Button cell and preparation method thereof

A button battery and equipment technology, applied in the field of button battery and its preparation, can solve the problems of easy accidental damage to the winding core, unqualified quality and performance of the button battery, and reduce the yield rate of the button battery, so as to achieve the goal of improving the yield rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

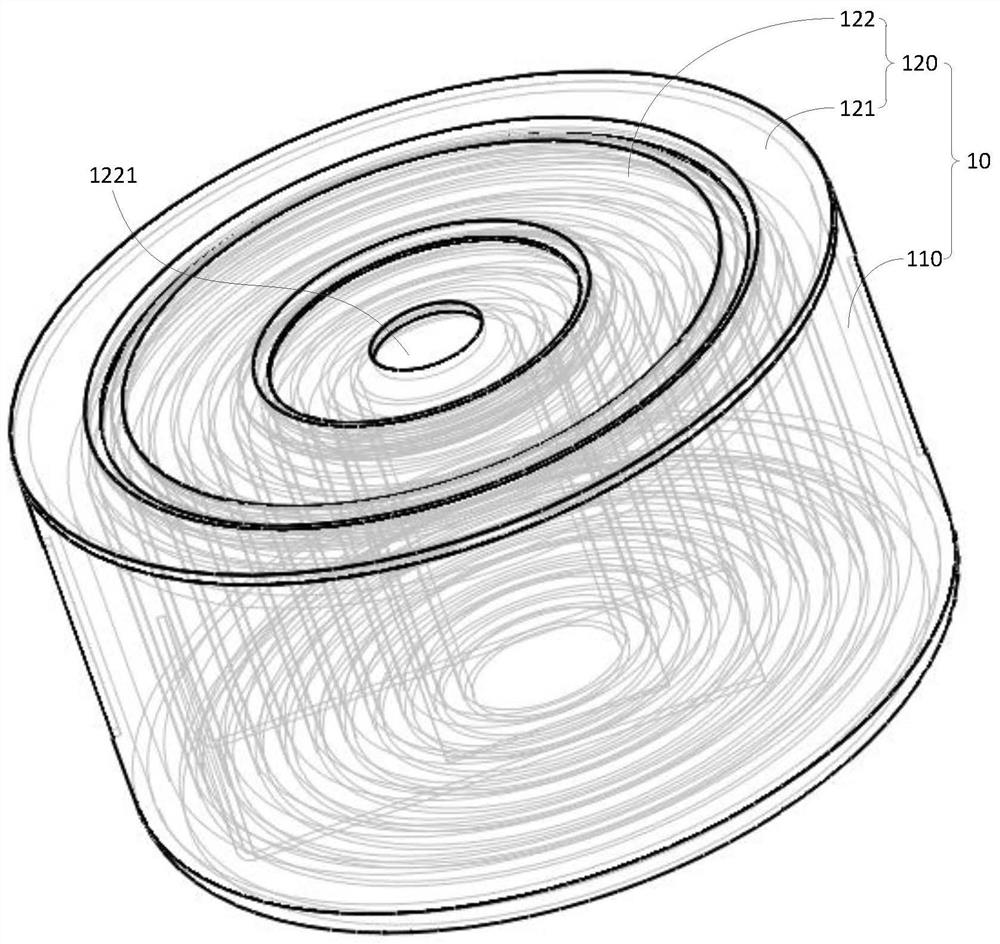

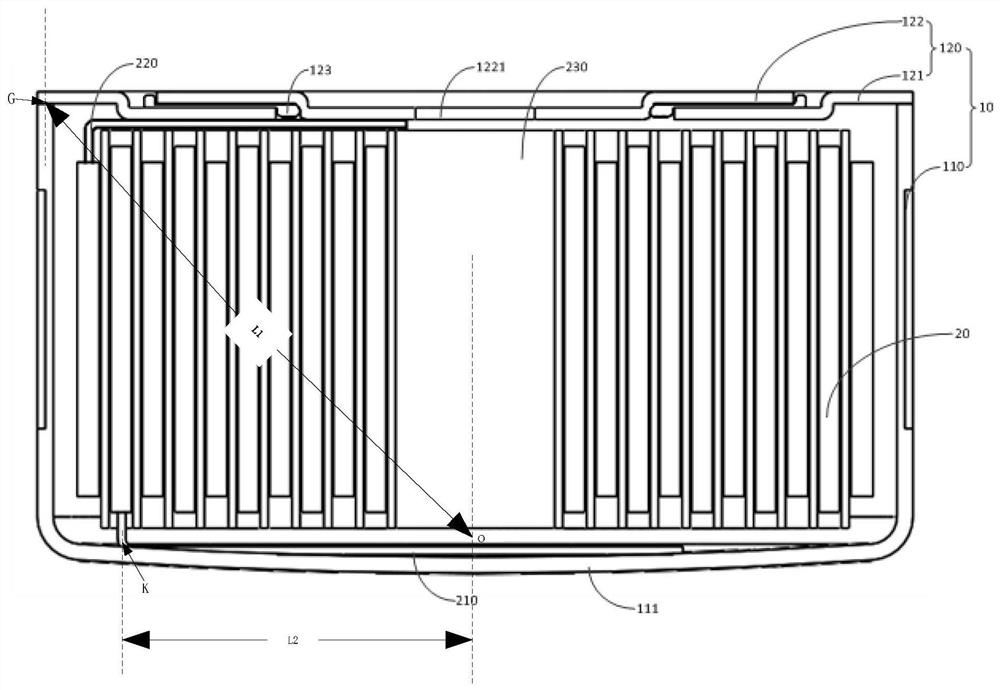

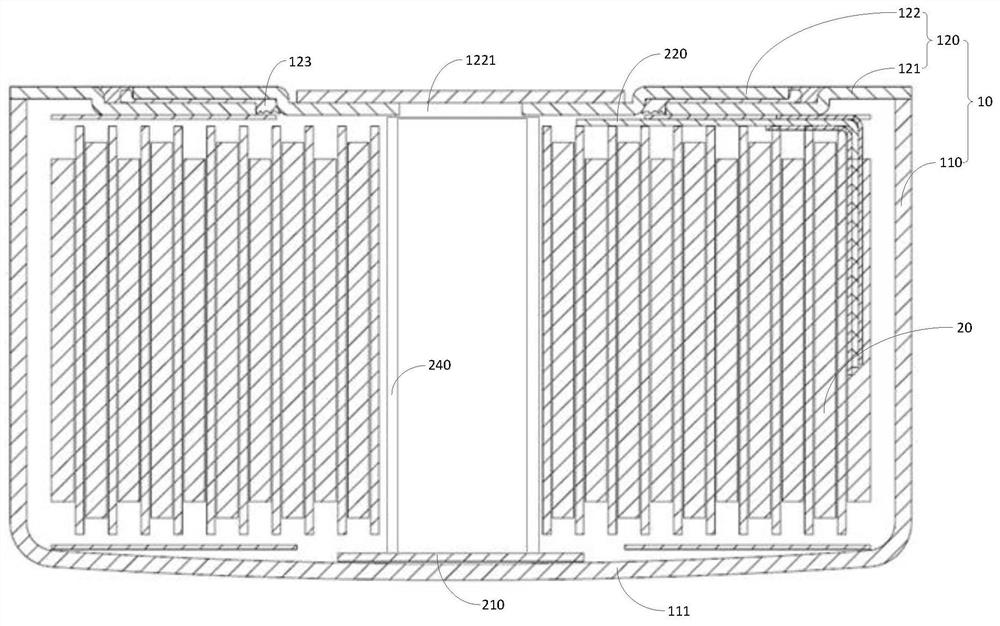

[0078] figure 1 Schematic diagram of the structure of the button battery provided in Embodiment 1 of the present invention; figure 2 Sectional view of the button battery provided for Embodiment 1 of the present invention Figure 1 ; image 3 Sectional view of the button battery provided for Embodiment 1 of the present invention Figure II .

[0079] refer to Figure 1 to Figure 3 As shown, the present embodiment provides a button battery, the button battery includes a casing 10 and a winding core 20, specifically, the casing 10 includes a casing 110 and a top cover assembly 120, and the casing 110 and the top cover assembly 120 together enclose An accommodating cavity for accommodating the winding core 20 is synthesized.

[0080] Wherein, the housing 110 includes: a bottom wall 111 and a side surrounding wall disposed along an outer edge of the bottom wall 111 and extending upward. The bottom wall 111 of the housing 110 may protrude downward to form a convex surface. Ex...

Embodiment 2

[0106] Figure 4 A structural schematic diagram of the second tab provided in Embodiment 2 of the present invention after being welded to the top cover and put into the casing; Figure 5 It is a schematic diagram of the process of loading the winding core into the casing provided by the second embodiment of the present invention; Figure 6 A structural schematic diagram of the top cover and the shell welded together provided by Embodiment 2 of the present invention; Figure 7 A cross-sectional view of the hollow tube passing through the liquid injection hole and the core cavity provided for Embodiment 2 of the present invention.

[0107] refer to Figure 4 to Figure 7 As shown, the present embodiment provides a method for preparing a button battery, and the method for preparing the button battery includes:

[0108] S100: The housing 10 is provided. Such as image 3As shown, the housing 10 includes a housing 110 and a top cover assembly 120, wherein the housing 110 include...

Embodiment 3

[0127] This embodiment provides an electronic product, which includes a button battery.

[0128] The button battery in this embodiment has the same structure as the battery provided in Embodiment 1, and can bring about the same or similar technical effects, which will not be described here one by one. For details, please refer to the description of the above embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com