Apparatus and method for press welding printed circuit to flat display panel

A printed circuit and equipment technology, applied in the direction of circuits, electrical solid devices, instruments, etc., can solve the problems of increased processing time, etc., and achieve the effects of easy bonding process, avoiding damage and cracks, and high-speed bonding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

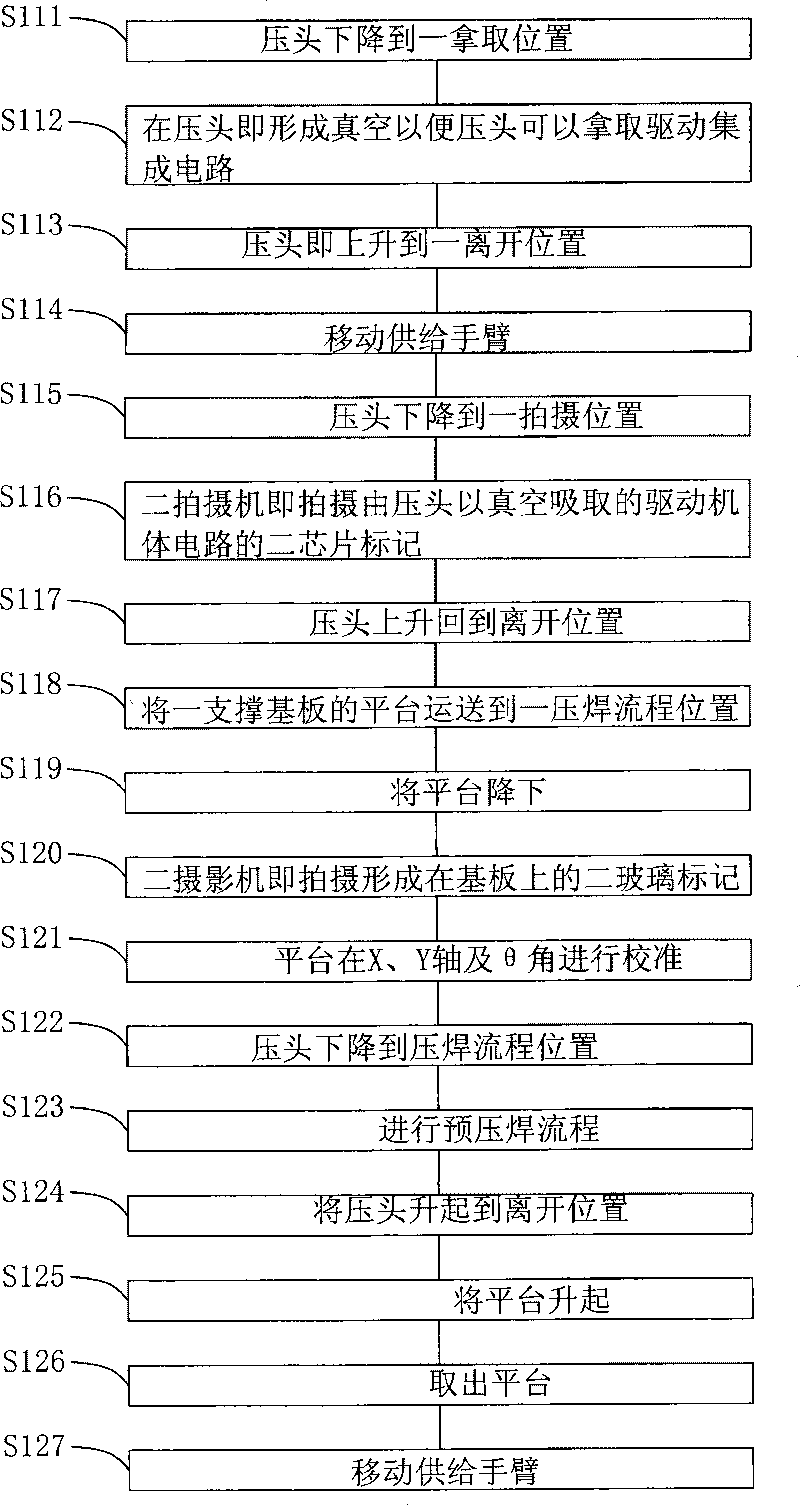

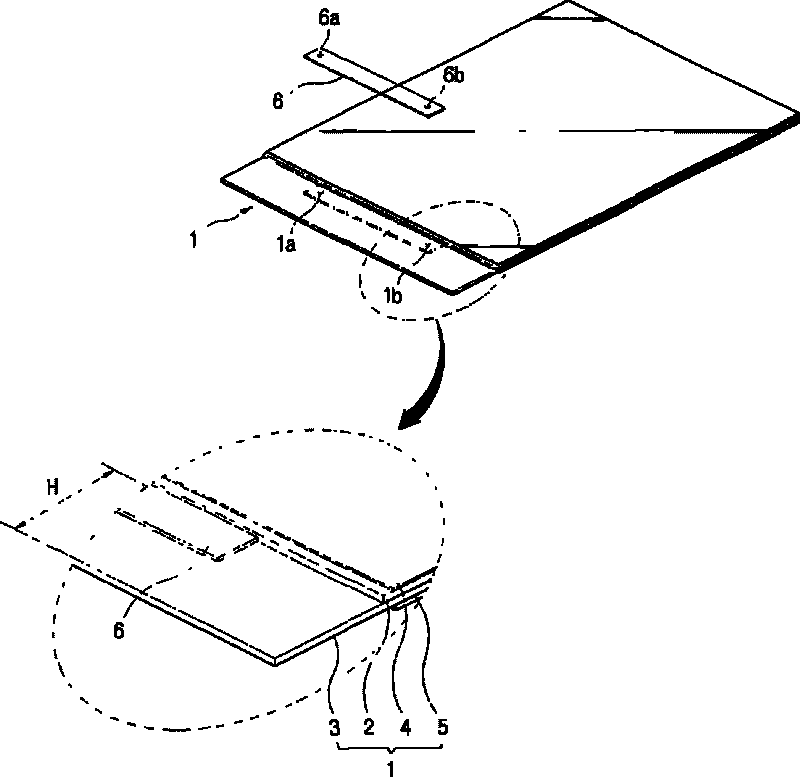

[0055] The present invention is used to illustrate the drawings attached to the preferred embodiments, so that the examiners can better understand the present invention, its advantages, and achieve the purpose of the present invention. In the following description of the present invention, preferred embodiments of the present invention will be described in detail with reference to the accompanying drawings. Wherein, the same element numbers represent the same elements.

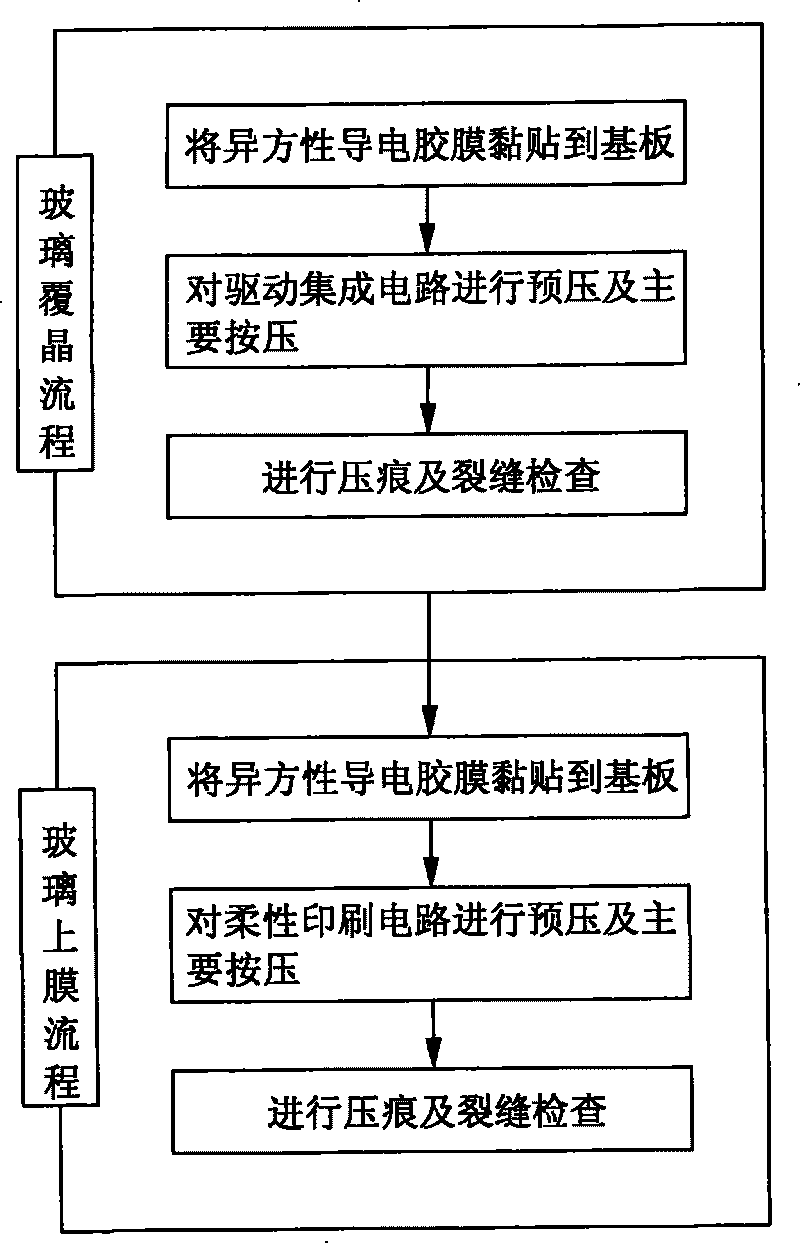

[0056]According to an embodiment of the present invention, an apparatus and method for bonding a printed circuit can be used to bond (pre-bond) a printed circuit to a substrate of a flat panel display (FPD), such as a flexible Printed circuit (FPC), tape and reel chip carrier package (TCP), general batch flexible circuit board (CBF) and driver IC (driver IC), and flat panel display is such as plasma display panel (PDP), liquid crystal display (LCD) and Organic Light Emitting Diodes (OLED). For the convenienc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com