Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42results about How to "Avoid uneven winding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Device and method for cleaning greasy dirt on surface of large-coil nickel strap

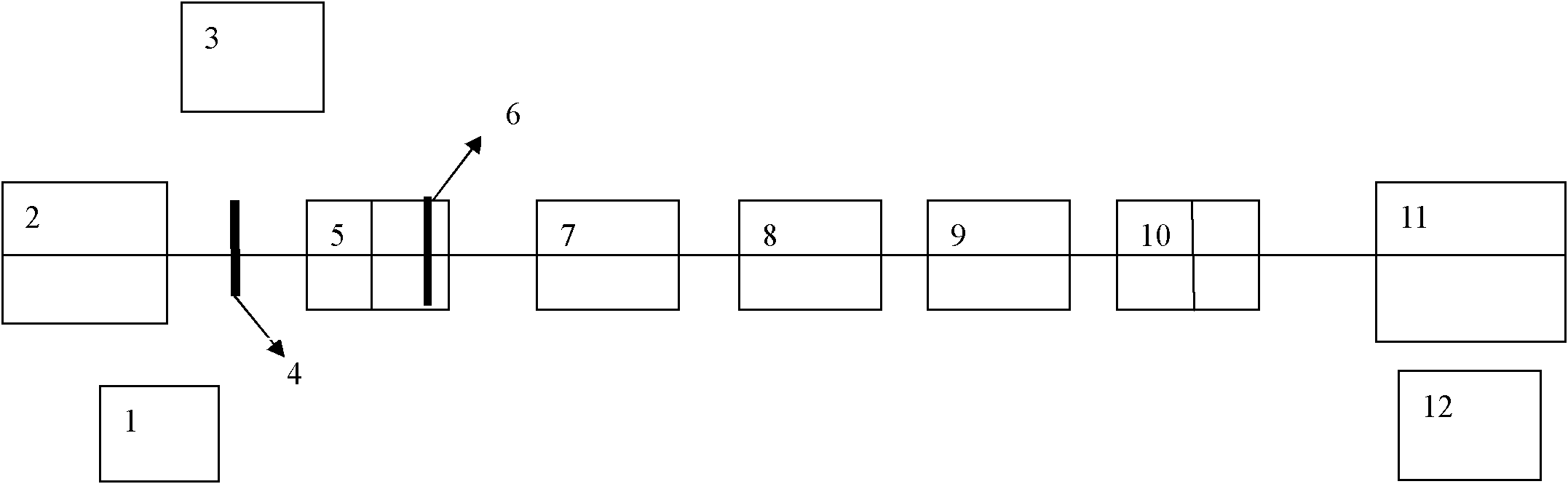

The invention relates to a device and a method for cleaning greasy dirt on the surface of a large-coil nickel strap. The device comprises a decoiling machine (2), a spray device (6), a closed cleaning device (7), a carbon hydrogen cleaning device (8) and a coiling machine (11) which are arranged sequentially, wherein the large-coil nickel strap is sleeved on the decoiling machine (2); and the nickel strap decoiled by the decoiling machine (2) sequentially passes through the spray device (6), the closed cleaning device (7) and the carbon hydrogen cleaning device (8) and then reaches the coiling machine (11) for coiling. By the device and the method, the greasy dirt on the large-coil nickel strap can be thoroughly cleaned, and the problem that rolling mill oil which exists for a long time cannot be thoroughly cleaned is solved; the device has a simple structure; and the device and the method are low in cost.

Owner:JIANGSU YUANHANG PRECISION ALLOY TECH

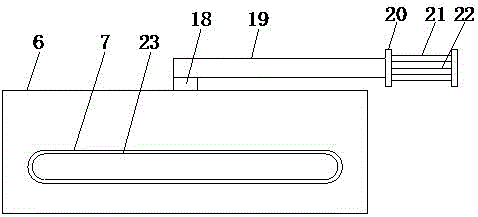

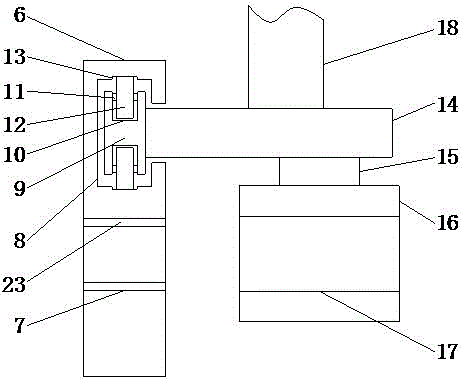

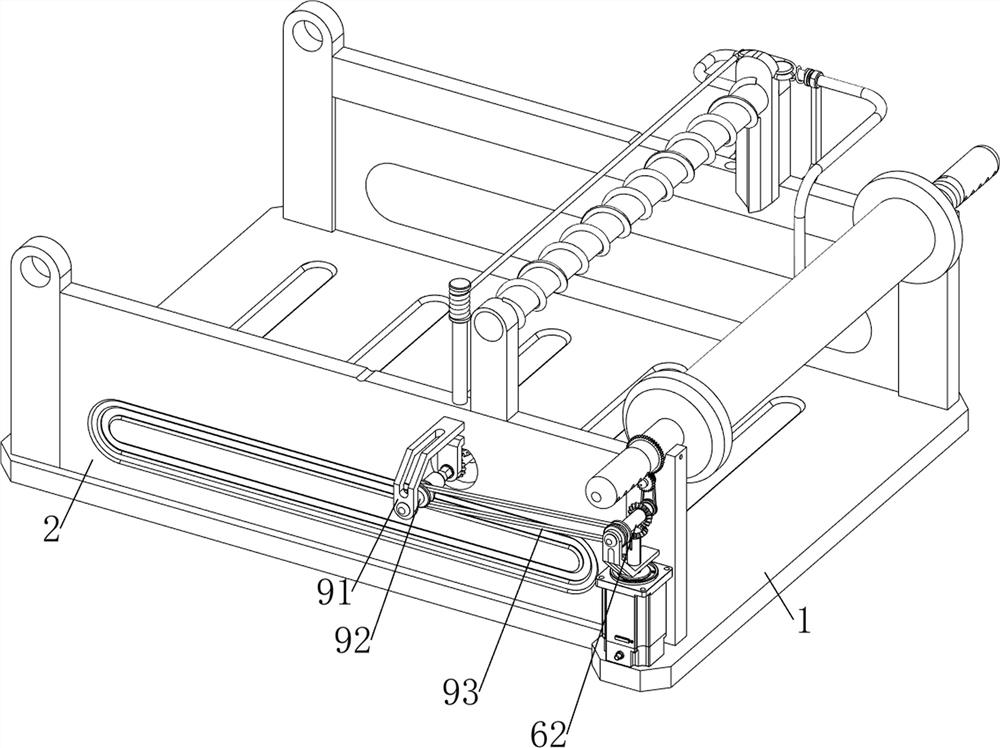

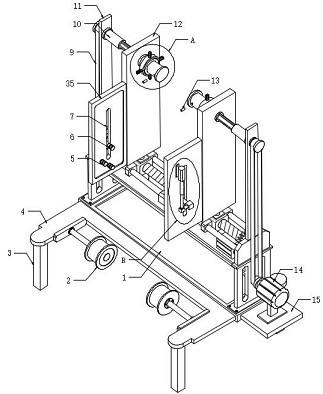

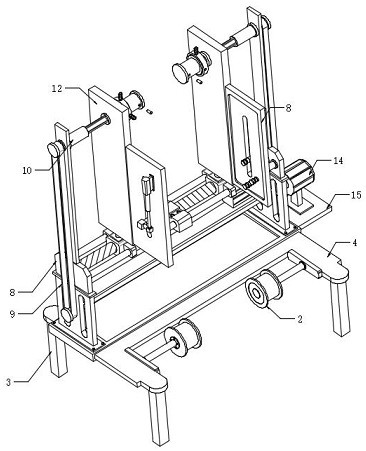

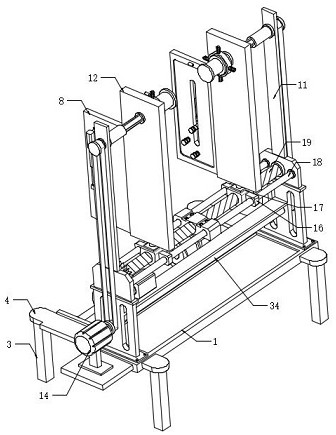

Ultra-long flexible rubber pipe winding device

PendingCN111003592AControl Zhang JinliWind evenlyFilament handlingHydraulic cylinderElectric machinery

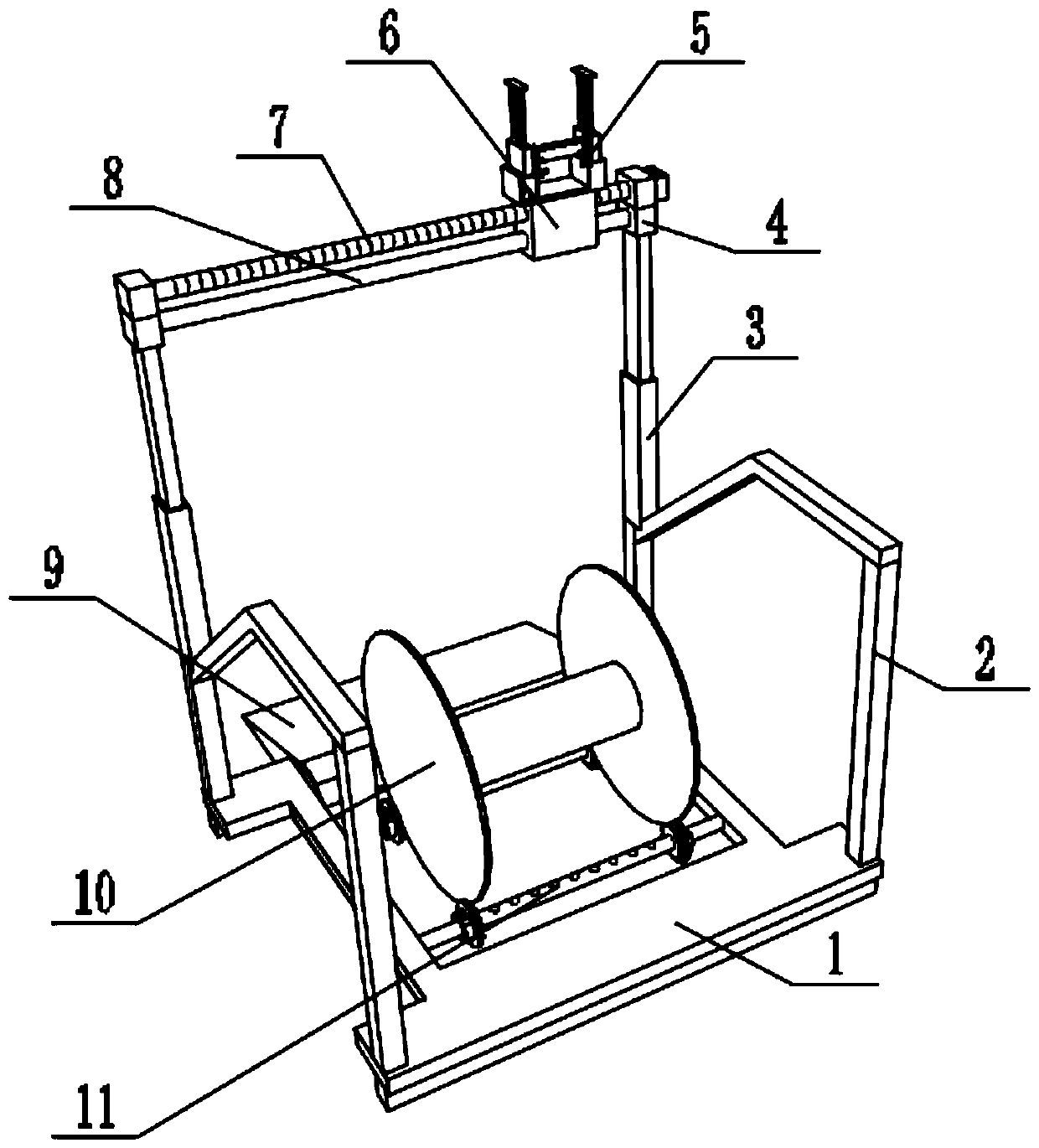

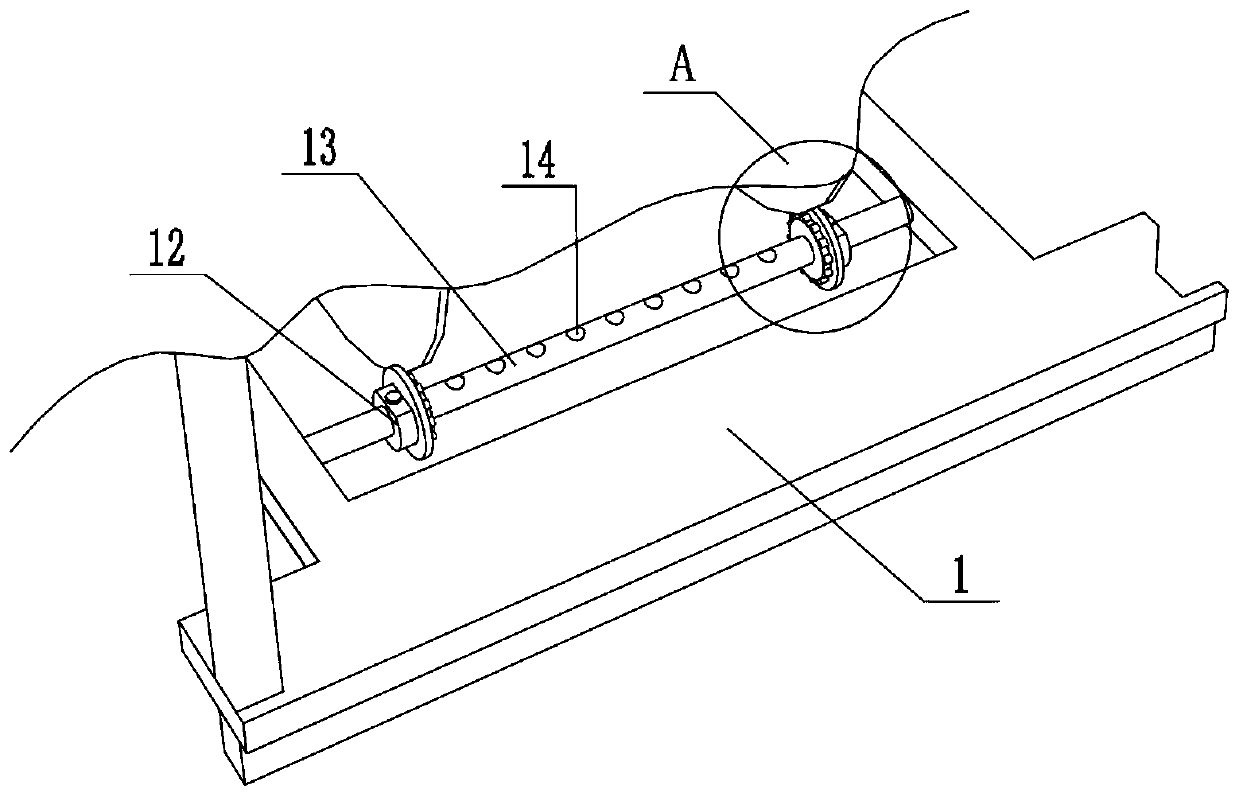

The invention discloses an ultra-long flexible rubber pipe winding device, and relates to the technical field of ultra-long flexible rubber pipes. A purpose of the invention is to solve the problem ofnon-uniform winding distribution of the ultra-long flexible rubber pipe. The ultra-long flexible rubber pipe winding device specifically comprises a base frame and a winding drum, wherein supportingframes are welded to the two sides of the top end of the base frame, first hydraulic cylinders are fixed to one side of the top end of the supporting frame through screws, connecting blocks are fixedto the top ends of the first hydraulic cylinders through screws, the two first hydraulic cylinders are connected with a synchronous hydraulic system and can synchronously drive the lifting connectingblocks, and a first motor is fixed to one side of one connecting block through a motor seat. By arranging the first motor and the first lead screw, the first motor can drive the first lead screw to rotate, the material guiding mechanism is driven to transversely move and be evenly wound on the winding drum, the first hydraulic cylinders are arranged, the height of the equipment can be adjusted according to needs, the tensile force of the ultra-long flexible rubber pipe can be effectively controlled, winding is stable, and the winding quality is improved.

Owner:NANTONG BECA MACHINERY TECH

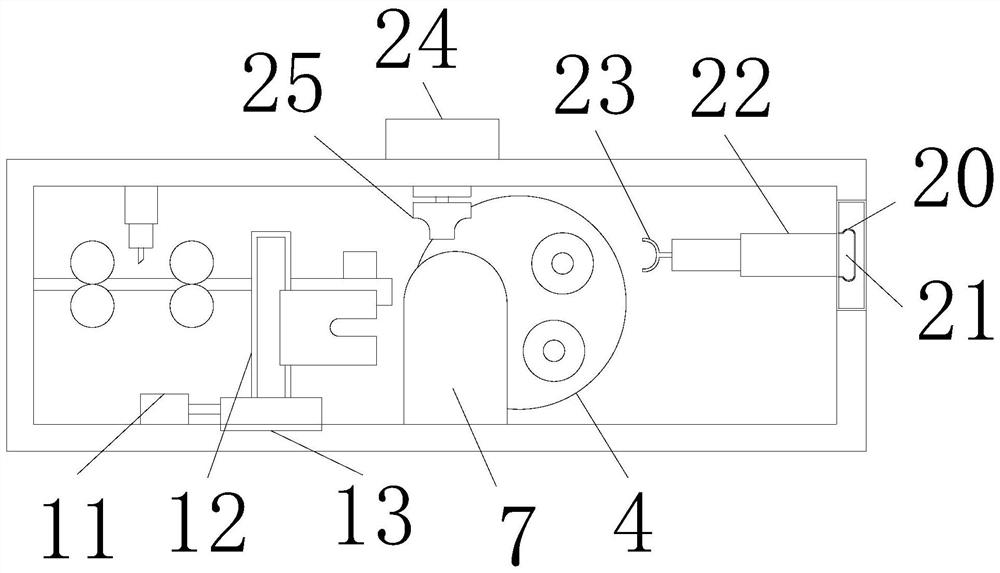

Cable winding disc

InactiveCN111204609AWinding effectContinuous and orderly winding and tilingFilament handlingControl theoryElectric cables

The invention relates to the field of tissue manufacturing equipment, in particular to a cable winding disc. The cable winding disc comprises a rack, a winding disc body rotationally arranged on the rack and used for winding a cable, a winding servo motor arranged on the rack and used for driving the winding disc body, and a guide device arranged on the rack, located in front of the winding disc body and used for guiding the cable, a sliding rail parallel to the axial direction of the winding disc is arranged at the position, in front of the winding disc, of the rack, the guiding device comprises an installation base capable of sliding along the sliding rail, a sliding driving device arranged on the rack and used for driving the installation base to slide, a clamping guiding wheel set arranged on the installation base and a guiding servo motor used for driving the clamping guiding wheel set to rotate, the clamping guiding wheel set comprises two guide wheels close to each other, arc-shaped guide grooves are formed in the circumferences of the guide wheels, and the arc-shaped guide grooves of the two guide wheels are matched to form a guide channel allowing the cable to pass through. According to the cable winging disc, the technical problems that cable winding tightness degree is inconsistent, and cables are stacked in a certain area are solved.

Owner:HENGAN (CHINA) PAPER IND CO LTD

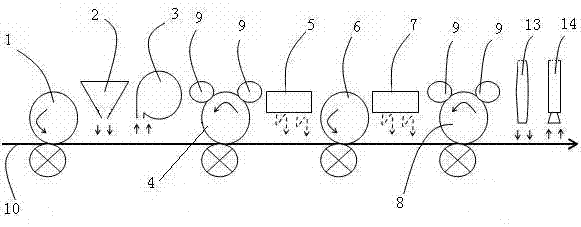

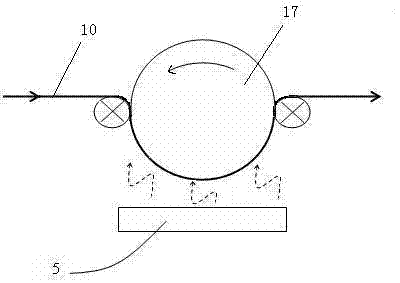

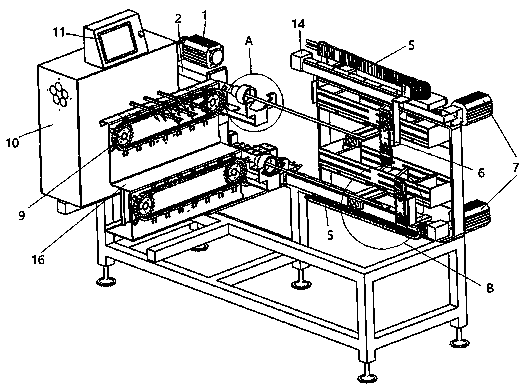

Fiber spreading printing system

InactiveCN102501579ARealize automated productionAvoid uneven windingPattern printingRotary pressesFiberMechanical engineering

The invention provides a fiber spreading printing system which sequentially comprises a feeding unit, an adhesive printing unit, a fiber spreading unit, a fiber adsorbing unit, a fiber pressing unit, a solidifying unit and a receiving unit. A material to be printed is delivered from the feeding unit to the receiving unit to be retracted. Due to the adoption of the fiber spreading printing system disclosed by the invention, the automated high-efficiency production of the local texture anti-counterfeiting printed material is realized.

Owner:KHAINAN YAYUAN ANTI TSOUNTERFEIT TECH RES INST

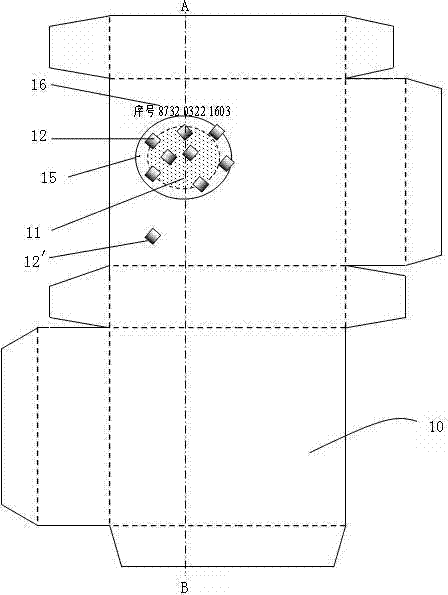

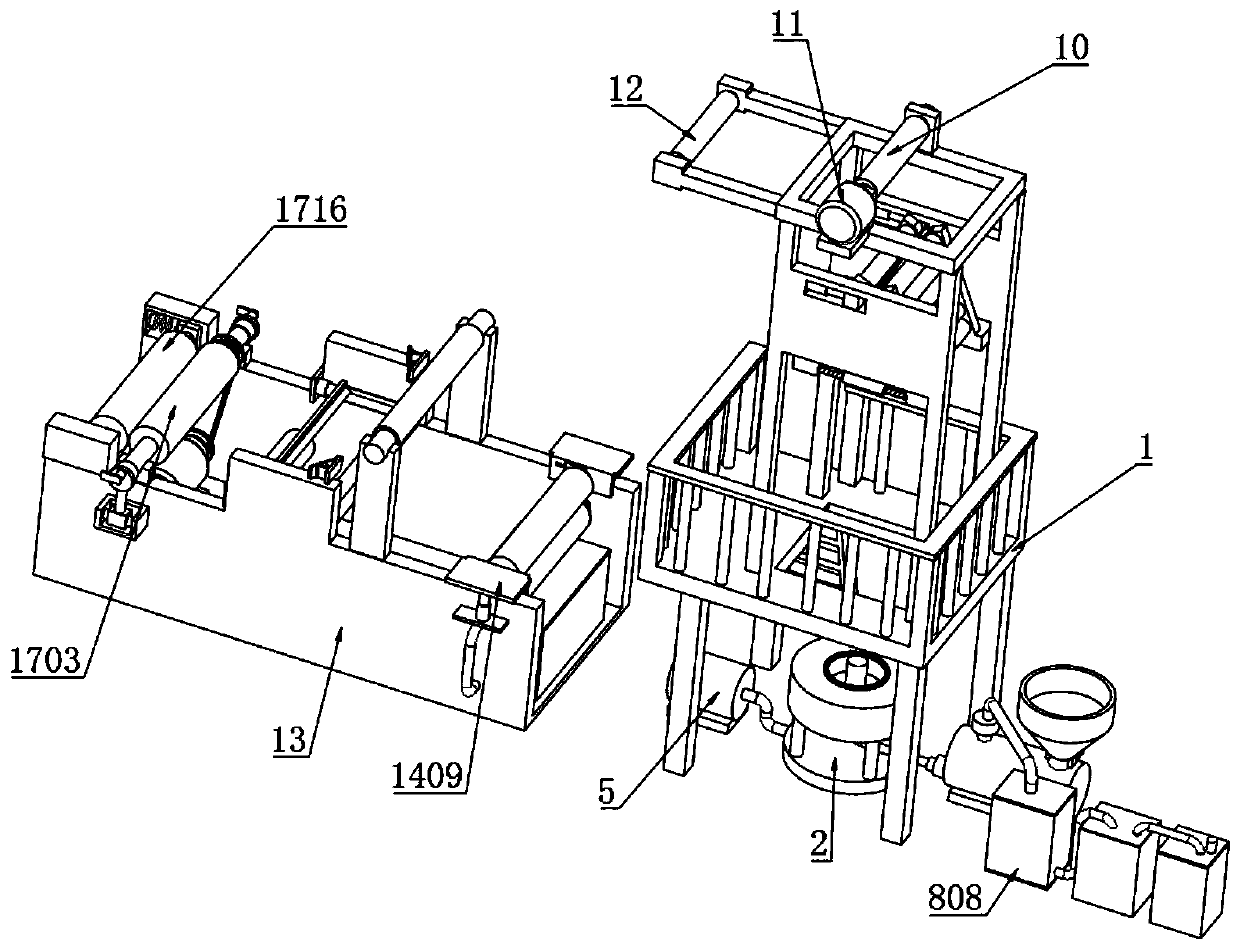

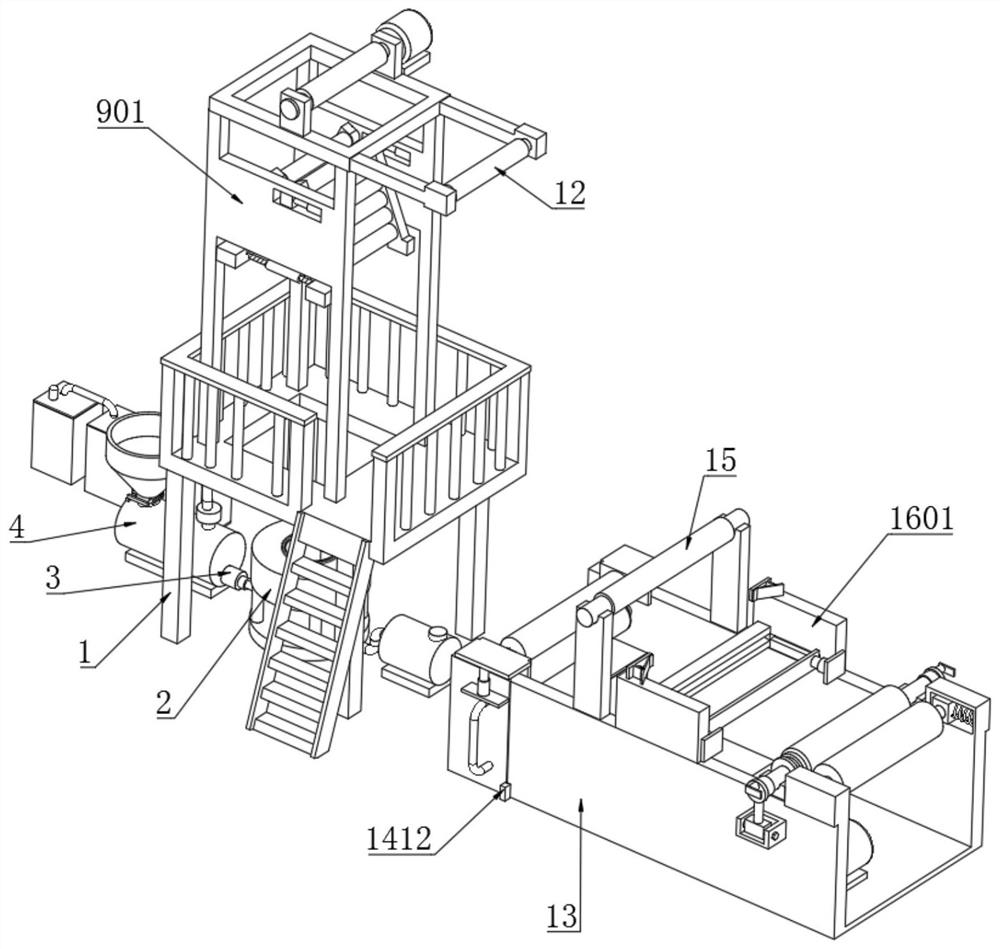

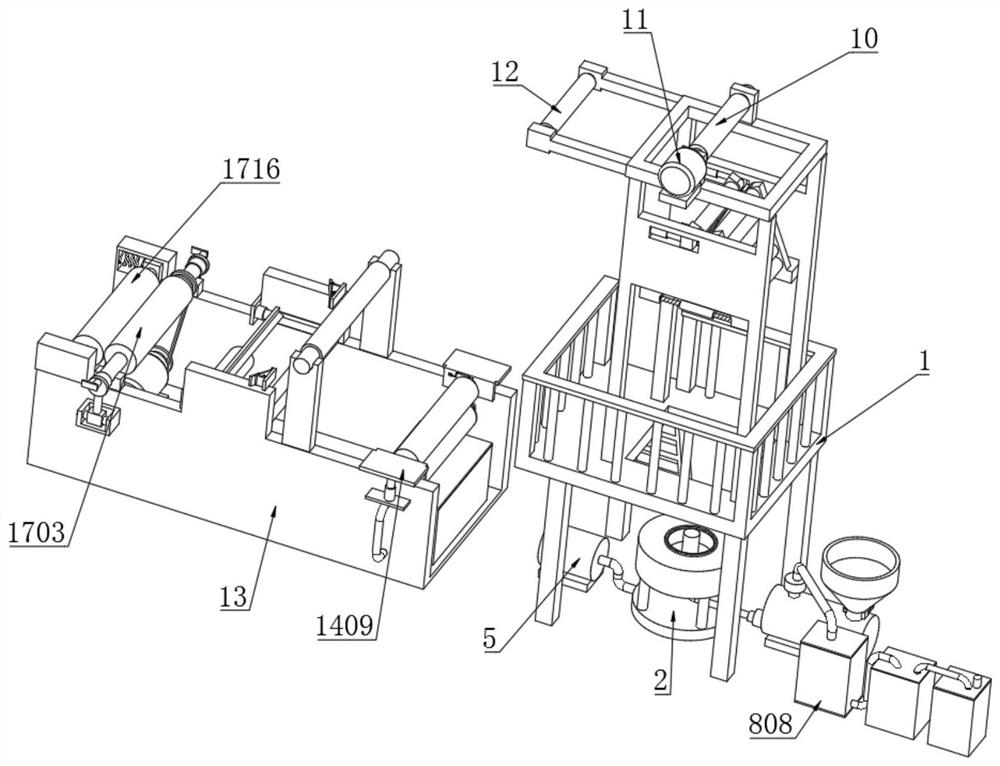

Glass fiber felt continuous production line

ActiveCN109051932AReduce human inputImprove work efficiencyPaper article packagingWork benchesGlass fiberYarn

The invention discloses a glass fiber felt continuous production line. The production line comprises a glass fiber yarn cluster cutting device, a settling chamber, a water spraying device, a powder scattering device, a drying device, a compaction and cutting device, a winding device and a packing device arranged in sequence. Glass fiber yarn clusters are treated by the cutting device, the settlingchamber, the water spraying device, the powder scattering device, the drying device, the compaction and cutting device, a detecting device and the winding device to form glass fiber felt rolls; and the glass fiber felt rolls are packed in cartons by the packing mechanism. Through the winding device, the electric control of an air expansion shaft is controlled to change among at least three stations, so that the labor investment is reduced, and the working efficiency is improved. Through the design of an auxiliary winding mechanism, the effective winding of the glass fiber felts on the air expansion shaft in a machining station is guaranteed, and the uneven winding is prevented. Through the design of a winding shaft placing platform, the operation efficiency of the production line is improved, and the labor cost is reduced.

Owner:嘉兴市宏宇新材料股份有限公司

High-efficient automatic film blowing device capable of preventing electrostatic interference

ActiveCN111497204AScientific and reasonable structureEasy to useDispersed particle filtrationMetal working apparatusActivated carbonDust control

The invention discloses a high-efficient automatic film blowing device capable of preventing electrostatic interference. The high-efficient automatic film blowing device capable of preventing the electrostatic interference is characterized in that a dust removing box body is fixedly connected to one end of an axial flow fan, a dust filtering plate is fixedly mounted at the top of the dust removingbox body, an activated carbon adsorption plate is fixedly mounted in the middle of the dust removing box body, a first connecting pipe is fixedly connected to one end of the bottom of the dust removing box body, a first adsorption box body is fixedly mounted at one end of the first connecting pipe, a second connecting pipe is fixedly connected to the top end of the first adsorption box body, anda second adsorption box body is fixedly mounted at one end of the second connecting pipe. The high-efficient automatic film blowing device is scientific and reasonable in structure and safe and convenient in use, through the cooperative use of the dust filtering plate and the activated carbon adsorption plate, waste gas generated by plastic melting is conveniently filtered, dust and substances with peculiar smells contained in the waste gas are removed, the situation that the dust and the substances with the peculiar smells are directly discharged into air, so that the atmosphere is polluted is avoided, and through the cooperative use of the first adsorption box body and the second adsorption box body, harmful gas dissolved in water and limewater in the waste gas is absorbed.

Owner:CHAOHU JINBANG PLASTIC PACKAGING

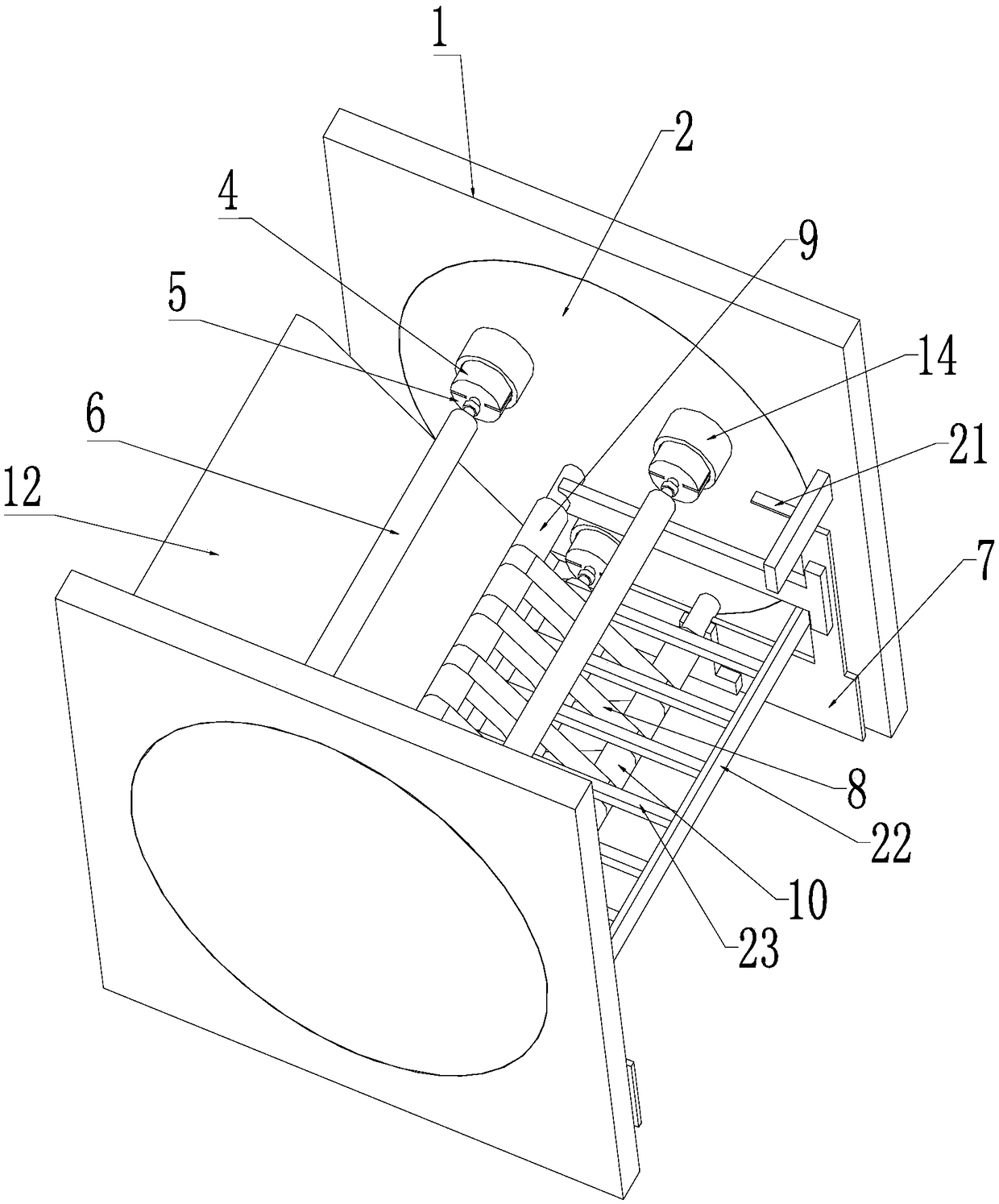

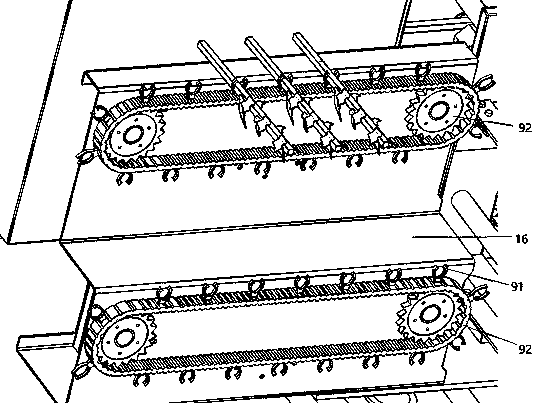

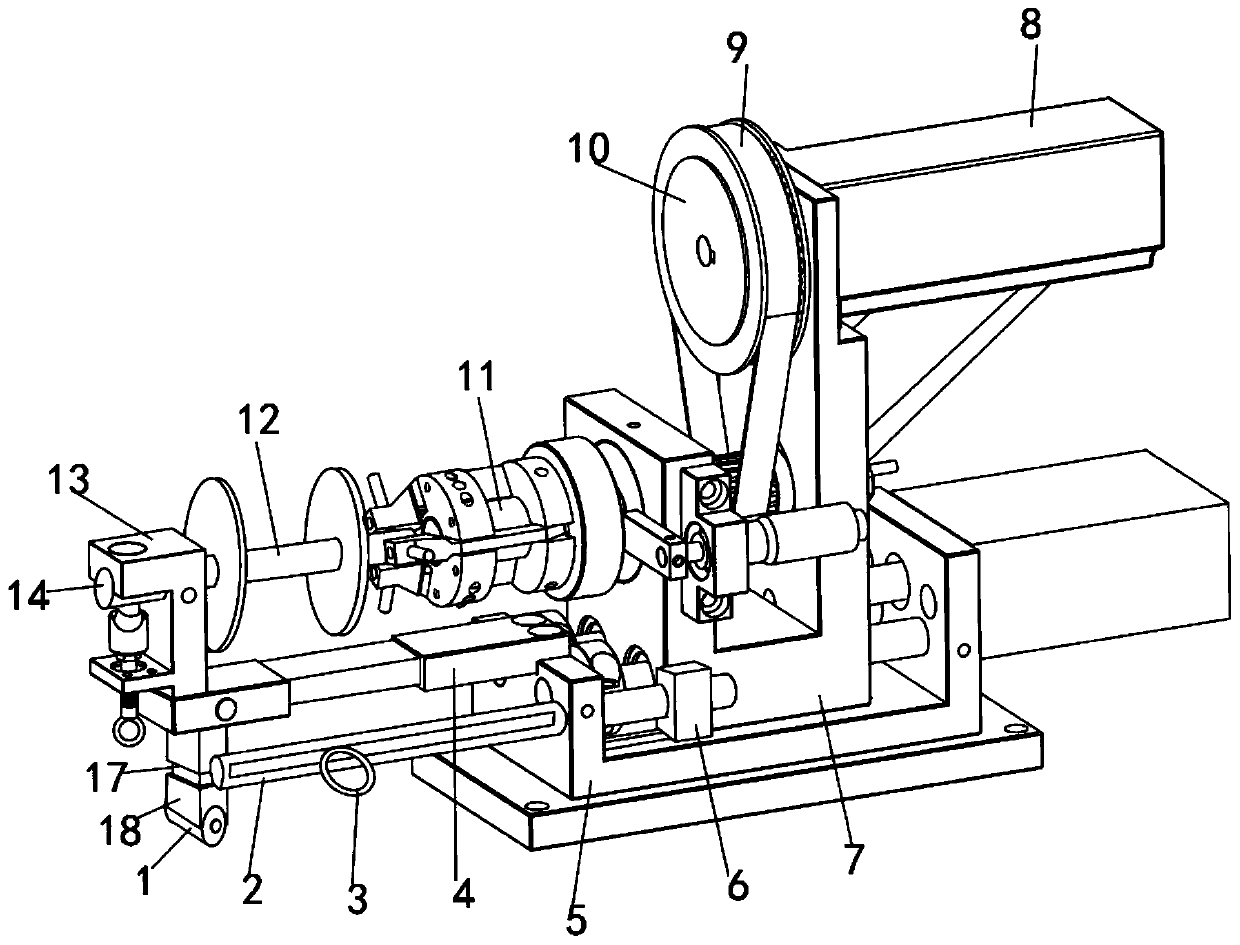

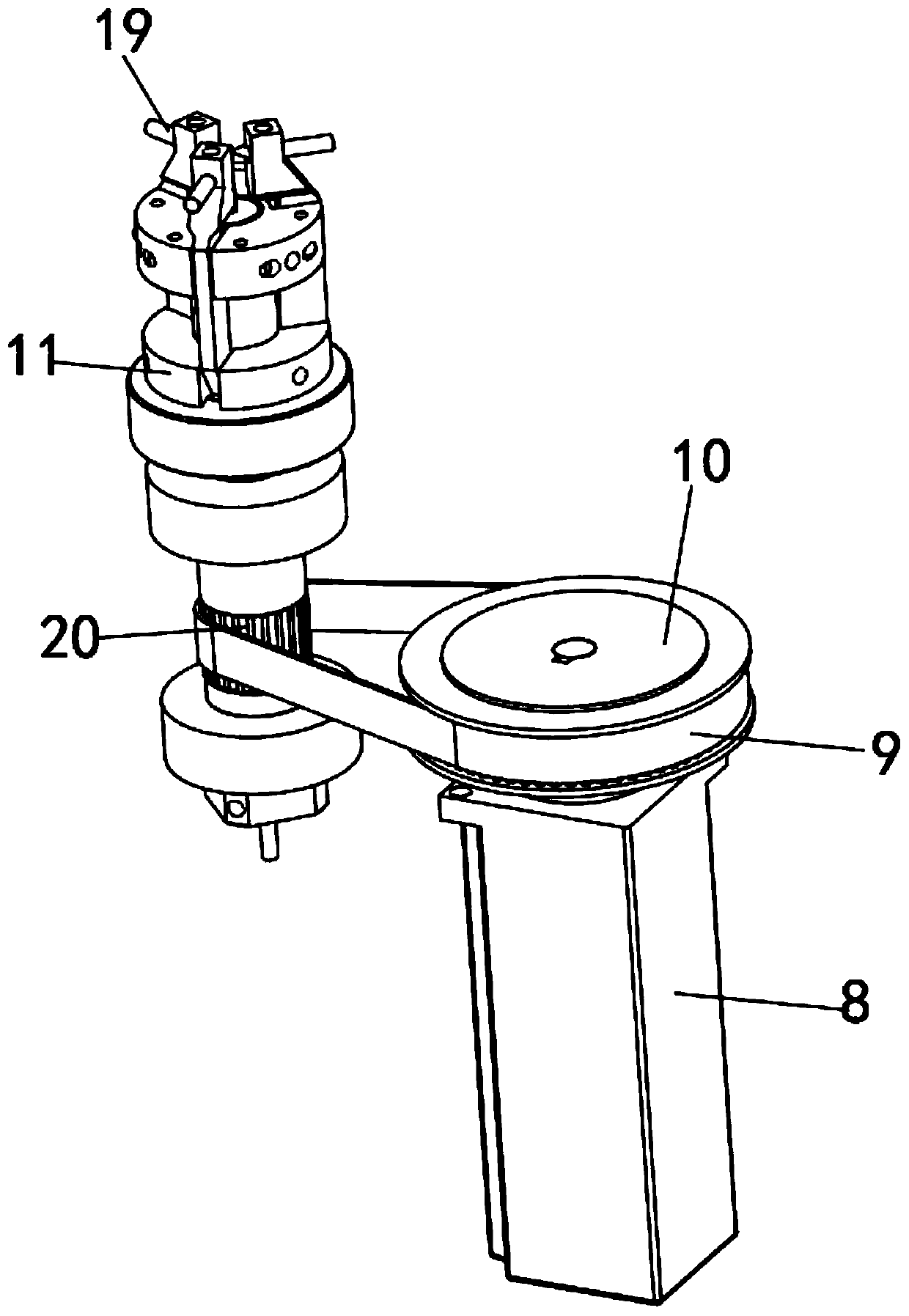

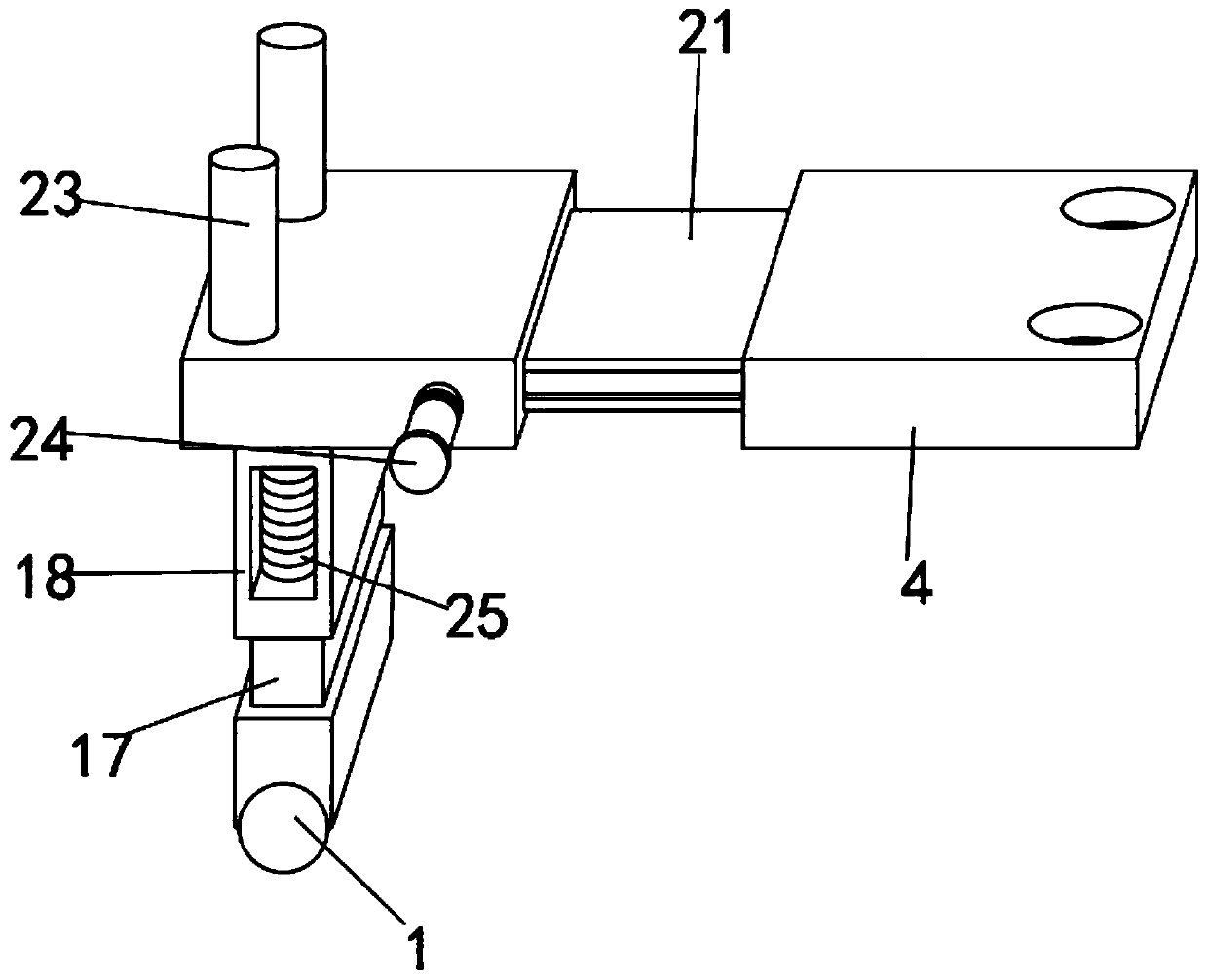

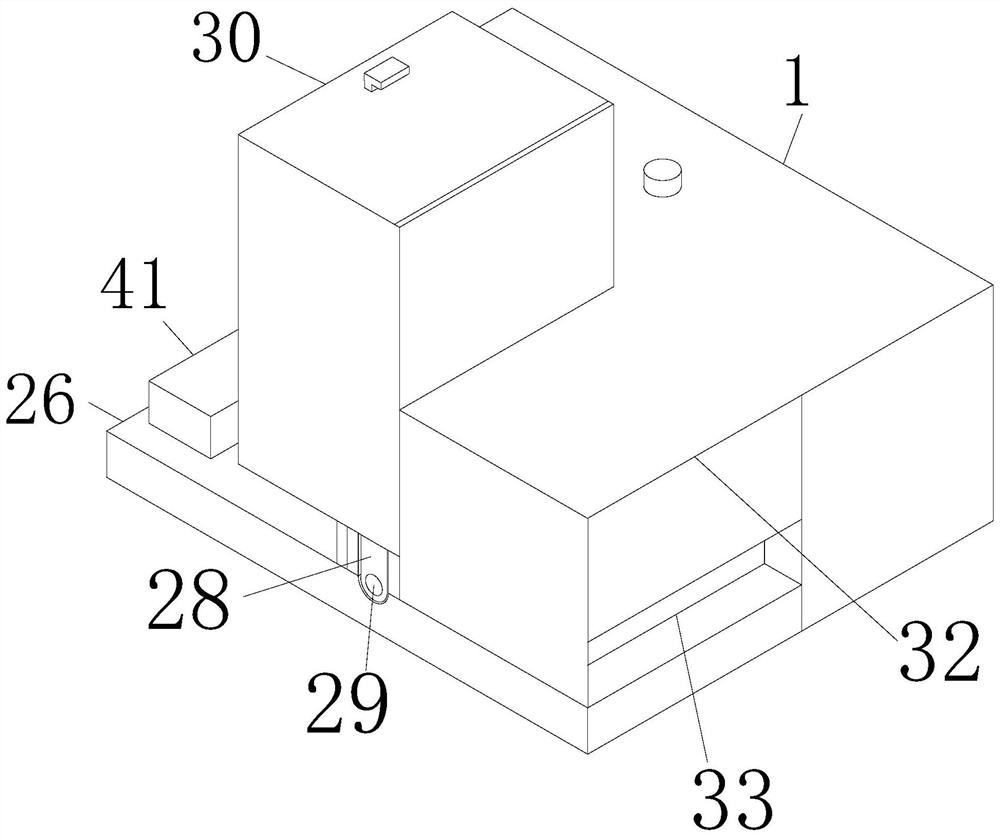

Branch bundling machine for Christmas tree branches

ActiveCN109288364AIncrease profitOptimize the discharge processReligious equipmentEngineeringMechanical engineering

The invention discloses a branch bundling machine for Christmas tree branches. The machine comprises a moving mechanism, a winding mechanism and a conveying mechanism; the moving mechanism is locatedat one side of the winding mechanism and is parallel to the winding mechanism, and the conveying mechanism is perpendicular to the winding mechanism and is located at the other side of the conveying mechanism; through the combination of the three mechanisms and the improvement and replacement of parts in the mechanisms, the operation procedures in the production process are simplified while the quality of products is improved, the production safety can be improved, multiple devices can be installed and carry out production simultaneously, and therefore the production efficiency is improved.

Owner:东阳市欧力工艺品有限公司

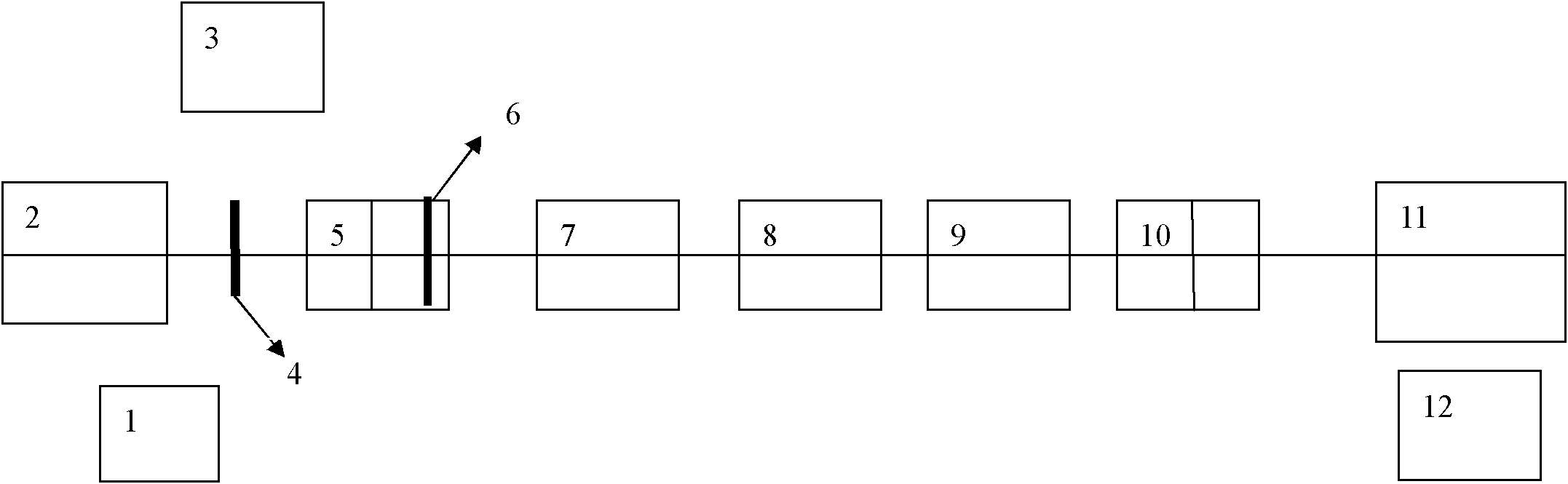

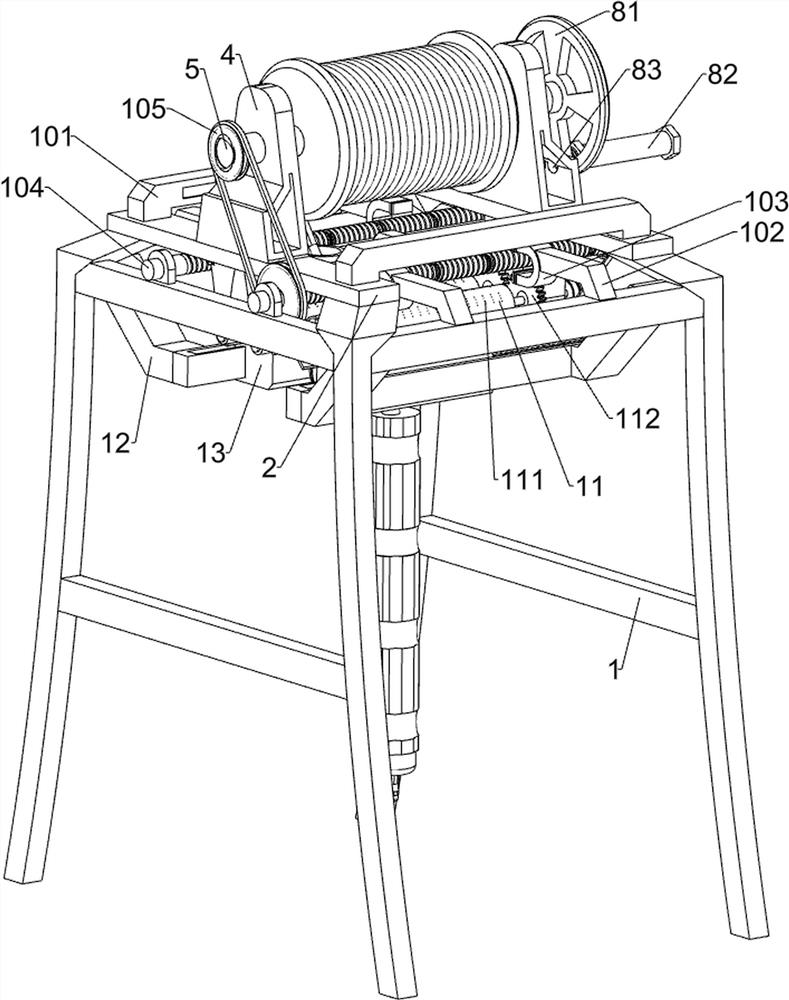

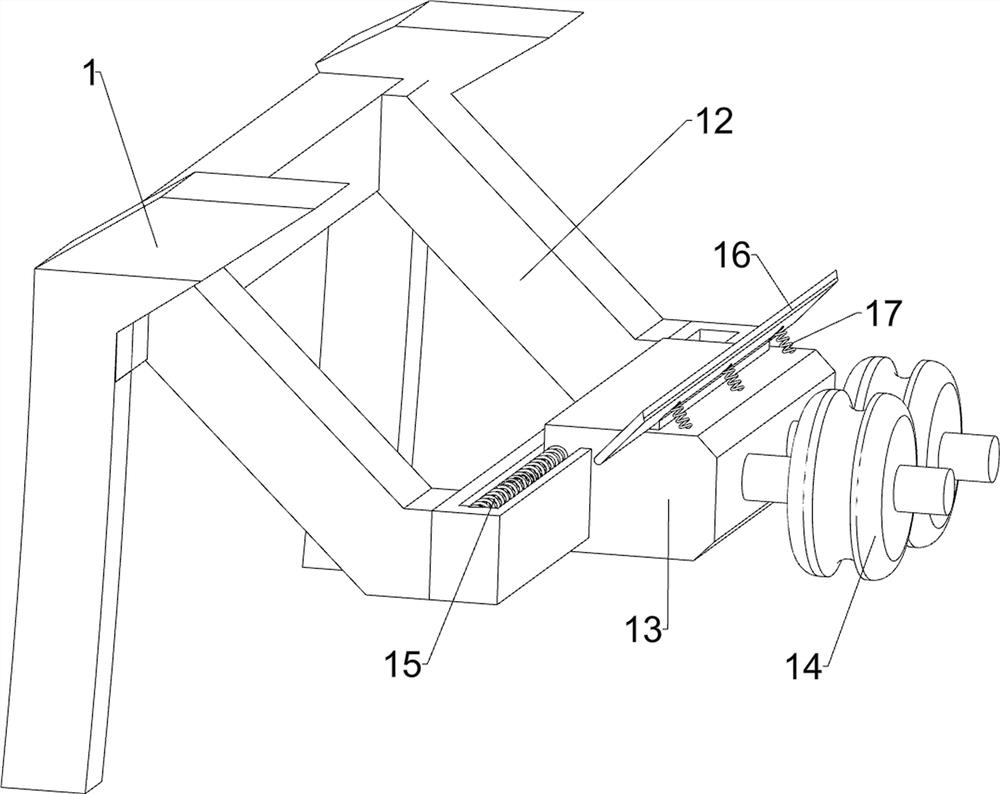

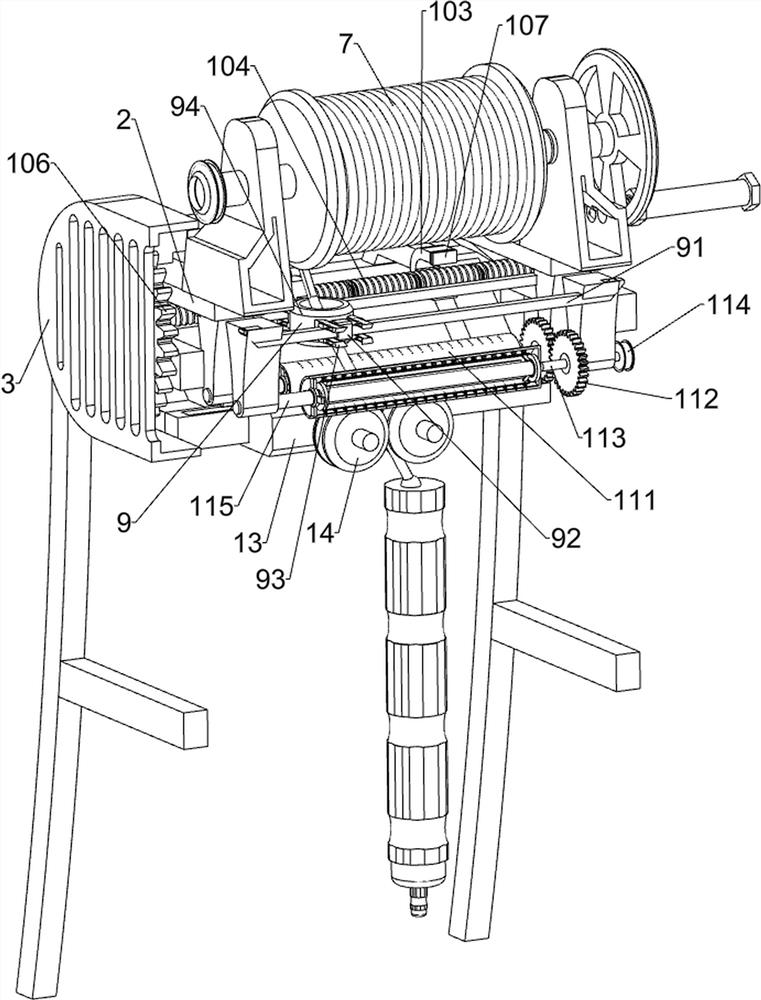

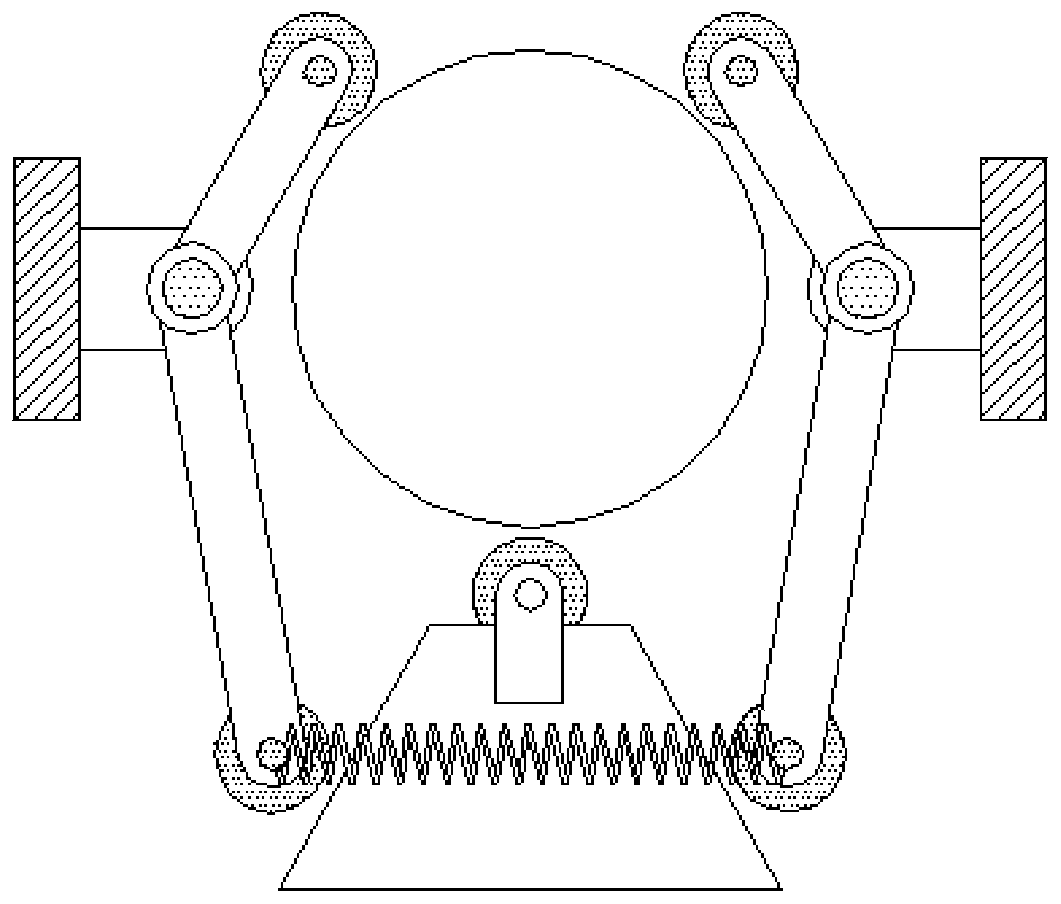

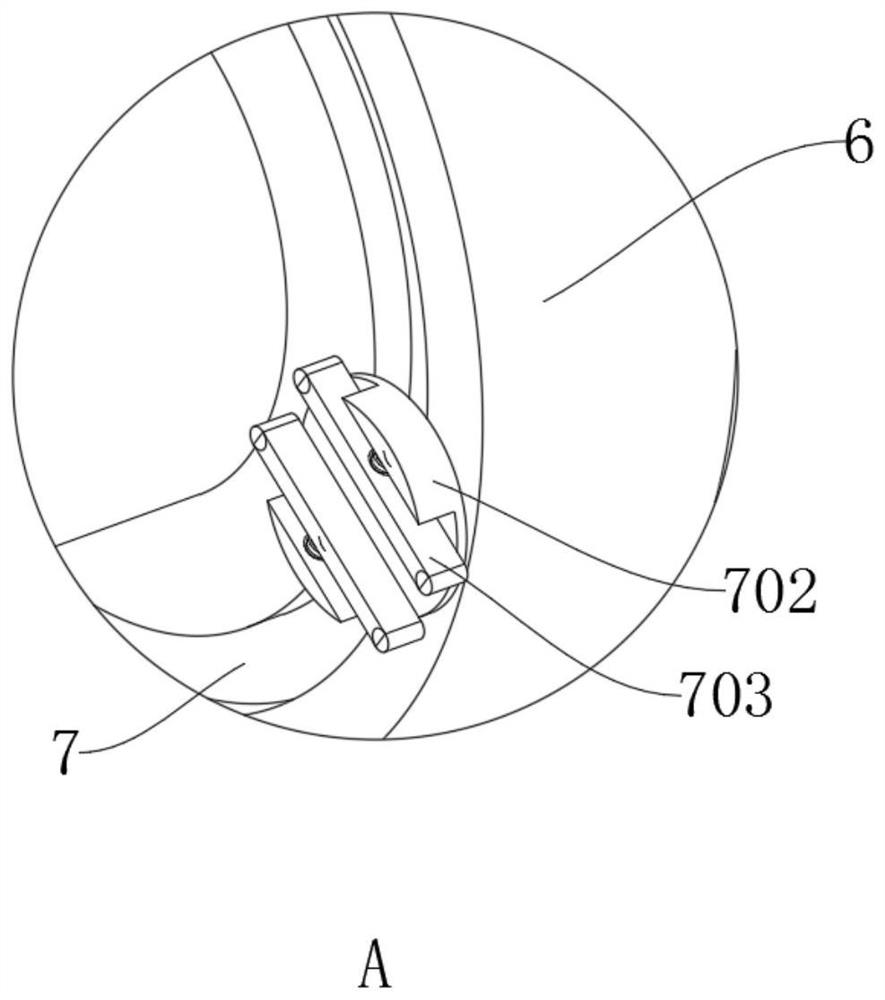

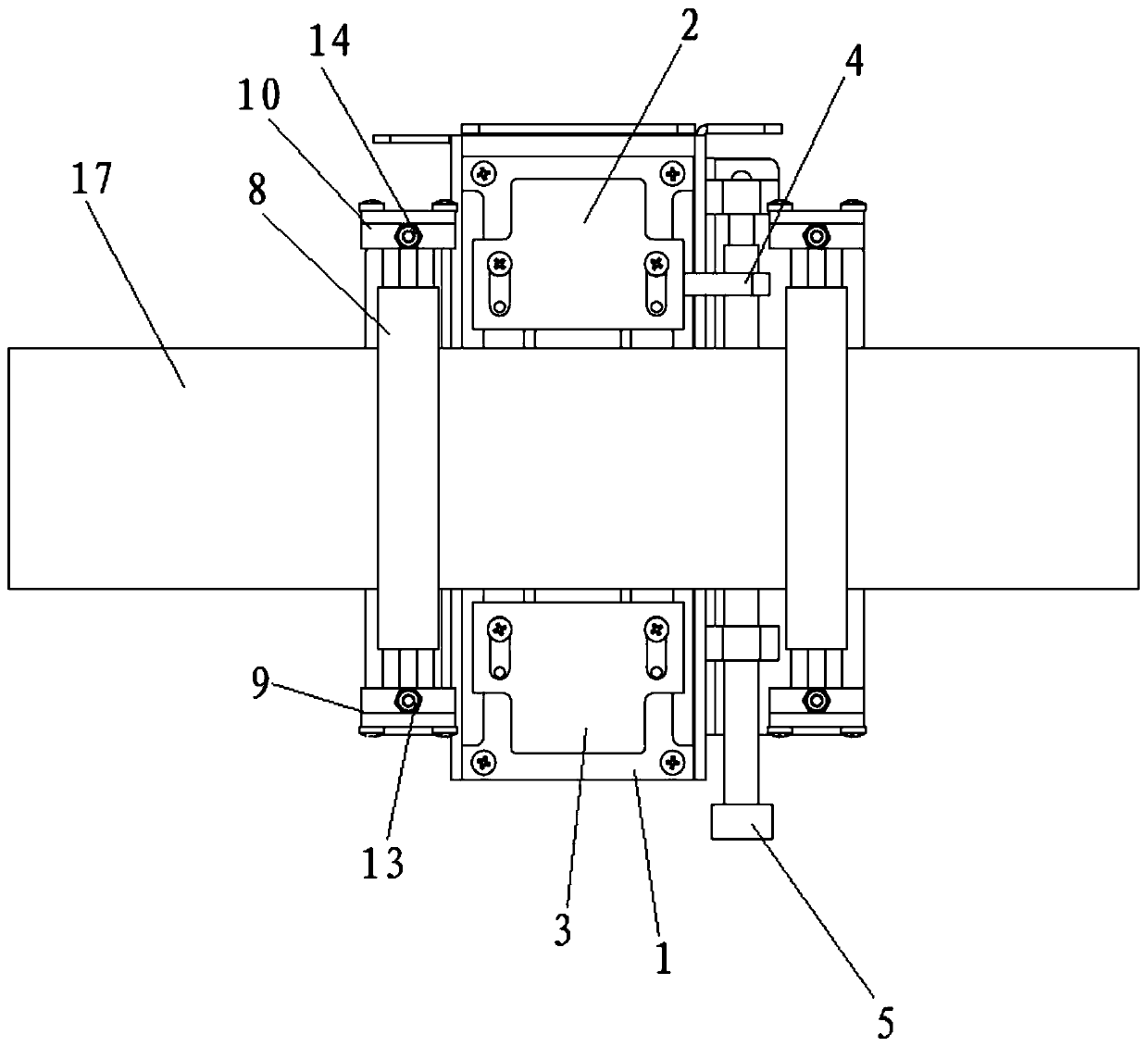

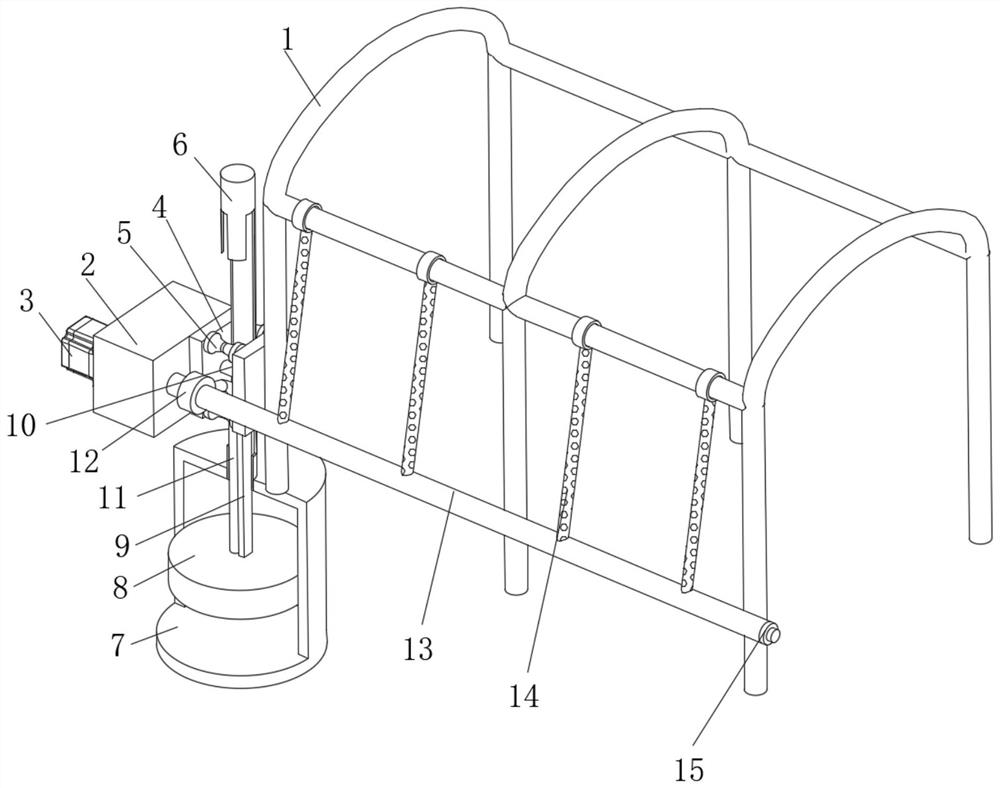

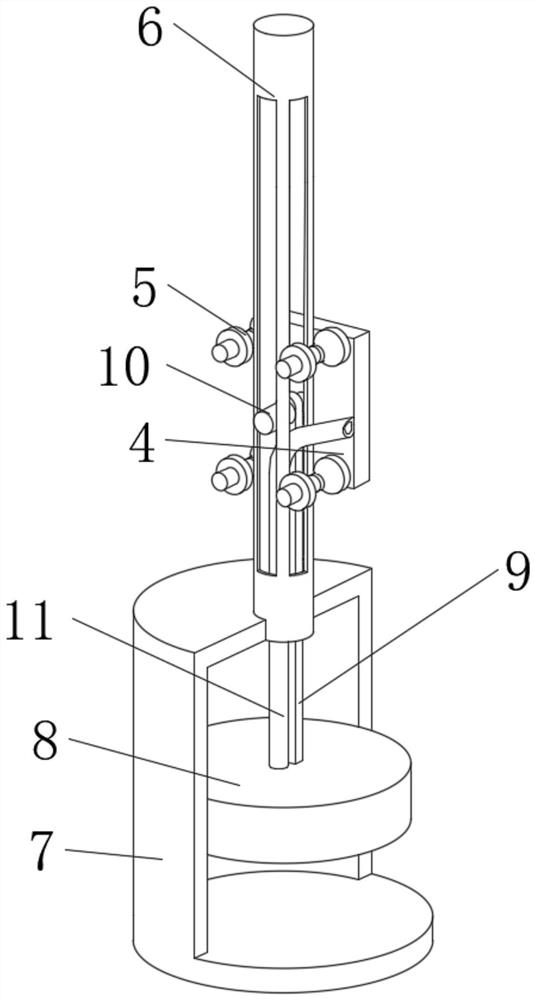

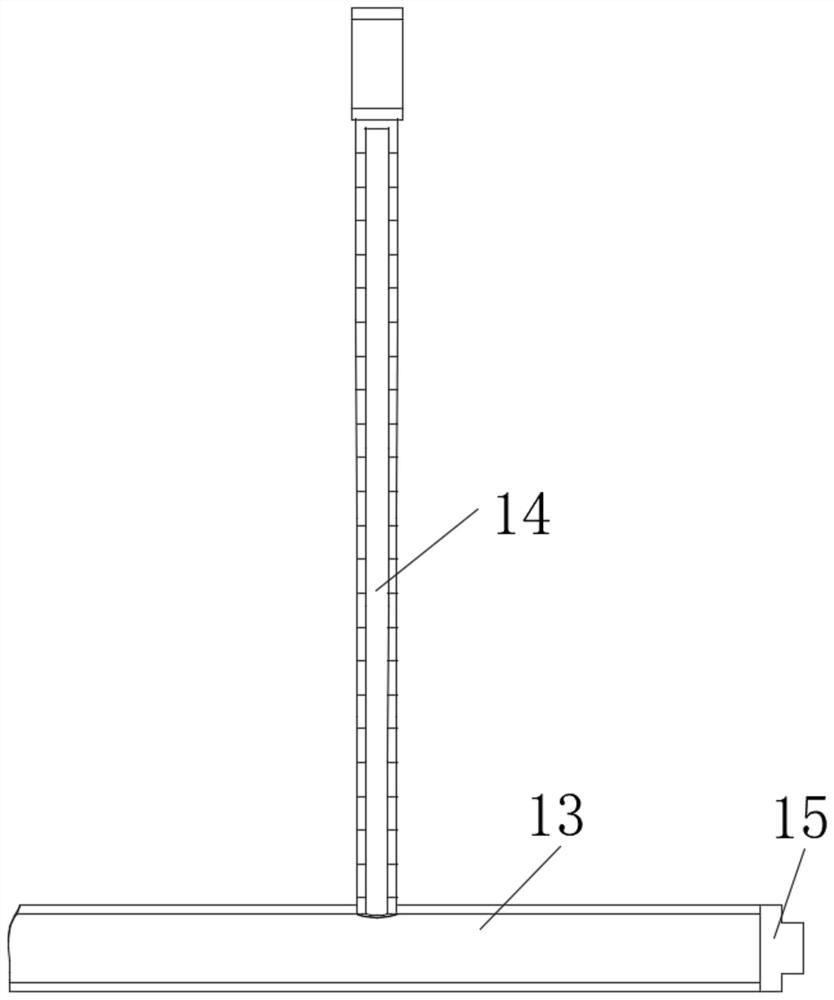

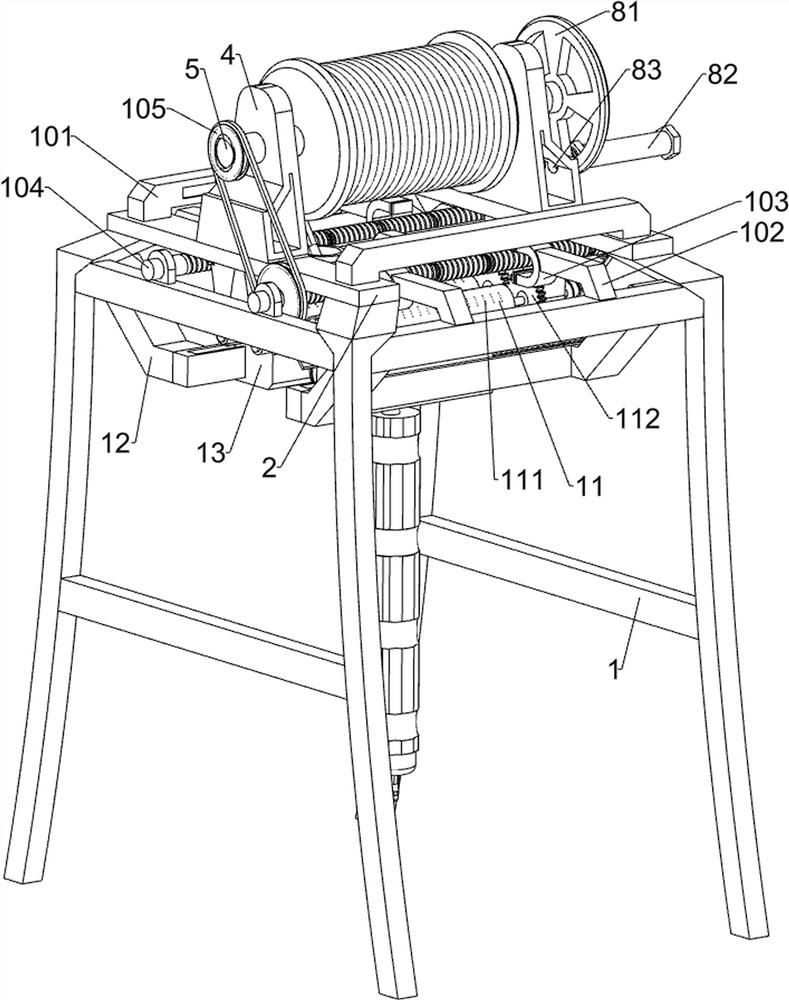

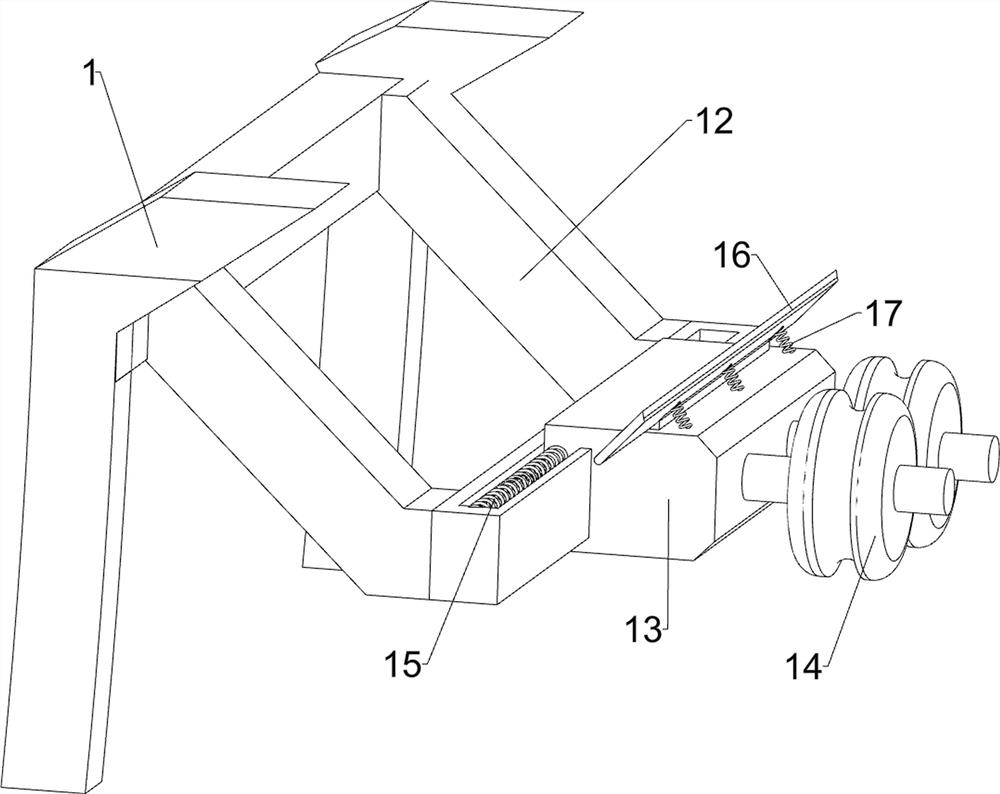

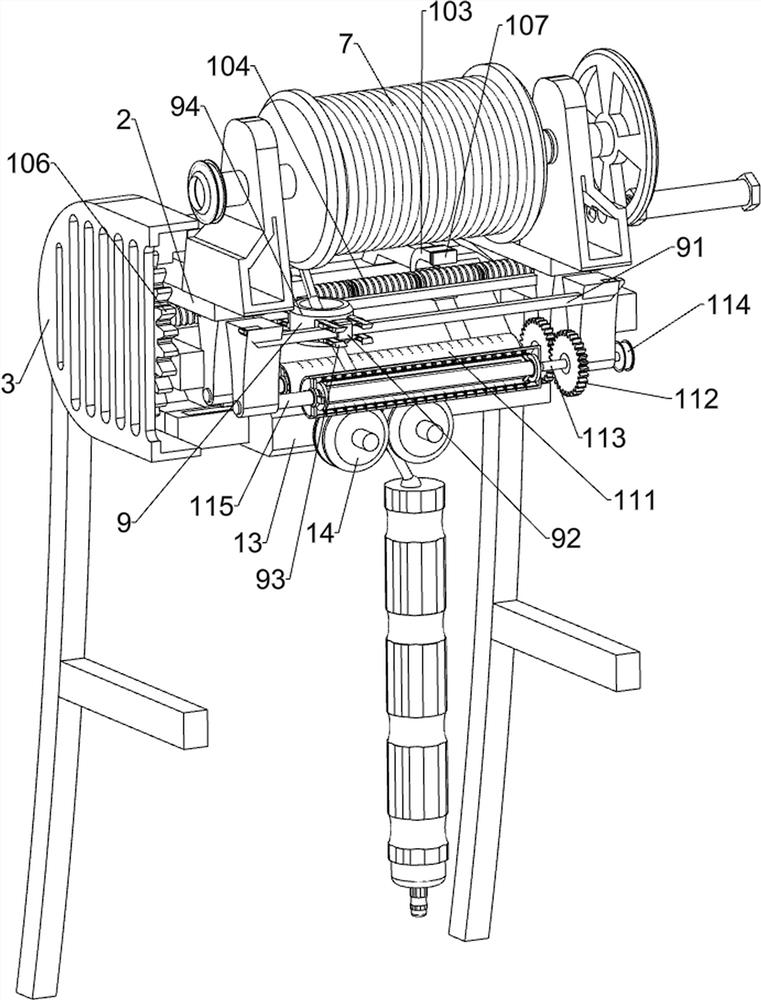

Winch cable take-up and pay-off wiring frame for drilling radar detector

The invention relates to a winch cable take-up and pay-off wiring frame for a drilling radar detector. The winch cable take-up and pay-off wiring frame comprises a mounting frame, fixing plates, a protective shell, vertical plates, a rotating shaft, a winch, a cable, a driving mechanism and a guide mechanism, wherein the fixing plates are fixedly connected between the two ends of each side of the mounting frame, the guide mechanism is arranged between the two fixing plates, and each vertical plate is fixedly connected to the middle of one side of each fixing plate. The radar detector is mounted at the tail end of the cable, the driving mechanism is pulled to be separated from the vertical plate on the right side, then the driving mechanism is pulled to rotate forwards to drive the winch to rotate forwards through the rotating shaft, the cable is loosened, and the radar detector moves downwards into a hole for detection; after detection in the hole is completed, the driving mechanism is pulled to rotate backwards to reset, the winch is driven to rotate backwards to wind up the cable, then the guide mechanism is pulled to move left and right to drive the cable to move left and right, and the cable is uniformly wound; and thus, the phenomenon of non-uniform winding of the cable can be avoided.

Owner:TONGLING NON FERROUS METAL GROUP CORP

Plastic reel convenient to use

Owner:菏泽智慧新材料科技有限公司

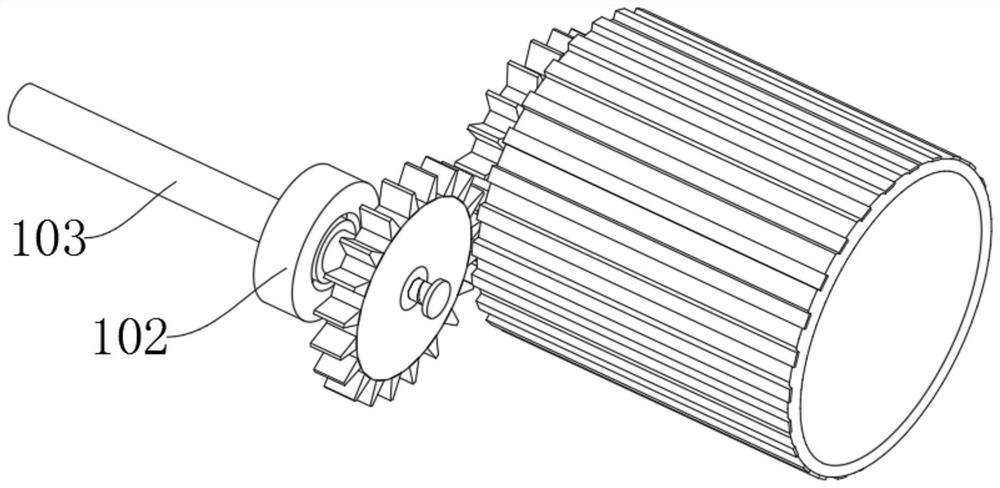

Winding equipment of high-frequency transformer coil

ActiveCN111223661AGuaranteed uniformityEvenly distributedInductances/transformers/magnets manufactureTransformerGear wheel

The invention relates to the technical field of transformers, and discloses winding equipment of a high-frequency transformer coil. The winding equipment comprises a base, wherein a supporting rod isfixedly connected to the upper part of the base, a first rotating shaft is supported, a transverse plate is fixedly connected above the supporting rod, the transverse plate is used for supporting a gear, a limiting ring is fixedly connected above the transverse plate, an electromagnetic wire is quantitatively cut through regular operation by means of the cooperative use of the gear, a turntable, apush rod and a cutting blade, so that quantitative winding is carried out, the uniformity of the transformer coil is ensured; a first rotating shaft, a second rotating shaft, a reel and a sleeve rodare used in a matched manner to enable a winding wheel to rotate and move left and right at the same time, so that it is guaranteed that coil is evenly distributed on the surface of the winding wheel,and uneven winding is avoided; and through cooperative use of a limiting rod and a trapezoidal plate, the winding wheel stops rotating while the winding is finished, so that the wound coil is prevented from loosening, and the compactness of the coil is guaranteed.

Owner:FUZHOU CITY SHUANGLING MAGNETIC MATERIALS

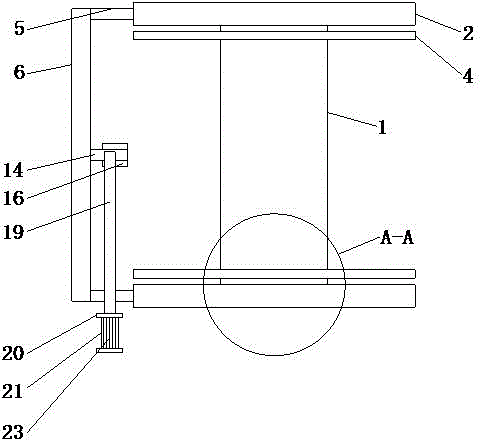

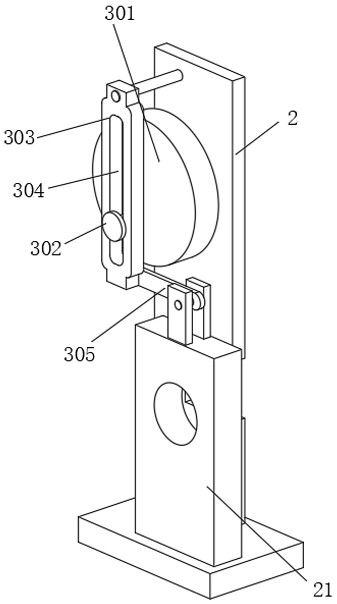

Manual workshop cloth winding machine

The invention relates to a winding machine, in particular to a manual workshop cloth winding machine. The manual workshop cloth winding machine can facilitate cloth winding by workers, the convenienceis achieved, cloth can be tightened, and disorderly cloth winding is avoided. According to the technical scheme, the manual workshop cloth winding machine comprises a base, a fixing device, a supporting column, a square plate, a friction block, a first spring, a guide rod, a pressing plate, an eccentric rod and the like, wherein the fixing device capable of fixing the machine is arranged on the left side of the bottom of the base, and the supporting column is fixedly connected to the right side of the top of the base. According to the machine, the cloth head end is moved to a slotted hole tobe pressed and fixed through the pressing plate, then a rocking handle is shaken, so that the square plate can reversely rotate so that the cloth can be wound, the condition that a person holds a reelbody by one hand, and winds the cloth around the reel body by the other hand is avoided, the convenience is achieved, the cloth can be more tightly wound by the effect of a first reel, so that the cloth is prevented from being disorderly wound.

Owner:胡少欢

Gauze coiling equipment for spinning

InactiveCN113788336AAvoid uneven windingConvenient winding workArticle deliveryWebs handlingElectric machineryScrew thread

The invention relates to coiling equipment, in particular to gauze coiling equipment for spinning. The gauze coiling equipment for spinning aims at achieving the technical effects that gauze can be automatically cut, and time and labor are saved. The gauze coiling equipment for spinning comprises a bottom plate, first fixing plates, first supporting plates, a roller, and a baffle, wherein the first fixing plates are installed on the two sides of the top of the bottom plate; the first supporting plates are symmetrically installed on the two sides of the top of the bottom plate, and the first supporting plates are located on the two sides of the first fixing plates on the same side; the roller is placed between the tops of the first supporting plates on one side; and the baffle is mounted on one side of the roller in a threaded manner. A motor is used as driving force to drive a first rotating shaft to rotate, so that the roller is driven to rotate, gauze can be automatically wound by the roller, time and labor are saved, the gauze can be limited by the baffle, and the phenomenon that the gauze falls to the ground or is wound irregularly is avoided.

Owner:吴维秀

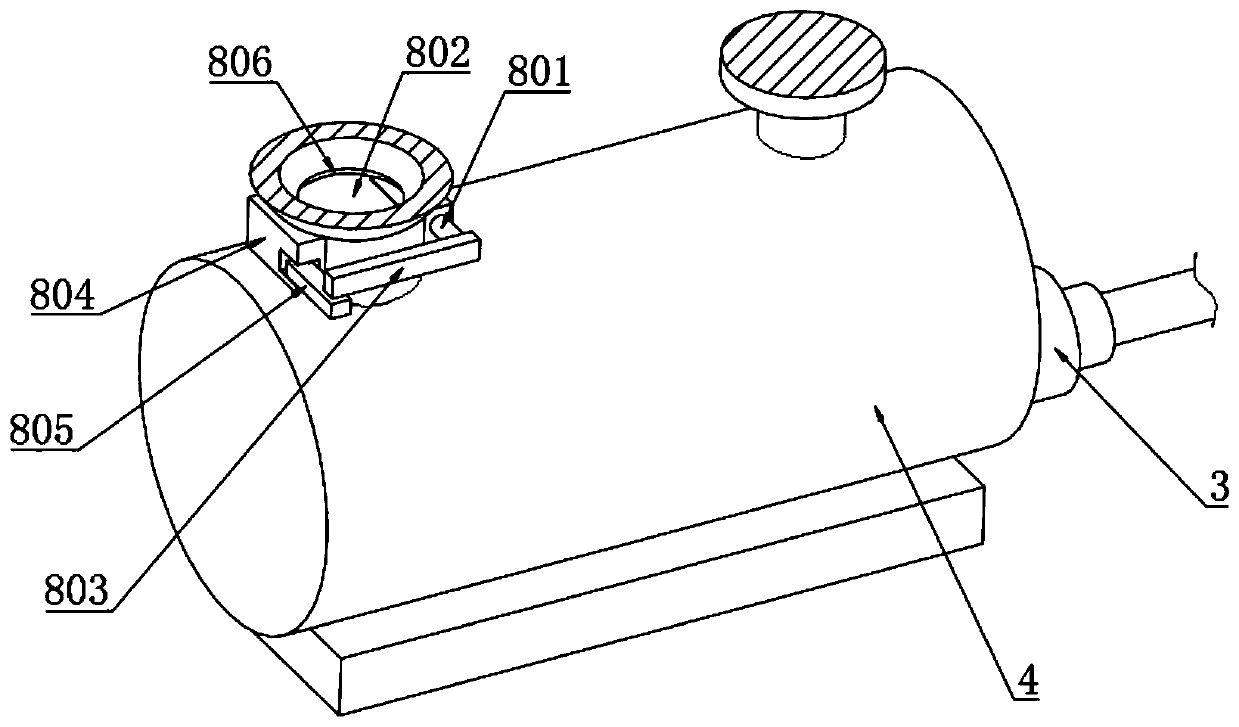

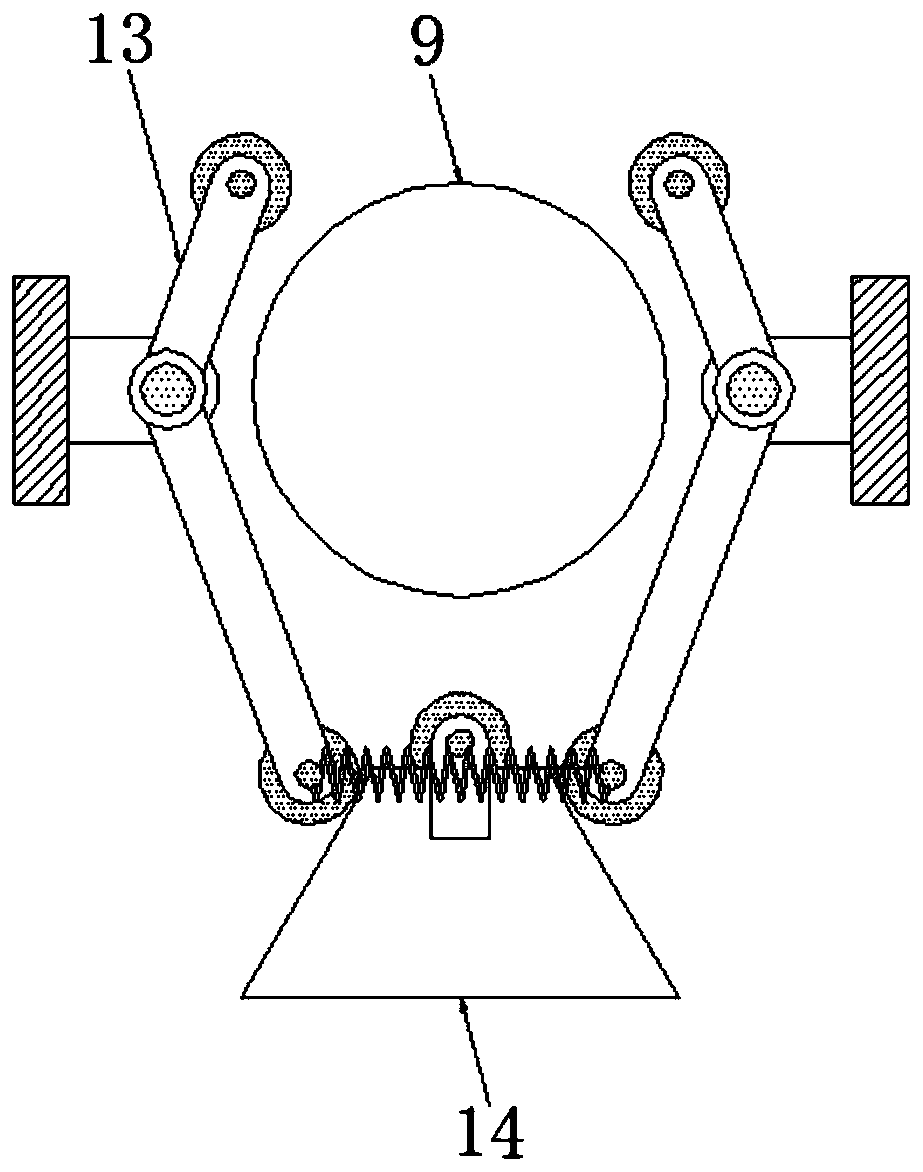

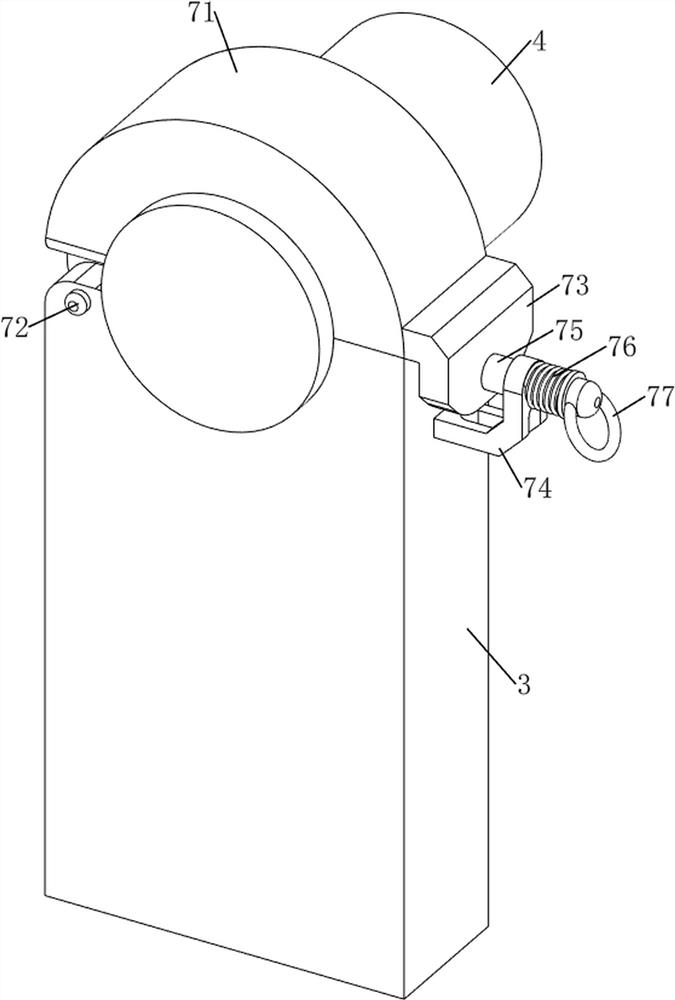

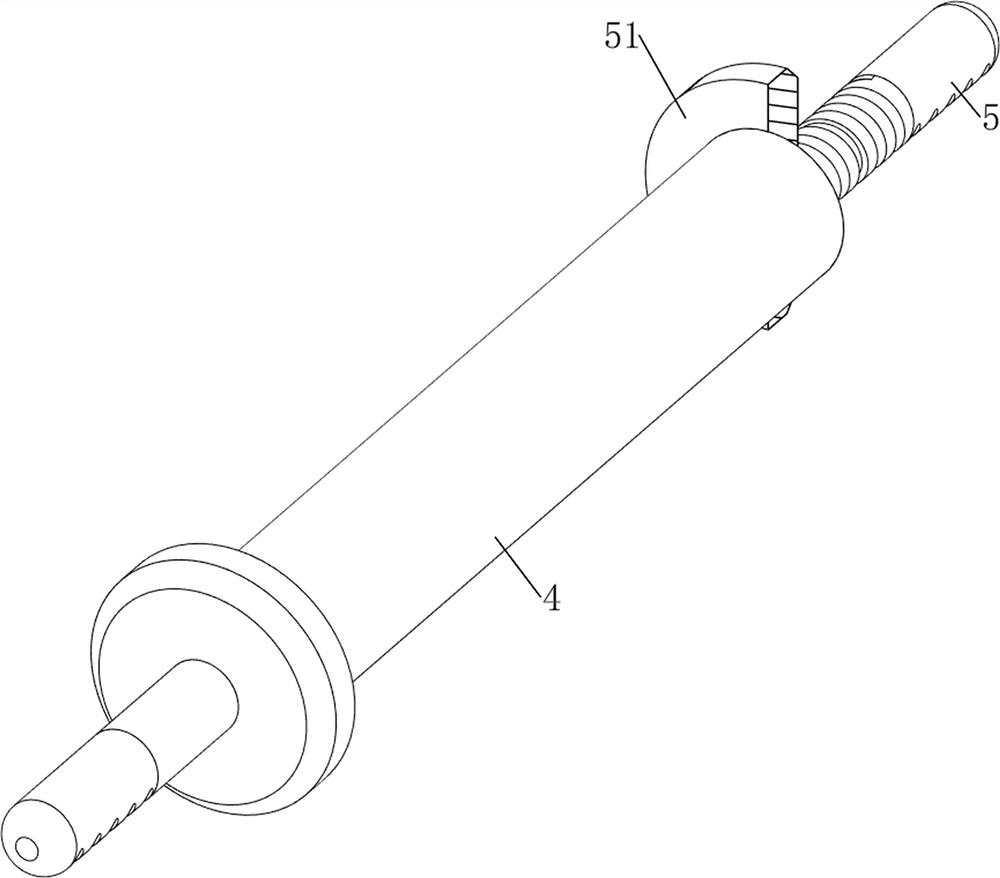

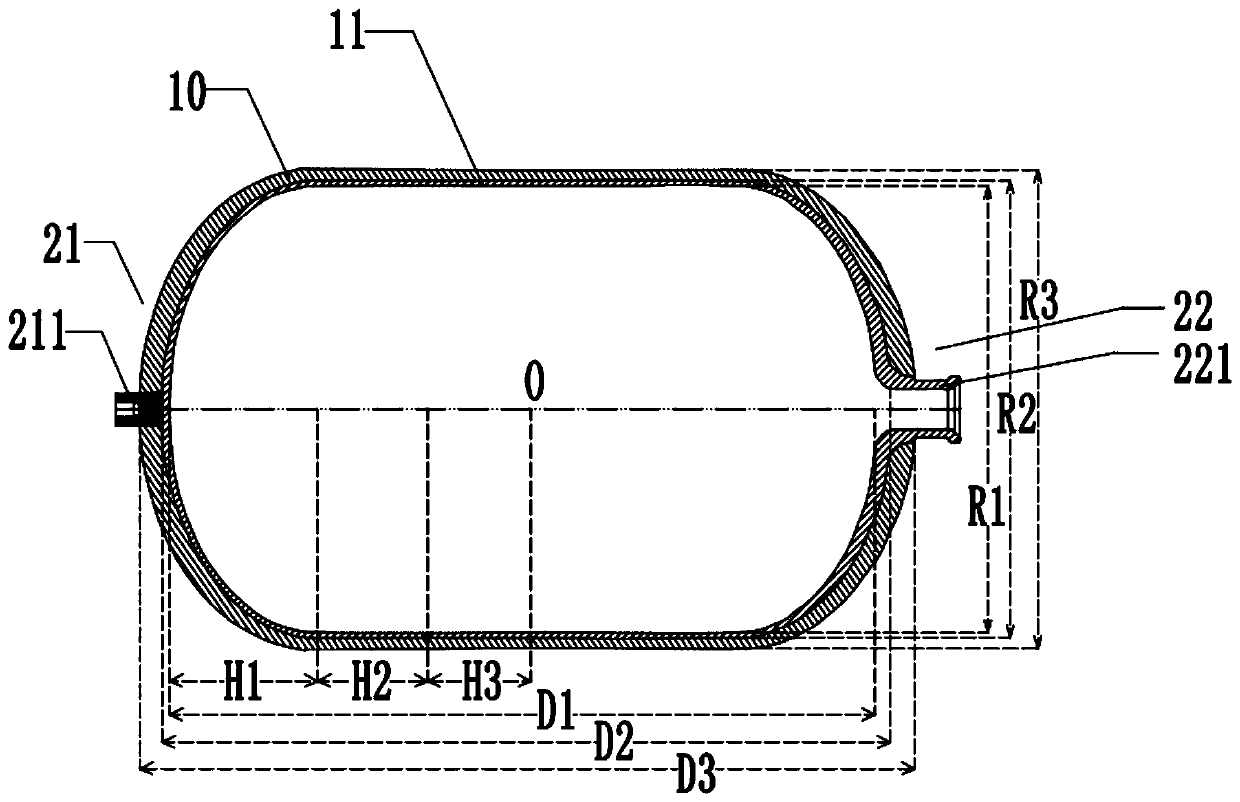

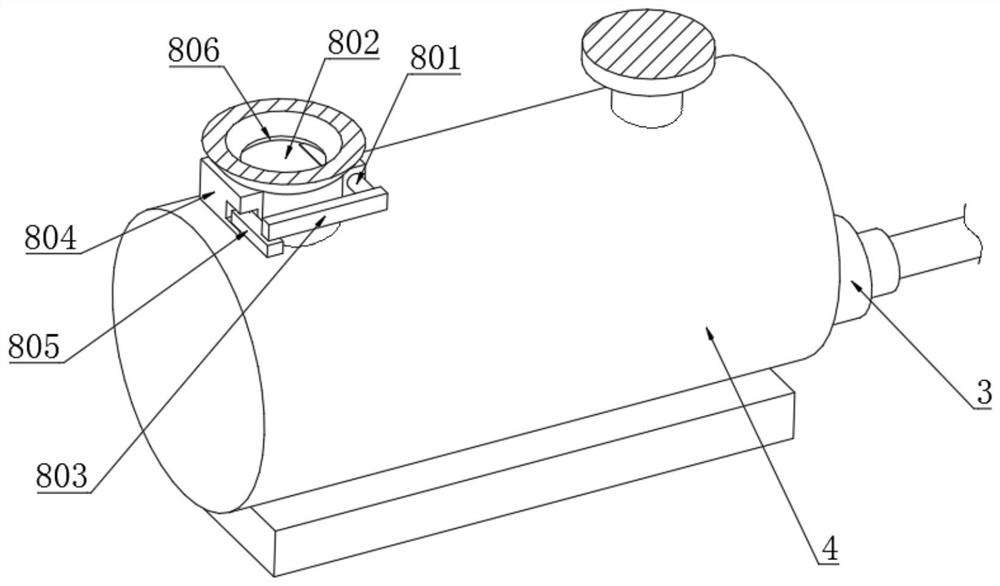

Machining method of fully-wound gas storage bottle

PendingCN110594576AImprove pressure resistanceAvoid uneven windingVessel mounting detailsVessel manufacturingCarbon fibersGas cylinder

The invention discloses a machining method of a fully-wound gas storage bottle and belongs to the technical field of high-pressure gas storage bottles. The machining method comprises the following steps that 1, an inner container is manufactured through a cold stamping and deep drawing manner; firstly, an aluminum blank is deeply drawn to form a cup-shaped semi-finished product, then the cup-shaped semi-finished product is strongly turned and thinned on strong turning equipment, and finally, the thinned ring-shaped semi-finished product is closed up on a closing-up machine to form the inner container; and 2, at least two layers of carbon fiber fully cover and are wound around the outer surface of the inner container in an intersecting manner to form winding layers, and the winding directions of two adjacent layers of carbon fiber are different. The gas storage bottle machined through the machining method solves the problem of uneven wining of the fiber, and the pressure-resisting ability of the gas storage bottle is better.

Owner:SINOMA SCI & TECH CHENGDU CO LTD

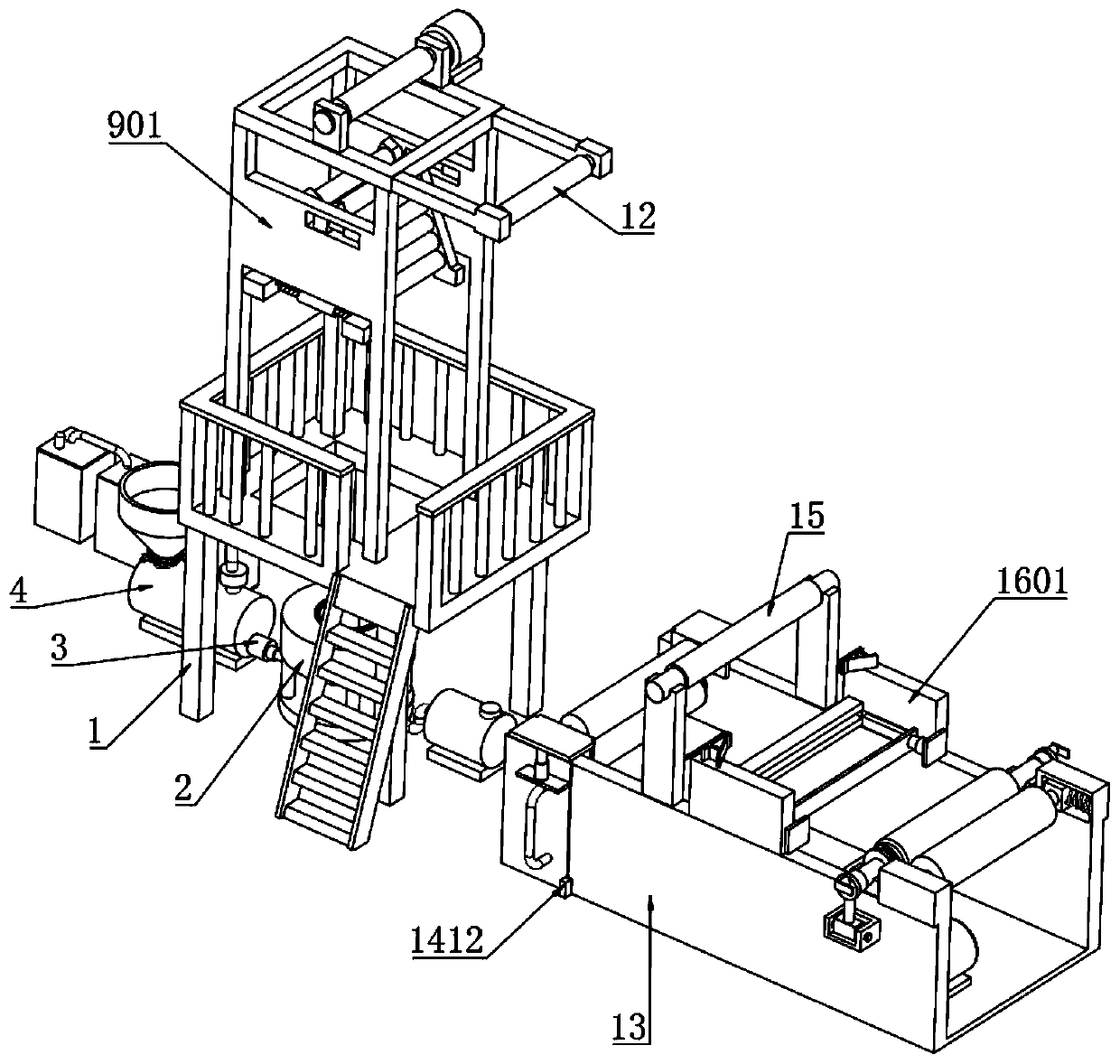

Glass fiber felt rapid continuous production system

PendingCN109051870AEvenly sprinkledQuality improvementPaper article packagingConveyorsGlass fiberYarn

The invention discloses a glass fiber felt rapid continuous production system. The production system comprises a glass fiber yarn coil cutoff device, a settlement chamber, a powder adhesive uniform discharging mechanism, a water spraying device, a powder scattering device, a drying device, a compaction shearing device, a detection device, a winding device and a packaging mechanism which are arranged in sequence. By making improvement on or adding the powder adhesive uniform discharging mechanism, the drying device, the detection device, the winding device and the packaging mechanism, the purpose of continuous non-halt is achieved through fewer manpower resources in the production process, and the working efficiency is improved.

Owner:嘉兴市宏宇新材料股份有限公司

Take-up device with safety protection structure

The invention discloses a take-up device with a safety protection structure. The take-up device comprises a fixed bottom plate, a fixed clamping seat, a telescopic supporting plate and a hollow sleeverod, wherein the fixed clamping seat is fixedly mounted on the outer surface of the upper end of the fixed bottom plate, the telescopic supporting plate is fixedly mounted on one side, close to the fixed clamping seat, of the upper end of the fixed bottom plate, a telescopic sleeve plate is movably sleeved on the inner surface of the inner side of the telescopic supporting plate, a supporting foot rod is fixedly mounted on the outer surface of the lower end of the telescopic supporting plate, a buffering sleeve rod is movably sleeved on the inner surface of the inner side of the supporting foot rod, the supporting foot rod and the buffering sleeve rod are elastically connected through a spring sleeve, and a first caster is movably mounted on the outer surface of the lower end of the supporting foot rod. According to the take-up device with the safety protection structure, the take-up device is provided with the safety protection structure, the phenomenon that a cable is wound and stuck in the take-up process is avoided, meanwhile, the take-up device is provided with a telescopic adjustment structure, and the application range of the take-up device is improved.

Owner:安徽英杰精工机械股份有限公司

Non-woven guiding device used for textile machine with drafting machine

The invention provides a non-woven guiding device used for a textile machine with a drafting machine, and relates to the technical field of textile device equipment so as to solve the problems that when an existing guiding device is used, impurities, including fluffy catkins or textile thread residues and the like, in the air fall to cloth materials, eyes can not observe the impurities in time andthe impurities can be rolled into a finished product along with the cloth materials to affect the quality of the product. The non-woven guiding device comprises a main body, a scraping plate and a carrying plate, wherein a top plate is arranged on the inner side of the main body, and in addition, a clamping plate on the bottom of the top plate is installed on the side surface of a cross rod; a surface plate is of a round plate shape structure and is inlaid into the side surface of the main body; the sliding plate is of an arc-shaped structure and is installed on the side surface of a draftingrod; and a sliding chute is of a T-shaped structure and is arranged on the side surface of the sliding plate. When weaving is carried out, after the cloth materials are pulled through the drafting machine, the cloth materials are likely to be stained with the impurities when the cloth materials rotate, the impurities on the cloth materials can be cleaned through the scraping plate, and a cloth material movement direction is controlled through the carrying plate.

Owner:张亚岗

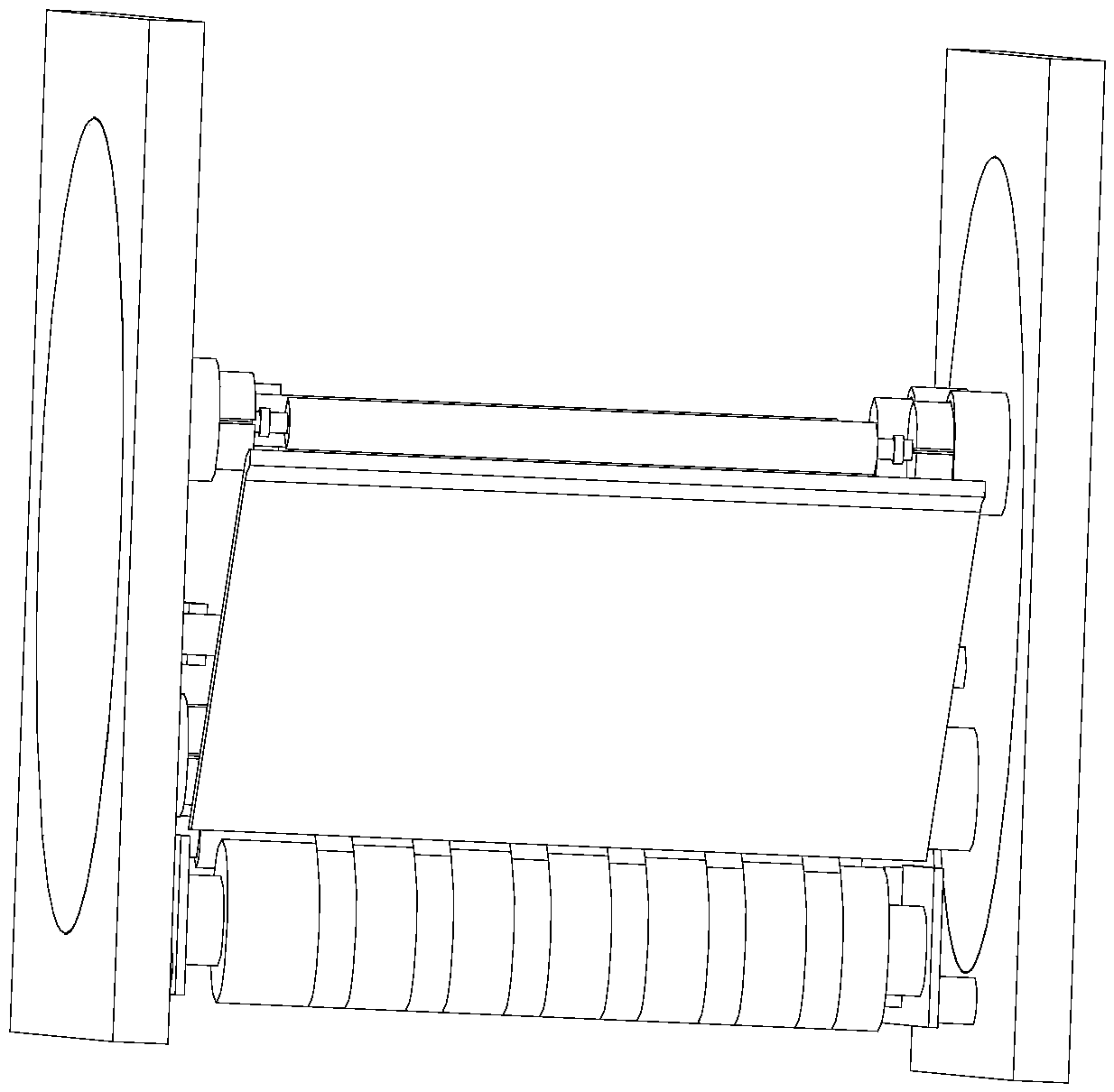

Double-roller-shaft light blocking device

PendingCN110255256AAchieving adaptive adjustmentAvoid uneven windingMaterial analysis by optical meansWebs handlingEngineeringPaper sheet

Owner:武汉市海维鑫科技有限公司

Winding device for film casting machine

ActiveCN112125013AImprove efficiencyAvoid wastingNatural electricityWebs handlingElectric machineryMotor control

The invention discloses a winding device for a film casting machine in the technical field of film winding. The winding device comprises a winding box, wherein a first supporting frame is fixedly mounted in the winding box, a servo motor is fixedly mounted at the top of the first supporting frame, the output end of the servo motor is fixedly connected with a rotary disc, and bearings are fixedly mounted at one side of the rotary disc; and a roller shaft is fixedly connected to one side of each bearing, a second supporting frame is fixedly installed in the winding box, a motor is fixedly connected to the top of the second supporting frame, and a clamping cylinder is fixedly installed at the output end of the motor. According to the winding device, the bearings are fixedly installed at one side of the rotary disc, one sides of the bearings are fixedly connected with the three roll shafts, and after winding is completed, the servo motor controls the rotary disc to rotate, the wound roll shaft can be taken out, the other roll shaft can conduct drum adding on the wound roll shafts, and the last roll shaft is wound simultaneously; and the three roll shafts work in a replacing manner, sothat the working efficiency is greatly improved, and human resources are saved.

Owner:娄底光华机械设备制造有限公司

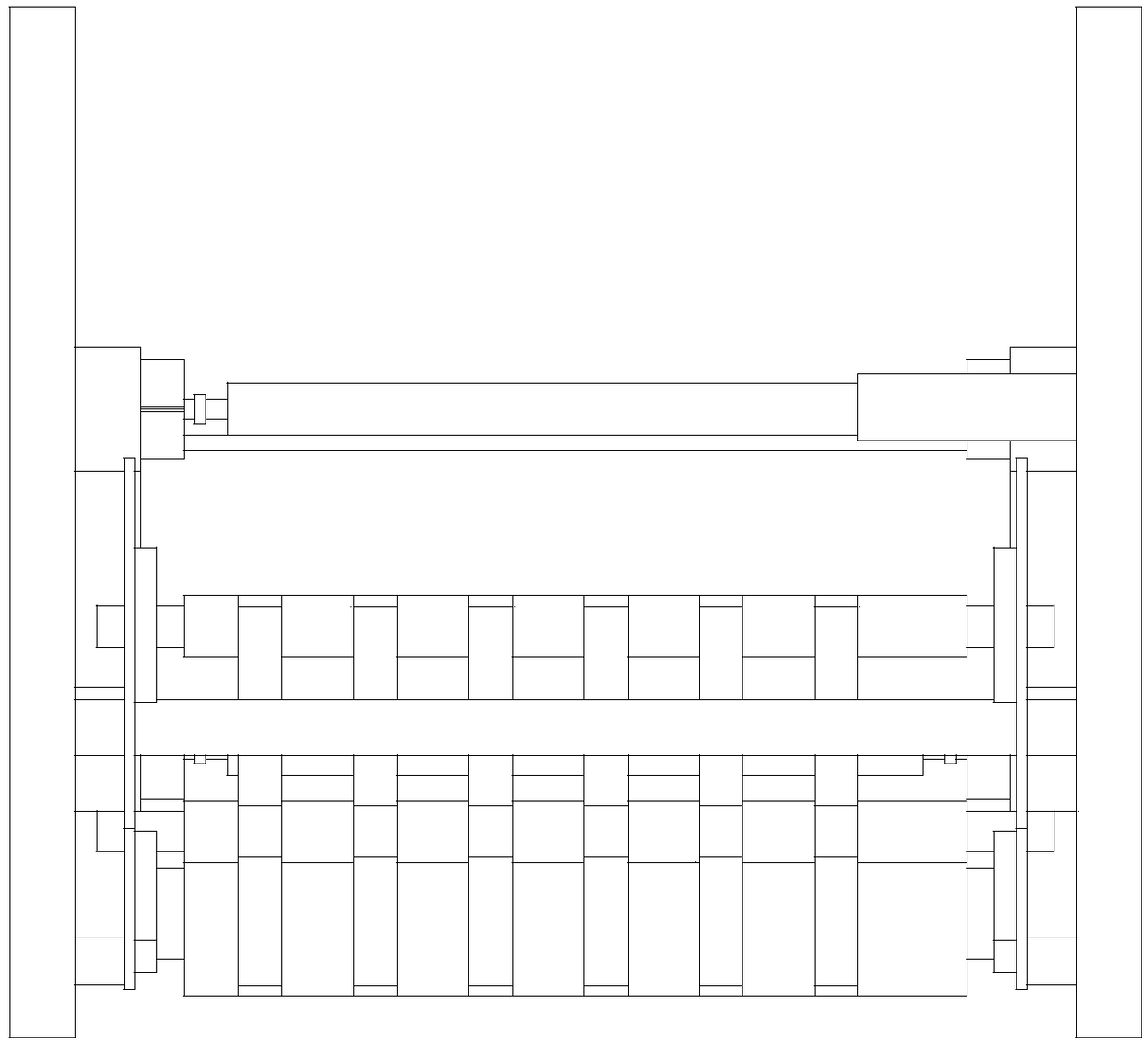

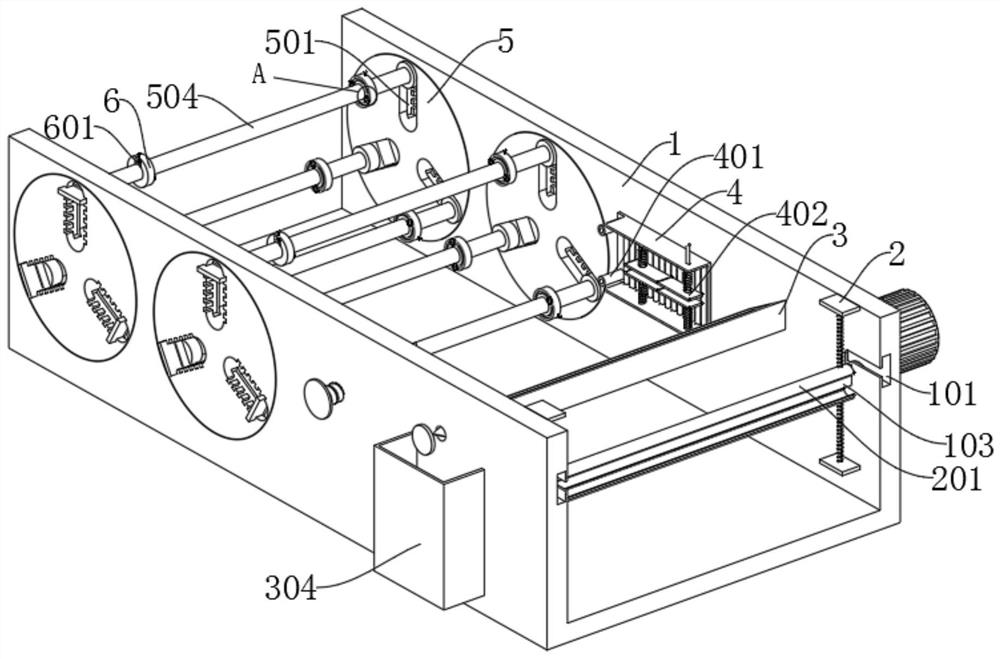

Multi-station motor automatic winding equipment

ActiveCN114583906BImprove winding efficiencyHigh degree of automationElectric machinesManufacturing dynamo-electric machinesBobbinElectric machine

The invention discloses automatic winding equipment for multi-station motors, which relates to the technical field of motor assembly equipment. A bobbin on one side of the workbench, and a wire take-up assembly, the wire take-up assembly includes a wire take-up spool, one end of the wire take-up spool is connected to a rotating mechanism that drives it to rotate, and the wire spool is matched with the bobbin for The rotor is wound. When winding the rotor, the end of the cable on the surface of the reel is fixed on the surface of the take-up reel, and then the reel is driven to rotate by the rotating mechanism, and the winding is wound during the rotation. The cable on the surface of the drum is wound on the surface of the take-up drum. Multiple spools and take-up drums can be set between the workbench and the rack at the same time, so as to realize the multi-station rotor winding. Compared with the traditional single-station Rotor winding, the automation degree of rotor winding is higher, and the efficiency of rotor winding is effectively improved.

Owner:江苏惠博机电科技股份有限公司

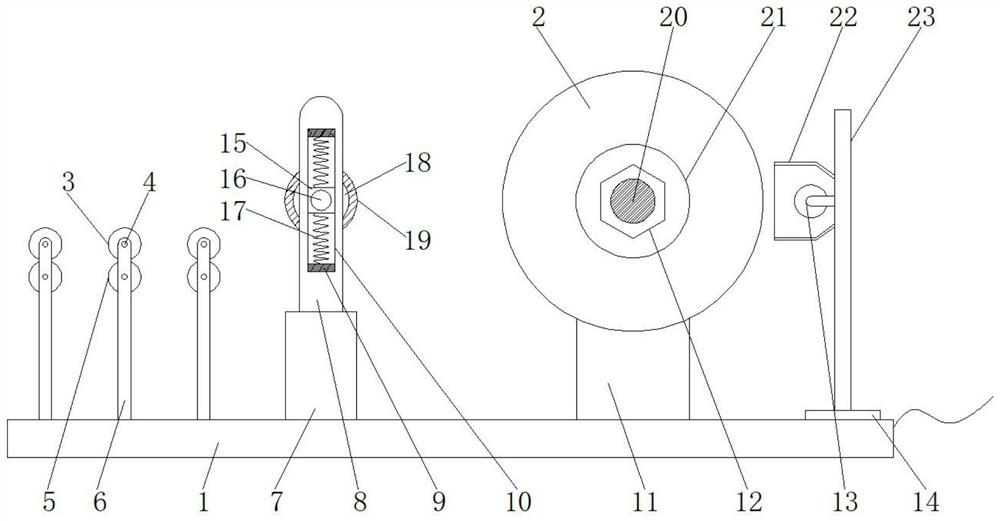

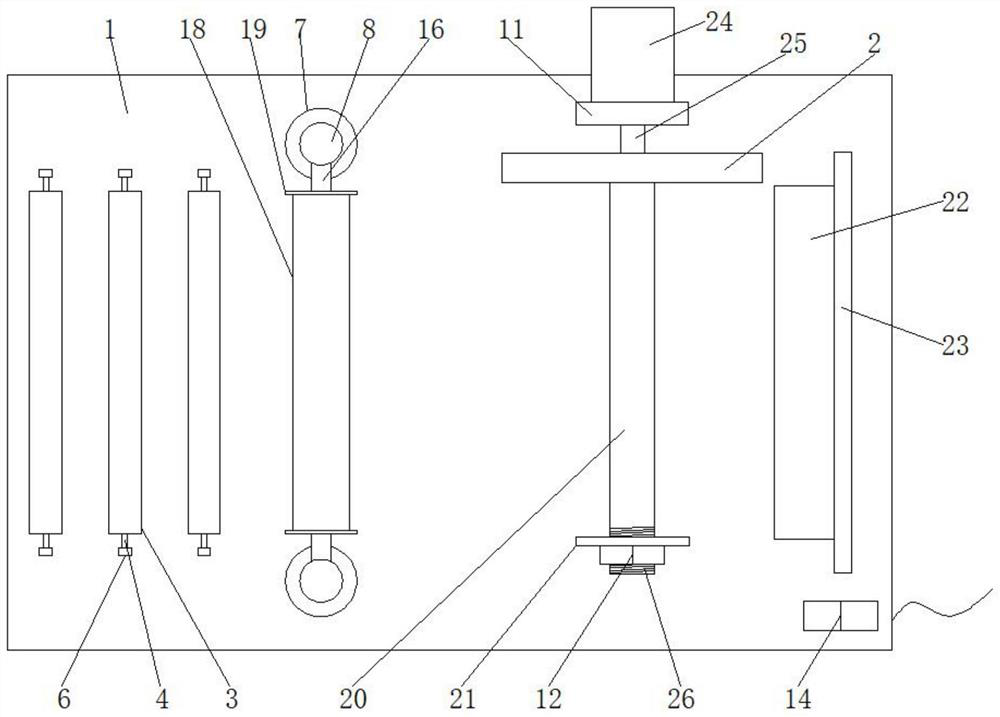

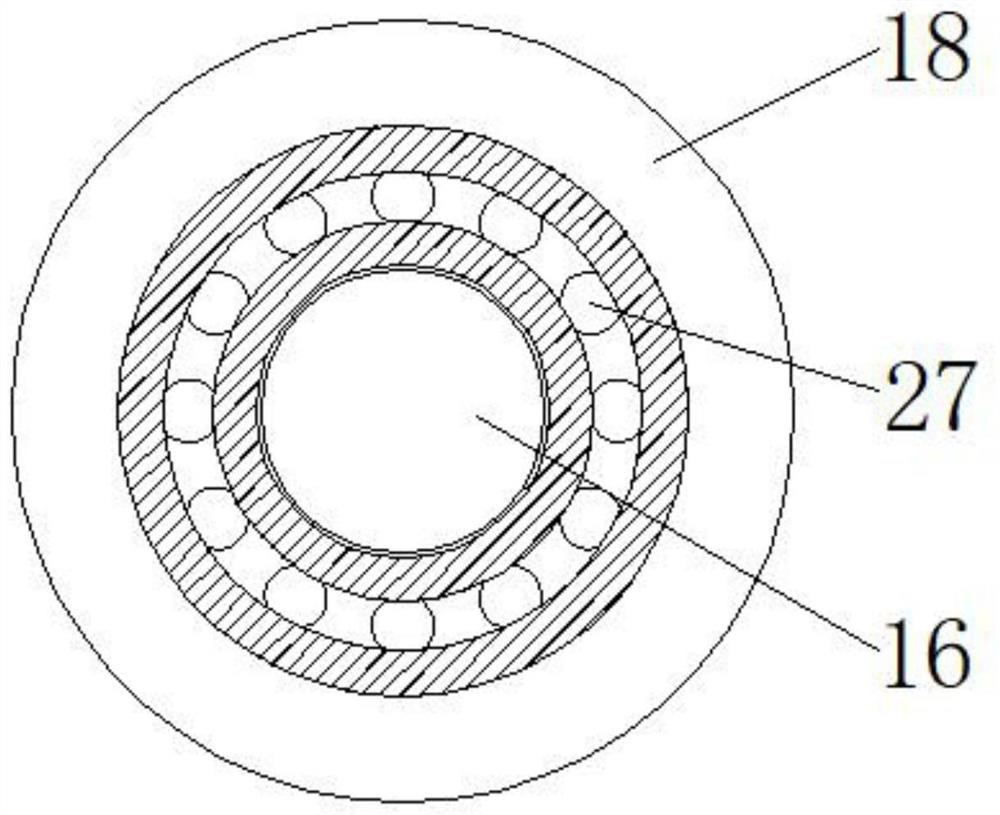

Auxiliary device for barreled welding wire production

ActiveCN113581927AWinding orderlyWinding automatically and evenlyFilament handlingElectric machineryEngineering

The invention discloses an auxiliary device for barreled welding wire production, and relates to the technical field of barreled welding wire machining auxiliary devices. The auxiliary device comprises a base, a pulley block, an auxiliary structure and a winding structure are sequentially arranged on the surface of the base from left to right, a barreled welding wire body winding the winding structure is arranged between the pulley block and the auxiliary structure, the auxiliary structure comprises a fixed seat located on the surface of the base, and a first motor is fixedly installed on the inner side of the fixed seat. By arranging a steering block to move upwards, the steering block can assist the barreled welding wire body to be wound on the surface of a winding frame, so that the barreled welding wire body is wound from inside to outside at the lowest position of the surface of the winding frame, and then the barreled welding wire body can be driven upwards by the steering block to be continuously wound from inside to outside on the surface of the winding frame, and the barreled welding wire body is wound in order, the automatic and uniform winding effect is achieved, and the situation that the barreled welding wire body is wound unevenly is avoided.

Owner:上海斯米克焊材有限公司

Winding equipment for halogen-free low-smoke flame-retardant polyolefin cable production and application method

The invention discloses winding equipment for halogen-free low-smoke flame-retardant polyolefin cable production and an application method, and belongs to the technical field of cable production. The winding equipment for halogen-free low-smoke flame-retardant polyolefin cable production comprises a protection frame, wherein a connecting plate is arranged on the surface of the protection frame; an adjusting mechanism is arranged on the surface of the connecting plate; a fixing block slidably connected with the protection frame is arranged at the bottom of the adjusting mechanism; a storage rod making contact with the protection frame is arranged at one end of the connecting plate; and an elastic belt is fixedly connected to the surface of the storage rod. According to the winding equipment for halogen-free low-smoke flame-retardant polyolefin cable production and the application method, the practicability is high; before a cable is wound, the winding thickness and the diameter of the cable can be adjusted through a transmission mechanism and a push rod; when the cable is wound, the position of the cable can be moved through the adjusting mechanism; and when deviation occurs in cable winding, the cable can be controlled to be straightened in time, and uneven winding is prevented.

Owner:上海沪安电缆(无锡)有限公司

A fabric winding machine for a manual workshop

The invention relates to a winding machine, in particular to a cloth winding machine for a manual workshop. The technical problem to be solved is: to provide a cloth winding machine in a hand-made workshop that is more convenient for people to wind up the cloth, and can tighten the cloth to avoid uneven winding of the cloth. The technical solution is: a cloth winding machine for a manual workshop, including a base, a fixing device, a support column, a square plate, a friction block, a first spring, a guide rod, a pressure plate, an eccentric rod, etc.; The fixing device fixed by the device has a support column fixedly connected to the right side of the top of the base. In the present invention, the head end of the cloth is moved into the slotted hole, pressed and fixed by the pressure plate, and then the handle is shaken, so that the square plate can be reversed to roll up the cloth, without the need for a person to hold the cylinder with one hand and roll the cloth with the other. On the cylinder, it is more convenient, and through the function of the first roller, the cloth can be rolled up more tightly, avoiding uneven winding of the cloth.

Owner:胡少欢

Modernized vegetable planting intelligent greenhouse film rolling device

InactiveCN111937644AAvoid uneven windingEfficient windingClimate change adaptationSnow trapsAgricultural scienceGreenhouse

The invention relates to the related technical field of agricultural machinery, and discloses a modernized vegetable planting intelligent greenhouse film rolling device. The device comprises a greenhouse body and a film rolling box, a driving motor is fixedly installed on an input shaft on one side of the film rolling box, and a mounting frame is fixedly installed on one side of the film rolling box. A traction pipe is arranged to be a hollow pipe with a side wall provided with air holes, when a greenhouse film is rolled up through a film rolling shaft, the mounting frame is synchronously driven to ascend, then a movable plug is dragged to ascend synchronously, meanwhile, pressure of a lower end of the movable plug in an inner cavity of a fixed box is reduced, and finally, an air guide pipe promotes the traction pipe to suck air through reduction of the pressure in the film rolling shaft. Meanwhile, when the film rolling shaft rolls the greenhouse film, the greenhouse film can be firmly adsorbed during rolling through continuous air suction of the traction pipe, so that the phenomenon that the film rolling shaft is non-uniform in rolling due to unwinding or less rolling is avoided,and finally, the purpose of efficient rolling is achieved.

Owner:安徽汇力农业发展股份有限公司

Protective film of photosensitive dry film

PendingCN106933038AEasy to separateTransport stablePhotosensitive materials for photomechanical apparatusOptical elementsPolymer sciencePolymer chemistry

The invention relates to a protective film of a photosensitive dry film. The protective film includes a film body, and the film body comprises a matt layer with a matt surface and a glossy layer with a glossy surface. The glossy layer has roughness Ra of 0-0.15 micrometer, surface energy of 0-25 dyne / cm, and a release force of 0-2000g; the matt layer has roughness Ra of greater than micrometer, surface energy of greater than 0-25 dyne / cm, and a release force of greater than 0-2000g. The film body also includes at least one intermediate layer, and the intermediate layer is disposed between the matt layer and the glossy layer to connect the matt layer and the glossy layer. According to the invention, through improvement of the existing technology, the film body has the matt surface and the glossy surface, wherein the glossy surface is compounded with a photosensitive layer, moderate release force ensures that the protective film and the photosensitive layer are attached together, and also guarantees that the protective film is easily separated at a film press link. The matt layer provides appropriate friction force, prevents untidy roll-up caused by interlayer slipping and offset of the dry film layer during roll-up and transportation, and enhances the product quality.

Owner:湖南五江高科技材料有限公司

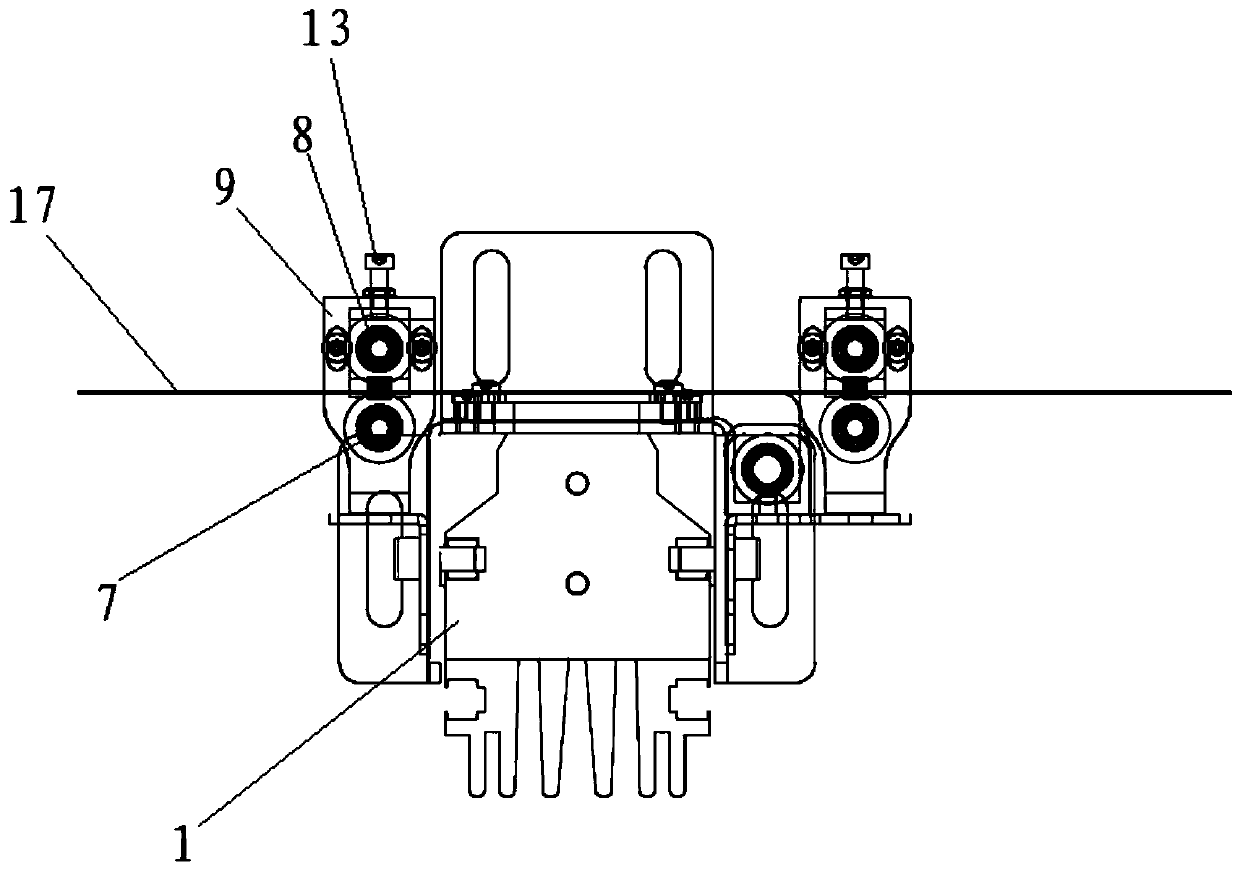

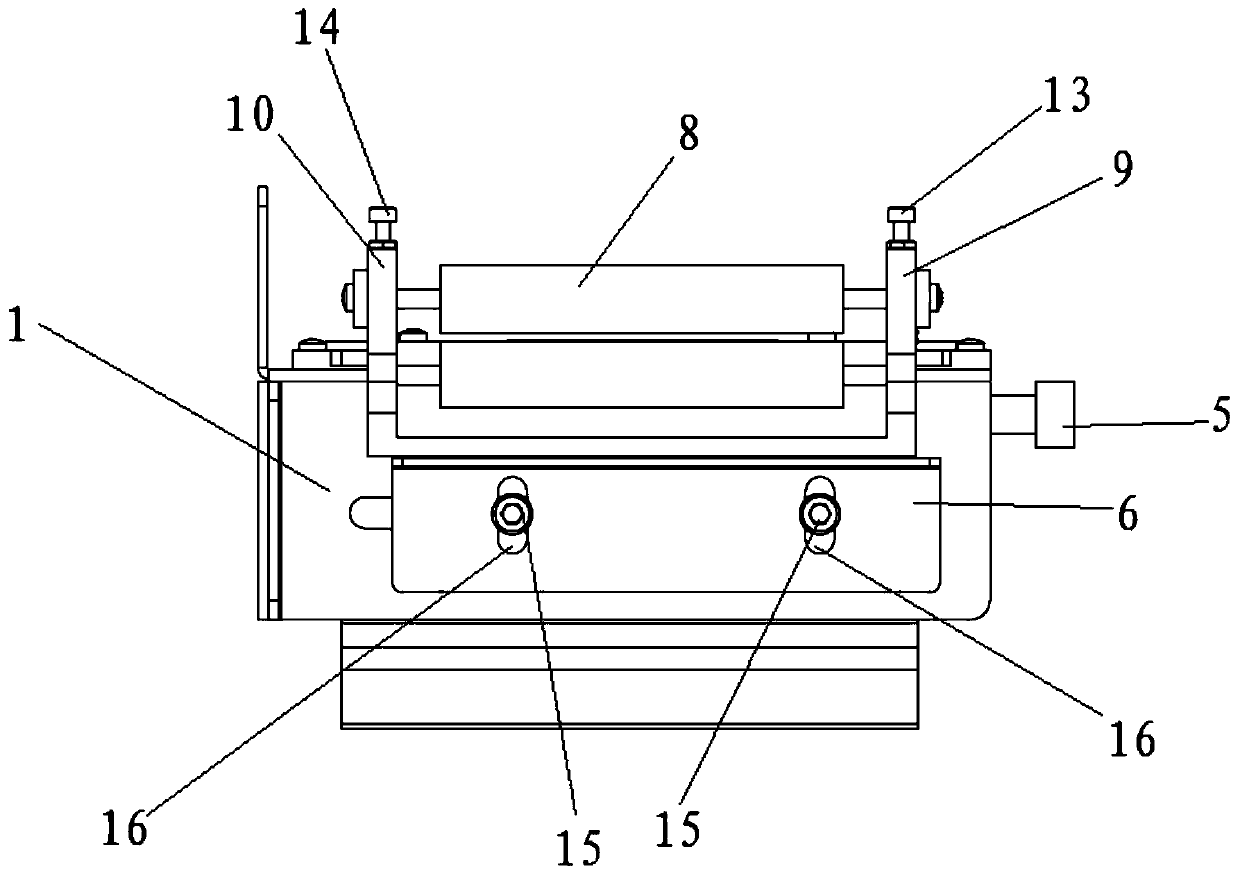

Cable retractable wiring frame for hoist for drilling radar detector

The invention relates to a cable retractable wiring frame for a winch of a drilling radar detector, which includes a mounting frame, a fixed plate, a protective shell, a vertical plate, a rotating shaft, a hoist, a cable, a driving mechanism and a guiding mechanism. A fixed plate is fixedly connected between the two ends of the side, the guide mechanism is installed between the two fixed plates, and the vertical plate is fixedly connected to the middle part of one side of the fixed plate. The invention installs the radar detector at the end of the cable, pulls the driving mechanism to separate from the right vertical plate, and then pulls the driving mechanism to rotate forward through the rotating shaft to drive the winch to rotate forward, the cable is loosened, and the radar detector moves downward. Go to the hole for inspection. After the inspection in the hole is completed, pull the driving mechanism to reverse and reset, which also drives the winch to reverse and roll up the cable. Then pull the guide mechanism to move left and right to drive the cable to move left and right, and the cable is evenly wound up. In this way, uneven winding of the cable can be avoided.

Owner:铜陵有色金属集团股份有限公司

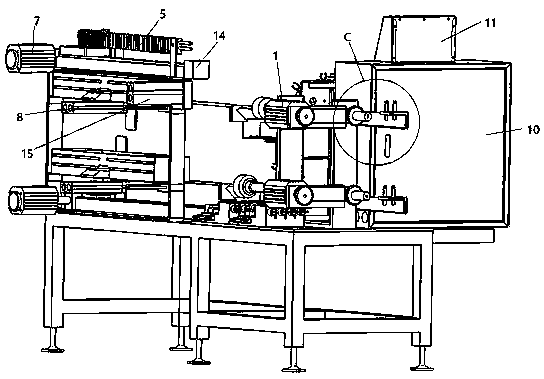

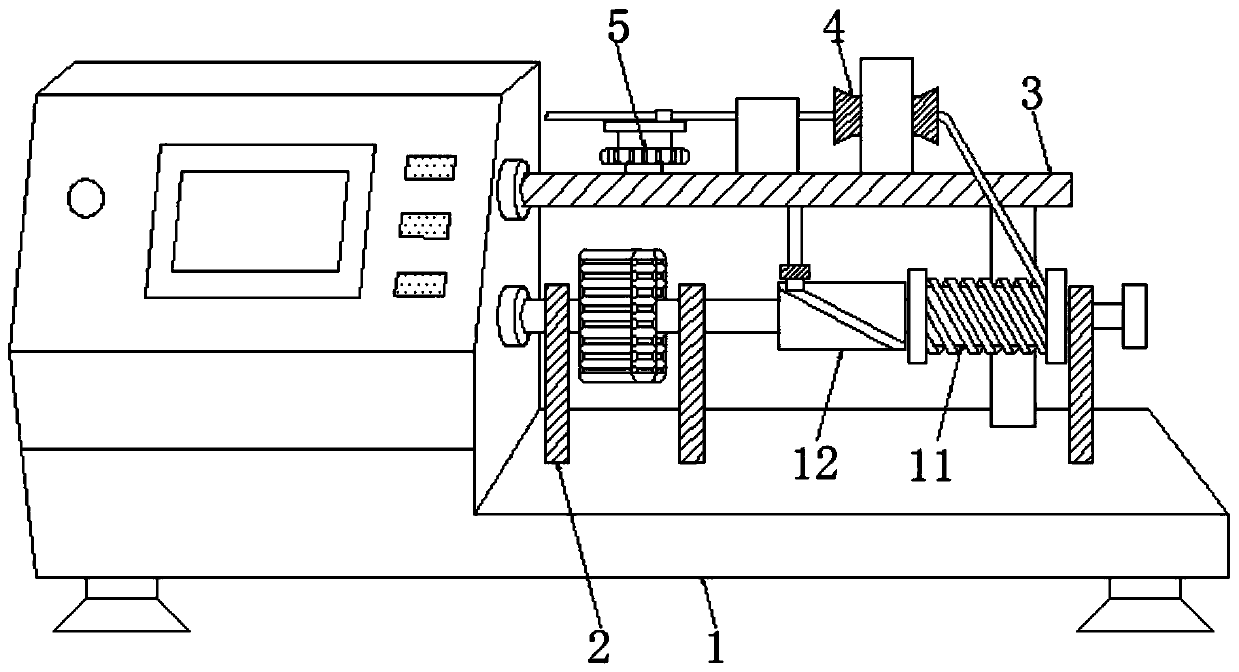

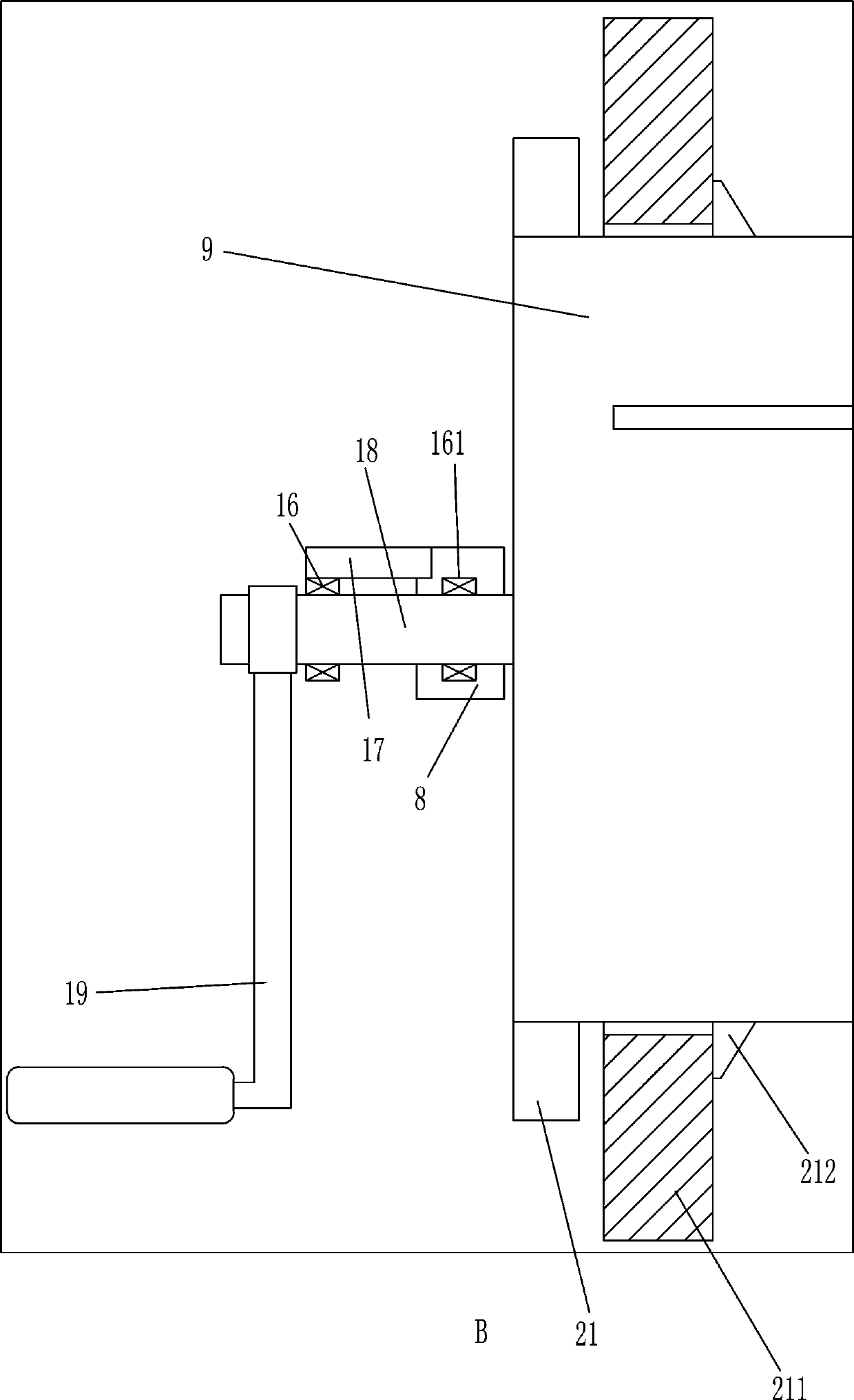

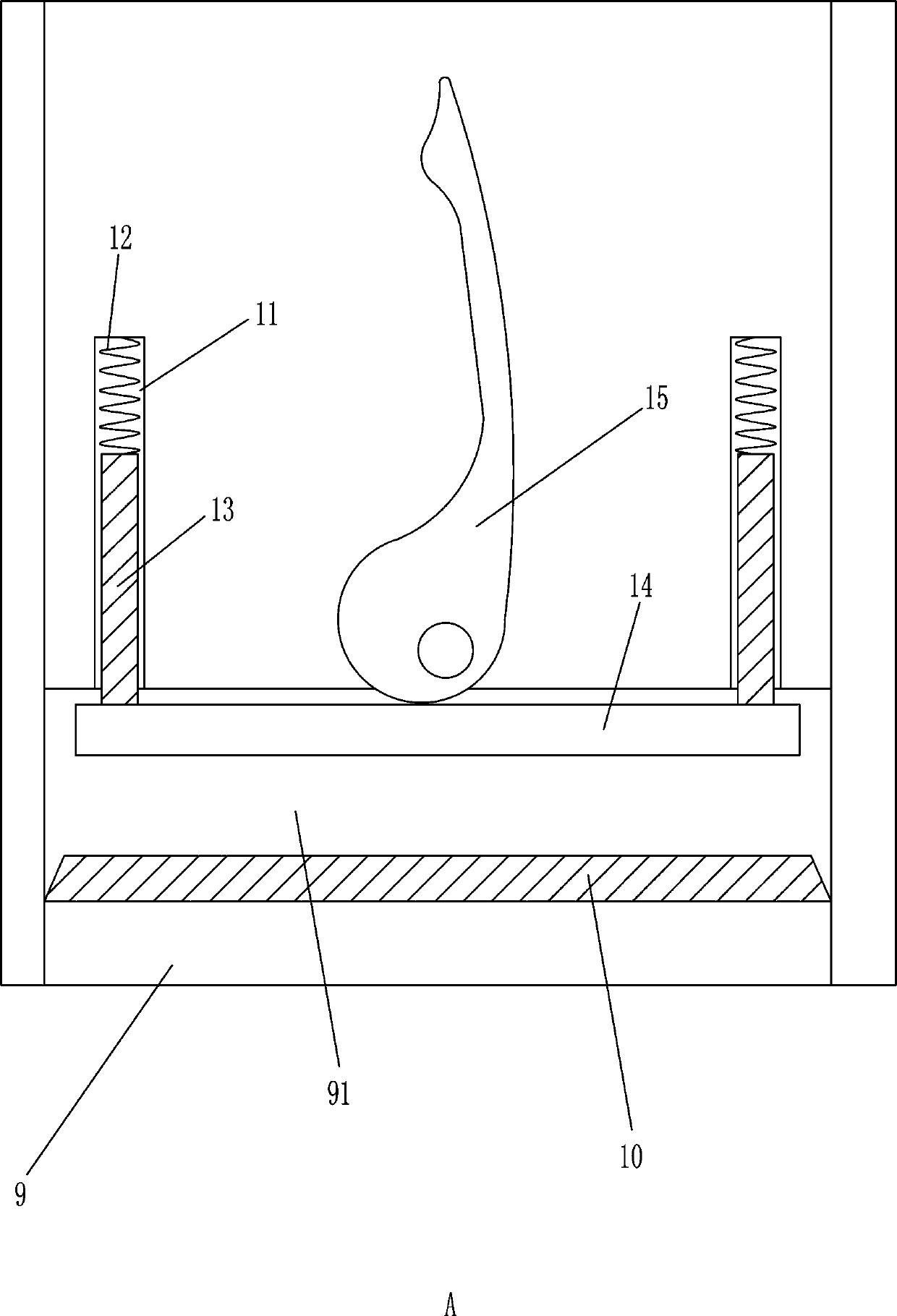

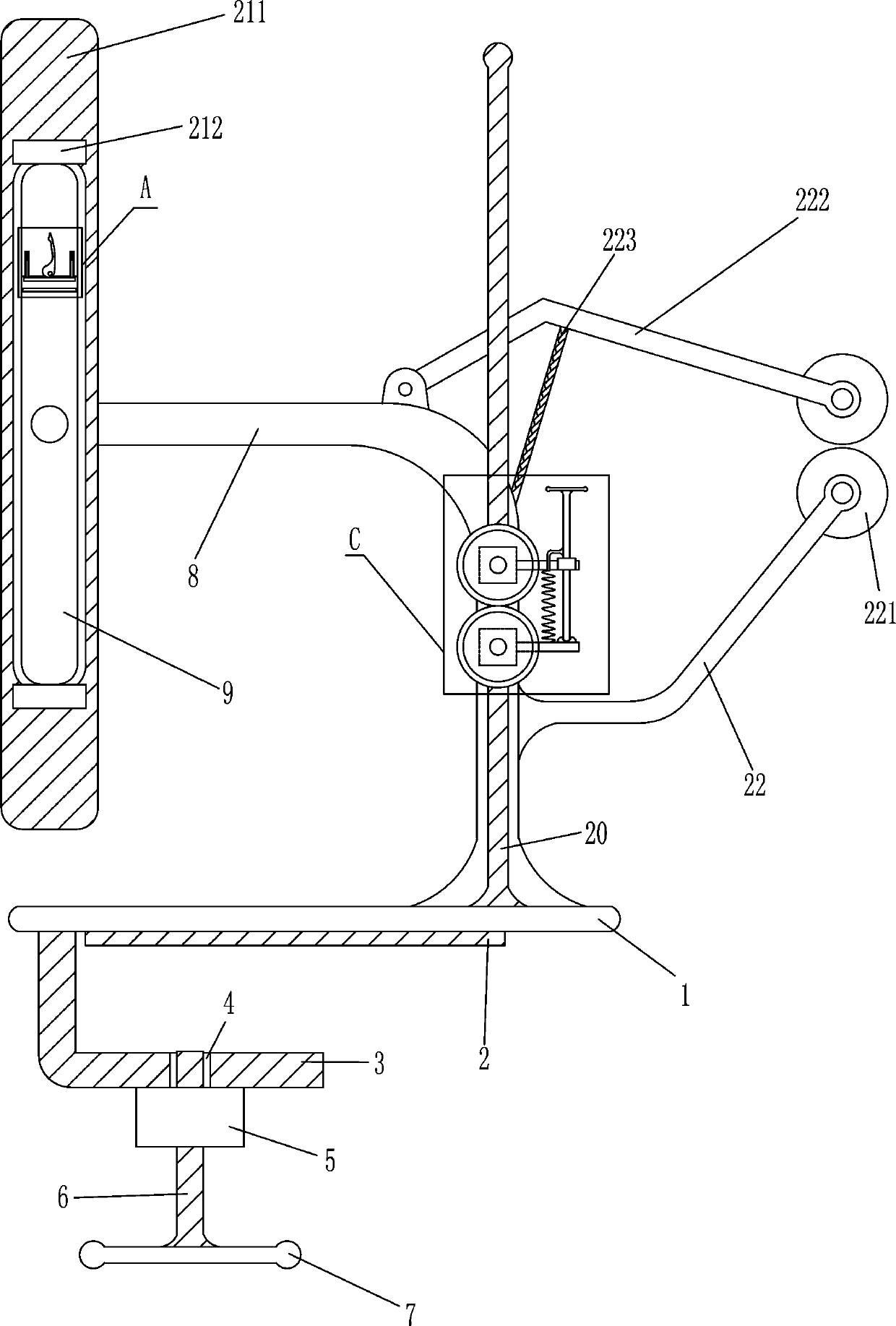

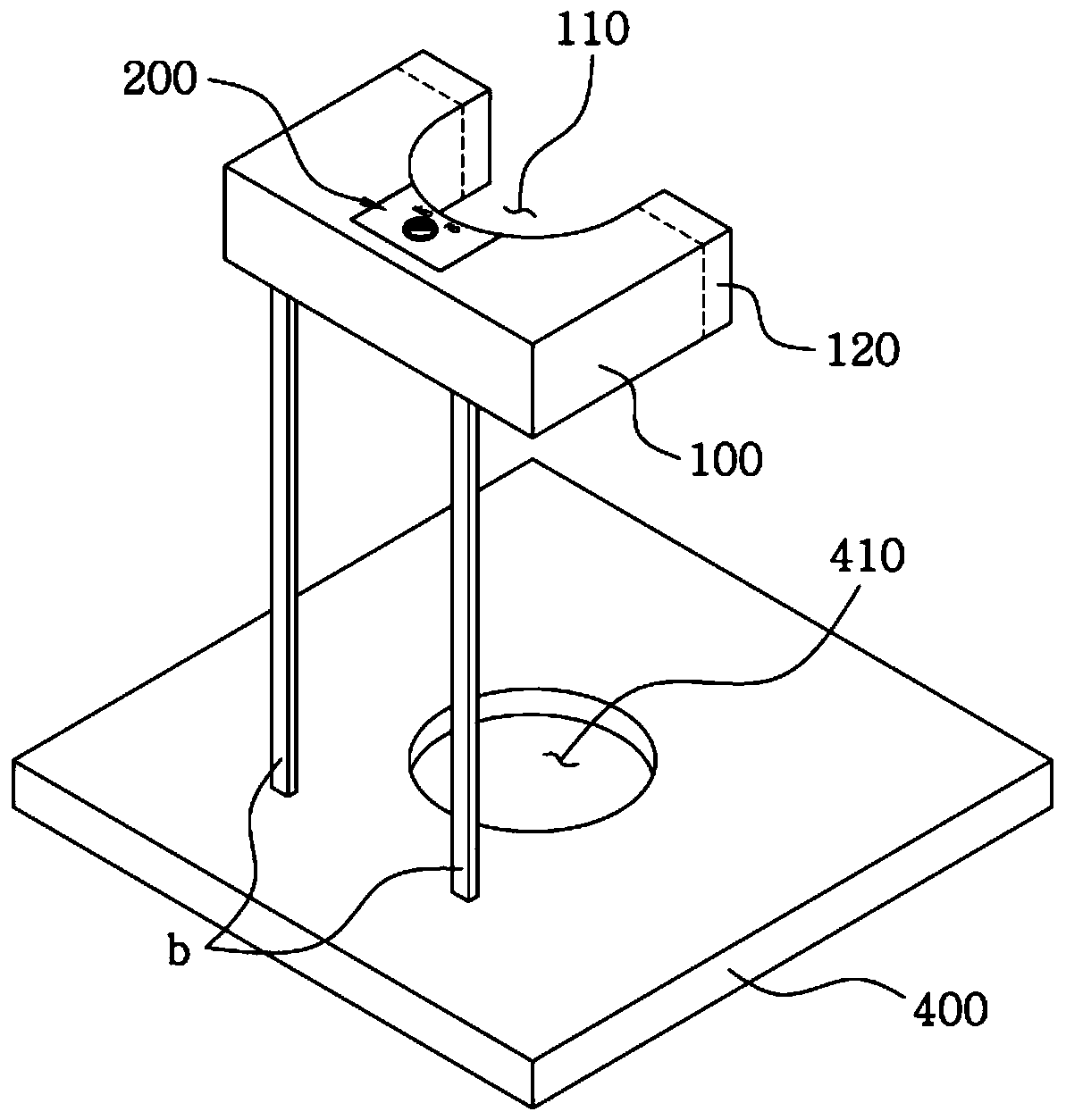

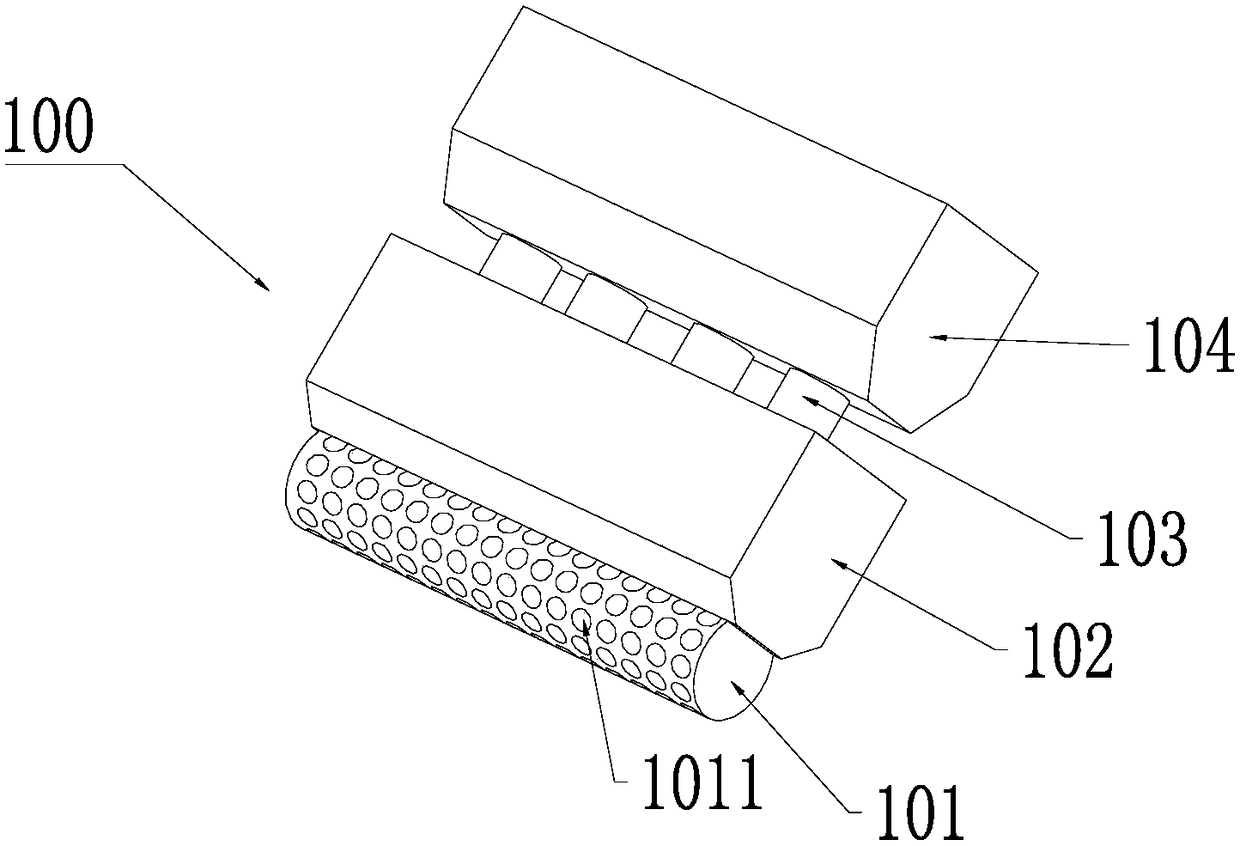

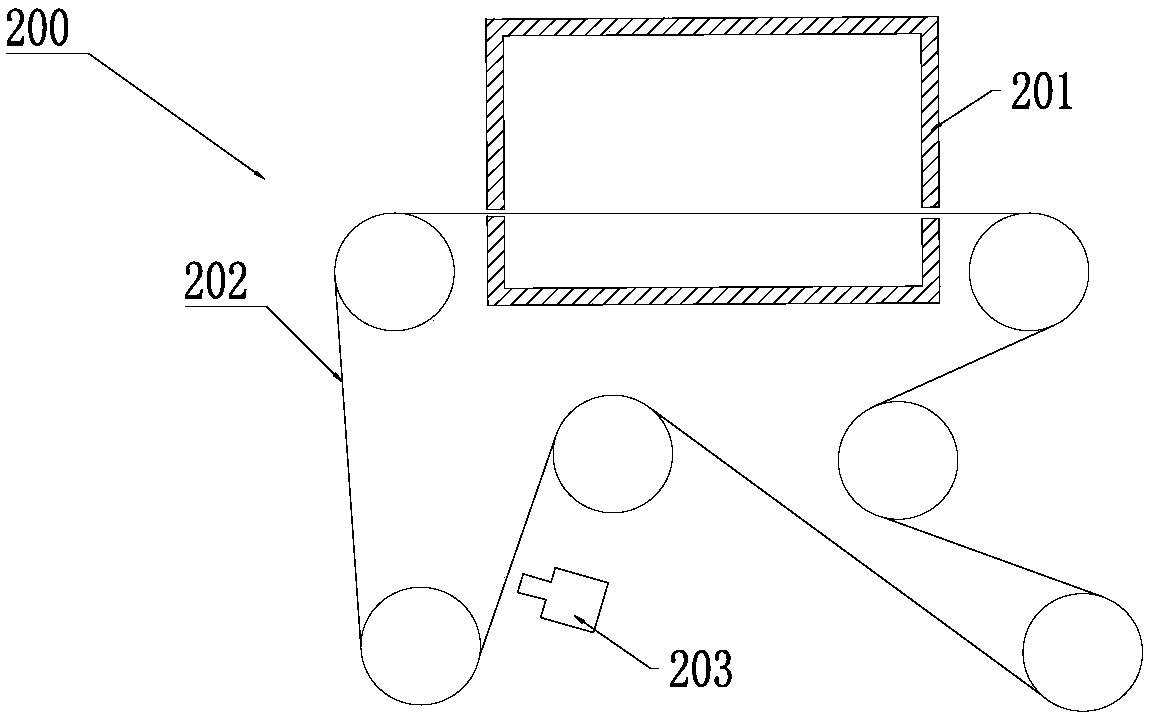

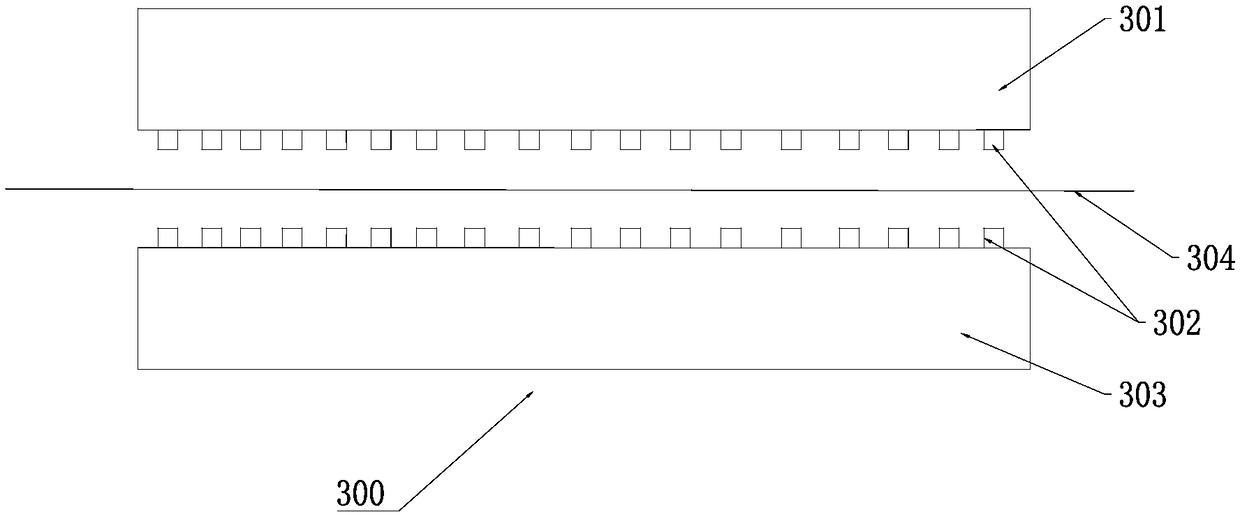

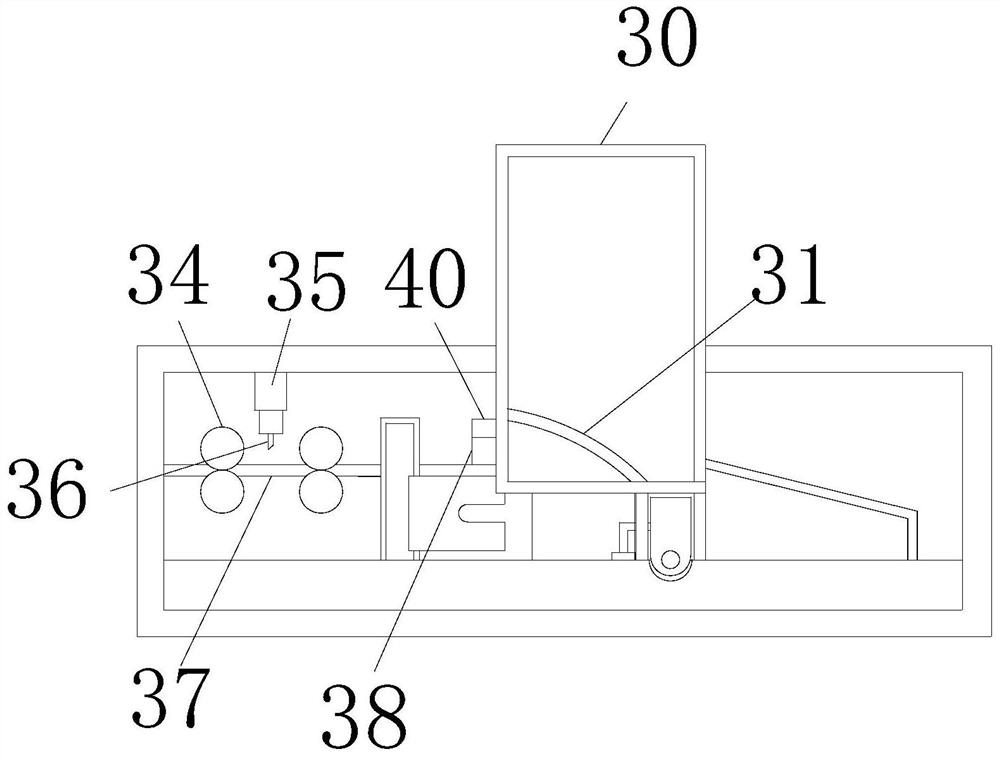

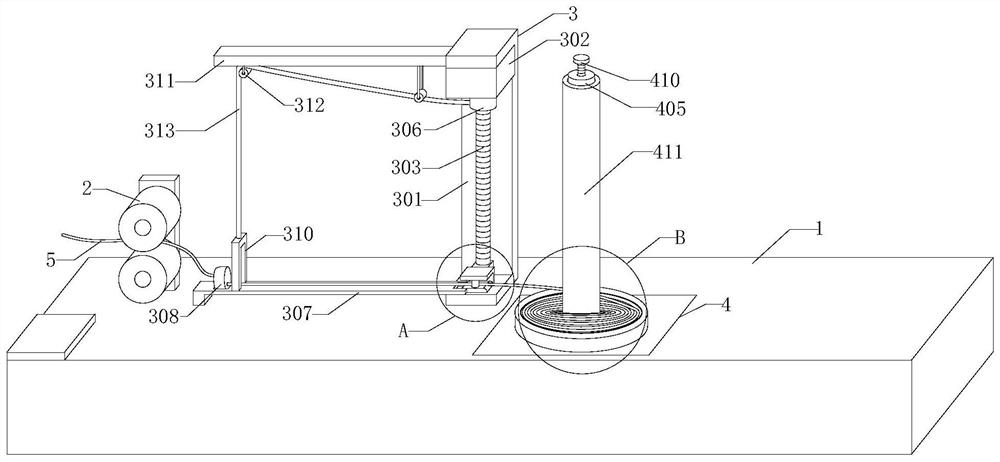

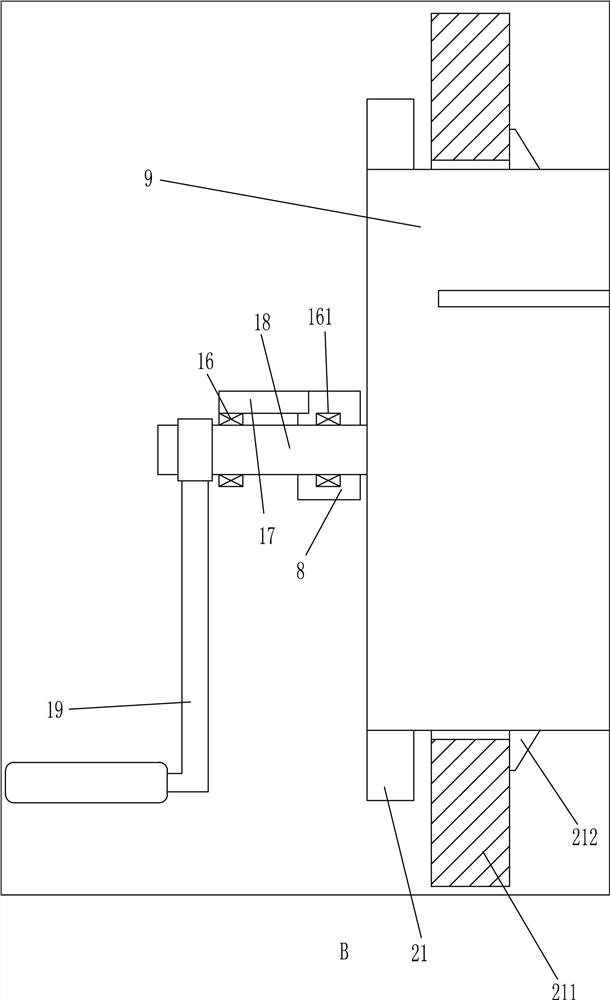

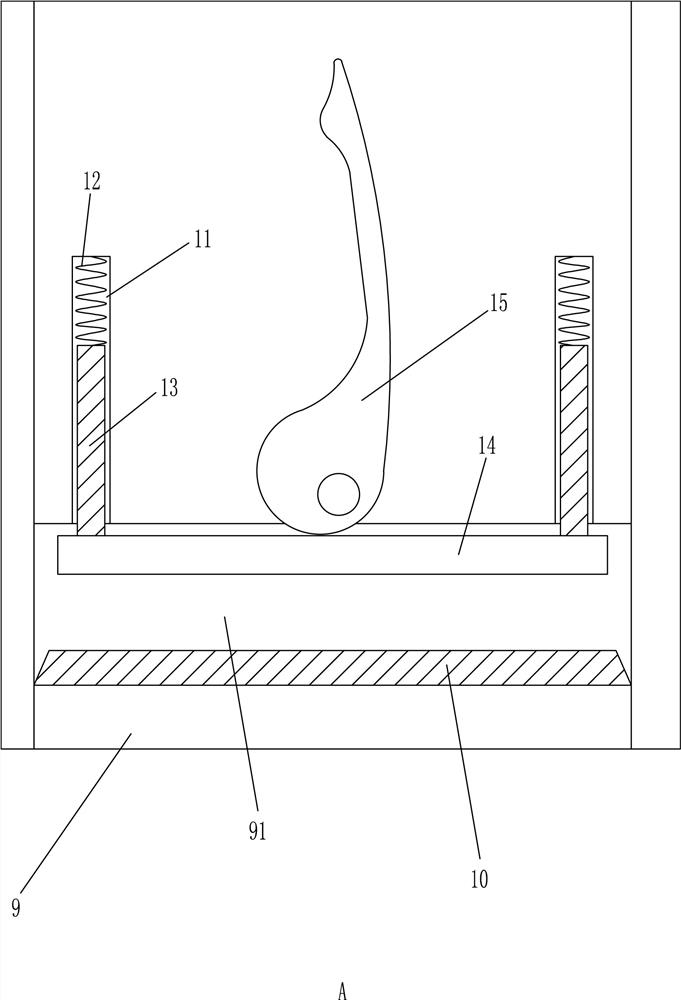

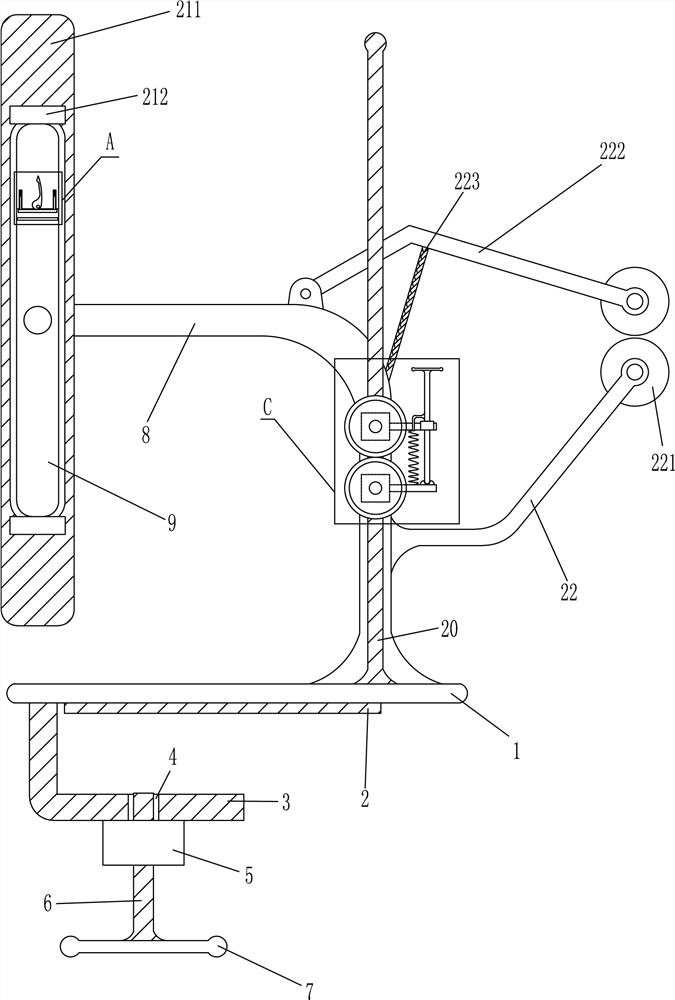

Silk winding and sliver production equipment

InactiveCN105696121BHigh synchronization accuracyGuaranteed synchronous deliveryServomotor componentsFilament handlingEngineeringMechanical engineering

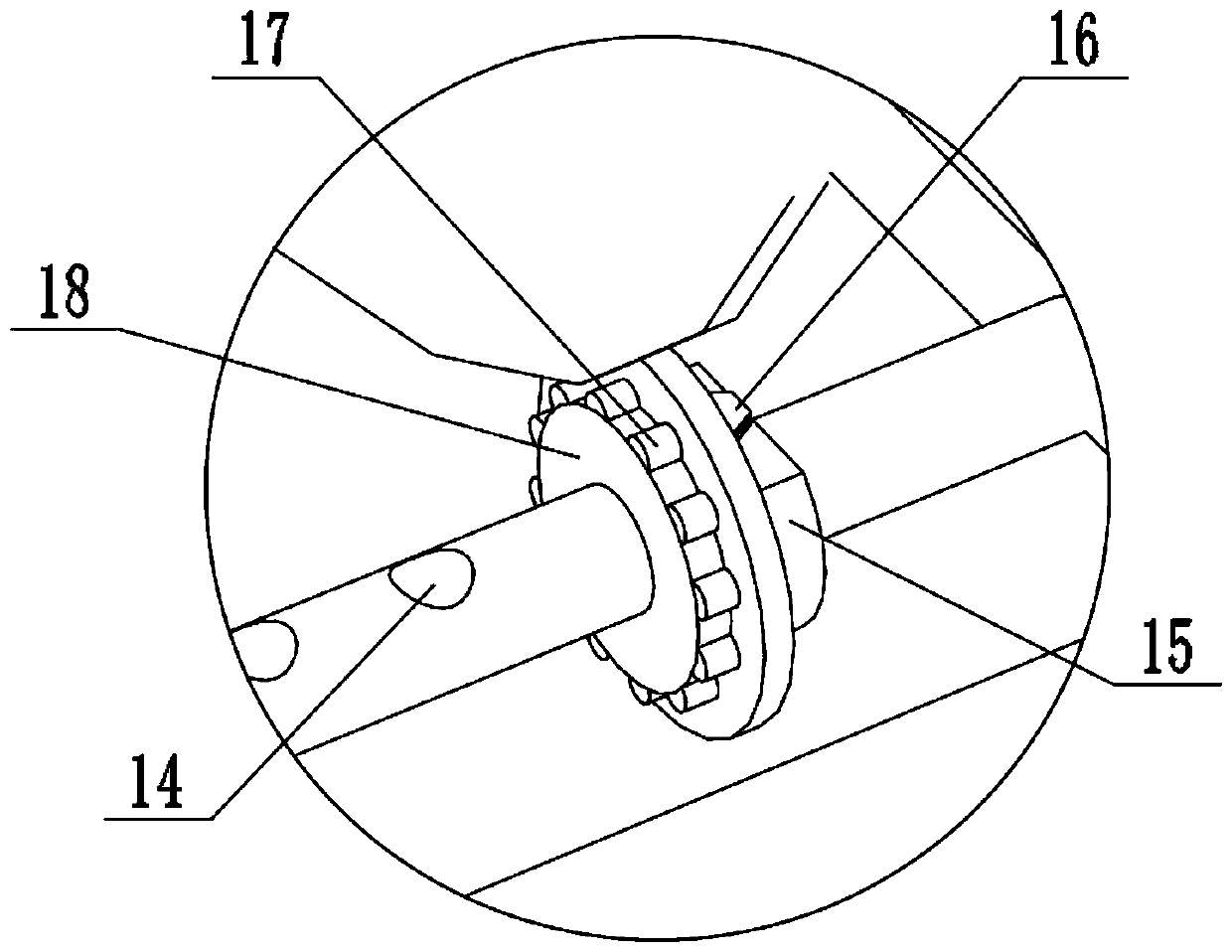

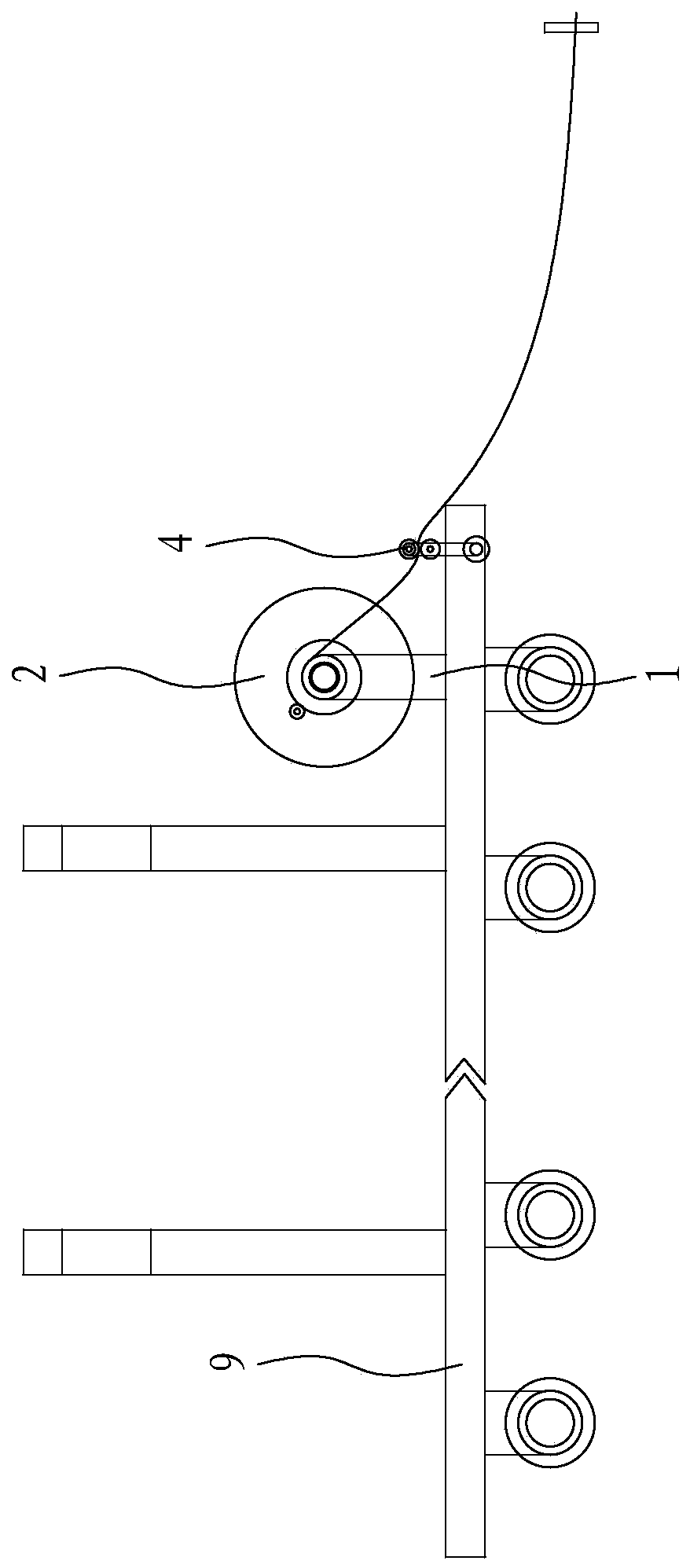

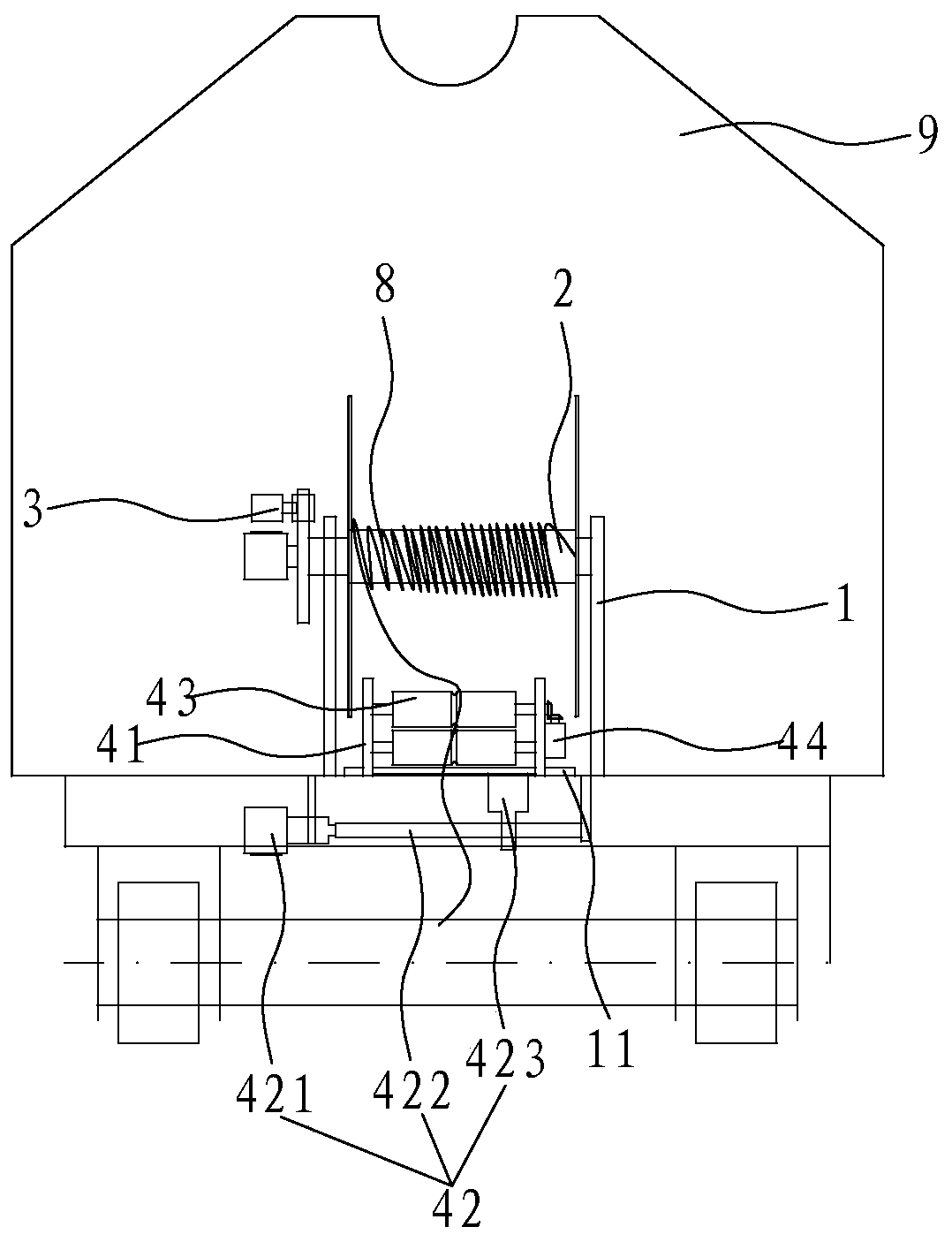

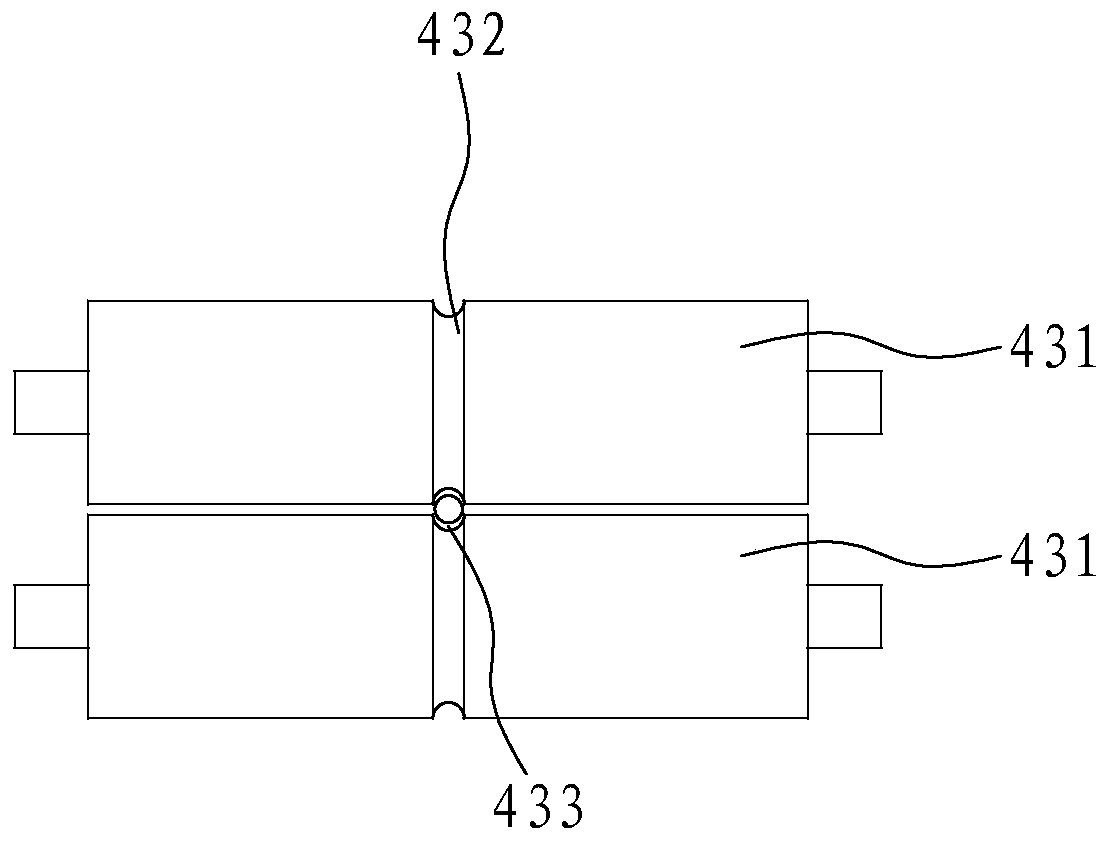

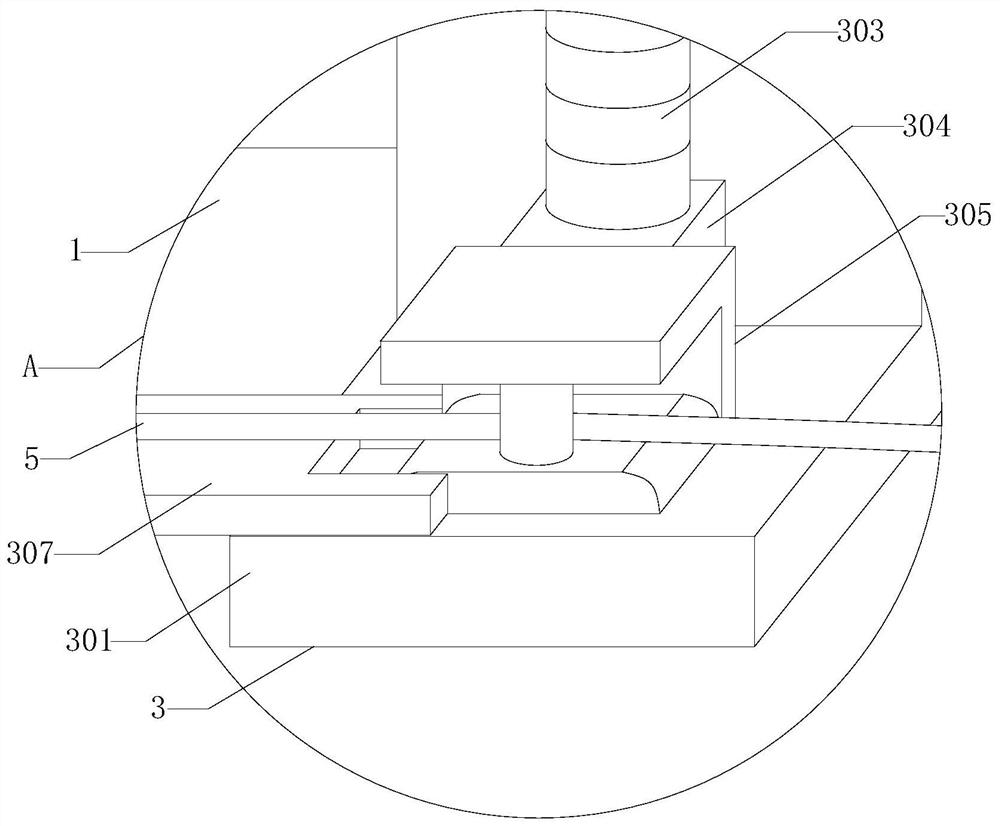

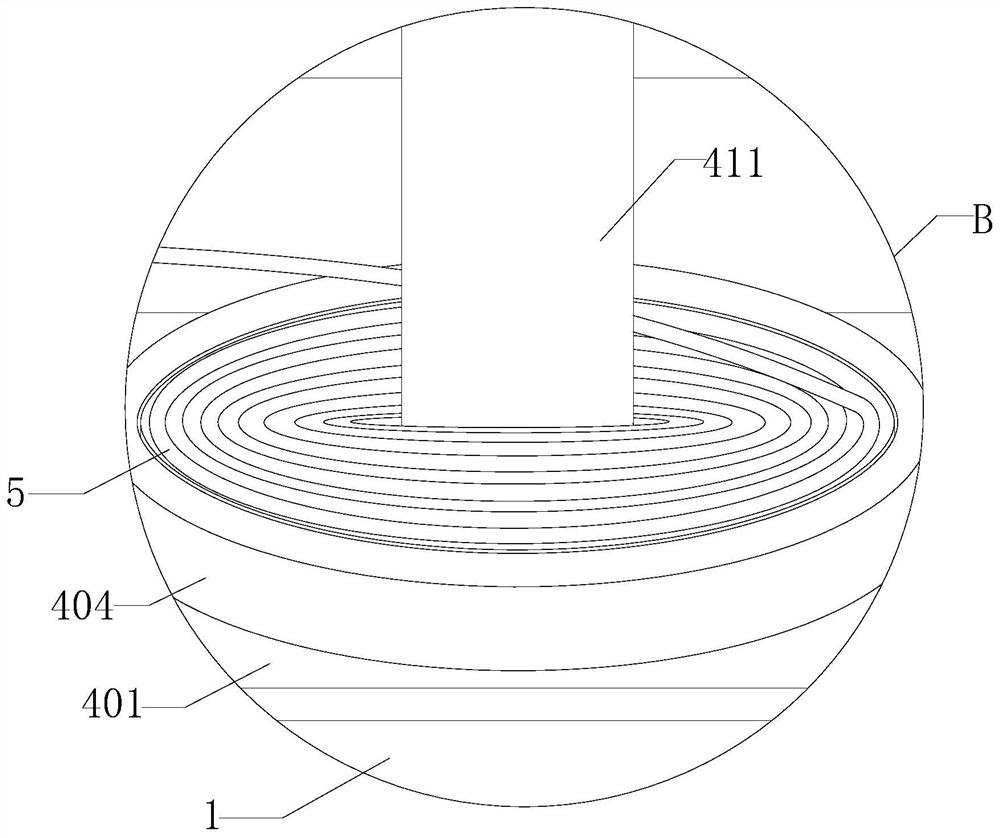

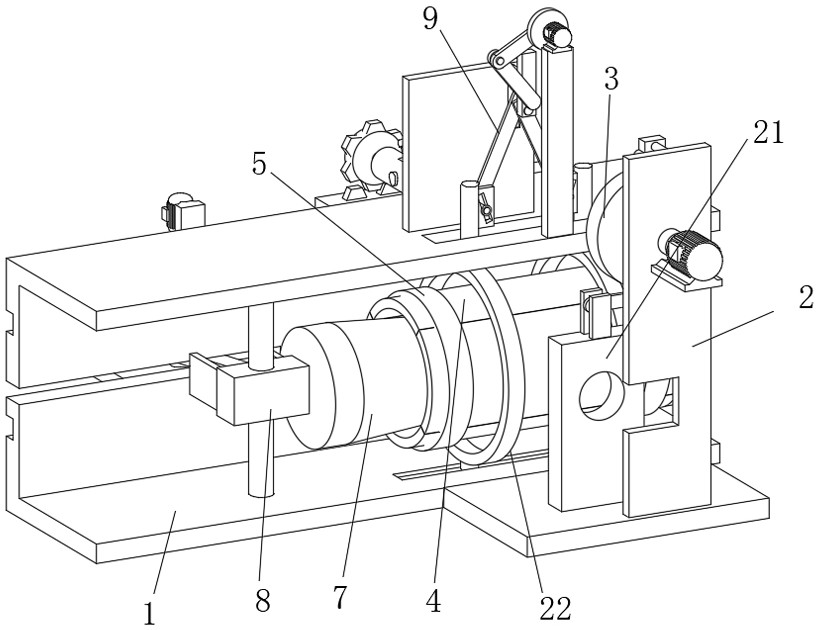

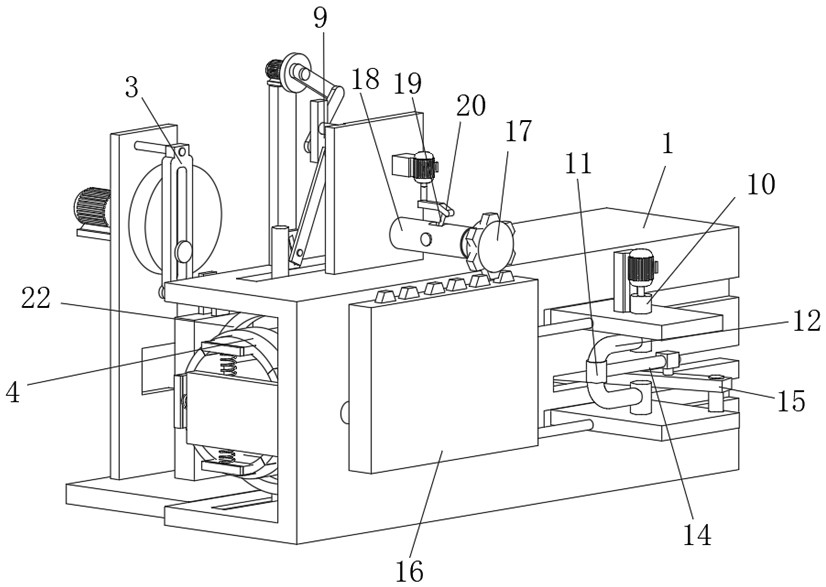

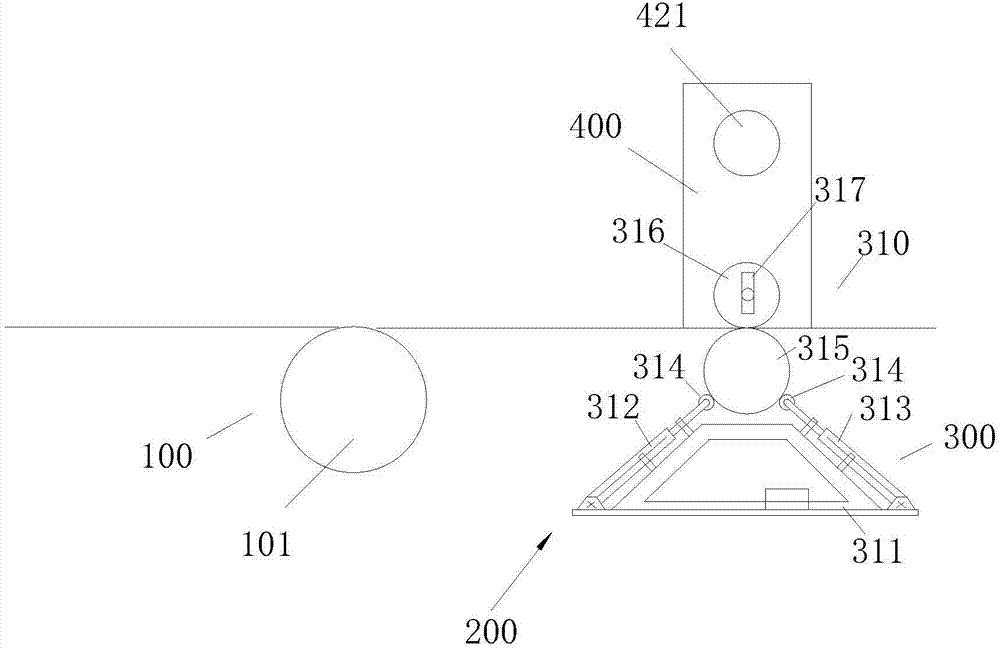

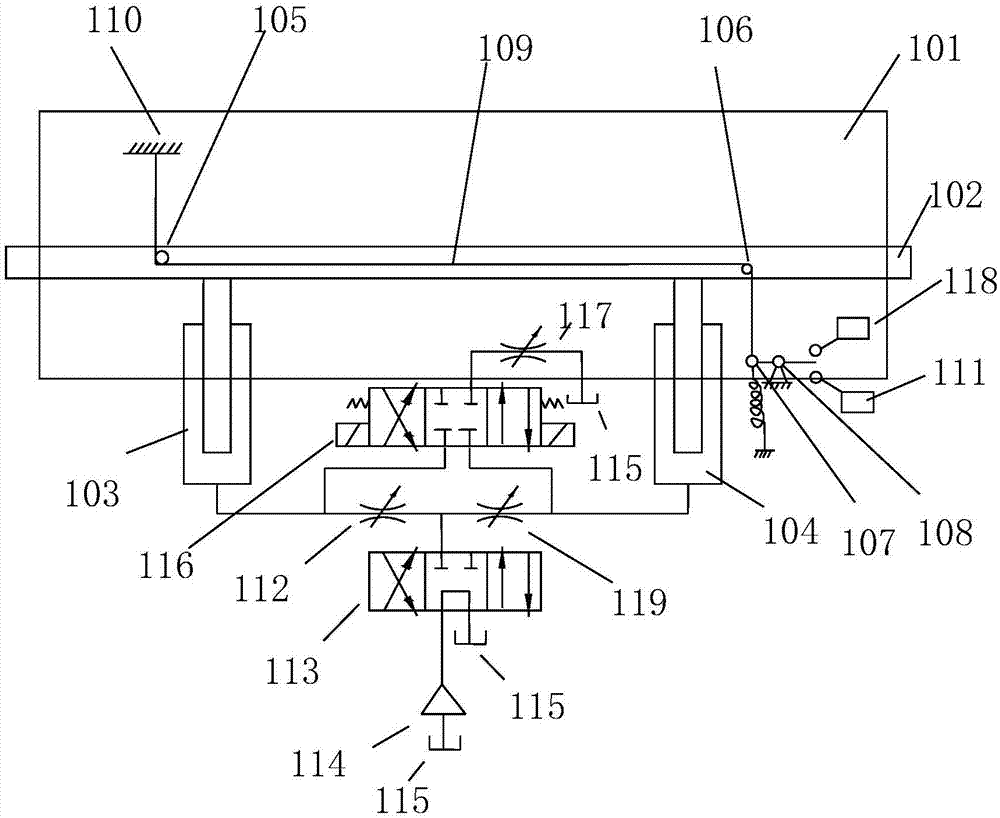

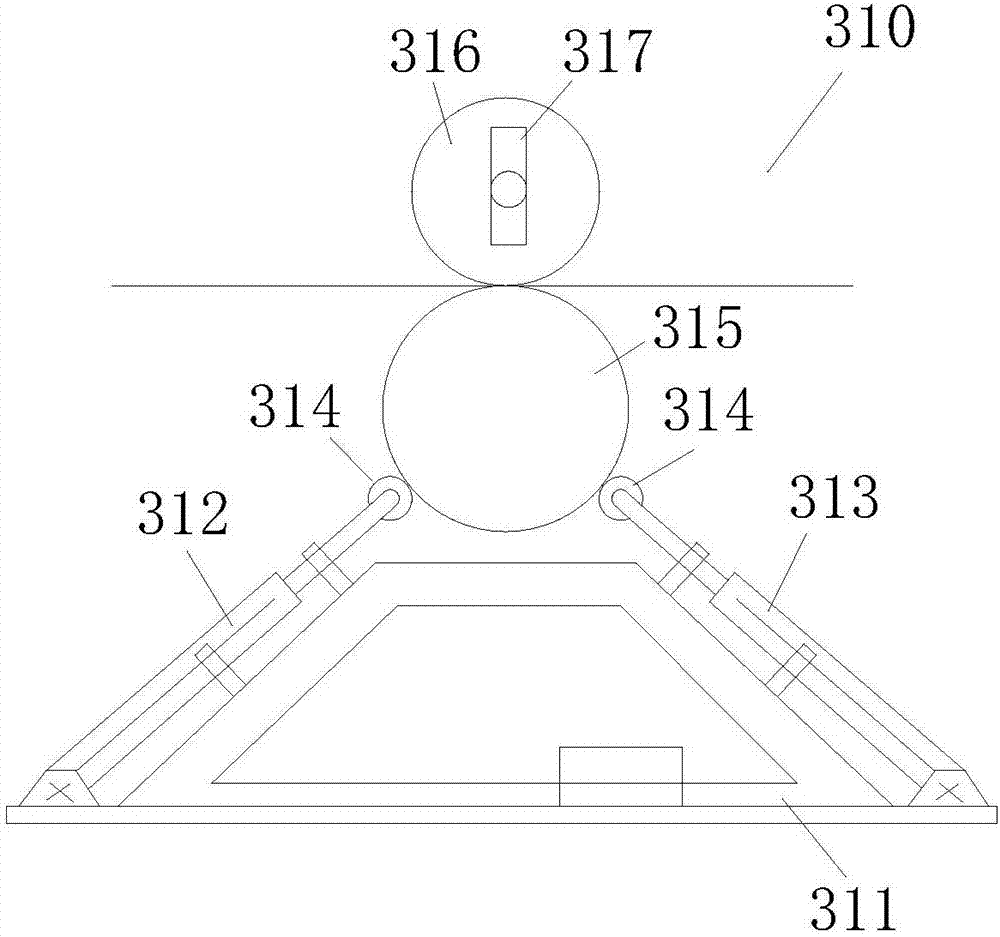

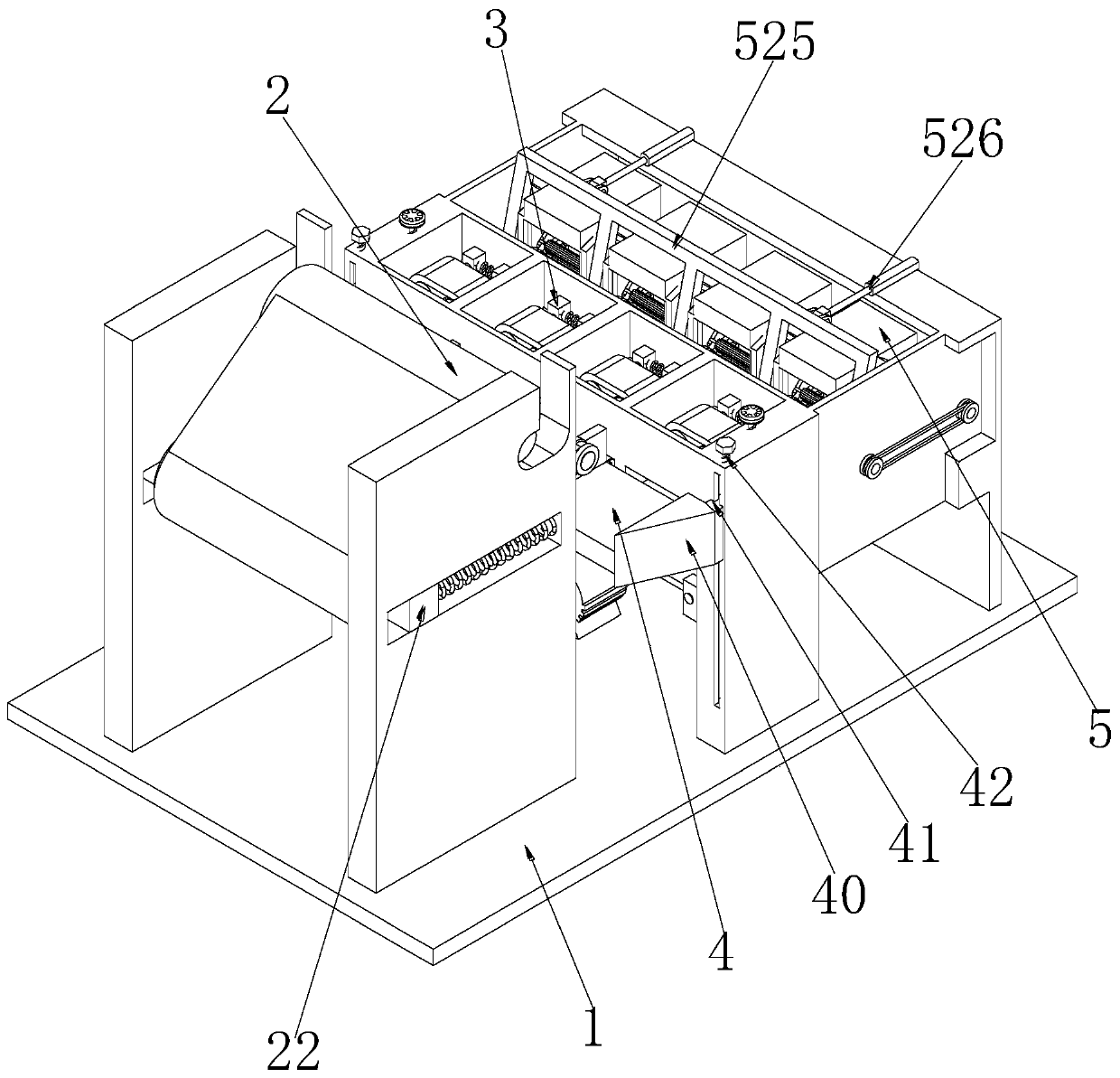

The invention discloses a production device for coiling silks into strips. The production device comprises a coiling mechanism (100), and a hot-pressing mechanism (200) is arranged behind the coiling mechanism (100); the hot-pressing mechanism (200) comprises a hot-pressing unit (300) and a silk coiling unit (400); the hot-pressing unit (300) comprises a hot-pressing mechanical part (310) and a hot-pressing hydraulic part (320), and the silk coiling unit (400) comprises a silk coiling hydraulic part (410) and a silk coiling mechanical part (420). By means of the production device, synchronous silk conveying can be guaranteed in real time, and uneven coiling caused by inclination of a coiling barrel is avoided; besides, a pressing roller and a hot pressing roller can be in close fit, and thus the hot pressing effect of silks is improved; a closed circuit adopting volumetric speed regulation is utilized, valve compensating oil is sucked in a vacuum mode, the oil path is simple, the structure is compact, the speed regulation range is wide, and operation energy is low.

Owner:湖州南浔中兴丝织有限公司

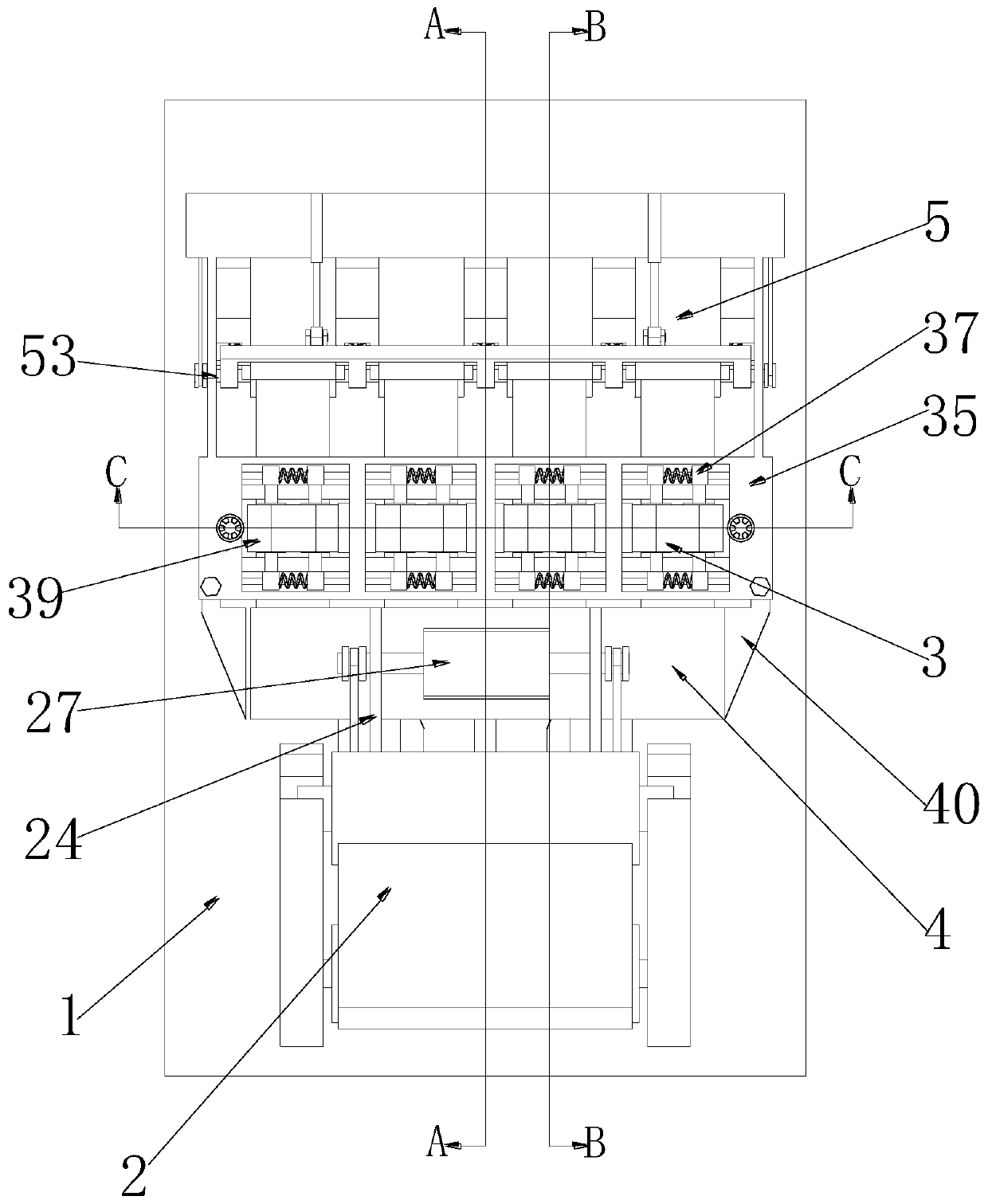

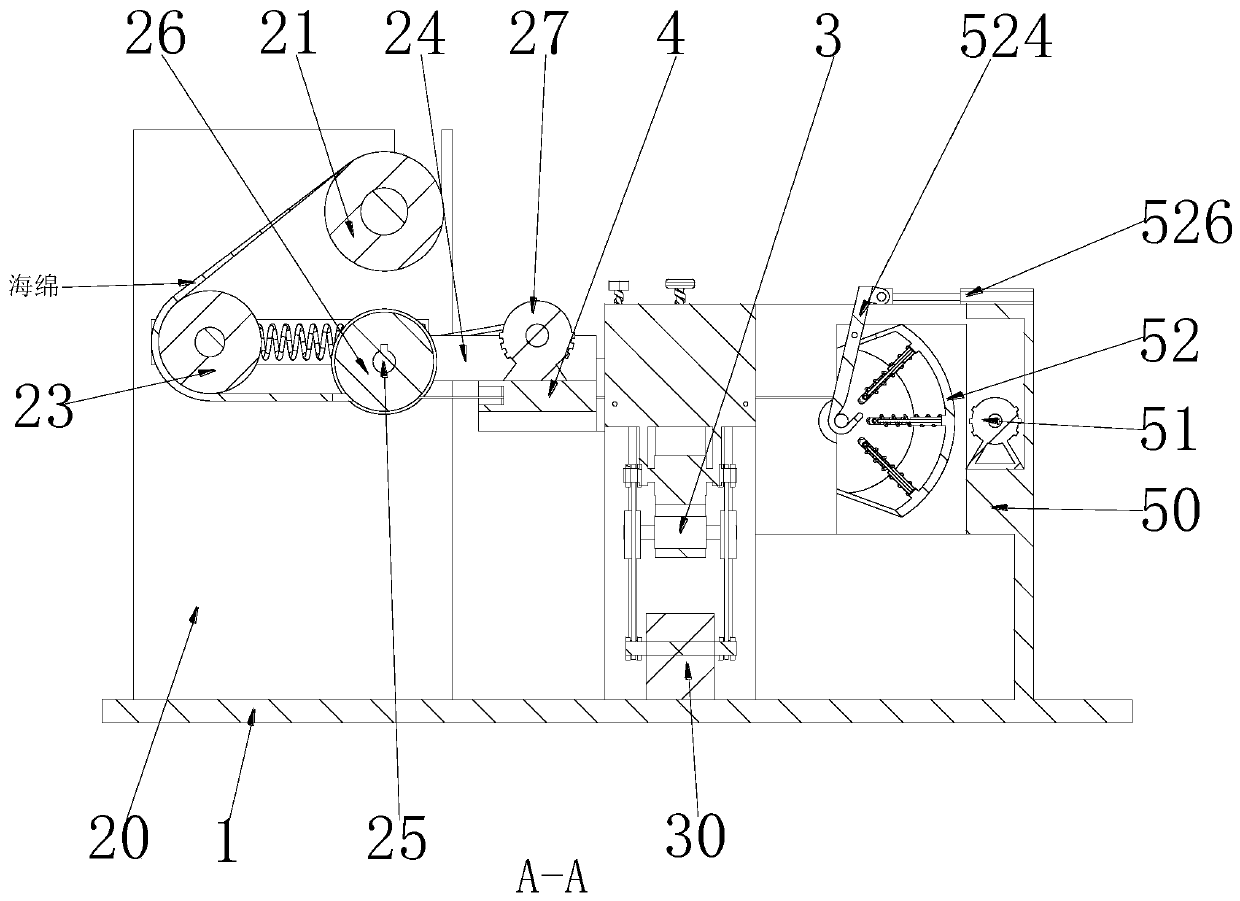

Industrial sponge preparation automatic winding and cutting processing machinery

ActiveCN111532857AAvoid uneven windingAvoid wrinklesArticle deliveryWebs handlingStructural engineeringMechanical engineering

The invention relates to industrial sponge preparation automatic winding and cutting processing machinery, comprising a base, a cutting unit, a sorting unit, a direction adjustment unit and a windingunit. The cutting unit is arranged on the left side of the upper surface of the base, the direction adjustment unit is arranged between the cutting unit and the sorting unit, and the winding unit is arranged on the right side of the sorting unit. The machinery solves the following problems of automatic winding and cutting of industrial sponge at present: firstly, after the whole piece of sponge iscut, the sponge is directly winded into a bundle without adjusting the direction, resulting in uneven winding of the sponge and wrinkles of the sponge, so that after the sponge is stored for a long time, the wrinkles are difficult to eliminate, and the use value is directly affected; secondly, the cut sponge has some irregularities or burrs on the edge, leading to untidiness of the sponge when winding, and the sponge cannot be more stable with a preset fixture or a carrier when in use.

Owner:保定惠康海绵制造有限公司

A high-efficiency automatic film blowing device to prevent electrostatic interference

ActiveCN111497204BAvoid dischargeAvoid pollutionDispersed particle filtrationMetal working apparatusActivated carbonDust control

The invention discloses a high-efficiency automatic film blowing device for preventing electrostatic interference. One end of the axial flow fan is fixedly connected with a dust removal box, the top of the dust removal box is fixed with a dust filter plate, and the middle part of the dust removal box is fixed with an activated carbon adsorption plate. , one end of the bottom of the dust removal box is fixedly connected with the first connecting pipe, one end of the first connecting pipe is fixedly installed with the first adsorption box, the top of the first adsorption box is fixedly connected with the second connecting pipe, the second connecting pipe One end is fixedly installed with the second adsorption box. The structure of the present invention is scientific and reasonable, and it is safe and convenient to use. Through the combined use of the dust filter plate and the activated carbon adsorption plate, it is convenient to filter the waste gas produced by melting plastic and remove the dust and peculiar smell contained in the waste gas. substances, to avoid direct discharge into the air and cause pollution to the atmosphere, through the combined use of the first adsorption box and the second adsorption box, the harmful gases dissolved in water and lime water in the waste gas are absorbed.

Owner:CHAOHU JINBANG PLASTIC PACKAGING

Following winding device for medical gauze production

The invention relates to the technical field of gauze production, and discloses a following winding device for medical gauze production. The device comprises a base and a rotating disc, wherein a support plate is vertically fixed above the rear end of the right side of the base, the rotating disc is rotationally arranged at the front side of the upper end of the support plate through a second rotating shaft, and a winding mechanism and a guide mechanism are arranged on the base; the winding mechanism comprises electric push rods, telescopic rods, chutes, an ultraviolet lamp, sliding blocks, rotating rods, springs, a rotating roller, an inserting rod, a vertical plate and a servo motor; and the inserting rod is fixed to the middle position of the front side of the rotating disc. According to the device, the rotating roller for tensioning is rotationally arranged between the telescopic rods, the rotating rods at the two ends of the rotating roller are arranged in the chutes through the sliding blocks, the springs are connected between the sliding blocks and the upper ends and the lower ends of the chutes, and when gauze bypasses the rotating roller and is wound by a winding drum on the inserting rod, the tension of the gauze can be automatically adjusted under the pulling action of the springs, the tension is kept constant, and the situation of non-uniform winding is avoided.

Owner:佛山市宾宏设备有限公司

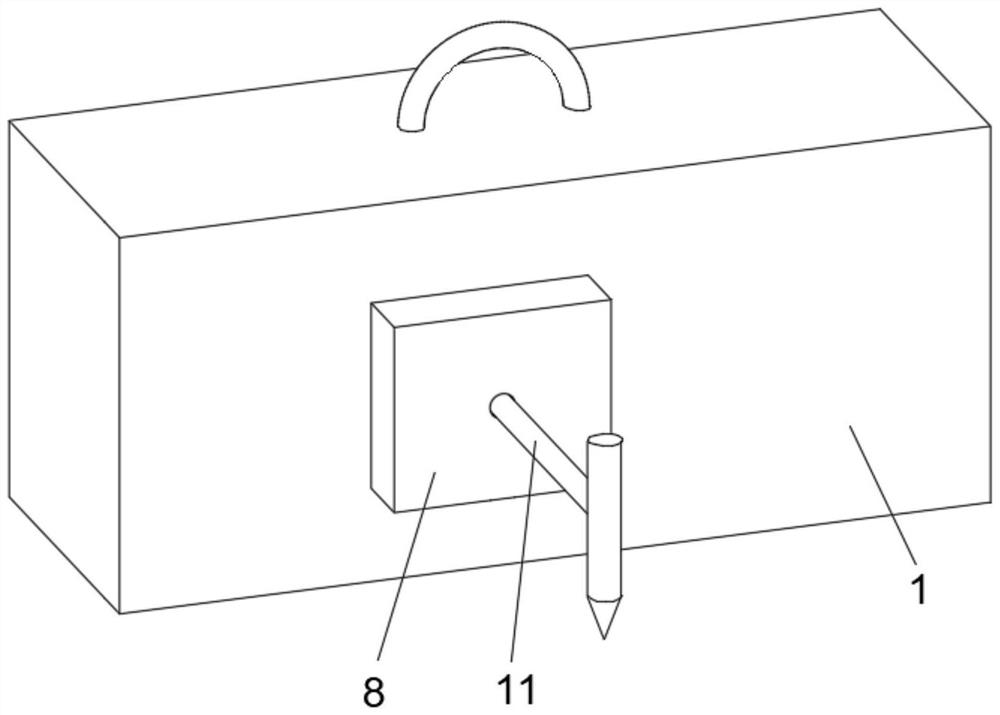

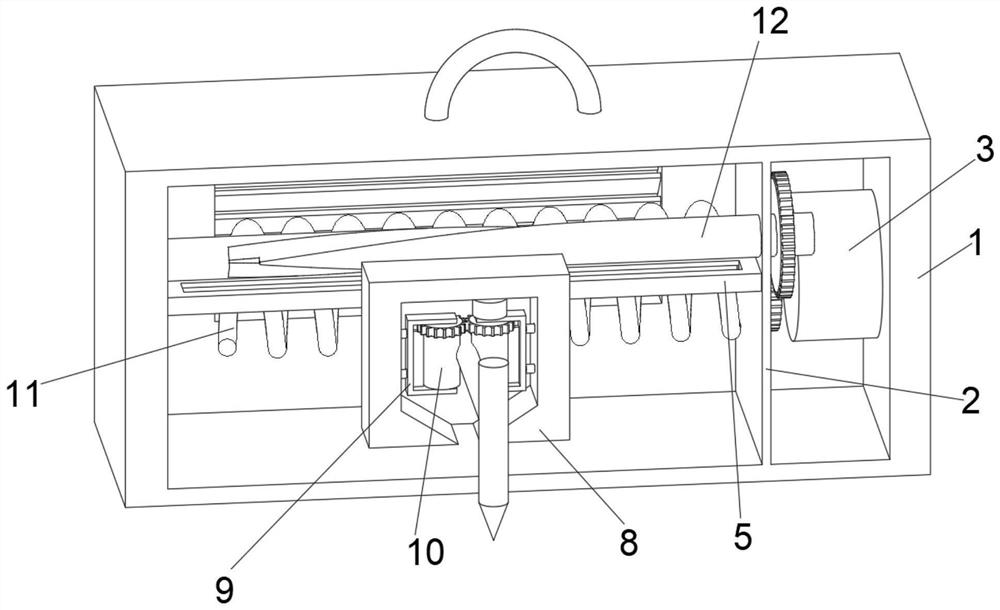

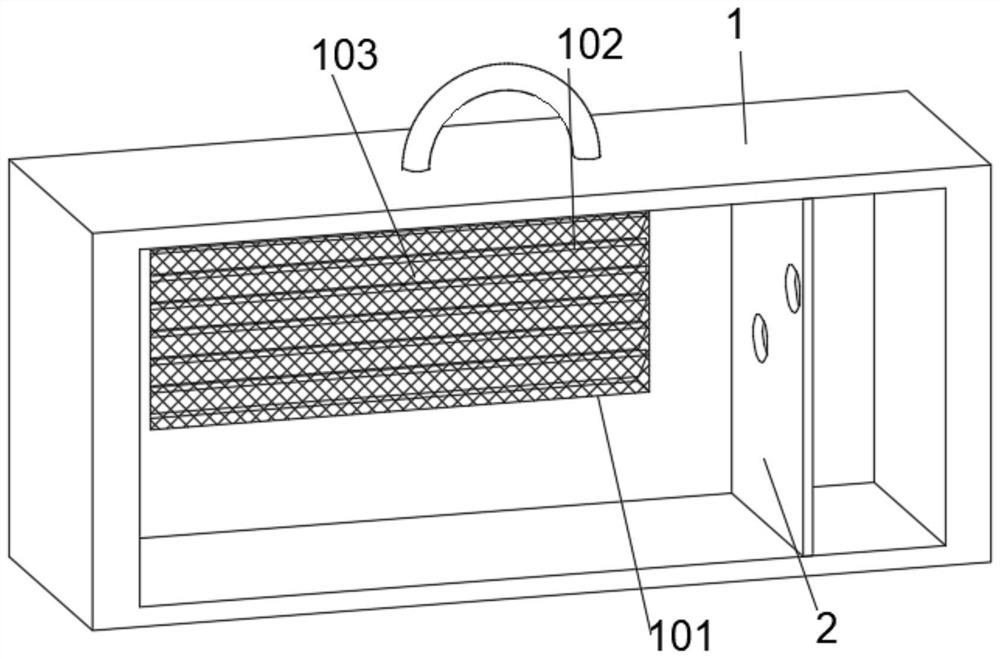

Rope bundle fixing device for surveying and mapping engineering

PendingCN114406924AExtended service lifeAvoid uneven windingSurveying instrumentsWork holdersElectric machineryLeft wall

The invention discloses a rope bundle fixing device for surveying and mapping engineering, and belongs to the technical field of auxiliary instruments for surveying and mapping engineering. A rope bundle fixing device for surveying and mapping engineering comprises a box body, a fixing plate is welded to the inner wall of the right side of the box body, a motor A is fixedly arranged on the inner wall of the right side of the box body, a winding rod is arranged on the left wall of the fixing plate, a measuring rope is wound around the outer wall of the winding rod, an adjusting rod is arranged above a limiting plate, a cleaning box is welded to the front wall of the box body, and two U-shaped frames are arranged in the cleaning box in a bilateral symmetry mode. And extrusion wheels are arranged in the U-shaped frame, and by arranging the extrusion wheels, when winding is carried out, a motor B is utilized to drive one extrusion wheel to rotate, so that the rotating gear drives the other meshed gear, then a spring is utilized to enable the U-shaped frame connected with a T-shaped rod to drive the two extrusion wheels to move towards the middle, and therefore the measuring rope containing water is extruded; therefore, water in the measuring rope is squeezed out, it is guaranteed that the measuring rope can be rapidly dried, and the service life of the measuring rope is greatly prolonged.

Owner:吴海岭

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com