Automatic punching machine for flowerpots

A punching machine, automatic technology, applied in the field of punching machines, can solve the problems of increasing the number of defective flowerpots, unable to automatically punch holes, affecting the efficiency of the factory, etc., to increase the scope of use, avoid impact damage, reduce The effect of the probability of defective products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

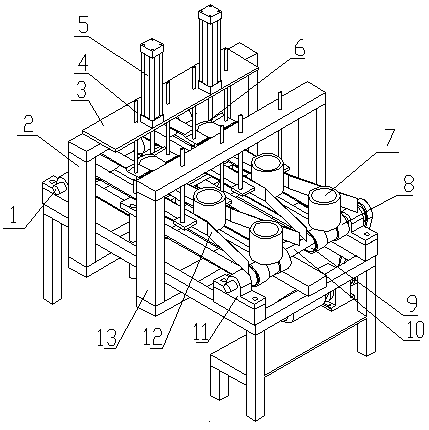

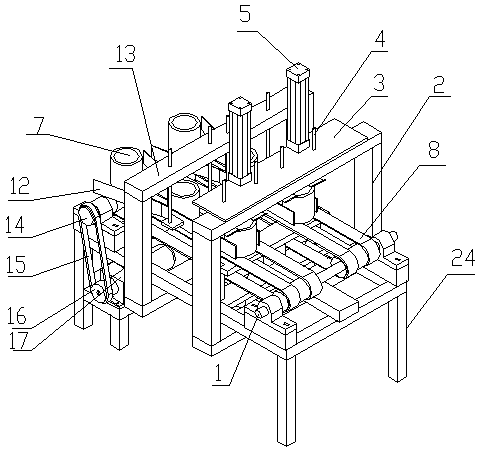

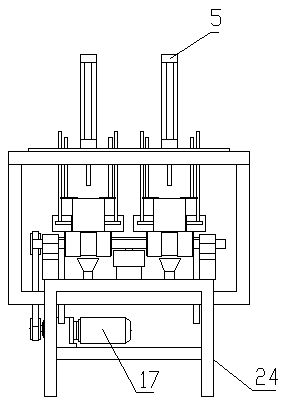

[0023] Example: such as Figure 1-6 As shown, a kind of flower pot automatic punching machine of the present invention comprises lower bracket 24, and the front and rear ends of lower bracket 24 are respectively equipped with driving shaft 10 and driven shaft 1, and two are fixed on driving shaft 10 and driven shaft 1. A corresponding No. 1 pulley 9, and the No. 1 pulley 9 on the driving shaft 10 and the No. 1 pulley 9 on the driven shaft 1 are connected by the No. 1 belt 8, and the corresponding two No. 1 pulleys 9 There are two No. 1 pulleys 8 connected between them; No. 2 pulley 14 is also fixed on one end of driving shaft 10, No. 3 pulley 16 is installed on the side corresponding to No. 2 pulley 14 below the lower support 24, No. 2 pulley 14 and No. three pulley 16 is connected by No. two belt 15, and this No. three pulley 16 also connects decelerating motor 17 by shaft; Upper cylinder support 2 and left and right guide plate supports 13 are fixed on the lower support 24, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com