Portable welding auxiliary device for electromechanical maintenance

An auxiliary device, portable technology, applied in auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., can solve the problems of damage and failure of electromechanical equipment, unable to assist welding master arc welding, low work efficiency, etc., to achieve welding The effect of accurate position, convenient welding process and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

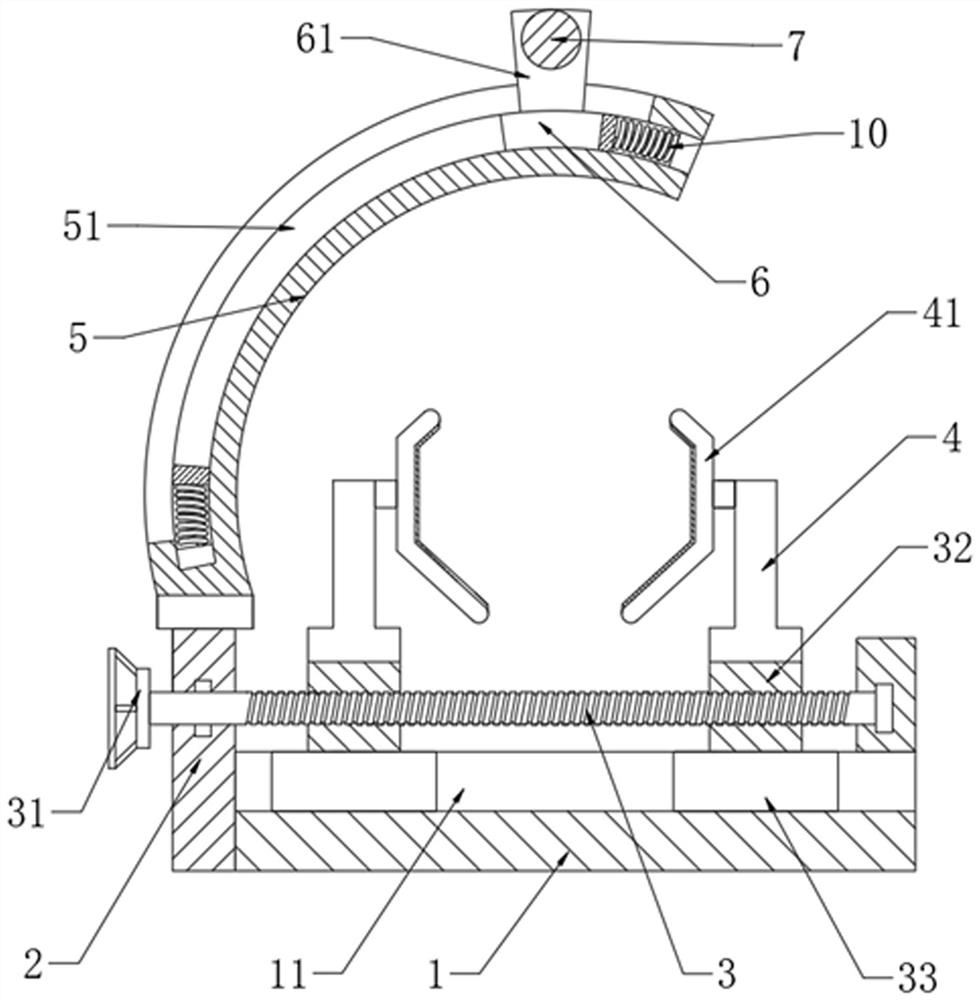

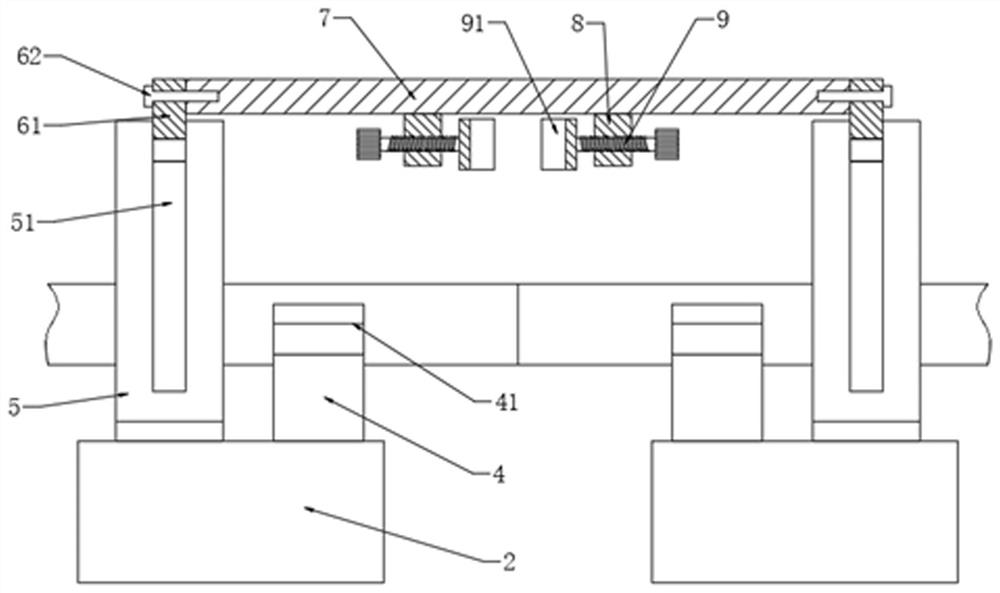

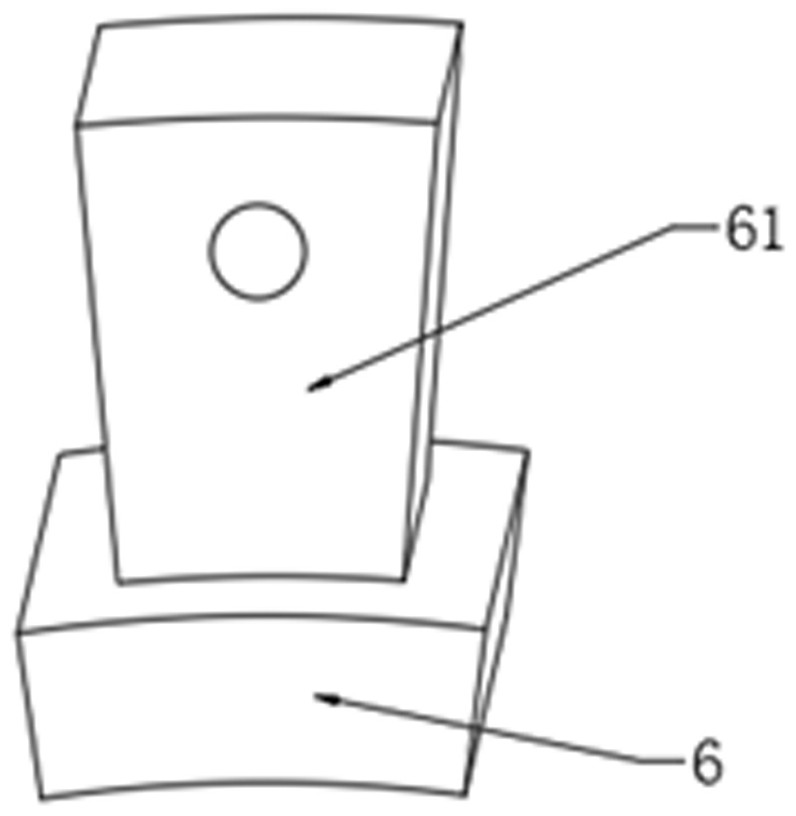

[0015] like Figure 1-Figure 3 As shown, a portable welding auxiliary device for electromechanical maintenance includes two symmetrical clamping devices and a cross bar 7. The clamping device includes: a bottom plate 1, a support plate 2, a threaded rod 3, a clamping plate 41, and a curved plate 5. The curved surface slider 6 and the limit block 61, the upper end of the bottom plate 1 is provided with a dovetail groove 11, the left side of the bottom plate 1 is welded with a support plate 2, and the side of the support plate 2 is provided with a threaded rod 3, and the threaded rod 3 and The supporting plate 2 is rotationally connected, and the threaded rod 3 is provided with movable blocks 32 left and right symmetrically, and a dovetail slider 33 is inserted symmetrically in the dovetail groove 11, and the dovetail slider 33 and the movable block 32 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com