Method for preparing TA2/Q235 composite plate by electric resistance welding and welding material

A welding material and resistance welding technology, applied in the direction of resistance welding equipment, welding/cutting medium/material, welding medium, etc., can solve problems such as poor joint performance and difficult control of welding process, and achieve convenient and easy welding process Processing and molding, wide adaptability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

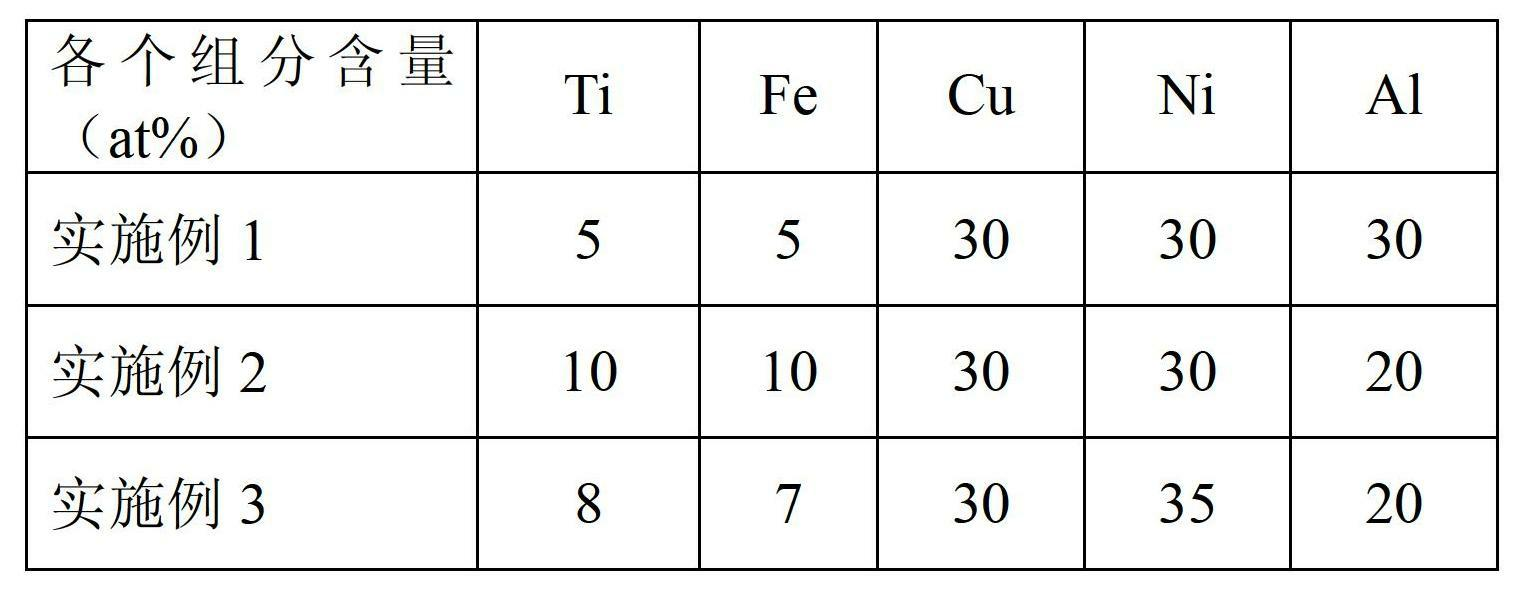

[0030] Select the content of each component element according to the data in Table 1, and prepare the Ti5Fe5Al30Ni30Cu30 intermediate layer alloy foil with a thickness of 150μm, a width of 5mm and a length of 0.5m according to the above steps.

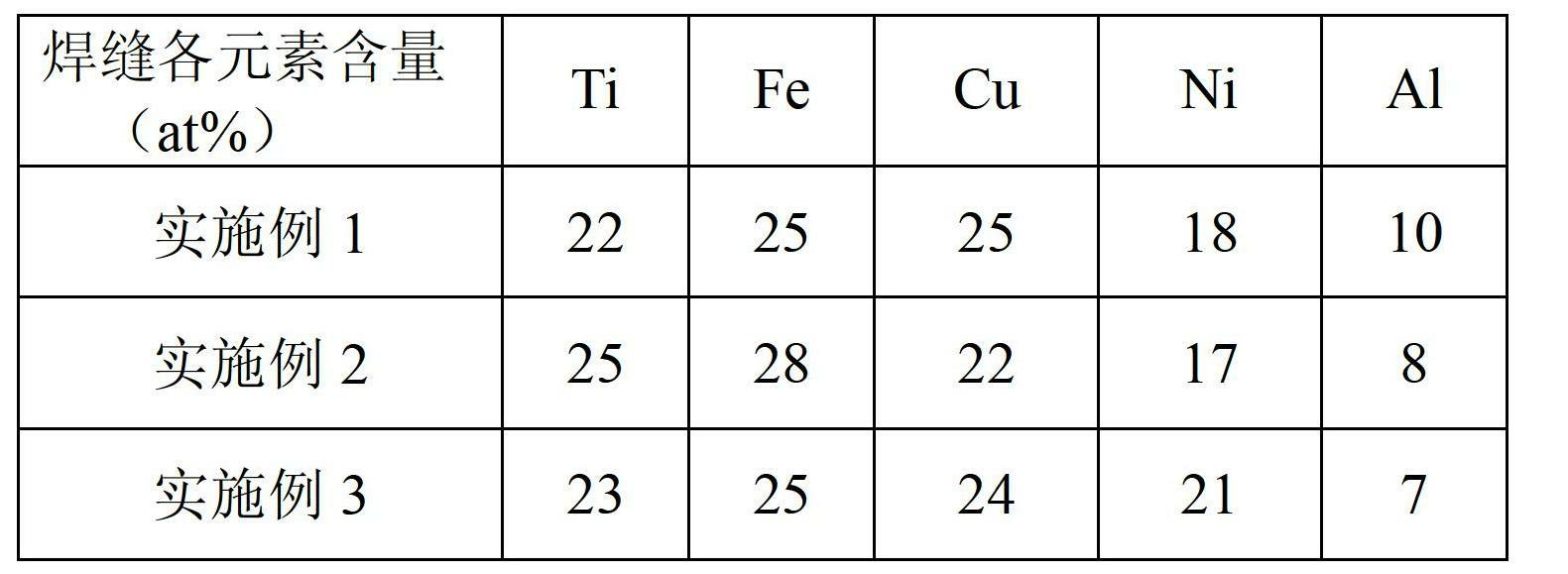

[0031] Using the folded intermediate layer alloy foil as the intermediate layer, resistance spot welding was performed on TA2 and Q235, and the tensile shear strength of the welded joint was about 281MPa.

Embodiment 2

[0033] According to the data of Example 2 in Table 1, each component element and content were selected, and the linear velocity of the roll surface was controlled at 5m / s to prepare Ti10Fe10Al20Ni30Cu30 intermediate layer alloy foil with a thickness of about 130μm, a width of about 5mm and a length of about 0.8m. Using the folded intermediate layer alloy foil as the intermediate layer, resistance spot welding was performed on TA2 and Q235, and the tensile shear strength of the welded joint was about 298MPa.

Embodiment 3

[0034] Example 3: According to the steps of Example 1 above, select each component element and content according to the data of Example 2 in Table 1, and control the linear velocity of the roller surface at 5m / s to prepare a thickness of about 130μm and a width of about 5mm. Ti8Fe7Al20Ni35Cu30 intermediate layer alloy foil with a length of about 0.8m. Using the folded intermediate layer alloy foil as the intermediate layer, resistance spot welding was performed on TA2 and Q235, and the tensile shear strength of the welded joint was about 296MPa.

[0035] In summary, the intermediate layer alloy of the present invention has good flexibility and is convenient for processing and assembly; it has good matching with titanium and alloy steel during welding, the weld (nugget) is a single-phase fcc solid solution structure, and the joint is integrated mechanically. The performance is significantly improved; the preparation method of the intermediate layer alloy foil is simple in process,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com