Machining method of fully-wound gas storage bottle

A processing method and technology of gas storage cylinders, applied in the field of high-pressure gas storage cylinders, can solve problems such as uneven winding and distribution of fiber yarns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

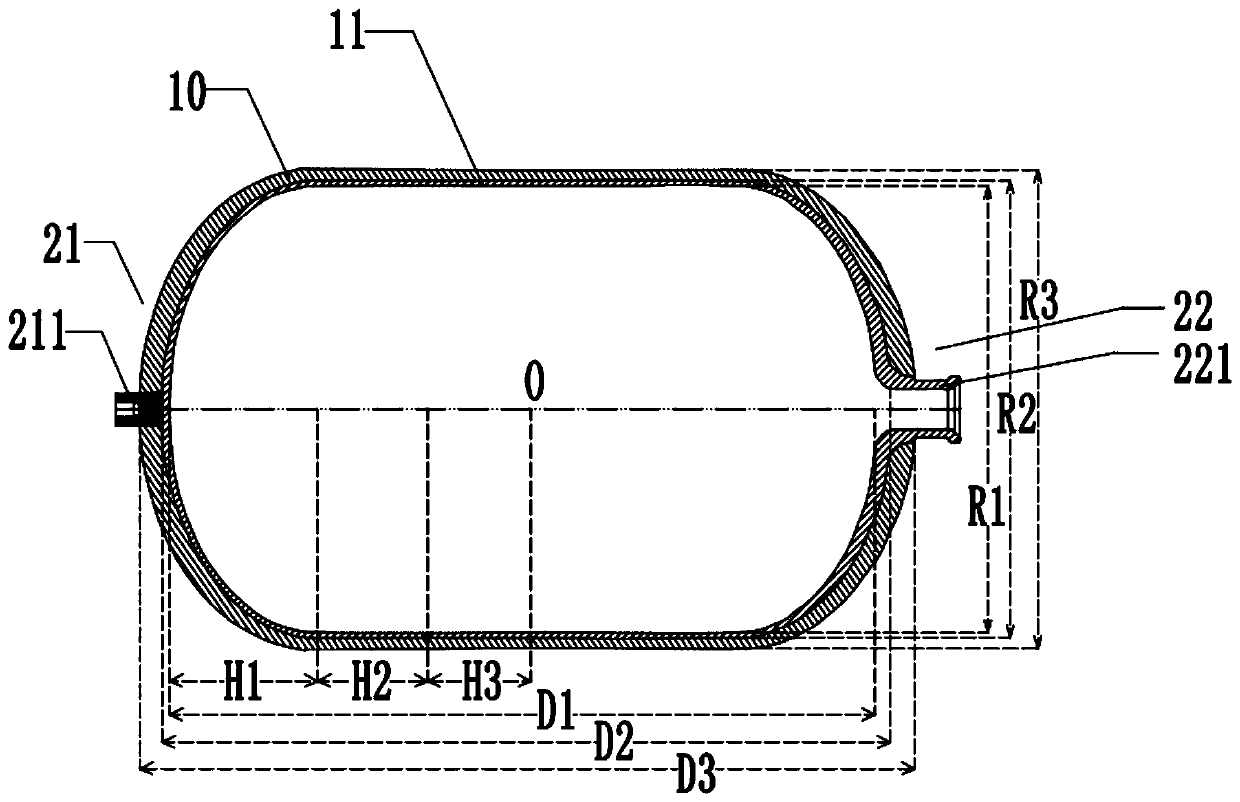

[0031] Embodiment one is basically as attached figure 1 As shown: a fully wound gas storage cylinder, including an inner tank 11 and a lightweight shell 10 that is close to and fully covers the inner tank 11 . The lightweight casing 10 includes a winding layer and a photocurable resin layer coated on the outer surface of the winding layer. Wherein, the photocurable resin layer is not necessary, and when there is no photocurable resin layer, the lightweight housing 10 is the wrapping layer. Wherein, the liner 11 includes a tail plug end seal 21 on the left and a bottle mouth end seal 22 on the right.

[0032] A tail plug end 211 protruding to the left and passing through the lightweight shell 10 is welded at the center of the tail plug end head 21 . The tail plug end 211 is coaxial with the inner tank 11, and the tail plug end 211 has a connection port facing the outside. Through the connection port, the tail plug end 211 can be connected with other fixed structures, which i...

Embodiment 2

[0064] In this embodiment, the weight-to-volume ratio of the fully wound gas cylinder is greater than 0.4 and less than or equal to 0.5. In this embodiment, the weight-to-volume ratio of the fully wound gas cylinder is 0.44. Compared with the prior art, the fully wound gas cylinder of this embodiment is lightweight and has a smaller weight-to-capacity ratio, which is more conducive to the battery life of the fuel cell and the use of the fuel cell for vehicles.

[0065] When drawing, the punch is used to draw the blank at 80-120°C to form a cup-shaped semi-finished product. Between each drawing process, it is necessary to carry out the primary cup-shaped body, secondary cup-shaped body and tertiary cup-shaped body. Annealing treatment. During strong-rotation thinning, the strong-rotation equipment thins the cup-shaped semi-finished product at a speed of 40-72 mm per minute.

[0066] This program is derived from the project of the Ministry of Communications of China, which is ...

Embodiment 3

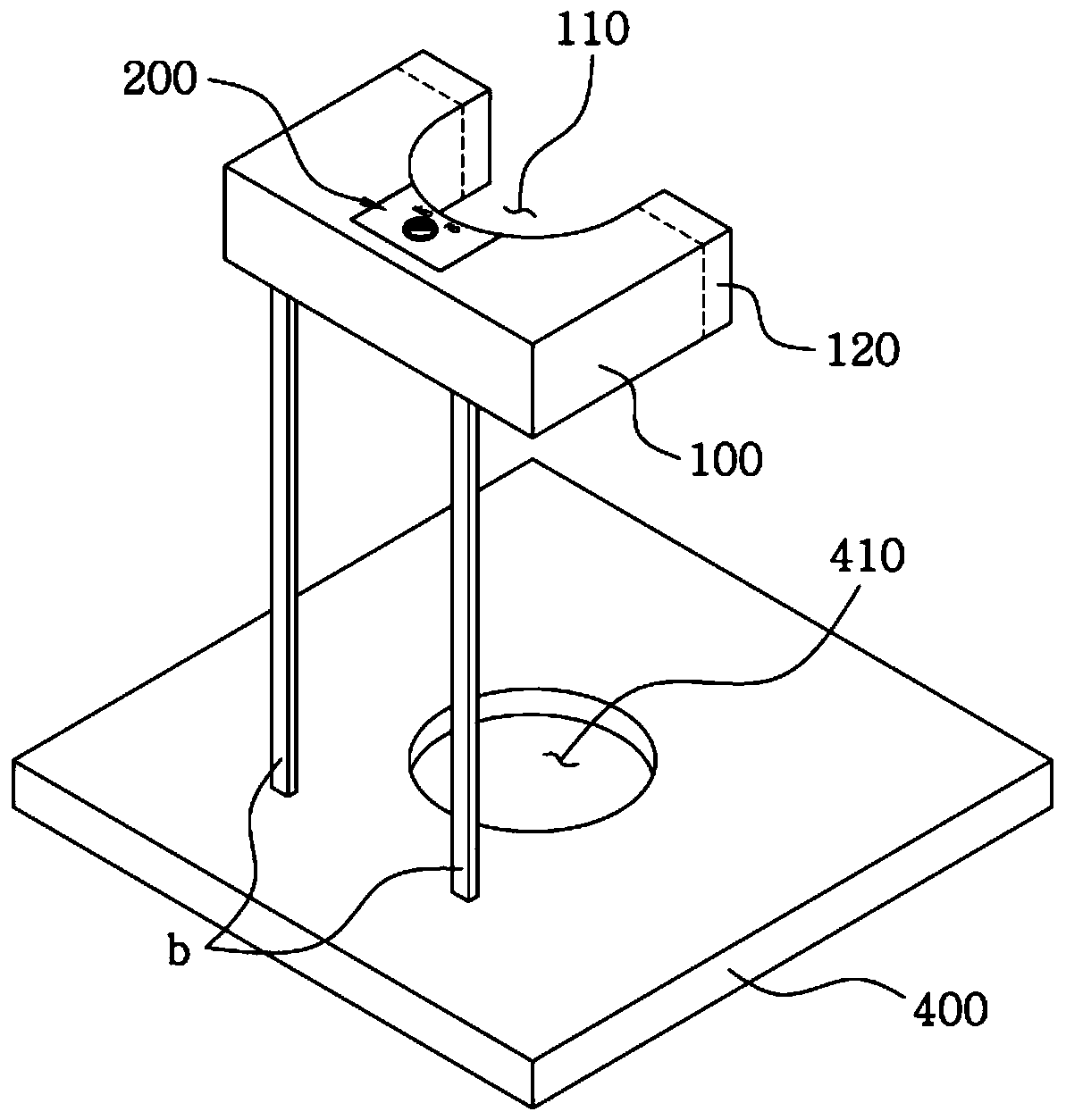

[0068] The difference between this embodiment and the first embodiment is that the fully wound gas storage cylinder is processed with a supporting base for supporting the fully wound gas storage cylinder during processing. As we all know, the transportation of high-pressure gas storage cylinders is a very critical link, which directly restricts the use of high-pressure gas storage cylinders. Therefore, when processing the fully wound gas storage cylinder, in order to better realize the movement and transportation, the matching processing forms a supporting seat that can be used together.

[0069] support such as figure 2 As shown, it includes a first card board 100 and a second card board 400 distributed up and down. The first pallet 100 and the second pallet 400 are connected by multiple (two in this embodiment) support bars b, and the support bar b and the first clamp 100 and the second clamp 400 are welded connect. The first clamping plate 100 has a "U"-shaped structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com