Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

52results about How to "Containment costs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

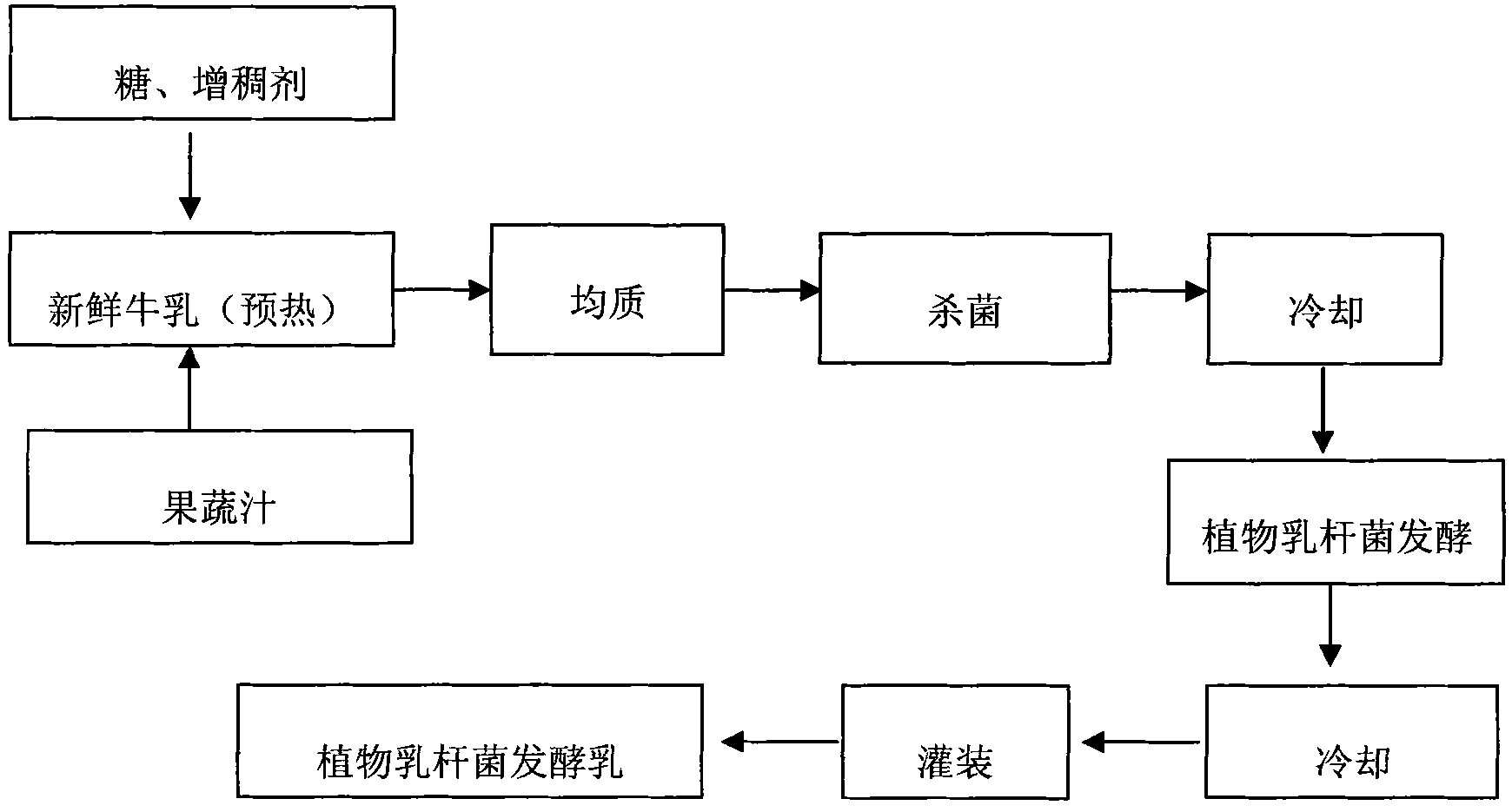

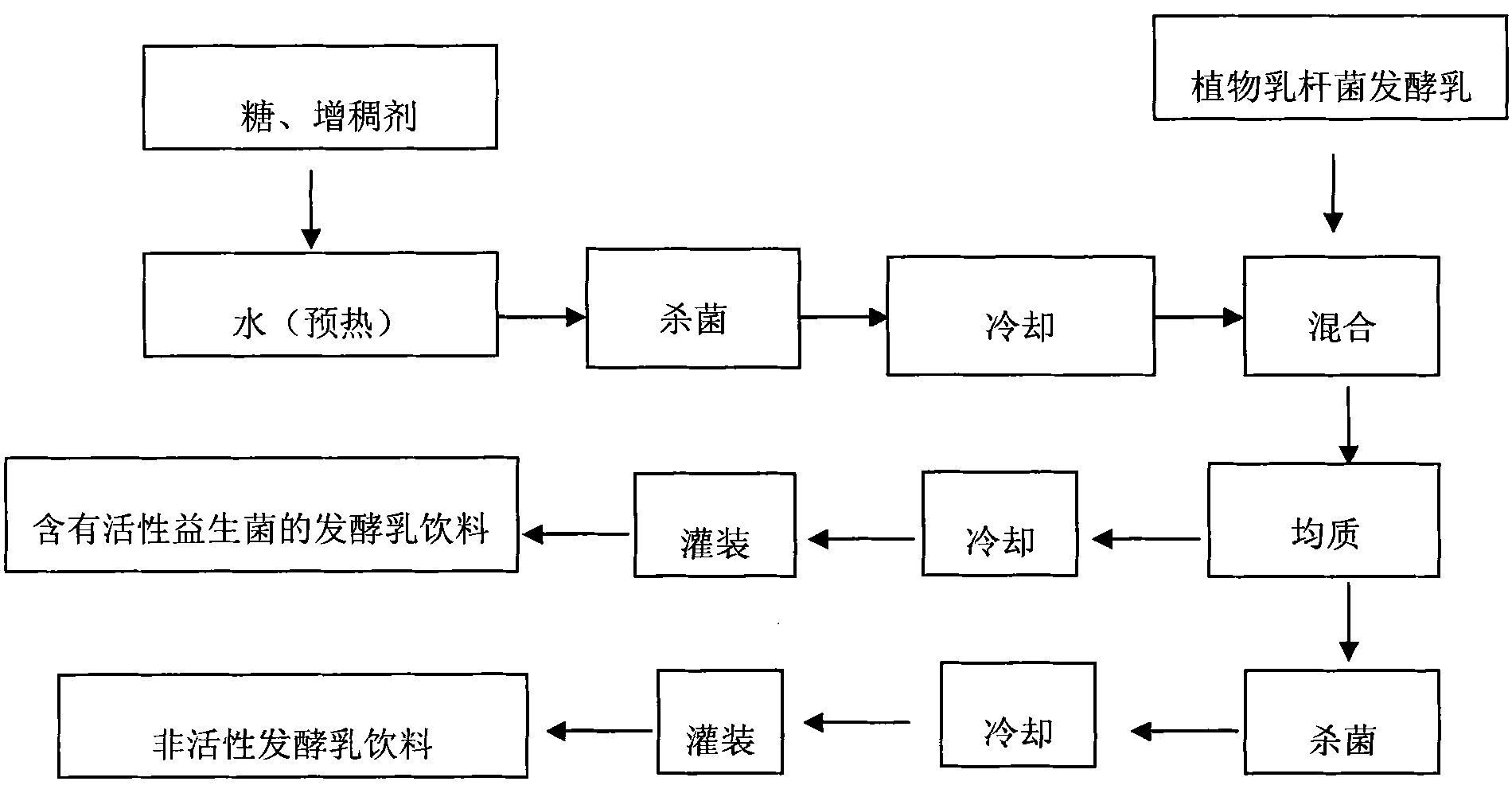

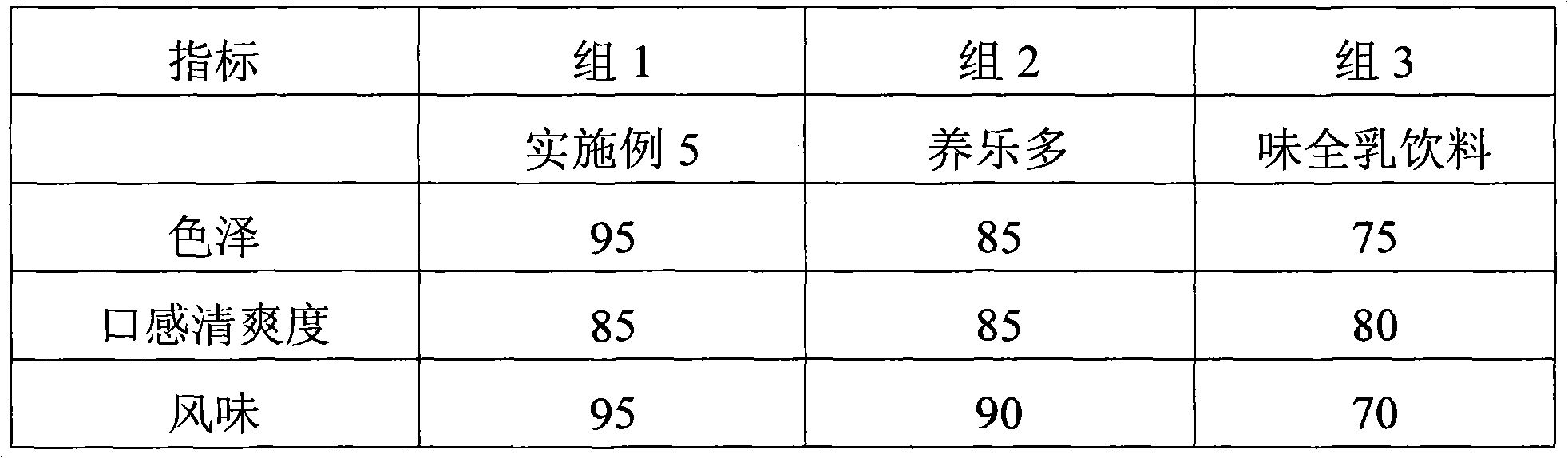

Fermented dairy product and preparation method and raw material composition thereof, lactobacillus plantarum application

InactiveCN102100252AIncrease varietyChange the status quo that cannot be applied in fermented dairy productsMilk preparationFlavorMetabolite

The invention discloses a raw material composition of a fermented dairy product, which comprises a milk raw material and a zymocyte strain; the milk raw material comprises the following compositions: animal milk, fruit and vegetable juice and a thickening agent; and the zymocyte strain is at least lactobacillus plantarum. The invention also discloses a method for preparing the fermented dairy product by the raw material composition of the fermented dairy product and the prepared fermented dairy product. The invention overcomes the defects in the prior art that lactobacillus plantarum grows slowly or can not grow in animal milk and can not be fermented to prepare dairy products; and the fermented dairy product provided by the invention contains lactobacillus plantarum and metabolites thereof, so the product facilitates the balance of intestinal microecology, is helpful to enhance body immunity, and has good flavor and mouthfeel. The invention further widens the application range of lactobacillus plantarum.

Owner:BRIGHT DAIRY & FOOD CO LTD

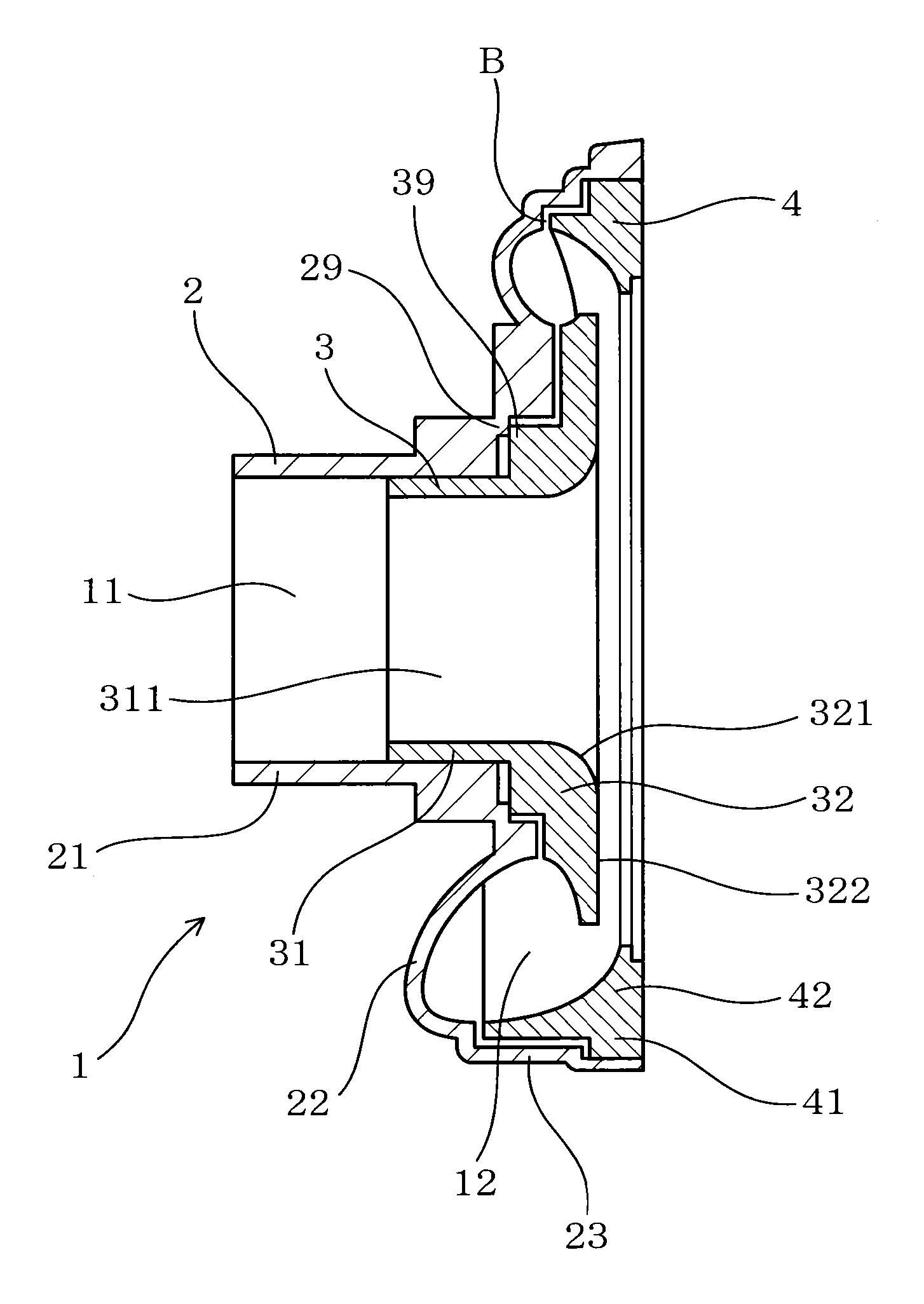

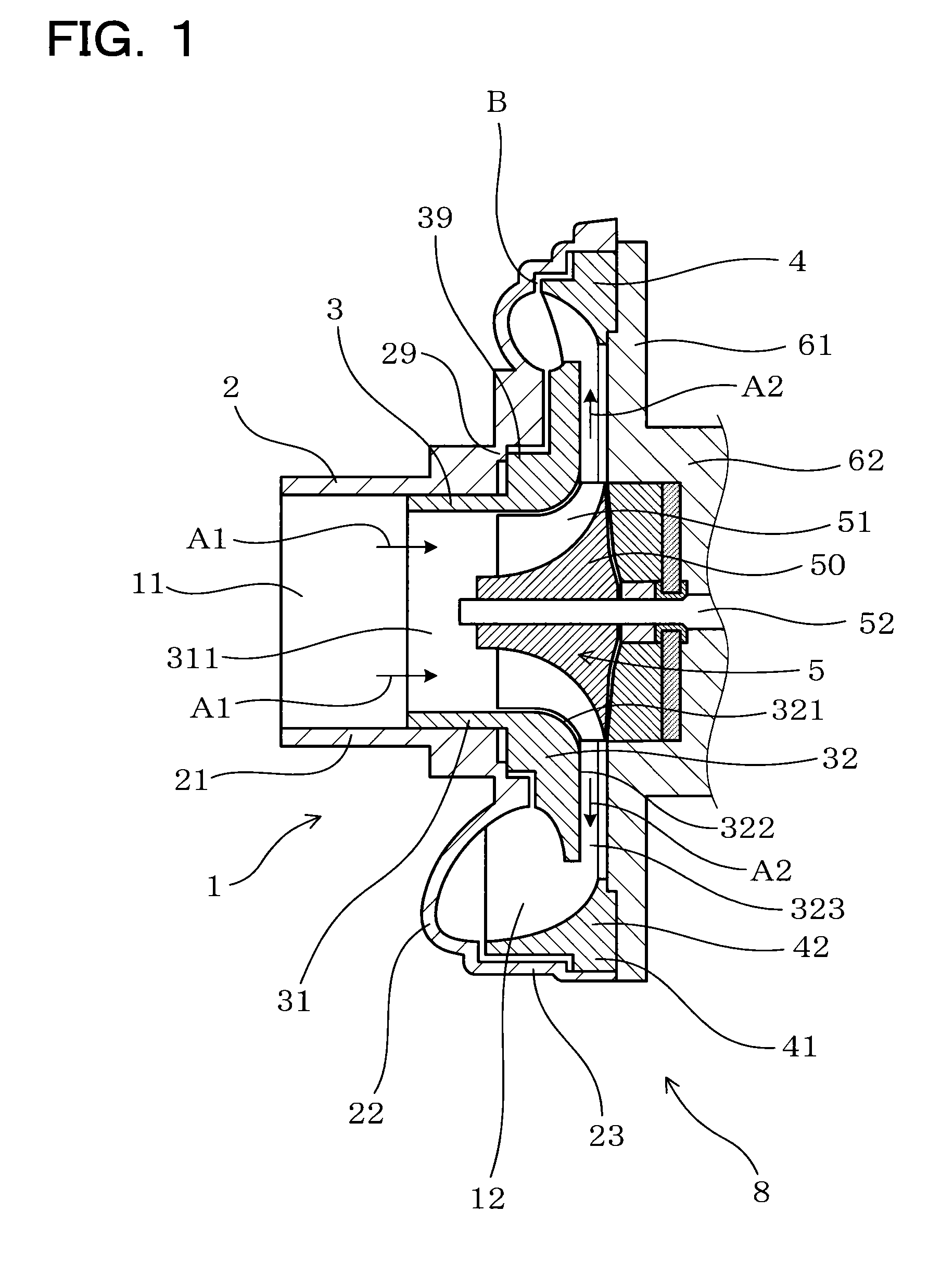

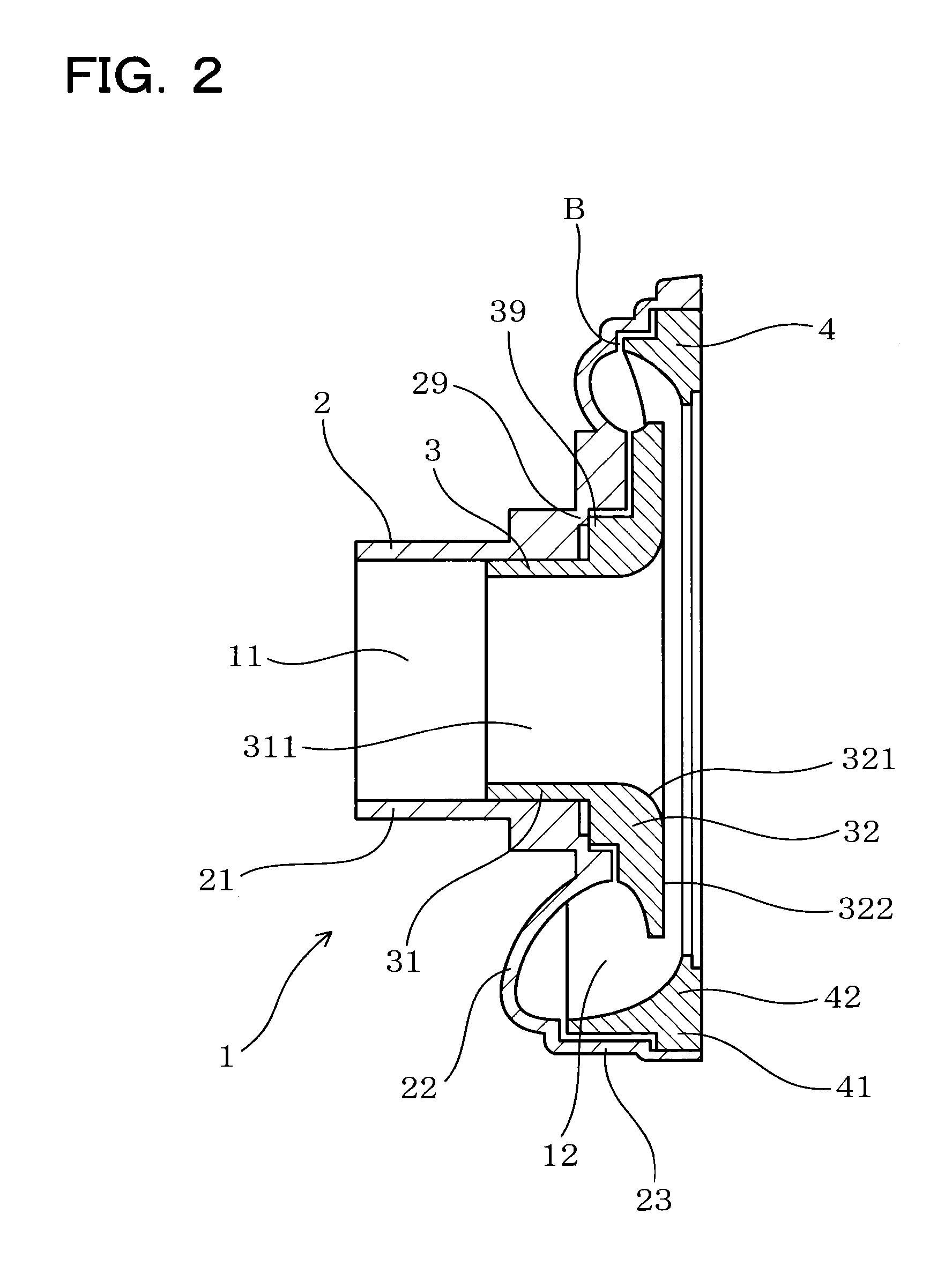

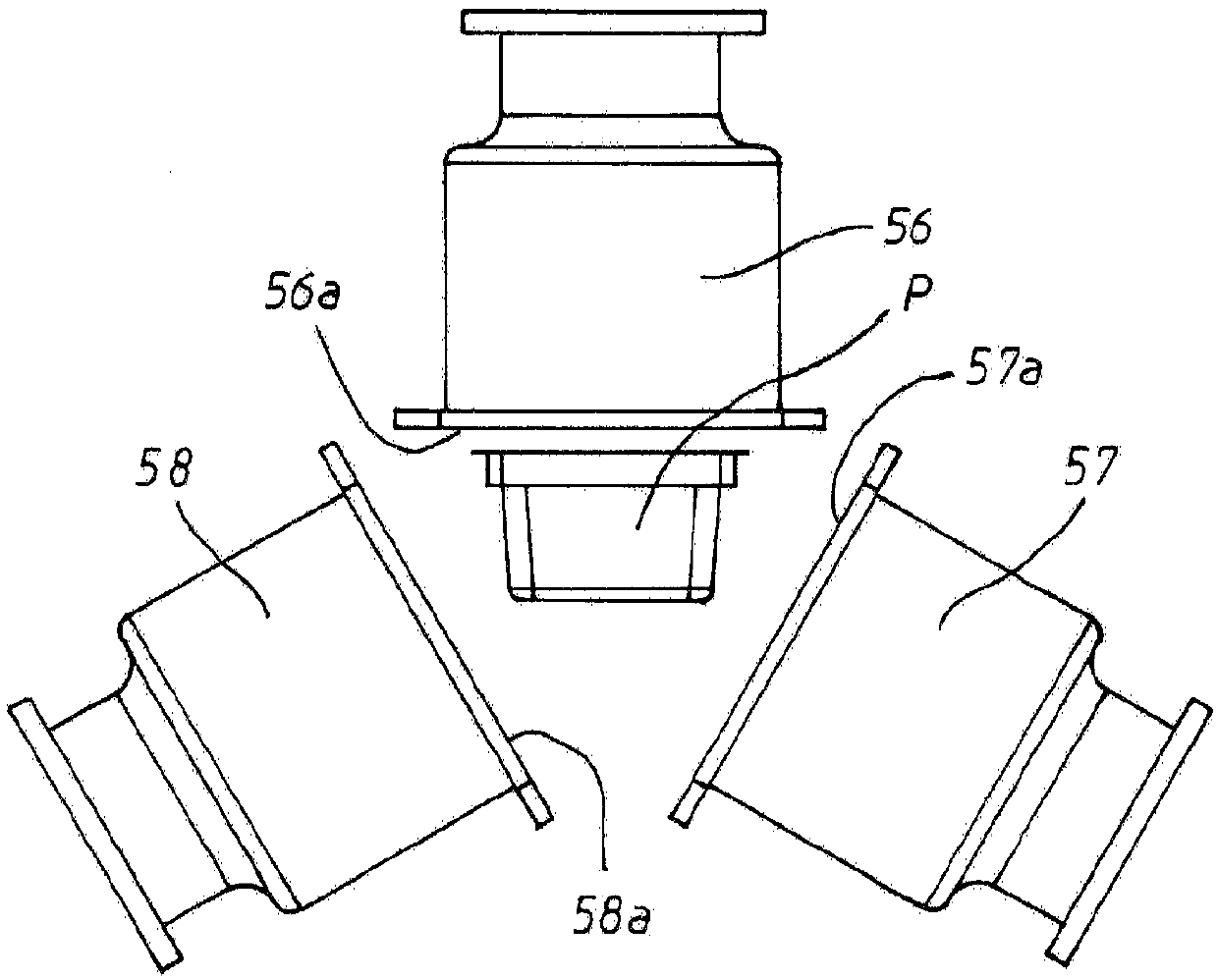

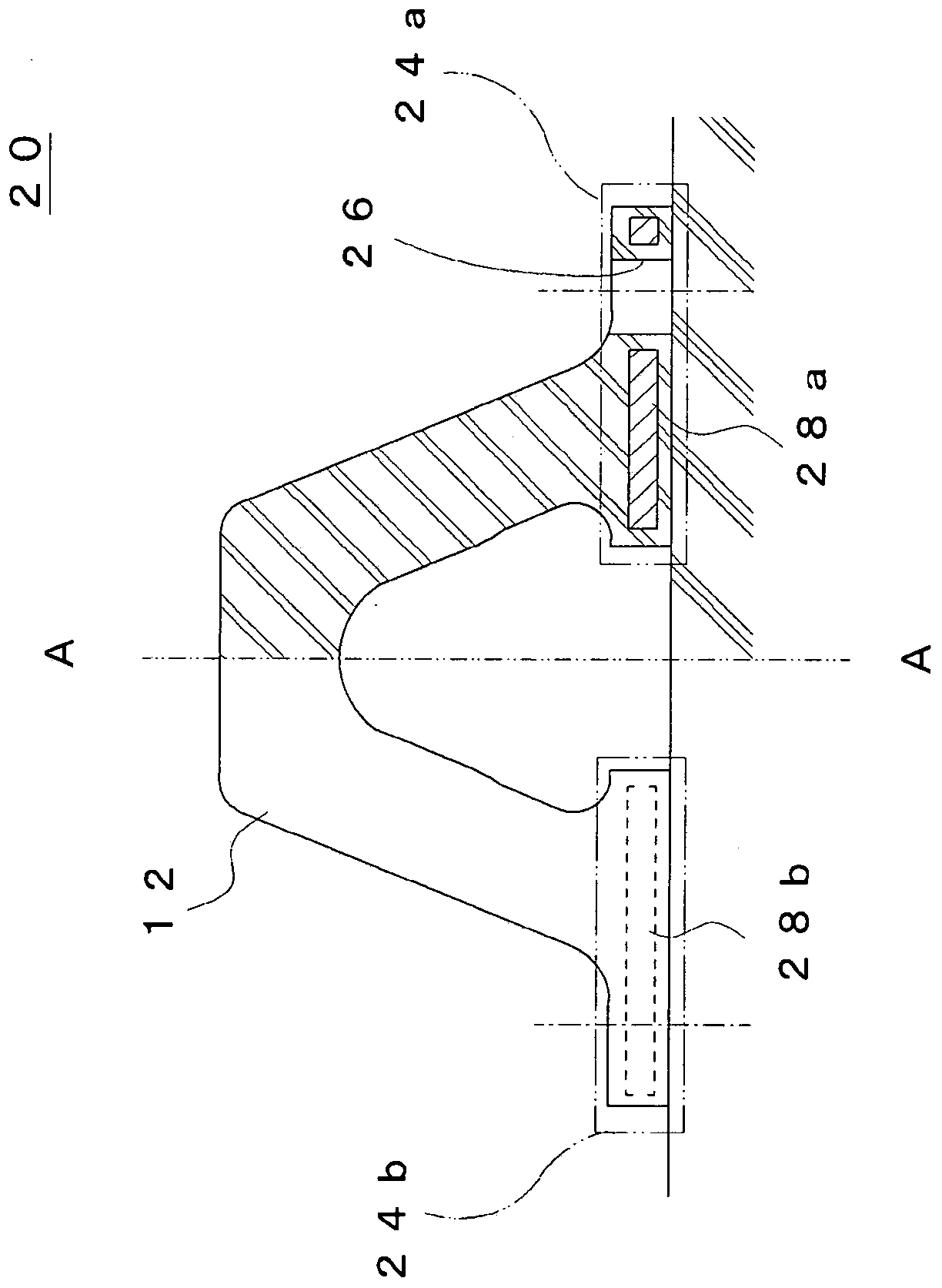

Compressor housing for supercharger and method for manufacturing the same

ActiveUS20130039750A1Improve productivityEasy to shapeEngine manufacturePump componentsImpellerEngineering

A compressor housing is provided with a scroll piece that includes a cylindrical intake port forming section that forms an intake port, a scroll wall surface forming section that forms an air-intake side wall surface of a discharge scroll chamber, and a scroll outer circumferential section that covers an outer circumferential side of the discharge scroll chamber; a shroud piece that includes a cylindrical shroud press fitted section press fitted into the intake port forming section, and a shroud wall surface forming section that forms an inner circumferential side wall surface of the discharge scroll chamber and also forms a shroud surface that opposes an impeller and a diffuser surface; and an outer circumferential annular piece that includes an outer circumferential annular press fitted section that is press fitted inside the scroll outer circumferential section, and an outer circumferential annular wall surface forming section that forms an outer circumferential side wall surface of the discharge scroll chamber.

Owner:OTICS CORP +1

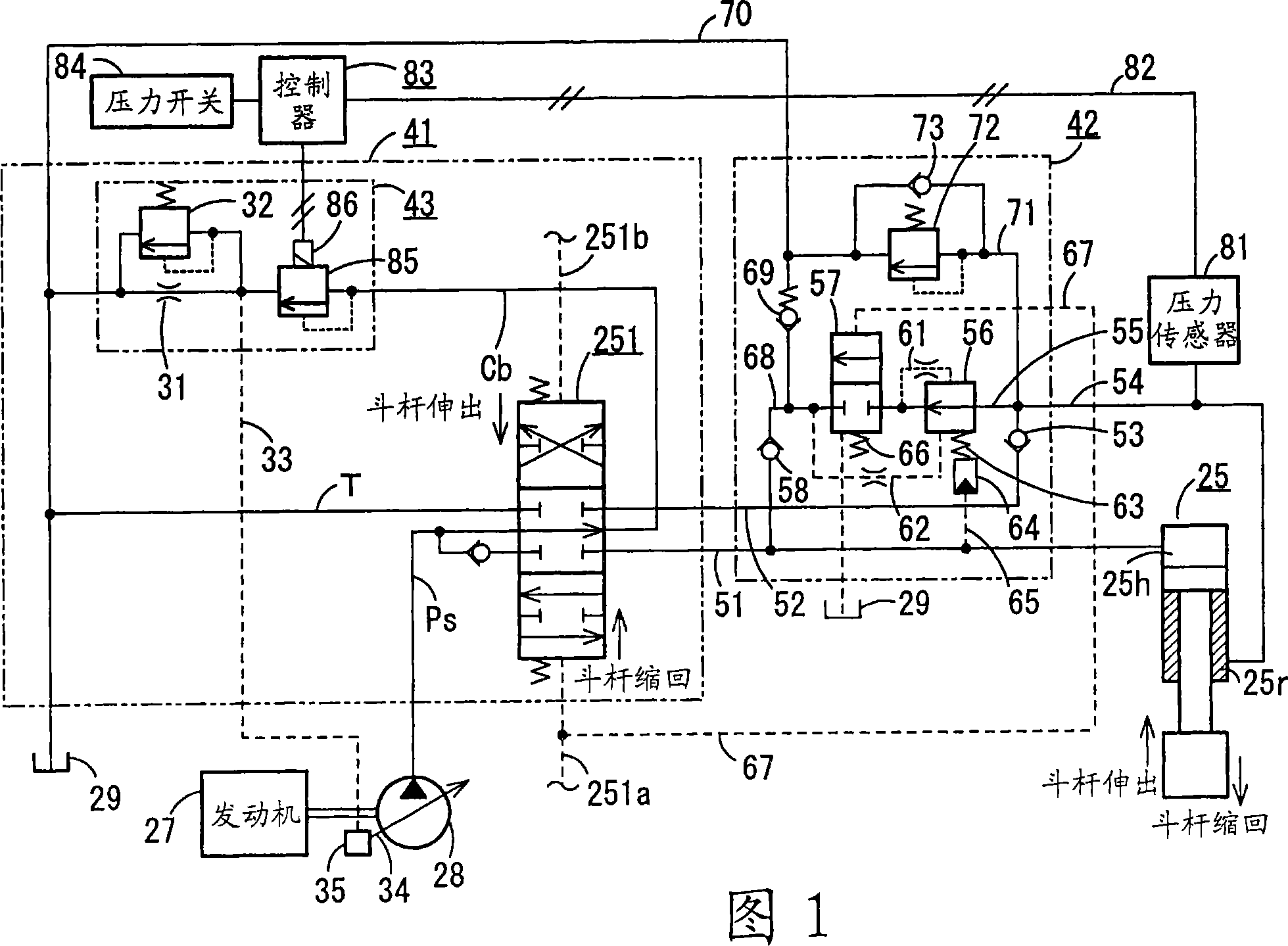

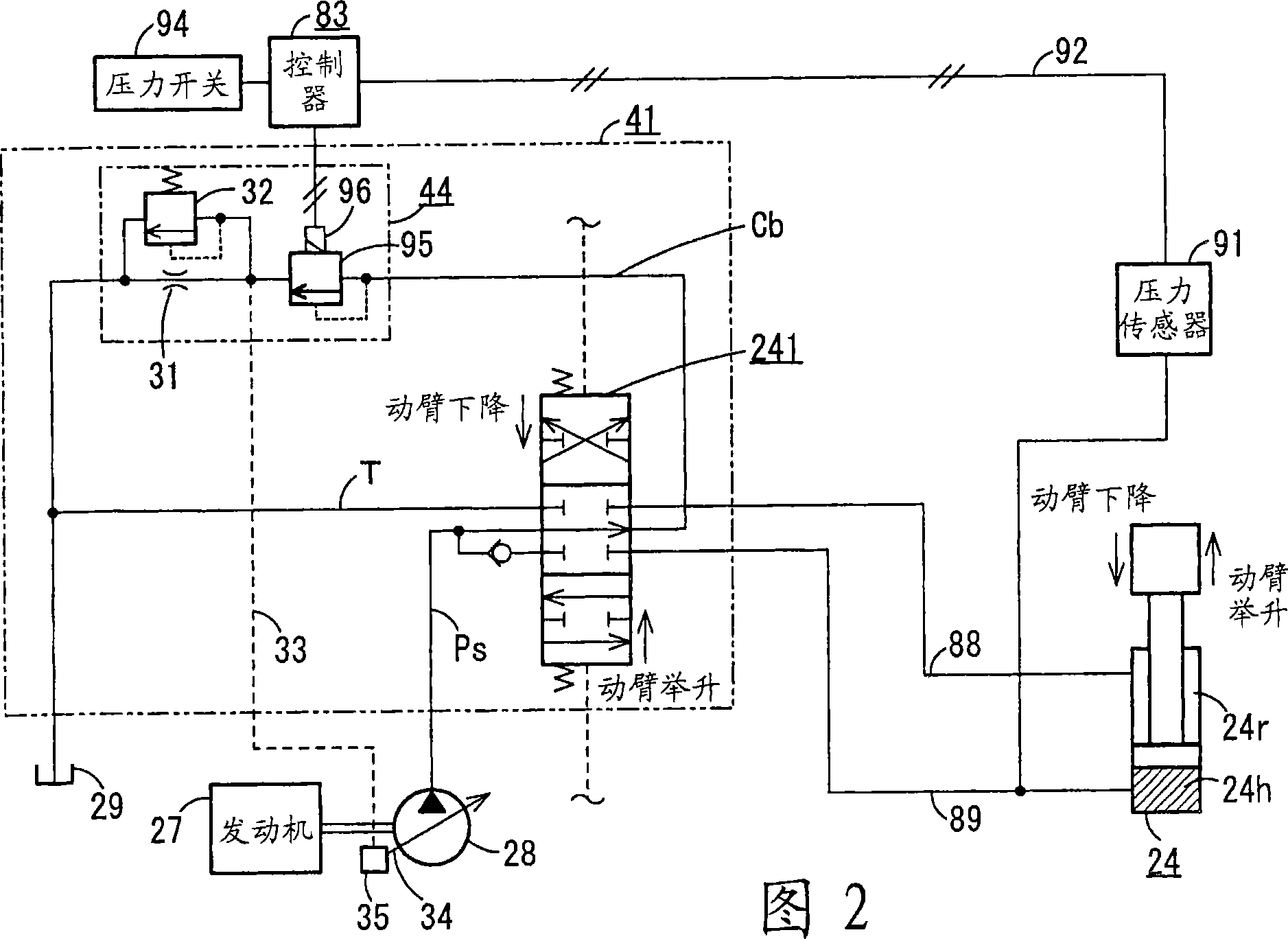

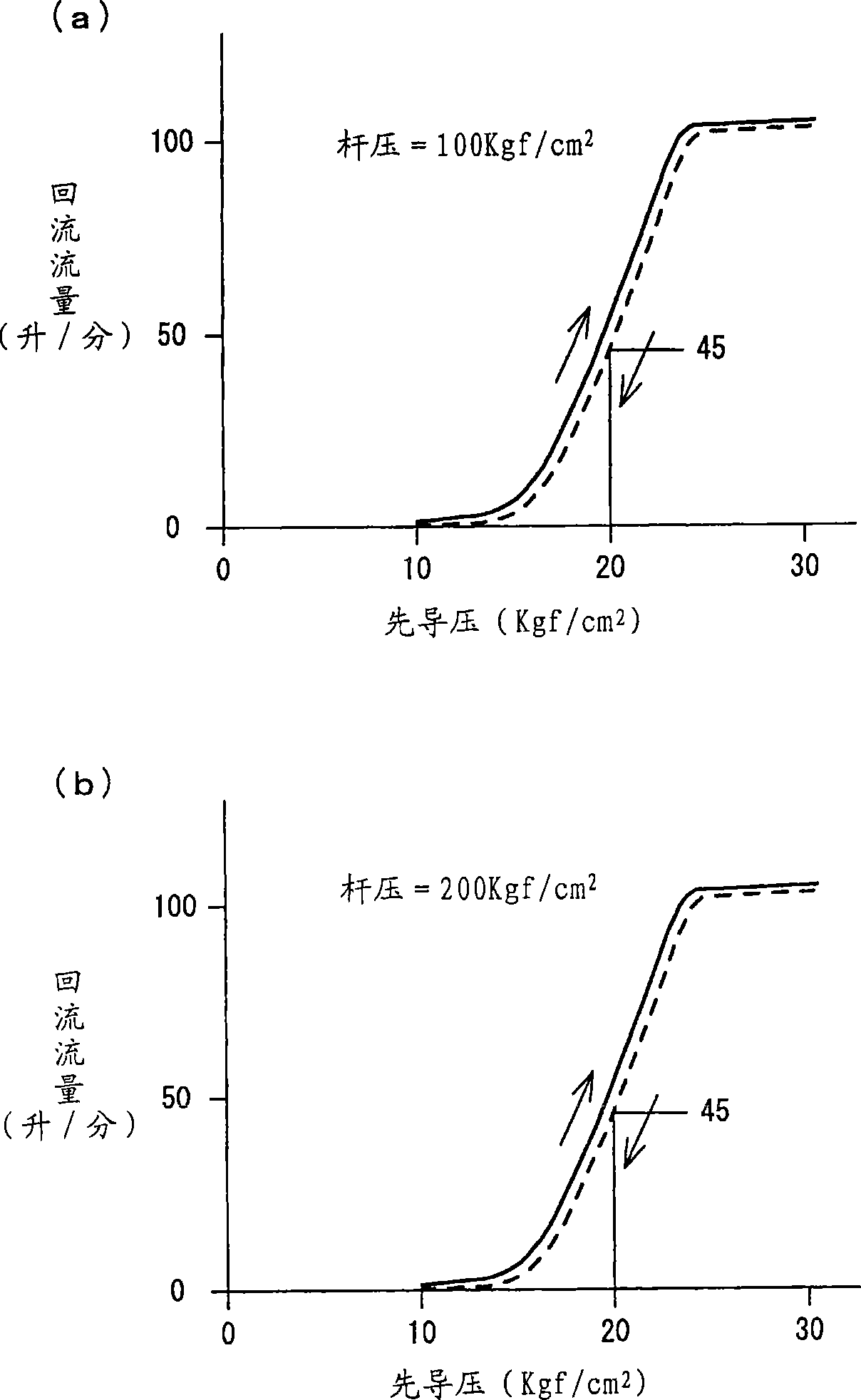

Control circuit of construction machine

InactiveCN1914384AStable flow characteristicsStable without changing flow characteristicsServomotorsSoil-shifting machines/dredgersHydraulic pumpControl engineering

A control circuit of a construction machine capable of securing a same operability as in a case where a hydraulic shovel having an open center circuit is tuned by using a standard bucket even when the bucket weight of the hydraulic shovel is changed. Center bypass lines (Cb) are installed for a boom operation valve and a stick operation valve (251) controlling an oil supplied from a hydraulic pump (28) to a boom cylinder and a stick cylinder (25). A stick-in meter-out load pressure compensating valve (42) is installed in a rod side return line (55) from the rod side (25r) of the stick cylinder (25) to a tank (29). A pressure sensor (81) detecting the pressure of the hydraulic oil supplied to the rod side (25r) is installed on the rod side (25r) of the stick cylinder (25). An electromagnetic proportional relief valve (85) controlling a center bypass line pressure on the downstream side of the stick operation valve (251) in an increasing direction according to the rise of the pressure detected by the pressure sensor (81) is installed in the center bypass line (Cb).

Owner:SHIN CATERPILLAR MITSUBISHI LTD CORP

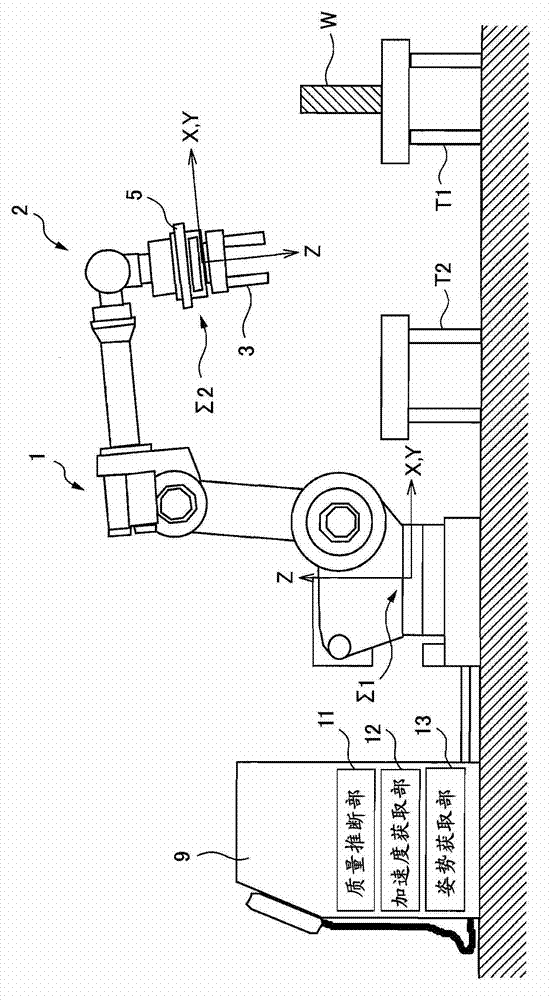

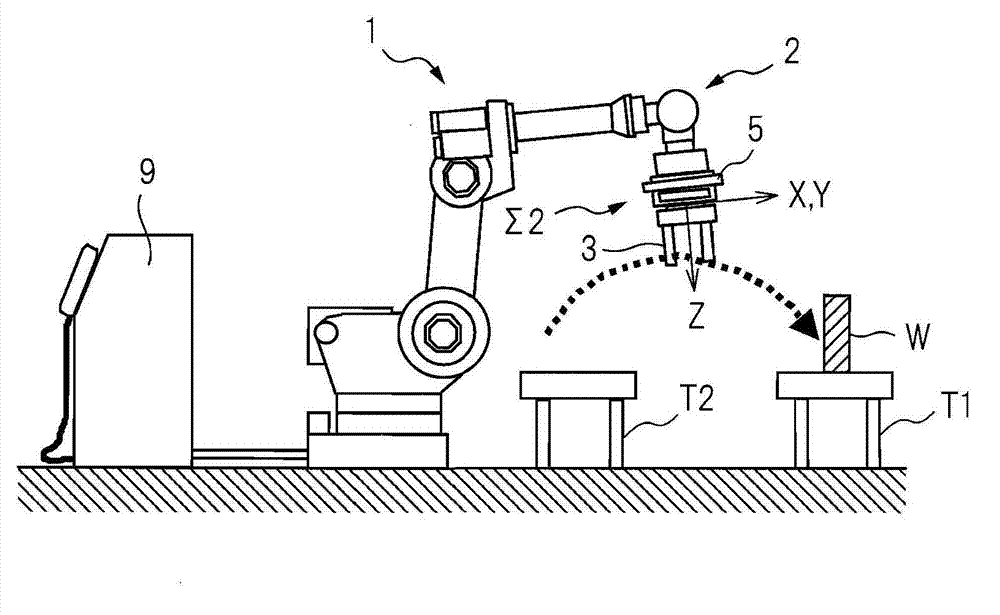

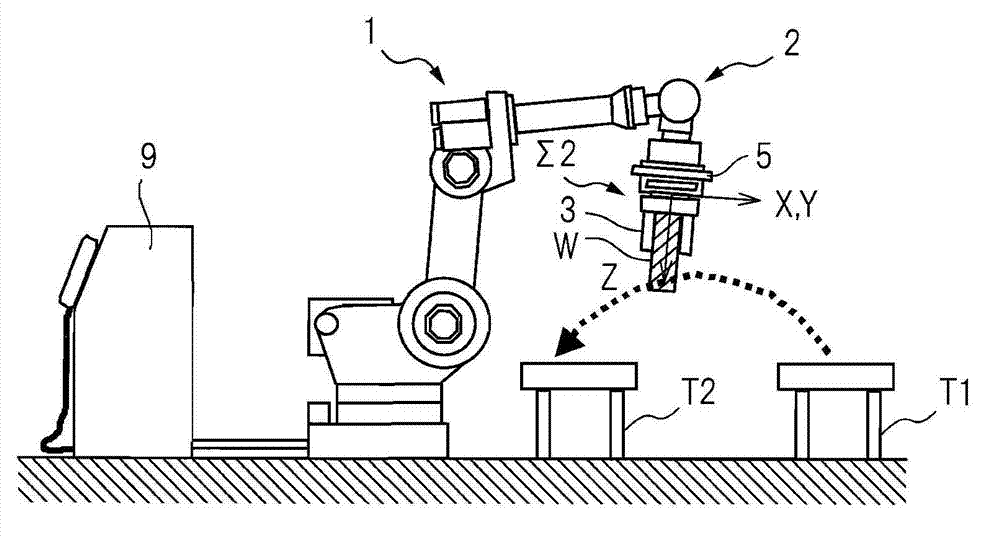

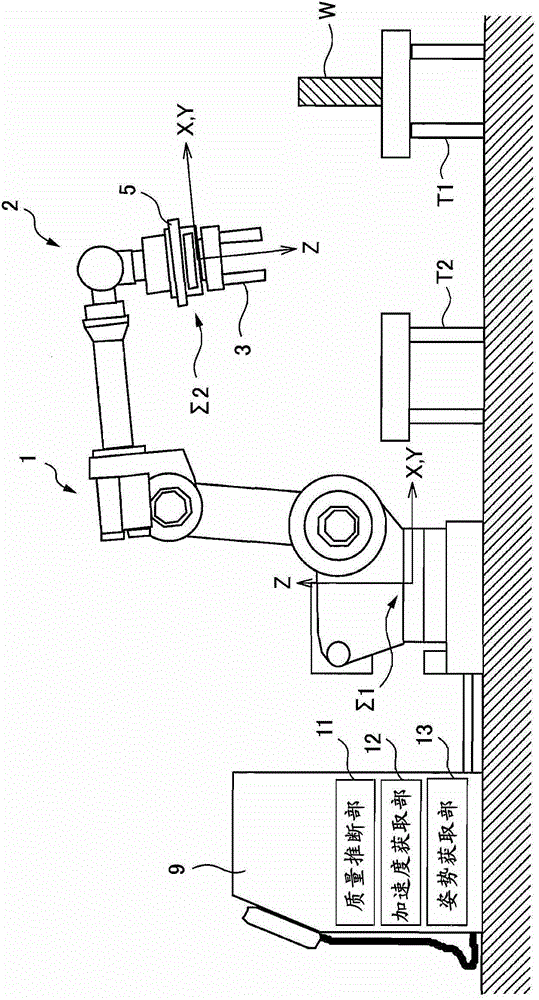

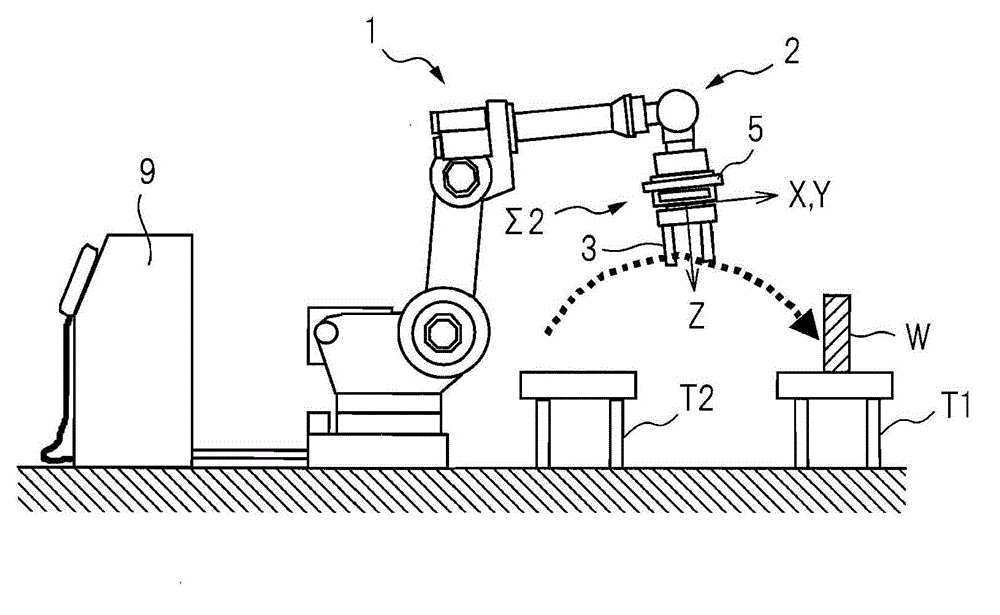

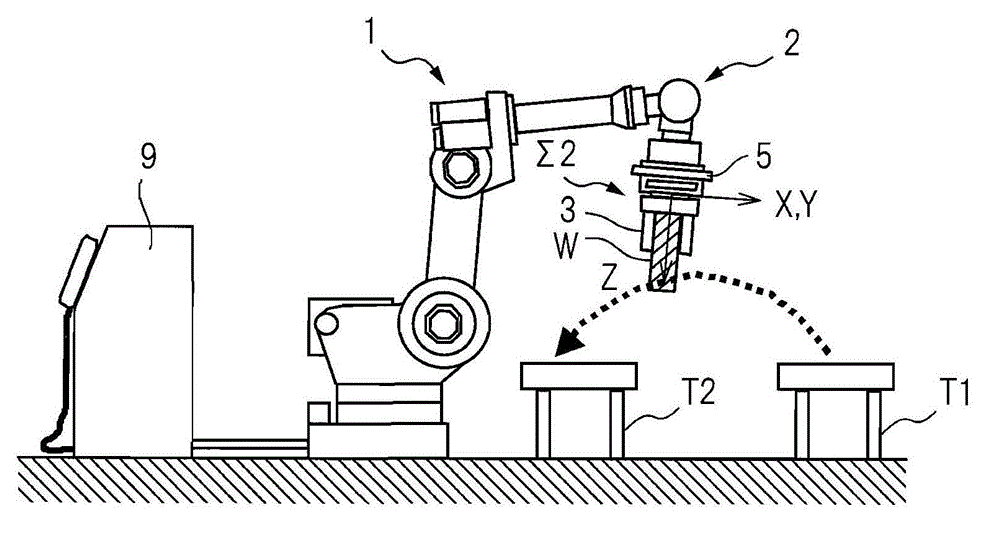

Robot having workpiece mass measurement function

ActiveCN102990642ALong cycleSimple structureProgramme controlProgramme-controlled manipulatorEngineeringMass measurement

The invention provides a robot having workpiece mass measurement function. Workpiece mass can be correctly obtained, even during operating. A robot (1) having a workpiece mass measurement function for measuring the mass of a workpiece that is held, includes a force measurement unit (5) that measures the force that is applied to the tip part (2) of the mechanism part of the robot (1), and a mass estimation unit (11) that estimates the mass of the workpiece that is held by the robot (1), based on information about the force acquired by the force measurement unit (5) while the robot (1) is moving. Workpiece mass can be correctly obtained, even during operating. Preferably, force measurement unit (5) estimates the mass of the workpiece according to a force measured value measured when the workpiece is held and a force measured value measured when the workpiece is not held.

Owner:FANUC LTD

Electronic beam irradiation device

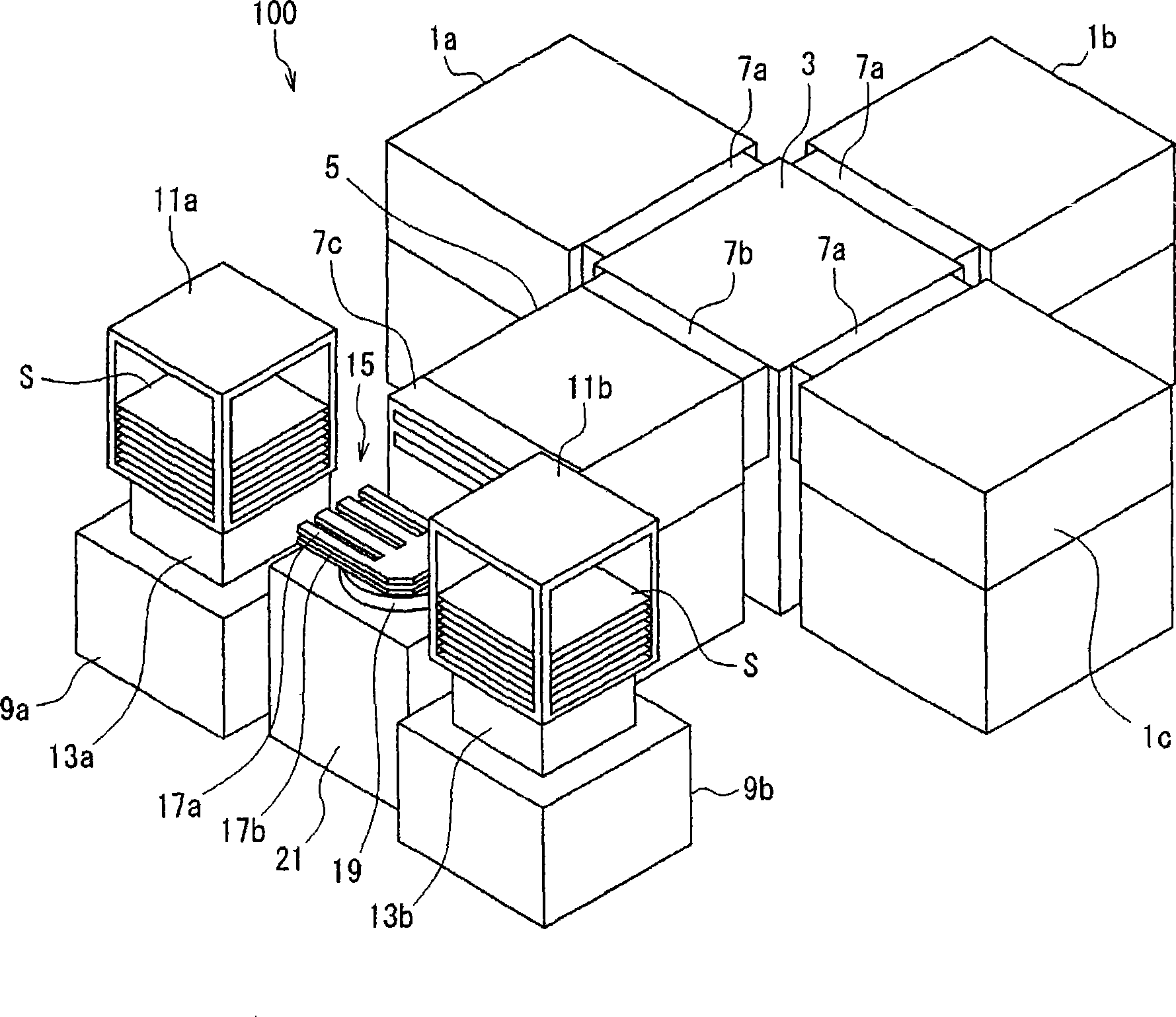

ActiveCN104335290AUniform irradiationDecrease the acceleration voltage actionIrradiation devicesRadiationEngineeringIrradiation

Provided is an electronic beam irradiation device that is able to: use a compact, low-energy electron accelerator with a narrow irradiation window to irradiate an electronic beam uniformly on the entire outer surface of an object for irradiation; keep the reliability and safety of sterilization performance high by making the sterilization level of each of multiple sites substantially the same; and reduce electron accelerator cost, and by extending usage limit (life), equipment initial cost and maintenance cost. The invention comprises an electron beam irradiation means forming an electron beam irradiation area, and a gripping / moving means that grips part of the object for irradiation, and passes said object through the inside of the electron beam irradiation area. The entire surface of the object for irradiation is capable of uniformly passing through the electron beam irradiation area by combining regripping of the object for irradiation by means of two gripping mechanisms that the gripping / moving means is provided with, rotating of the object for irradiation by means of two rotating mechanisms, and moving of the object for irradiation by means of two movement mechanisms.

Owner:AIREX

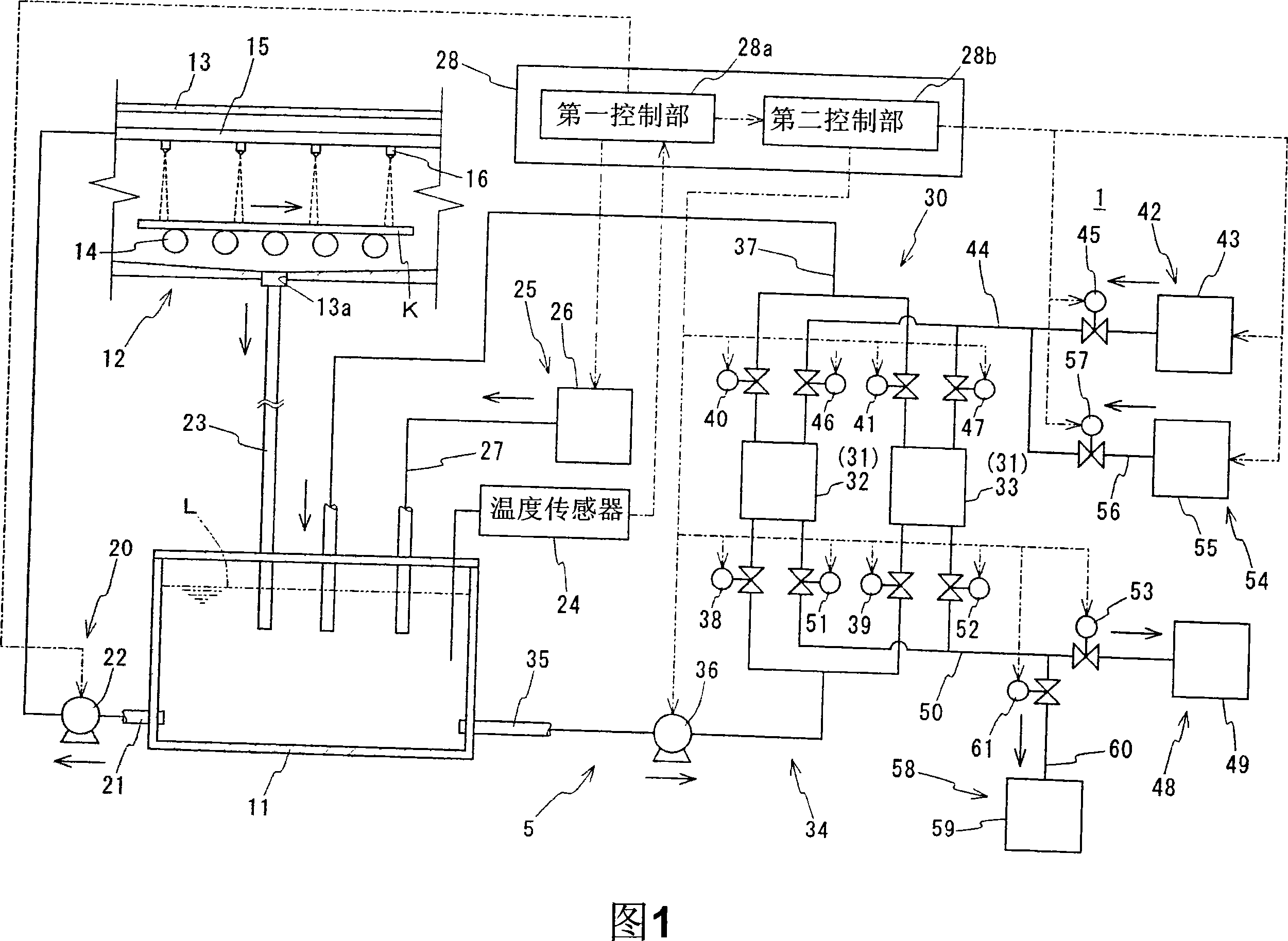

Processing device for processing fluid and substrate processing device having the same

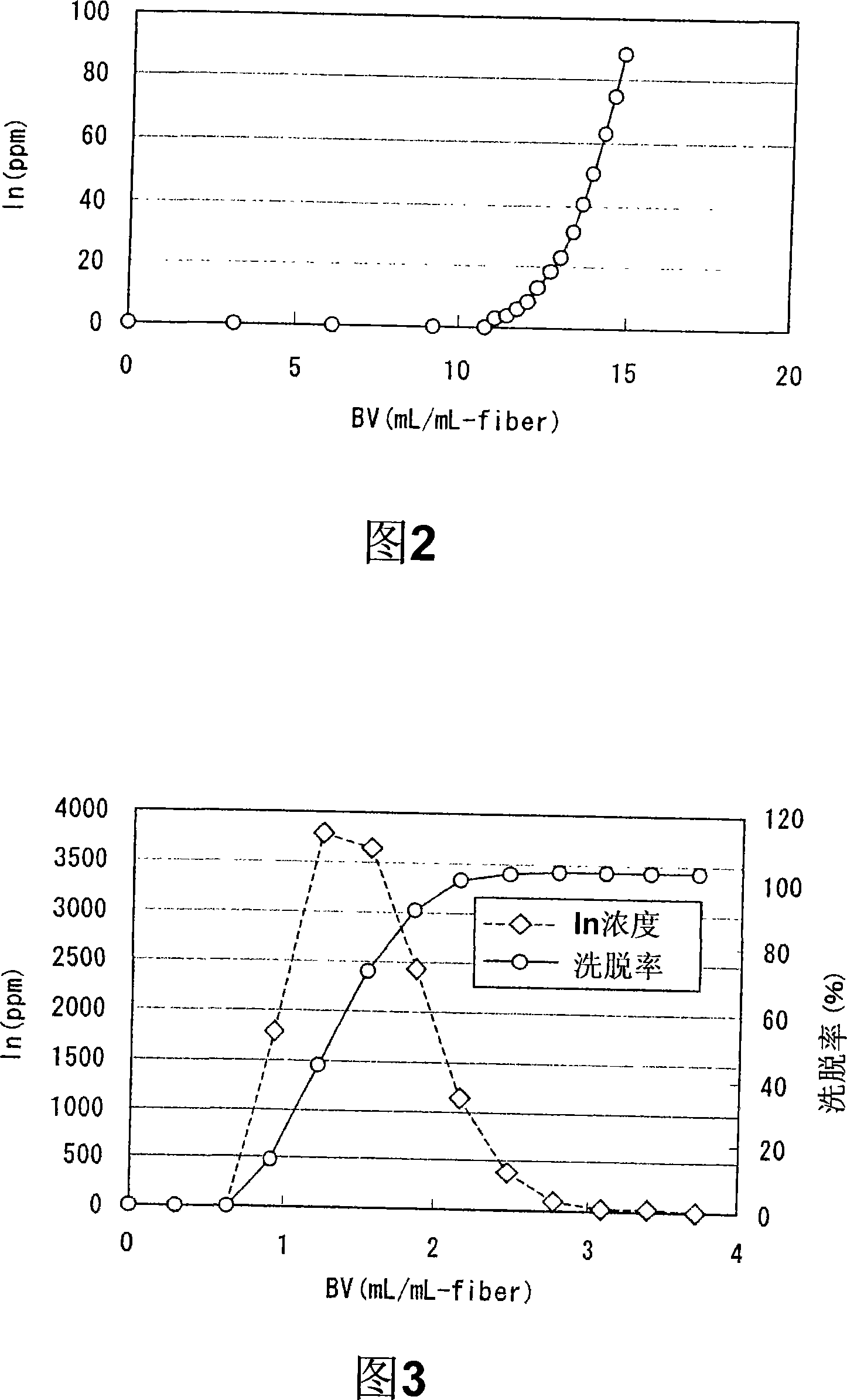

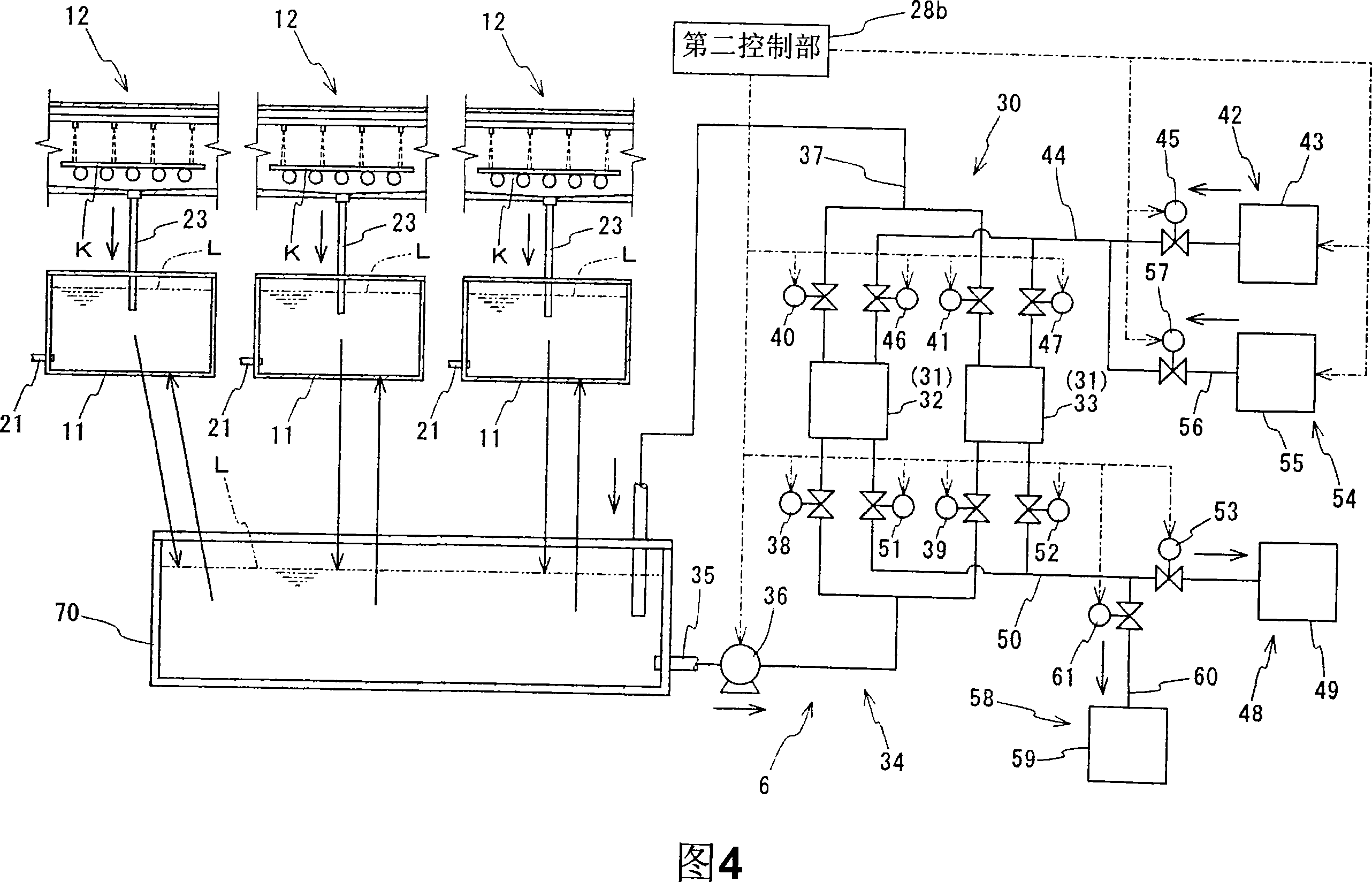

InactiveCN101122024AContainment costsEfficient removalIon-exchange process apparatusIon-exchanger regenerationEngineeringTower

The present invention provides a substrate processing device which prolongs the replacing period of the processing liquid, prevents substrate processing efficiency from reducing and restrains substrate processing cost. The substrate processing device (1) comprises: a first processing liquid cycle mechanism (20) to ensure the processing liquid cycle between a storage trough (11) and a substrate processing mechanism (12); two absorption towers (32, 33), for absorbing metal ions contained in the processing liquid after the substrate processing of the substrate processing mechanism (12); a second processing liquid cycle mechanism (34), for supplying processing liquid of the storage trough (11) for arbitrary one of the absorption towers (32, 33) and ensuring the processing liquid cycle; and a control device (28), for controlling the motion of the second processing liquid cycly mechanism (34), so as to make the absorption towers (32, 33) be switched alternately based on prescribed time interval.

Owner:SUMITOMO PRECISION PROD CO LTD

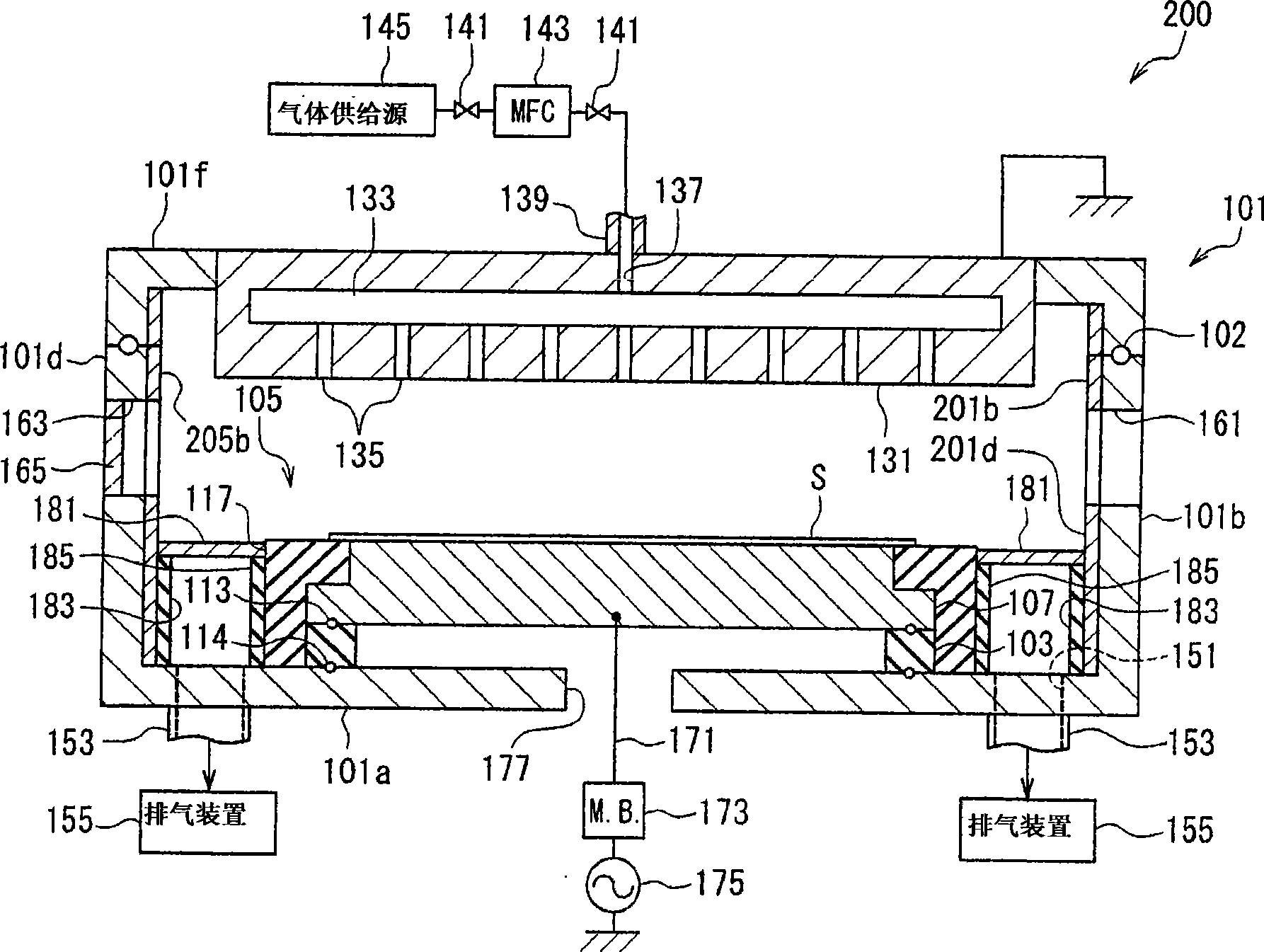

Processing container an plasma processing device

ActiveCN101452805AContainment costsSuppression of switching frequencyElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringPlasma processing

The present invention provides a processing container and a plasma processing device, capable of exchanging a protective member for protecting inner surface of the processing container easily in the plasma processing device, and restraining cost of members. In the processing container (101) of the plasma processing device, the inner surface with side wall (101b) with opening (161) for conveying substrates is covered with pads (201a,201b, 201c, 201d) as protective member. Because plasma concentrated at a corner portion (161a) of the opening (161) for conveying substrates is easy to consume, the surrounding pads (201a, 201c) are configured to be separable to the pads (201b, 201d) with slower consumption than the pads (201a, 201c) in manner of independent members.

Owner:TOKYO ELECTRON LTD

Power generating facility

ActiveCN103089341AEfficient use ofHigh outputEnergy industrySteam generation plantsBoiling pointEngineering

To provide a power generating facility for increasing heat utilization efficiency by recovering and utilizing heat from low-temperature exhaust gas of not more than 150 C and increasing steam turbine generation. In a power generating facility provided with heat exchangers (61, 62) for heat exchange between a heat medium and water and a vacuum flasher (63) that supplies steam to a vacuum stage of a steam turbine (41), the amount of generated power is increased by supplying the heat medium to the heat exchangers (61, 62) so as to generate water fluid with a temperature exceeding the water boiling point under vacuum in the vacuum stage, supplying the water fluid to the vacuum flasher (63) so as to produce steam under the vacuum of the vacuum stage, and feeding the steam to the vacuum stage of the steam turbine (41).

Owner:KAWASAKI JUKOGYO KK

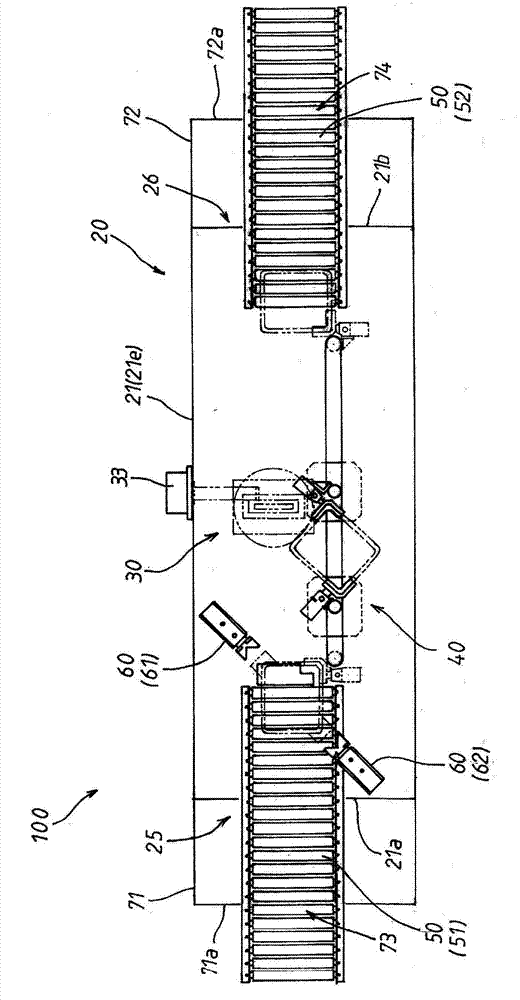

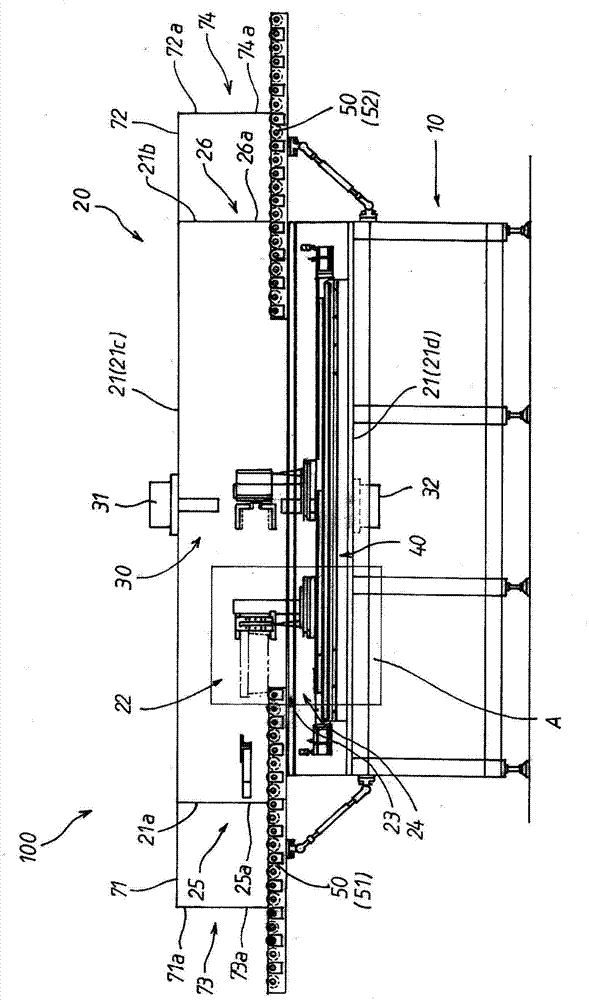

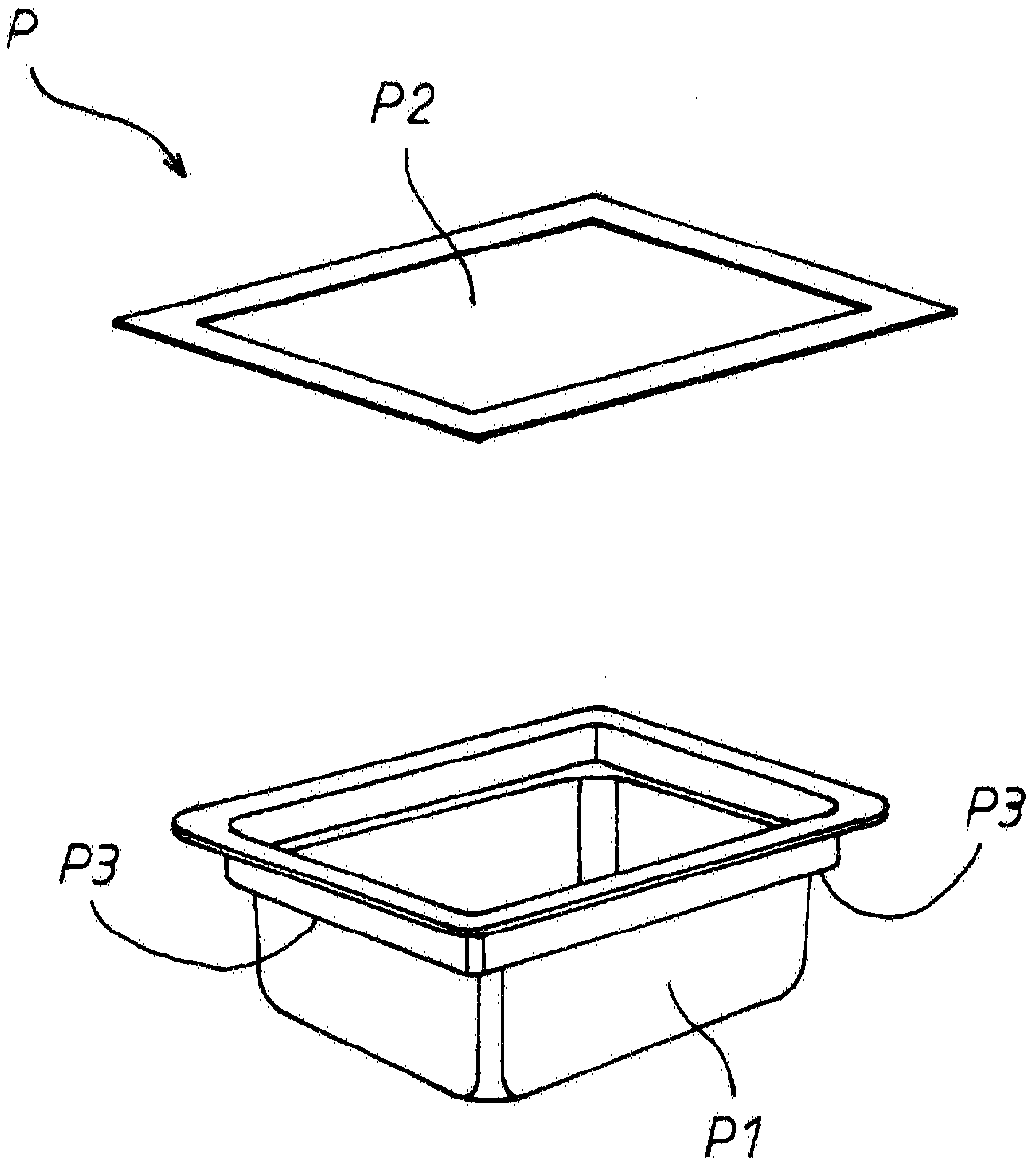

Electron beam irradiation device

ActiveCN107614021AReduce acceleration voltageMaintain reliabilityPackage sterilisationChemicalsNuclear engineeringElectron acceleration

Provided is an electron beam irradiation device that is capable of uniformly irradiating the entire outer surface of a container with electron beams using small-sized low-energy electron accelerators,and is able to maintain the reliability and safety of the sterilization effect at high levels by sterilizing each part to be sterilized to equal degrees, and is also able to keep the initial costs and maintenance costs of the device low by reducing the costs of the electron accelerators and extending the usage limit (service life) of the electron accelerators. When the side surface portions of the container are irradiated with electron beams with the bottom surface portion of the container supported by a support means, the position of the container is moved by the support means so that the distances between the side surface portions of the container and irradiation windows of the electron accelerators are substantially equal. Next, when an upper surface portion and the bottom surface portion of the container are irradiated with electron beams with the side surface portions of the container held by a holding means, the position of the container is moved by the holding means so that thedistances between the upper surface portion and the bottom surface portion of the container and the irradiation windows of the electron accelerators are substantially equal.

Owner:AIREX

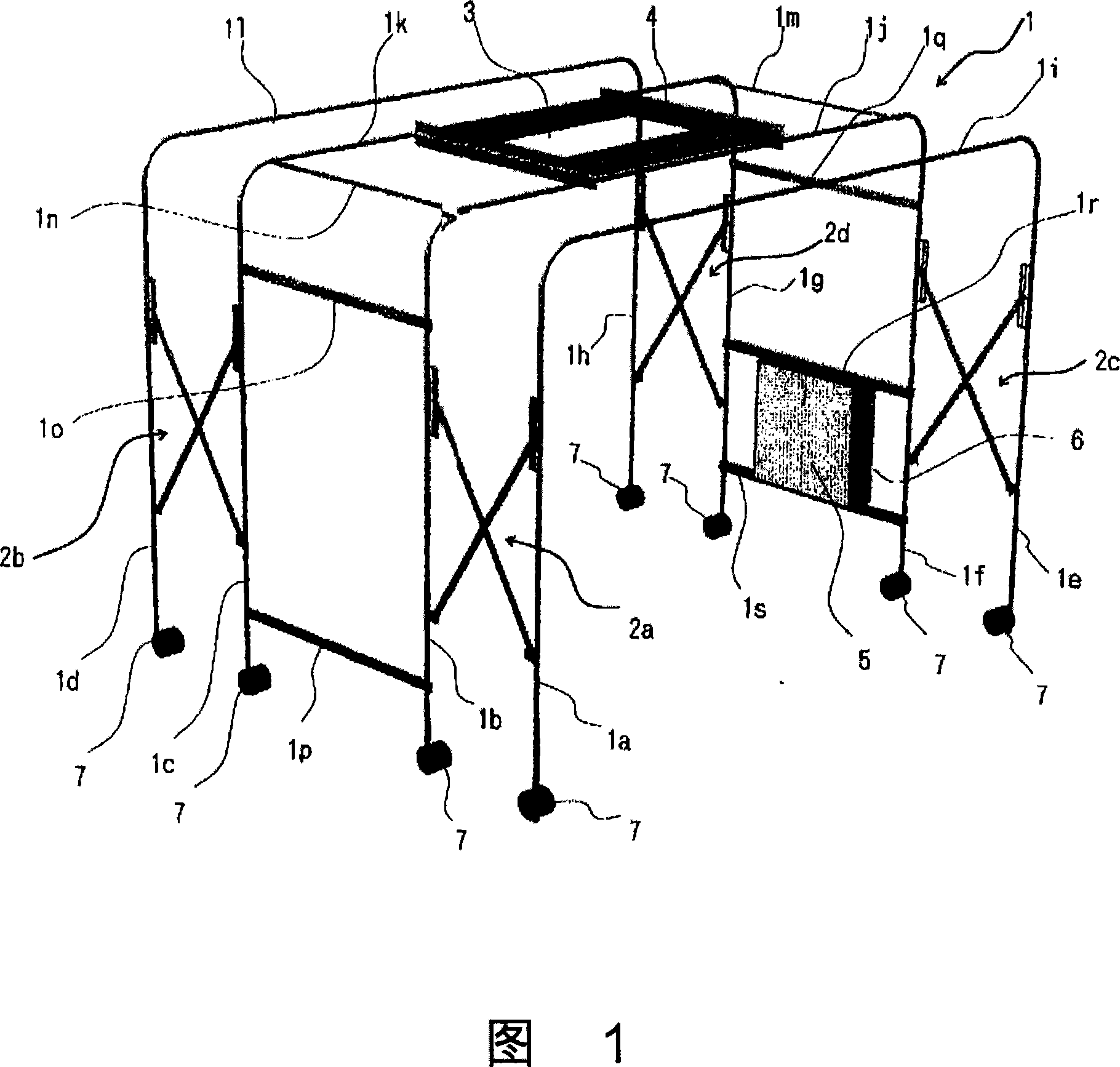

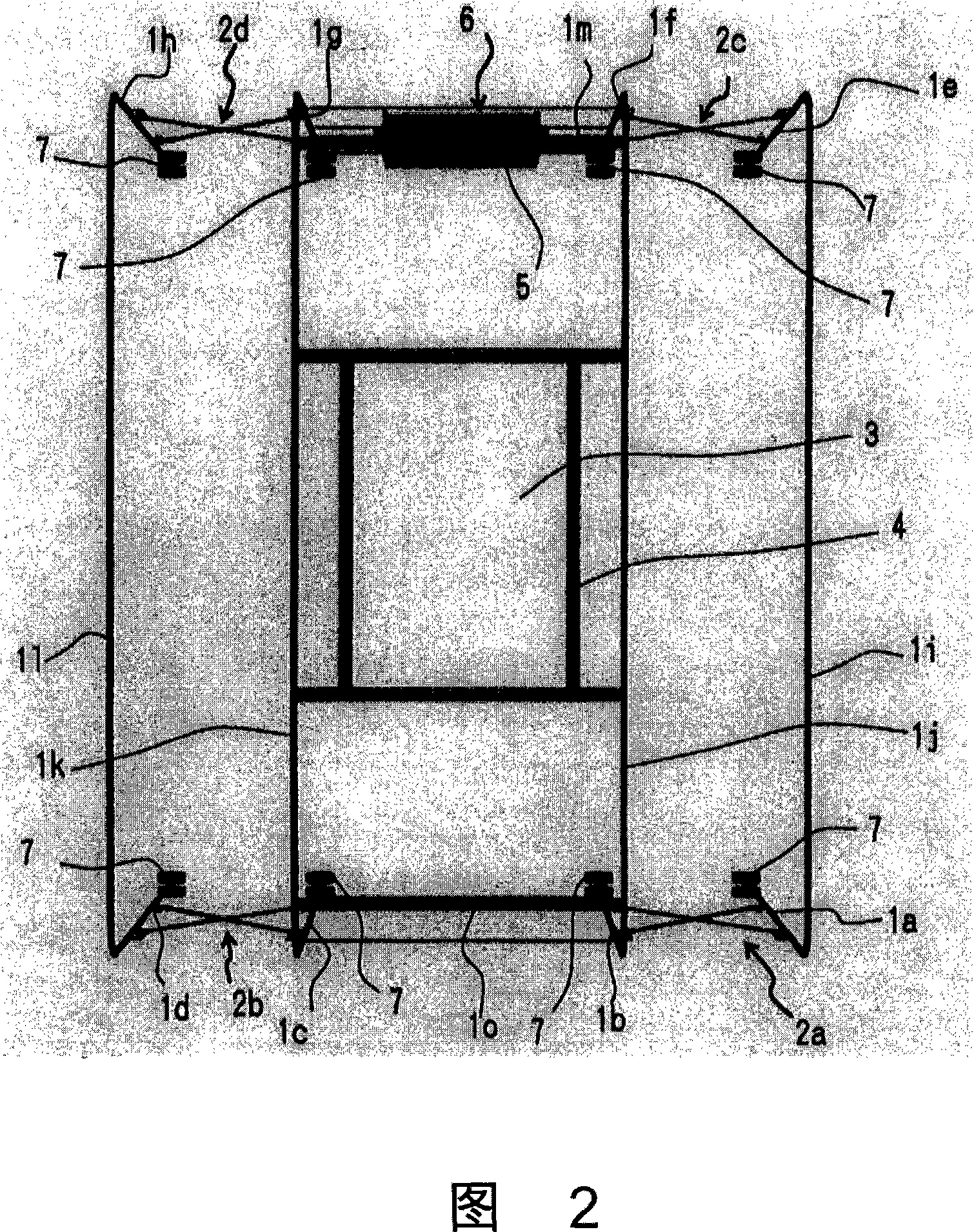

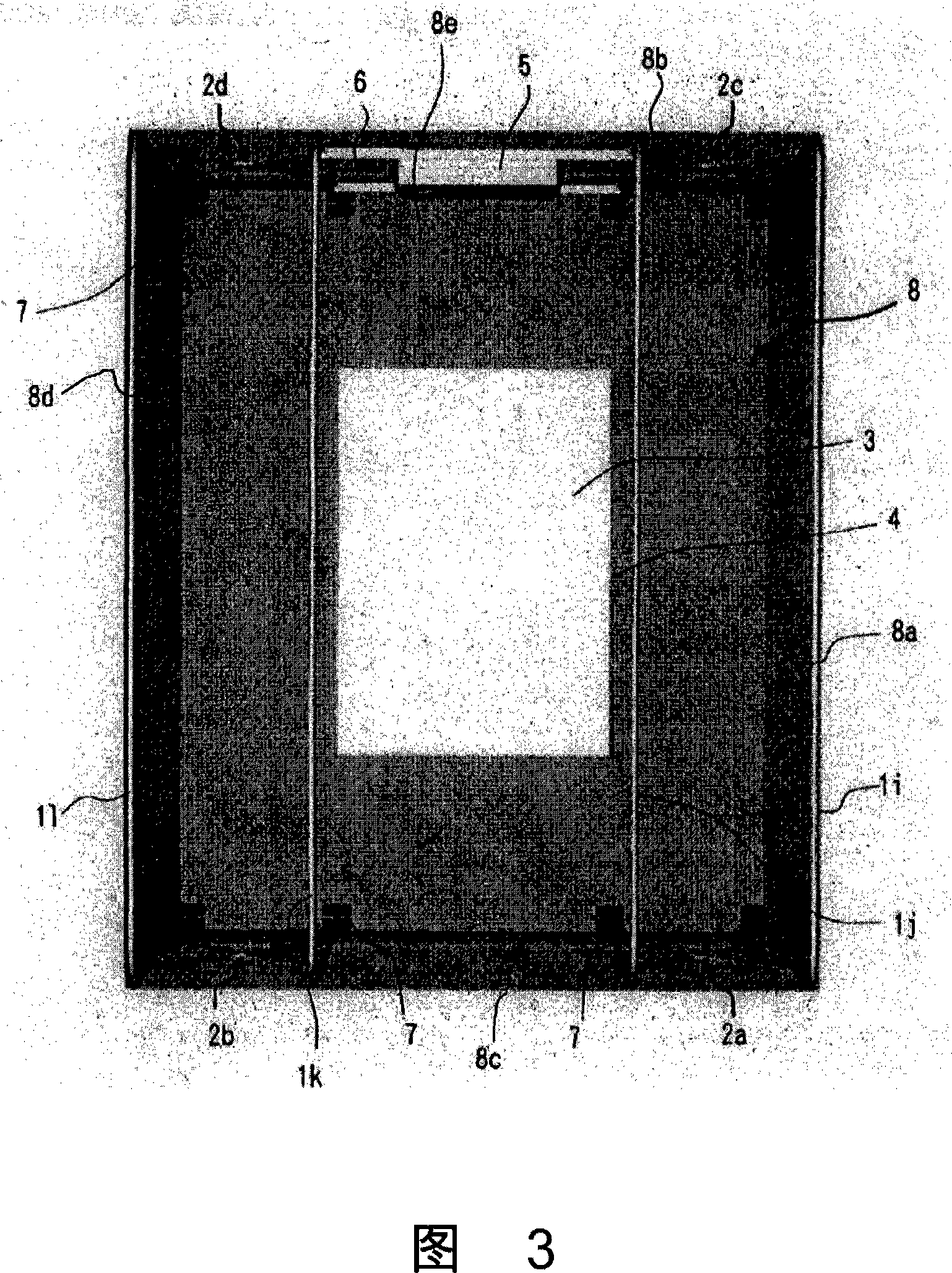

Paint booth

InactiveCN101062497ADry fastTotal paint job time reducedPretreated surfacesCoatingsWork performanceDrying time

A painting spraying room covers the skeleton surface side except the undersurface of the skeleton group member (1) by cover member (8). The facade of the cover member (8) is stroked from the bottom up. An exhaust opening part (5) and an exhaust device mounting rack (6) with a filter, an exhaust fan and an extract duct around are set on the right side (8b). An air-supply opening part and a drier mounting rack (4) for installing the drier (10) are set on the upper surface (8e). The painting spraying room and the drier (10) can make a cross move together, so without engagement of workplaces, thereby increasing space efficiency. The invention can shorten coating operation time including drying time, thereby markedly enhancing coating working performance and increasing space efficiency in the workspace without choosing the workspace. It achieves the functions of reaching the environmental criteria and adequately suiting for the water paint.

Owner:上野 信

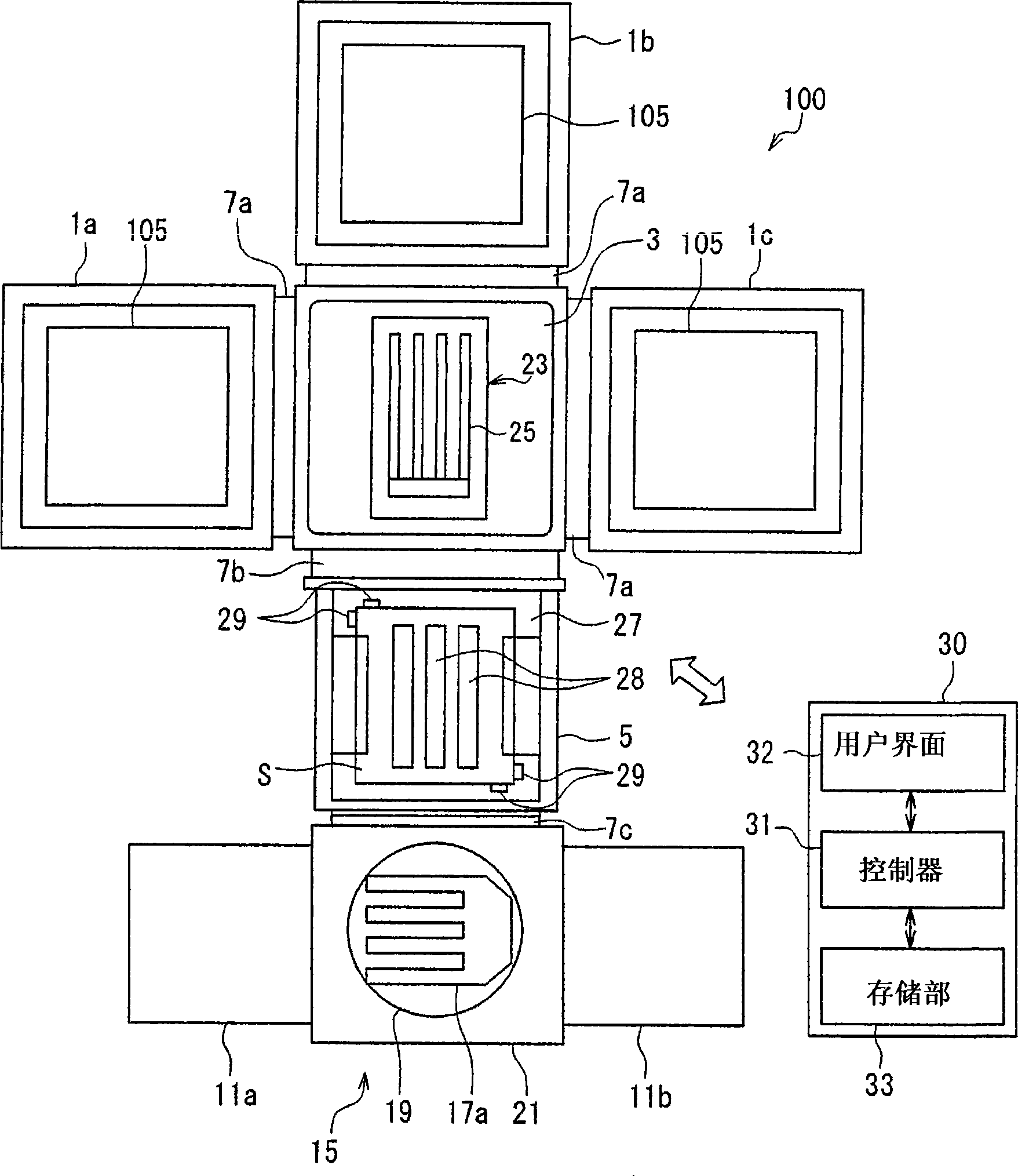

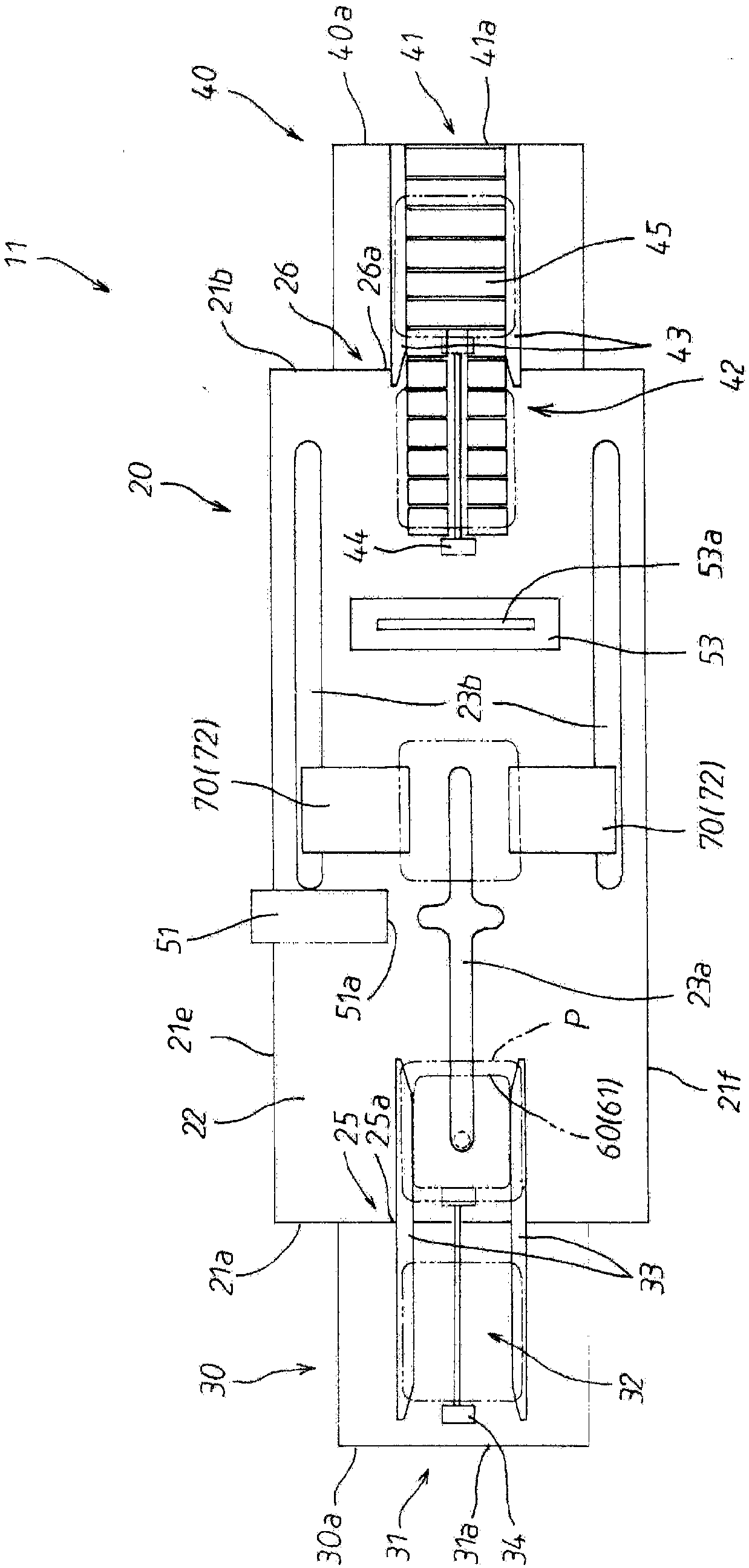

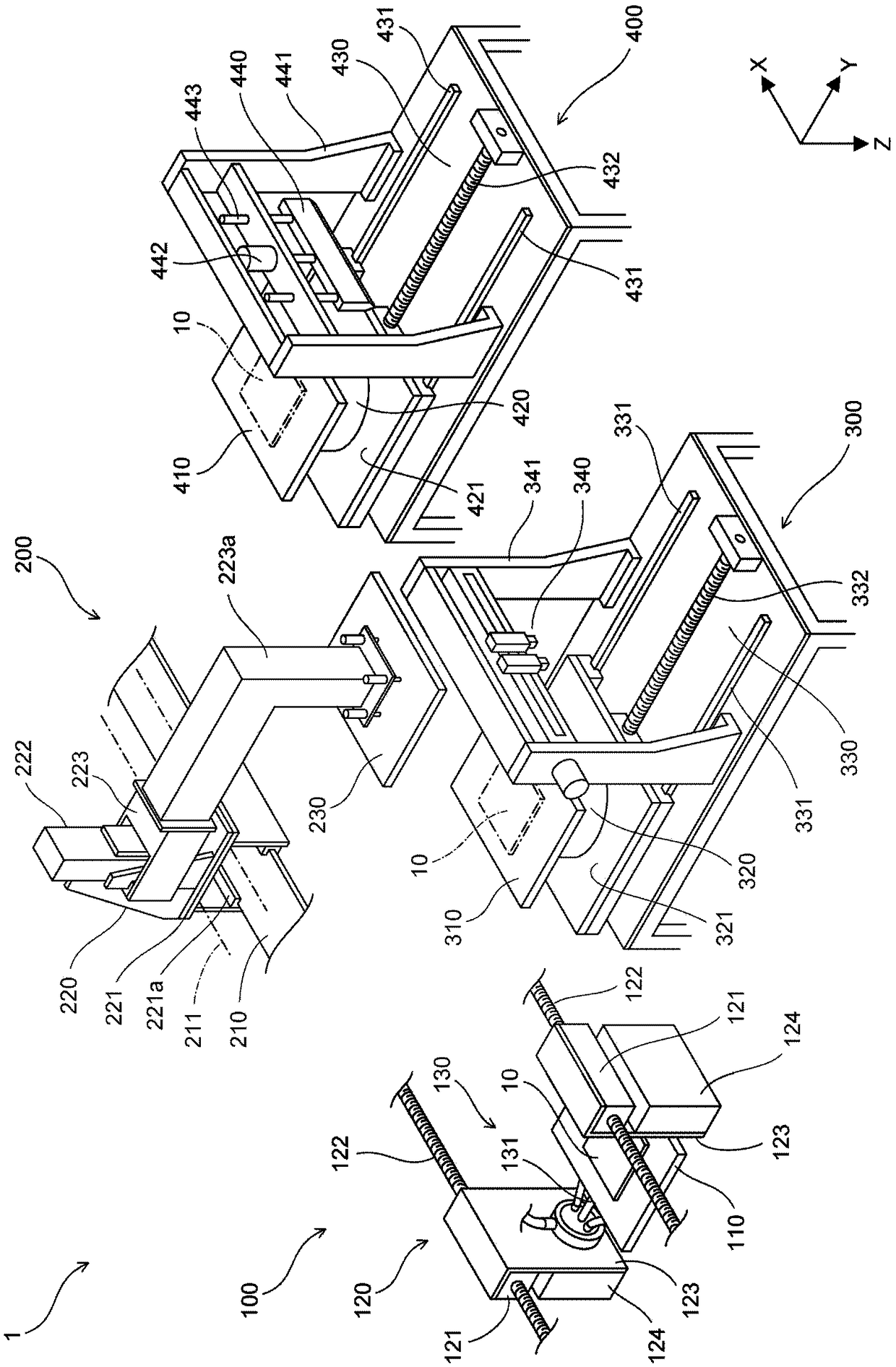

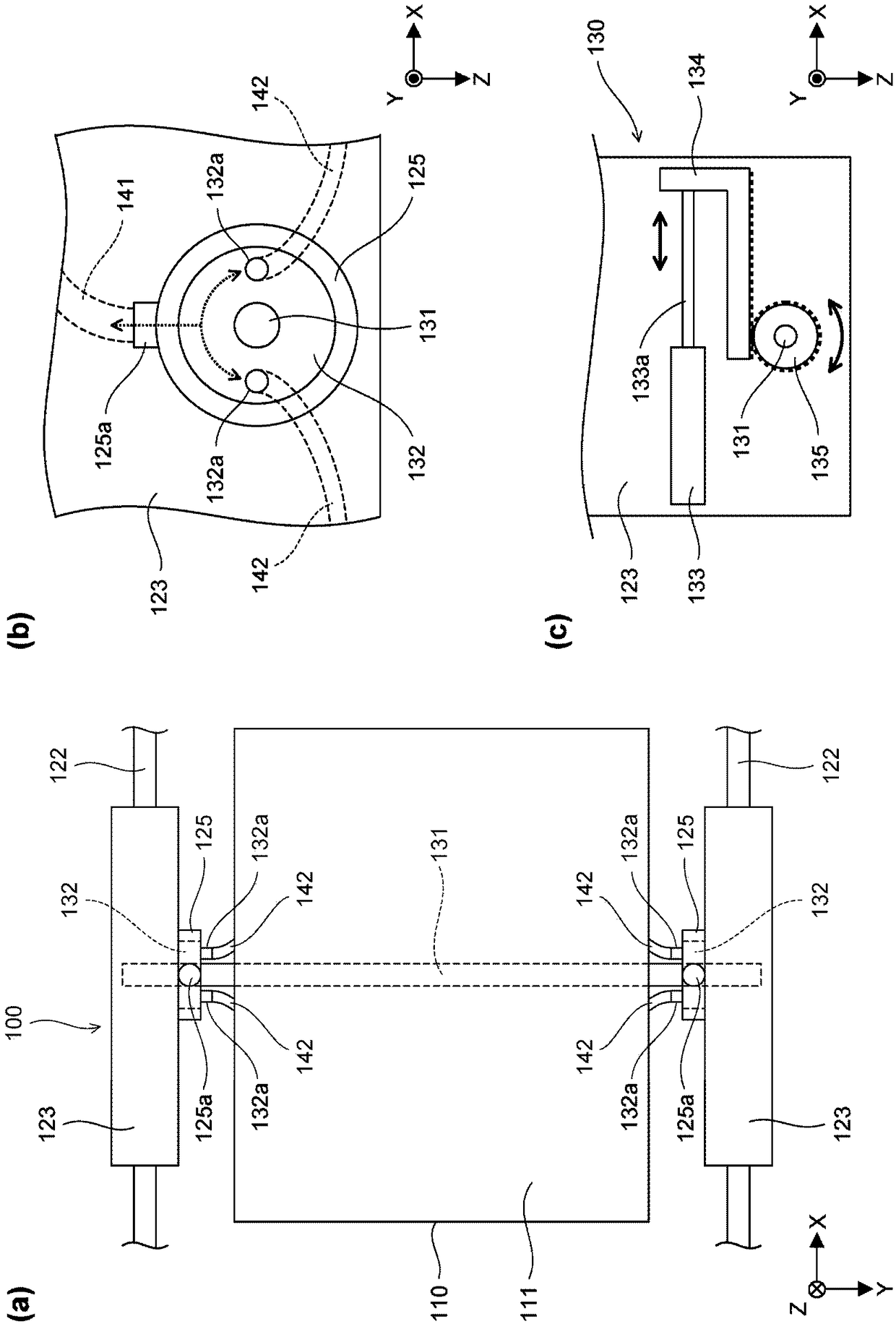

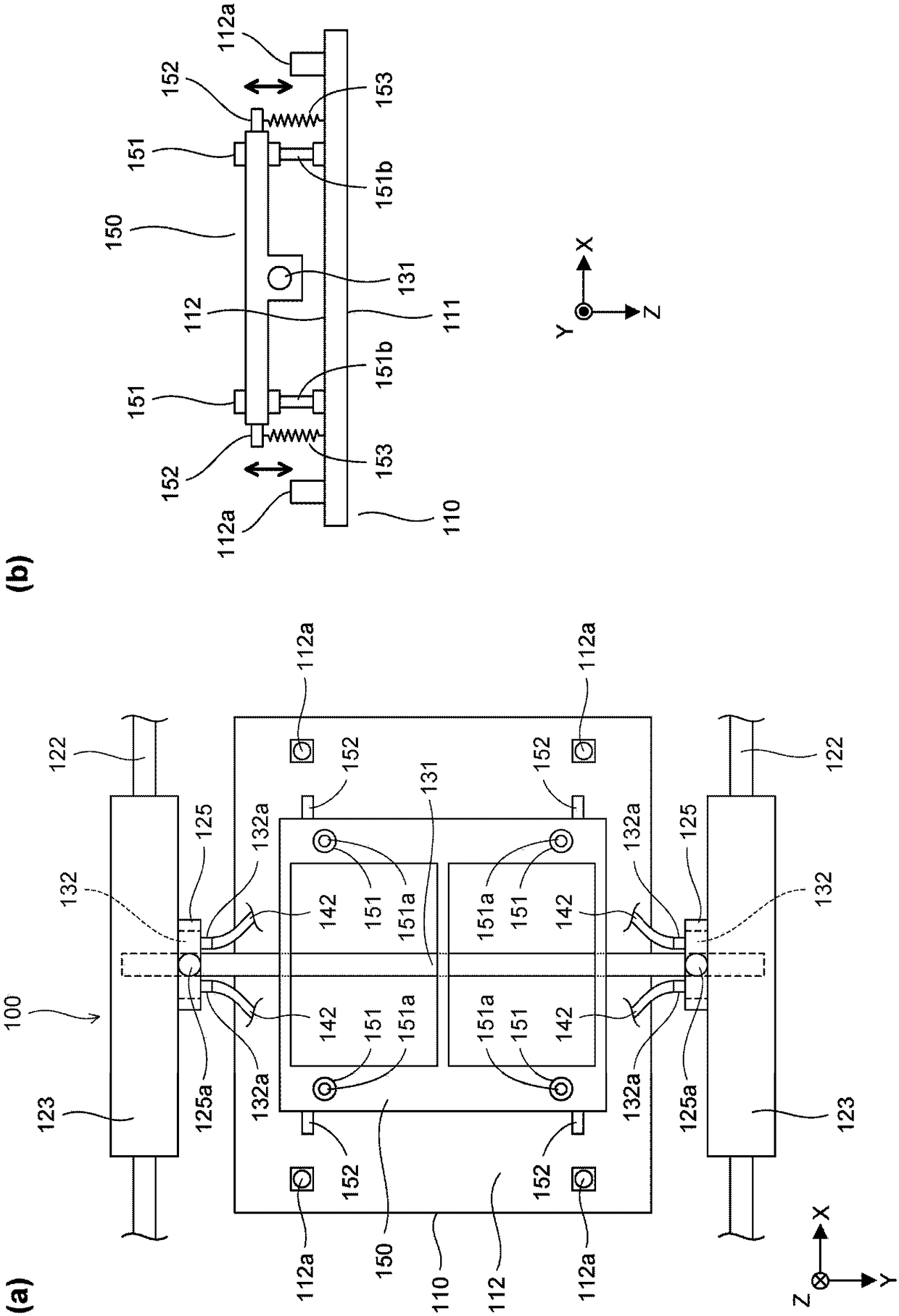

Substrate processing device

InactiveCN108274445ASuppression setting areaContainment costsSemiconductor/solid-state device manufacturingWork benchesEngineeringMechanical engineering

The present invention provides a substrate processing apparatus capable of suppressing the installation area of the apparatus and the cost of the apparatus. A substrate processing apparatus (1) includes a scribing unit (300) for forming a scribe line on a surface of a substrate (10); a feeding table (110) for carrying the substrate 10 and attracting the carried substrate (10); a carrying unit (120) for carrying the feeding table (110) between a first position for carrying the substrate (10) on the feeding table (110) and a second position for delivering the substrate (10) to the scribing unit(300); a rotating part (130) for rotating the feeding table (110) up and down; and a control part. The control part delivers the substrate (10) on which the scribe line is formed by the scribing unit(300) at the second position to the feeding table (110) and attracts the substrate (10) to the feeding table (110), and then drives the rotating part (130) to rotate the feeding table (110) up and down and invert the front and back of the substrate (10).

Owner:MITSUBOSHI DIAMOND IND CO LTD

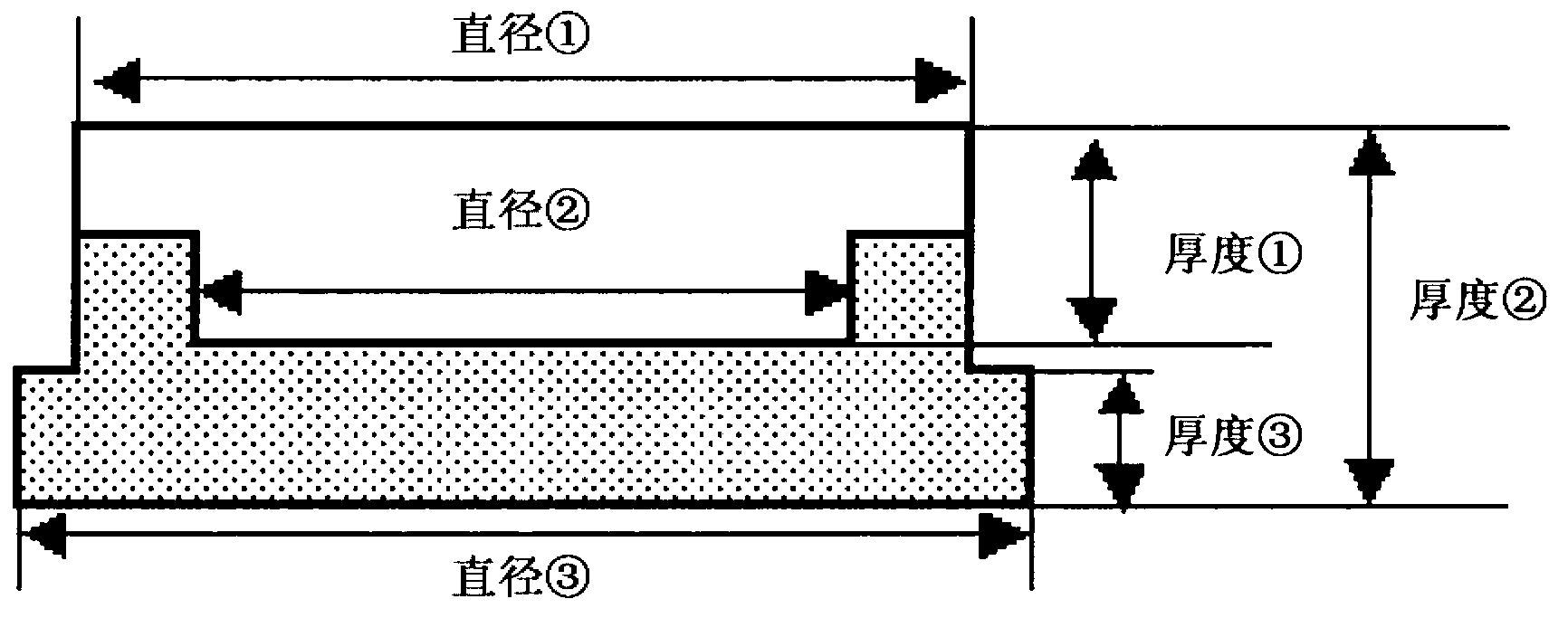

Sputtering target-backing plate assembly

InactiveCN102812152AImprove qualityHigh quality productsVacuum evaporation coatingSputtering coatingSputteringMetallurgy

Owner:JX NIPPON MINING & METALS CORP

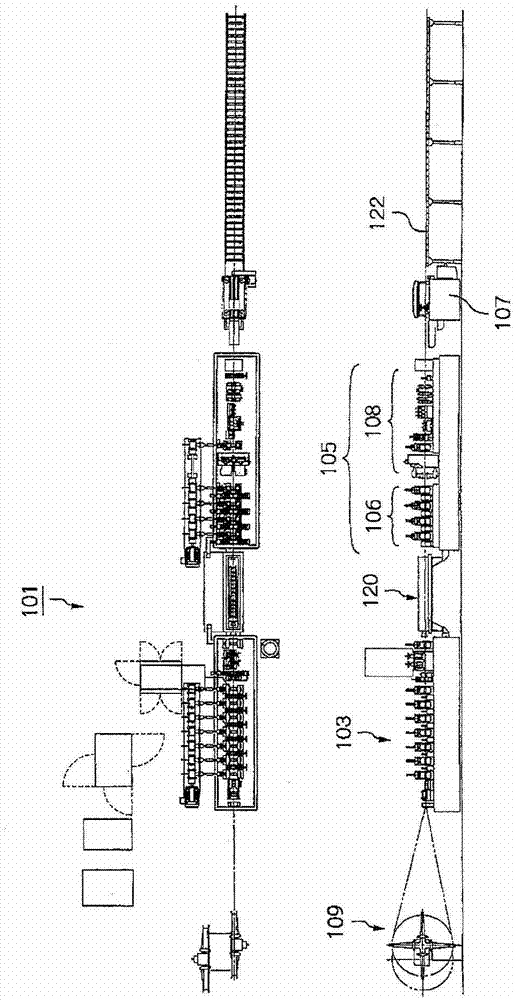

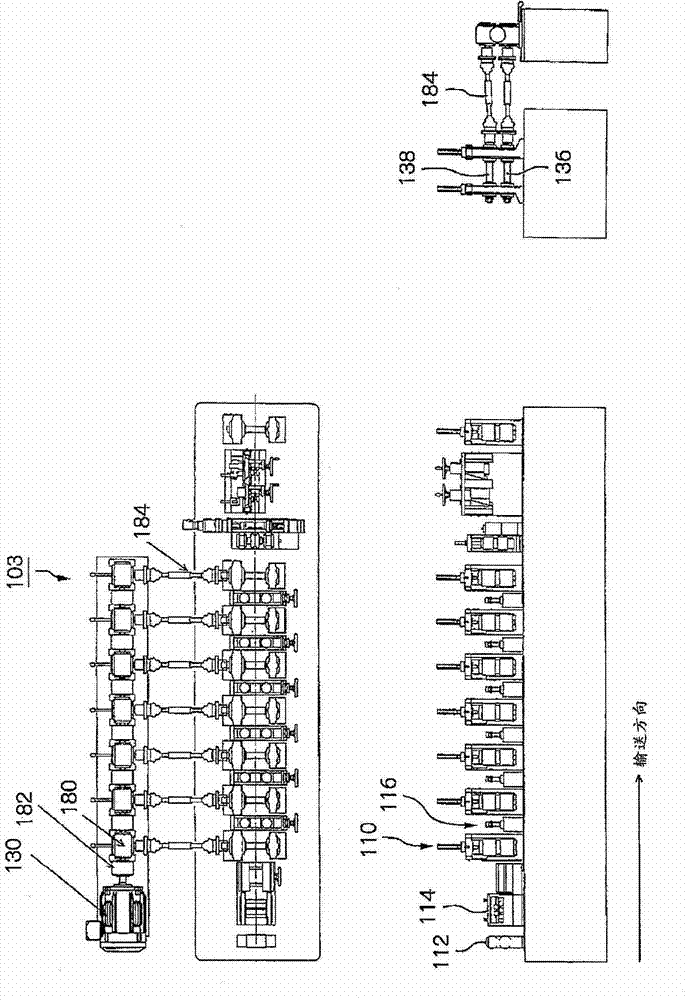

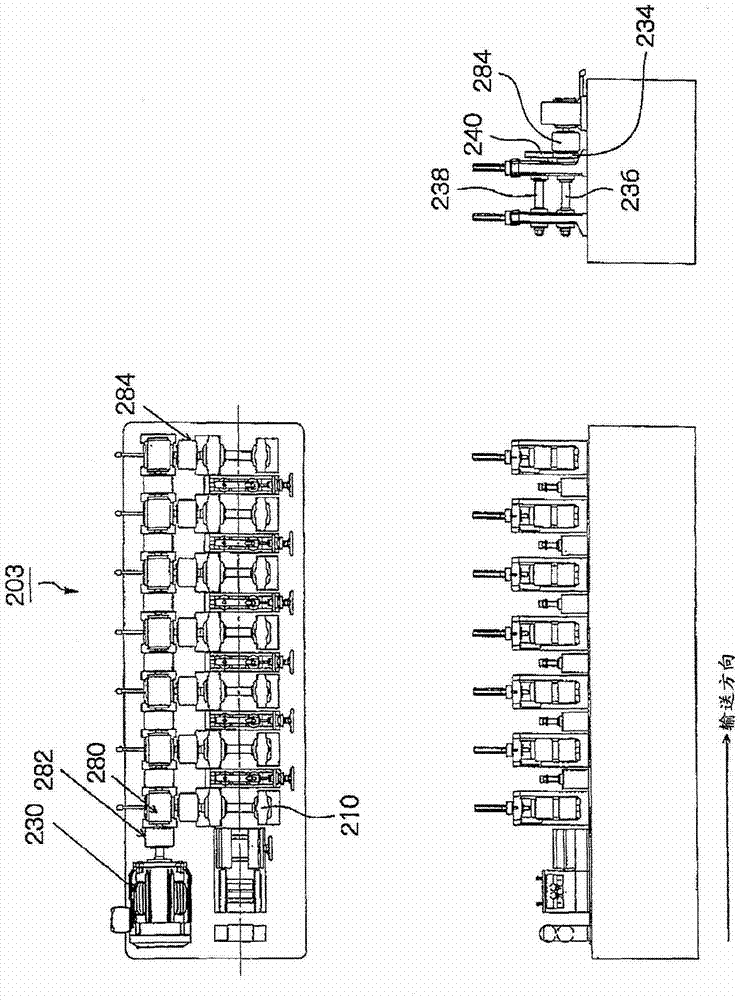

Synchronous belt type cold rolling forming machine and cold rolling pipemaking machine

ActiveCN103372568AContainment costsReduce noiseMetal rolling stand detailsRolling mill drivesDrive motorMultiple stages

Provided is a cold rolling forming machine which can provide low noises and can retain the setting environment in a cleaning state without the need for grease in a power transmission mechanism. The cold rolling pipemaking machine (1) is provided with multiple stages of roller forming supports (10) which are arranged on the conveying direction and perform cold rolling forming on blanks in stages. Each stage of each roller forming support includes a driving belt pulley (34) driven by a driving motor; a lower roller being squarely to the conveying direction of the blanks and performing the cold rolling forming on the blanks; a lower roller shaft directly connected with the driving belt pulley and arranged on the lower roller; an upper roller being opposite to the lower roller over the blanks and performing the cold rolling forming on the blanks together with the lower roller; an upper roller shaft arranged on the upper roller; a driven belt pulley directly connected with the upper roller shaft; a synchronous belt wound on the driving belt pulley and the driven pulley to transmit the rotating force of the driving belt pulley to the driven belt pulley, and an assist belt pulley wound on the synchronous belt and being capable of adjusting the position of the driven belt pulley with respect to the driven belt pulley.

Owner:AIDA ENG LTD

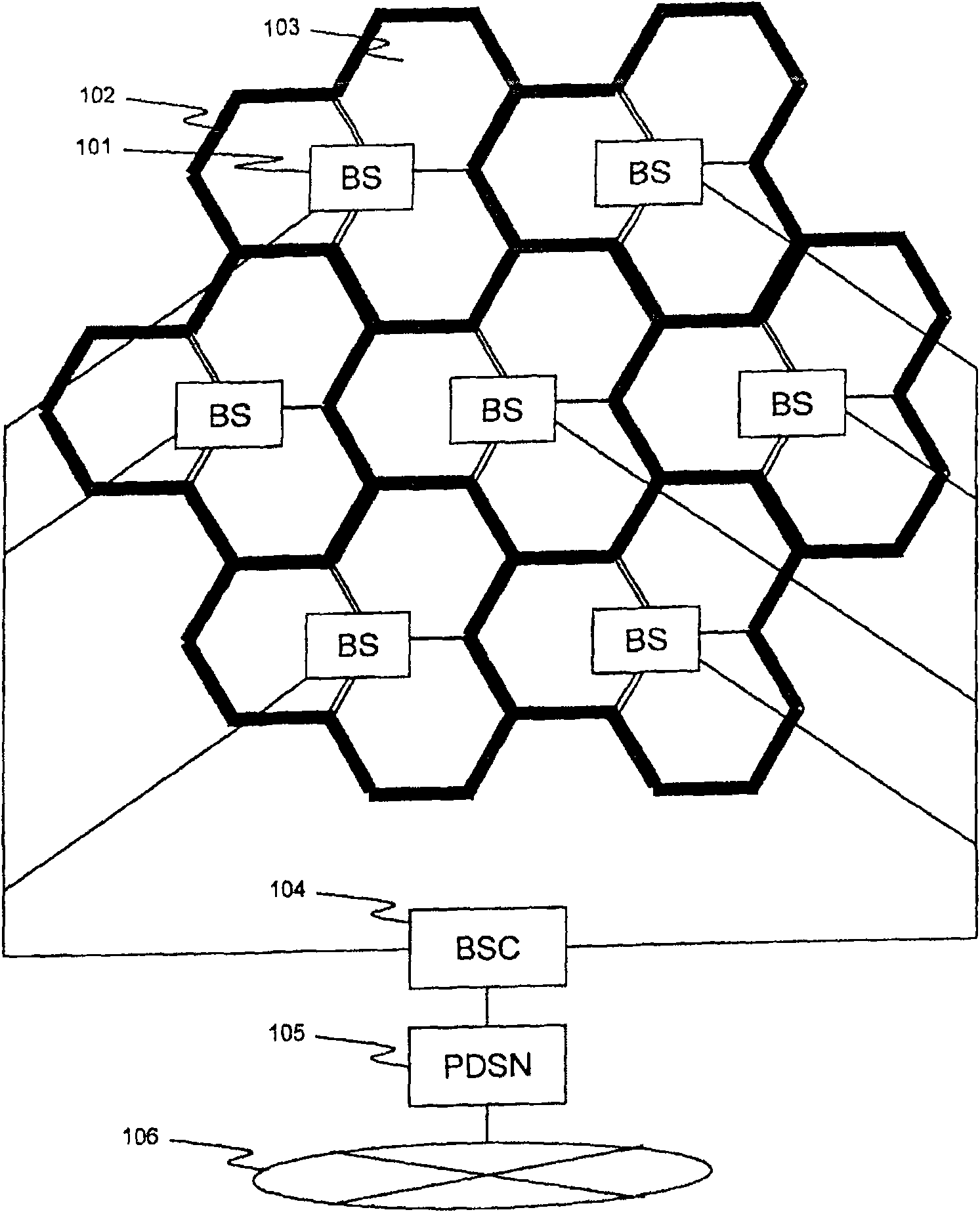

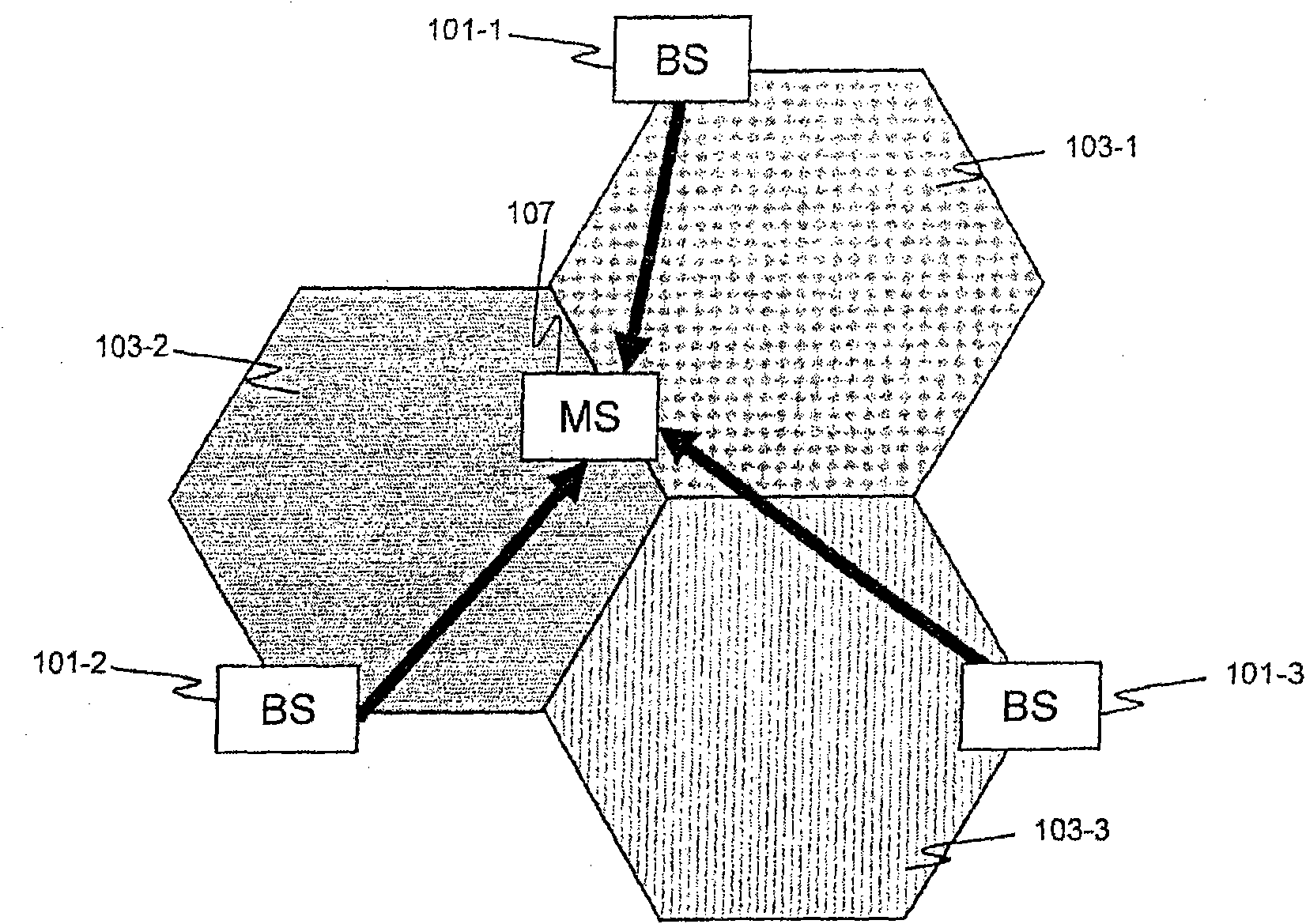

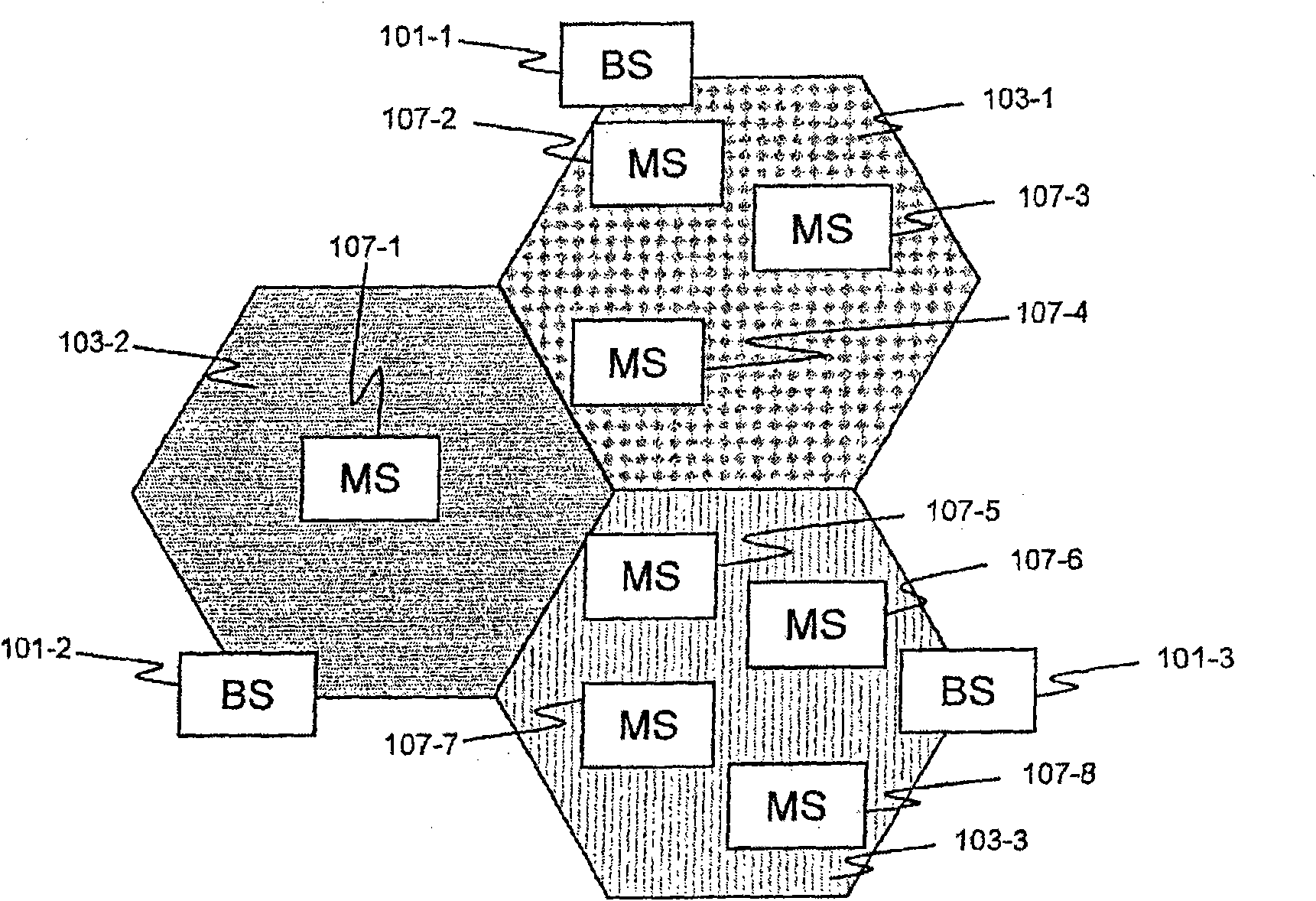

A radio communication system, a repeater apparatus and a control method of the repeater

InactiveCN101646181AImprove cost-effectiveness of settingsImprove throughputNetwork traffic/resource managementRadio transmissionCommunications systemA domain

Provided is a radio communication system including a plurality of base stations and a repeater apparatus, in which the repeater apparatus amplifies and transmits a radio signal received from at leastone of the plurality of base stations, and controls a domain in which the radio signal is transmitted based on a traffic amount of each of the plurality of base stations. Accordingly, the number of installed base stations which are costly is reduced, and an operating rate of the respective base stations is gained along with the decrease in number of installed base stations.

Owner:HITACHI LTD

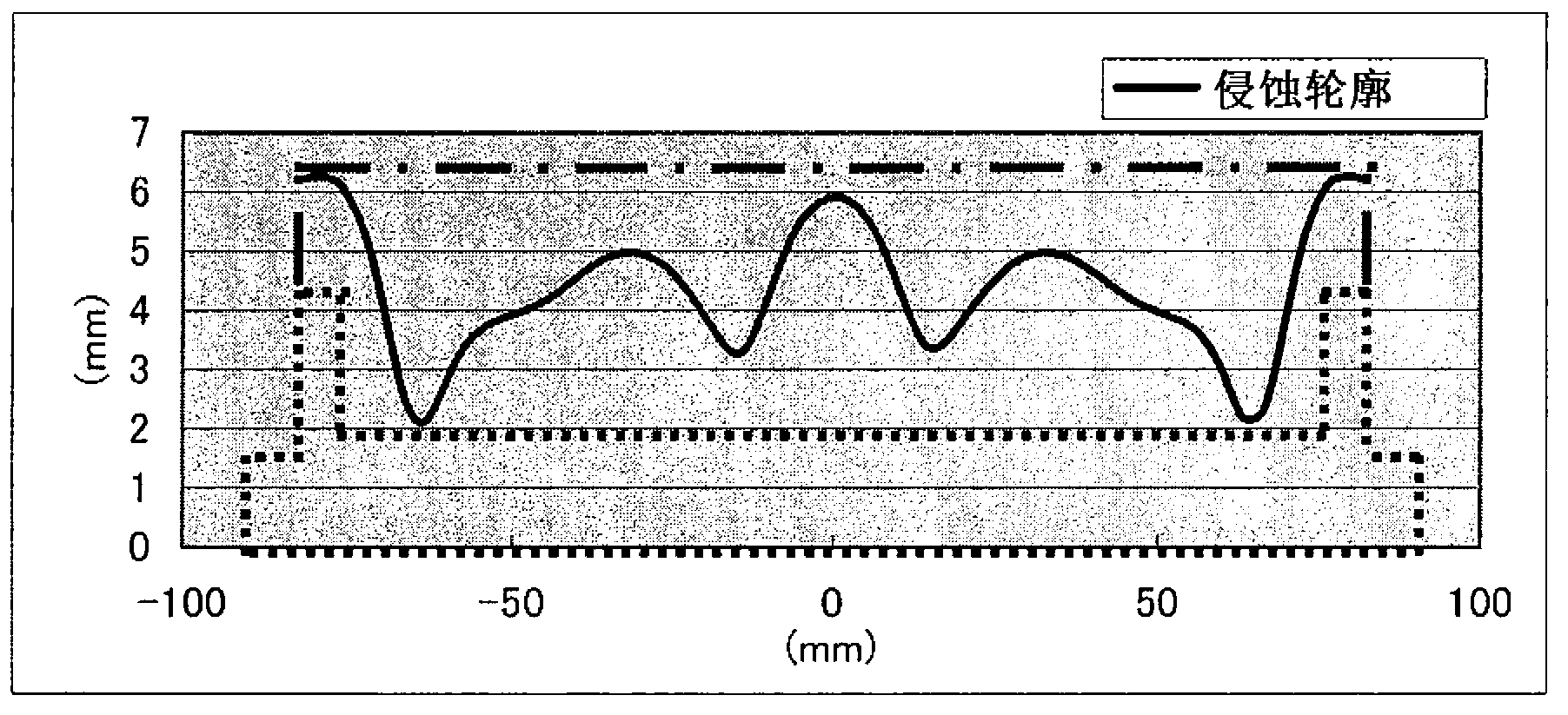

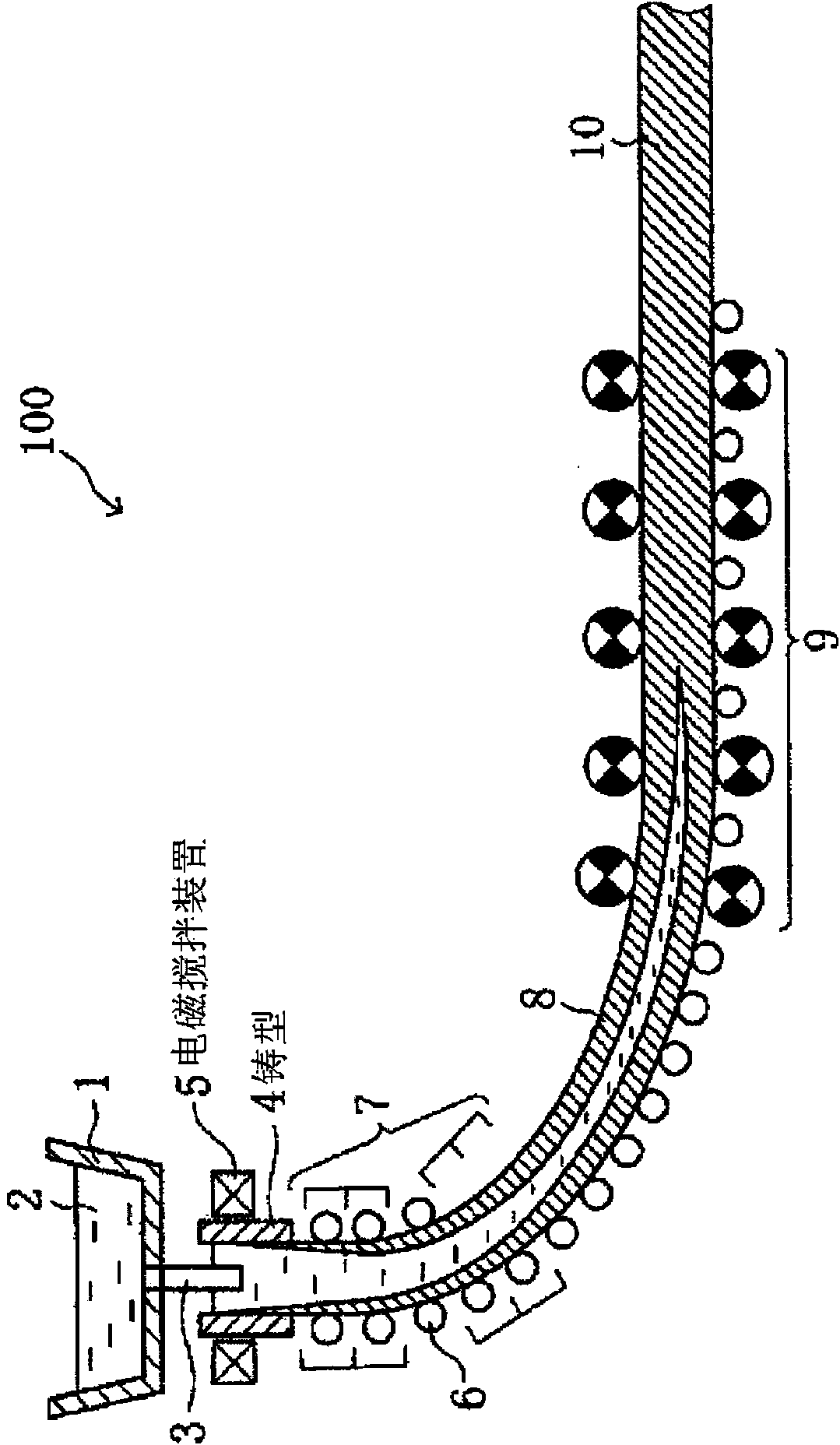

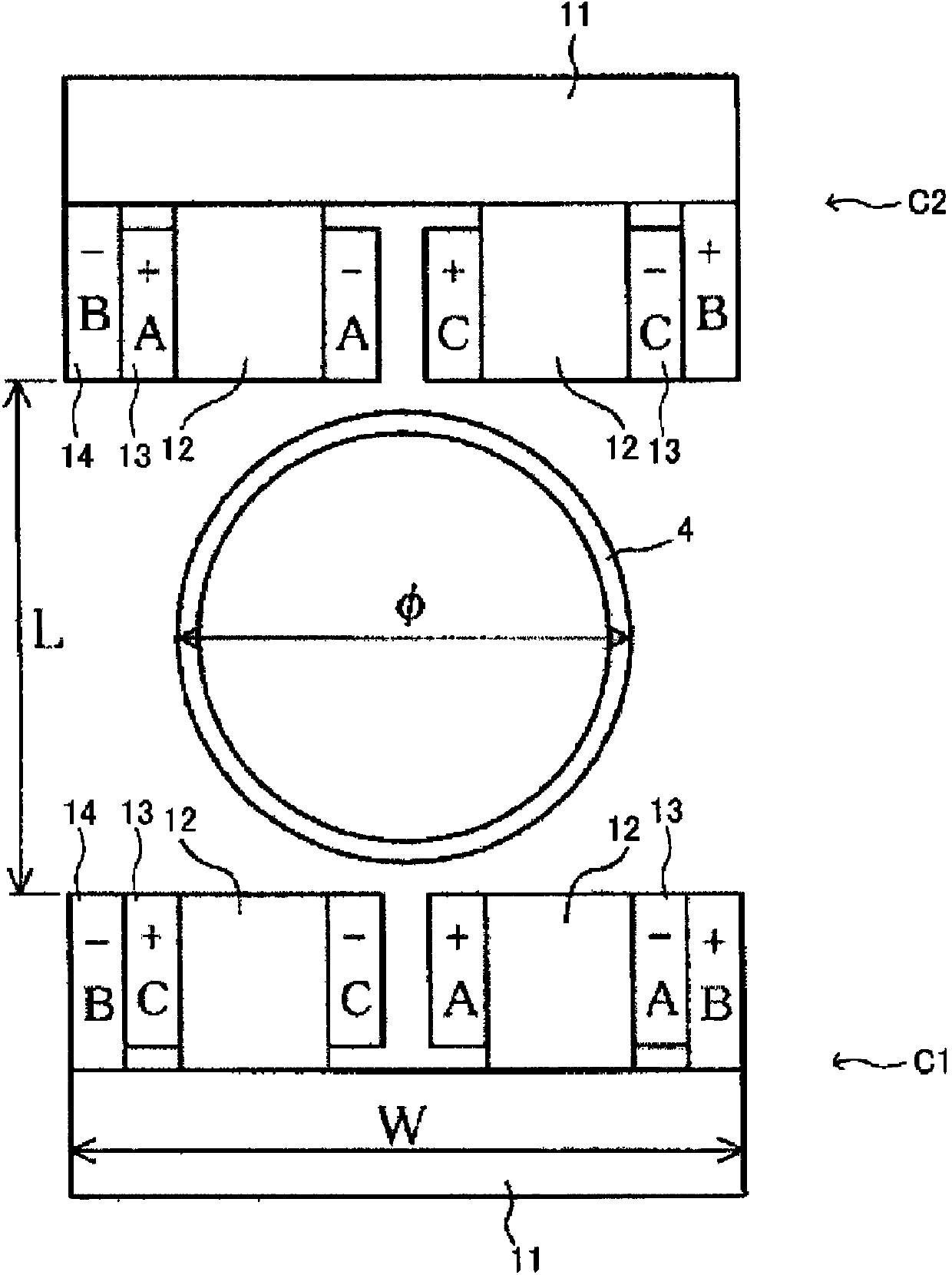

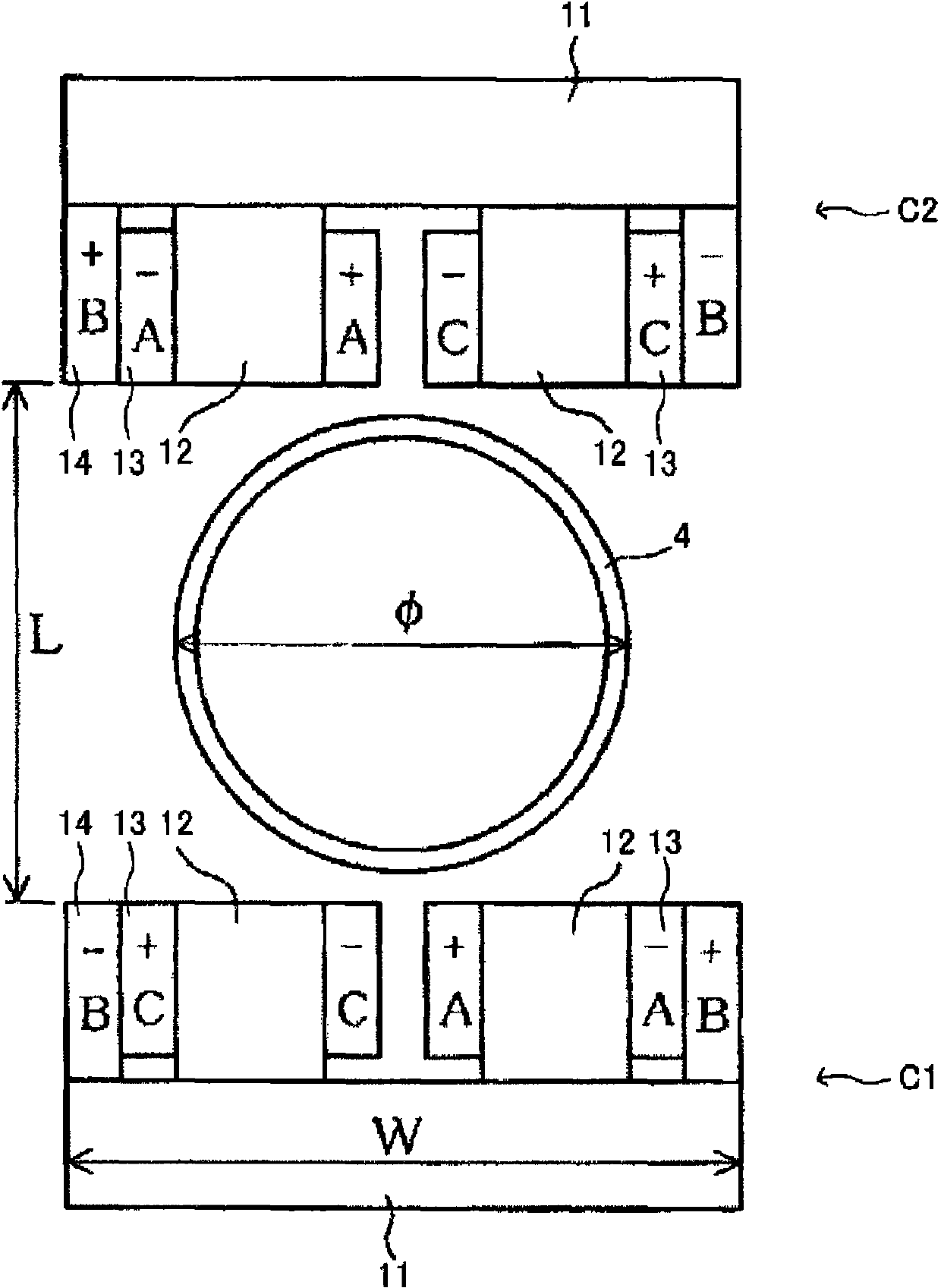

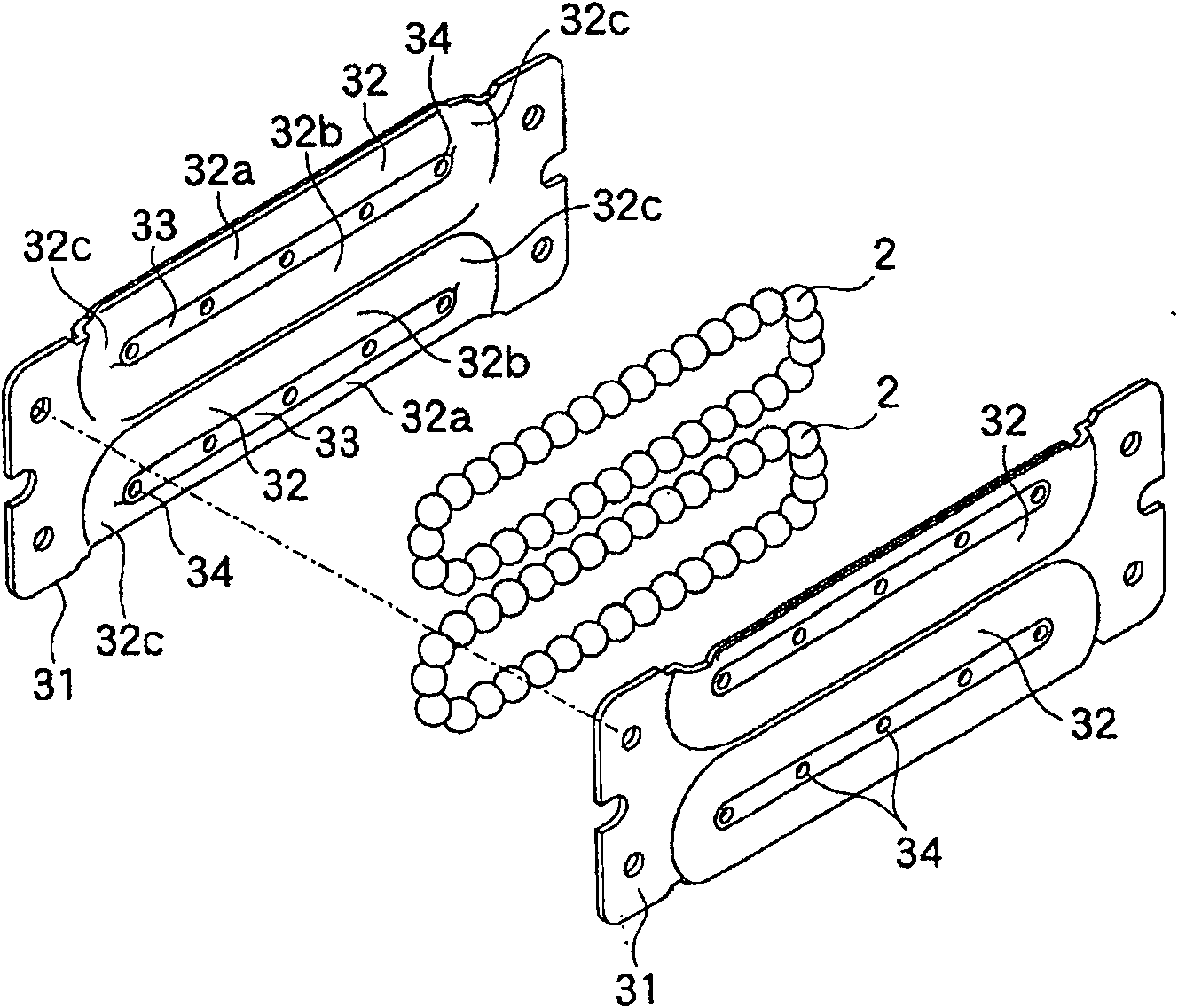

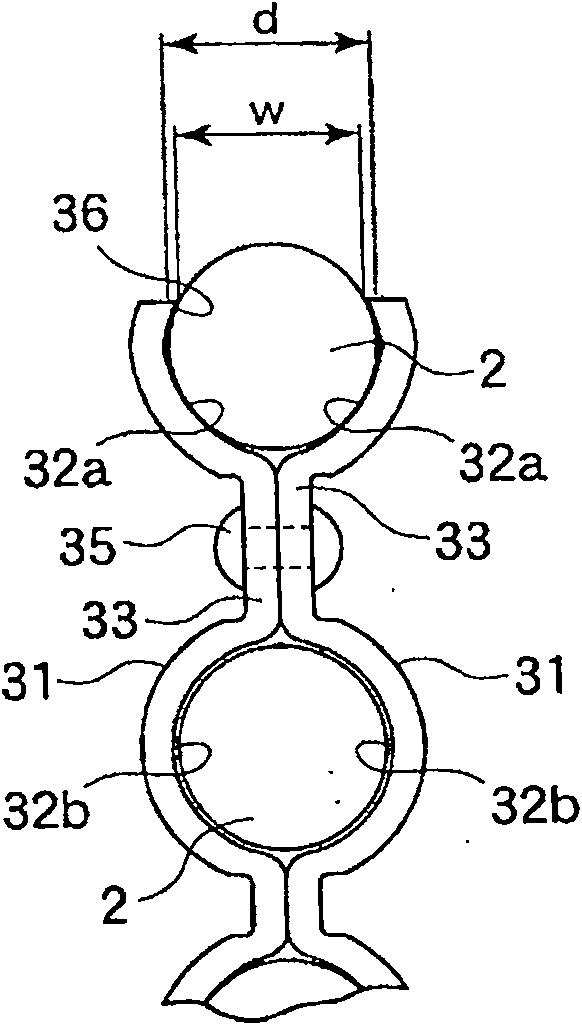

Electromagnetic stirring apparatus, and continuous casting method

The main purpose of the present invention is to provide an electromagnetic stirring apparatus such that uniform electromagnetic force can be supplied to each mold. In an electromagnetic stirring apparatus (5) according to the present invention, two teeth portions (12) are disposed on cores (11) of a pair of electromagnetic coils (C1, C2) disposed across a mold (4), with inner windings (13) disposed on the outside of the teeth portions (12) and outer windings (14) disposed on the outside of the inner windings (13). The windings are supplied with currents A, B, and C with phase differences of 120º from a three-phase alternating current power supply. The directions of the currents in order from one end of the direction of casting to the other are -B, +C, -C, +A, -A, +B for the coil (C1) and -B, +A, -A, +C, -C, +B for the coil (C2) when the distance (L) between the coils (C1, C2) is not less than 500 mm, or -B, +C, -C, +A, -A, +B for the coil (C1) and +B, -A, +A, -C, +C, -B for the coil (C2) when the distance (L) is less than 500 mm. The mold disposed between the coils (C1, C2) satisfies n × phi < W, where n is the number of molds, phi is the outer size of each mold, and W is the width of the electromagnetic coil.

Owner:NIPPON STEEL CORP

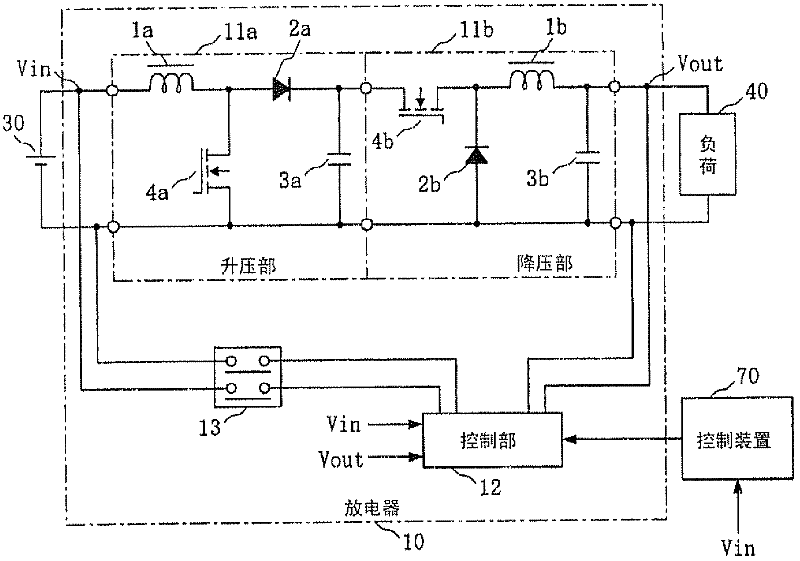

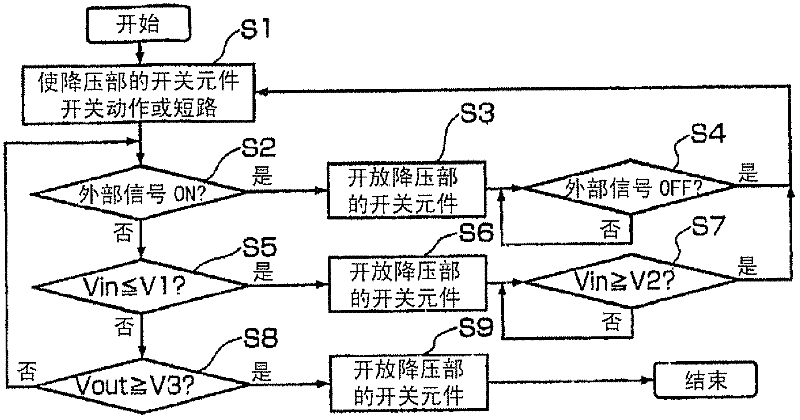

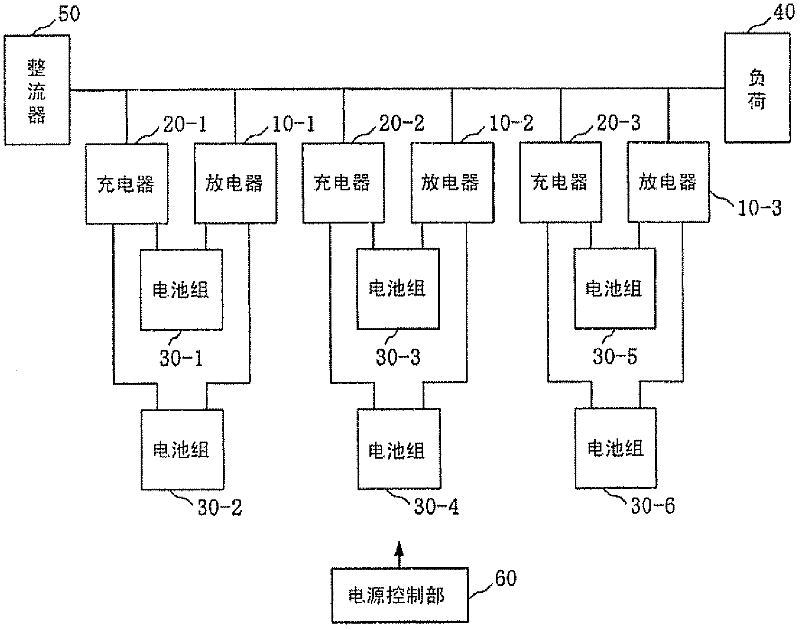

Discharger and discharger control method

InactiveCN102386653ASuppression spaceContainment costsDc-dc conversionSecondary cells charging/dischargingOvervoltageEngineering

Upon detecting an external signal which instructs to stop discharge, an input voltage equal to or less than a set value for the prevention of overdischarge, or an output voltage equal to or more than a set value for the prevention of output of an overvoltage, a control unit (12) stops discharge to a load (40) by opening a switching element (4b) of a step-down unit (11b). Upon detecting that an external signal is reset or an input voltage equal to or more than a set value larger than the set value for the prevention of overdischarge, the control unit (12) resumes discharge to the load (40) by setting the switching element (4b) in a switching operation state or short-circuiting it.

Owner:NIPPON TELEGRAPH & TELEPHONE CORP

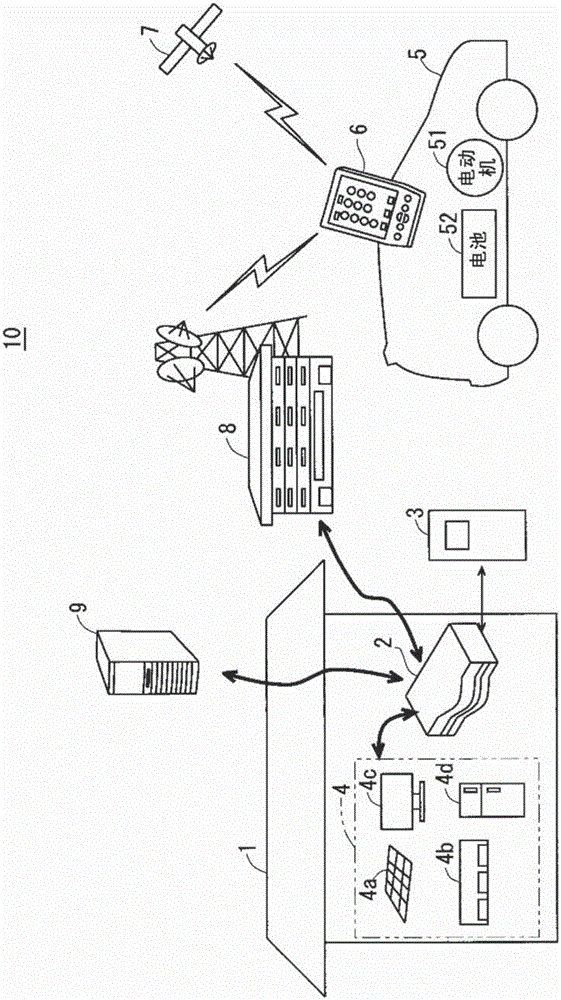

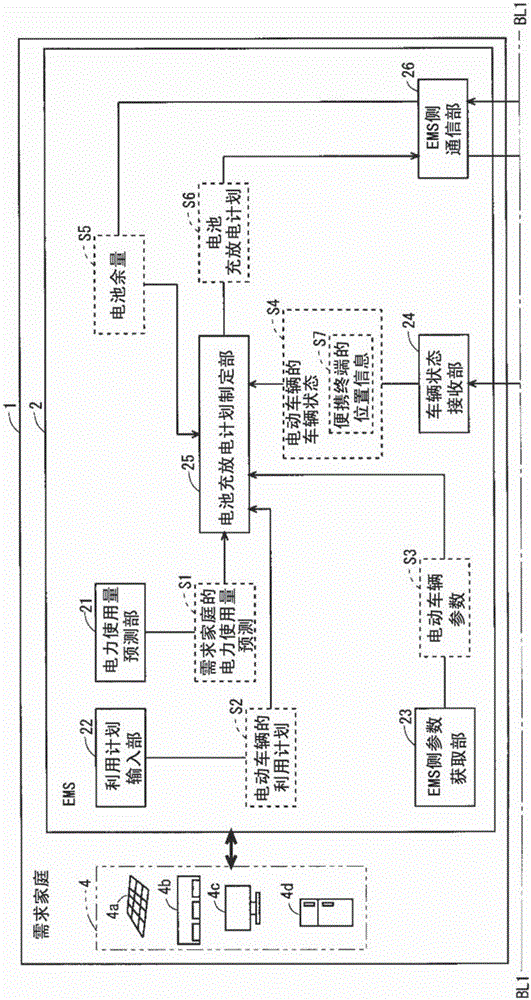

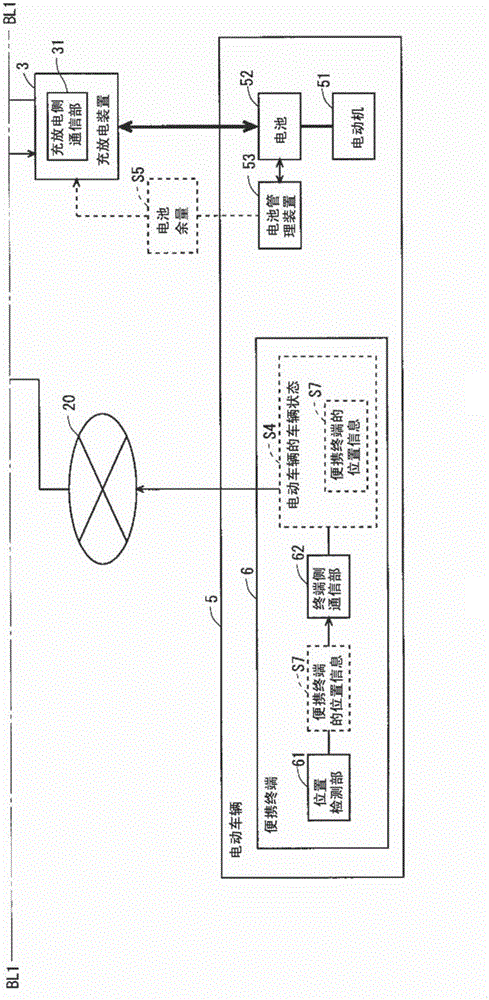

Electric vehicle management system

InactiveCN105122585AContainment costsRealize managementBatteries circuit arrangementsVehicular energy storageBattery chargeCharge discharge

In this electric vehicle management system, a user's mobile terminal (6) in an electric vehicle (5) transmits vehicle state information (S4) about the electric vehicle (5), including position information (S7) of the mobile terminal (6) detected by a position detection unit (61) of the mobile terminal (6), to a vehicle state receiving unit (24) of an energy management system (EMS) (2) installed in a customer's house (1). A battery charge-discharge planning unit (25) of the EMS (2) uses the vehicle state information (S4) about the electric vehicle (5) to determine a charge-discharge plan (S6) for the battery (52). A charge-discharge device (3) then charges and / or discharges the battery (52) of the electric vehicle (5) according to the determined charge-discharge plan (S6).

Owner:MITSUBISHI ELECTRIC CORP

Robot having workpiece mass measurement function

ActiveCN102990642BLong cycleSimple structureProgramme controlProgramme-controlled manipulatorEngineeringMass measurement

A robot (1) having a workpiece mass measurement function for measuring the mass of a workpiece that is held, includes a force measurement unit (5) that measures the force that is applied to the tip part (2) of the mechanism part of the robot (1), and a mass estimation unit (11) that estimates the mass of the workpiece that is held by the robot (1), based on information about the force acquired by the force measurement unit (5) while the robot (1) is moving.

Owner:FANUC LTD

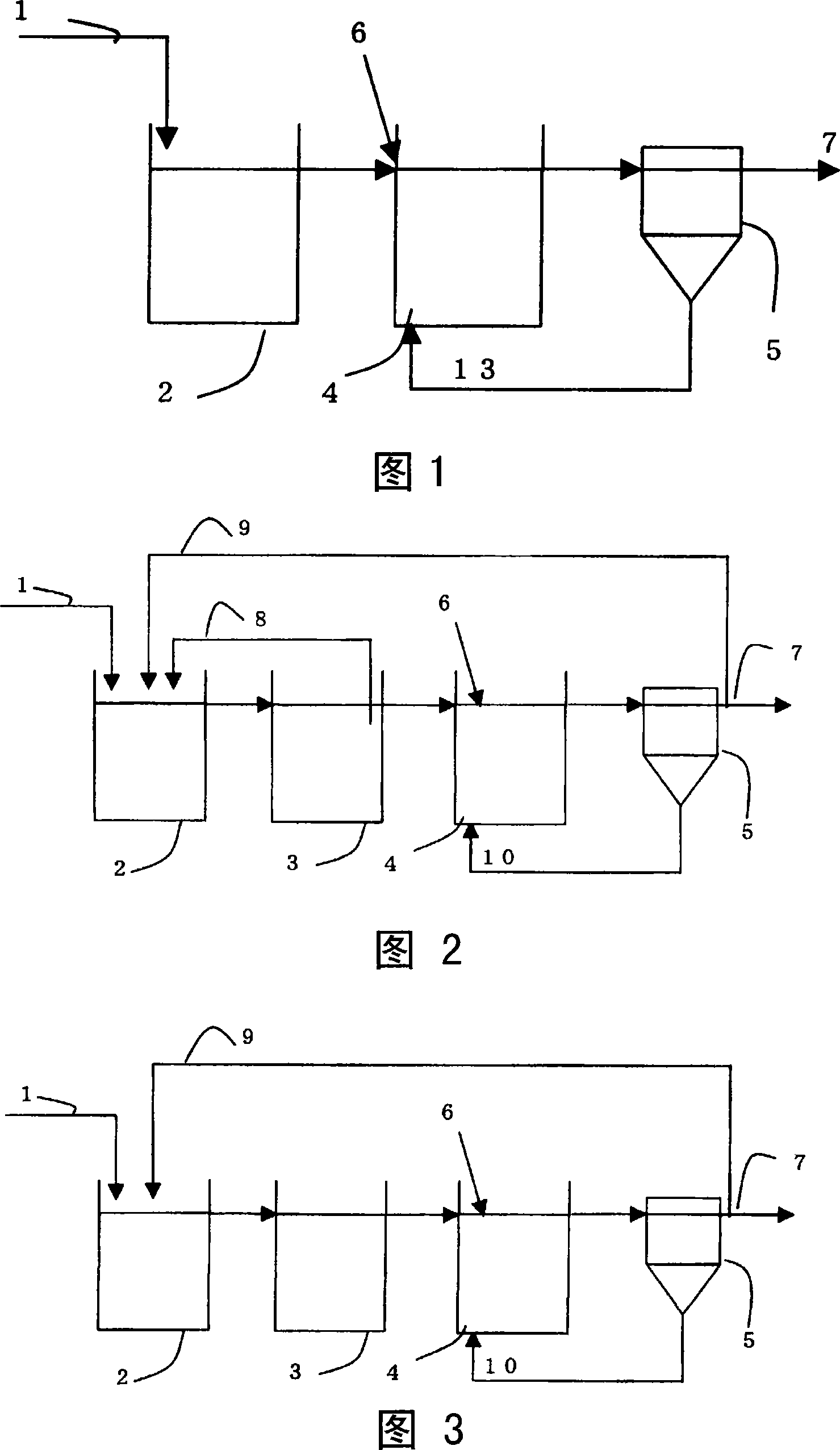

Method of wastewater treatment with excess sludge withdrawal reduced

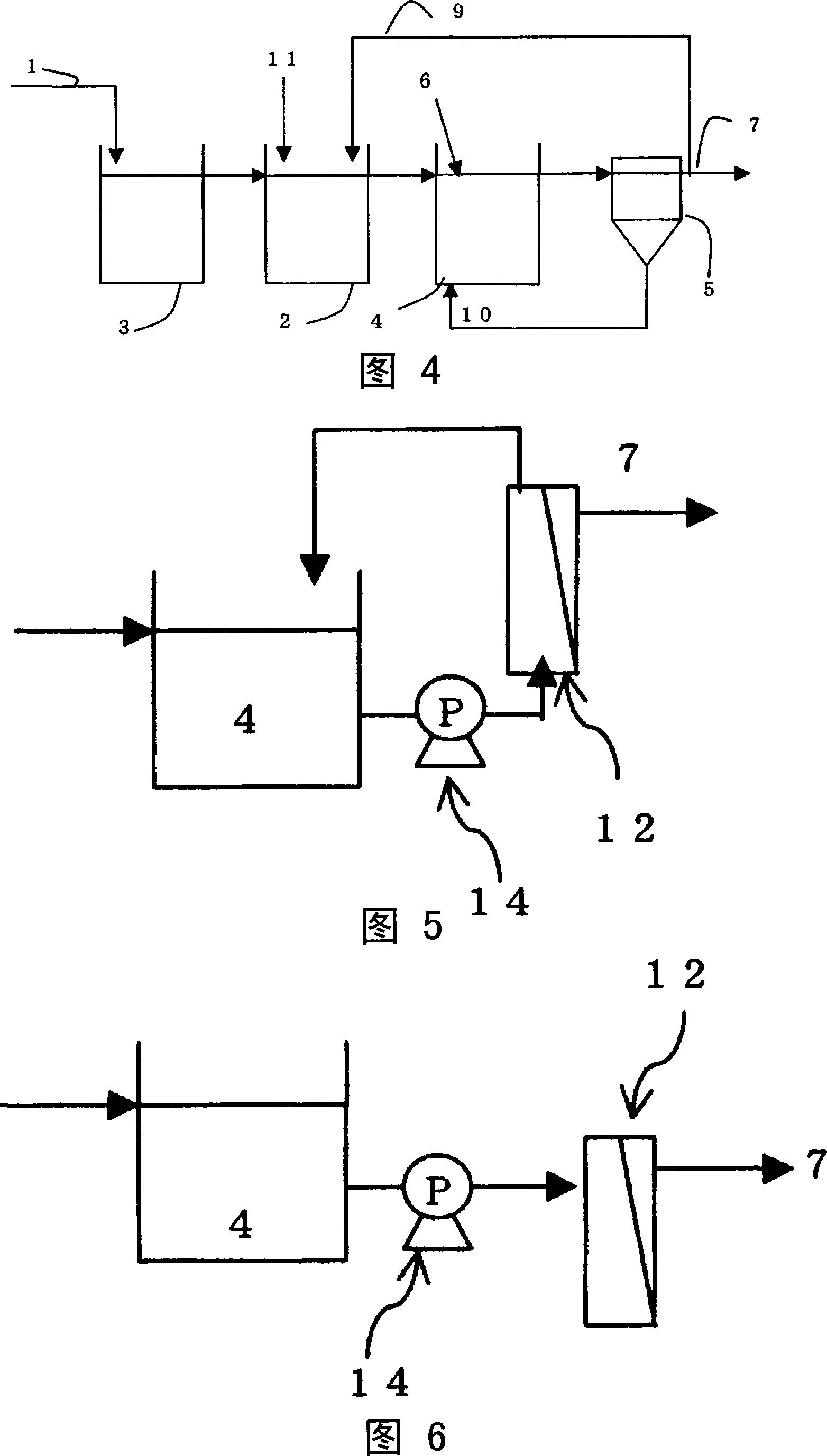

ActiveCN1984847AReduce the amount of extractionGood effectTreatment using aerobic processesWater contaminantsOperational costsSludge

A method of wastewater treatment that reduces equipment cost and running cost and realizes high-efficiency implementation and further tank miniaturization, and that reduces excess sludge withdrawal. There is provided a method of wastewater treatment with excess sludge withdrawal reduced, characterized in that there are installed an aeration tank wherein wastewater is brought into contact with carrier particles under aerobic conditions, a complete oxidation tank and a sedimentation tank, and that operation is made while maintaining the BOD sludge load in the complete oxidation tank at = 0.08 kg-BOD / kg-MLSS day, and that a coagulant is charged in the complete oxidation tank in order to improve the settling in the sedimentation tank.

Owner:KURARAY CO LTD

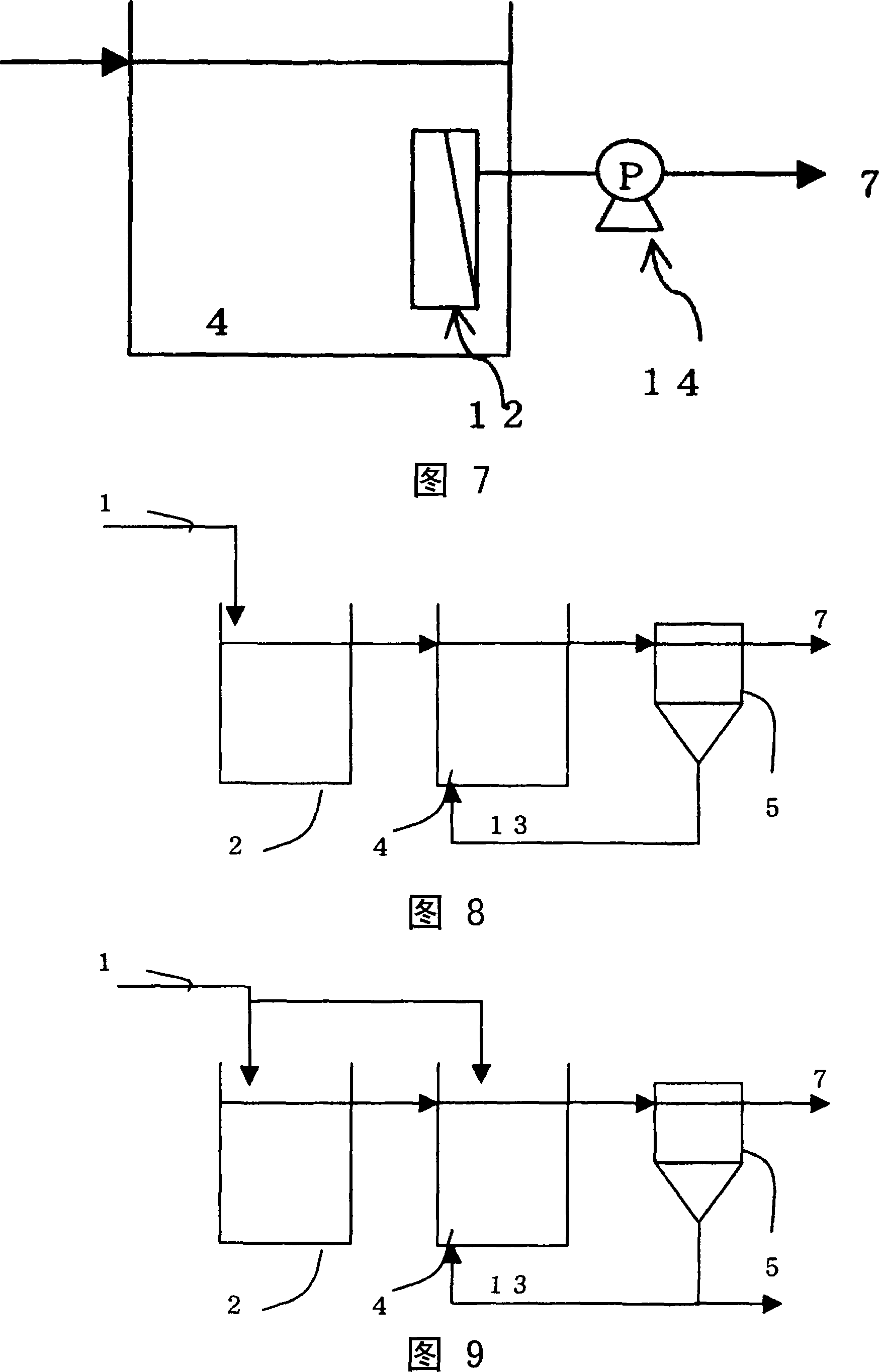

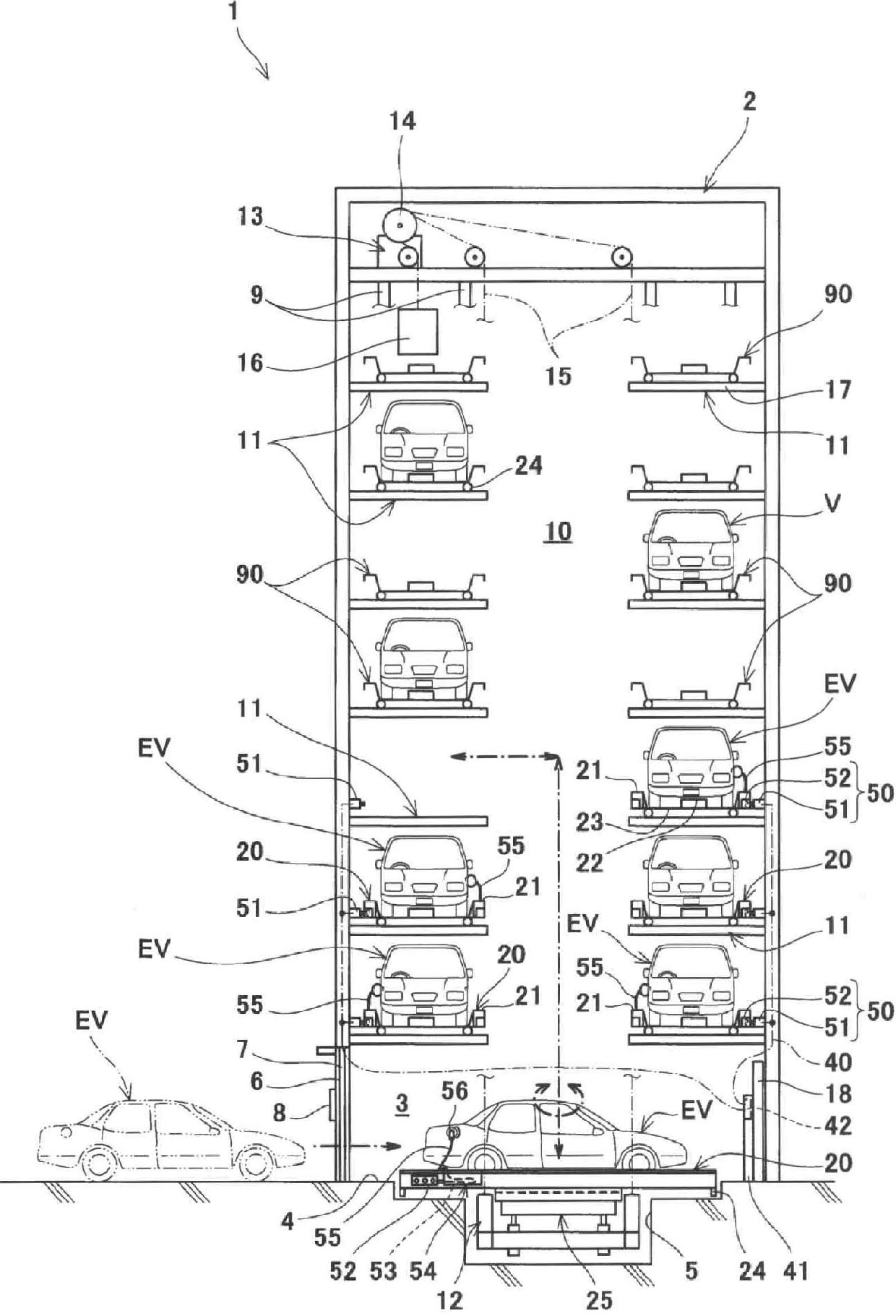

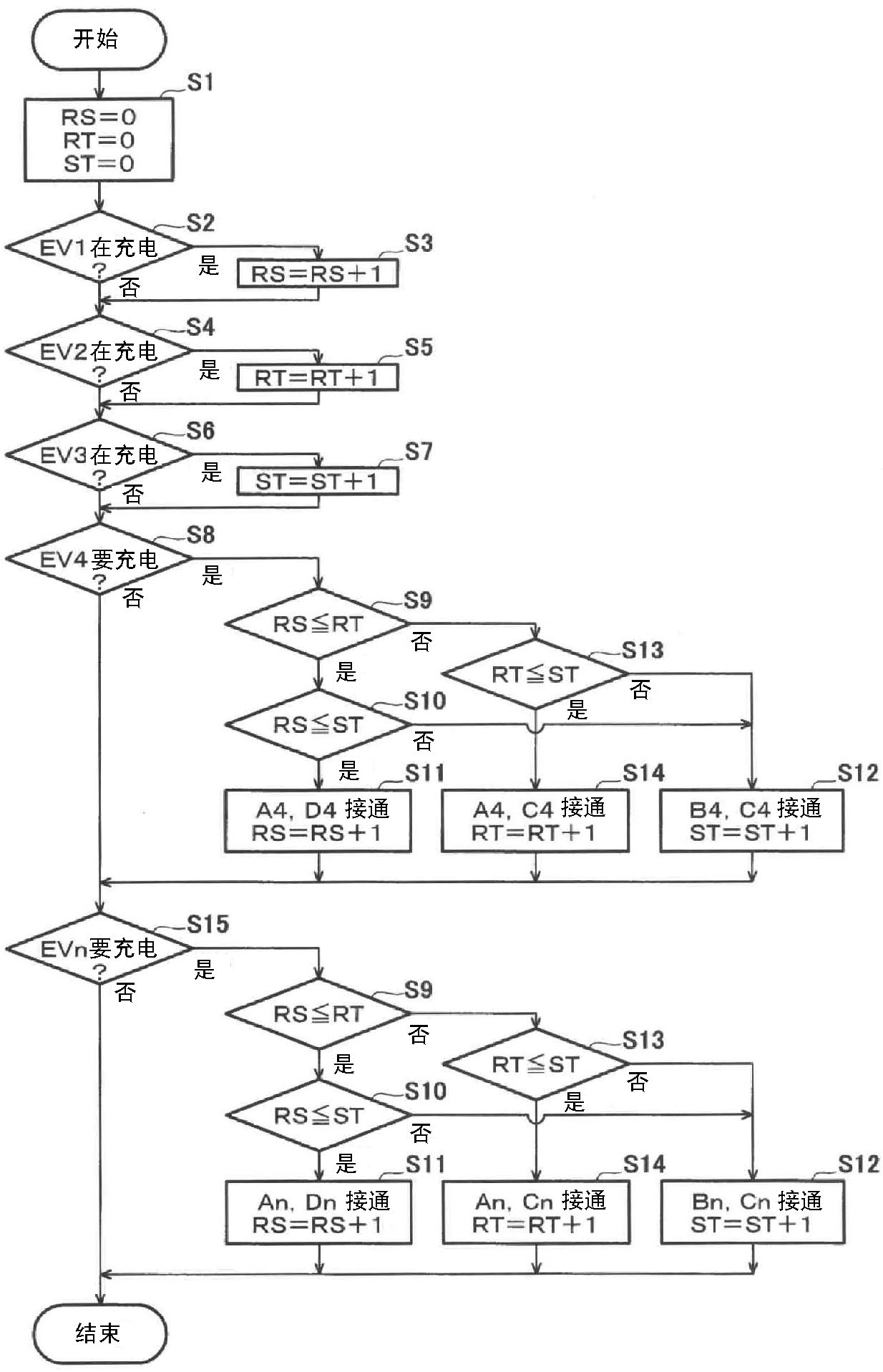

Charging control method of mechanical parking equipment and control device thereof

InactiveCN102035227AAdd charging functionDisequilibrium SuppressionBatteries circuit arrangementsPolyphase network asymmetry elimination/reductionContactorSingle phase

The present invention provides a charging control method of mechanical parking equipment and a control device thereof, wherein a three-phase power supply of the mechanical parking equipment is used for taking out a plurality of single-phase power supplies for charging with excellent balance. For taking out a plurality of single-phase power supplies for charging electric vehicles from the three-phase power supply for the power of the mechanical parking equipment, the contacts of each two-phase electromagnetic contactor, which are combined for taking single-phase power from the three-phase power supply, are controlled for selectively switching the contacts of each electromagnetic contactor thereby selecting two phases of the three-phase power, monitoring the charging states of a plurality of electric vehicles and preventing current balance deterioration.

Owner:SHIN MEIWA IND CO LTD

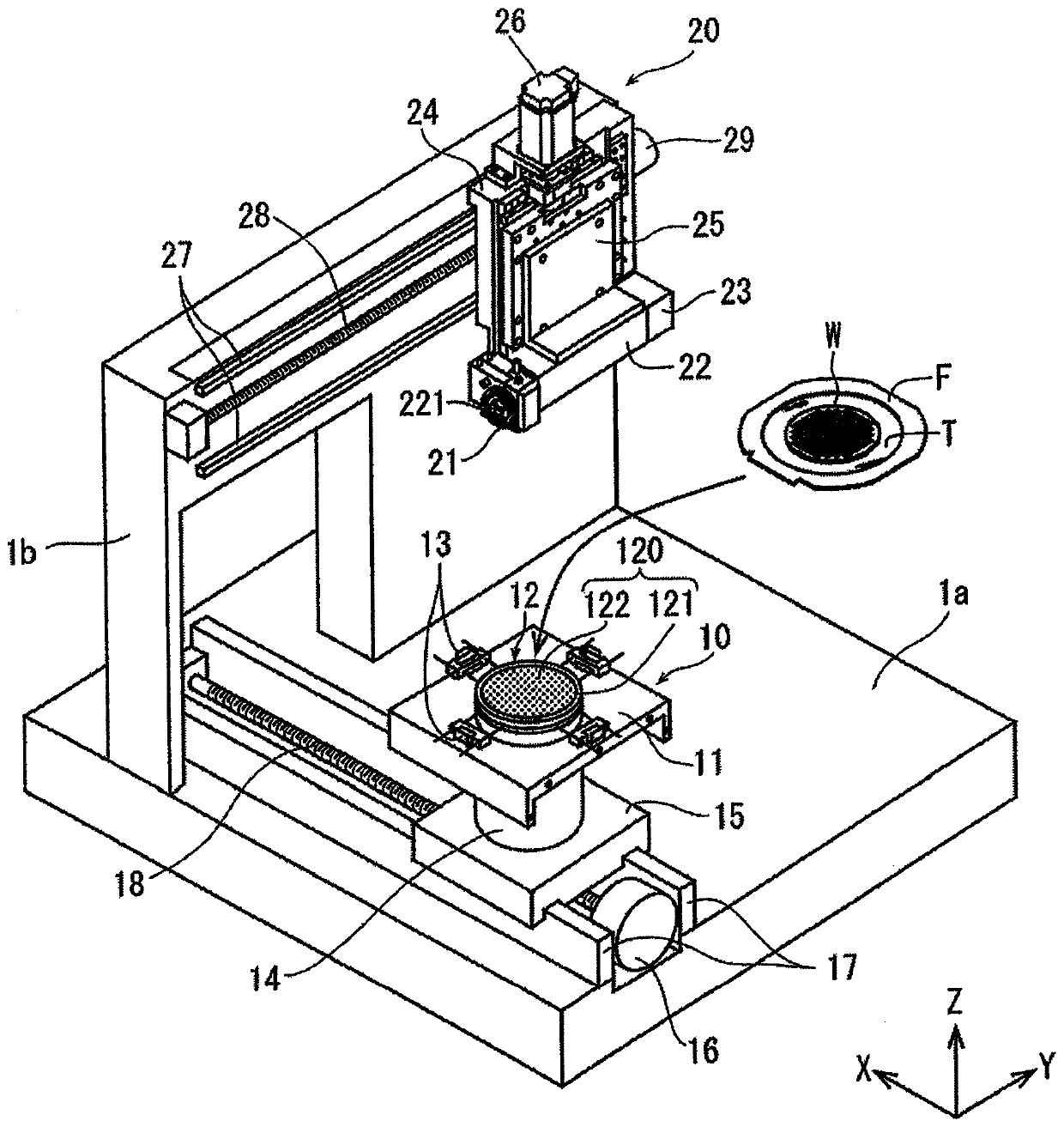

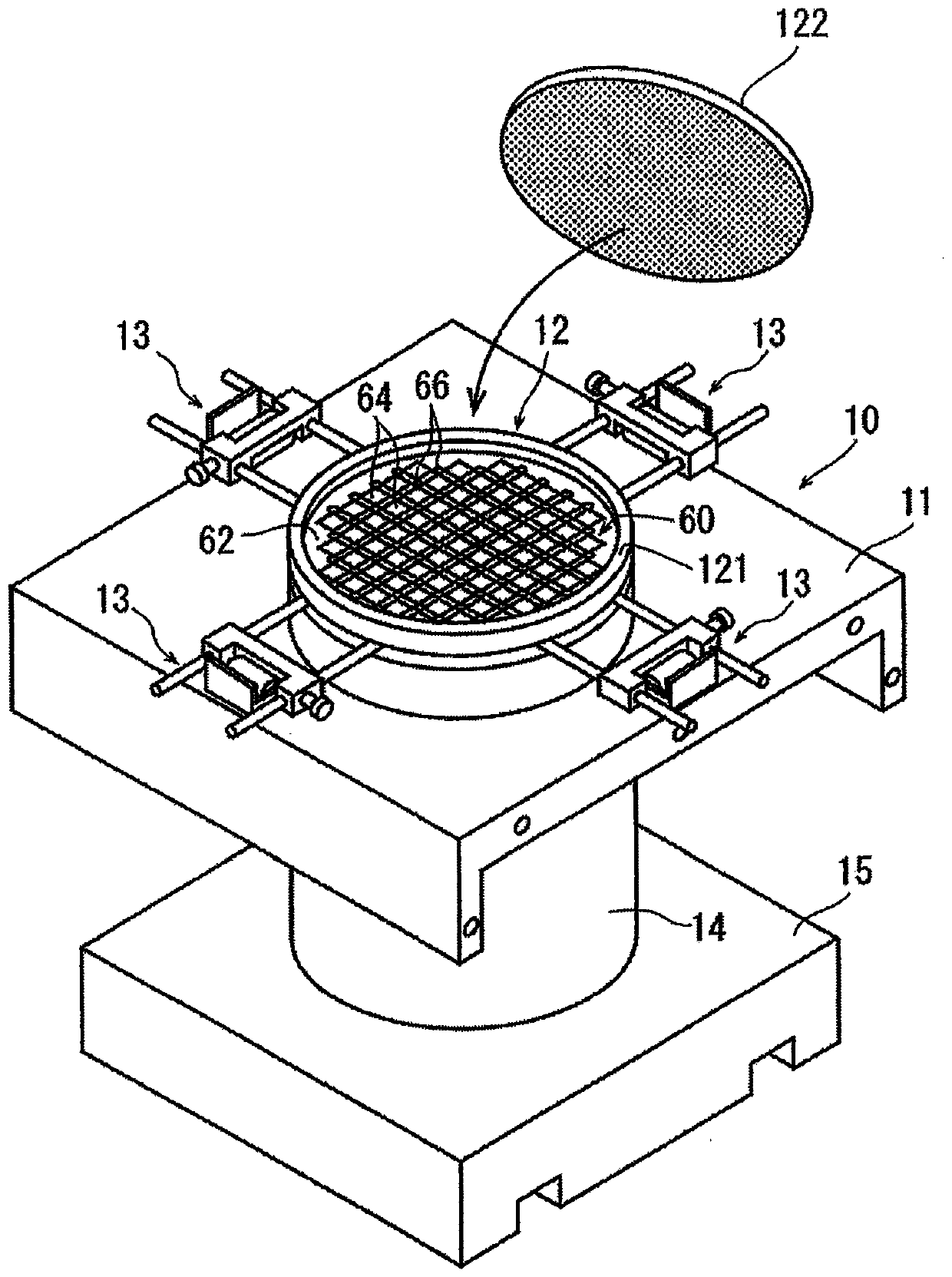

Cutting device

PendingCN111261504ARealize space savingContainment costsSolid-state devicesSemiconductor/solid-state device manufacturingWaferingUltraviolet lights

Provided is a cutting device capable of saving space and suppressing equipment costs when processing requiring a cutting device and an ultraviolet irradiation device is performed. The cutting device divides a wafer supported on an annular frame through an adhesive tape into individual device chips. The cutting device includes: a chuck table including a wafer support table that supports the wafer and a frame support portion (13) that is disposed on an outer periphery of the wafer support table and supports the annular frame; and a cutting unit that performs cutting processing on the wafer supported by the wafer supporting table. The wafer support table includes an ultraviolet irradiation unit that irradiates ultraviolet light to reduce an adhesive force of the adhesive tape in a region corresponding to the wafer.

Owner:DISCO CORP

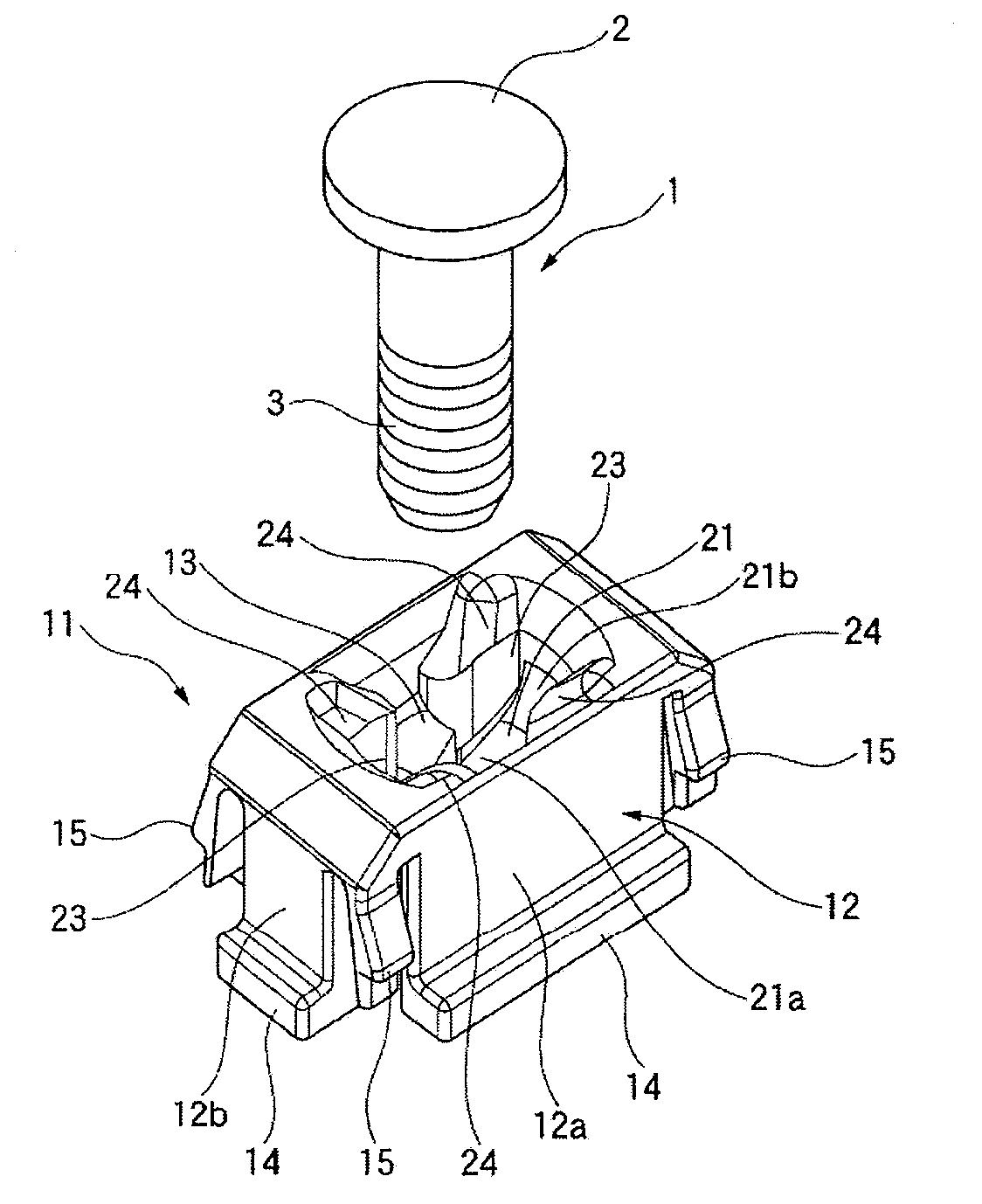

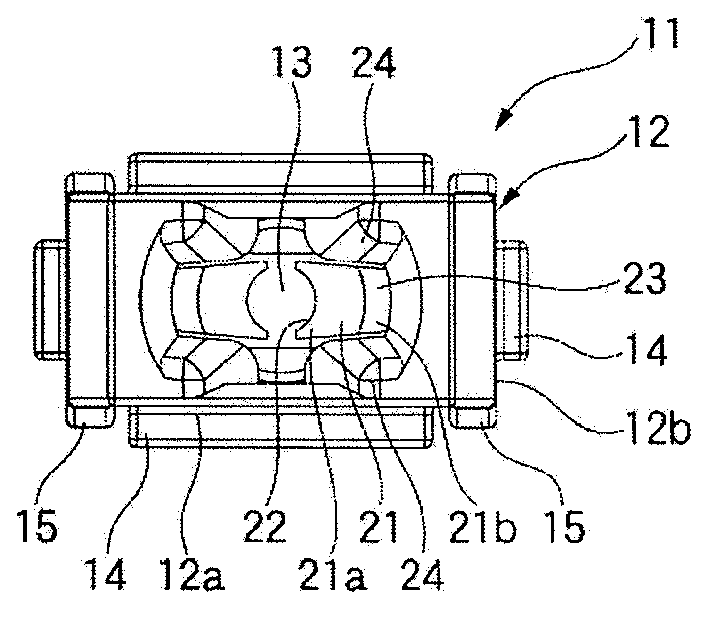

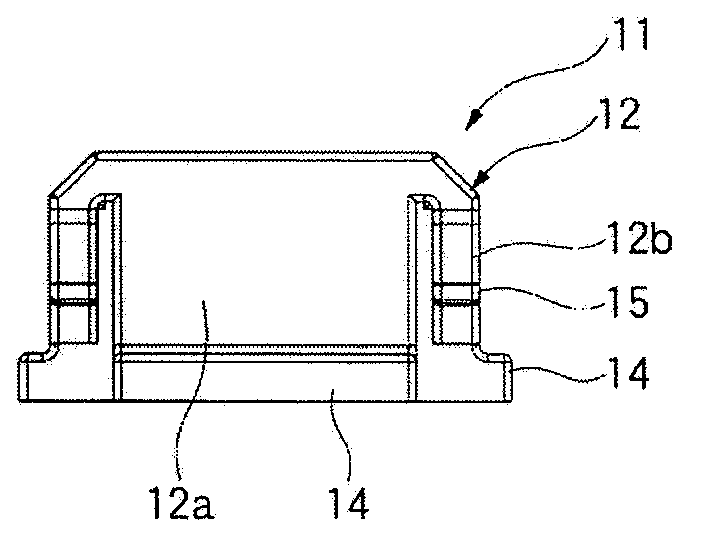

Clamping member

Owner:YAZAKI CORP

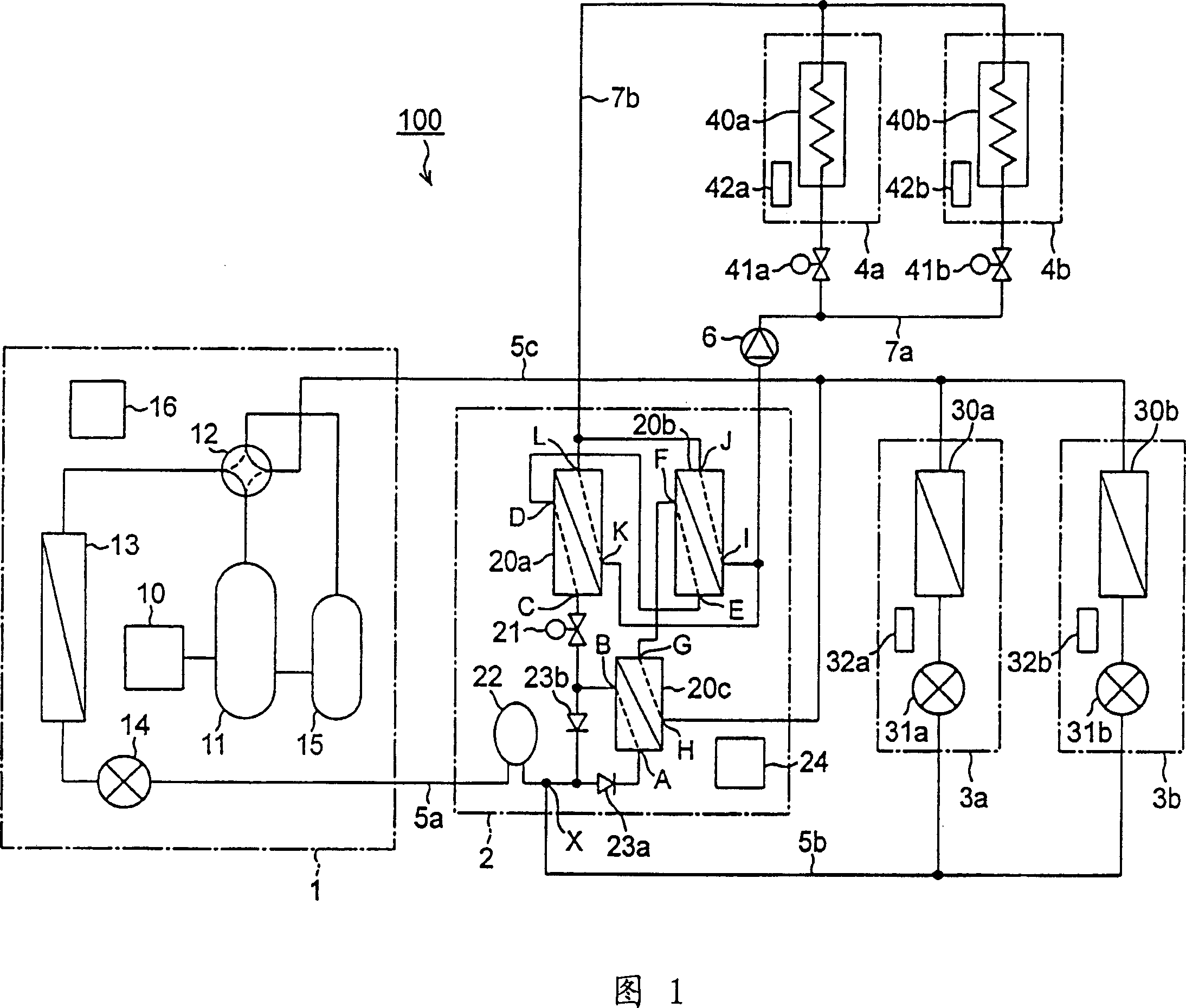

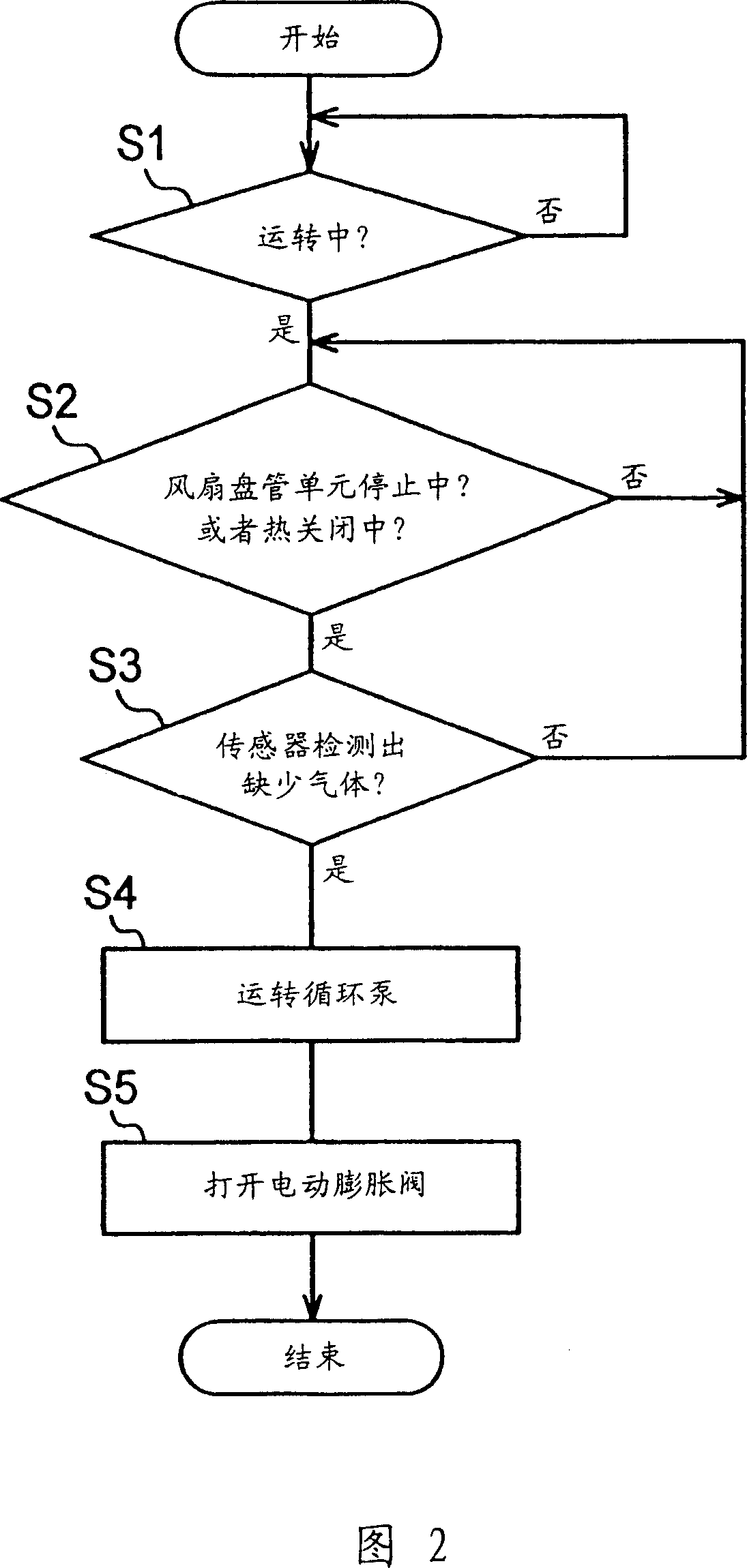

Air conditioner

InactiveCN1322275CImprove performanceContainment costsClimate change adaptationAir conditioning systemsPlate heat exchangerWarm water

An air conditioner provided with a heat source unit built in with a compressor, and carrying out air conditioning operation by supplying heat sources from both a refrigerant pipe and a water pipe. The air conditioner 100 is composed of an outdoor unit 1 built in with a compressor 11, direct expansion indoor units 3a and 3b provided with indoor heat exchangers 30a and 30b having a refrigerant delivered from the compressor 11 directly carry out heat exchange with indoor air via liquid pipes 5a and 5b and a gas pipe 5c, a chiller unit 2 carrying out heat exchange with the refrigerant to produce cold water or hot water, and fan coil units 4a and 4b provided with water heat exchangers 40a and 40b circulating the cold water or the hot water produced by the chiller unit 2 by operating a circulating pump 6 and carrying out heat exchange with indoor air. In a gas lacking state, the circulating pump 6 is operated, and an electric expansion valve 21 is opened to avoid the gas lacking state, and to prevent freezing of cold temperature water.

Owner:SANYO ELECTRIC CO LTD

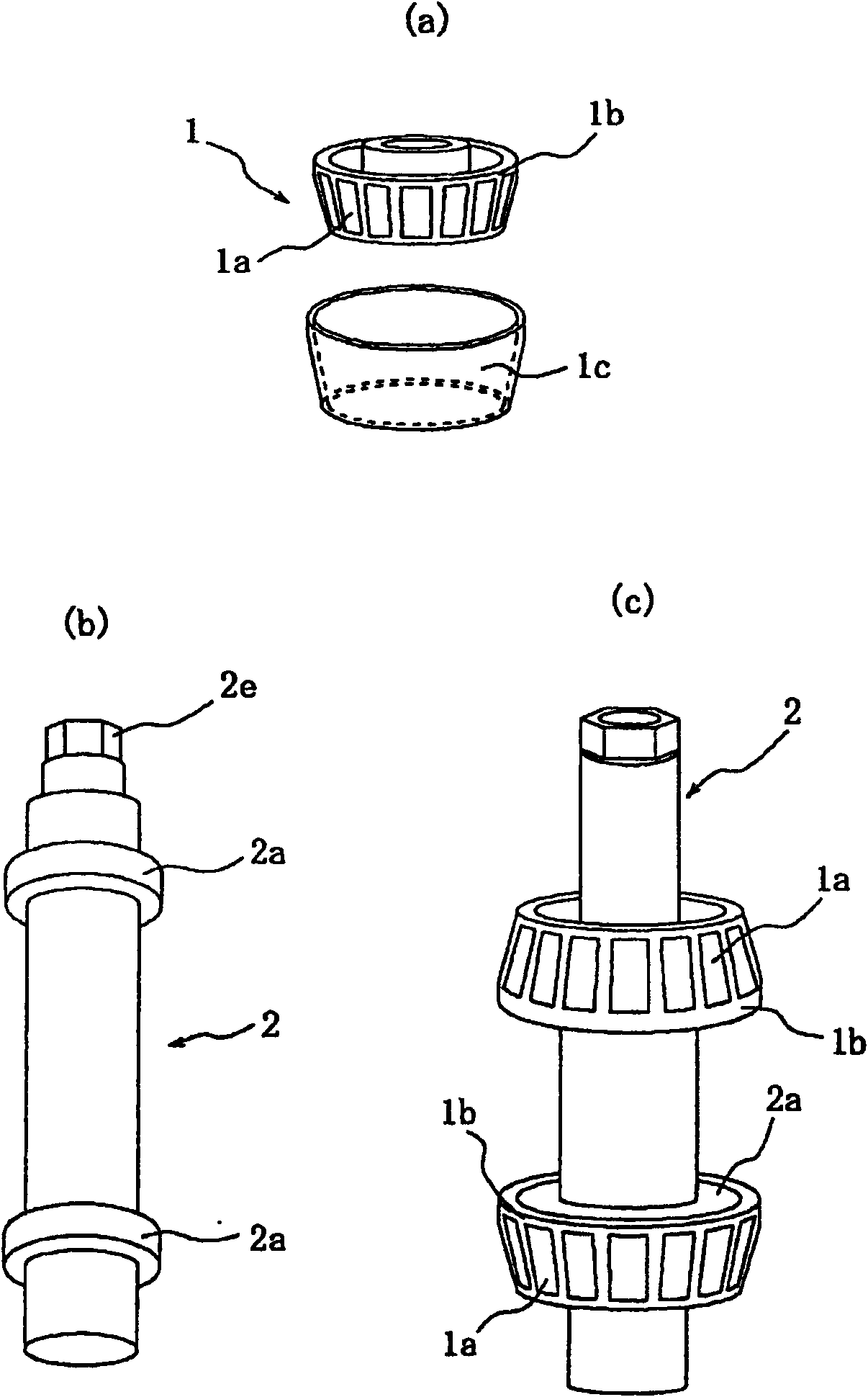

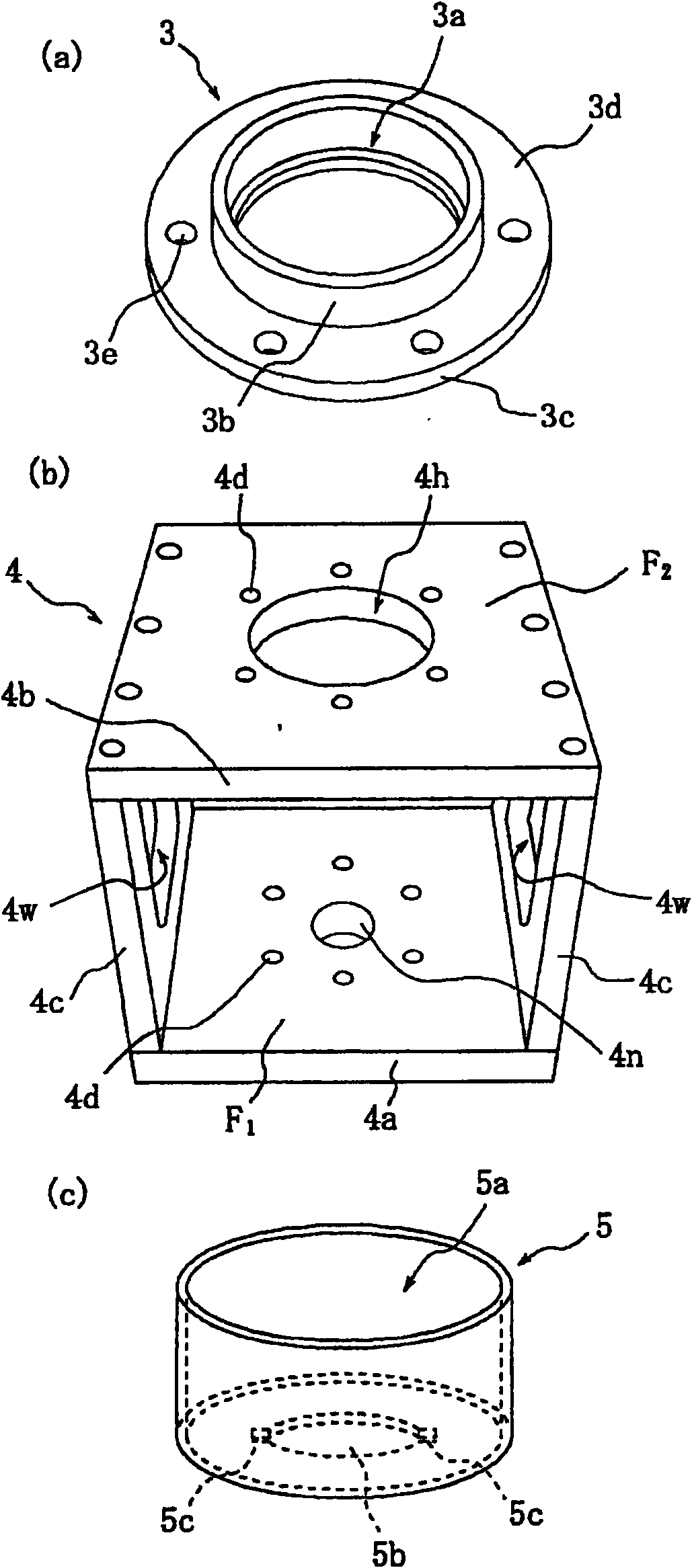

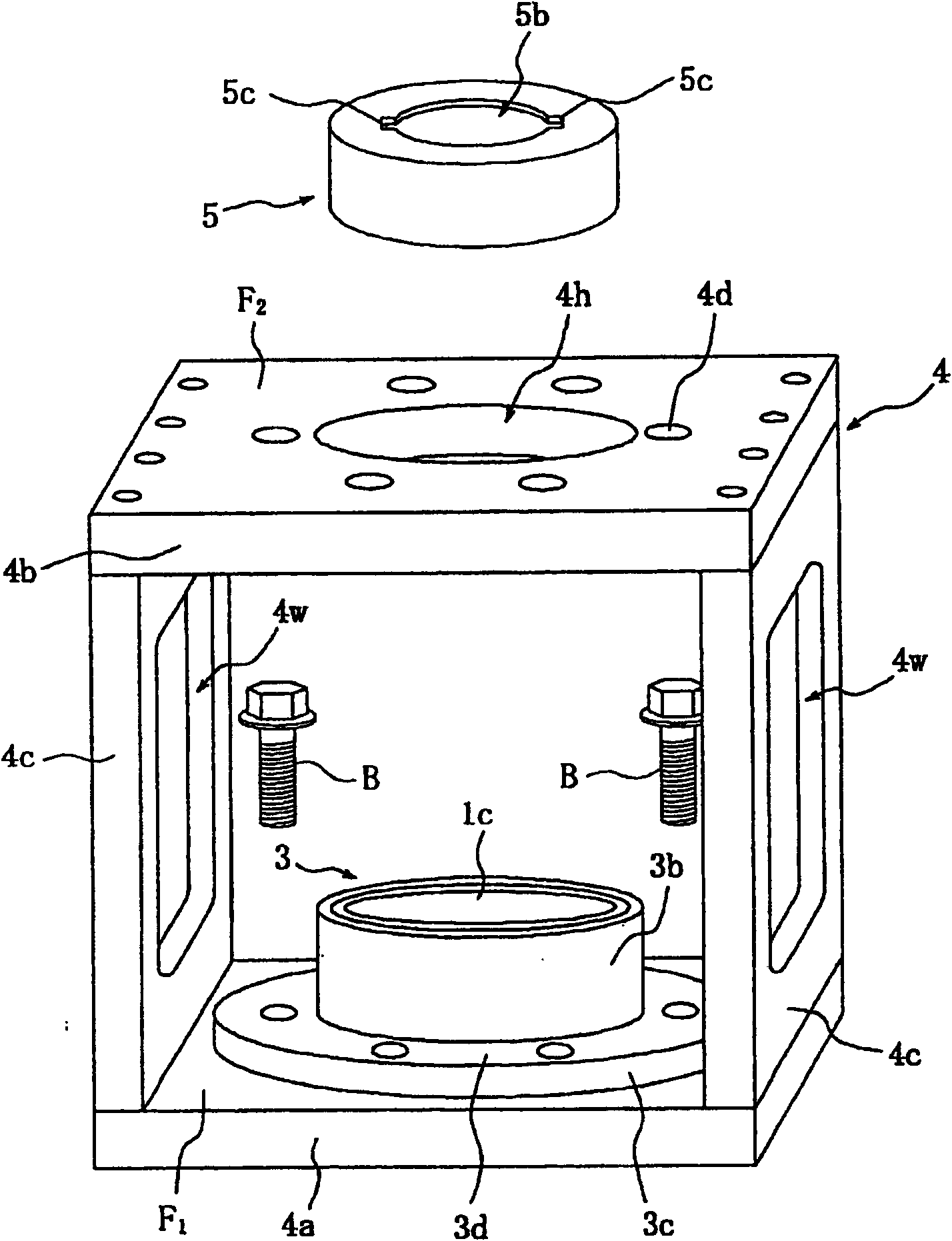

Educational outfit with axial shell assembled by bearing

The invention relates to an educational outfit with an axial shell assembled by a bearing, comprising a set of tapered bearings which can separate from each other with an inner ring and an outer ring mutually rotating, a bearing which can keep the two rings of roller separated from each other, a first bracket which has a dent part with an outer ring inserted in, a shell which has a bottom board forming a flat surface and a top board, with an opening bigger than the external diameter of the outer ring, of an upper end face parallel to the flat surface, a second bracket which has a flange fastened on the upper end face of the top board and a dent part formed inside for keeping the bearing upright between the bottom board and the top board and forming a clearance between the bottom of the dent part and the end face of the outer ring on the bearing, a first measuring apparatus which can measure the height size between the upper end face of the top board and the end face of the outer ring, and a plurality of gaskets which has different thickness corresponding to the clearance between the bottom of the dent part of the second bracket and the end face of the outer ring.

Owner:JATCO LTD

Fastening device

InactiveCN102753773AGuaranteed rigidityAvoid breakingSpringsNon-rotating vibration suppressionEngineeringFastener

Owner:大仓宪峰

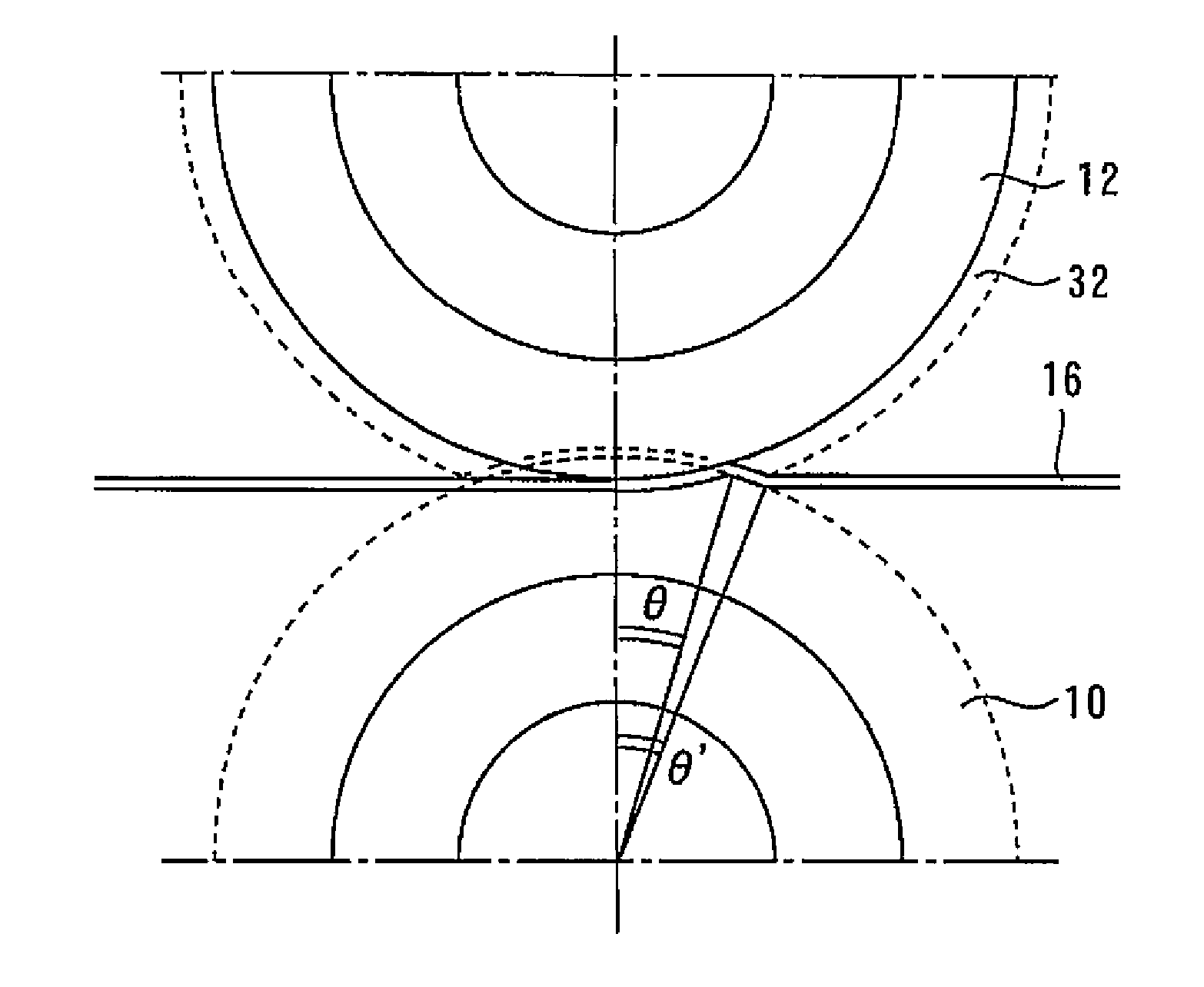

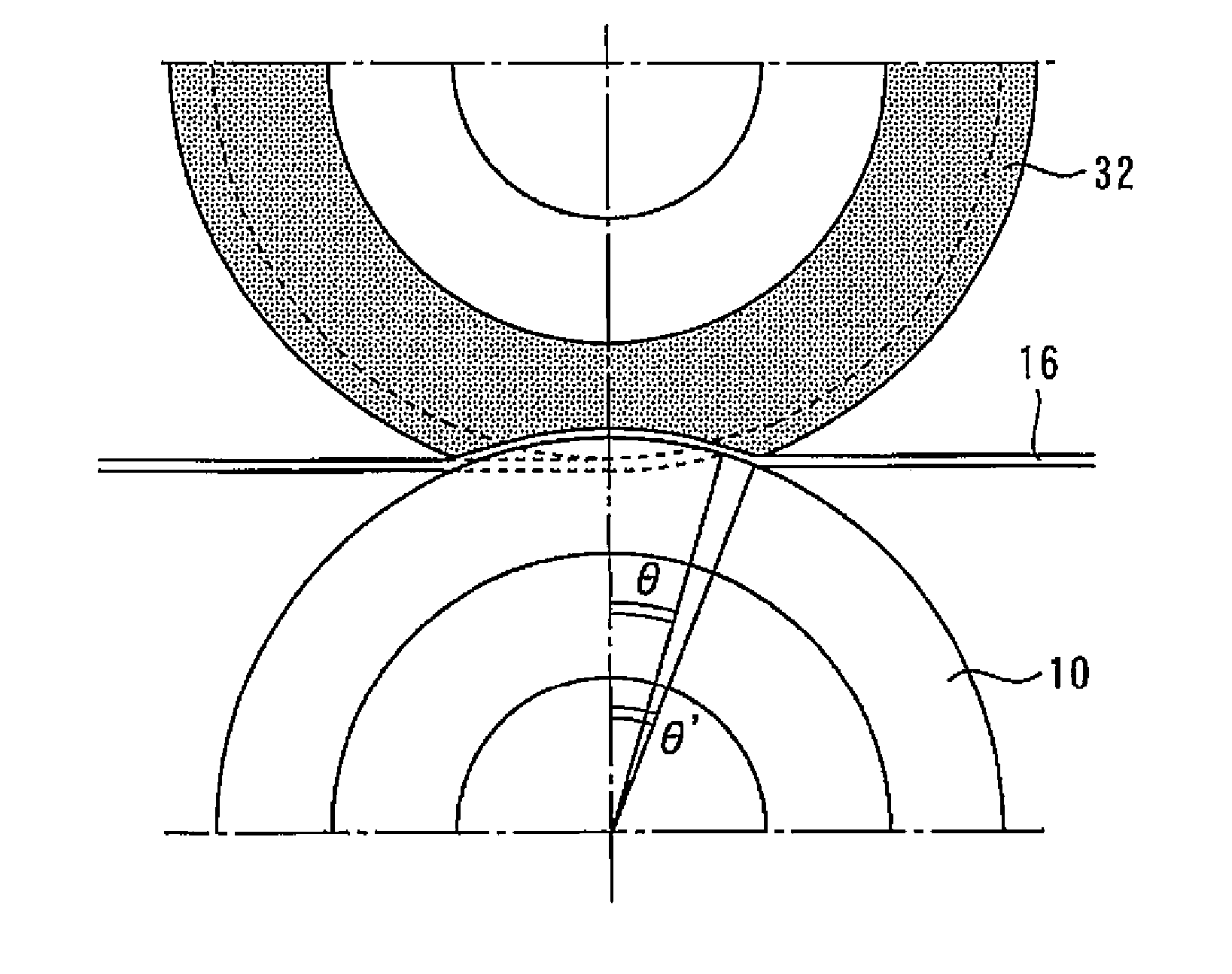

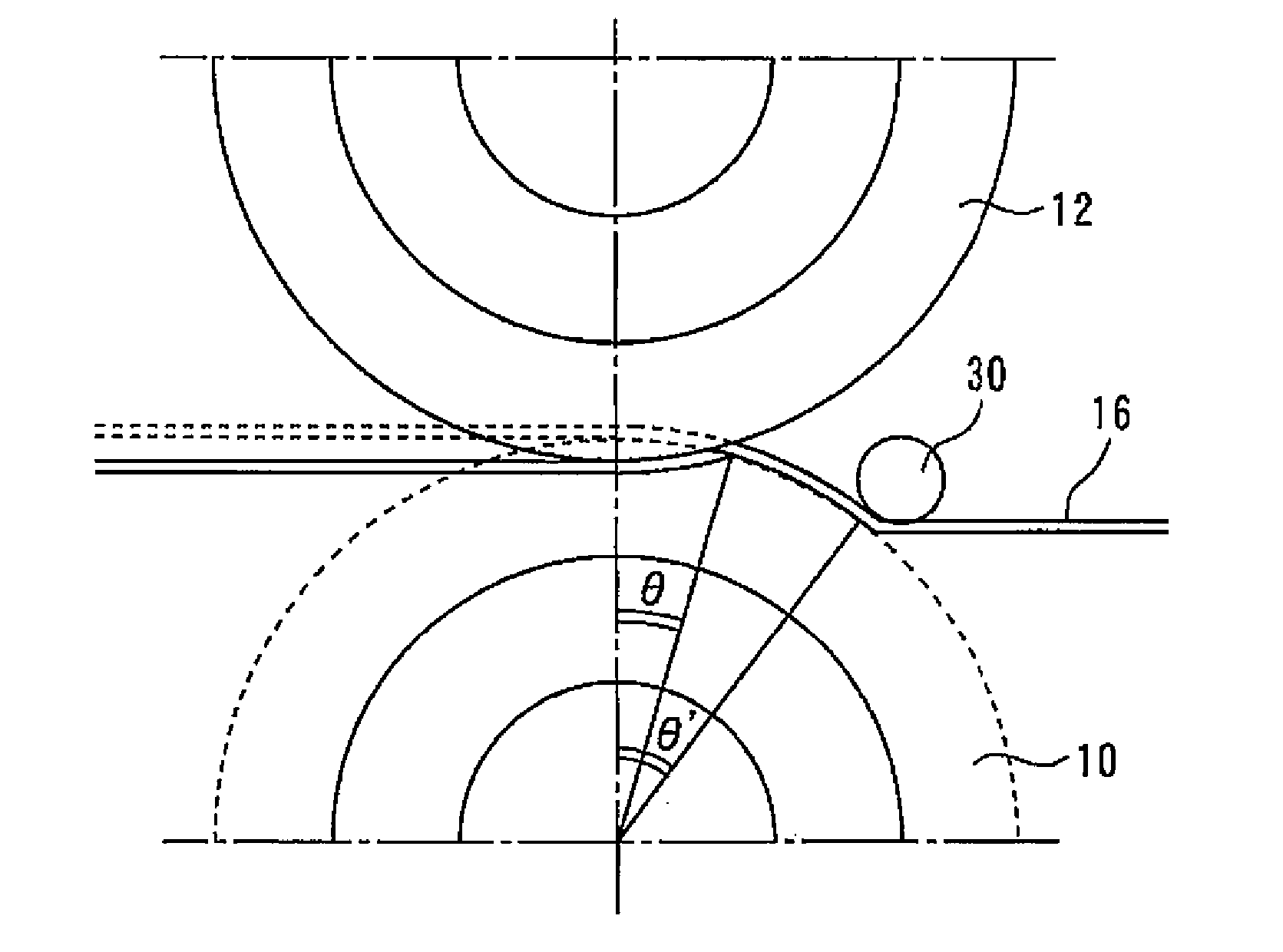

Method for producing slit material

InactiveCN103153512AContainment costsEasy to shapeShearing machinesShearing toolsElectrical and Electronics engineering

First and second round blades 10 and 12 each having a plurality of laterally arranged blades of rectangular section are opposed to each other, and each blade of the first round blade 10 is disposed so as to be displaced laterally to the same side of the corresponding blade of the second round blade 12. Subsequently, a metal strip 16 is wound around the first round blade 10 without contacting the second round blade 12. Subsequently, while the metal strip 16 is being pressed to the first round blade 10, the metal strip 16 is bitten into the rotating first and second round blades 12 and thereby sheared. Accordingly, a slit material 18 having a predetermined width is formed.

Owner:MITSUBISHI ELECTRIC CORP +1

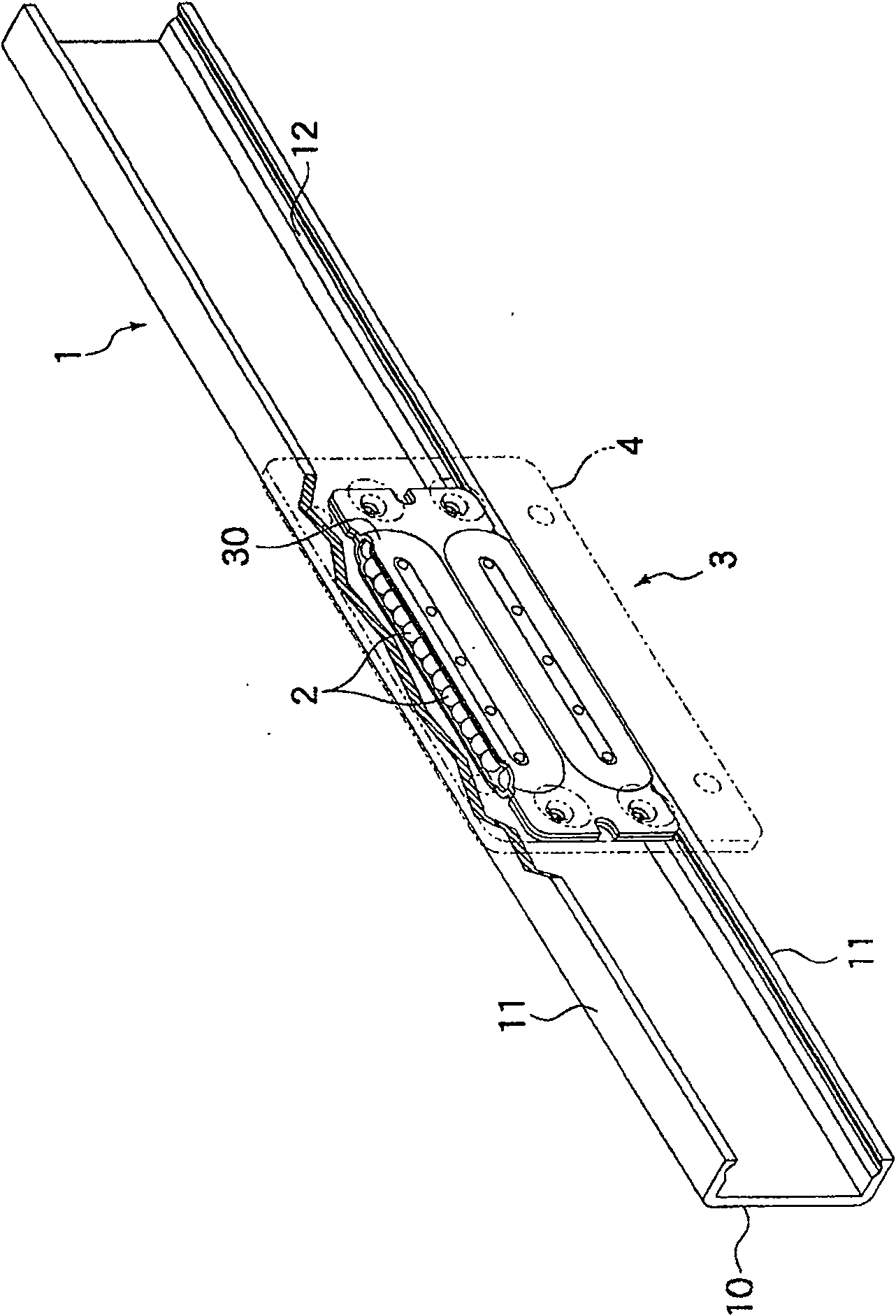

Thin slide unit

ActiveCN100554708CBrisk reciprocating motionEasy to assembleLinear bearingsBearing componentsReciprocating motionEngineering

Owner:THK CO LTD

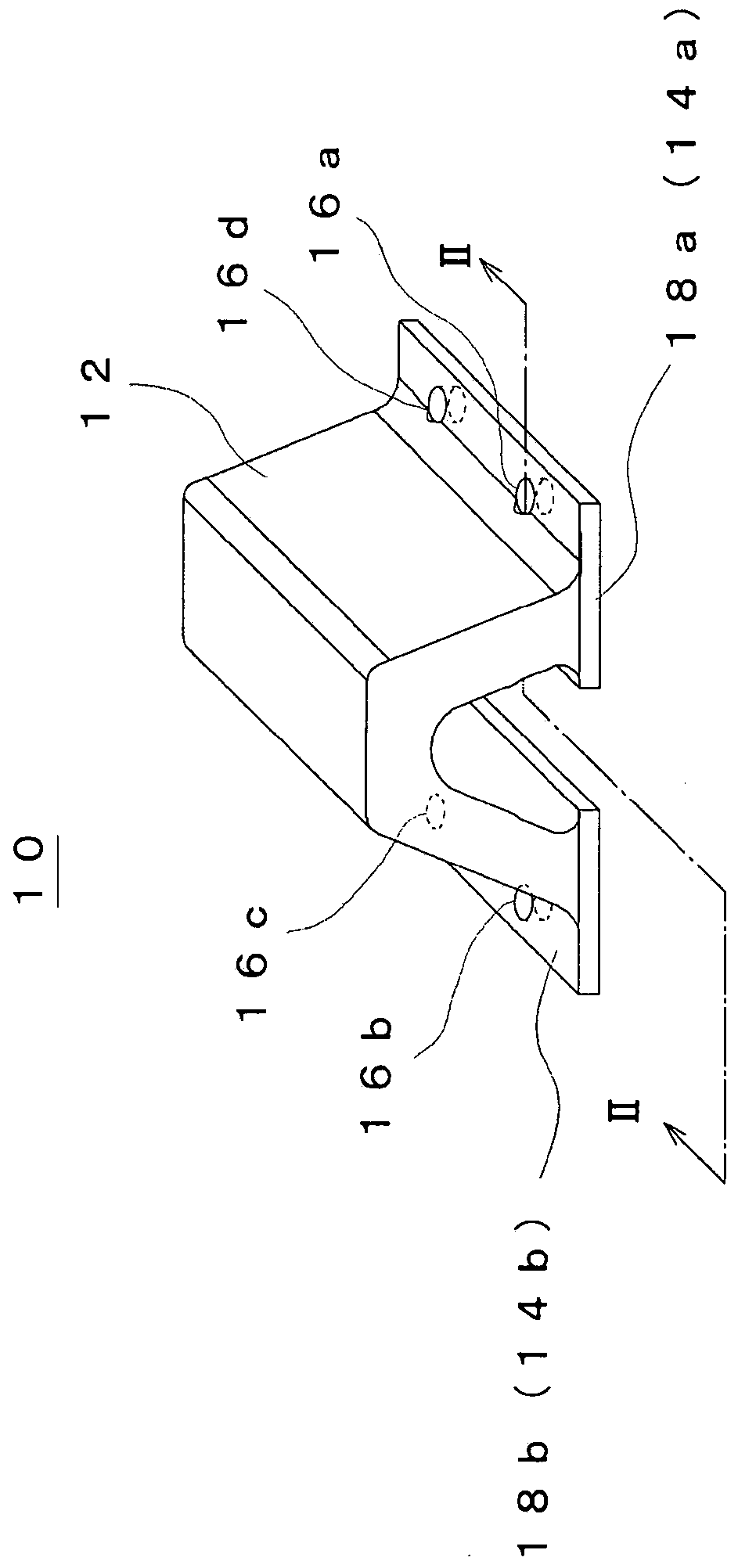

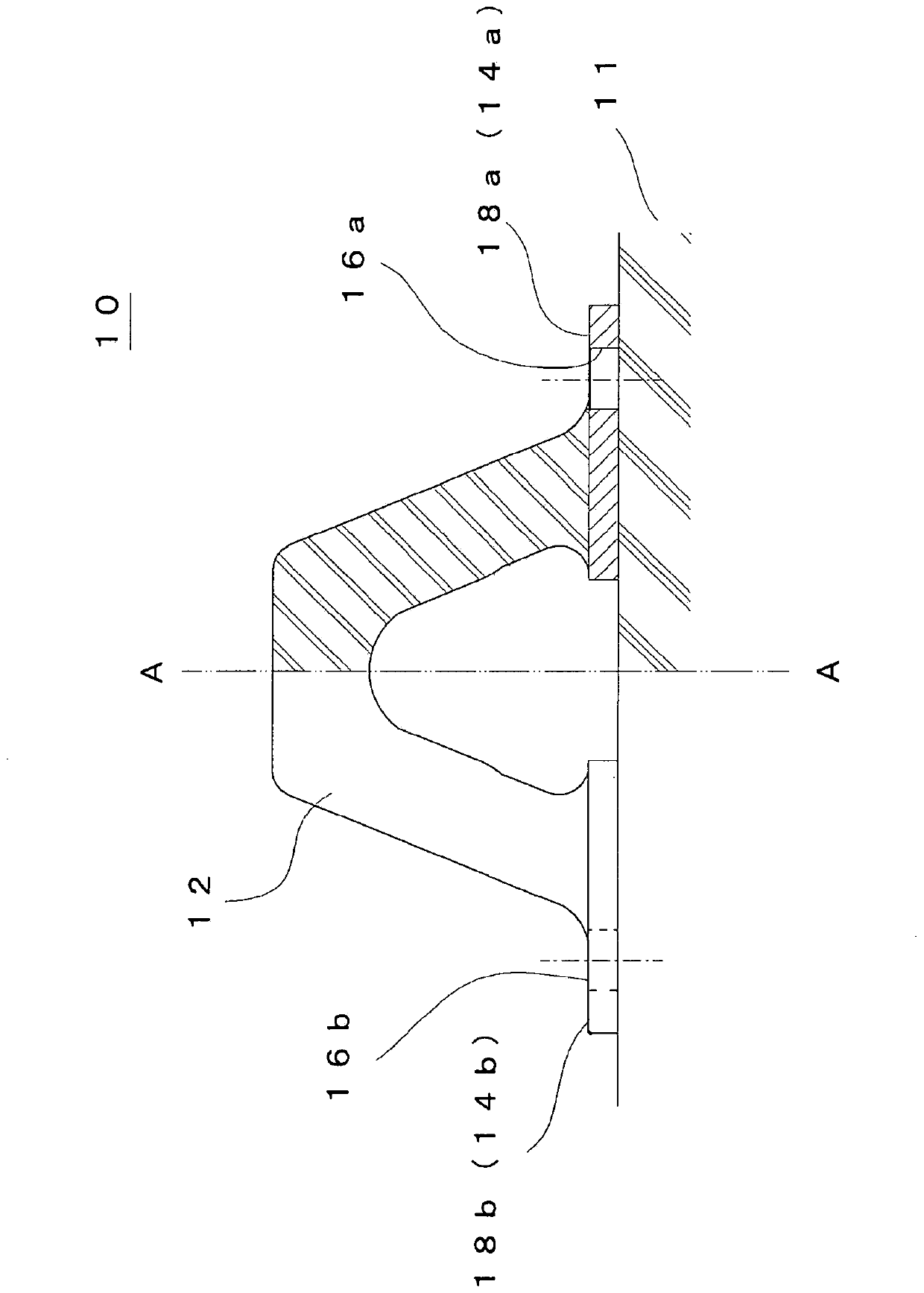

Fender, installation method of fender and manufacturing method of fender

ActiveCN106661853BIncreased durabilityReduce generationVessel cleaningClimate change adaptationFenderMarine engineering

A fender, a method for installing the fender, and a method for manufacturing the fender, wherein the fender (10) installed on a quay (11) has a buffer portion (12) for relieving the impact of a ship when it is connected to the ship's side ) and shore wall fixing parts (14a, 14b) for installing the buffer part (12) on the shore wall (11). In addition, the shore wall fixing portion (14a, 14b) includes fixing members (18a, 18b) having higher rust resistance than iron materials. Furthermore, the quay wall fixing portion (14a, 14b) has through holes (16a to 16d) through which bolts for attaching the fender (10) to the quay wall (11) are inserted. If constituted in this way, the fixing members (18a, 18b) have higher rust resistance than iron materials, so even if the surfaces of the fixing members (18a, 18b) and the through holes (16a-16d) passing through the fixing members (18a, 18b) ) is in a state exposed to the outside, and the occurrence of rust can also be reduced.

Owner:SHIBATA IND

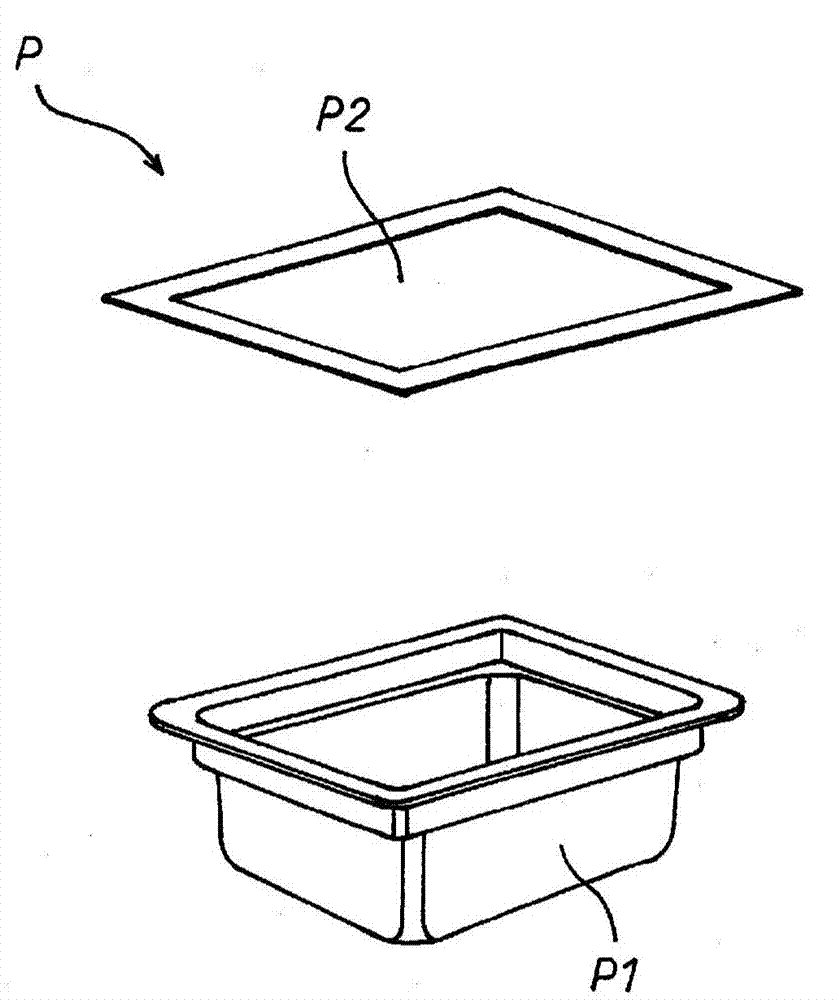

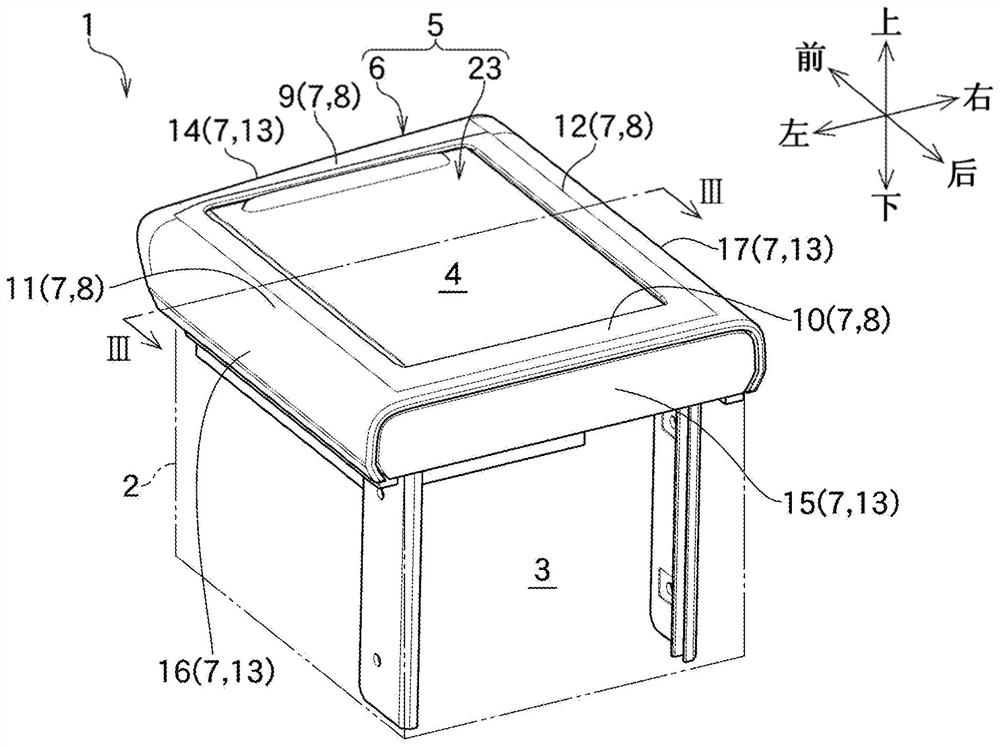

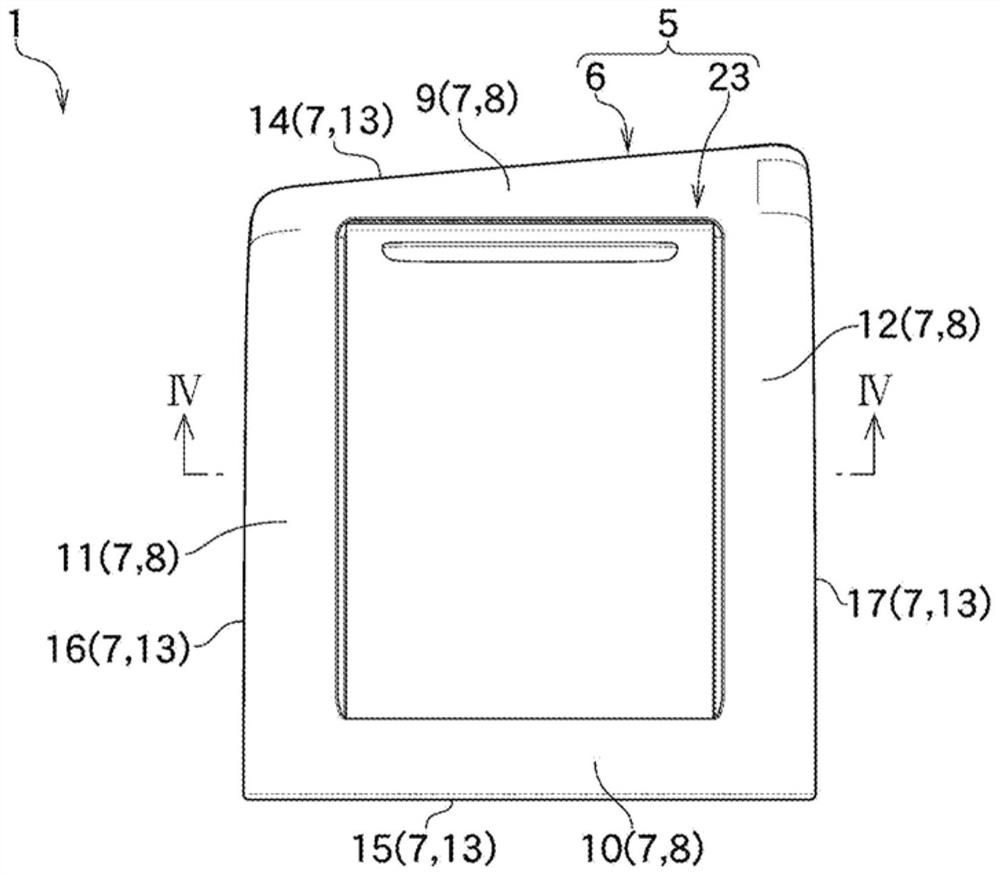

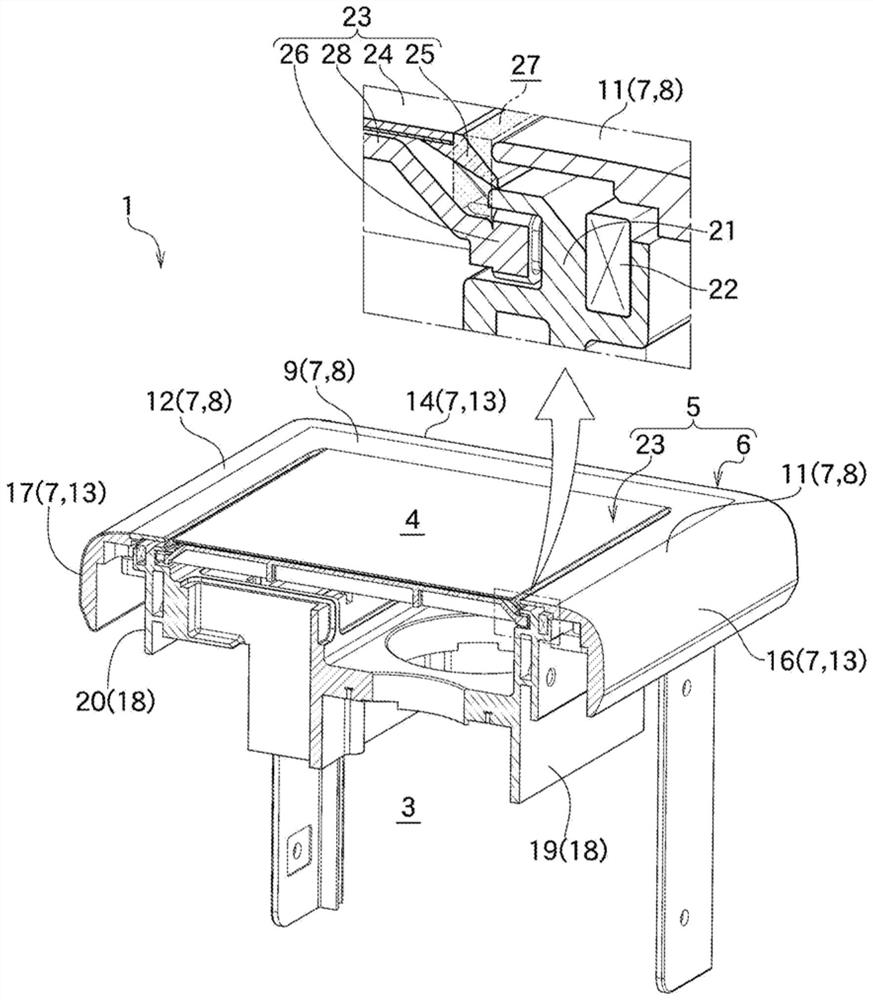

Storage device and cover for storage device

PendingCN114555424AThe resistance can be determined arbitrarilyContainment costsPassenger spaceVehicle arrangementsShutterStructural engineering

The invention provides a storage device and a cover body for the storage device. The storage device and the cover body for the storage device can shield a gap which exposes an internal structure without damaging appearance. In the cover body (5) for the storage device, a gap (27) is formed between the end part of the shutter (23) and the left and right upper decorative parts (11, 12), the end part of the shutter (23) on the side of the gap (27) is composed of a shielding member (25), and the shielding member (25) extends towards the space between the left and right upper decorative parts (11, 12) and the frame part side guide rail part (21) to the lower side of the left and right upper decorative parts (11, 12).

Owner:NIFCO INC

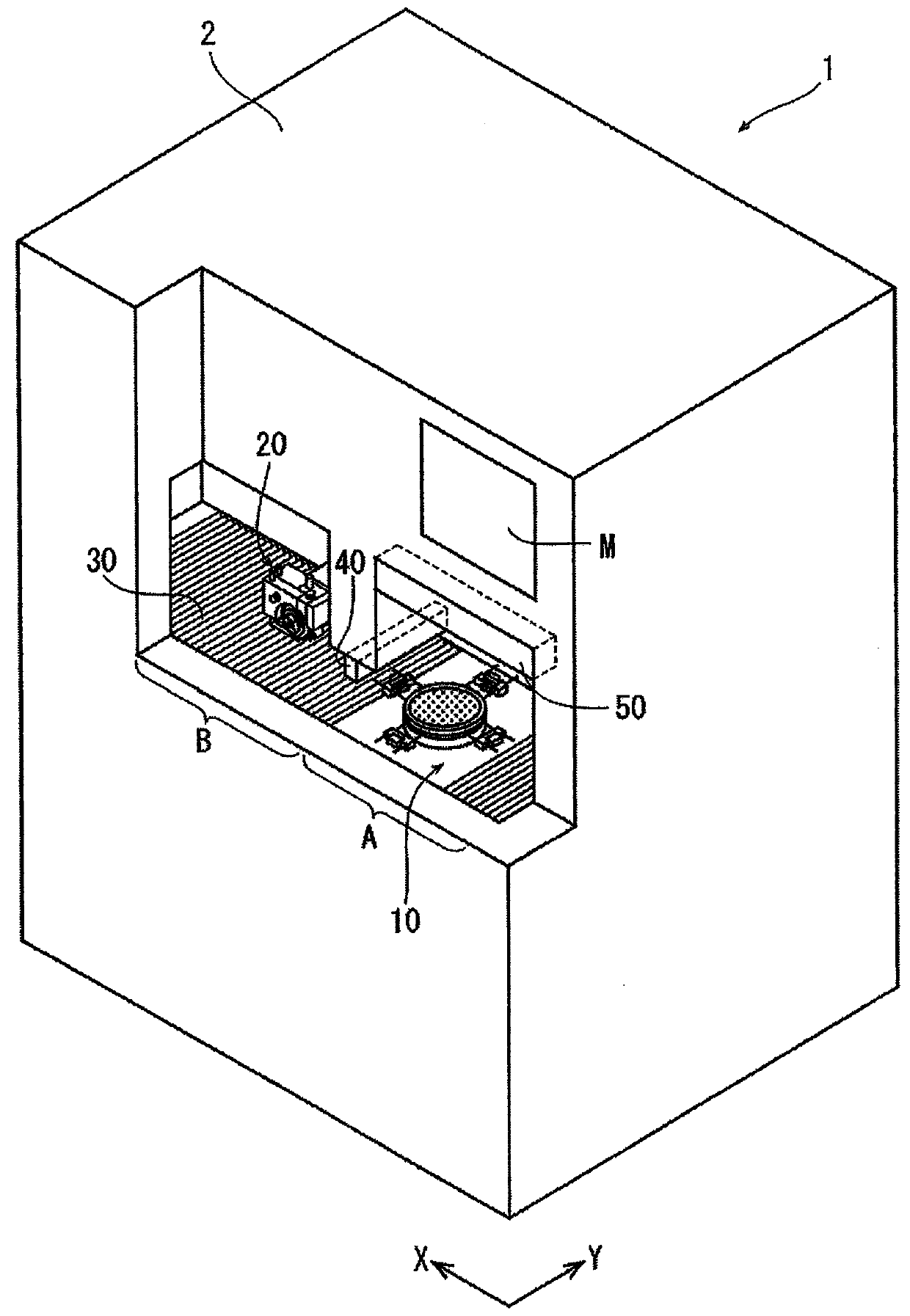

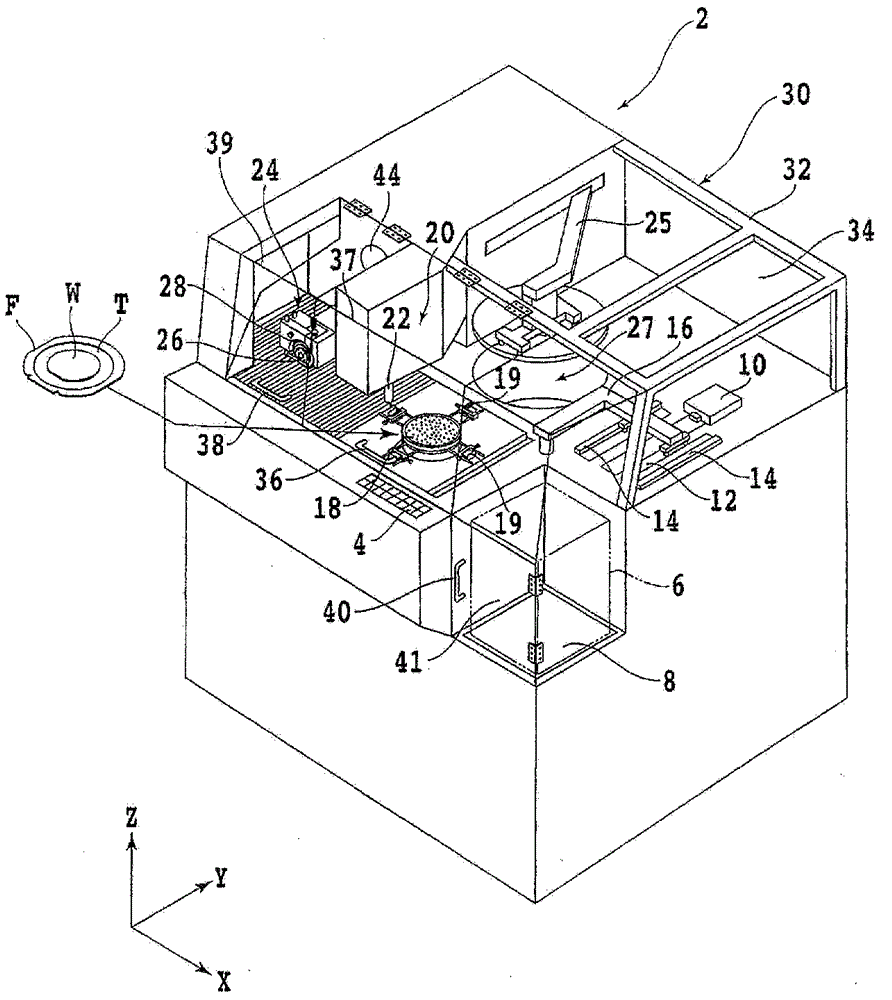

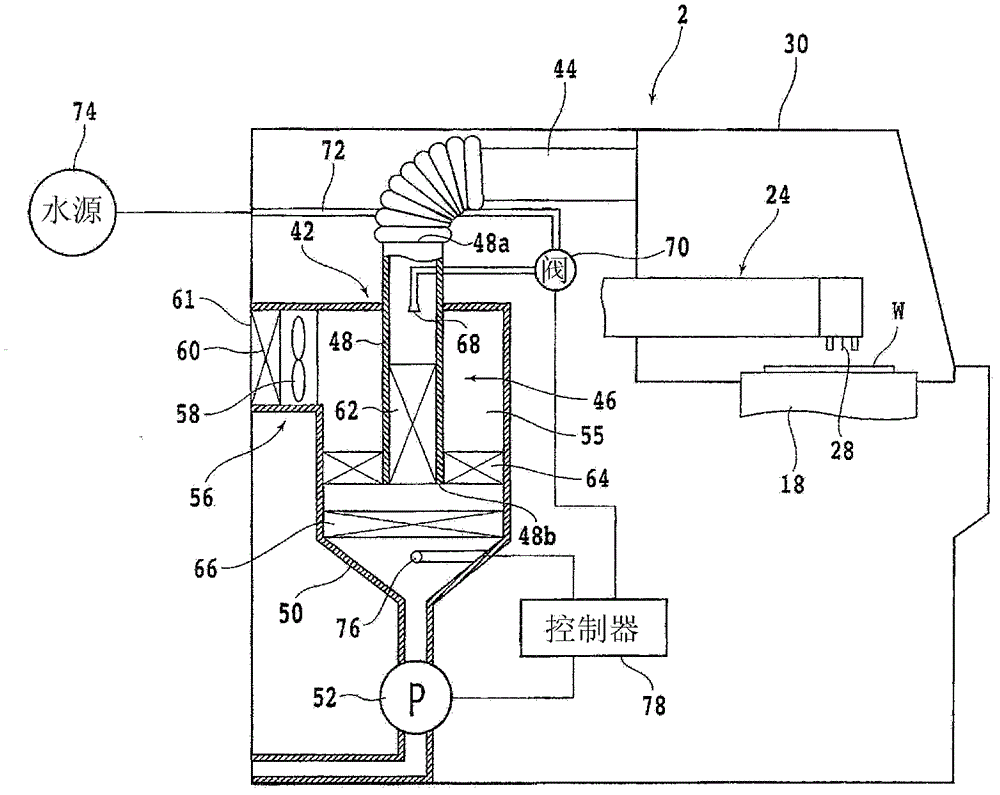

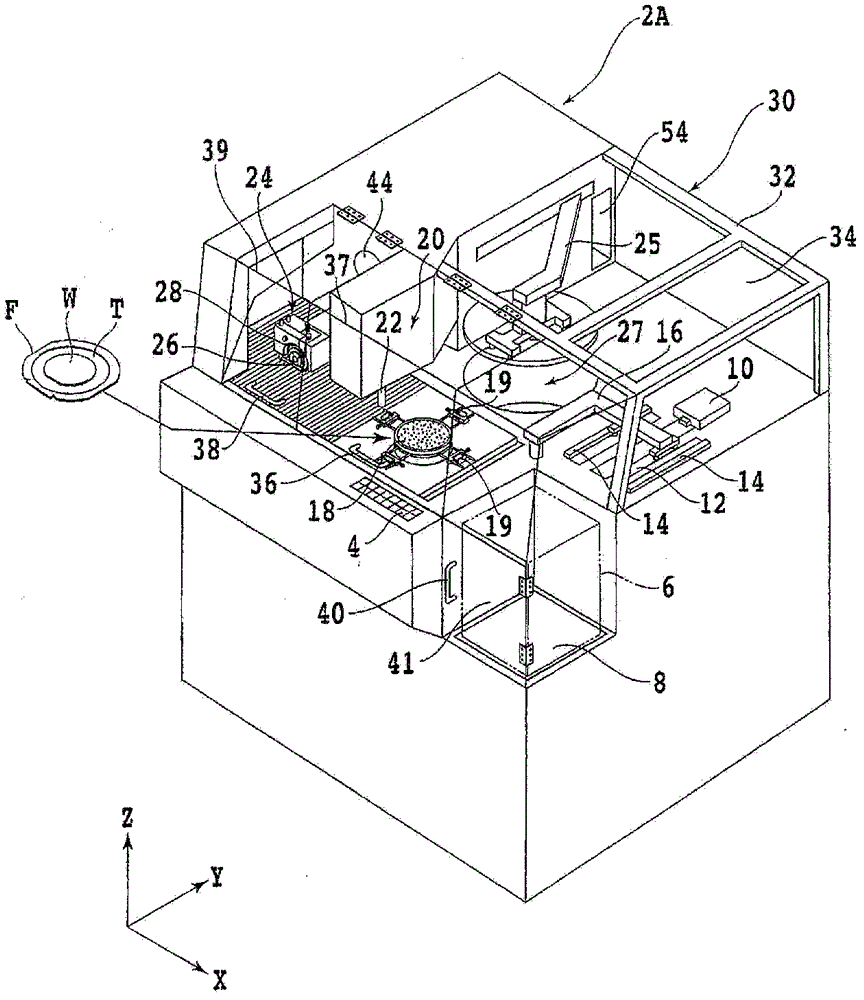

Machining device

ActiveCN102600690BAvoid dischargeLess quantityCombination devicesSemiconductor/solid-state device manufacturingMachining processWorkbench

The invention provides a machining device, which can reduce the running cost on a cleaning room and facilities. The machining device comprises a clamping workbench for holding objects to be machined; a machining mechanism used for machining objects while supplying machining liquid at the same time; and a casing for covering the clamping workbench and the machining mechanism. The machining device is characterized by being provided with a mist machining unit for machining mists. The mist machining unit consists of a pumping pipeline and a mist removal mechanism .The pumping pipeline is connected with the interior of the casing and is used for pumping mists generated during the machining process. The mist removal mechanism is connected with the pumping pipeline and is used for removing mists from air. The mist removal mechanism consists of an anti-mist unit and a fan unit.

Owner:DISCO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com