Feeding device for micromotor rotor winding machine

A winding machine and micro-motor technology, which is applied in the direction of electromechanical devices, workpiece clamping devices, manufacturing motor generators, etc., can solve the problems of easy deviation and low feeding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

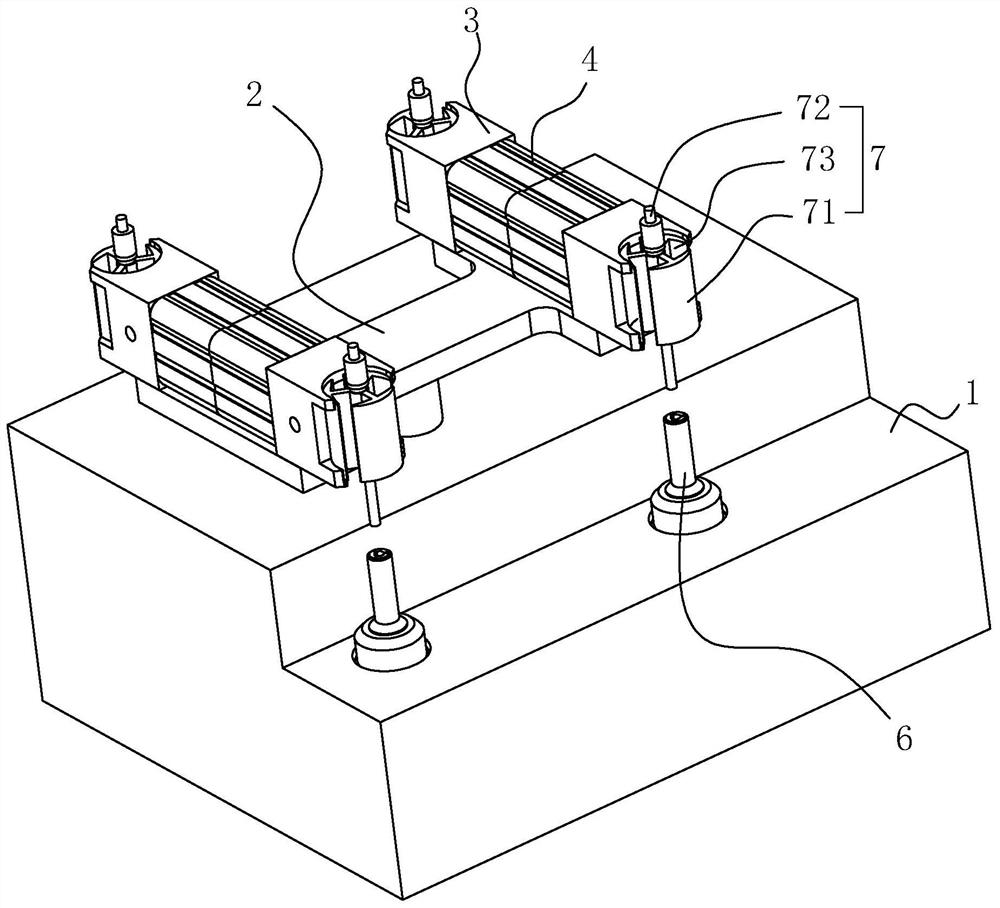

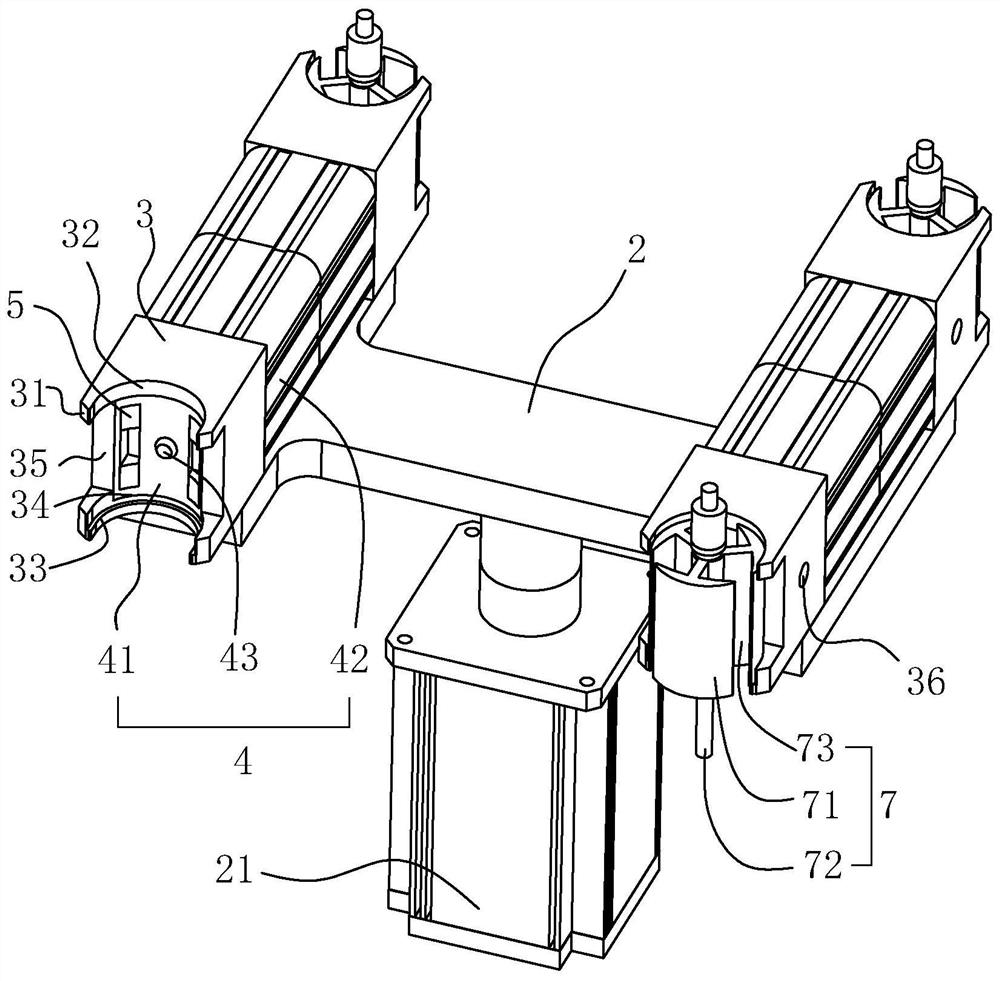

[0035]Contraction belowFigure 1-4Further detailed description of the present application.

[0036]Such asfigure 1 As shown, the micromotor rotor 7 mainly includes a rotor core 71 and a rotor shaft 72 through the center of the rotor core 71, and the rotor core 71 side wall is provided with several winding grooves 73, such as the rotor core 71 circumferential array Three winding grooves 73, by winding machine, a set of winding groups are formed around the copper wire in adjacent two winding grooves 73, and three sets of winding groups are formed in turn around the rotor core 71, thereby completing the micro motor rotor. 7 winding work.

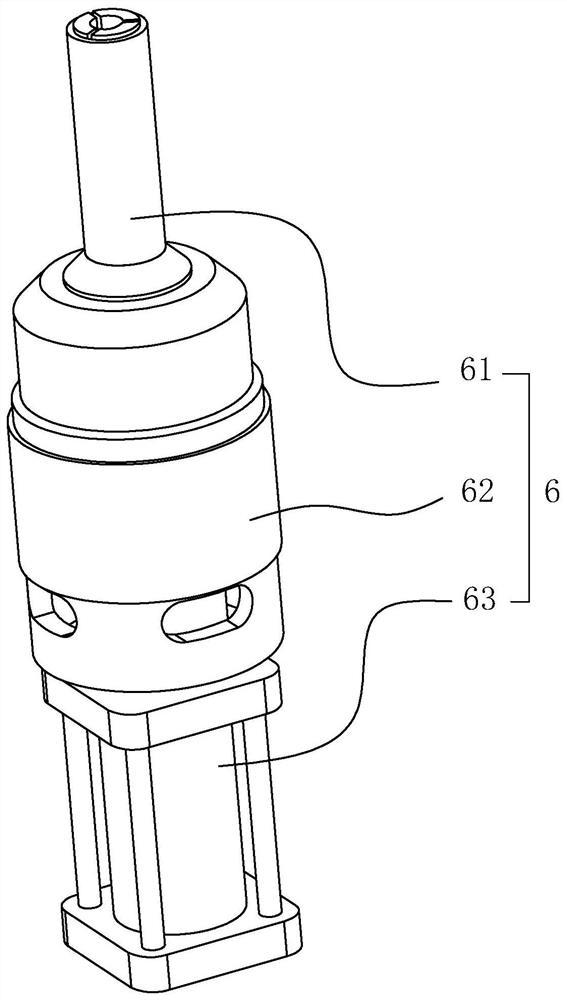

[0037]Such asfigure 1 As shown, the winding machine mainly includes an upper plate 1, a winder head, an amplifier portion, wherein the upper pad 1 is provided with a fixed micromotor rotor 7 and the angle regulator 6 rotating, and when the winding is processed, The microcomputer rotor 7 is fixed to the angle adjuster 6, and the wired head is rely toward the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com