Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

46results about How to "Easy welding process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

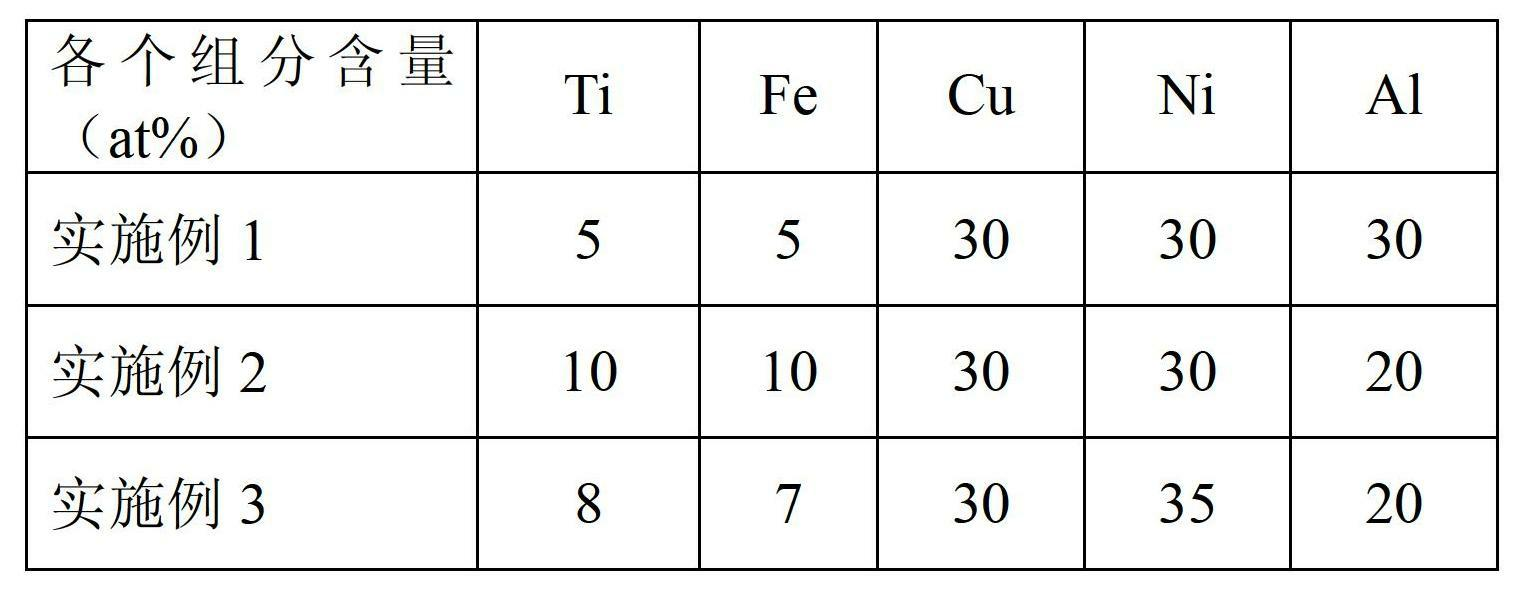

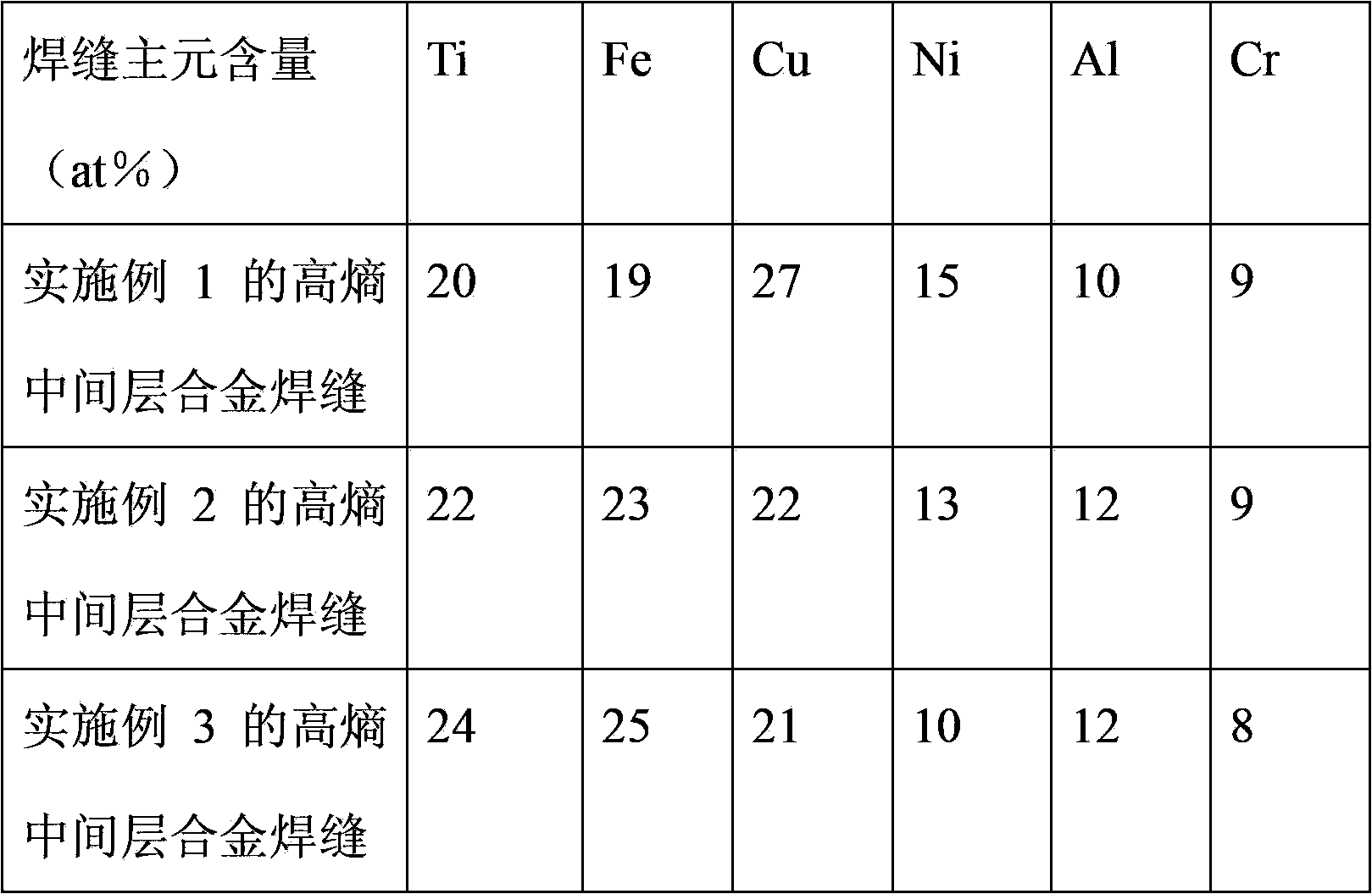

Material and method used for TA2/0Cr18Ni9Ti welded by high-entropy effect

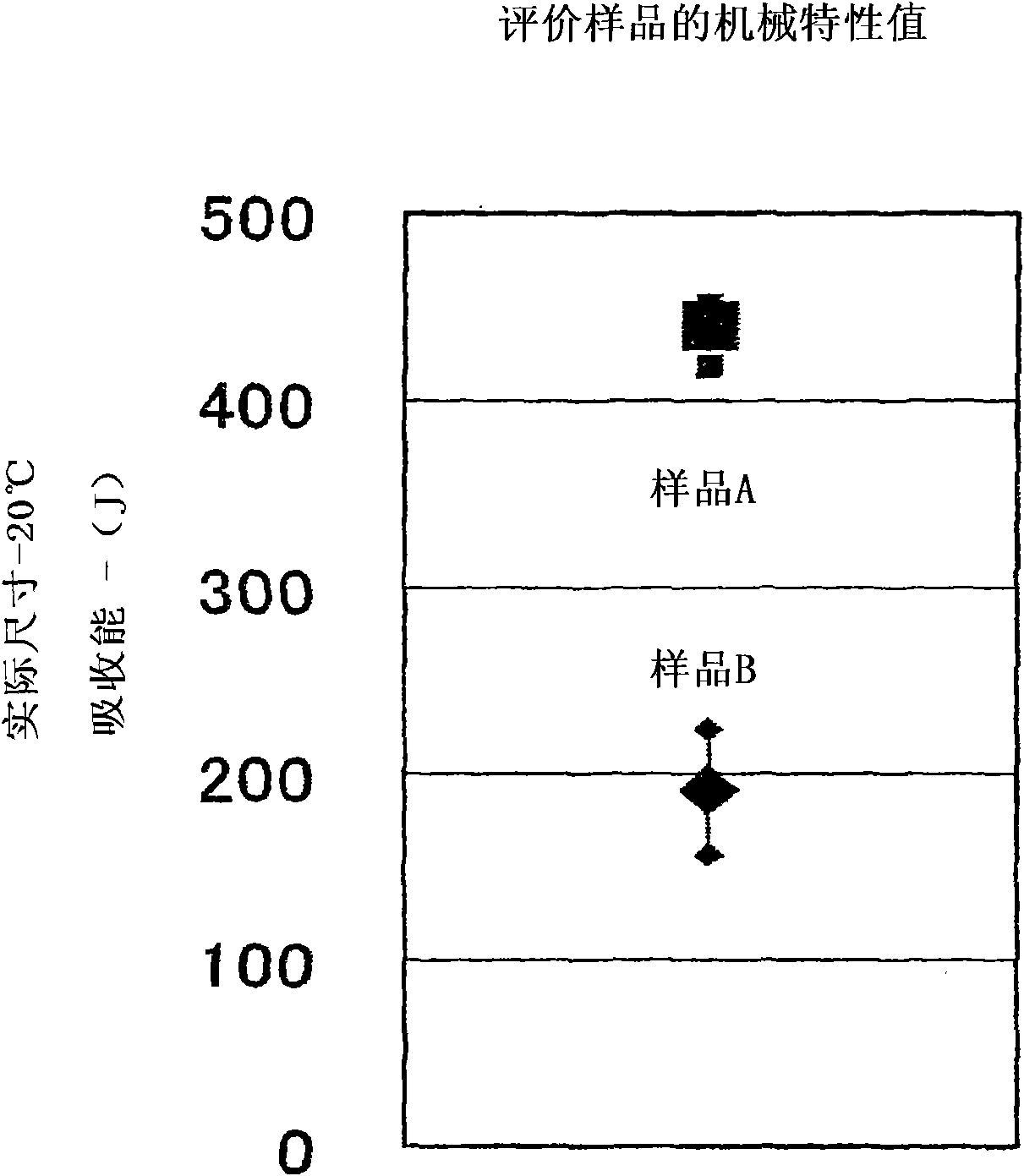

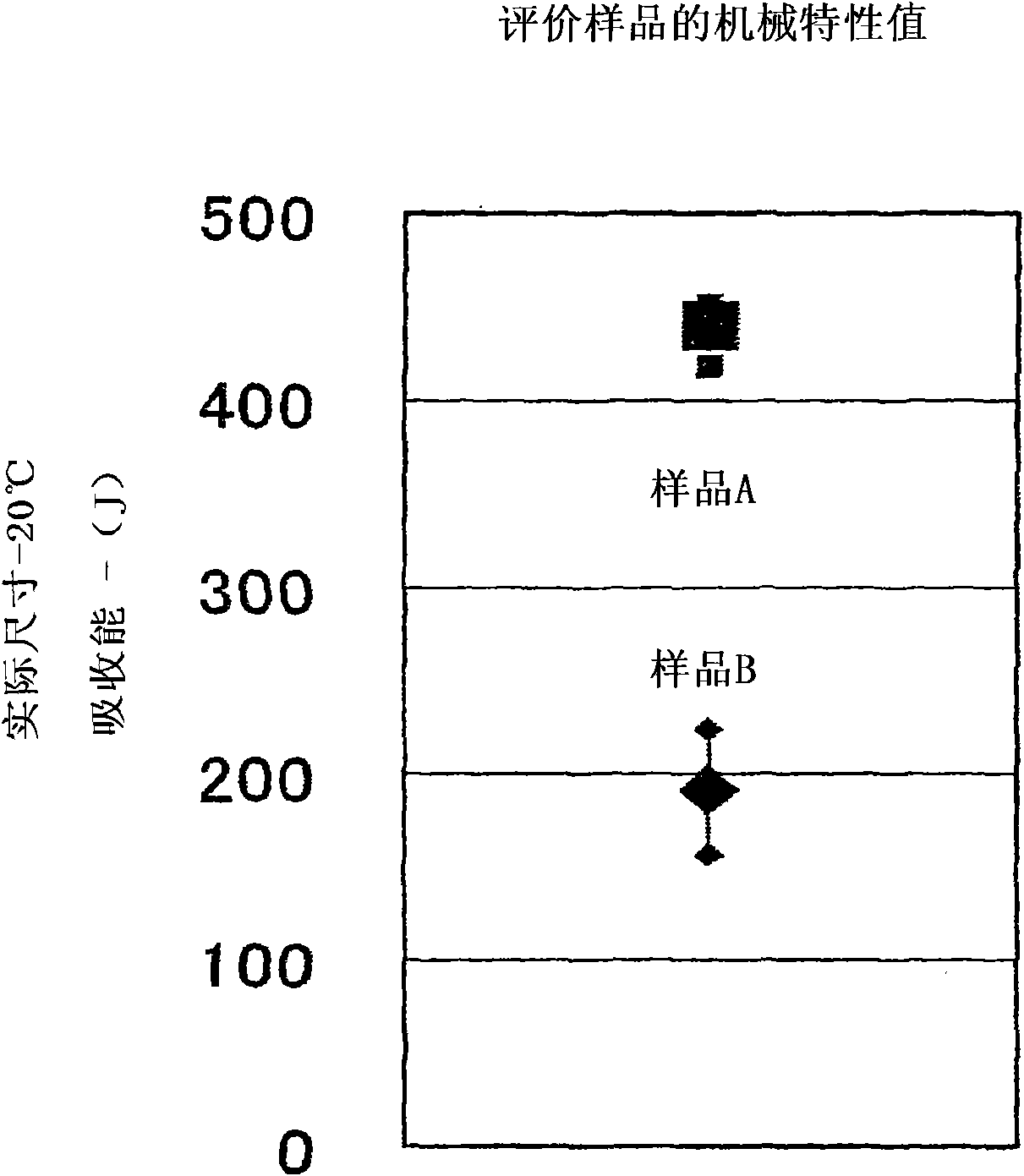

InactiveCN102676904AGood strengthImprove performanceWelding/cutting media/materialsSoldering mediaCorrosionSpot welding

The invention discloses a high-entropy interlayer alloy, which comprises the following components in atomic percentage: 5-10% of Ti, 5-10% of Fe, 25-30% of Al, 15-20% of Ni, 30-35% of Cu and 5-10% of Cr. The invention also discloses a method for welding TA2 / 0Cr18Ni9Ti by the high-entropy effect, which comprises the following steps that: high-entropy interlayer alloy is placed between the two plates to be welded, the high-entropy interlayer alloy is in a foil folding structure, and the high-entropy interlayer alloy and local parent metal are subjected to heat fusing by an interface resistor ina resistance spot welding mode, so that the high performance welding of TA2 / 0Cr18Ni9Ti can be realized. According to the method and the high-entropy interlayer alloy of the method, which are disclosed by the invention, the high-entropy interlayer alloy has the advantages of favorable strength, toughness and corrosion resistance, is easy to process and form and is convenient to weld and assembly. The preparation method has the advantages of simple step and low manufacture cost and is convenient to popularize.

Owner:XIAN UNIV OF TECH

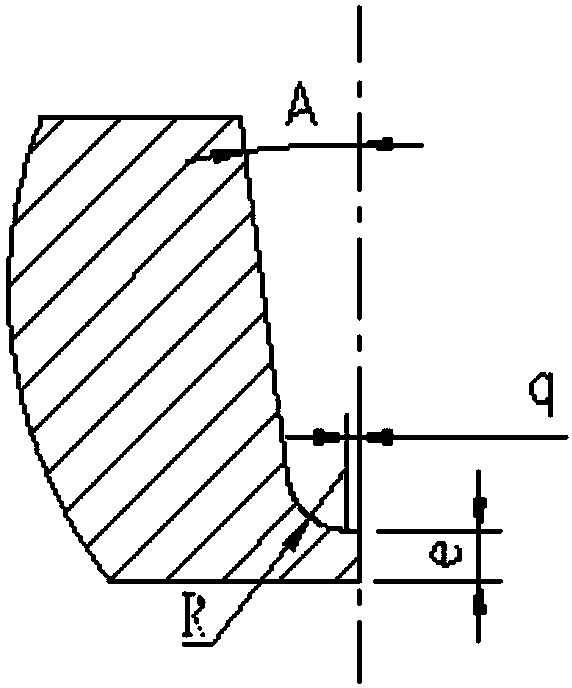

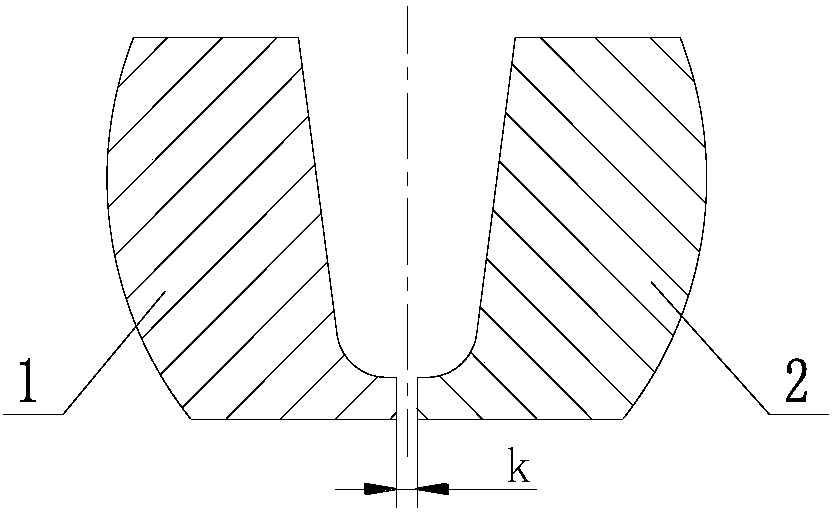

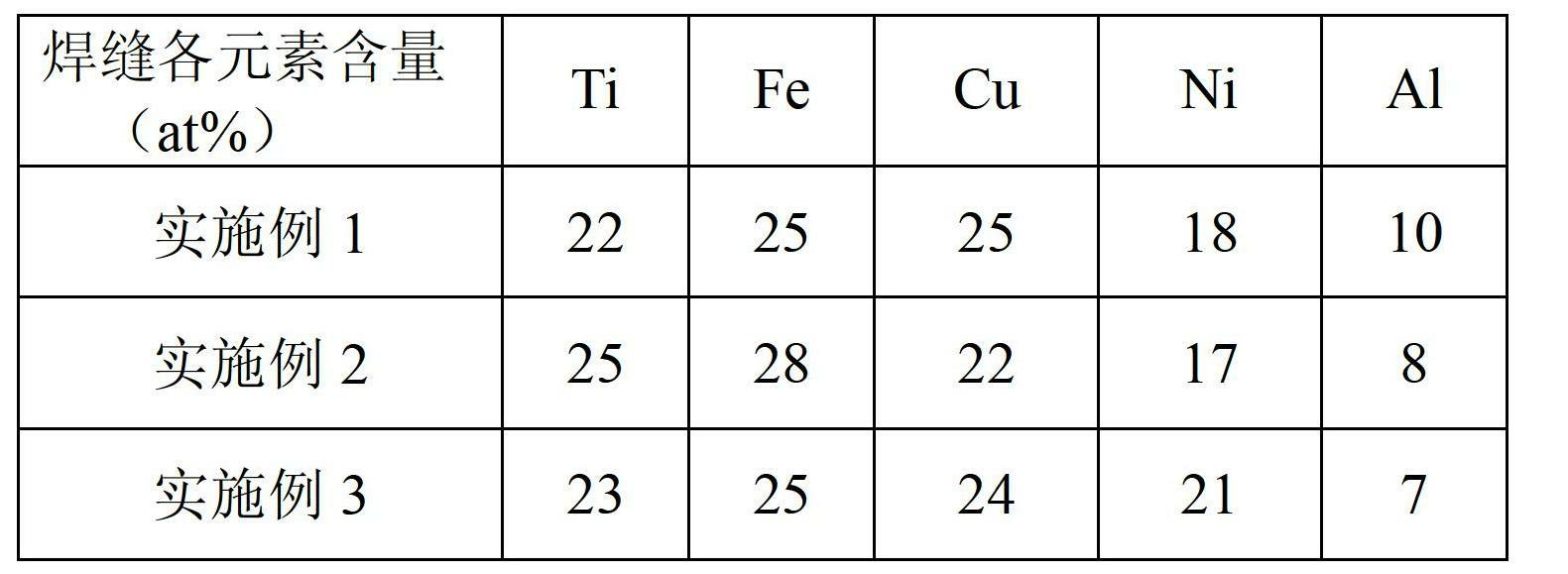

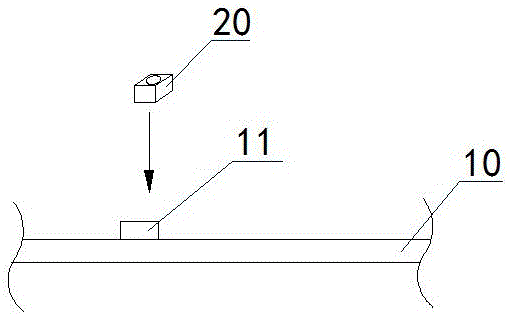

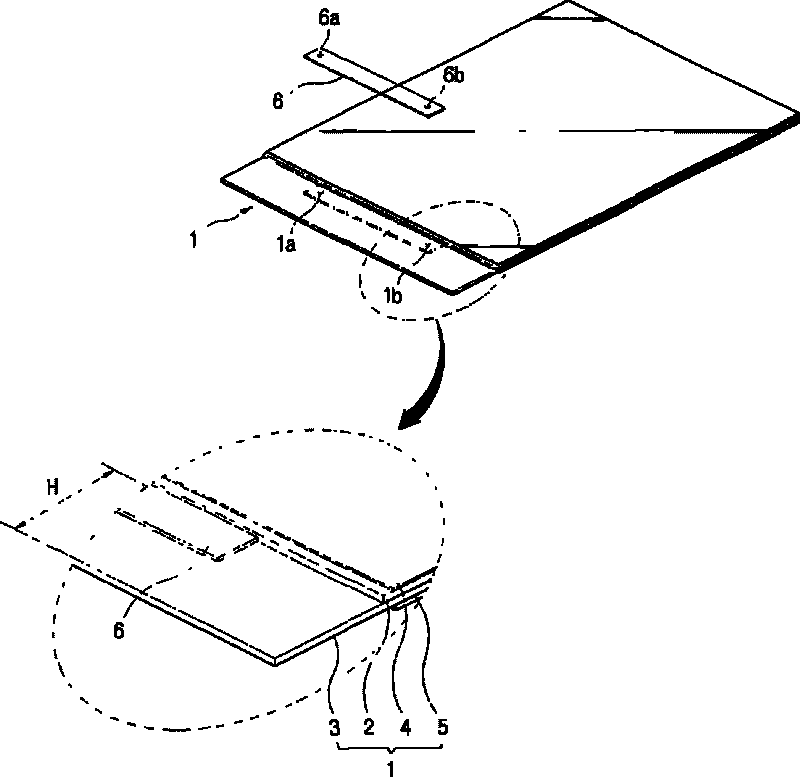

Method for welding titanium and steel by applying high-entropy effect and welding material

InactiveCN102672328AWide adaptabilityEasy to processWelding/cutting media/materialsSoldering mediaWeld seamTitanium

The invention discloses a method for welding titanium and steel by applying the high-entropy effect. A folded middle-layer alloy foil is arranged between a titanium plate to be welded and a steel plate to be welded, and the welding operation is carried out by adopting a resistance spot-welding mode, then the interface resistance heat melts the middle-layer alloy and local base materials, and the molten metals are mixed, so that the high-performance welding of titanium and steel is realized. The invention also discloses a middle-layer alloy and a preparation method of the middle-layer alloy. The middle-layer alloy comprises the following components in the terms of atomic percent: 20-30% of Al, 35-40% of Ni and 35-40% of Cu, wherein the total percent is 100%. The invention has the advantages that the middle-layer alloy is well matched with the titanium and the alloy steel in welding, welding seams (nugget) are single-phase fcc solid-solution structures, and the comprehensive mechanical performance of joints is obviously improved. The preparation method of the middle-layer alloy foil is simple in process and low in manufacturing cost.

Owner:XIAN UNIV OF TECH

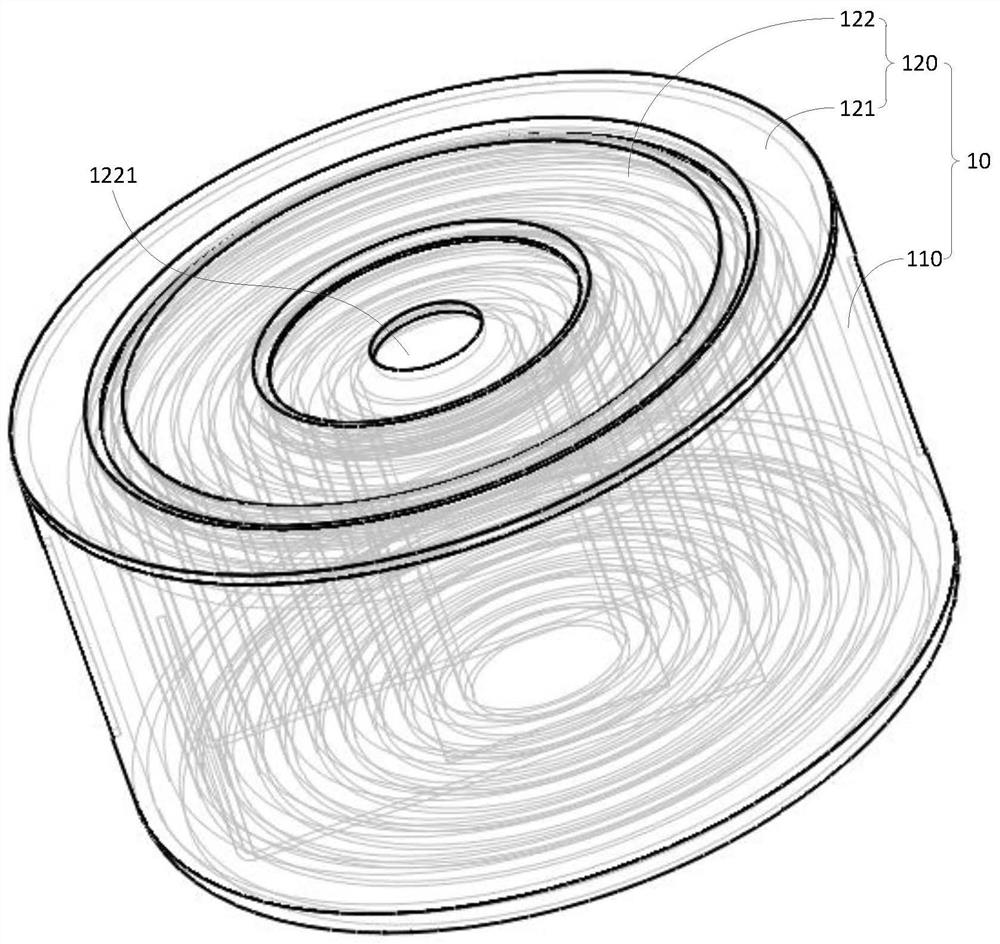

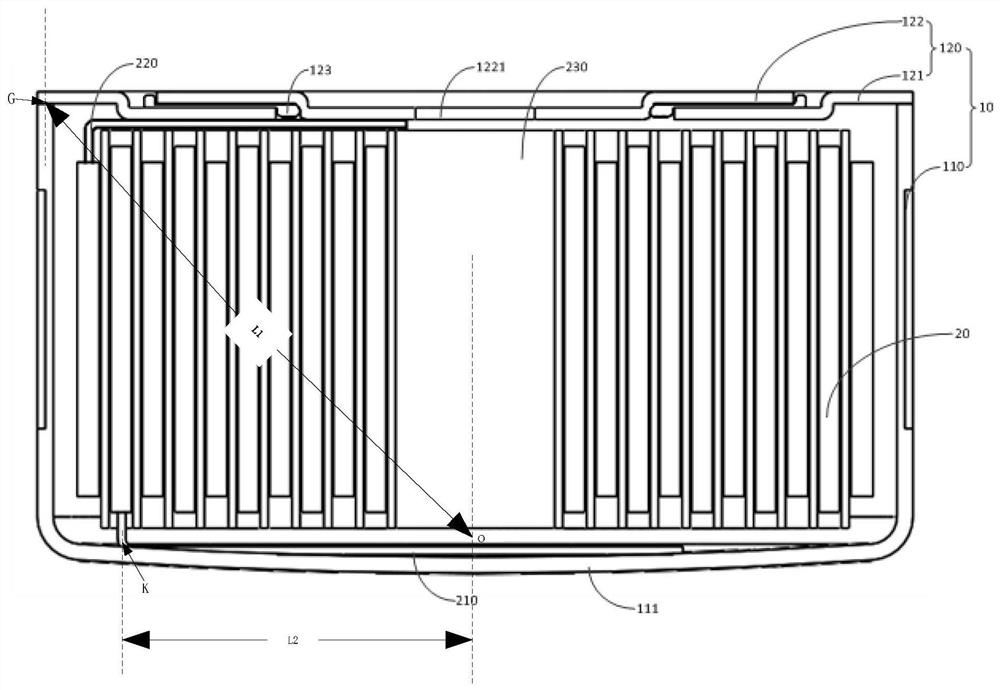

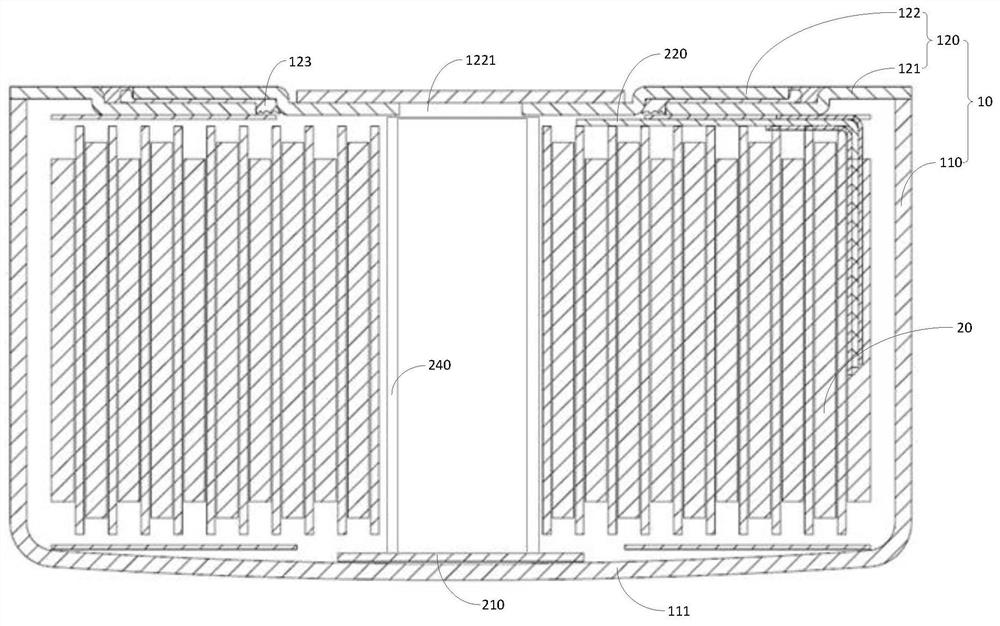

Button cell and preparation method thereof

InactiveCN111900275AQuality assuranceGuaranteed performanceFinal product manufactureWound/folded electrode electrodesButton batteryBattery cell

The invention provides a button cell and a preparation method thereof. The button cell comprises a shell and a roll core, the shell comprises a shell body and a top cover assembly, and the shell bodyand the top cover assembly jointly define a containing cavity used for containing the roll core. The roll core comprises a first tab and a second tab, the first tab is welded with the bottom wall of the shell, and the second tab is connected with the top cover; the top cover is provided with a liquid injection hole, and the liquid injection hole is at least partially overlapped with the cavity ofthe roll core; and the welding marks of the first tab and the bottom wall are positioned in the overlapped parts of the bottom wall, the cavity and the liquid injection hole. According to the invention, the quality and performance of the button cell can meet the requirements, and the yield of the button cell can be improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

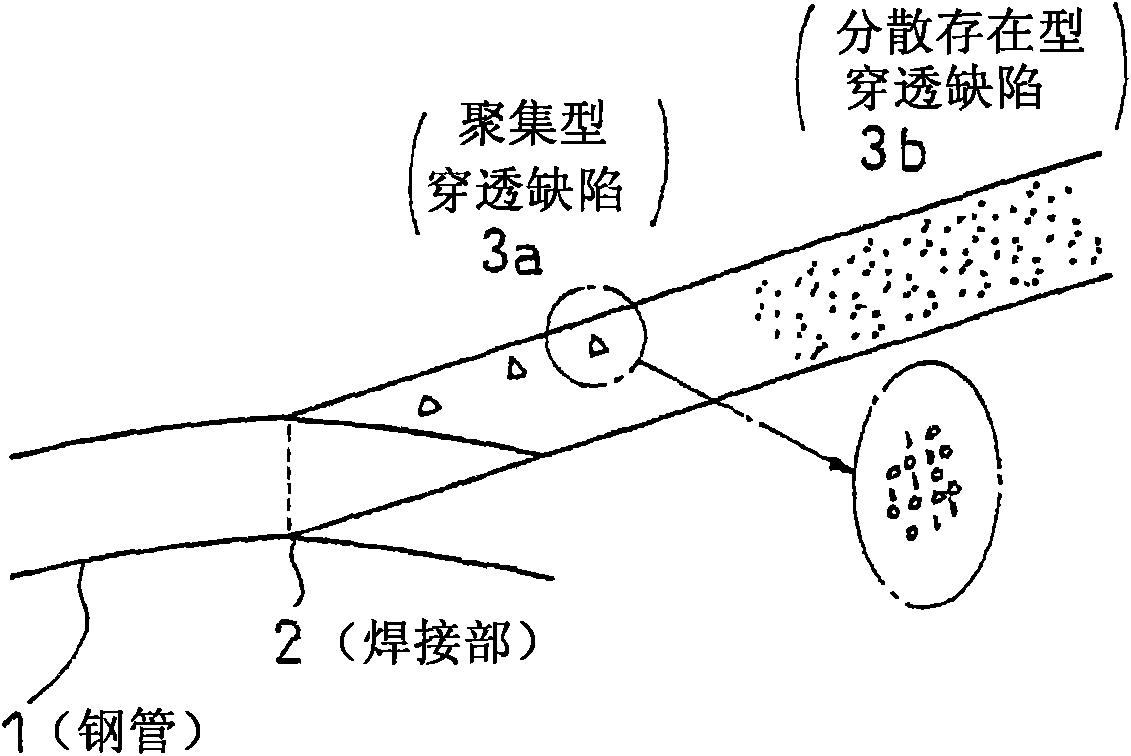

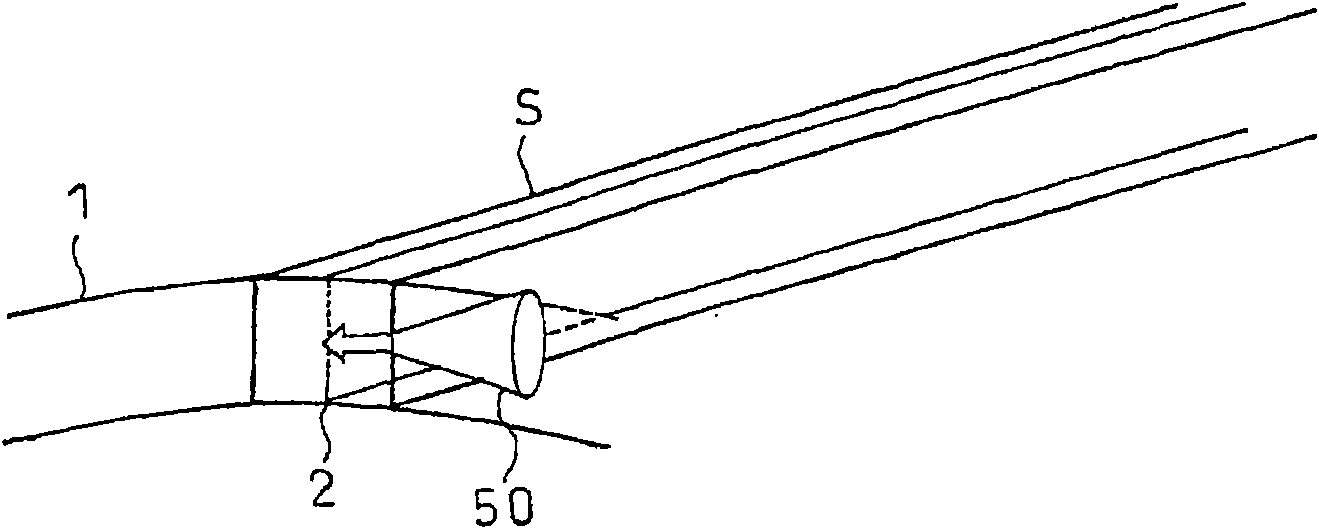

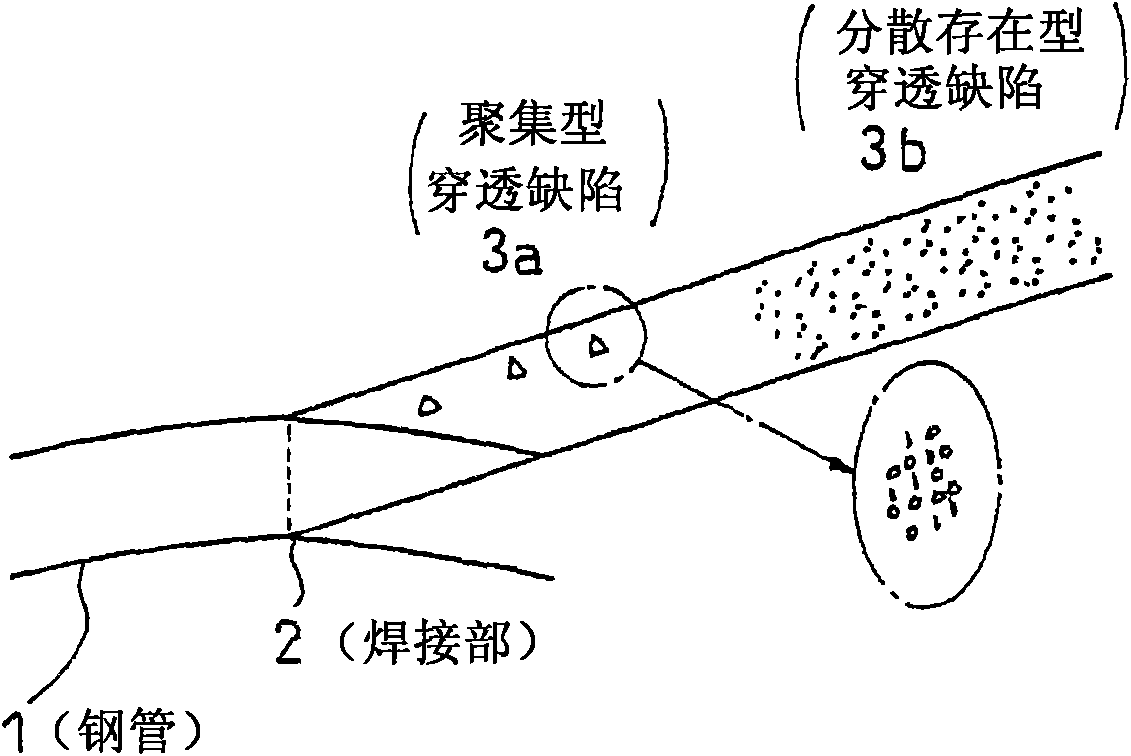

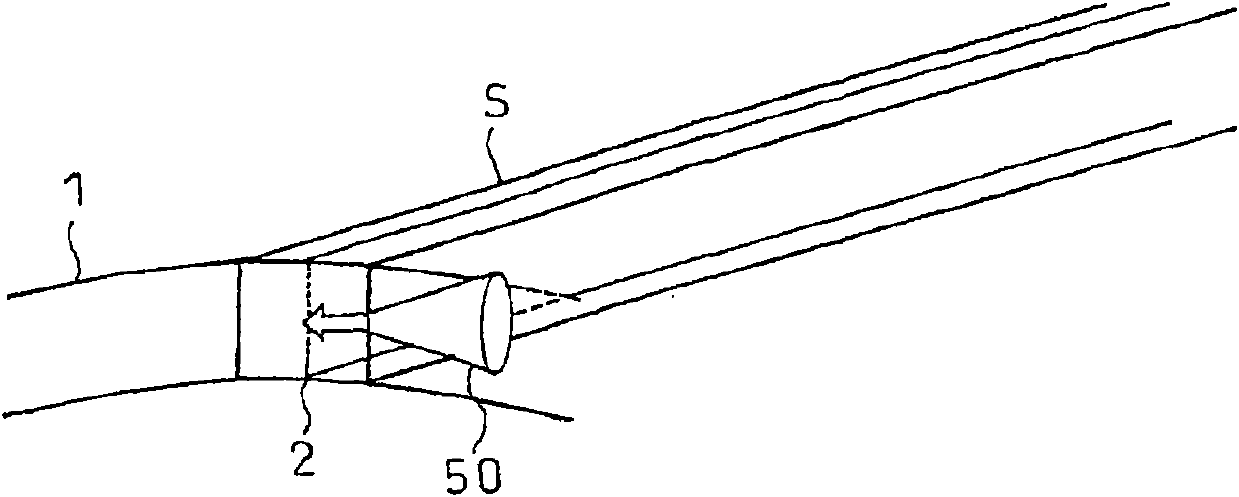

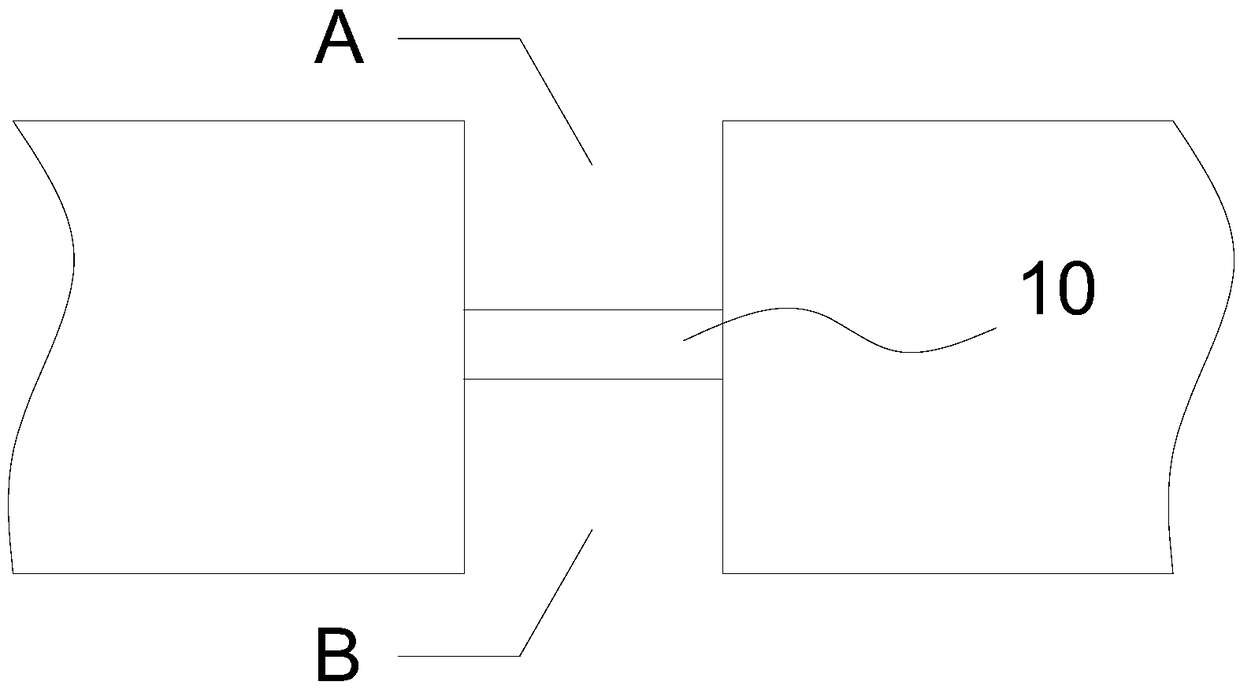

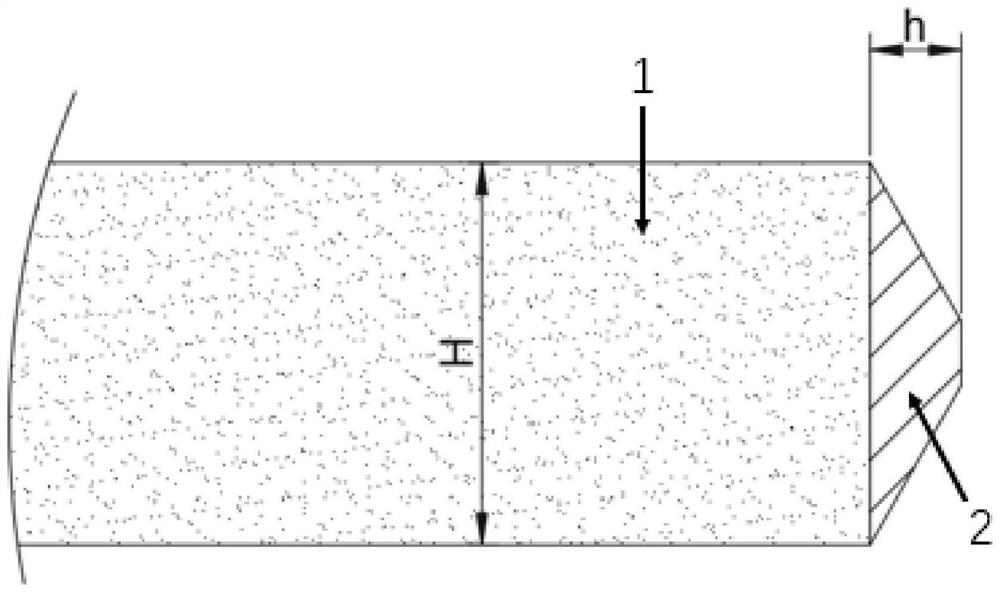

Calibration method of ultrasonic flaw detection and quality control method and production method of tubular body

ActiveCN101617223AImprove qualityEasy welding processAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalUltrasonic beamQuality level

Ultrasonic flaw detection at the welded portion (2) of a tubular body (1) is performed at least in the axial direction of the tubular body, a defect judgment threshold is determined based on the difference of signal strength between the total area of defects existing in the region of an ultrasonic beam on the welded surface and an artificial defect, and then quality control of the tubular body isperformed by the defect judgment threshold. From the defect density on the welded surface at the welded portion in the axial direction of tubular body determined from a desired quality level and the area of the ultrasonic beam on the welded surface, an equivalent defect diameter is determined based on the total area of defects existing in the region of the ultrasonic beam and then the defect judgment threshold is determined based on the difference of signal strength between the equivalent defect diameter and the artificial defect.

Owner:JFE STEEL CORP

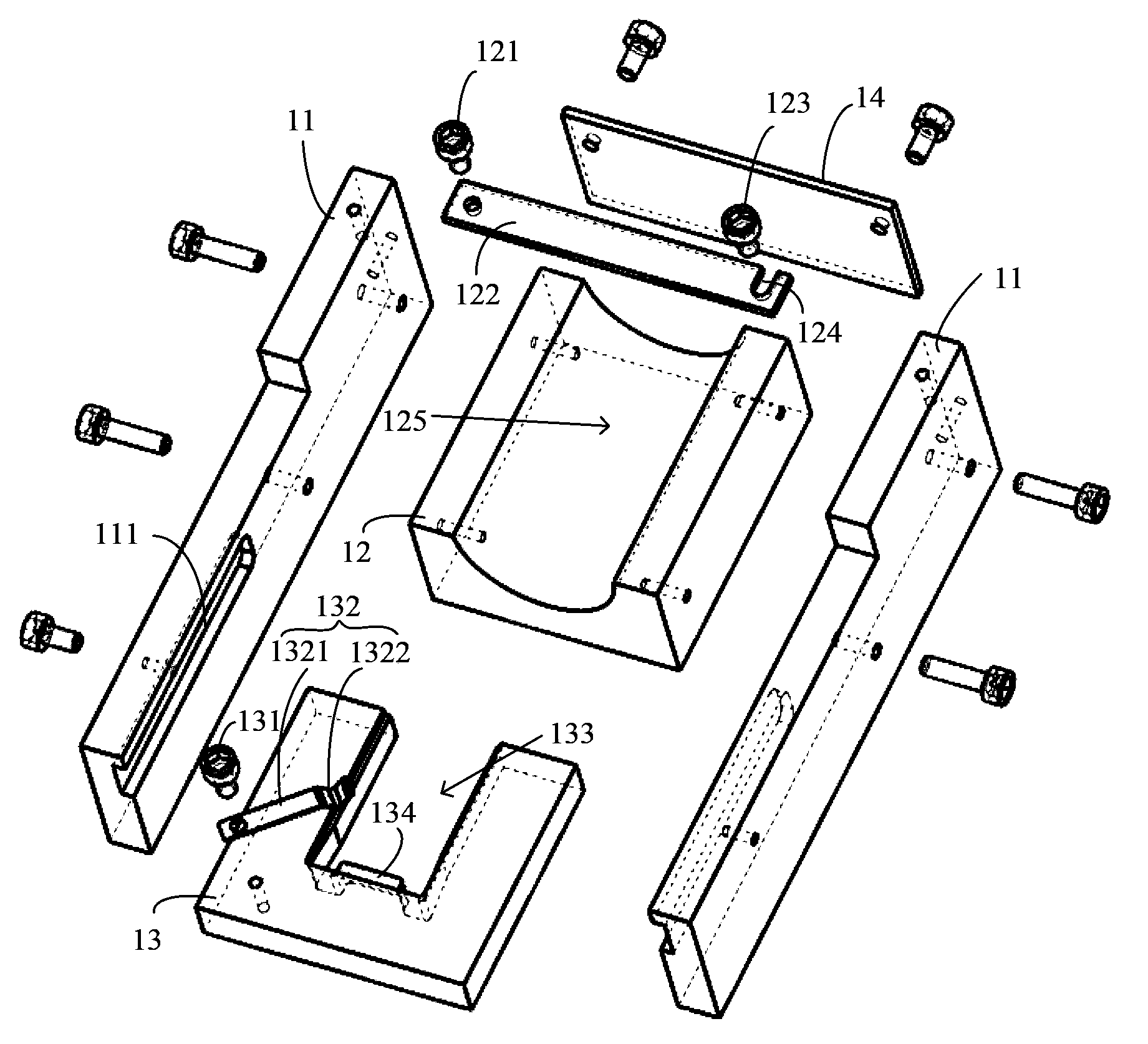

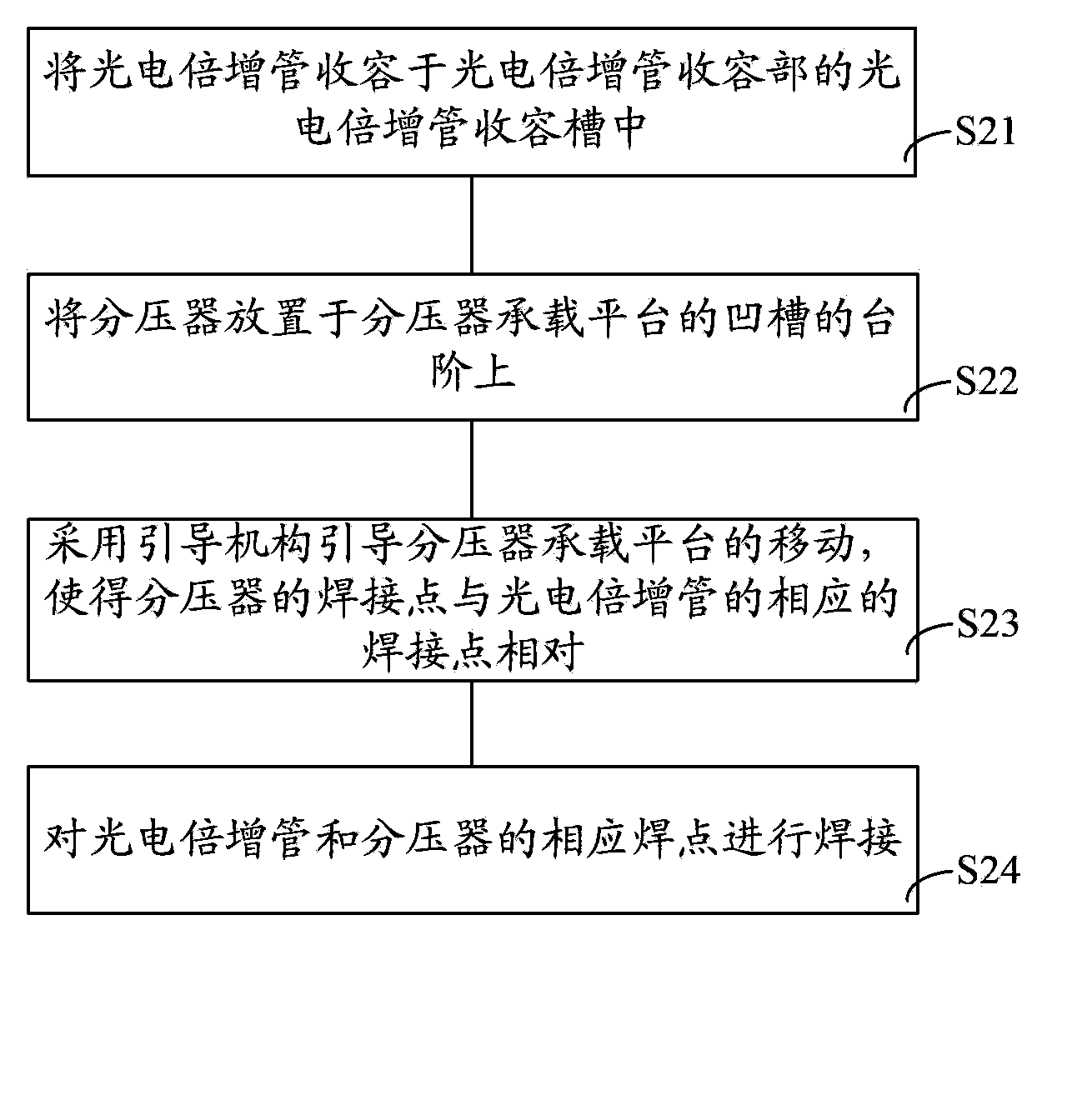

Welding device for photomultiplier and voltage divider

ActiveCN103567685AEasy to control spacingGuaranteed to be verticalWelding/cutting auxillary devicesAuxillary welding devicesPhotomultiplierEngineering

The invention provides a welding device for a photomultiplier and a voltage divider. The welding device comprises a photomultiplier fixing mechanism for fixing the photomultiplier, a voltage divider fixing mechanism for fixing the voltage divider and a guiding mechanism for guiding the photomultiplier fixing mechanism and the voltage divider fixing mechanism to move relatively, so that a welding point of the photomultiplier fixed on the photomultiplier fixing mechanism is opposite to a corresponding welding point of the voltage divider fixed on the voltage divider fixing mechanism. By means of the welding device and method, a welding process can be convenient and fast, and good welding quality can be guaranteed.

Owner:SHANGHAI UNITED IMAGING HEALTHCARE

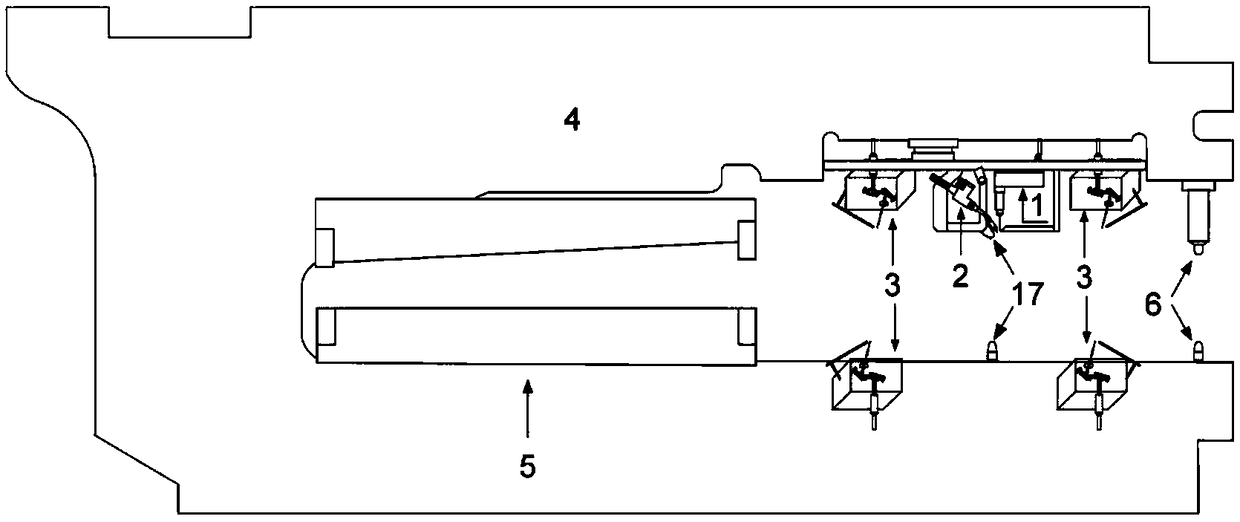

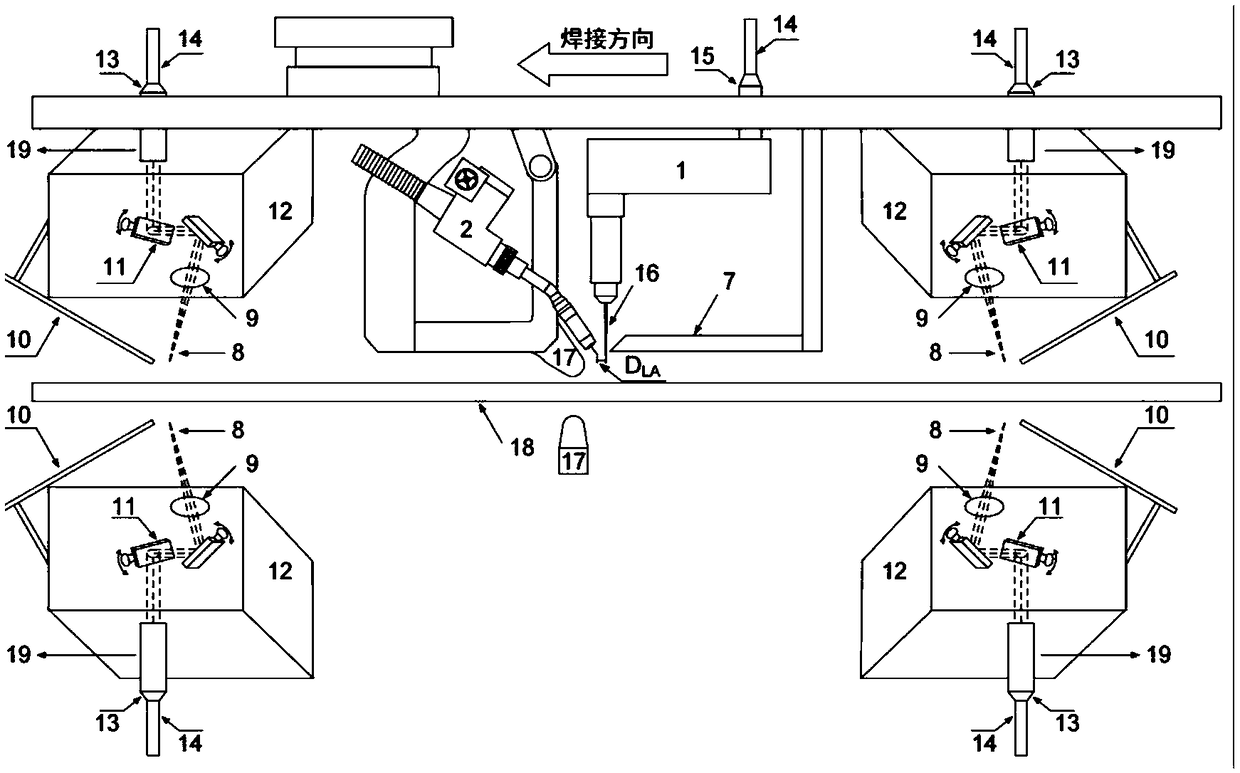

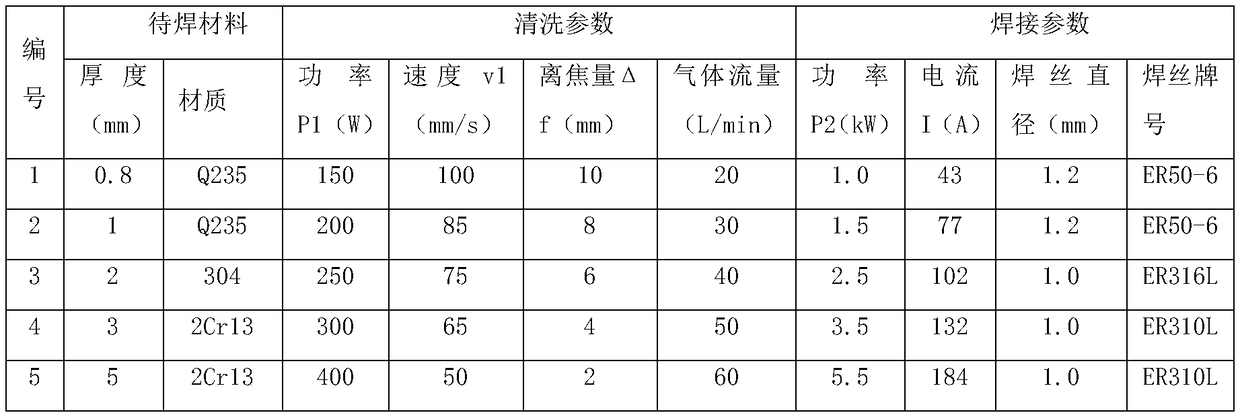

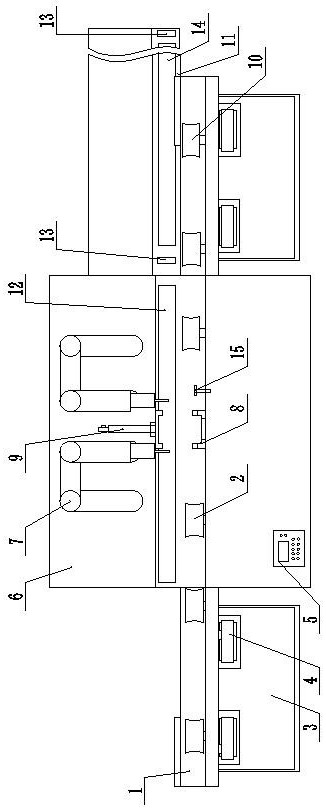

Cleaning and welding integration device for black volume endless rolling

ActiveCN109014943AImprove surface qualityImprove energy utilizationOther manufacturing equipments/toolsLaser beam welding apparatusMelting tankLaser-hybrid welding

The invention belongs to the technical field of hybrid welding and discloses a cleaning and welding integration device for black volume endless rolling. The cleaning and welding integration device comprises a hybrid welding module and a laser cleaning module. Hybrid heat source is formed by the hybrid welding module through laser and electric arc, and the hybrid heat source and the hybrid weldingmould cooperate on the surface of black coil steel to be welded to trigger the molten pool, meanwhile, the laser attracts the electric arc so that drift of arc root of the electric arc can be restrained; the laser cleaning module is used for partial cleaning of the upper and lower surfaces before and after welding of the joint of the black coil steel ; the hybrid welding module and the laser cleaning module are both arranged on the same support, and a integrative structure of cleaning-welding-cleaning is formed, therefore, that on-line cleaning and welding are conducted simultaneous is achieved. The invention further discloses a welding method of the cleaning and welding integration device for black volume endless rolling. According to the cleaning and welding integration device for the black volume endless rolling, metallurgical defects of air holes, inclusion and incomplete fusion in the welding process are prevented efficiently, seam quality and smooth after welding in the hybrid welding process are guaranteed, efficiency and stability of endless rolling are improved, and risk of strip breakage is reduced.

Owner:HUAZHONG UNIV OF SCI & TECH +1

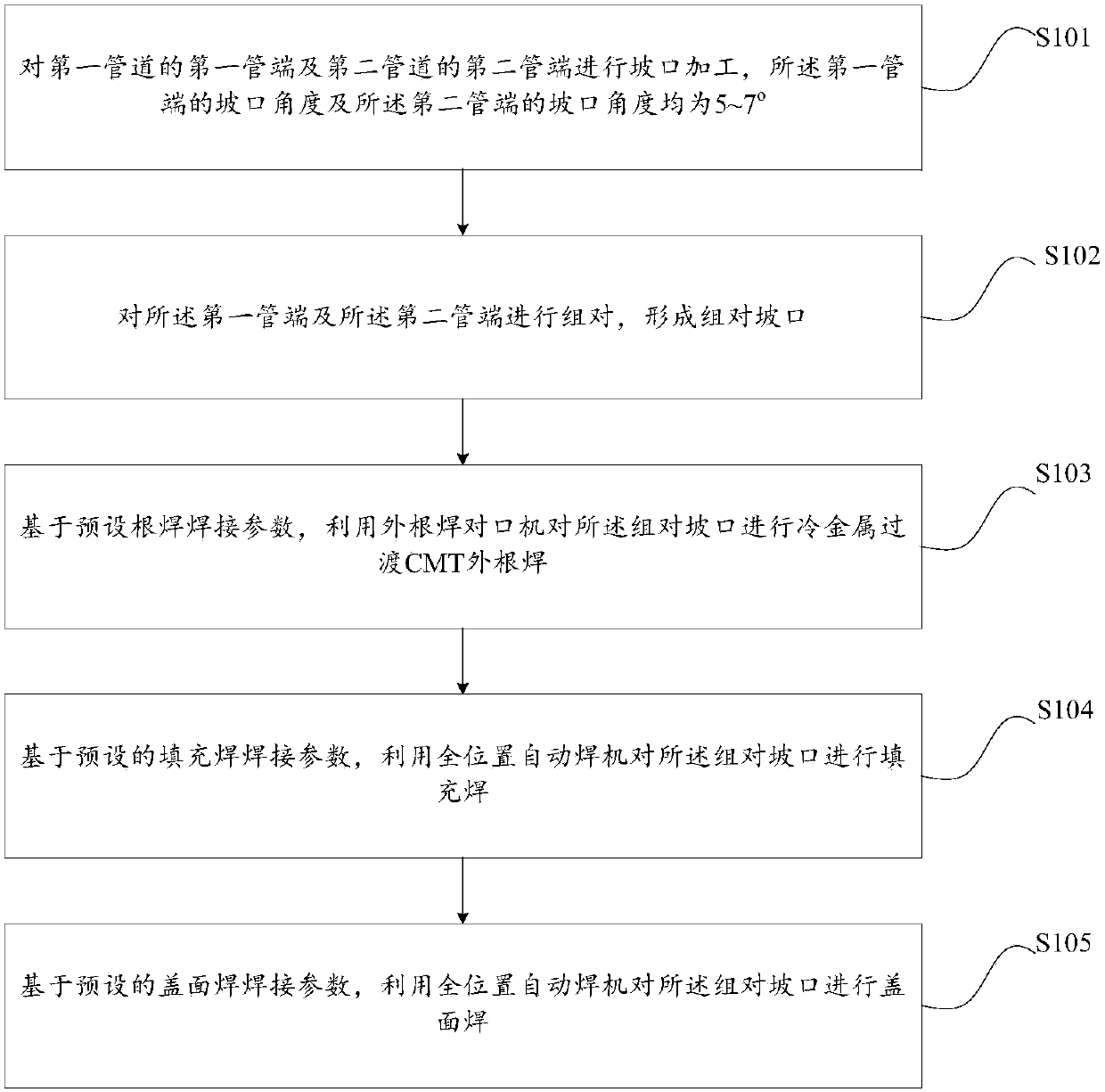

Welding method

ActiveCN107900499AReduce welding costsEasy welding processArc welding apparatusPower flowEngineering

The invention provides a welding method. The welding method comprises the following steps: carrying out groove preparation on a first pipe end of a first pipeline and a second pipe end of a second pipeline, wherein the bevel angles of the first and second pipe ends are 5-7 degrees; assembling the first and second pipe ends to form an assembled groove; based on preset root welding parameters, carrying out cold metal transitional CMT outer root welding on the assembled groove by means of an outer root welding aligning machine; based on preset filling welding parameters, carrying out filling welding on the assembled groove by means of a full position automatic welding machine; and based on preset cosmetic welding parameters, carrying out cosmetic welding on the assembled groove by means of the full position automatic welding machine, wherein the root welding parameters comprise following parameters: welding voltage: 12.5-13.5 V, welding current: 165-175 A, welding wire diameter: 1.0 mm, and welding speed: 50 cm+ / -3cm / min; the filling welding parameters are equal to the cosmetic welding parameters: welding voltage: 22.5-26 V, welding current: 155-185 A, welding wire diameter: 1.0mm andwelding speed: 45-55 cm / min.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Method for preparing TA2/Q235 composite plate by electric resistance welding and welding material

InactiveCN102672331AWide adaptabilityHigh strengthWelding/cutting media/materialsSoldering mediaAlloyTitanium

The invention discloses a method for preparing a TA2 / Q235 composite plate by electric resistance welding. A folded middle-layer alloy foil is arranged between a TA2 plate to be welded and a Q235 plate to be welded, and the welding operation is carried out by adopting a resistance spot-welding mode, so that the welding of the TA2 / Q235 plates is realized. The invention also discloses a middle-layer alloy and a preparation method thereof. The middle-layer alloy comprises the following components in the terms of the atomic percent: 5-10% of Ti, 5-10% of Fe, 20-25% of Al, 30-35% of Ni and 30-35% of Cu, wherein the total percent is 100%. The method is convenient and easy, and is wide in applicability; the welding material has excellent strength, toughness and corrosion performance; brittle intermetallic compound phases are not easily formed, a high-performance titanium-steel composite structure is easily obtained; and the welding material is simple in process and low in manufacturing cost.

Owner:XIAN UNIV OF TECH

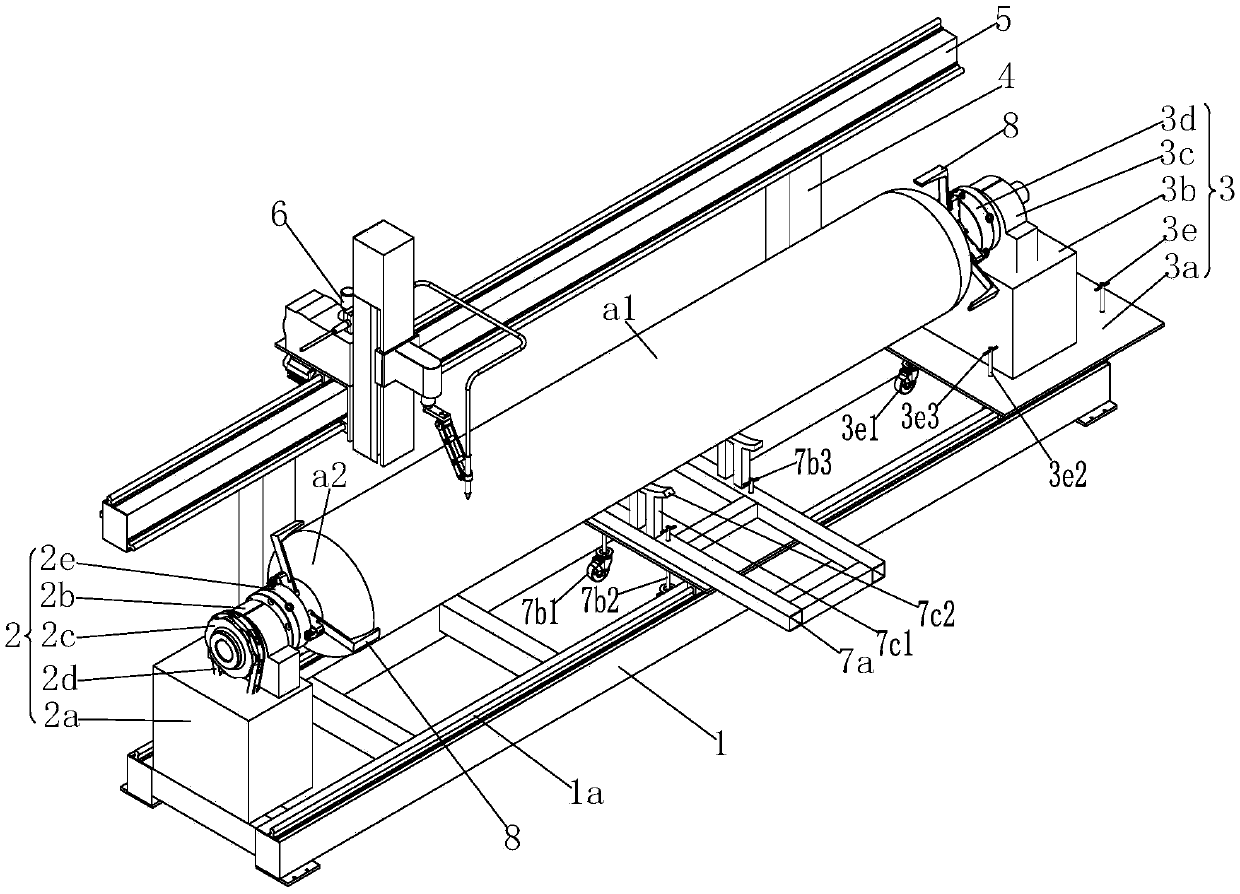

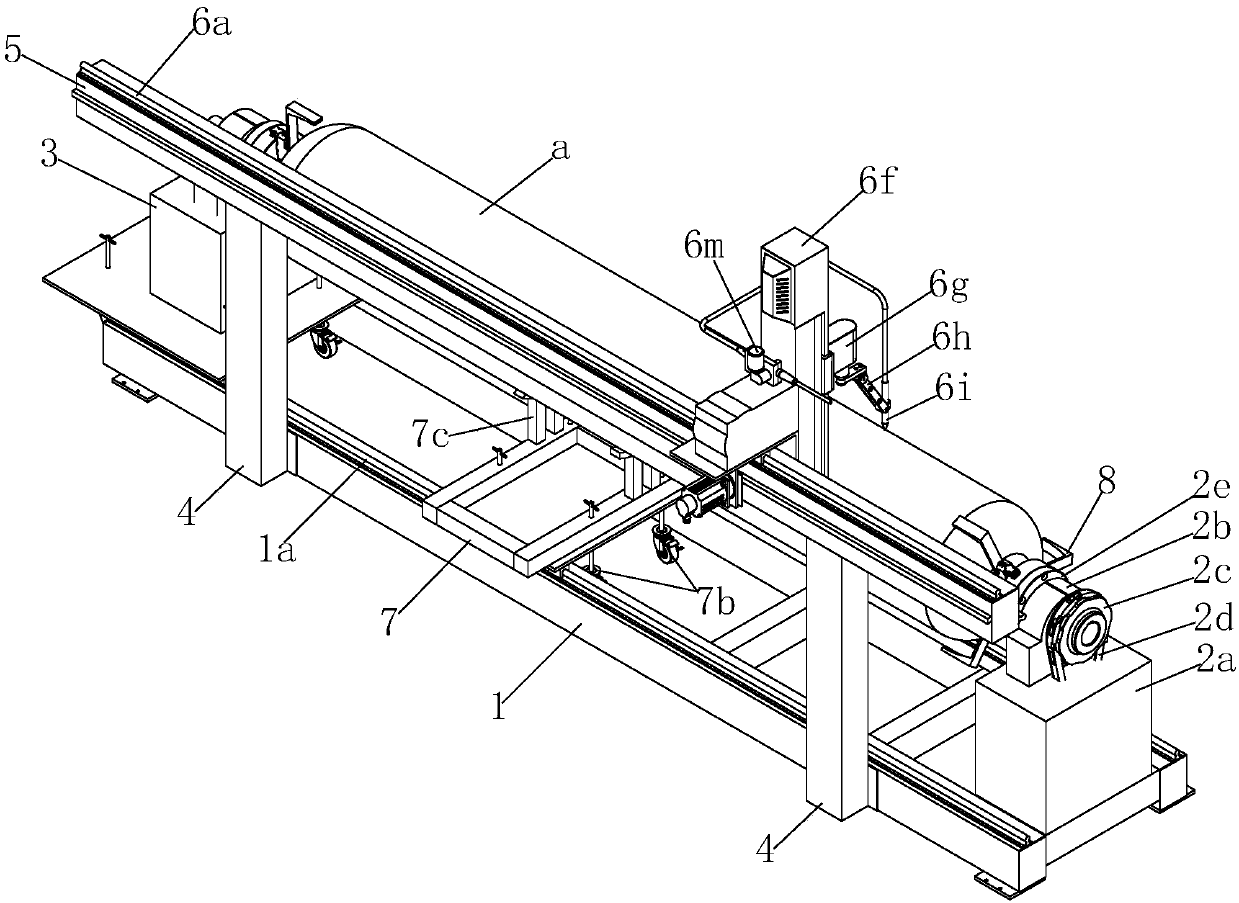

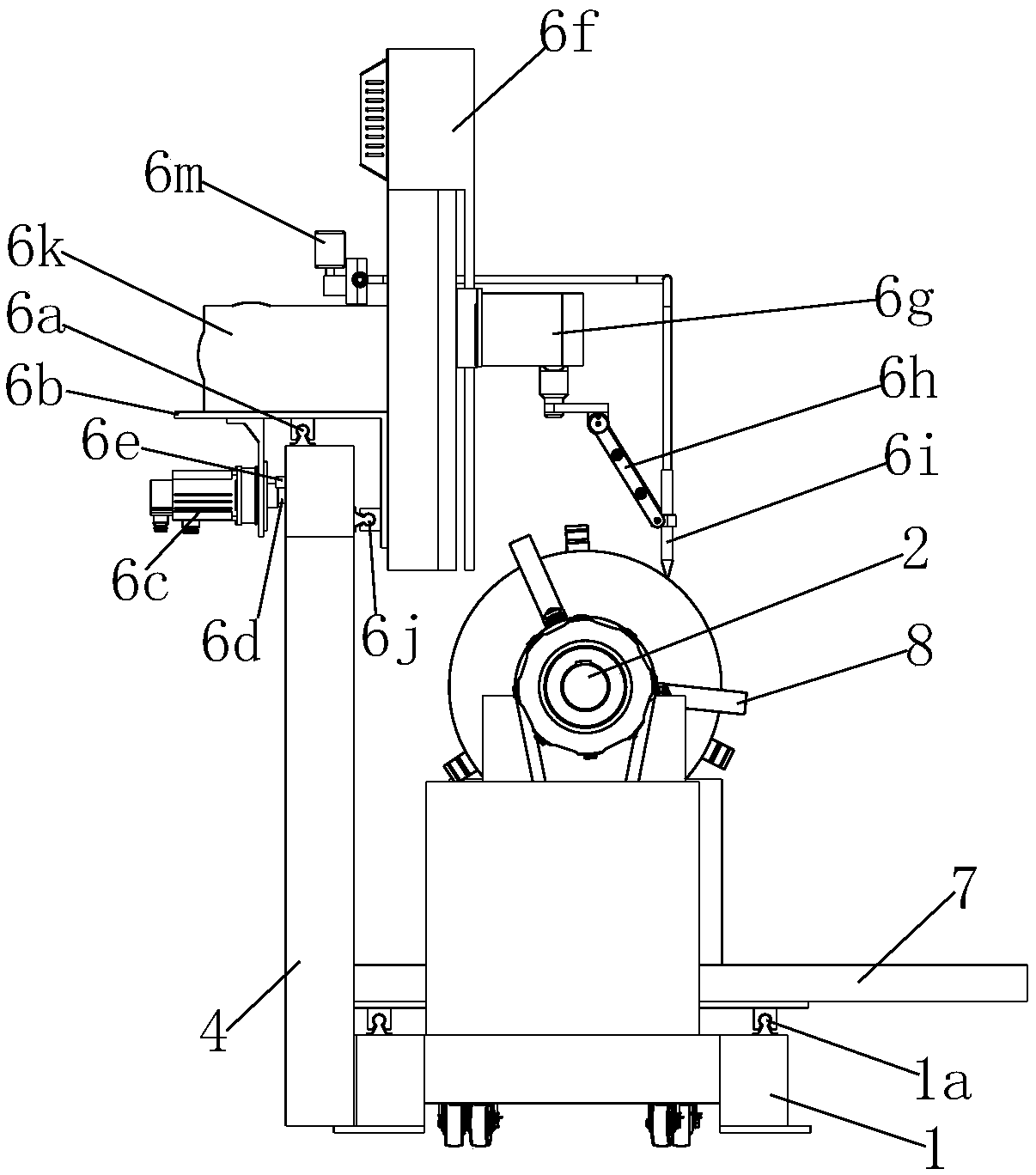

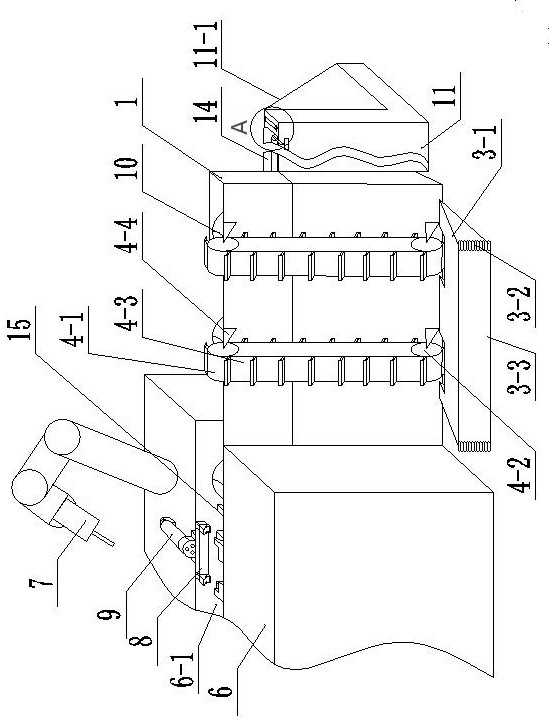

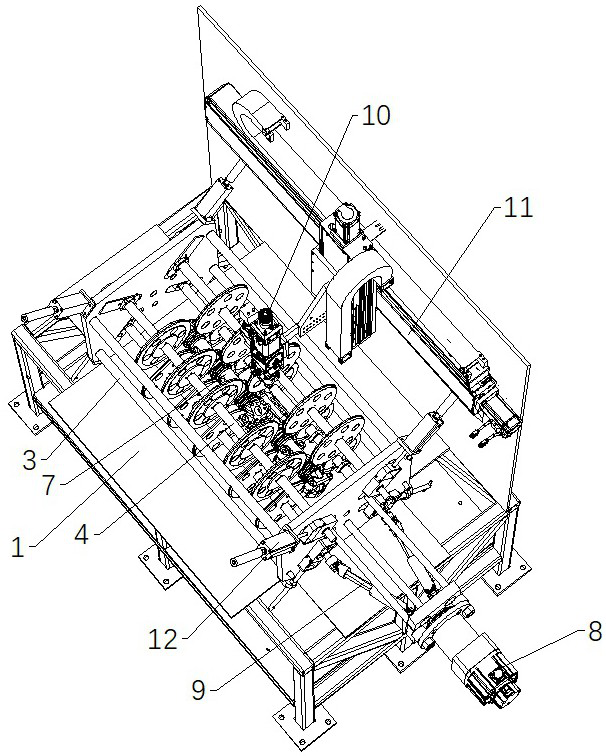

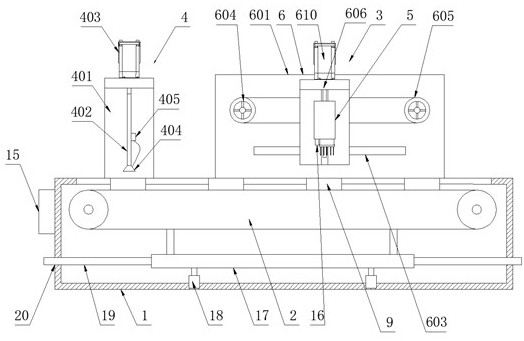

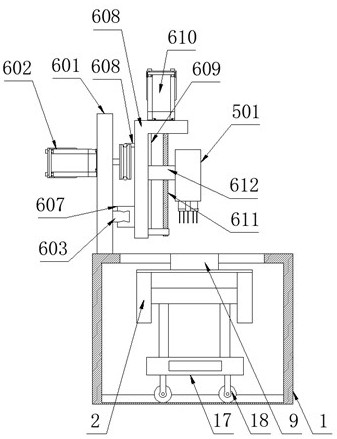

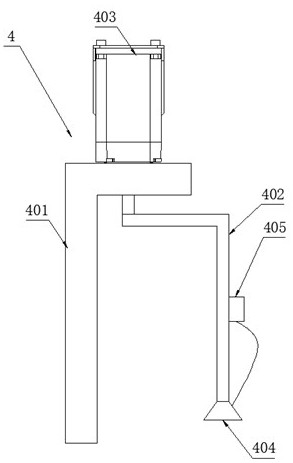

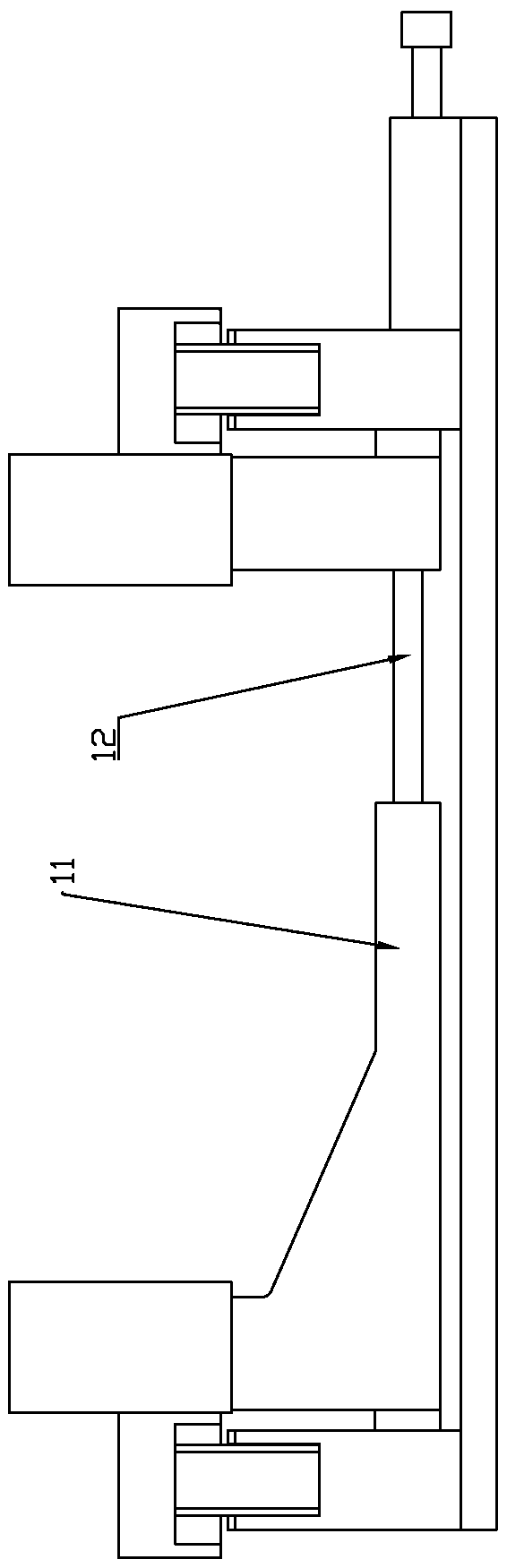

Tank body welding robot

PendingCN109530948AAchieve weldingEasy welding processWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDrive motor

The invention discloses a tank body welding robot. The tank body welding robot comprises a base, wherein a tank body support driving assembly is arranged at one end of the base; base guide rails are arranged on the two sides of the base, a tank body supporting assembly is arranged at the other end of the base, the tank body supporting assembly comprises a supporting table bottom plate arranged onthe base guide rails and a second supporting table arranged on the supporting table bottom plate, a second bearing block is arranged on the second supporting table, and a second rotating shaft with asecond three-jaw chuck is arranged in the second bearing block; an X-axis cross beam is arranged on one side of the base, a welding assembly is arranged on the X-axis cross beam, the welding assemblycomprises a top surface X-axis guide rail, the top surface X-axis guide rail is laid on the top surface of the X-axis cross beam, an X-axis rack is laid on the outer side surface of the X-axis cross beam, and an L-shaped sliding plate cross arm is arranged on the top surface X-axis guide rail; and an X-axis driving motor with an X-axis driving gear is arranged on the L-shaped sliding plate cross arm, a Z-axis electric sliding table is arranged on the L-shaped sliding plate, a welding gun mounting base is arranged on a sliding table sliding block, a position fine adjusting assembly is arrangedon the welding gun mounting base, and the position fine adjusting assembly is provided with a welding gun. The tank body welding robot is suitable for welding of the tank body.

Owner:WUHAN ENG SCI & TECH RESINST +1

Drive-control LED digital display screen

PendingCN106128321AAchieve modularityRealize integrationStatic indicating devicesIdentification meansLead bondingEngineering

The invention relates to a drive-control LED digital display screen, and belongs to the technical field of display. The LED digital display screen comprises a PCB, LED patch lamps and a plastic shell; the PCB comprises a preset number of LED bonding pads which are arranged on the PCB, the LED bonding pads are correspondingly connected with a universal communication port connection socket through circuits, and the PCB further comprises an LED driving chip and positioning holes; each LED patch lamp is installed on the corresponding LED bonding pad of the PCB in an attached mode; the surface side of the plastic shell is provided with reflection cavities, the position of the center of the bottom cavity opening of each reflection cavity corresponds to one LED patch lamp, the back side of the plastic shell is provided with positioning columns, and the positioning columns and the positioning holes in the PCB are riveted in an aligned mode respectively. According to the LED digital display screen, the LED driving chip is integrated into the LED digital display screen, modularization and integration of the LED digital display screen and the drive control function are achieved, connection with an electric appliance control panel adopts the universal communication port connection socket instead of a guide needle pin connection mode of a traditional LED digital display screen, and installation is more standardized and simplified.

Owner:ZHONGSHAN YOUYANG OPTOELECTRONICS TECH

Method for welding titanium and steel by applying high-entropy effect and welding material

InactiveCN102672328BWide adaptabilityEasy to processWelding/cutting media/materialsSoldering mediaWeld seamTitanium

The invention discloses a method for welding titanium and steel by applying the high-entropy effect. A folded middle-layer alloy foil is arranged between a titanium plate to be welded and a steel plate to be welded, and the welding operation is carried out by adopting a resistance spot-welding mode, then the interface resistance heat melts the middle-layer alloy and local base materials, and the molten metals are mixed, so that the high-performance welding of titanium and steel is realized. The invention also discloses a middle-layer alloy and a preparation method of the middle-layer alloy. The middle-layer alloy comprises the following components in the terms of atomic percent: 20-30% of Al, 35-40% of Ni and 35-40% of Cu, wherein the total percent is 100%. The invention has the advantages that the middle-layer alloy is well matched with the titanium and the alloy steel in welding, welding seams (nugget) are single-phase fcc solid-solution structures, and the comprehensive mechanical performance of joints is obviously improved. The preparation method of the middle-layer alloy foil is simple in process and low in manufacturing cost.

Owner:XIAN UNIV OF TECH

Material and method used for TA2/0Cr18Ni9Ti welded by high-entropy effect

InactiveCN102676904BImprove performanceSimple preparation stepsWelding/cutting media/materialsSoldering mediaElectrical resistance and conductanceAlloy

The invention discloses a high-entropy interlayer alloy, which comprises the following components in atomic percentage: 5-10% of Ti, 5-10% of Fe, 25-30% of Al, 15-20% of Ni, 30-35% of Cu and 5-10% of Cr. The invention also discloses a method for welding TA2 / 0Cr18Ni9Ti by the high-entropy effect, which comprises the following steps that: high-entropy interlayer alloy is placed between the two plates to be welded, the high-entropy interlayer alloy is in a foil folding structure, and the high-entropy interlayer alloy and local parent metal are subjected to heat fusing by an interface resistor in a resistance spot welding mode, so that the high performance welding of TA2 / 0Cr18Ni9Ti can be realized. According to the method and the high-entropy interlayer alloy of the method, which are disclosed by the invention, the high-entropy interlayer alloy has the advantages of favorable strength, toughness and corrosion resistance, is easy to process and form and is convenient to weld and assembly. The preparation method has the advantages of simple step and low manufacture cost and is convenient to popularize.

Owner:XIAN UNIV OF TECH

Calibration method of ultrasonic flaw detection and quality control method and production method of tubular body

ActiveCN101617223BImprove qualityEasy welding processAnalysing solids using sonic/ultrasonic/infrasonic wavesProcessing detected response signalQuality levelUltrasonic beam

An ultrasonic flaw detection is performed to a welded portion 2 of a pipe body 1 in at least a pipe axis direction, a defect detection threshold value is determined based on the signal intensity difference between the total area of the defects existing in the region of an ultrasonic beam on a welded surface and an artificial defect, and a quality control of the pipe body is performed based on the defect detection threshold value. An equivalent defect diameter is determined from the defect density, which is determined from a desired quality level, on the welded surface of the welded portion of the pipe body in a pipe axis direction and the area of the ultrasonic beam on the welded surface based on the total area of the defects existing in the region of the ultrasonic beam, and the defect detection threshold value is determined based on the equivalent defect diameter and the signal intensity difference of the artificial defect.

Owner:JFE STEEL CORP

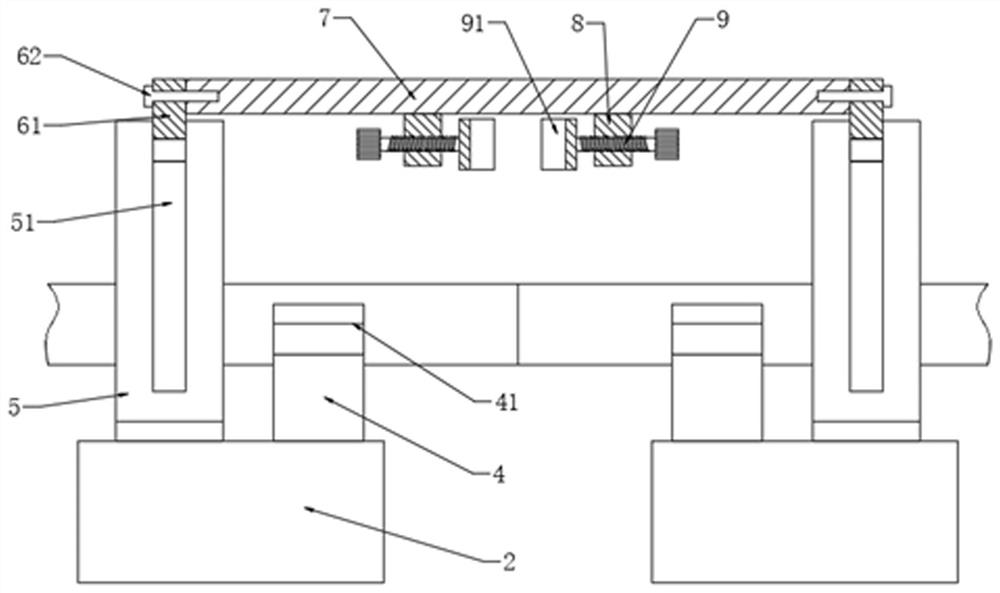

Portable welding auxiliary device for electromechanical maintenance

PendingCN114515925ASimple designEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesEngineeringBilateral symmetry

The portable welding auxiliary device for electromechanical maintenance comprises two clamping devices in bilateral symmetry and a transverse rod, each clamping device comprises a bottom plate, a supporting plate, a threaded rod, a clamping plate, a curved plate, a curved surface sliding block and a limiting block, a dovetail-shaped groove is formed in the upper end of each bottom plate, the supporting plates are welded to the left sides of the bottom plates, and the threaded rods are arranged on the supporting plates; a threaded rod penetrates through the side face of the supporting plate. Two sections of round pipes needing to be welded are aligned and placed in the two clamping devices correspondingly, the two clamping plates are driven to move relatively by rotating the threaded rod, the two clamping plates clamp and fix the round pipes, then a welding head of the welding device is placed between the two V-shaped plates, the welding head is fixed by rotating the clamping bolt, the device is started, and the round pipes are welded. The transverse rod is pushed downwards along the convex groove, the transverse rod drives the welding head to rotate in an arc shape, and therefore the round pipe is welded.

Owner:XIANGTAN SHUANGHUAN MACHINERY DEV

Length-specified machining platform for formed automobile rear axle shell piece

The invention discloses a length-specified machining platform for a formed automobile rear axle shell piece. The length-specified machining platform for the formed automobile rear axle shell piece comprises an upper die frame and a lower die frame, male die insert assemblies are detachably arranged on two sides of the lower portion of the upper die frame, two ends below the upper die frame are detachably provided with adjustable cut-off male die inserts, the two sides above the middle of the lower die frame are provided with a female die insert assembly, two ends of the female die insert assembly are also provided with adjustable cutting-off female die inserts detachably connected with the lower mold frame, the position of the male die insert assemblies corresponds to the position of the female die insert assembly, and the position of the adjustable cut-off male die inserts corresponds to the position of the adjustable cutting-off female die inserts. According to the length-specified machining platform for the formed automobile rear axle shell piece, on the basis of a cold stamping machining-free automobile rear axle forming technique in the prior art, reshaped axle shells are finely trimmed in the length direction, so that the same die is utilized to realize the lengthening of the axle shells with different lengths while long parts left at the two ends are cut off, and each cut forms a neat Y-shaped section which can be used as a welding slope surface during subsequent welding.

Owner:HEFEI JIUXIANG MACHINERY

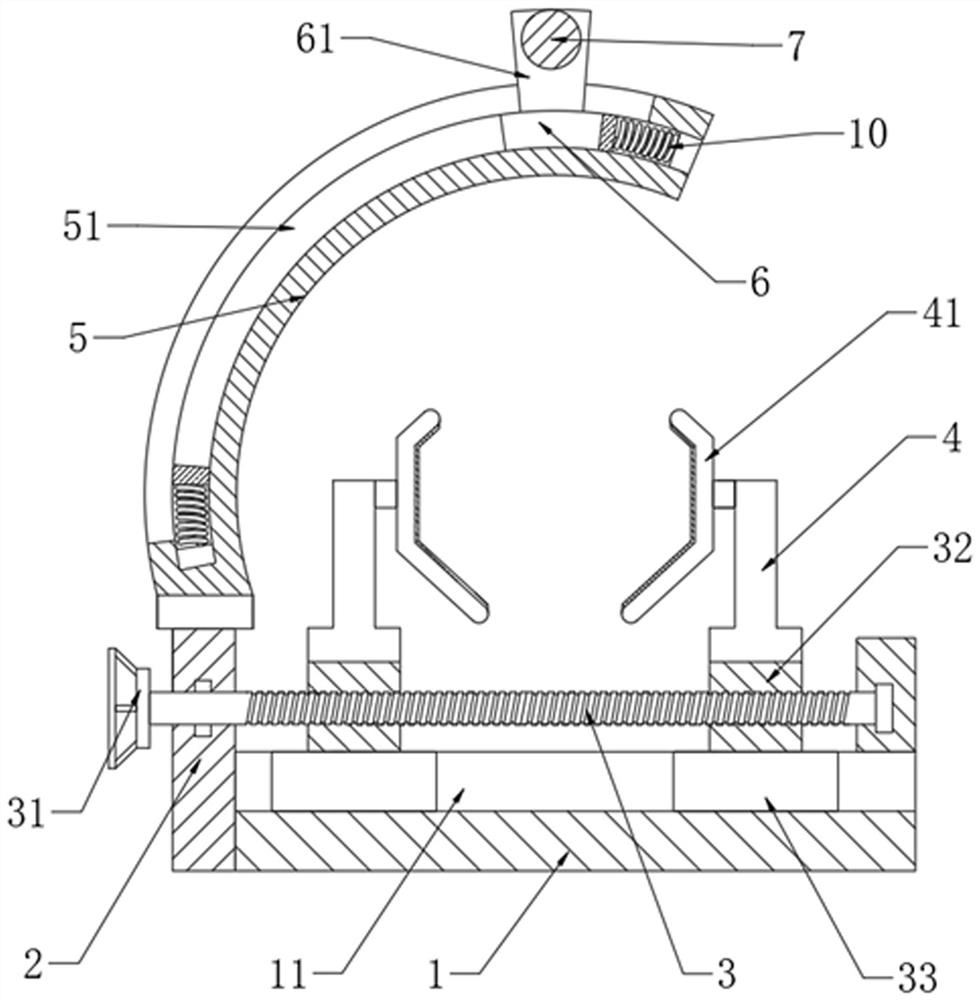

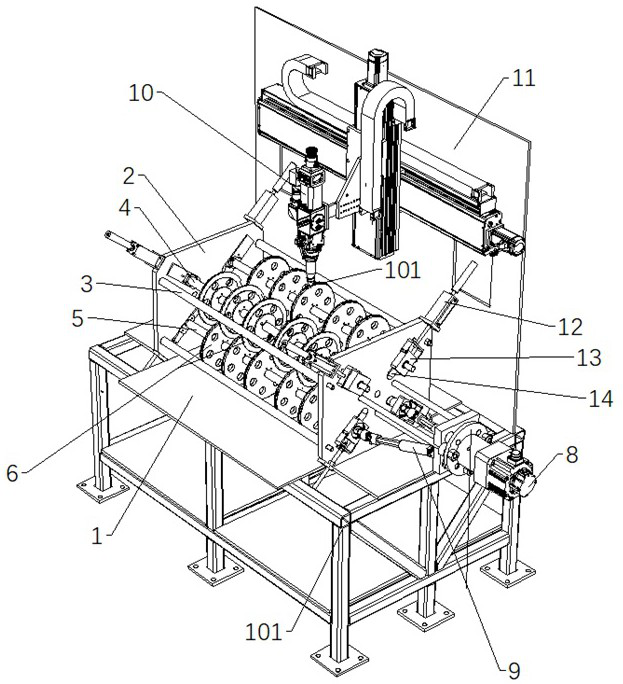

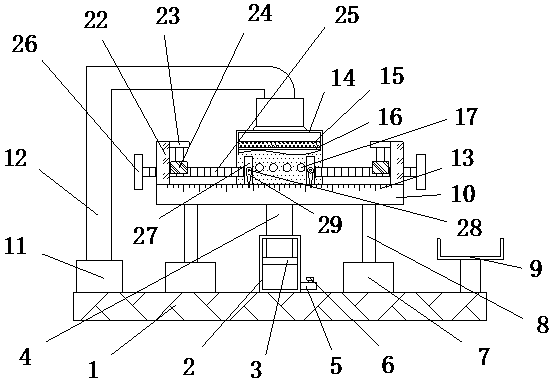

Reinforcing steel bar lap joint welding machine

ActiveCN113649722AEasy welding processImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesRebarLap joint

The invention discloses a reinforcing steel bar lap joint welding machine, relates to the technical field of welding, and solves the problems that in the prior art, welding operation is complex, and large-demand reinforcing steel bar welding cannot be met. The reinforcing steel bar lap joint welding machine comprises an operation table, a left feeding mechanism, a right feeding mechanism, a discharging mechanism and a control mechanism, a welding mechanical arm is arranged on the operation table, the left feeding mechanism is arranged on the left side of the operation table, the right feeding mechanism is arranged on the right side of the operation table, and the discharging mechanism is arranged on the right side of the operation table and located behind the right feeding mechanism; and a welding groove is formed in the operation table, a first rolling wheel mechanism, a clamping mechanism and a pushing mechanism are arranged in the welding groove, each of the left feeding mechanism and the right feeding mechanism comprises a second rolling wheel assembly, the first rolling wheel mechanism corresponds to the second rolling wheel assemblies, and the feeding end of the discharging mechanism is arranged in the welding groove and located below the first rolling wheel mechanism, the clamping mechanism and the pushing mechanism. The reinforcing steel bar lap joint welding machine is easy and convenient to operate, high in welding efficiency and good in welding effect, and reinforcing steel bar welding stability is guaranteed.

Owner:CCT TECH HENAN CO LTD

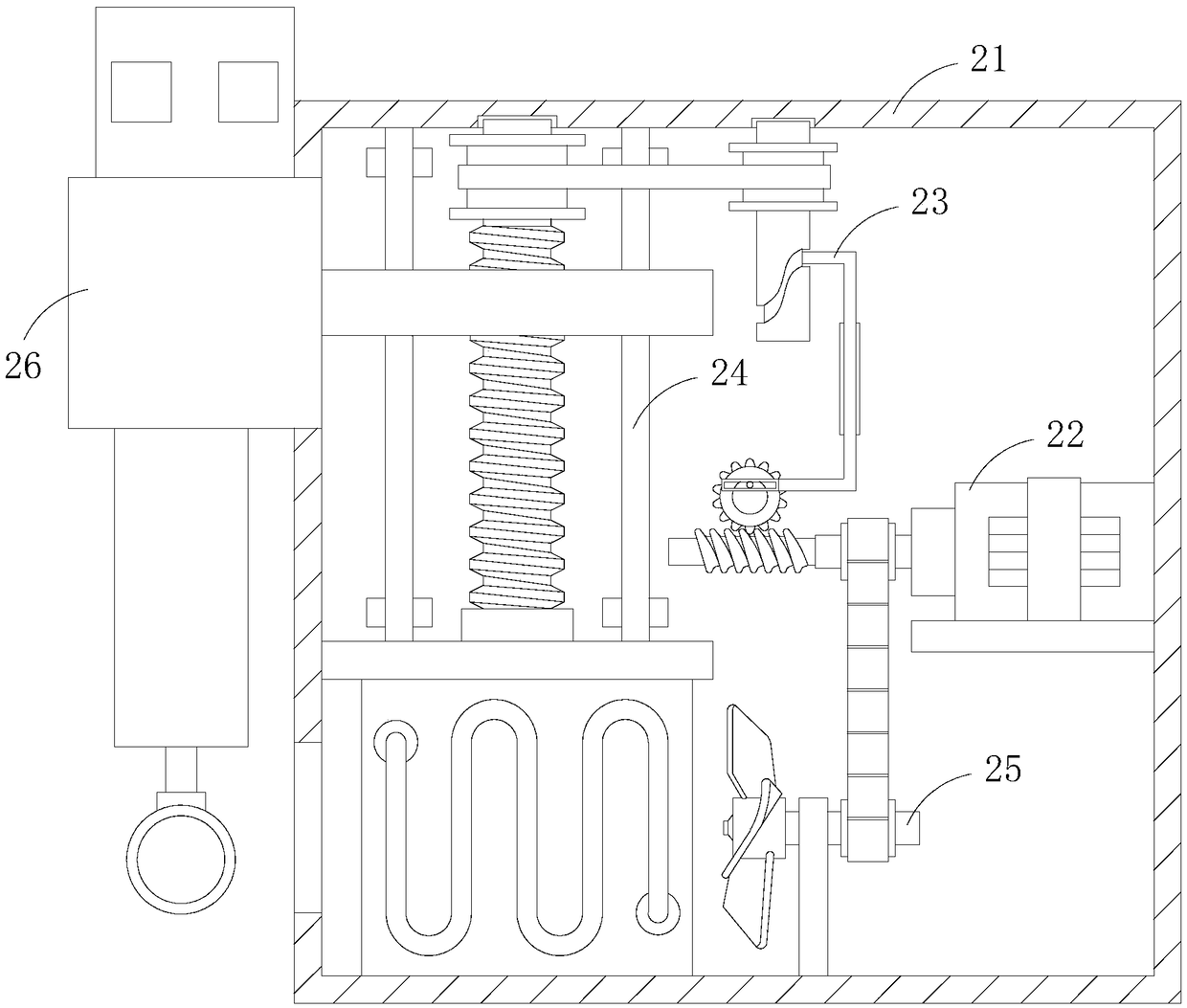

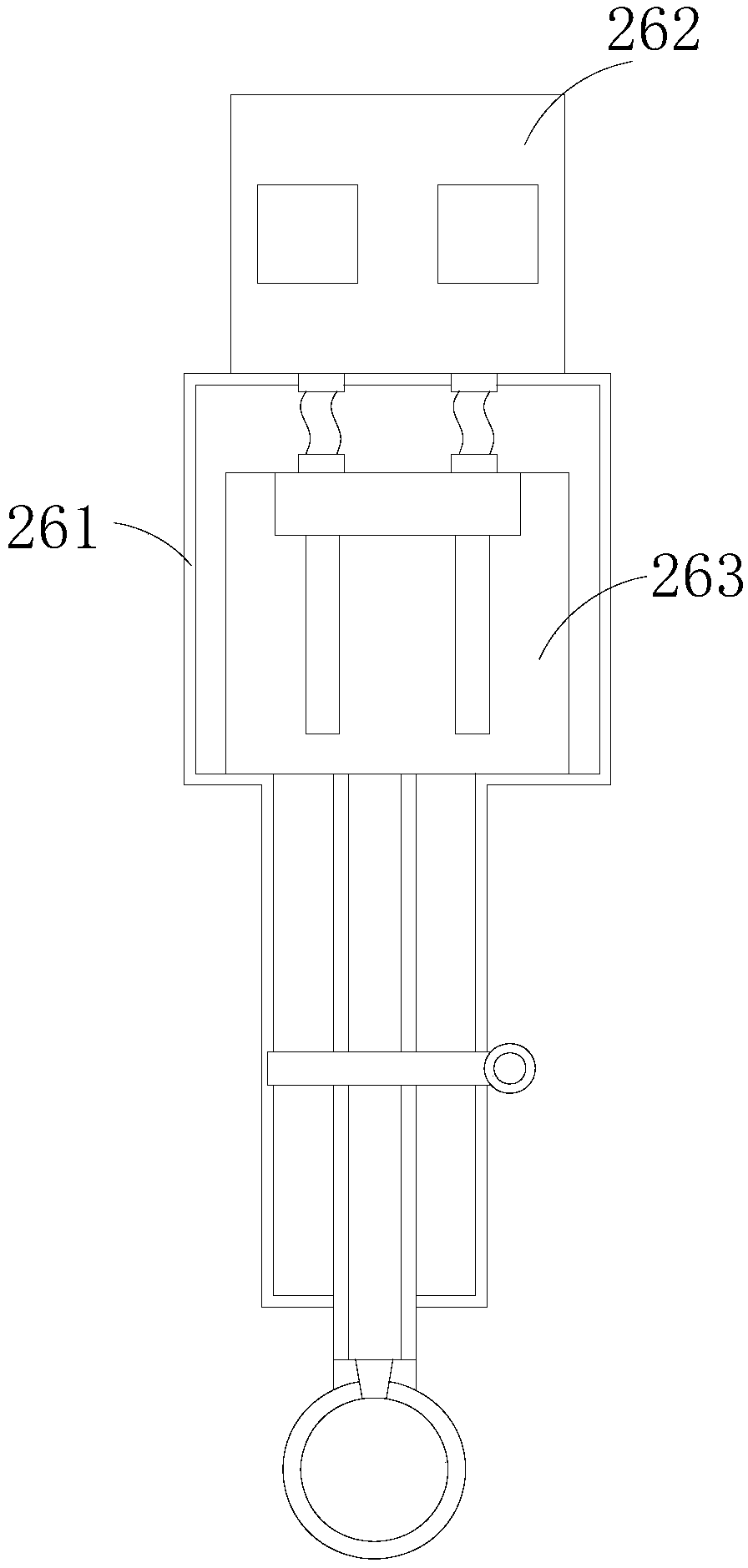

Diesel engine exhaust manifold corrugated pipe welding device

ActiveCN112207471AAchieve circular weldingAutomated batch productionWelding/cutting auxillary devicesAuxillary welding devicesElectric machineryPipe welding

Owner:苏州市环宇汽车配件有限公司

PCB tin soldering equipment and PCB machining technology

ActiveCN113290296AInhibit sheddingAvoid burnsPrinted circuit assemblingMetal working apparatusAir volumeElectric machine

The invention relates to the technical field of circuit board tin soldering equipment, and discloses PCB tin soldering equipment and a PCB machining technology. A hot melting gun is aligned with a circuit board to extrude a hot melt adhesive, a sliding hemisphere is in contact with the circuit board, an extrusion spring generates elastic deformation, a top ring is pressed to move towards a fixed bottom ring, the skin of a user can be prevented from being scalded when the hot melt adhesive is pressed, a driving motor is started, the output end of the driving motor drives an input shaft to rotate through a coupler, the input shaft enables a fan to rotate, the fan rotates at a high speed to generate certain air volume, air is blown into a cooling box through a cooling pipe and is blown to the circuit board through rectangular air outlet holes, a bonding pad can be cooled, the phenomenon that the bonding pad falls off caused by thermal expansion and cold contraction due to the fact that a metal plate of the bonding pad generates large temperature difference is avoided, the circuit board can slide in an operation table through the arrangement of multiple balls, and therefore the circuit board can be conveniently taken out of the operation table, and time and labor are saved.

Owner:浙江航都科技有限公司

Fillet weld positioning method based on point cloud geometric features

ActiveCN113177983AReduce dependenceReduce manual interventionImage enhancementImage analysisFillet weldPoint cloud

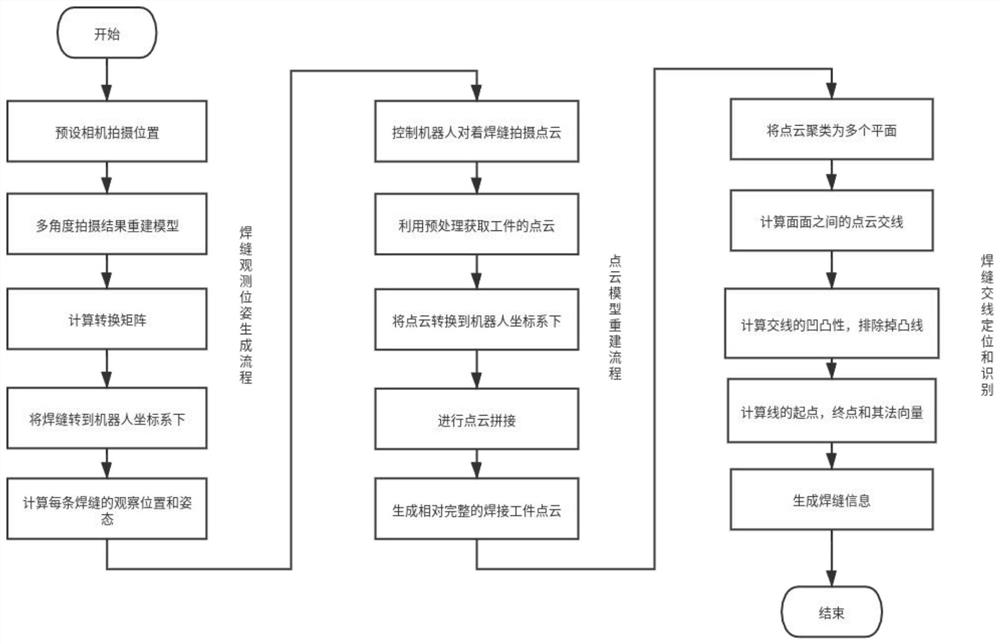

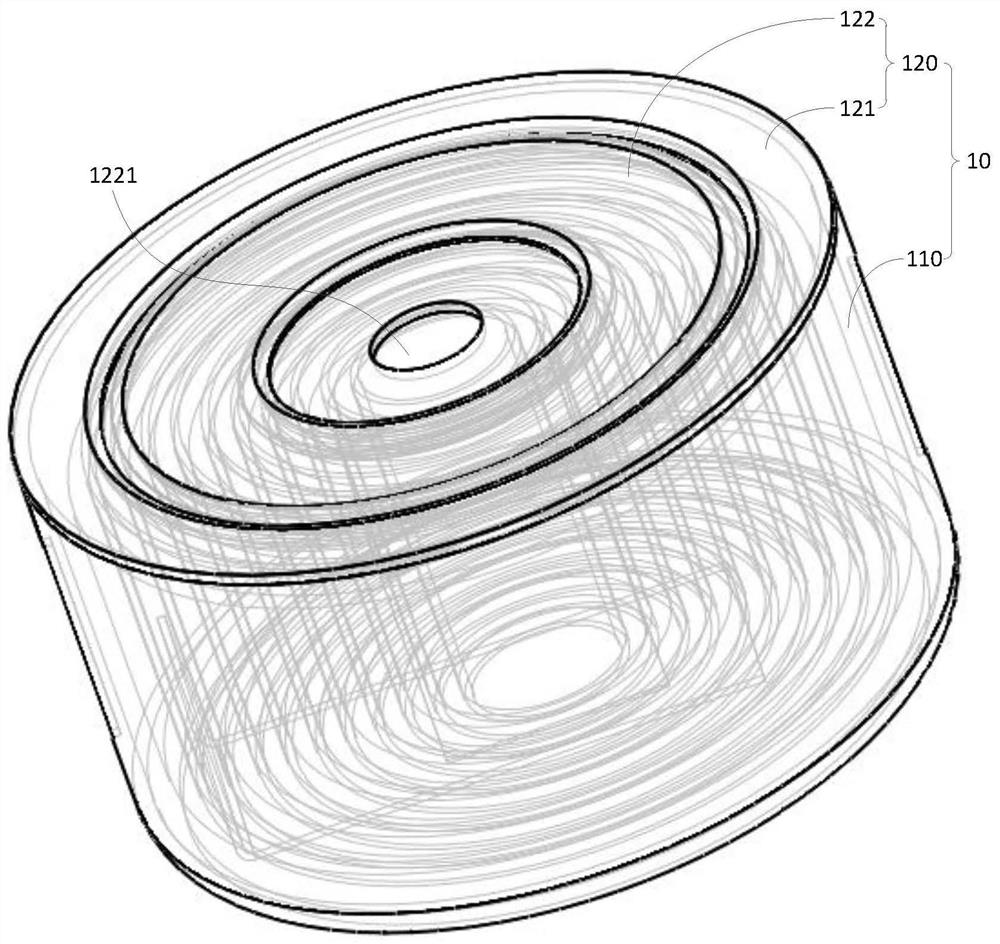

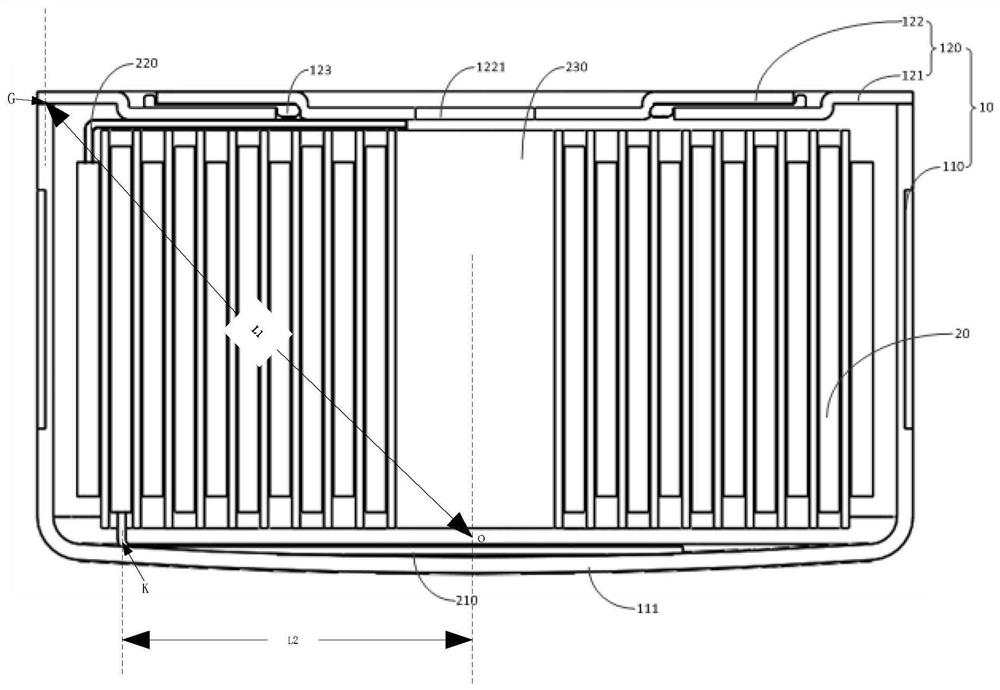

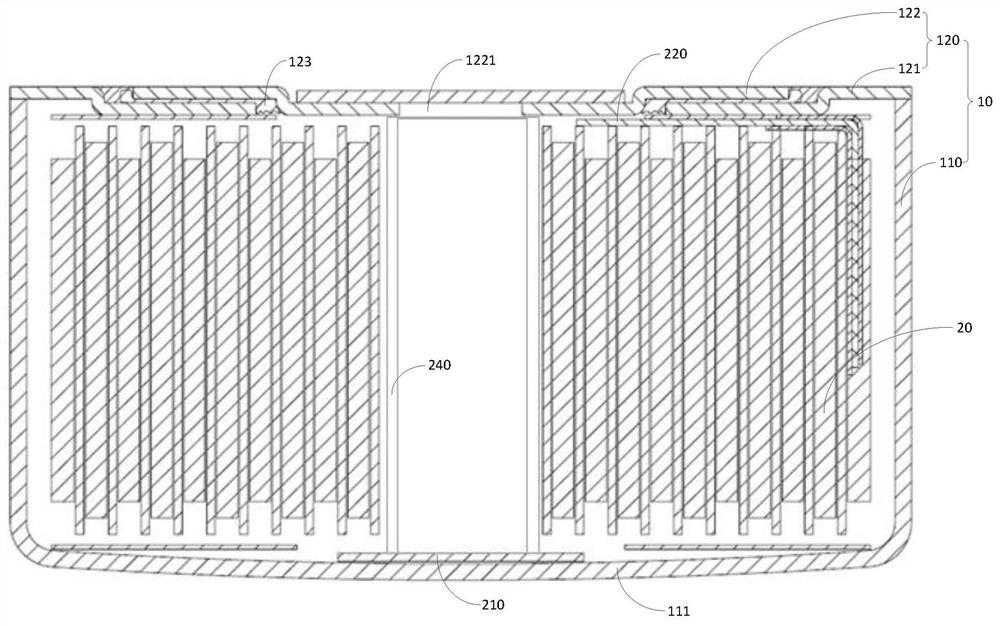

The invention relates to the field of welding automation, in particular to a fillet weld positioning method based on point cloud geometric features, which comprises the following specific steps: S1, presetting the initial position of camera shooting; S2, adopting a multi-angle shooting result reconstruction model; S3, calculating a conversion matrix; S4, transferring to a robot coordinate system; S5, calculating the observation position and posture of each welding seam; S6, controlling the robot to move to the corresponding pose to shoot the point cloud; S7, obtaining the point cloud of the workpiece through preprocessing; S8, converting the point cloud into a robot coordinate system; S9, carrying out point cloud splicing; S10, generating a welding workpiece point cloud; S11, segmenting the point cloud cluster into a plurality of planes; S12, calculating a point cloud intersection line between faces; S13, calculating concavity and convexity of intersecting lines, and eliminating concave lines; S14, calculating a starting point, a key point and a normal vector of the line; and S15, generating and executing final welding seam information by the robot, and fusing point clouds of all the positions into a relatively complete workpiece point cloud model.

Owner:EFORT INTELLIGENT EQUIP CO LTD +1

Button cell and preparation method thereof

PendingCN113437410APlay a protective effectAvoid accidental injuryFinal product manufactureWound/folded electrode electrodesButton batteryBattery cell

The invention provides a button cell and a preparation method thereof. The button cell comprises a shell and a roll core; the shell comprises a shell body and a top cover assembly, and the shell body and the top cover assembly jointly define a containing cavity used for containing the roll core; the roll core comprises a first tab and a second tab, the first tab is in welded connection with the bottom wall of the shell body, and the second tab is connected with the top cover; the top cover is provided with a liquid injection hole, and the liquid injection hole is at least partially overlapped with the cavity of the roll core; and the welding marks of the first tab and the bottom wall are positioned in the overlapped part of the bottom wall, the cavity and the liquid injection hole. According to the invention, the quality and performance of the button cell can meet the requirements, and the yield of the button cell can be improved.

Owner:ZHUHAI COSMX BATTERY CO LTD

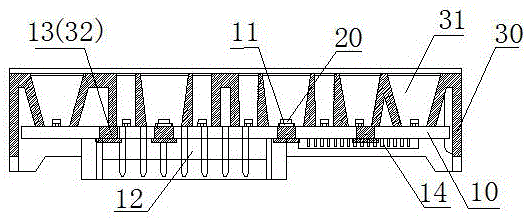

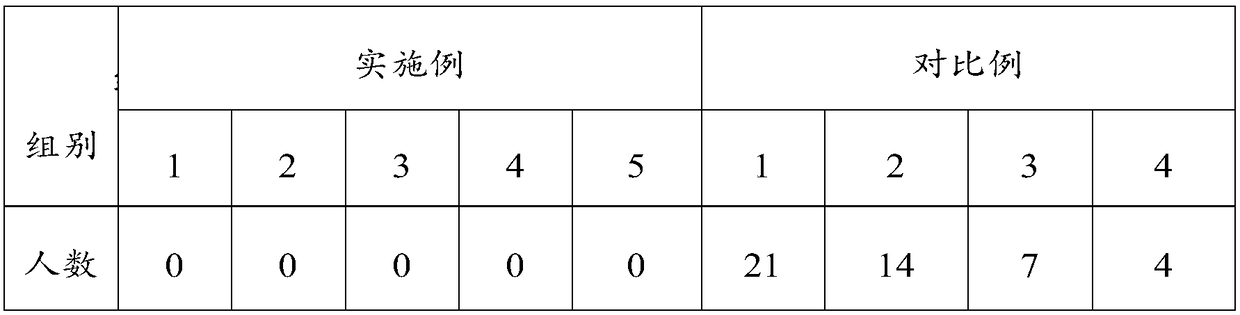

Electromagnetic pulse welding equipment for electronic packaging and welding method thereof

PendingCN114682898AWill not deformImprove welding qualityNon-electric welding apparatusElectromagnetic pulseMagnetic pulse welding

The invention discloses electromagnetic pulse welding equipment for electronic packaging and a welding method of the electromagnetic pulse welding equipment, welding spots on the back of a PCB (printed circuit board) are welded at a time through the electromagnetic pulse welding equipment, hot melting welding in an electronic packaging welding technology is replaced, the PCB does not generate a large amount of heat in the electromagnetic pulse welding process, the PCB does not deform, and the welding quality of the PCB is improved. The welding quality of PCB welding spots is improved, in the actual machine welding process, the PCBs only need to be placed in the mounting grooves to be fixed, the PCBs are automatically conveyed to the welding station and the taking station through the conveying belt, the PCBs at the welding station are automatically welded through the electromagnetic pulse welding device, the welding efficiency is greatly improved, and the welding efficiency is improved. And the welded PCBs on the taking station are unloaded and transferred by the taking device, so that the whole welding process is quick and convenient, manpower is saved, and the welding working efficiency is high.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

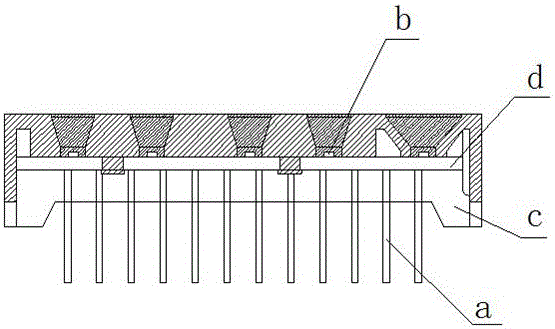

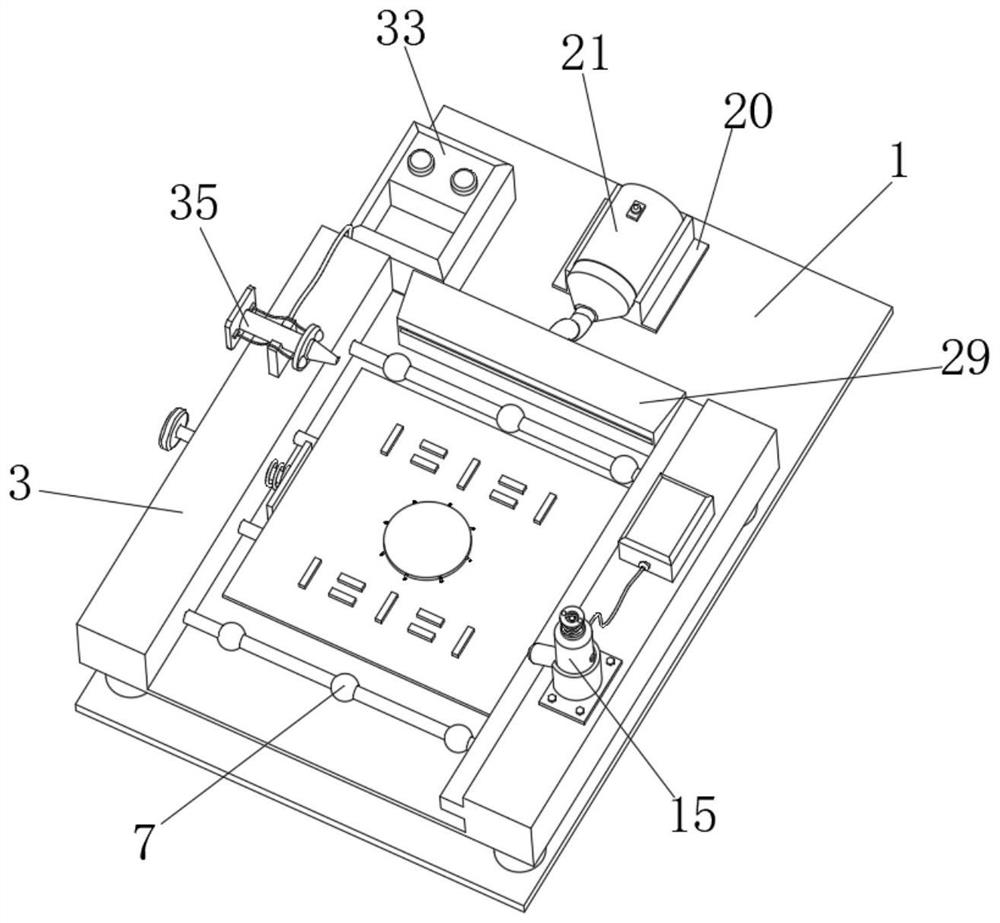

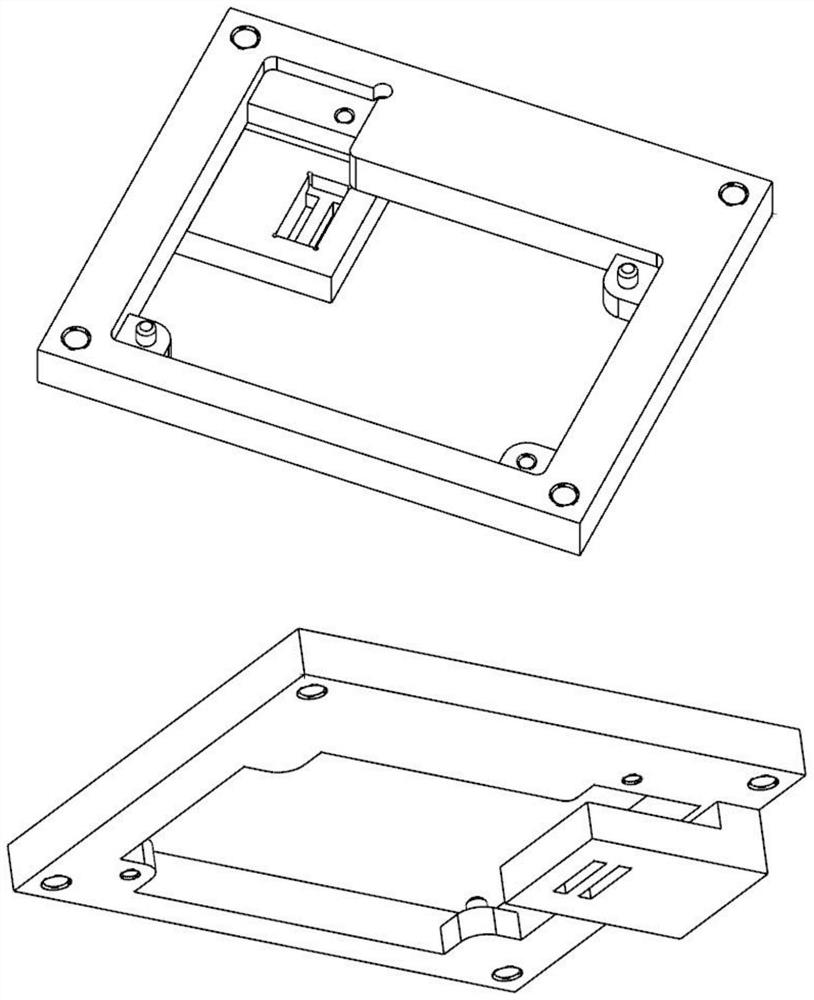

Tooling jig facilitating welding of circuit board

ActiveCN109434238AThe welding process is convenientEasy to fixWelding/cutting auxillary devicesAuxillary welding devicesActivated carbonEngineering

The invention discloses a tooling jig facilitating welding of a circuit board. The tooling jig comprises a base, a support cylinder, a slide block, a support column, a gas pipe, a valve, an air cylinder, an cylinder arm, a placement shell, a placement plate, an air pump, a connecting pipe, a calibration line, a purification shell, an activated carbon granular layer, a filter screen, a through hole, a water layer, a drainage pipe, a drainage valve, a water injection pipe, a fixing plate, a T-shaped block, a limit block, and a thread groove, a screw rod, a rotating handle, a clamping plate, a rotating column and a pointer. An injection mould with material flow speed easy to control is simple in structure, and can easily stably fix the circuit board, so that the fixing effect of the circuit board is improved; at the same time, it is easy for workers to perform the process of welding the surface of the circuit board, so that the rejection rate of the circuit board welding is reduced, and the injection mould is convenient for the workers to carry out welding operation; and the placement height of the placement plate is convenient to adjust under the action of the air cylinder arm drivenby the air cylinder, so that the injection mould is convenient to weld for the workers with the heights of different requirements, and is convenient to use.

Owner:LIAONING TECHNICAL UNIVERSITY

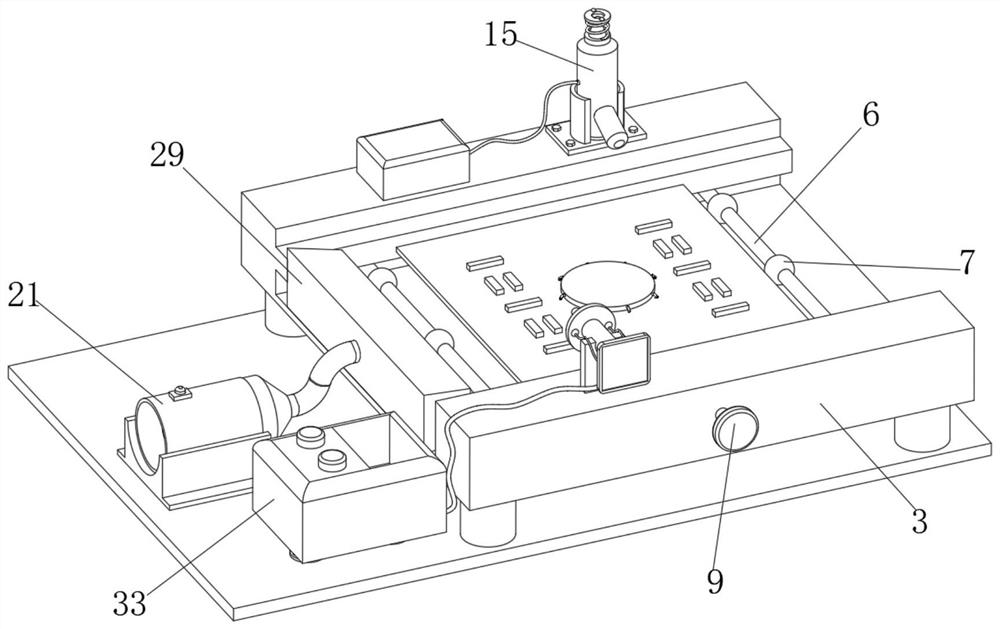

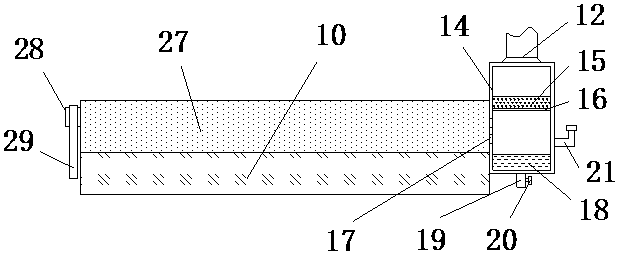

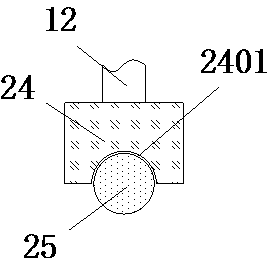

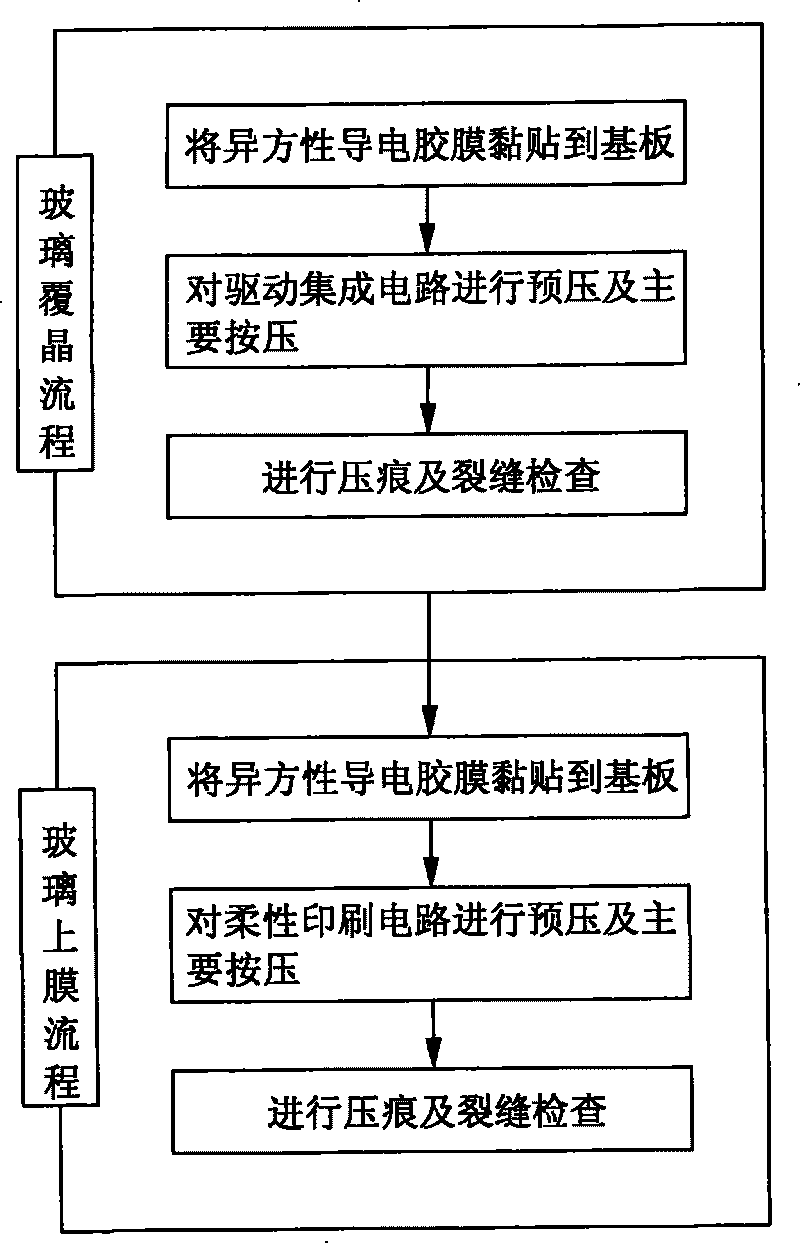

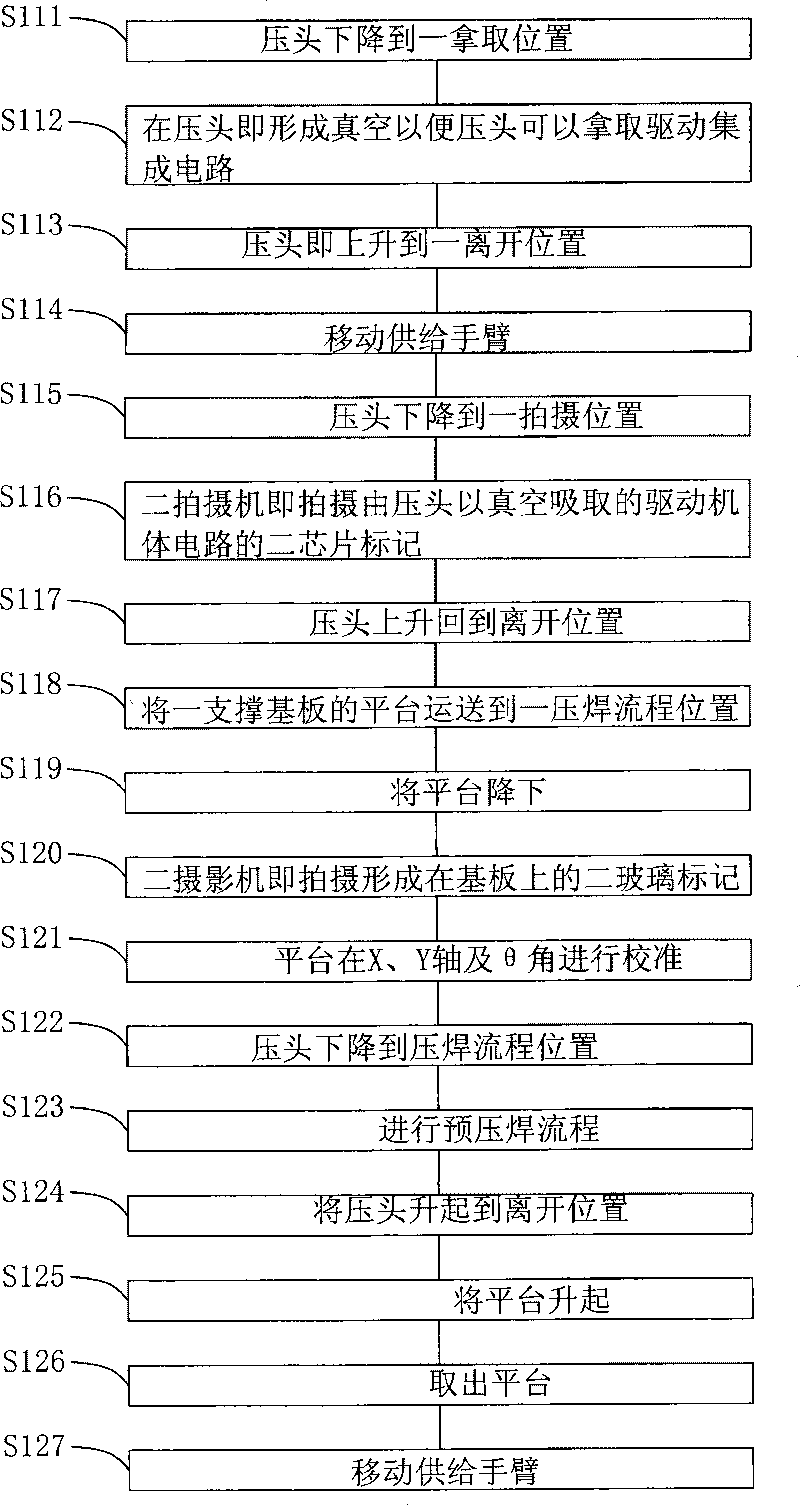

Apparatus and method for press welding printed circuit to flat display panel

InactiveCN101308274BStable supportAvoid damageSolid-state devicesNon-linear opticsDisplay deviceEngineering

A device for pressure-welding a printing circuit comprising a platform with a supporting surface; the supporting surface is a supporting substrate moving and picking up the substrate to a pressure-welding procedure position; the printing circuit is a pressure-welding substrate; a pressing head provided on the pressure-welding procedure position which can be raised absorbing the printing circuit and being pressure-welded to the substrate opposite to the printing circuit absorbed by the substrate; a device for obtaining the checking video information; at least a chip mark forming on the printing circuit for simultaneous shooting on at least one glass mark on the substrate to obtain the checking video information; thereby, the printing circuit is pressure-welded to the substrate by a simple and convenient method, and processing time of the pressure-welding procedure is shortened to achieve the high-speed pressure-welding procedure.

Owner:SFA ENG CORP

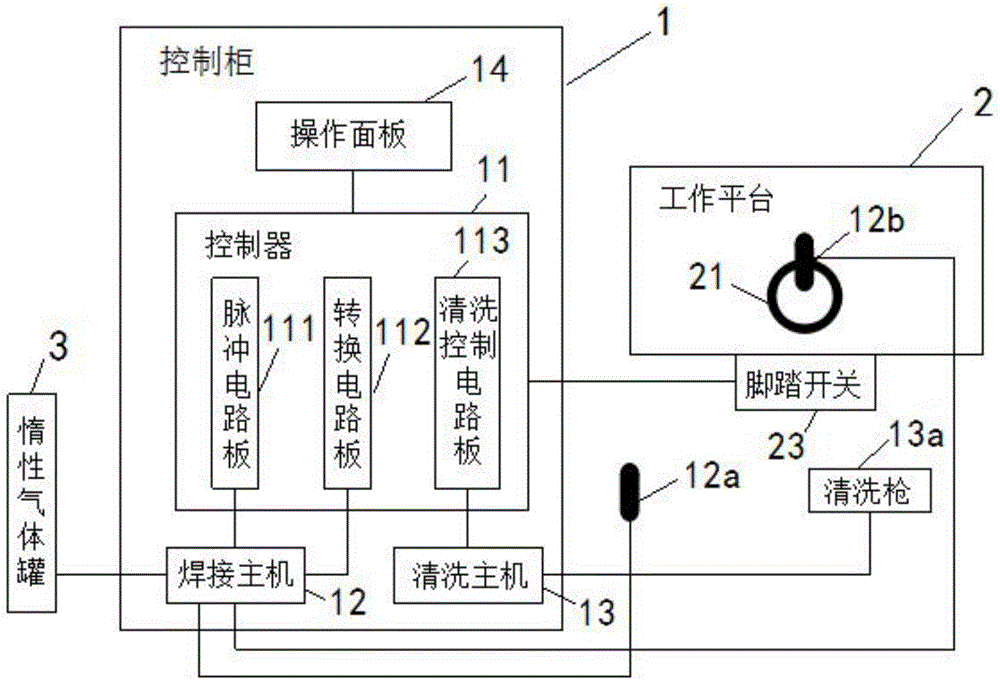

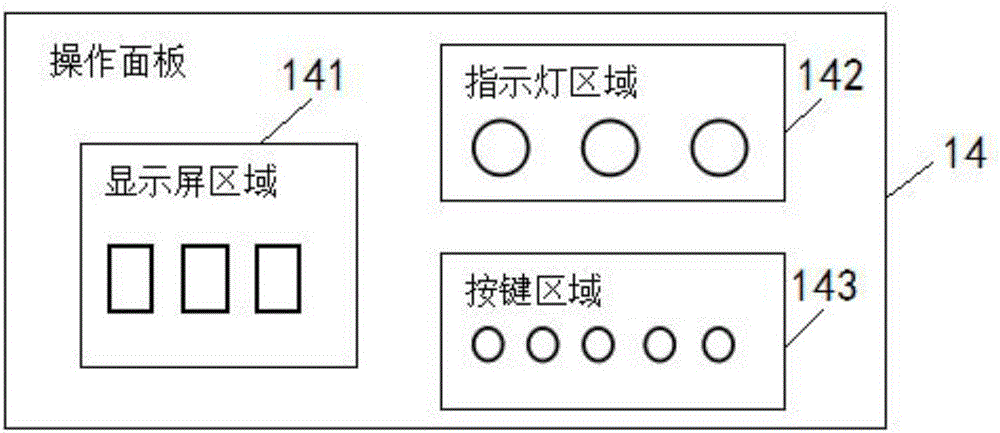

Semi-automatic spot welding machine

ActiveCN105689845APrecise positioningHigh speedWeld torches cleaningElectrode holder supportersEngineeringMechanical engineering

The invention discloses a semi-automatic spot welding machine. The semi-automatic spot welding machine comprises a control cabinet and a work platform. A controller, a welding host and a cleaning host are arranged in the control cabinet, and the controller is used for controlling the welding host and the cleaning host to work. The welding host is connected with a movable weld gun and a fixed weld gun. The work platform is provided with a bonding pad capable of rotating. A body of the fixed weld gun is fixedly arranged below the bonding pad, a gun head stretches out of the bonding pad, and the gun head can be adjusted in the up-down direction, the front-back direction and the left-right direction. A positioning needle is arranged on the work platform and used for limiting the welding range. The cleaning host is connected with a cleaning gun and used for cleaning welding spots. A pedal switch is arranged at the bottom of the work platform and is capable of controlling the welding host to start or stop working. The work of the spot welding machine is controlled through the pedal switch, the welding speed is increased, and the welding efficiency is improved. In cooperation with a control function of the controller, people with or without welding experience can rapidly know how to operate the semi-automatic spot welding machine, meanwhile, the cleaning function is achieved, and the welding effect can be improved.

Owner:朱攀高

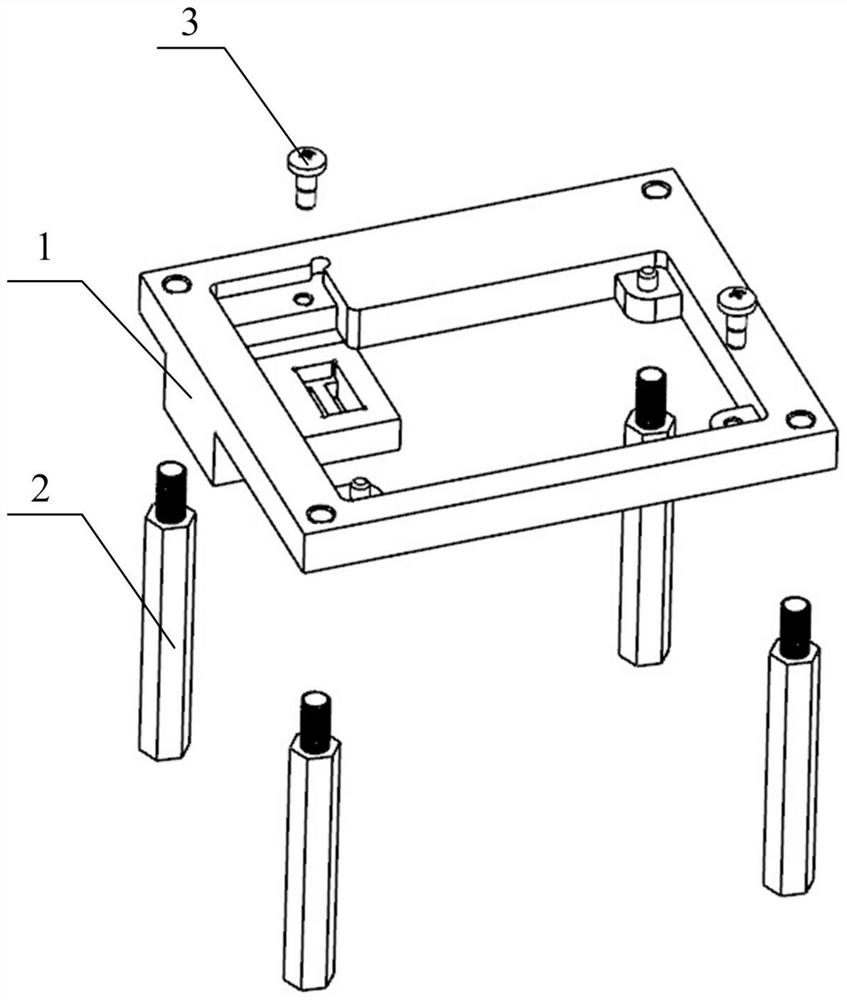

Positioning and fixing tool and method for welding fuzz button connector to printed board

PendingCN113953743AHigh positioning accuracyGet rid of dependenceWelding/cutting auxillary devicesAuxillary welding devicesEngineeringScrew thread

The invention relates to a positioning and fixing tool and method for welding a fuzz button connector to a printed board, and belongs to the technical field of printed board assembly. The positioning and fixing tool is composed of a fixing frame, a hexagonal stud and a screw. The special welding positioning and fixing tool is positioned by utilizing a thread penetrating hole in the printed board, and positioning of a fuzz button device in three directions of X, Y and Z during welding is realized by limiting the relative position between the elastic pin inserting end of the fuzz button and the printed board. According to the welding positioning and fixing method, the positioning of the fuzz button by means of manual experience in the welding process of the fuzz button is converted into the positioning through the tool, so that the positioning precision of the fuzz button during welding is improved, and the dependence on the manual experience is avoided.

Owner:CNGC INST NO 206 OF CHINA ARMS IND GRP

Wide gap welding method and welding part

InactiveCN108907418AHigh strengthNo crackArc welding apparatusWelding/cutting media/materialsReduction rateGas metal arc welding

The invention relates to the technical field of welding, and provides a wide gap welding method. The method is used for welding of a gap with the welding width ranging from 5 mm to 9 mm, and the method comprises the steps that a gasket plate with the material the same with that of a part to be welded is additionally welded to the middle of a groove, and the part to be welded is preheated to 210 to230 DEG C; when the temperature of the part to be welded reaches 210 to 230 DEG C, welding is carried out, in the welding process, the part to be welded is subject to heat preservation, the part to be welded is kept at 210 to 230 DEG C, gas metal arc welding is adopted to carry out welding on the two sides of the gasket plate in sequence; after welding is finished, cooling is carried out, when the temperature reduction rate of the welding line is controlled to range from 230 to 500 DEG C / h, in the cooling process, and the welding part is still subject to heat preservation; when the temperature of the welding line is reduced to 210 to 230 DEG C, heat preservation is stopped, and the whole cooling rate of the welding part is controlled to range from 50 to 80 DEG C / h. The welding part obtained through the welding of the method is free of crack and is high in strength. The invention further provides the welding part. The welding part is obtained through the wide gap welding method.

Owner:四川汇源钢建装配建筑有限公司

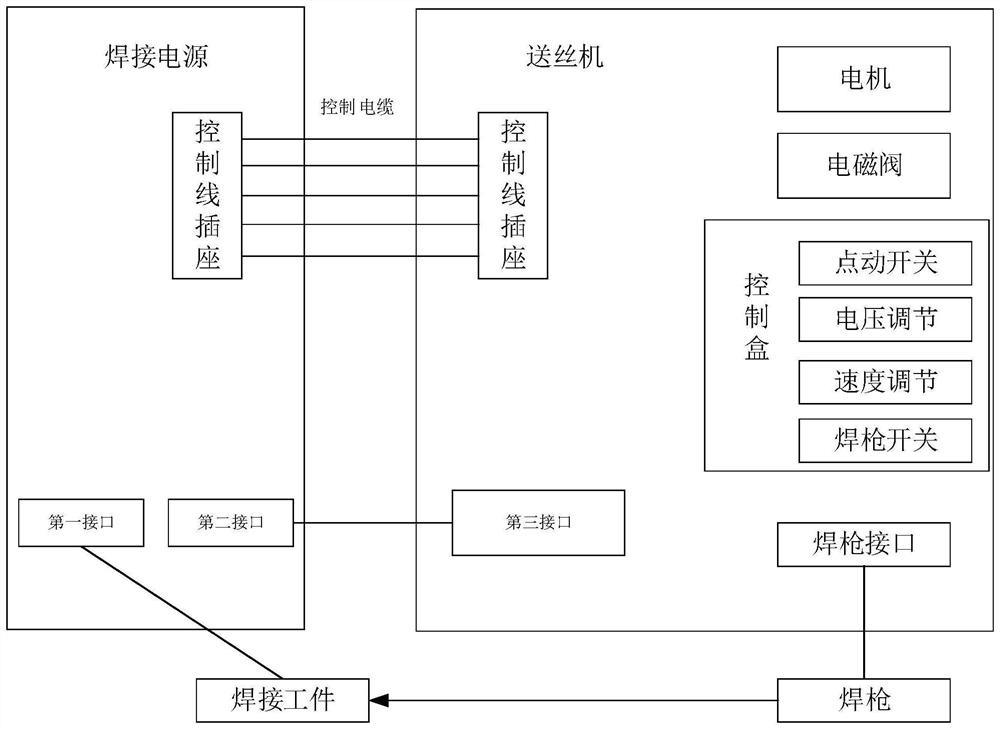

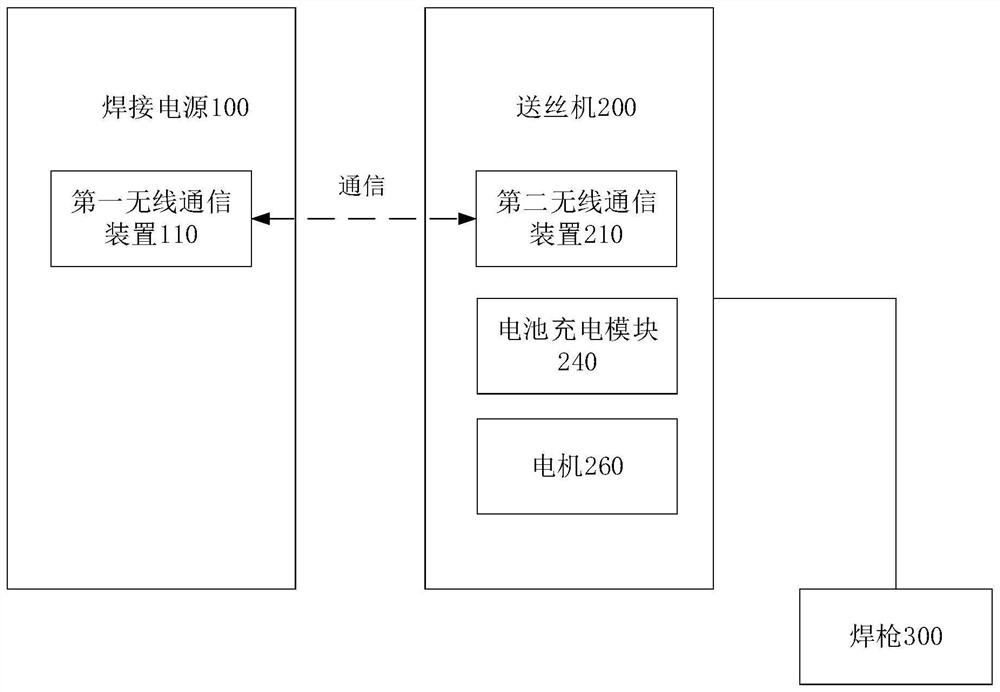

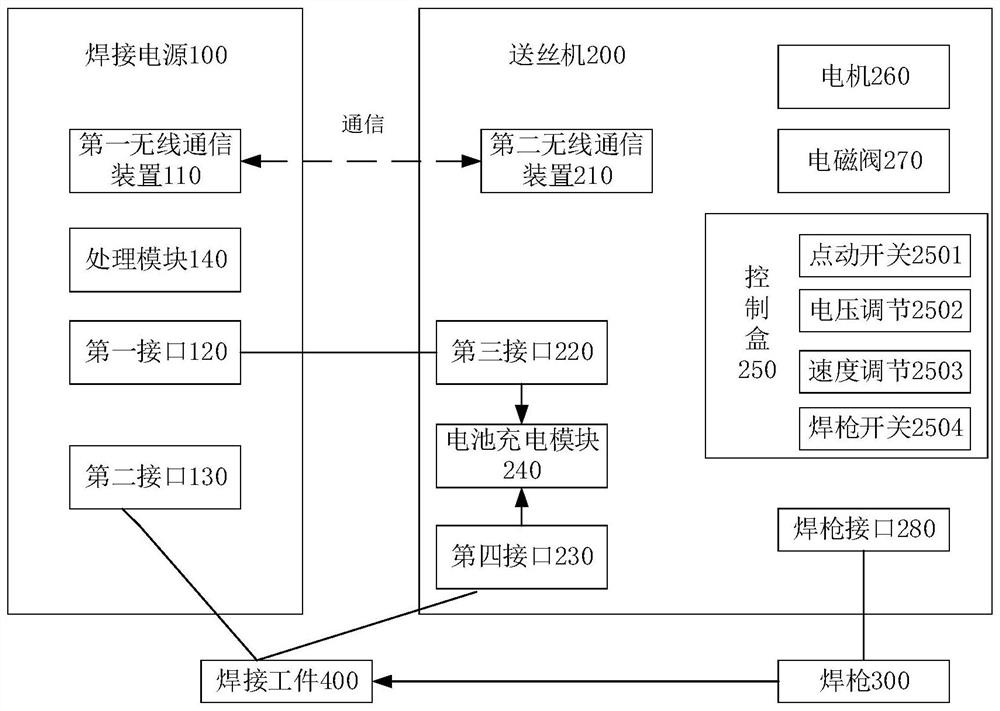

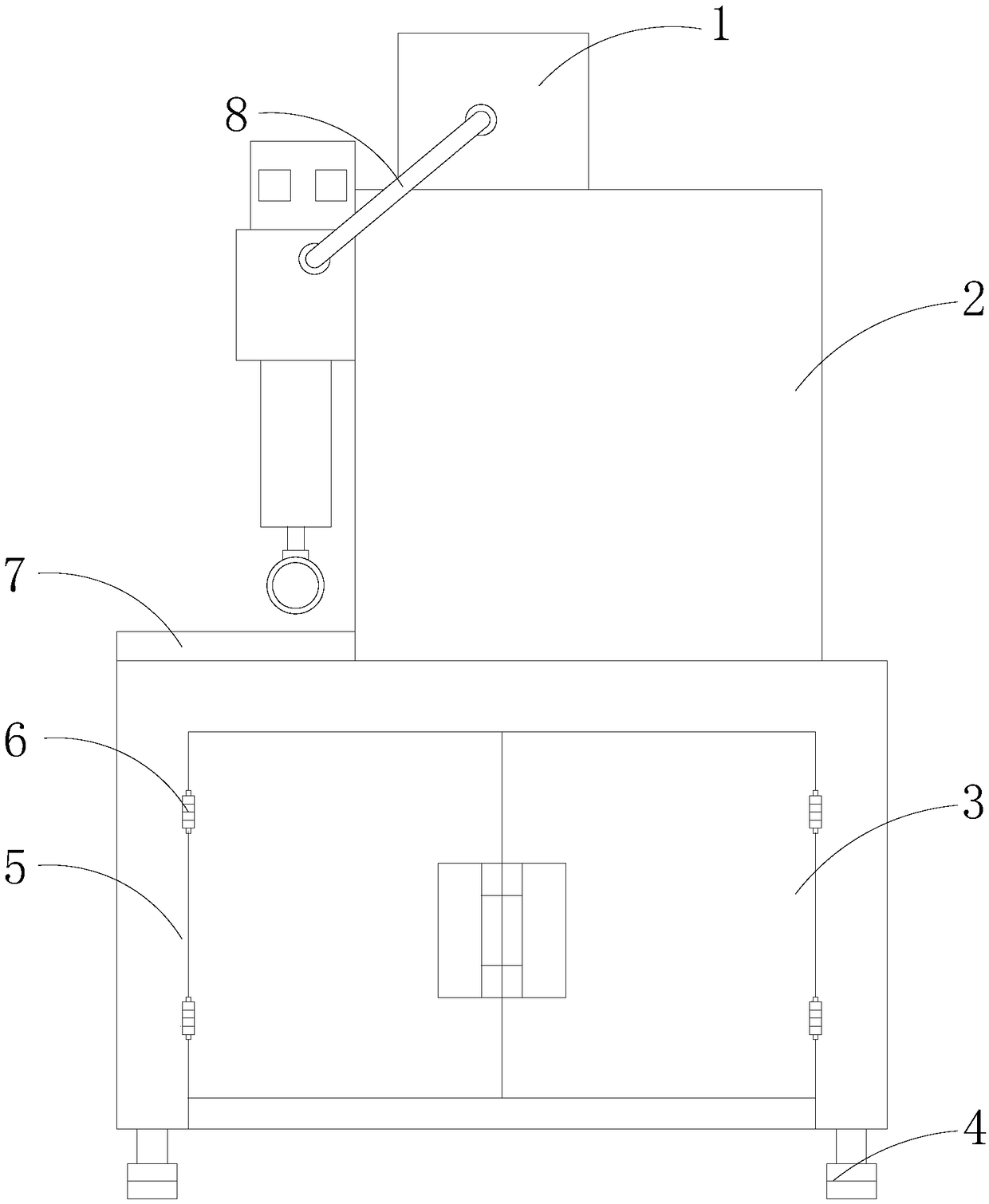

Welding system, welding power source and wire feeder

PendingCN114012198AThe welding process is convenientEasy welding processMetal working apparatusSolder feeding devicesBattery chargeControl signal

The invention provides a welding system. The welding system comprises a welding power source and a wire feeder; the welding power source comprises a first wireless communication module; the wire feeder comprises a second wireless communication device, a motor and a battery charging module; the battery charging module is used for supplying power to the second wireless communication device and the motor; and the welding power source communicates with the wire feeder through the first wireless communication device and the second wireless communication device. According to the welding system, signal transmission is carried out in a wireless communication mode, meanwhile, a charging device is arranged in the wire feeder, a traditional control cable is replaced to control signal transmission and power supply of the wire feeder, various problems caused by the control cable in the welding process are solved, and great convenience is brought to the welding process.

Owner:SHENZHEN JASIC TECH

Welding robot device

InactiveCN108746917AAvoid offsetPrevent false weldingWelding/cutting auxillary devicesAuxillary welding devicesSolderingFiller metal

The invention discloses a welding robot device. The welding robot device structurally comprises a brazing filler metal box, a welding host, a box door, supporting feet, a bottom cabinet, a hinge, a welding base and a connection pipe; the brazing filler metal box is fixedly installed on the upper surface of the welding host; the box door is installed on the surface of the bottom cabinet through thehinge; the four supporting feet are arranged and fixedly installed at the bottom four corners of the bottom cabinet; the upper surface of the bottom cabinet is welded to the lower surface of the welding host; the welding base is welded to the upper surface of the bottom cabinet and located on the left side of the welding host; the upper end of the connection pipe is connected with the brazing filler metal box; the lower end of the connection pipe is connected with the welding host; the position of a welding head mechanism is adjusted through a displacement mechanism, so that the welding process is more convenient and faster; due to the fact that a heating mechanism and a brazing filler metal discharging mechanism are combined into a whole, the operation that a worker carefully aligns thepositions of a welding head and brazing filler metal is reduced, the work efficiency is improved, and meanwhile the pseudo soldering condition is avoided; and after brazing ends, brazed finished products are fast cooled through a cooling mechanism, and it is prevented that welded products fall off or welded positions deform.

Owner:FOSHAN JIELAN ROBOT CO LTD

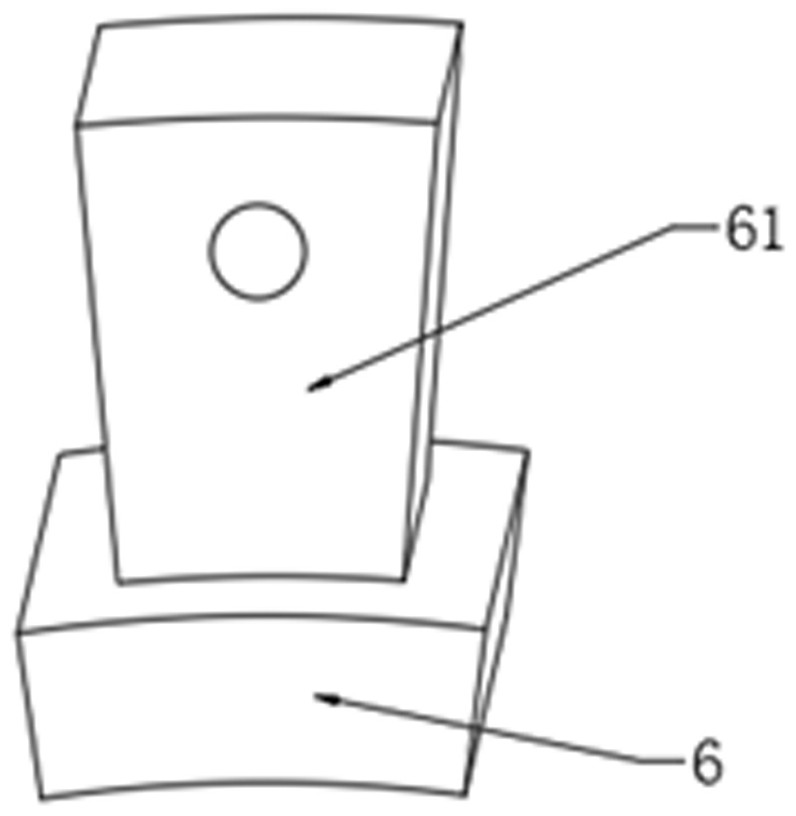

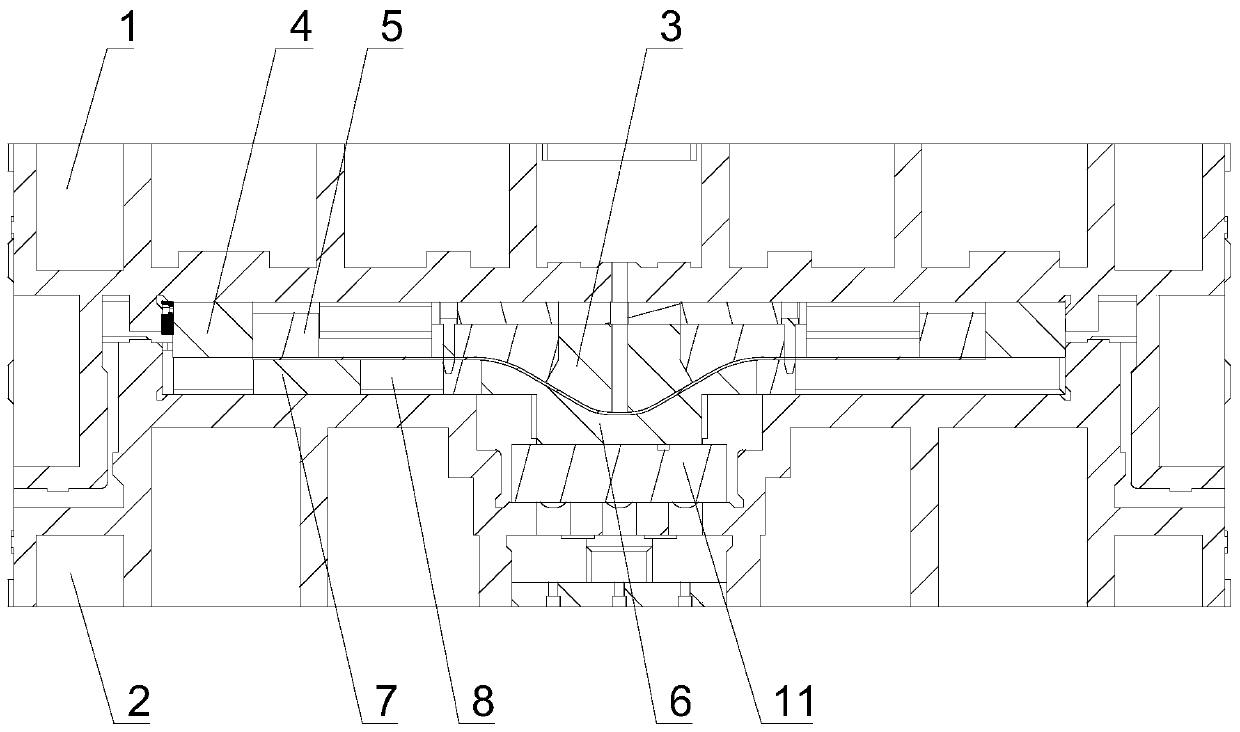

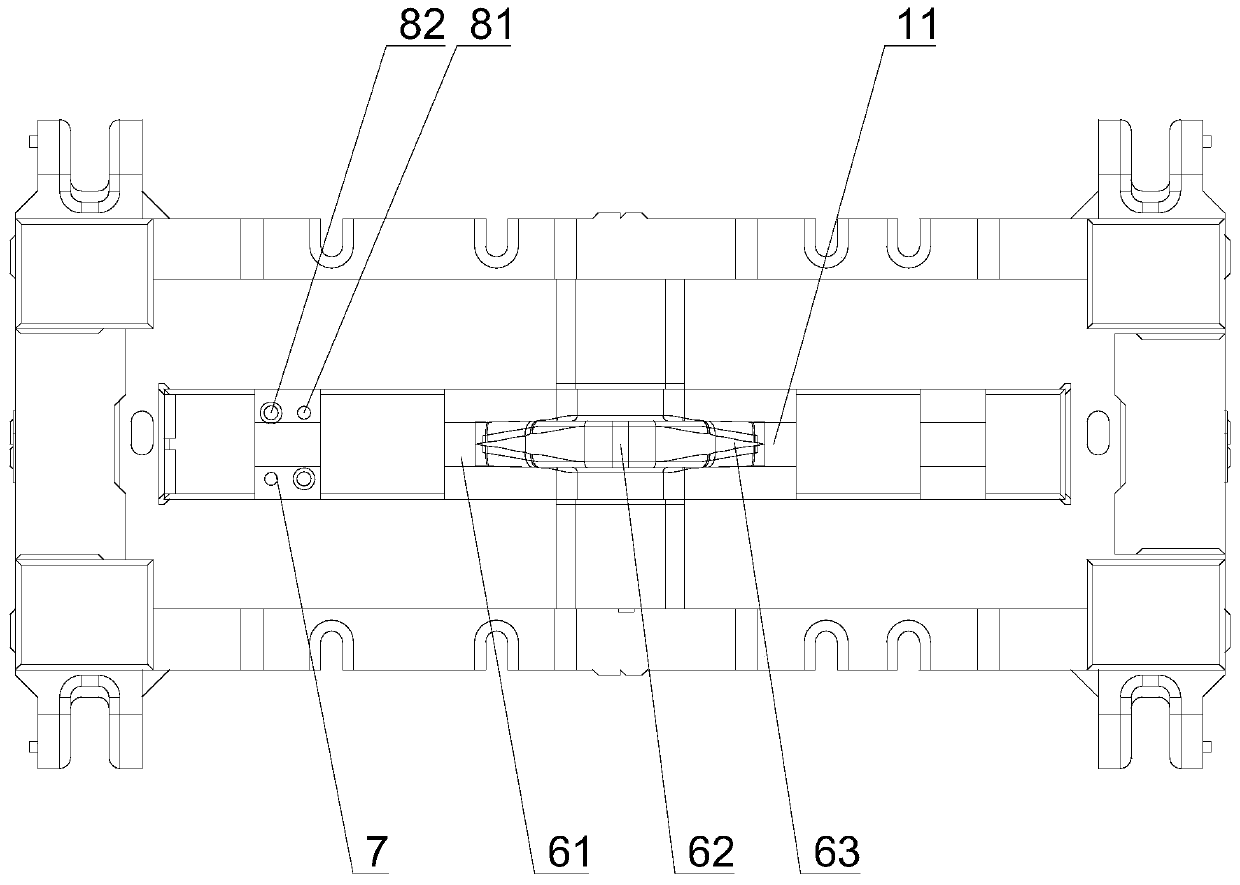

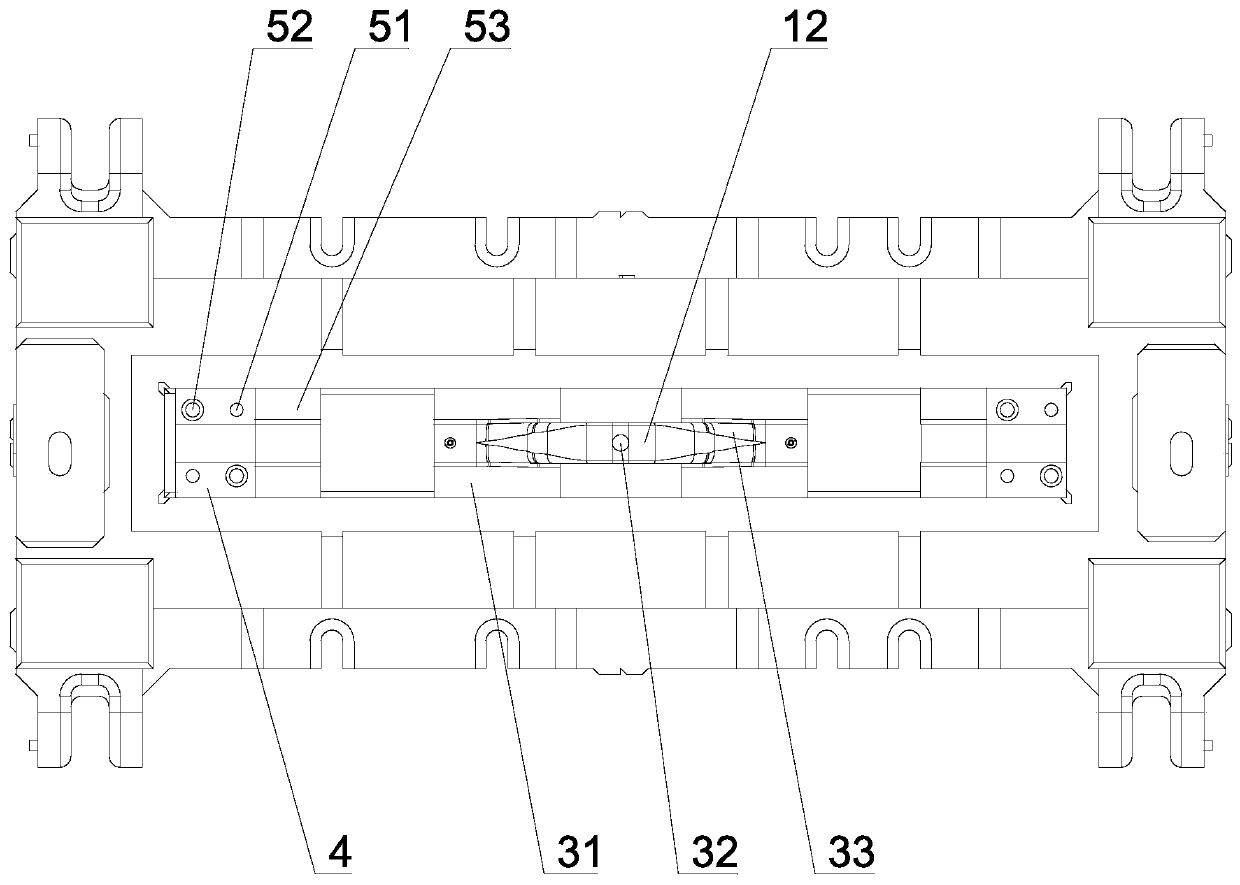

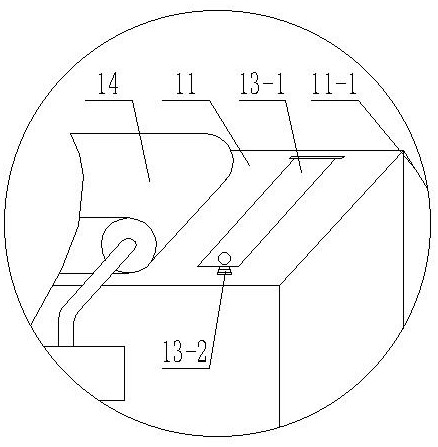

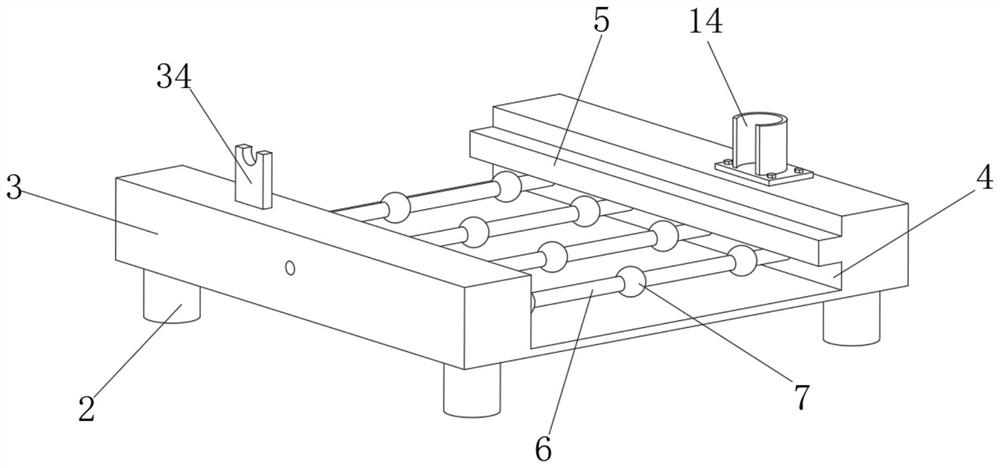

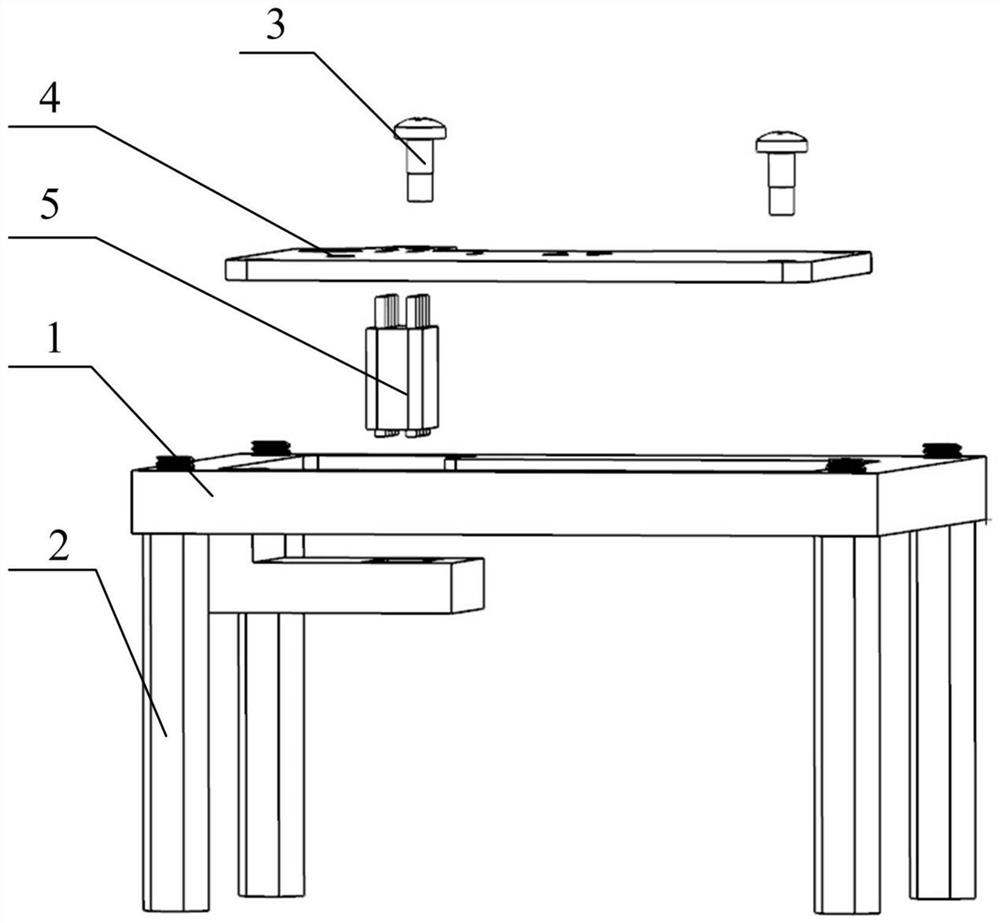

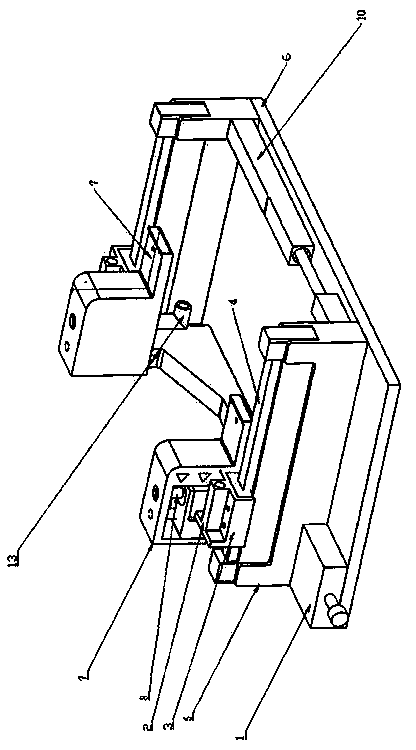

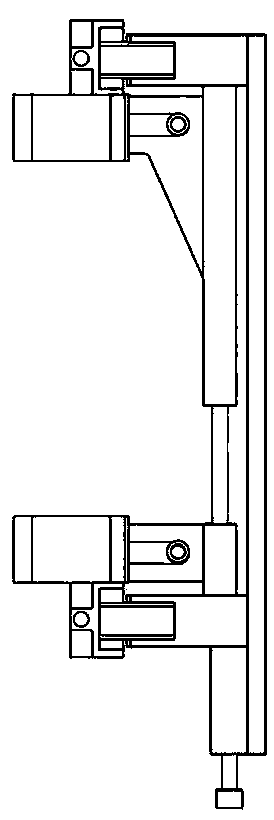

OCT guide pipe welding tool

PendingCN110614472ASolve the urgent needs of productionIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringPipe welding

The invention relates to an OCT guide pipe welding tool which comprises a base (6). The OCT guide pipe welding tool is characterized in that linear guideway fixing seats (5) are arranged at two ends of the base (6); the linear guideway fixing seat (5) at one end is fixed into the base (6); the linear guideway fixing seat (5) at the other end is connected with a displacement platform (1) and can move opposite to the first linear guideway fixing seat (5) under the drive of a displacement platform (1); linear guideways (4) are arranged on the linear guideway fixing seats (5); sliding blocks (3) are arranged on the linear guideways (4); air cylinder fixing seats (2) are arranged on the sliding blocks (3); air cylinders (8) are arranged on the air cylinder fixing seats (2); guide pipe fixture fixing seats (7) are arranged on air cylinder rods of the air cylinders (8); and fixtures for clamping guide pipes (9) are arranged on the guide pipe fixture fixing seats (7). According to the OCT guide pipe welding tool provided by the invention, the urgent production need is met, the production efficiency is favorably improved, and the processing quality is ensured.

Owner:南京沃福曼医疗科技有限公司

Welding method for thickened opaque quartz glass plate

The invention belongs to the technical field of semiconductors, and particularly relates to a welding method for thickened opaque quartz glass plates. A welding method for a thickened opaque quartz glass plate comprises the following steps that S1, the welding end face of first material quartz is ground, and a first groove to be welded is obtained; s2, the second material quartz is ground, the target thickness is achieved, and the welding end face is a plane; s3, a quartz glass piece is fused on the welding end face of the second material quartz, the quartz glass piece is made of the same material as the first material quartz, and another to-be-welded second groove is obtained; and S4, the first groove and the second groove are subjected to filler welding, and a butt welding finished product is obtained. The method is suitable for welding the opaque quartz glass thick plate and the transparent quartz glass, and particularly welding the opaque quartz glass with the thickness of 20 mm or above and even 30 mm or above.

Owner:SHANGHAI USTRON QUARTZ GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com