Method of wastewater treatment with excess sludge withdrawal reduced

一种排水处理、剩余污泥的技术,应用在水/污泥/污水处理、生物水/污水处理、水/污水多级处理等方向,能够解决膜过滤装置大、透射流束小、大活性污泥槽等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

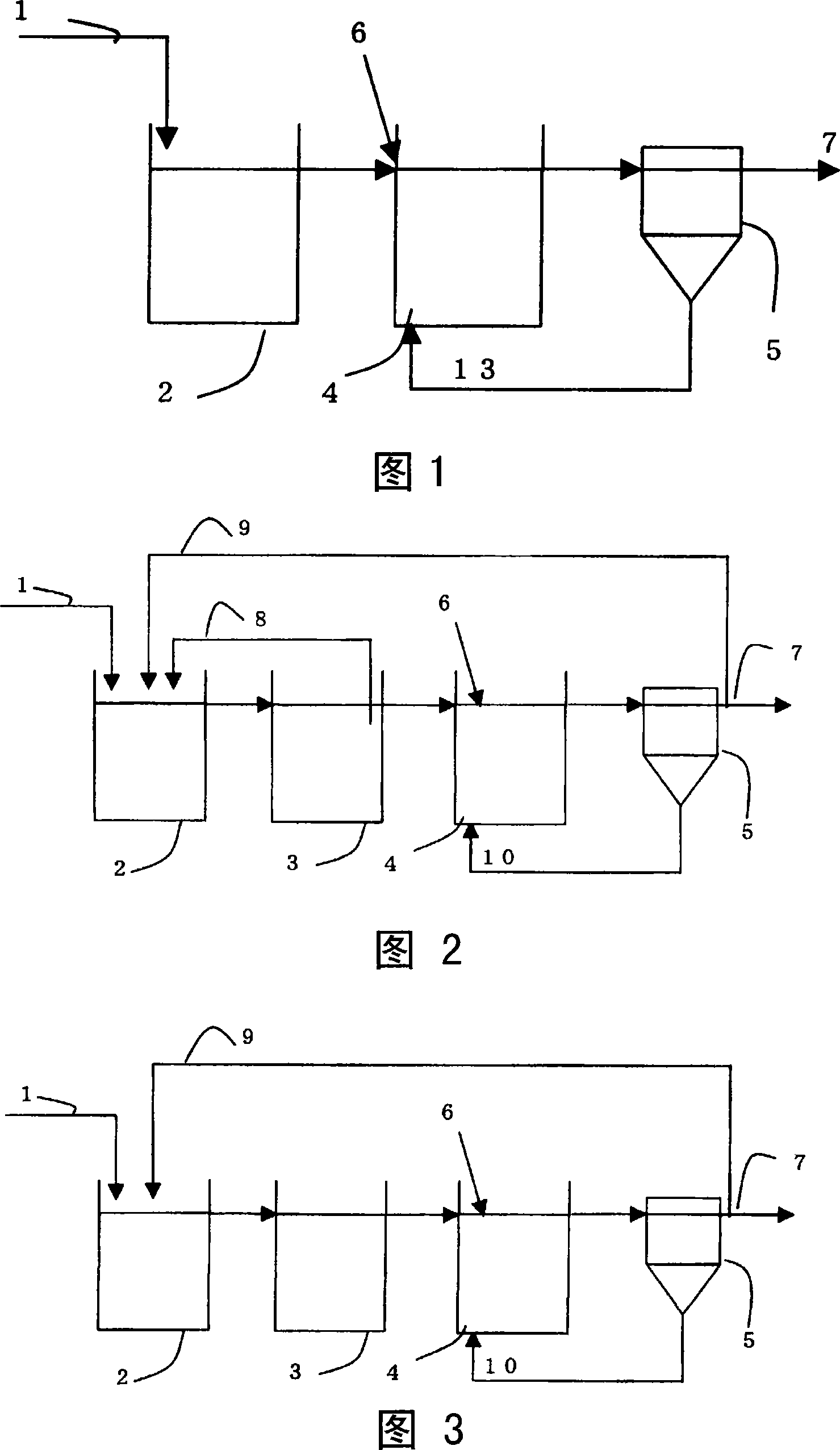

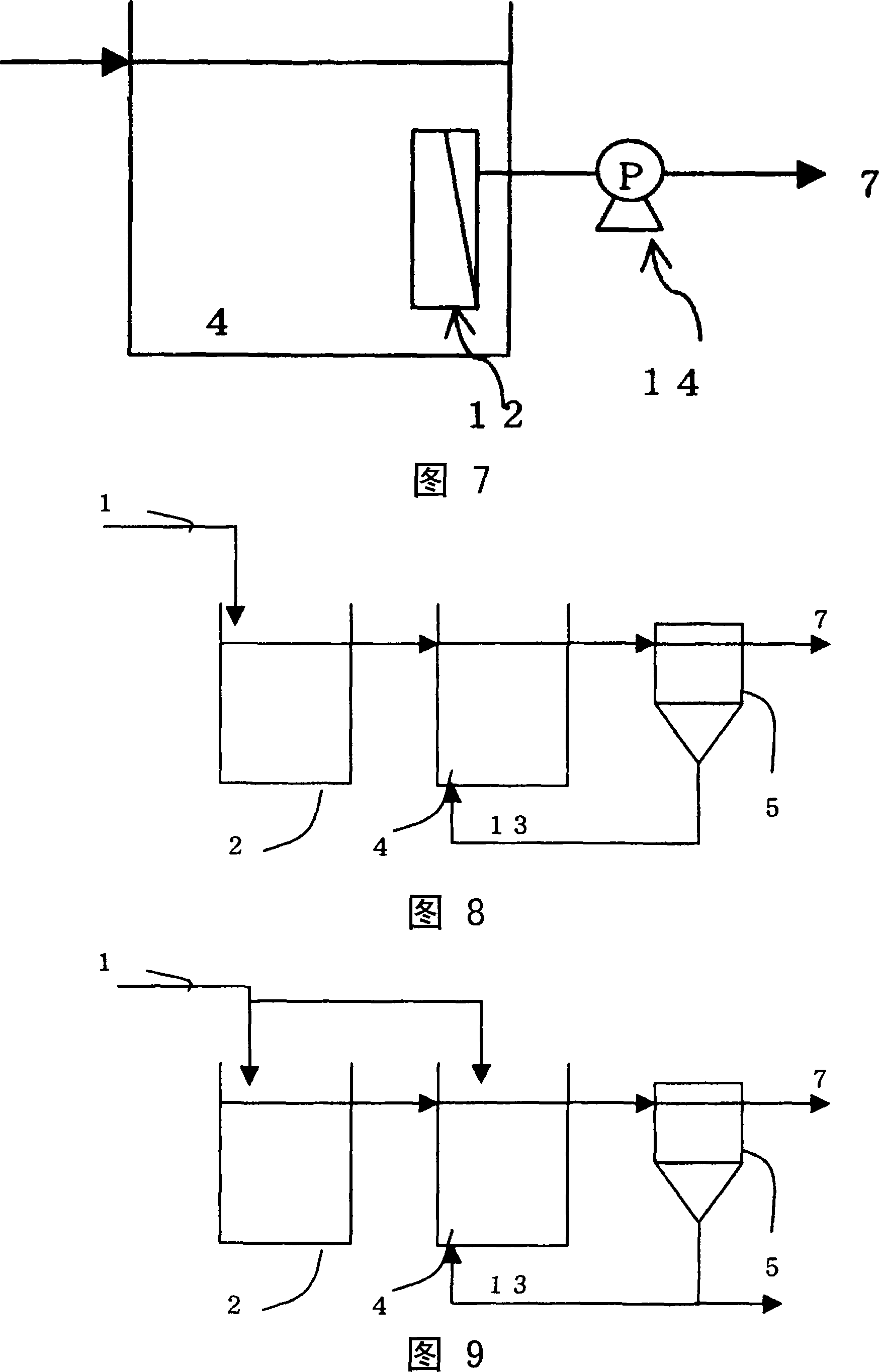

Embodiment 1

[0058] According to the process shown in Figure 1, the capacity is 320m 3 The carrier flow aeration tank with a capacity of 240m 3 of full oxidation tanks and a capacity of 50m 3Drainage treatment device formed by sedimentation tank, carried out 400m 3 / day of chemical drainage treatment. In the carrier flow aeration tank, put 32m 3 Acetal polyvinyl alcohol-based colloid carrier (about 4mm in diameter). In addition, 10 mg / L of polyaluminum chloride (inorganic flocculant) was added to the wastewater treated in the carrier flow tank. According to the present invention, the BOD volume load of the aeration tank according to the carrier flow is 2.5kg / m 3 When operating in the daily mode, the MLSS of the total oxidation tank increases slowly, but when the BOD sludge load is 0.05kg-BOD / kg-MLSS per day, the MLSS of the total oxidation tank is about 10000mg / L, which is basically constant.

[0059] The coagulant was continuously supplied for about one month from the start of the o...

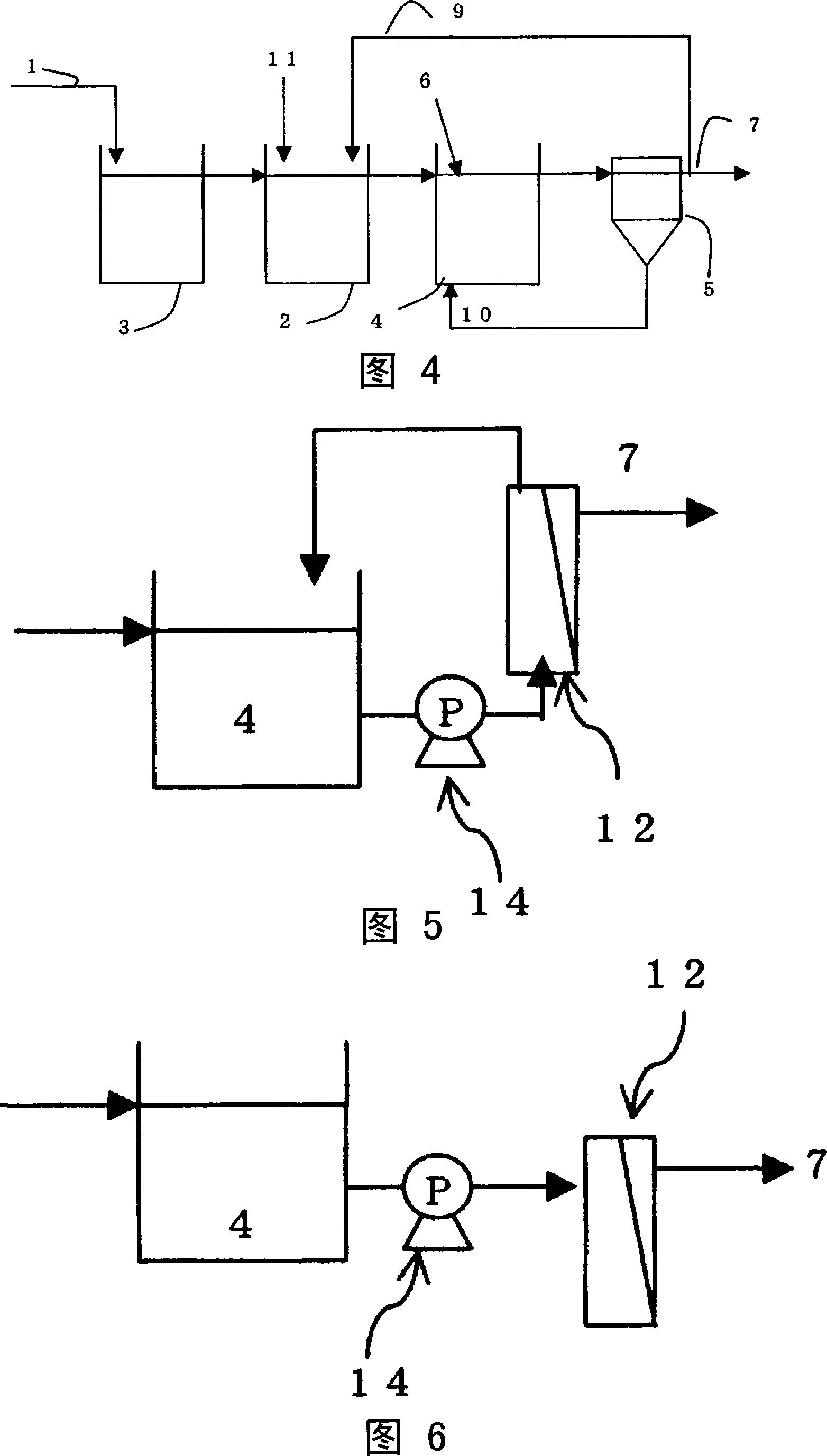

Embodiment 2

[0067] According to the process shown in Figure 2, the capacity is 30m 3 denitrification tank with a capacity of 30m 3 Nitrification tank with a capacity of 25m 3 of full oxidation tanks and a capacity of 25m 3 The drainage treatment device formed by the settling tank, the ammoniacal nitrogen is 50mg / L, the BOD is 200mg / L, and the drainage is 200m 3 / day of chemical drainage treatment. In the denitrification tank and nitrification tank, put 3.3m 3 Acetal polyvinyl alcohol-based colloid carrier (about 4mm in diameter), according to 600m 3 / day level, return the drainage from the nitrification tank to the denitrification tank. In addition, 10 mg / L of polyaluminum chloride (inorganic flocculant) was added to the wastewater treated by the nitrification tank. In addition, according to 600m 3 / day level, return the drainage from the outlet of the sedimentation tank to the denitrification tank. According to the present invention, according to the nitrogen volume load of den...

Embodiment 3

[0069] According to the process shown in Figure 3, the capacity is 270m 3 denitrification tank with a capacity of 270m 3 Nitrification tank with a capacity of 100m 3 of full oxidation tanks and a capacity of 250m 3 The drainage treatment device formed by the settling tank, the ammoniacal nitrogen is 40mg / L, the BOD is 160mg / L, and the drainage is 2000m 3 / day of chemical drainage treatment. In the denitrification tank and nitrification tank, put 27m 3 Acetal polyvinyl alcohol-based colloid carrier (about 4mm in diameter). In addition, 10 mg / L of aluminum sulfate (inorganic flocculant) was added to the wastewater treated by the nitrification tank. In addition, according to 6000m 3 / day level, return the drainage from the outlet of the sedimentation tank to the denitrification tank. According to the present invention, according to the nitrogen volume load of denitrification tank and nitrification tank is 0.3kg / m 3 When operating in the daily mode, the MLSS of the full o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com