Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Control delivery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

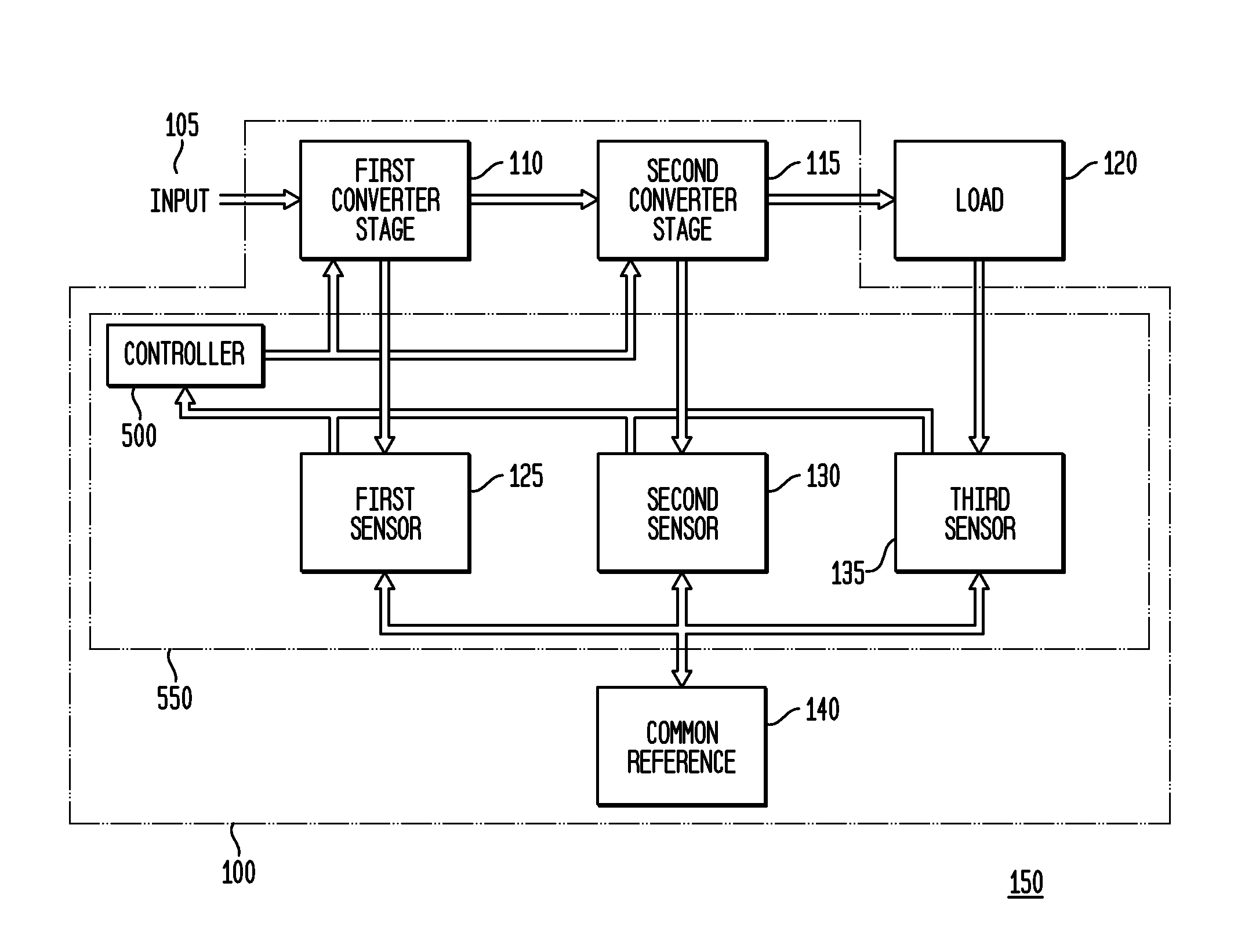

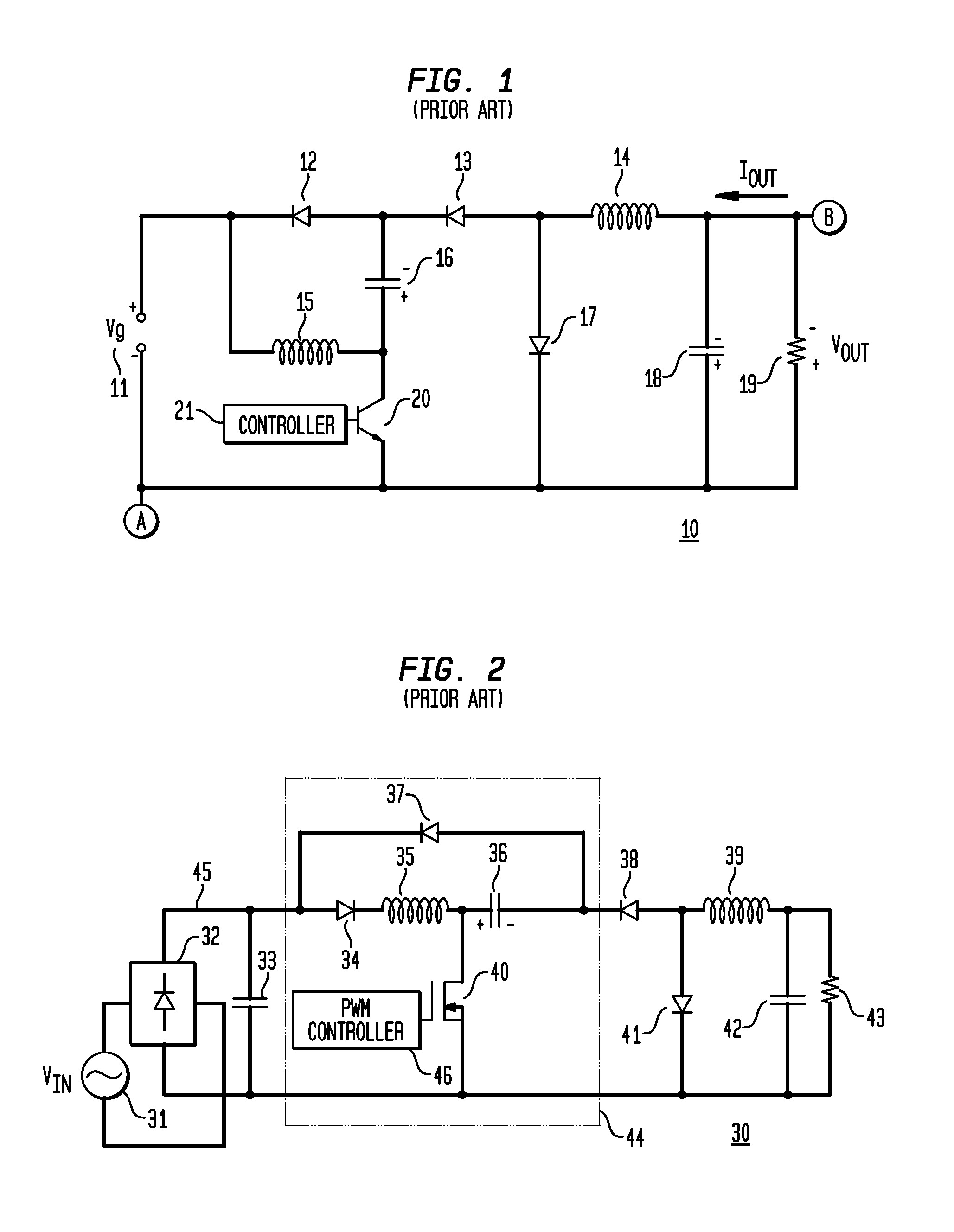

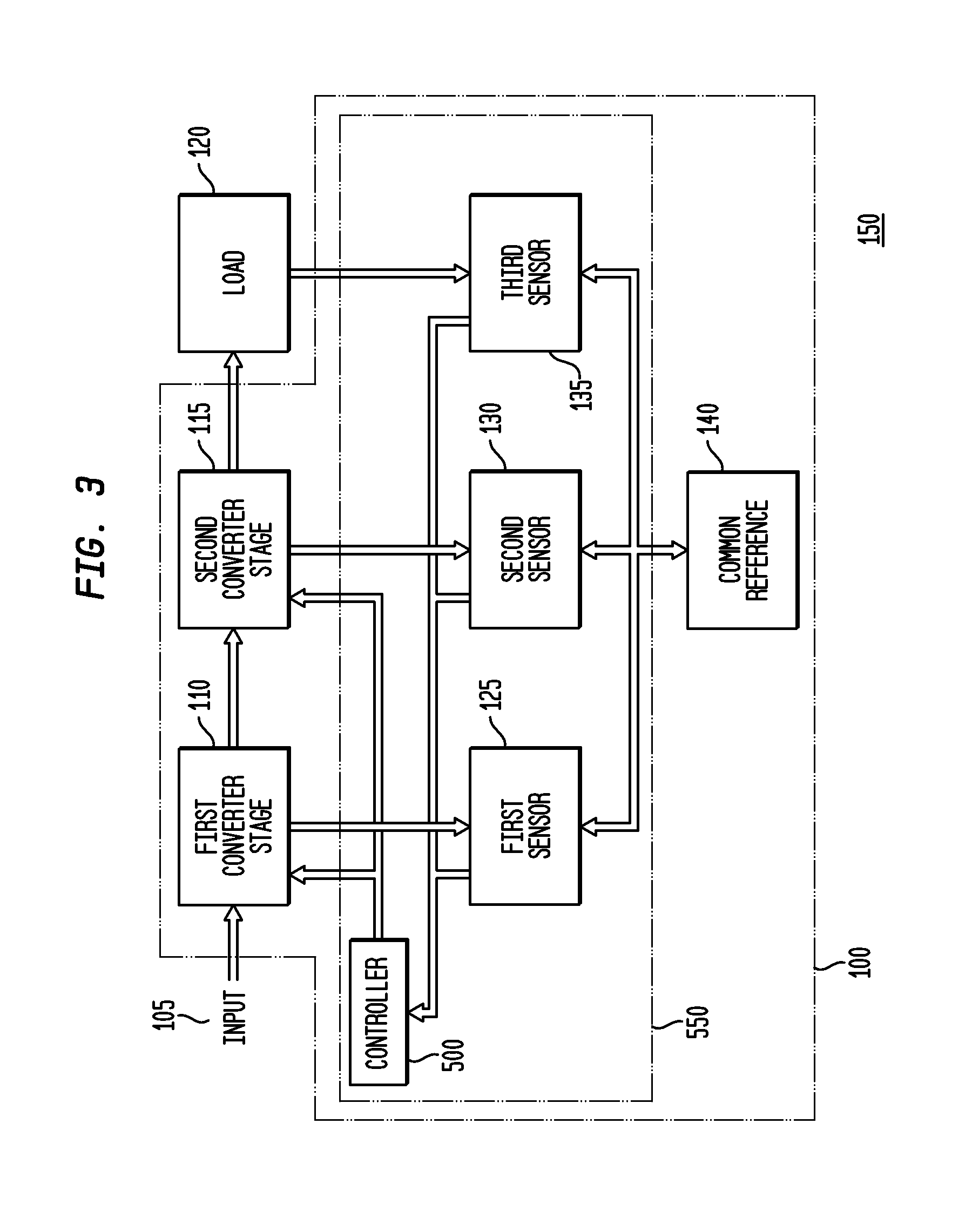

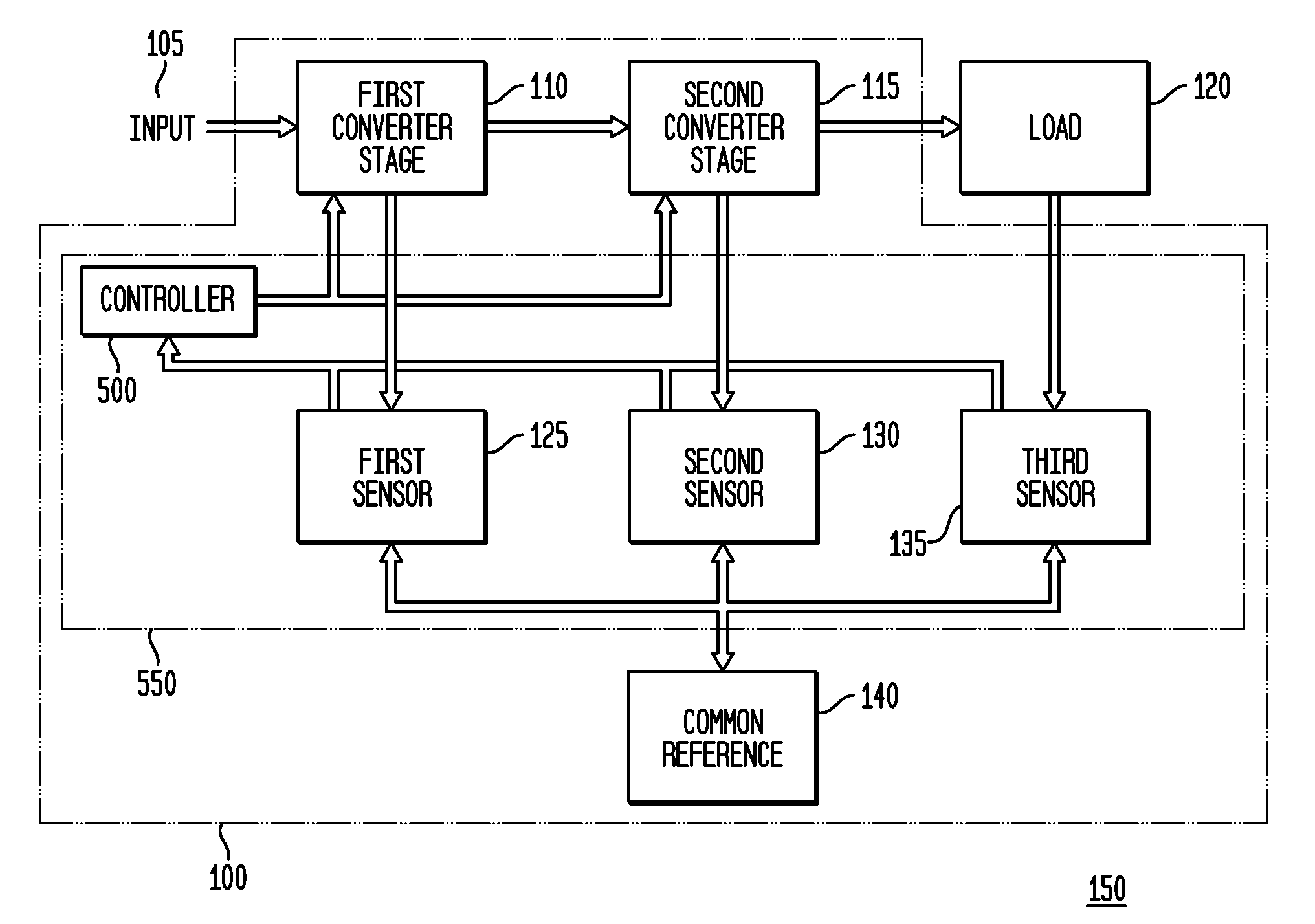

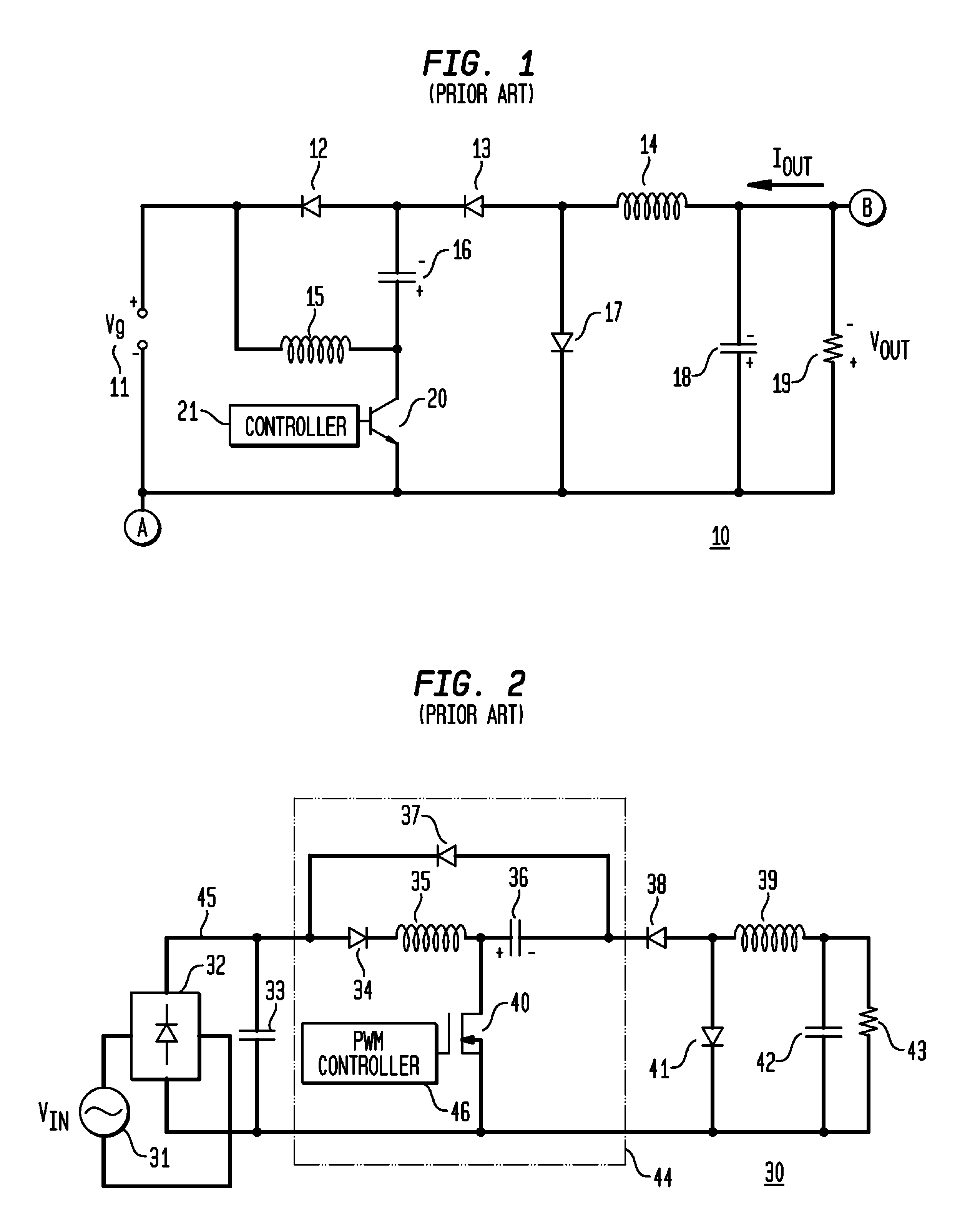

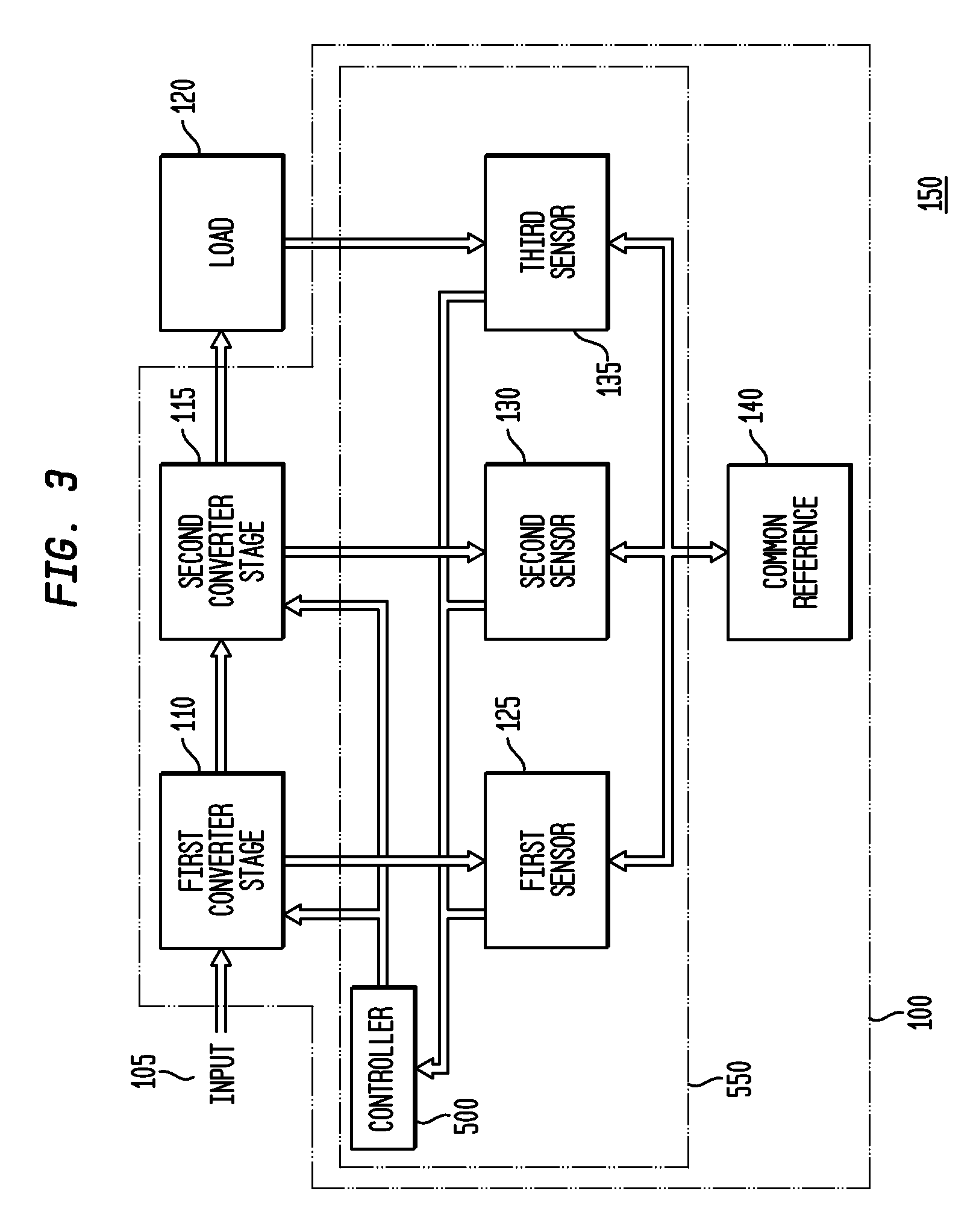

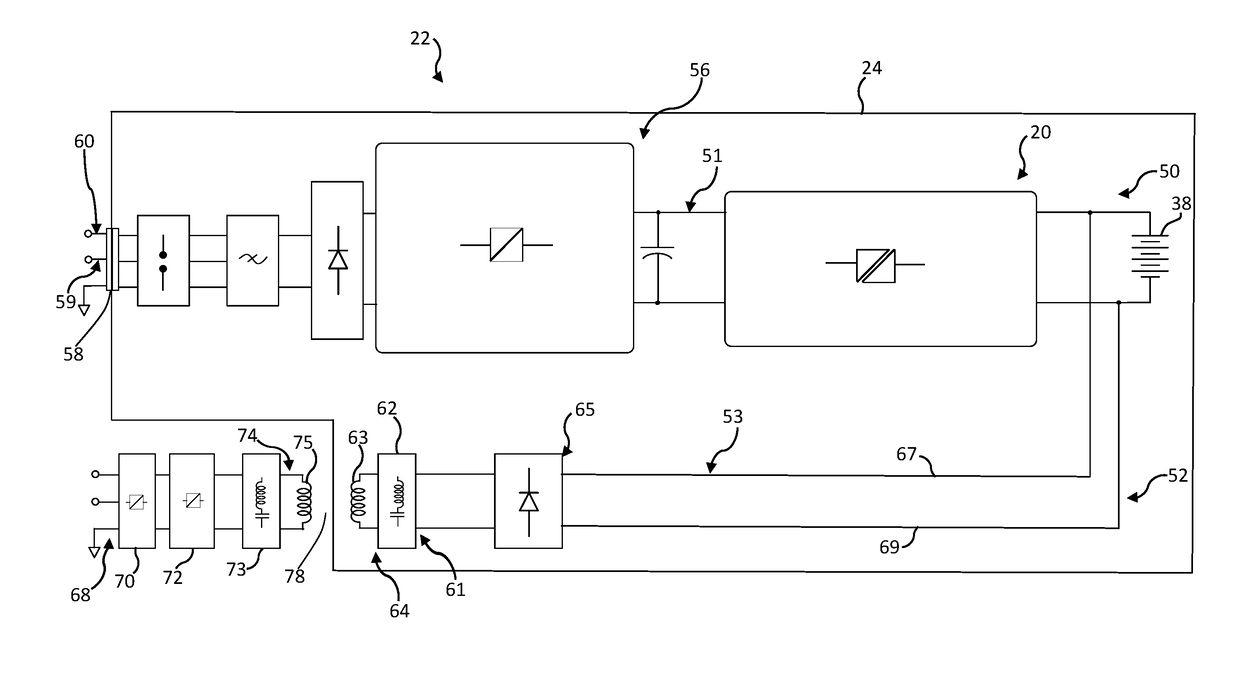

Apparatus, System and Method for Cascaded Power Conversion

InactiveUS20090251934A1Improved feedback signalingSimpler and robust control electronicsElectroluminescent light sourcesAc-dc conversionInductorLight-emitting diode

An apparatus method and system are provided for power conversion, to supply power to a nonlinear load such as a plurality of light emitting diodes. An exemplary apparatus comprises a first power converter stage, a second power converter stage, a plurality of sensors such as first and second sensors, and a controller. The first power converter stage includes a power switch and a first inductor having a first inductance. The first and second sensors are both coupled to a common reference node, with the first sensor adapted to sense a first parameter of the first power converter stage, and the second sensor adapted to sense the output current level. The second power converter stage includes a second inductor having a second inductance, and is coupleable to provide an output current to the nonlinear load such as LEDs. The controller is coupled to the power switch, the first sensor and the second sensor, and the controller is adapted to turn the power switch into an on state for an on-time duration substantially proportional to a ratio of the second inductance to the first inductance.

Owner:CHEMTRON RES

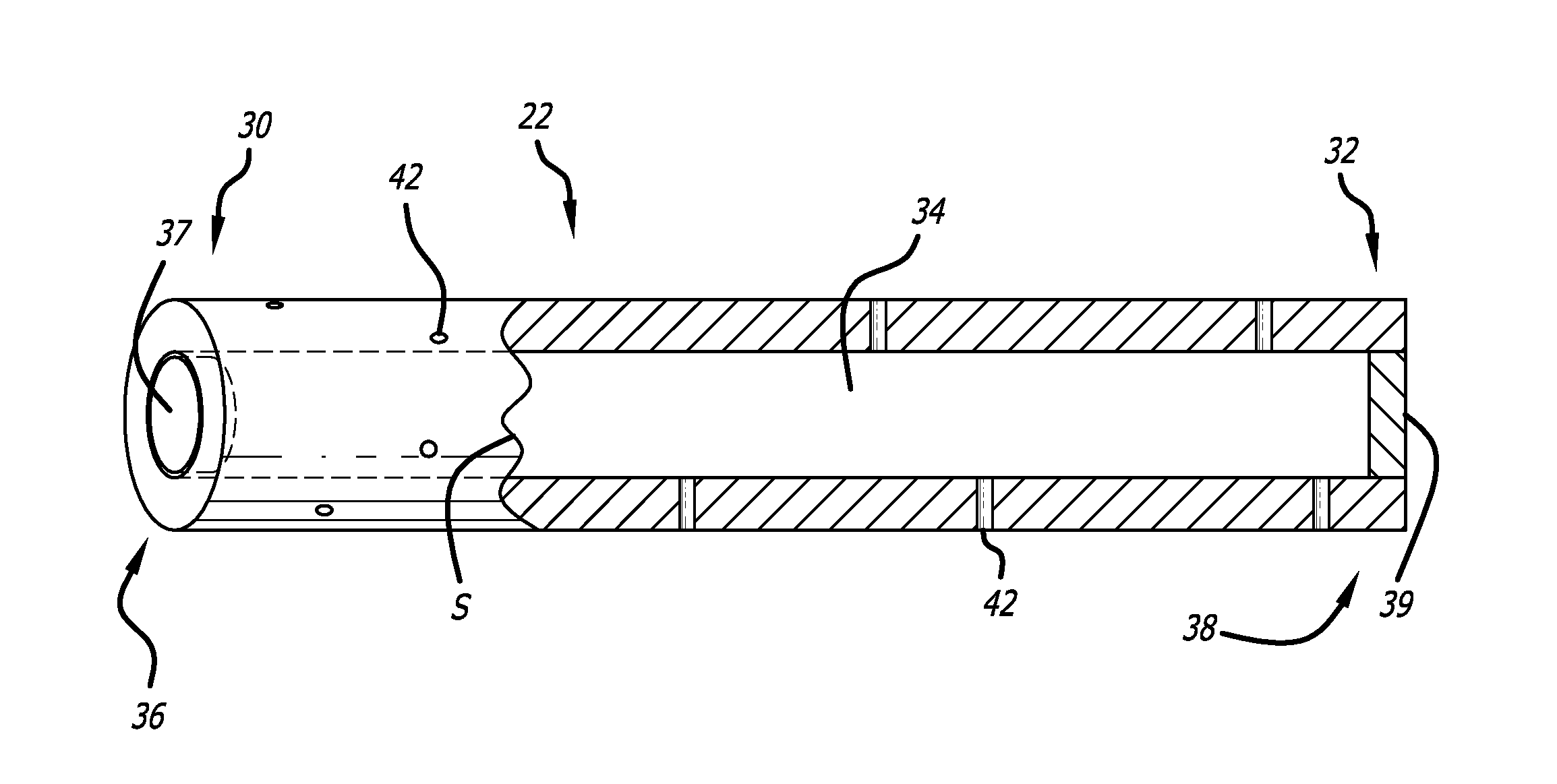

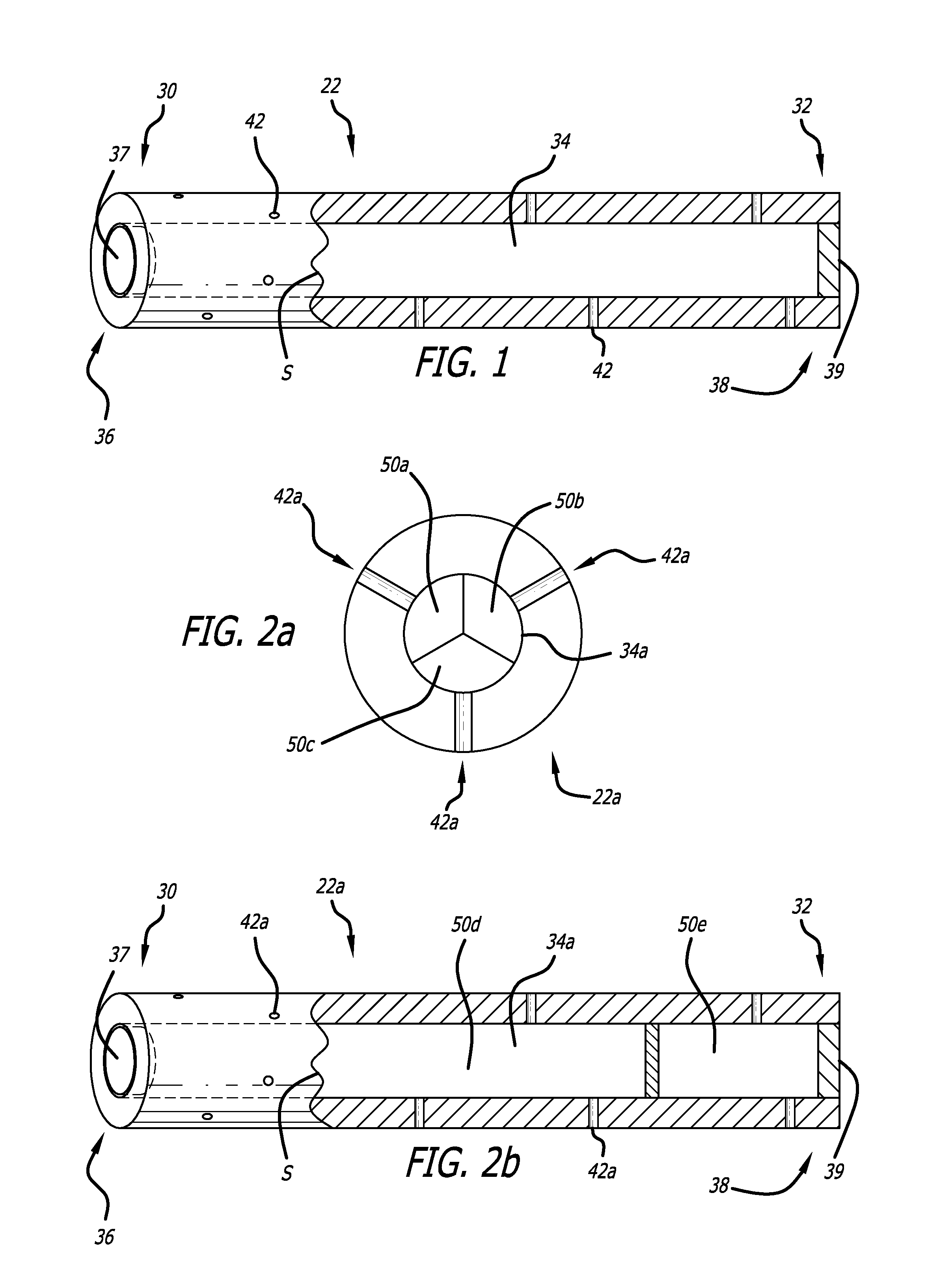

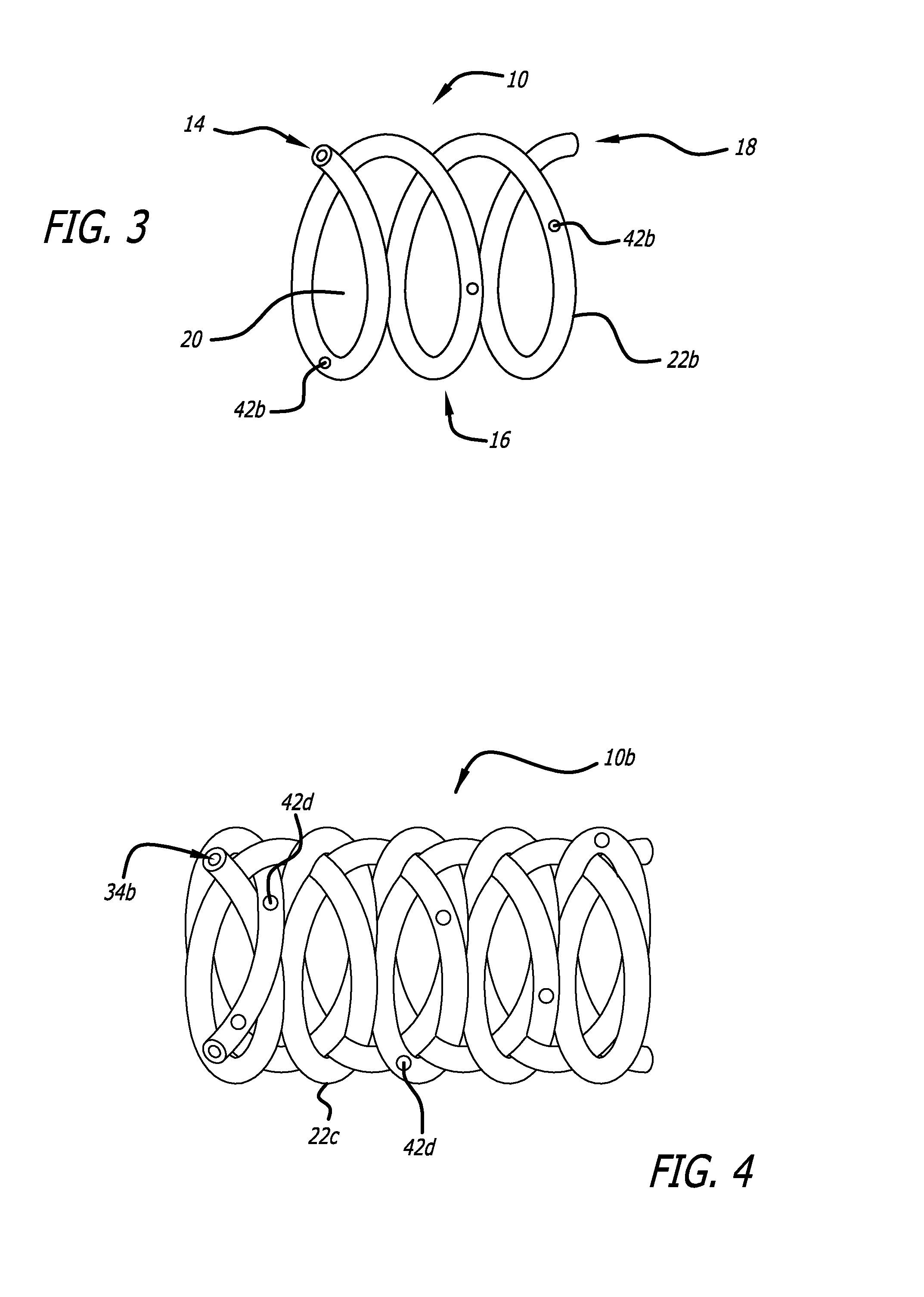

Hypotubes for Intravascular Drug Delivery

An implantable device capable of delivering drugs is disclosed. An example of the device is a stent that comprises at least one hypotube having a lumen and one or more pores. The lumen of the hypotube is configured to retain drugs that can be eluted through the one or more pores after deployment at a treatment site.

Owner:MEDTRONIC VASCULAR INC

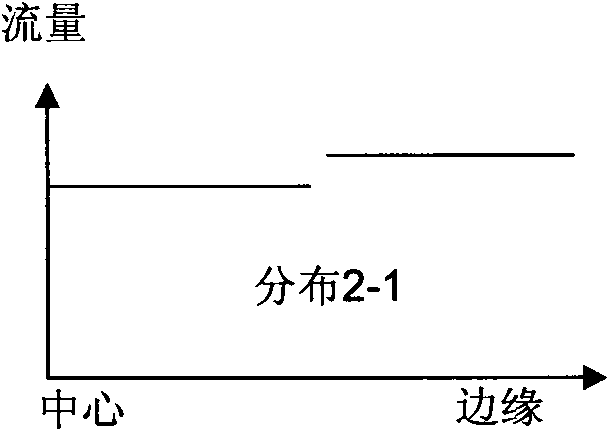

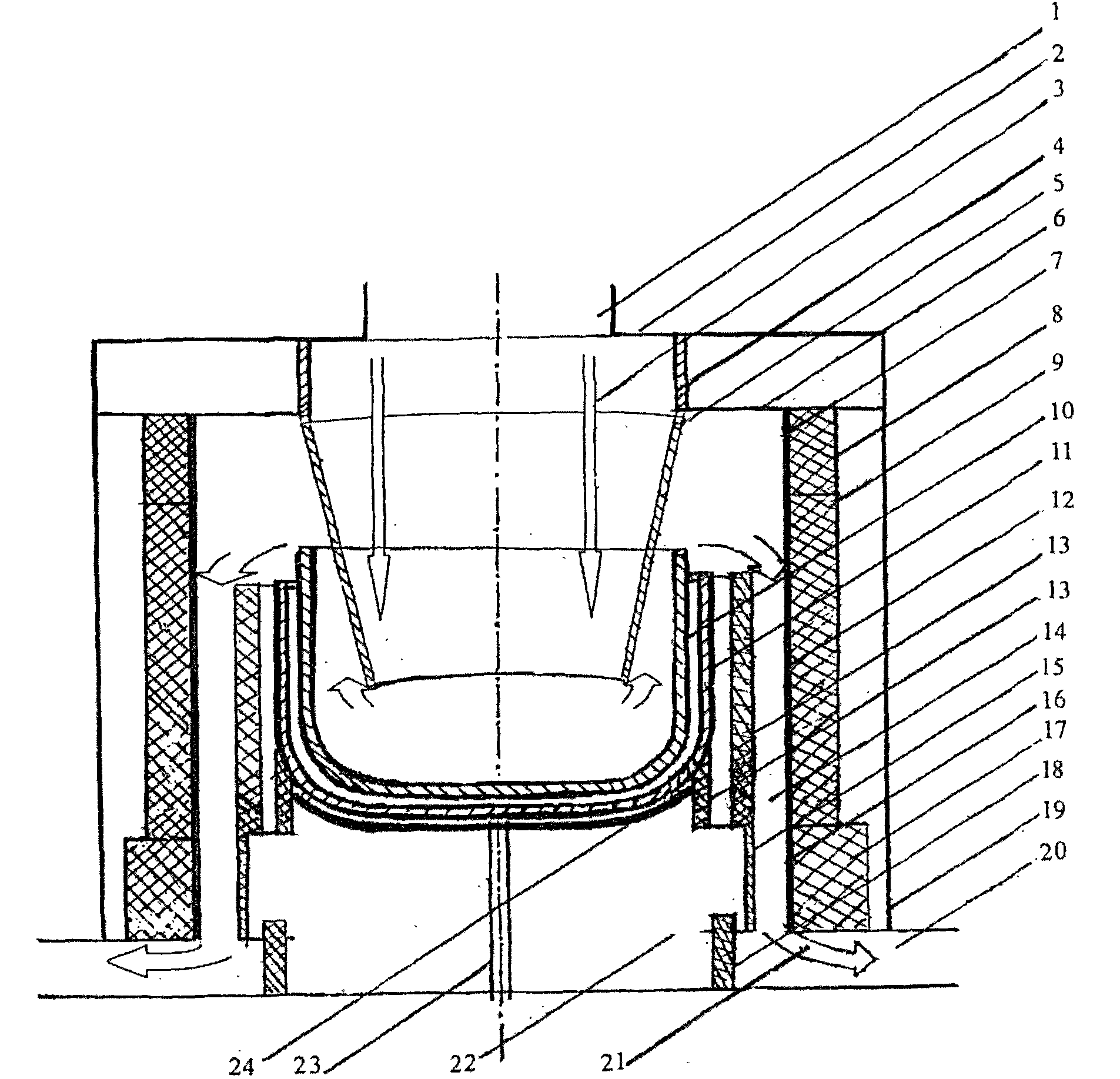

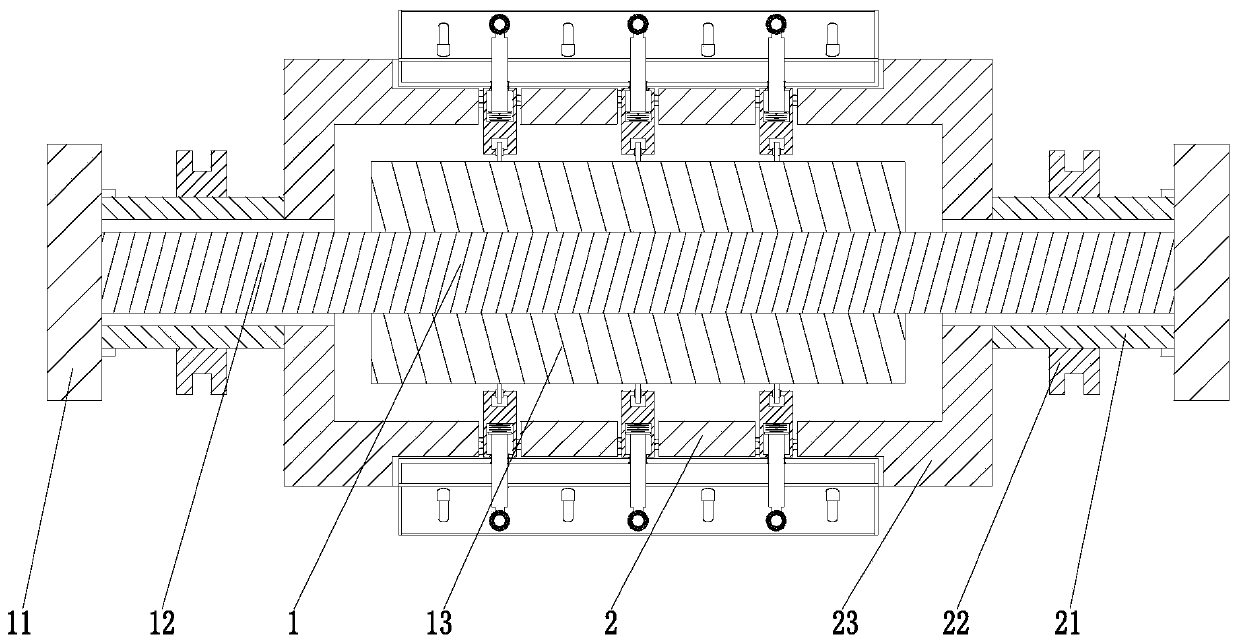

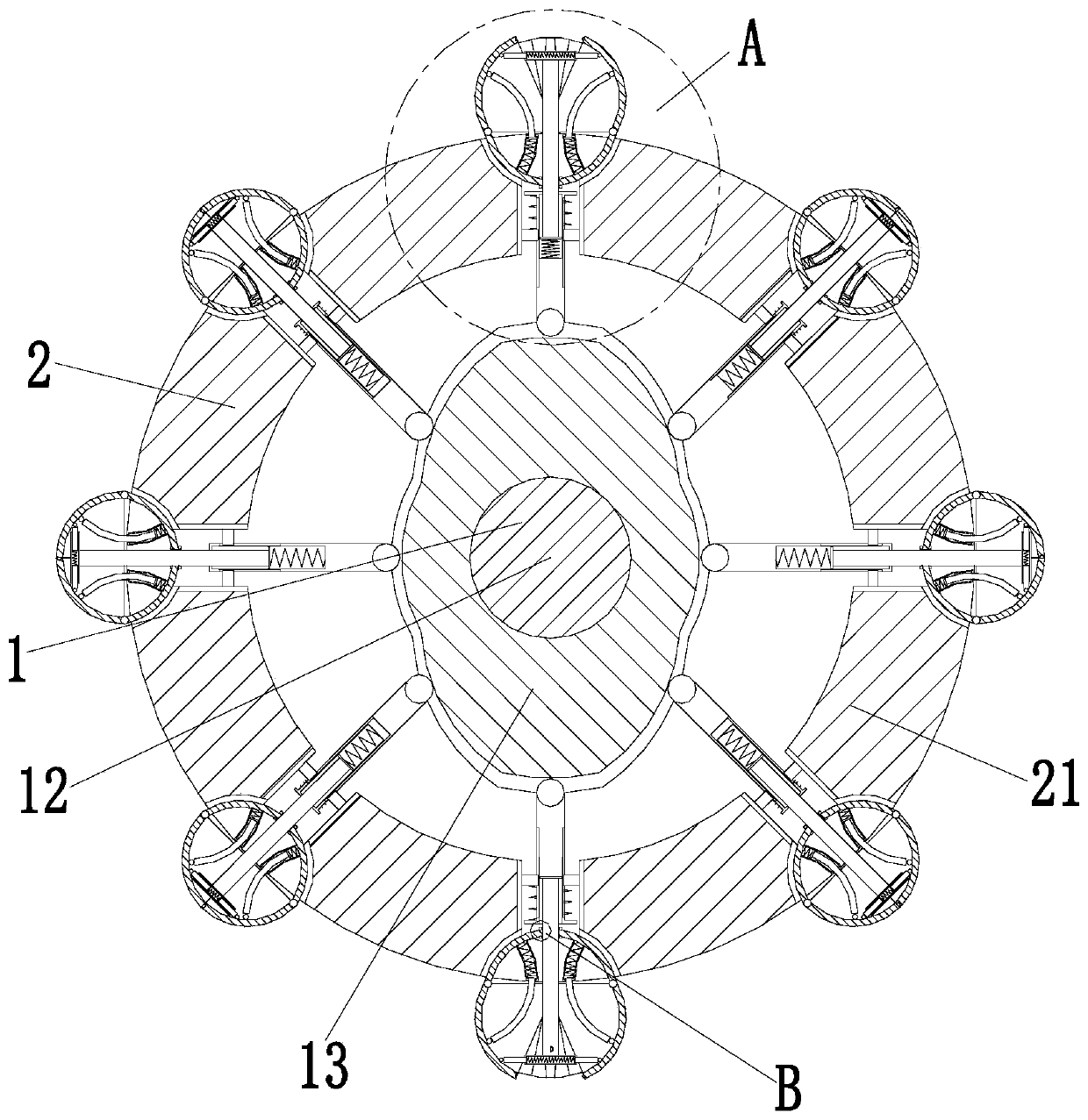

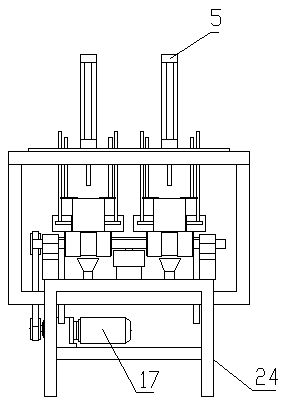

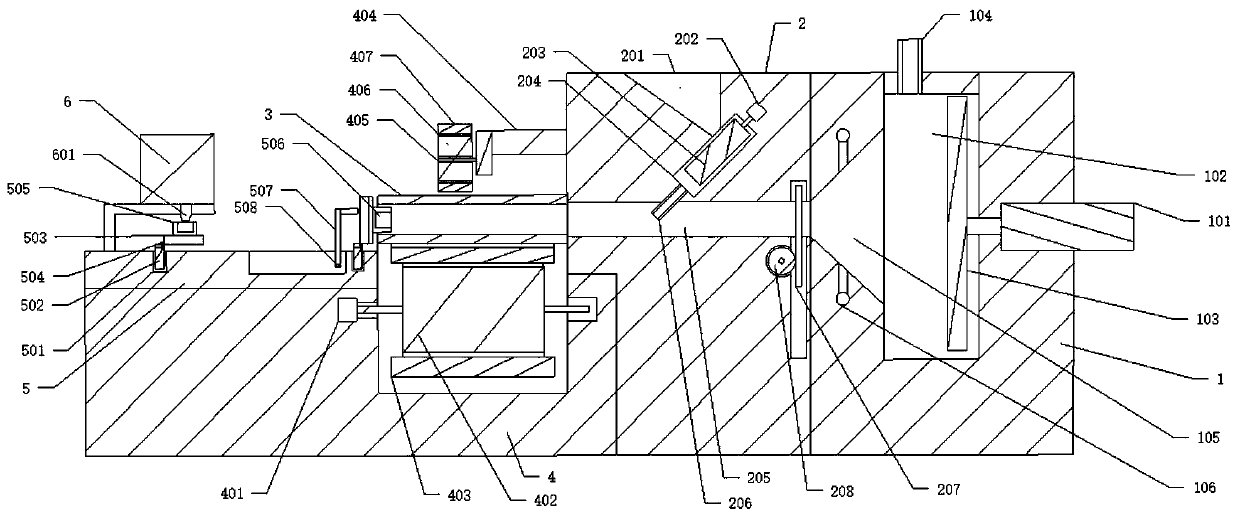

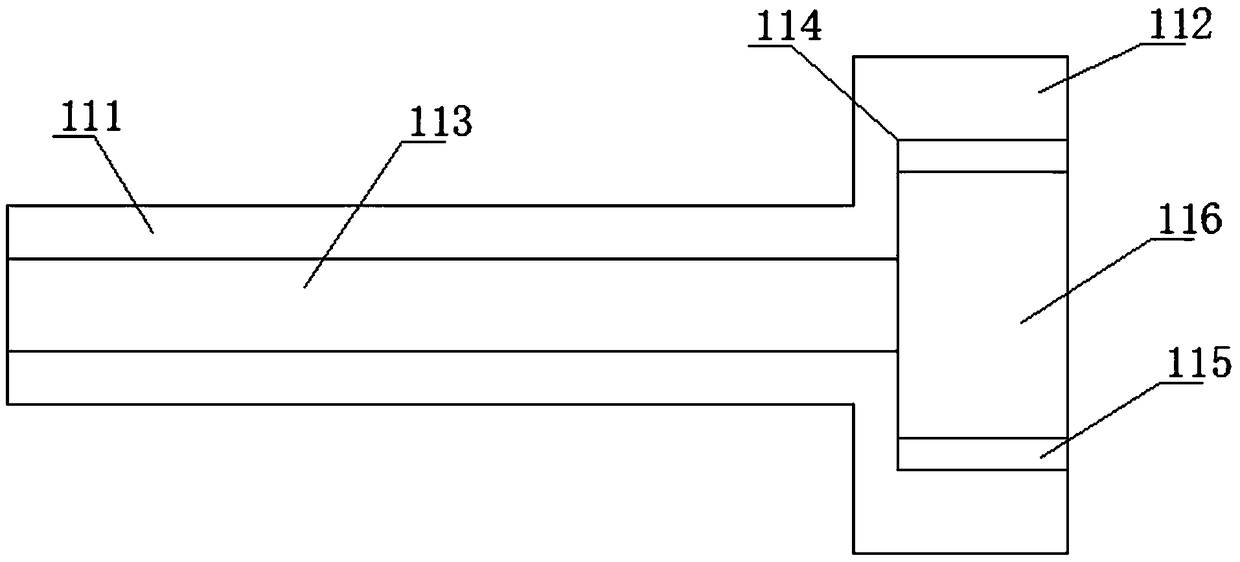

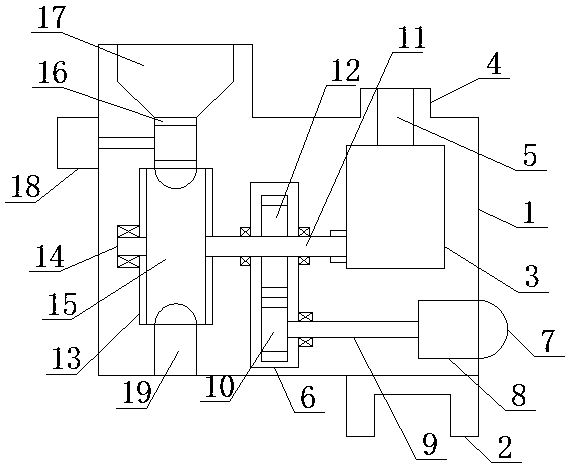

Device for controlling delivery and uniform distribution of reaction gases in MOCVD reaction chamber

ActiveCN101914761AReduce manufacturing costControl consumptionChemical vapor deposition coatingSystem capacityEngineering

The invention discloses a device for controlling the delivery and the uniform distribution of reaction gas in a MOCVD reaction chamber. By respectively controlling the flow of gas passages non-uniformly distributed radially on a front gas homogenizing plate and input passages at different positions, at least two reaction gases are respectively introduced into two paths which are radially and axially crossed on a spray header, and can be secondarily distributed by nozzles in different shapes, so the uniformly distributed boundary layer concentration, speed and temperature required are achieved on the surface of a rotary epitaxial wafer, the quality of massively produced epitaxial films and the finished product ratio of massively produced epitaxial wafers are improved, the consumption of expensive reaction gases can be effectively controlled and the epitaxial production cost is reduced. By properly increasing the distance between the surface of the spray header and the epitaxial wafer, deposits generated on the surface of the spray header and the nozzles in the epitaxial growth are reduced, the cleaning period is prolonged, and the production efficiency and system capacity are improved. The device also can reduce the processing difficulty and manufacturing cost of the nozzles of the spray header and cooling medium passages.

Owner:JIANGSU ZHONGSHENG SEMICON EQUIP

Apparatus, system and method for cascaded power conversion

InactiveUS7952294B2Enhanced signalEasy to controlElectroluminescent light sourcesAc-dc conversionPower switchingEngineering

An apparatus method and system are provided for power conversion, to supply power to a nonlinear load such as a plurality of light emitting diodes. An exemplary apparatus comprises a first power converter stage, a second power converter stage, a plurality of sensors such as first and second sensors, and a controller. The first power converter stage includes a power switch and a first inductor having a first inductance. The first and second sensors are both coupled to a common reference node, with the first sensor adapted to sense a first parameter of the first power converter stage, and the second sensor adapted to sense the output current level. The second power converter stage includes a second inductor having a second inductance, and is couplable to provide an output current to the nonlinear load such as LEDs. The controller is coupled to the power switch, the first sensor and the second sensor, and the controller is adapted to turn the power switch into an on state for an on-time duration substantially proportional to a ratio of the second inductance to the first inductance.

Owner:CHEMTRON RES

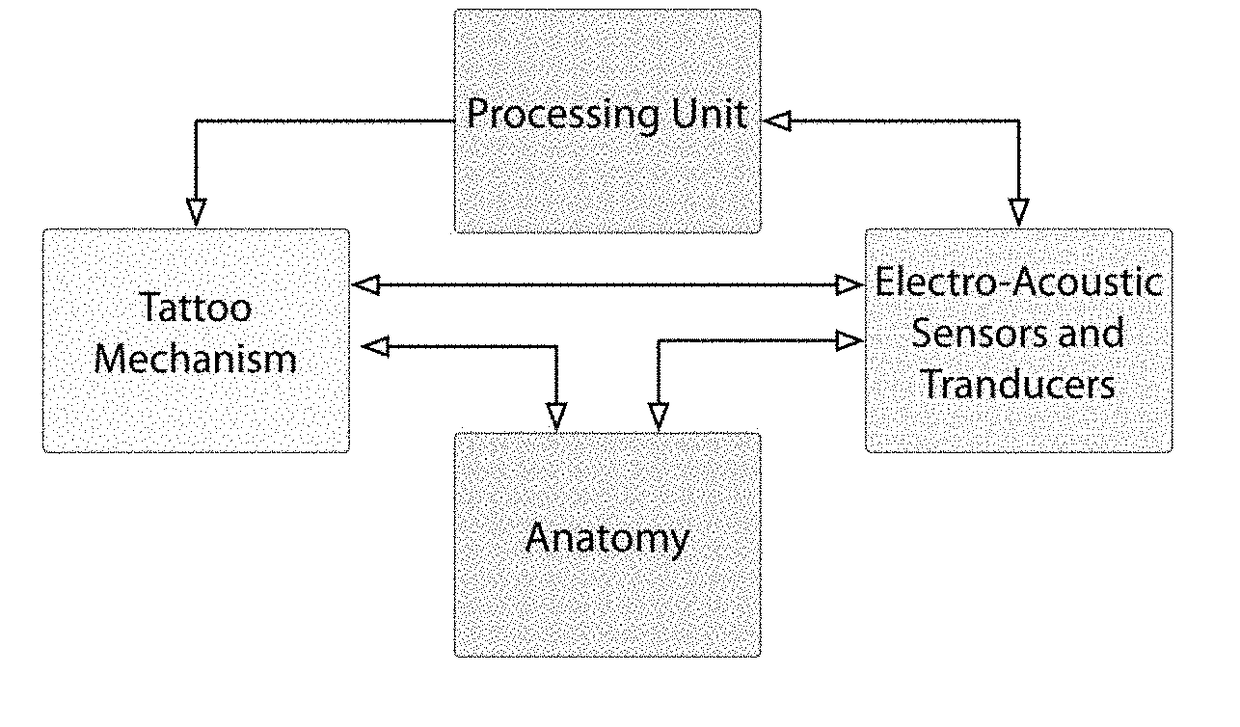

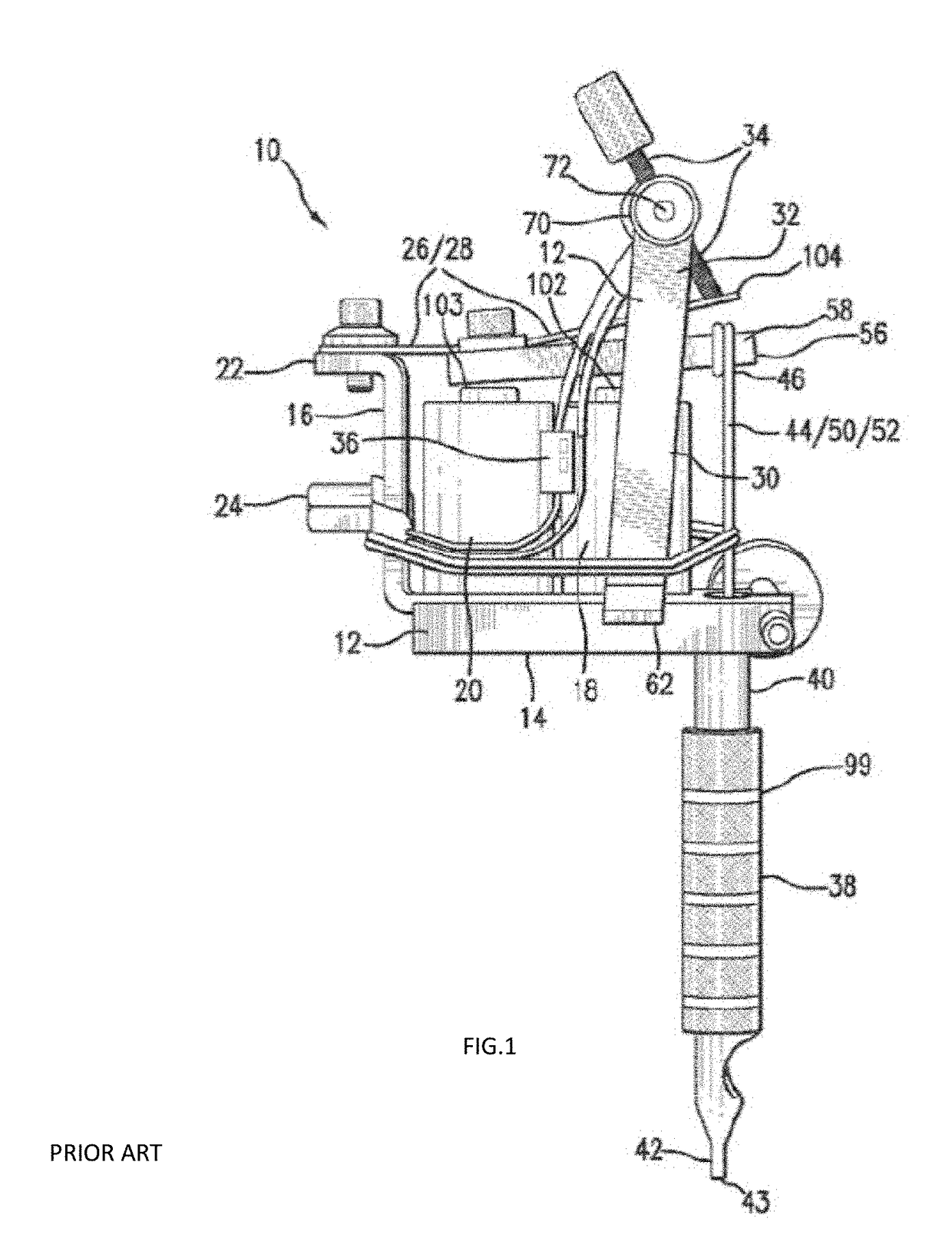

Automated measurement and control system for tattoo delivery

InactiveUS20180000419A1Control deliveryReduce exposureMedical devicesDiagnostic recording/measuringSelf adaptiveAdaptive control

Tattooing, or delivery of pigment into the skin, producing temporary or permanent markings on the skin, is practiced for aesthetic and practical purposes. Human and mechanical control of tattooing may be augmented by sensors, coupled to an adaptive control system capable of improving the results, and relieving demands on the operator.

Owner:RASSMAN WILLIAM

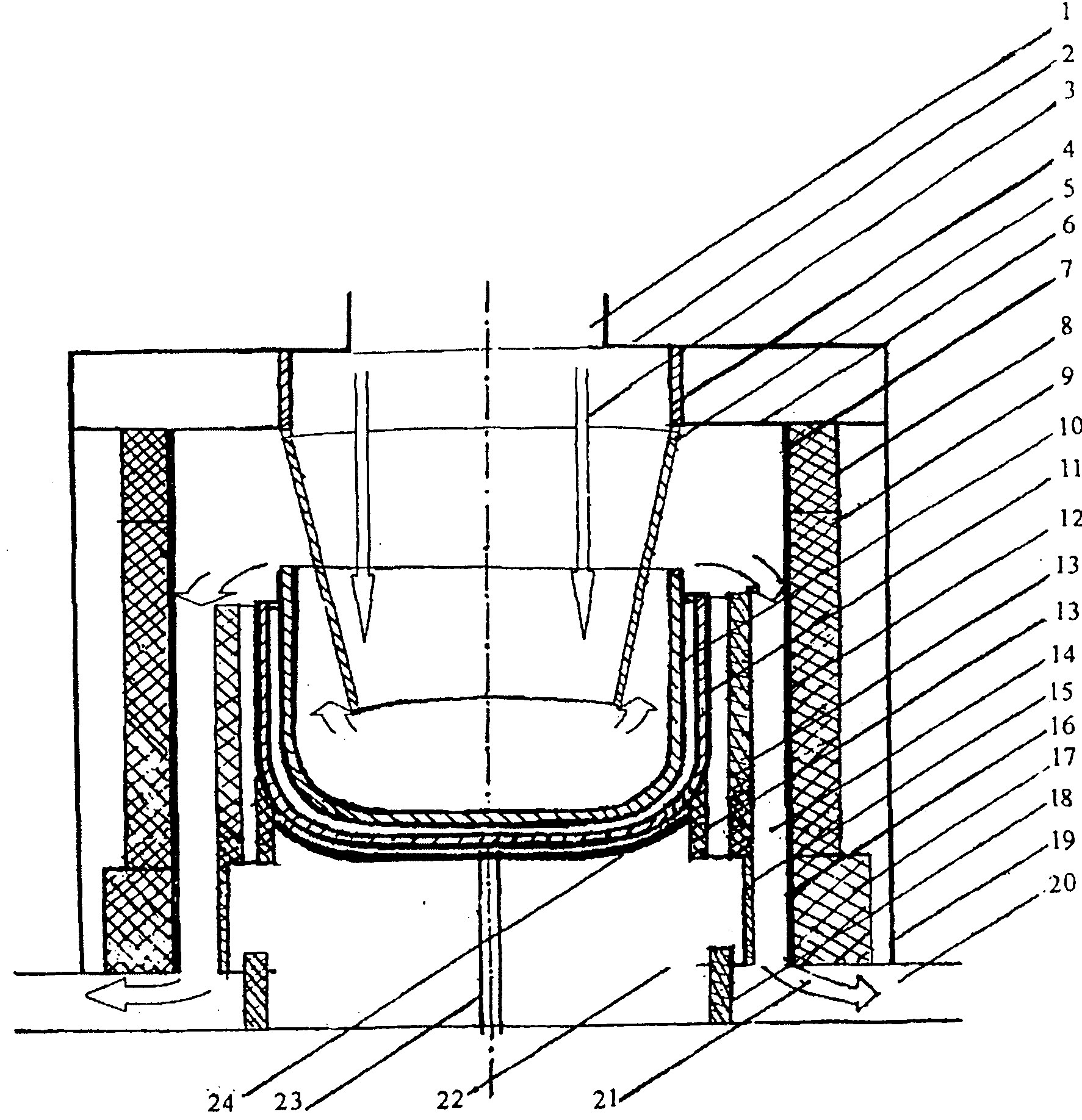

Device of oxygen control growth in single crystal furnace

InactiveCN101922040AImprove insulation effectReduce generationPolycrystalline material growthBy pulling from meltEngineeringInsulation system

The invention belongs to the technical field of semiconductor separation and particularly relates to a device of oxygen control growth in processes of producing and separating single crystal silicon. The device is formed by improving a heater, a guiding cylinder and a lower insulation system in a single crystal furnace, the height of a blade of the heater is reduced, the hot source area at the bottom of a crucible is decreased, the bottom of the quartz crucible is heated little and less oxygen in the production process is generated; a sealing guide system is reconstructed, an encryption type guiding cylinder is additionally arranged on an upper cover plate, and can accelerate the cooling speed; and a lower insulation system in the furnace is reconstructed, therefore, the insulation effect of a lower insulation cylinder is reinforced, more oxygen from a crystal and melt interface can be taken away, the oxygen content is reduced and generated boroxol complex is decreased. The invention can effectively reduce generation and retention of the oxygen in the production process and control generation and transportation of the oxygen, reduces the process and the quantity of the oxygen entering a single crystal, and has the advantages of simple structure, low cost and convenient installation, use and operation.

Owner:江国庆

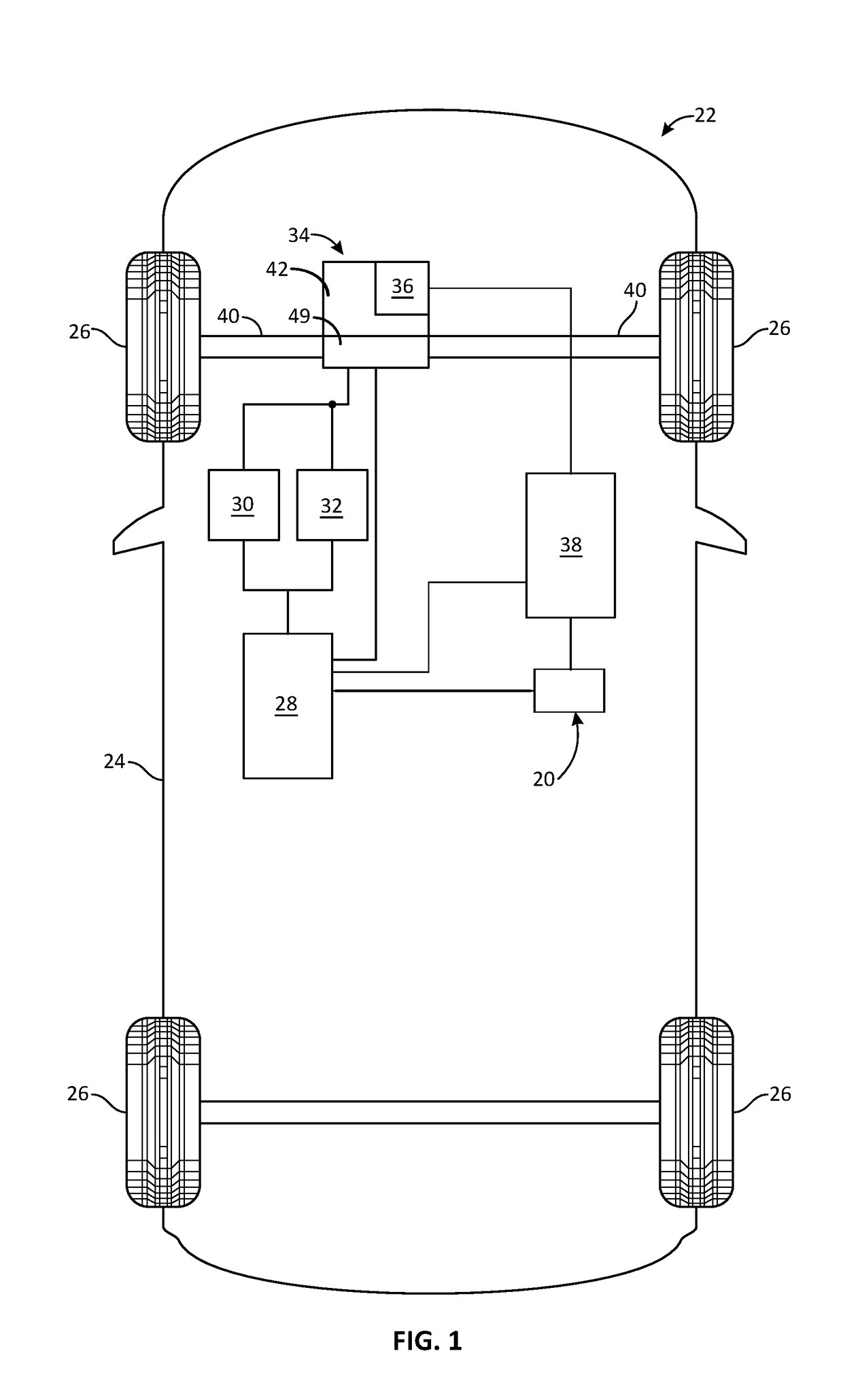

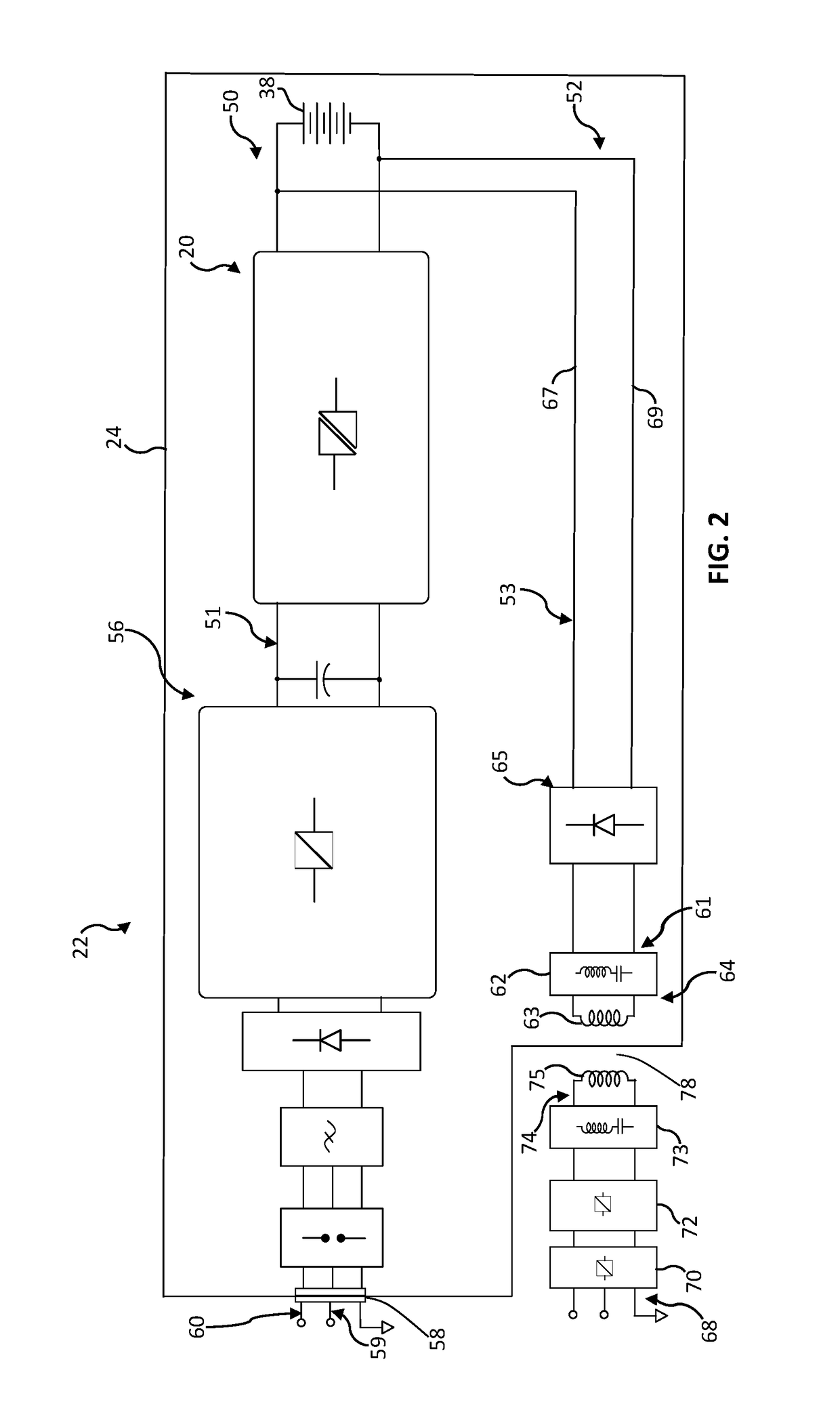

Inductive and conductive onboard charging systems

ActiveUS20180281608A1Control deliveryBatteries circuit arrangementsCharging stationsElectricityEngineering

An onboard charging system for charging from a power source may include an energy storage system. A connector may be configured to couple the onboard charging system with the power source. A charging circuit may be electrically connected between the connector and the energy storage system. A converter may be electrically connected in the charging circuit between the connector and the energy storage system. A rectifier may be electrically connected in the charging circuit between the connector and the converter. Output of an inductive receiver may be electrically connected with the charging circuit between the connector and the converter. The converter may control the delivery of voltage and current to the energy storage system from the power source and from the inductive receiver.

Owner:GM GLOBAL TECH OPERATIONS LLC

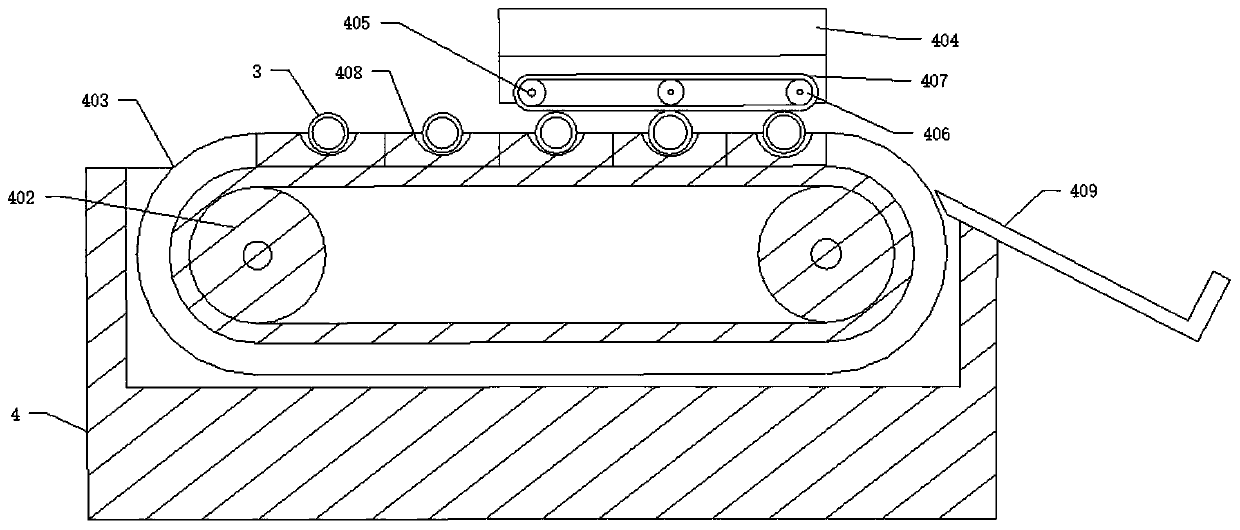

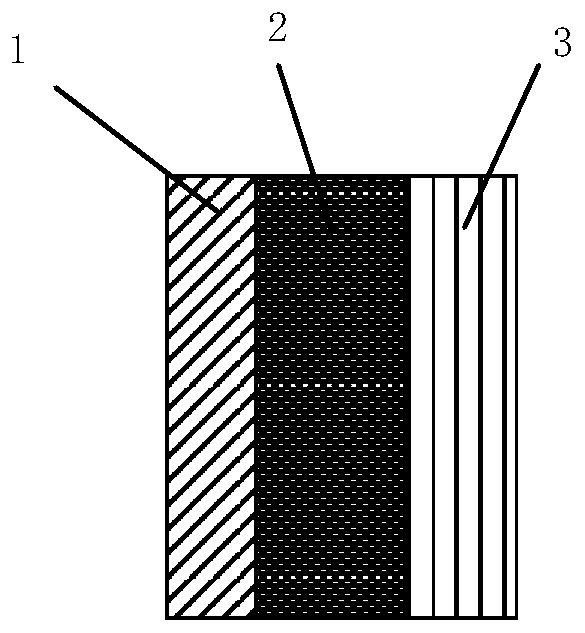

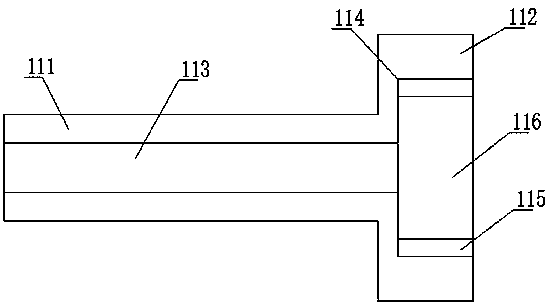

Packaging printing ink transfer roller

ActiveCN110341305ASolve the phenomenon of inconsistency between the front and backQuality assurancePrinting press partsEngineeringPrinting ink

The invention provides a packaging printing ink transfer roller. The ink transfer roller comprises an outer executing unit and an ink transfer mechanism; the outer executing unit is of a left-right symmetric structure; and the ink transfer mechanism is arranged on the outer executing unit through a bearing. According to the ink transfer roller, the phenomenon that in an ink transfer process, ink cannot be transferred to a printing plate due to the fact that parts of ink holes of an existing ink transfer roller are blocked frequently, so that printing products are different in front and back color shade is avoided; and the problem that the surface of the existing ink transfer roller is in contact with an ink scraping knife and is seriously worn after a long time, the ink cannot be stored and transferred, the ink supply is not in time, and the printing quality is influenced is solved.

Owner:浙江朗讯印刷新材料有限公司

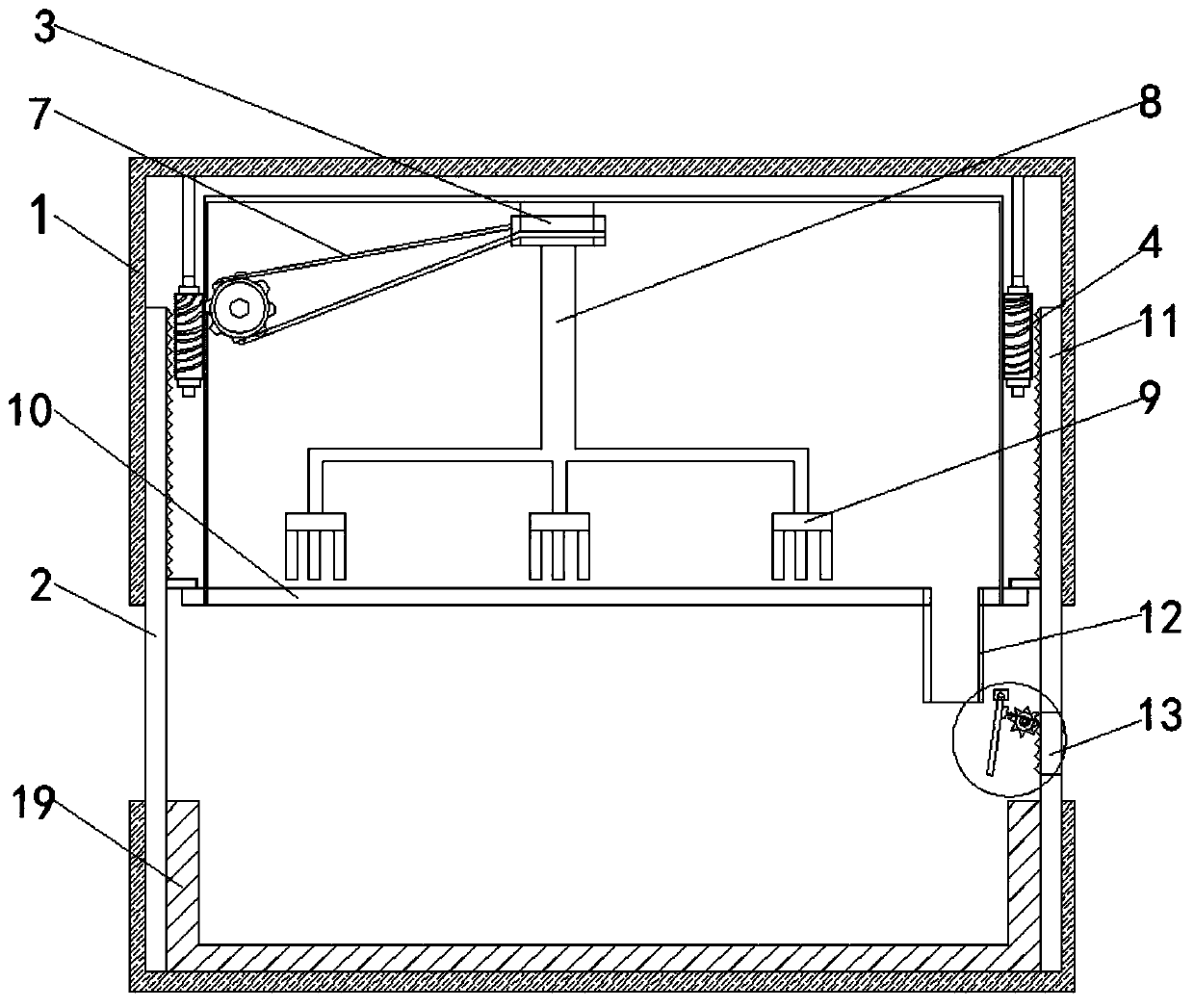

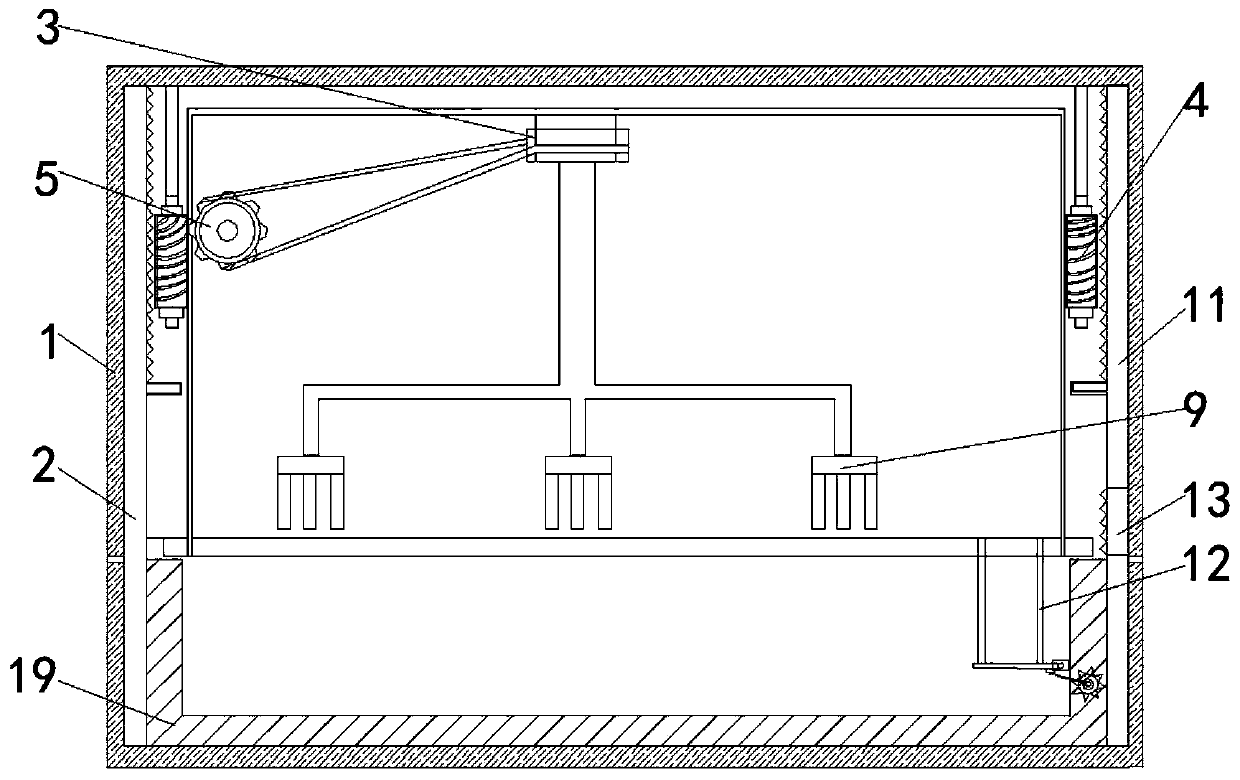

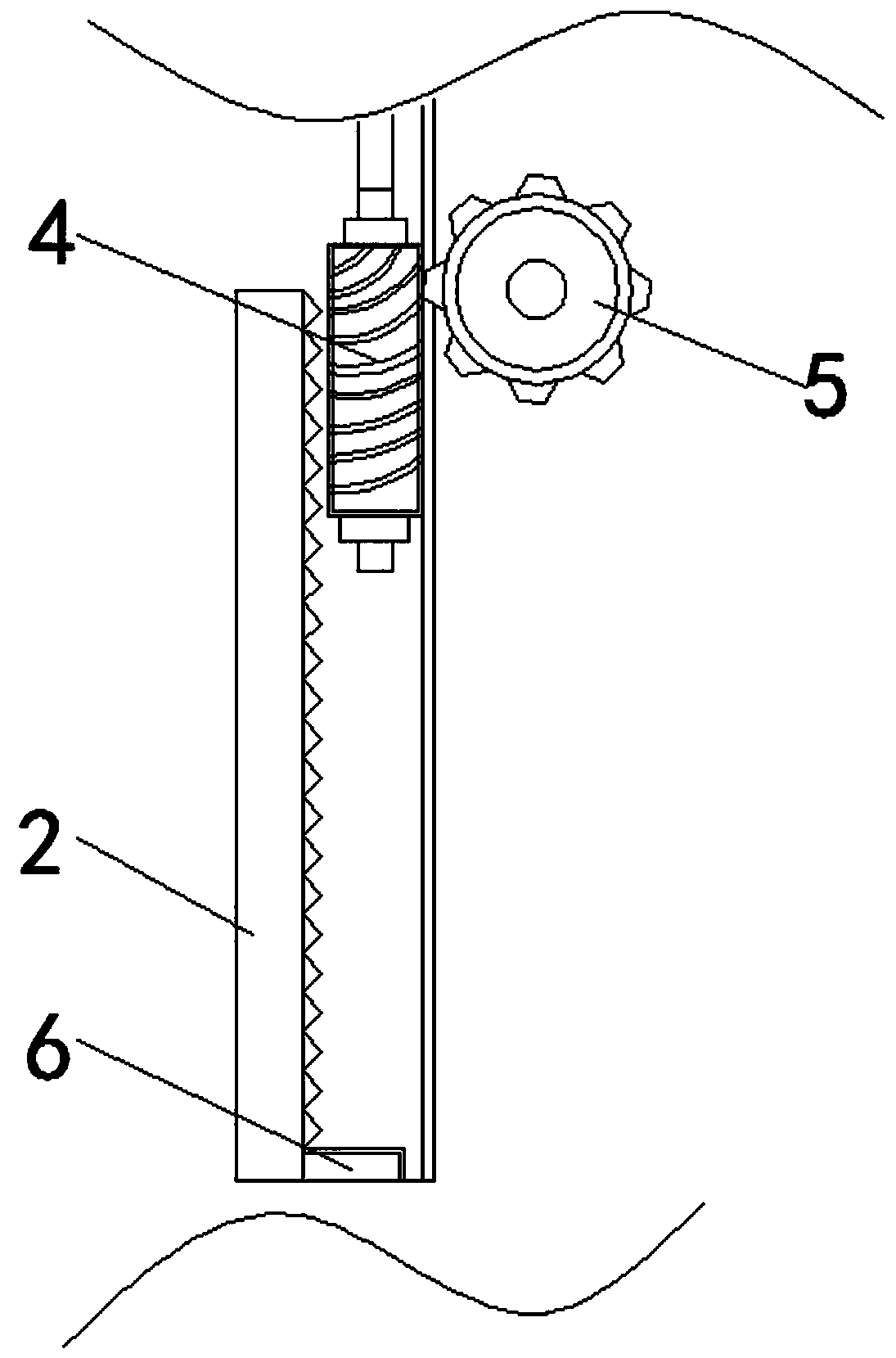

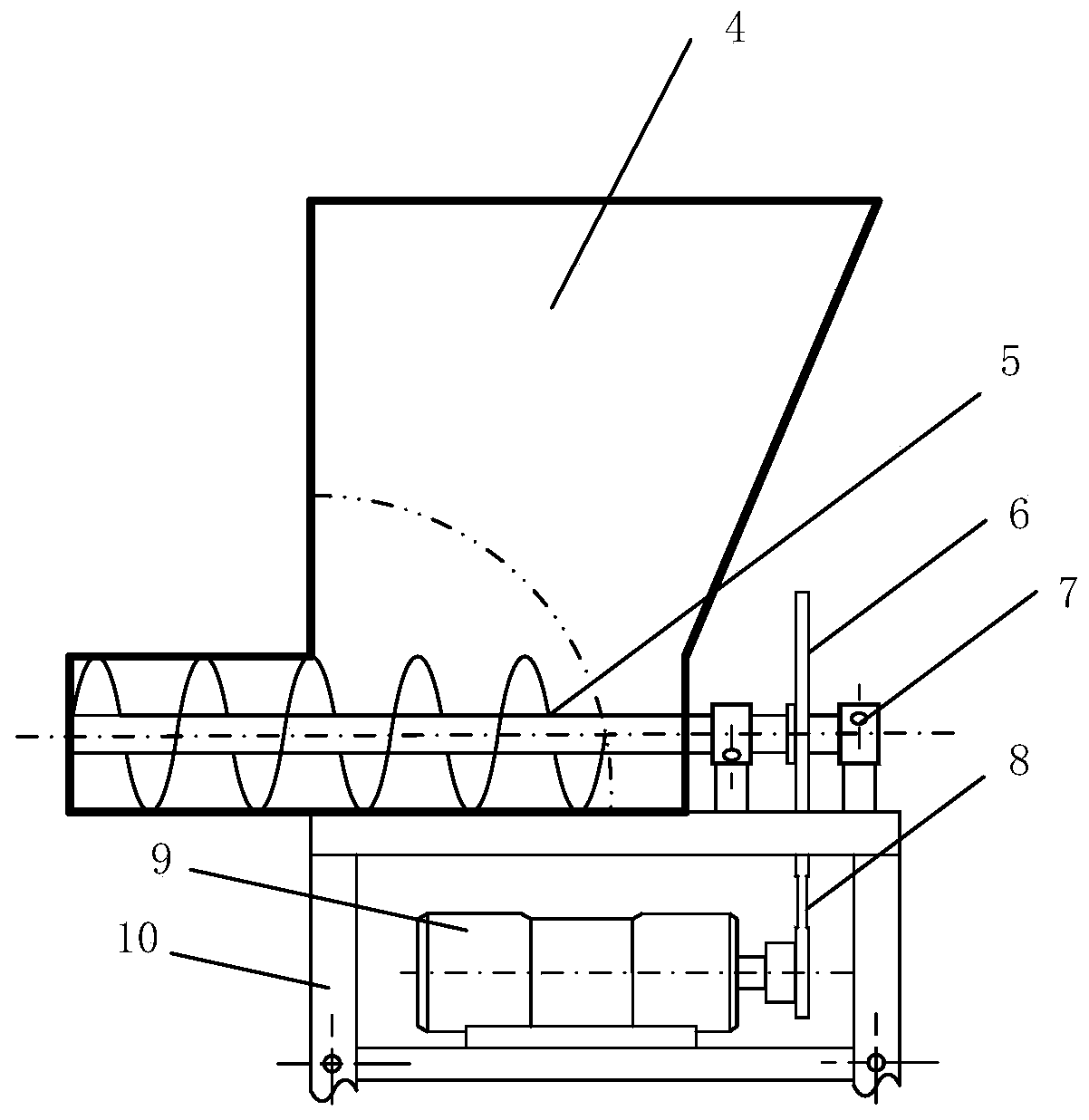

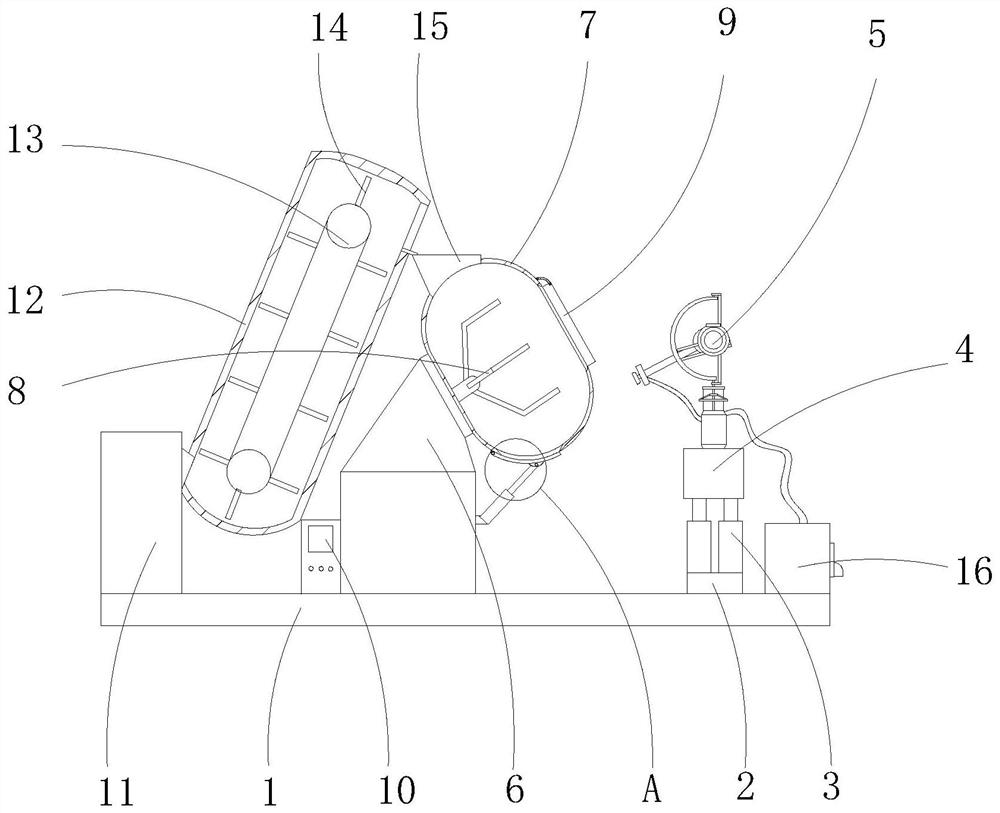

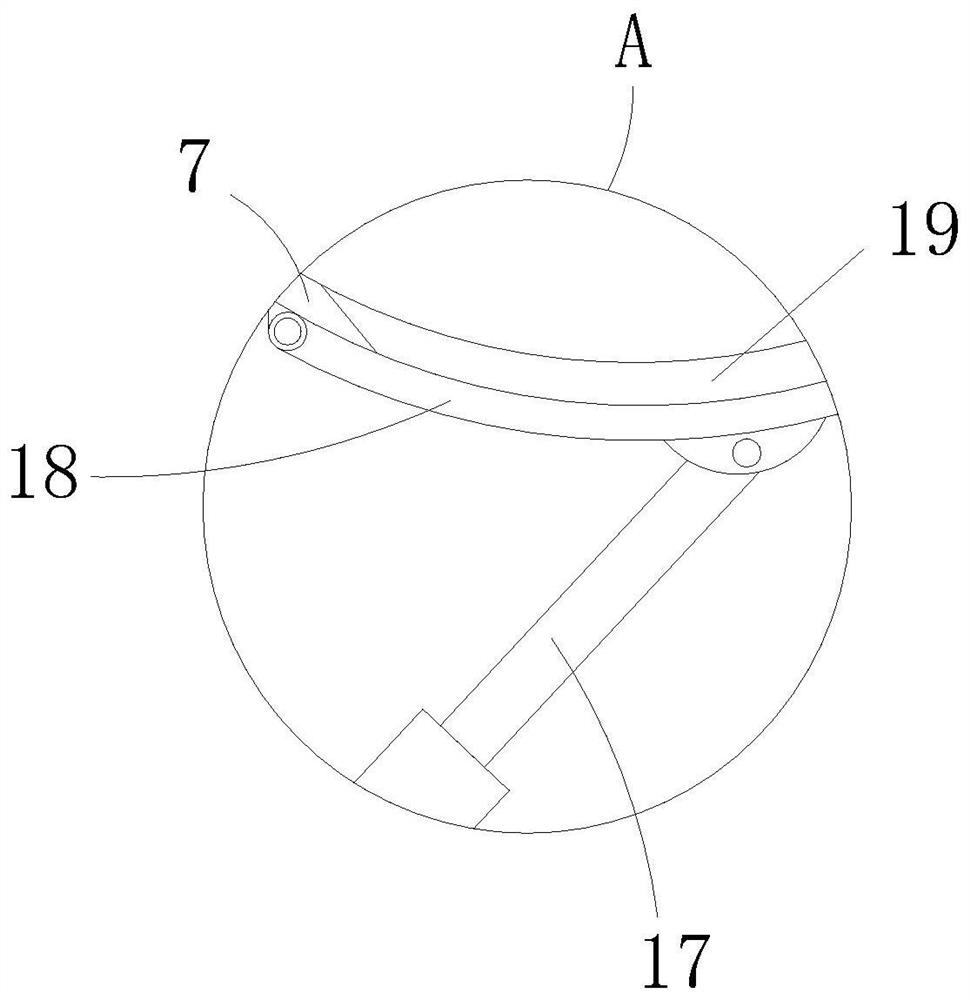

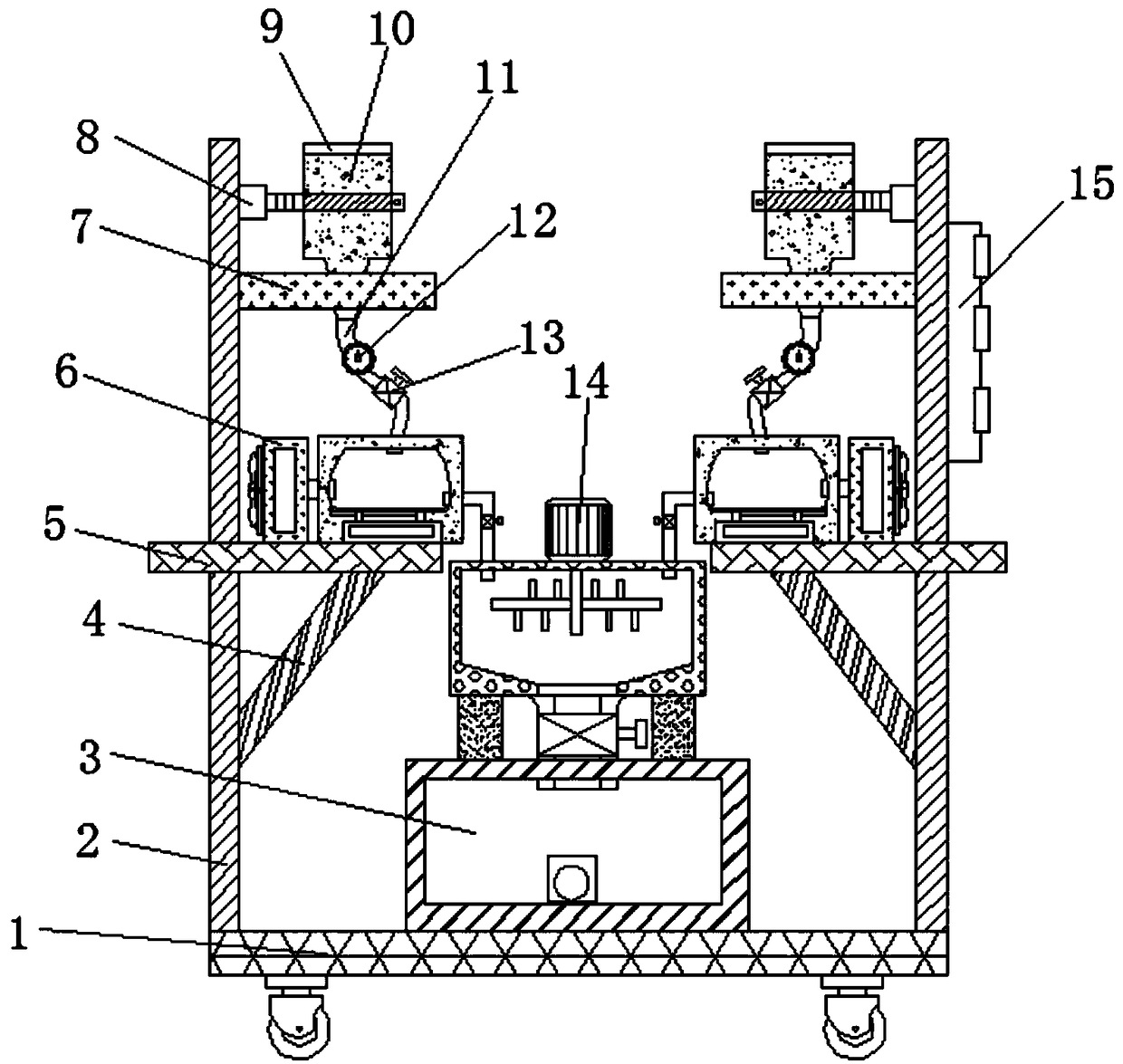

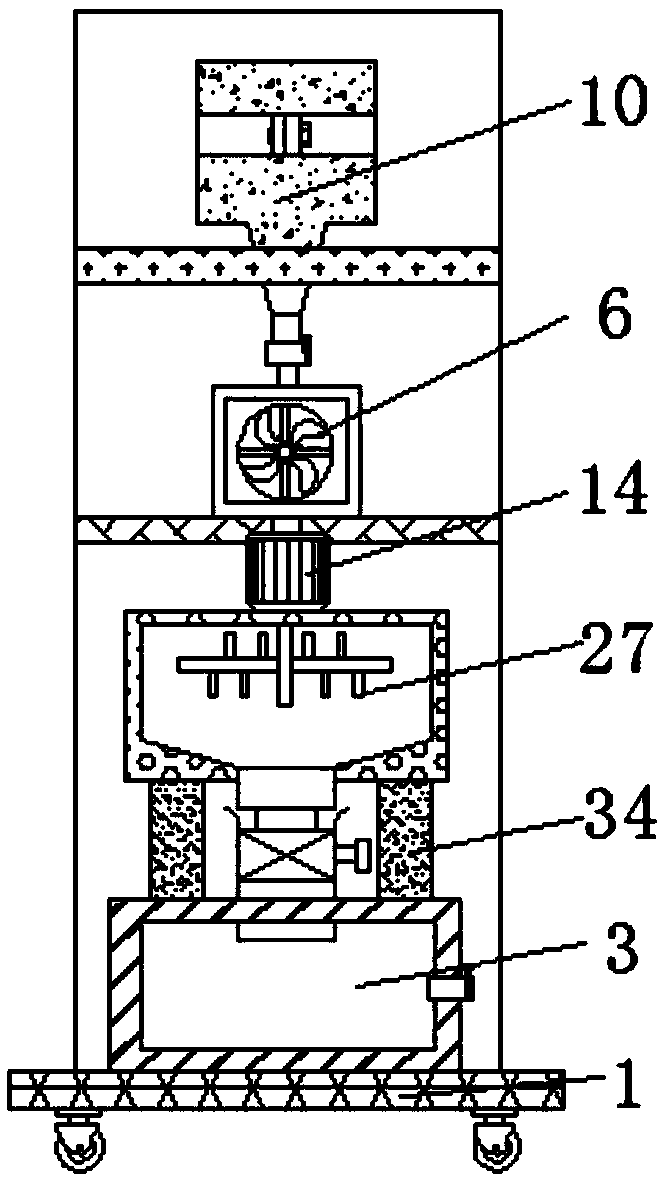

Lifting type automatic feeding device

ActiveCN110352861AIncrease living spaceAutomated Feeding RealizationAnimal feeding devicesGear wheelEngineering

The invention relates to the technical field of breeding industry, and discloses a lifting type automatic feeding device. The lifting type automatic feeding device comprises a machine body, wherein two sides of the inner wall of the machine body are respectively provided with a lifting rack and an auxiliary rack, a roller, a feed box and a clamping block are arranged inside the machine body, a rotating gear and a rotating wheel are arranged inside the feed box, the outer side of the rotating wheel is movably connected with a chain, a stirring shaft is movably connected to the lower portion ofthe rotating wheel, a stirring claw is movably mounted below the stirring shaft, and a feed trough is arranged below the feed tank. According to the lifting type automatic feeding device, rollers mounted on the two sides in the machine body are driven to rotate clockwise through a power supply, so that the lifting rack and the auxiliary rack are driven to descend along with the feed trough, feed is put down during feeding, the feed trough is taken up at ordinary times, the living space of livestock is enlarged, automatic feeding is realized, the rotating wheel drives the stirring shaft to rotate, the feed is stirred to prevent caking, and livestock growth is facilitated.

Owner:湖南百园嘴农业科技股份有限公司

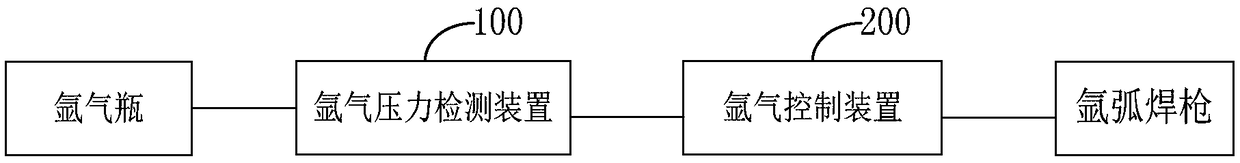

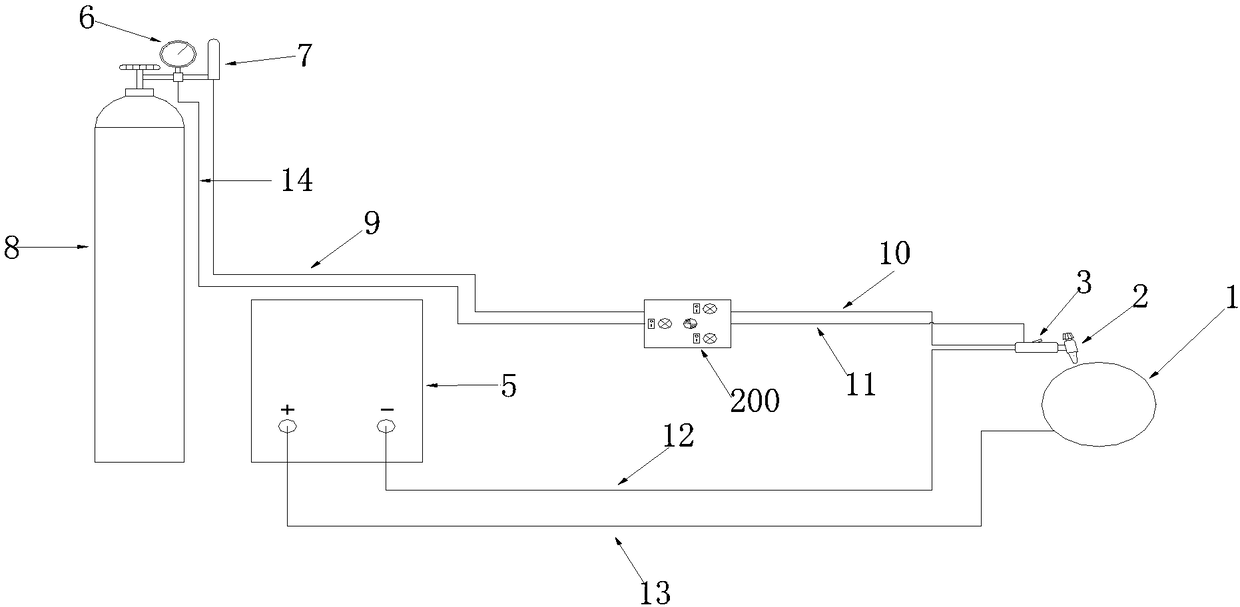

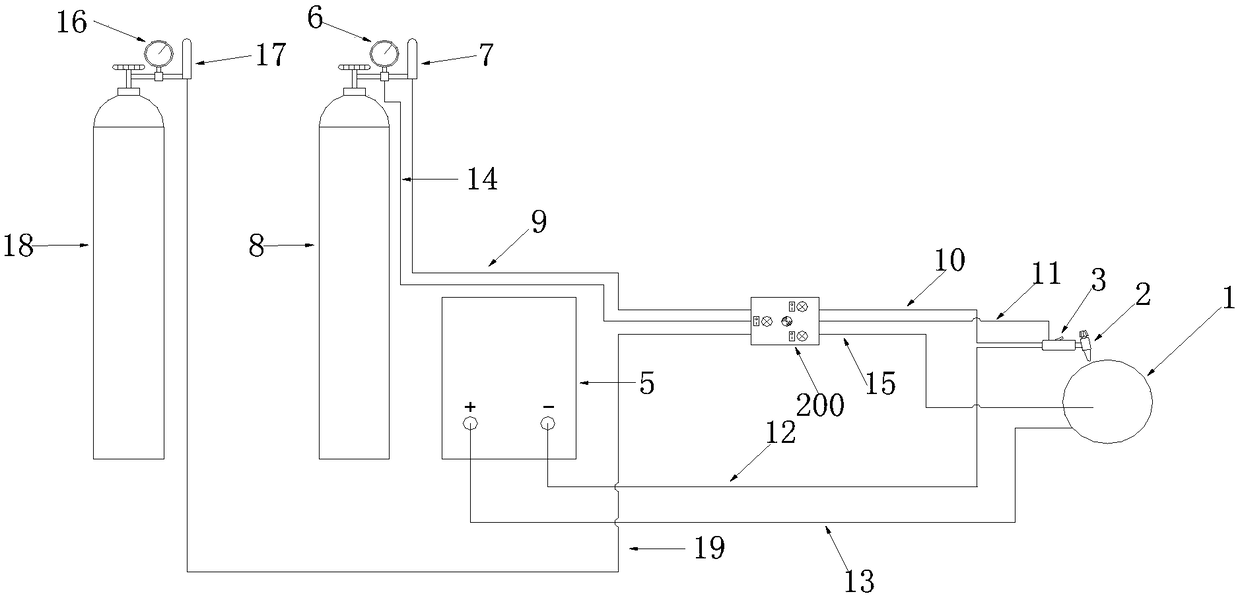

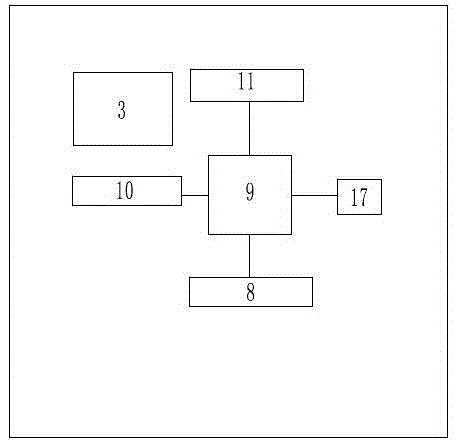

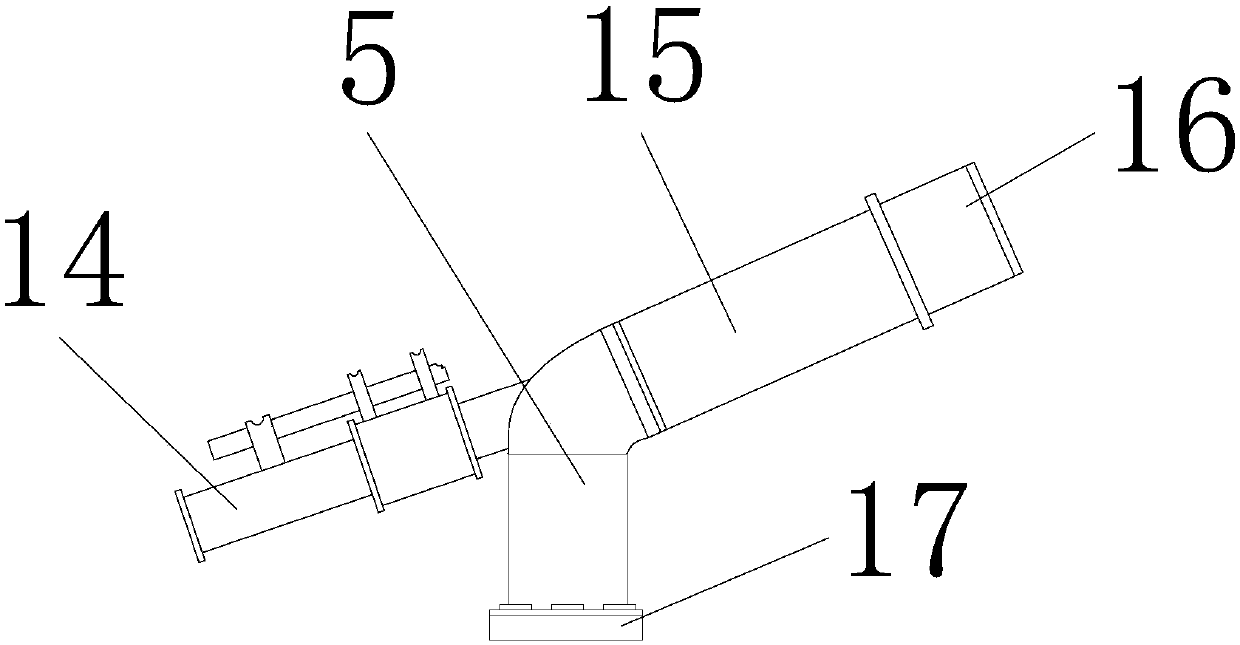

Argon gas throttling detection control device and system

PendingCN108655549AIncrease profitImprove protectionShielding gas supply/evacuation devicesProcess engineeringEngineering

The invention provides an argon gas throttling detection control device and system which are applied to an argon arc welding device. The argon arc welding device comprises an argon arc welding gun andan argon gas bottle, and the argon gas bottle is connected with the argon arc welding gun through a gas delivery pipe; the argon gas throttling detection control device comprises an argon gas pressure detection device and an argon gas control device which are connected with each other; the argon gas pressure detection device is connected with the argon gas bottle and used for detecting the pressure in the argon gas bottle; and the argon gas control device is connected with the argon arc welding gun and used for controlling argon gas delivery in the argon gas bottle. The argon gas amount in the argon gas bottle is known by detecting the pressure in the argon gas bottle, argon gas delivery can be controlled, therefore, the argon gas utilization rate is increased, and the protection effect is improved.

Owner:山东电建建设集团有限公司 +1

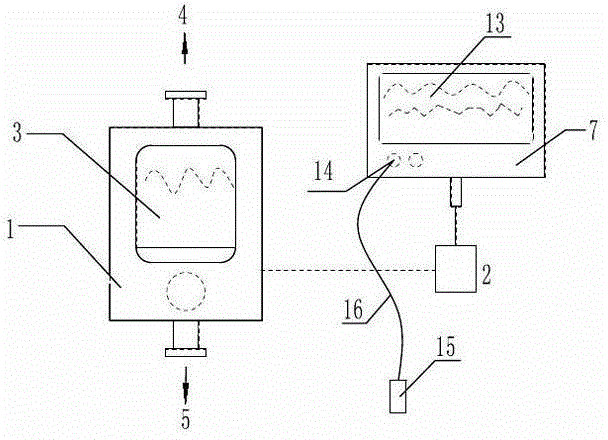

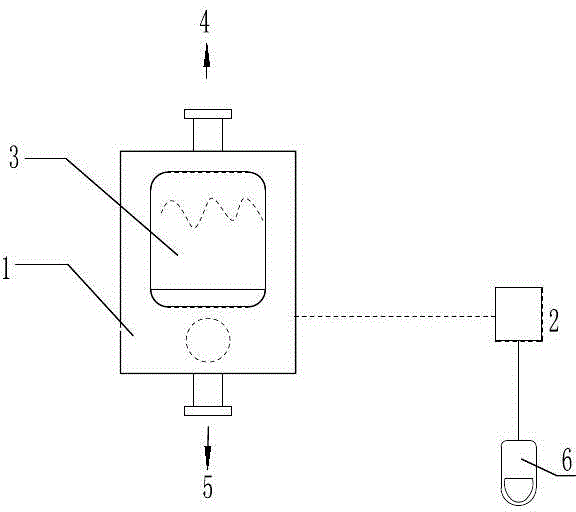

Controllable oxygen transferring throttling system

InactiveCN104587576AImprove comfortAutomatically adjust the time of oxygen deliveryRespiratorsFlow control using electric meansEngineeringOxygen content

The invention provides a controllable oxygen transferring throttling system. The controllable oxygen transferring throttling system comprises a blood oxygen parameter controller and an oxygen flow control device receiving signals of the blood oxygen parameter controller, one end of the oxygen flow control device is connected with an oxygen pump, the other end of the oxygen flow control device is connected with an oxygen uptake tube, a main board is arranged in the oxygen flow control device, and a display screen is arranged outside the main board; the main board is connected with a flow control valve, an operation key and a buzzer, and the main board receives blood oxygen signals of the blood oxygen parameter controller; the blood oxygen parameter controller is connected with a monitor or a blood oxygen finger clip. According to the controllable oxygen transferring throttling system, oxygen transferring is controlled according to the blood oxygen content of a patient; after the blood oxygen content of the patient reaches a normal value, doctors can set an oxygen transferring switch according to practical requirements, and oxygen transferring time is adjusted automatically.

Owner:GUANGDONG EDA MEDICAL TECH CO LTD +1

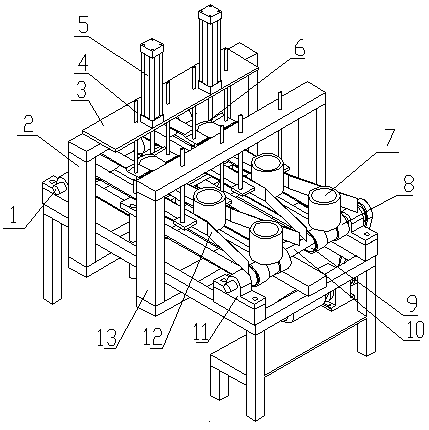

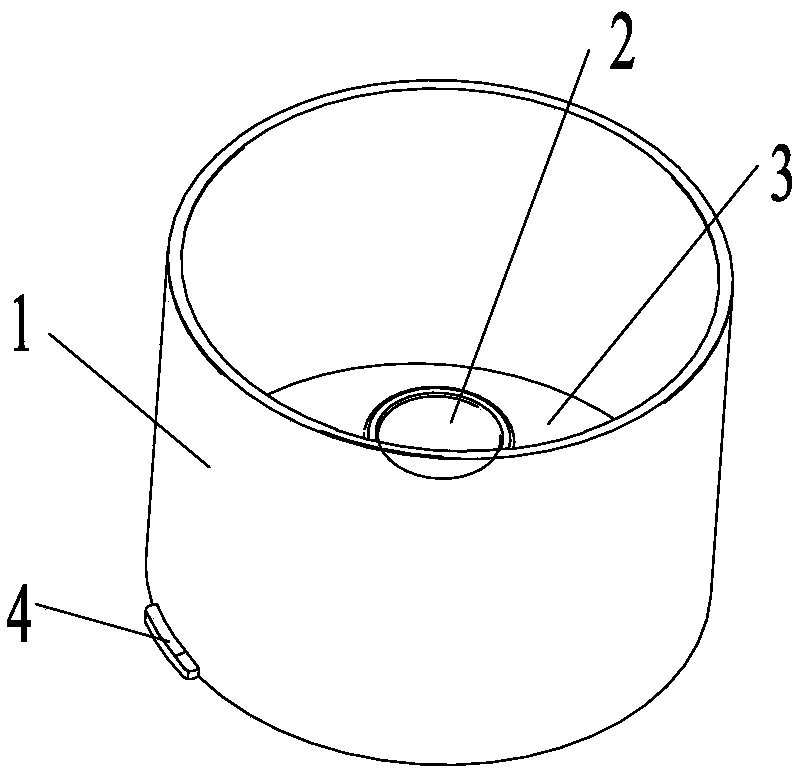

Automatic punching machine for flowerpots

PendingCN107599186AControl deliveryAvoid impact damageStone-like material working toolsPunchingEngineering

The invention discloses an automatic punching machine for flowerpots. A left guide plate and a right guide plate are arranged, so that the conveying of ceramic bodies can be controlled, and incorrectpunching positions caused by easiness in left-right deviation of the ceramic bodies during conveying are avoided so as not to influence the attractive appearance of the flowerpots; an upper cylinder and a punching cylinder are arranged, so that the punching cylinder is arranged just in the middle of a group of belts I, the punching positions can be determined, the punching force and position are stable by punching by virtue of the punching cylinder, the punching is facilitated, and the punching efficiency can be improved; a lower punching die is arranged, so that the punching impact force canbe relieved, the ceramic bodies can be prevented from being damaged by the punching impact force, and the probability of defective products can be reduced; and a lower cylinder is arranged, a lower cylinder fixing plate and an upper limiting rod can be replaced according to the height of the ceramic bodies, and the height of a lower punching die fixing plate is changed by the lower cylinder, so that the ceramic bodies with different heights can be punched, and the use range of the punching machine is extended.

Owner:QUANZHOU KUNTAI MACHINERY PRECISION MFG CO LTD

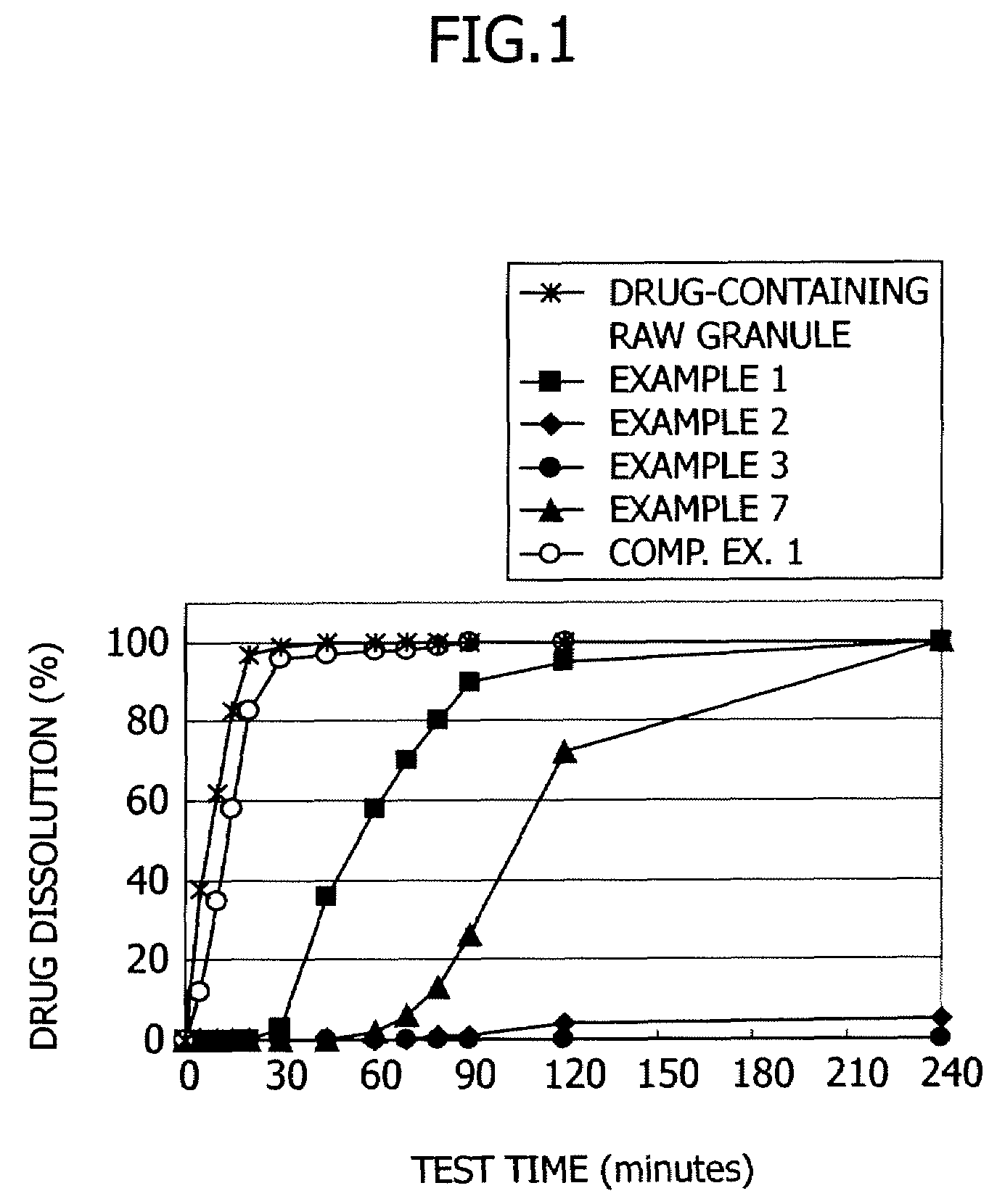

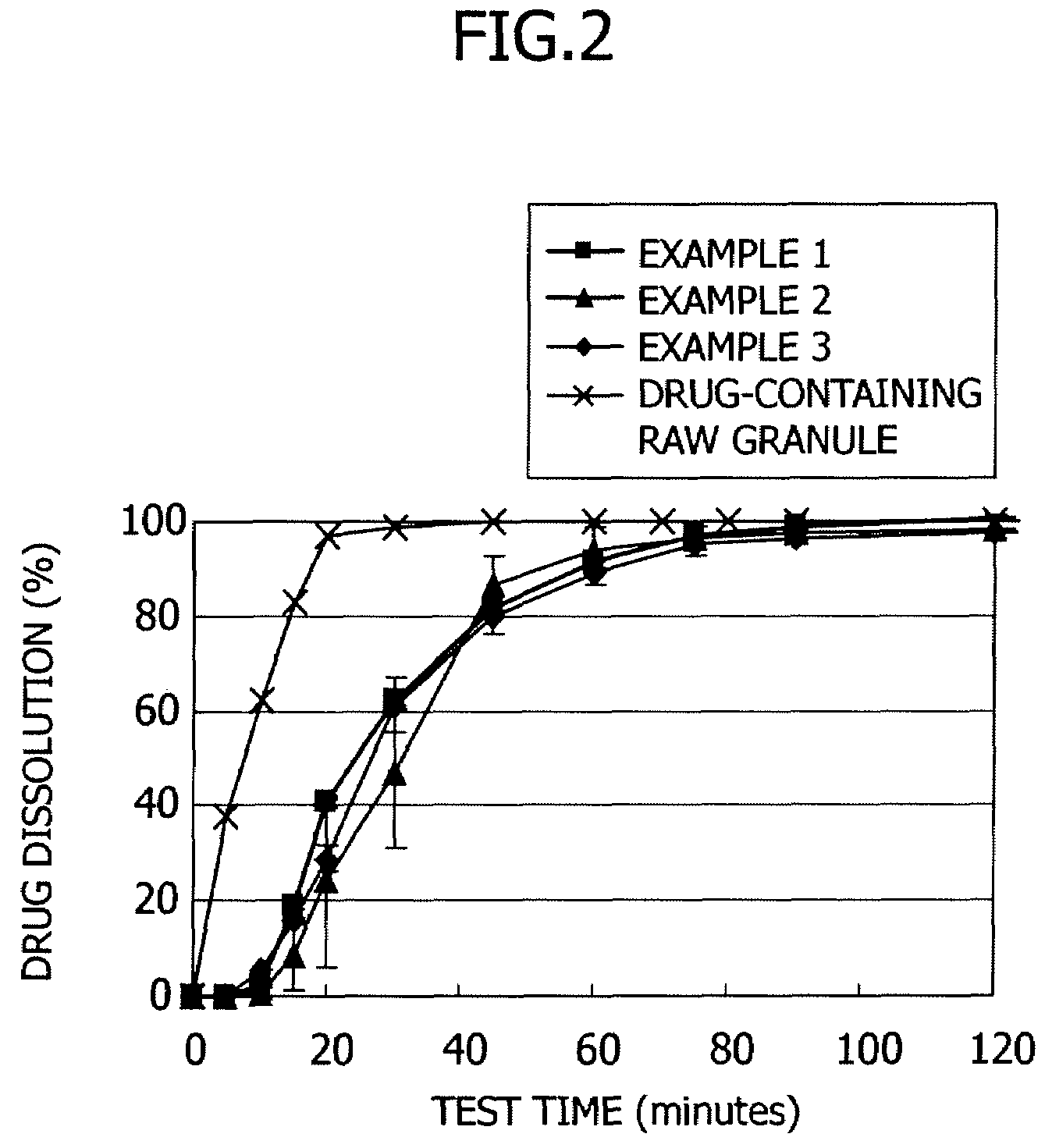

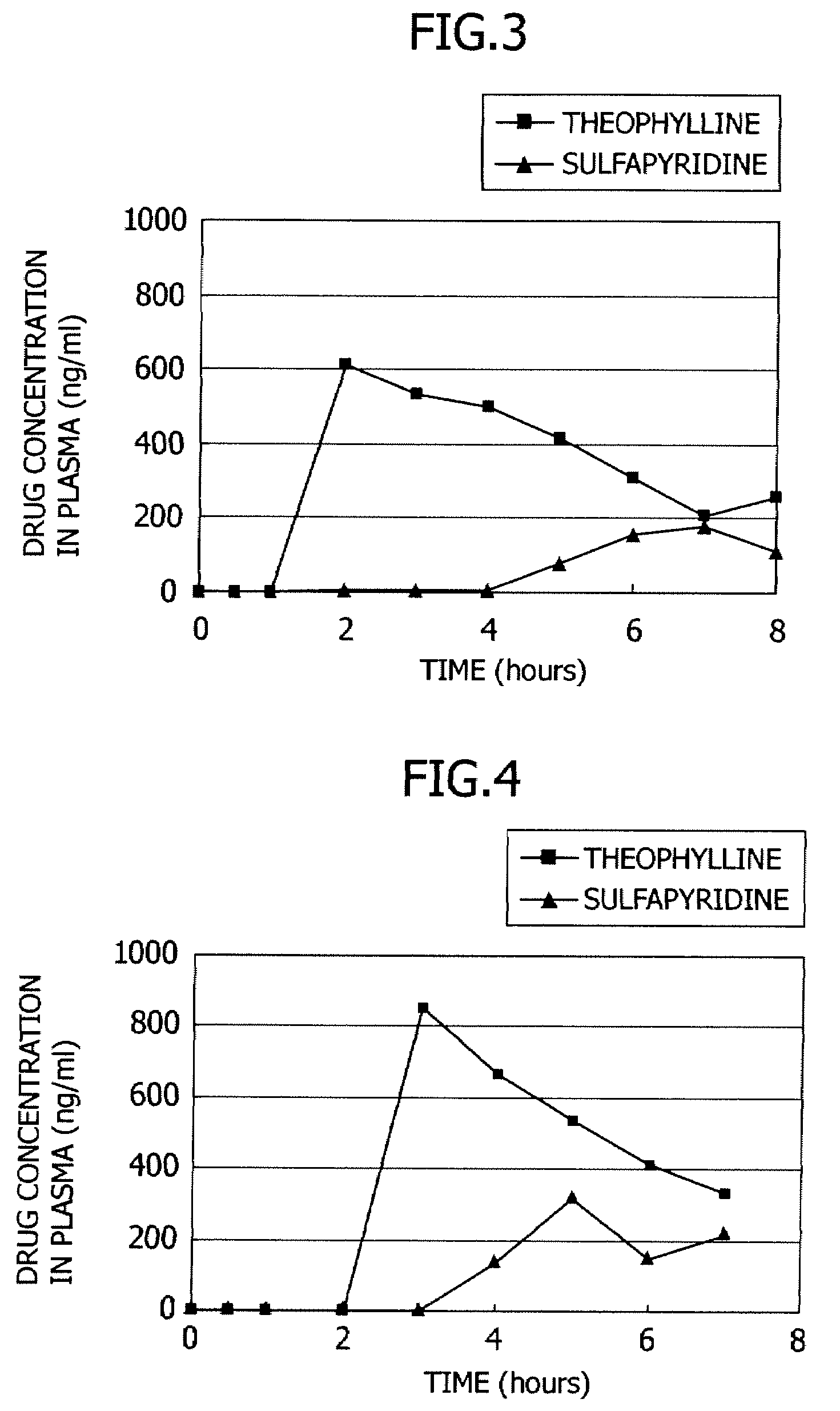

Enteric-coated preparation covered with enteric coating material for site-specific delivery of drug to site within the small intestine

InactiveUS20070196399A1Control deliveryReduce negative influencePill deliveryPharmaceutical non-active ingredientsHydroxypropylmethyl celluloseMethylethylcellulose

Provided is an enteric-coated preparation comprising an enteric coating material capable of delivering a drug to a site within the small intestine in a site-specific manner. More specifically, provided is an enteric-coated preparation for delivering a drug to a site within the small intestine in a site-specific manner, comprising a drug-containing preparation and an enteric coating material which covers the preparation, wherein, in Dissolution Test as specified in the Japanese Pharmacopoeia Fourteenth Edition, no dissolution of the drug is observed in the Japanese Pharmacopoeia first fluid (pH 1.2) while dissolution of the drug is observed in the Japanese Pharmacopoeia second liquid (pH 6.8) 20 minutes or later from start of the Dissolution Test. The enteric coating material is preferably selected from the group consisting of hydroxypropylmethyl cellulose acetate succinate, hydroxypropylmethyl cellulose phthalate, methacrylic acid copolymer and carboxymethylethyl cellulose.

Owner:SHIN ETSU CHEM IND CO LTD

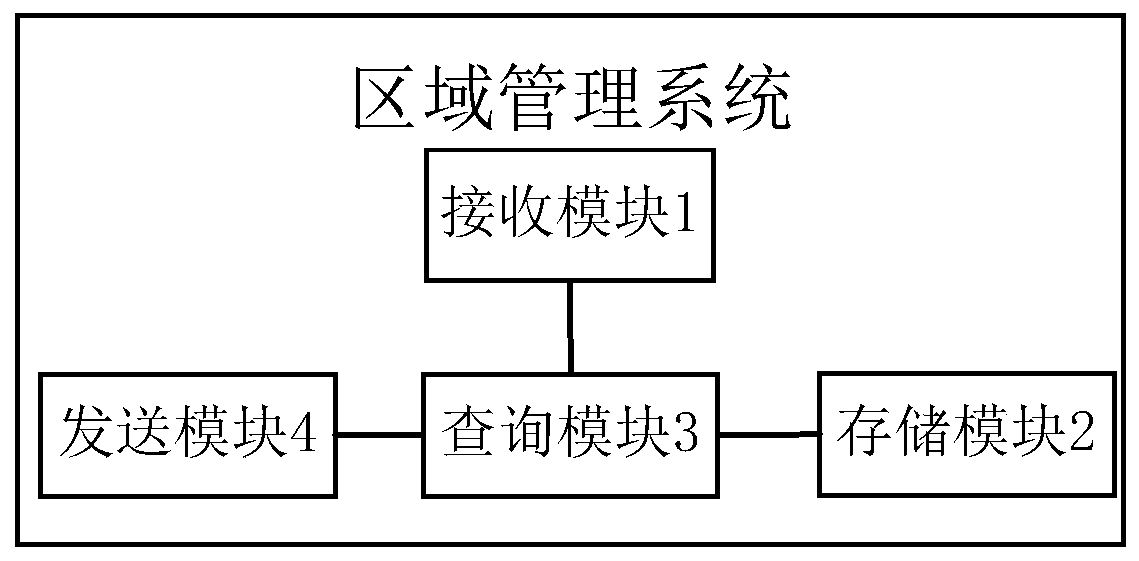

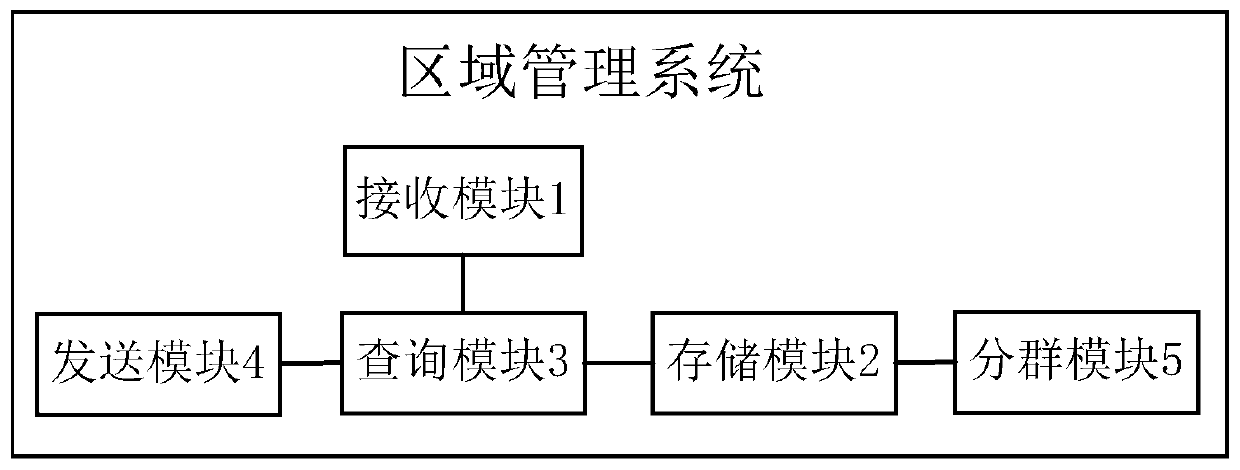

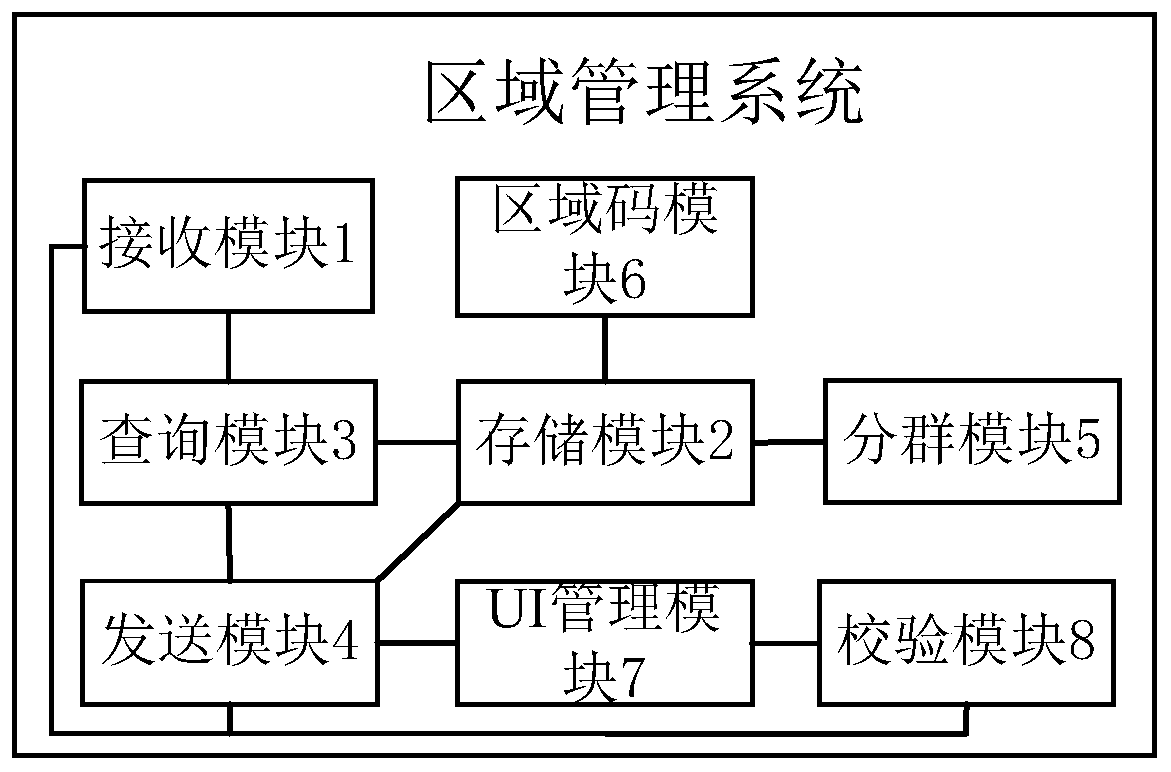

UI interface area management system, distribution system and distribution method

ActiveCN109947802AThe disadvantages of a single display are obviousReduce operating pressureSpecial service provision for substationDigital data information retrievalDistribution methodDistribution system

The invention discloses a UI (user interface) region management system, a distribution system and a distribution method, and relates to the field of radio and television. The system comprises a receiving module, a storage module, a query module and a sending module, the receiving module is used for receiving a UI acquisition request which is sent by a terminal and carries the CA card number; the storage module is used for storing the association information of the CA card number and the group and the association information of the group and the UI download address; the query module is used foracquiring the CA card number from the receiving module, finding a group associated with the CA card number according to the association information of the CA card number and the group, and finding aUI download address according to the association information of the group and the UI download address; and the sending module is used for sending the UI downloading address to the terminal. Accordingto the invention, the group where the terminal is located is found according to the card number of the CA card so as to find the UI download address, and different UI interfaces are put according to the user information.

Owner:湖北省广播电视信息网络股份有限公司

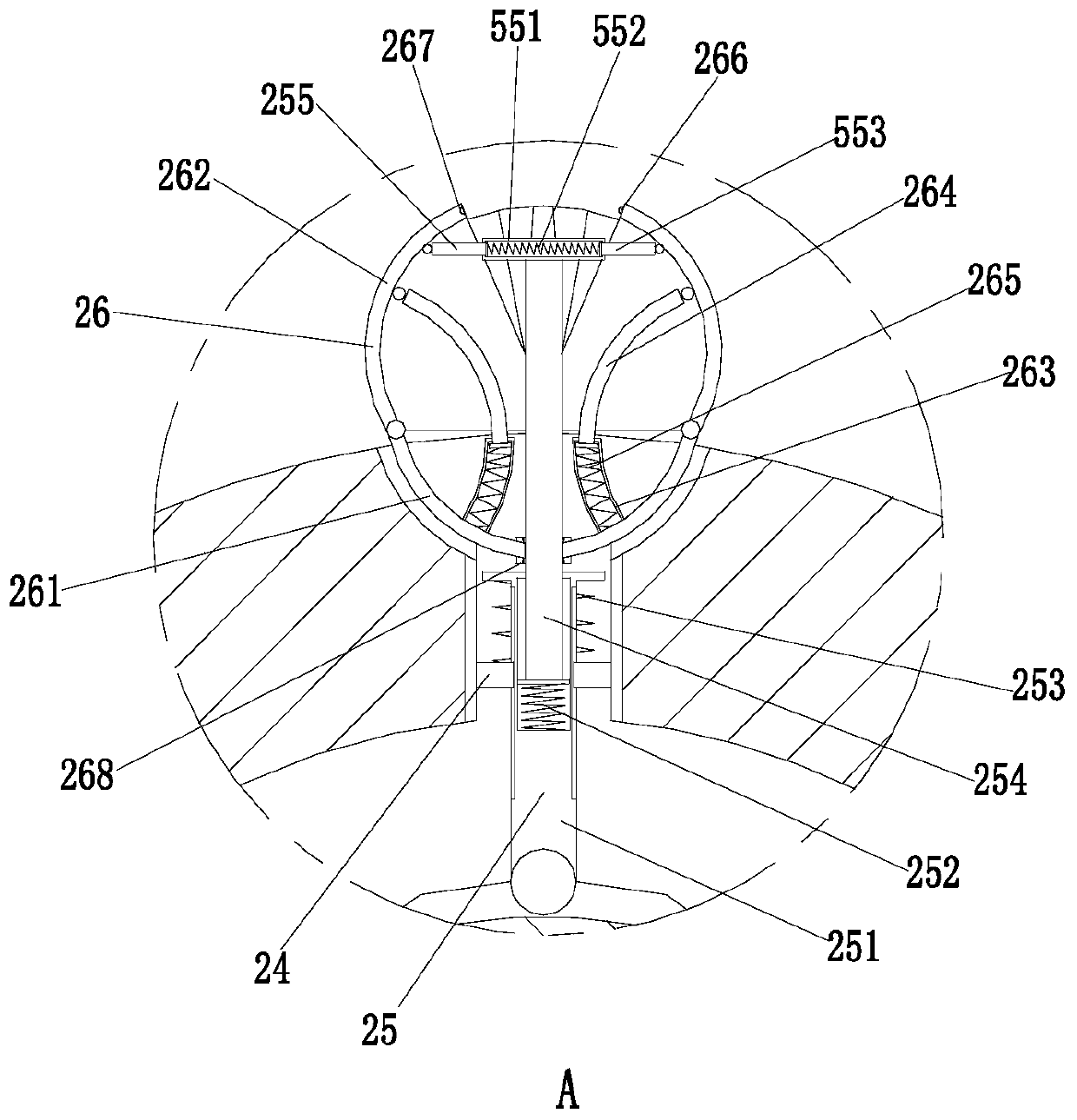

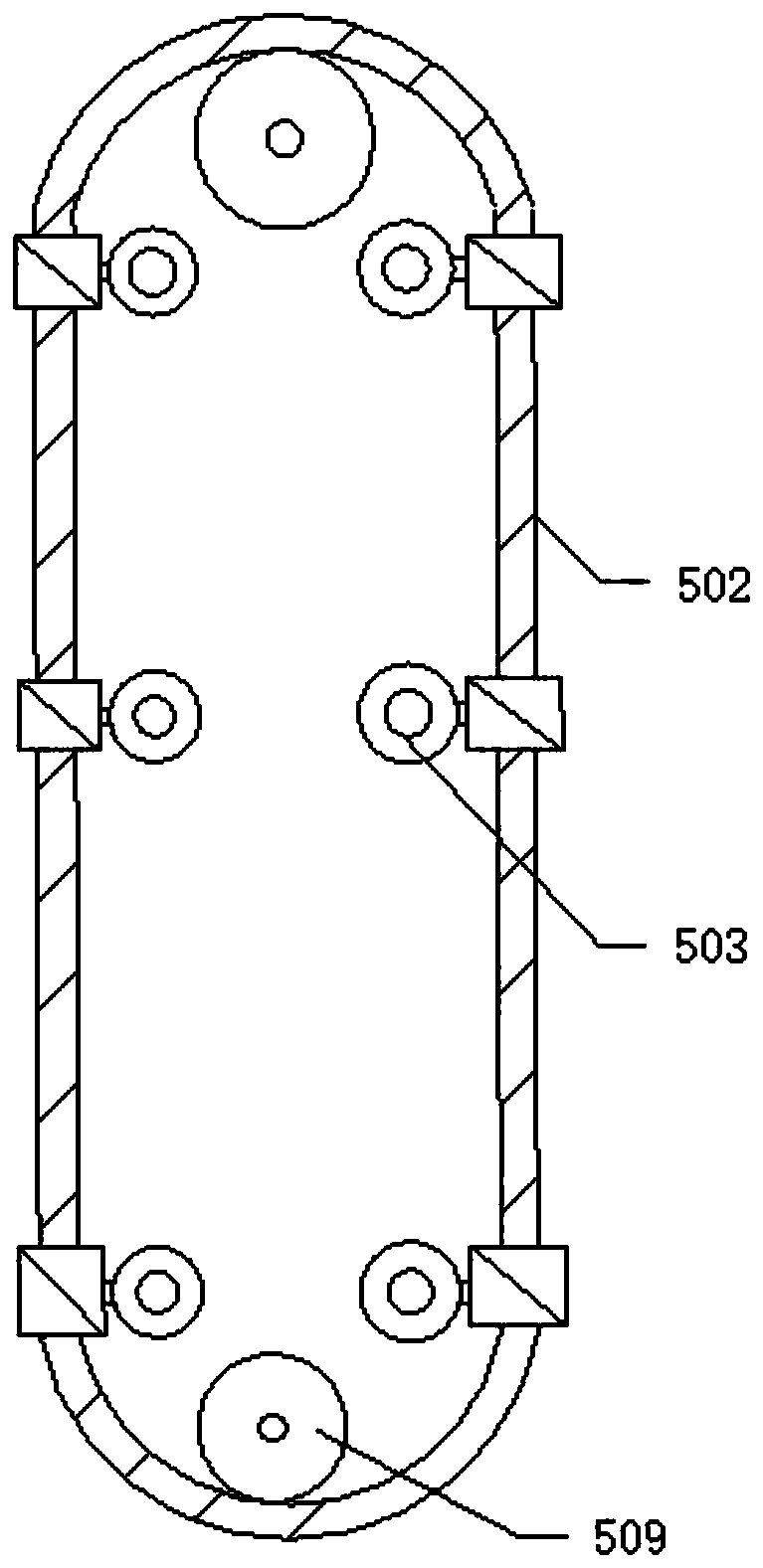

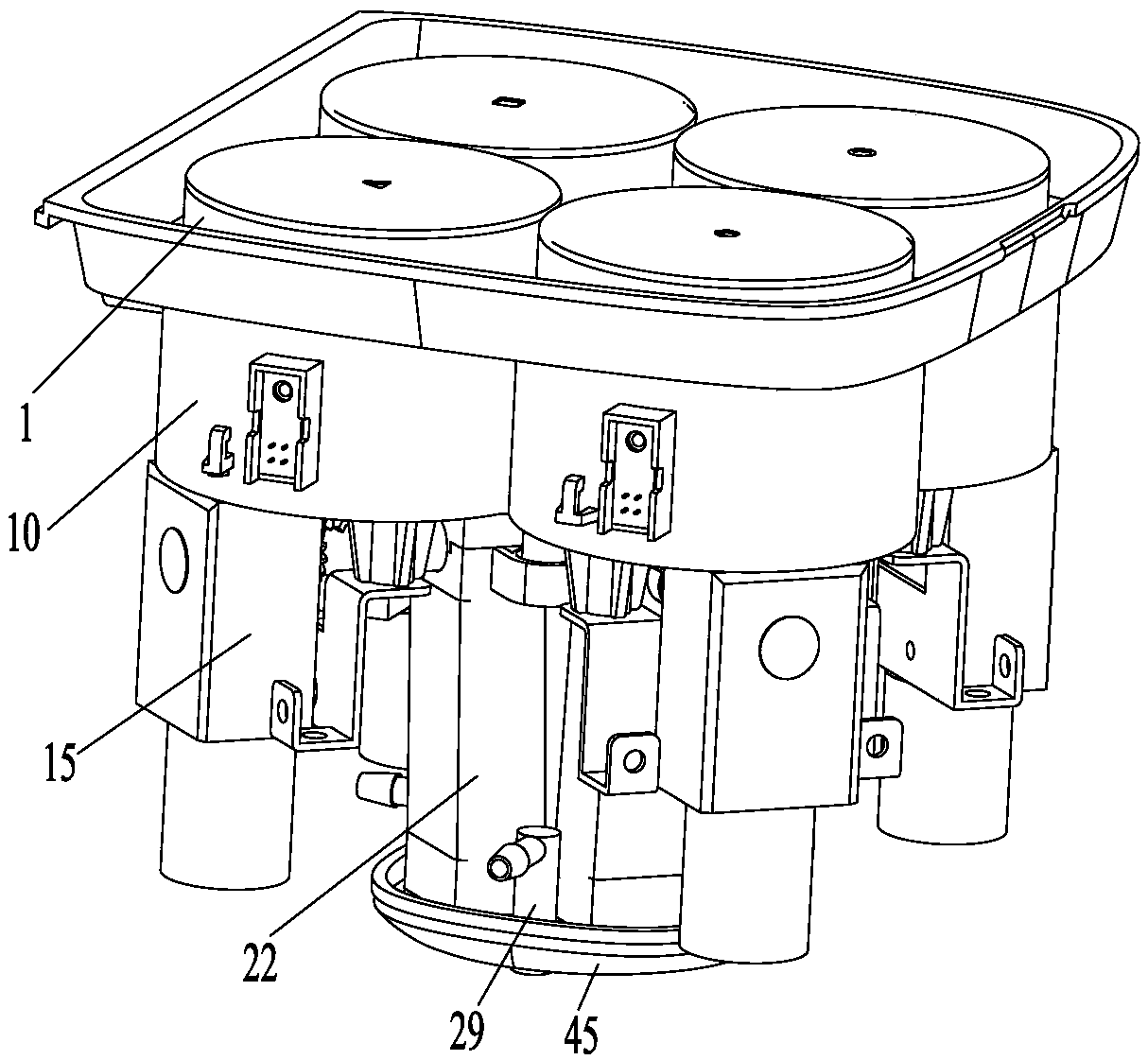

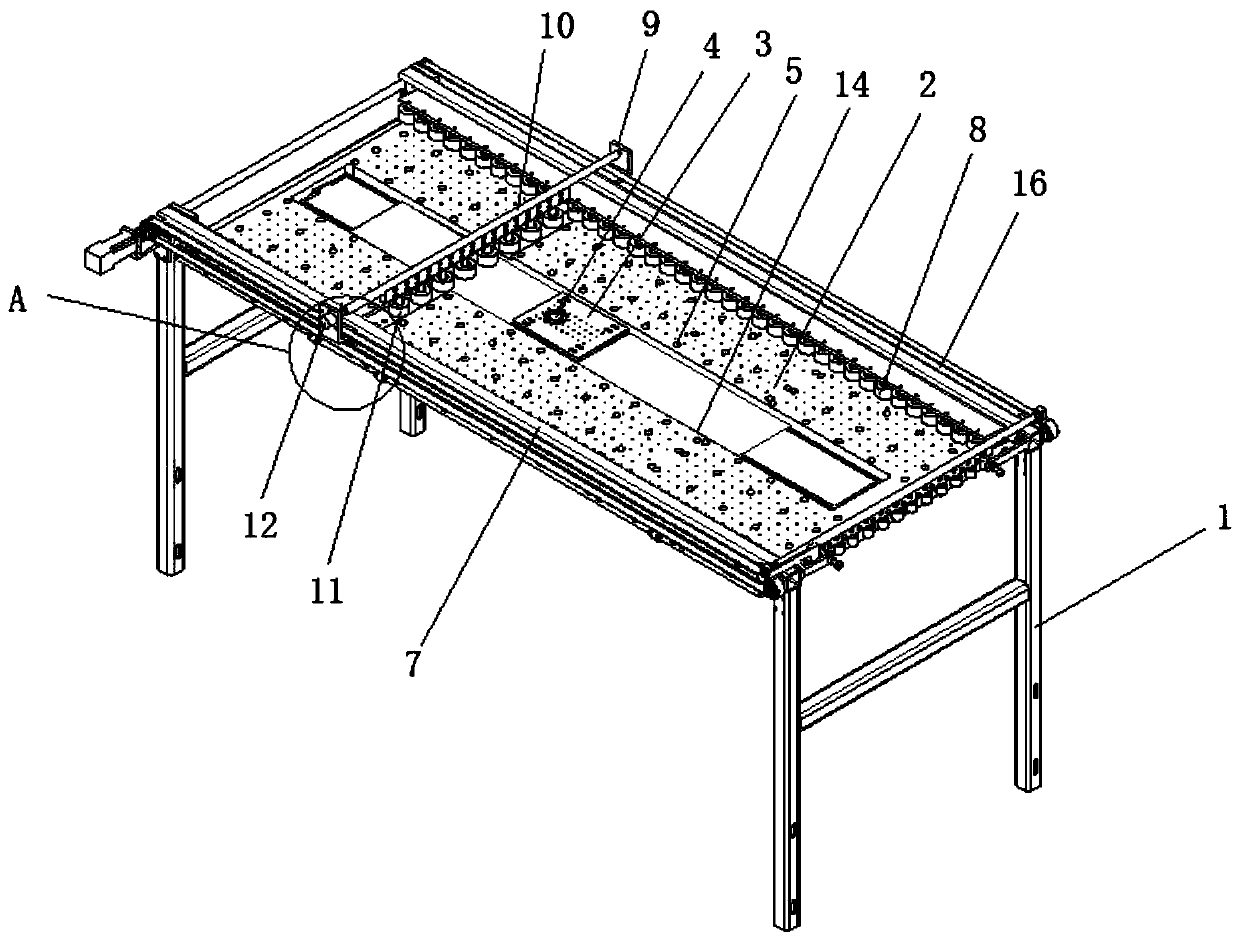

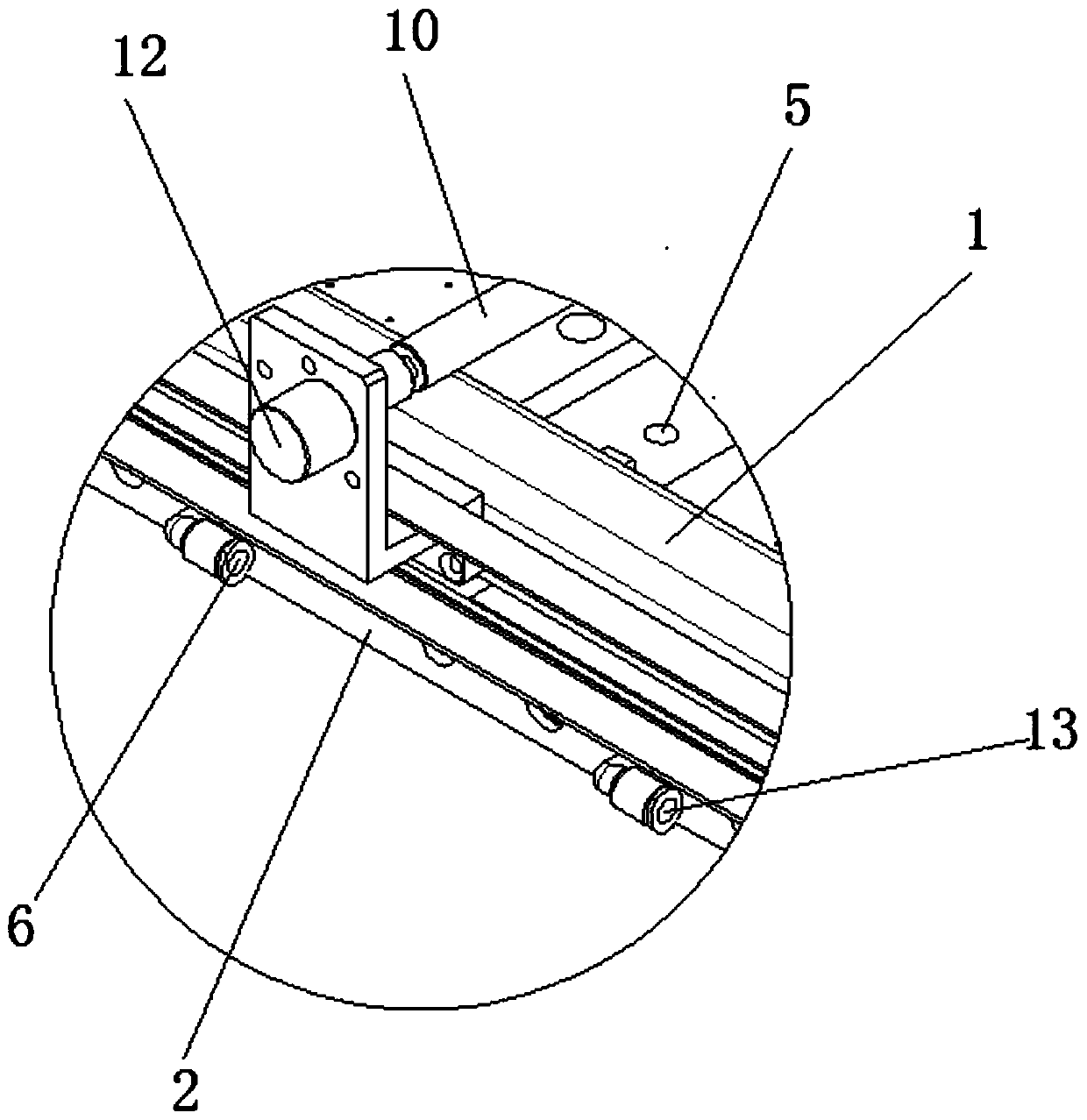

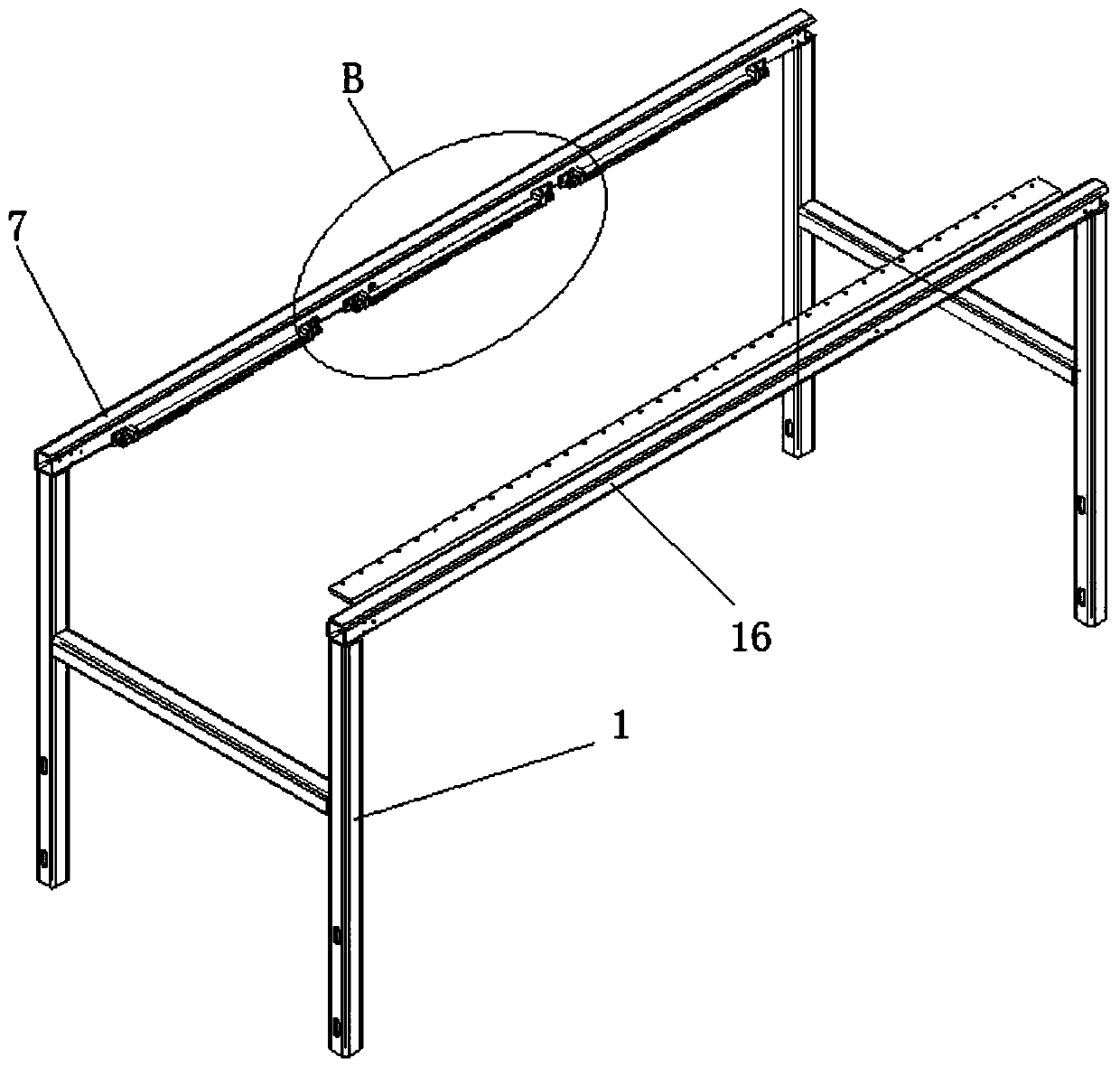

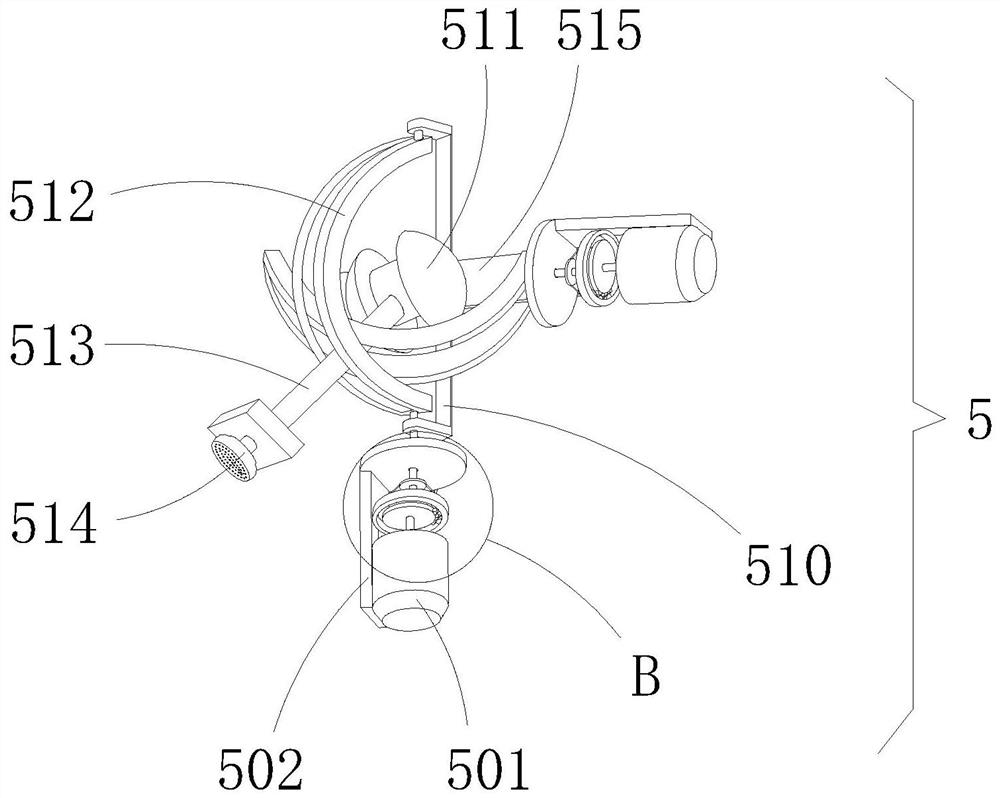

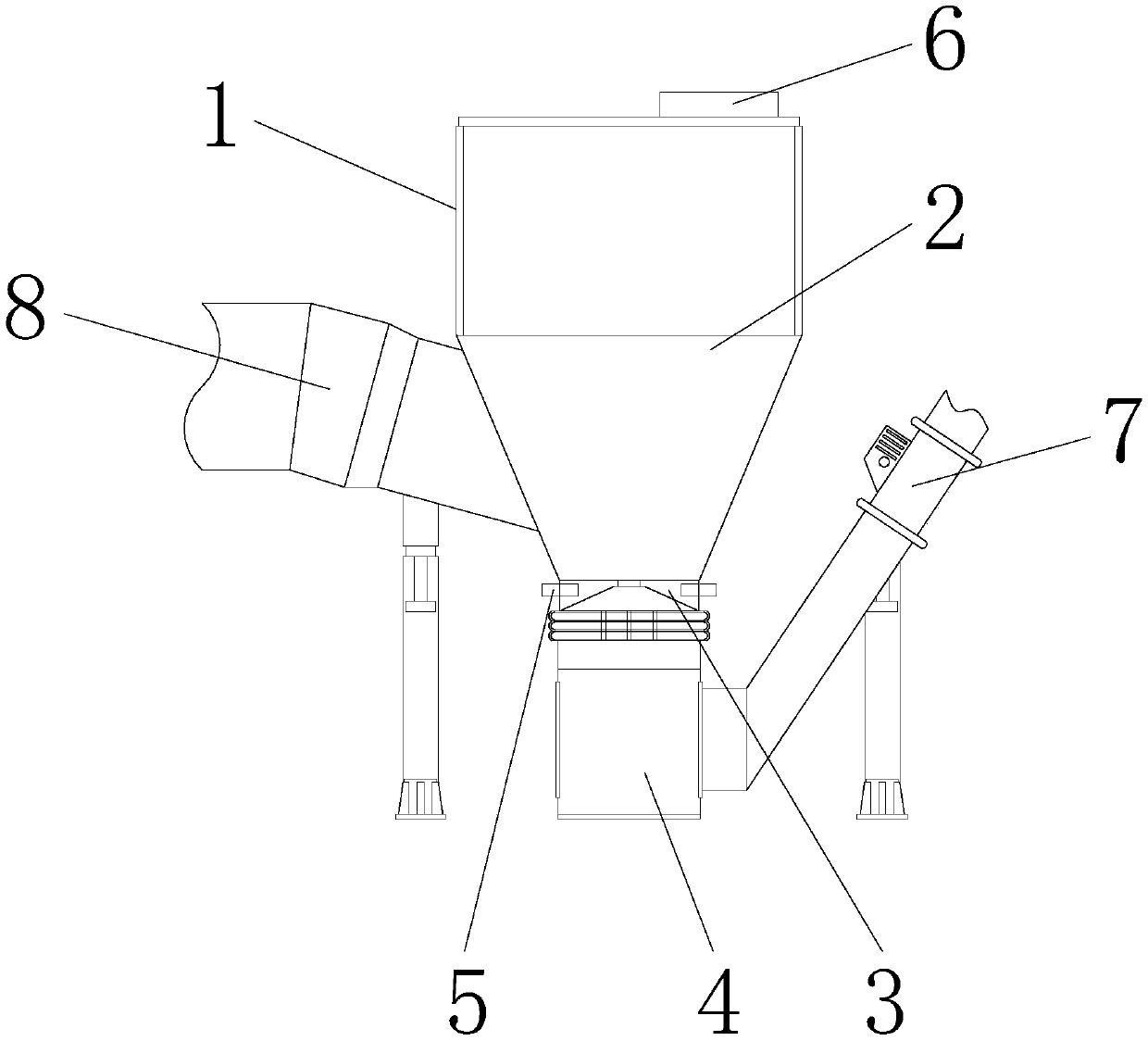

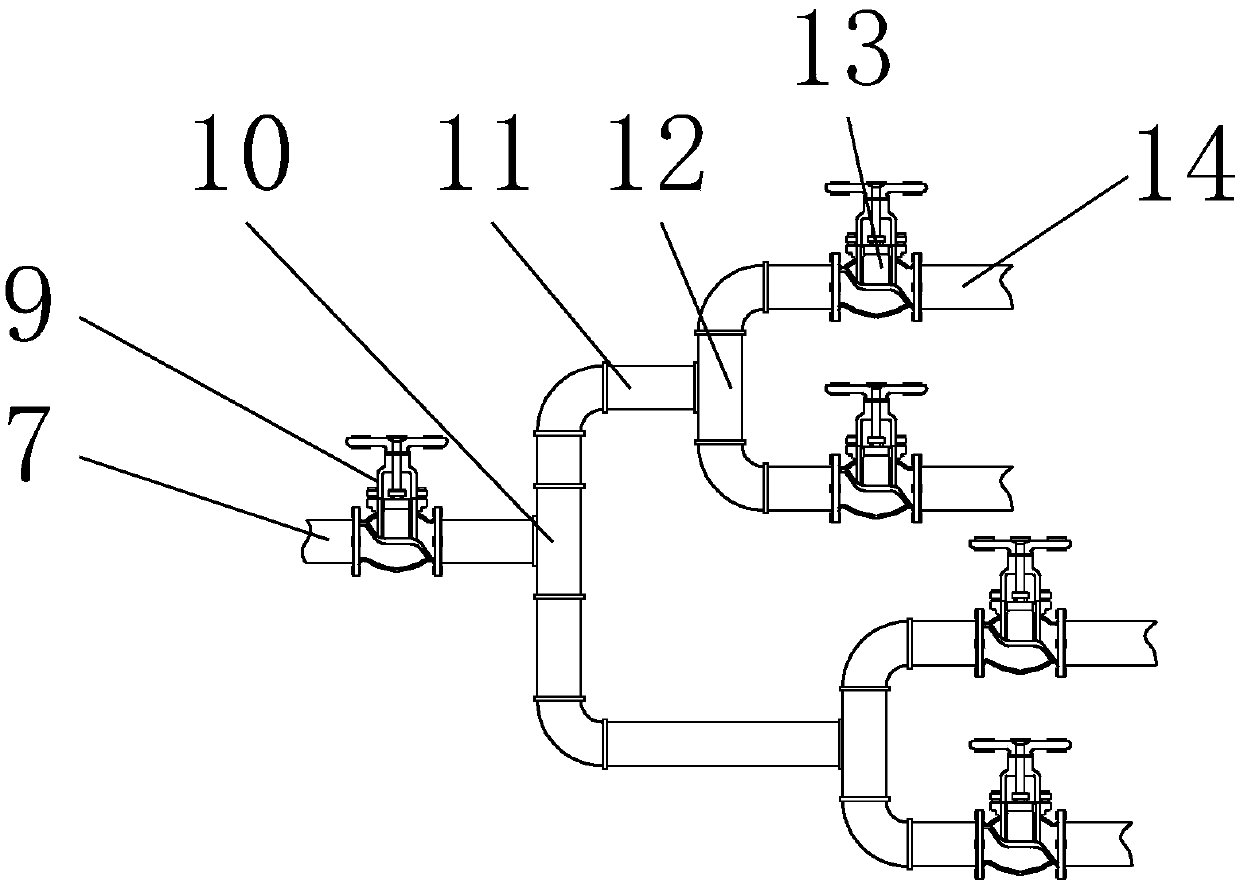

Earthworm feeding mechanism of device for intelligently using earthworms to dispose garbage

ActiveCN111389882AControl deliveryImprove delivery efficiencySolid waste disposalAgricultural scienceAgricultural engineering

The invention discloses an earthworm feeding mechanism of device for intelligently using earthworms to dispose garbage. The earthworm feeding mechanism comprises a feeding box, an earthworm storage disc, storage holes and sealing strips, wherein the earthworm storage disc is arranged in a disc shape, the earthworm storage disc rotates in the feeding box, the storage holes are arranged on the earthworm storage disc, the sealing strips seal the storage holes, the earthworm feeding mechanism further comprises a sealing strip drawing mechanism and a sliding module, the sealing strip drawing mechanism draws the sealing strips to slide, the earthworm storage disc is disc-shaped, the storage holes are provided with a plurality of circles, each circle of storage holes is respectively provided withone row, the sealing strips are strip-shaped and sequentially seal each circle of storage holes, quantitative throwing of earthworms can be realized through the earthworm storage disc, troubles caused by manual throwing are avoided, and throwing efficiency of the earthworms is improved.

Owner:绍兴米苏机械设备有限公司

Continuous paint coating method

InactiveCN111992455AControl deliveryAvoid wastingLiquid surface applicatorsCoatingsInterference fitCoating

The invention discloses a continuous paint coating method. The continuous paint coating method mainly comprises the following steps: S1, feeding; S2, discharging and coating; S3, material stopping andcoating; and S4, turbulent flow mixing. The invention discloses continuous paint coating equipment. The continuous paint coating equipment comprises a movable block and a handle mounted on the movable block for matched use, wherein a liquid storage groove and a temporary storage groove are sequentially formed in the movable block from top to bottom; a communicating pipe is arranged between the inner bottom wall of the liquid storage groove and the inner top wall of the temporary storage groove in a communicating mode; a mounting groove is formed in the lower end face of the movable block; a rotating rod is horizontally and rotationally mounted in the mounting groove; a brush roller is in interference fit with the rotating rod; and cams are symmetrically arranged on the rotating rod in a sleeving mode through one-way bearings. When the continuous paint coating equipment is used, paint coating can be continuously carried out, and a worker does not need to carry a paint barrel or repeatedly stoop to dip the paint when carrying out coating work, so that the labor amount of the worker is reduced. Meanwhile, feeding of the paint on the brush roller can be flexibly controlled, use is convenient, and waste of the paint can be avoided.

Owner:蔡昂

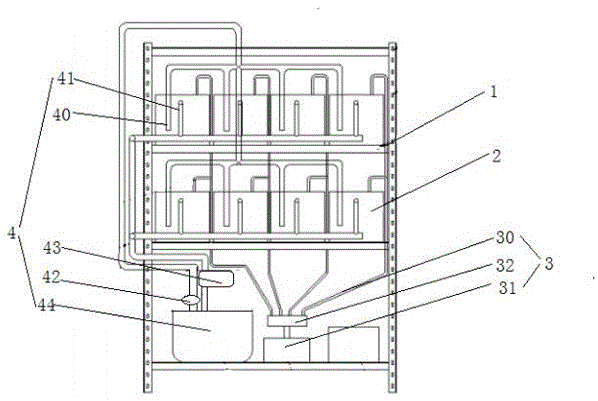

Small automatic ornamental crab breeding system

InactiveCN105454129ARealize scientific feedingControl deliveryClimate change adaptationPisciculture and aquariaFiltrationWater quality

The invention discloses a small automatic ornamental crab breeding system. The system is characterized in that the system comprises a support, breeding tanks, an automatic feeding device, a water circulation filtration system and auxiliary devices; the automatic feeding device comprises feeding pipes, a feed storage box and a feeding control device; one end of each feeding pipe is connected to the corresponding breeding tank, and the other end of the feeding pipe is connected to the feed storage box; a valve is arranged at the connection of each feeding pipe and the feed storage box; and the valves are switched on / off through the feeding control device. The small automatic ornamental crab breeding system comprises the automatic feeding device, the valves can be switched on / off through the feeding control device, and the feed can be provided in a timing and quantitative manner, so that ornamental crabs can be scientifically bred. The system employs simple devices, the breeding is convenient to carry out, the ornamental crabs can be fed without manual operation, and the labor cost is saved. Furthermore, by employing the water circulation filtration system, the waste of water resources is greatly reduced, the pollution to the environment is reduced, and a good water quality environment can be provided for the ornamental crabs.

Owner:苏州蟹家族生态农业有限公司

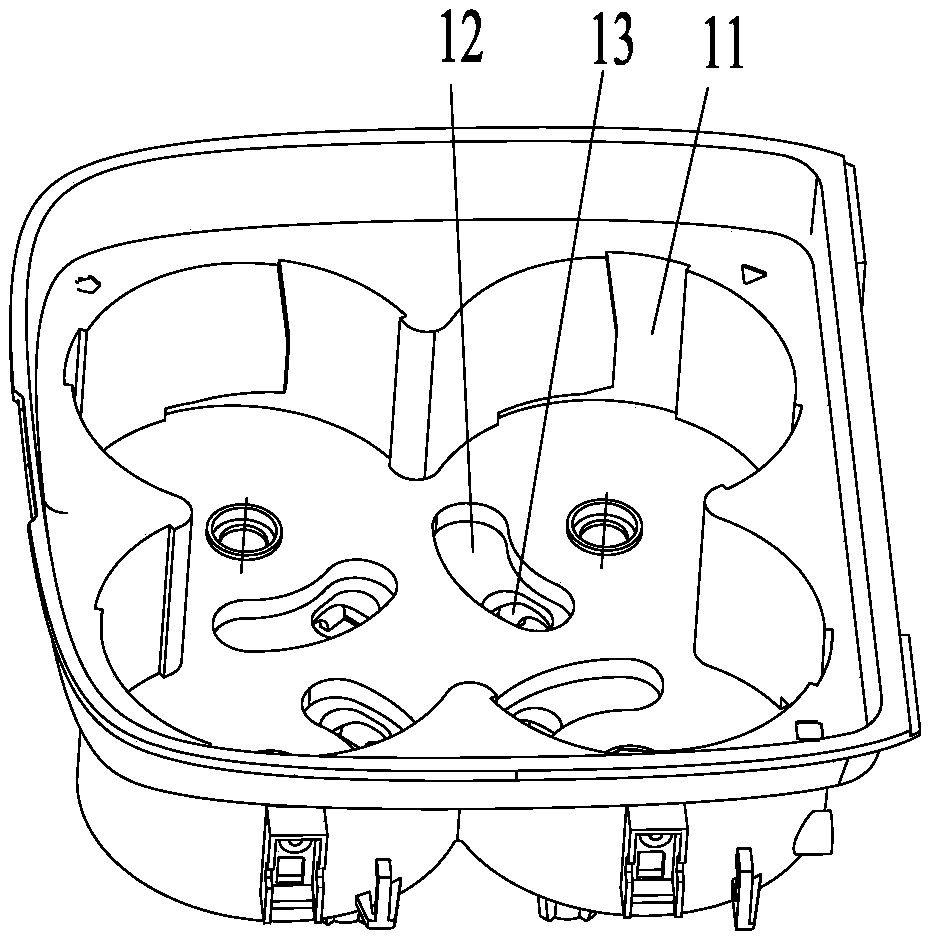

Material adding structure and seasoning machine

The invention provides a material adding structure and a seasoning machine. The material adding structure comprises a container, a sealing piece and a container seat; an open hole is formed in a container bottom plate of the container; the sealing piece is positioned outside the container and is rotatably arranged on one side of the open hole; the container can rotate to one side, which is adheredto the sealing piece, of the open hole; the container seat is provided with a hollow cavity which is open at one end; the container is placed in the hollow cavity; the sealing piece is tightly clamped to the container seat bottom plate of the container seat; a first through hole which penetrates through the container seat bottom plate is formed in the container seat bottom plate; and the container can rotate to the open hole and is overlapped with the first through hole along the axial direction of the open hole. The material adding structure and the seasoning machine provided by the invention are simple in structure and are convenient to operate.

Owner:GUANGDONG MIDEA WHITE GOODS TECH INNOVATION CENT CO LTD +1

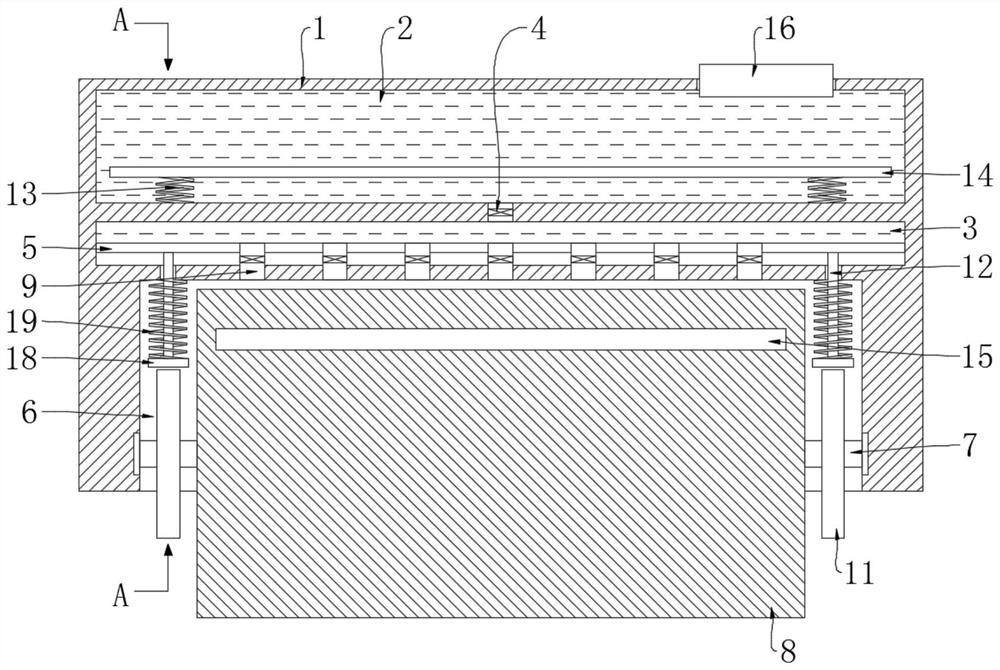

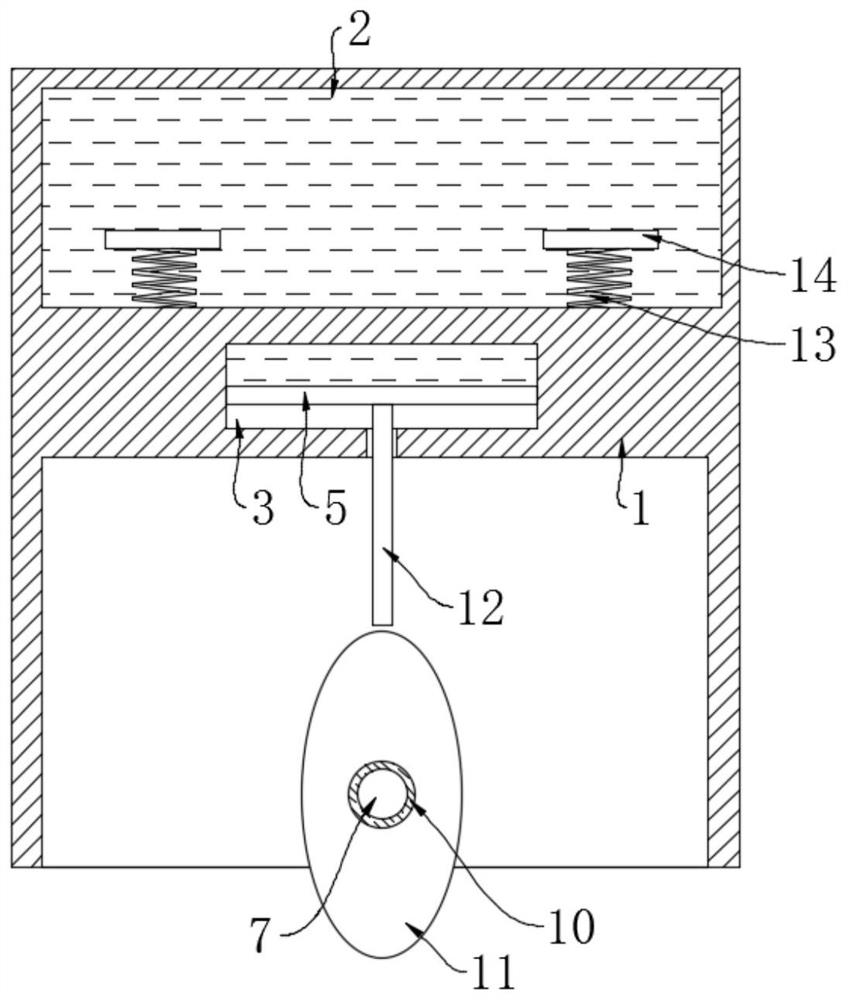

Drilling device for preventing thick paper from being scratched after being printed

InactiveCN109732697AAvoid scratchesControl deliveryMetal working apparatusFixed framePulp and paper industry

The invention relates to a drilling device for preventing thick paper from being scratched after being printed. The device comprises supporting legs, a workbench and a fixing frame, wherein the fixingframe is fixed at the tops of the supporting legs, the workbench is located on a guide rail of a drilling machine and corresponds to the position below the fixing frame; sliding blocks capable of horizontally sliding towards the two ends of the fixing frame are arranged on the workbench, and a to-be-drilled thick paper which is conveyed from a conveying belt is arranged above the workbench, and positioning holes corresponding to the drilling positions of the thick paper are formed in the sliding blocks; and the workbench and the fixing frame are further provided with an air pressure mechanismfor suspending the thick paper above the workbench and side pressing the thick paper on the fixing frame. The drilling device has the beneficial effects that when the printed thick paper is subjectedto drilling positioning, the thick paper does not need to be moved back and forth, and the printed patterns or characters on the thick paper can be effectively prevented from being scratched.

Owner:邹已威

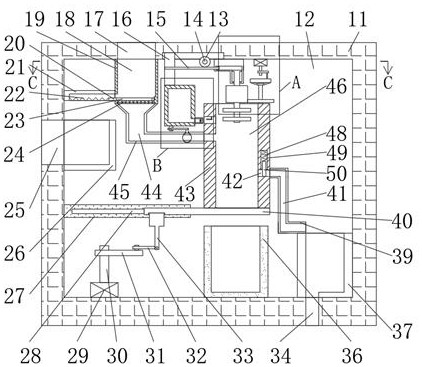

Air purification system for central air conditioner

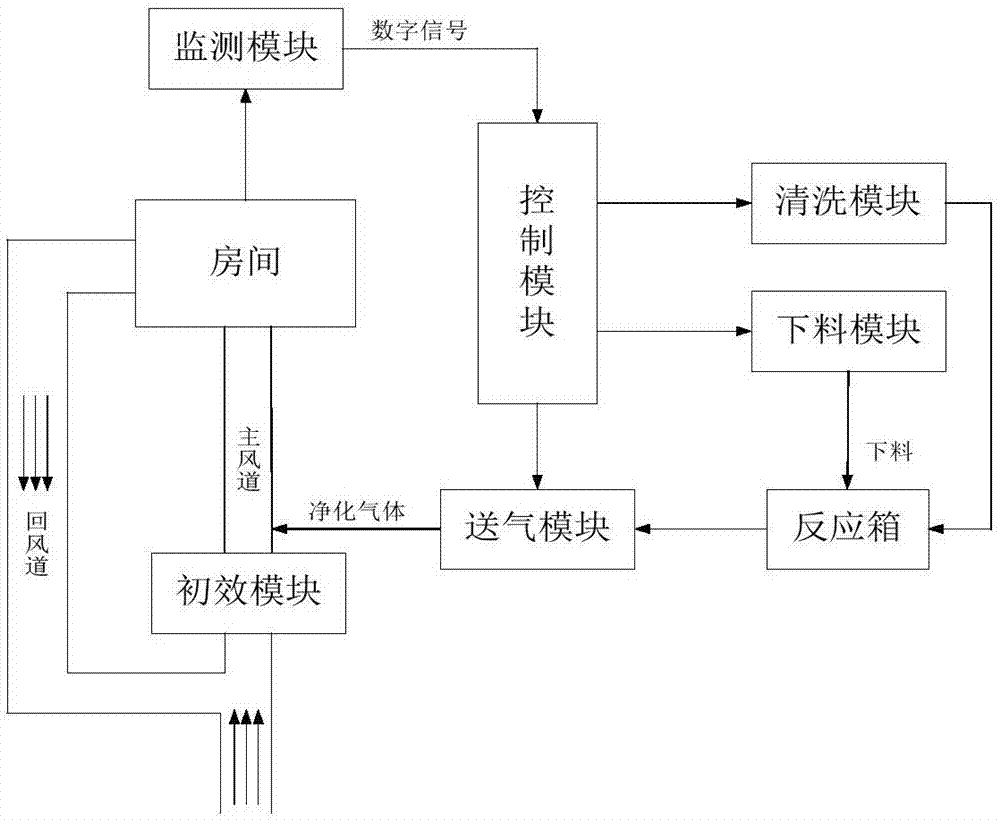

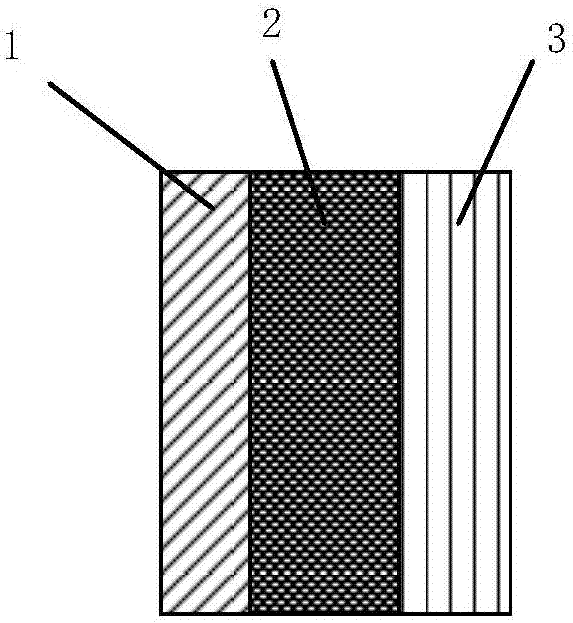

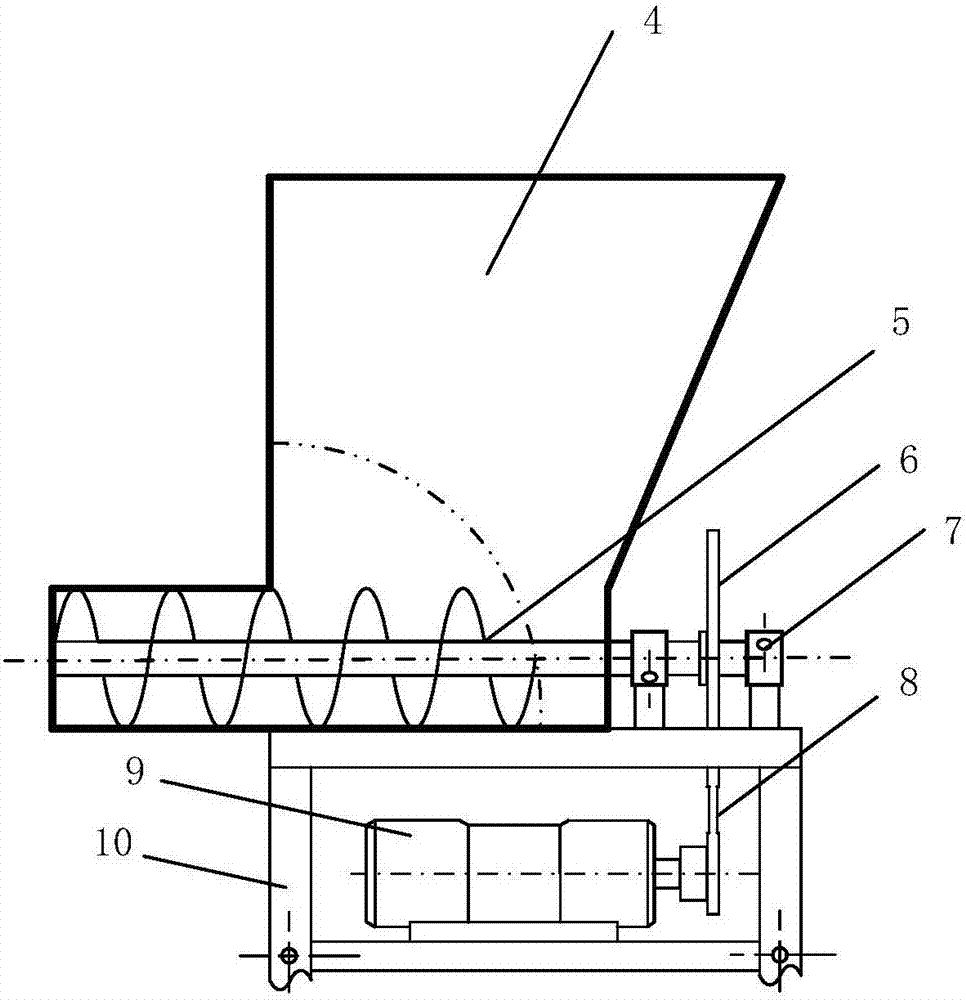

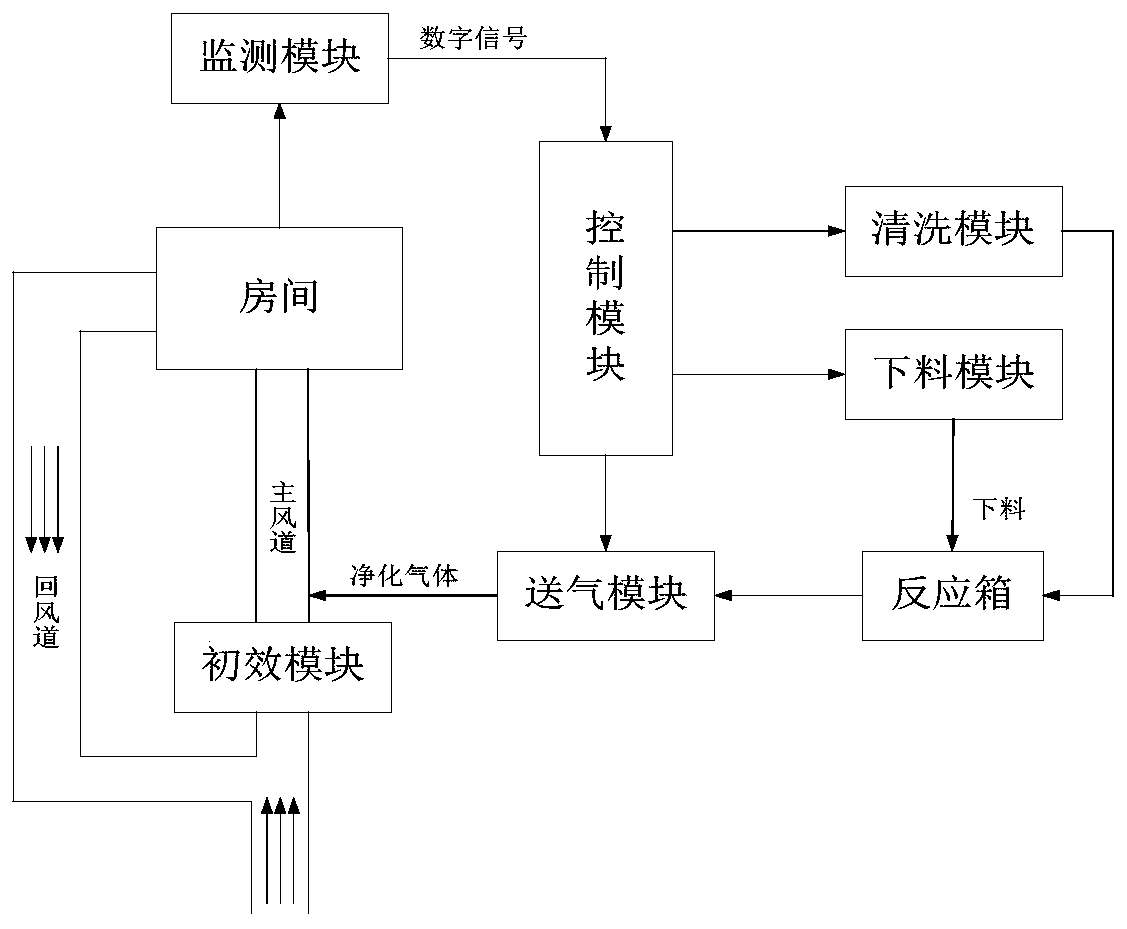

ActiveCN107477733AQuality improvementPlay the role of sterilization and disinfectionMechanical apparatusSpace heating and ventilation safety systemsIndoor air qualityWorking environment

The invention discloses an air purification system for a central air conditioner. The air purification system comprises a monitoring module, a control module, a discharging module, an air supply module, a cleaning module, a primary effect purification module and a reaction box. By means of the monitoring module, the cleanliness degree of indoor air is monitored through sensors mounted inside a room. The primary effect purification module is located behind an air returning and air inlet convergence opening of the air conditioner and mainly filters particulate and dust type pollutants. The control module, the discharging module, the air supply module and the cleaning module constitute whole purification equipment. The purification equipment is connected with a main air duct. By means of the purification system, quality of the indoor air can be effectively improved; in addition, the hidden danger of pathogenic bacteria in pipelines of the central air conditioner can be eliminated; the probability of cross infection is reduced; and the healthy and comfortable living and working environment is provided. The air purification system can be used in multiple types of places such as hotels, office buildings, shopping malls, hospitals and subways.

Owner:湖南精准信息科技有限公司

A central air-conditioning air purification system

ActiveCN107477733BQuality improvementPlay the role of sterilization and disinfectionMechanical apparatusSpace heating and ventilation safety systemsIndoor air qualityWorking environment

The invention discloses an air purification system for a central air conditioner. The air purification system comprises a monitoring module, a control module, a discharging module, an air supply module, a cleaning module, a primary effect purification module and a reaction box. By means of the monitoring module, the cleanliness degree of indoor air is monitored through sensors mounted inside a room. The primary effect purification module is located behind an air returning and air inlet convergence opening of the air conditioner and mainly filters particulate and dust type pollutants. The control module, the discharging module, the air supply module and the cleaning module constitute whole purification equipment. The purification equipment is connected with a main air duct. By means of the purification system, quality of the indoor air can be effectively improved; in addition, the hidden danger of pathogenic bacteria in pipelines of the central air conditioner can be eliminated; the probability of cross infection is reduced; and the healthy and comfortable living and working environment is provided. The air purification system can be used in multiple types of places such as hotels, office buildings, shopping malls, hospitals and subways.

Owner:湖南精准信息科技有限公司

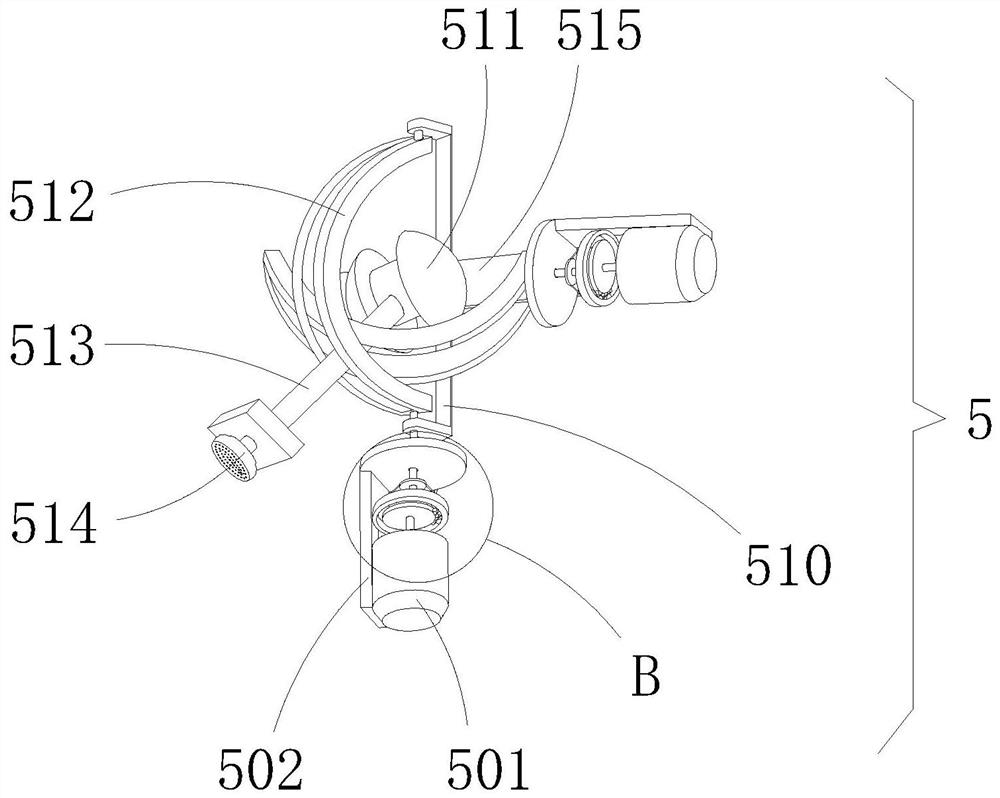

Multifunctional flour wrapping equipment for roasted seed and nut foods

The invention discloses multifunctional flour wrapping equipment for roasted seed and nut foods. The multifunctional flour wrapping equipment comprises a base plate, a moving mechanism and an adjusting mechanism, wherein the moving mechanism is arranged in the base plate, lifting air cylinders are fixedly connected to the top of the base plate through the moving mechanism, and a lifting block is fixedly connected to the tops of the lifting air cylinders; and the adjusting mechanism is fixedly connected to the top of the lifting block. Through the arrangement of the adjusting mechanism, the spraying range of syrup is conveniently adjusted, the use effect is good, syrup spraying is more uniform, a spray gun is convenient to support, manual hand holding is not needed, the labor intensity is reduced, use is convenient, and besides, safety and sanitation are better achieved; and a movable plate I or a movable plate II moves along with a hydraulic cylinder I or a hydraulic cylinder II; and asliding column slides back and forth, the sliding block, the lifting air cylinders and the lifting block at the top of the sliding column are conveniently driven to move, the left-right distance andthe front-back distance are conveniently adjusted, the syrup is conveniently sprayed, the lifting air cylinders are started to conveniently drive the lifting block and the adjusting mechanism to lift,and practicability is better.

Owner:合肥市刚凯食品有限公司

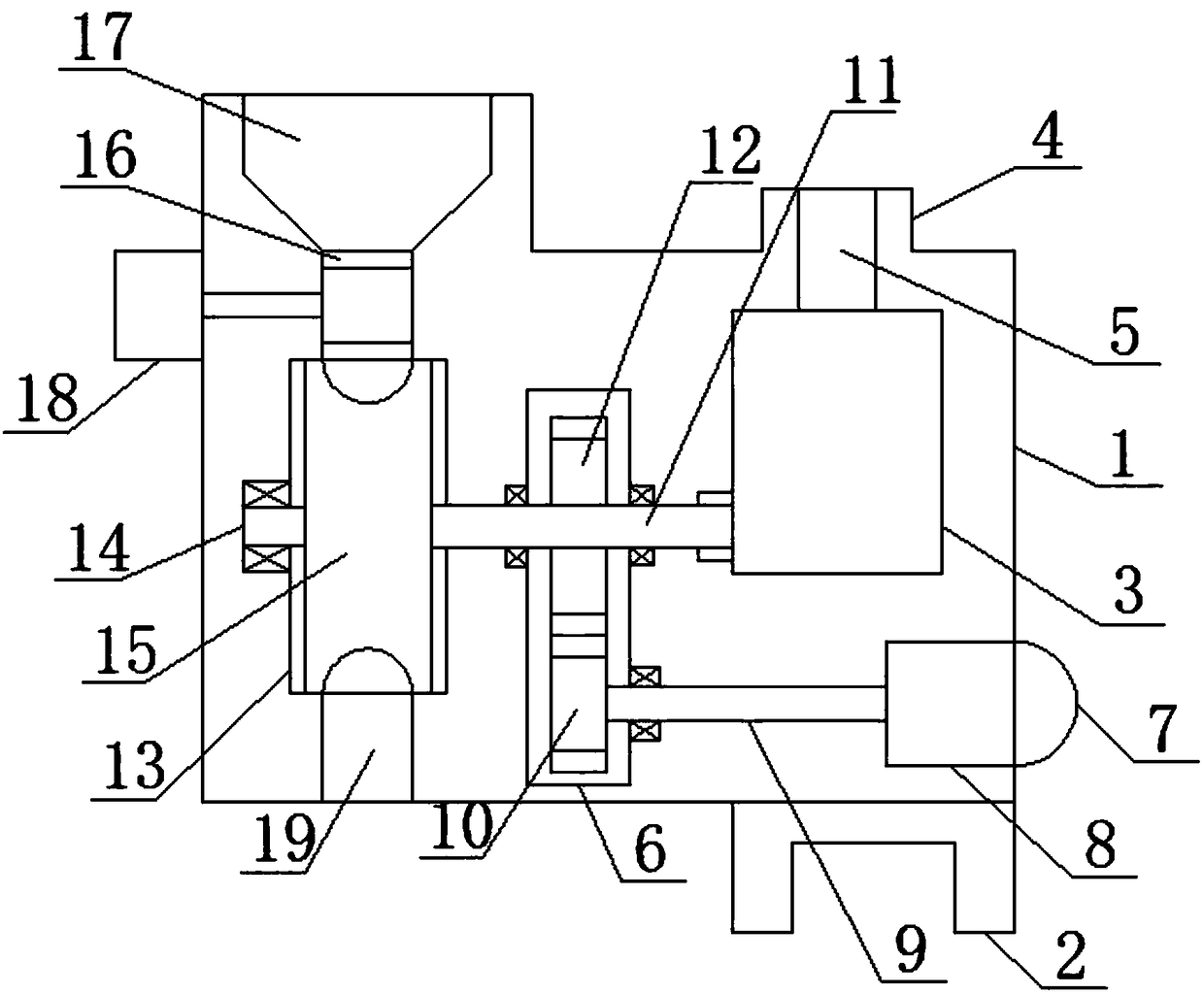

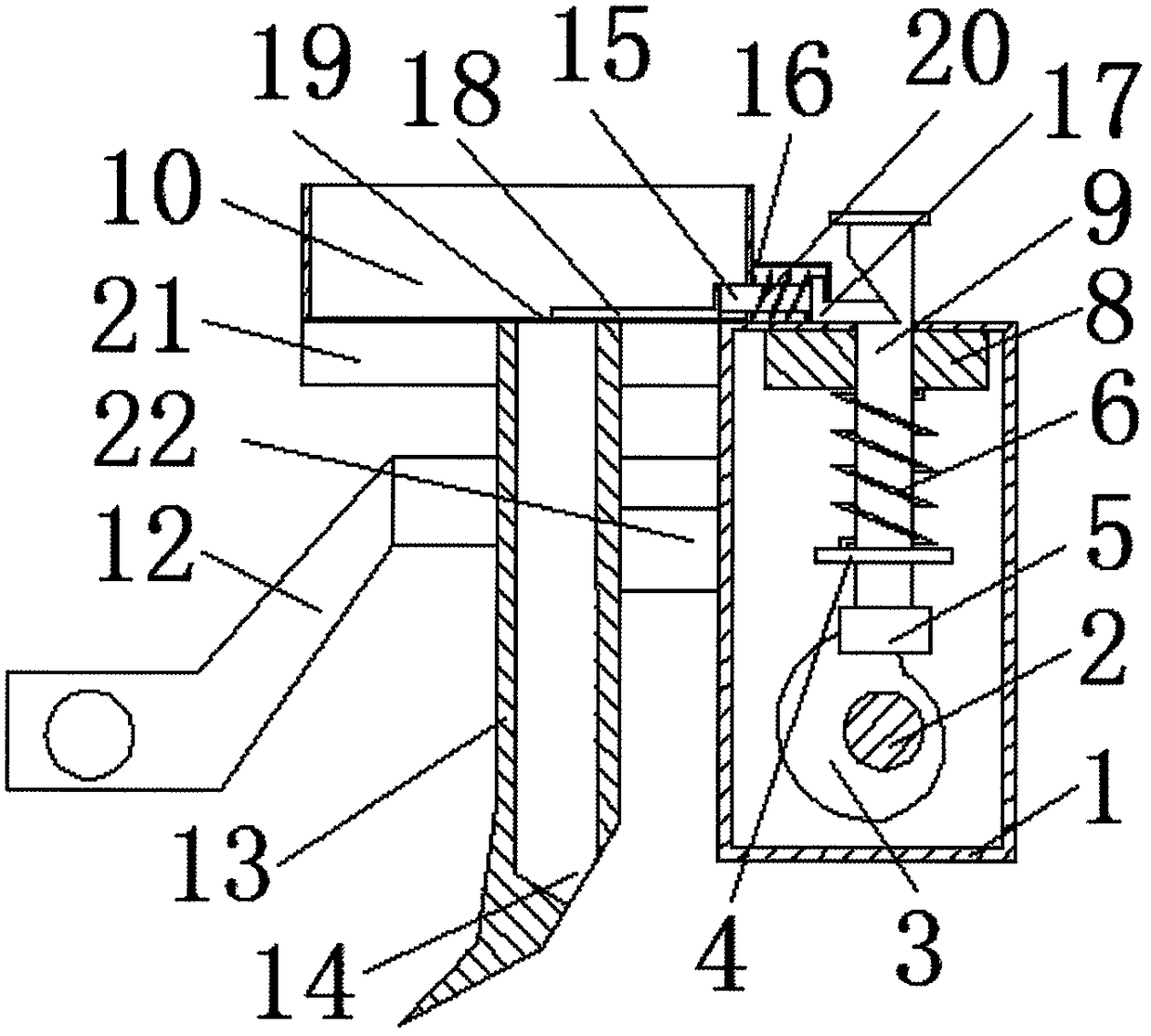

Synchronous adding device for liquid additive and solid additive

InactiveCN108607377ARealize the injectionRealize inputTransportation and packagingMixer accessoriesPulp and paper industryAutomation

The invention discloses a synchronous adding device for a liquid additive and a solid additive. The device comprises a main hollow casing, wherein a bottom clamping positioning mechanism is mounted onone side of the bottom of the main hollow casing. The solid additive and the liquid additive can be added synchronously by use of a motor, so that the added additives have the characteristics of automation and addition uniformity. Besides, the device can be clamped at an adding hole part of a raw material storage casing through the bottom clamping positioning mechanism, so that the following workcan be realized. In addition, the device is provided with a liquid injection rotating connecting mechanism, so that the injection of the liquid additive can be realized while connection drive is realized. Moreover, the device is provided with a solid and liquid additive rotating adding mechanism, so that injection of the solid additive can be realized on the premise of rotation. Besides, the device is provided with a solid additive conveying control mechanism, so that the conveying effect and speed of the solid additive can be controlled.

Owner:董洁 +3

Device for synchronously feeding liquid additives and solid additives

InactiveCN108745191ARealize the injectionRealize inputTransportation and packagingMixer accessoriesEngineeringLiquid injection

The invention discloses a device for synchronously feeding liquid additives and solid additives. The device comprises a main hollow shell, wherein a bottom clamping and positioning mechanism is mounted on one side of the bottom of the main hollow shell. The device is capable of feeding the liquid additives and the solid additives in synchronization status by using an electromotor, so that the fedadditives are automatically and uniformly fed; meanwhile, the bottom clamping and positioning mechanism is arranged in the device and is capable of clamping the device in a material feeding hole partof a raw materials storage shell, so that the subsequent operations can be achieved; in addition, a liquid injecting, rotating and connecting mechanism is arranged in the device and is capable of achieving the effect of injecting the liquid additives while achieving connection driving; furthermore, a solid-liquid additive rotating and feeding mechanism is arranged in the device and is capable of achieving the effect of feeding the solid additives under the precondition of rotating; and a solid additive conveying control mechanism is arranged in the device and is capable of controlling the conveying speed and the conveying effect of the solid additives.

Owner:JINHUA ZHICHAN MAOYUAN INFORMATION TECH CO LTD

Raw material mixing device with raw material weighing function for electronic product production

InactiveCN108854681AIncreased weighing capacityRich device structureTransportation and packagingRotary stirring mixersRaw materialFunctional diversity

The invention belongs to the technical field of electronic product production, and particularly relates to a raw material mixing device with a raw material weighing function for electronic product production. By aiming at the problems that the design structure is simple, the functions are single, raw materials cannot be weighed, and the use is inconvenient, the raw material mixing device has the following scheme that the raw material mixing device comprises a bottom plate, wherein connecting plates in equal-distance distribution and vertical placement are fixed at the outer wall of the top ofthe bottom plate through screw bolts; a connecting block in horizonal placement is fixed at the top of the outer wall of one side of the connecting plate through screw bolts; hinges in equal-distancedistribution are fixed at the outer wall of one side of the connecting block through screw bolts; the hinges are respectively hinged to a first holding clamp and a second holding clamp; the specification of the first holding clamp is matched with the specification of the second holding clamp. The raw material mixing device has the advantages that the raw materials can be weighted; the input quantity of the raw materials can be conveniently controlled; the weighing capability of the device is enhanced; the structure is rich; the functions are diversified; the functions of blast feeding, weighing, stirring and the like are realized; the diversity and the practicability of the device are improved.

Owner:ZHENGZHOU SOUQU INFORMATION TECH CO LTD

Dye production industrial sewage treatment equipment for removing heavy metals

InactiveCN112225359AImprove the effectAvoid Solvent WasteWater contaminantsTreatment involving filtrationSewage treatmentSewage

The invention discloses dye production industrial sewage treatment equipment for removing heavy metals. The equipment comprises a support seat, wherein an inner cavity is formed in the support seat, the upper wall of the inner cavity communicates with a feeding port with an upward opening, the upper wall of the inner cavity is fixedly connected with a filtering box, a filtering cavity which is through up and down and provided with a leftward opening is formed in the filtering box, a filter screen is fixedly connected to the lower wall of the filtering cavity, a sliding plate sliding left and right is arranged on the filter screen, and a temporary storage cavity penetrating up and down is formed in the sliding plate. According to the present invention, a stirring roller can be indirectly controlled to slowly rotate through the meshing of an inner gear and an outer gear, such that heavy metals in sewage can completely react with a heavy metal capturing agent so as to indirectly shift a spherical valve through a rotating block, sewage flowing is blocked, and the heavy metal precipitation effect is enhanced; and a flow limiting valve is matched with a torsional spring, so that feedingof the heavy metal trapping agent is controlled, and solvent waste is avoided.

Owner:HANGZHOU WAXING INTELLIGENT TECH CO LTD

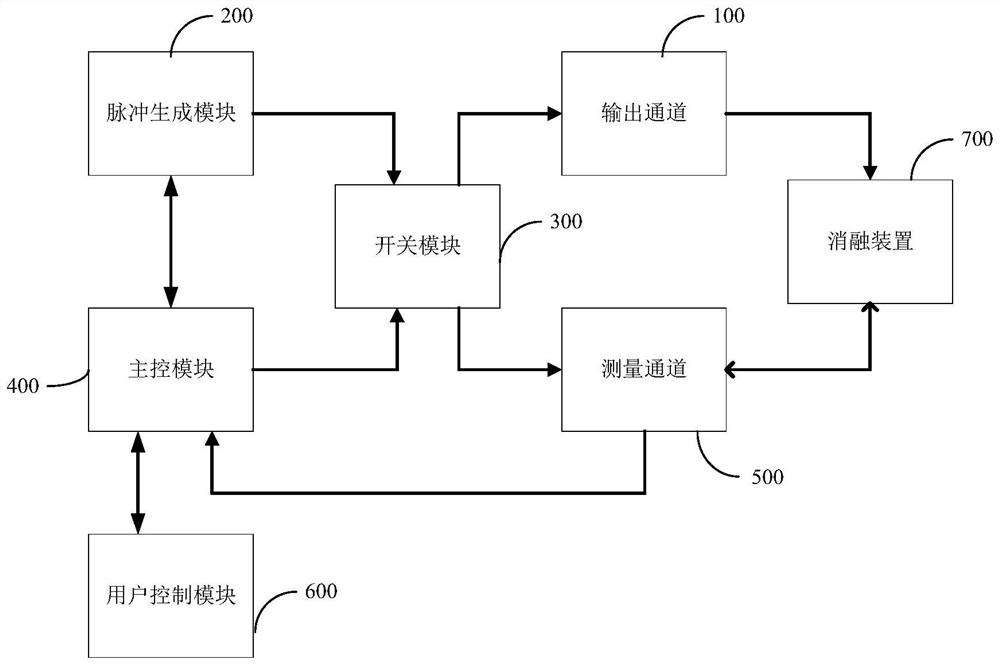

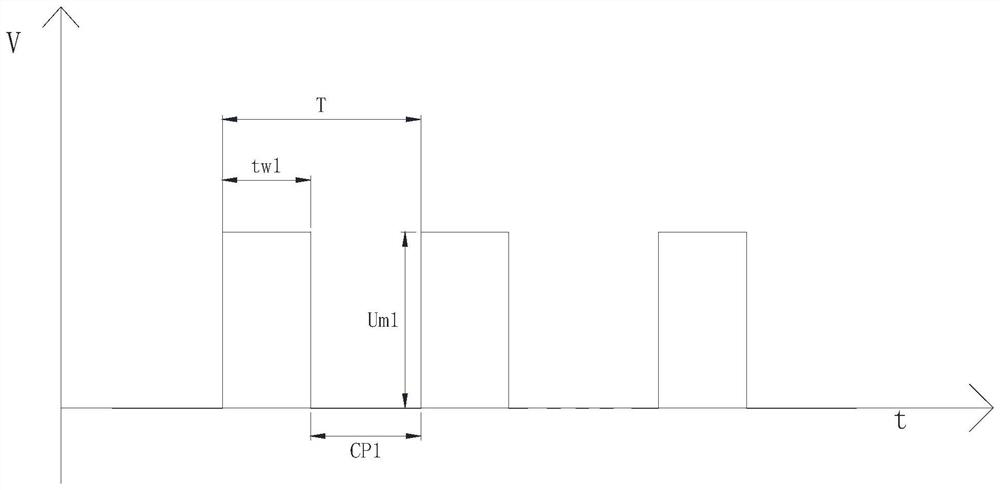

Pulse electric field generator

InactiveCN114259296AControl deliveryControl distributionSurgical instruments for heatingEngineeringPulse sequence

The invention discloses a pulsed electric field generator, which comprises a group of output channels, and each output channel is respectively connected with or disconnected from one electrode in a group of electrodes of an ablation device; the pulse generation module is used for generating a pulse sequence and is connected with one group of output channels; the switch module is used for controlling connection or disconnection between the output channel and the electrode; and the main control module is used for controlling the pulse generation module to generate a pulse sequence during use and controlling the switch module to control the output channel to be connected with the electrode, so that the pulse sequence is transmitted to the electrode. The pulse generation module of the pulse electric field generator generates the pulse sequence under the control of the main control module, and the main control module also controls the connection and disconnection between the group of output channels of the pulses and the group of electrodes through the switch module, so that the generated pulses can be accurately delivered to tissues needing ablation.

Owner:ENCHANNEL MEDICAL GUANGZHOU INC

A multi-functional coating equipment for roasted seeds and nuts

The invention discloses a multi-functional powder-coating equipment for roasted seeds and nuts, which comprises a base plate, a moving mechanism and an adjusting mechanism. The inside of the base plate is provided with a moving mechanism. The top of the cylinder is fixedly connected with a lifting block, and the top of the lifting block is fixedly connected with an adjustment mechanism. Through the setting of the adjustment mechanism, it is convenient to adjust the spraying range of the syrup, the use effect is good, the spraying of the syrup is more uniform, the spray gun is convenient to support, and does not need to be manually held, which reduces the labor intensity. It is convenient to use and more safe and hygienic. Start the hydraulic cylinder one or When the hydraulic cylinder is in the second position, the moving plate 1 or the moving plate 2 will move accordingly, and the sliding column will slide back and forth, which will facilitate the movement of the sliding block, the lifting cylinder and the lifting block on the top of the sliding column, which will facilitate the adjustment of the distance between the left and right and the front and rear, and facilitate the syrup Spraying, starting the lifting cylinder is convenient to drive the lifting block and the adjustment mechanism to lift, and the practicability is better.

Owner:合肥市刚凯食品有限公司

Kiln tail low-ammonia combustion equipment and implementation method thereof

InactiveCN111189328ALess investmentRetrofit fastIncreasing energy efficiencyIncinerator apparatusNitrogen oxidesProcess engineering

The invention discloses kiln tail low-ammonia combustion equipment. The kiln tail low-ammonia combustion equipment comprises a kiln, wherein a smoke exhaust pipe is fixed to the top of the kiln, a kiln body is fixed above the interior of the kiln, the kiln tail is arranged below the kiln body, the kiln tail is fixedly connected with the kiln, a base is fixed to the bottom of the kiln, a main coalsupply pipe is fixed to the outer side wall of the base, a feeding pipe is arranged on the outer side wall of the kiln, and the end, penetrating through the kiln, of the feeding pipe is fixedly connected with the kiln. The invention further discloses an implementation method of the kiln tail low-ammonia combustion equipment. The kiln tail low-ammonia combustion equipment is formed by combining coal spray pipes, gate valves and tee joints, and is small in investment, quick to transform, good in effects and stable and reliable to operate; and combustors change combustion from an original high-oxygen area to a low-oxygen area, so that coal is decomposed into carbon monoxide and other substances, the substances such as carbon monoxide as reducing agents are subjected to reduction reaction withNOx in the kiln, and the use amount of ammonia water is saved by 30%-50% on the original basis after use.

Owner:FUJIAN JINNIU CEMENT CO LTD

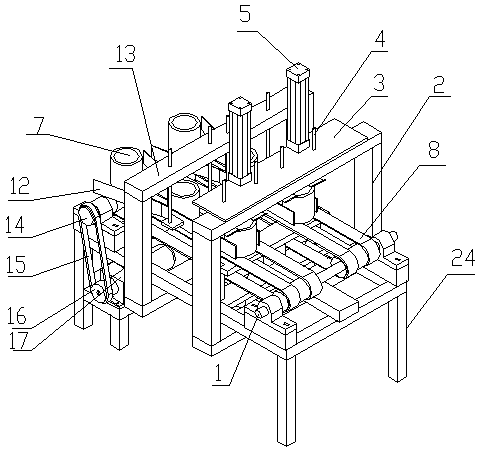

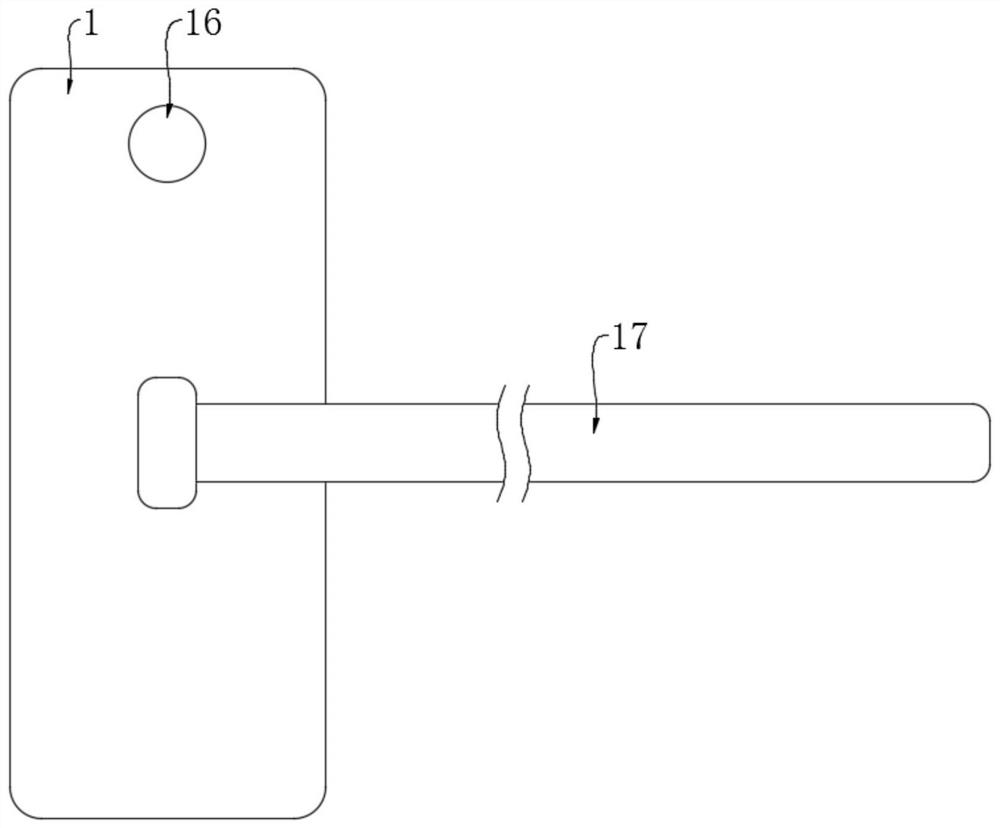

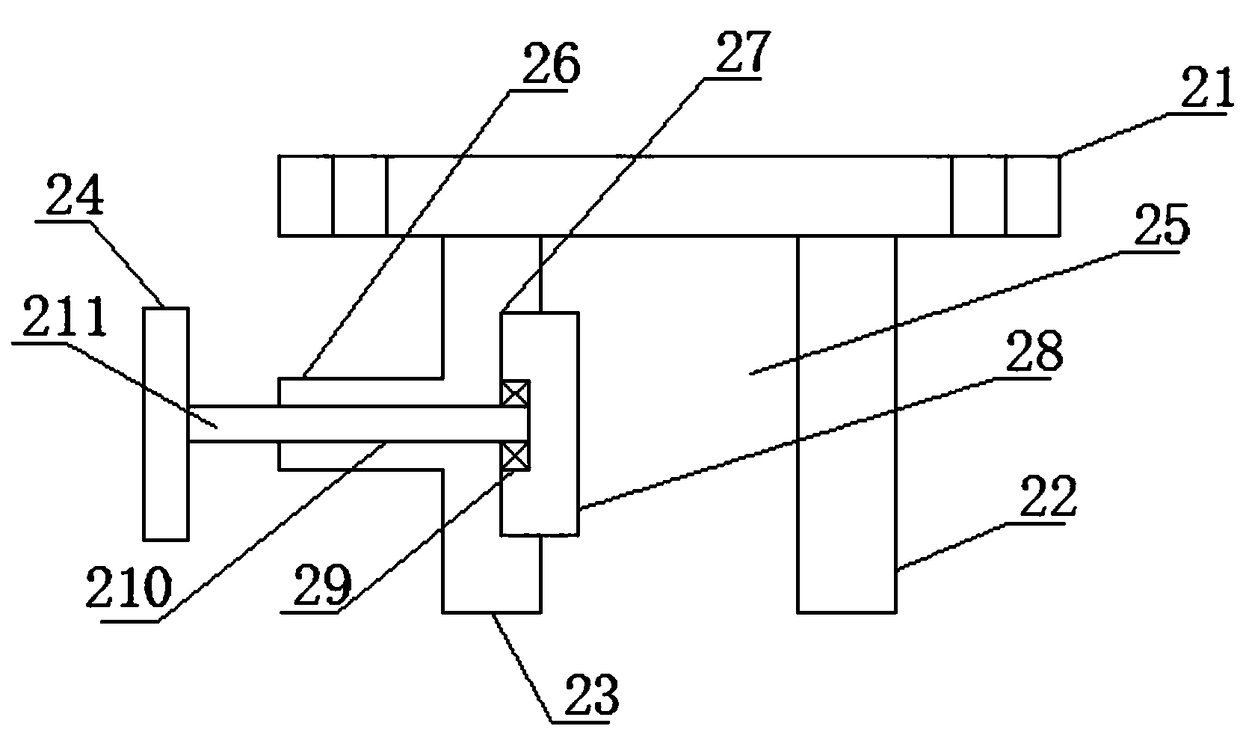

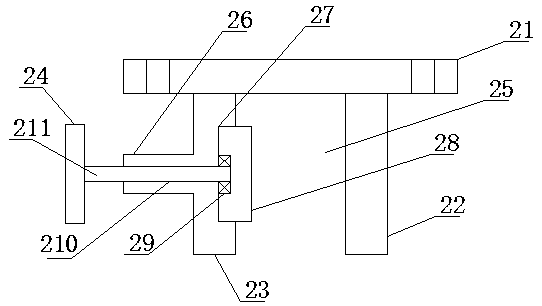

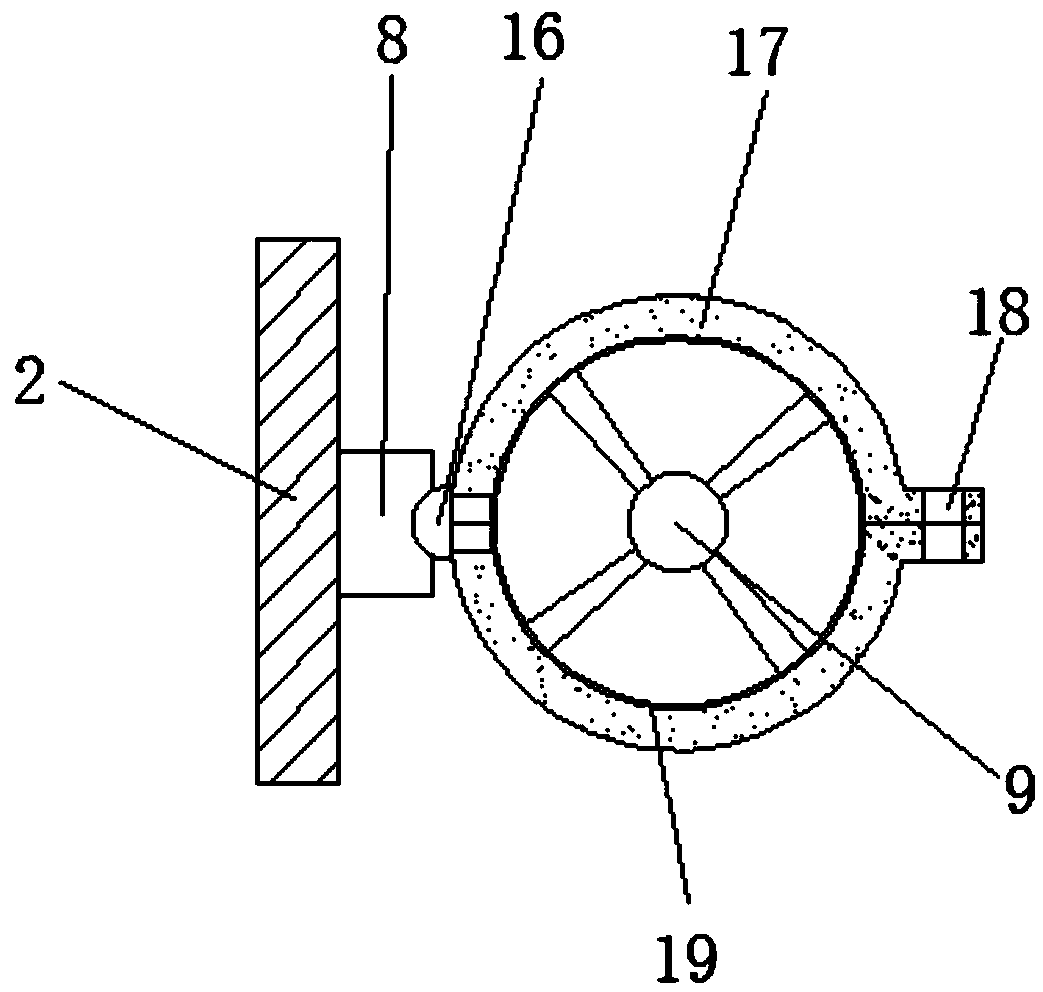

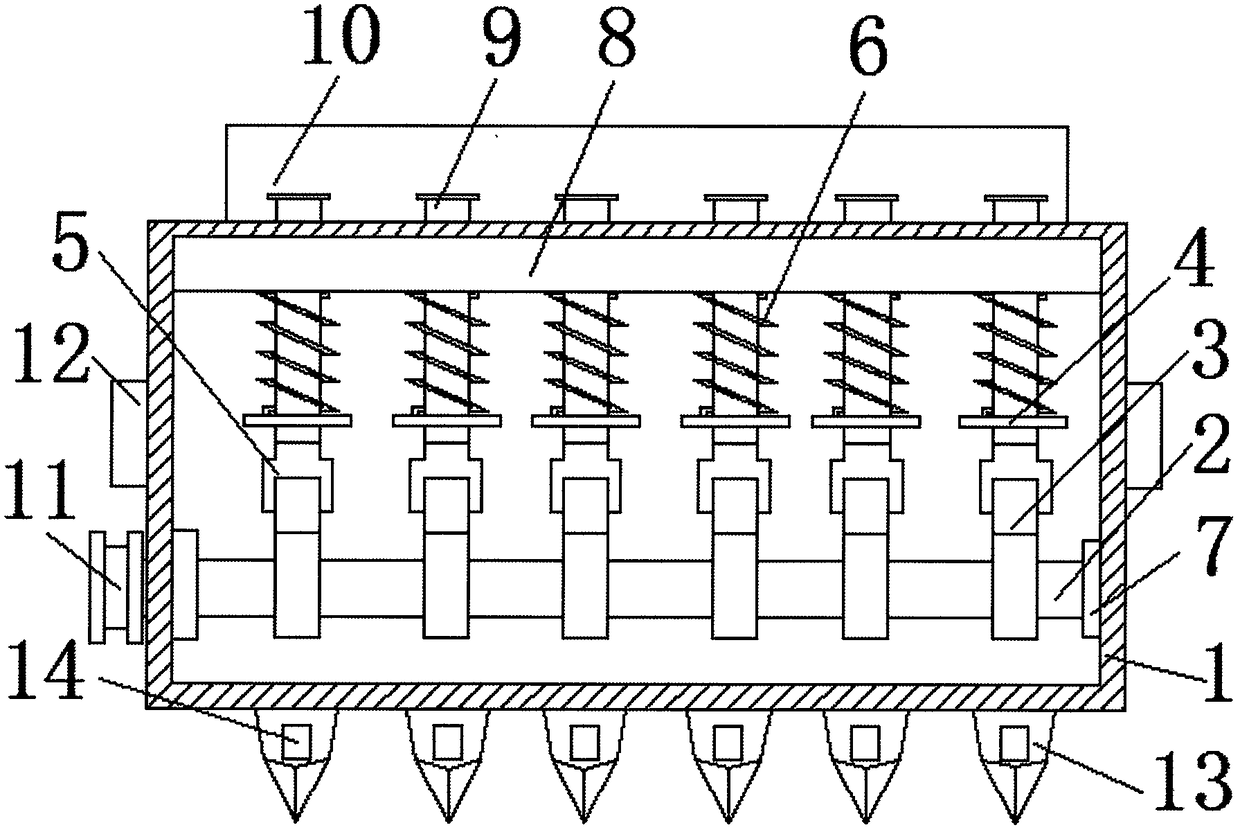

An intermediate transmission device for agricultural machinery

InactiveCN106508208BControl deliveryControl outflow frequencyBroadcast seedersFertiliser equipmentsAgricultural engineeringMaterial resources

The present invention discloses an intermediate transmission device of agricultural farming machinery. The device comprises a shell, the left side and the right side of the interior of the shell are connected with a rotation shaft by bearings; a pulley is arranged at the side, extending out of the shell, of the left end of the rotation shaft, and the pulley is connected with an external power unit by a belt; the middle side of the rotation shaft is provided with cams, and the upper end of each cam is connected with a supporting bar by a clamping component; the lower end of the side of each supporting bar is provided with a ring-shaped baffle, and the middle of the side of each supporting bar is sleeved with a first spring, and the bottom of each first spring is fixedly connected with the upper surface of the corresponding ring-shaped baffle; and the top of the interior of the shell is provided with a mounting panel. The intermediate transmission device of the agricultural farming machinery is simple in structure and low in cost. The external power unit drives the pulley to rotate by the belt, multi-channel sowing is realized by the transmission device, and meanwhile the seed outflow frequency is controlled, the waste of the seeds is reduced, and the human and material resources are saved. Meanwhile, multi channel simultaneous sowing is performing, the sowing speed can be ensured and time is saved.

Owner:SHANDONG ACADEMY OF AGRI MACHINERY SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com