Educational outfit with axial shell assembled by bearing

A technology of bearings and shells, applied in the field of educational appliances, can solve the problems of large size and weight, relying on assembly experience, and difficult preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0145] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings.

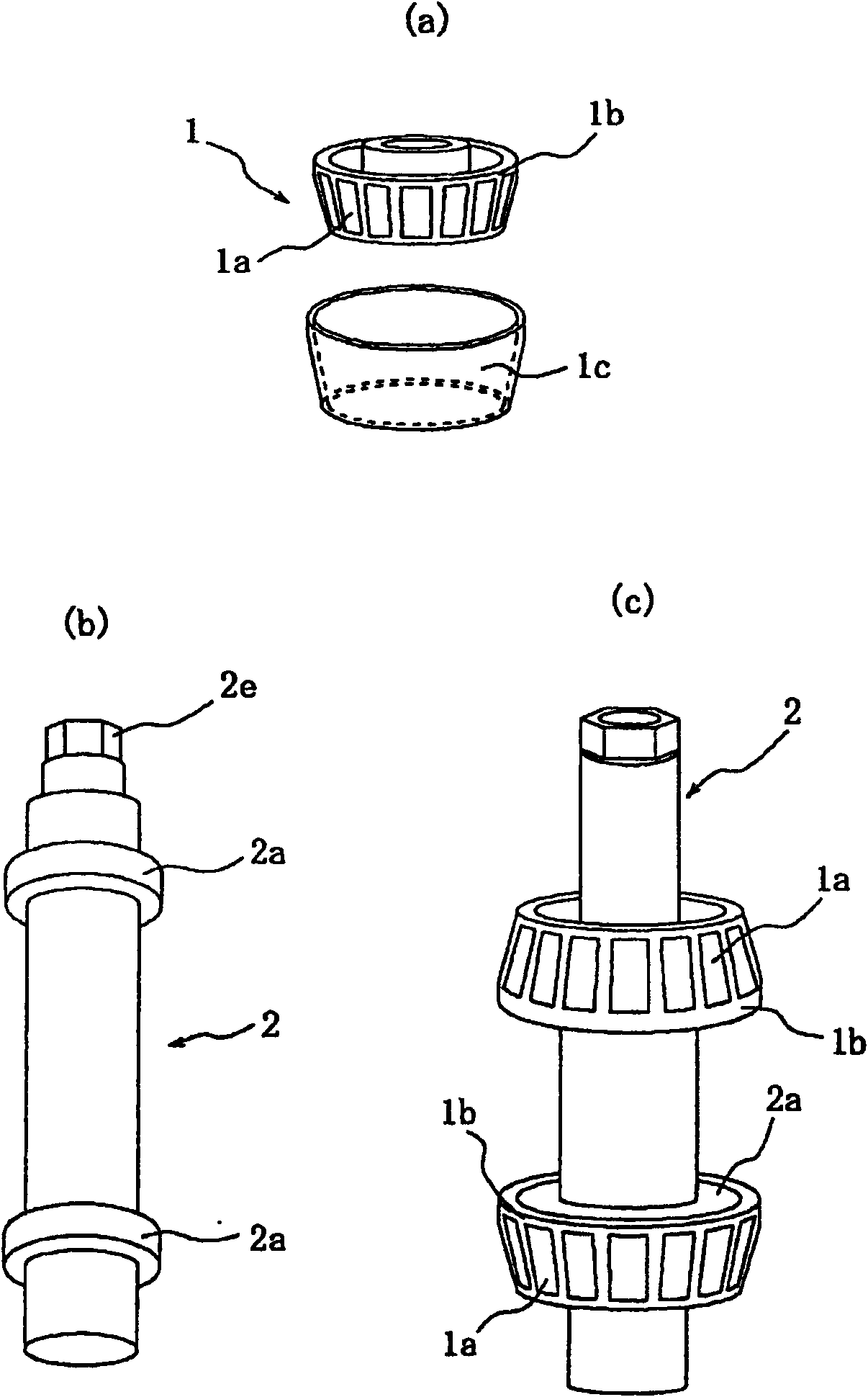

[0146] figure 1 (a) to (c) schematically show the first embodiment of the present invention, that is, the tapered bearing, which is a component part of an educational tool in which the first shaft (hereinafter referred to as "the first shaft") 2 is assembled using the tapered bearing 1. 1 is an exploded perspective view, and a perspective view schematically showing the first shaft 2 and its assembled state.

[0147] like figure 1 As shown in (a), the tapered bearing 1 has an inner ring 1b that holds the roller 1a, an outer ring 1c that is mutually rotatable relative to the inner ring 1b by contacting the roller 1a, and an inner ring 1b that holds the roller 1a and The outer rings 1c are separable from each other.

[0148] like figure 1 As shown in (b), two flanges 2 a are integrally formed on the first shaft 2 at intervals. Therefore, if the inner rings 1b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com