Calibration method of ultrasonic flaw detection and quality control method and production method of tubular body

A calibration method and quality management technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and processing detection response signals. Insufficient detection performance, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

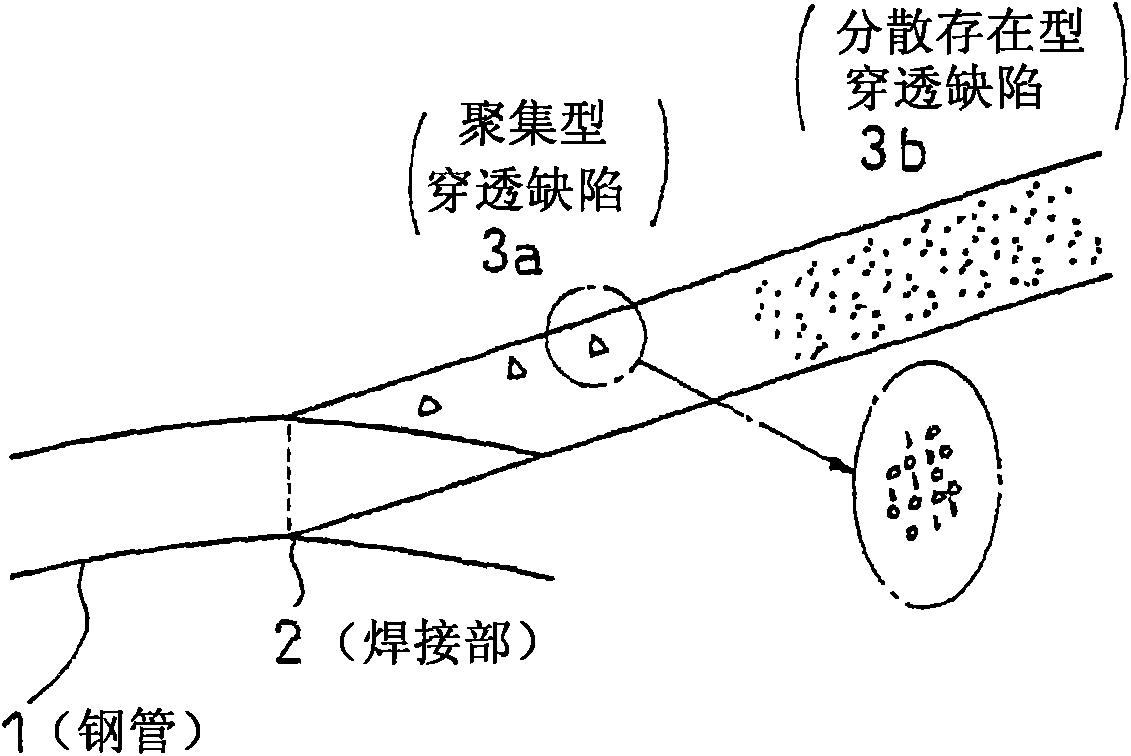

[0172] Embodiments of the present invention will be described below with reference to the drawings.

[0173] Figure 28 It is a diagram showing an example of the functional configuration of an ultrasonic flaw detection device related to tandem flaw detection. In the object size input unit 30 , an operator or a processing computer inputs the outer diameter and wall thickness of the steel pipe used for flaw detection. In the array probe storage unit 31 , the number of frequencies, the pitch of transducers, and the number of transducers of the array probe 5 are stored.

[0174] The aperture width control unit 32 controls the aperture width corresponding to the beam width (beam size) during transmission and reception, and calculates the position of the array probe, the number of scanning lines for transmission, and the number of scanning lines for each scan according to the size of the steel pipe and the specification of the array probe. The path of the beam used for the launch ...

Embodiment 2

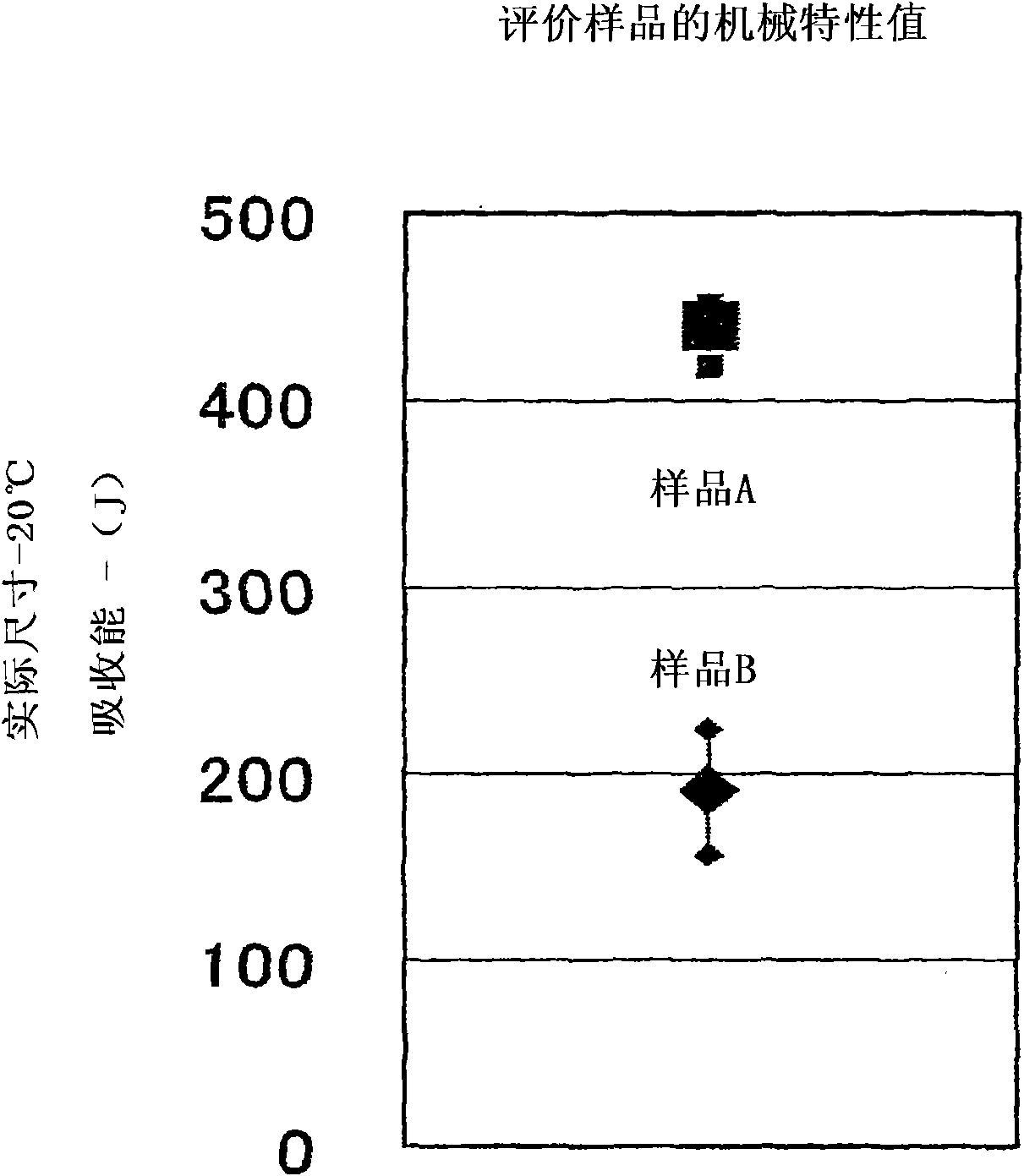

[0204] Next, use Figure 29 A structural example in which the ultrasonic flaw detection method described in Example 1 is applied to the manufacturing process of an electric seam steel pipe will be described. Figure 29 The devices in include an unwinding machine 151 for providing a strip, a straightening machine 152 for correcting a shape, a calender forming machine 154, a fin forming machine 155, an induction heating device 156, a squeeze roll 157, and a sorting machine 158, such as A strip plate with a plate width of 1920 mm×a plate thickness of 19.1 mm was electric seam welded, and a steel pipe of φ600 was manufactured by a classifier 158 . 159 is a pipe cutting machine among the figure.

[0205] Here, the array probe 5 for tandem flaw detection is disposed, for example, on the inlet side or the outlet side of the sorter 158 after welding, or on the outlet side of the pipe cutter 159, and the mechanical characteristics are evaluated based on the results, thereby enabling q...

Embodiment 3

[0209] Embodiment 1 and Embodiment 2 described examples in which sensitivity correction was performed on a steel pipe, but the same correction method can also be applied to the case of using a C-scan other than a steel pipe, which will be described below.

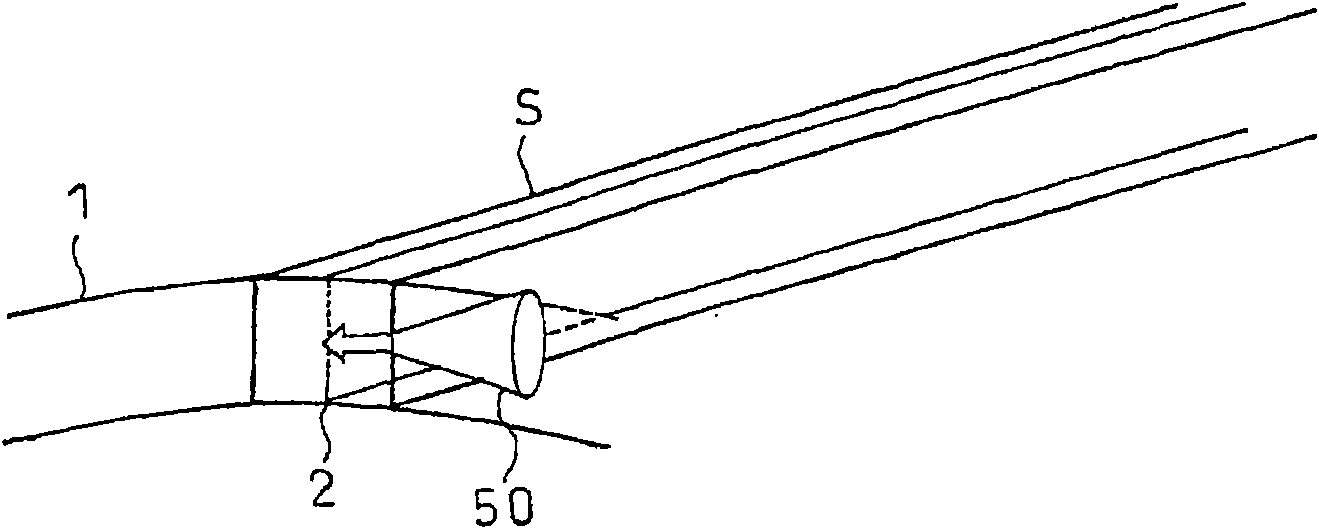

[0210] An example of a structure for implementation using the C-scan method is shown in Figure 30 superior. It is composed of the following: a probe 50, which transmits and receives ultrasonic waves to the cut-out welding surface for ultrasonic flaw detection; an ultrasonic transmitting and receiving unit 52, which controls the sending and receiving of ultrasonic waves in the probe 50; Carry out C-scanning on the welding surface, so that the probe scans sequentially along the direction of the tube axis and the direction of the tube thickness; the received signal storage unit 56 stores the C-scan data; the signal processing unit 58 performs calculation processing on the C-scan data; the parameter input unit 60 uses Paramet...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Beam width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com