Fender, installation method of fender and manufacturing method of fender

The technology of an installation method and a manufacturing method, which is applied in the field of fenders, can solve problems such as reinforcement plate exposure, and achieve the effects of improved reliability, firm fixation, and lighter weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

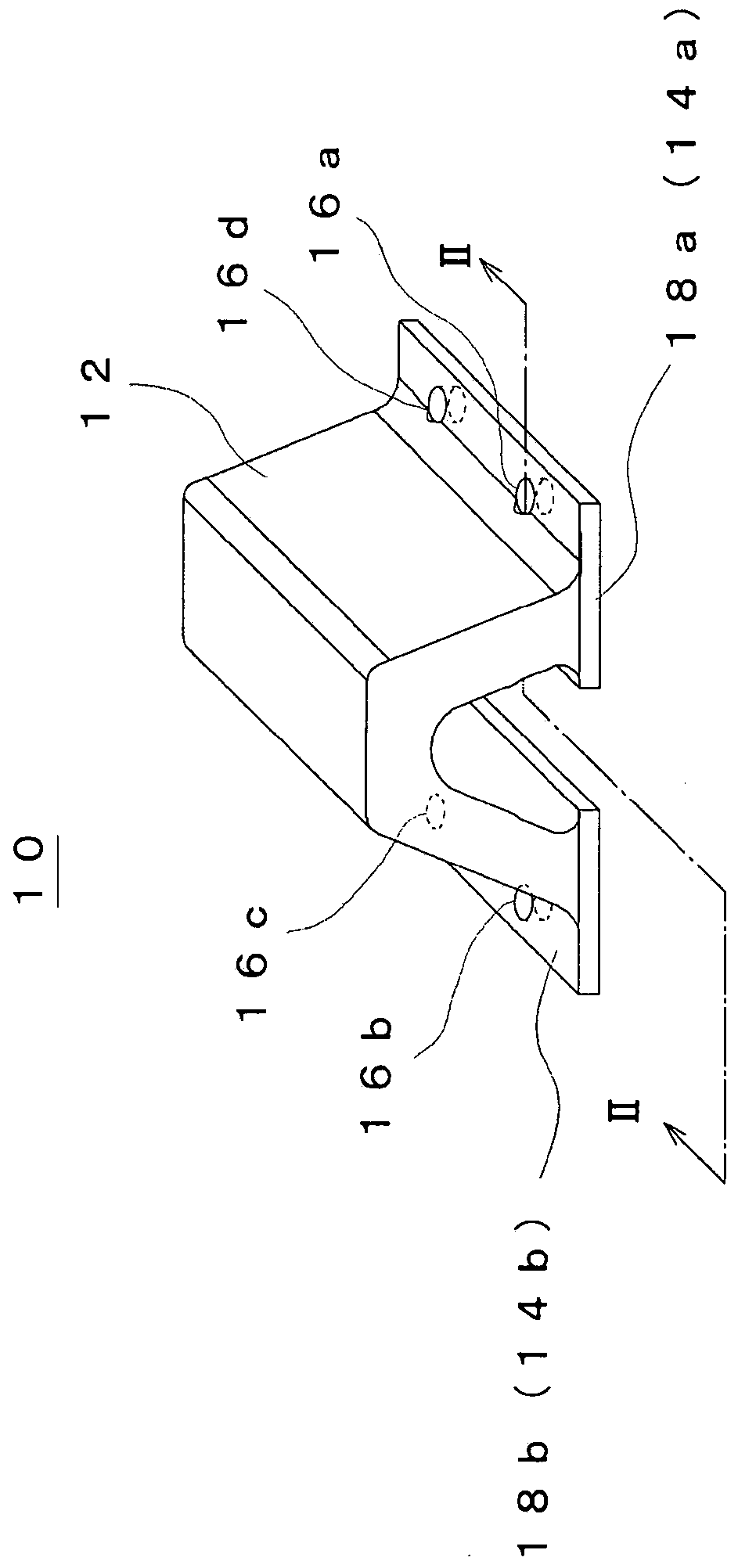

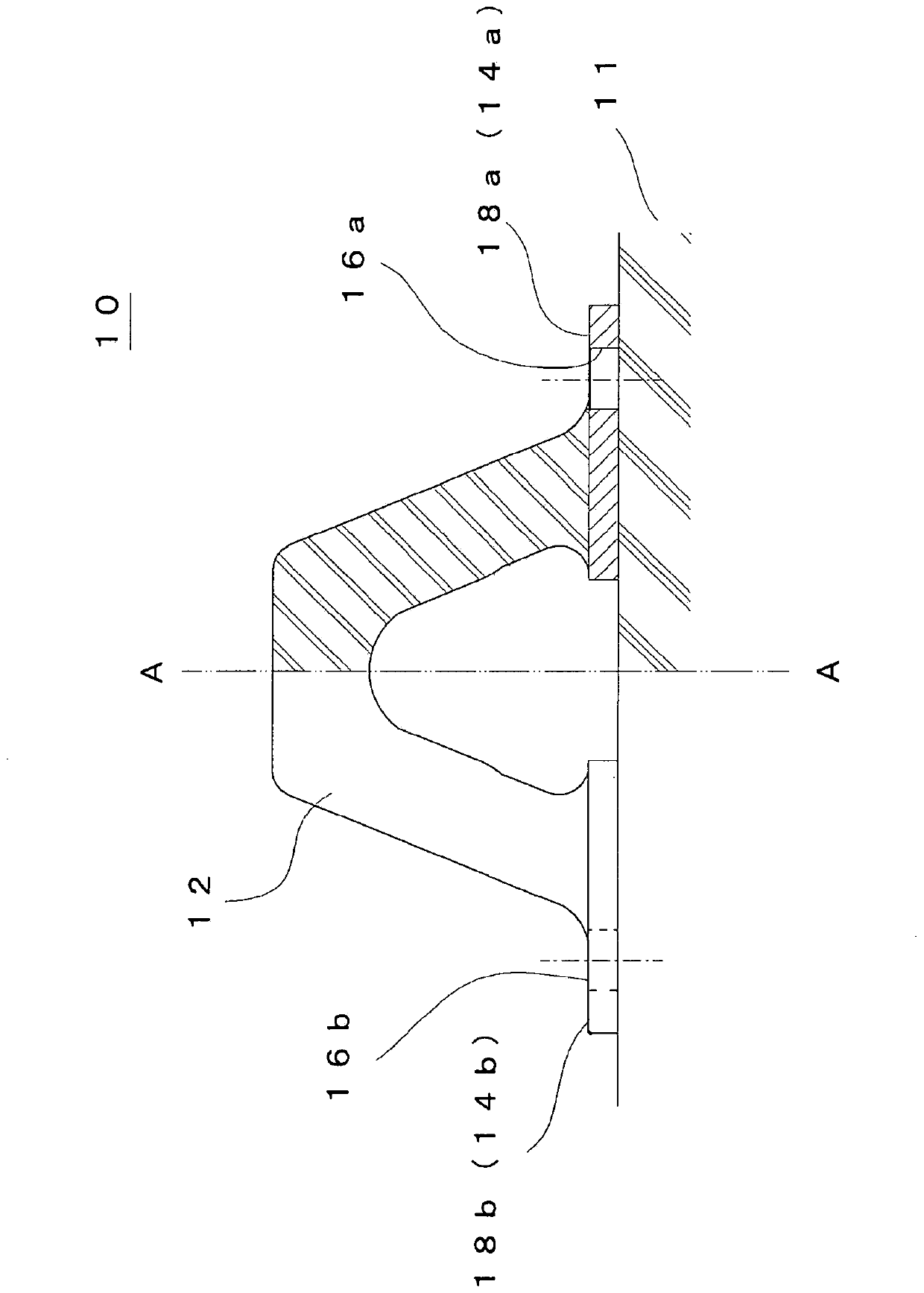

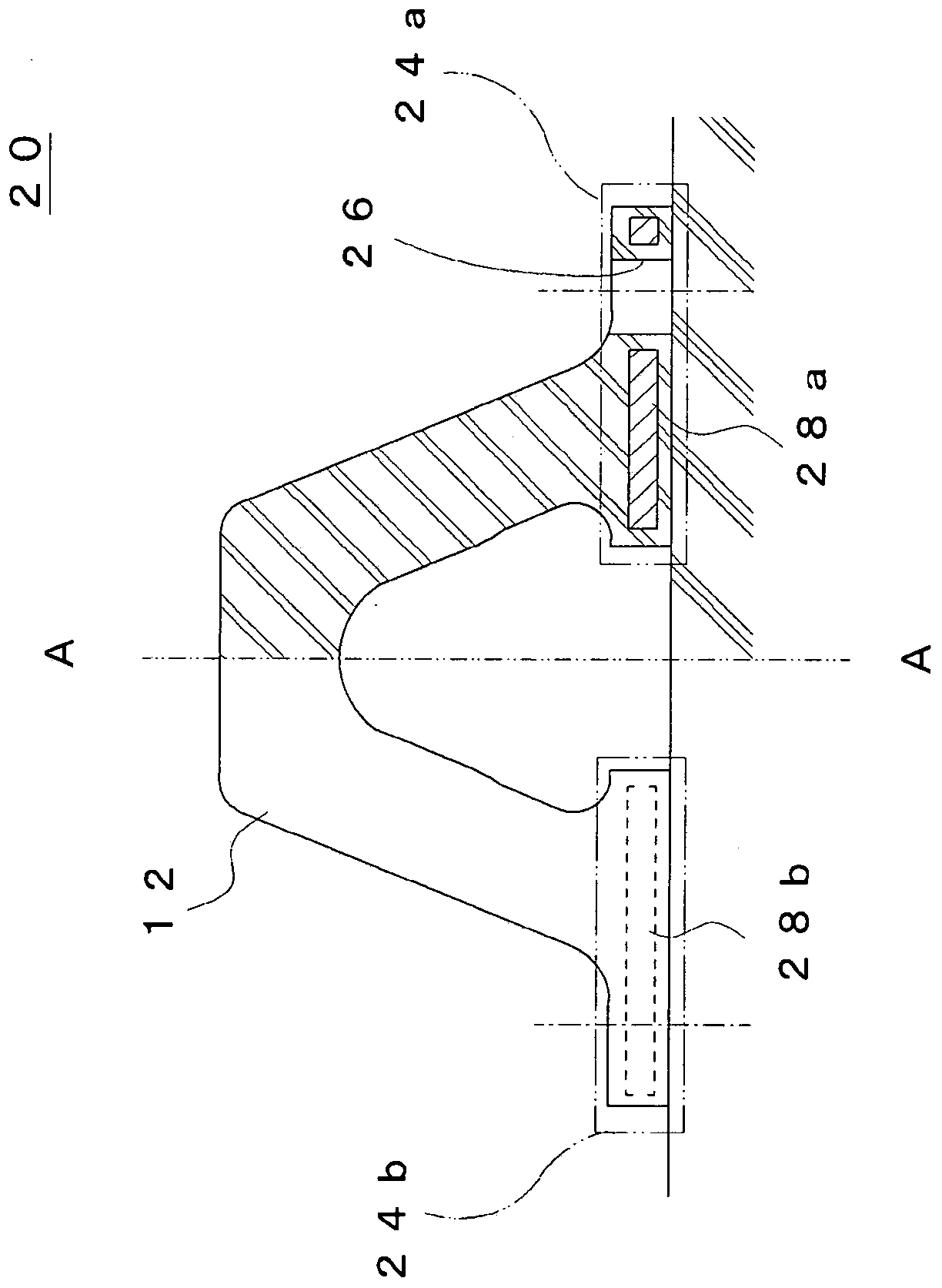

[0052] figure 1 It is a perspective view showing the appearance of the fender according to the first embodiment of the present invention, figure 2 yes figure 1 A partial schematic cross-sectional view along line II-II shown. In addition, in figure 2 In FIG. 2 , a front view is shown on the left side, and a schematic cross-sectional view is shown on the right side, with the center line (two-dot chain line A-A) of the fender 10 as the boundary.

[0053] Referring to these figures, the fender 10 includes a buffer portion 12 for alleviating the impact when the ship is connected to the ship;

[0054] The cushioning portion 12 is formed of an elastic body such as a polymer material, and is formed into a substantially inverted V shape when viewed from a cross section. The elastic body such as the polymer material is made of rubber (natural rubber, styrene-butadiene rubber (SBR), neoprene Polyethylene rubber (CR), etc.) is composed of elastic polyurethane or the like.

[0055] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com