Semi-rotary kettles for sewing machines and sewing machines

A semi-rotary, sewing machine technology, applied in the direction of sewing machine components, sewing equipment, cloth feeding mechanism, etc., can solve the problems such as the deterioration of the tension balance of the lower suture, the easy weakening of the tension of the upper suture, and the decline of sewing quality, so as to achieve a relaxation line The influence of traces, the improvement of sewing quality, and the effect of improving sewing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

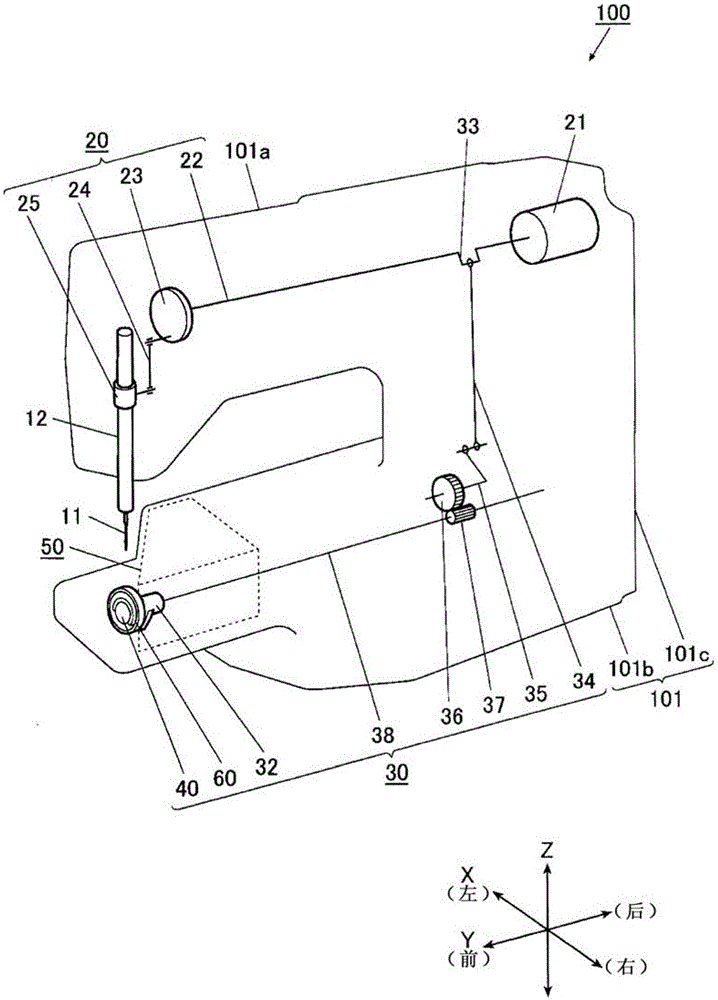

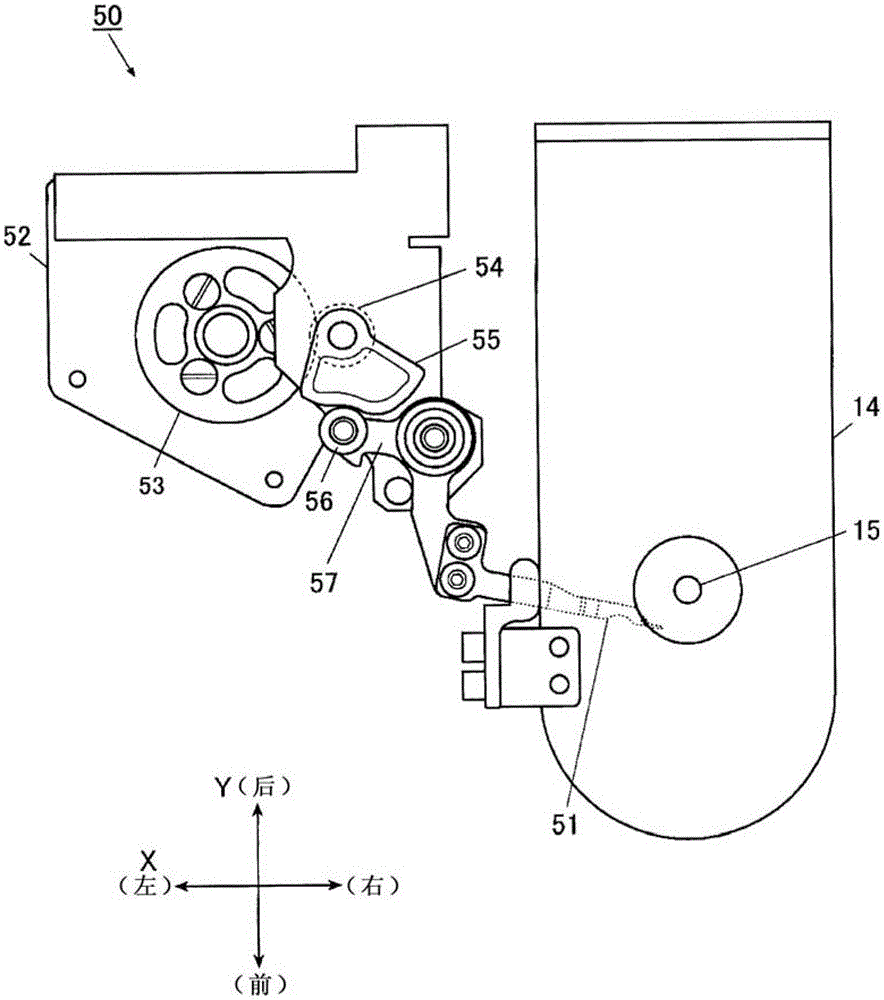

[0073] according to Figure 1 to Figure 14 , the first embodiment of the present invention will be described.

[0074] Here, the direction in which the sewing needle 11 described later moves up and down is defined as the Z-axis direction or the up-and-down direction, and a direction perpendicular thereto is defined as the X-axis direction or the left-right direction. The direction orthogonal to both is defined as the Y-axis direction or the front-back direction.

[0075] In addition, the direction parallel to the Y-axis direction and relative to the needle bar 12 side of the upper shaft 22 described later is referred to as "front", and the direction parallel to the Y-axis direction and relative to the sewing machine motor 21 side of the upper shaft 22 is referred to as "front". For "after". In addition, let the left-hand side parallel to the X-axis direction and face the "rear" direction be "left", and let the right-hand side be "right" when it is parallel to the X-axis dire...

no. 2 approach

[0188] As a second embodiment of the present invention, a sewing machine having a new kettle mechanism 30A will be described. In addition, in the following description, the same code|symbol is attached|subjected to the same structure as the sewing machine 100 demonstrated as 1st Embodiment, and the description is abbreviate|omitted.

[0189] This kettle mechanism 30A is used to solve the problems caused by having the wire gathering mechanism 50 .

[0190] First, in the kettle mechanism 30 of the first embodiment, problems that may arise due to the thread gathering operation by the thread gathering mechanism 50 will be described.

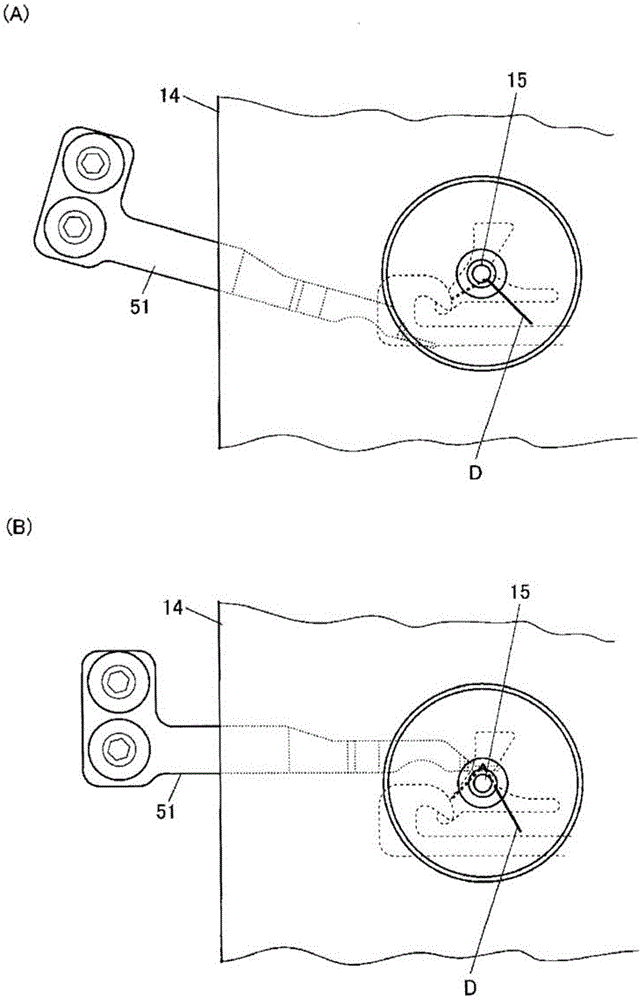

[0191] The wire gathering part 51 of the wire gathering mechanism 50, as above-mentioned image 3 As shown in (A), the front end is far away from the pinhole 15 in front and is on standby. image 3 As shown in (B), the wire gathering member 51 rotates and moves backward in such a way that its front end passes directly under the needle hole 15 , so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com