Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

113results about How to "Winding orderly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

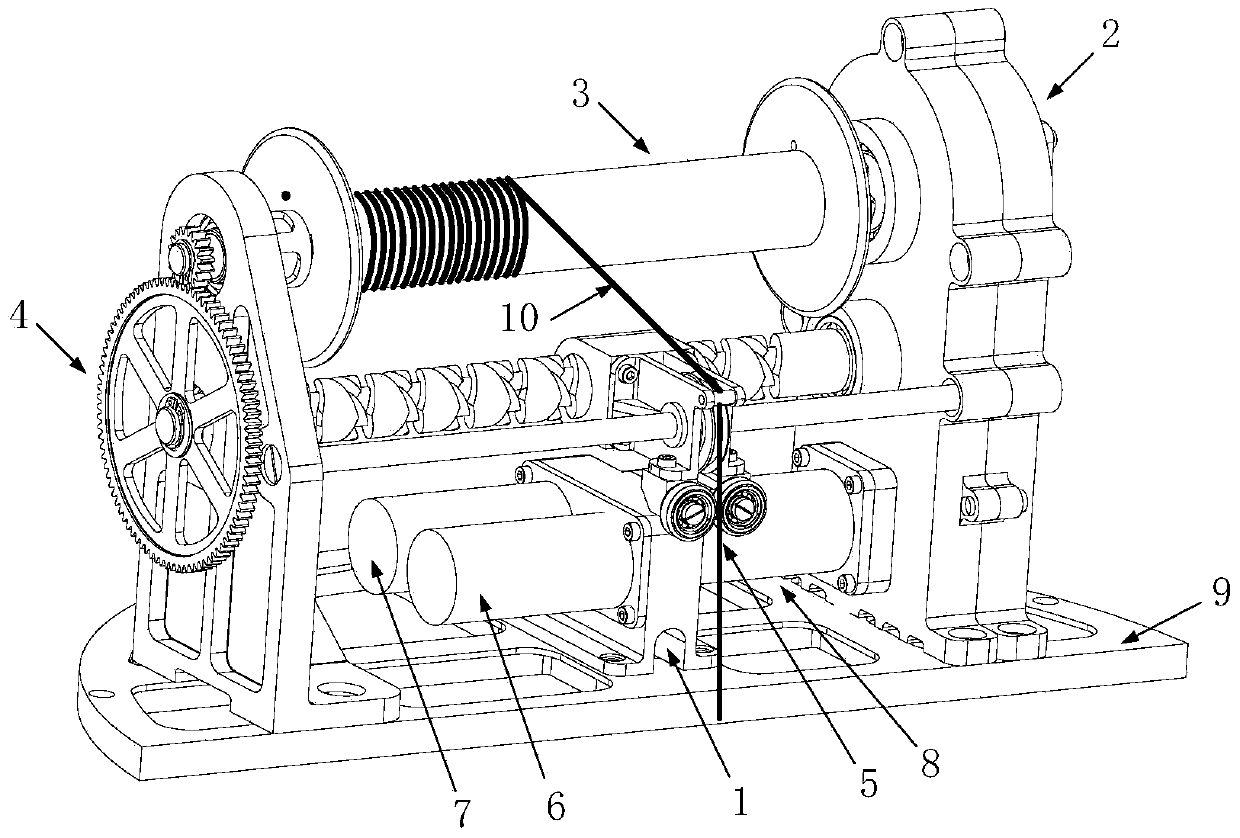

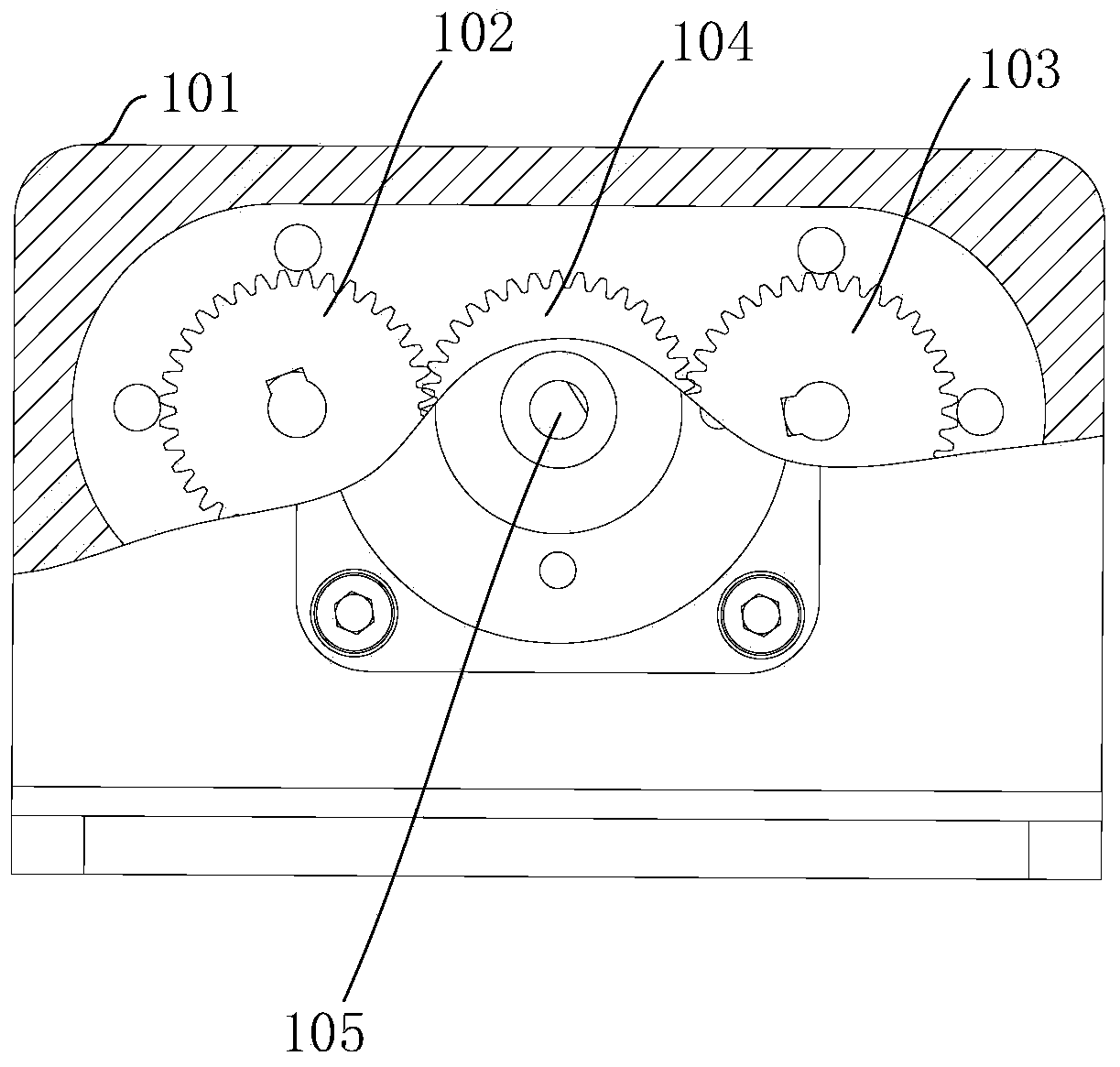

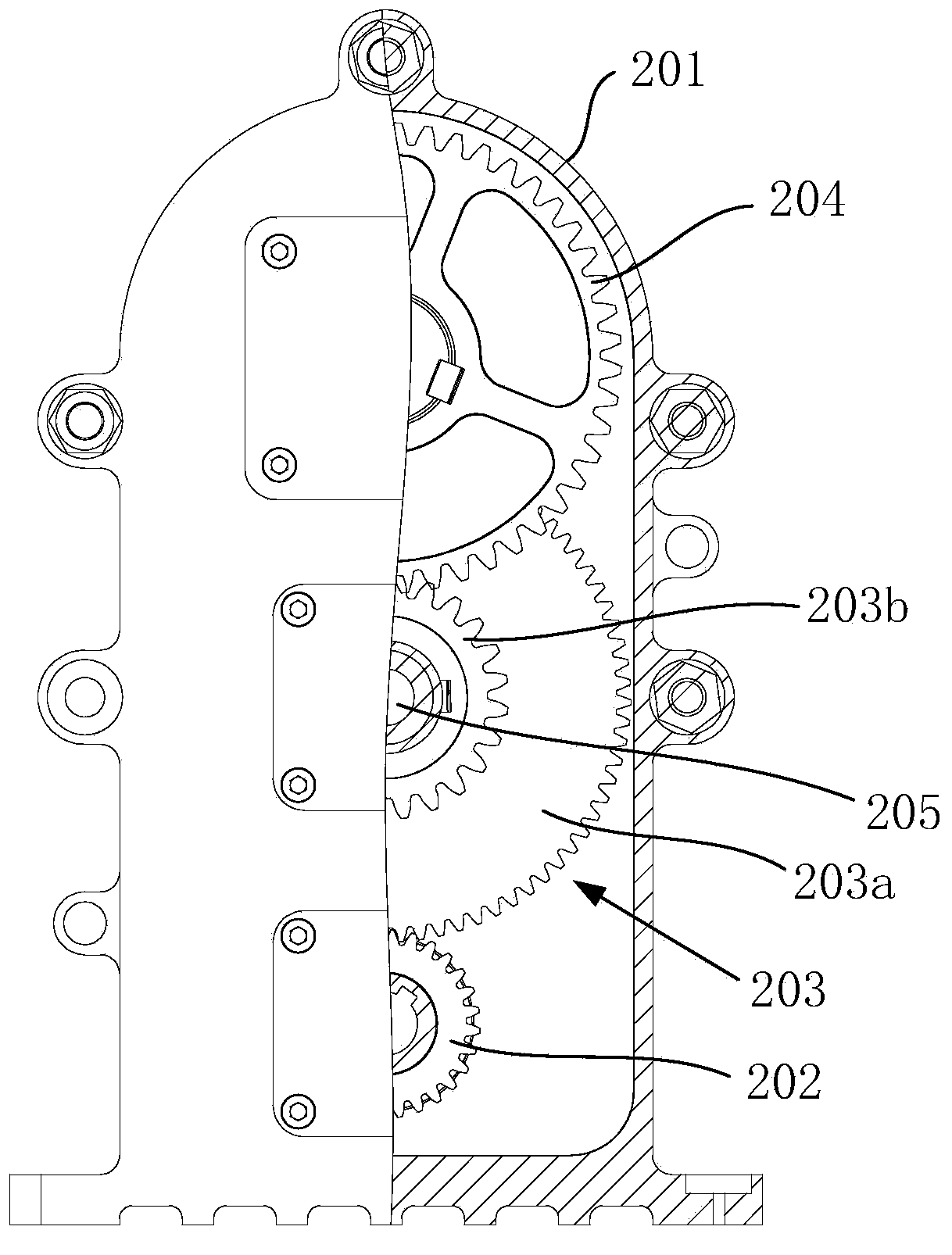

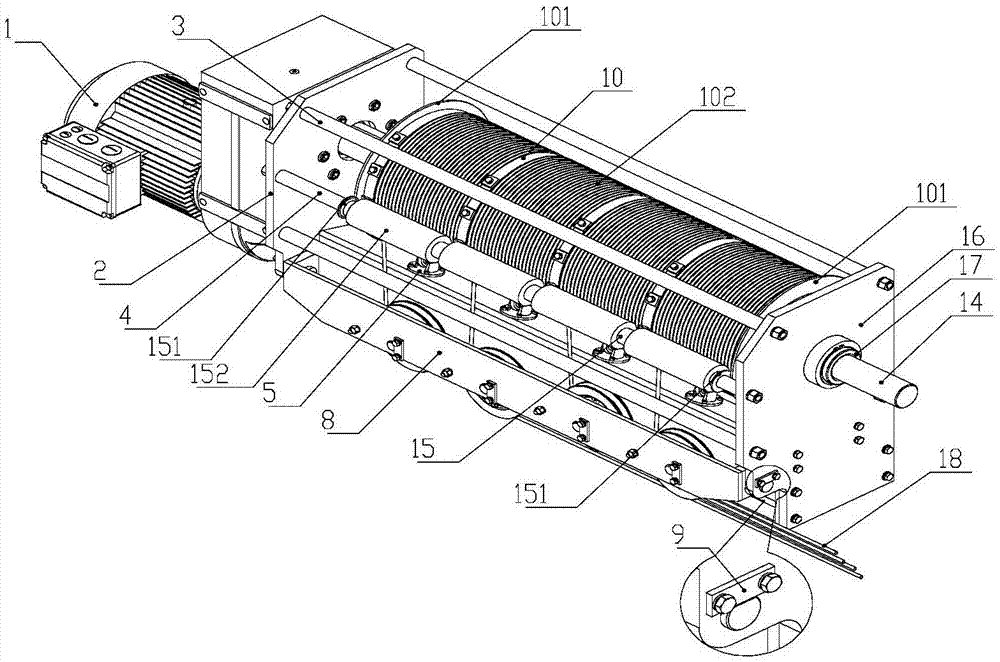

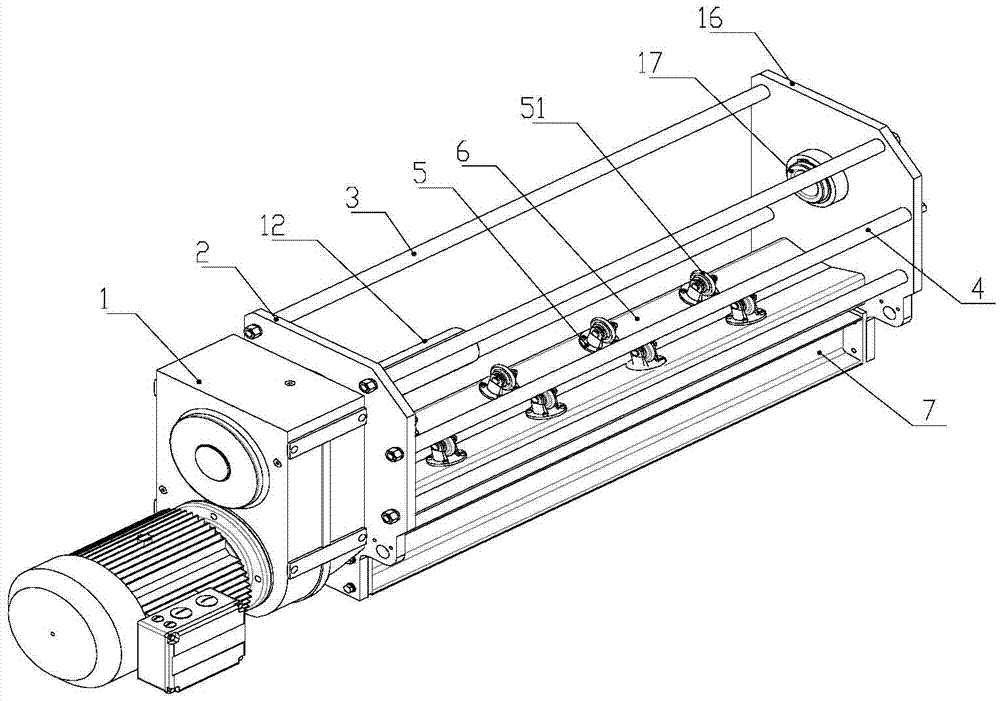

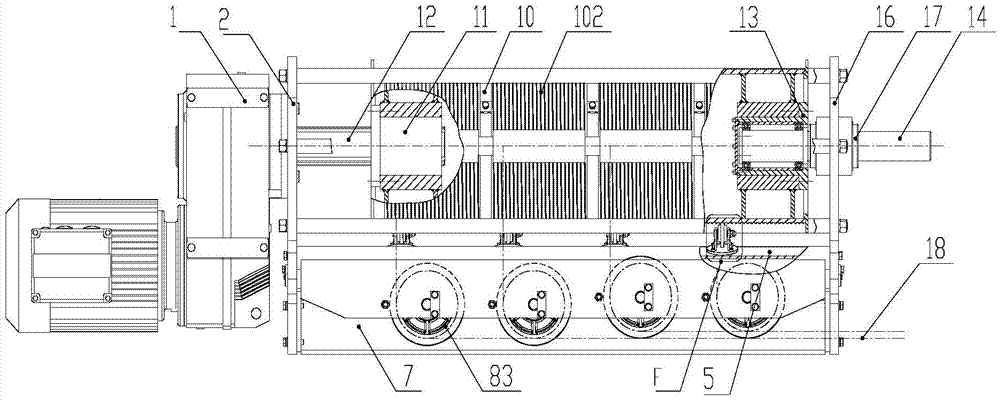

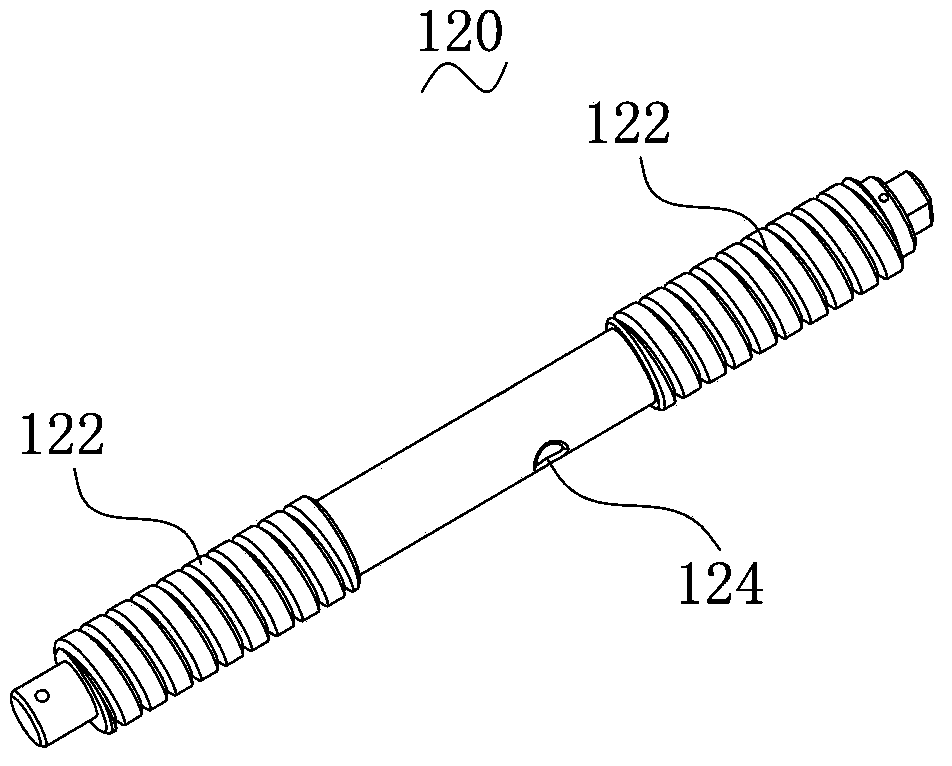

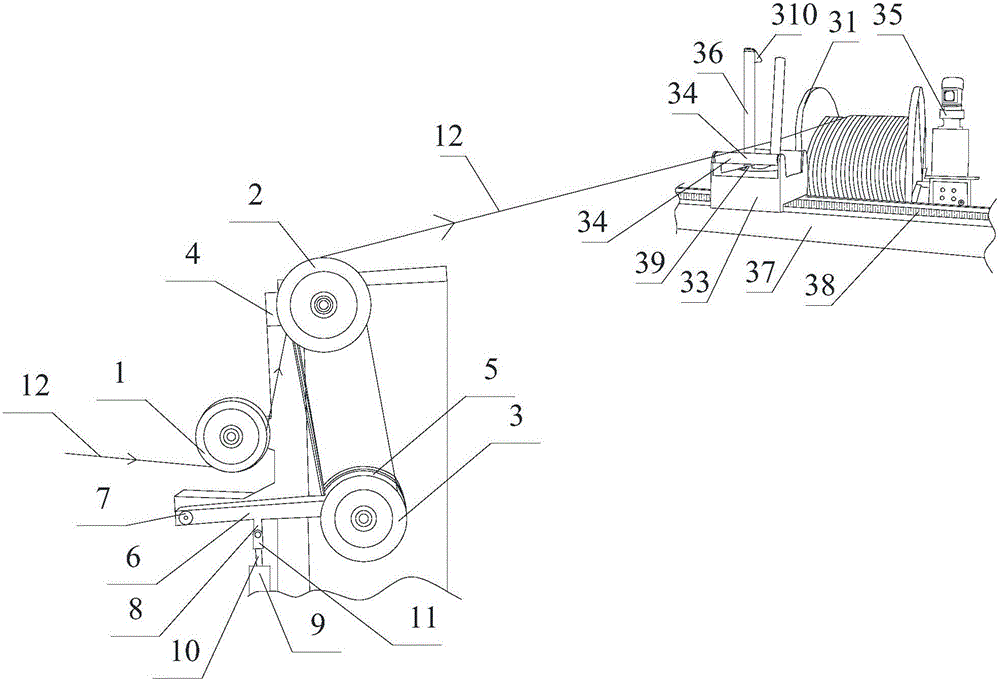

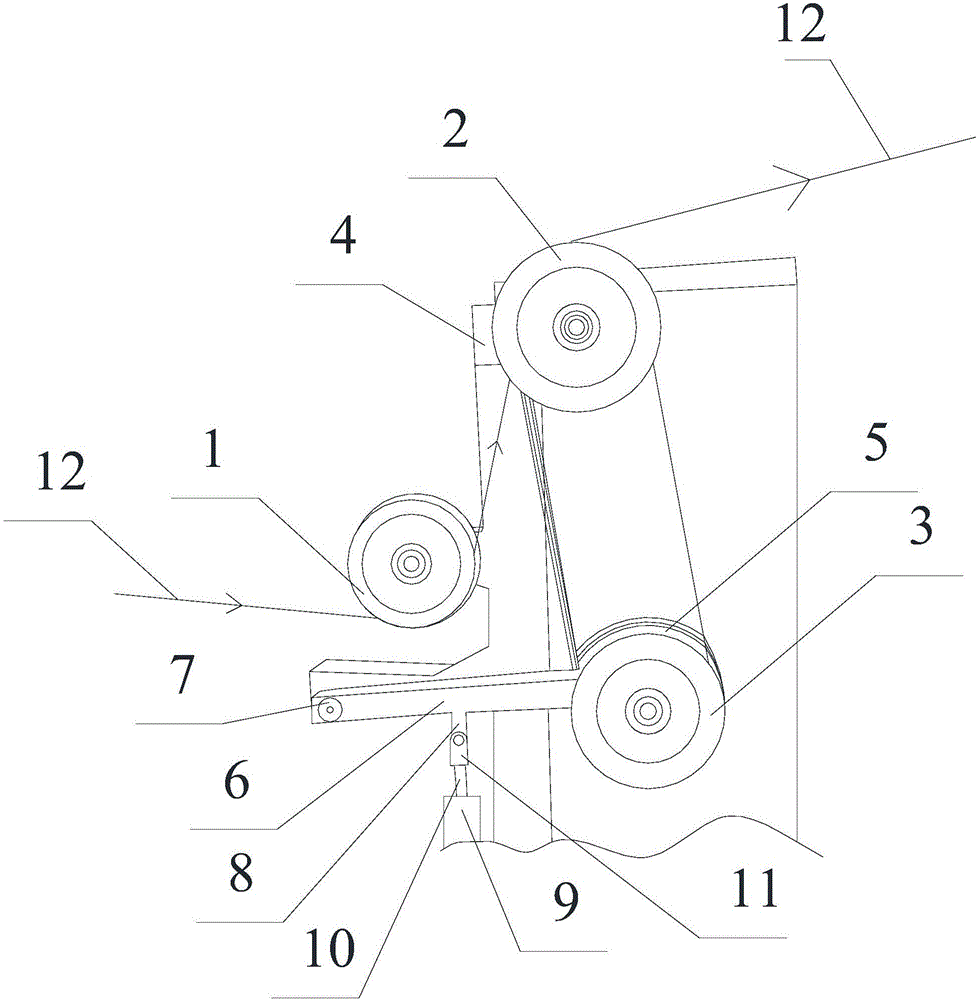

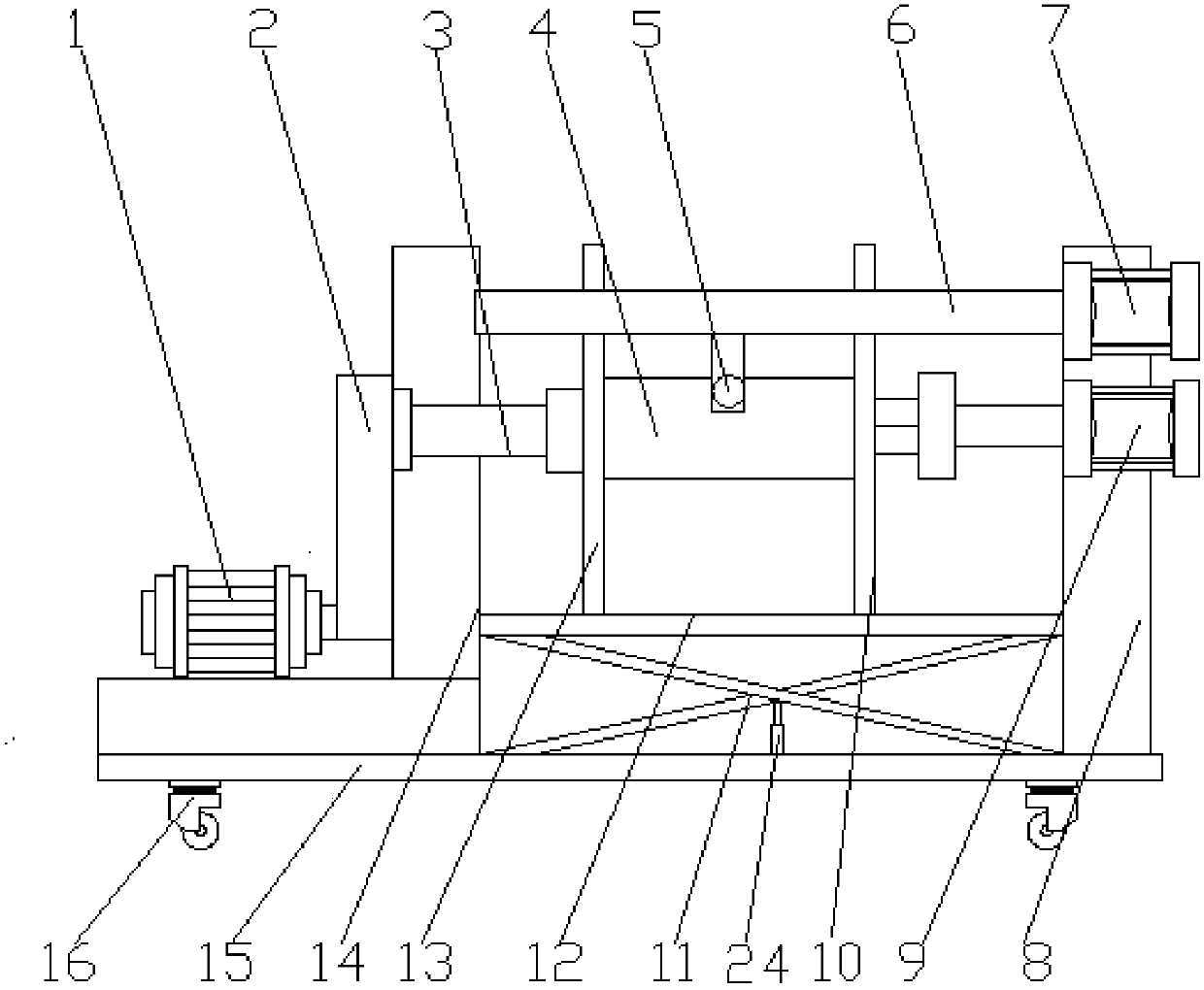

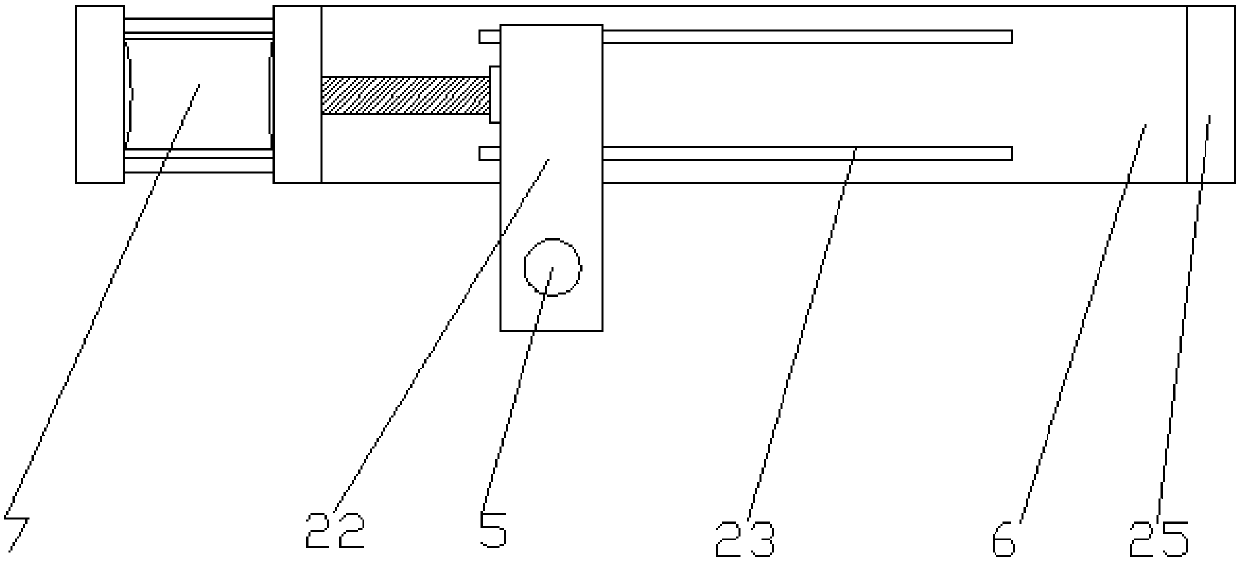

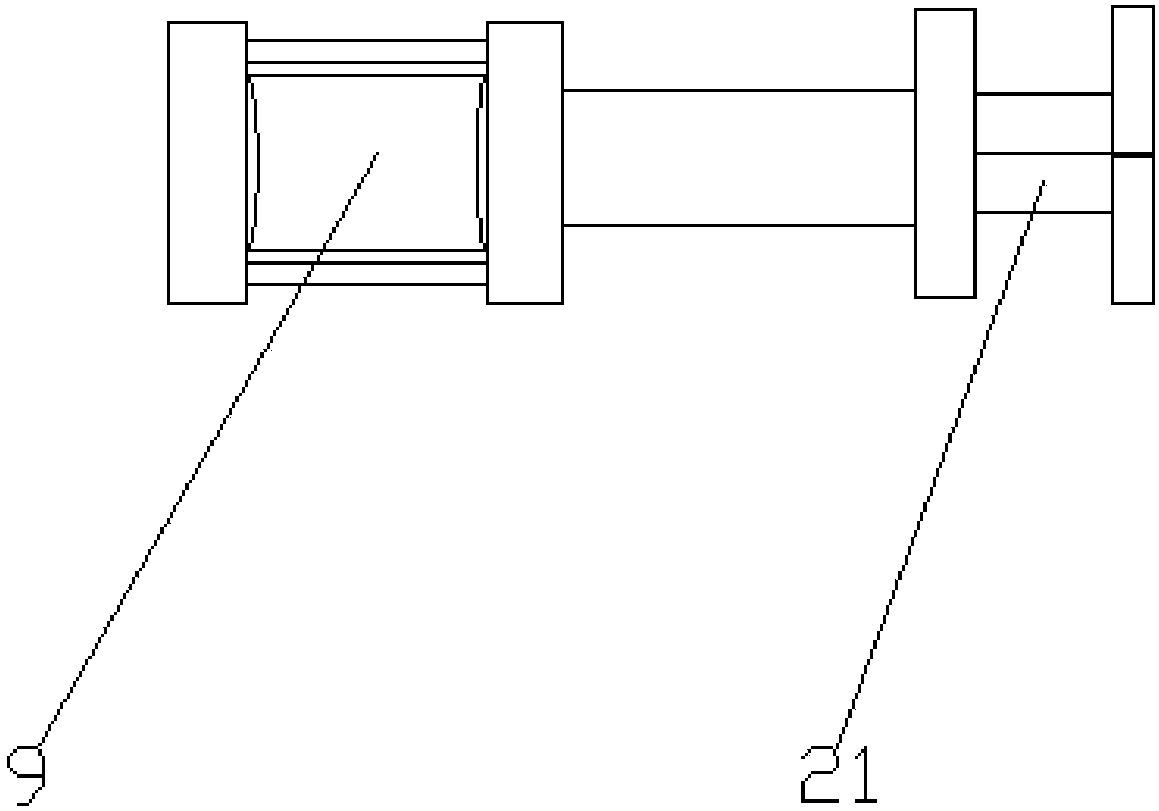

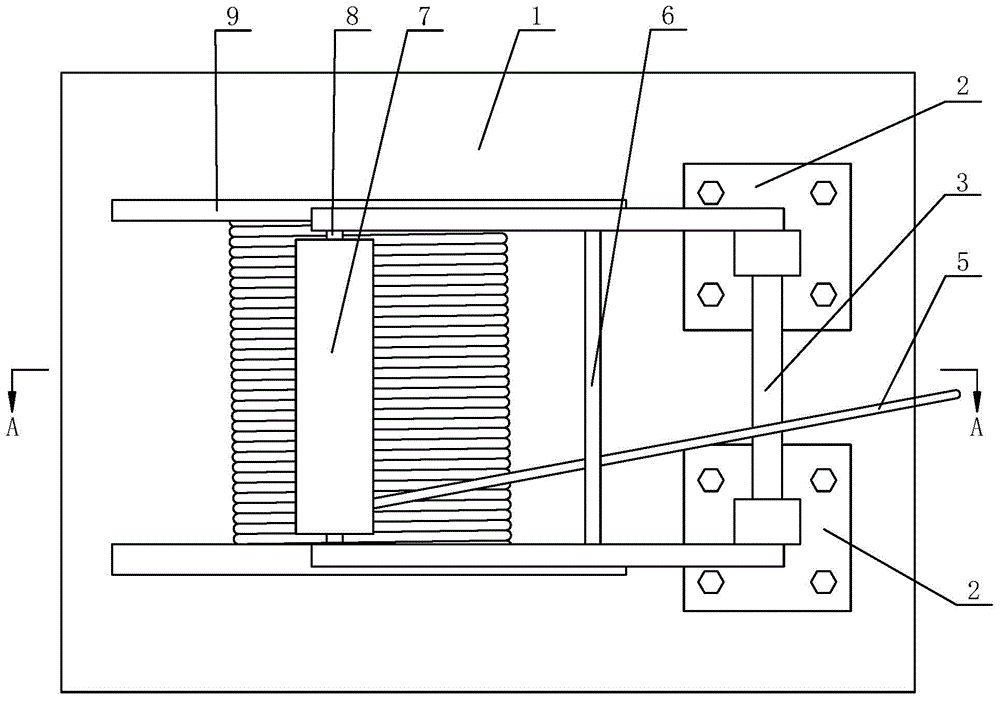

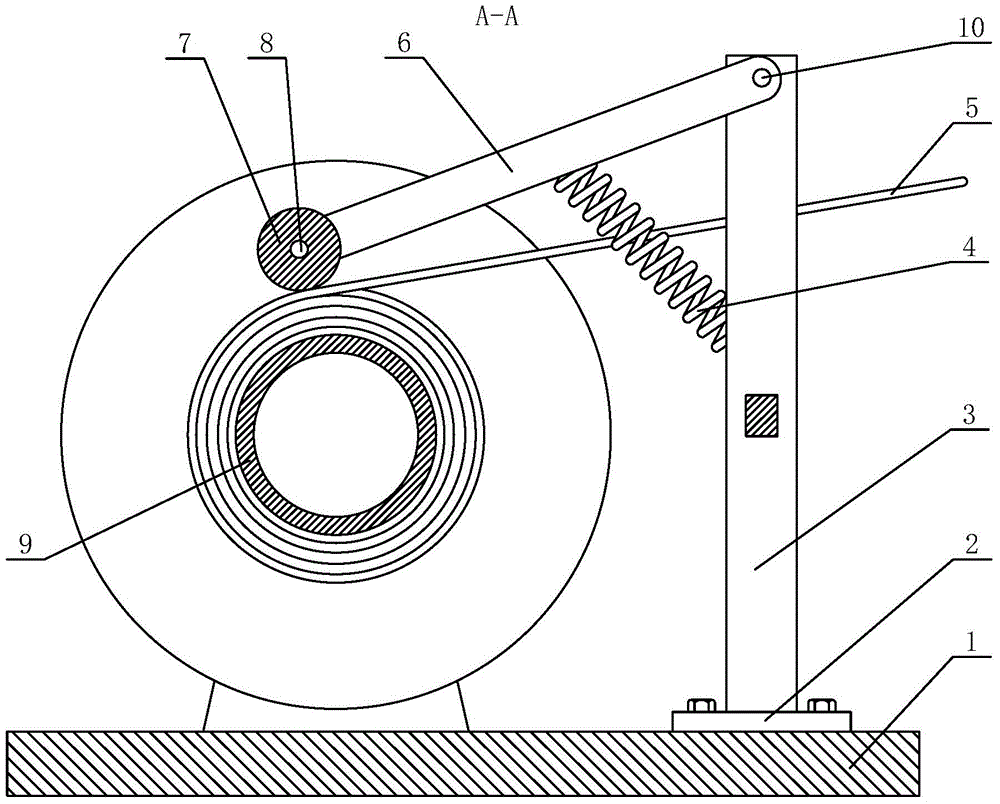

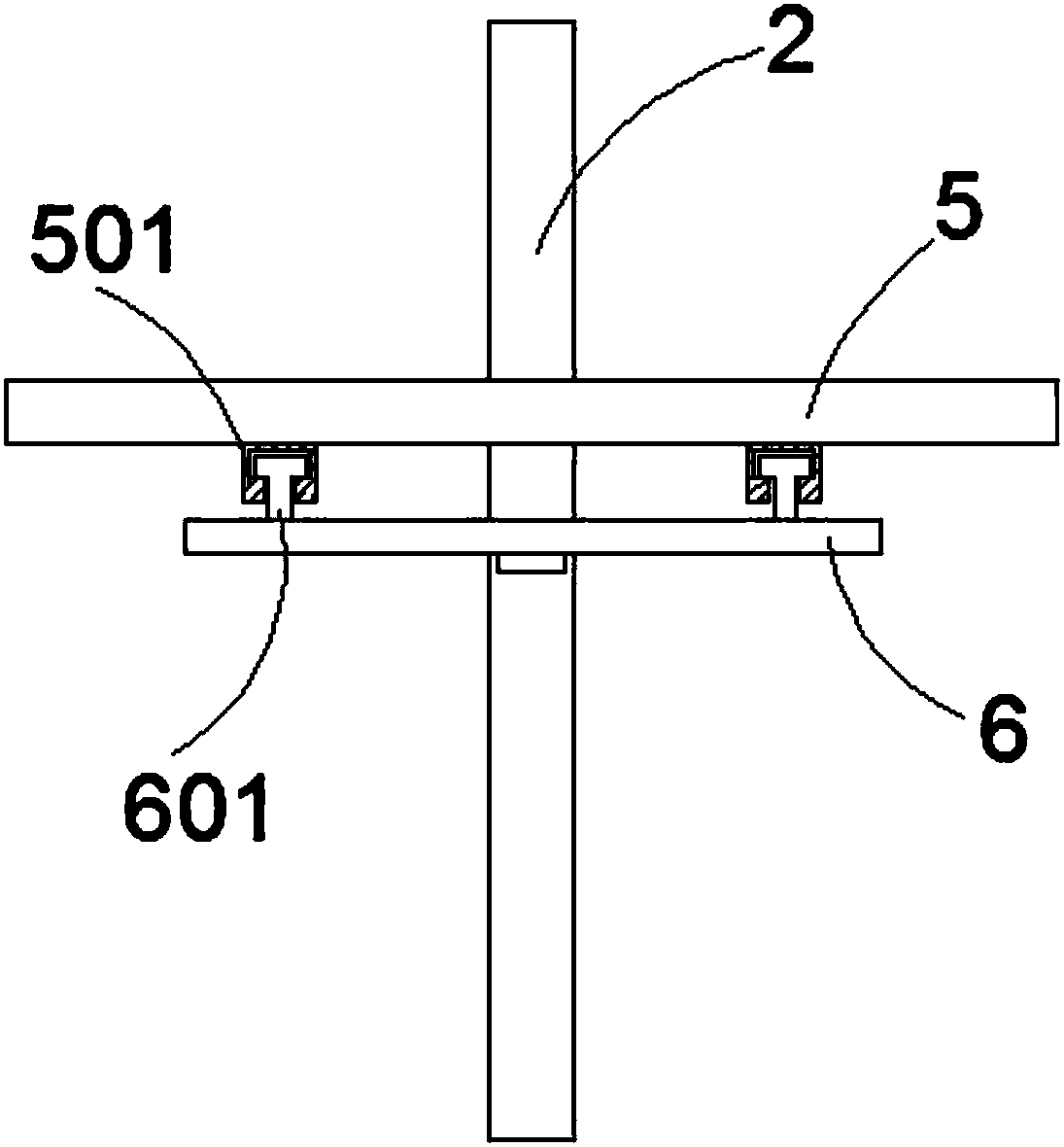

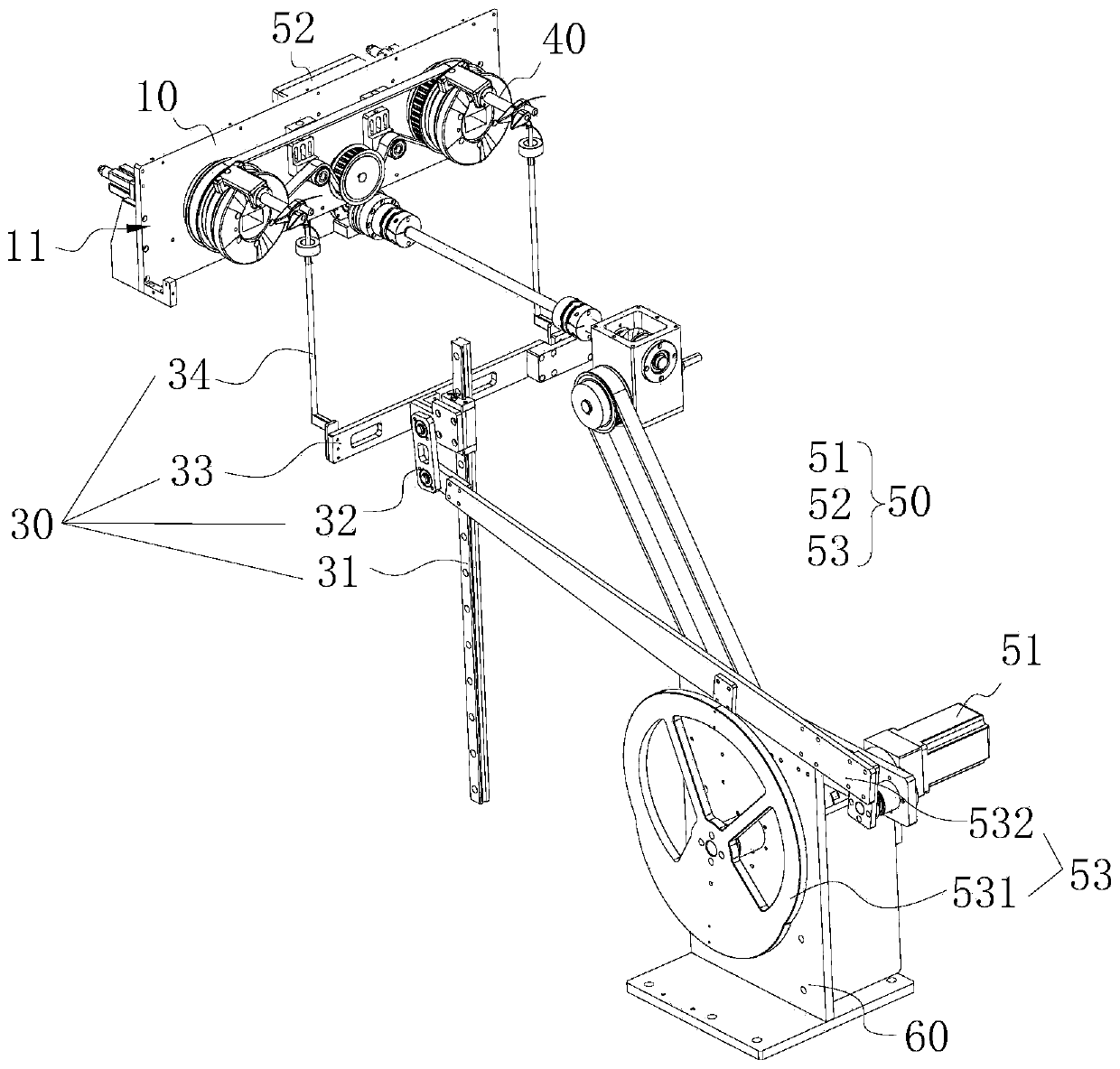

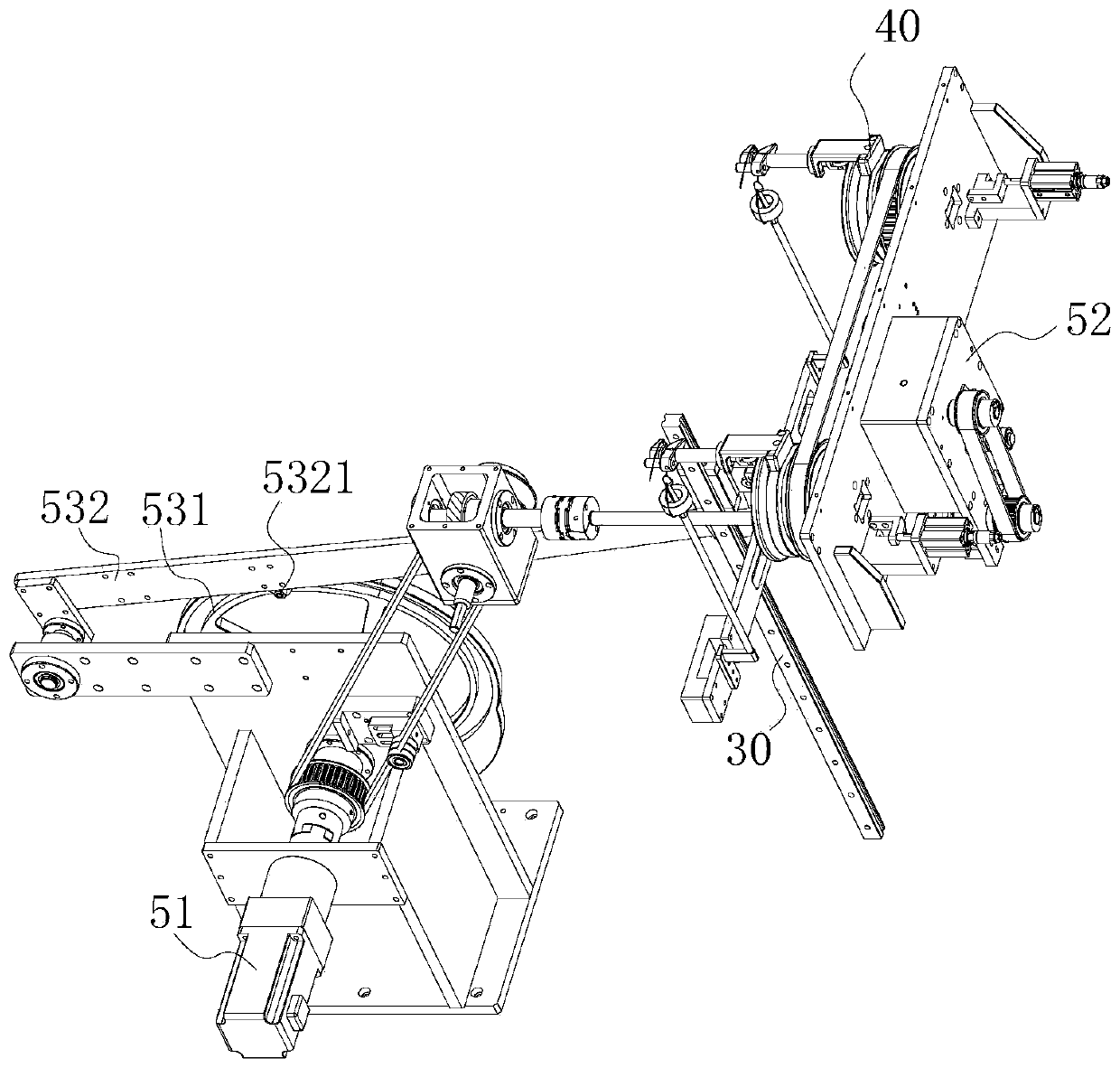

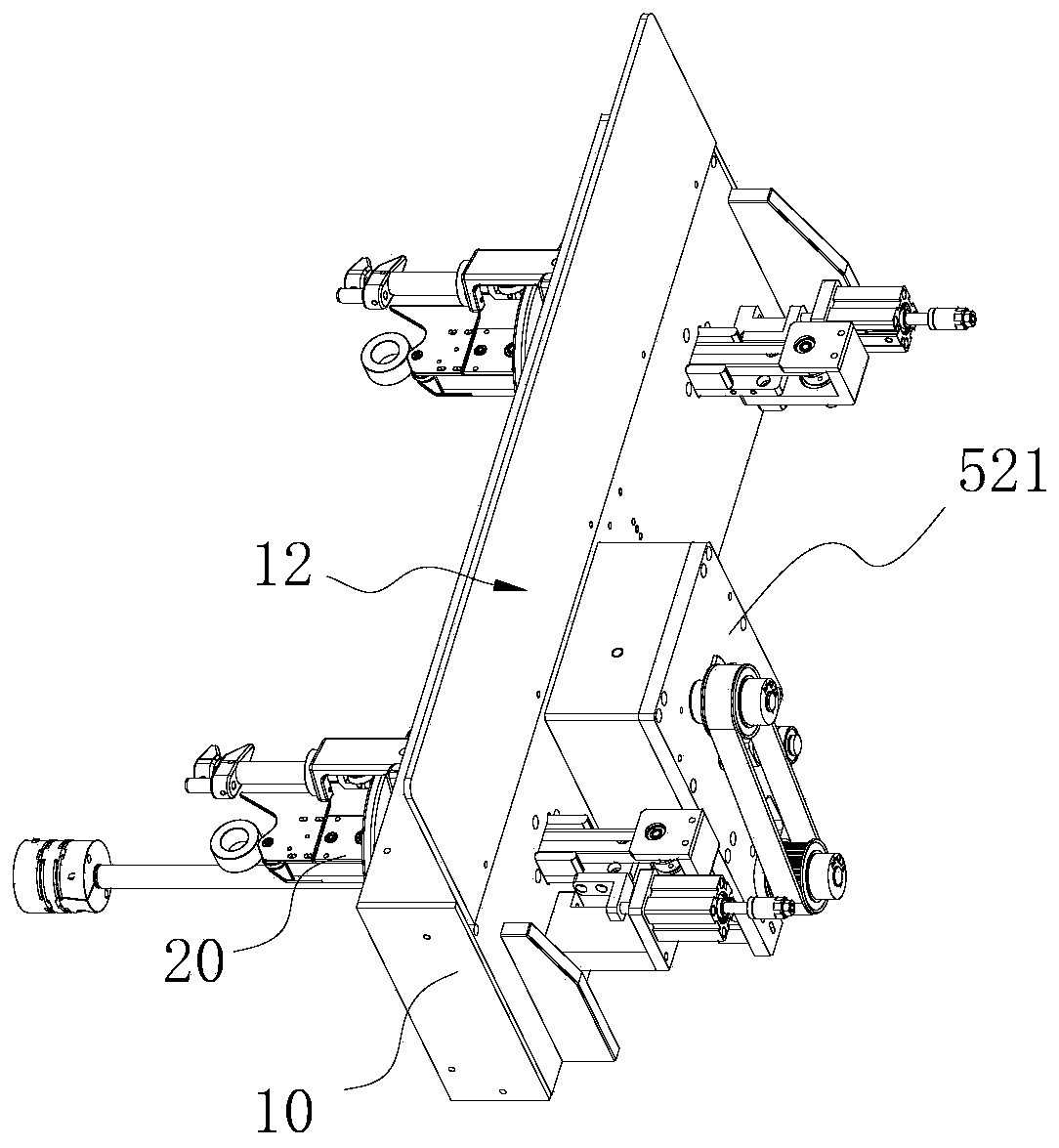

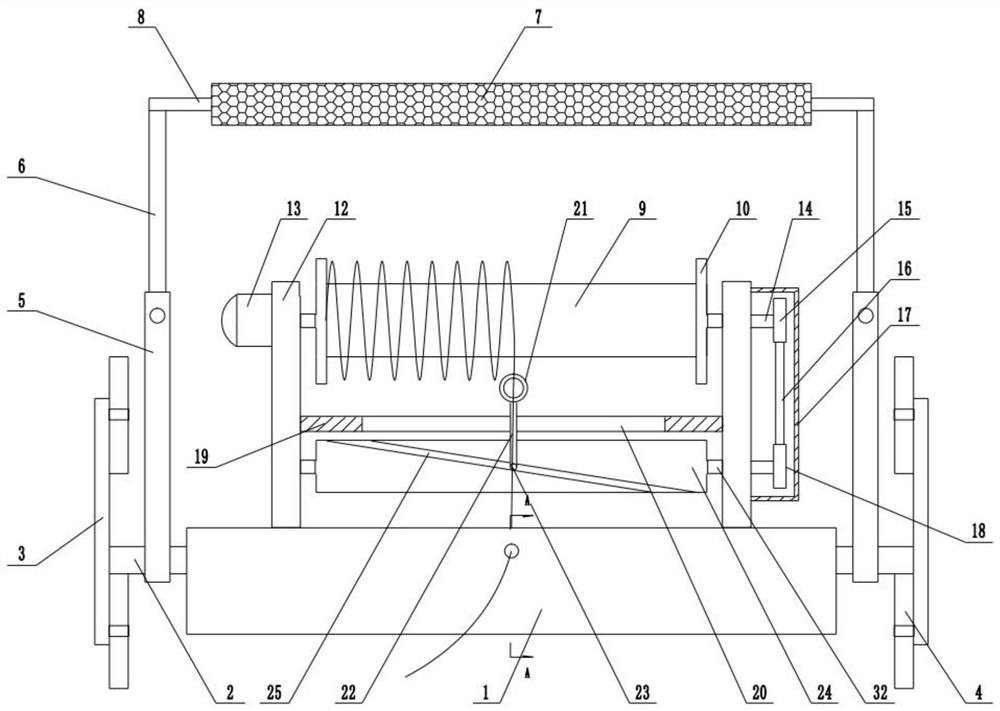

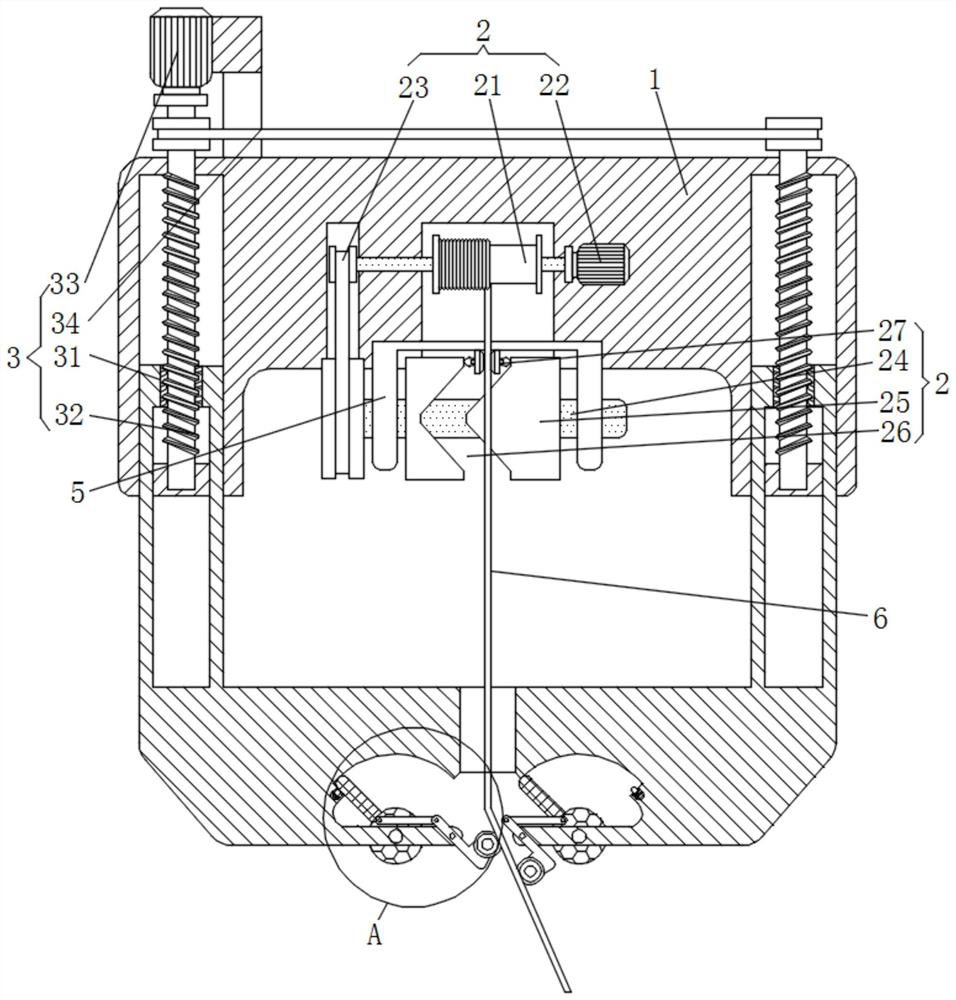

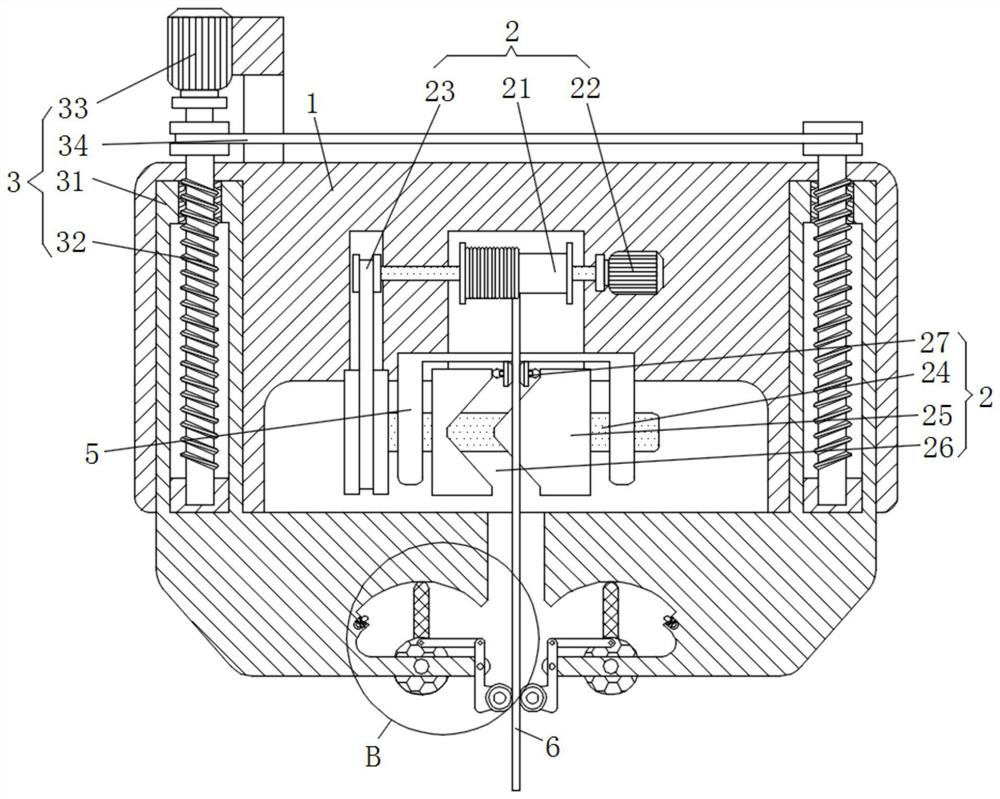

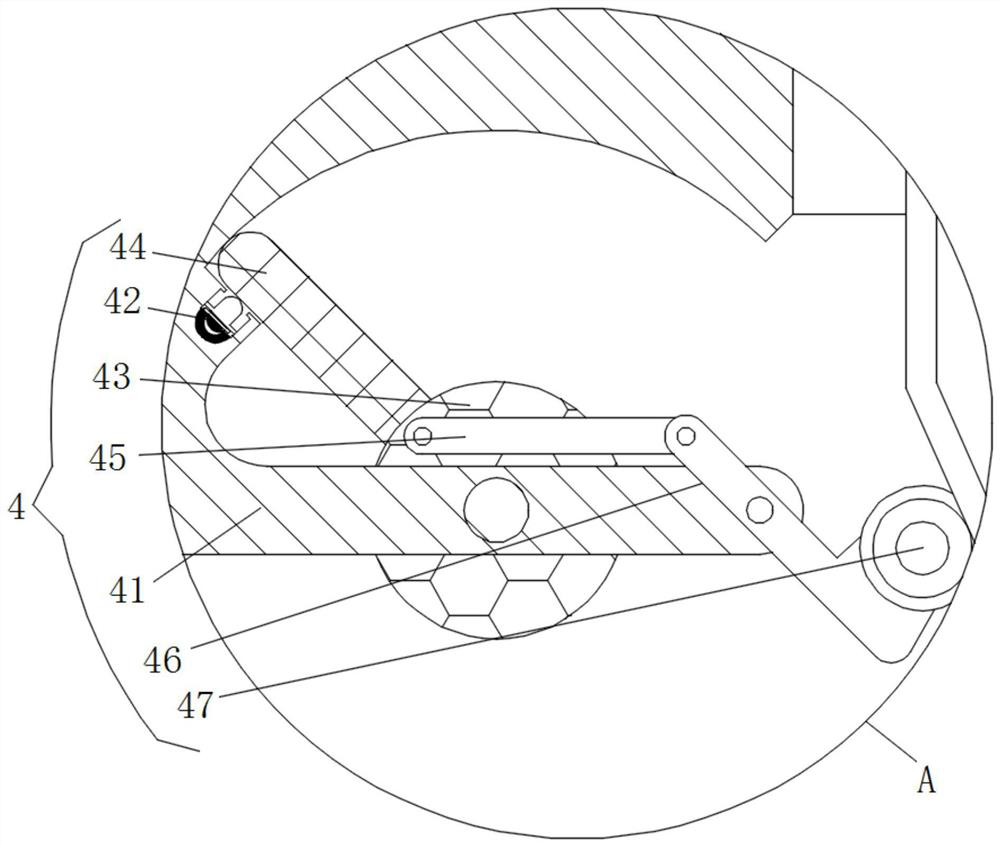

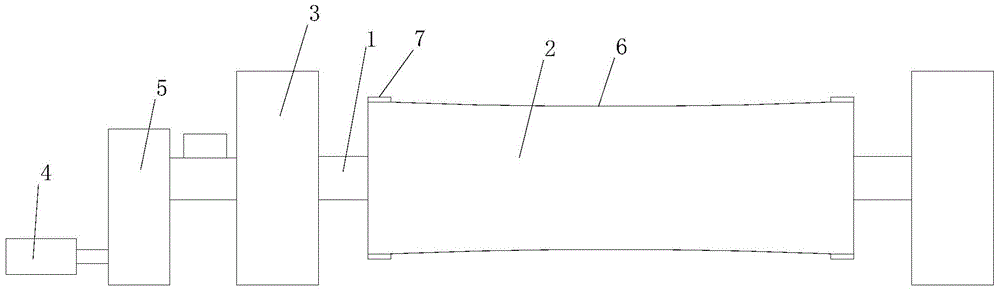

Rope drive device with reciprocating wire arrangement function

ActiveCN104192637AWith reciprocating cable functionWinding orderlyFilament handlingReciprocating motionGear wheel

The invention discloses a rope drive device with a reciprocating wire arrangement function. The rope drive device comprises a backup motor gearbox, a rope roller reducer, a winding roller, a reciprocating screw mechanism and an arrangement guide wheel set. A driving motor is connected with an output shaft of a backup motor and an input shaft of a planetary reducer through the backup motor gearbox, so that both the driving motor and the backup motor can drive the motor gearbox to move. The rope roller reducer transmits rotation of an output shaft of the planetary reducer to the winding roller according to a specified speed ratio, and a large torque is obtained. The winding roller is mounted at an output shaft of the rope roller reducer; a drive rope is wound on and unwound from the winding roller. A reciprocating screw of the reciprocating screw mechanism is connected with the winding roller through a gear and drives a nut slider mounted on the reciprocating screw, to reciprocate. The arrangement guide wheel set is fixedly connected with the screw slider and reciprocates with the screw slider to guide the drive rope being tightly wound on the winding roller in a reciprocating manner. The rope drive device allows winding and unwinding of the rope and allows the rope to be regularly and tightly wound.

Owner:BEIHANG UNIV

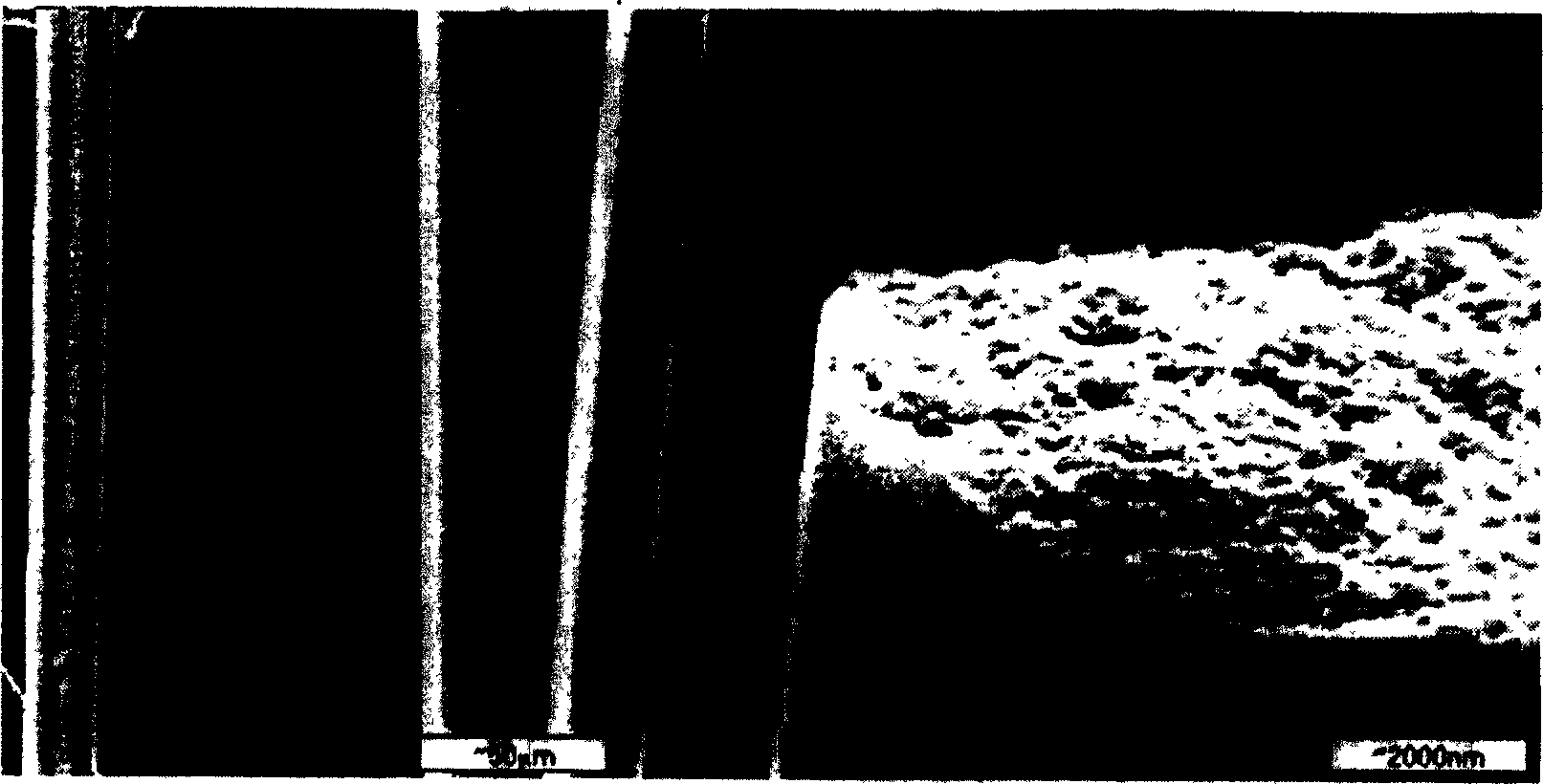

Method and equipment of preparing high performance zirconium oxide continuous fiber

InactiveCN1459418AGood effectHigh molecular weightInorganic material artificial filamentsZirconium oxidesFiberStructure and function

A process for preparing high-performance continuous fibre of zirconium oxide includes such steps as synthesizing acetylacetone-zirconium polymer as precursor from acetylacetone and zirconium oxychloride as main materials, dissolving in methanol to obtain the spinning solution, drying spinning to obtain continuous fibre of precursor, heat treating in a multifunctional sintering furnace by special atmosphere and high-temp. airflow spraying for stretching. Its advantages are high tensile strength (over 2.6 GPa) and long length up to several kilometers.

Owner:绍兴市圣诺超高温晶体纤维材料有限公司

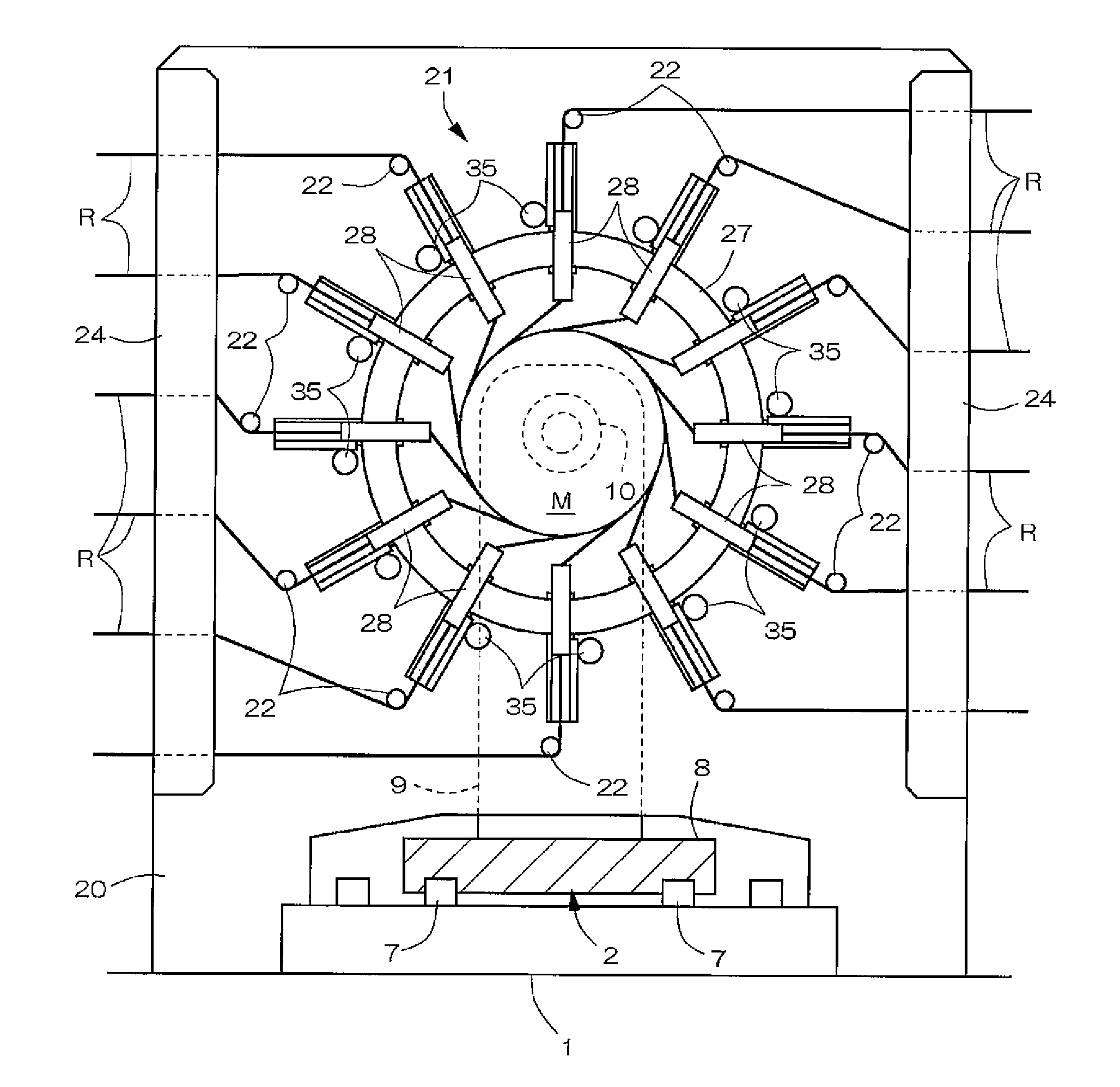

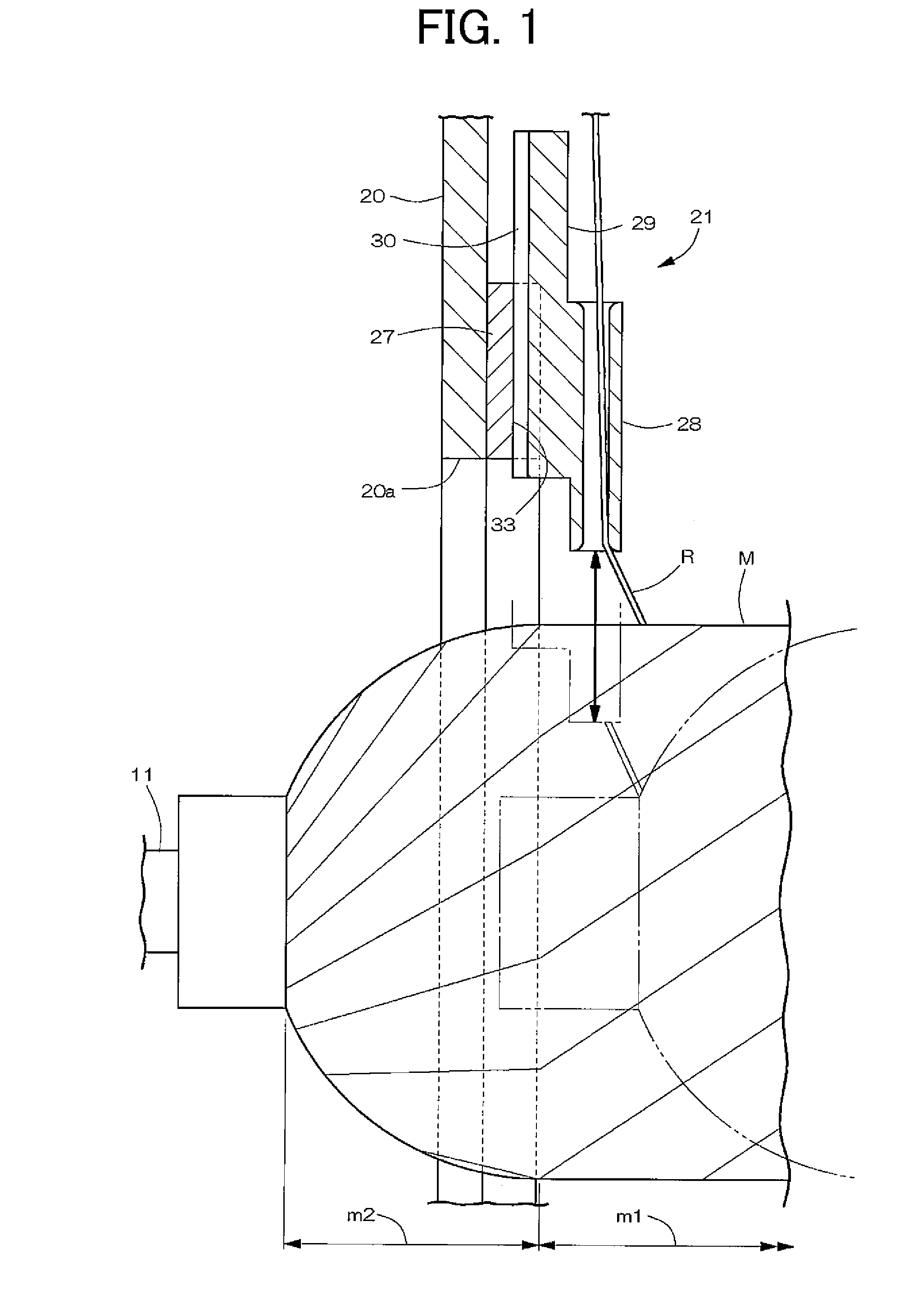

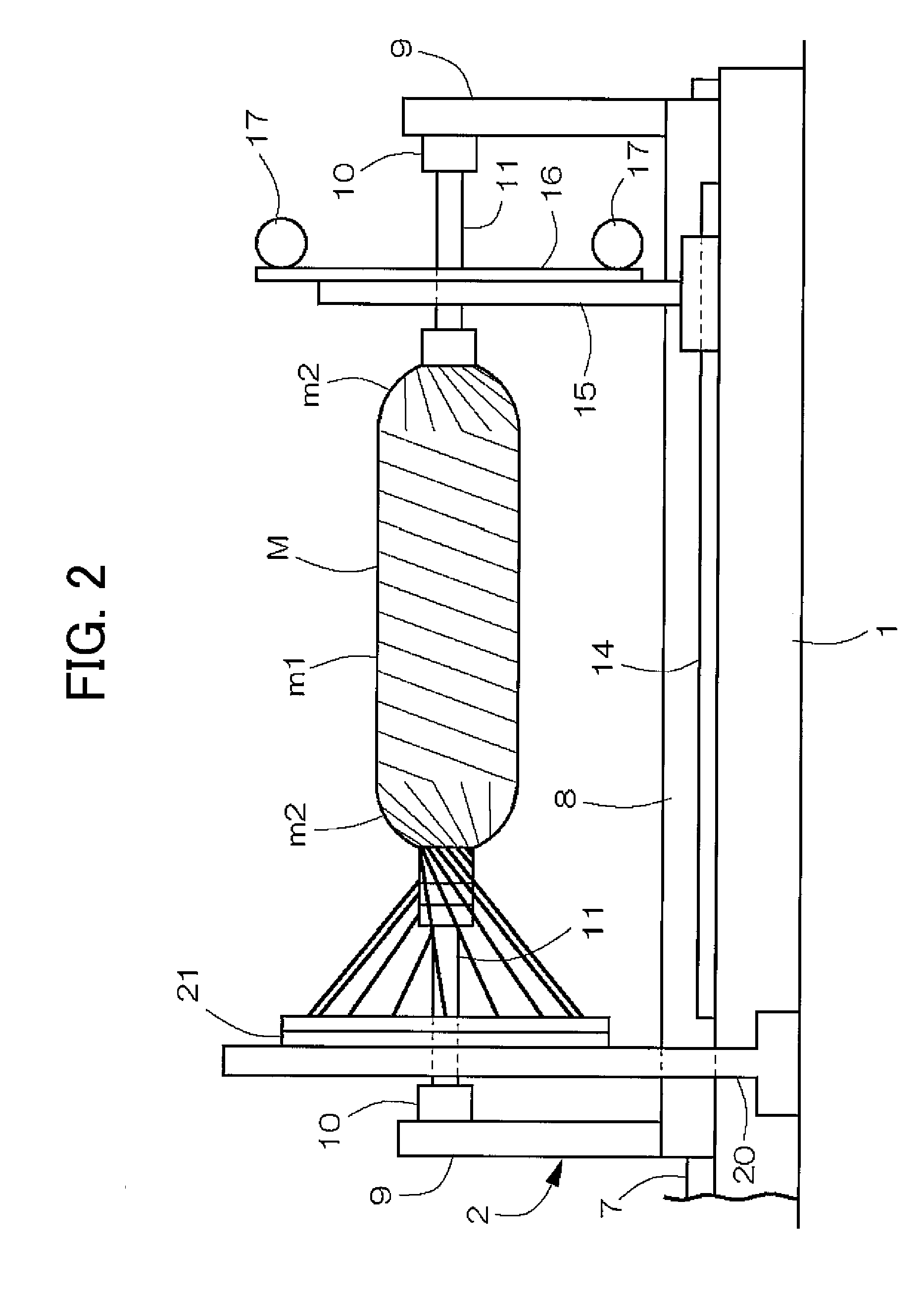

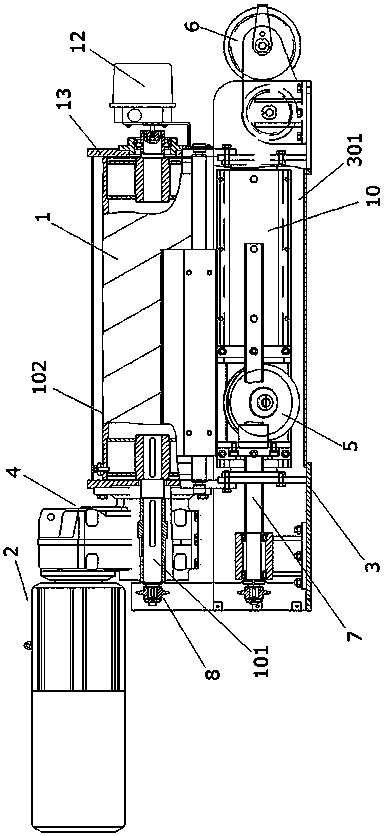

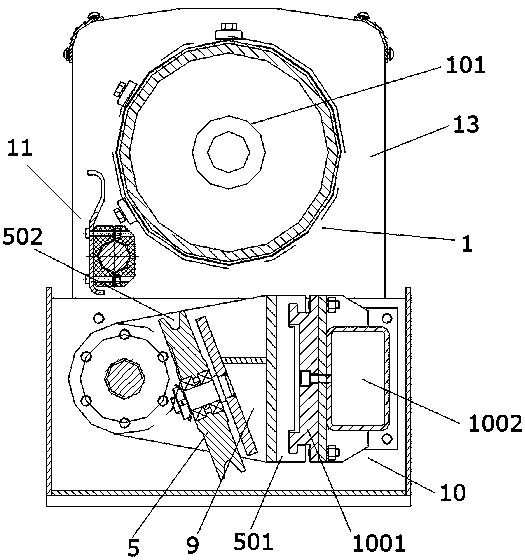

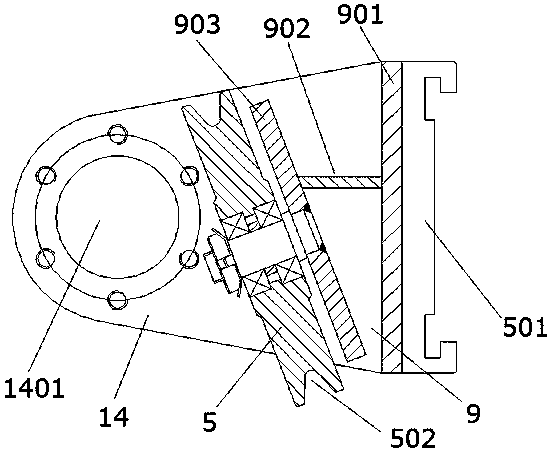

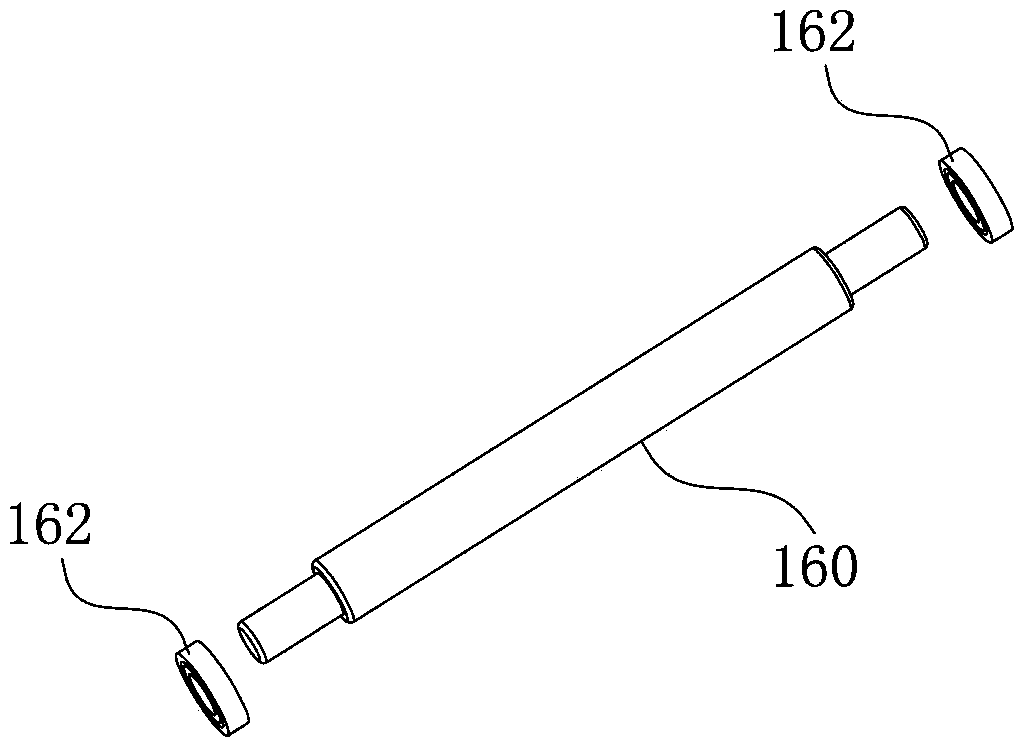

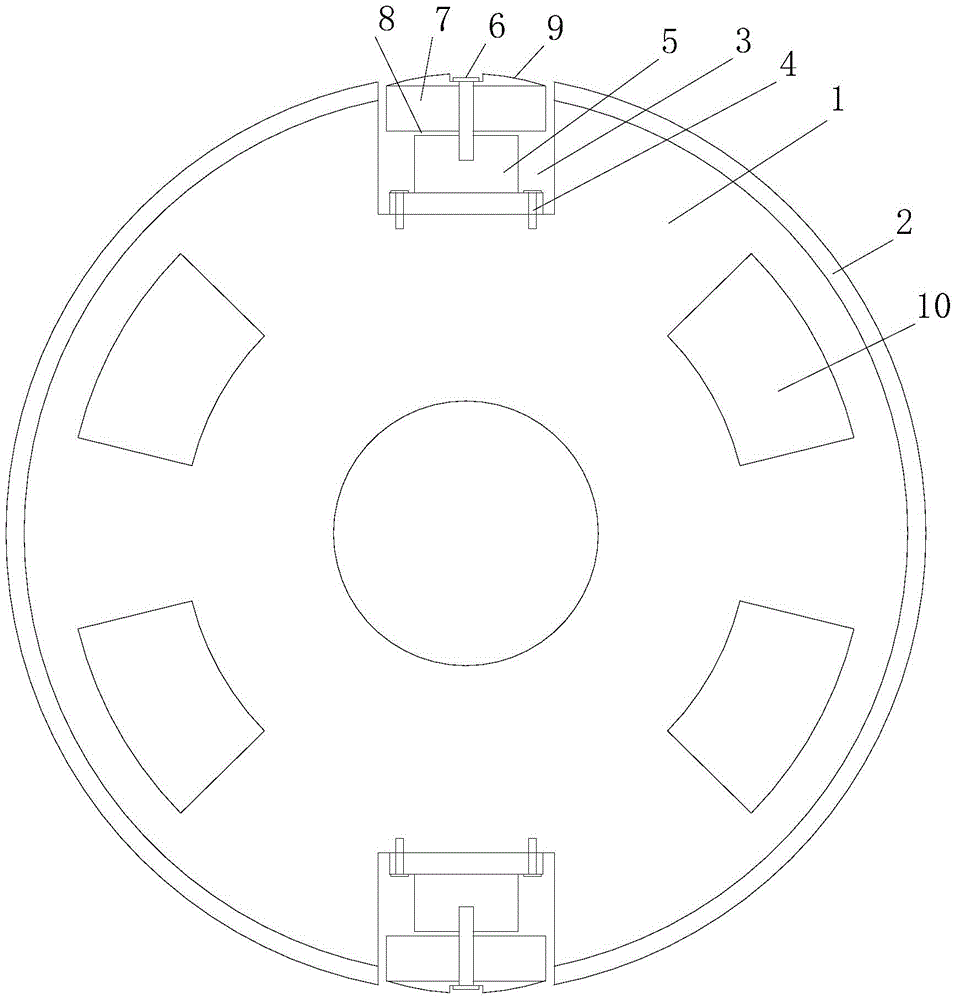

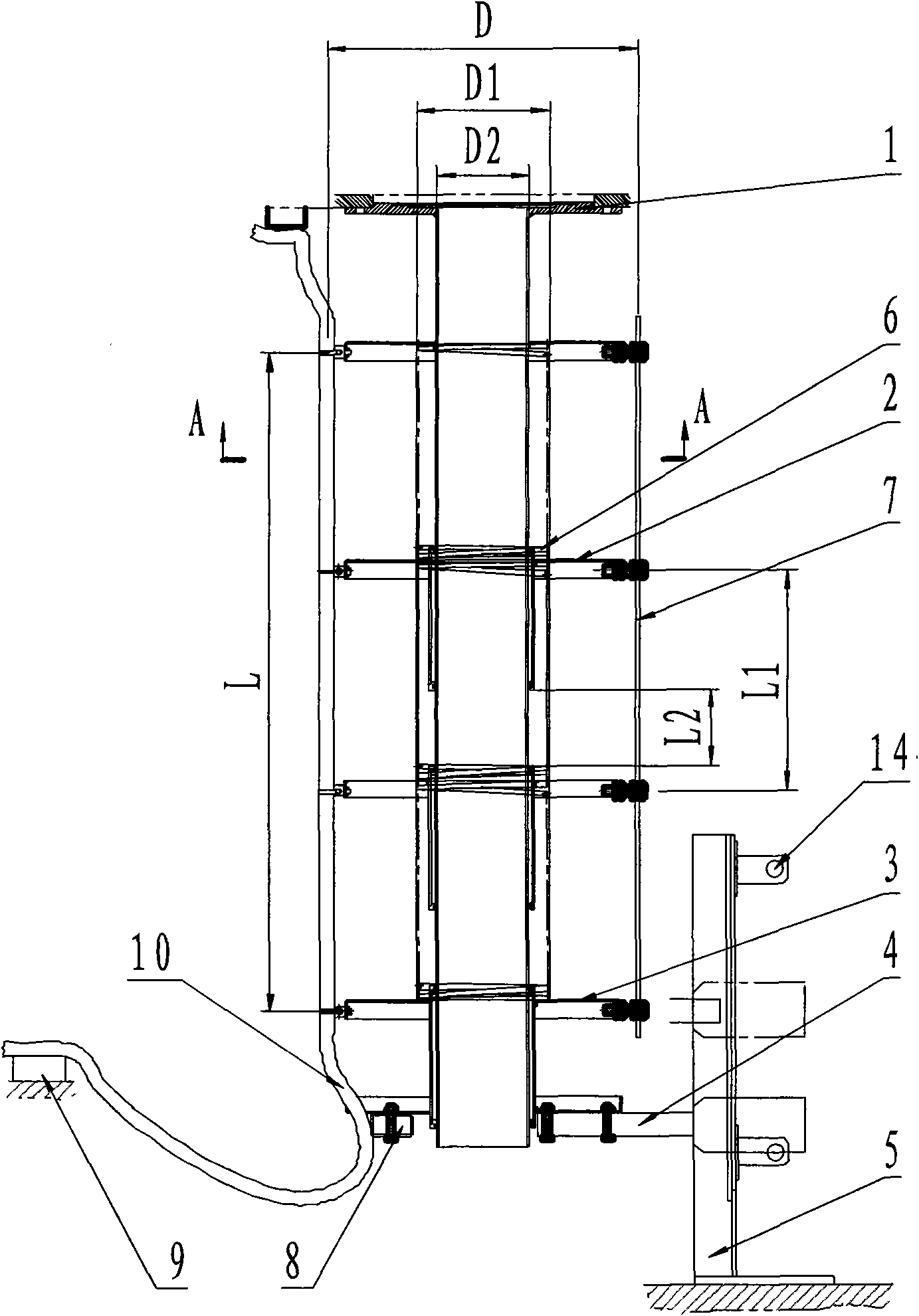

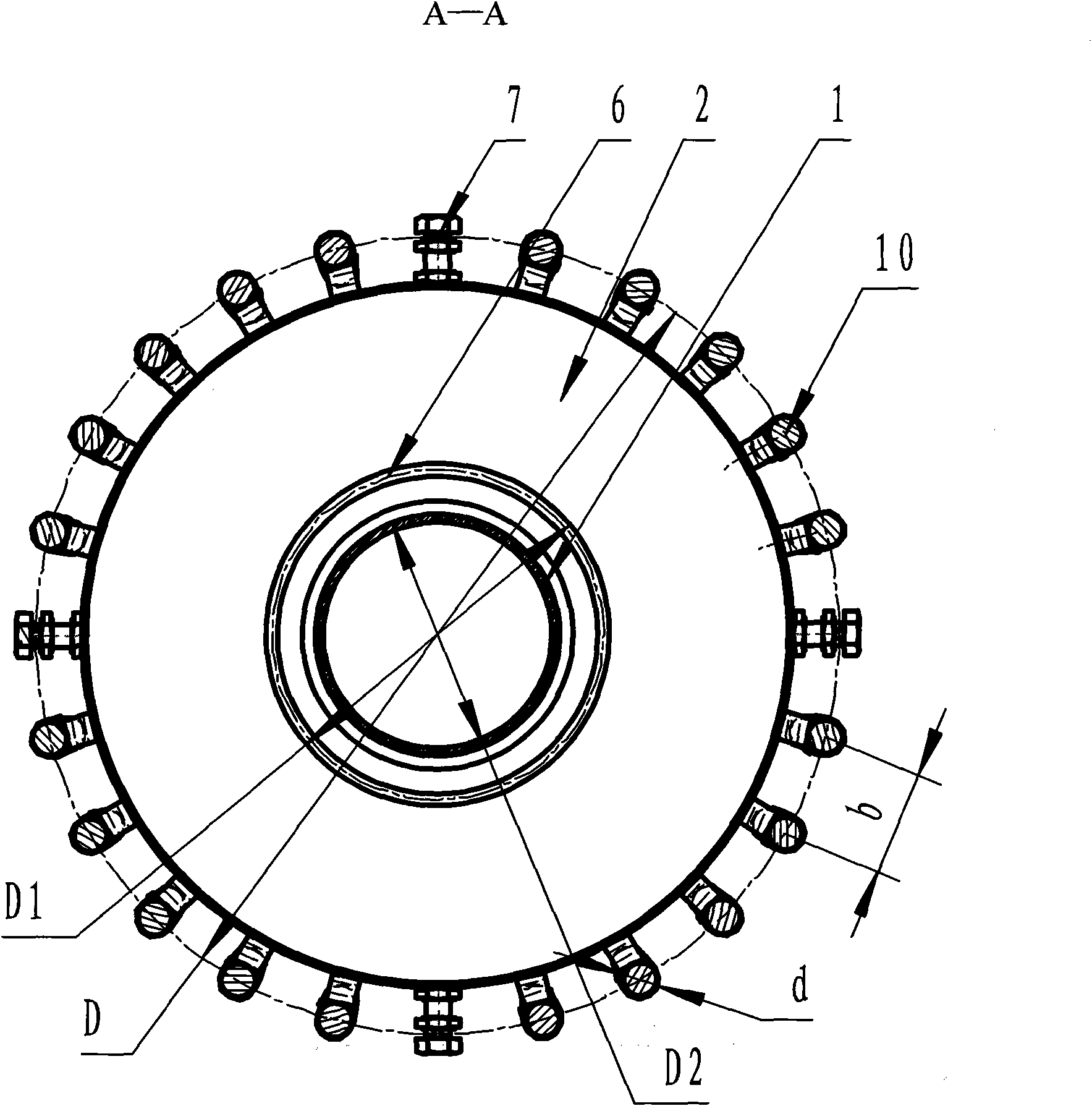

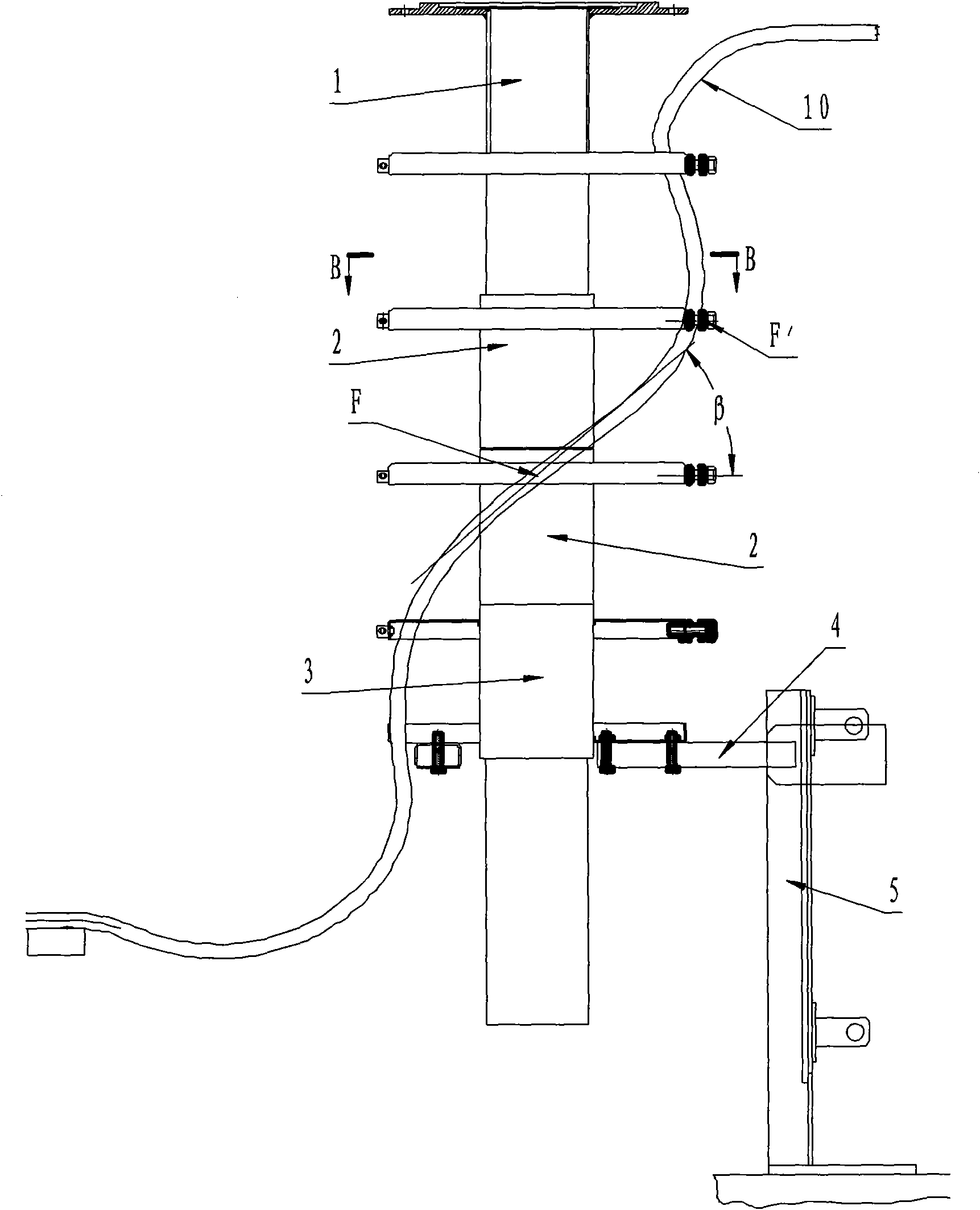

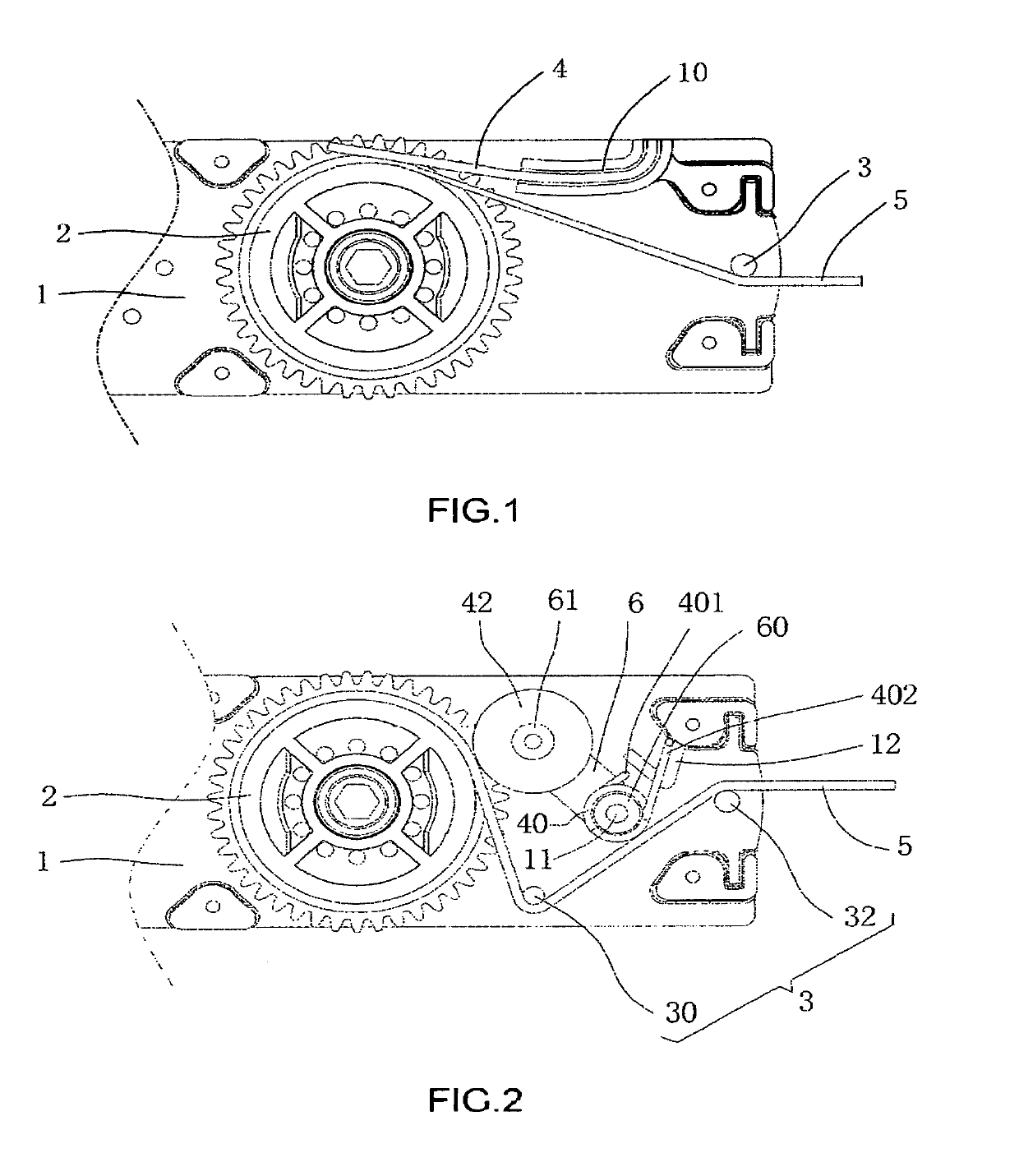

Filament winding apparatus

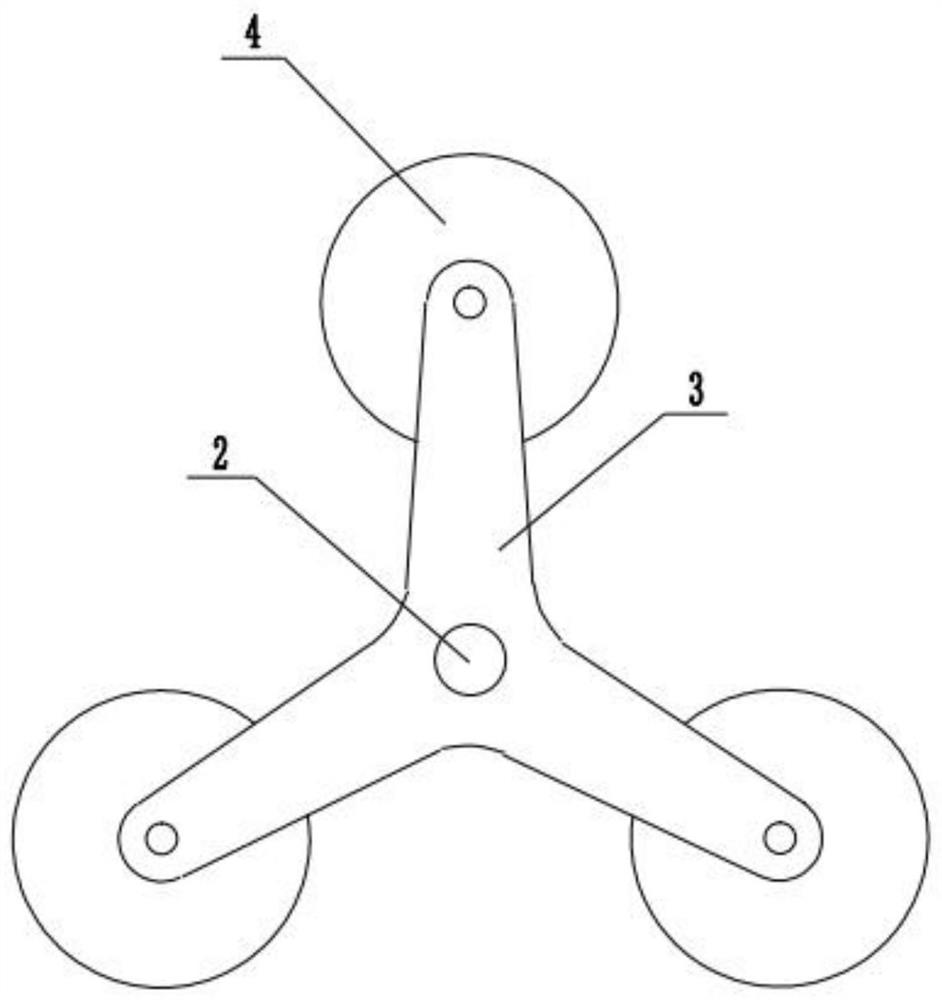

ActiveUS7815141B2Efficient executionWinding orderlyFilament handlingCoils manufactureFiber bundleReciprocating motion

A filament winding apparatus that efficiently and orderly winds a fiber bundle with respect to a mandrel in a short period of time. A supporting board supports the mandrel, and a helical winding head supplies and guides the fiber bundle towards the mandrel. The helical winding head includes a group of guide tubes radially arranged on a circumferential surface of a guide ring, and a tube operation mechanism that reciprocates the guide tube along a tube axis center direction. The guide tube is moved closer to a circumferential surface of the dome part when the guide tube is facing a dome part of the mandrel such that the distance between the winding position of the fiber bundle and the guide tube at the dome part can be reduced, and the fiber bundle is orderly wound according to an appropriate winding trajectory.

Owner:MURATA MASCH LTD

Filament Winding Apparatus

ActiveUS20090127373A1Quality improvementReduce distanceFilament handlingCoils manufactureFiber bundleReciprocating motion

A filament winding apparatus that efficiently and orderly winds a fiber bundle with respect to a mandrel in a short period of time. A supporting board supports the mandrel, and a helical winding head supplies and guides the fiber bundle towards the mandrel. The helical winding head includes a group of guide tubes radially arranged on a circumferential surface of a guide ring, and a tube operation mechanism that reciprocates the guide tube along a tube axis center direction. The guide tube is moved closer to a circumferential surface of the dome part when the guide tube is facing a dome part of the mandrel such that the distance between the winding position of the fiber bundle and the guide tube at the dome part can be reduced, and the fiber bundle is orderly wound according to an appropriate winding trajectory.

Owner:MURATA MASCH LTD

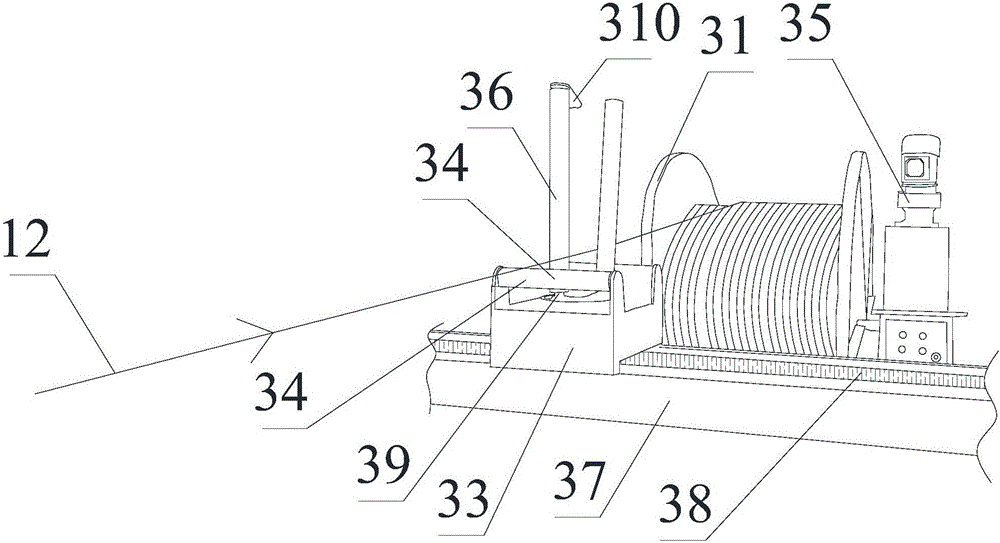

Self-rope-arranging winch

The invention discloses a self-rope-arranging winch. The self-rope-arranging winch comprises a winding drum, a motor and a base. The motor is connected with a speed reducer, and the winding drum is installed on the base. The speed reducer is connected with a winding drum shaft of the winding drum to drive the winding drum to rotate. The self-rope-arranging winch further comprises pulleys. The pulleys move in the axial direction of the winding drum and further comprises a rope guide wheel. Steel wire ropes are unwound from the winding drum and are arranged by the rope guide wheel after bypassing the pulleys. By arranging the pulleys and the rope guide wheel, the horizontal installation, ceiling installation and vertical installation of the self-rope-arranging winch can be realized on the basis of the fixed and unified rope output direction without affecting the rope output direction, the use is convenient, the steel wire ropes can be orderly wound around the winding drum, and the synchronous lifting of all lifting points can be ensured.

Owner:江苏中惠舞台设备技术有限公司

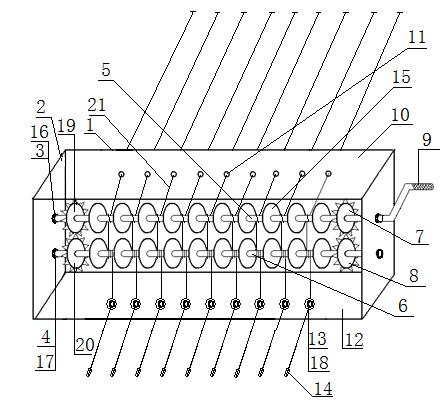

Sintering furnace for preparing continuous fiber made form zirconia

InactiveCN1601213AGood effectHigh molecular weightMuffle furnacesInorganic material artificial filamentsFiberMaterials science

The invention is a method and device of preparing high-performance continuous cobalt oxide fiber, including: using acetylacetone and cobalt oxide as main raw materials to synthesize a precursor cobalt acetyl-acetonate polymer, dissolving the precursor in methanol to obtain spinning solution, using dry-spinning to obtain continuous precursor fiber, making thermal processing of sintering to obtain continuous cobalt oxide fiber, adopting special atmosphere thermal processing process on the precursor fiber, and blowing air flow to the continuous cobalt oxide fiber at high temperature so as to strengthen the fiber extensibility. The thermal processing is made in a functional sintering furnace which contains inner pipe, outer pipe, and heater wire coiled on the outer pipe, and at the time of aerating, the air flow can be radiantly blown out through a fine slit in the inner pipe. The process of the invention is simple and easy to operate, able to prepare smooth and uniform continuous cobalt oxide fiber with tensile strength over 2.6 Gpa and length able to be several kilometers.

Owner:绍兴市圣诺超高温晶体纤维材料有限公司

Multi-hoist-point single-layer winding winch with deflecting pulley

ActiveCN105439021AGuaranteed to be verticalEliminate the danger of tangled ropesWinding mechanismsBlock and tackleEngineering

The invention discloses a multi-hoist-point single-layer winding winch with a deflecting pulley. A speed reduction motor is connected with a coiling block through a rolling spline pair, and a linear bearing sleeve is connected with the coiling block through a right shaft stretching assembly. A plurality of sections of rope grooves on which steel wire ropes is wound are formed in the surface of the coiling block in the axial direction. Coiling block supporting wheel assemblies are fixedly installed at the upper portions of the parts, below all the sections of rope grooves, of a base, and the coiling block supporting wheel assemblies are connected with the coiling block to form a spiral sliding block pair. A rope blocking rod is arranged between a left side plate and a right side plate in front of the coiling block, and provided with a rope blocking sleeve assembly. A pulley set is arranged at the front portion of the base in the axial direction of the coiling block. The steel wire ropes are connected to the pulley set from the front of the coiling block in the spiral tangent line direction of the coiling block rope grooves and then turned to be in the horizontal direction to be led out of the winch. The multi-hoist-point single-layer winding winch is safe, reliable, small in size and simple in structure, the danger of disorderly rope winding on the coiling block is effectively eradicated, and the requirement for installing stage electric hanging rod systems in the space with the insufficient height or entertainment places without fly galleries can be met.

Owner:ZHEJIANG SCI-TECH UNIV

Electrocardiograph lead storage device

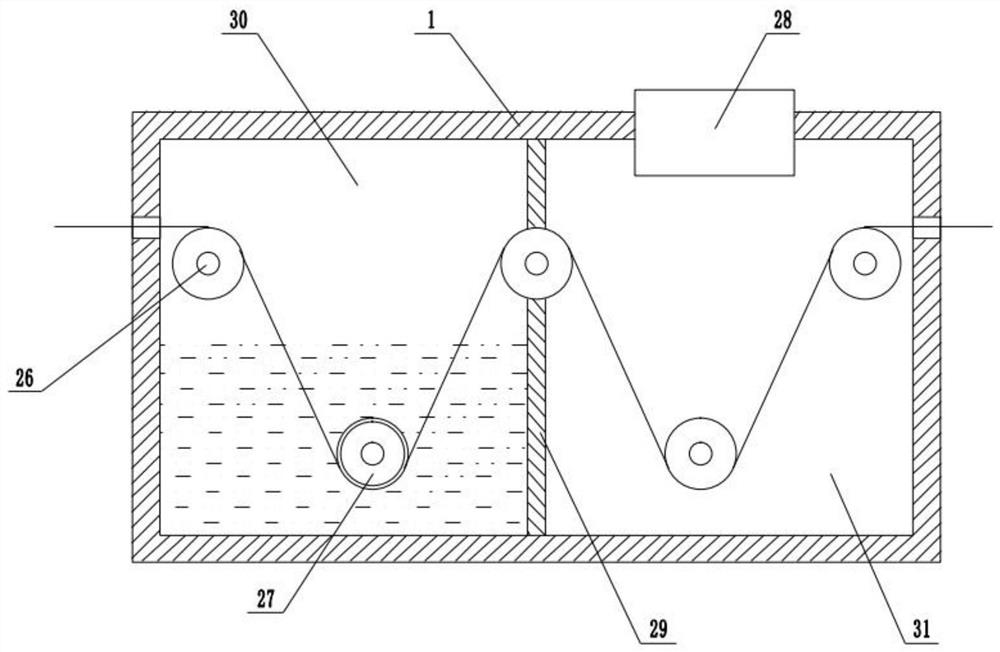

InactiveCN102551702AStorage is easy and convenientSimple structureDiagnostic recording/measuringSensorsElectrocardiograph leadDrive shaft

The invention relates to an electrocardiograph lead storage device. A driving shaft hole (3) and a driven shaft hole (4) are respectively arranged on two opposite side walls (2) of a box (1), a driving shaft (5) penetrates into the driving shaft hole (3), a driven shaft (6) penetrates into the driven shaft hole (4), a driving gear (7) is fixed on the driving shaft (5), a driven gear (8) is fixed on the driven shaft (6), the driving gear (7) and the driven gear (8) are identical and are meshed mutually, a crank (9) is disposed at one end of the driving shaft (5), lead guiding holes (11) are arranged on a front wall (10) of the box (1), lead outlet holes (13) are arranged on a rear wall (12) of the box (1), one end of each lead (21) is wound on the driving shaft (5) after penetrating into the box (1) via the corresponding lead guiding hole (11), continues being reversely wound on the driven shaft (6), and then penetrates out via the corresponding lead outlet hole (13), and a wiring terminal (14) is arranged at an end of each lead.

Owner:莱芜钢铁集团有限公司医院

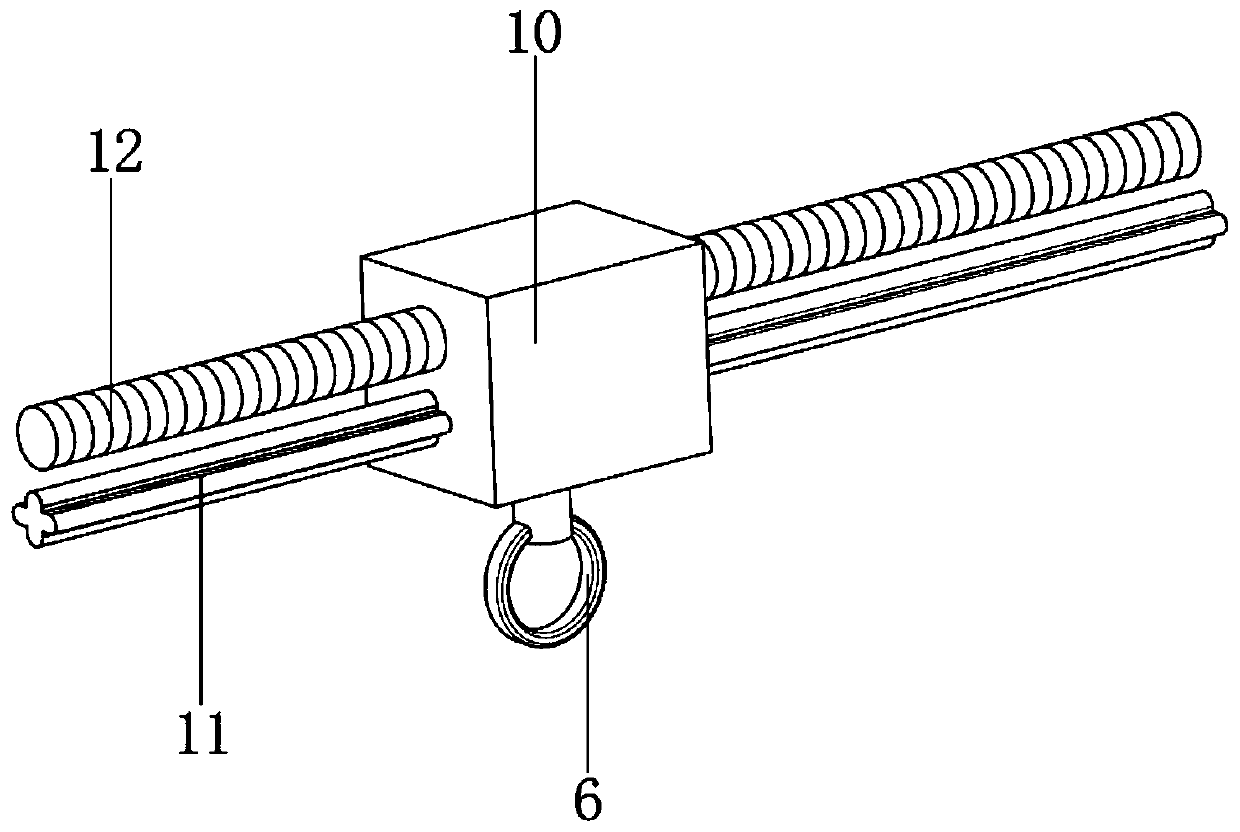

Cable winding device

The invention discloses a cable winding device which comprises a bracket, a winding rod, a guide component and a driving component, wherein a thread hole is formed in the bracket; the winding rod is provided with a rotating thread matched with the thread hole; the winding rod is arranged in the thread hole through the rotating thread, so that the winding rod can move relative to the bracket along the axial direction of the winding rod when winding a cable; the guide component is arranged on the bracket to limit side movement of the cable when the cable is wound; the driving component is connected with the winding rod and is used for driving the winding rod to rotate. According to the cable winding device, the driving component is used for driving the winding rod to wind the cable, so that the efficiency is higher; manual winding by a laboratory technician is not needed; fatigue of the laboratory technician and superposition of the cable which are caused by the manual winding are avoided.

Owner:OCEANKING DONGGUAN LIGHTING TECH +2

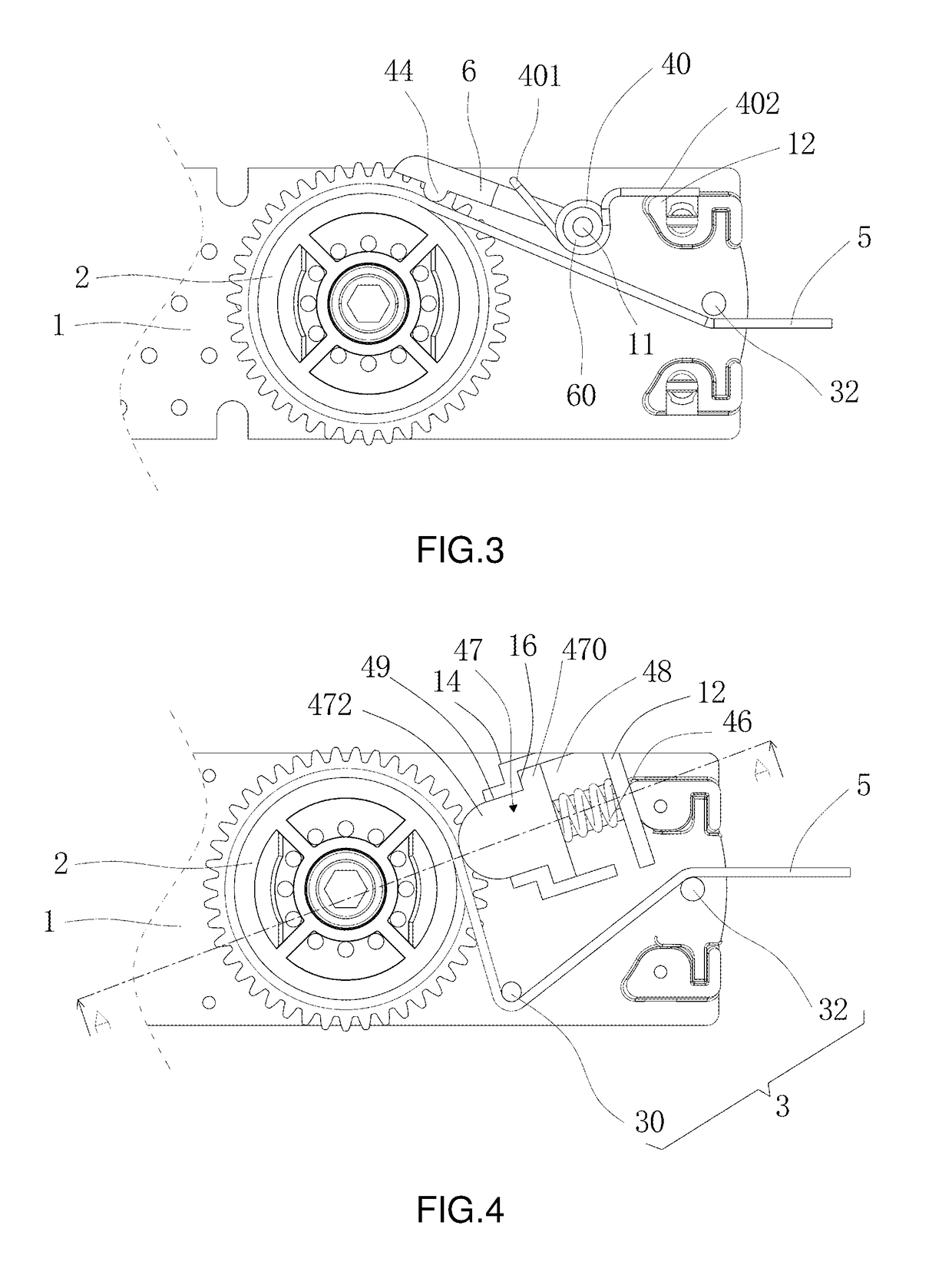

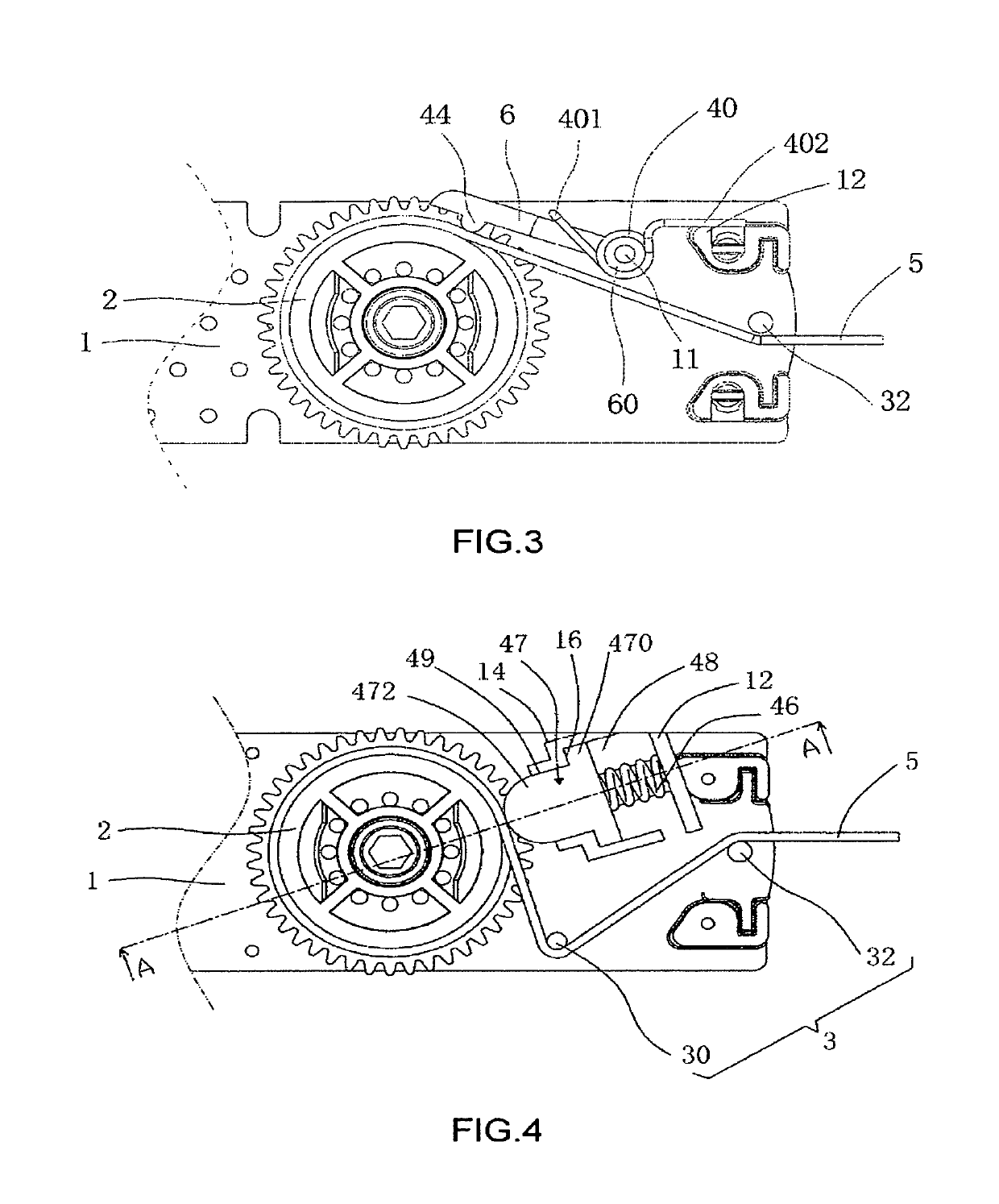

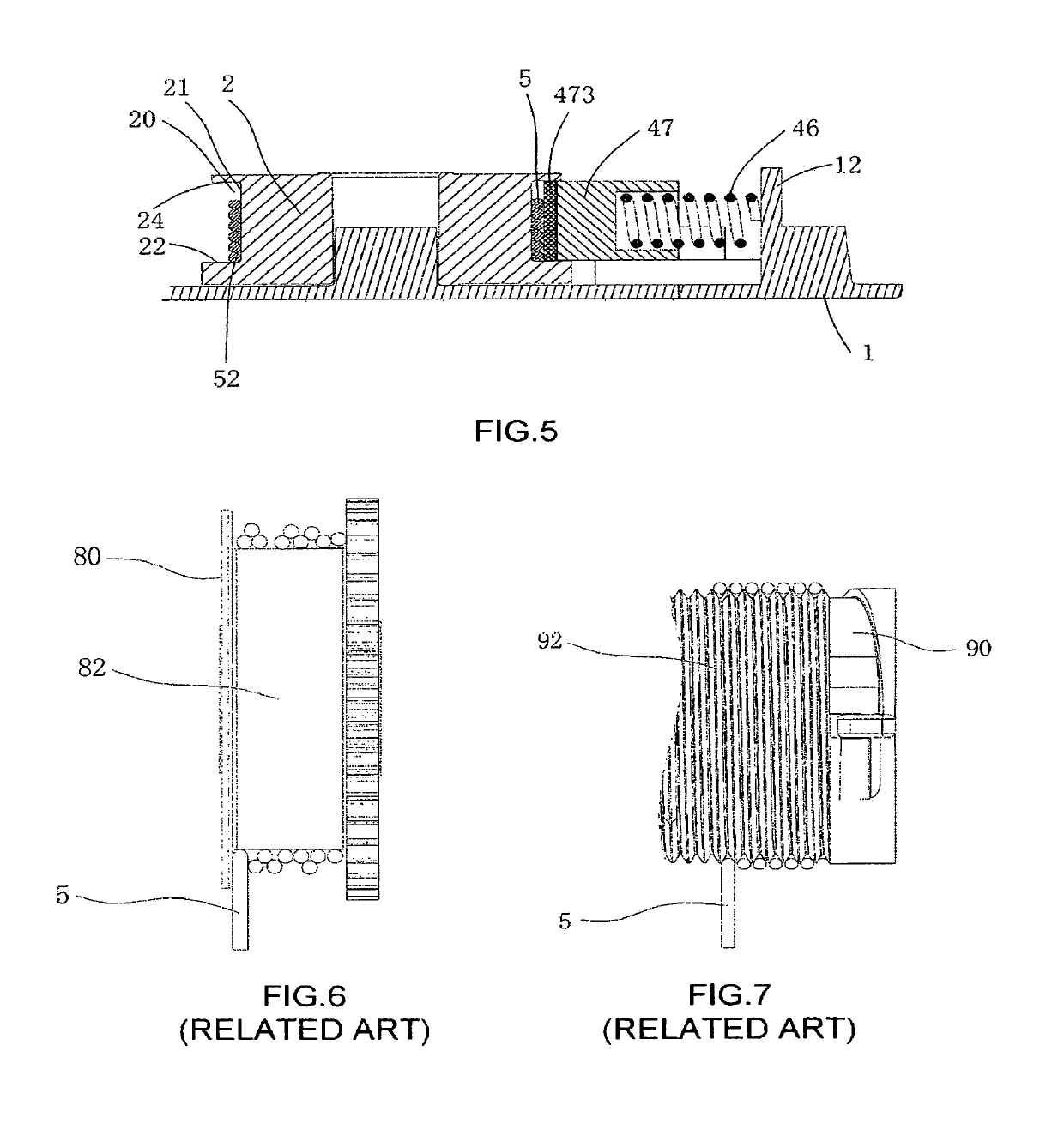

Cord winding mechanism for a cordless window blind

ActiveUS20170145743A1Winding orderlyLight protection screensConductor CoilElectrical and Electronics engineering

A cord winding mechanism for a blind cord with a first end fixed to a window blind includes a base, a cord winder rotatably mounted to the base, a cord guiding assembly mounted to the base, and an elastic press member mounted to the base. The cord winder defines an annular slot to wind the blind cord layer by layer. The cord guiding assembly is abutted against an unwound portion of the blind cord between the cord winder and the window blind. A second end of the blind cord is fixed to an end of the cord winder in the slot. The press member is elastically abutted against a portion of the blind cord just separate from the cord winder.

Owner:LEI ZHENBANG +1

Cable processing winding machine

The invention discloses a cable processing winding machine. The cable processing winding machine comprises a base, wherein brake wheels are fixedly installed at the four corners of the bottom of the base, the two sides of the top of the base are respectively and fixedly provided with a first side supporting plate and a second side supporting plate which are vertically arranged, and the opposite sides of the first side supporting plate and the second side supporting plate are rotationally connected with the same winding roller through bearings; the sides, close to the second side supporting plate, of the base is provided with a driving mechanism, and the side, close to one side of the first side supporting plate, of the base is fixedly provided with a stand column; and the top end of the stand column and the top end of the first side supporting plate are fixedly provided with the same mounting plate, the mounting plate is provided with a reciprocating moving mechanism, and the reciprocating moving mechanism comprises a forward and reverse rotating motor fixedly mounted on the mounting plate. Under the control of a controller, by controlling the operation direction of the forward andreverse rotation motor, a lead screw and a sliding rod are matched to drive a moving block to reciprocate back and forth, and a cable is driven to move back and forth through a sleeve ring, so that the winding of the cable is tidy and orderly, and the advantage of preventing cable knotting is acheived.

Owner:惠州市鑫弘诚电子科技有限公司

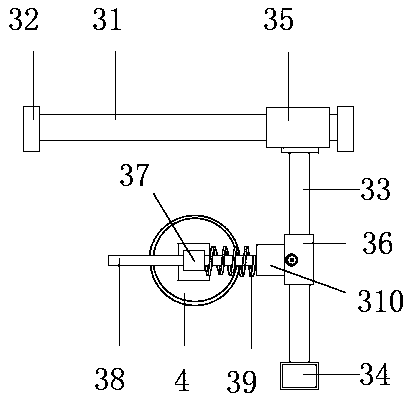

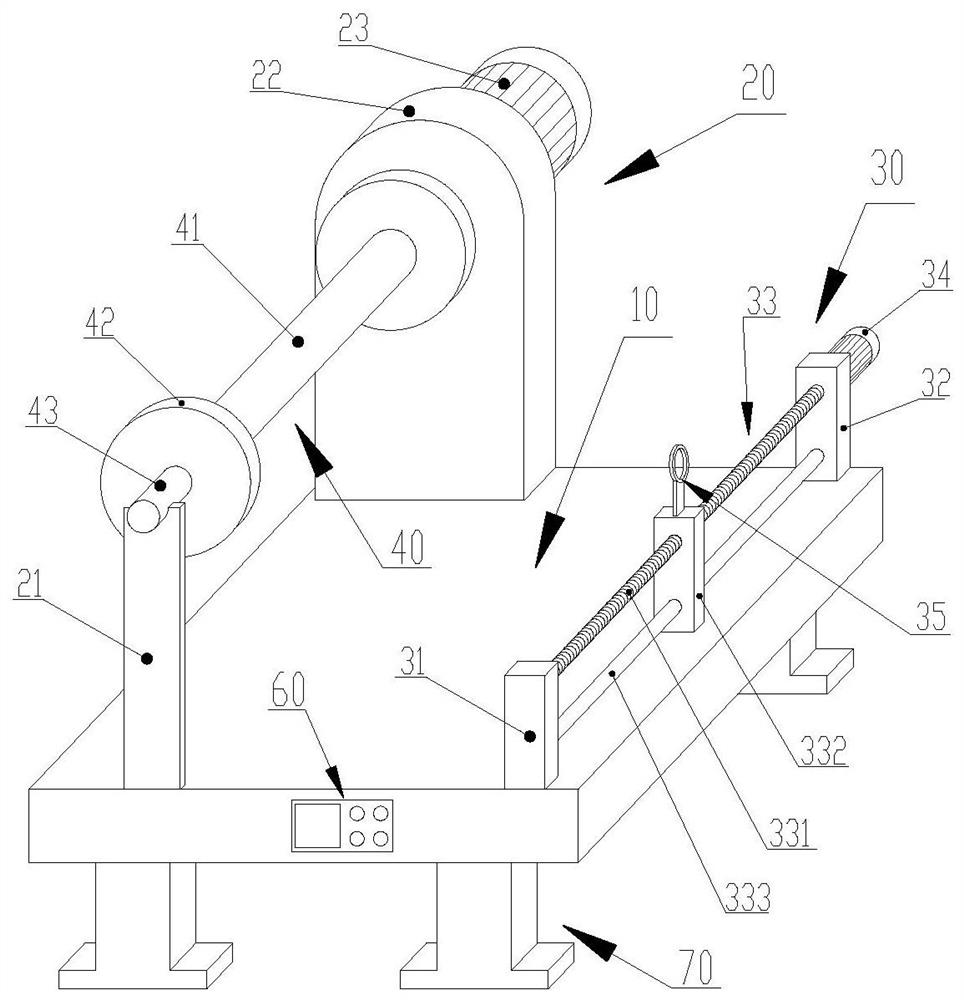

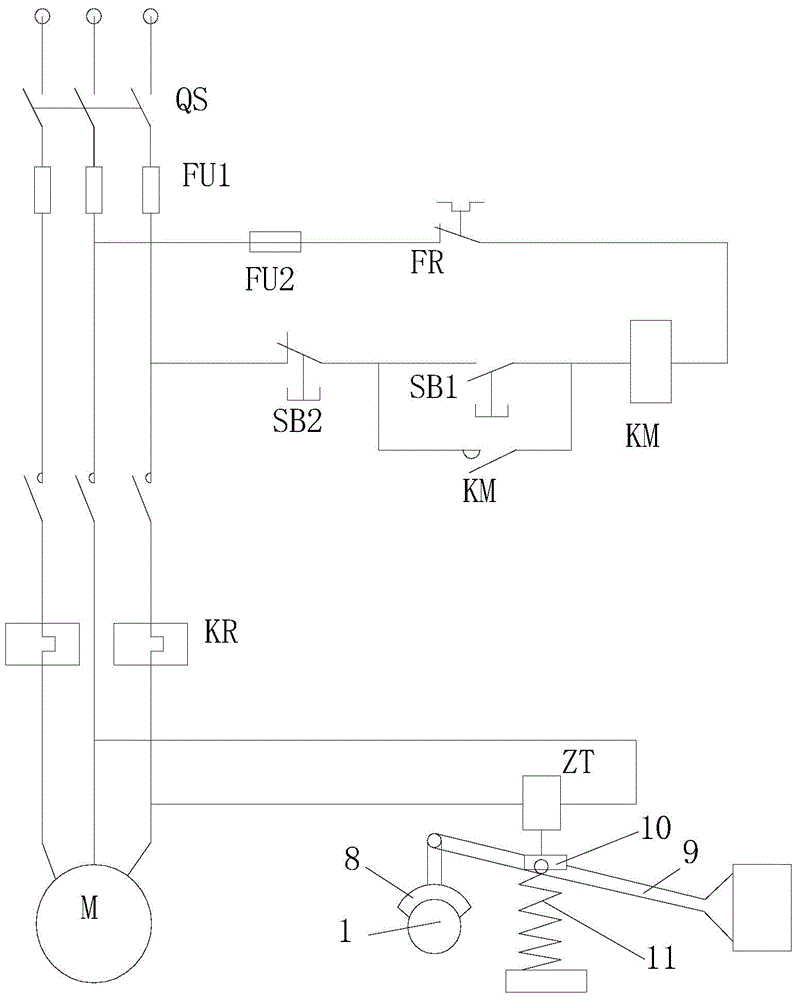

Auxiliary device of wire drawing machine

InactiveCN105084110APrevent improper adjustmentSimple structureFilament handlingEngineeringConductor Coil

The invention discloses an auxiliary device of a wire drawing machine. The auxiliary device comprises a take-up tension adjusting mechanism and a creel stand. The take-up tension adjusting mechanism is used for adjusting take-up tension when a cable is wound. The creel stand guides the to-be-wound cable to be wound on a wire winding frame. The take-up tension adjusting mechanism comprises a transmission wheel, a fixed wheel, a movable wheel, a first rack and an adjusting assembly. A center shaft of the transmission wheel and a center shaft of the fixed wheel are both fixed to the first rack. The transmission wheel and the fixed wheel rotate relative to the first frame. The movable wheel is movably installed on the first rack through the adjusting assembly and can move relative to the first rack while rotating relative to the first rack. The circumferential end faces of the transmission wheel, the fixed wheel and the movable wheel are all provided with annular grooves. The number of the annular grooves in the fixed wheel and the number of the annular grooves in the movable wheel are both larger than one. The annular grooves and the corresponding wheels are coaxially arranged. According to the design of the auxiliary device, a preset interval is kept between the fixed wheel and the movable wheel through an adjusting assembly, and therefore the auxiliary device will not be fatigue even after being used for a long time, and the auxiliary device is simple in structure.

Owner:ANQING SUN & MOON CABLE

Wire take-up device for electric power

InactiveCN107804746AComplete reelWinding orderlyFilament handlingElectric power systemArchitectural engineering

The invention discloses a wire take-up device for electric power, comprising a motor, a wire take-up turntable, a first support column, a second support column and a base, the first support column and the second support column are fixed above the base, the The upper end of the second supporting column is equipped with a rotating shaft through a bearing, and the rotating shaft runs through the second supporting column. One end of the rotating shaft is equipped with a take-up turntable, and the two ends of the take-up turntable are respectively fixed with a first limiting plate and a second The limit plate, the upper end of the first support column is respectively equipped with a first cylinder and a second cylinder, the output end of the second cylinder is equipped with a jaw, and the gap between the first support column and the second support column A fixed rod is fixed on the upper end, and a chute is provided on the side of the fixed rod, and a motor is fixed on the base on one side of the second support column. The wire take-up device for electric power of the present invention can keep winding orderly, is convenient for loading and unloading, reduces labor intensity, improves work efficiency, and is convenient to use.

Owner:李笑美

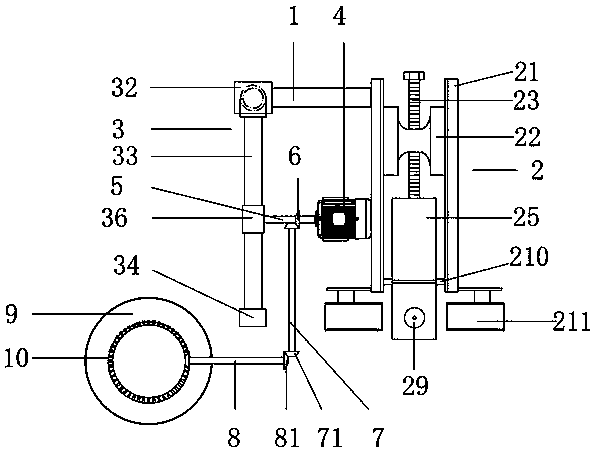

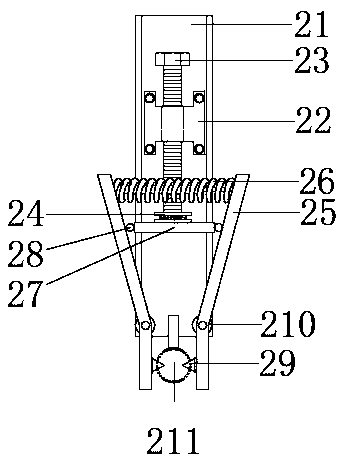

Rope pressing device for mining winch rope guider

InactiveCN105565195AExtended service lifeSimple production processWinding mechanismsEngineeringWinch

The invention discloses a rope pressing device for a mining winch rope guider. The rope pressing device for the mining winch rope guider includes a rectangular base plate; one end of the upper side of the rectangular base plate is fixedly provided with an H-shaped support through two installation plates; the upper end of the H-shaped support is rotatably connected to one end of an H-shaped press roller frame through a pin shaft, and the other end of the H-shaped press roller frame is rotatably provided with a press roller for pressing a steel wire rope on a winding drum through a press roller shaft; and a tension spring for applying pulling force on the H-shaped press roller frame is arranged between the H-shaped support and the H-shaped press roller frame. The rope pressing device for the mining winch rope guider has the advantages that: a design is reasonable, orderly winding can be achieved, rope loosening can be prevented, a structure is simple and compact, disassembly is simple, maintenance is easy, the service life is long, the application range is wide, the production cost is low, and the rope pressing device is easy to promote and use.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

Waste wire recovery device

InactiveCN110155802AMeet recycling needsRealize mechanized productionFilament handlingBasic electric elementsWorkloadConductor Coil

The invention discloses a waste wire recovery device which comprises a fixing support. One side of the fixing support is connected with a wire stripping mechanism, and one side, far away from the wirestripping mechanism, of the fixing support is connected with a wire swinging mechanism. The waste wire recovery device has the beneficial effects that 1, Due to the arrangement of the wire strippingmechanism, the outer skin of waste wires can be cut, the whole process is simple and efficient, mechanical production can be realized, the stripping efficiency is high, the practicability is strong, and the recovery requirement of the waste wires is met; and 2, the horizontal transverse back-and-forth movement of a No. 2 wire passing pipe is realized, the orderly winding on a winding drum during the recovery of the waste wires is ensured, rope skipping is avoided, the packaging efficiency of the waste wires is increased, the adopted mechanism is simple in structure, high in efficiency and easyto maintain and maintain, the workload of workers can be reduced, and the recovery operation efficiency of the waste wires is greatly improved.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO LONGKOU POWER SUPPLY CO

Plastic packaging film winding roller

The invention relates to the technical field of plastic package production equipment, in particular to a plastic packaging film winding roller. The plastic packaging film winding roller comprises a roller body, wherein a rubber layer is arranged on the outer surface of the roller body; an accommodating groove is formed in the axial direction of the outer surface of the roller body; at least two clamping mechanisms used for clamping a packaging film are arranged in the accommodating groove; each clamping mechanism comprises a first clamping block connected to the bottom of the accommodating groove through a screw; a second clamping block is connected to each first clamping block through a screw; a clamping space used for clamping the packaging film is arranged between each first clamping block and the corresponding second clamping block. One end of the packaging film can be clamped between the first clamping blocks and the second clamping blocks through the matching between the first clamping blocks and the second clamping blocks, so that the packaging film can be easily wound on the roller body sequentially; meanwhile, due to the fact that the rubber layer is arranged on the outer surface of the roller body, the plastic packaging film can be protected.

Owner:常州小河水清包装材料厂

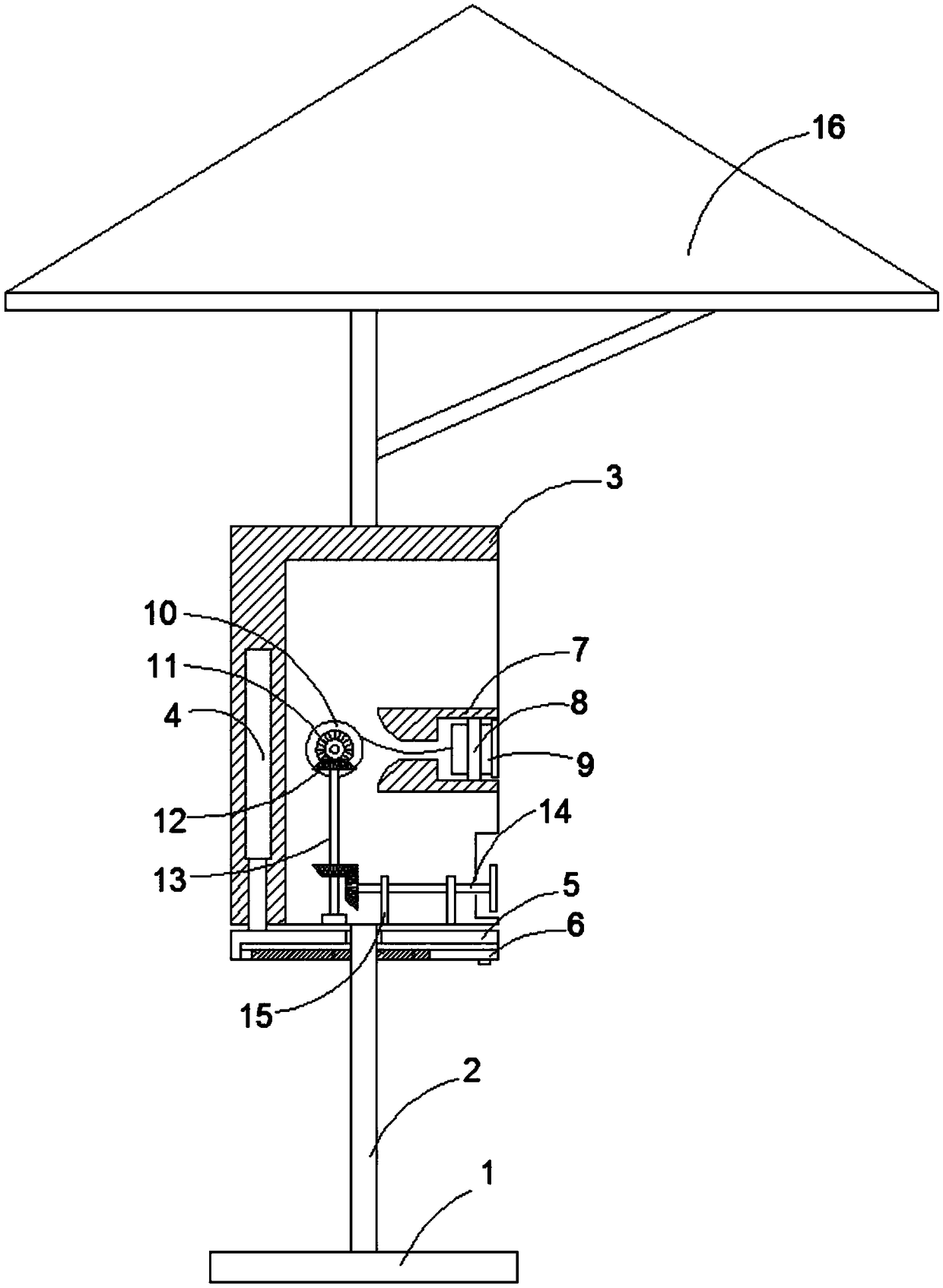

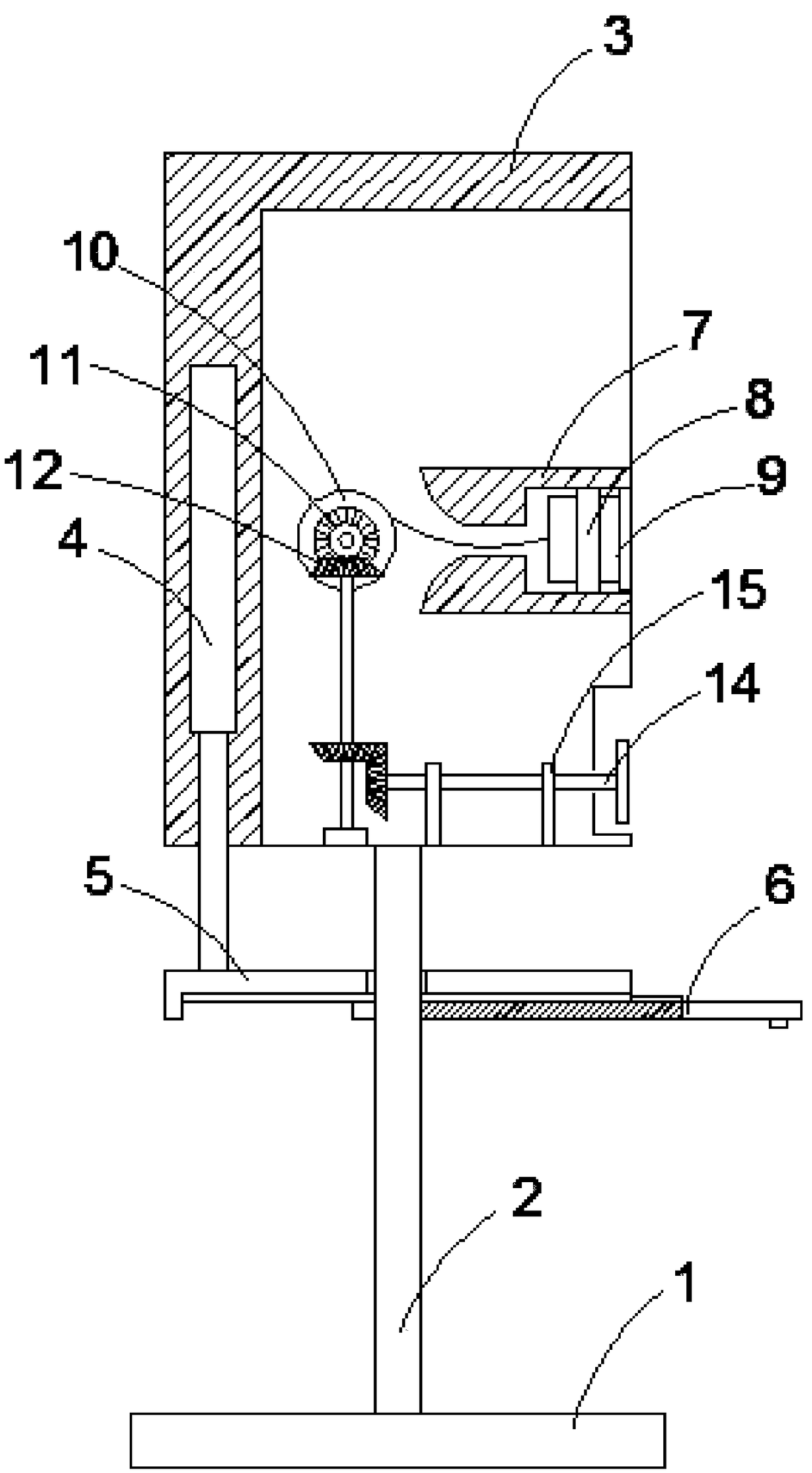

Electric vehicle charging pile with rainproof function

InactiveCN108556676AReduced service lifeFunction as a shelter from rainCharging stationsTents/canopiesShortest distanceFixed frame

The invention relates to the technical field of charging piles, in particular to an electric vehicle charging pile with a rainproof function. The electric vehicle charging pile with the rainproof function comprises a base, a supporting rod, a shell, a telescopic rod, a fixing board, a sliding board, a socket placement groove, a fixing frame, a socket, a winding reel, a longitudinal bevel gear, a transverse bevel gear, a rotating shaft, a rotating rod, a fixing rod and a rain shelter, wherein the supporting rod is arranged at the top end of the base, the shell is fixedly arranged at the top endof the supporting rod, the telescopic rod is arranged on the left side of the interior of the shell, the bottom end of the telescopic rod extends out of the shell and is fixedly connected with the fixing board, the sliding board is arranged at the bottom end of the fixing board, the socket placement groove is formed in the right side wall of the interior of the shell, and the fixing frame is arranged in the socket placement groove. The electric vehicle charging pile with the rainproof function is simple in structure and convenient to operate and has a rain sheltering function, meanwhile, an electric vehicle can be charged in long distance, and when the electric vehicle is charged in short distance, a placement board for charger placement can be provided, so that the phenomenon of hangingdragging of a charger in the charging process is prevented, and thus the electric vehicle charging pile with the rainproof function has very high practicability.

Owner:浙江盛安电力科技有限公司

Method and equipment of preparing high performance zirconium oxide continuous fiber

InactiveCN1206397CHigh molecular weightShorten molecular weight distribution rangeInorganic material artificial filamentsZirconium oxidesStructure and functionZirconium oxychloride

A preparation method and equipment for high-performance zirconia continuous fibers belong to the field of structural and functional fiber materials. Including using acetylacetone and zirconium oxychloride as the main raw materials to synthesize the precursor zirconium acetylacetonate polymer, dissolving it in methanol to obtain spinning solution, using dry spinning to obtain continuous precursor fiber, heat treatment and sintering to obtain continuous zirconia fiber , a special atmosphere heat treatment process is adopted for the precursor fiber, and the zirconia continuous fiber is blown by air at high temperature to make the fiber stretch and strengthen. The heat treatment is carried out in a multifunctional sintering furnace, which includes an inner tube, an outer tube, and a heating furnace wire wound on the outer tube. When ventilating, the airflow can be blown radially from the inner tube through small slits to the outside of the tube. The process of the invention is simple and easy, and the smooth and uniform zirconia continuous fiber can be prepared with a tensile strength exceeding 2.6 GPa and a continuous length of several kilometers.

Owner:绍兴市圣诺超高温晶体纤维材料有限公司

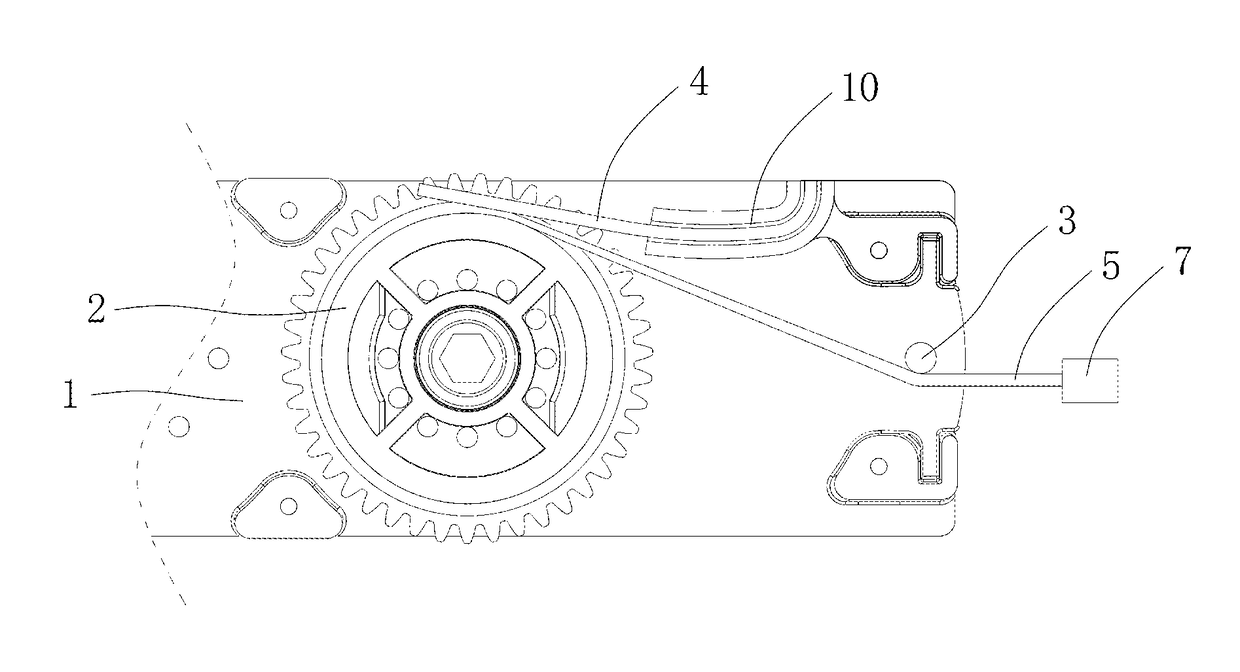

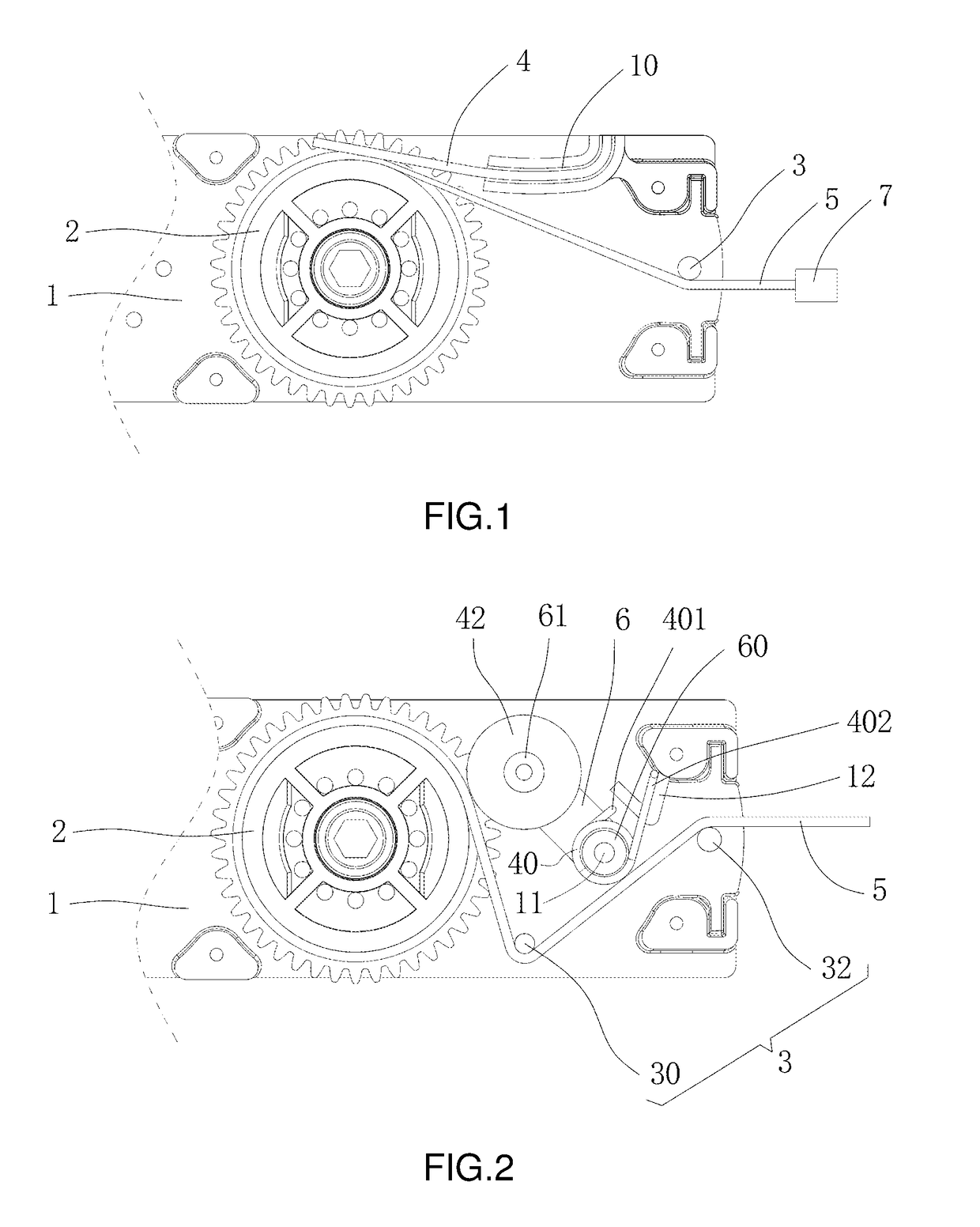

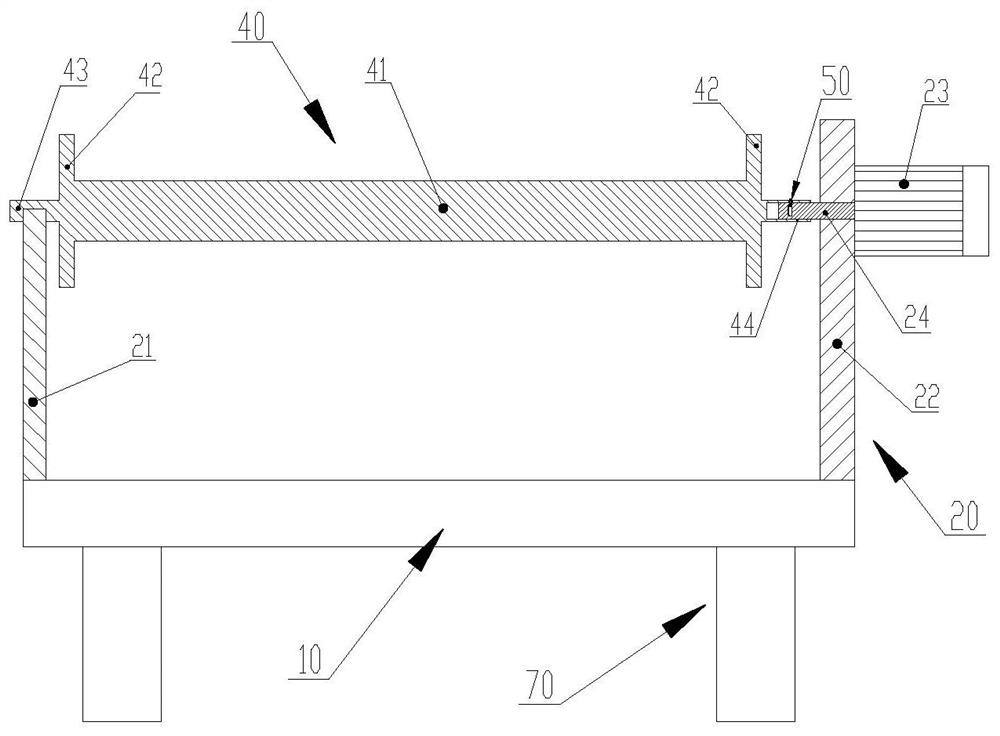

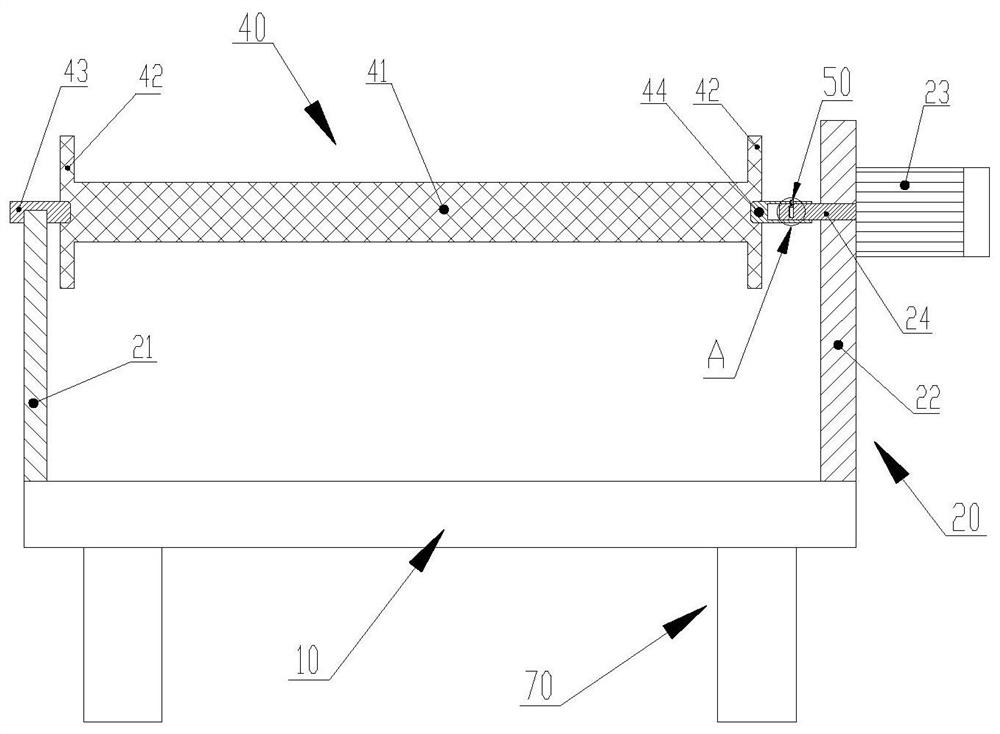

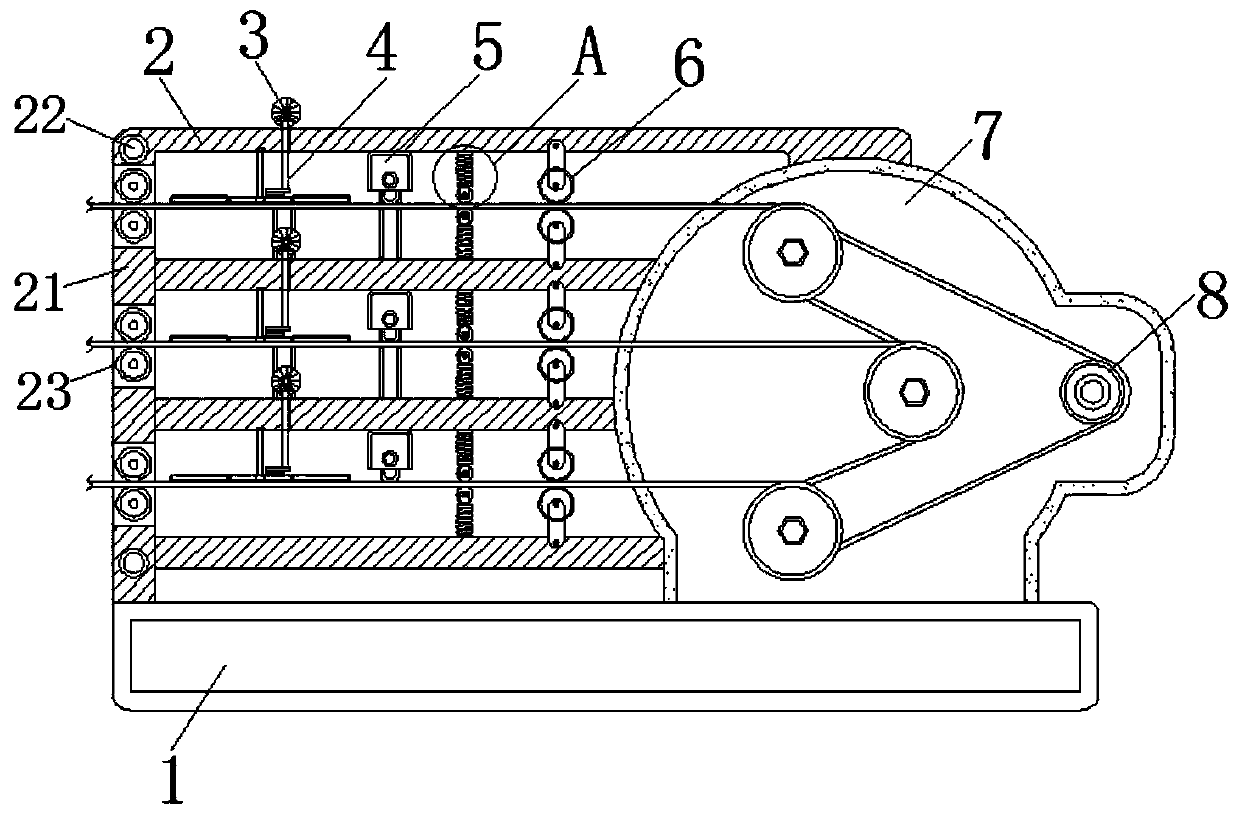

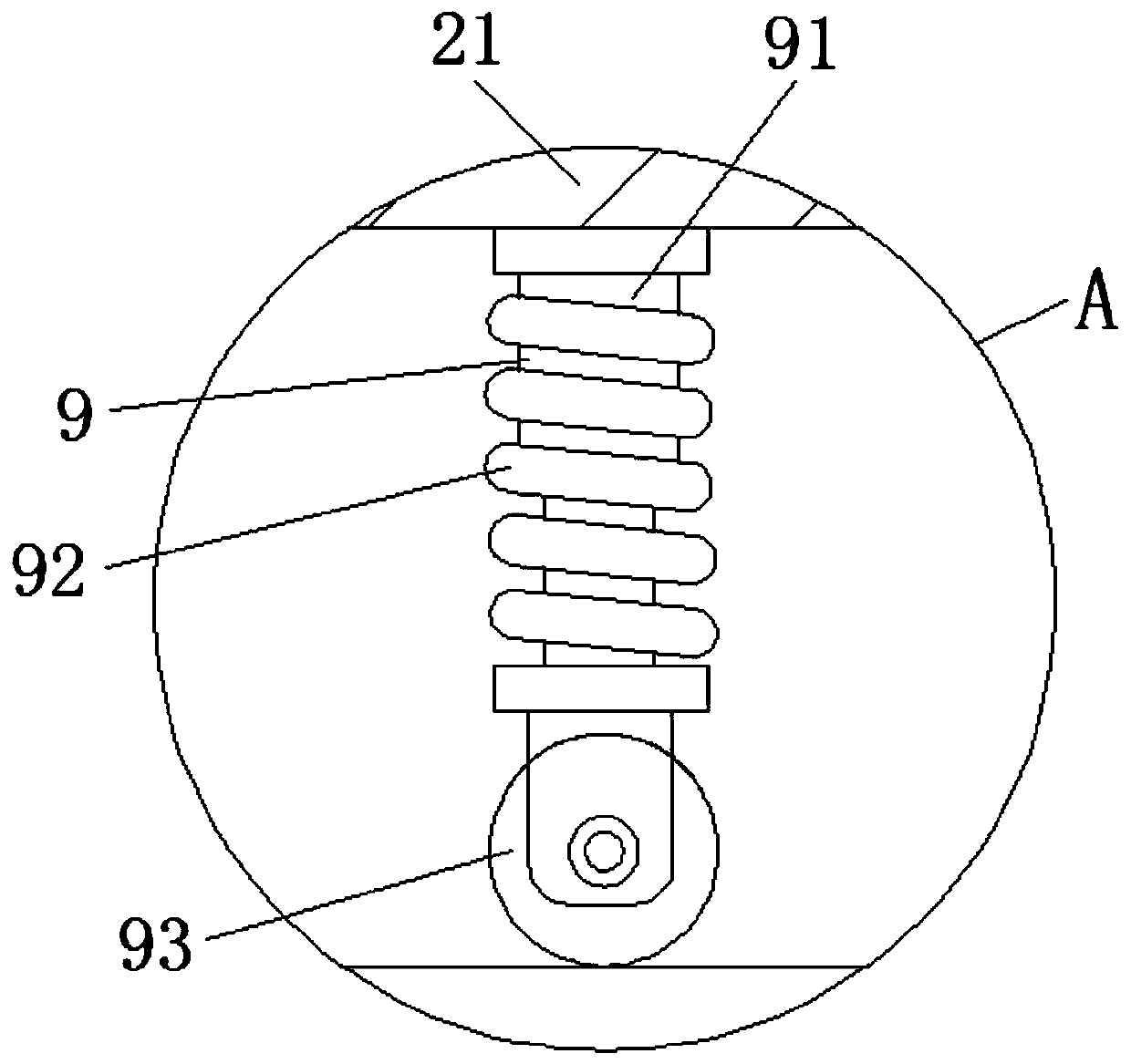

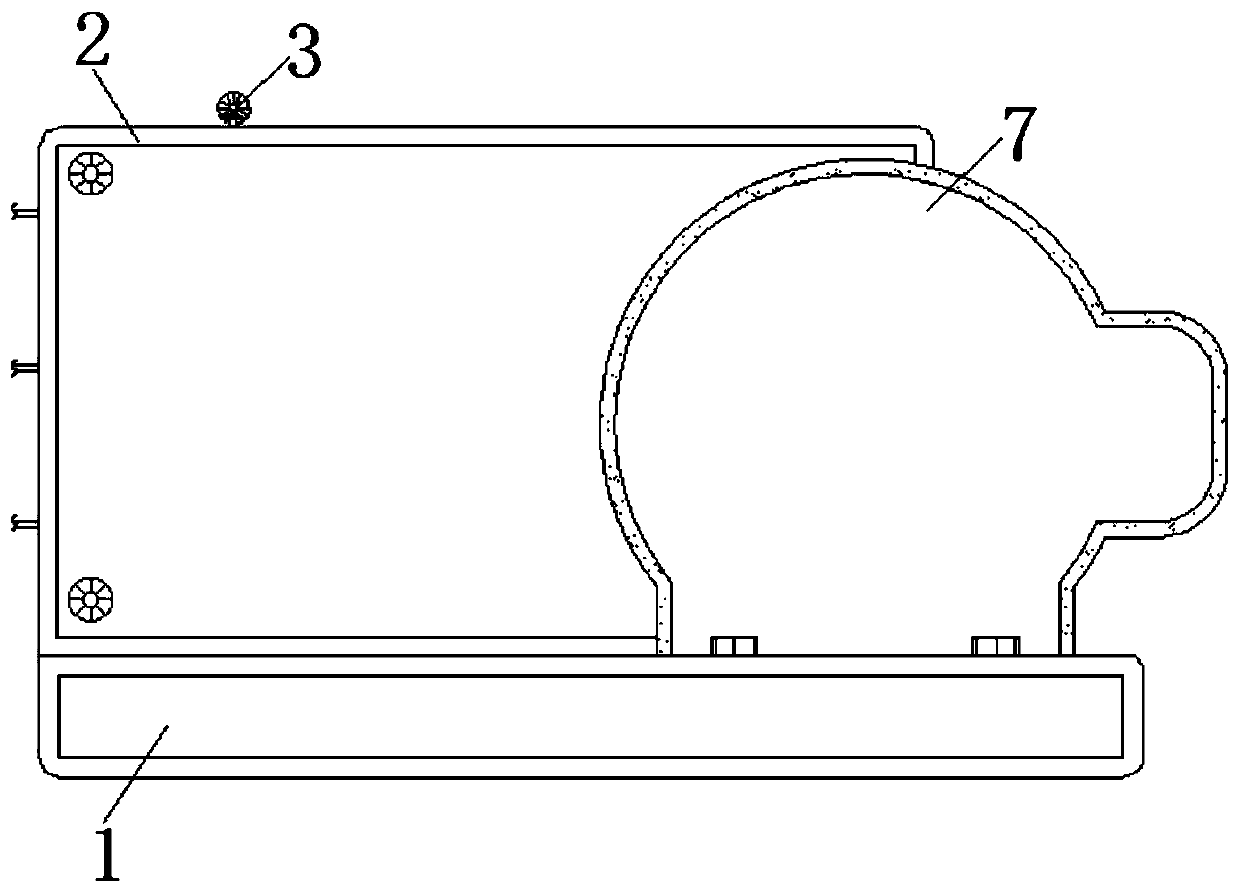

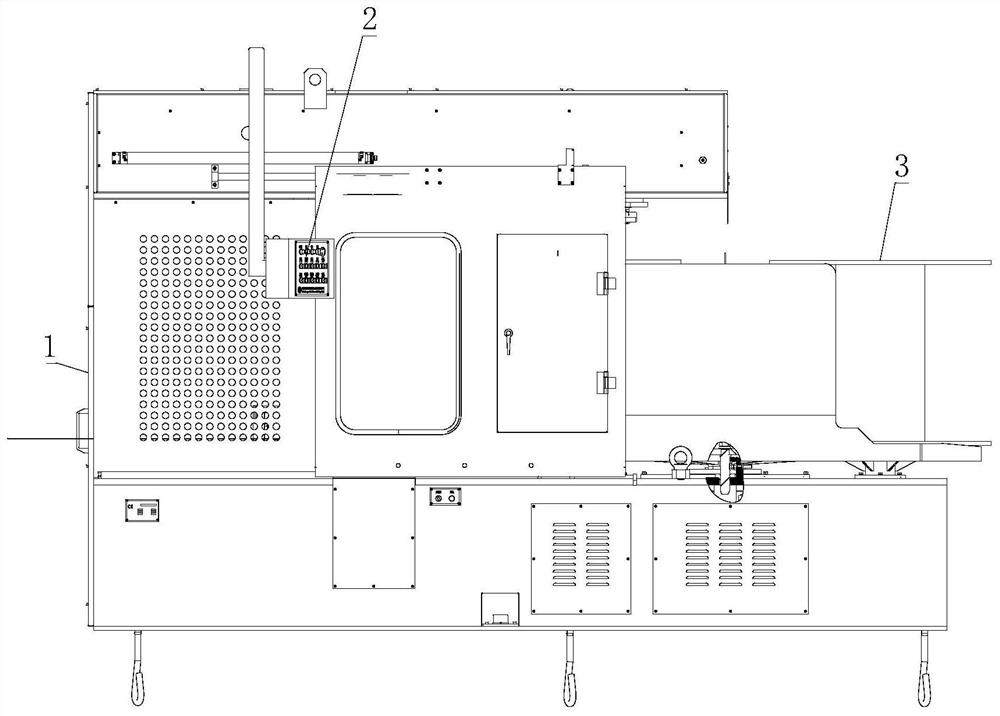

Winding machine and winding mechanism

The invention belongs to the technical field of annular inductance coil production equipment, and particularly relates to a winding machine and a winding mechanism. The winding mechanism comprises a wire hooking component by taking a swing arm cam mechanism as a main body, a winding component transmission device by taking an incomplete gear mechanism as a middle connecting component, a rotary winding device used for controlling a winding rotary clamping jaw through a cylindrical end face cam, and a servo motor group used for driving the three parts to operate. The servo motor group drives theincomplete gear mechanism to rotate and the swing arm mechanism to operate, so that the winding rotary clamping jaw component and the wire hooking crochet hook respectively perform intermittent rotating winding motion and variable-speed crochet hook reciprocating motion, and further complex combined motion conforming to a crochet hook type winding production process is formed, high-speed interpenetration matching of wire hooking and winding is achieved, the annular iron core is quickly and orderly hooked and wound, and the production efficiency and the stability of equipment are greatly improved.

Owner:何子全

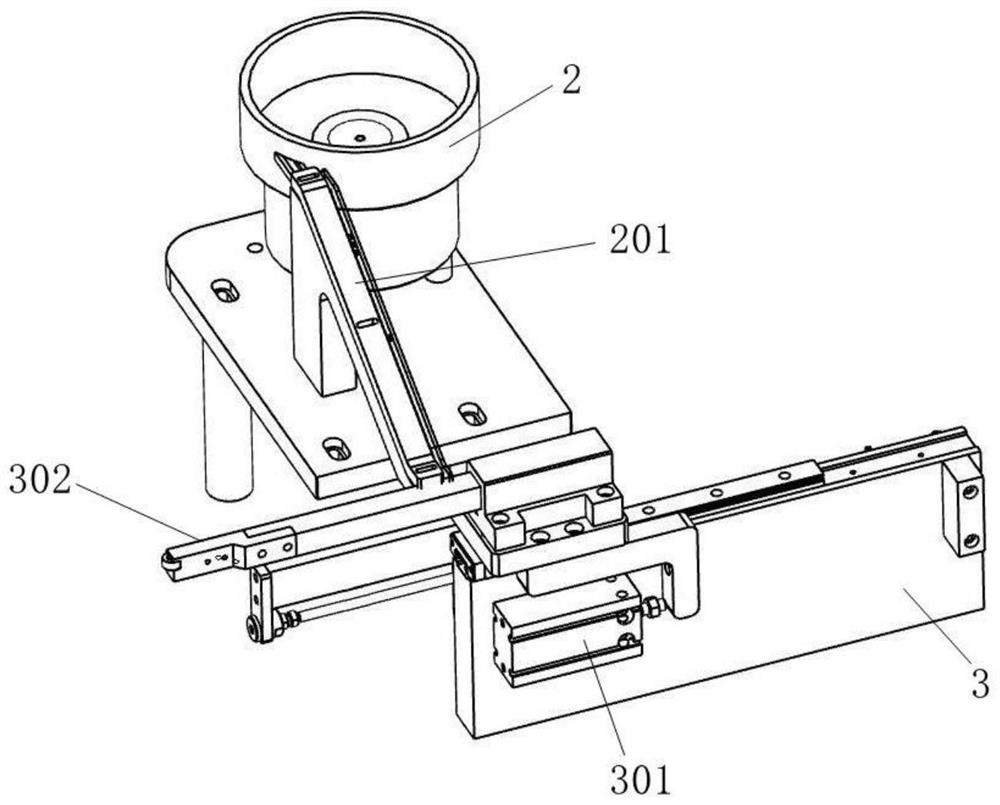

Cable winding device and application method thereof

The invention discloses a cable winding device and an application method thereof. The cable winding device comprises a workbench, a cable winding component, a cable adjusting component and a cable winding roller, wherein the cable winding component and the cable adjusting component are arranged at the two sides of the same face of the workbench correspondingly; the cable winding component comprises a first roller shaft support, a second roller shaft support and a cable winding motor, and a driving shaft is further arranged on the second roller shaft support; the cable winding motor drives thedriving shaft to rotate and further drives the cable winding roller erected on the first roller shaft support and the second roller shaft support to rotate in order to wind a cable; and the cable adjusting component comprises a first adjusting support, a second adjusting support, a lead screw and a cable adjusting motor, the cable adjusting motor drives a screw to rotate, a lantern ring is arranged at the top of a nut, and the lantern ring reciprocates between the first adjusting support and the second adjusting support along with the nut when the screw rotates, so that the cable penetrating through the lantern ring can be evenly wound on the cable winding roller. According to the cable winding device and the application method thereof, the winding and stacking problems existing for a longtime in the cable winding process are thoroughly solved.

Owner:MCC5 GROUP CORP SHANGHAI

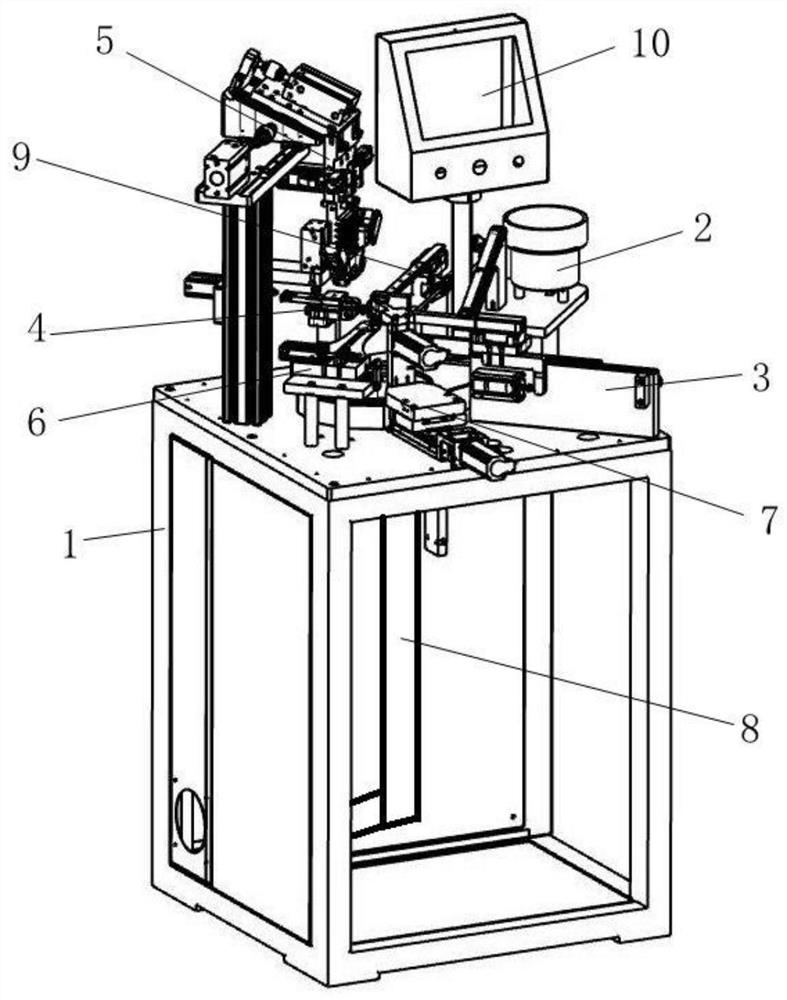

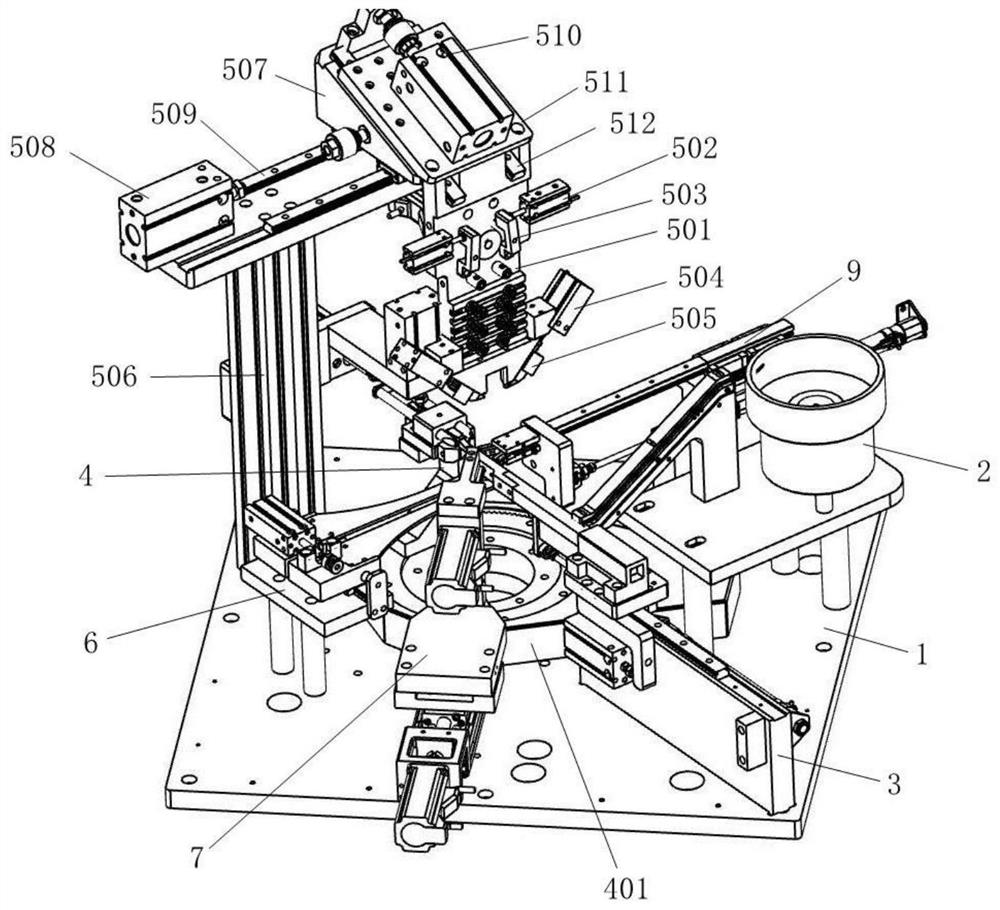

Multi-wire winding method and winding machine

ActiveCN112992525ARealize orderly supply lineWinding orderlyCoils manufactureWinding machineEngineering

The invention relates to a multi-wire winding method. When wires are wound, a rotating disc rotates by a constant angle, the winding starting points of different wires are staggered, it is guaranteed that the different wires are sequentially wound on an iron core in order, the positions of the different wires are determined, and the problem of dislocation or partial overlapping cannot occur. The invention also designs a winding machine for winding two wires, which comprises a rack, and a loading module, a rotary clamping module, a wire feeding module, a wire hooking module and a wire end rotating module which are arranged on the rack, so that the two wires are preferably wound in sequence. According to the multi-wire winding method, a plurality of wires can be sequentially wound on the same iron core in order, the problem that a previous wire and a next wire are partially staggered or partially overlapped is solved, the winding machine can be used for winding two wires, and the problem that the previous wire and the next wire are partially staggered or partially overlapped is solved.

Owner:广东成蔚电子科技有限公司

Vamp cloth rolling device of anti-deviation structure for production of cotton shoes

ActiveCN111422667AAvoid offsetTight windingMechanical cleaningPressure cleaningMechanical engineeringIndustrial engineering

Owner:RUIAN DAHU SHOES IND CO LTD

Manufacturing method of self-reset cable winding device

The invention discloses a manufacturing method of a self-reset cable winding device, relating to a manufacturing technology of a fixing and twisting mechanism for cables and leads of limited angle rotation such as the orientation, pitching and polaxis, and the like of an antenna pedestal in the field of a radar antenna. The winding device consists of a rotary back shaft assembly, a cable supporting component, a tip cable supporting component, a stopping rotation deflector rod, a fixed sliding chute component, a spring, a wire cable, a cable holder, cables, a limit switch and other parts. The method winds and resets the cables and leads by adopting the principle that the rotary back shaft assembly arranged on a rotary revolving table is taken as a rotary back shaft and sequential rotation is conducted by combining N cable supporting components sheathed on the rotary back shaft assembly and the tip cable supporting component under the actions of the spring and the wire cable. The method has the advantages of simple structure, low manufacturing cost, controllable rotation angle, safe and reliable performance and the like, and is especially applicable to the cable winding device in the radar antenna where the rotating axle of the radar does overturning rotation with the carrier of the radar.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Intelligent take-up device for power construction

The invention relates to the technical field of power construction and discloses an intelligent take-up device for power construction. The intelligent take-up device for power construction comprises abottom box, wherein fixed shafts are mounted on two sides of the bottom box, a rotary rack is rotatably connected to the end, far away from the bottom box, of the fixed shaft, a walking wheel is rotatably connected to an edge position of the rotary rack, supporting columns are mounted on two sides of the upper end of the bottom box, a driving shaft is mounted between the top ends of the supporting columns, a winding barrel is mounted in the middle of the driving shaft, a driven shaft is mounted between the lower ends of the supporting columns, the rotary drum is mounted in the middle of the driven shat, a rotary groove is formed in the outer side of the rotary drum, a sliding ball is slidably arranged in the rotary groove, a sliding rack is mounted at the upper end of the sliding ball, and the upper end of the sliding rack penetrating through a limiting plate fixed between the middle portions of the supporting columns is connected to a threading ring. According to the intelligent take-up device for power construction, cables are wound orderly when being taken without a malposition phenomenon. Meanwhile, a cleaning cavity and a drying cavity are formed, so that the cable can be cleaned effectively before being taken, and therefore, the take-up quality is further improved.

Owner:闫永贵

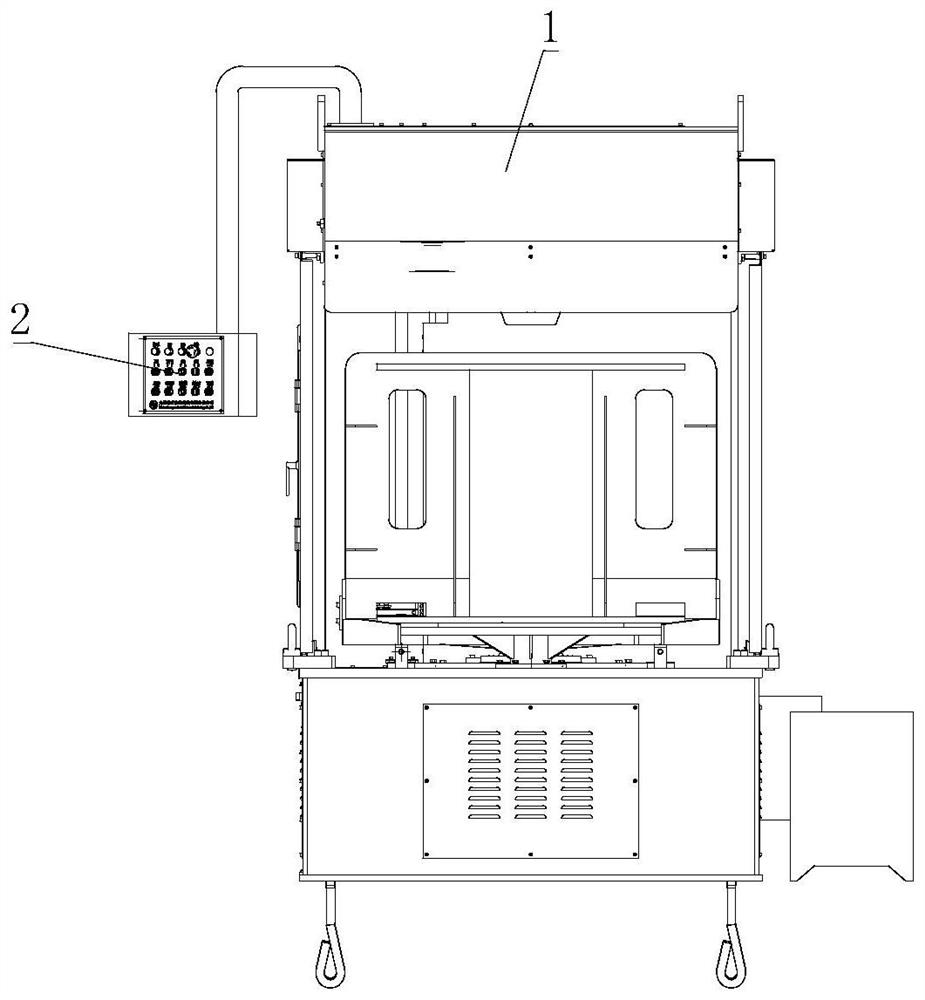

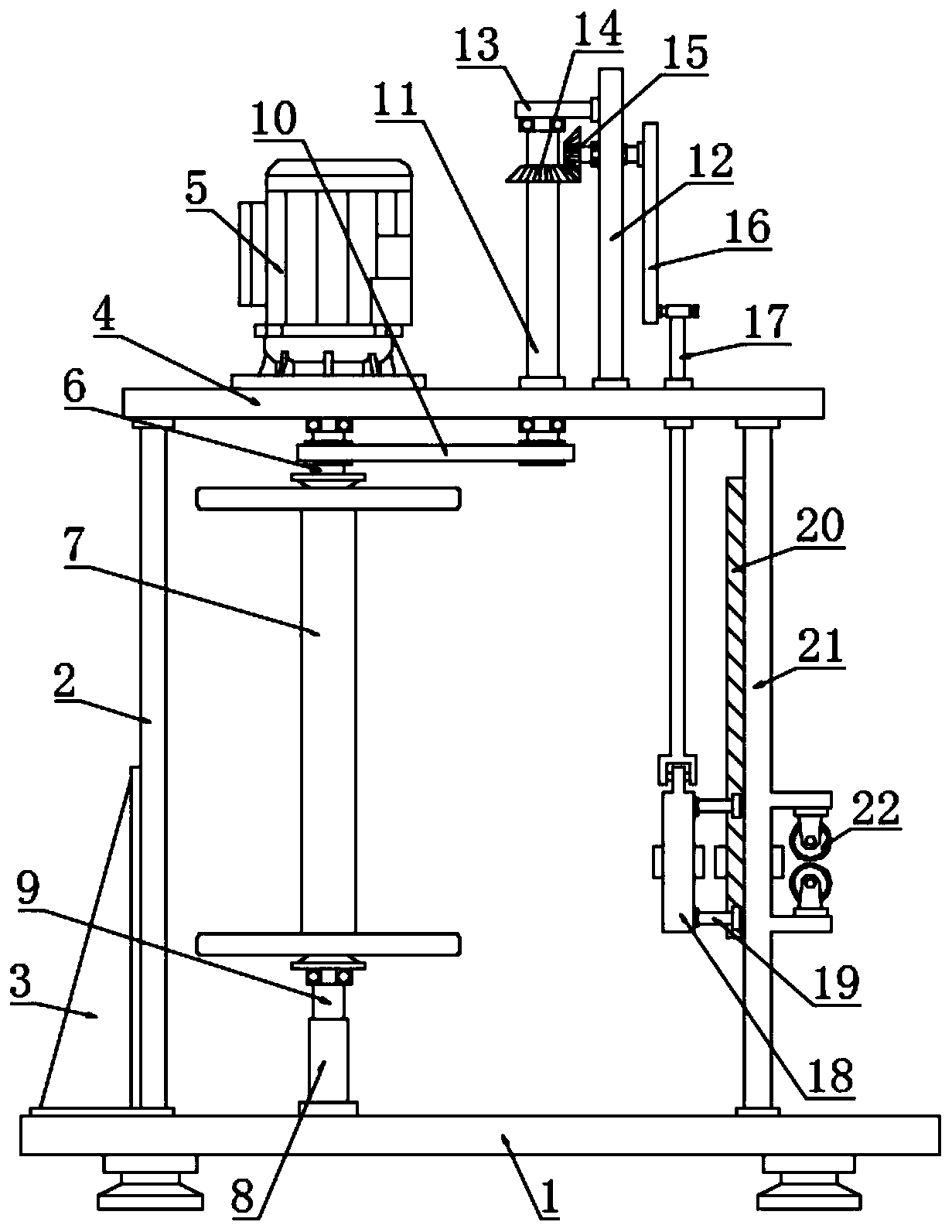

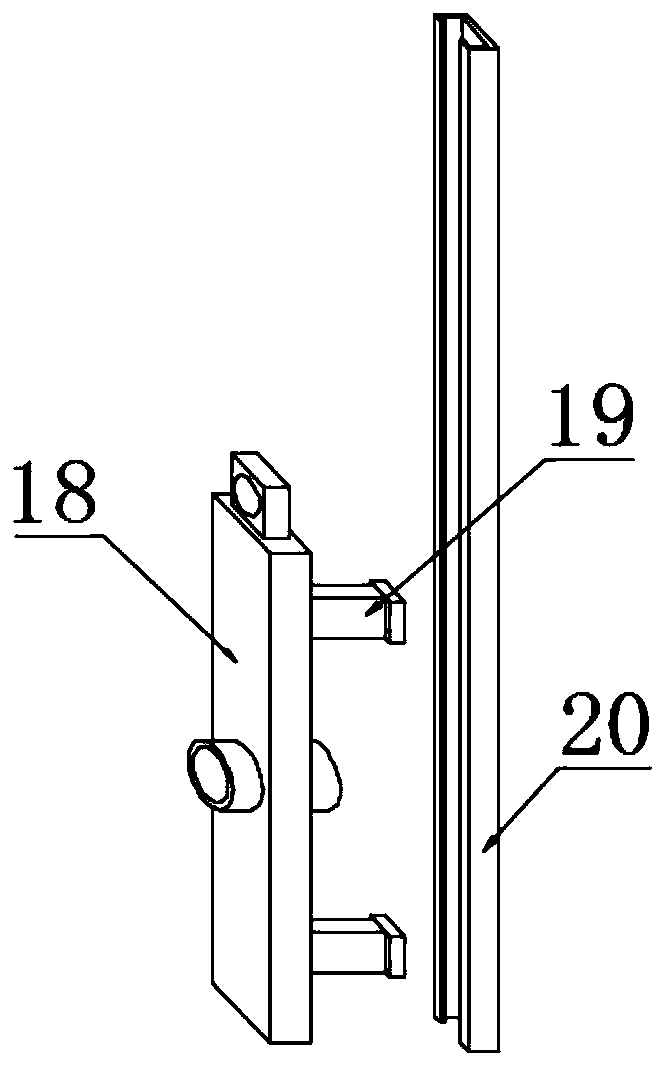

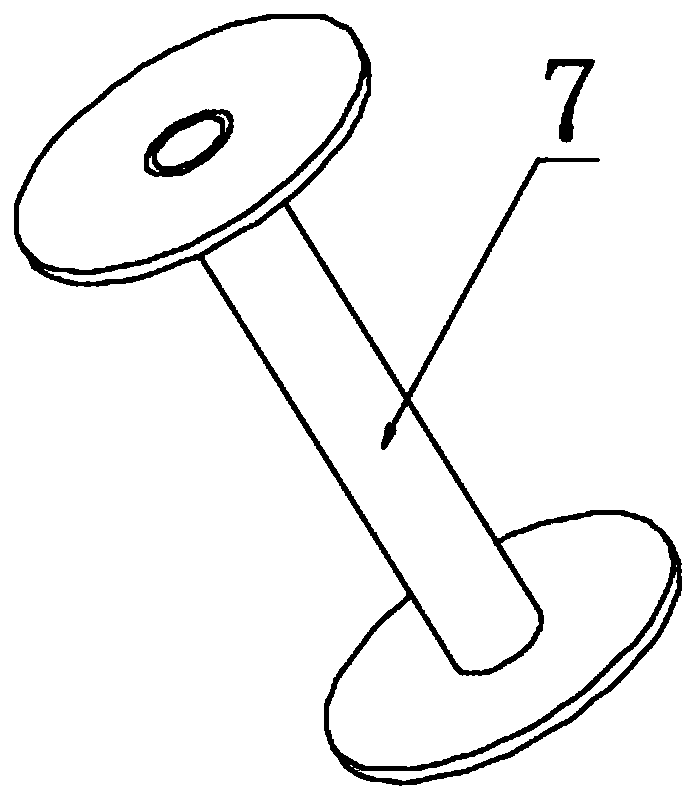

Vertical double-station wire winding machine

The invention discloses a vertical double-station wire winding machine, and belongs to the technical field of vertical wire winding equipment. The wire winding machine comprises a rack, a wire winding driving mechanism, a supporting plate assembly, an idle positioning mechanism and a lifting rotating mechanism, wherein the wire winding driving mechanism, the idle positioning mechanism and the lifting rotating mechanism are all arranged on the rack; the lifting rotating mechanism is located between the wire winding driving mechanism and the idle positioning mechanism; an anti-slip assembly is arranged on the wire winding driving mechanism; the supporting plate assembly is arranged on the lifting rotating mechanism; and receding openings are formed in the positions, corresponding to the wire winding driving mechanism and the idle positioning mechanism, on the supporting plate assembly. The upper end of the anti-slip assembly extends into a clamping hole in the lower end of a winding drum, so that the winding drum is prevented from slipping relative to a bearing plate in the wire winding process, and smooth wire winding work is guaranteed.

Owner:GUIZHOU AEROSPACE NANHAI SCI & TECH

Winding device for uniformly winding enameled wire

InactiveCN110980405AImprove storage space utilizationNot prone to cross-knottingFilament handlingDrive shaftElectric machine

The invention discloses a winding device for uniformly winding an enameled wire, relates to a winding device capable of uniformly pulling and winding the enameled wire on a wire roller, and solves theproblem of non-uniform wire winding caused by the lack of winding and guiding dual effects in the prior art. According to the specific technical scheme, the lower part of a driving motor is rotationally connected with an output shaft, the lower end of the output shaft is fixedly provided with a conical roller, and the lower part of the conical roller is provided with a wire roller; the output shaft is connected with the lower end of a driven shaft through a synchronous belt; a first bevel gear is fixedly connected to the upper part of the driven shaft and meshed with a second bevel gear, thesecond bevel gear is fixed to the end of a rotating shaft, a the other end of the rotating shaft is fixedly connected with an eccentric disc, the eccentric position of the outer edge of the eccentricdisc is rotationally connected with the upper end of a connecting rod, and the lower end of the connecting rod is rotatably connected with a movable plate; a sliding rod is fixed on one side of the movable plate at the position deviating from the center, the sliding rod is slidably connected with a guide groove, the guide groove is fixed to a fixed plate, a guide pipe is fixed to and communicateswith the fixed plate, and another guide pipe is fixed to and communicates with the center of the movable plate.

Owner:梧州市同润铜业有限公司

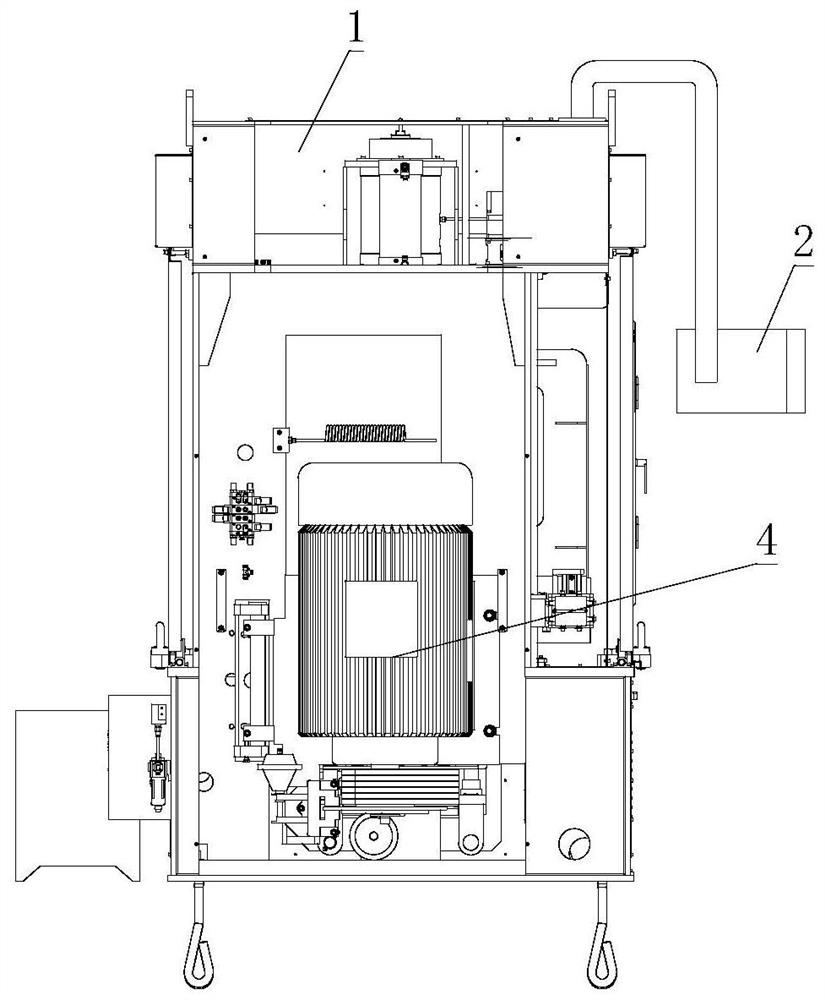

Electric hoist hoisting equipment capable of achieving ordered winding and reduction of swing amplitude

InactiveCN113651259AWinding orderlyReduce swingPortable liftingWinding mechanismsElectric machineControl theory

The invention relates to the technical field of electromechanical equipment, and discloses electric hoist hoisting equipment capable of achieving ordered winding and reduction of a swing amplitude. The equipment comprises a frame body, the top of the frame body is rotatably connected with a winding mechanism, the left end and the right end of the frame body are slidably connected with lifting mechanisms, the bottom of the frame body is slidably connected with an adjusting mechanism, a fixing frame is fixedly connected to the middle of the frame body, and a steel rope is wound in the frame body. According to the electric hoist hoisting equipment capable of achieving ordered winding and reduction of the swing amplitude, when the swing amplitude of a steel rope is too large, the steel rope swings to abut against a guide roller and is matched with a first connecting rod for transmission, so that a rubber rod rotates to abut against a contact point, a second motor drives a screw to rotate, a sliding frame drives a movable frame to ascend, the swing radius of the steel rope is increased; and when a first motor is started for rotation, a first rotating shaft drives a groove disc to rotate, based on limiting of a limiting ring groove, the guide roller gradually conducts feeding from left to right, and the effect of synchronous feeding and ordered winding is achieved.

Owner:杭州大趴菜科技有限公司

Cord winding mechanism for a cordless window blind

ActiveUS10273749B2Winding orderlyLight protection screensEngineeringElectrical and Electronics engineering

Owner:LEI ZHENBANG +1

Roll-type take-up device

InactiveCN104444523ASimple structureReasonable designFilament handlingWebs handlingEngineeringReducer

The invention relates to a roll-type take-up device. The roll-type take-up device comprises a take-up shaft, a take-up roll which is arranged on the take-up shaft and rotates along with the take-up shaft, and a drive mechanism, wherein the two ends of the take-up roll are rotationally arranged on supports; the drive mechanism is used for driving the take-up roll to rotate and comprises a motor and a reducer between the take-up roll and the motor; the outer surface of the take-up roll is concave towards a take-up roll body; the roll-type take-up device further comprises a locking system which locks the take-up shaft under an outage state. The take-up roll winds a wound object, as the surface of the take-up roll is in a concave shape, the wound object has the tendency of being wound to the middle of the take-up roll in the take-up process, and the problem that the wound object disengages from the take-up roll is avoided. In addition, when power fails, the locking system will lock the take-up shaft, the take-up roll is prevented from continuing to carry out take-up under the inertia effect, and the wound object will not be damaged.

Owner:CHANGZHOU CHANGYUAN NONWOVENS PROD

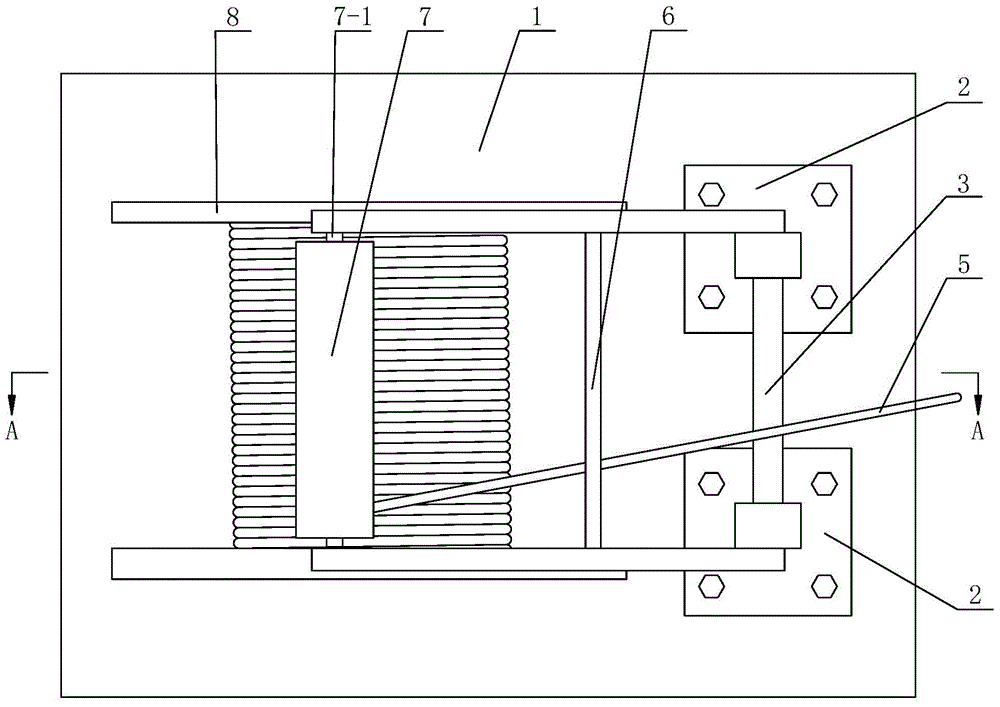

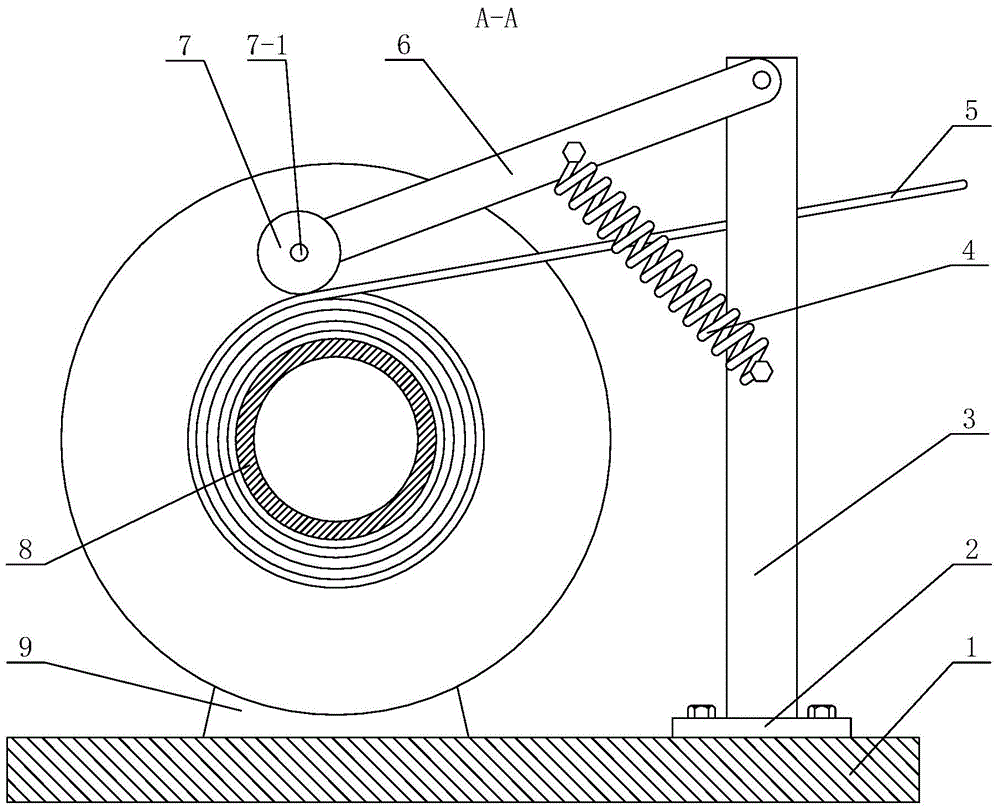

Press roll type rope arranging device for mining hoist

InactiveCN104418254AReasonable designWinding orderlyWinding mechanismsMechanical engineeringH shaped

The invention discloses a press roll type rope arranging device for a mining hoist. The press roll type rope arranging device for the mining hoist comprises a bottom plate; a winding drum mounting seat is fixedly arranged at one side of the bottom plate; a winding drum for winding or unwinding a steel wire rope is arranged on the top end of the winding drum mounting seat; two mounting plates are fixedly arranged at the other side of the bottom plate; an H-shaped bracket is fixedly arranged at the upper sides of the two mounting plates; the top end of the H-shaped bracket is in rotating connection with one end of an H-shaped press roll frame, and the other end of the H-shaped press roll frame is equipped with a press roll through a press roll shaft; a tension spring for applying a tension force to the H-shaped press roll frame is arranged between the H-shaped bracket and the H-shaped press roll frame. The press roll type rope arranging device for the mining hoist has the characteristics of being reasonable in design, preventing a rope from being loosen and enabling ordered arranging and winding, and being simple and compact in structure, simple to dismount and mount, convenient to maintain, long in service life, wide in applicable scope, low in production cost, and convenient to popularize and use.

Owner:XIAN ZHIYUE ELECTROMECHANICAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com