Automatic adhesive tape packaging method for FOSB assembly line

A packaging method and assembly line technology, which can be used in packaging, conveyor belt wrapping, and rotating wrapping of items, etc., can solve the problems of low degree of automation, high work efficiency, and difficulty in finding tape heads.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

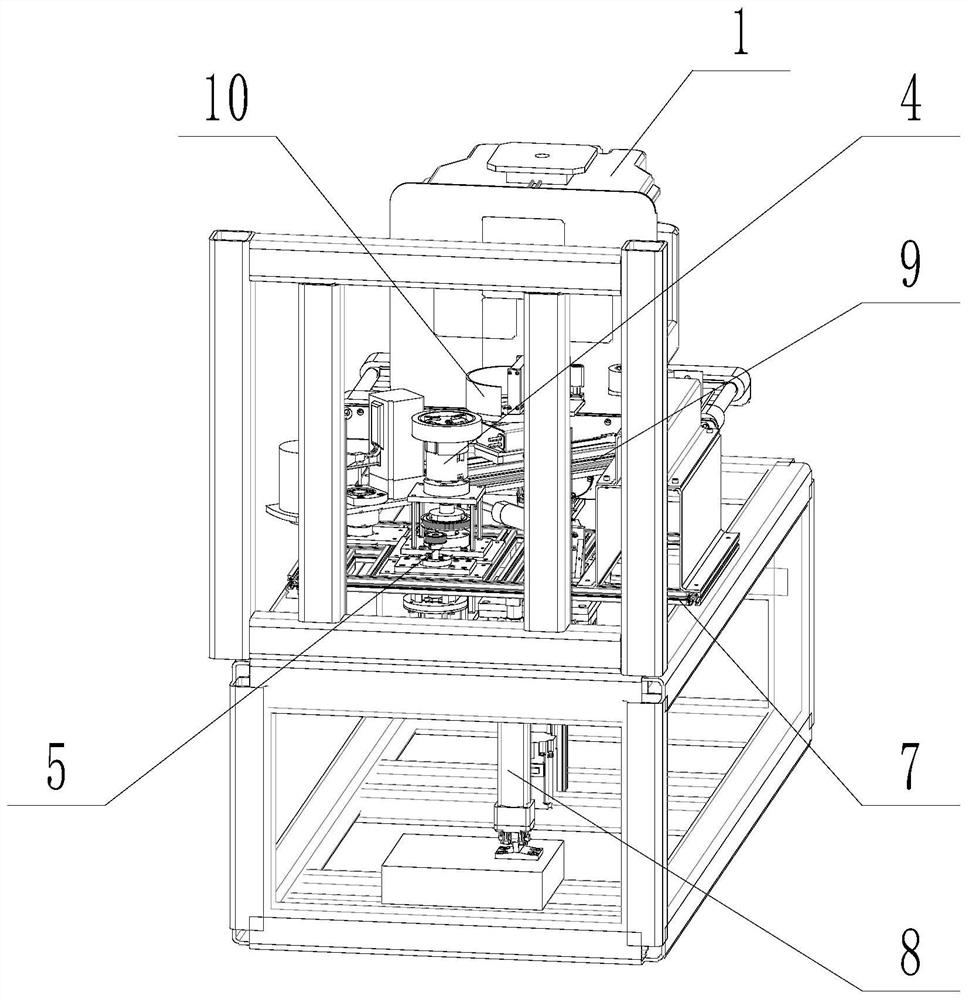

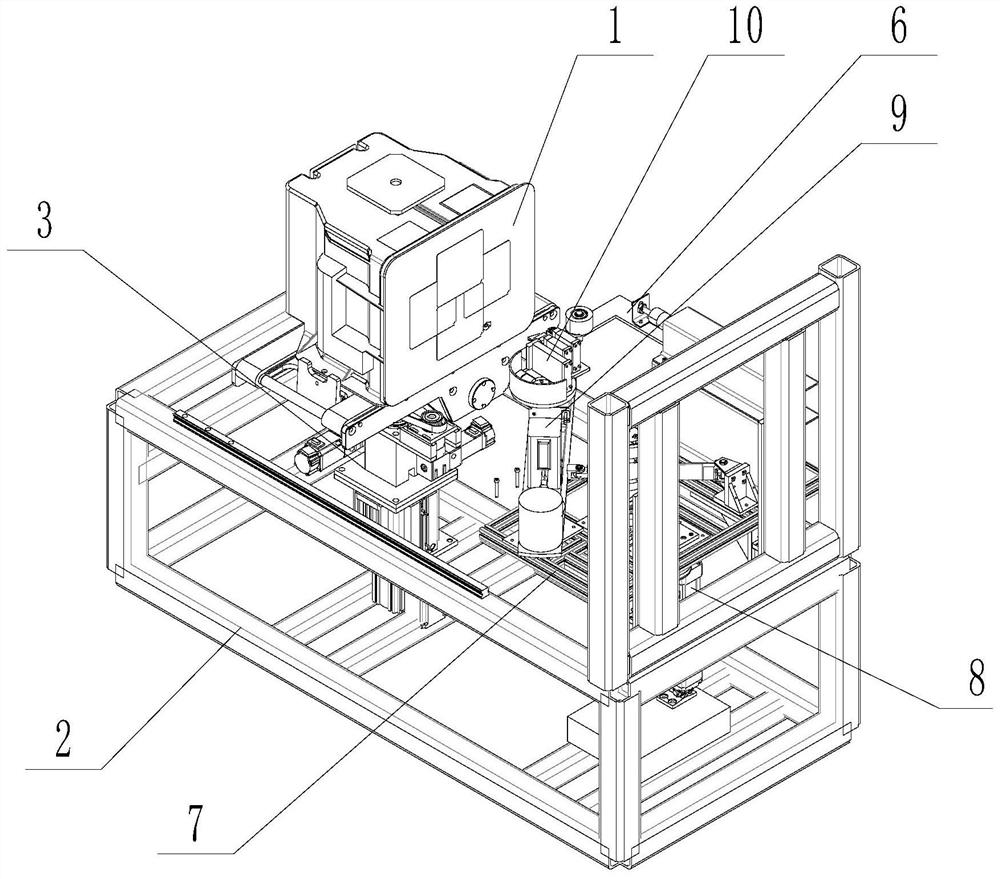

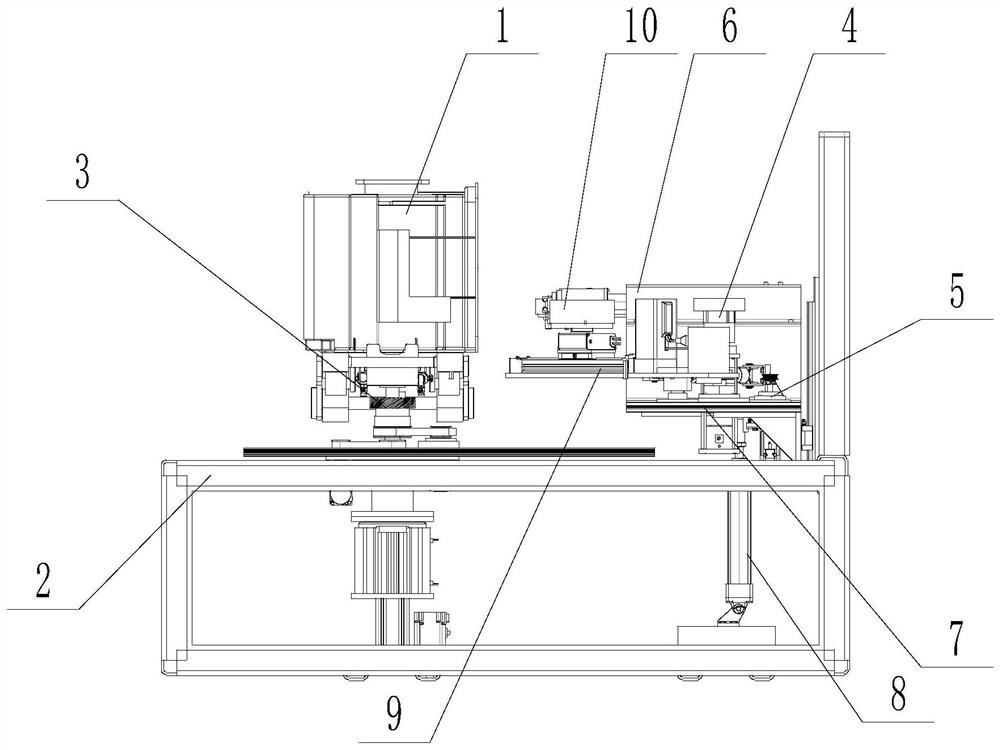

[0057] The present invention will be further described below in conjunction with accompanying drawing:

[0058] Such as Figure 1-13 Shown, a kind of automatic adhesive tape packaging method of FOSB assembly line, specifically comprises the following steps:

[0059] Step 1: Fix the wafer packaging box 1 on the workpiece support rotary transmission device 3 that can drive the wafer packaging box 1 to rotate, and at the same time fix the tape with the tape head on the tape fixing device 4 through the pneumatic three-jaw chuck 41 , the tape rotating drive device 5 is connected to the tape fixing device 4 and drives the pneumatic three-jaw chuck 41 on the tape fixing device 4 to rotate together with the tape, so that the tape head rotates with the tape;

[0060] Step 2: Utilize the cantilever rotating cylinder 95 to drive the cantilever device 9 to rotate close to the tape fixing device 4, and the cantilever linear module 94 on the cantilever device 9 drives the tape taking head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com