Thin slide unit

A thin, rolling groove technology, which is applied to bearing components, linear motion bearings, bearings, etc., can solve the problems of increased sliding resistance of sliding parts, short life of roll forming dies, and decreased rigidity of guide rails. Effects of small size, reduced manufacturing cost, and reduced frequency of replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The thin sliding unit of the present invention will be described in detail below with reference to the drawings.

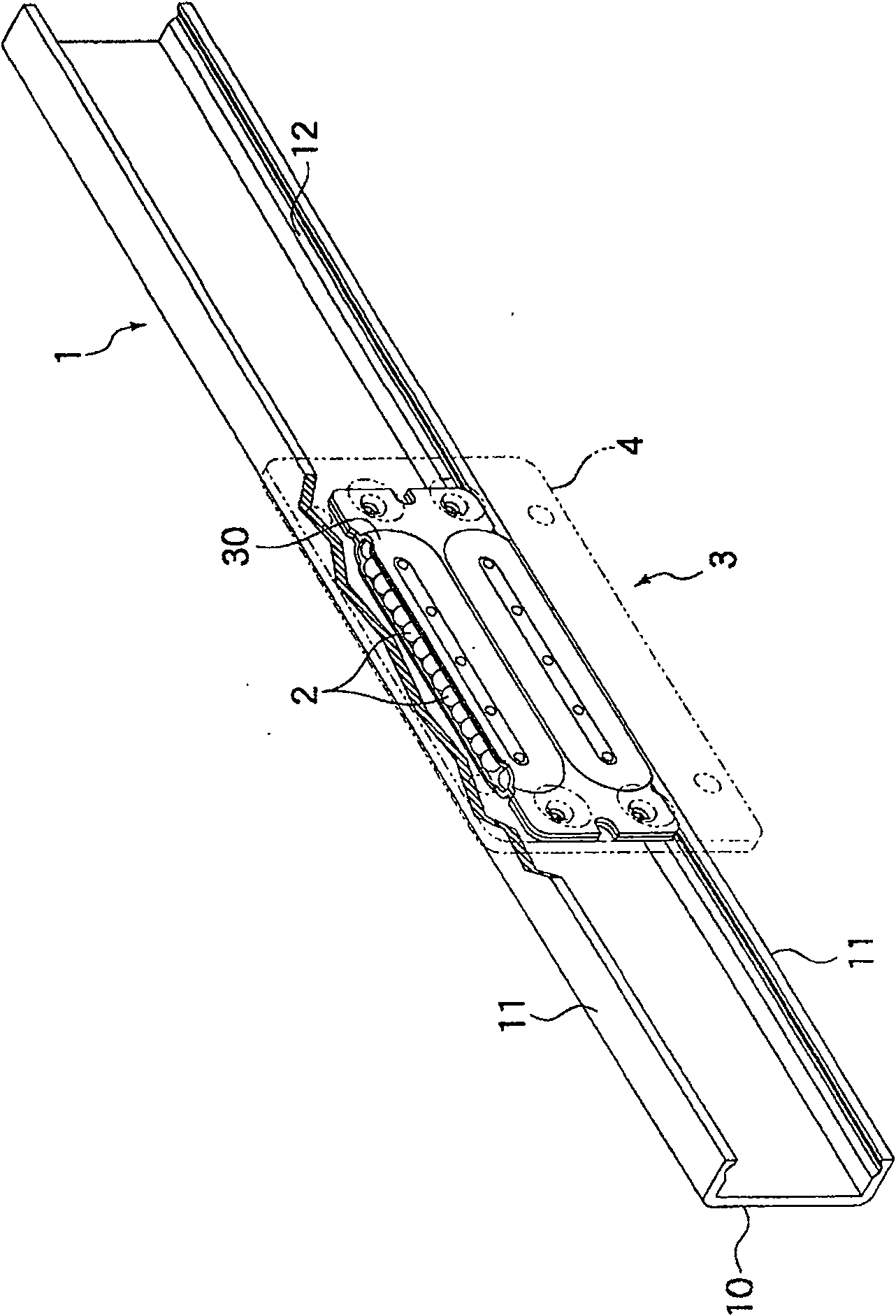

[0029] figure 1 It is a figure which shows an example of the slide unit to which this invention is applied. The sliding unit is composed of a guide rail 1 and a slider 3 assembled on the guide rail 1 via a plurality of balls 2 , and the slider 3 is configured to freely reciprocate along the guide rail 1 .

[0030] The guide rail 1 is formed in a channel shape in which a pair of side walls 11 and 11 stand up from a base 10 , and a space surrounded by the base 10 and the side walls 11 serves as a guide path for the slider 3 . On the inner side of each side wall 11 facing the guide way, a rolling groove 12 of the ball 2 is formed along the longitudinal direction of the guide rail 1, and these rolling grooves 12 face each other via the guide way. Each rolling groove 12 is formed in a so-called Gothic arch shape in which two ball rolling surfaces intersect at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com