Plastic packaging film winding roller

A packaging film and winding roller technology, applied in the field of plastic packaging production equipment, can solve the problems of packaging film damage, inconvenience, and plastic packaging film folding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

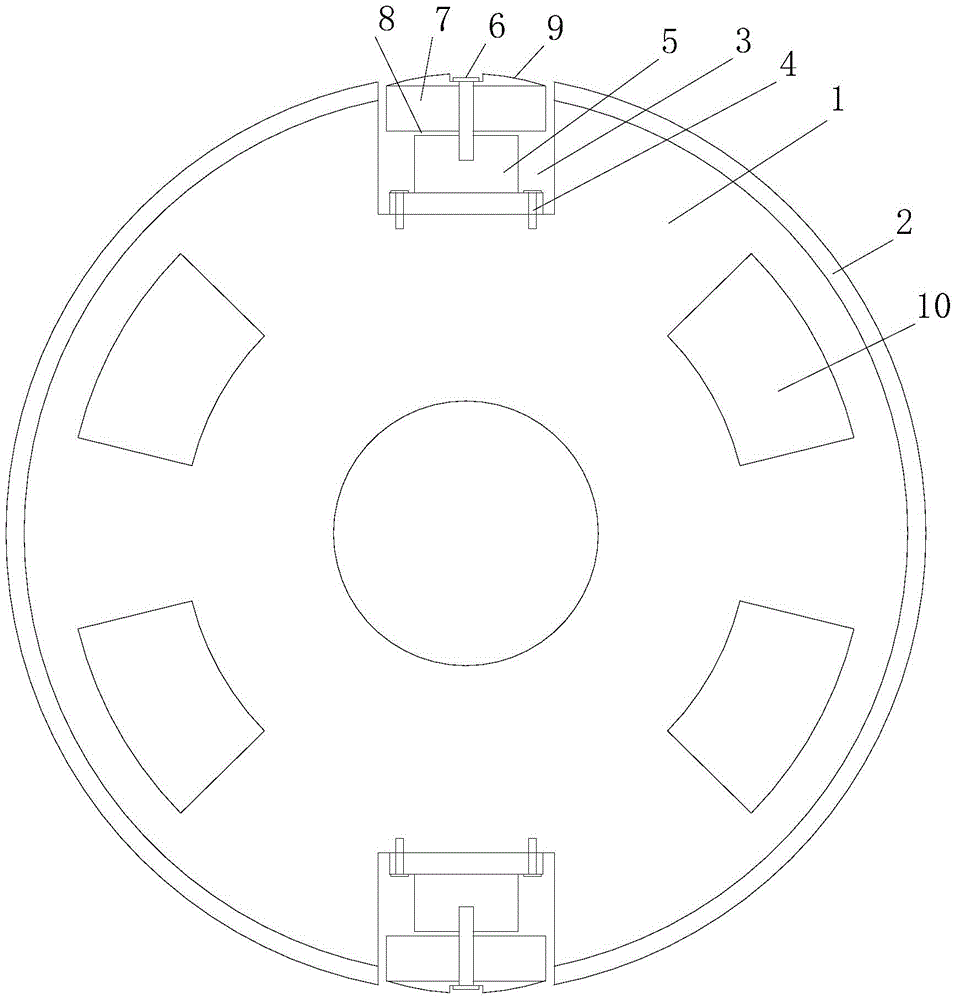

[0014] see figure 1 , plastic packaging film rewinding roller, including a roller body 1, a layer of rubber layer 2 is arranged on the outer surface of the roller body, and an accommodating groove 3 begins to be arranged on the axial direction of the outer surface of the roller body, in which at least Two clamping mechanisms for clamping the packaging film, which include the first clamping block 5 connected to the bottom of the storage tank through screws 4, and multiple sets of screw holes for the insertion of the screws 4 can be opened at the bottom of the storage tank In this way, the axial position of the first clamping block 5 in the accommodating groove can be adjusted, so that plastic packaging films of different widths can be rolled up, and the second clamping block is connected to the first clamping block by screws 6 7. Between the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com