Press roll type rope arranging device for mining hoist

A technology of rope arranging device and pressure roller, which is applied in hoisting device, clockwork mechanism, etc., can solve the problems of uneven winding of wire rope, economic waste, forming safety, etc., achieves wide application range, improved service life, and is easy to promote The effect of using

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

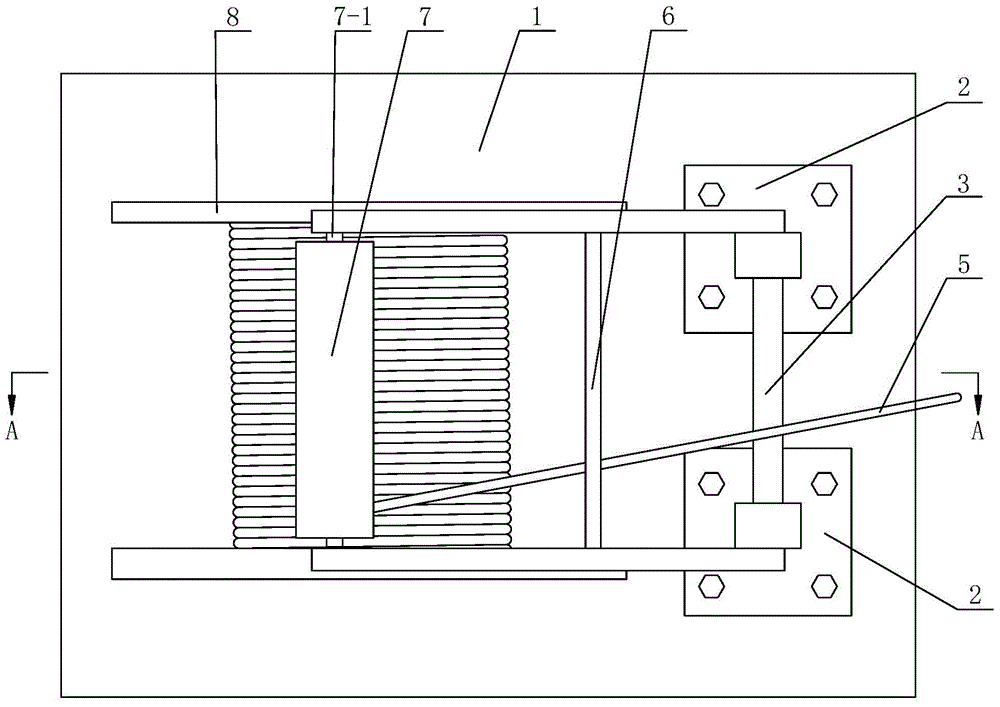

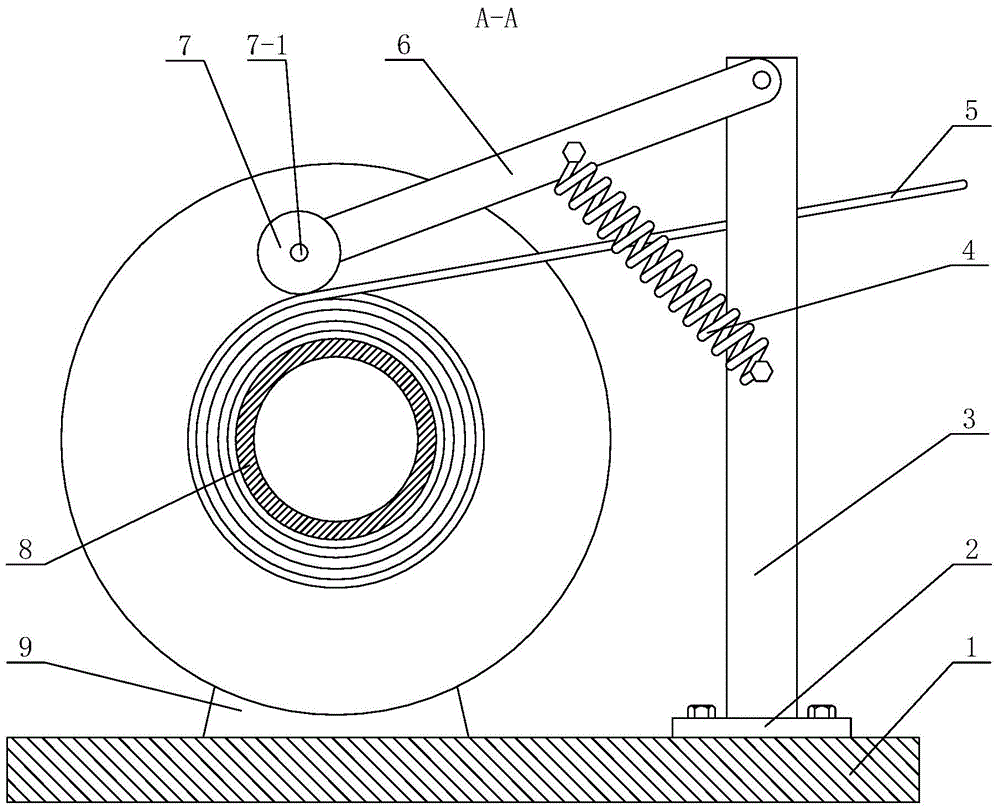

[0020] Such as figure 1 and figure 2 The shown roller-type mining winch rope rower includes a bottom plate 1, a reel mounting seat 9 is fixedly arranged on one side of the bottom plate 1, and a top end of the reel mounting seat 9 is provided for retracting and unwinding a steel wire rope 5. Reel 8, the other side of the bottom plate 1 is installed with two mounting plates 2 through bolts, and the upper side of the two mounting plates 2 is welded with an H-shaped bracket 3, and the top of the H-shaped bracket 3 is connected with the H-shaped pressure roller through a pin shaft One end of the frame 6 is rotatably connected, and the other end of the H-shaped pressure roller frame 6 is equipped with a pressure roller 7 through the pressure roller shaft 7-1. The outer surface of the pressure roller 7 is coated with a rubber layer, and the rubber layer can greatly increase the pressure of the pressure roller 7. For the contact area wrapped around the steel wire rope 5, the mutual ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com