Non-woven guiding device used for textile machine with drafting machine

A technology of textile machinery and guiding devices, which is applied in the direction of mechanical cleaning, textile and paper making, and fabric elongation, and can solve problems that affect product quality, cannot fix textiles, and cannot remove debris in time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

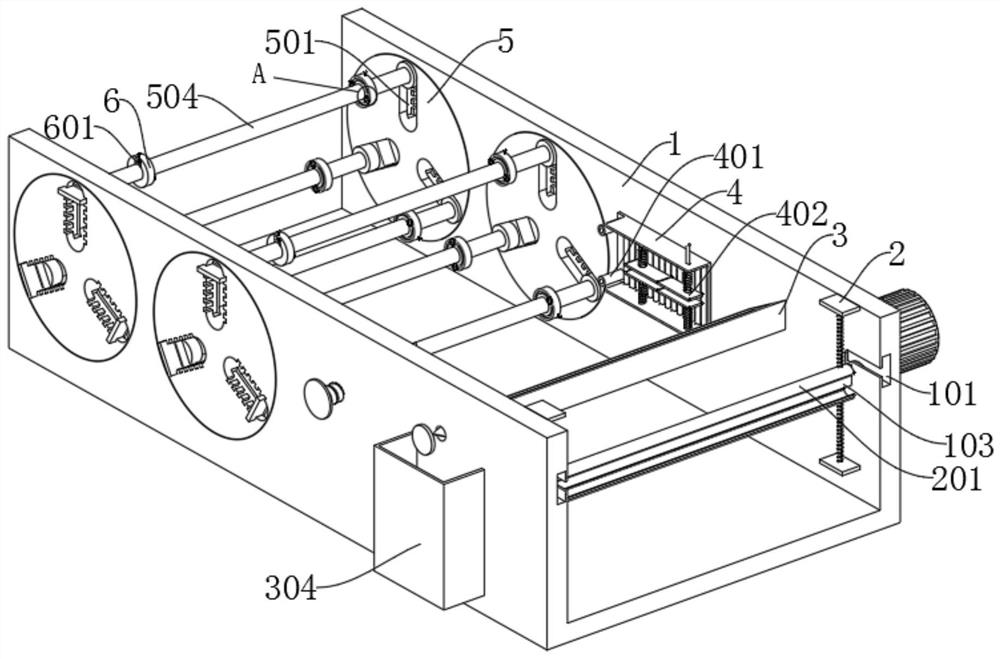

[0035] as attached figure 1 to attach Figure 9 Shown:

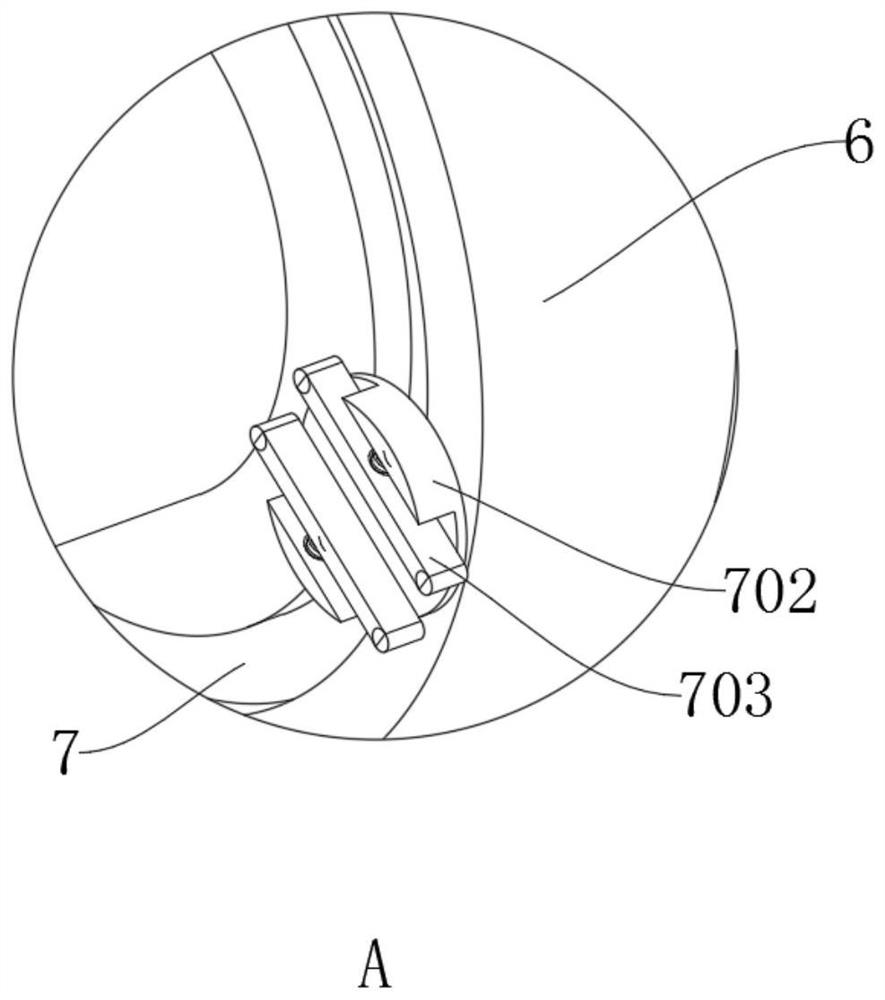

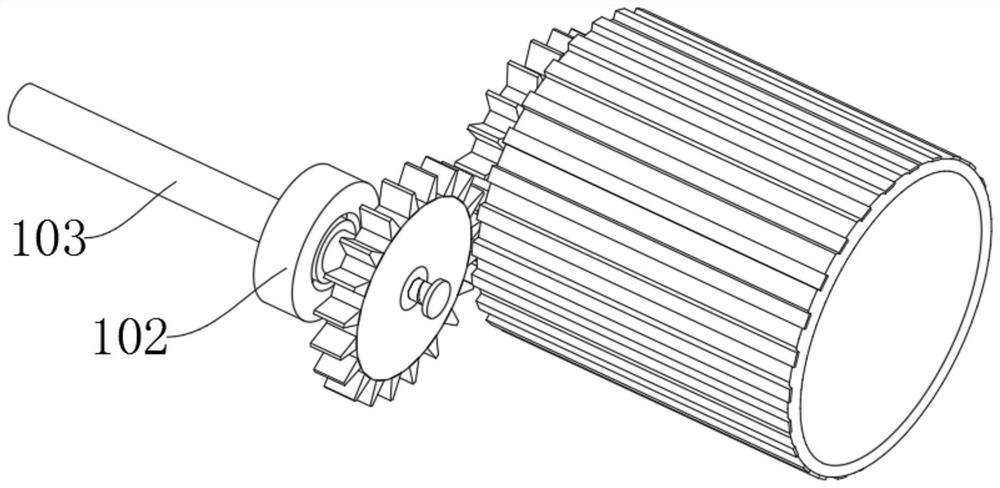

[0036]The invention provides a non-textile guiding device for a textile machine with a drafting machine, comprising a main body 1, a top plate 2, a scraper 3, a carrier plate 4, a panel 5, a sliding plate 6 and a chute 7; the main body 1 is a rectangular plate structure, and the motor is installed on the side of the main body 1; the top plate 2 is set on the inner side of the main body 1, and the splint 201 at the bottom of the top plate 2 is installed on the side of the cross bar 103; the panel 5 is a circular plate structure, and the panel 5 is embedded in the main body 1 The side of slide plate 6 is an arc structure, and slide plate 6 is installed on the side of drafting bar 504;

[0037] The scraper 3 includes an inner cavity 301, a rotating rod 302, a bottom plate 303, and a material storage box 304; the inner cavity 301 is arranged inside the scraper 3, and a rotating rod 302 is installed inside the inner cavity ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com