Sintering furnace for preparing continuous fiber made form zirconia

A continuous fiber and zirconia technology, which is applied in the preparation of zirconia continuous fiber and high-performance high-temperature oxide fiber, can solve the problems of uneven dispersion of zirconium in the mixing method, easy clogging of spinning, and affecting spinning, etc. Achieve the effects of reducing performance unevenness, simple and easy routes, and shortening the distribution range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

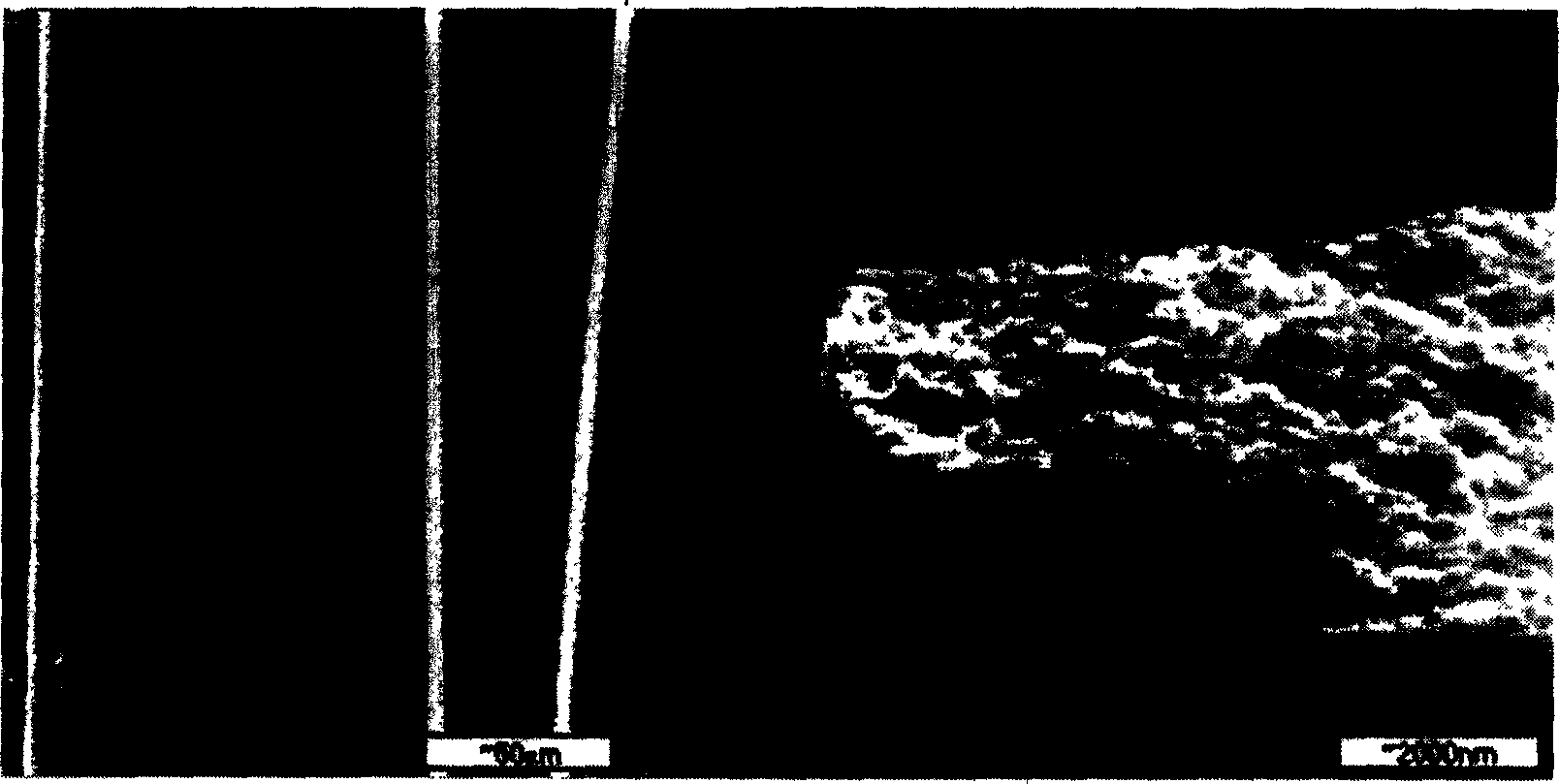

Image

Examples

Embodiment 1

[0055] (1) 97.0 grams of high-purity zirconium oxychloride (ZrOCl 2 ·8H 2 O) be dissolved in 1000 milliliters of methanol, under ice bath at 0~4 ℃, according to the ratio of zirconium oxychloride: acetylacetone: triethylamine=1: 1.5: 2 in molar ratio, successively add 46.0 milliliters of acetylacetone dropwise and 84.0 ml of triethylamine, stirring continuously during the dropwise addition, after the dropwise addition, remove the ice bath, continue to stir at room temperature for 2 hours, evaporate the solvent methanol with a rotary evaporator, until dry, add 500 ml of tetrahydrofuran, stir vigorously After 1 hour, filter with suction to remove the white precipitate, then use a rotary evaporator to evaporate the solvent tetrahydrofuran from the filtrate until a dried light yellow hardened substance is obtained, add 700 ml of n-hexane, stir vigorously for 24 hours, filter with suction, and dry the precipitated filter cake to obtain 61.2 grams of zirconium polyacetylacetonate w...

Embodiment 2

[0060] As described in Example 1, the difference is that 97.0 grams of high-purity zirconium oxychloride is replaced by 97.0 grams of commercially pure zirconium oxychloride in step (1), and the tensile strength of the continuous zirconia fiber obtained is the result of comparative example 1 slightly worse.

Embodiment 3

[0062] As described in Example 1, the difference is that the ratio of zirconium oxychloride in step (1): the molar ratio of acetylacetone=1:1.5 is changed to 1:1, that is, 46.0 milliliters of acetylacetone is changed to 30.7 milliliters of acetylacetone , The tensile strength of the obtained zirconia continuous fiber is slightly higher than that of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com