Electromagnetic stirring apparatus, and continuous casting method

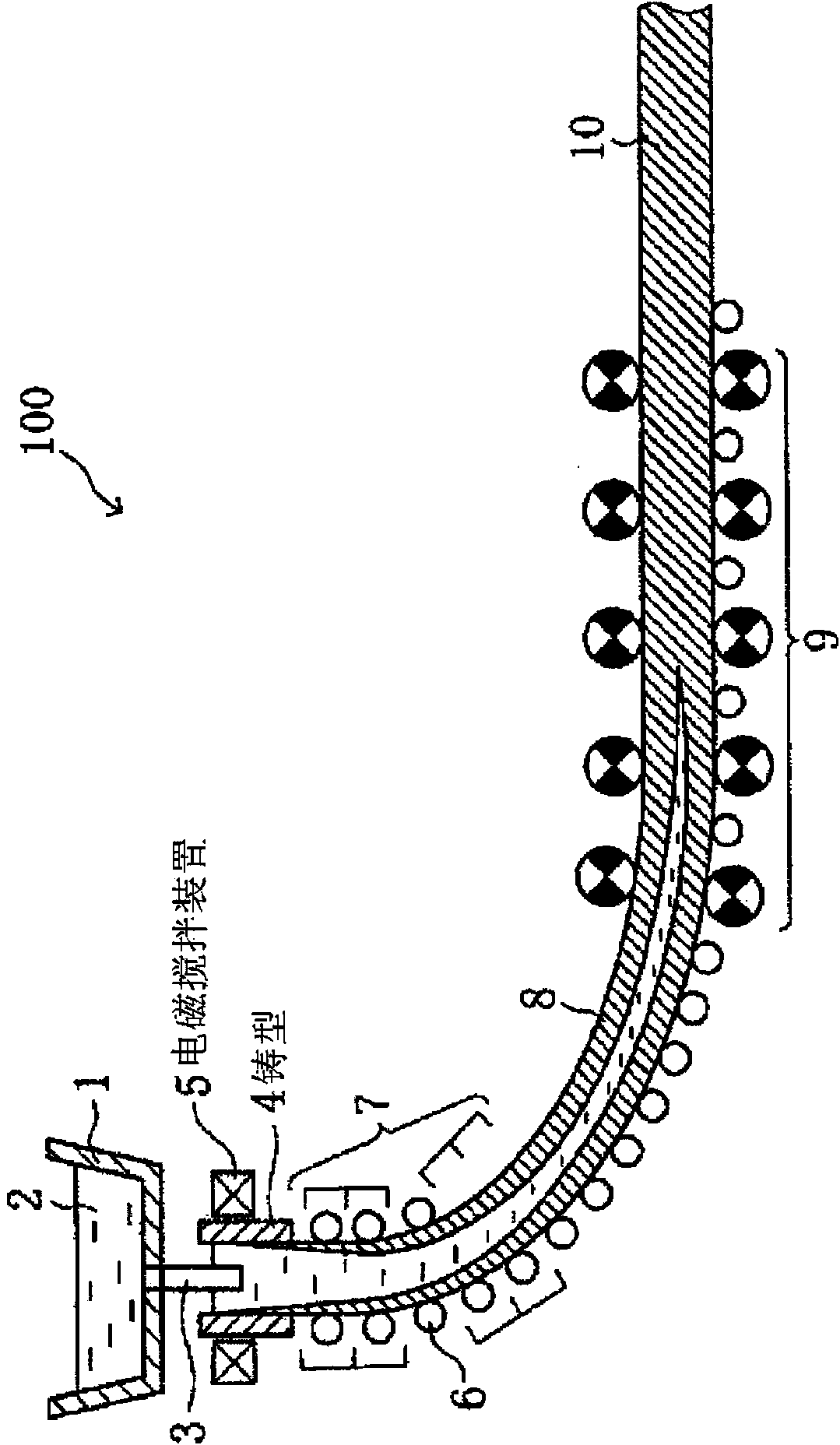

A technology of electromagnetic stirring and electromagnetic coils, which is applied in the field of electromagnetic stirring devices, can solve problems such as difficulty in forming a moving magnetic field and discontinuous penetration of electromagnetic force, and achieve the effect of suppressing equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Hereinafter, examples performed to confirm the effects of the present invention will be described.

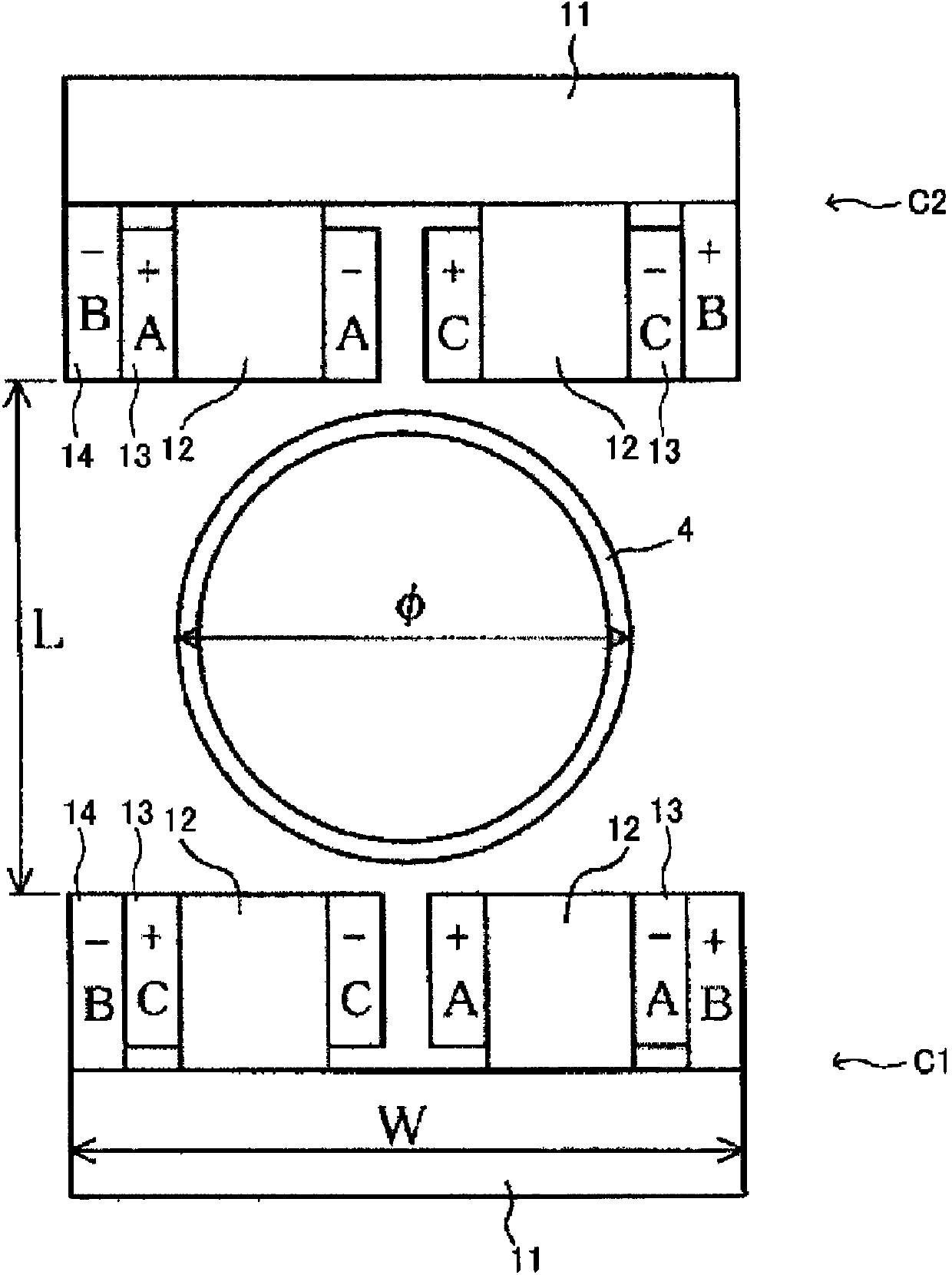

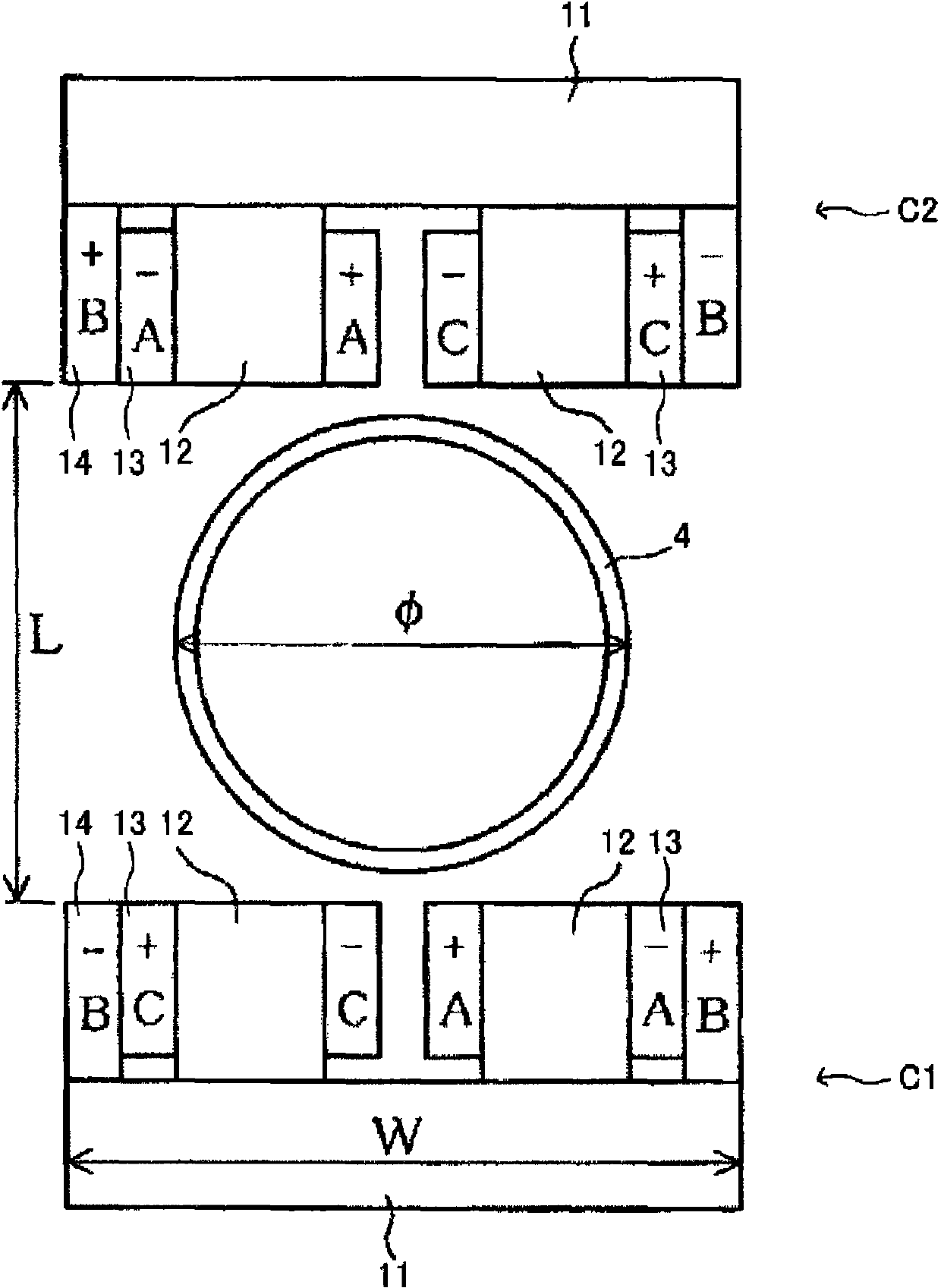

[0054] The present invention imparts electromagnetic force in the mold 4 by using the following electromagnetic stirring device 5, thereby making the molten steel flow uniformly, as a result, improving the internal quality of the cast sheet, wherein the width of the electromagnetic stirring device 5 configured in the casting direction is In the electromagnetic coils C1 and C2 of W, there is a position where a meniscus exists in a region sandwiched between an end surface on one end side in the casting direction and an end surface on the other end side.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com