an automated well planner tool that designs realistic wells that satisfy drilling and construction constraints. A subset of these locations is then selected based on dynamic flow simulation using a cost function that maximizes recovery or economic benefit. In particular, a large population of candidate targets, drain holes and trajectories is initially created using fast calculation analysis tools of cost and value, and as the workflow proceeds, the population size is reduced in each successive operation, thereby facilitating use of increasingly sophisticated calculation analysis tools for economic valuation of the reservoir while reducing overall time required to obtain the result. In the final operation, only a small number of full reservoir simulations are required for the most promising FDPs.

Owner:SCHLUMBERGER TECH CORP

Compact natural gas steam reformer with linear countercurrent heat exchanger

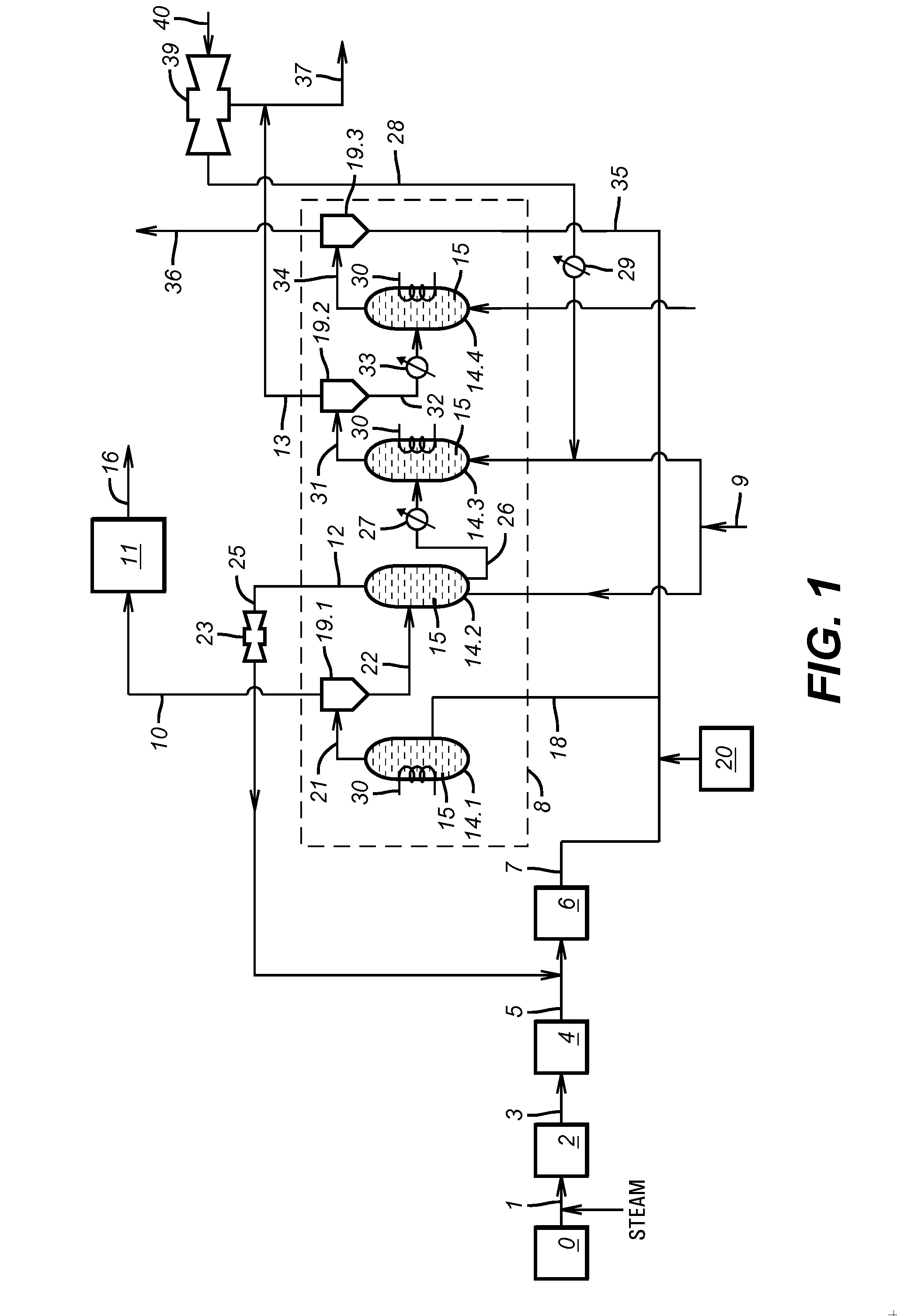

InactiveUS20110014088A1Cheap productionEconomic recoveryExhaust apparatusElement comparisonSteam reformingCombustion chamber

The present invention is natural gas steam reforming apparatus for generating an output gas mixture of carbon dioxide and hydrogen. The apparatus is made from two enclosures. A first enclosure contains a source of water, superheated steam, and channels, located within a lower portion of the first enclosure, which contain a water-gas-shift catalyst for converting CO into CO2 and H2. The heat from hot gas flowing through the channels is released into the first enclosure to boil the water to generate the superheated steam. A second enclosure, contained within an upper portion of the first enclosure, includes a steam inlet for receiving the superheated steam from the first enclosure; a combustion chamber; and a reformation chamber. The combustion chamber is used for combusting a portion of the natural gas to generate additional steam, heat, and a hot gas mixture of CO2, CO, and H2. The reformation chamber is used for steam reforming a remaining portion of the natural gas to generate additional hot gas mixture of CO2, CO, and H2. The hot gas mixture is directed through the channels installed in the first enclosure in which the water-gas-shift catalyst converts residual CO into additional CO2 and additional H2, to produce an output gas mixture of carbon dioxide and hydrogen. In the present invention, the first and second enclosures function as a top-to-bottom linear countercurrent heat exchanger. In one embodiment of the present invention, an external third enclosure containing a combustion chamber and a boiler for combusting natural gas with ambient air may be used to boil additional water into superheated steam which is then fed into the first enclosure.

Owner:PIONEER ENERGY

Automated field development planning of well and drainage locations

ActiveUS8005658B2Reduce in quantityWithout significantly compromising the accuracy of the more complex algorithmsElectric/magnetic detection for well-loggingFluid removalEconomic benefitsAnalysis tools

A hybrid evolutionary algorithm (“HEA”) technique is described for automatically calculating well and drainage locations in a field. The technique includes planning a set of wells on a static reservoir model using an automated well planner tool that designs realistic wells that satisfy drilling and construction constraints. A subset of these locations is then selected based on dynamic flow simulation using a cost function that maximizes recovery or economic benefit. In particular, a large population of candidate targets, drain holes and trajectories is initially created using fast calculation analysis tools of cost and value, and as the workflow proceeds, the population size is reduced in each successive operation, thereby facilitating use of increasingly sophisticated calculation analysis tools for economic valuation of the reservoir while reducing overall time required to obtain the result. In the final operation, only a small number of full reservoir simulations are required for the most promising FDPs.

Owner:SCHLUMBERGER TECH CORP

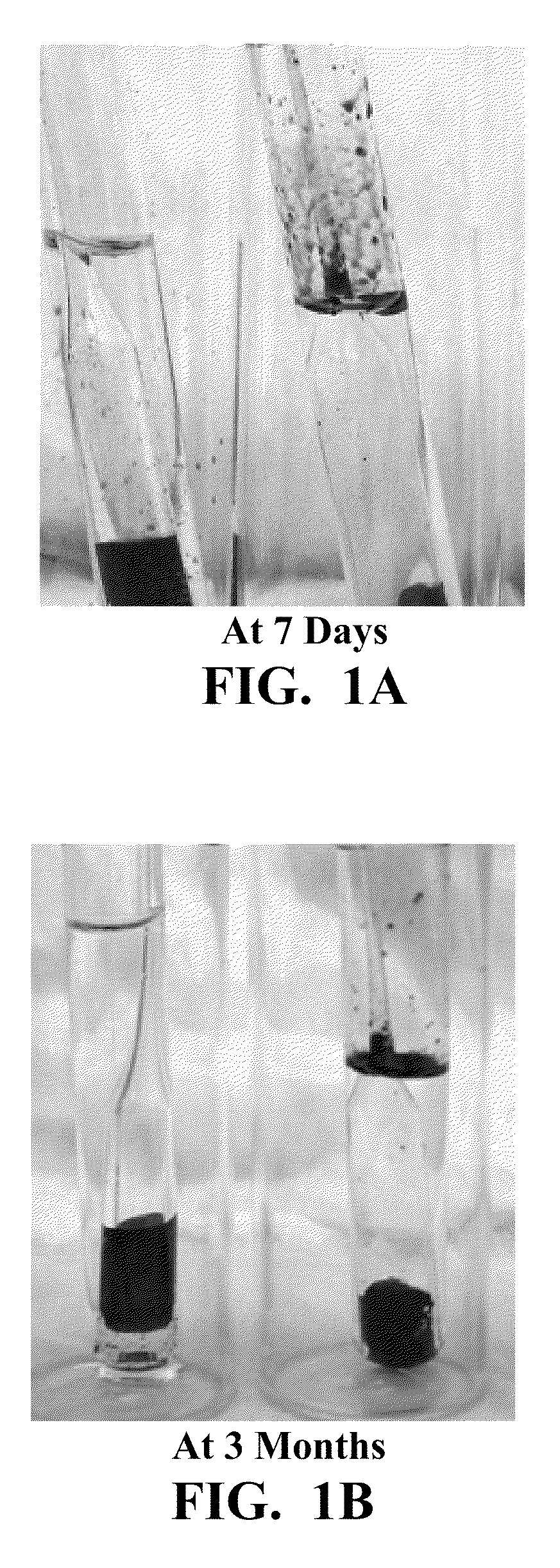

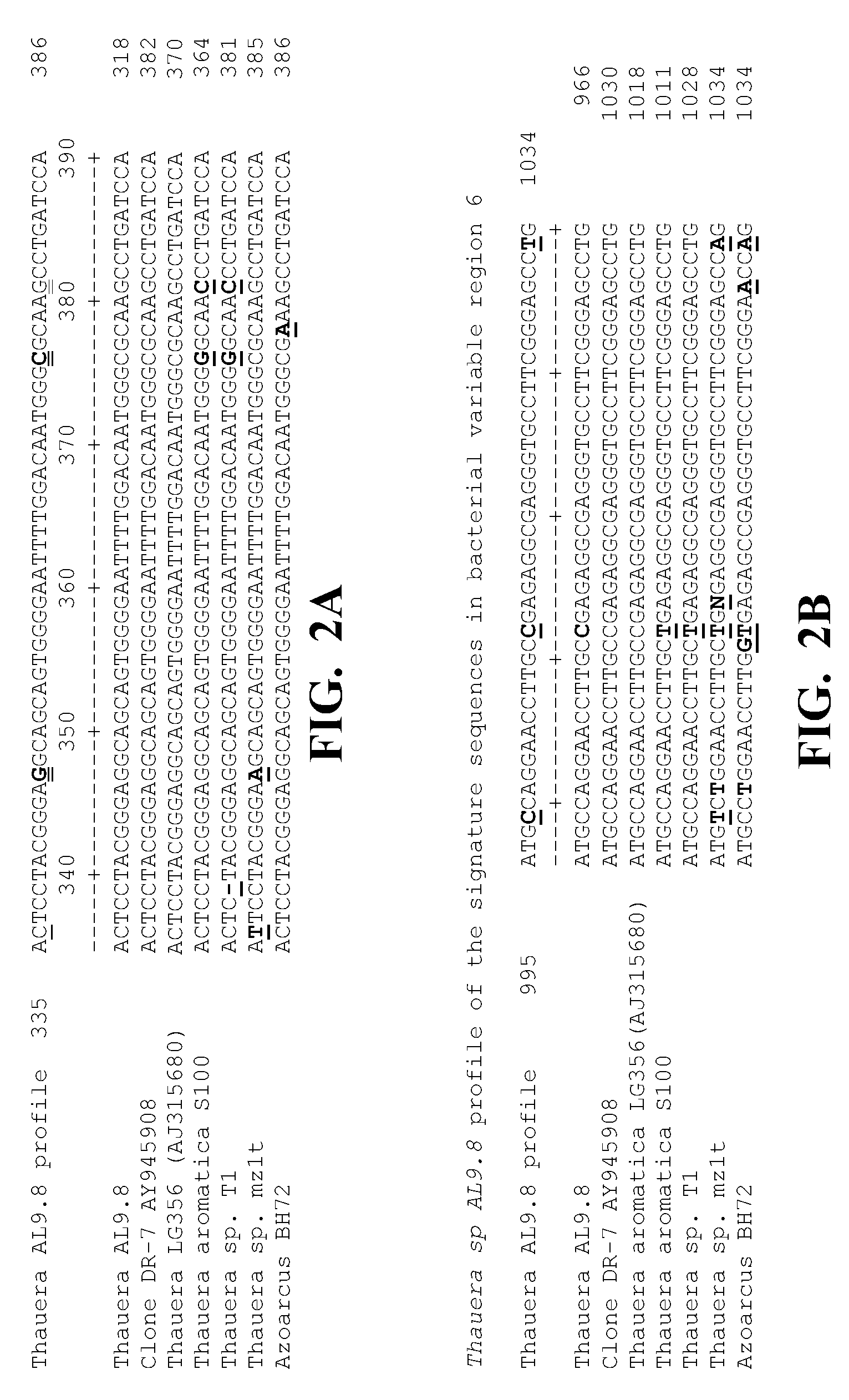

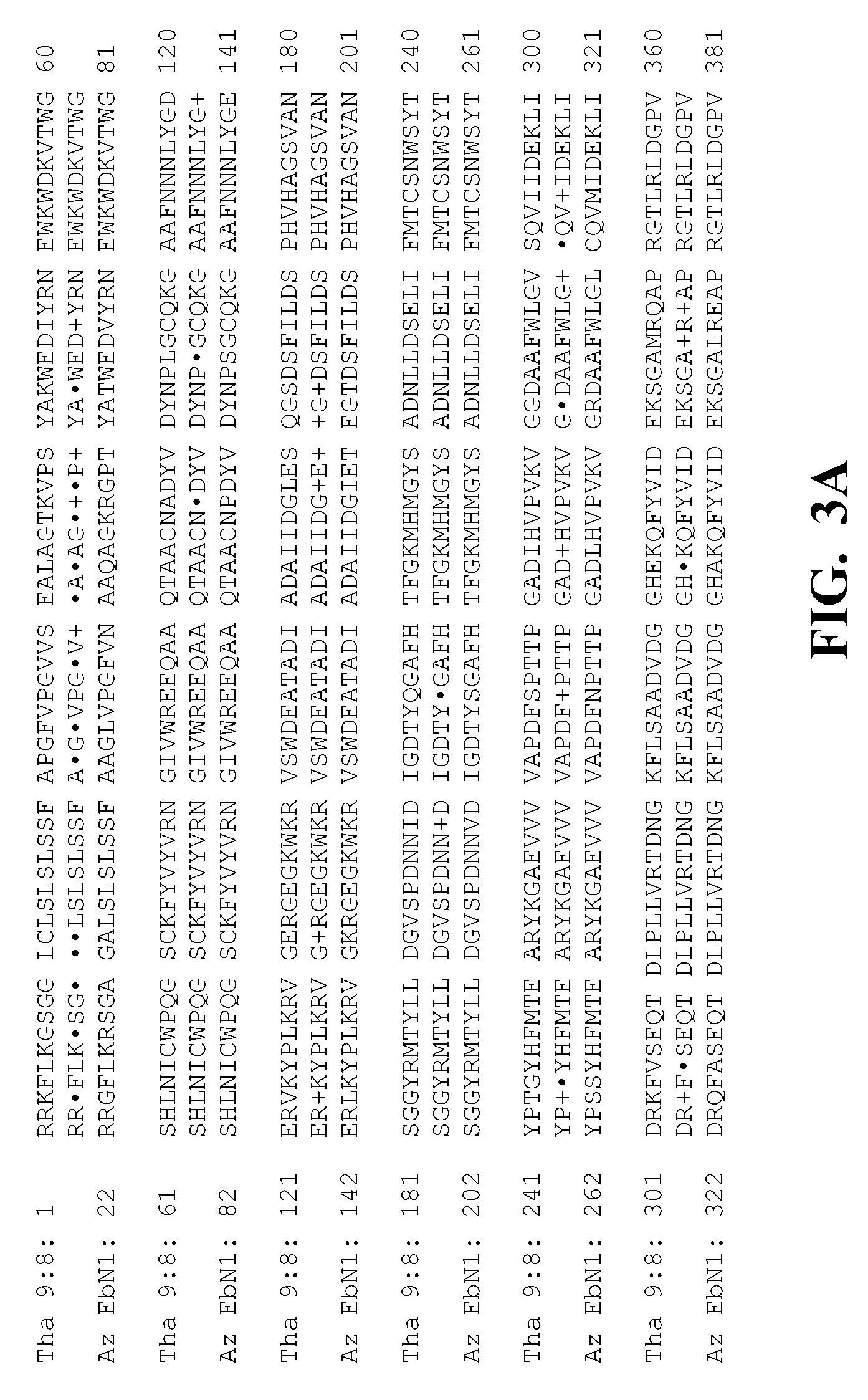

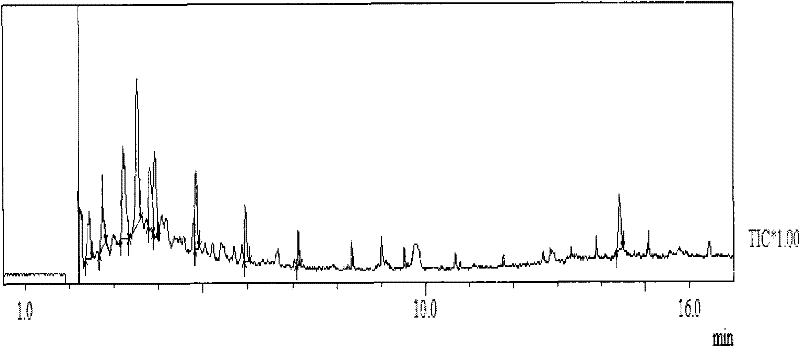

Identification, characterization, and application of Thauera sp. AL9:8 useful in microbially enhanced oil recovery

InactiveUS7708065B2Enhanced overall recoveryEconomic recoveryMicroorganismsFluid removalThaueraBioremediation

The present disclosure relates to isolation, identification and application of Thauera strain AL9:8 which grows on crude oil as the sole carbon source under denitrifying anaerobic conditions Thauera strain AL9:8 can be used alone or in concert with other microorganisms to improve oil recovery, bioremediation of oil or hydrocarbons in contaminated soil, ground water or bodies of water, such as lakes, rivers or oceans and / or applying to method for promoting oil pipeline maintenance, removing a build up hydrocarbon on the intersurfaces of the pipeline.

Owner:EI DU PONT DE NEMOURS & CO

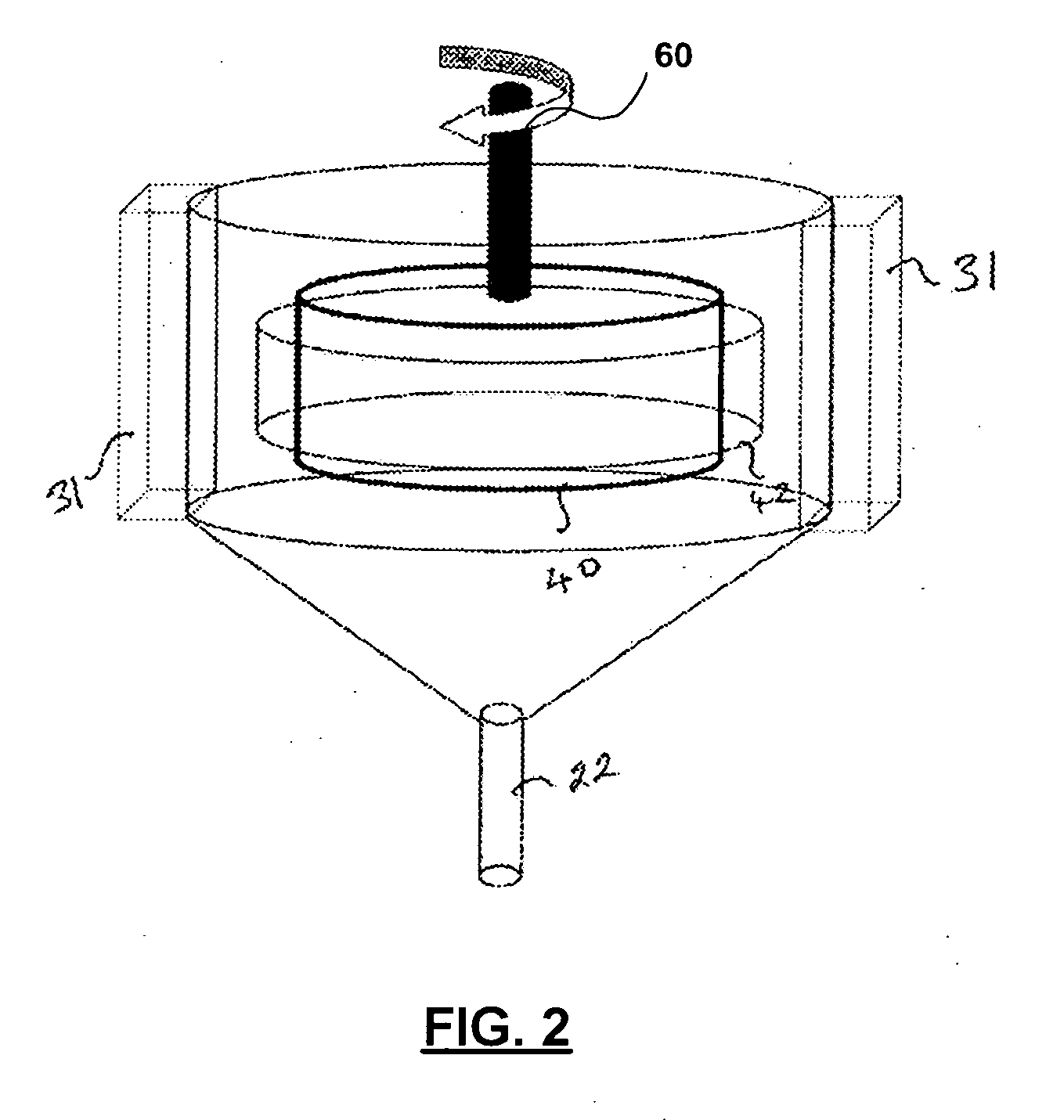

Electrolytic cell for removal of material from a solution

InactiveUS20050183947A1Economic recoveryEasy to separateCellsWater contaminantsElectrochemical responseMetal powder

Disclosed is an electrolytic cell for removal of material from a solution. The cell comprises a cavity for receiving the solution, a rotatable electrode located within the cavity, a counter-electrode in spaced relation to the rotatable electrode, and an ultrasonic generator coupled to said cavity for directing ultrasonic energy toward the rotatable electrode to displace solid material extracted from the solution by an electrochemical reaction. The rotatable electrode may form a cathode, and the counter-electrode may form an anode, wherein metal in the solution is deposited on the cathode as a metal powder, such that the ultrasonic energy displaces the metal powder from the cathode. Alternatively, the rotatable electrode may form an anode, and the counter-electrode may form a cathode, wherein organic waste in the solution is deposited on the anode, such that the ultrasonic energy removes the deposited organic waste from the anode.

Owner:GLOBAL IONIX INC

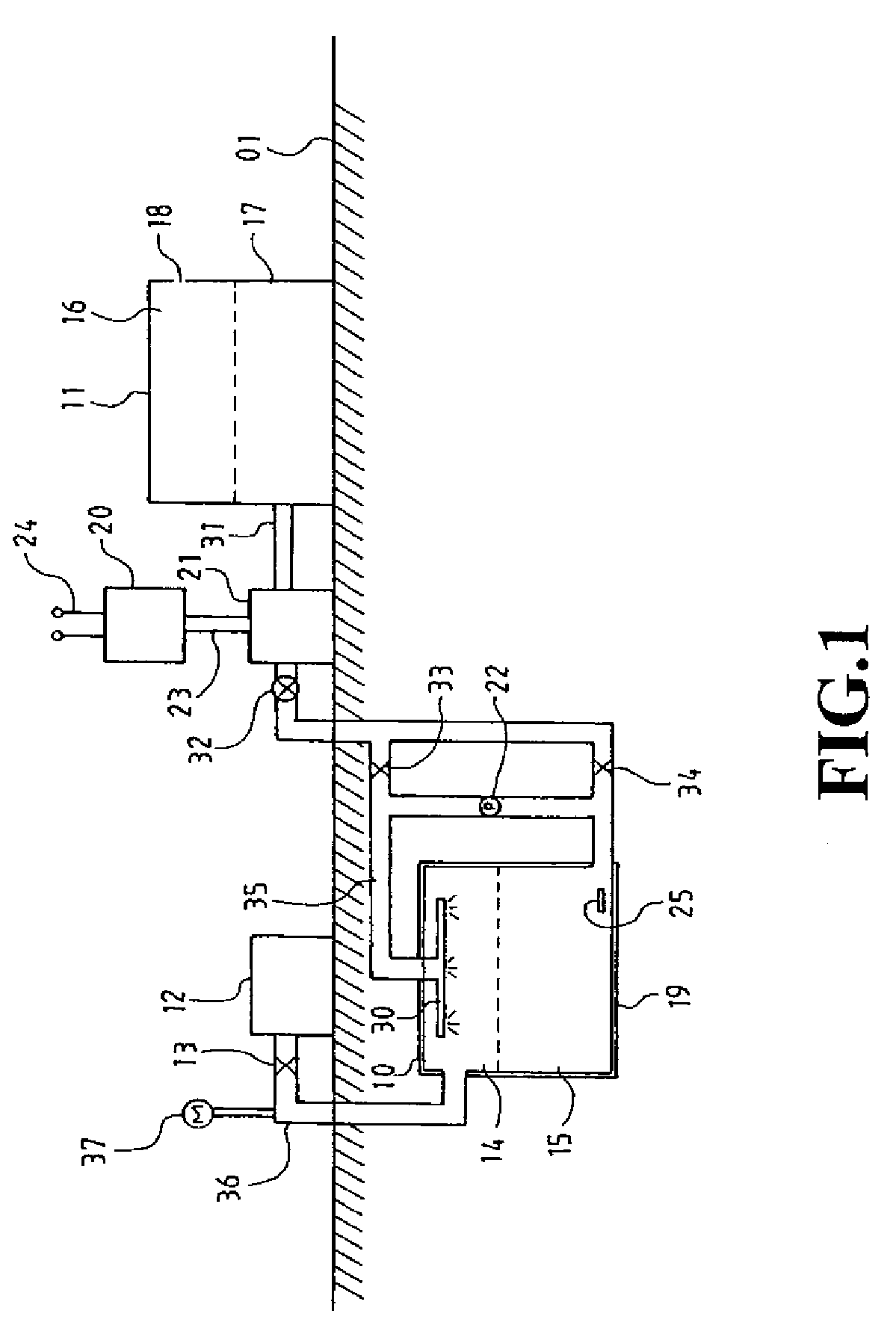

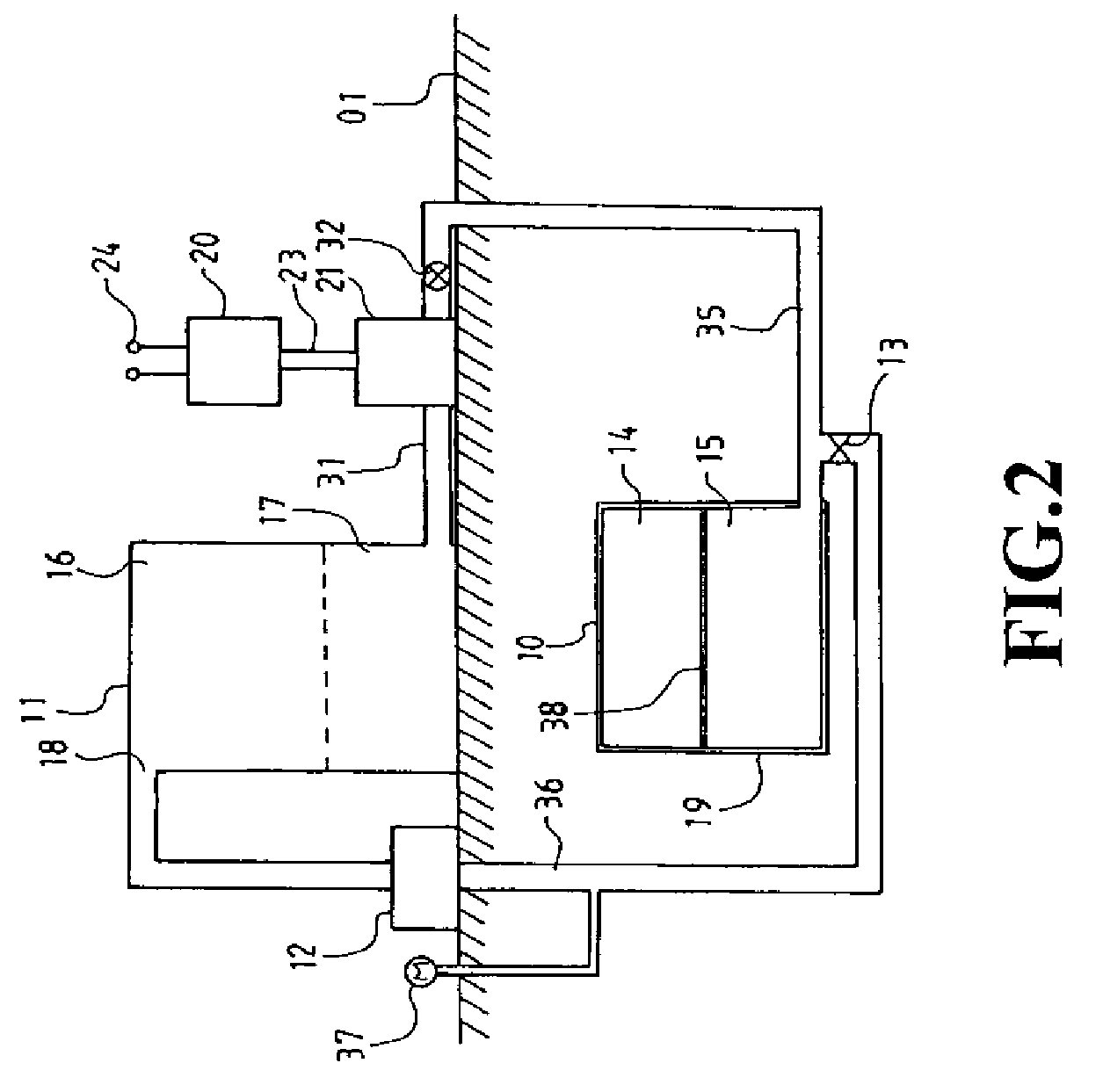

Electricity storage and recovery system

InactiveUS20100270801A1Reduce construction costsReduce solubilityAccumulator installationsGas turbine plantsElectricityMotor drive

The electricity storage and recovery system. At first, injects high-pressure gas in a high-pressure tank and then, the normal-pressure fluid from a normal-pressure tank is pumped into the high-pressure tank by a motor-driven pump so that the electrical energy is converted to high-pressure potential energy of the fluid stored inside the high-pressure tank. To recover the potential energy back to electrical energy, the high-pressure fluid flows from the bottom of the high-pressure tank to the normal-pressure tank through a turbine. The turbine in turn drives a generator to produce electricity. The pump and the turbine are of a same device running in opposite directions. The motor and the generator are also of a same device running in opposite directions.

Owner:HOULY

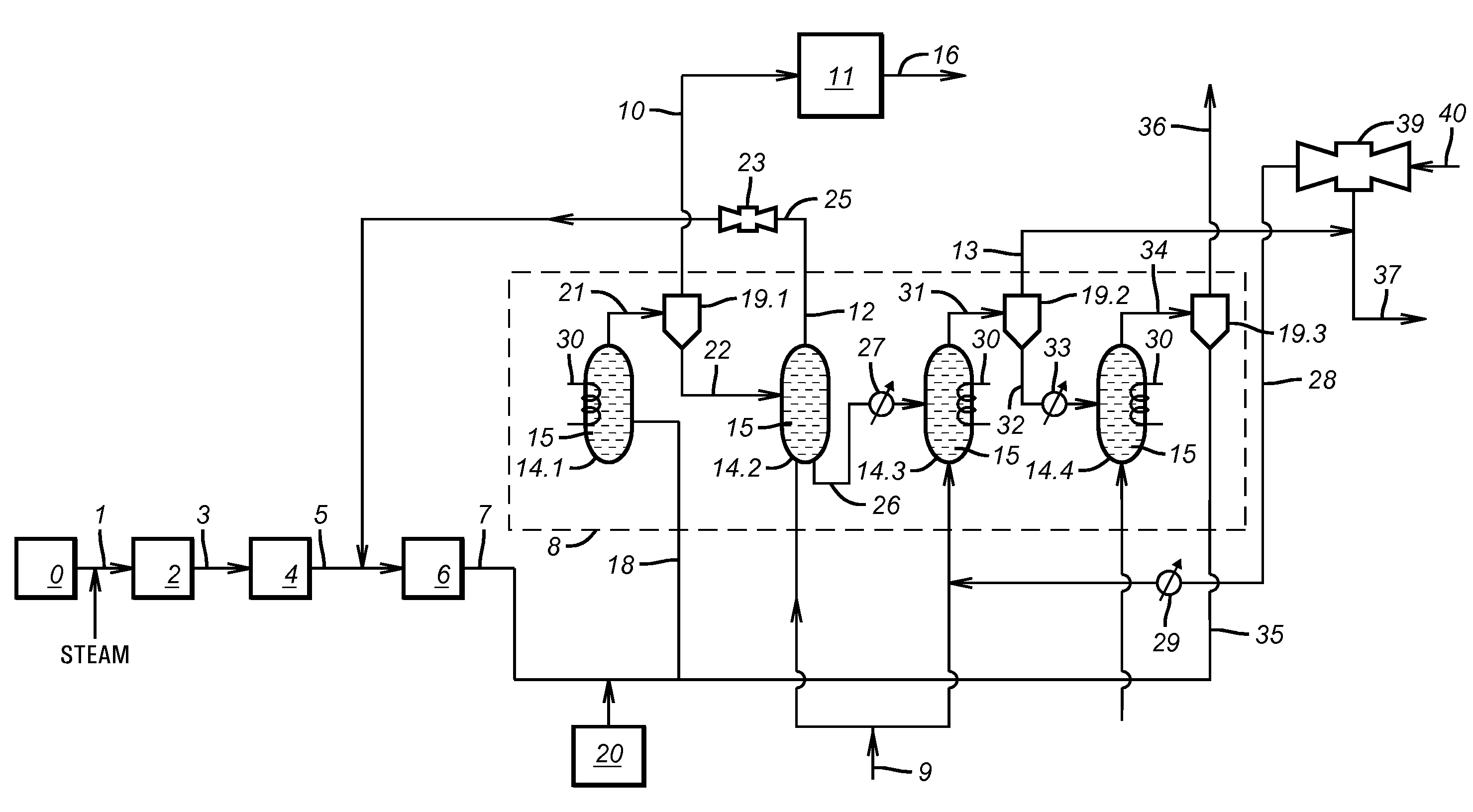

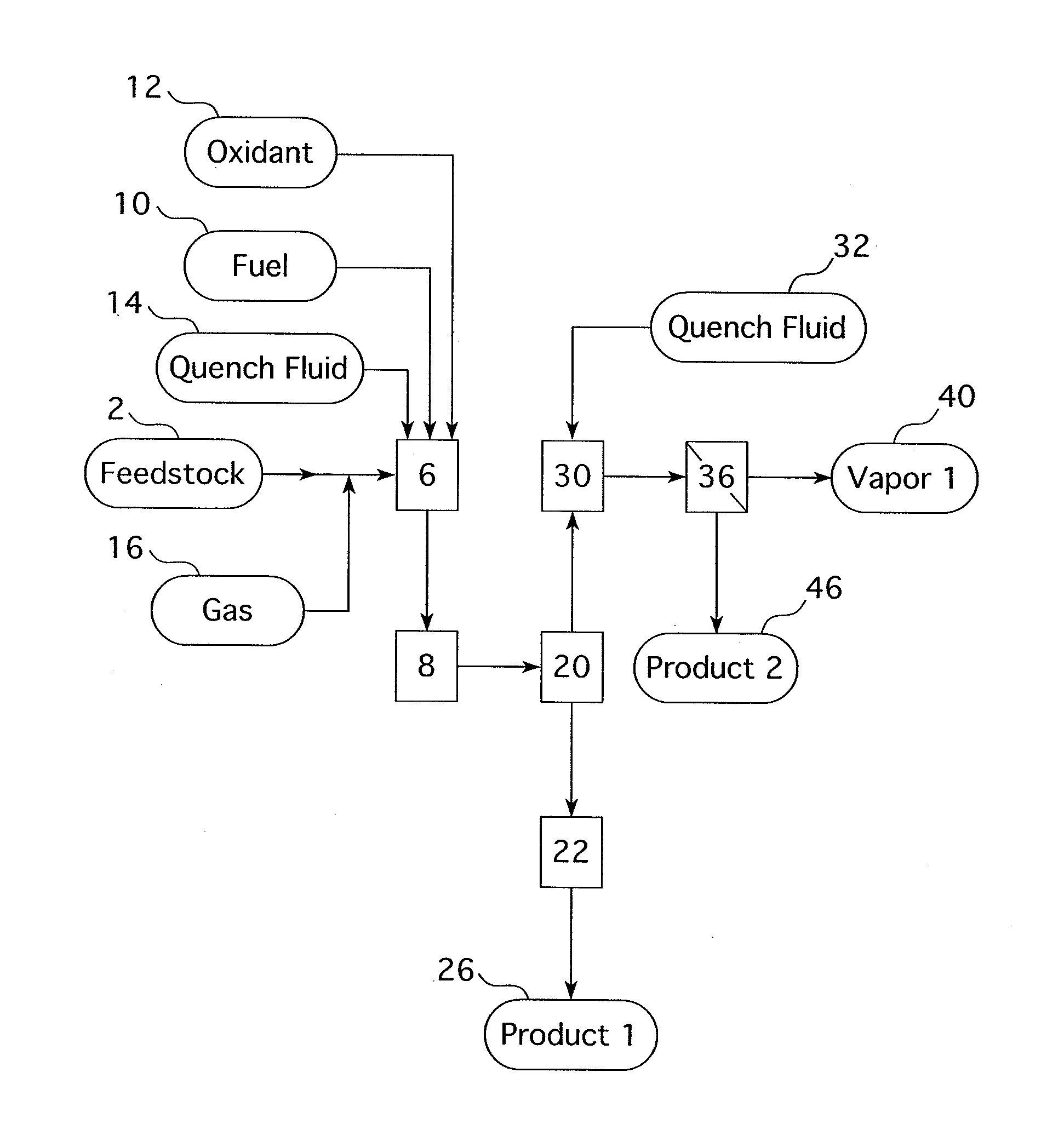

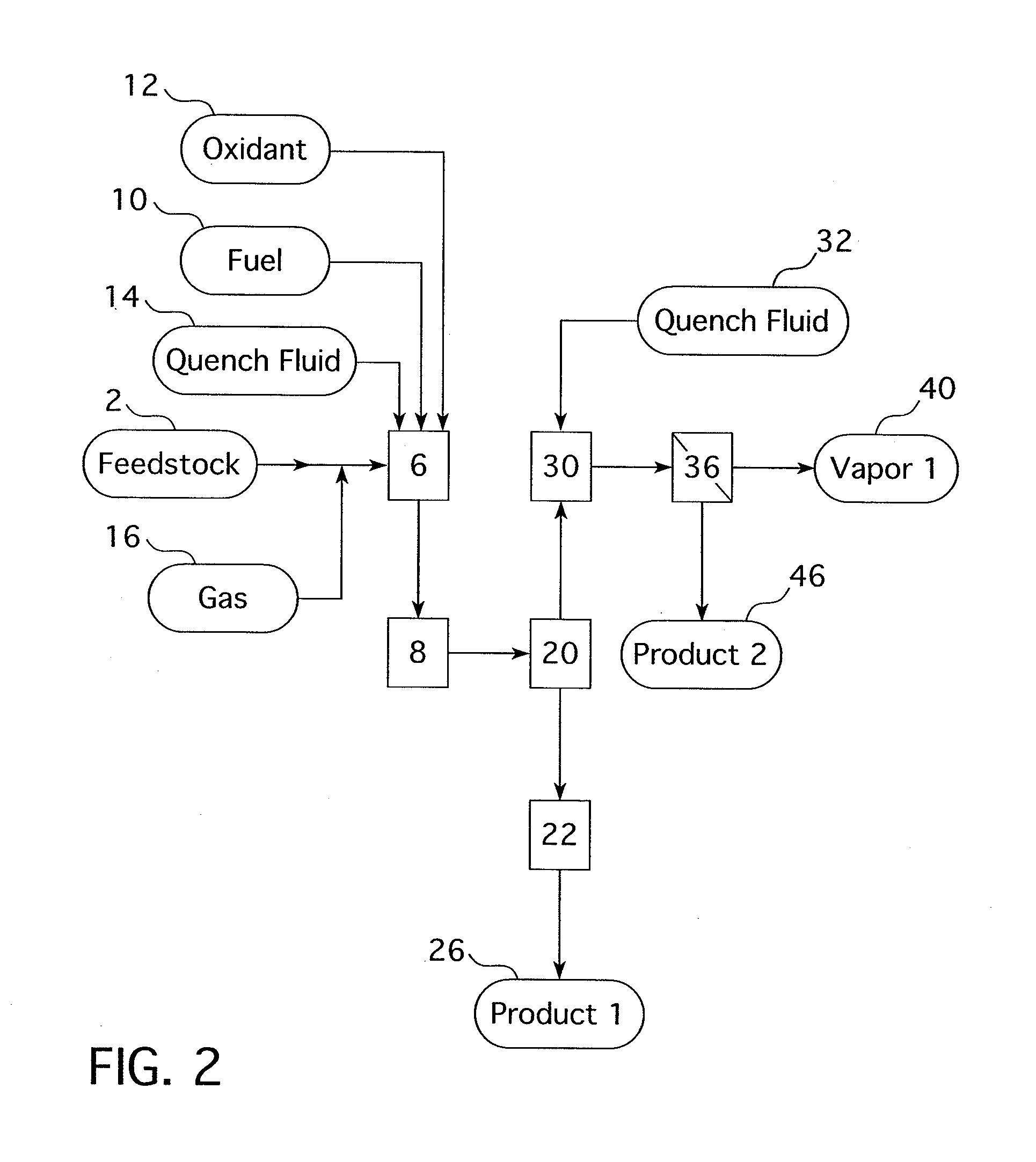

Process For The Production Of Hydrogen And Carbon Dioxide Utilizing Magnesium Based Sorbents

InactiveUS20130011326A1Economic recoveryImprove economyCarbon compoundsHydrogen separation using solid contactSorbentHydrogen pressure

The present invention relates to a process for recovering hydrogen along with high temperature high pressure carbon dioxide from one or more hydrocarbon gas streams by incorporating a carbon dioxide recovery unit which utilizes a fluidized magnesium based sorbent into a process that includes a gasification unit, an optional sulfur removal unit, a water gas shift reactor and a hydrogen pressure swing adsorption unit.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Natural gas steam reforming method with linear countercurrent heat exchanger

InactiveUS20110046244A1Cheap productionEconomic recoveryHydrogen productionHydrogen/synthetic gas productionSteam reformingSuperheated steam

The present invention is a natural gas steam reforming method for generating an output gas mixture of carbon dioxide and hydrogen, including the following steps. (1) Combusting a portion of the natural gas with an oxidizing agent to generate heat, superheated steam, and a gas mixture of carbon dioxide, carbon monoxide, and hydrogen. (2) Steam reforming the gas mixture with additional superheated steam under steam-rich conditions to transform a remaining portion of the natural gas into carbon dioxide, carbon monoxide, and hydrogen. (3) Water-gas-shifting any residual carbon monoxide into additional carbon dioxide and additional hydrogen by utilizing a water-gas-shift catalyst downstream of the steam reforming step, thereby producing an effluent gas mixture that is predominantly carbon dioxide and hydrogen. (4) Boiling water in a top-to-bottom linear countercurrent heat exchanger to generate the superheated steam by transferring heat released in the water-gas-shifting step, where as the water is gravitationally and thermally stratified from top to bottom with a top portion boiling into steam, the steam continues to rise and is additionally heated in the top-to-bottom linear countercurrent heat exchanger. (5) And, utilizing the superheated steam produced as a reactant in the steam reforming step and the water-gas-shifting step to assist in reformation of the natural gas into carbon dioxide and hydrogen.

Owner:PIONEER ENERGY

Repair process for bearing base shaft hole

The invention discloses a repair process for a bearing base shaft hole. The repair process is characterized by comprising the following requirements that 1, the abrasion depth of the shaft hole is detected, and if the abrasion depth is smaller than 4 mm in the diameter direction, to-be-repaired parts are polished and deepened through an electric tool; 2, the to-be-repaired surface of a bearing hole is cleaned through a cleaning agent, and an outer ring of a bearing is sprayed with a layer of a release agent so that disassembling of the bearing can be facilitated; 3, the bearing is positioned, and a shaft and the bearing are assembled together with glue; and 4, the back half portion of the outer ring of the bearing is coated with a repairing agent, the coating amount should ensure that the position between the outer ring of the bearing and the shaft hole cannot lack the glue, the bearing coated with the repairing agent is pushed into the shaft hole and cured for 8-16 hours at the temperature of 30 DEG C-50 DEG C, corners are trimmed through abrasive cloth or a file, and the bearing base shaft hole can be used after being completely cured. The repair process for the bearing base shaft hole is reasonable in process, low in cost, reasonable and coordinated in parameter collocation, short in time and easy to operate.

Owner:CHONGQING BATENG MACHINERY CO LTD

Method for degrading polychlorinated biphenyl in soil by utilizing mixed powder of zero-valence iron and magnesium metals

InactiveCN102211109AReduce repair costsEasy to fixContaminated soil reclamationSoil sciencePolychlorinated biphenyl

The invention relates to a method for degrading polychlorinated biphenyl in soil by utilizing mixed powder of zero-valence iron and magnesium metals. The method comprises the following steps of: adding the mixed powder of iron and magnesium metals with the mol ratio of 0.4-0.8 into a polychlorinated biphenyl-polluted soil sample, adding NH4Cl or NH4NO3 solution with the mass fraction of 0-10% to regulate the humidity of the soil, and standing and reacting for more than 1 hour at room temperature, thus the polychlorinated biphenyl in the soil is degraded and the degrading efficiency reaches more than 98%. In the method, the reaction raw materials are available, the reaction conditions are simple, and the operation is easy, thus the method has good economic benefit and environmental benefit and has a better application prospect in the large-area polychlorinated biphenyl-polluted soil repairing.

Owner:BEIJING UNIV OF CHEM TECH

Repairing technique for vertical reducer body

The invention discloses a repairing technique for a vertical reducer body. The repairing technique includes the following requirements: (1) surface treatment: <1> clearing old paint to expose a reducer body, removing an original welding blocking by a flat shovel, and machining a crack into a 45-degree V-shaped groove by a grinding wheel; and <2> rust and stain clearing, performing washing with gasoline, and then performing wiping with acetone for 3-5 times, and drying in air; (2) sticking technique: <1> hole repairing, pasting 3 layers of glass cloth to the inner side of a hole with a repairing agent, wherein the diameter of the first layer of the glass cloth is 4-5 cm greater than that of the hole, and the second layer and the third layer of the glass cloth are 4-5 cm greater than the previous layer respectively; and <2> crack repairing, filling the repairing agent in the V-shaped groove of the crack, performing curing at the indoor temperature for 24 hours, performing leveling through filing, then pasting three layers of glass cloth to the inner side and the outer side with the repairing agent, and performing ground flush after 12 hours. The repairing technique is reasonable in processes, is low in cost, is reasonable and coordinated in parameter collocation, is short in time, and is simple in operation.

Owner:CHONGQING BATENG MACHINERY CO LTD

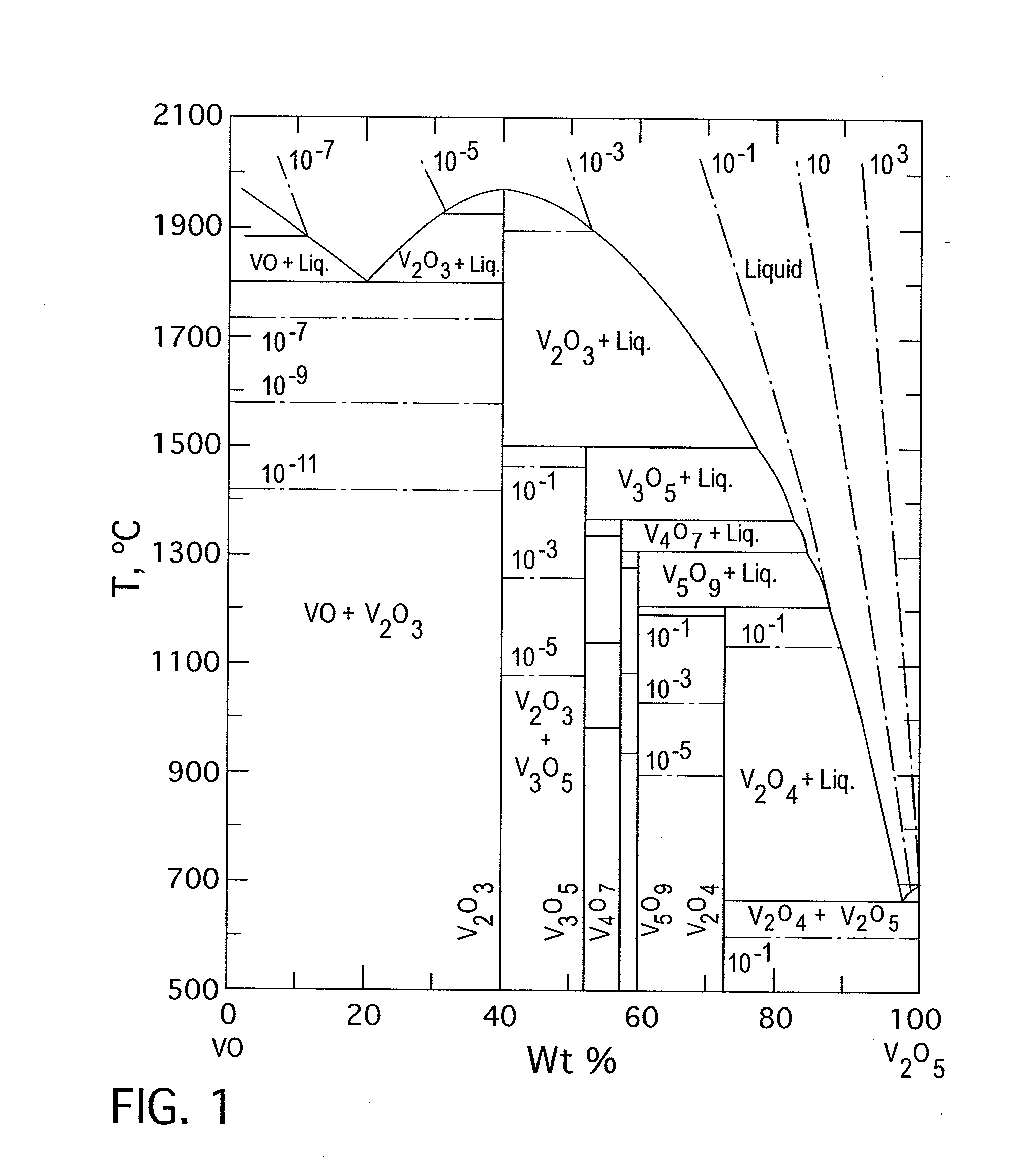

Methods for the concentration of vanadium from carbonaceous feedstock materials

InactiveUS20120164040A1Increased vanadium contentEfficient heat recoveryTantalum compoundsVanadium oxidesCycloneUnit operation

This invention relates to a process that utilizes high-temperature oxidation with controlled stoichiometry in the concentration of vanadium from carbonaceous feedstock materials containing vanadium, such as residues, ashes and soots resulting from the combustion or gasification of petroleum vacuum residuum, petroleum coke, kerogen from oil shale, and bituminous sand, e.g., tar sand or oil sand, or extra heavy oil or other carbonaceous feedstocks that contain vanadium. A preferred embodiment uses a counter-rotating vortex reactor and a cyclonic, entrained-flow reactor to rapidly heat and oxidize feedstock at temperatures in the range of about 2100° F. to 2900° F., resulting in a vapor stream with entrained, solid materials comprising the concentrated vanadium species. The entrained, vanadium-rich product solids may be removed from the high-temperature vapor stream by a high-temperature filter assembly, with or without the aid of a high-temperature cyclone separator which removes a portion of the vanadium-rich solids upstream of the filter. The filtered vapor stream may be stored or then ducted to suitable unit operations for possible oxidation and heat recovery, followed by entailed pollution control prior to its final discharge to the atmosphere.

Owner:HNAT JAMES G +1

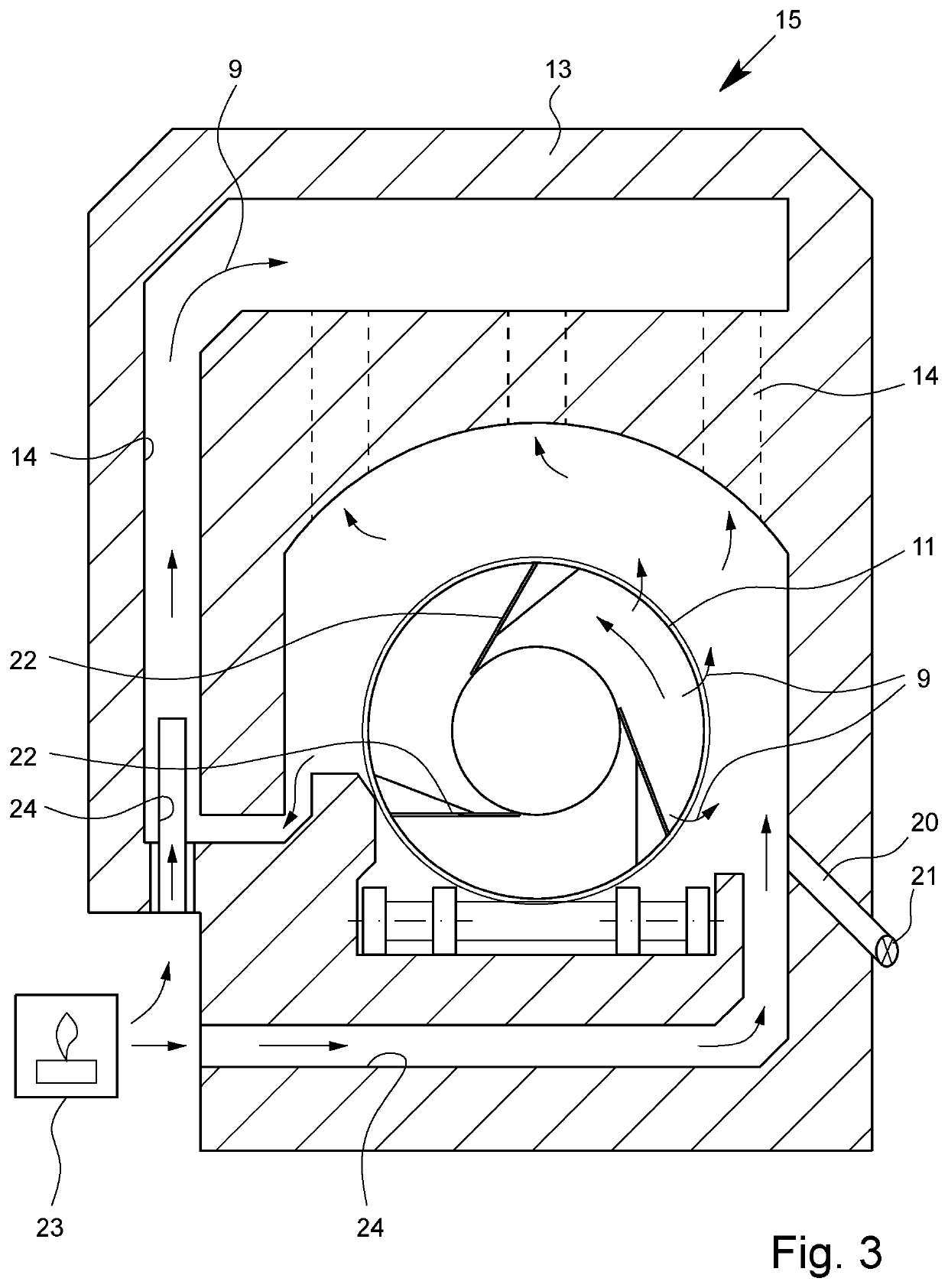

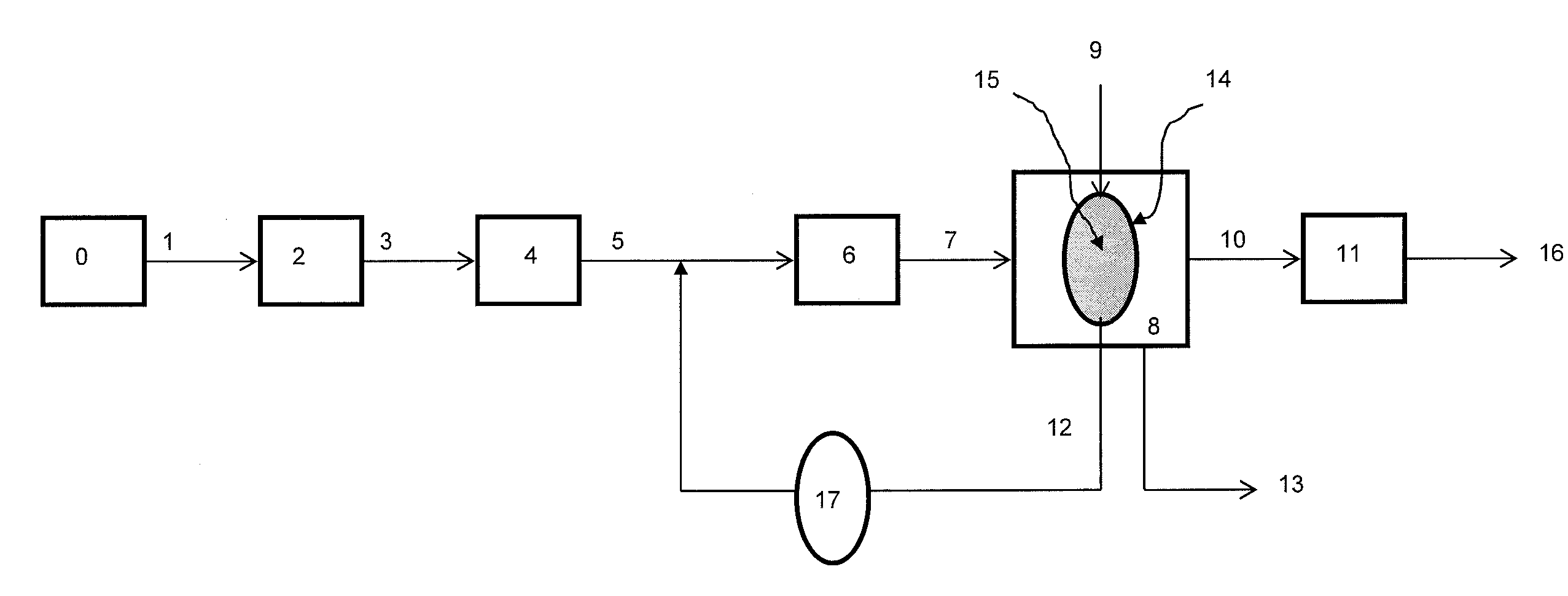

Method and device for recycling gas

InactiveUS20060165533A1Improve performanceImprove compression performanceFluid removalProcess efficiency improvementProduct gasEngineering

A device and method for recycling of gas used during the quenching process in a thermal treatment, for example, in which the gas is removed directly from a quenching chamber and is compressed to the pressure prevailing in the high-pressure container rather than being decompressed into a gas buffer, an additional compression step being connected if the pressure inside the chamber lies below a threshold value, wherefore conduits comprising overflow regulators lead to the individual compression steps.

Owner:LINDE AG

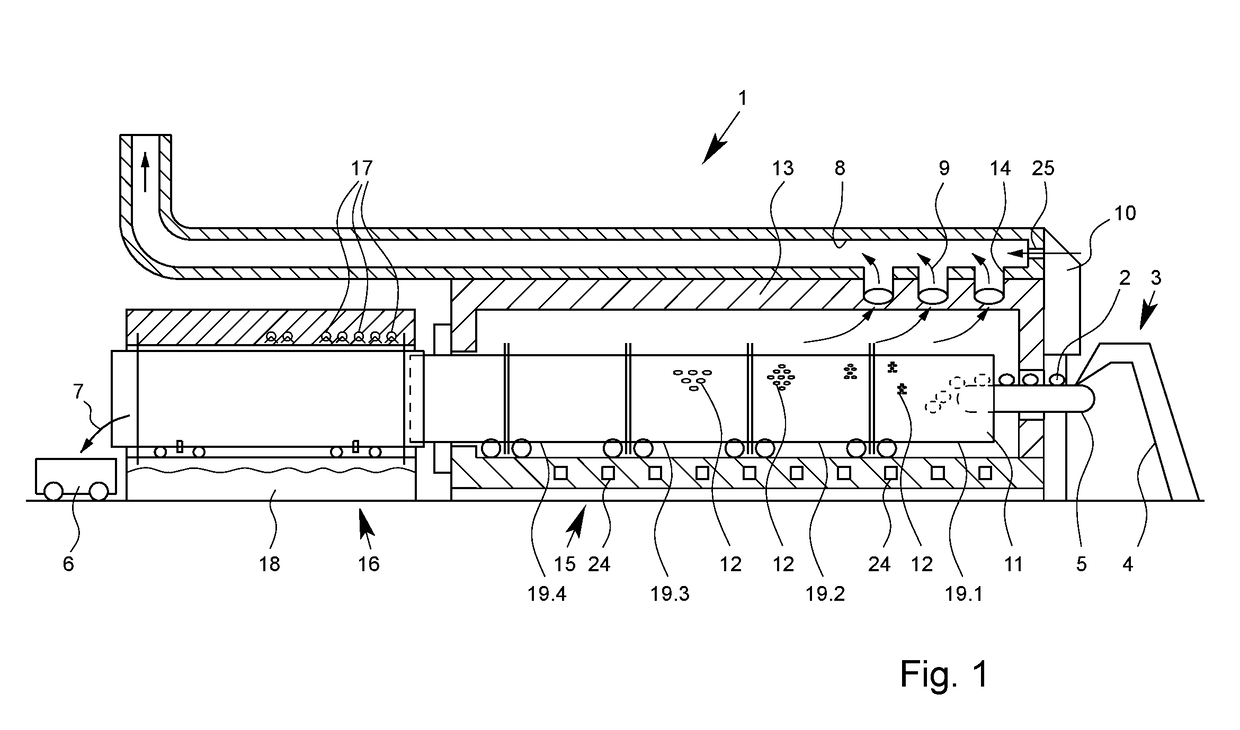

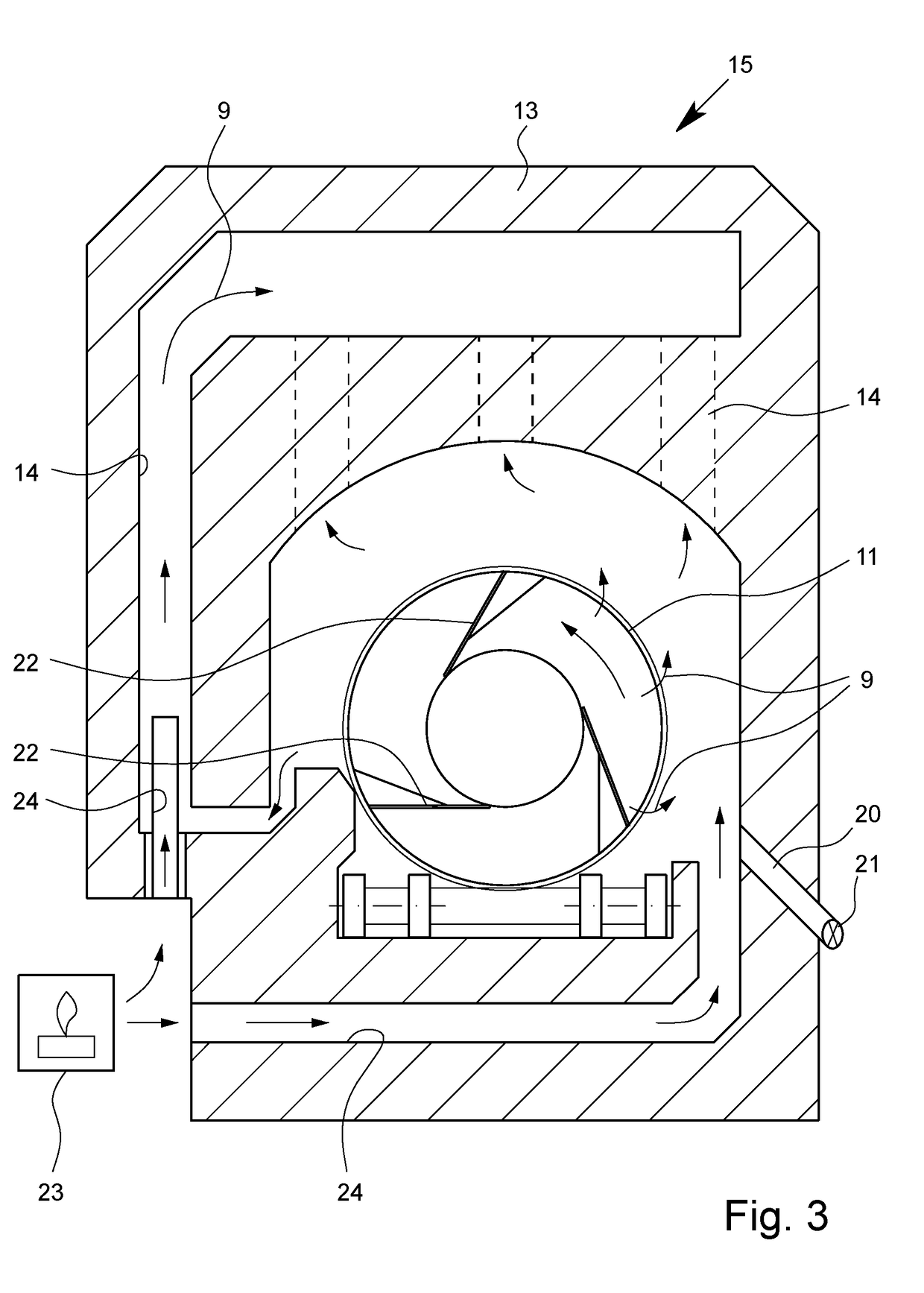

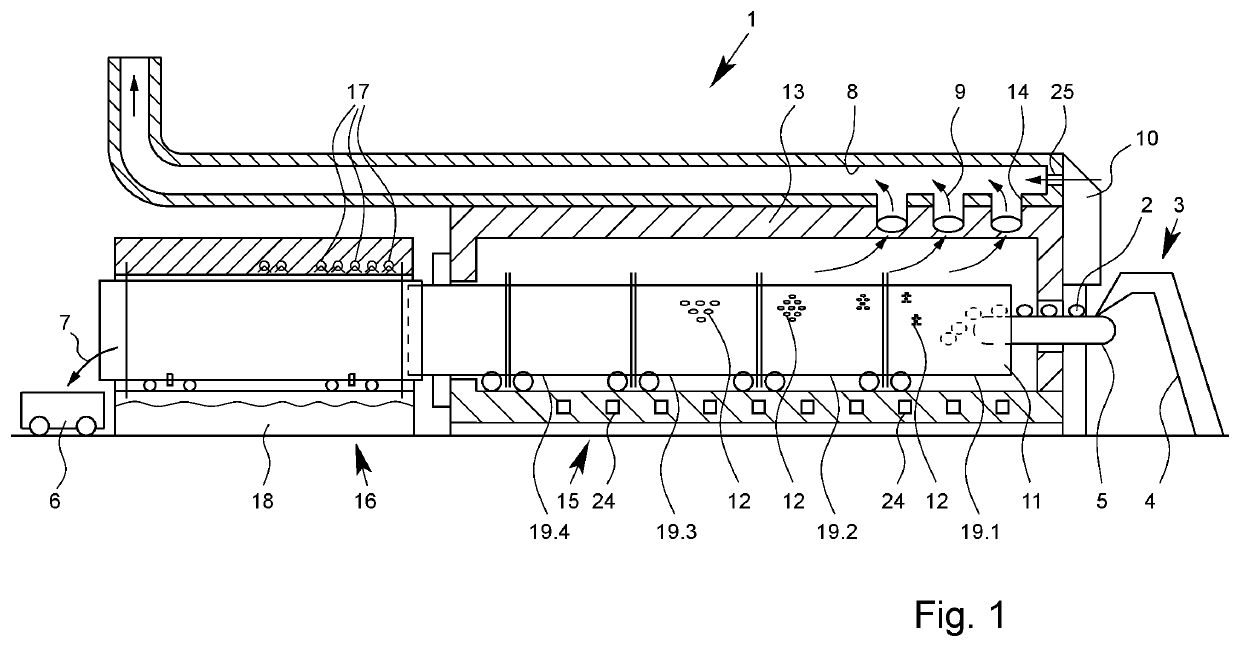

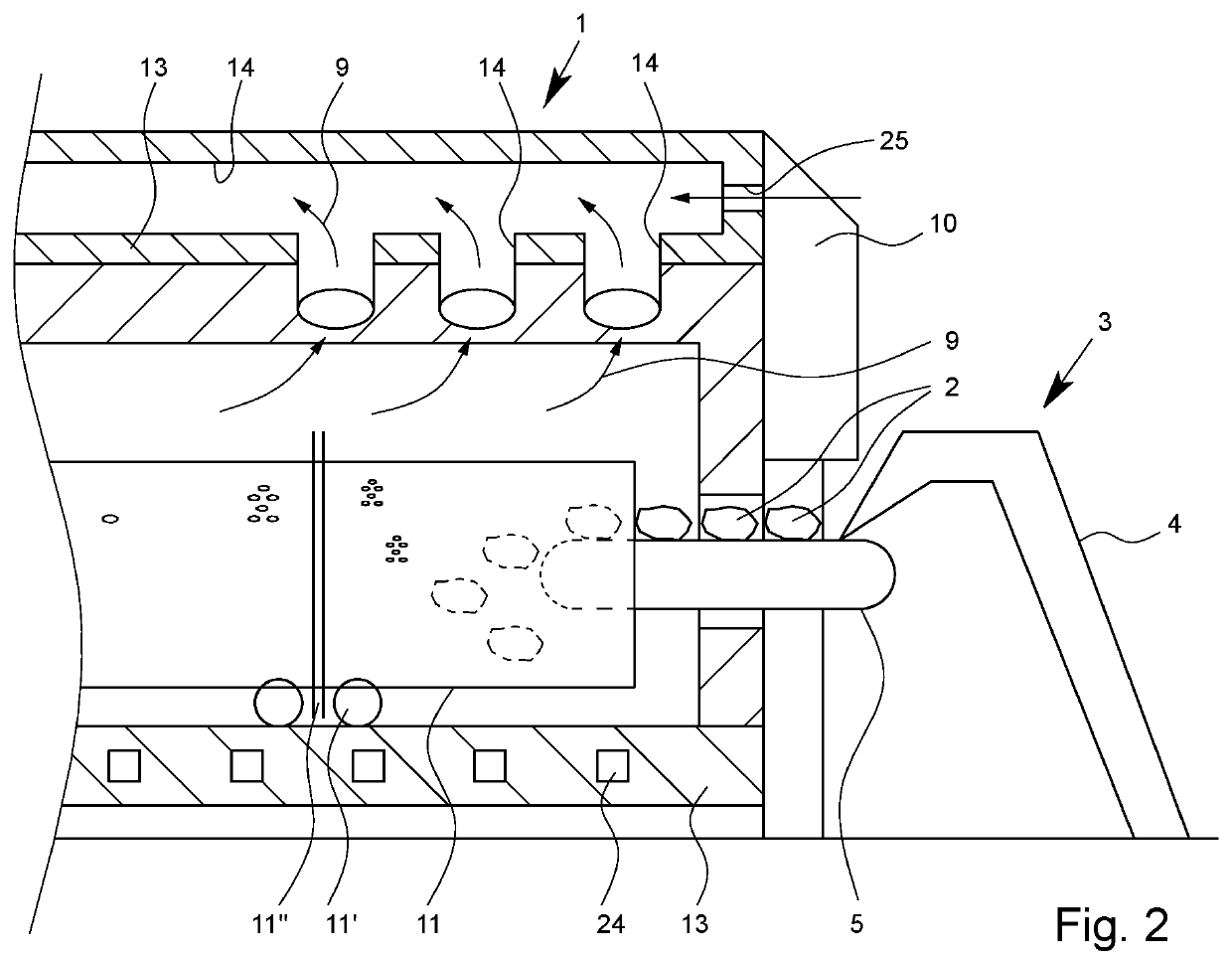

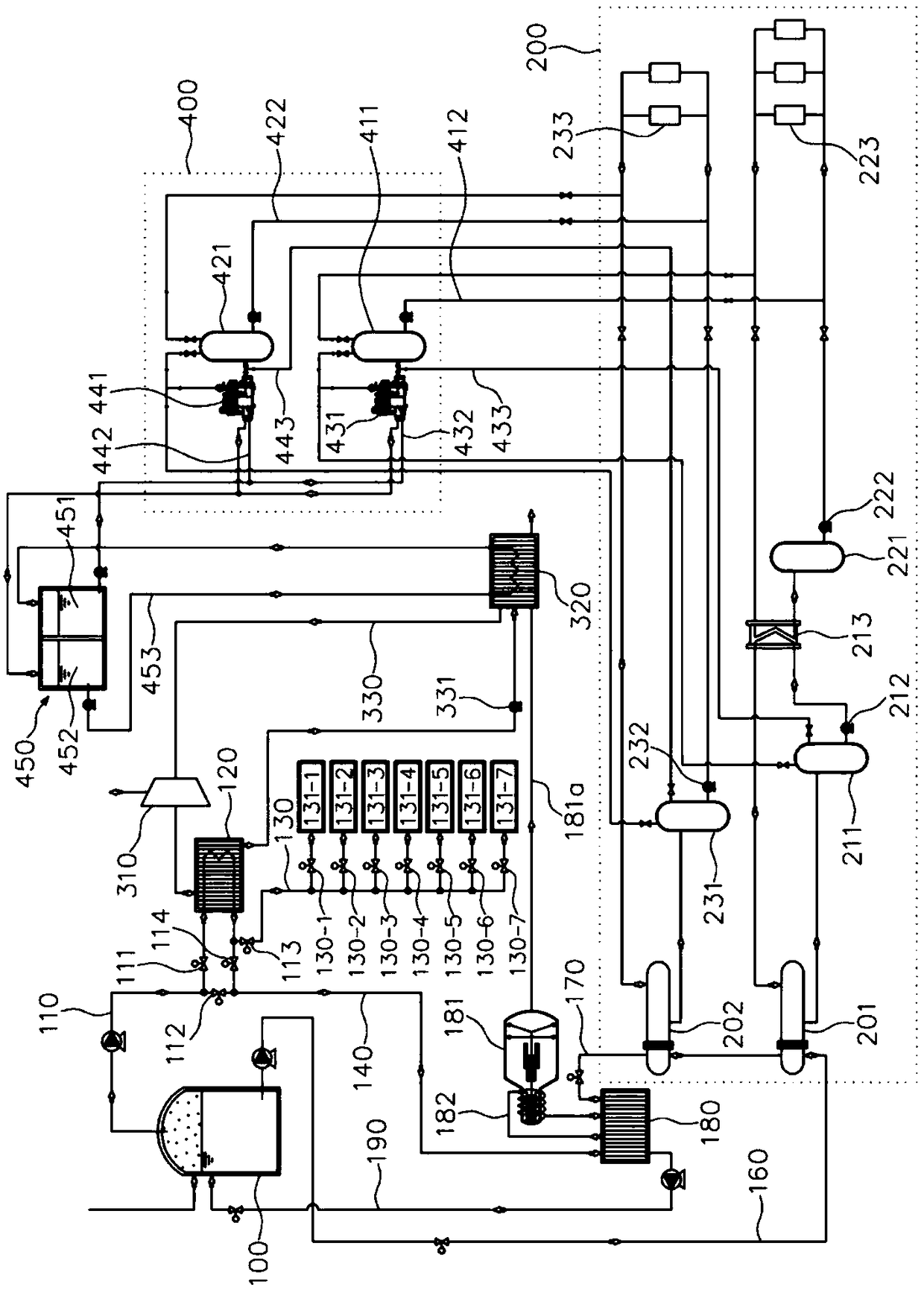

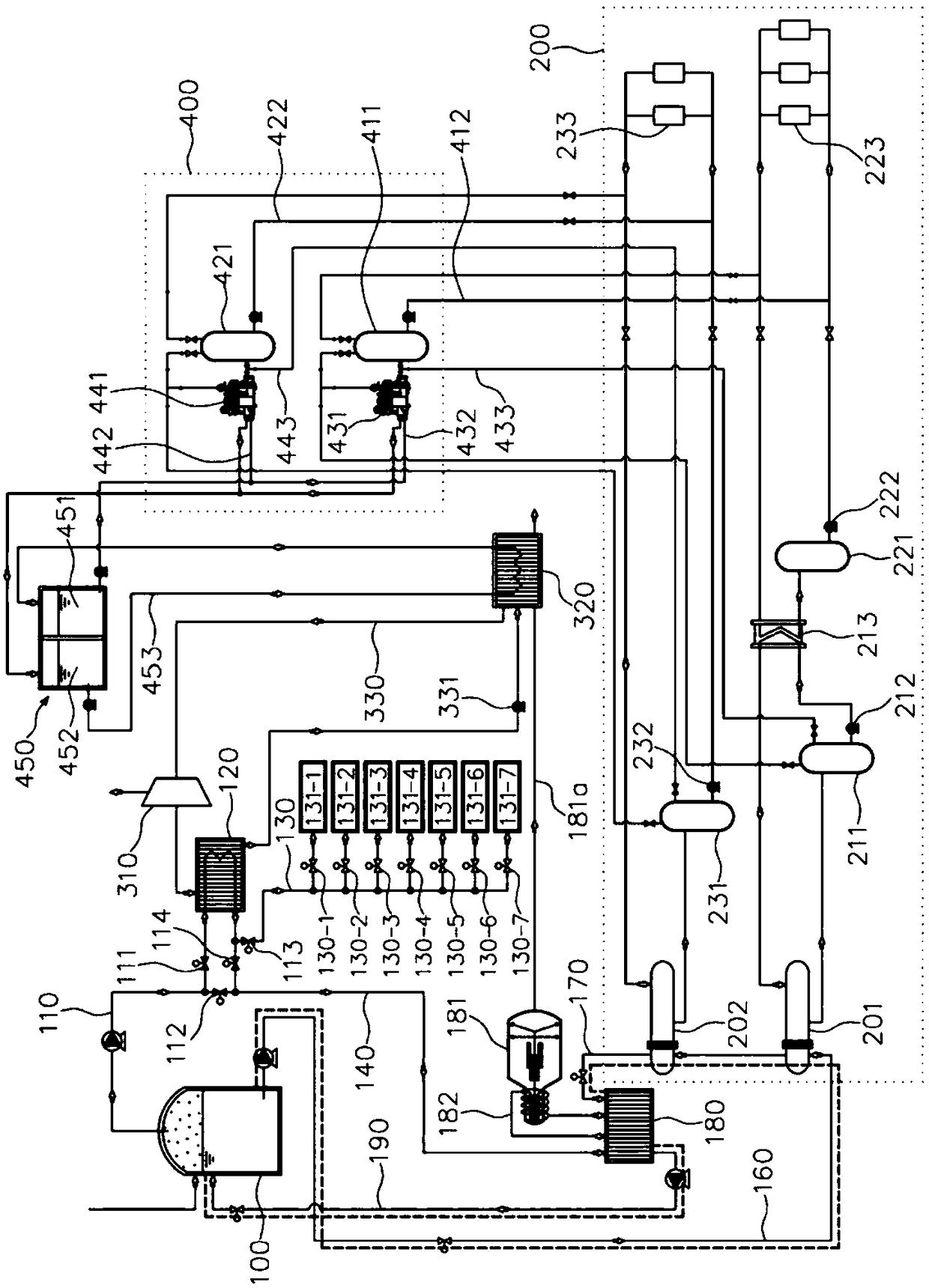

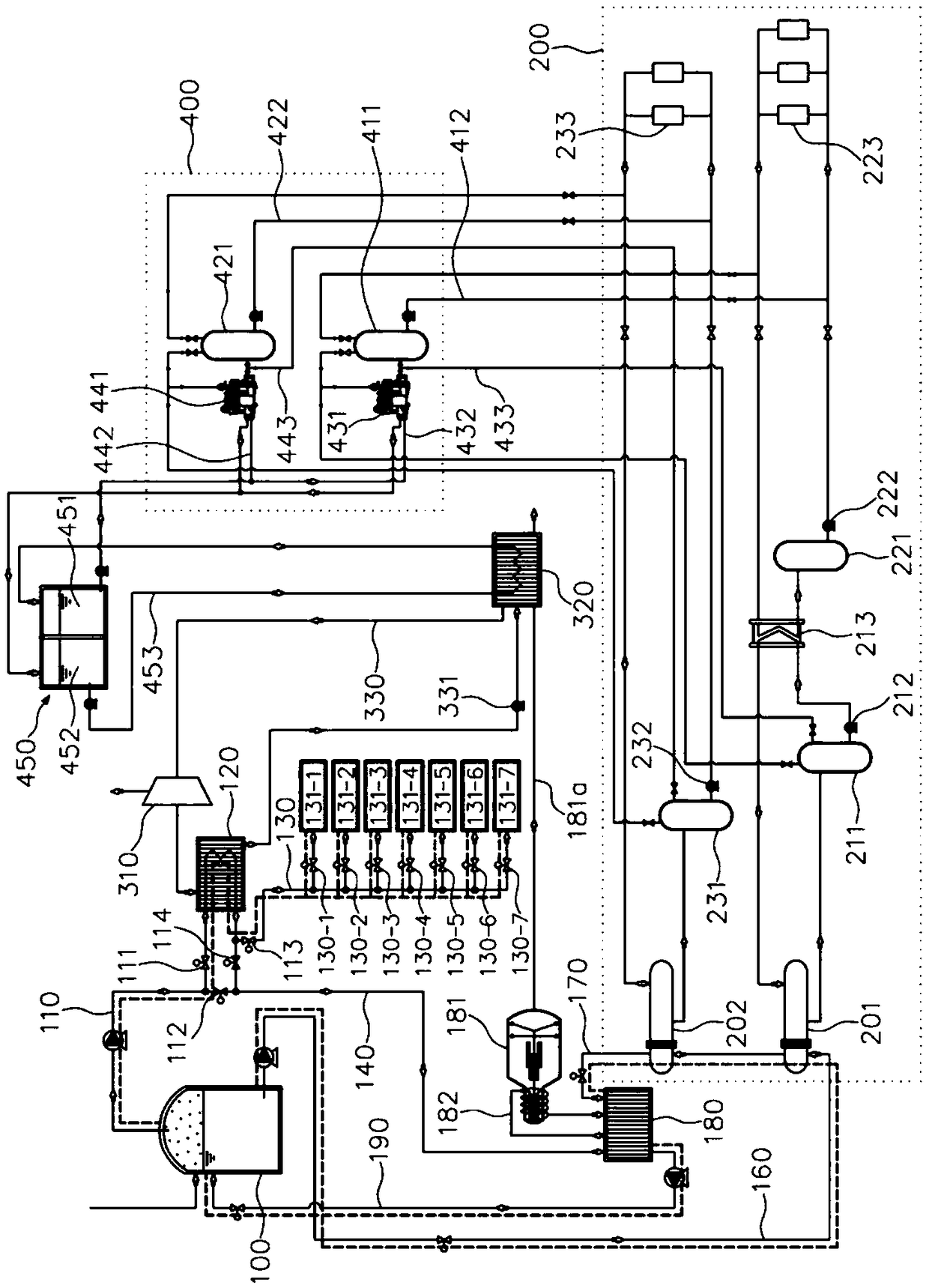

Pyrolysis system and method of recovering carbon fibres from carbon-fibre-containing plastics

ActiveUS20190039266A1Efficient dischargeOptimizationProductsReagentsFiberCarbon fiber reinforced composite

The invention relates to a pyrolysis plant and a process for recovering (recycling) carbon fibers from carbon fiber-containing plastics, in particular from carbon fiber-reinforced plastics (CFPs or CFP materials), preferably from carbon fiber-containing and / or carbon fiber-reinforced composites (composite materials).

Owner:ELG CARBON FIBER INT

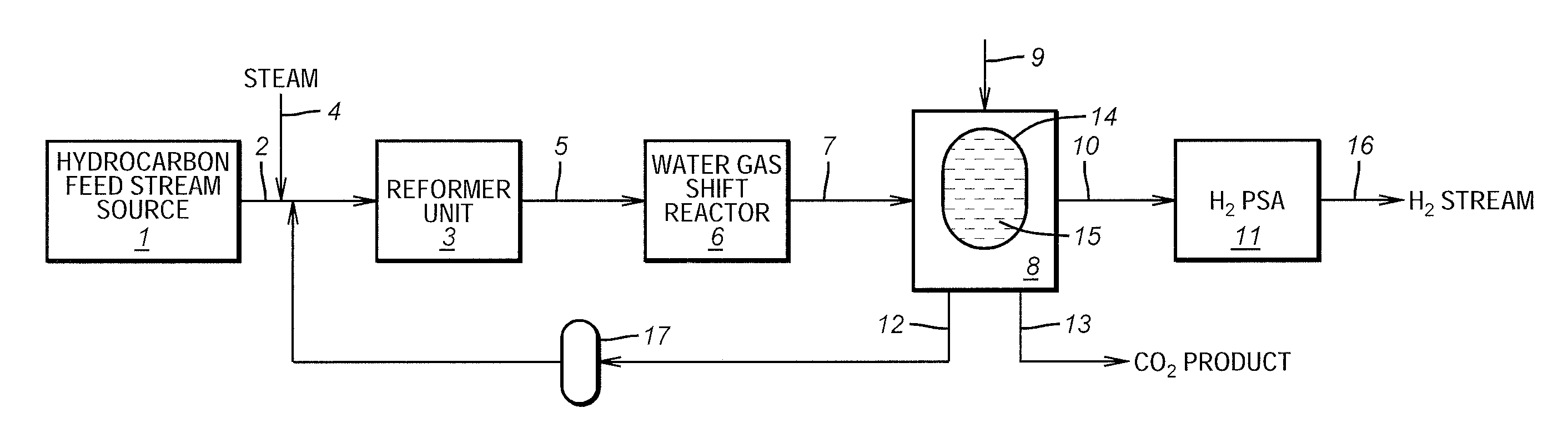

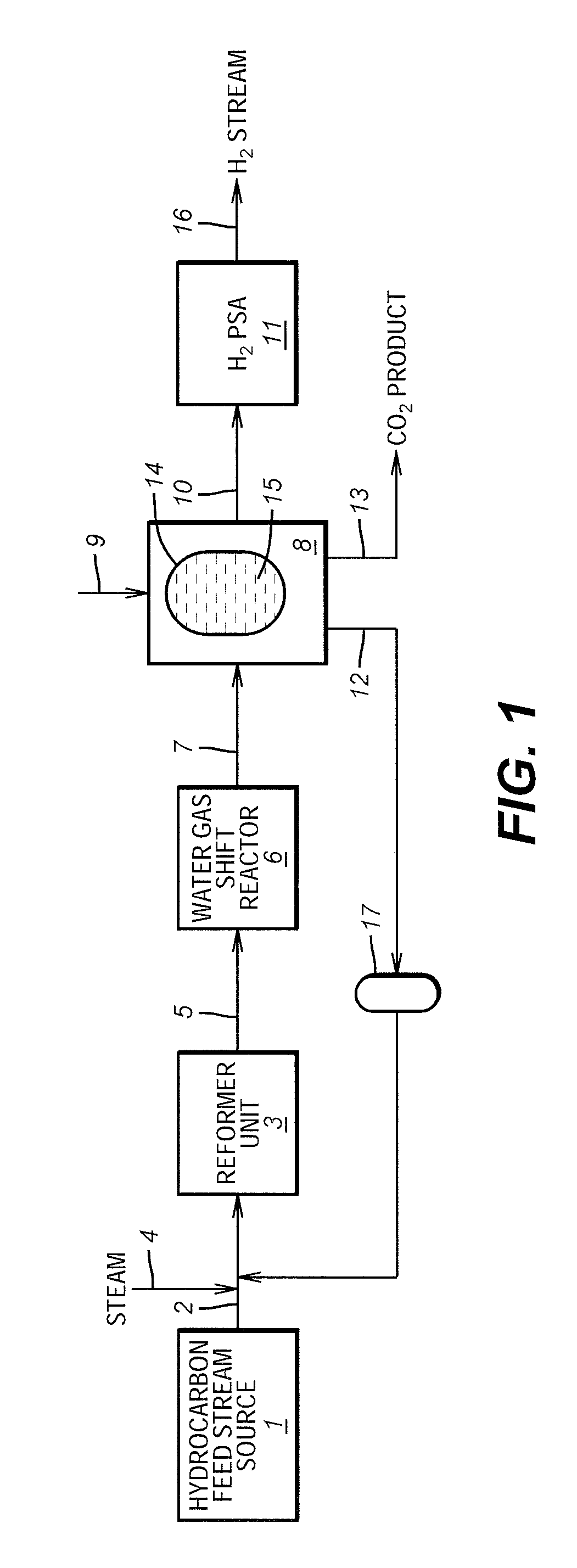

Process For The Production Of Hydrogen And Carbon Dioxide Utilizing Magnesium Based Sorbents In A Fixed Bed

InactiveUS20130011323A1Economical recovery of carbonImprove economyCarbon compoundsEnergy inputSorbentHydrogen pressure

The present invention relates to a process for recovering hydrogen along with high temperature high pressure carbon dioxide from one or more hydrocarbon gas streams by incorporating a carbon dioxide recovery unit which utilizes a magnesium based sorbent into a process that includes a reformer unit, a water gas shift reactor and a hydrogen pressure swing adsorption unit.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Repairing technique for piston rod of hydraulic oil cylinder

The invention discloses a repairing technique for a piston rod of a hydraulic oil cylinder. The repairing technique includes the following requirements: (1) surface treatment: heating all the damaged parts through flame, melting out all the liquid or oil liquid dipped in the deep parts of metal, and cleaning the piston rod with a cleaning agent until all the pollutants are removed; machining two ends of a scratch orderly through a drill, deepening and widening the scratch along the whole length through a handheld angle grinder which is provided with a suitable cutting grinding wheel, allowing a repaired position to be groove-shaped, and cleaning all the parts to be repaired again through the cleaning agent; (2) a repairing technique: coating parts on which surface treatment is performed with a repairing agent, allowing the repairing agent to attach to the grinded rough surface, and then continuously coating the parts; and (3) repairing and recovering the parts into an original shape profile through fine emery paper after the repairing agent is solidified completely. The repairing technique is reasonable in processes, is low in cost, is reasonable and coordinated in parameter collocation, is short in time, and is simple in operation.

Owner:CHONGQING BATENG MACHINERY CO LTD

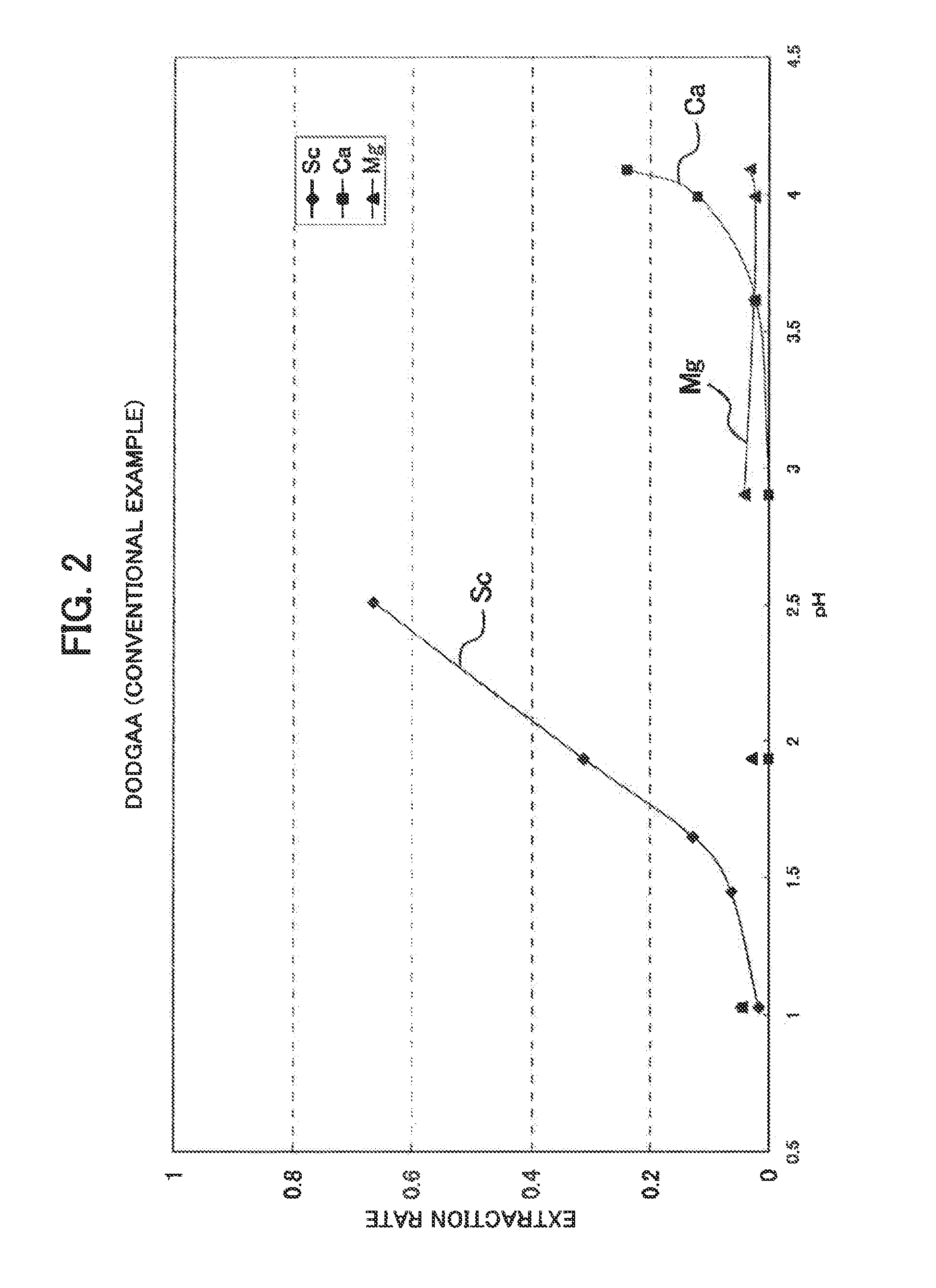

Scandium extraction method

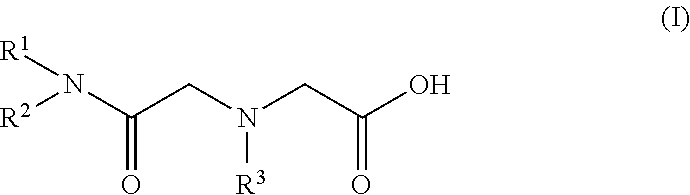

ActiveUS9481638B2Efficient separationHigh recovery rateOrganic chemistryProcess efficiency improvementHydrogen atomSolvent

Provided is a method for selectively extracting and inexpensively recovering scandium from an acidic solution containing calcium, magnesium, and scandium. The scandium extraction method according to the present invention involves subjecting an acidic solution containing calcium, magnesium, and scandium to solvent extraction using an extraction agent consisting of an amide derivative represented by the general formula below. In the formula, R1 and R2 represent the same or different alkyl groups, and R3 is a hydrogen atom or alkyl group. The amide derivative preferably consisting of one or more derivatives selected from glycine amide derivatives, histidine amide derivatives, lysine amide derivatives, and aspartic acid amide derivatives. The pH of the acidic solution is preferably pre-adjusted to between 1 and 4.

Owner:KYUSHU UNIV +1

Pyrolysis system and method of recovering carbon fibres from carbon-fibre-containing plastics

ActiveUS10899042B2Economic recoveryGood incorporability into plasticsProductsReagentsFiberPolymer science

The invention relates to a pyrolysis plant and a process for recovering (recycling) carbon fibers from carbon fiber-containing plastics, in particular from carbon fiber-reinforced plastics (CFPs or CFP materials), preferably from carbon fiber-containing and / or carbon fiber-reinforced composites (composite materials).

Owner:ELG CARBON FIBER INT

A method for repairing heavy metal polluted soil

InactiveCN103894404BWide variety of sourcesUnique in natureContaminated soil reclamationMetal contaminationRaw material

The invention discloses a method for repairing heavy metal-contaminated soil. The method comprises: using acrylic acid modified chitosan as a repairing agent, placing the polluted soil in an aqueous repairing agent solution for stirring and eluting, or applying the aqueous repairing agent to Plow and harrow the paddy fields to be plowed to transfer the heavy metals from the contaminated soil to the eluate, so as to realize the remediation of heavy metal (Pb, Cr, Cu) contaminated soil. Acrylic acid-modified chitosan, a repairing agent, is prepared by Michael reaction between chitosan and acrylic acid. It has the advantages of environmental protection, non-toxic, harmless, biodegradable, no secondary pollution, and rich sources of raw materials. The remediation agent has a good remediation effect on soil polluted by heavy metals, and the heavy metal content of the remediation soil reaches the first-class standard of farmland land. The chitosan derivative restoration agent adopted in the method is environmentally friendly, has good water solubility, and has a strong ability to chelate heavy metals.

Owner:SOUTH CHINA UNIV OF TECH

Process For The Production Of Hydrogen And Carbon Dioxide Utilizing Dry Magnesium Based Sorbents In A Fixed Bed

InactiveUS20130011325A1Economical recovery of carbonImprove economyProductsGas treatmentHydrogen pressureSorbent

The present invention relates to a process for recovering hydrogen along with high temperature high pressure carbon dioxide from one or more hydrocarbon gas streams by incorporating a carbon dioxide recovery unit which utilizes a magnesium based sorbent into a process that includes a gasification unit, an optional sulfur removal unit, a water gas shift reactor and a hydrogen pressure swing adsorption unit.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

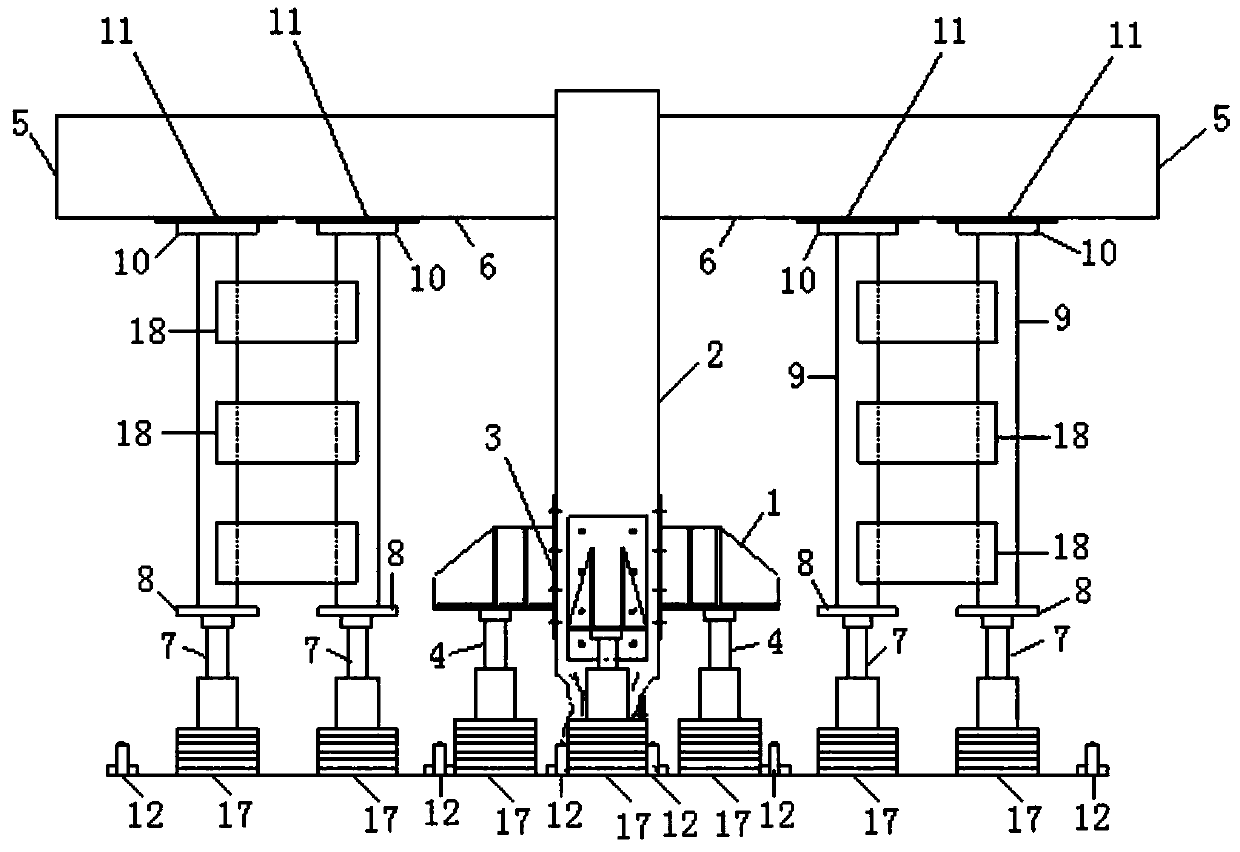

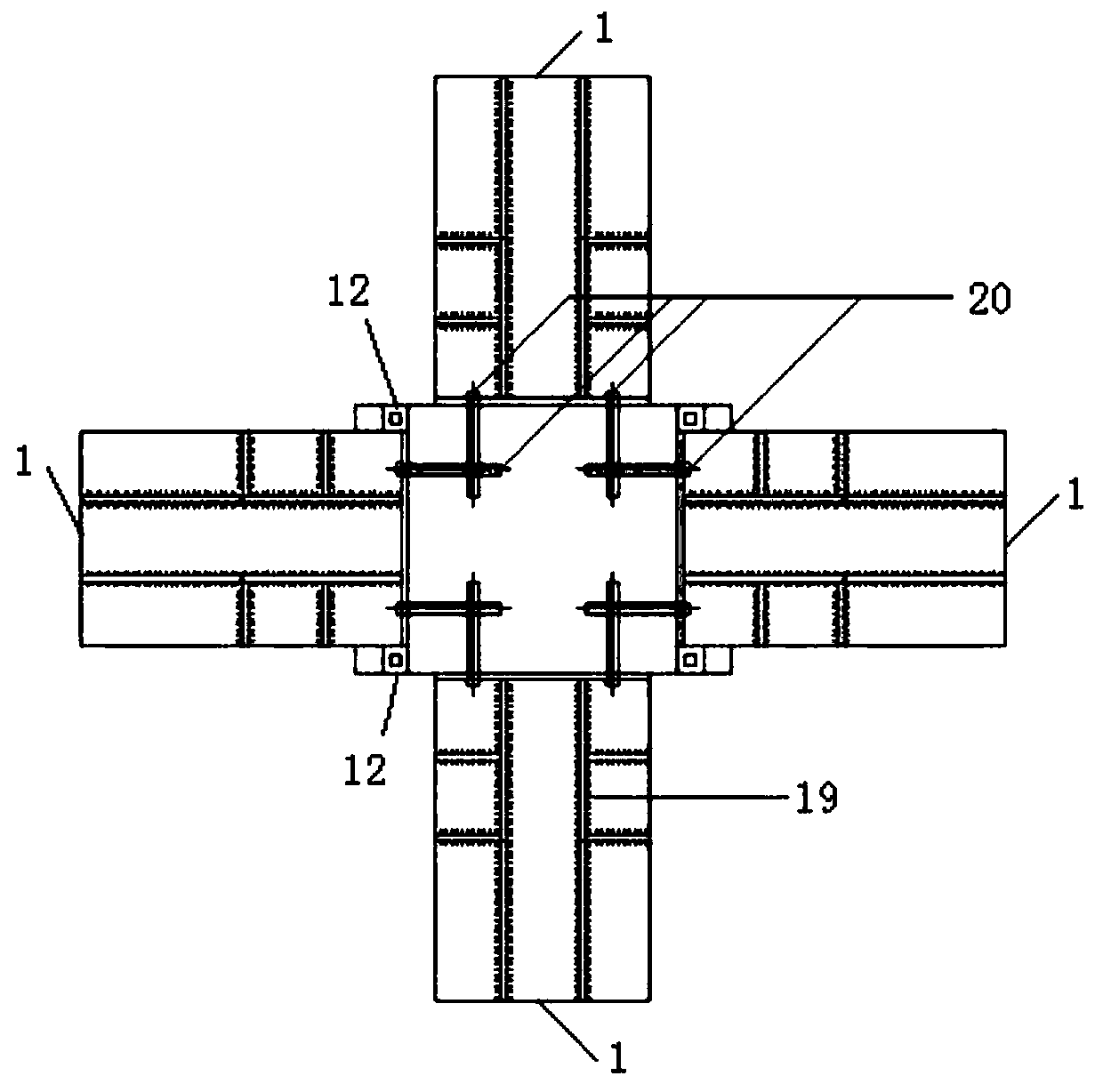

Jacking and reinforcing method for buckling reinforced concrete column

ActiveCN109653436AEfficient repairEconomic recoveryStrutsBuilding repairsReinforced concrete columnFloor slab

The invention discloses a jacking and reinforcing method for a buckling reinforced concrete column. The method comprises the following steps: step one: manufacturing a steel bracket; step two: installing the steel bracket and a jacking device; step three: installing an unloading device; step four: arranging a laser range finder; step five: unloading the buckling reinforced concrete column; step six: jacking the buckling reinforced concrete column; step seven: chipping away a crushing area of the buckling reinforced concrete column and concrete near the area, and enabling a buckling reinforcedsteel bar to be exposed; step eight: welding a new reinforced steel bar at the edge side of the buckling reinforced steel bar; step nine: supporting and installing a template, preparing the high-strength fine aggregate concrete, and pouring a chipped area; step ten: restoring the reinforced concrete column; step eleven: implanting a new longitudinal bar and a spiral stirrup around the buckling reinforced concrete column after reinforced; and step twelve: restoring a frame beam and a floor. The reinforcing method is short in operation project period, rapid in efficacy, simple in construction process, and capable of realizing simple, efficient and economic repair to the buckling reinforced concrete column.

Owner:徐州市政建设集团有限责任公司

Repair process for cast micropores and cracks

The invention discloses a repair process for cast micropores and cracks. The repair process is characterized by comprising the following steps that (1) water removing is conducted first on a casting in a heating mode, the casting is put into a drying oven, and heat preservation is conducted at the temperature of 120-150 DEG C for 2-4 hours; (2) after heating and water removing, the casting is cooled to 30-50 DEG C in a soaked mode and then put into a trough, an appropriate amount of a penetrant is added, and the casting is taken out after being soaked for 30 minutes; (3) after water removing, a 121 penetrant is dripped into the loose micropores, the 121 penetrant is dripped repeatedly for two to three times, the time interval is 5-10 minutes, and room temperature solidification is conducted for 8 to 10 hours; and (4) the residual 121 penetrant on the surface layer of the casting cannot be solidified and can be wiped away with cotton yarn after construction. The repair process is reasonable in working procedure and low in cost. All parameters are matched reasonably and harmoniously, time is short, and operation is simple.

Owner:CHONGQING YINGRUISHENG DIE CASTING

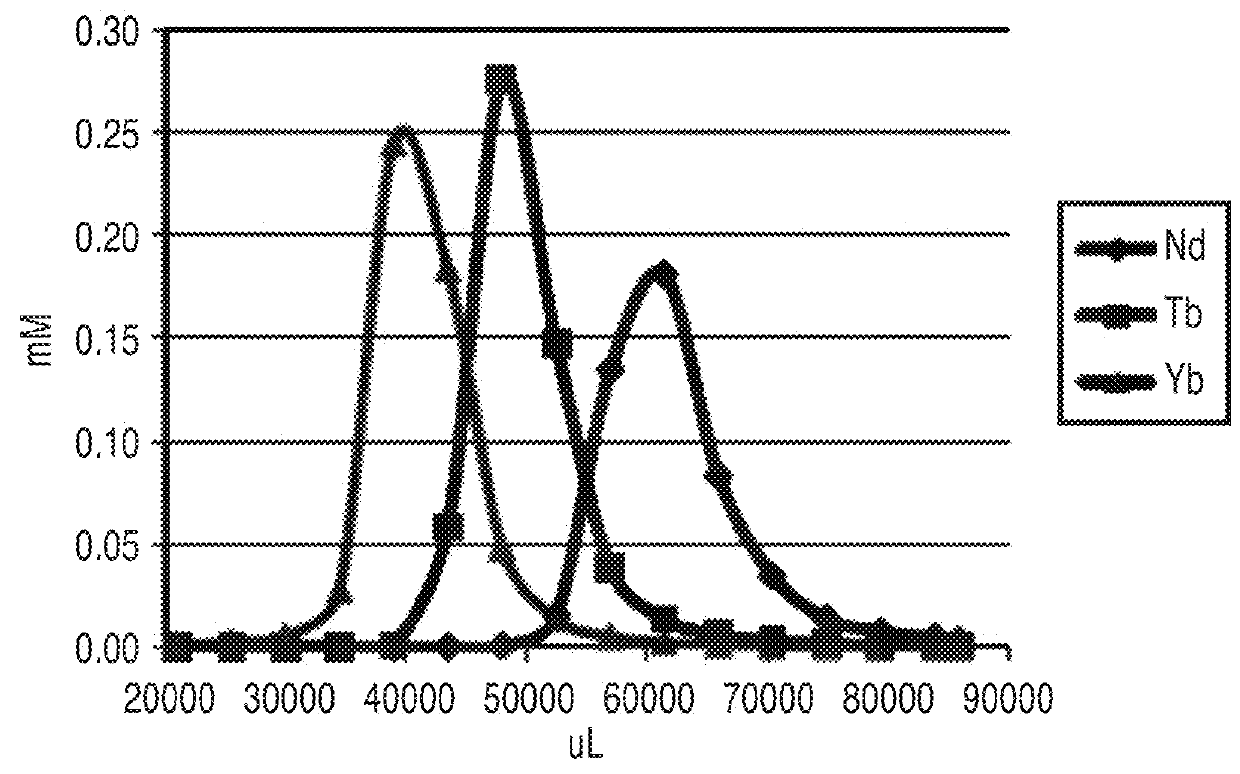

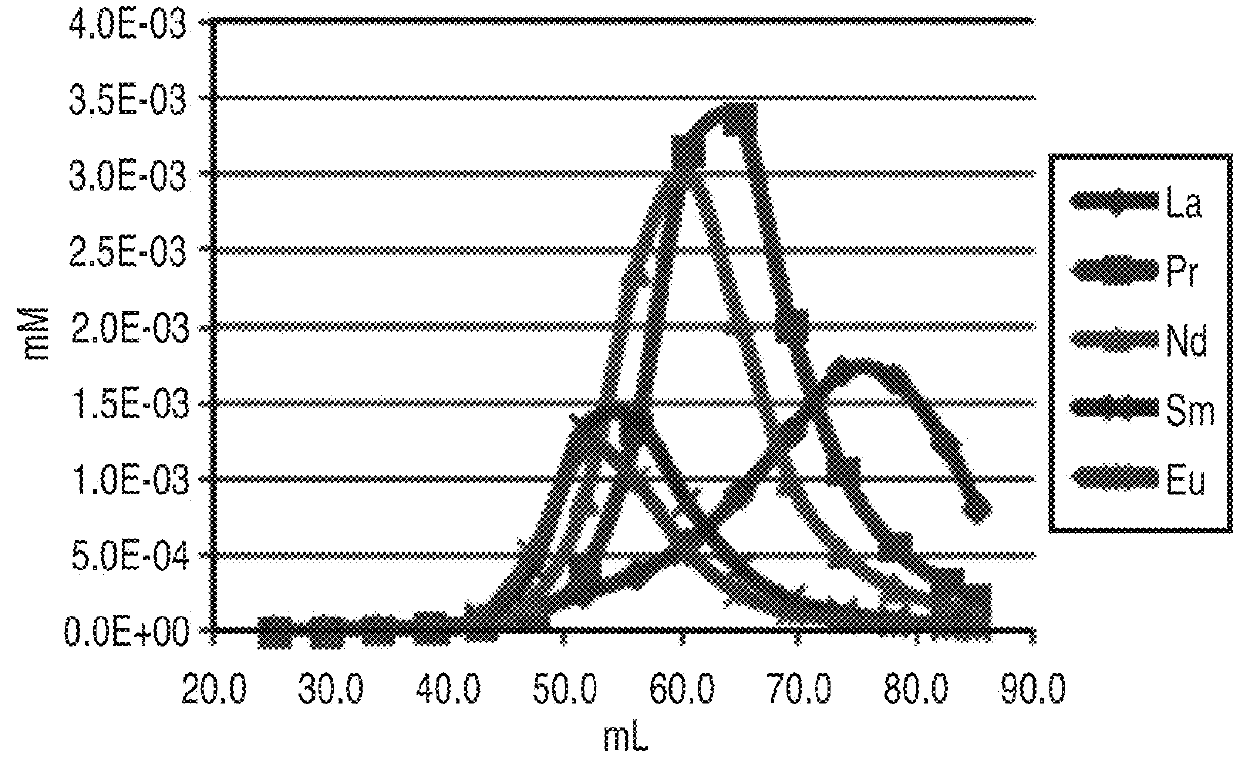

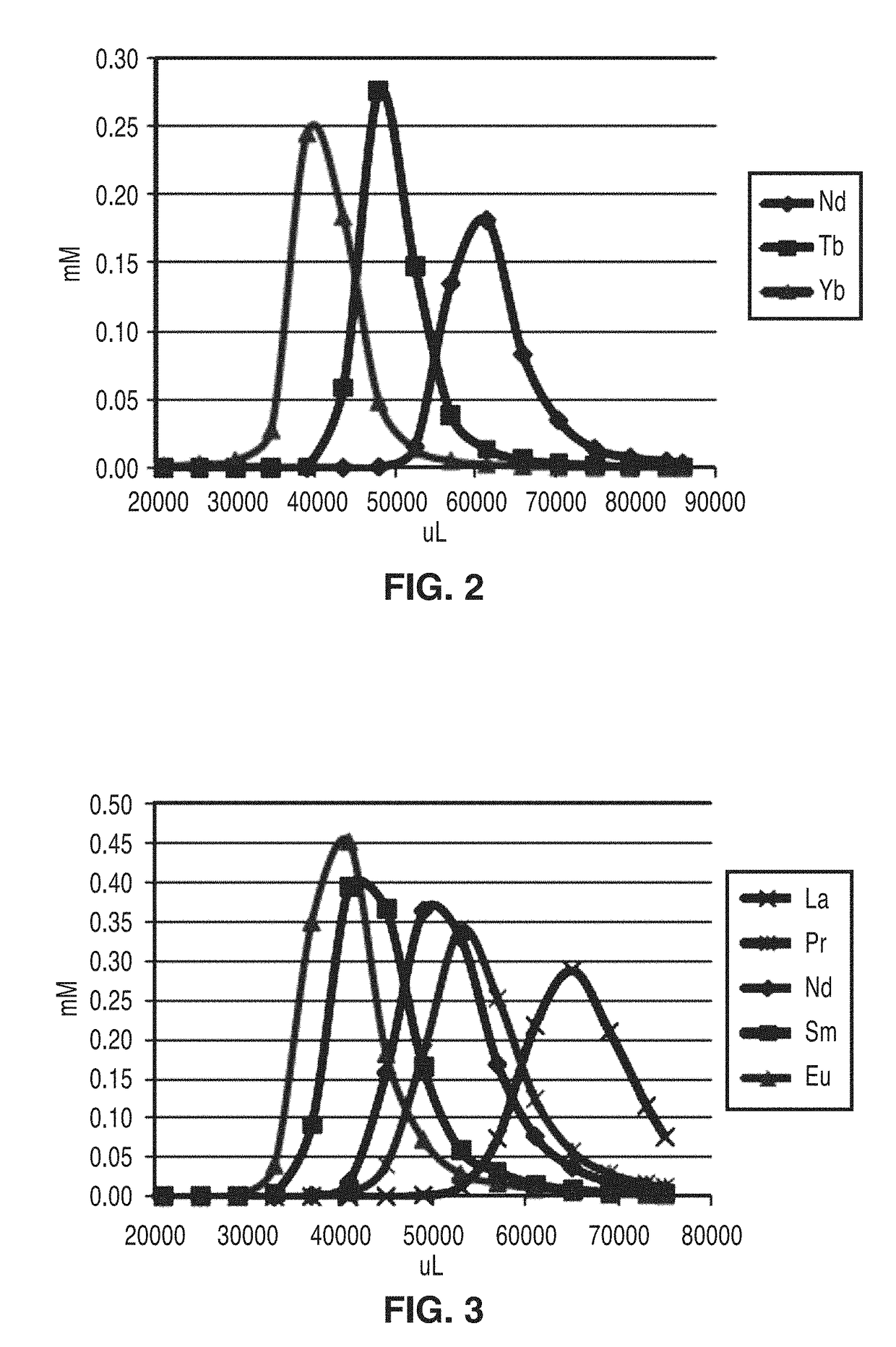

Sulfonamide-based separation media for rare earth element separations

InactiveUS20160053344A1High yield recoveryLow production costProcess efficiency improvementOrganic acidRare-earth element

A sulfonamide based rare earth element ion separation media and method of synthesis and use are provided. A bed or column of sulfonamide resin for separations can be prepared by exposing a sulfonate resin to chlorosulfonic acid to form a sulfonyl chloride resin; exposing the sulfonyl chloride resin to aqueous ammonia to form a sulfonamide resin; and then packing the sulfonamide resin into a separation column. Mixtures of lanthanide and other rare earth ions with very similar atomic radii and characteristics can be separated by flowing a mixture of lanthanide ions through a bed of sulfonamide resin followed by a mobile phase of an organic acid such as lactic acid to elute the separated rare earth element ions separated by the sulfonamide resin. Collected fractions of eluate can also be recycled through the sulfonamide media.

Owner:RGT UNIV OF CALIFORNIA

Device and method for underwater repair of a hole of a nuclear reactor part

PendingCN108701498AReliable repairEconomic recoveryFuel elementsNuclear energy generationNuclear reactorDrive shaft

The invention relates to a repair device, which includes a holder (32), a cutting tool (22) held by the holder (32) and having at least one cutting tooth (70) for re-machining an inner surface of thehole, the cutting tool (22) having a suction channel (44) extending into the cutting tool (22) between at least one inlet opening (46) and at least one outlet opening (48), a drive shaft (34) for rotating the cutting tool (22), the drive shaft (34) being held by the holder (32), and a suction tube (36) connected to the holder (32) and fluidly coupled to the outlet opening (48) of the suction channel (44).

Owner:FRAMATOME ANP

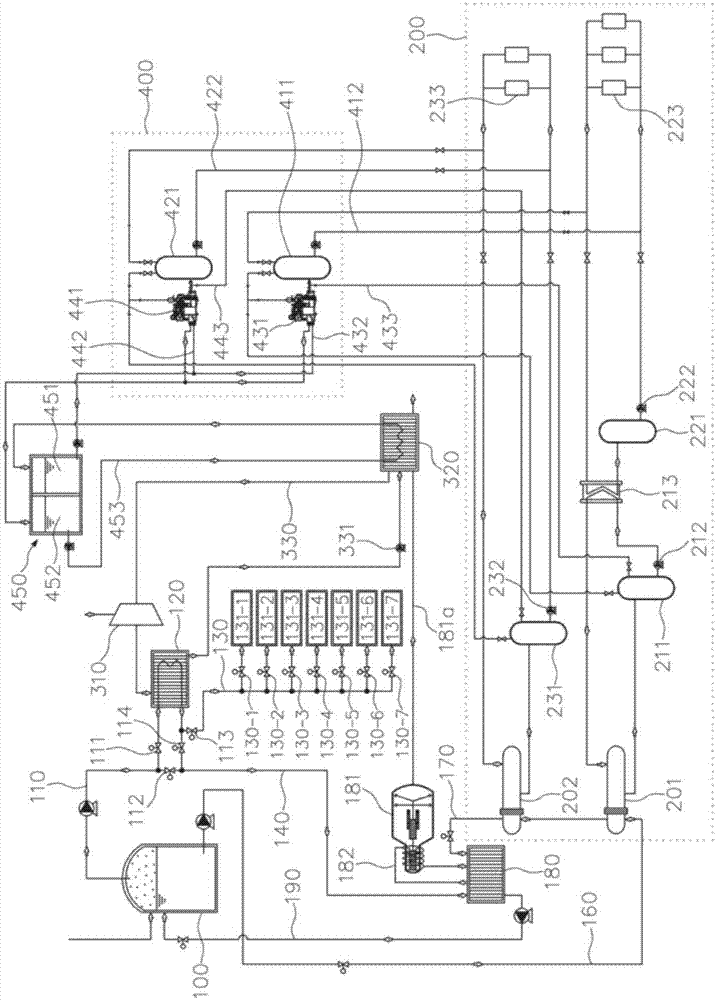

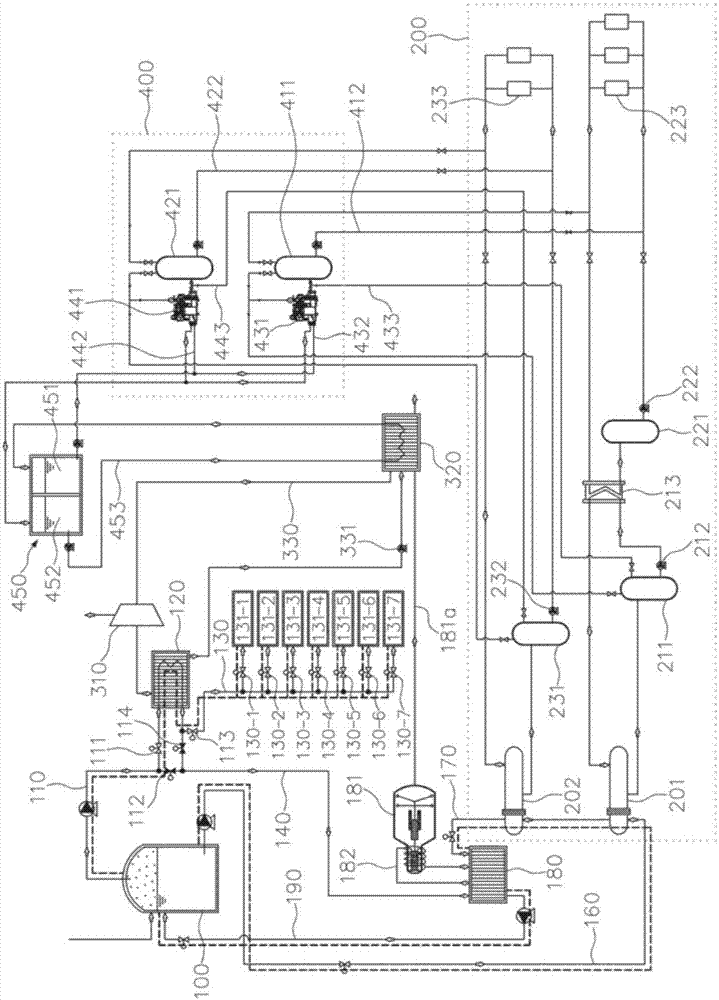

LNG optimum control reliquefaction system for recovering LNG low-temperature waste heat generated during LNG vaporization

ActiveCN107124894AEconomic recoveryContainer filling methodsNon-pressured vesselsSupply energyProcess engineering

The invention relates to an LNG optimum control reliquefaction system for recovering LNG low-temperature waste heat generated during LNG vaporization. The present invention is configured to: supply gaseous LNG to a gaseous LNG consumer while allowing liquid LNG to discharge cold energy through a heat exchanger for a load of a cold energy supply unit for a warehouse, so as to supply a sufficient amount of the gaseous LNG within an LNG storage tank, thereby increasing the temperature of or vaporizing the liquid LNG; allow the LNG with an elevated temperature or vaporized to be supplied to a gaseous LNG consumer supply line, thereby expanding the cold energy use and dissemination of the LNG; and optimally control and reliquefy the flux of the liquid LNG and gaseous LNG, thereby economically recovering the low-temperature waste heat of the LNG generated during LNG vaporization.

Sulfonamide-based separation media for rare earth element separations

InactiveUS9970075B2Minimal waste productionReduced operating requirementsRecovering materialsSulfonyl chlorideRare-earth element

A sulfonamide based rare earth element ion separation media and method of synthesis and use are provided. A bed or column of sulfonamide resin for separations can be prepared by exposing a sulfonate resin to chlorosulfonic acid to form a sulfonyl chloride resin; exposing the sulfonyl chloride resin to aqueous ammonia to form a sulfonamide resin; and then packing the sulfonamide resin into a separation column. Mixtures of lanthanide and other rare earth ions with very similar atomic radii and characteristics can be separated by flowing a mixture of lanthanide ions through a bed of sulfonamide resin followed by a mobile phase of an organic acid such as lactic acid to elute the separated rare earth element ions separated by the sulfonamide resin. Collected fractions of eluate can also be recycled through the sulfonamide media.

Owner:RGT UNIV OF CALIFORNIA

LNG optimal control reliquefaction system for recovery of LNG low-temperature waste heat generated in LNG gasification process

ActiveCN107124894BEconomic recoveryContainer filling methodsNon-pressured vesselsLNG storage tankPetroleum engineering

The present invention relates to an LNG optimum control reliquefaction system for recovering low-temperature waste heat of LNG generated in the LNG gasification process. According to the present invention, the gaseous LNG is supplied to the place where the gaseous LNG is required. At this time, in order to be able to supply in the LNG storage tank A sufficient amount of gaseous LNG makes the liquid LNG pass through the load heat exchanger of the cold and heat supply part of the logistics warehouse to discharge cold and heat, and thereby raise the temperature of the liquid LNG or vaporize the liquid LNG, and can heat up or gasify the liquid LNG in this way. By supplying the liquefied LNG to the supply line where the gaseous LNG is needed, it is possible to expand the use and popularization of cold and heat of LNG, and to optimally control the flow of liquid LNG and gaseous LNG for reliquefaction, thereby enabling economical recovery of LNG Low-temperature waste heat of LNG generated in the gasification process.

Owner:株式会社韩国超低温平泽

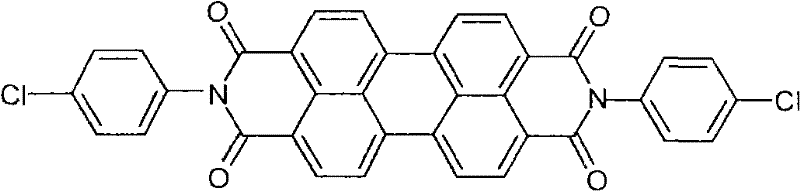

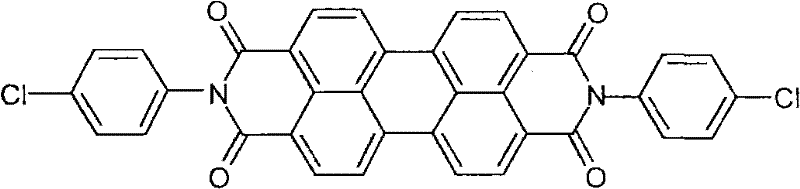

Method for preparing vat brilliant red RB

The invention relates to a method for preparing vat brilliant red RB (Algol Scarlet B), comprising the following steps: adding 3, 4, 9, 10-perylene tetracid dianhydride into KOH water solution and heating the solution to fully dissolve it, and cooling the solution to 50 degrees centigrade and neutralizing KOH in the solution by H2SO4 until the pH value equals to 5-6, and orange perylene tetra-formic acid is separated out; filtering and washing the perylene tetra-formic acid, and mixing a perylene tetra-formic acid filter cake with water, and adding parachloroaniline and pyridine into the solution, and uniformly stirring them, and transferring the material into a pressure kettle and closing the kettle, and raising the temperature to 130-150 degrees centigrade and performing heat preservation reaction until the perylene tetracid dianhydride is used up, wherein the reaction pressure is 0.2-0.4 MPa; cooling the material to the room temperature, and filtering it and washing it by hot water until no green fluorescence to obtain a vat brilliant red RB rough product filter cake, and heating and processing the rough product filter cake by sodium hypochlorite solution, and filtering, water washing and drying the cake to obtain a vat red RB dry product. The invention provides a safe, environment-friendly and economic preparation method.

Owner:上海华元实业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com