Rope pressing device for mining winch rope guider

The technology of a rope pressing device and a rope arranging device is applied in the direction of a hoisting device, a spring mechanism, etc., which can solve the problems of safety, rope disorder, economic waste, etc., and achieves easy popularization and use, simple production process, and improved service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

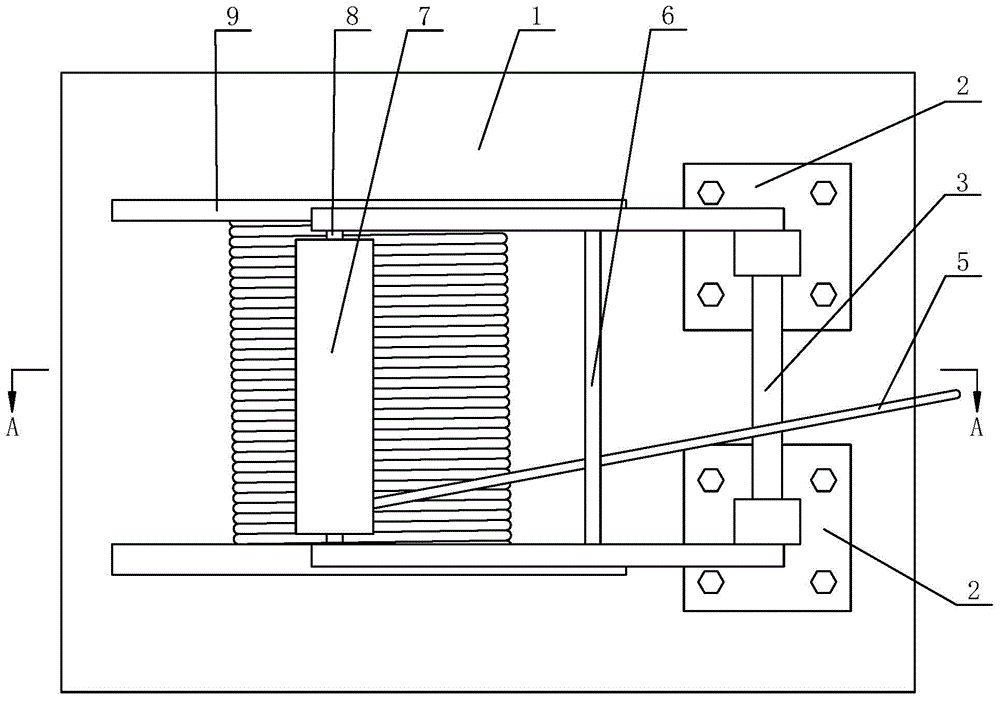

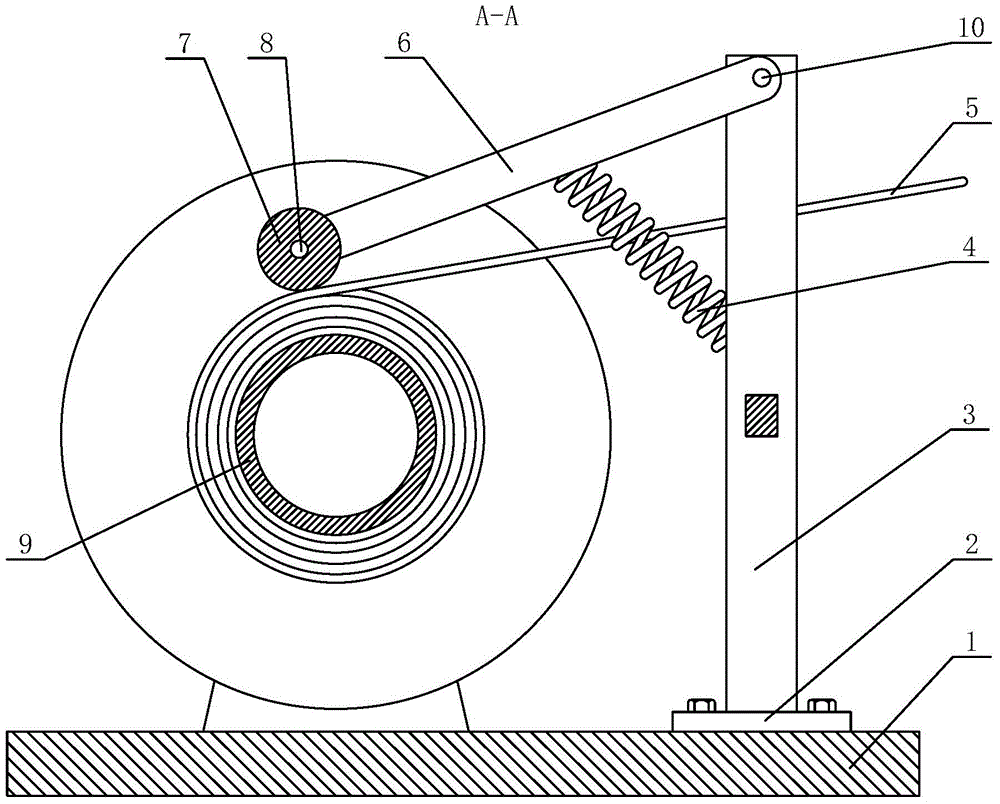

[0020] Such as figure 1 and figure 2 The shown rope pressing device for a mine winch rope rower includes a rectangular bottom plate 1 for fixedly installing a reel 9 and an H-shaped support 3, and also includes a pressure roller 7 for pressing the steel wire rope 5 on the reel 9, The H-shaped pressure roller stand 6 for rotating and installing the pressure roller 7, the H-shaped bracket 3 for rotating and installing the H-shaped pressure roller stand 6, and the extension spring 4 that provides elastic driving force for the pressure roller 7; One end of the upper side of the rectangular bottom plate 1 is fixedly installed with the H-shaped bracket 3 through two mounting plates 2, and the upper end of the H-shaped bracket 3 is connected to one end of the H-shaped pressure roller frame 6 through a pin shaft 10 in rotation. The other end of roller frame 6 is installed with the pressure roller 7 that is used to compress the steel wire rope 5 on the reel 9 through the rotation of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com