Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

82results about How to "Convenient winding work" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

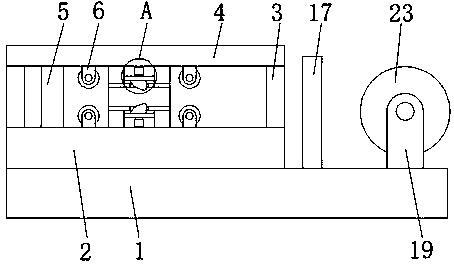

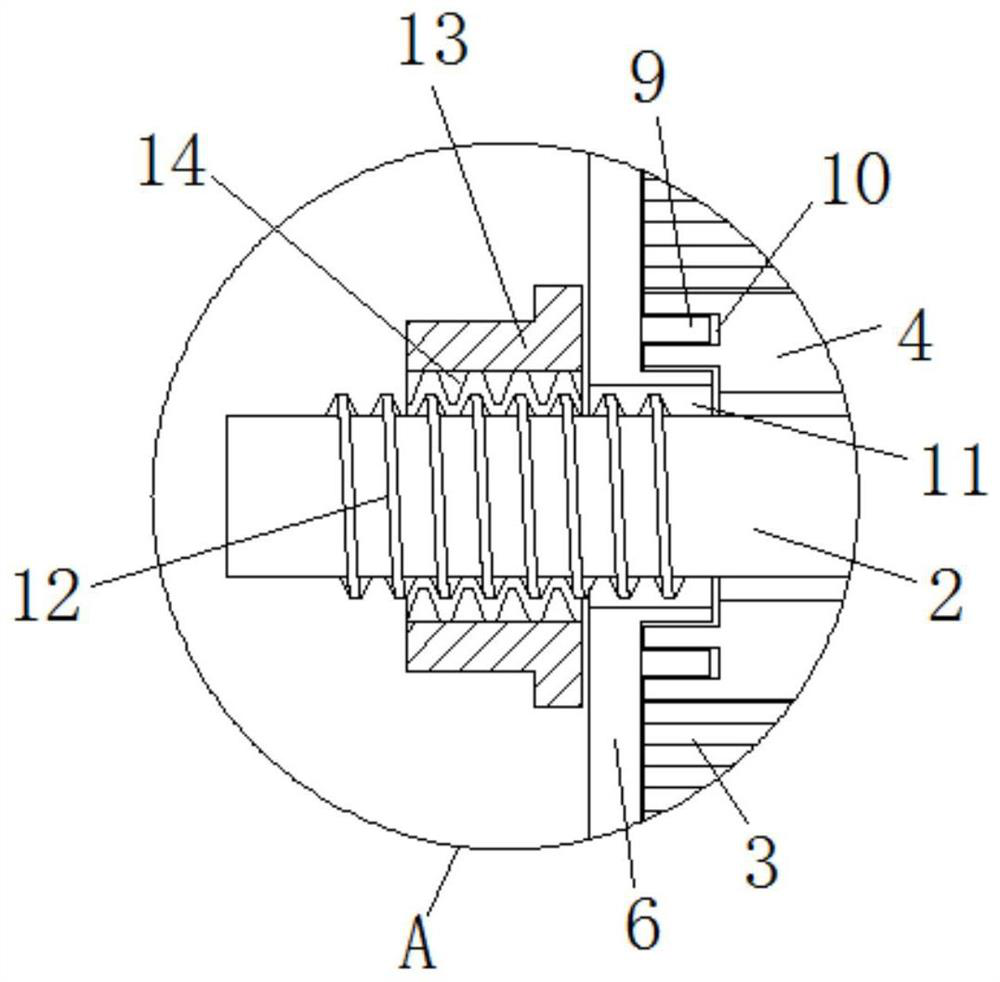

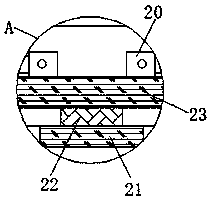

An adjustable cable peeling device

ActiveCN109066490AEasy to cleanImprove cleanlinessApparatus for removing/armouring cablesAgricultural engineeringCushion

The invention relates to the technical field of scrap cable peeling, and discloses an adjustable cable peeling device, including the base, and a backing plate is fixedly installed on the top of the base, two groups of first brackets are fixedly installed on the top of the backing plate, and the number of first supports in each group is two, A support plate is fixedly mount between the tops of thetwo group of first brackets, The bottom of the support plate and the top of the cushion plate are fixedly installed with a cleaning mechanism, two guide wheels, two fixing blocks and a pillar, a sleeve is fixedly installed between one end of the four fixing blocks, two symmetrical openings are arranged on the outer surface of the sleeve, and circular grooves are arranged on the outer surfaces of the two pillars. The invention solves the problems of incomplete exploitation, inconvenient recovery, serious waste of resources, inability to adjust the exploitation according to the size of the cableand poor processing quality of the existing cable skinning device, achieves good exploitation quality, facilitates collection and utilization in the later period, and improves the effect of work efficiency.

Owner:ANHUI CABLE

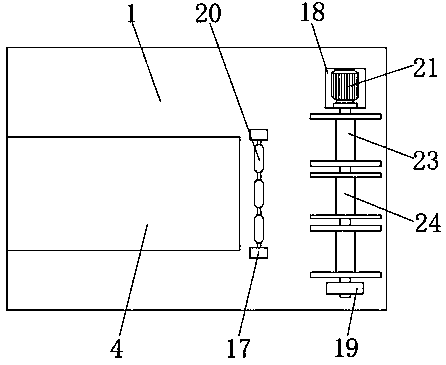

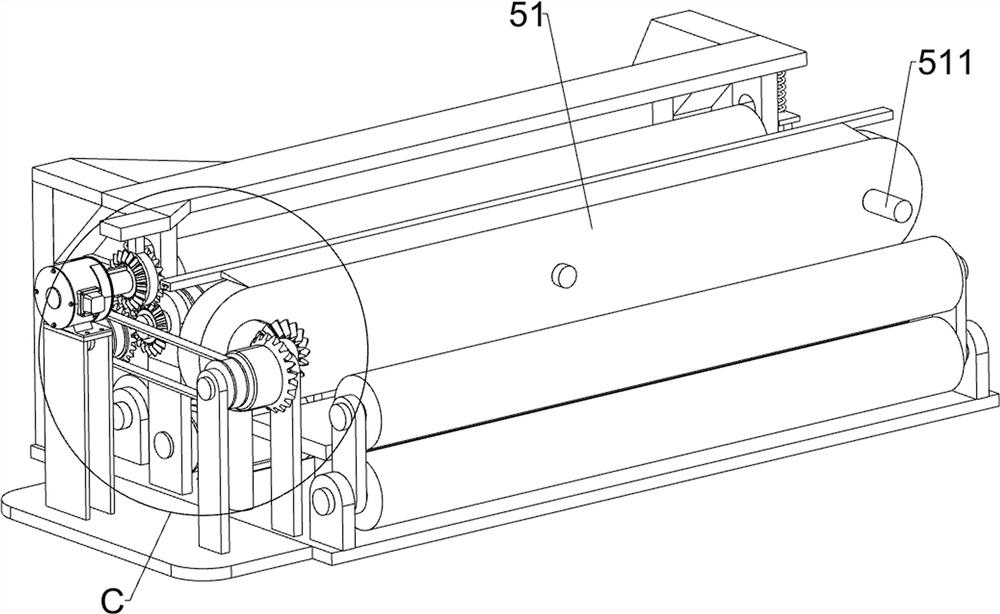

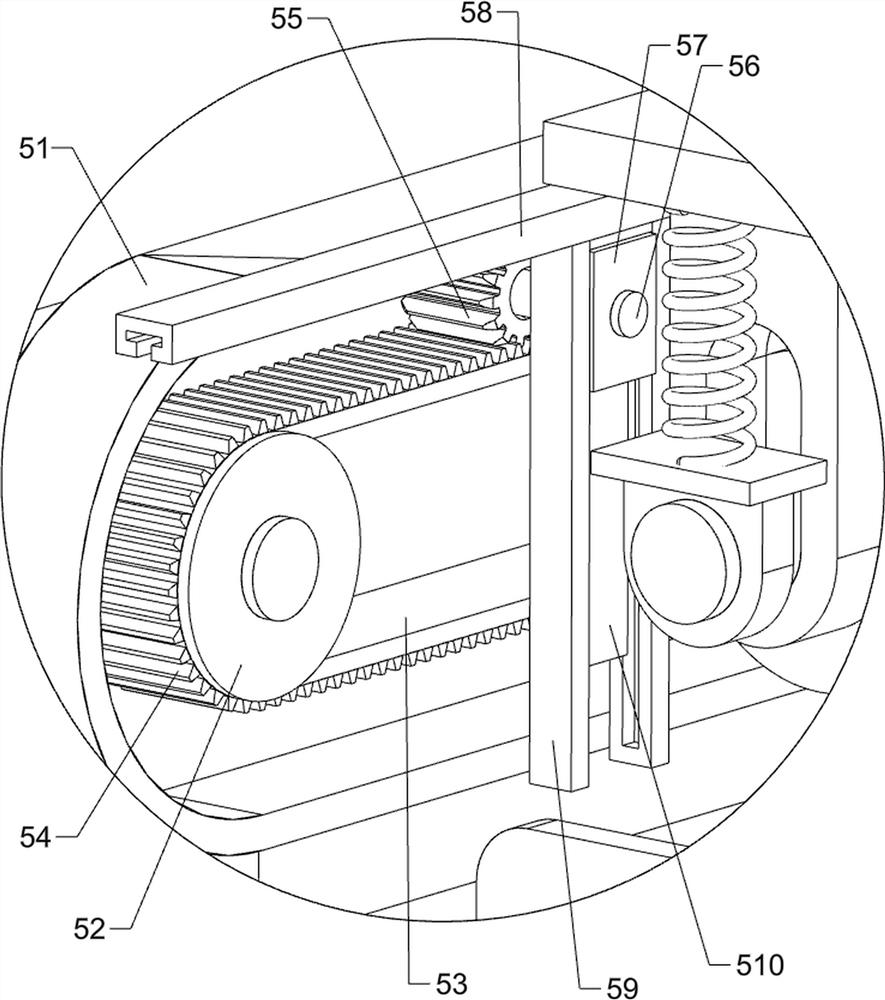

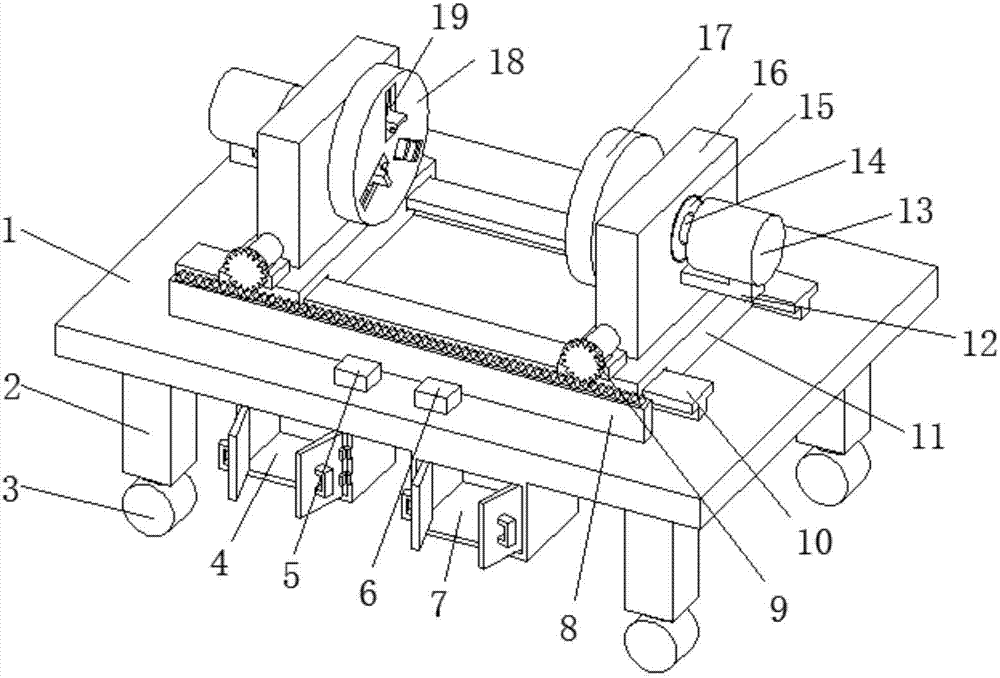

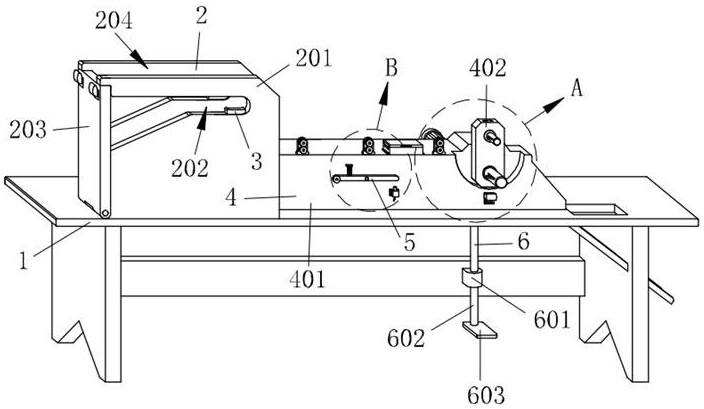

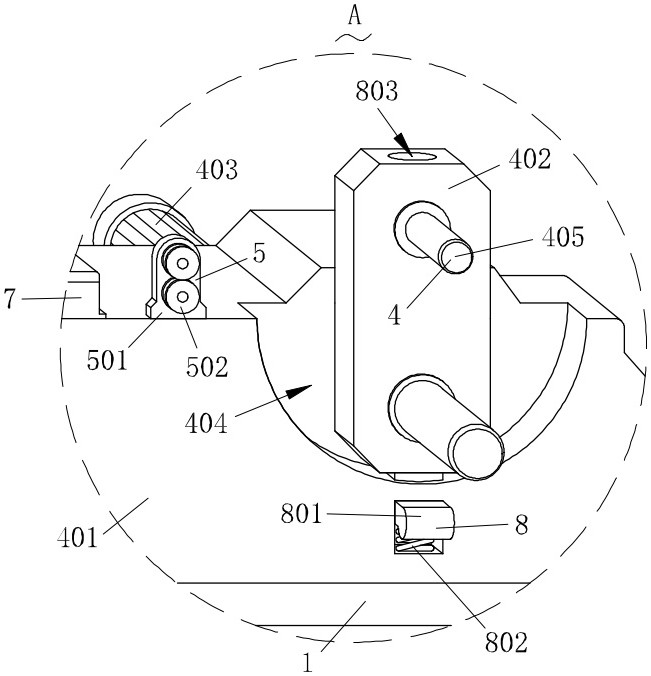

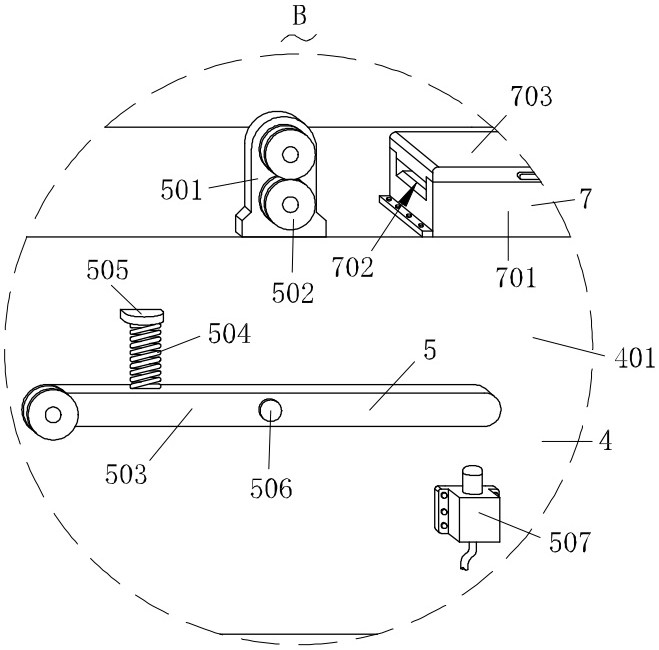

Cloth rolling device for garment production

ActiveCN111891804AEasy to removeConsistent winding lengthWebs handlingMechanical engineeringIndustrial engineering

The invention relates to a rolling device, in particular to a cloth rolling device for garment production. Through the provided cloth rolling device for garment production, rolled cloth can be taken down conveniently, cloth rolling lengths can be kept consistent, and the cloth can be cut off automatically. The cloth rolling device for garment production comprises a bottom plate, a cloth spreadingtable plate, a rolling mechanism and a cut-off mechanism. Two limiting rotary rollers are rotationally connected to one side of the bottom plate. The cloth spreading table plate is connected to the side, close to the limiting rotary rollers, of the bottom plate. The rolling mechanism is installed on the bottom plate. The cut-off mechanism is installed on the bottom plate. According to the cloth rolling device, a reel can rotate to roll the cloth, the cloth can be cut off by the cut-off mechanism, a trigger mechanism can assist the rolling mechanism and the cut-off mechanism in work, and thus rolling work can be conducted better.

Owner:山东靓华制衣有限公司

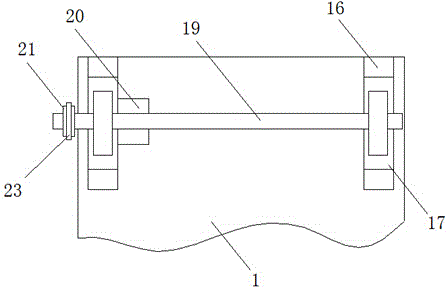

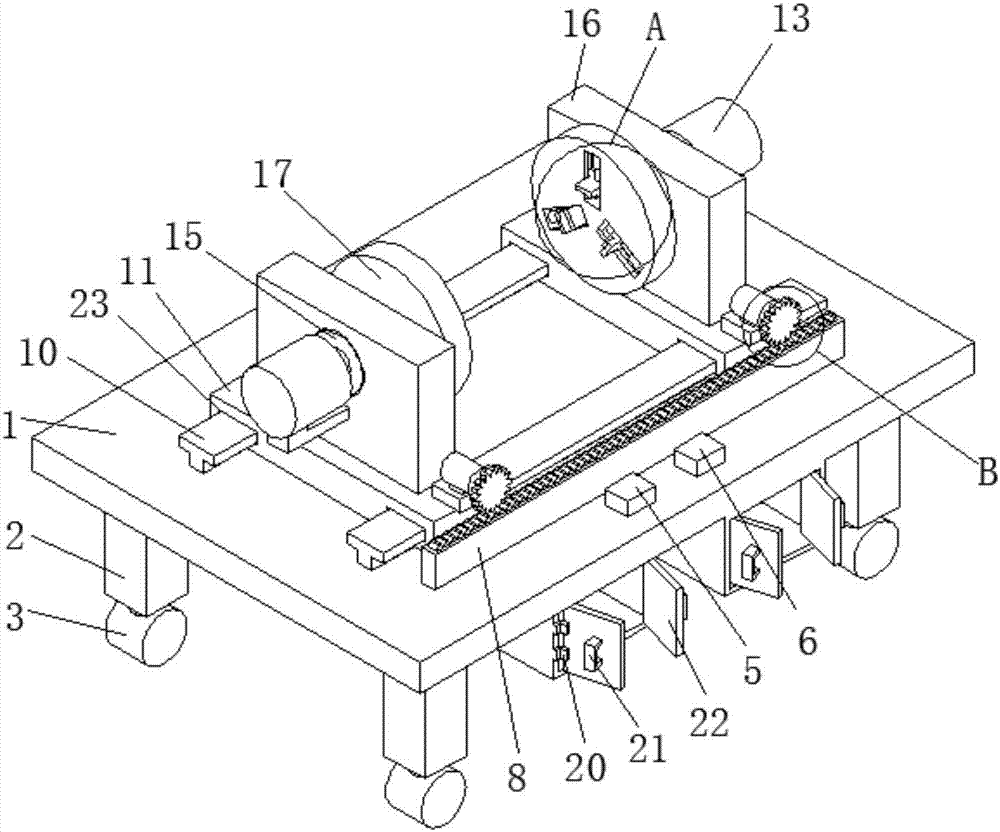

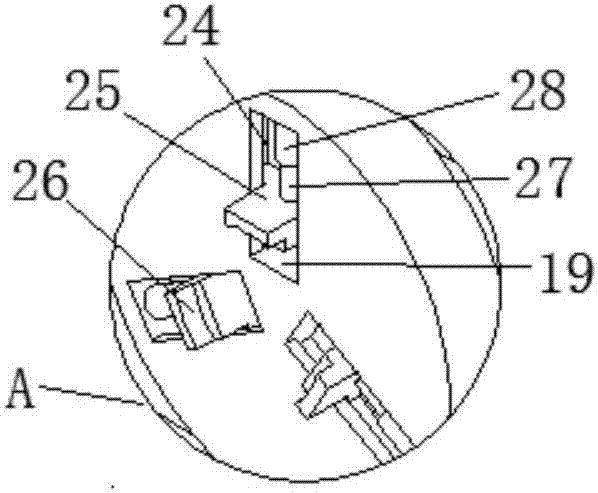

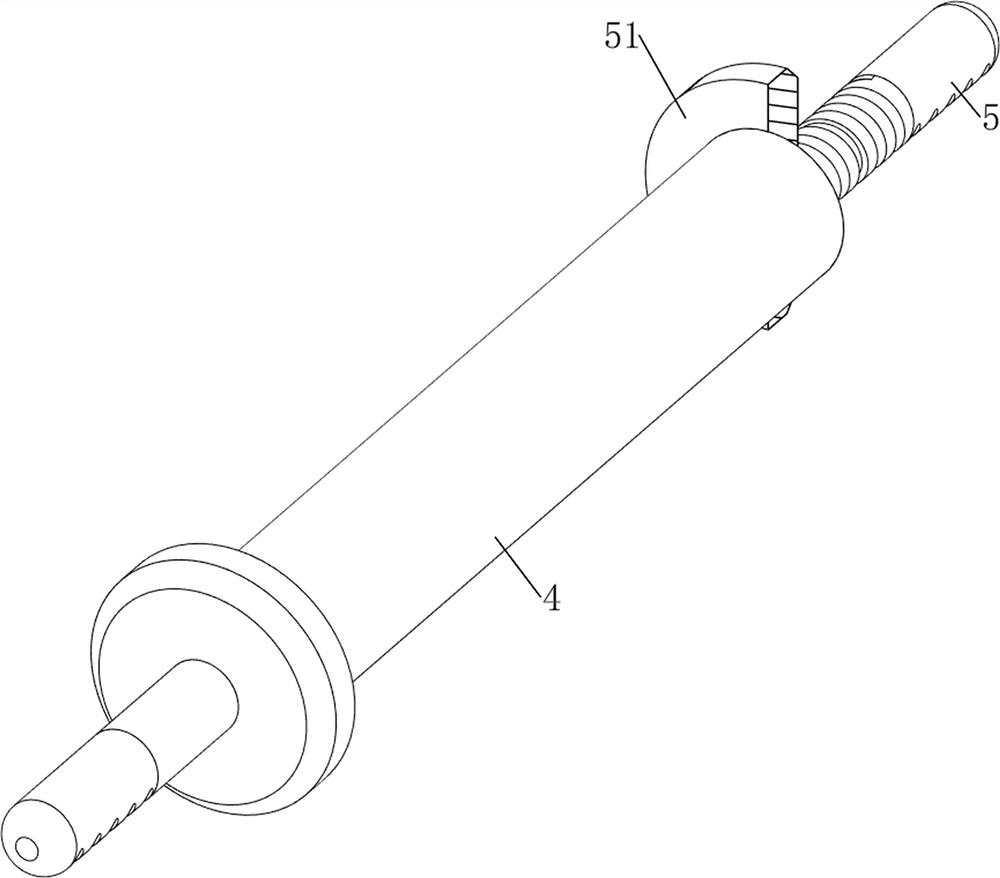

Cable processing and winding machine and operating method thereof

The invention discloses a cable processing and winding machine and an operating method thereof. The cable processing and winding machine comprises a winding device and a recovery device, and the winding device and the recovery device are arranged on the bottom plate. The cable processing and winding machine is characterized in that the winding device comprises a first support, a winding shaft, a rotary plate, a first motor and a fixing plate, and the recovery device comprises a second support, a cushion, a second bearing, a rotary shaft and a second motor. A plurality of cable fixing blocks are arranged on the rotary plate, so that cables can be wound conveniently, application range of the cable processing and winding machine is broadened, cost is reduced, the cables can thread into wire guide holes and can be conveyed in the hollow winding shaft, wear of the cables by the processing and winding machine is reduced, and quality of the cables after winding is improved; the first motor and the second motor control the winding device and the recovery device respectively, and operation efficiency is improved.

Owner:芜湖市科特电线电缆有限公司

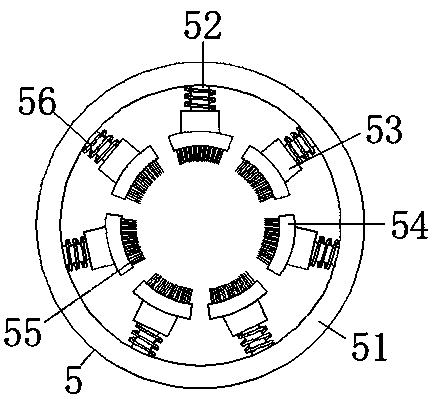

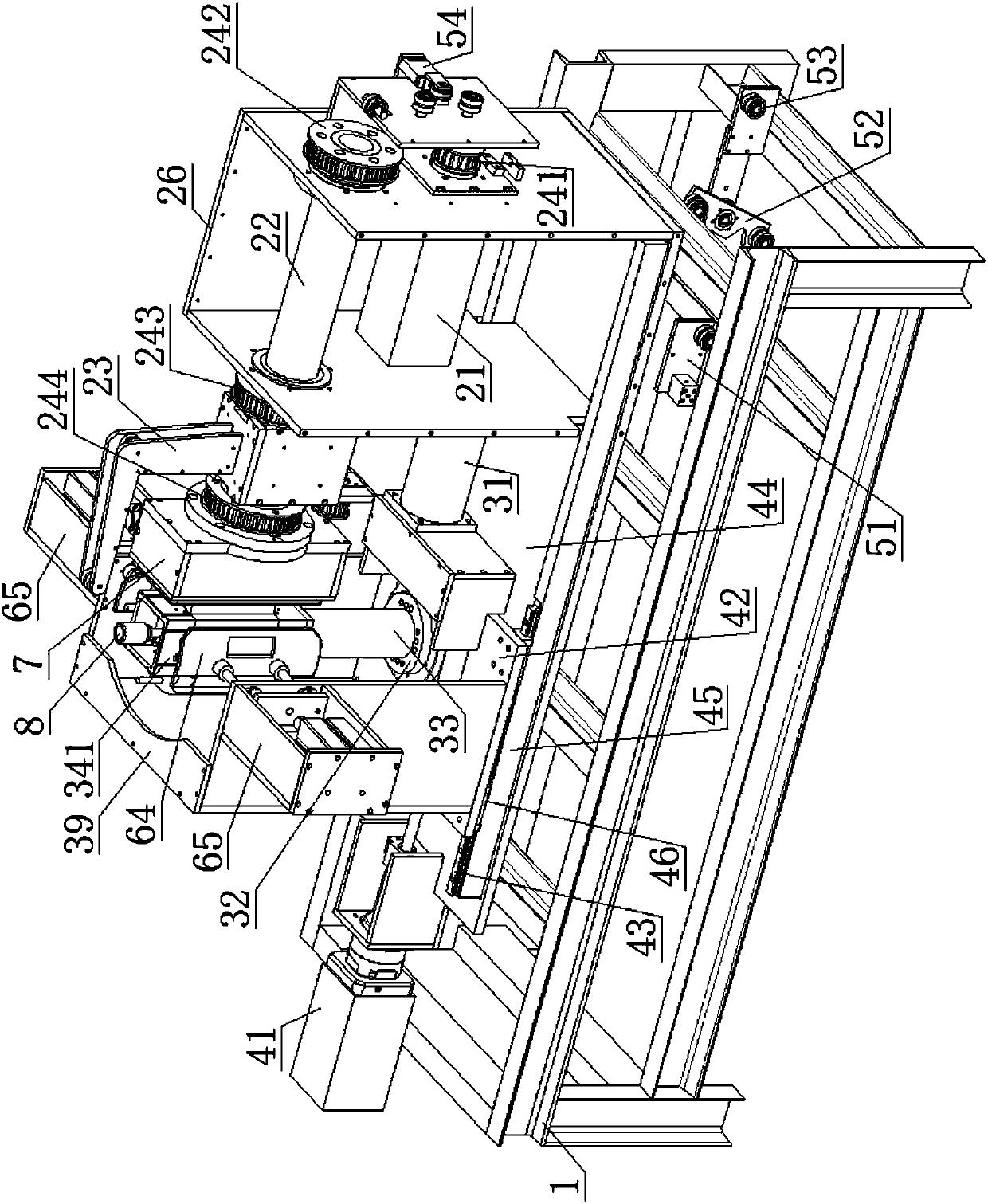

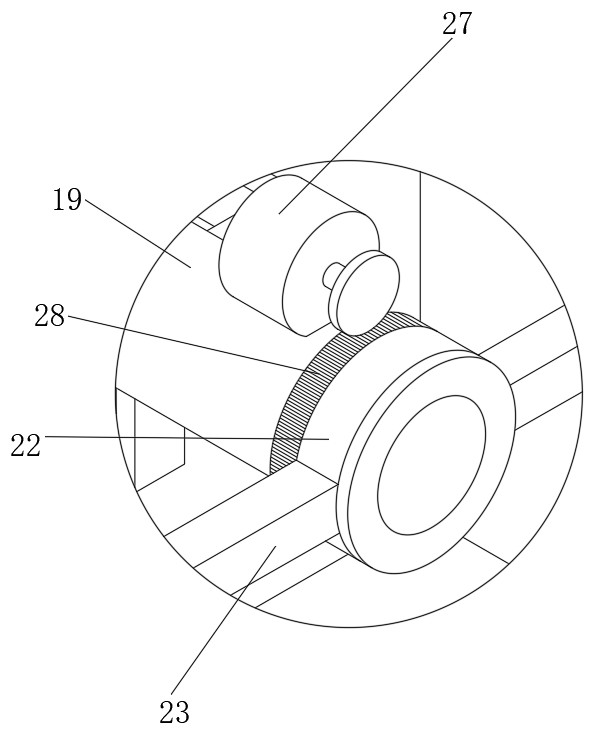

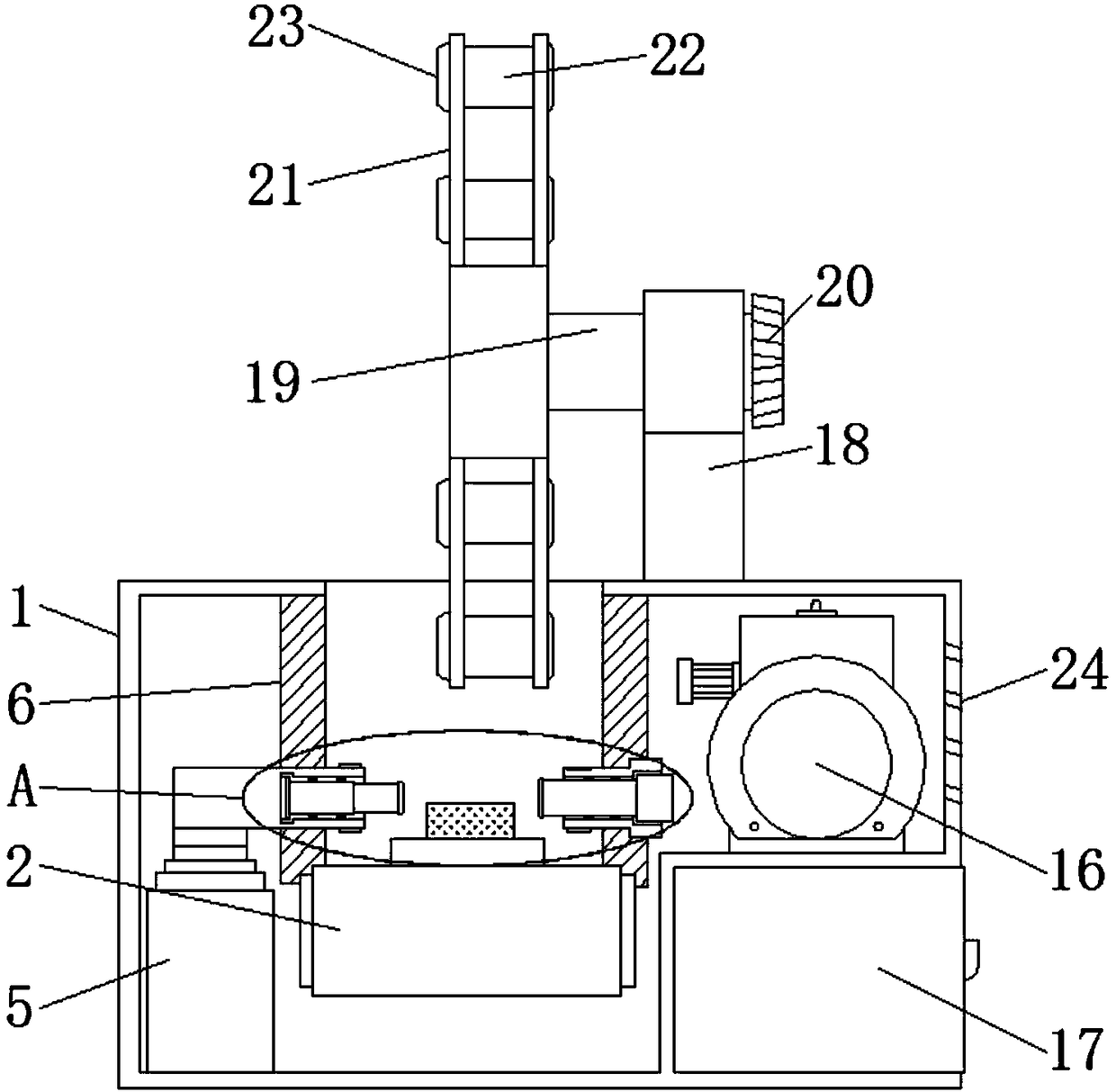

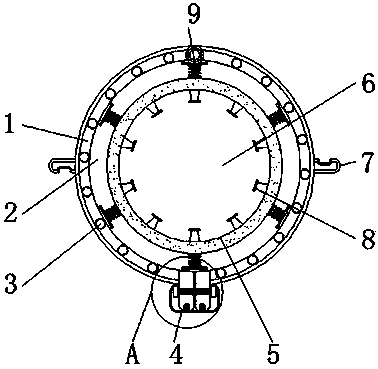

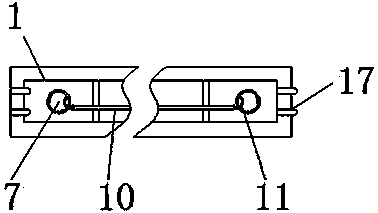

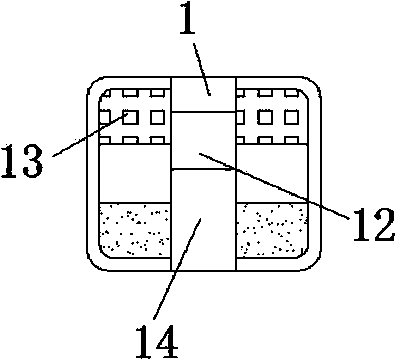

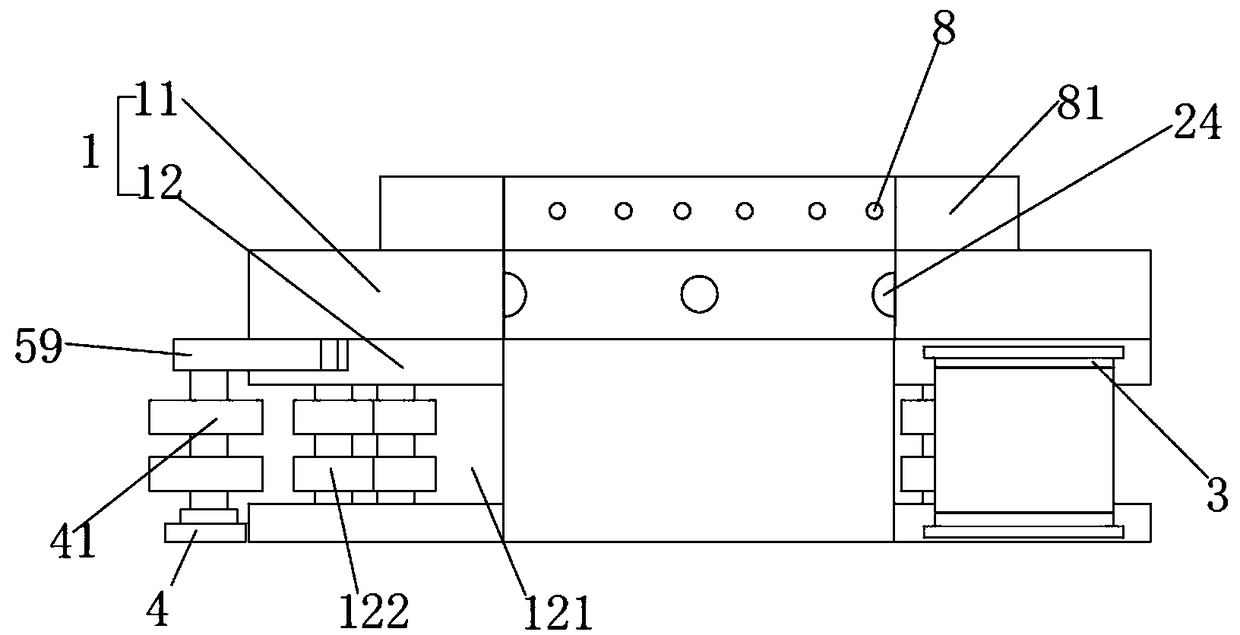

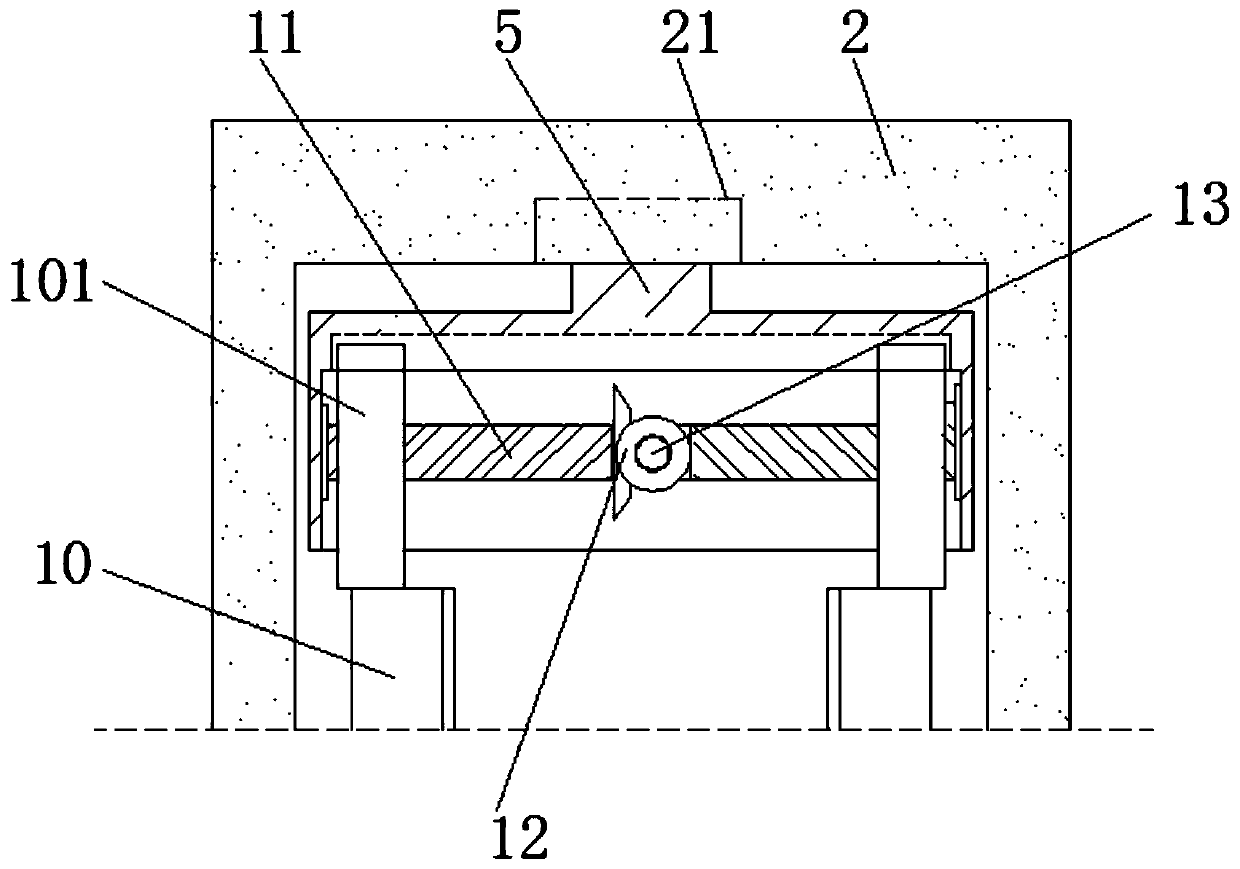

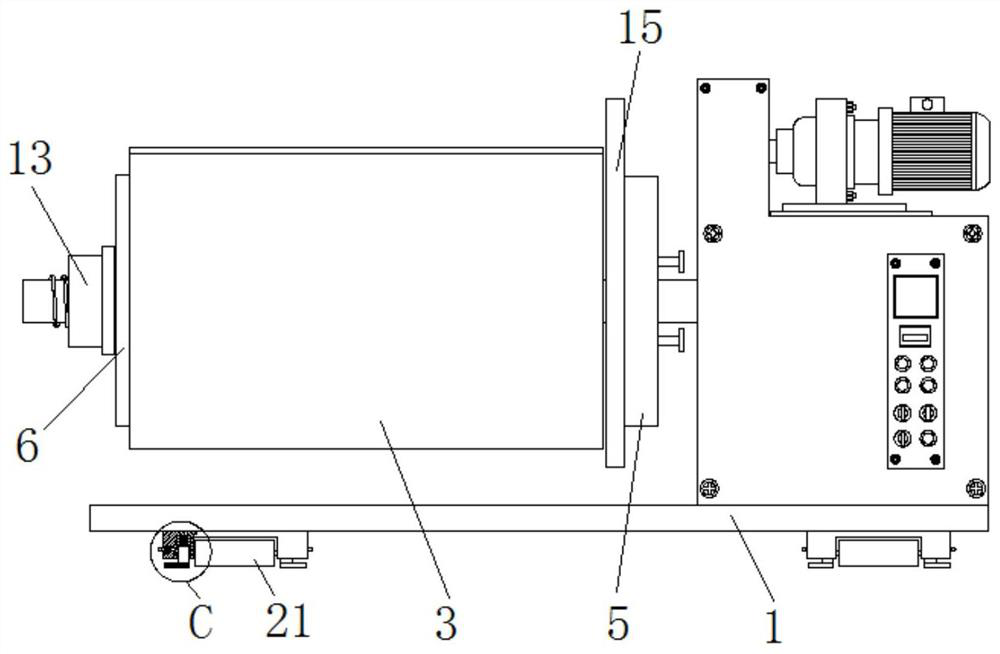

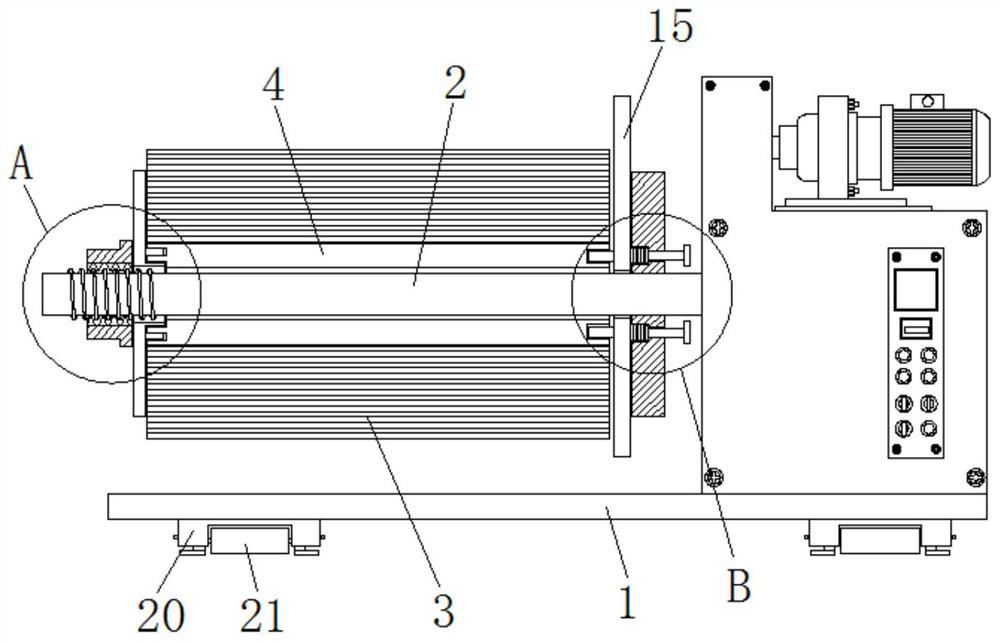

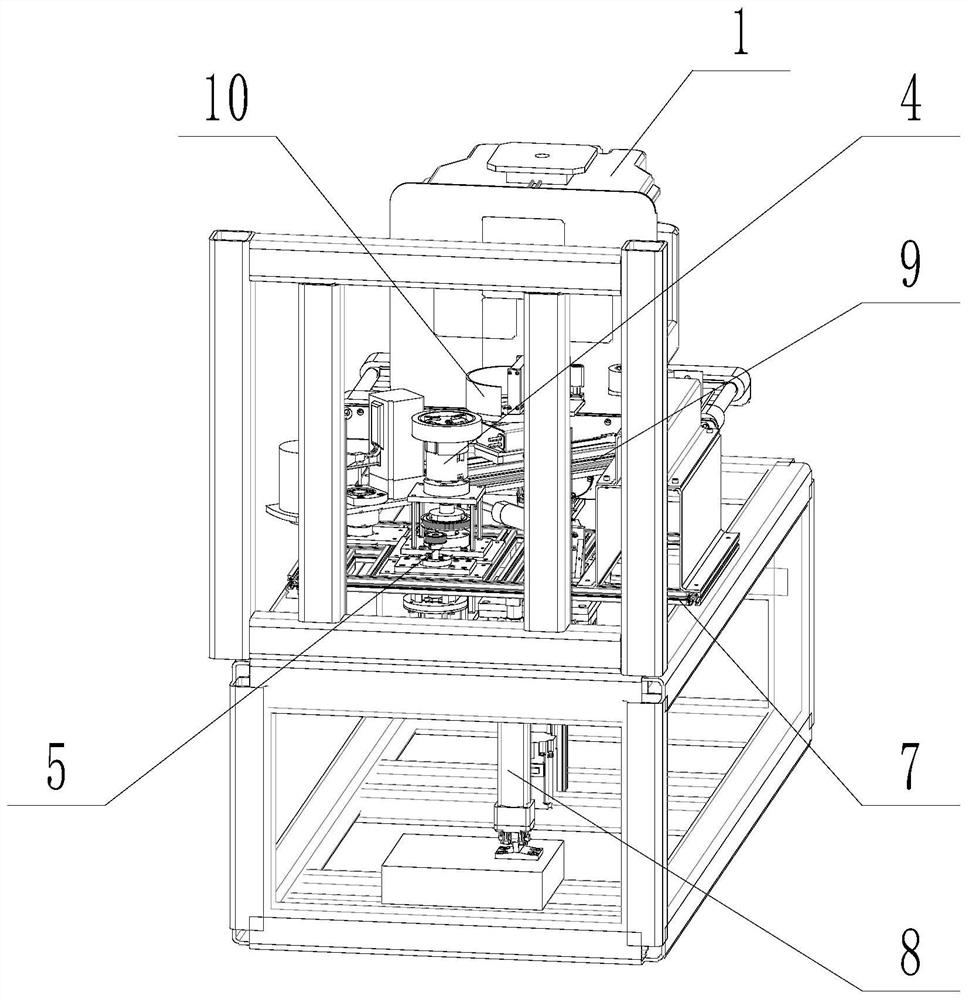

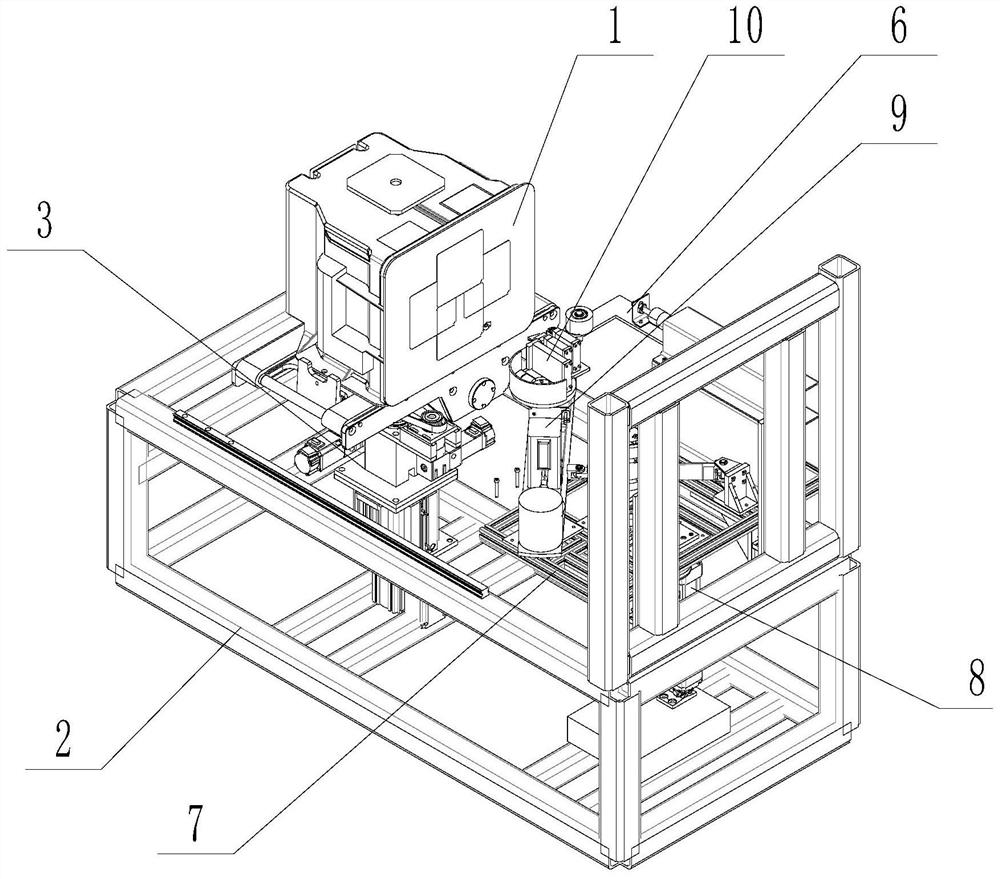

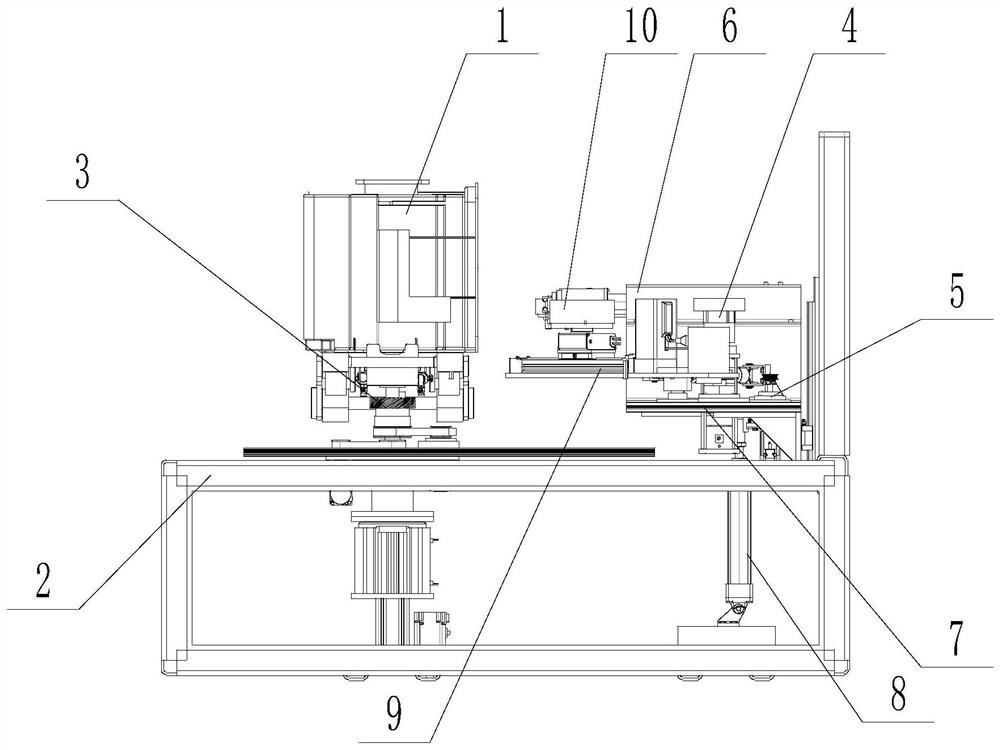

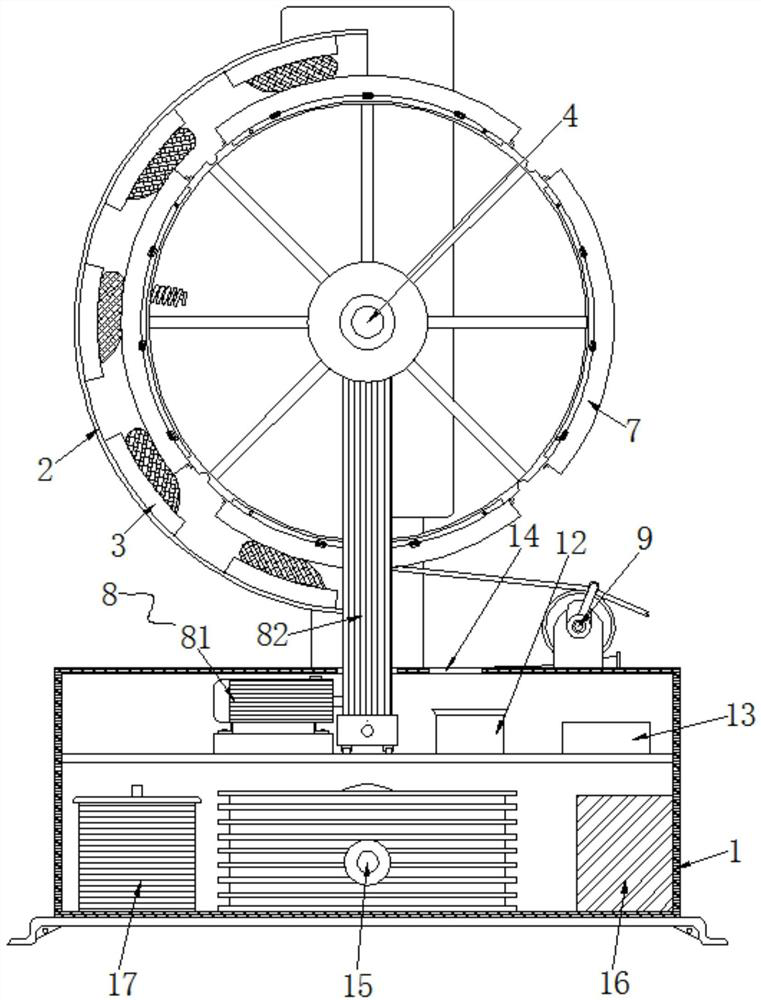

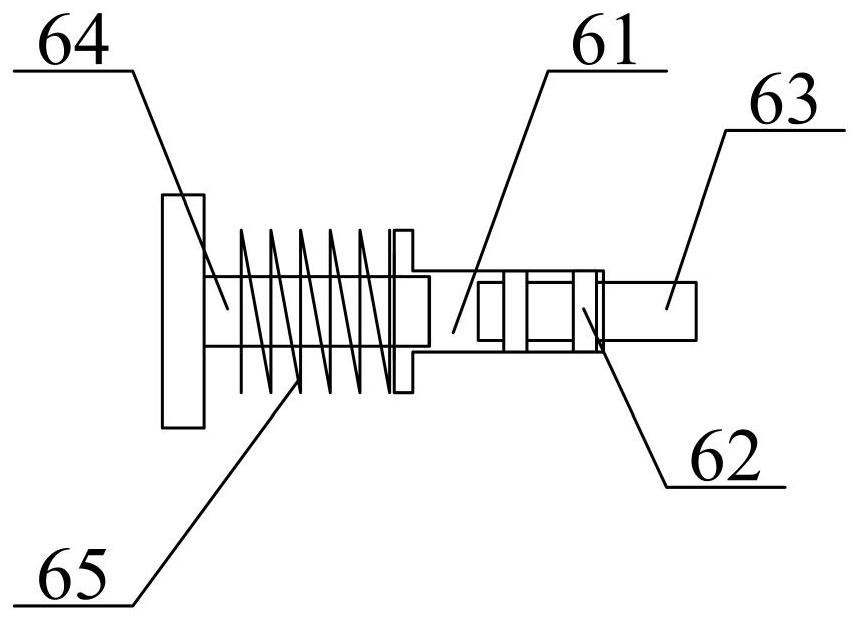

AC synchronous generator rotor full-automatic winding machine

PendingCN107707088ARealize automatic reversal of magnetic polesImprove work efficiencyManufacturing dynamo-electric machinesWinding machineTransducer

The invention relates to an AC synchronous generator rotor full-automatic winding machine which comprises a base, a winding device which can rotate forwardly or reversely, and a pole changing device.The winding device and the pole changing device are oppositely arranged and are installed on the base. A rotor is fastened in the pole changing device. The pole wings of the rotor are aligned with thewinding direction of the winding device. The winding device carries out winding on the pole wings of the rotor. The pole changing device drives the rotor to rotate. The rotor is fastened to the polechanging device, and the winding device carries out winding on the pole wings of the rotor. After winding on one pole wing is completed, the pole changing device drives the rotor to rotate to make next pole wing aligned with the winding direction of the winding device and to continue winding on the pole wing. At the moment, the winding device rotates reversely to reverse an enameled wire coil, andthus, the magnetic poles of the rotor are automatically reversed. The whole winding machine automatically completes all work of rotor winding. There is no need for manual pole changing, there is no need to cut off enameled wire ends, and there is no need to weld enameled wire ends. The work efficiency of generator rotor production and the quality of products are improved.

Owner:王江锋

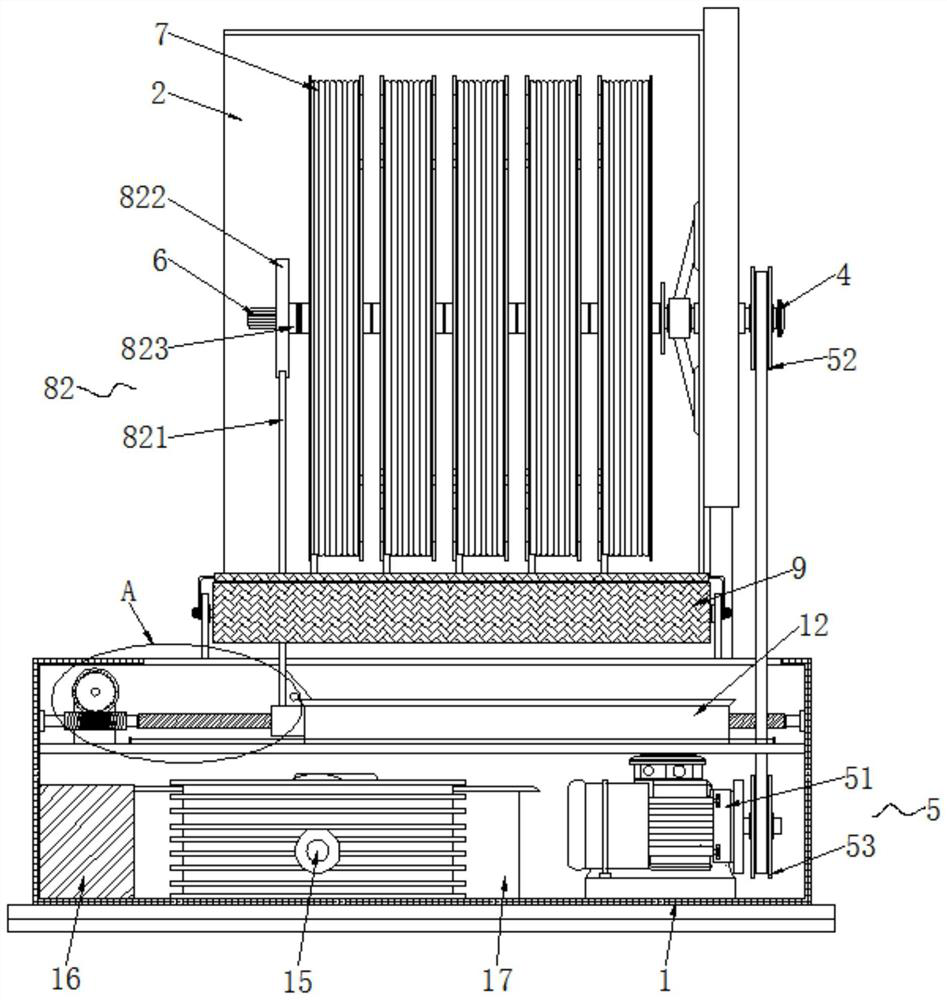

Textile fabric winding mechanism with embossing protection function and working method of textile fabric winding mechanism

InactiveCN111410068AFor precise adjustmentMeet regulatory needsPattern makingWebs handlingRotational axisManufacturing engineering

The invention relates to the field of textile devices, in particular to a textile fabric winding mechanism with an embossing protection function and a working method of the textile fabric winding mechanism. The mechanism comprises a base and further comprises a controller, a guiding device, a pressure adjusting device and a winding device; the guiding device comprises two guiding roller assemblies; the pressure adjusting device comprises a bearing table, a rotating shaft, two sliding assemblies and a plurality of rollers; the winding device is arranged at the top of the base and used for winding embossed textile fabric, and the winding device comprises a winding roller and a transmission assembly; and the transmission assembly, the two guiding roller assemblies and the two sliding assemblies are electrically connected with the controller. According to the textile fabric winding mechanism with the embossing protection function and the working method of the textile fabric winding mechanism, the embossing force can be accurately controlled, the embossing deformation is prevented, and meanwhile, a buffering structure is designed, so that the situation that the surface of the fabric isscratched or even damaged when the embossing force is large is prevented, the product quality is guaranteed, and benefits of enterprises can be increased.

Owner:朱蕾

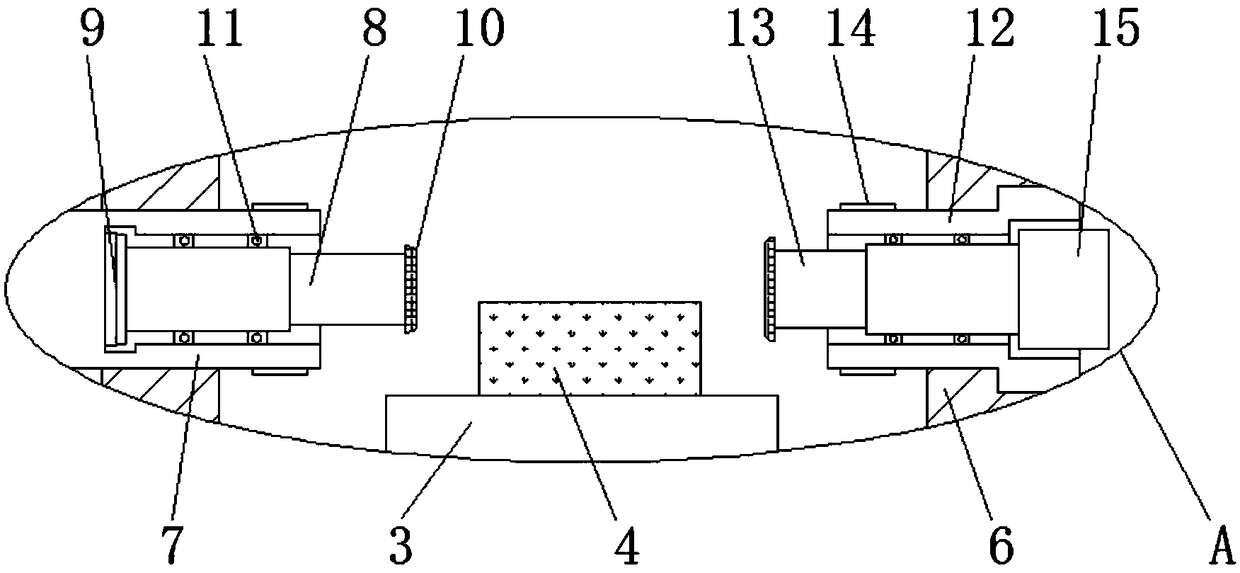

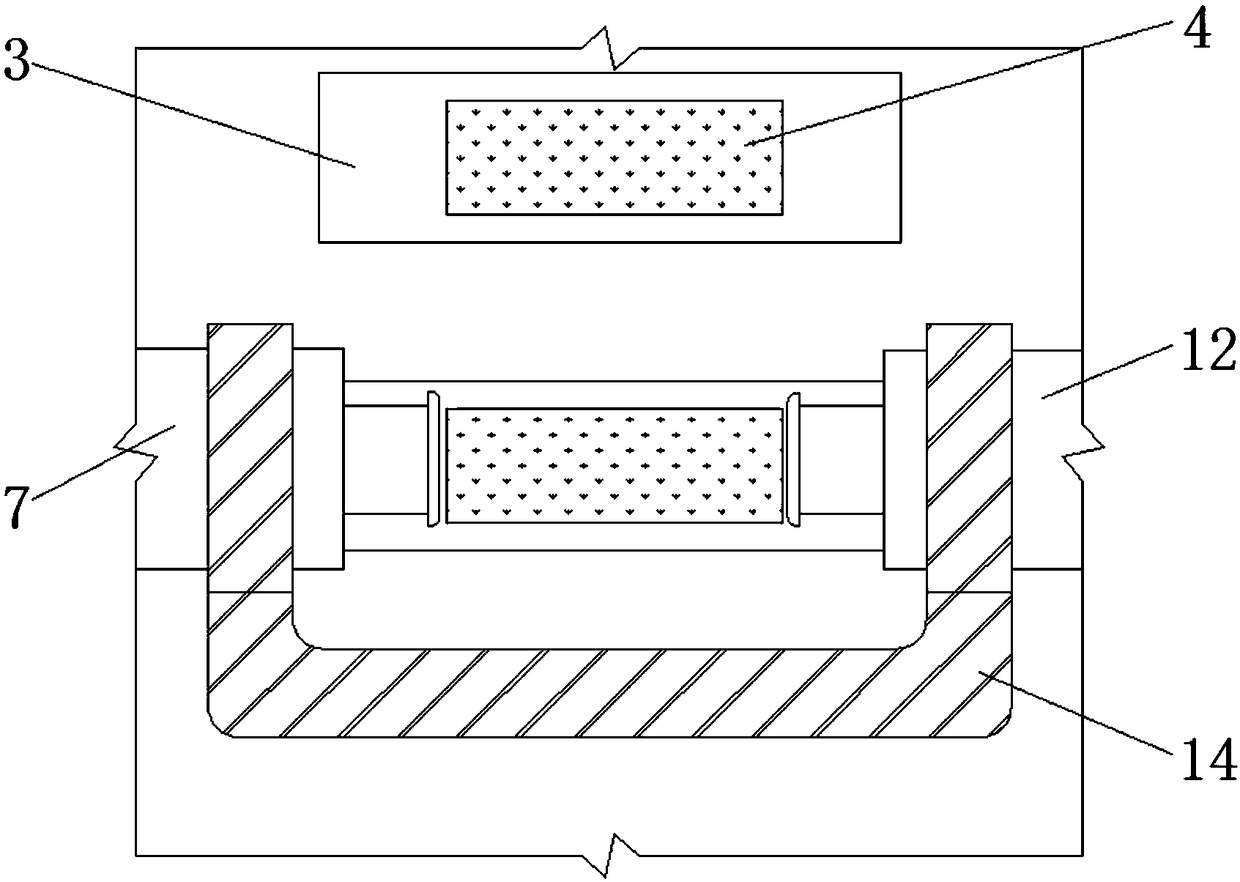

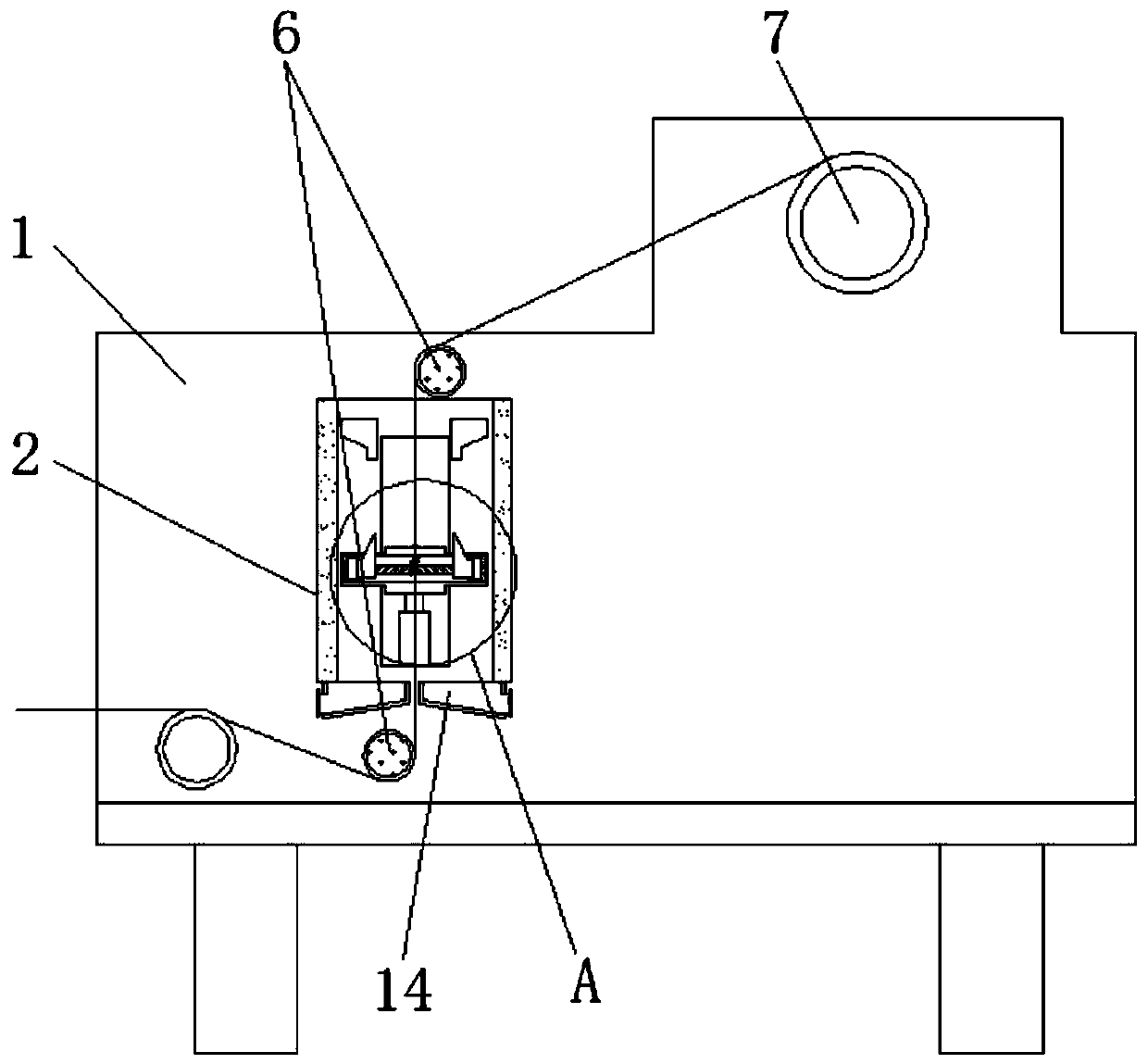

Electronic product magnetic core clamping device

The invention discloses an electronic product magnetic core clamping device. The device comprises a bottom plate, a first control switch and a second control switch are arranged on one side of the upper surface of the bottom plate, two sliding rails are arranged on the upper surface of the bottom plate at equal intervals, sliding plates are clamped at the left ends and the right ends of the two sliding rails in a sliding mode respectively, support plates are arranged on the upper surfaces of the sliding plates, bearings are clamped in through grooves inside the support plates, a first motor isfixed to one side of one support plate through a first motor fixing base, an input end of the first motor is electrically connected with an output end of the first control switch, an output shaft ofthe first motor is connected with a first rotating shaft through a coupling, and the first rotating shaft penetrates through an inner rings of the bearings. According to the electronic product magnetic core clamping device, use is convenient, magnetic cores of different lengths can be clamped, the two ends are fixed and clamped simultaneously, automatic clamping is achieved, the magnetic cores ofdifferent diameters can be clamped, the device is uses widely, subsequent winding work is facilitated, and the working efficiency is improved.

Owner:珠海美源智科技有限公司

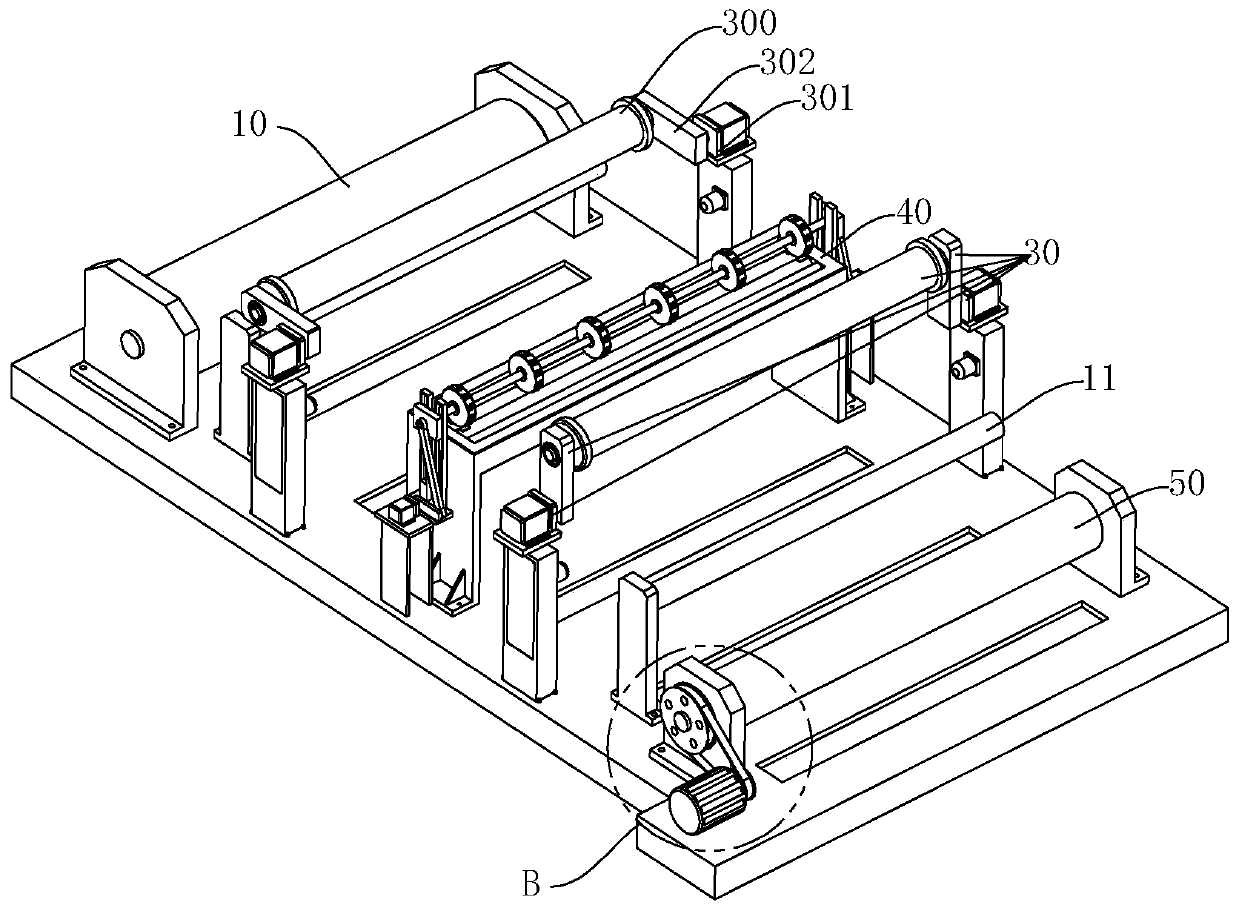

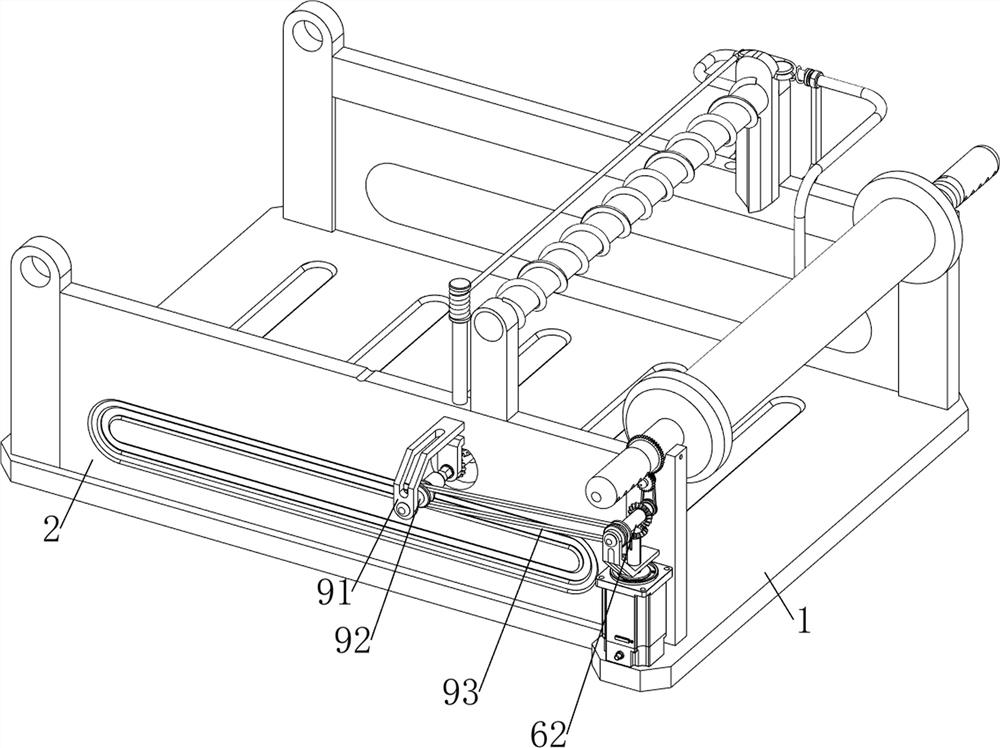

Optical fiber winding machine suitable for manufacturing optical fiber coils with different diameters

InactiveCN113104259AEasy to locate and moveEasy to wrapWrapping material feeding apparatusConveyor wrappingWinding machineWire rod

The invention discloses an optical fiber winding machine suitable for manufacturing optical fiber coils with different diameters. A bottom plate is of a rectangular plate-shaped structure, and a rotating structure, a traction structure, fixing plates, a tension detection structure and the other rotating structure are sequentially arranged at the top of the bottom plate from left to right. Extending plates are integrally formed at the two ends of the bottom plate, positioning structures are arranged at the positions, corresponding to passing cavities, of the adjacent side edges of the two fixing plates, three cooperation plates are fixed to the positions, corresponding to the outer edges of the passing cavities, of the sides provided with the positioning structures, extending cylinders are fixed to one ends of the three cooperation plates, and winding structures for assisting in winding of wires are mounted on the two extending cylinders. Wire inlets and wire outlets of the traction structure and the tension detection structure are on the same axis as the passing cavities. The optical fiber winding machine suitable for manufacturing the optical fiber coils with different diameters is reasonable in design, can avoid manual winding and attaching to protective layers during manufacturing of the optical fiber coils, improves the overall working efficiency, and is suitable for popularization and application.

Owner:南京欧汉智能设备有限公司

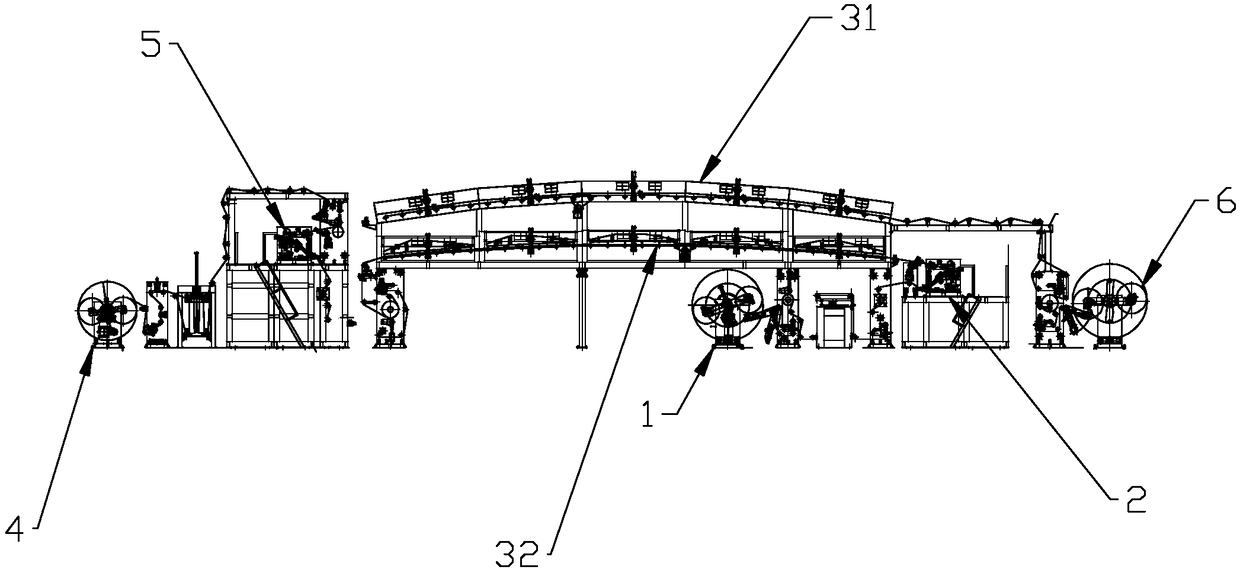

Stone paper coating process and device

InactiveCN109433565AAccelerate emissionsConducive to high-speed operationPretreated surfacesCoatingsMechanical engineeringComposite material

The invention discloses a stone paper coating process and device. Stone paper is unwound through a first unwinding mechanism, coating liquid for scrape coating of one surface of the stone paper is input into a coating mechanism, at the moment, a second unwinding mechanism can be selectively started to input a wet composite material, the material is wetly composited with the stone paper by a wet composite machine, then the stone paper is dried by a lower drying mechanism, then the stone paper is reversely rotated to the other surface of the stone paper, the other surface of the stone paper is subjected to the processes of coating, wet compositing and the like, then drying is conducted by an upper drying box, and finally, the stone paper is wound into a winding mechanism.

Owner:RUIAN DONGFANG MACHINERY MFG

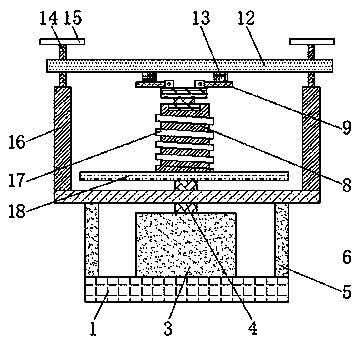

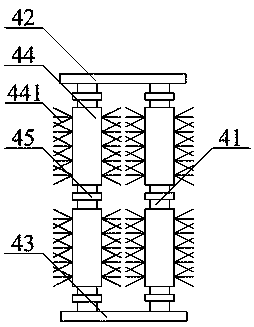

Anti-vibration capacitor film winding device

ActiveCN108447707AEasy to replaceIncrease production capacityWinding capacitor machinesCapacitanceBall bearing

The invention discloses an anti-vibration capacitor film winding device comprising a bottom box, an elevating rod, a second sleeve rod and a supporting column. The bottom box is internally provided with a conveying belt. The elevating rod is installed on the left side of the conveying belt. A first sleeve rod is arranged in an elevating separating plate. A rotating disc is connected on the left end of a first telescopic rod, and a buffer layer is installed on the right end of the first telescopic rod. A ball bearing is arranged on the external side of the first telescopic rod. The second sleeve rod is installed on the right side of the first sleeve rod. The right end of a second telescopic rod is provided with a connecting plate, and the right side of the connecting plate is provided witha driving motor. An accommodating groove is installed below the driving motor. The supporting column is installed on the upper end of the bottom box. The external side of a rotating rod is provided with a fixing rod. According to the anti-vibration capacitor film winding device, the vibration influence in the winding process can be avoided so that replacing of the film material can be facilitatedand production of the film capacitor can be accelerated.

Owner:NISTRONICS JIANGXI

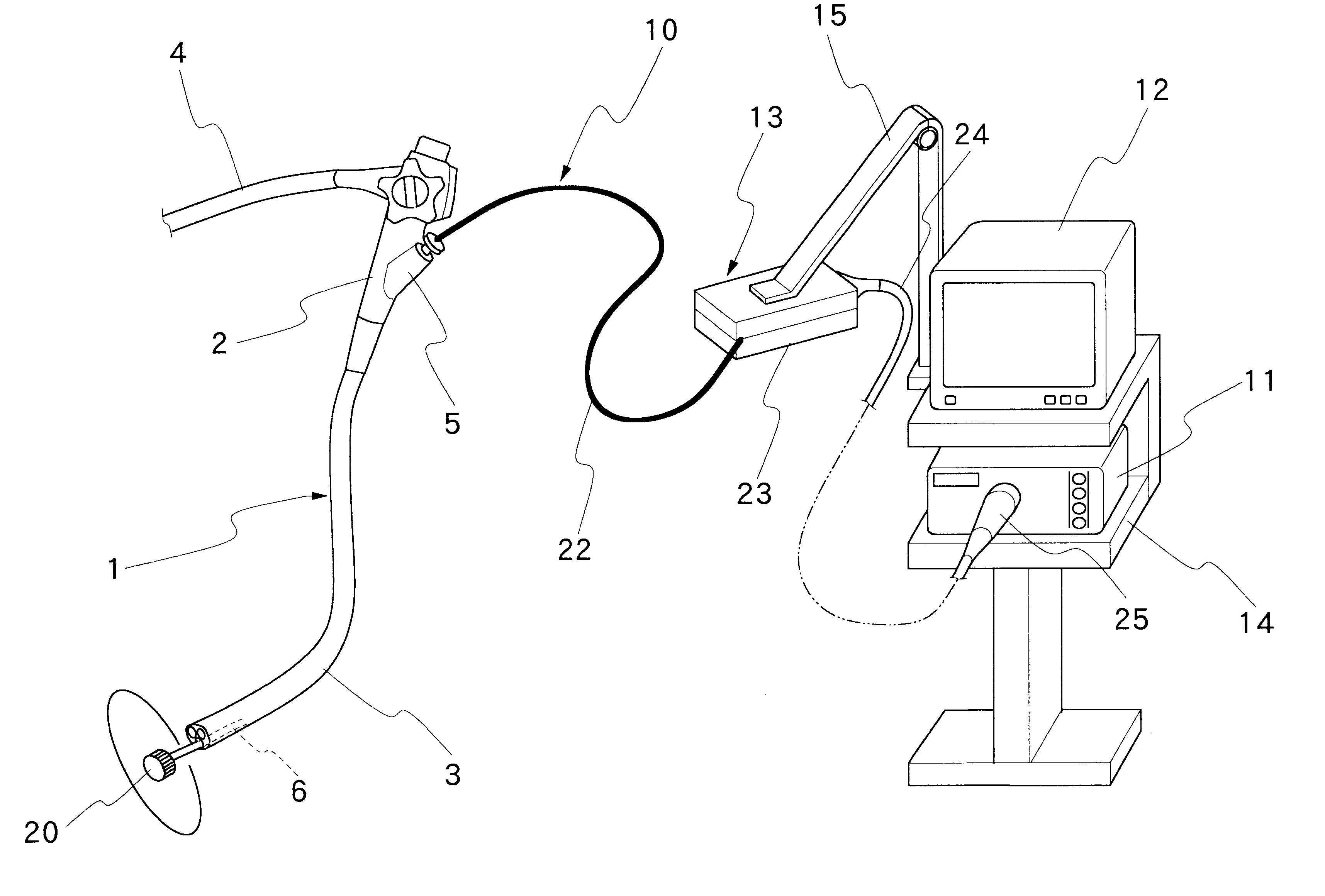

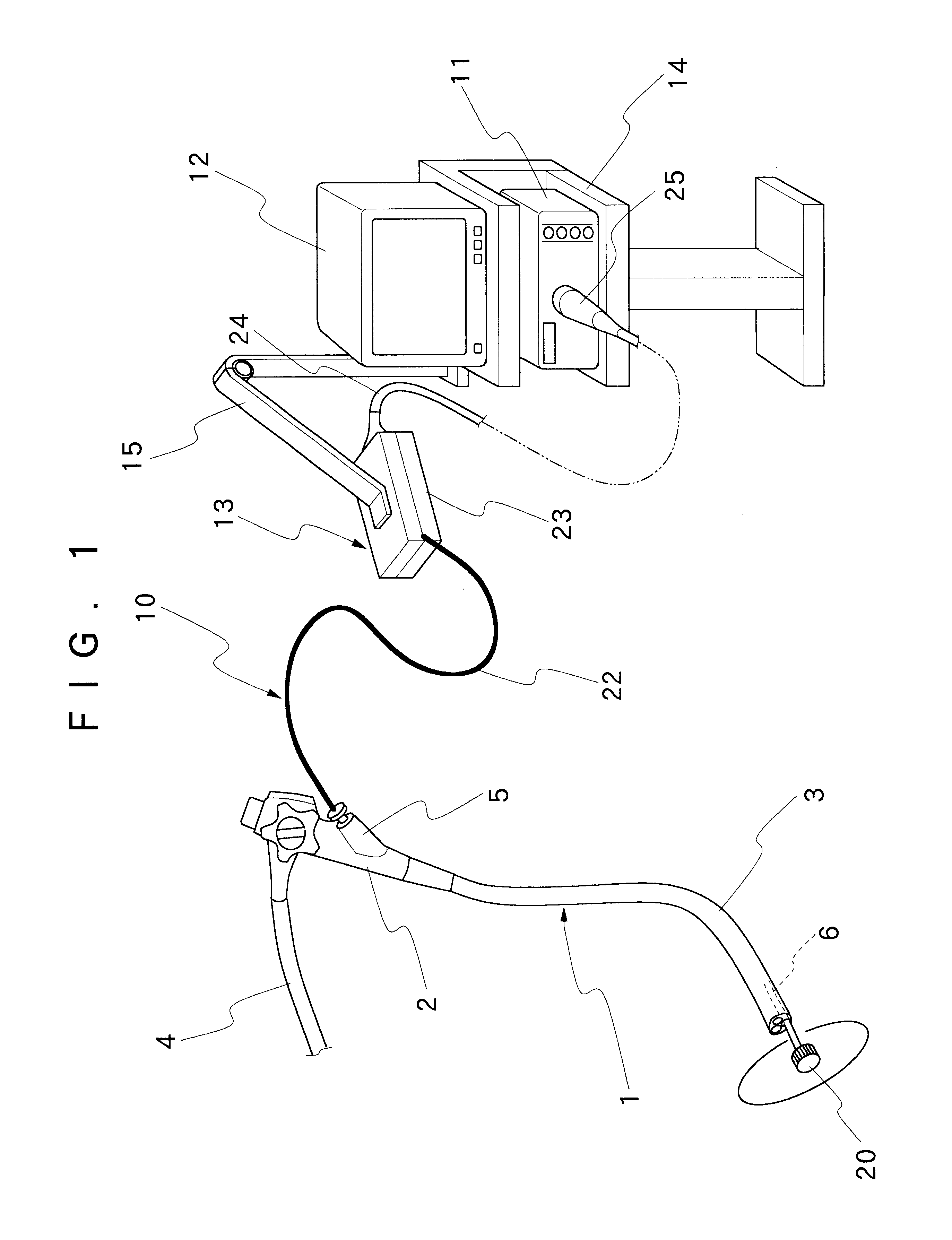

Ultrasound probe for ultrasound examination system

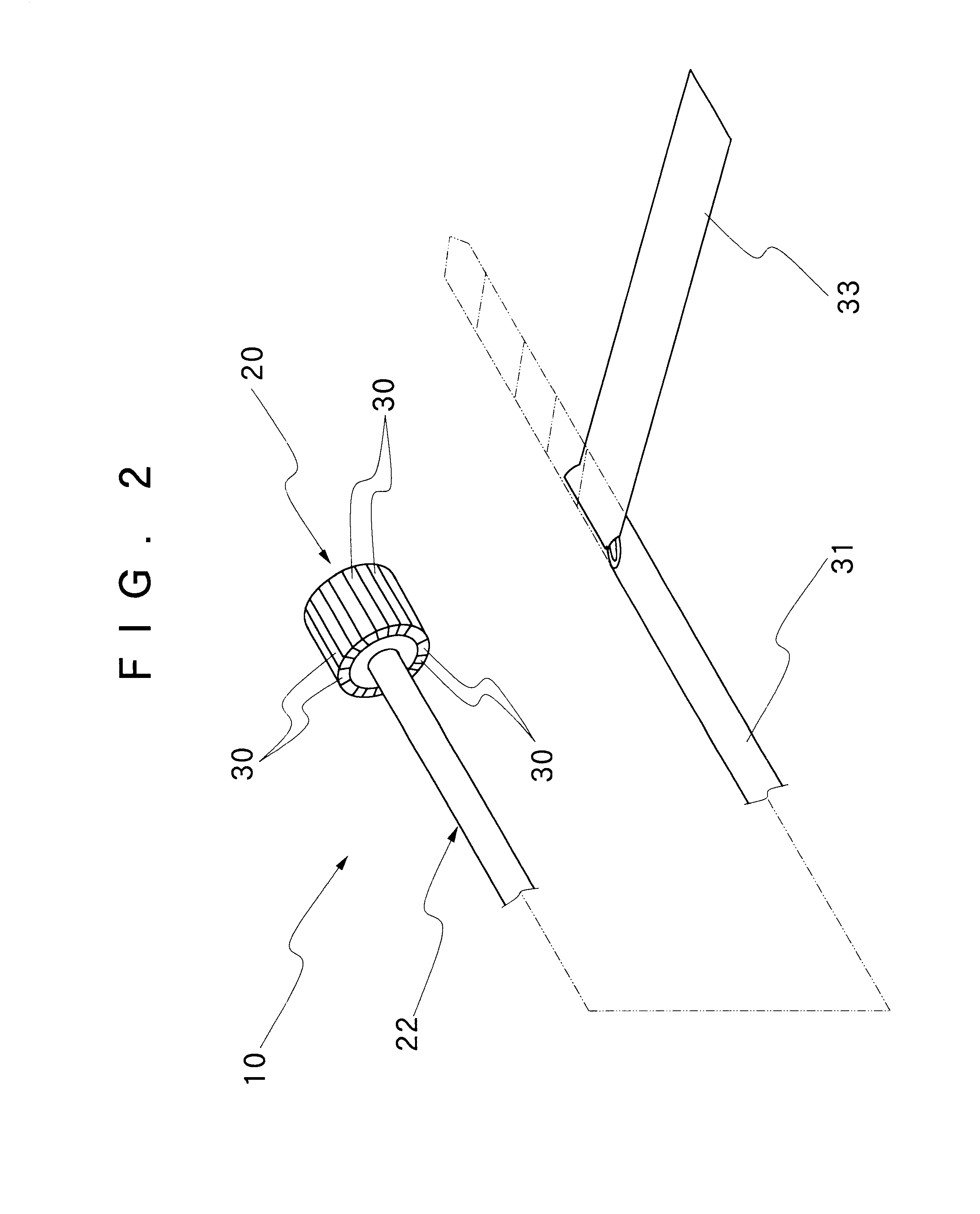

InactiveUS6673021B2Easy to passEasy windingUltrasonic/sonic/infrasonic diagnosticsSurgeryElectricitySonification

Attached to a proximal end portion of a flexible cord of an ultrasound probe of an ultrasound examination system, to be introduced into a body cavity through a narrow guide passage, is a flexible wiring film which can be coiled into a helical roll of a narrow cylindrical shape extending along an axial extension line of the flexible cord at the time of passing same through the narrow guide passage. Formed on a surface of the flexible wiring film are a plural number of wire connection points for connection of signal lines from transducer elements of an ultrasound transducer which is provided at a fore distal end of the flexible cord of the probe, and a corresponding number of electrodes which are electrically connected with the wire connection points through a wiring pattern. The electrodes on the flexible wiring film are disconnectibly connected to corresponding contact points on a contact assembly of a relay means.

Owner:FUJI PHOTO OPTICAL CO LTD

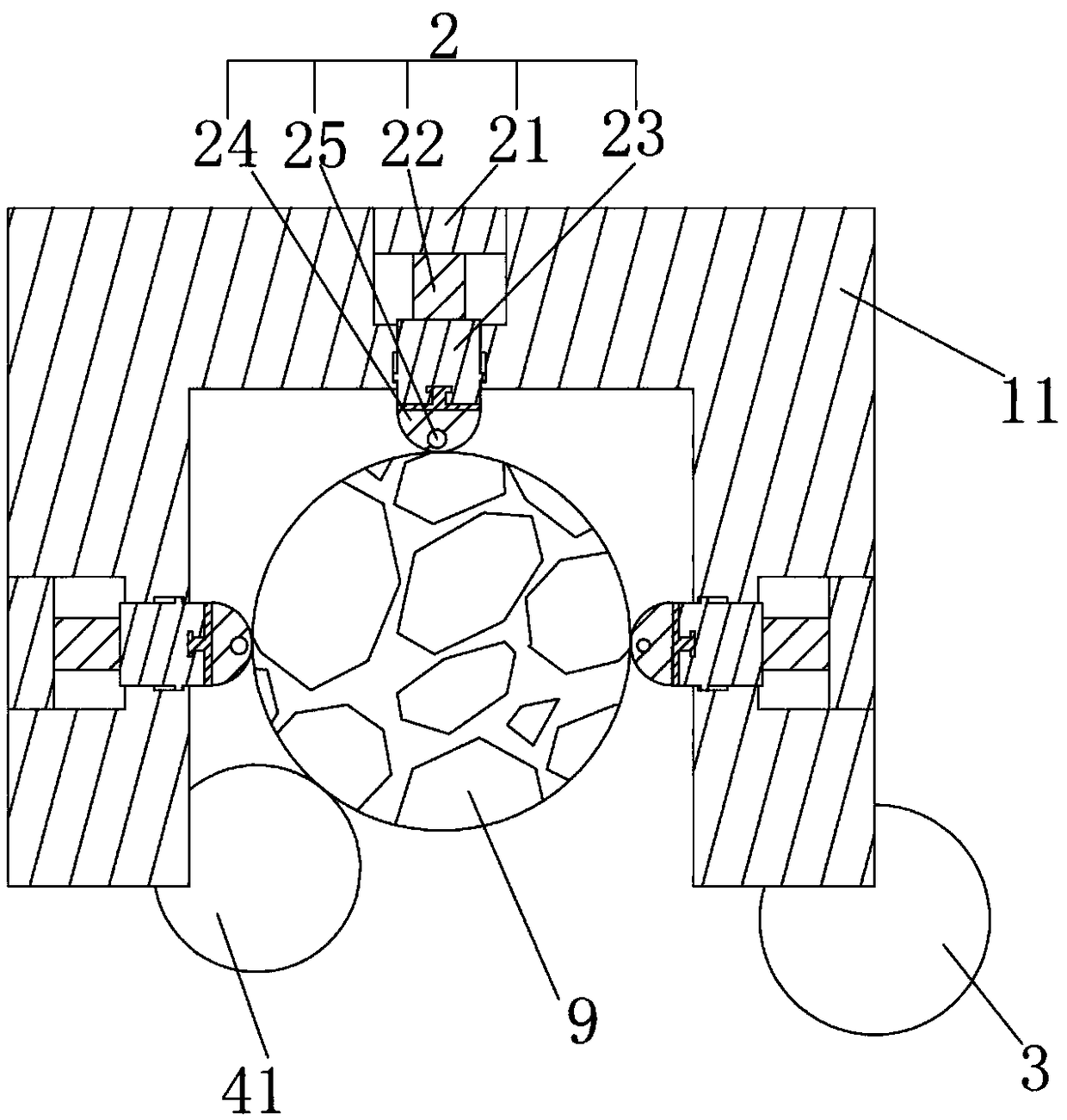

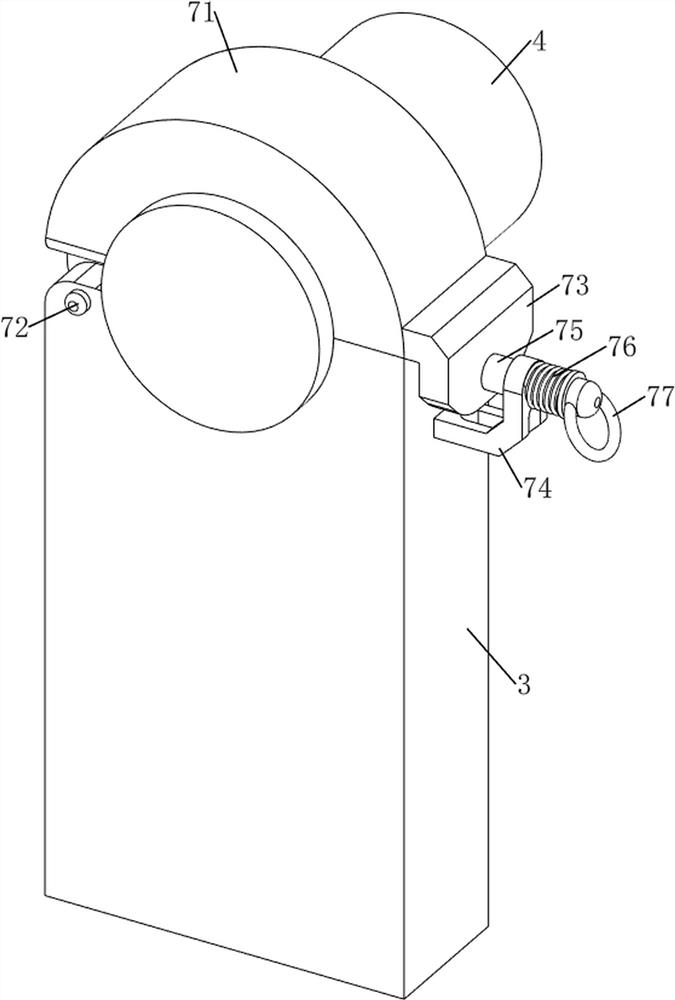

High-precision roundness detection device for tire mold production

InactiveCN112729071AConvenient detection workEasy to moveMechanical counters/curvatures measurementsRotational axisGear wheel

The invention discloses a high-precision roundness detection device for tire mold production, and the device comprises an operation main body, a motor, a first rotating disc, and supporting legs; one side of the bottom surface of the operation main body is provided with the supporting legs, one side of the interior of each supporting leg is provided with an auxiliary supporting rod, and one side of each auxiliary supporting rod is provided with a second gear; a winding wheel is arranged on one side of the second gear, a pull rope is arranged on the surface of the winding wheel, a threaded rod is arranged at one end of the pull rope, a rotating block is fixedly connected to the bottom end of the threaded rod, and supporting legs are arranged on the bottom surface of the rotating block. According to the roundness detection device for high-precision tire mold production, through rotation of a rotating shaft, a second rotating disc can be in sliding connection with a second moving rod through a second sliding groove for moving work conveniently, the second moving rod can drive a moving block to move conveniently, and the moving block can clamp the inner side of a tire mold conveniently; the tire mold can be limited, and the tire mold is prevented from moving in the detection process.

Owner:山东力创模具股份有限公司

Multistage type mechanical arm protection case

InactiveCN107671895AExtended service lifeStable working environmentManipulatorFiltrationAgricultural engineering

The invention discloses a multistage type mechanical arm protection case, which comprises a case body, hanging rings, a filter layer and a fixing block. A protection sleeve is arranged on the bottom part of the case body; a bolt is fixedly connected above the protection sleeve; a waterproof layer is connected into a shock absorption cavity; rubber strips are fixedly arranged above the waterproof layer; the case body is fixedly connected above the hanging rings; the upper parts of the hanging rings are connected with pothooks through pull ropes; a mechanical arm placing hole is formed in the middle of the rubber strips; the case body is arranged above damping springs; through holes are fixed to the upper side and the lower side of the filter layer; protection layers are arranged on the leftside and the right side of the filter layer; a protection sleeve is arranged under the fixing block; and a bolt is connected above the fixing block. The multistage type mechanical arm protection caseis provided with the shock absorption cavity, so that a machine can not be affected by an external factor during a working process, meanwhile, a mechanical arm can be well protected, and the servicelife of the whole mechanical arm is prolonged.

Owner:刘和勇

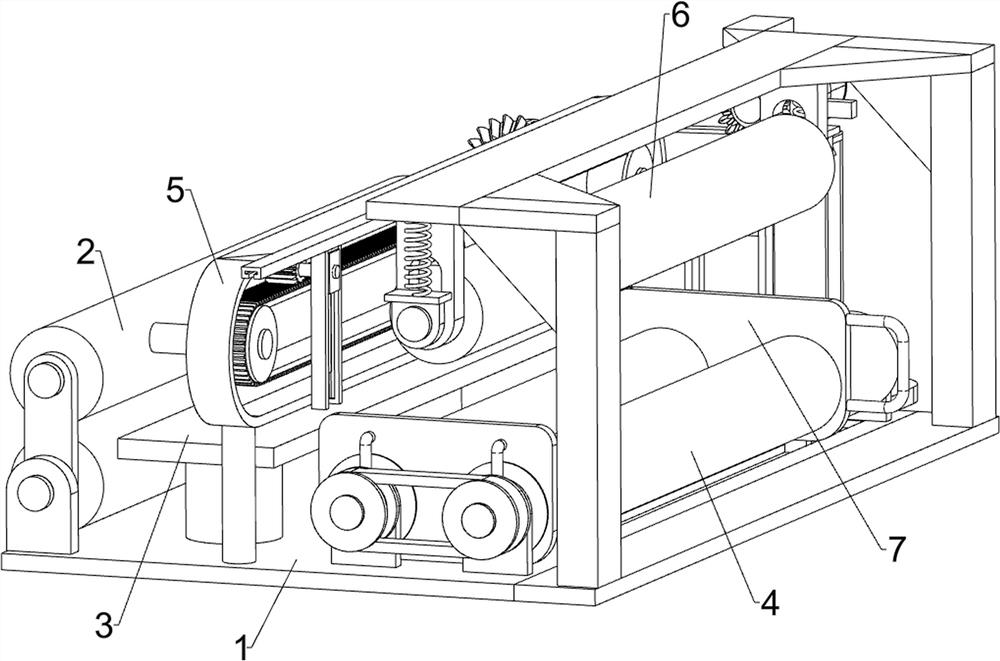

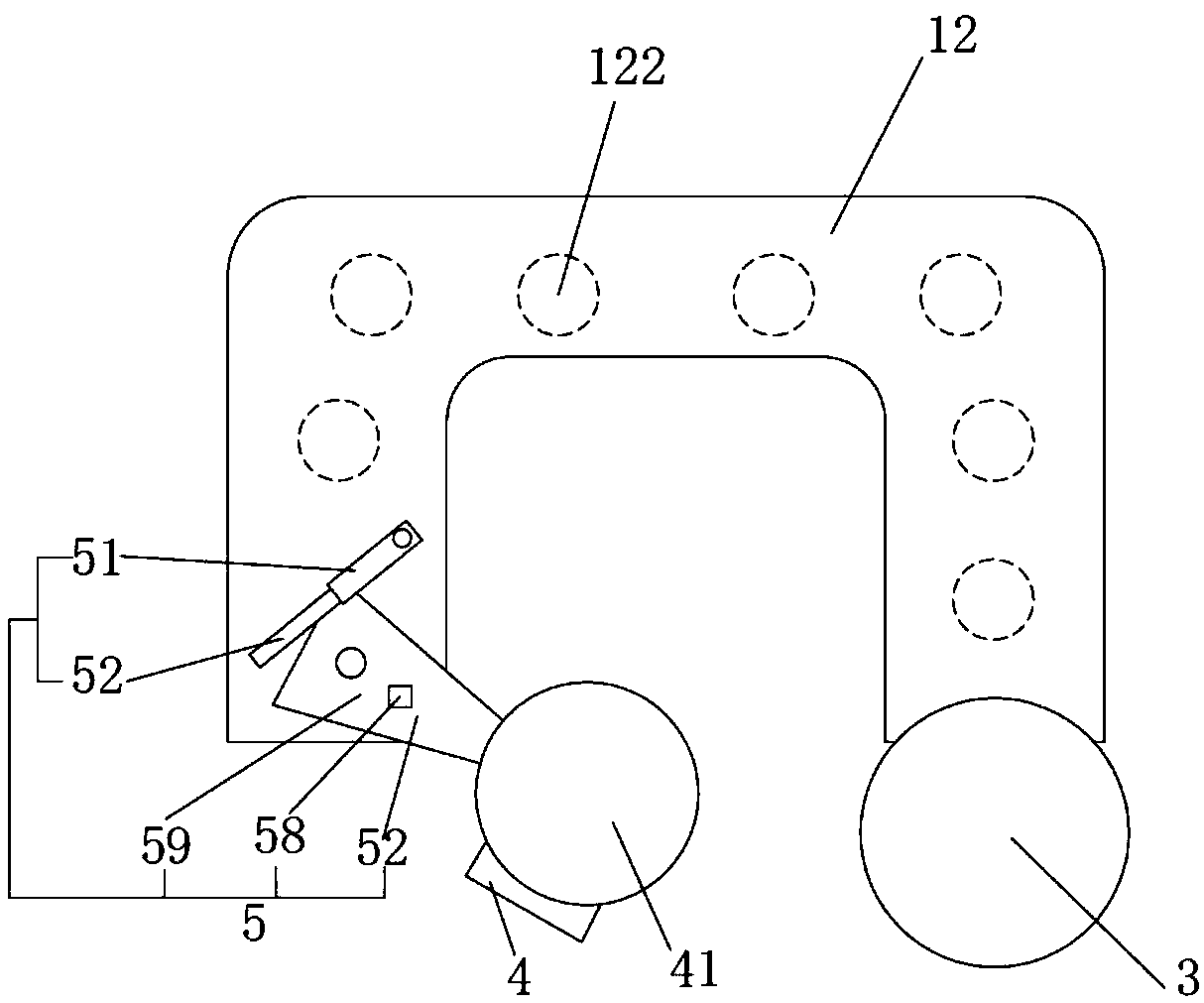

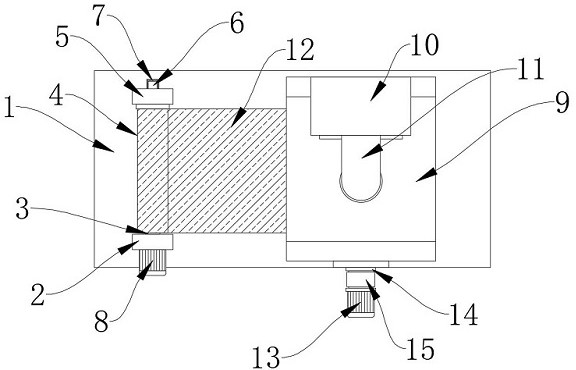

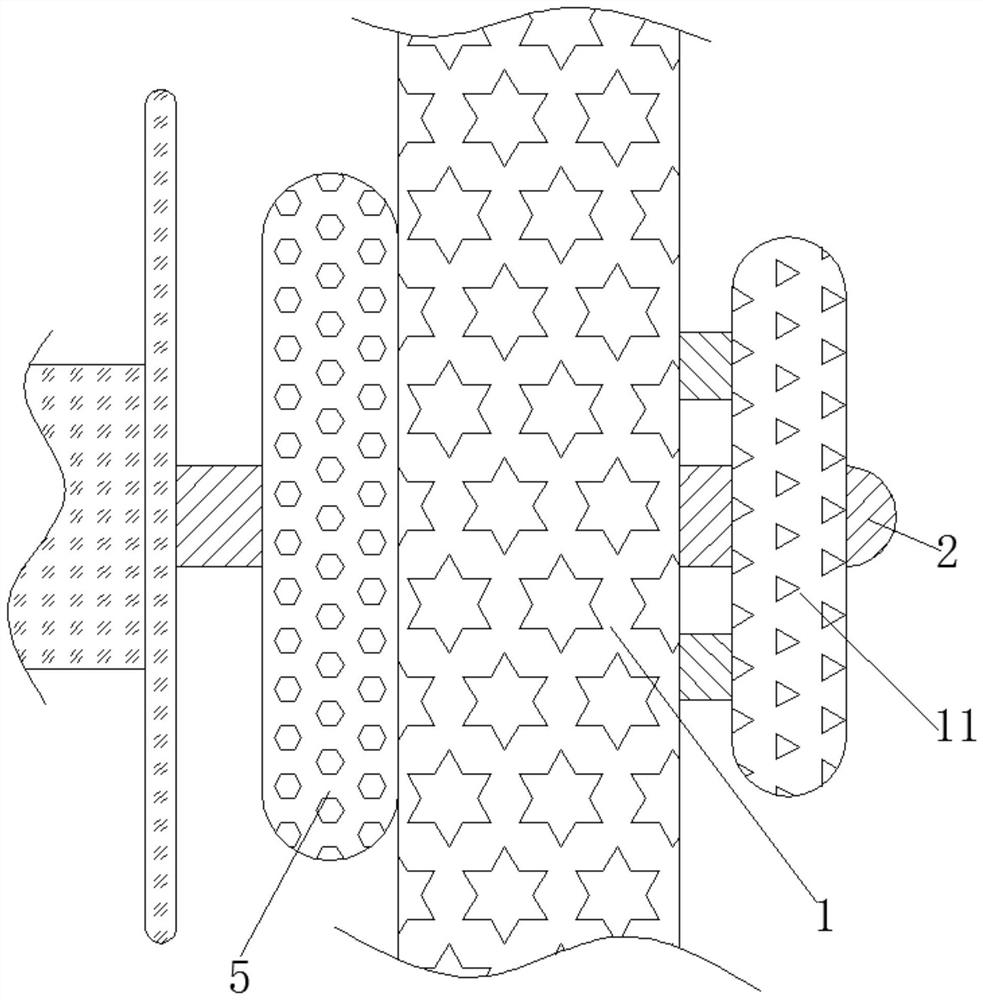

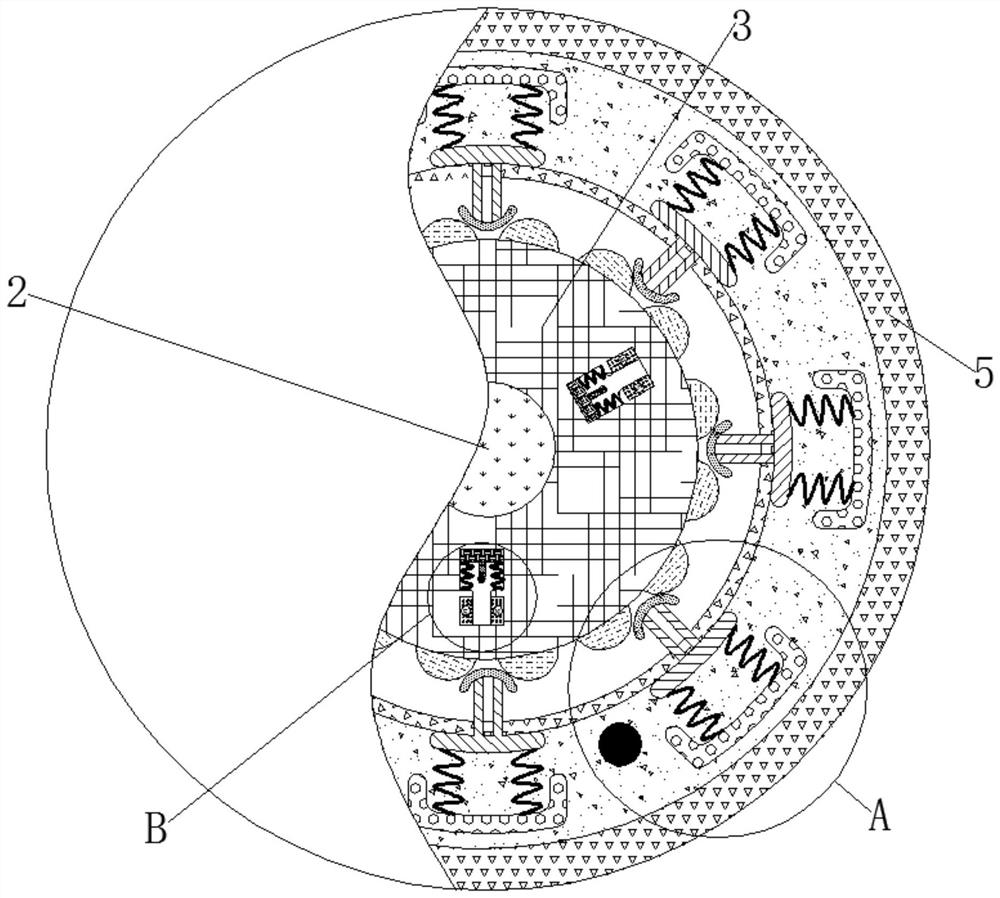

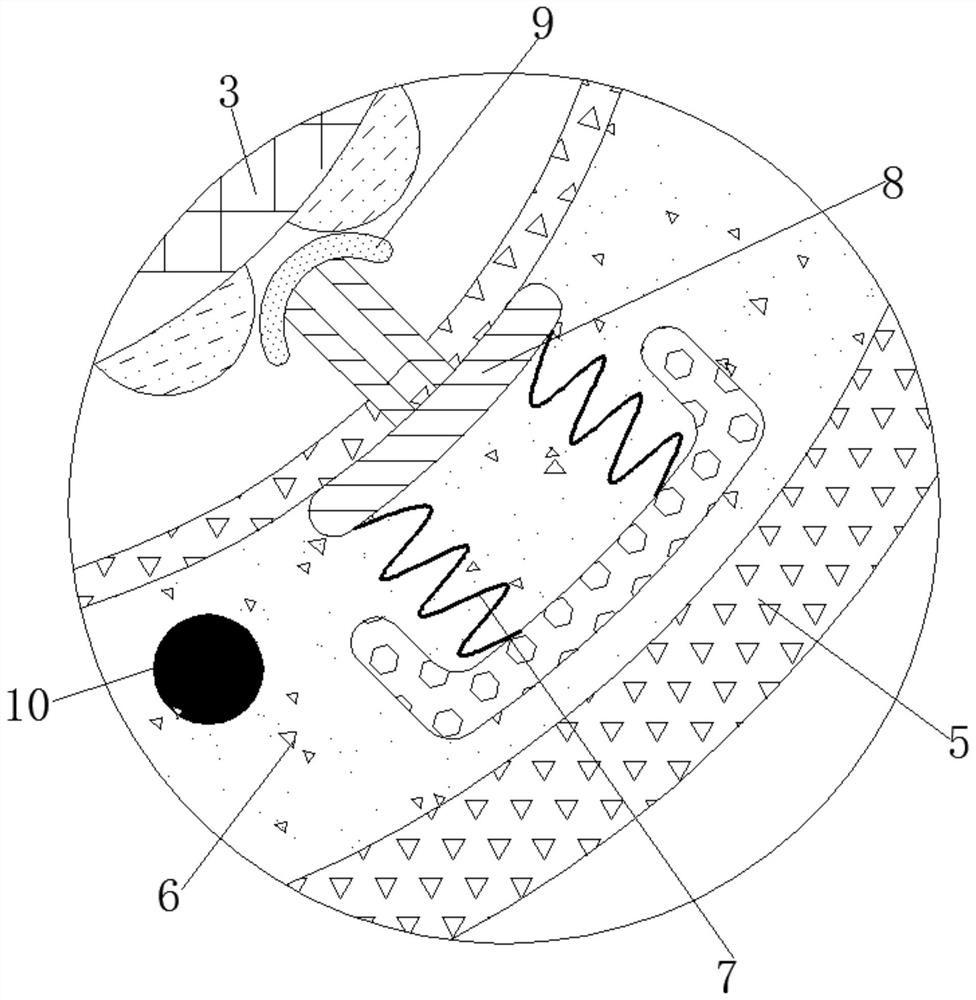

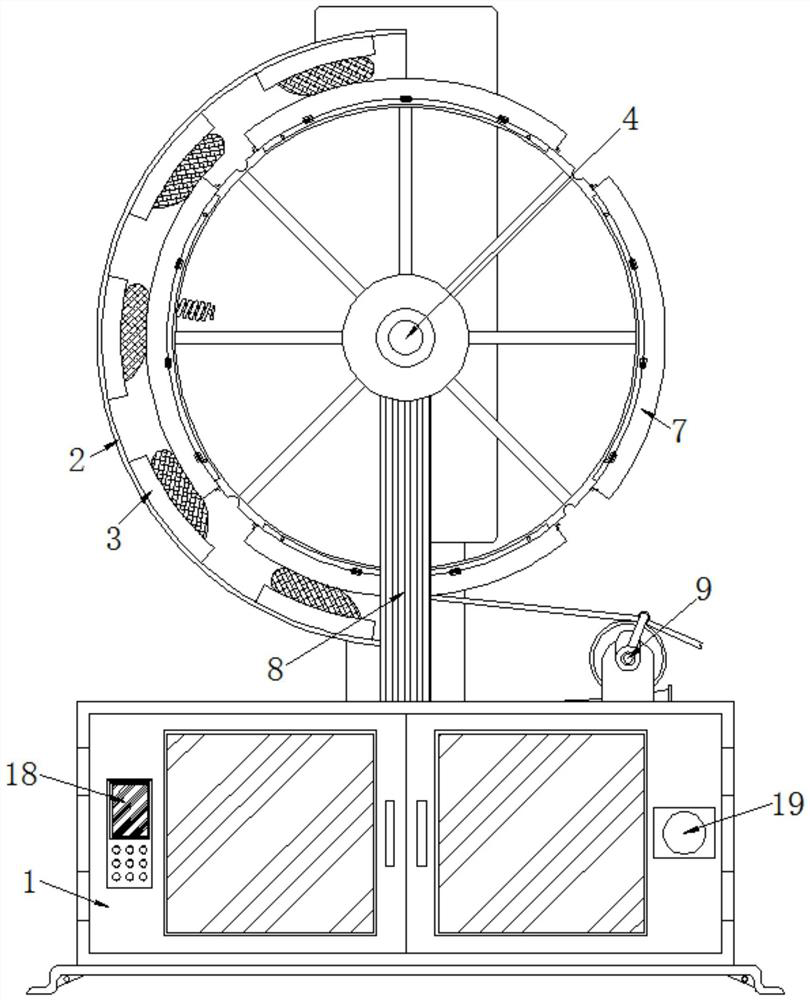

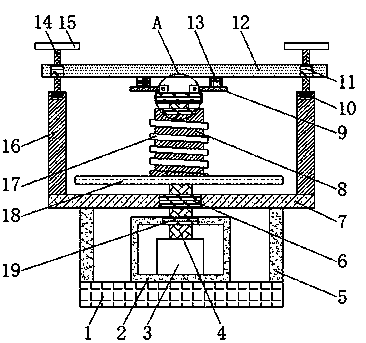

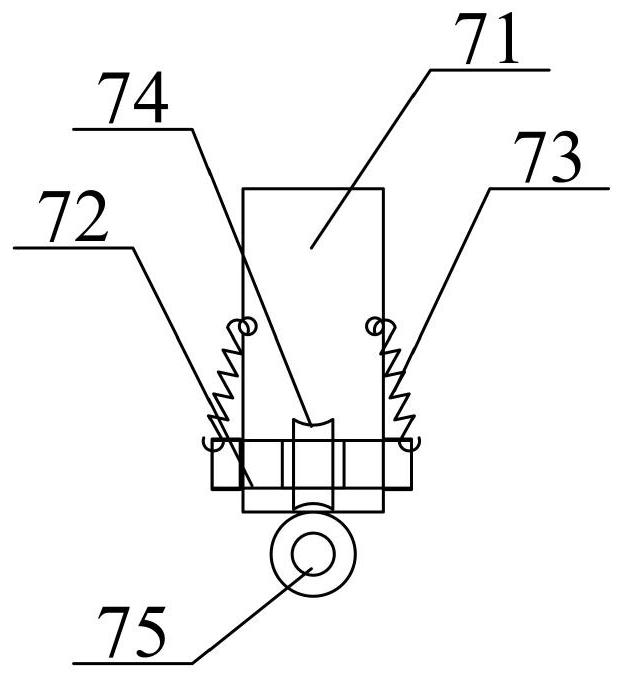

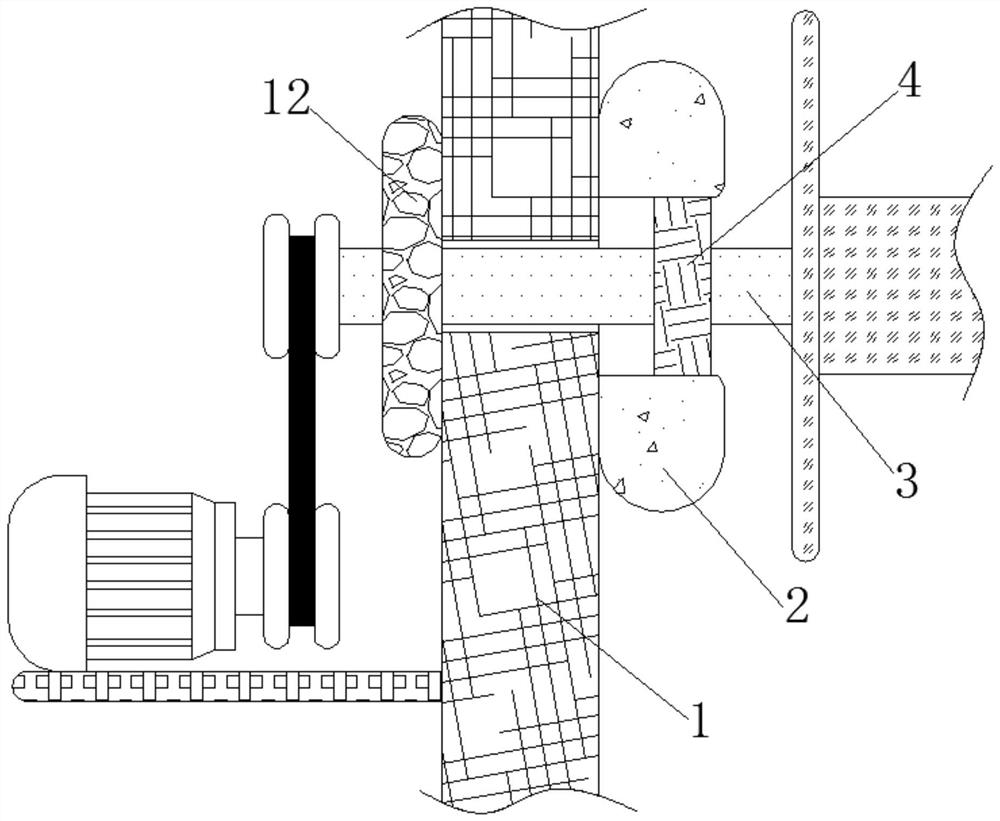

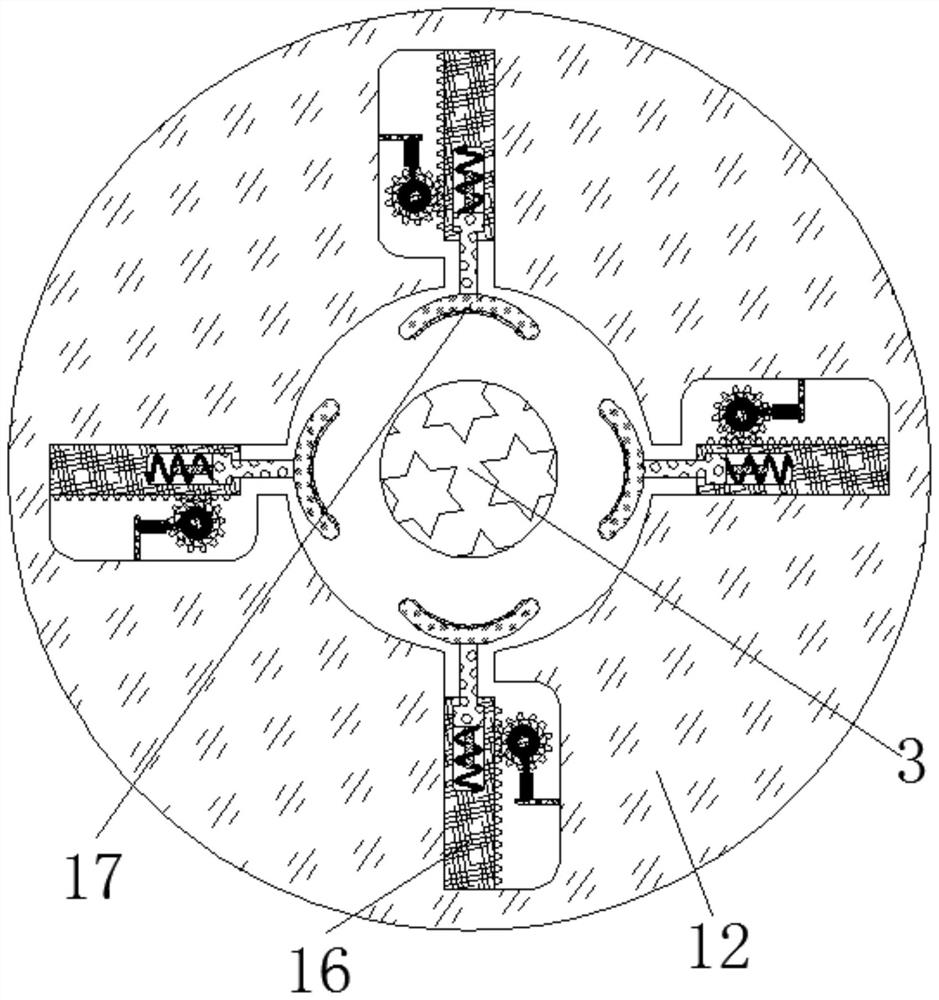

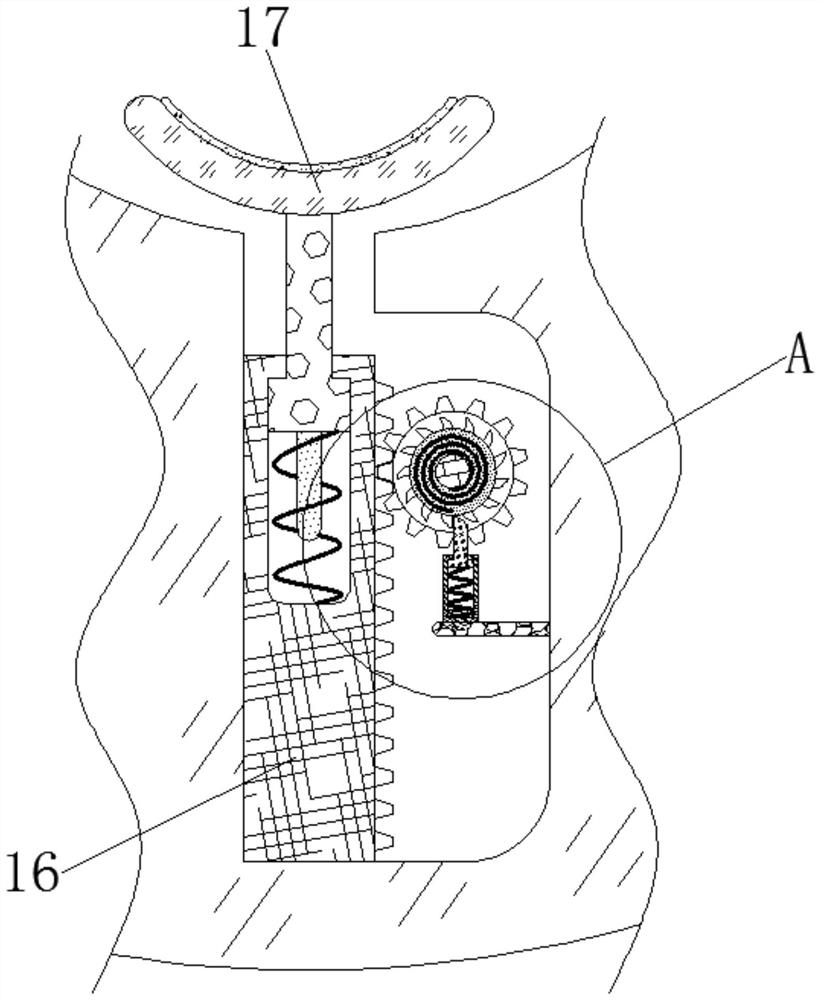

Novel heat-insulation device for trunks of gardening trees

InactiveCN108849133AConvenient winding workLabor savingPlant protective coveringsInsect catchers and killersDrive wheelElectric machinery

The invention discloses a novel heat-insulation device for trunks of gardening trees. The novel heat-insulation device comprises a frame housing, wherein the frame housing comprises an upper frame anda lower frame, the upper frame is internally provided with three compressing mechanisms abutting against the outer surface of a trunk along its inner wall in an array way, one end of the lower frameis rotatably provided with a roller for a heat-insulation rope to be wound for storage, a driving wheel driven by a first driving motor is hinged to the other end of the lower frame, achieves positionlocking through a limiting mechanism and is compressed with the outer surface of the trunk of a tree, the lower frame is provided with a storage groove communicated with the outside in its circumferential direction, multiple guiding wheels are arranged in the storage groove in an array way, and the upper frame is provided with a horizontal adjusting mechanism. The novel heat-insulation device replaces the manual work of winding straw ropes around the trunk of the tree and achieves automatic winding of the heat-insulation ropes around the trunk of the tree, the working efficiency is effectively improved, the labor intensity of workers is reduced, and the work of winding around trees is quicker and more convenient.

Owner:陈宏涛

Winding device capable of removing thread ends for spinning

The invention discloses a winding device capable of removing thread ends for spinning. The winding device comprises a storing frame main body, a storing frame, guide rollers, a winding roller, a motorand an electric telescopic rod, wherein the storing frame is arranged inside the storing frame main body; a first bidirectional screw rod is fixedly arranged at the front end inside the storing frame; upper pressing plates are connected to the rear side of the first bidirectional screw rod; a fixing plate is arranged below the rear end of each upper pressing plate; and the guide rollers are arranged above and below the storing frame. According to the winding device, two undercutting tools and the two upper pressing plates are arranged, the thread ends on a passing spinning can be convenientlyfixed through the fixing of the upper pressing plates and can be conveniently cut off through the contact of the undercutting tools and the upper pressing plates when the undercutting tools rise; andmeanwhile, the rectangular storing frame open at two ends and the two guide rollers are arranged, so that two undercutting tools cut two sides of a spun yarn well at the same time.

Owner:杭州兴裕丝绸有限公司

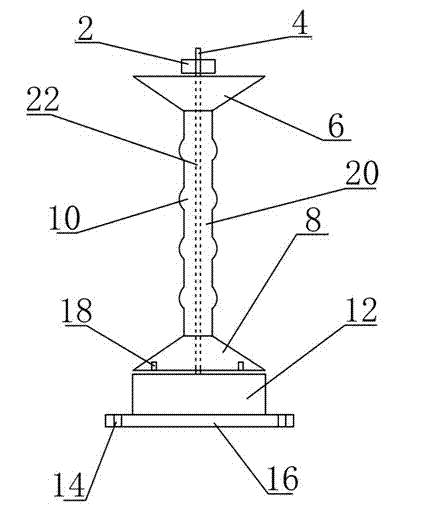

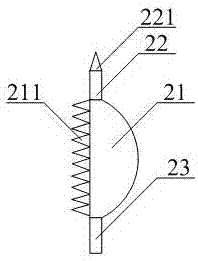

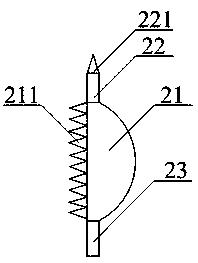

Yarn winding device

The invention discloses a yarn winding device. The yarn winding device comprises a body and a base which is arranged below the body, wherein the body comprises a tip cone, a vertical rod and a bottom cone. The yarn winding device is characterized in that a plurality of circles of protrusions are arranged on the vertical rod, the tip cone is an inverted cone which is big-end-up, and the bottom cone is a cone which is big-end-down. According to the yarn winding device, the structure of the body is improved, yarn can not be disengaged or knotted easily due to the arrangement of the tip cone and the bottom cone, friction and resistance are increased when the device works due to the fact that the circles of protrusions are additionally arranged on the vertical rod, and slipping and disengaging of the yarn can not occur easily. The yarn winding device has the advantages of being simple in structure, convenient and fast to use, low in cost and the like.

Owner:WUJIANG QIANQIANHE TEXTILE

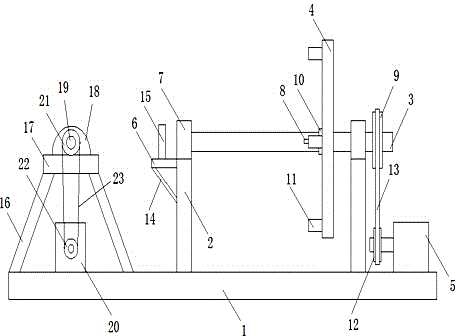

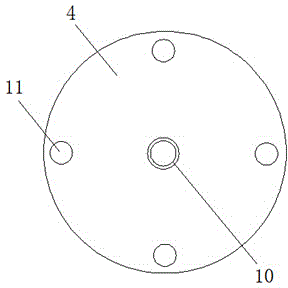

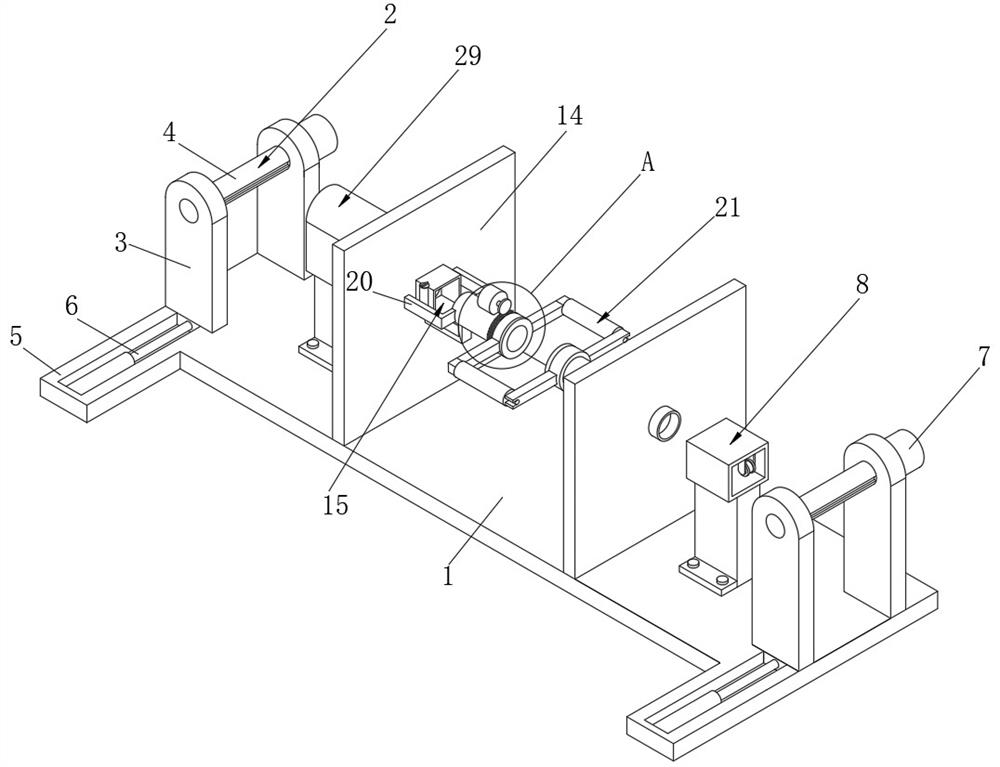

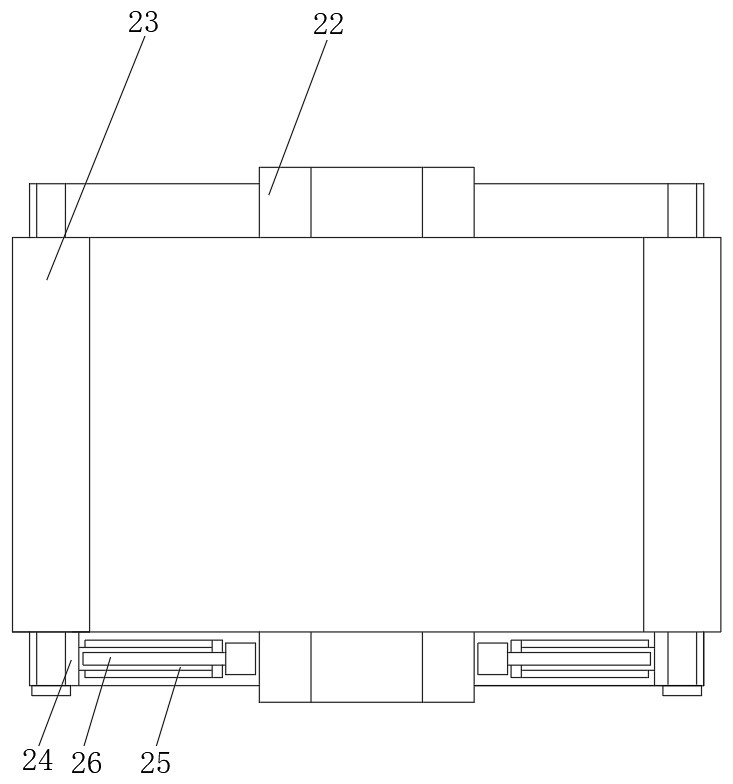

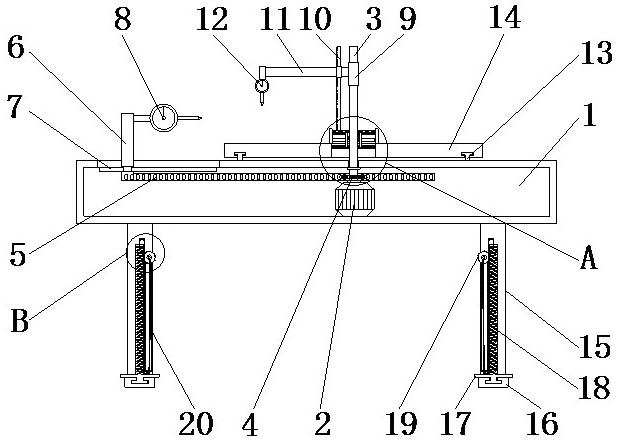

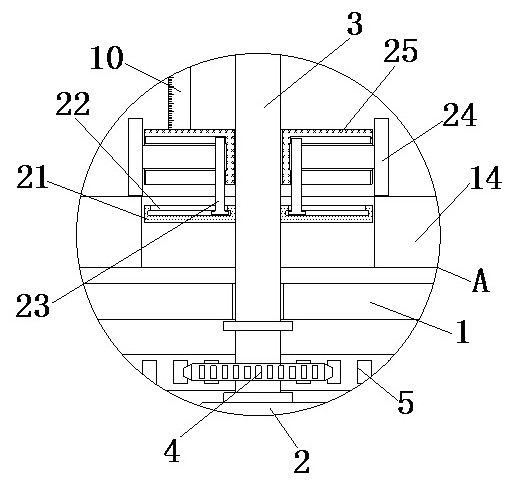

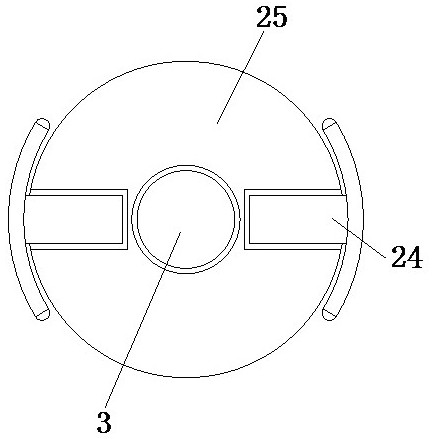

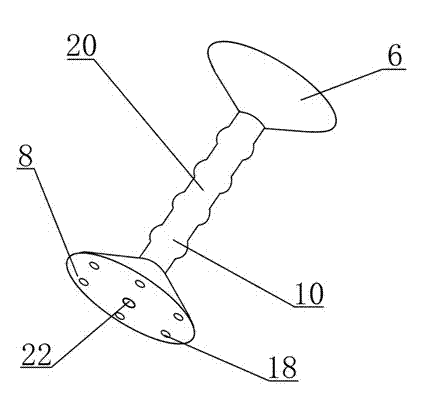

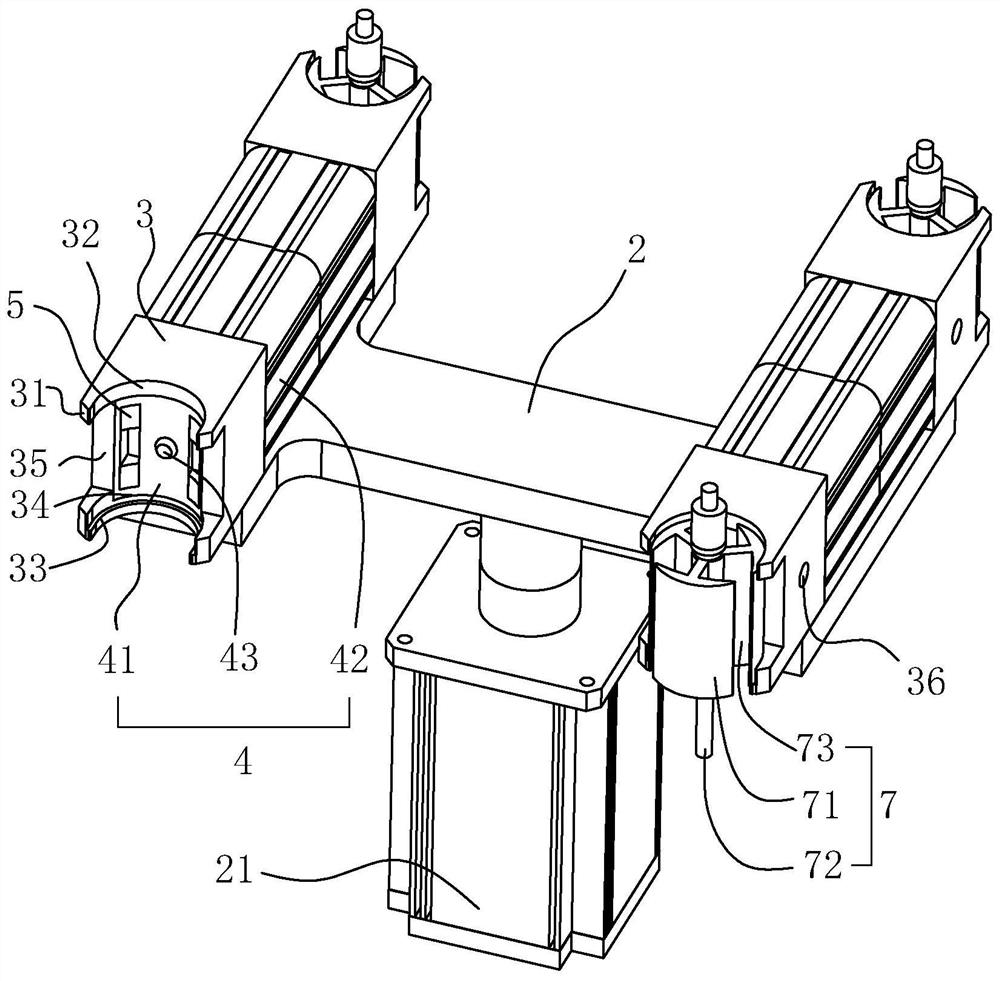

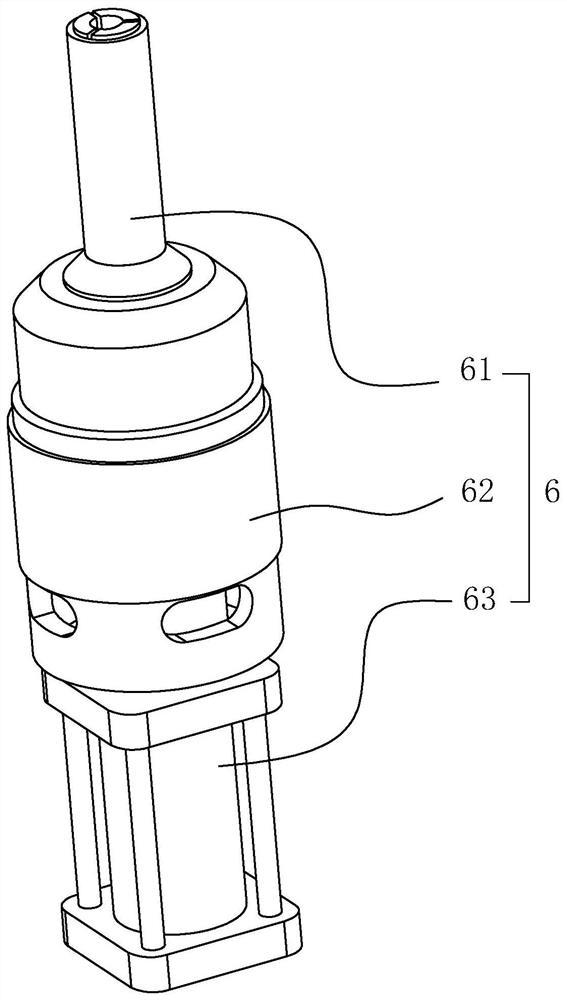

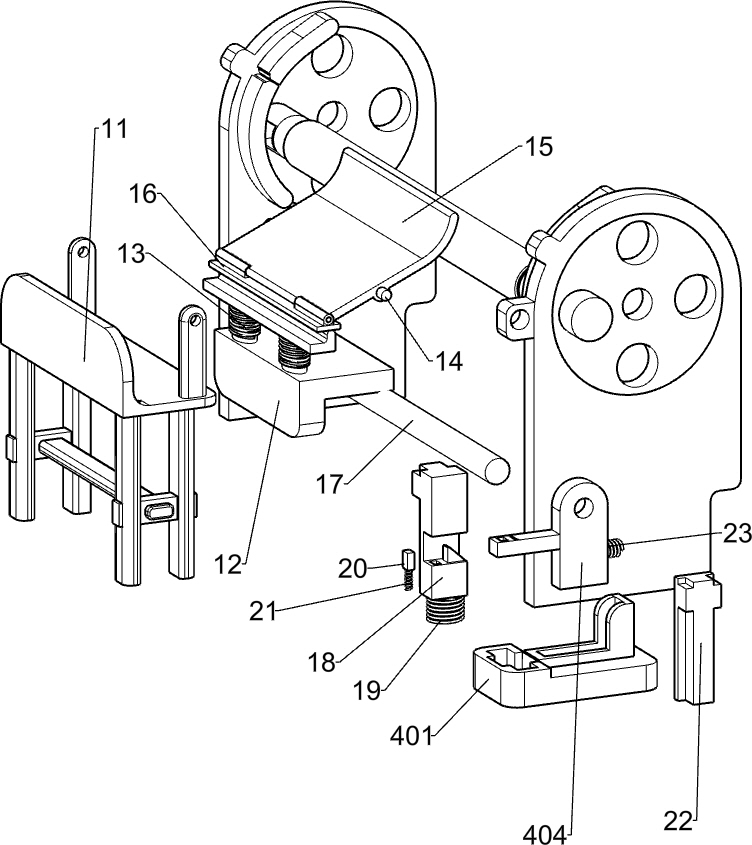

Feeding device for micromotor rotor winding machine

ActiveCN112636553AHigh precisionImprove processing efficiencyWork holdersManufacturing dynamo-electric machinesWinding machineMicromotor

The invention relates to the field of micromotor rotor winding machines, and in particular to a feeding device for a micromotor rotor winding machine. The device comprises a feeding table and further comprises a rotating table with the center rotationally connected to the feeding table, a driver for driving the rotating table to rotate is arranged on the feeding table, and rotor limiting heads are symmetrically arranged at the two ends of the rotating table with respect to the rotating center axis. The rotor limiting heads are provided with rotor positioning assemblies, a micromotor rotor can be effectively positioned before being wound, and in the winding process of the micromotor rotor in the rotor limiting head on one side, the micromotor rotor can be taken and placed in the rotor limiting head on the other side, so that the winding positioning accuracy is improved, and the winding efficiency is effectively improved.

Owner:温岭市新纪元微电机厂(普通合伙)

Winding device for brass strip machining

The invention discloses a winding device for brass strip machining. The winding device comprises a winding device body, a rotary shaft, a winding drum, a push plate, a fixing mechanism, a push plate mechanism and a limiting mechanism. The rotary shaft is connected with the surface of one side of the winding device body. The rotary shaft penetrates through the winding drum and a push plate. The surface of one side of the push plate is fixedly connected with clamping blocks. The positions, opposite to the outer surface of the push plate, of the surface of one side of the winding drum is providedwith clamping grooves. The fixing mechanism comprises a baffle. Thus, the winding drum can be rapidly fixed and is effectively clamped between the push plate and the baffle. Meanwhile, clamping blocks and the clamping grooves are clamped for fixation, and straight bars are in a limiting state in limiting grooves so that the rotary shaft can rotate to drive the winding drum to rotate to achieve the rotation transfer effect and facilitate winding of a brass strip better. Moreover, through threaded connection and fixation of a clamp bolt, the winding device is easier to disassemble and assembleand tighter and brings convenience to winding of the brass strip during machining.

Owner:GUIXI AOTAI COPPER IND

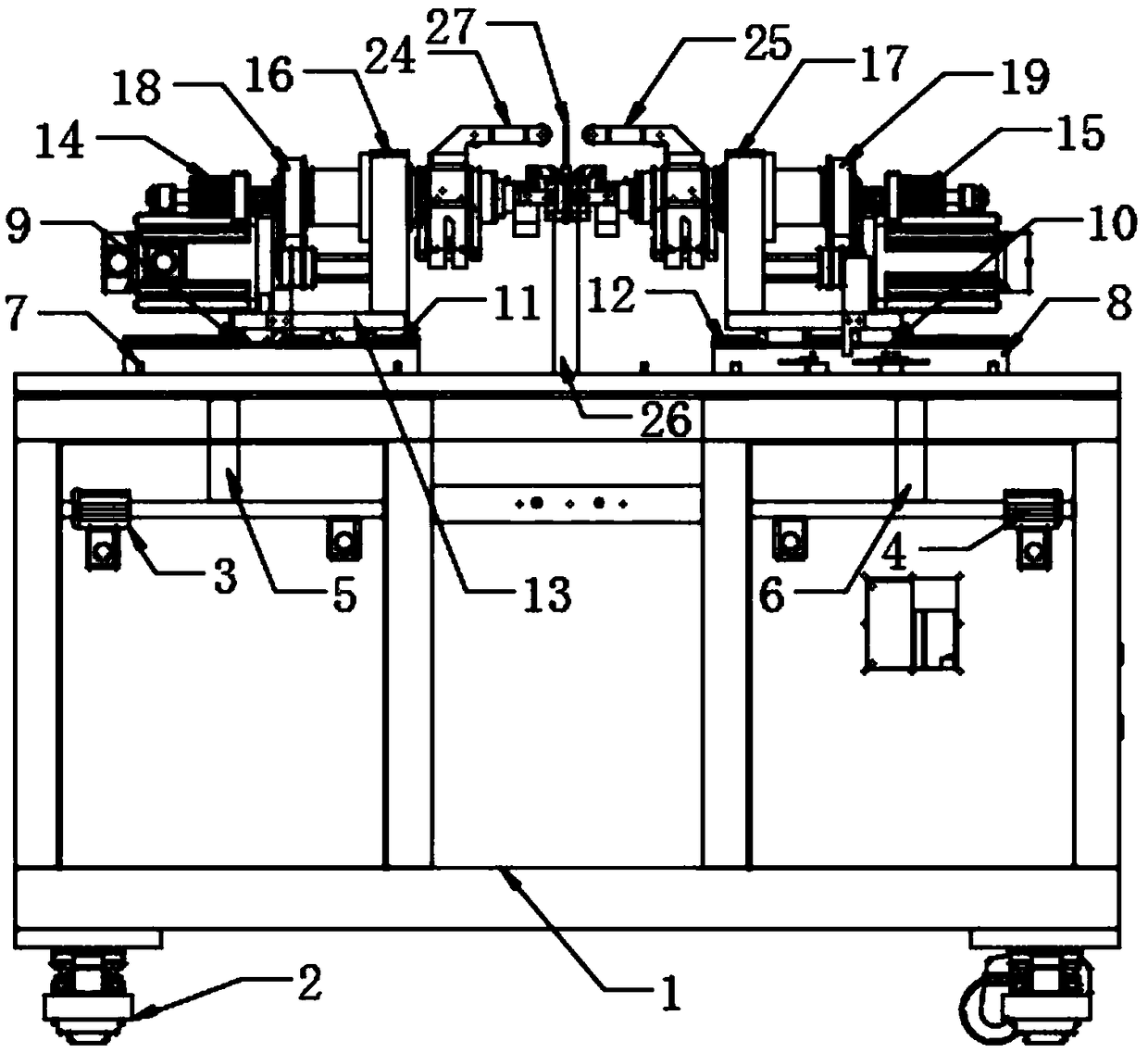

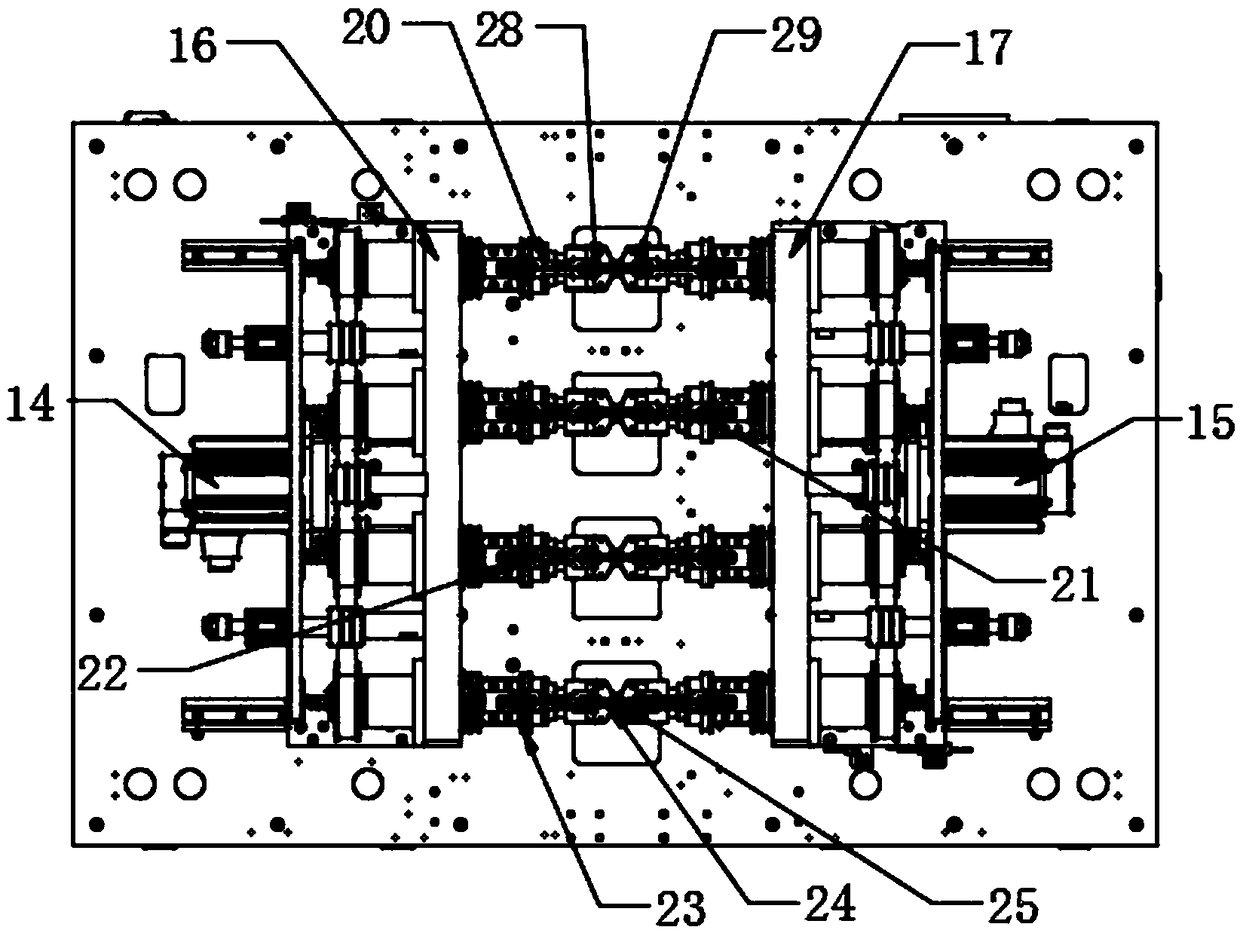

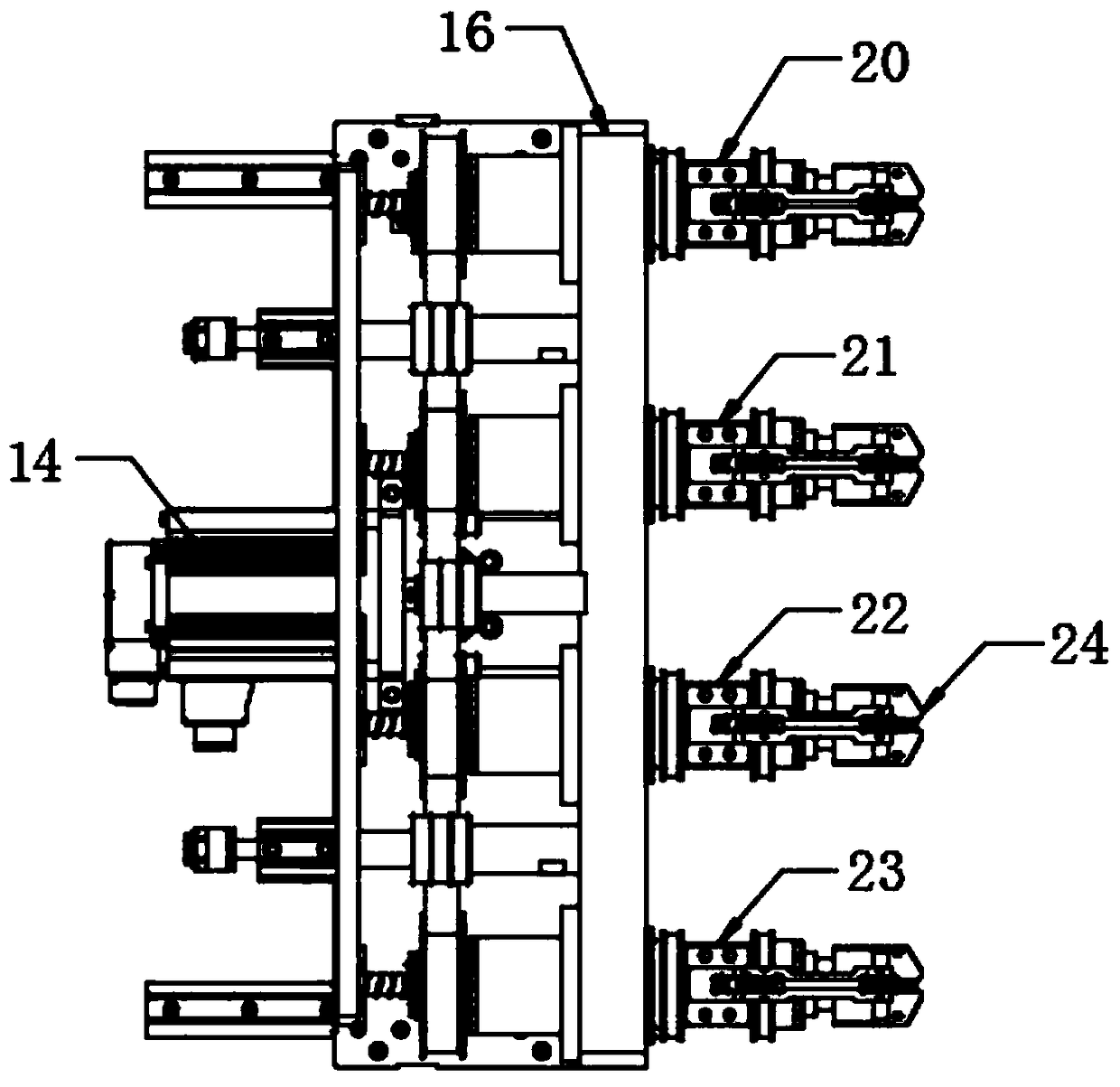

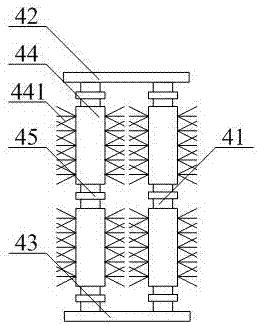

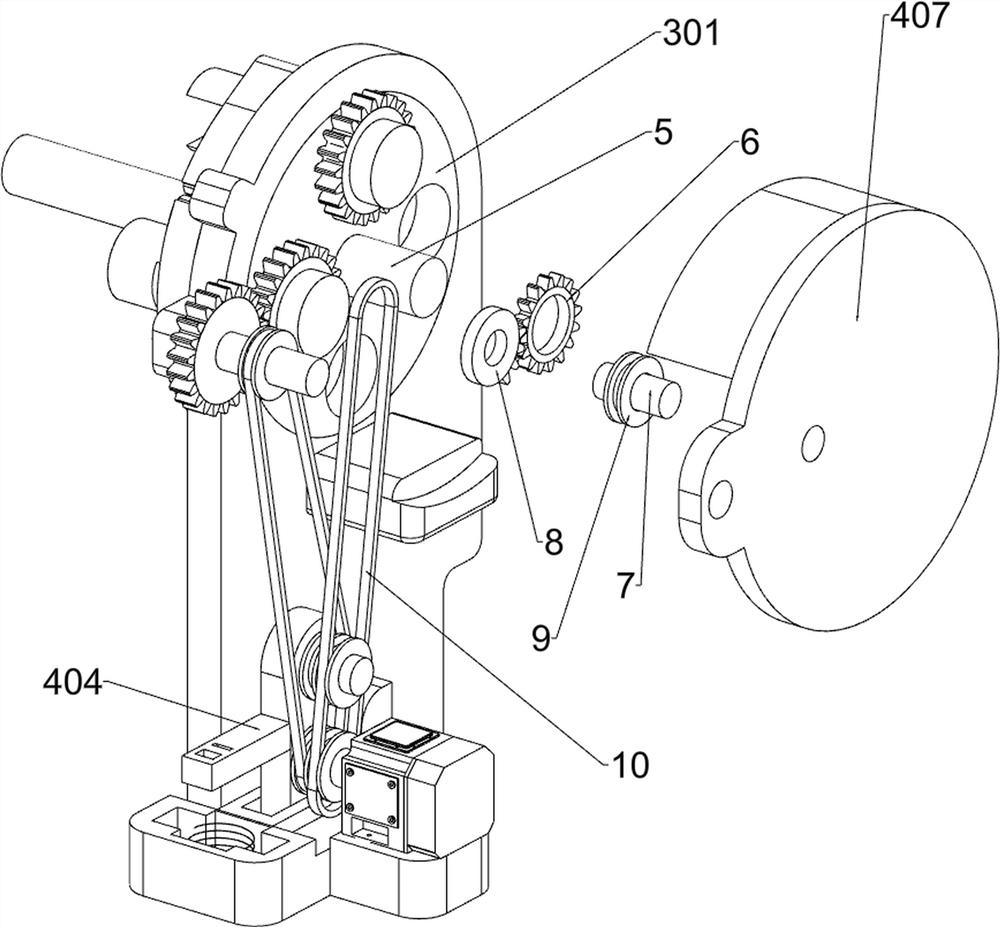

Multi-station full automatic double-flying fork winding machine

InactiveCN108880142AImprove winding efficiencySimple structureManufacturing dynamo-electric machinesWinding machineDrive wheel

The invention discloses a multi-station full automatic double-flying fork winding machine which comprises a box body, wherein a rolling wheel is fixedly arranged in the lower end surface of the box body, a left wire arranging motor and a right wire arranging motor are fixedly arranged on two sides of the inner part of the box body respectively, a first driving wheel and a second driving wheel aremovably arranged on the left wire arranging motor and the right wire arranging motor respectively, a first screw rod assembly and a second screw rod assembly are fixedly arranged on two sides of the upper end surface of the box body respectively, a plurality of first driven wheels and second driven wheels are movably arranged on the first screw rod assembly and the second screw rod assembly respectively, a first wire arranging mechanism and a second wire arranging mechanism are fixedly arranged in one side end surface of the first driven wheel and the second driven wheel respectively. According to the multi-station full automatic double-flying fork winding machine, a multi-head double-flying fork winding machine is derived by redesigning the equipment layout and maximizing the space layoutof the equipment, the production efficiency is greatly improved, the structure is compact, the cost is low, and the blank of the multi-head double-flying fork winding machine on the market is made up.

Owner:深圳市合利士智能装备有限公司

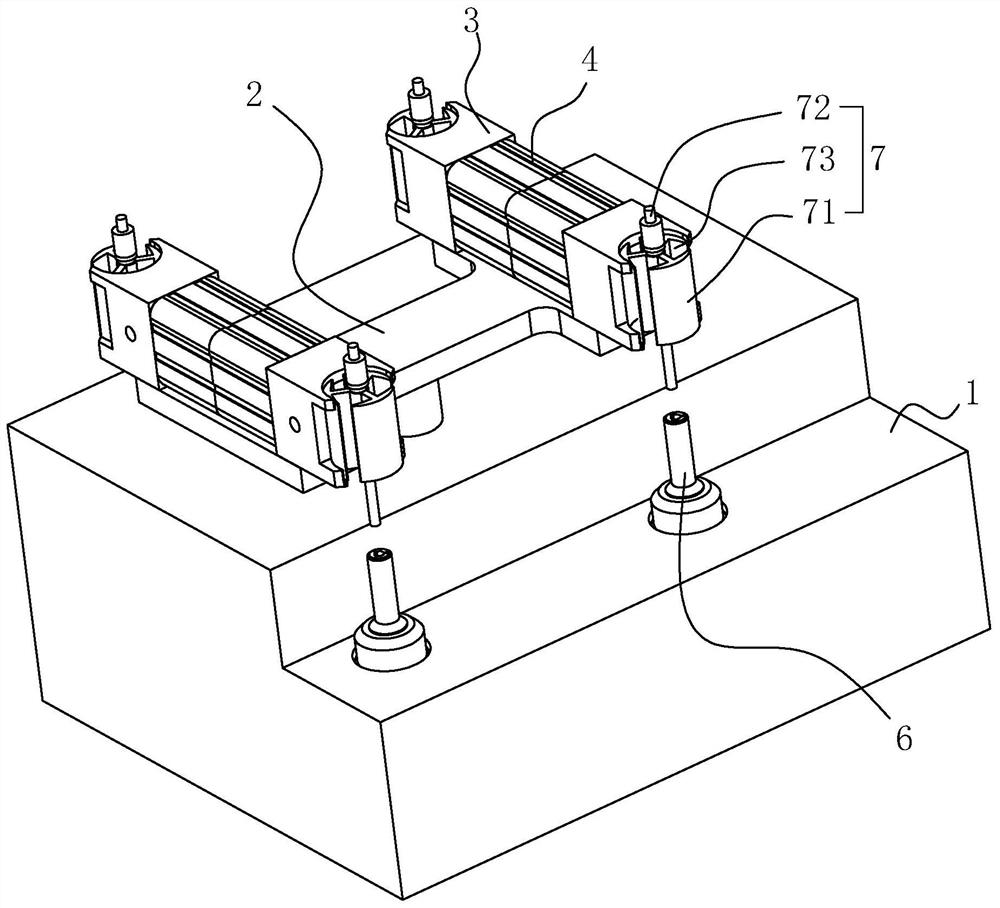

Automatic adhesive tape packaging method for FOSB assembly line

InactiveCN112429295AImprove efficiencyReduce labor costsConveyor wrappingWrapping with article rotationSilicone tapeMaterials science

The invention discloses an automatic adhesive tape packaging method for an FOSB assembly line. The automatic adhesive tape packaging method specifically comprises the following steps that an adhesivetape head is conveyed into an adhesive tape penetrating channel through the cooperation of the rotation of the adhesive tape penetrating channel and the rotation of the adhesive tape head in the step1; and an adhesive tape head cylinder is taken to push an adhesive tape head push plate to press the adhesive tape head on the inner side wall of the adhesive tape penetrating channel; a pressing block cylinder pushes an adhesive tape pressing block to move forwards to press an adhesive tape onto a wafer packaging box; meanwhile, the adhesive head push plate is loosened, a workpiece supporting rotary conveying device drives the wafer packaging box to rotate to start adhesive tape winding work; after winding is completed, an adhesive tape rotation driving device rotates to straighten the adhesive tape extending section and send the adhesive tape extending section into the adhesive tape penetrating channel, the adhesive tape head is pressed on the inner side wall of the adhesive tape penetrating channel through the adhesive tape head push plate, a blade cylinder pushes a shear blade to shear off the adhesive tape, and one-time adhesive tape winding process is completed. According to theautomatic adhesive tape packaging method for the FOSB assembly line, automatic adhesive tape winding work of wafer packaging box packaging bags can be achieved, the adhesive tape winding efficiency ishigh, the whole process is fully automatically carried out, and the labor cost is reduced.

Owner:无锡迪渊特科技有限公司

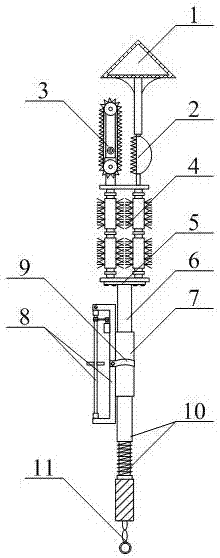

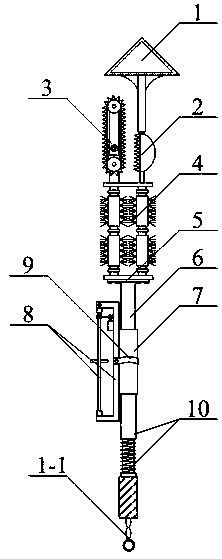

Line cleaning device for electric power maintenance

ActiveCN107482561AEasy to break iceEasy to installOverhead installationApparatus for overhead lines/cablesDrive wheelBrush device

The invention provides a line cleaning device for electric power maintenance. The line cleaning device includes an anti-dazzling umbrella device, a de-icing cutter device, a branch cleaning saw device, a brush wire impurity removing brush device, a stable plate, a connecting rod, a connecting sleeve, a line breaking collection wheel device, a connecting sheet, a telescopic rod device, and an antistatic conductive chain device. By arranging a fixing shaft, a primary connecting plate, a secondary connecting plate, a brush sleeve, and a clamp ring, the cleaning of the impurities on the line is facilitated, the rotary cleaning can be realized, and the use is convenient; by arranging a semicircle cutter, a screw rod, and a support rod, the de-icing is facilitated, and the installation and maintenance are facilitated; and by arranging a driven wheel, a saw plate, a driving wheel, a primary motor, a connection plate, and a conveyor belt, the branch breaking is facilitated, and the work of the lines can be prevented from being influenced by the branch wire touching.

Owner:国网甘肃省电力公司超高压公司

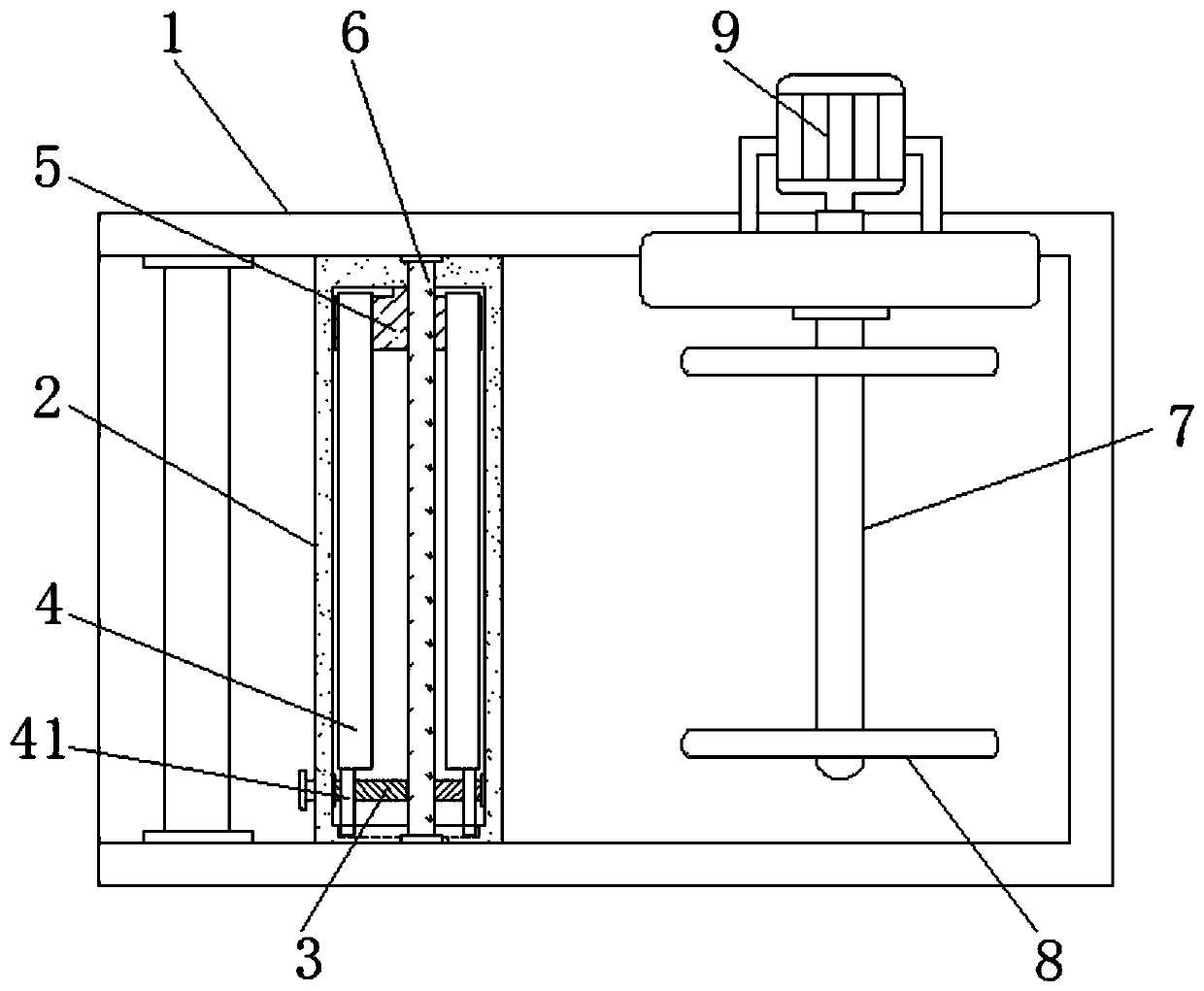

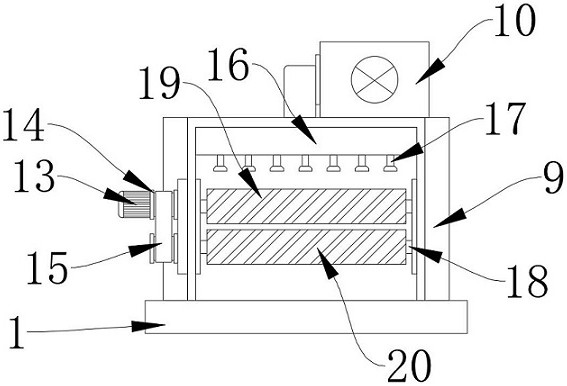

Gauze coiling equipment for spinning

InactiveCN113788336AAvoid uneven windingConvenient winding workArticle deliveryWebs handlingElectric machineryScrew thread

The invention relates to coiling equipment, in particular to gauze coiling equipment for spinning. The gauze coiling equipment for spinning aims at achieving the technical effects that gauze can be automatically cut, and time and labor are saved. The gauze coiling equipment for spinning comprises a bottom plate, first fixing plates, first supporting plates, a roller, and a baffle, wherein the first fixing plates are installed on the two sides of the top of the bottom plate; the first supporting plates are symmetrically installed on the two sides of the top of the bottom plate, and the first supporting plates are located on the two sides of the first fixing plates on the same side; the roller is placed between the tops of the first supporting plates on one side; and the baffle is mounted on one side of the roller in a threaded manner. A motor is used as driving force to drive a first rotating shaft to rotate, so that the roller is driven to rotate, gauze can be automatically wound by the roller, time and labor are saved, the gauze can be limited by the baffle, and the phenomenon that the gauze falls to the ground or is wound irregularly is avoided.

Owner:吴维秀

Textile winding device capable of quickly winding

PendingCN112224965AGood cleaning effectGood winding effectMechanical cleaningPressure cleaningElectric machineryStructural engineering

The invention discloses a textile winding device capable of quickly winding, and relates to the technical field of textiles. The textile winding device capable of quickly winding aims to solve the problems that an existing textile winding device is not good enough in winding effect in use, textile cloth is prone to wrinkling, and dust is not easy to treat. A fixed winding column is installed on one side of the upper portion of a winding device base, a first motor is installed on one side of the fixed winding column, a rotating shaft is installed in the fixed winding column, a protective winding drum is installed outside the rotating shaft, and textile cloth is installed outside the protective winding drum. A movable adjusting winding column is installed on the other side of the protectivewinding drum, a rapid dust and fold removing box is installed on the other side of the upper portion of the winding device base, a dust collector is installed on the upper portion of the rapid dust and fold removing box, and a dust collecting pipe is installed in one side of the dust collector.

Owner:禹州市顺通纺织有限公司

Production and machining device of cooling liquid conveying hose for machine tool machining

PendingCN112897245AConvenient winding workIntelligent monitoring of rotation speedFilament handlingEngineeringMachine tool

The invention relates to the technical field of machine tool accessory machining equipment, and discloses a production and machining device of a cooling liquid conveying hose for machine tool machining. The production and machining device of the cooling liquid conveying hose for machine tool machining comprises a support, wherein the exterior of the support is movably connected with a rotating rod; the exterior of the rotating rod is fixedly connected with a limiting wheel; and the interior of the limiting wheel is movably connected with a monitoring assembly. Through interaction among a shell, the limiting wheel, an electrorheological fluid, a first spring, a movable rod, a movable block and a power connection column, the rotating speed of the rotating rod can be intelligently monitored, and the rotating rod is stopped in time when the rotating speed of the rotating rod exceeds a normal rotating speed range, so that the situation that the rotating speed of the rotating rod is suddenly increased and exceeds the normal rotating speed range, the rotating speed of a winding roller is too high, and consequently the hose deforms due to the too large tension degree is avoided, the tension degree of the hose in the winding process can be kept in a normal state, and normal winding work of the hose is facilitated.

Owner:姜强

Recovery process for large-batch waste steel wires

InactiveCN112453019AImprove recycling efficiencyConvenient winding workSolid waste disposalElectronic waste recyclingProcess engineeringIndustrial engineering

The invention discloses a recovery process for large-batch waste steel wires and relates to the technical field of steel wire recovery. The process specifically comprises the following steps: S1, firstly, winding the waste steel wires to be recovered and treated through large-batch steel wire winding equipment in a recovery field; S2, transporting the steel wires wound in the step S1 from the recovery field to a waste steel wire centralized treatment workshop; S3, carrying out cleaning, acidizing and machining procedures on the waste steel wires in sequence; and S4, collecting the steel wirestreated through the treatment procedures in the step S3 in a centralized mode for reuse. According to the recovery process for the large-batch waste steel wires, multiple bundles of steel wires can bewound at the same time for use, the purpose of winding the multiple bundles of steel wires on a large scale at the same time is achieved, the recovery efficiency of the large-batch steel wires is improved, single or single-strand steel wires can be wound, and in addition, some large-batch waste steel wires can be efficiently recovered.

Owner:姚梦辉

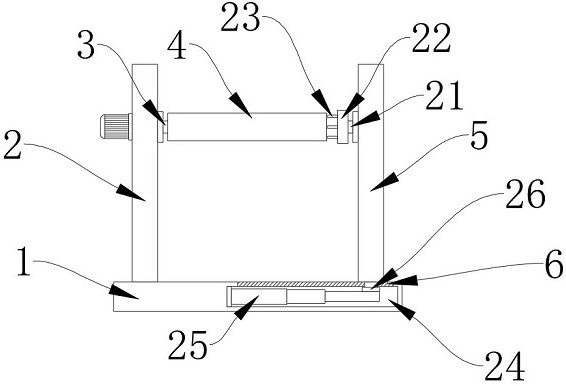

Winding device for straight wire tube

InactiveCN109399350AAffect the winding workAvoid the misalignment of winding and detachment from the rotating columnFilament handlingEngineeringMechanical engineering

Owner:JIANGYIN YONGCHANG TRAFFIC MACHINERY PARTS

Winding machine for chemical fiber production

The invention provides a winding machine for chemical fiber production. The machine comprises a base, movable brake wheels, first support plates, first fixing plates, a support cross beam, a buffer pull insertion rotation rod structure, a reciprocating guide buffer frame structure, a slide protection box structure, support protection buffer rod structures, inclined T-shaped transmission pipes, a winding motor, an inverted U-shaped frame, a U-shaped connecting frame, a sliding groove, a second fixing plate, a reciprocating threaded pipe and a guide motor. According to the machine, through arrangement of a reciprocating block, a U-shaped buffer seat, a buffer spring, a guide wheel and a guide ring, chemical fibers penetrate through the guide ring and then bypass the outer wall of the upper end of the guide wheel in a chemical fiber winding process, then the guide wheel is pulled in the winding process, the front end of the U-shaped buffer seat is pulled through the guide wheel, then the U-shaped buffer seat is pulled through the buffer spring, the buffer work in the winding process is facilitated, and the chemical fibers are prevented from being broken in the winding process.

Owner:常州市盛杰合力化纤有限公司

Efficient winding equipment for clothing materials

ActiveCN113184588AEasy to collectConvenient winding workSevering textilesWebs handlingElectrical and Electronics engineeringSupport plane

Owner:天马服装集团有限公司

Stable-winding auxiliary device for automobile tire cord fabric production

InactiveCN112357641AWind evenlyReal-time monitoring of rotation speedWebs handlingAutomotive engineeringElectrical and Electronics engineering

The invention relates to the technical field of automobile accessory production equipment, and discloses a stable-winding auxiliary device for automobile tire cord fabric production, the auxiliary device comprises a bracket, a limiting plate is fixedly connected to the outer part of the bracket, a rotating rod is movably connected to the outer part of the bracket, and a rotating disc is fixedly connected to the outer part of the rotating rod. Through interaction among a monitoring assembly, a movable block, an electric wire, a first spring, an electrorheological body, a movable rod and the limiting plate, the rotating speed of the rotating rod can be monitored in real time in the cord fabric winding process, and the rotating rod can be stopped in time when the rotating speed of the cord fabric is suddenly increased or continuously increased to exceed the normal rotating speed range. The situation that the rotating speed of the rotating rod is too high, so that the tension degree of thecord fabric is too large, the rolled cord fabric is in a stretched state, the internal structure of the cord fabric is damaged due to the fact that the cord fabric is in the stretched state for a long time, the quality of the cord fabric becomes poor, and the actual use requirement cannot be met is avoided.

Owner:义乌凤尾电子商务有限公司

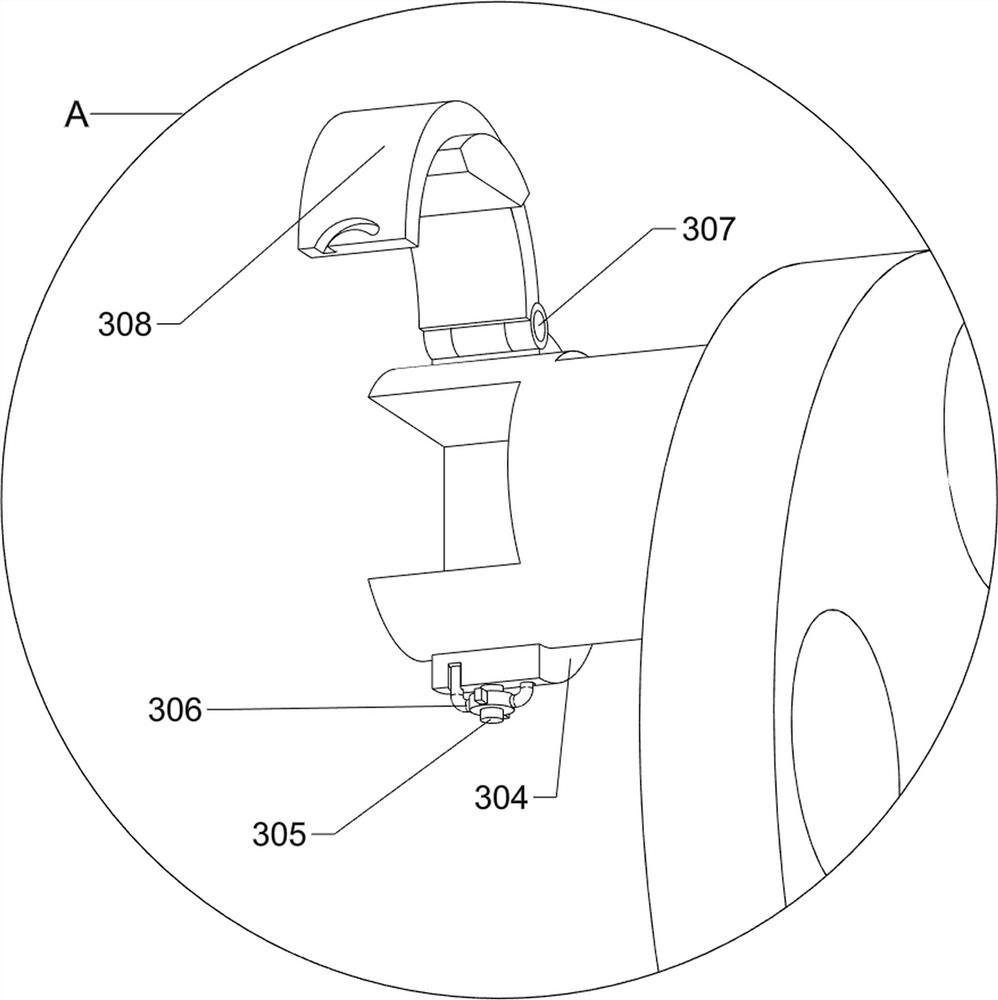

Anti-fracture onboard transformer coil winding device

The invention relates to the technical field of transformer winding protection, in particular to an anti-fracture onboard transformer coil winding device. The device comprises a base, a placement mechanism is mounted on the base, two abutting mechanisms are mounted in the placement mechanism, a winding mechanism is fixedly connected to the base, a protection mechanism is mounted on the winding mechanism, a cleaning mechanism is mounted on the winding mechanism, a control mechanism is mounted in the winding mechanism, and a limiting mechanism is mounted in the winding mechanism; a wire coil is conveniently protected under the action of the placement mechanism and the abutting mechanisms, winding work is conveniently carried out under the action of the winding mechanism and the control mechanism, damage caused by frequent starting and stopping of a motor is reduced, copper wires are conveniently protected under the action of the protection mechanism, and the wire coil is prevented from being stuck, so that the copper wires will not be fractured to due to pulling; and the copper wires can be conveniently cleaned under the action of the cleaning mechanism, so that the damage to equipment is reduced, and the production quality is improved.

Owner:徐州中顺尚奕机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com