Method for extracting Natsucitrine I

A technology of extracting liquid and resin column, applied in the field of separation of natural products, can solve the problem of less research on torcianine I, and achieve the effects of reducing the amount of extraction, large processing capacity and lowering cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

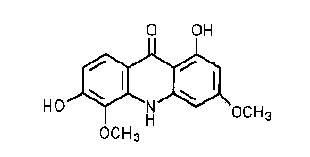

Image

Examples

Embodiment 1

[0016] Take the root of big tangerine, crush it and take 10kg, reflux and extract 50kg60% methanol solution for 3 times (the third extraction solution will be used for the next extraction), add 1kg diatomaceous earth activated carbon (5:1) to the extraction solution for decolorization, filter out solid impurities, Recover methanol under reduced pressure, adjust pH to 7.5 with ammonia water in the concentrate, add 2LXDA-5 resin column for adsorption, wash the resin column with deionized water until neutral, take 10L of 30% methanol solution (pH9) to elute the active ingredients, and concentrate the eluent under reduced pressure. 200 ml of the concentrated solution was obtained, and the concentrated solution was added with 150 ml of chloroform to extract three times, the chloroform layer was concentrated to 100 ml, refrigerated and crystallized, and the crystal was dried to obtain the citronine I product with a content of 91.3%.

[0017]

Embodiment 2

[0019] Take the root of big tangerine, crush it and take 10kg, reflux and extract 70kg60% methanol solution twice, add 2kg diatomaceous earth activated carbon (10:3) to the extract to decolorize, filter out solid impurities, recover methanol under reduced pressure, and adjust the pH of the concentrated liquid ammonia water to 8. 5. Add 2L SPD450 resin column for adsorption, wash the resin column with deionized water to neutrality, take 6L of 40% methanol solution (pH8) to elute the active ingredients, and concentrate the eluent under reduced pressure to obtain 250ml of concentrated solution, which is extracted by adding 200ml of chloroform to the concentrated solution 2 The second time, the chloroform layer was concentrated to 80ml, refrigerated and crystallized, and the crystals were dried to obtain the citronine I product, with a content of 87.8%.

[0020]

Embodiment 3

[0022] Take the root of tangerine, crush it and take 10kg, 70kg 60% methanol solution reflux and extract twice, add 2kg diatomite activated carbon (10:3) to the extract to decolorize, filter out solid impurities, recover methanol under reduced pressure, and adjust the pH of the concentrated liquid ammonia water to 8, Add 2L of SPD450 resin column for adsorption, wash the resin column with deionized water until neutral, take 8L of 50% methanol solution (pH8) to elute the active ingredient, concentrate the eluent under reduced pressure to obtain 200ml of concentrated solution, add 200ml of chloroform to the concentrated solution for extraction twice, Concentrate the chloroform layer to 120ml, refrigerate and crystallize, and dry the crystals to obtain the citronine I product with a content of 90.8%.

[0023]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com