Kiln tail low-ammonia combustion equipment and implementation method thereof

An ammonia combustion and kiln tail technology, which is applied in the field of kiln equipment, can solve the problems of lack of ammonia consumption, rising production cost and high production cost, and achieves the effects of good effect, small investment and improved service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

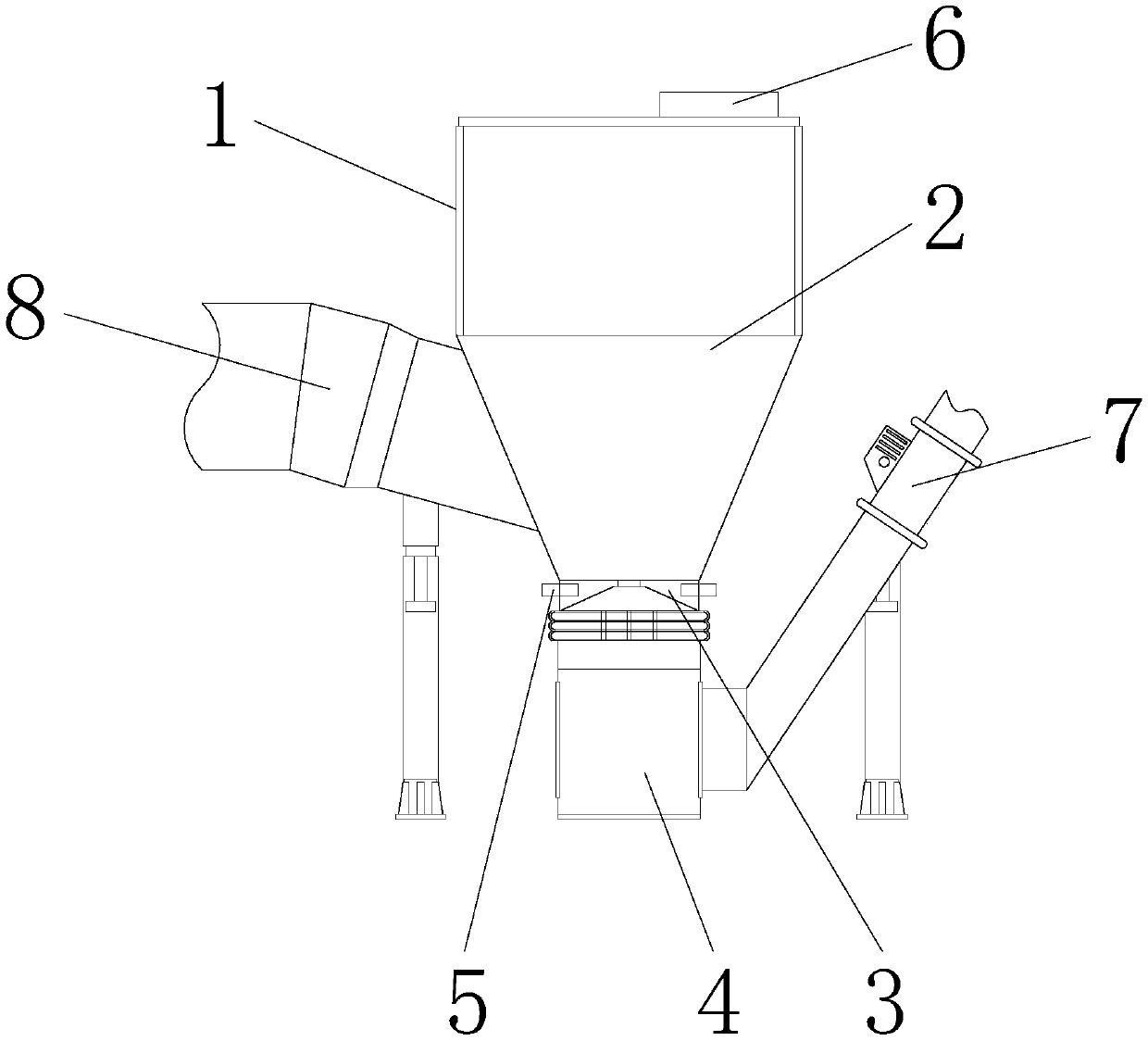

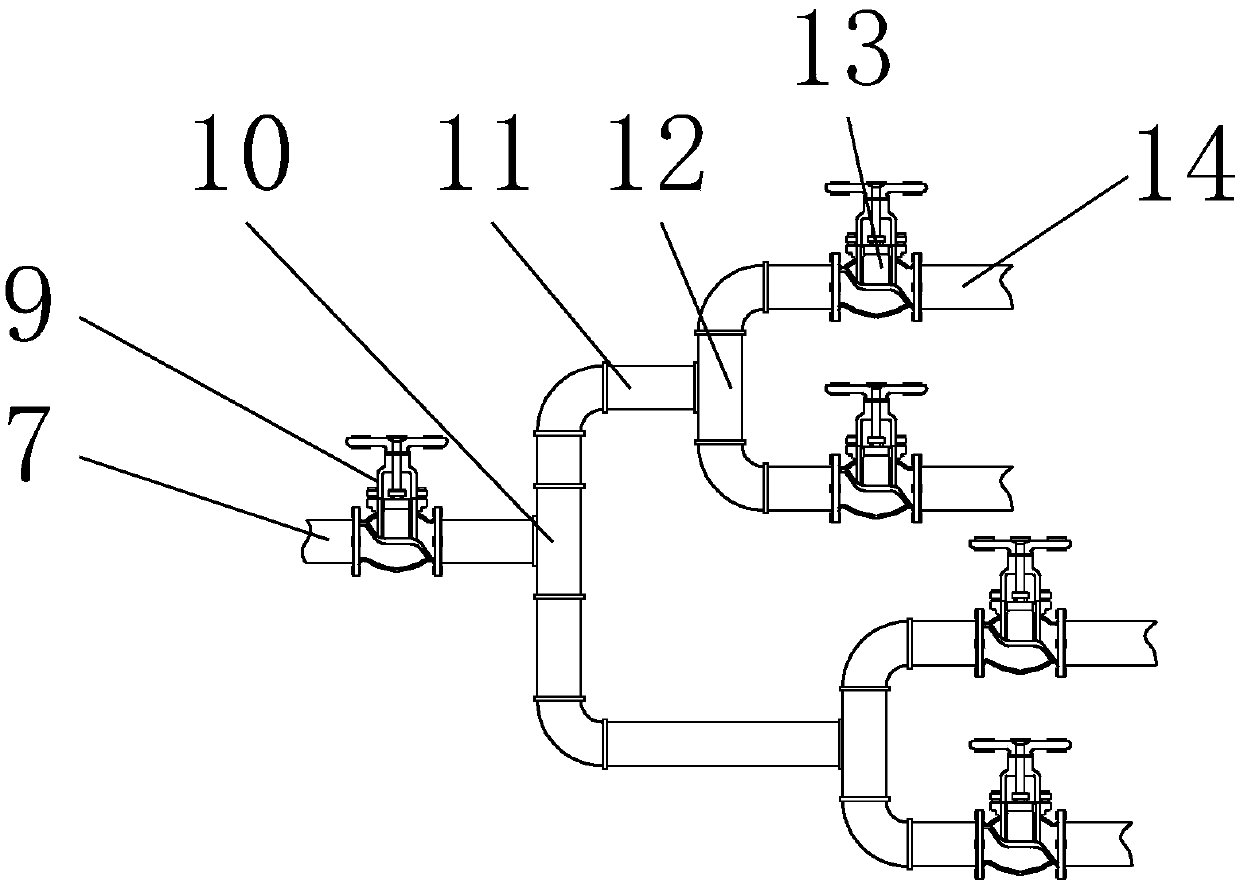

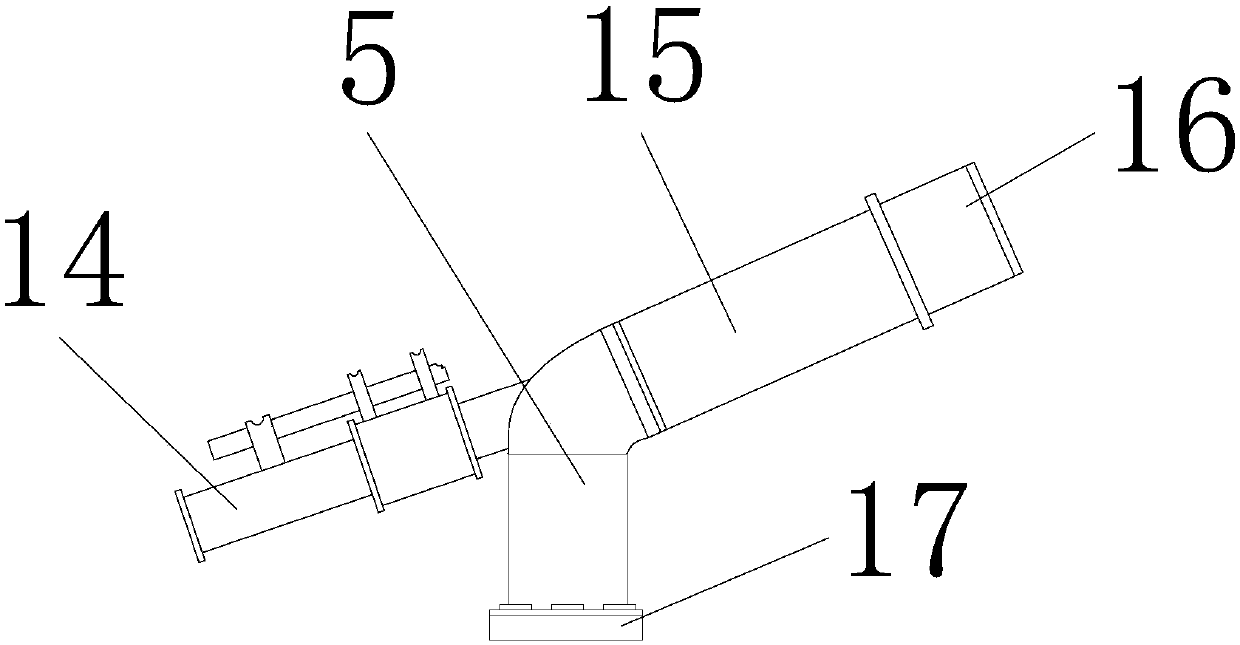

[0031] see Figure 1-3 , the present invention provides the following technical solutions: a kiln tail low ammonia combustion equipment, including a kiln 1, the top of the kiln 1 is welded with a smoke exhaust pipe 6, and the top of the kiln 1 is welded with a kiln body 2, the kiln body 2 There is a kiln tail 3 below the kiln tail 3, which is welded to the kiln 1, the bottom of the kiln 1 is screwed to the base 4, the outer wall of the base 4 is connected to the main coal delivery pipe 7 through the flange, and the outer wall of the kiln 1 is provided with an inlet One end of feed pipe 8 and feed pipe 8 passing through kiln 1 is connected with kiln body 2 through flange, the end of coal feeding main pipe 7 close to base 4 is fixed with supervisory gate valve 9 , and the output end of supervisory gate valve 9 is fixed with supervisory tee 10 , the output end of the competent tee 10 is fixed with two coal delivery branch pipes 11, and the end of the coal delivery branch pipe 11 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com